Circulating cooling water scale inhibitor and preparation method and application thereof

A technology of circulating cooling water and scale inhibitor, which is applied in chemical instruments and methods, natural water treatment, scale removal and water softening, etc., can solve the problems of difficult silica fouling water treatment system, complicated method and high production cost , to achieve the effect of excellent resistance to colloidal silica scale and silicate scale, less dosage and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A scale inhibitor used in circulating cooling water system, which is copolymerized with acrylic acid, sodium methacrylic sulfonate and ethyl acrylate.

[0017] The above-mentioned scale inhibitor adopts the following preparation method: add acrylic acid, sodium methacryl sulfonate, and ethyl acrylate, and the mass percentage of each monomer component is: acrylic acid: sodium methacryl sulfonate: ethyl acrylate: =60: 25:15. Add sodium persulfate and stir evenly, adjust the pH of the solution to 3~4, keep warm at 60°C for 65min, and negative pressure at -0.09Mpa for 45min to obtain the scale inhibitor.

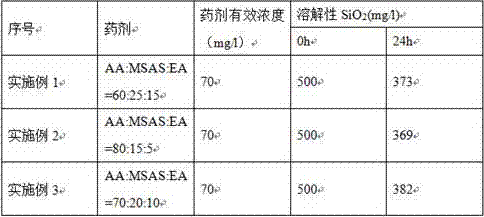

[0018] The prepared antiscalant was tested for static silicon scale inhibition, and the experimental results are shown in the table below.

Embodiment 2

[0020] A scale inhibitor for circulating cooling water systems, composed of acrylic acid, sodium methacrylate, and ethyl acrylate.

[0021] The above antiscalant adopts the following preparation method: add acrylic acid, sodium methacryl sulfonate, and ethyl acrylate, and the mass percentage of each monomer component is: acrylic acid: sodium methacryl sulfonate: ethyl acrylate: =80: 15:5. Add sodium persulfate and stir evenly, adjust the pH of the solution to 3~4, keep warm at 70°C for 55min, and negative pressure at -0.09Mpa for 50min to obtain the scale inhibitor.

[0022] The prepared antiscalant was tested for static silicon scale inhibition, and the experimental results are shown in the table below.

Embodiment 3

[0024] A scale inhibitor for circulating cooling water systems, composed of acrylic acid, sodium methacrylate, and ethyl acrylate.

[0025] The above antiscalant adopts the following preparation method: add acrylic acid, sodium methacrylic sulfonate, and ethyl acrylate, and the mass percentage of each monomer component is: acrylic acid: sodium methacrylic sulfonate: ethyl acrylate=70:20 :10. Add the initiator and stir evenly, adjust the pH of the solution to 3~4, keep warm at 65°C for 60min, and negative pressure at -0.09Mpa for 45min to obtain the scale inhibitor.

[0026] The prepared antiscalant was tested for static silicon scale inhibition, and the experimental results are shown in the table below.

[0027] Effect test

[0028] Test water: NaSiO 3 .9H 2 O 500mg / l.

[0029] Test conditions: water temperature 40±1℃, time 24h, pH=7±0.1, scale inhibitor dosage 70mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com