Patents

Literature

117results about How to "Works well together" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

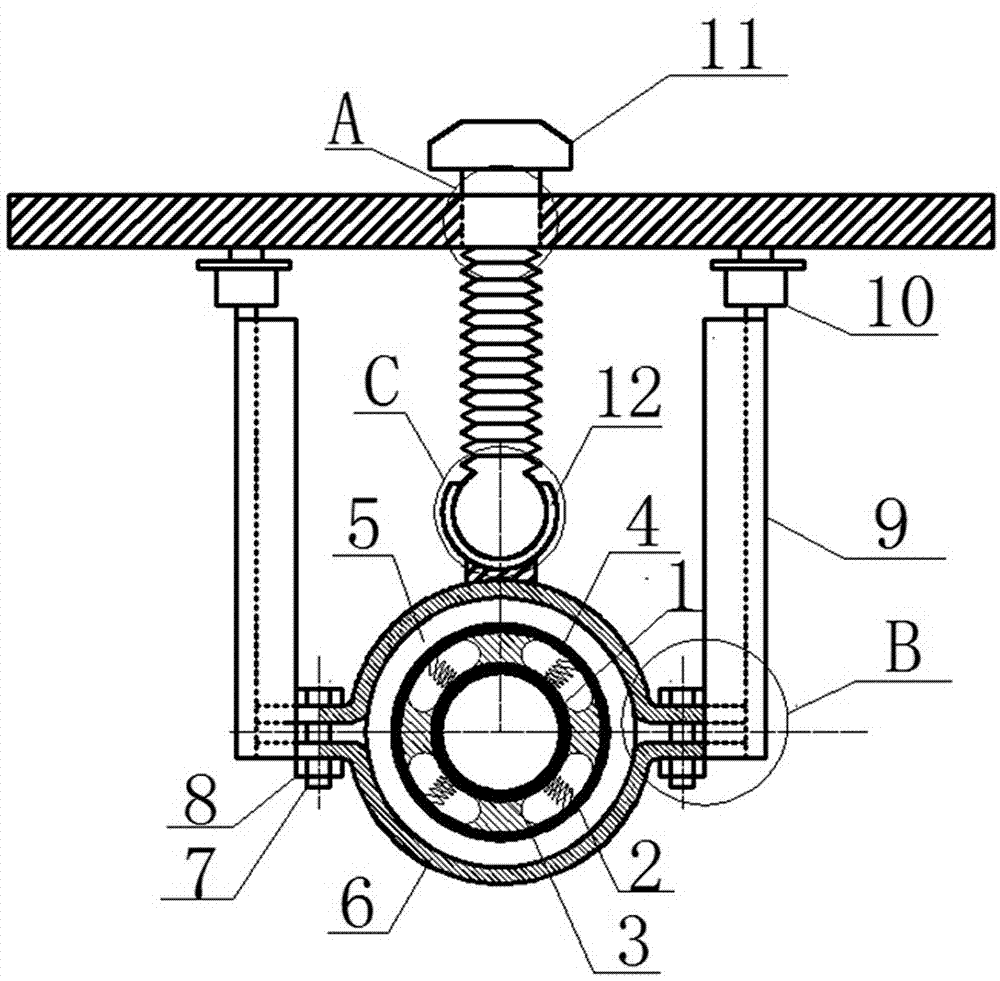

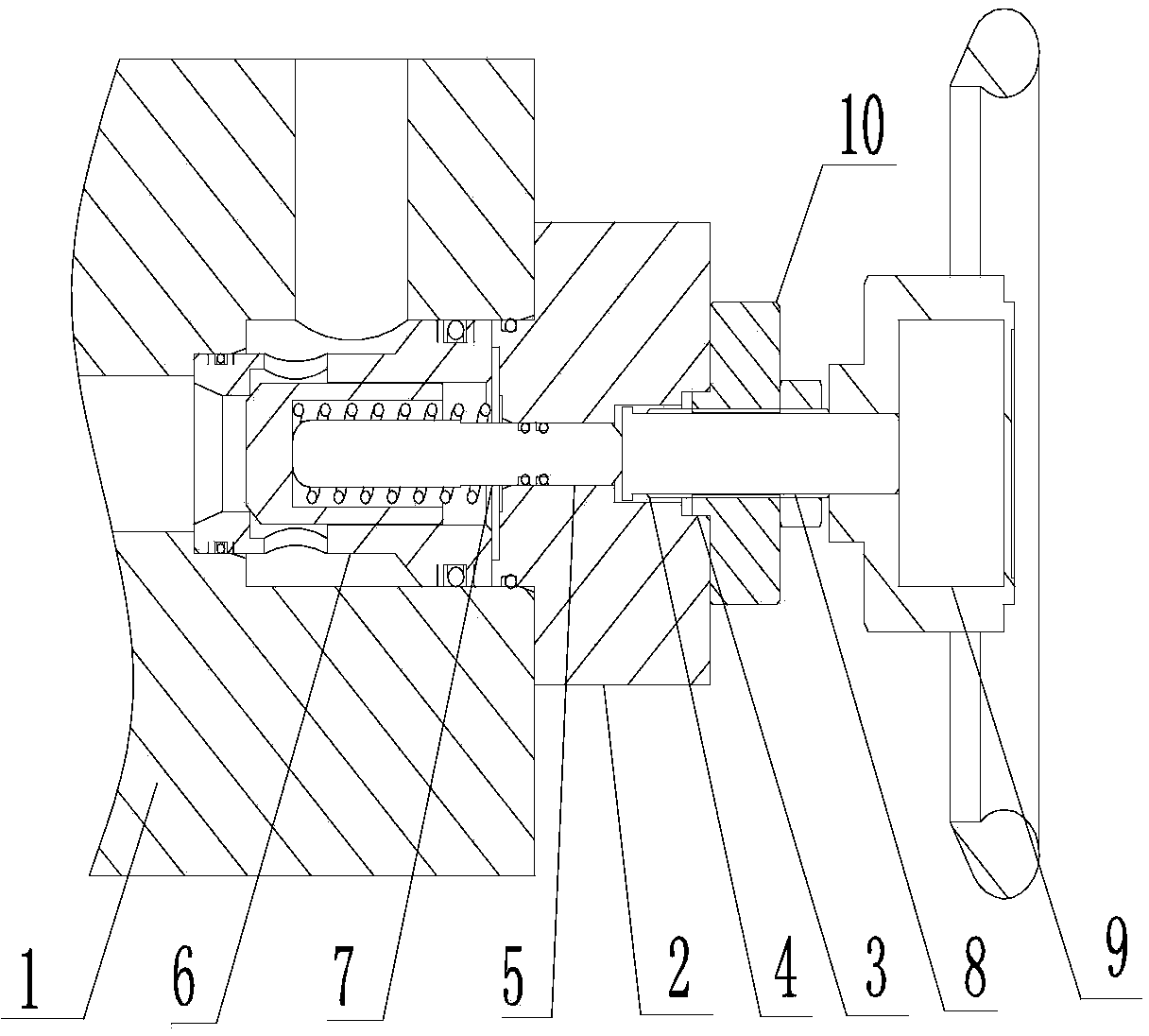

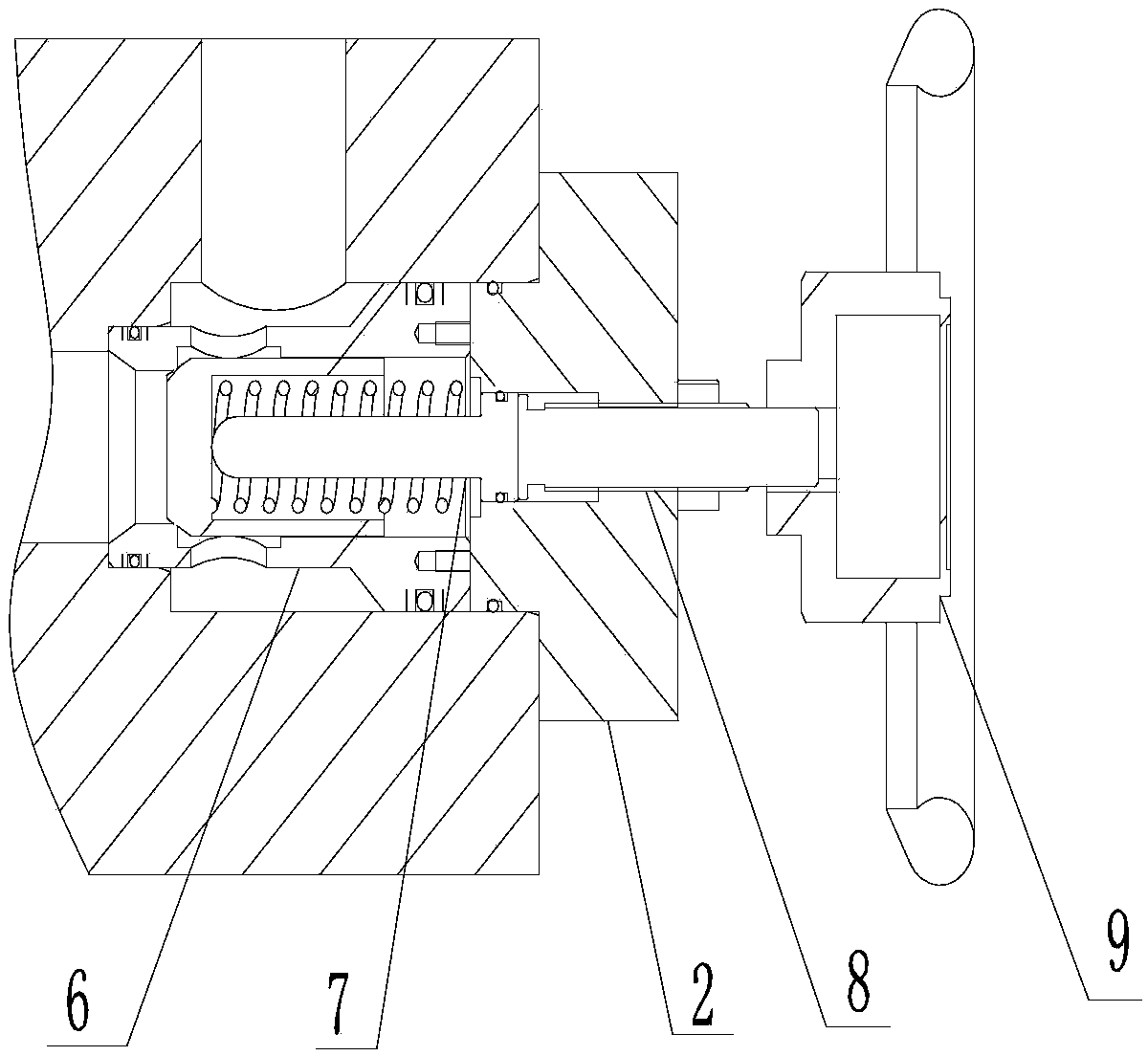

Adjustable pipe hanging bracket and adjustable hanging bracket assembly for suppressing ship pipe vibration noise

InactiveCN103791167ASimple structureReduce manufacturing costPipe supportsPipe elementsEngineeringScrew thread

The invention discloses an adjustable pipe hanging bracket and an adjustable hanging bracket assembly for suppressing ship pipe vibration noise, wherein the adjustable hanging bracket assembly comprises the hanging bracket. The hanging bracket comprises a base plate and an adjustment bolt, and the base plate is fixedly connected with a ship body. The hanging bracket is characterized in that the adjustment bolt comprises a bolt part on the upper portion and a spherical part at the bottom, outer threads are arranged on the bolt part, a bolt hole matched with the bolt part is formed in the base plate, the adjustment bolt is installed in the bolt hole, the spherical part of the adjustment bolt is embedded into a spherical clamping groove, an opening is formed in the top of the spherical clamping groove, the diameter or width of the opening is smaller than the diameter of the spherical part, and the bottom of the spherical clamping groove is fixedly connected to the outer wall of a pipe or the top of a pipe clamp device. The adjustable pipe hanging bracket is flexible and adjustable in connecting mode, good in vibration resistant effect and suitable for the ship pipe, meanwhile, the hanging bracket assembly based on the hanging bracket discloses a pipe clamp structure matched with the hanging bracket, and the hanging bracket assembly has the advantages of further suppressing the pipe vibration noise and being convenient to install and use.

Owner:JIANGSU MARITIME INST +1

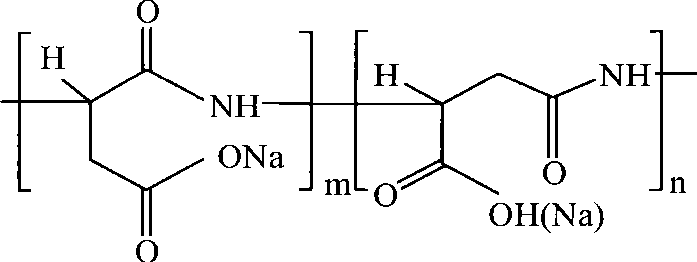

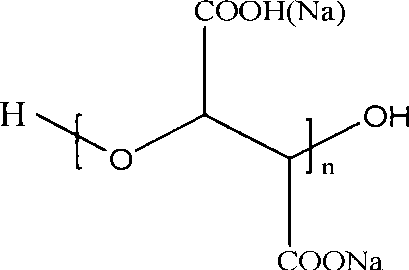

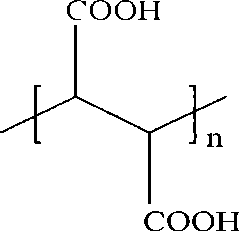

Environment-friendly composite dirt dispersion agent for oil-field flooding treatment

InactiveCN101508492ACausing eutrophication pollutionGood scale inhibition and dispersibilityWaste water treatment from quariesScale removal and water softeningWater floodingOil field

The invention belongs to the technical field of industrial water treatment, and particularly relates to an environmental protection type composite dirt dispersion agent used for oil field water flooding treatment. The dirt dispersion agent takes polyasparagic acid, polyepoxy sodium succinate and hydrolyzed polymaleic anhydride as effective components; and the total content of the effective components is no less than 35 percent. The weight ratio of the effective components of polyasparagic acid: polyepoxy sodium succinate: hydrolyzed polymaleic anhydride is 4-12.5:1-5: 5-9. The environmental protection type composite dirt dispersion agent is phosphorus free, innocuous and biologically degradable, and has low use cost. The environmental protection type composite dirt dispersion agent can effectively prevent the sedimentation of calcium carbonate, calcium sulphate and barium sulphate, and is suitable for the dirt dispersion treatment in an oil field water flooding system.

Owner:TONGJI UNIV

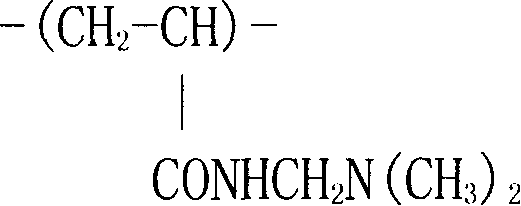

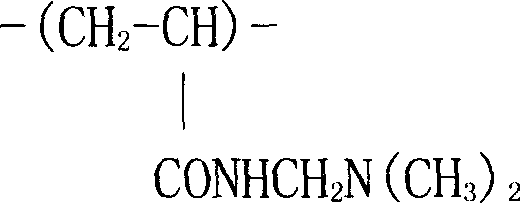

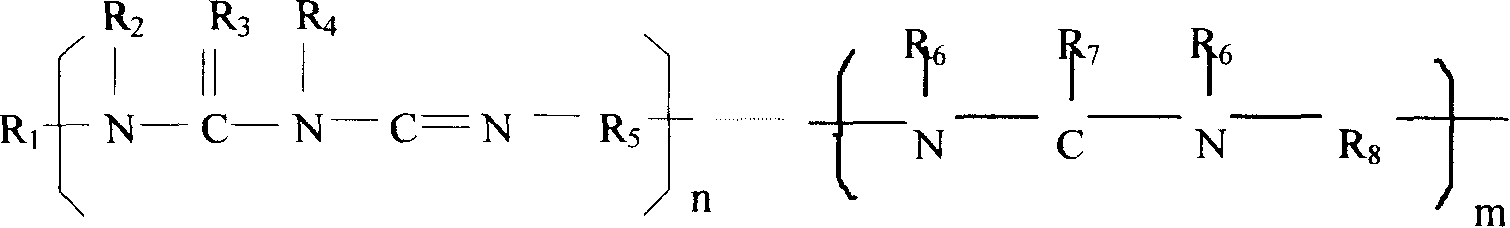

Sludge dewatering agent and its preparation method

ActiveCN1769221AGood performanceSimple equipmentSludge treatment by de-watering/drying/thickeningChemical industryIon

The invention relates to a cationic polymer dehydrator for sludge. It is a colloid water solution with am-methyl polyacrylamide as main component, which is prepared by anion or non-ion polyacrylamide, formaldehyde, organic amine and fresh water, reacting at a definite temperature assisted with chelating agent and reaction promoter. The invention is characterized in that the technique and device is simple, the reaction process is stable, and it is easy to operate. Said cationic polymer dehydrator can be more effective cooperated with organic flocculant in Chinese patient 98121074. 0. The test of refinery sludge dehydration shows that the invention is more effective than the import at the same adding-quantity of the agent; COD of treated filtrate is substantially lower than 2000mg / L, and the oil content is lower than 1000 mg / L. It can be used to deal with sewage and sludge in oil and chemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

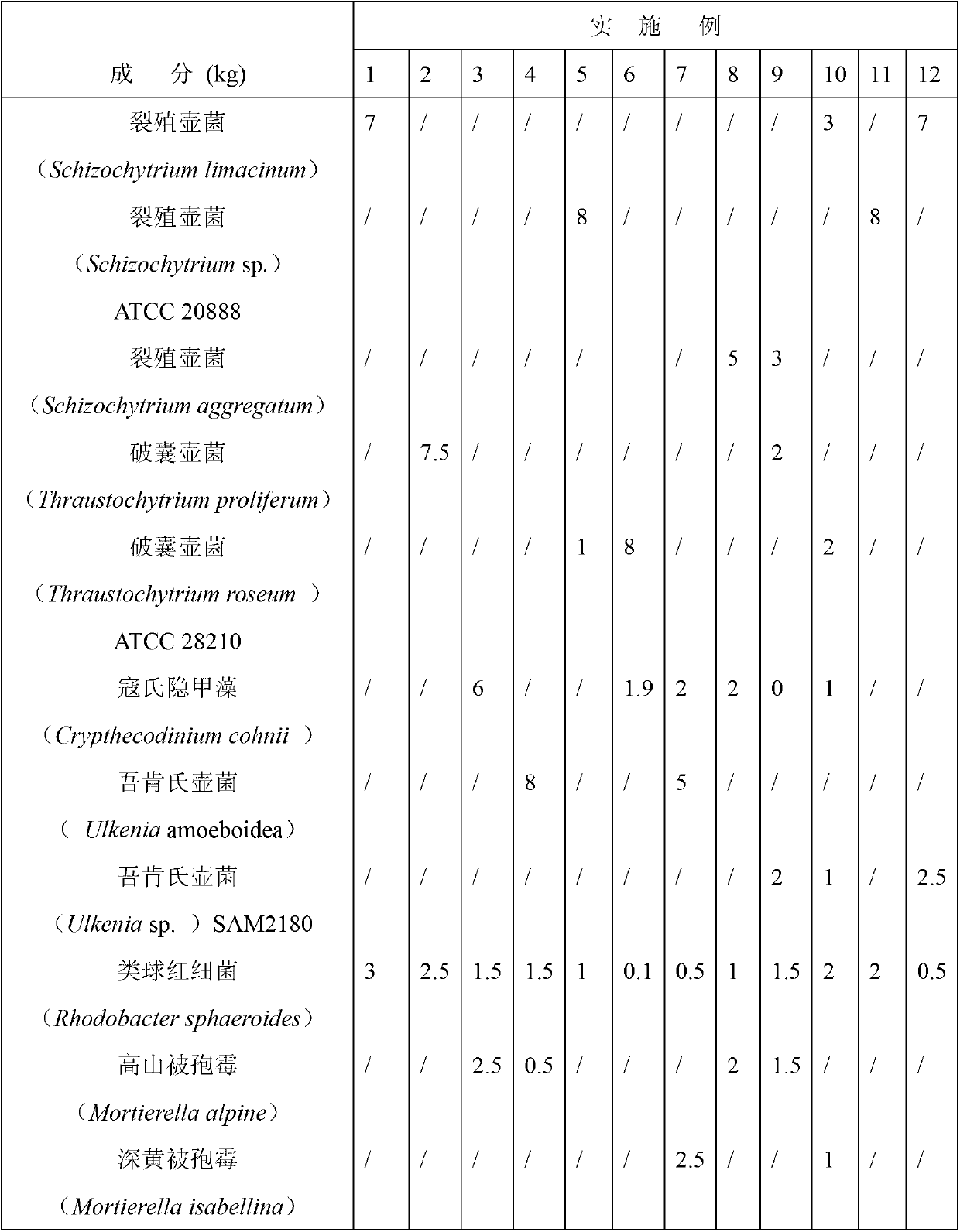

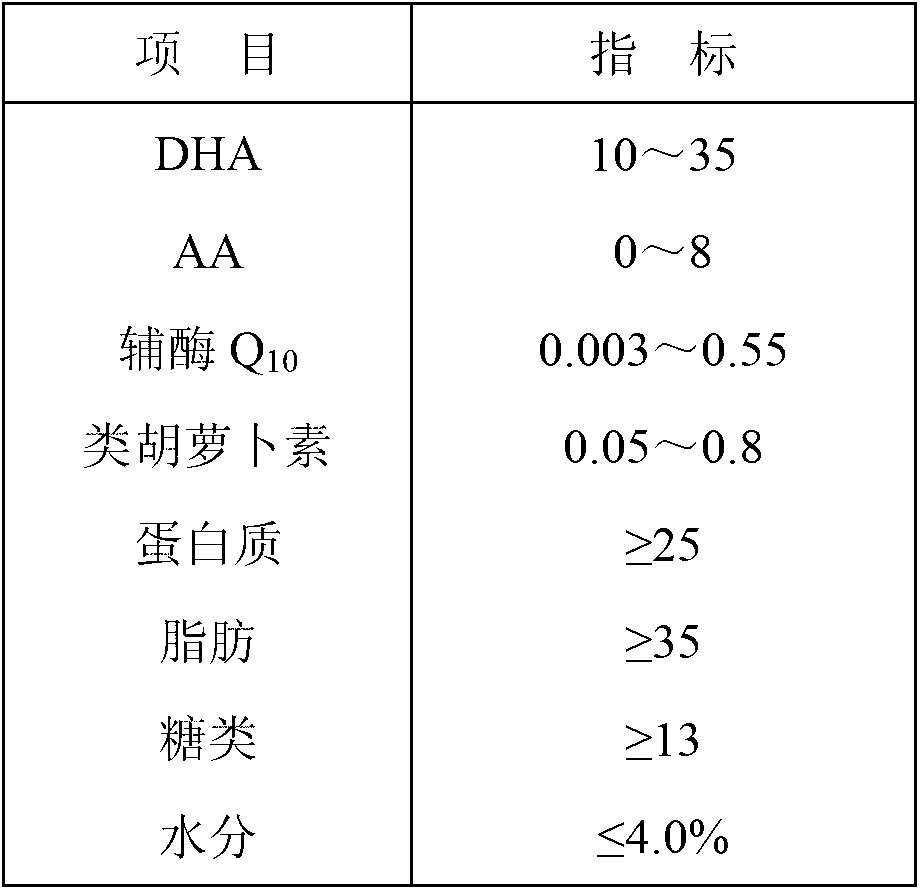

Microbiological feed additive and preparation method and application thereof

ActiveCN102987096AEasy to useAddressing resource scarcityAnimal feeding stuffNutritive valuesDisease

The invention relates to a microbiological feed additive and a preparation method and an application thereof, relating to a feed additive. The invention provides a microbiological feed additive compounded with various microbiological fermented powders and a preparation method and an application thereof. The microbiological feed additive consists of the following compounds according to weight percentages: 60%-99% of DHA (Docosahexenoic acid) fermented powder, 0-25% of AA (Arachidonic acid) fermented powder and 1%-30% of R. spkaeroides fermented powder. After the nutrition compositions are mixed uniformly after being crashed respectively; and then sieving, checking, weighing and packing are performed. The microbiological feed additive can be used as an active in aquatic product, poultry and livestock cultivation feeds, and the addition accounts for 0.2%-5.0% of total mass of basal feed. The contents of the nutrition compositions in the feed are increased, so that the resistance against diseases, survival rate, growth rate and nutritive value of fed animals are improved; rich coenzyme Q10 and carotenoid are used as antioxidants, so that the oxygenization of polyunsaturated fatty acid can be inhibited, the stability and using effect of polyunsaturated fatty acid are improved, and the compounding effect is obvious.

Owner:KINGDOMWAY BIOTECH (JIANGSU) CO LTD +2

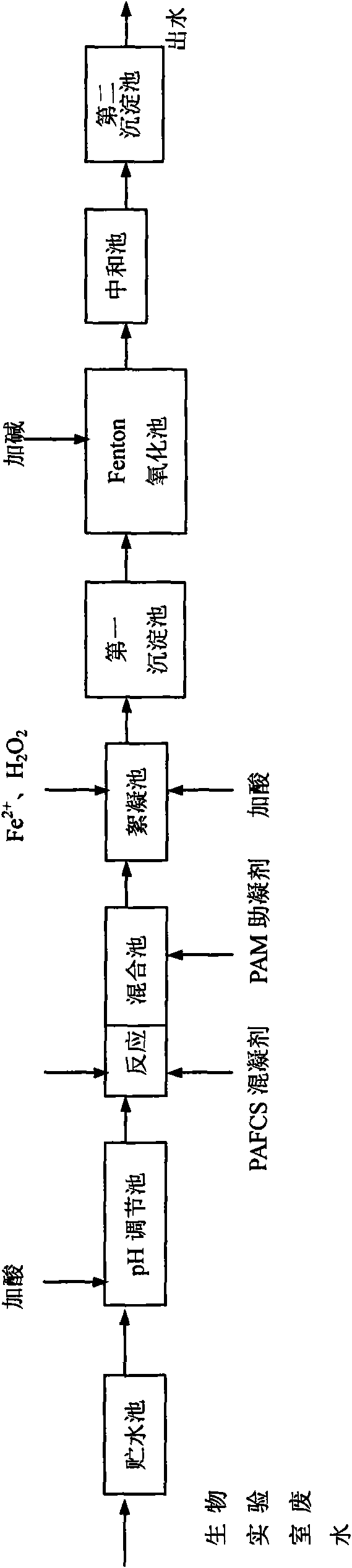

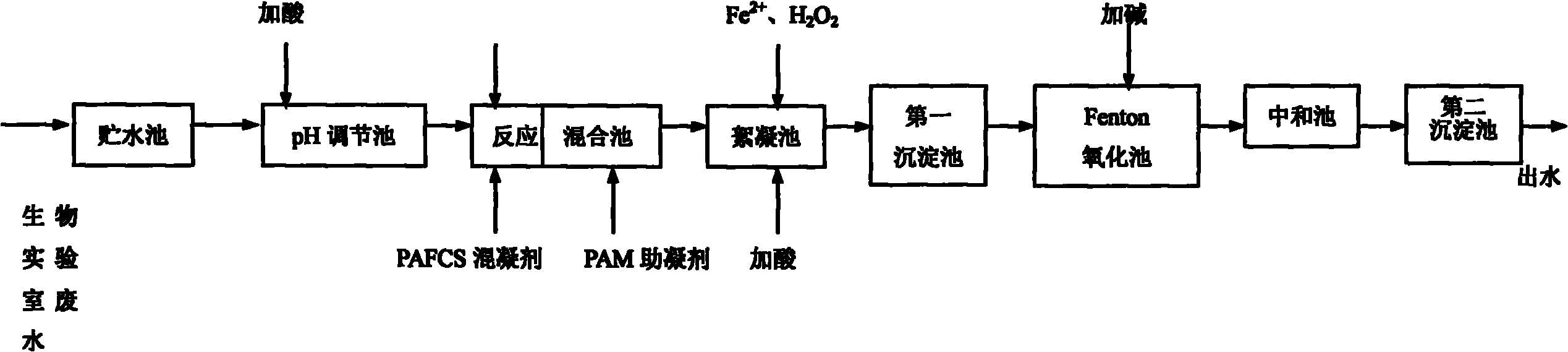

Method for treating biological laboratory wastewater

InactiveCN101851036ASolve new problems of biological pollutionAvoid it happening againMultistage water/sewage treatmentWater/sewage treatment by neutralisationLuminescent bacteriaChemical reaction

The invention belongs to the technical field of environmental protection, and relates to a method for treating biological laboratory wastewater. In the method, a pH regulator 30 percent dilute H2SO4 is adopted to perform preliminary sterilization; a chemical reactant calcium oxide, a coagulant polyaluminum ferric chlorine sulfate and a coagulant aid polyacrylamide are matched to perform coagulating sedimentation to remove pollutants in the biological laboratory wastewater; the method combines a Fenton oxidation method to fulfill the aim of continuously removing organic pollutants CODcr and LAS and has the effects of killing bacteria, removing ATP and reducing the biological toxicity; the pH of effluent is adjusted by using calcium hydroxide and the effluent is settled, and the CODcr and LAS concentration, NH3-N, T-N and T-P in the discharged biological laboratory wastewater reach or precede secondary discharge standard after measurement; and the removing rate of the total number of the bacteria reaches 100 percent, the index value of the biological activity of the bacteria is 0, and the biological toxicity index, namely the inhibition ratio of luminescent bacteria is less than 30 percent.

Owner:FUDAN UNIV

Anti-freezing and heat preserving method for greening trees in northeast China

InactiveCN104429734AWorks well togetherLess likely to make mistakesPlant protectionAnti freezingPlastic film

The invention provides an anti-freezing and heat preserving method for greening trees in northeast China, and relates to the technical field of greening tree winter protection. The method is characterized by comprising the steps of root collar ridging, soil covering, windbreak erecting, whitewashing and white spraying, plastic film winter protection and medicament prevention and control. The method is reasonable, convenient to implement, and prevention and control of the greening trees can be conveniently achieved.

Owner:安徽省龙海种业有限公司

Cistanche salsa planting method

ActiveCN104160859APromote seed germinationImprove stress resistanceSeed coating/dressingHorticultureRoot systemTamarix africana

The invention discloses a cistanche salsa planting method. The cistanche salsa planting method includes the following steps that first, seeds are treated, wherein cistanche salsa seeds are soaked with a mixed solution of VitaCat and High Yield solution to be treated for 1.5 h to 2.5 h, and the soaked cistanche salsa seeds, the mixed solution for treatment and fine sand are fully stirred to be evenly mixed; second, planting holes are handled, planting holes with the centers 45 cm to 55 cm away from trunks of hosts are dug, the planting holes are 40 cm to 50 cm long, 25 cm to 35 cm wide and 45 cm to 55 cm deep, the bottoms of the planting holes are made to be slopes, the included angles between the slopes and the horizontal plane range from 40 degrees to 50 degrees, and the bevels are opposite to the hosts; third, the roots of the hosts are handled, wherein the roots broken due to digging on the sections of the planting holes are pruned through a pruner, and then GGR solution is sprayed onto the roots of the hosts on the perpendicular sections of the planting holes; fourth, the seeds are scattered and planted, wherein the cistanche salsa seeds treated in the first step are scattered onto the bevels of the bottoms of the planting holes, and the planting holes are backfilled. The cistanche salsa planting method is easy and convenient to operate and low in cost, and the cistanche salsa survival rate can reach 95%; according to the method, sacsaoul and tamarix are used as the hosts for planting cistanche salsa, and high economic benefits are achieved.

Owner:张掖市林业科学技术推广站 +1

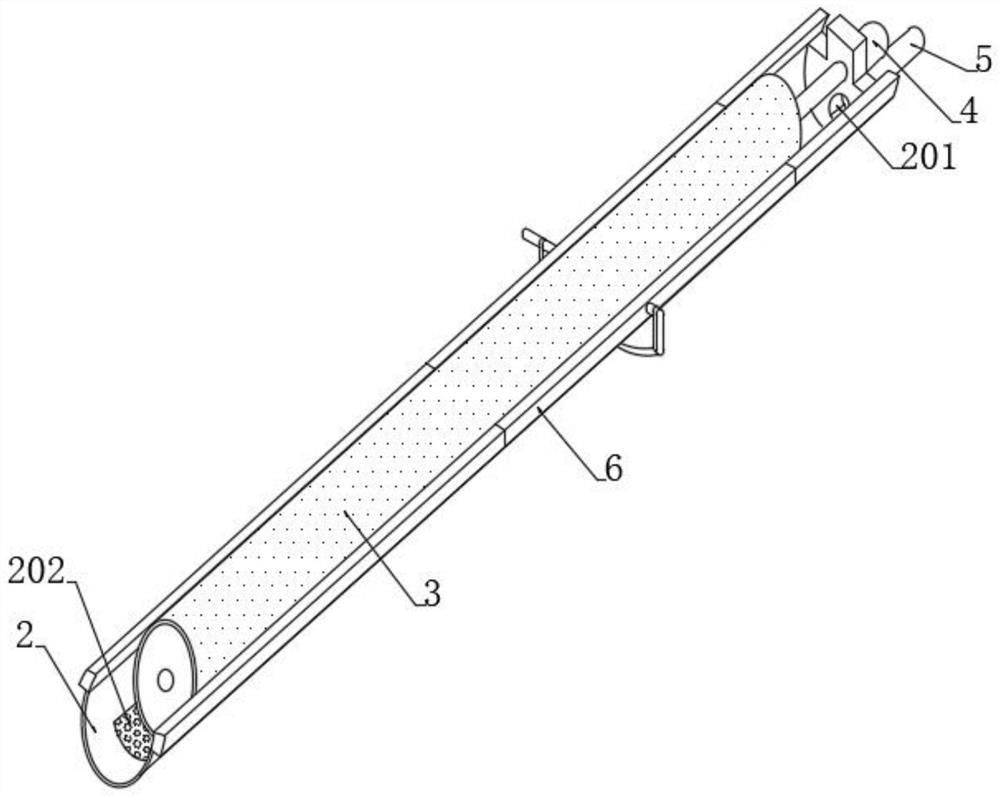

Guniting corn bran preparation method and production system

InactiveCN105249506APromote digestion and absorptionEasy to prepareFeeding-stuffAgricultural scienceAgricultural engineering

The invention discloses a guniting corn bran preparation method and production system; the method comprises the following steps: 1, using a mixer to mix the corn bran with corn steepwater according to volume ratio of 1:0.38-0.69; 2, using a loading device to convey the mixed wet corn bran into a feeding device, and using the feeding device to convey the wet corn bran into a rotation roller; 3, turning the wet corn bran in the rotation roller, using an air guide device and a heat supply system to enable the wet corn bran to make fully contact with hot air in the rotation roller, thus realizing heat transfer and mass transfer drying purpose; 4, the dried corn bran dregs are discharged by a discharge device through a material outgoing device at the end of the rotation roller, and cooled by a cooling system so as to obtain the guniting corn bran finished product. The method is simple, fast, and suitable for flow production.

Owner:马鞍山中粮生物化学有限公司

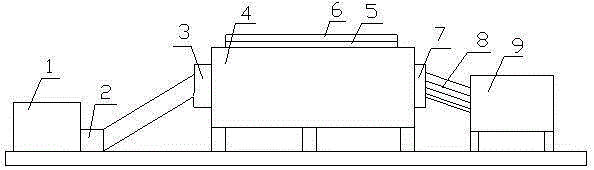

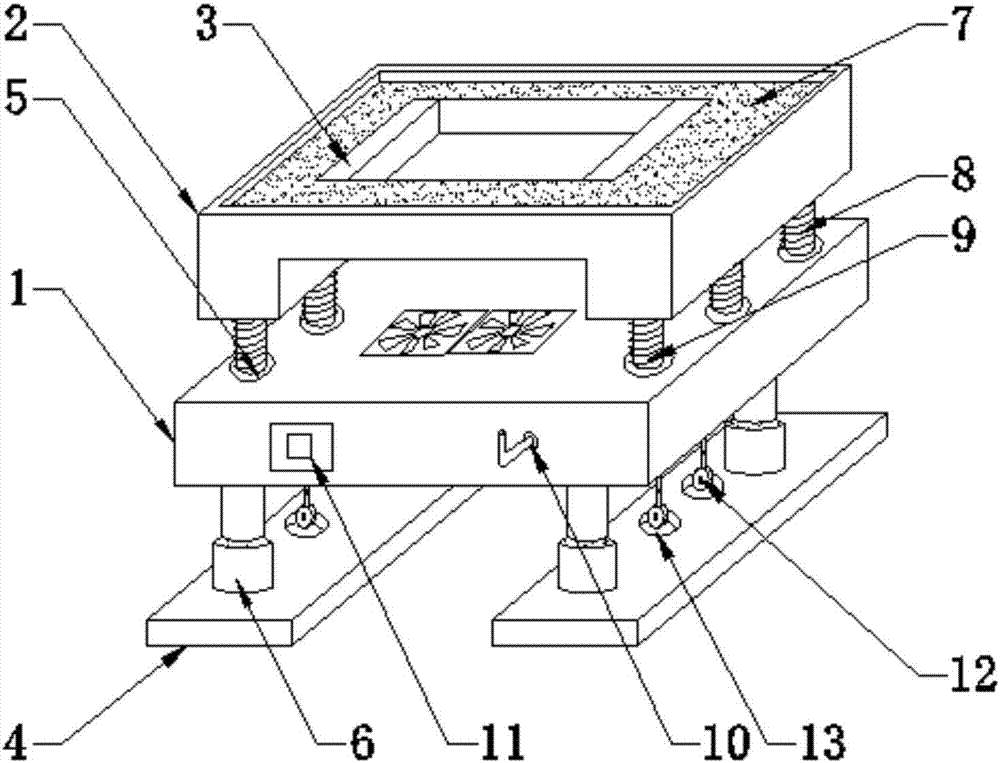

Electromechanical equipment installation supporting base with heat dissipation function

InactiveCN107489862AWith cooling functionReduce vibrationNon-rotating vibration suppressionStands/trestlesPhysical hard workSoftware engineering

Disclosed is an electromechanical equipment installation supporting base with a heat dissipation function. The electromechanical equipment installation supporting base with the heat dissipation function comprises a supporting pedestal. Outer shock-absorbing pipes are arranged on the top of the supporting pedestal, and inner shock-absorbing pipes are arranged inside the outer shock-absorbing pipes. A supporting panel is installed on the tops of the inner shock-absorbing pipes, and an installation groove is formed in the upper portion of the supporting panel. Heat conduction plates are symmetrically arranged in the middle of the supporting panel, and are made of silicon carbide. Locating holes are formed inside the heat conduction plates, and a square ventilation opening is formed between the heat conduction plates. A dust cover is arranged on the top of the supporting pedestal, Y2-90L-4 motors are arranged at the bottom of the dust cover, and rotating rods are arranged on the tops of the Y2-90L-4 motors. A lifting handle is arranged on the front portion of the supporting pedestal, telescopic supporting legs are arranged at the bottom of the supporting pedestal, and stress plates are arranged at the bottoms of the telescopic supporting legs. According to the electromechanical equipment installation supporting base with the heat dissipation function, due to the fact that universal wheels are arranged, the supporting base is easily moved, the physical labor of porters can be reduced, and the electromechanical equipment installation supporting base with the heat dissipation function has the high application value.

Owner:安徽华艾堂医疗科技有限公司

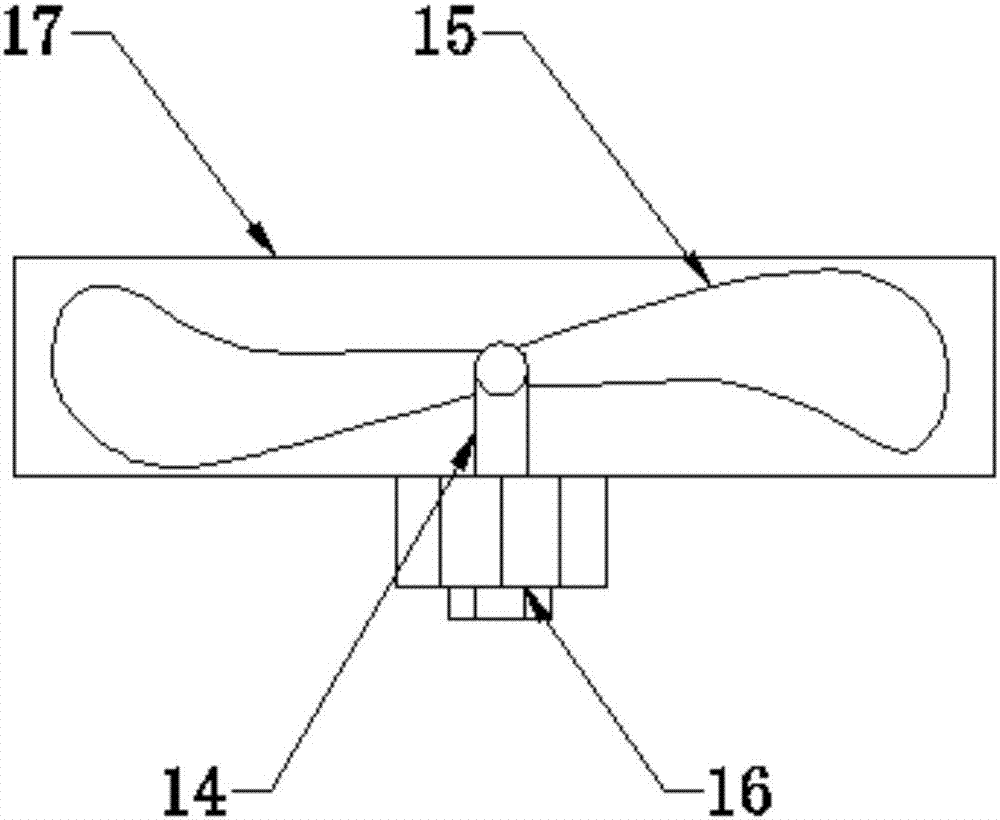

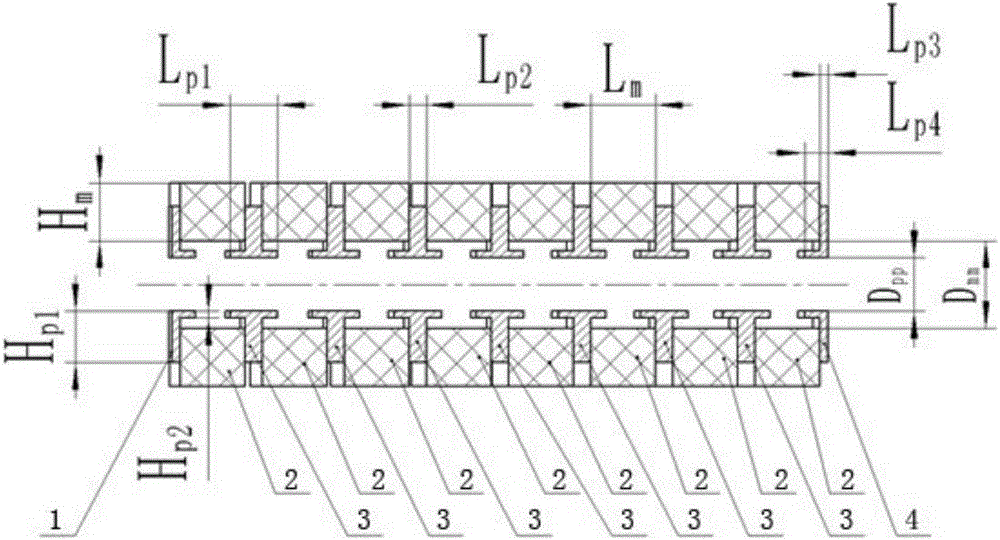

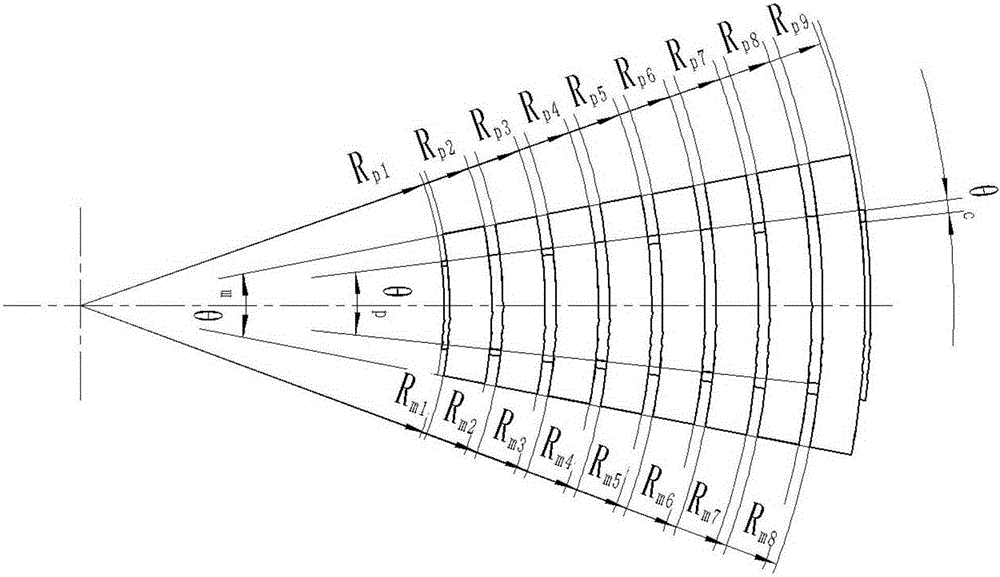

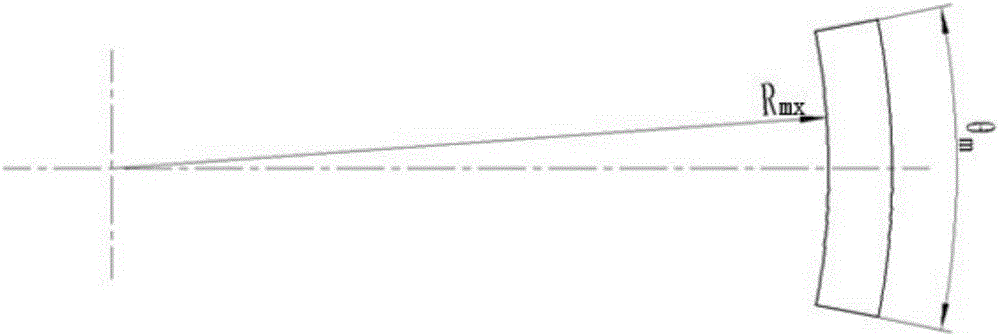

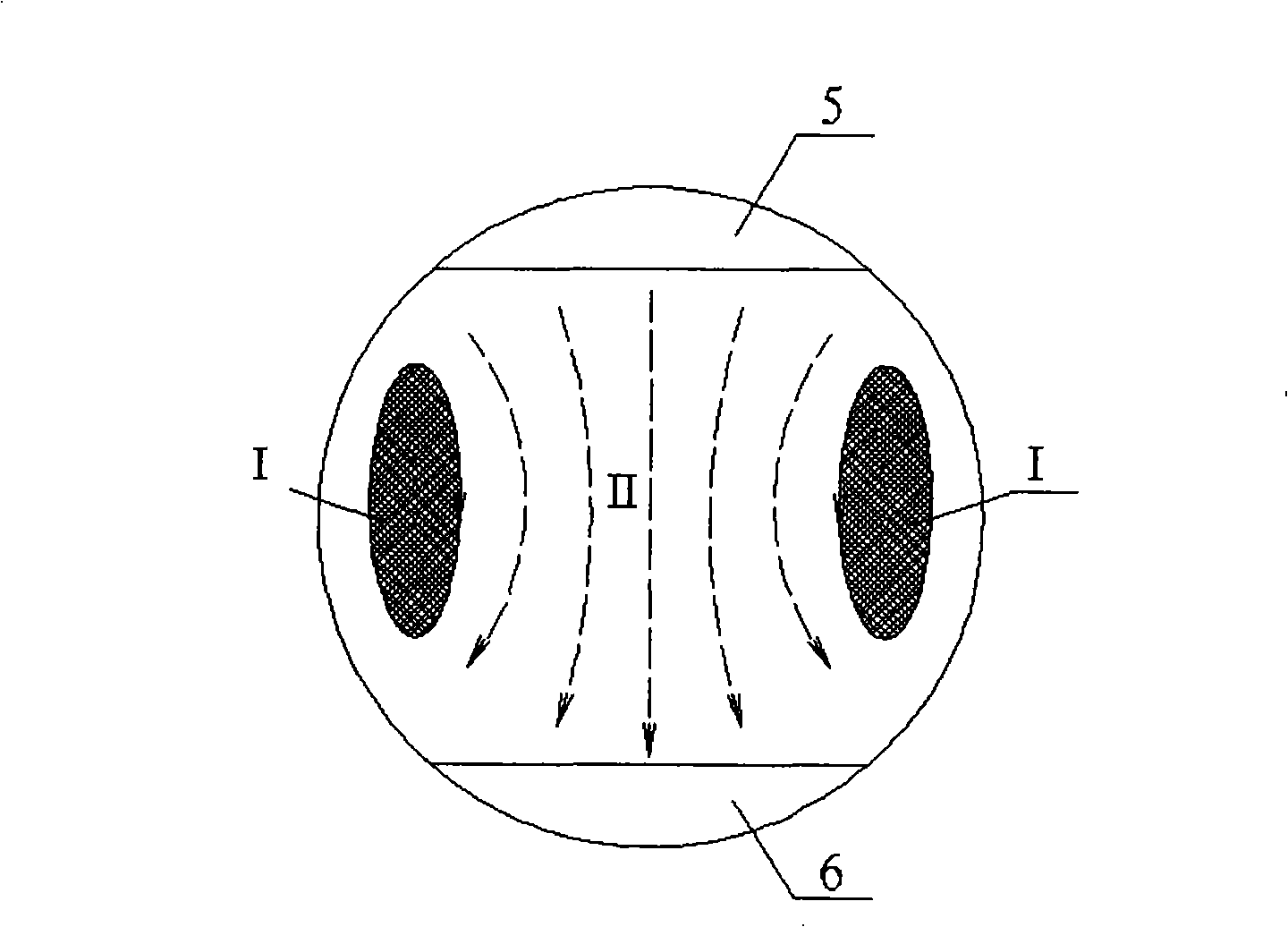

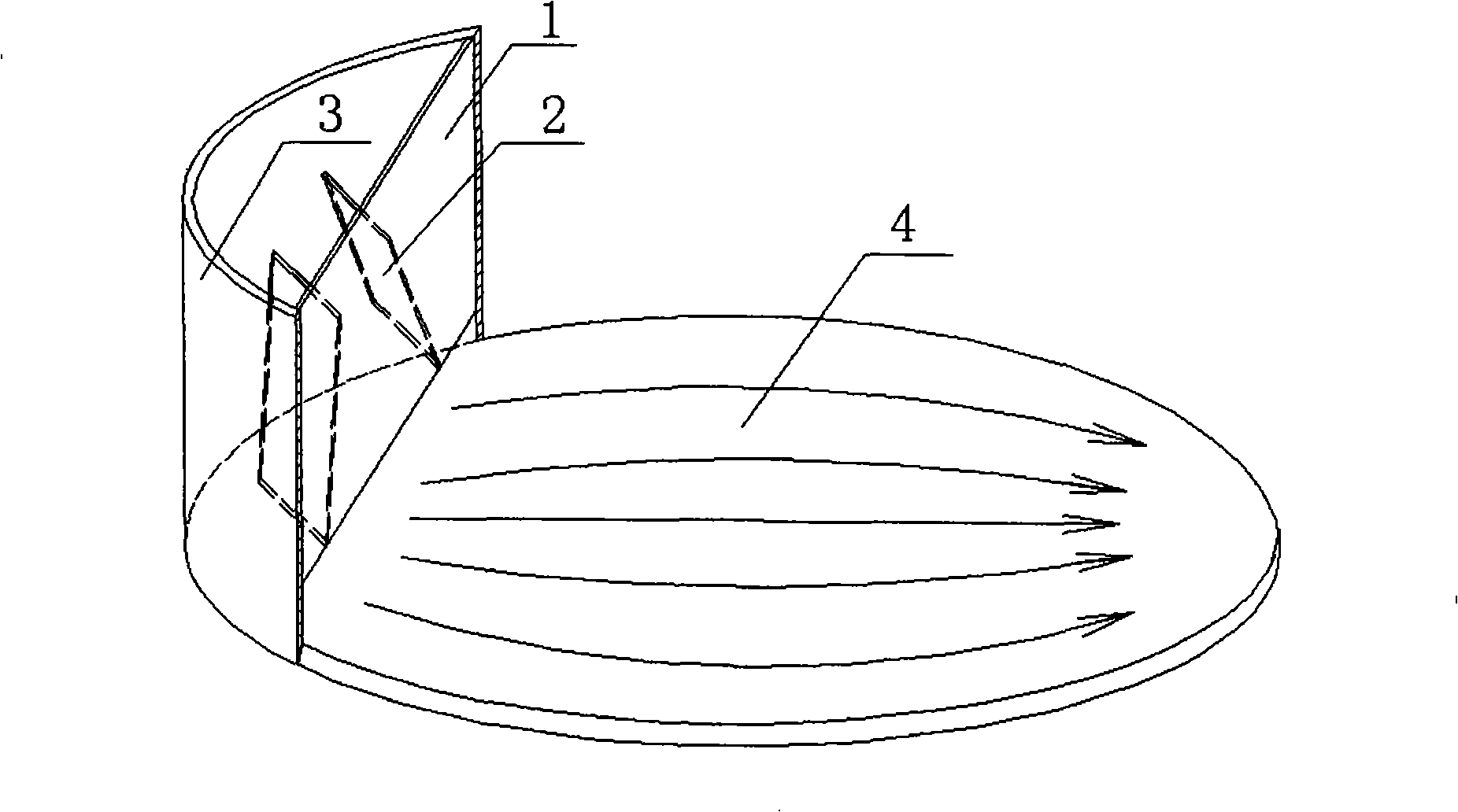

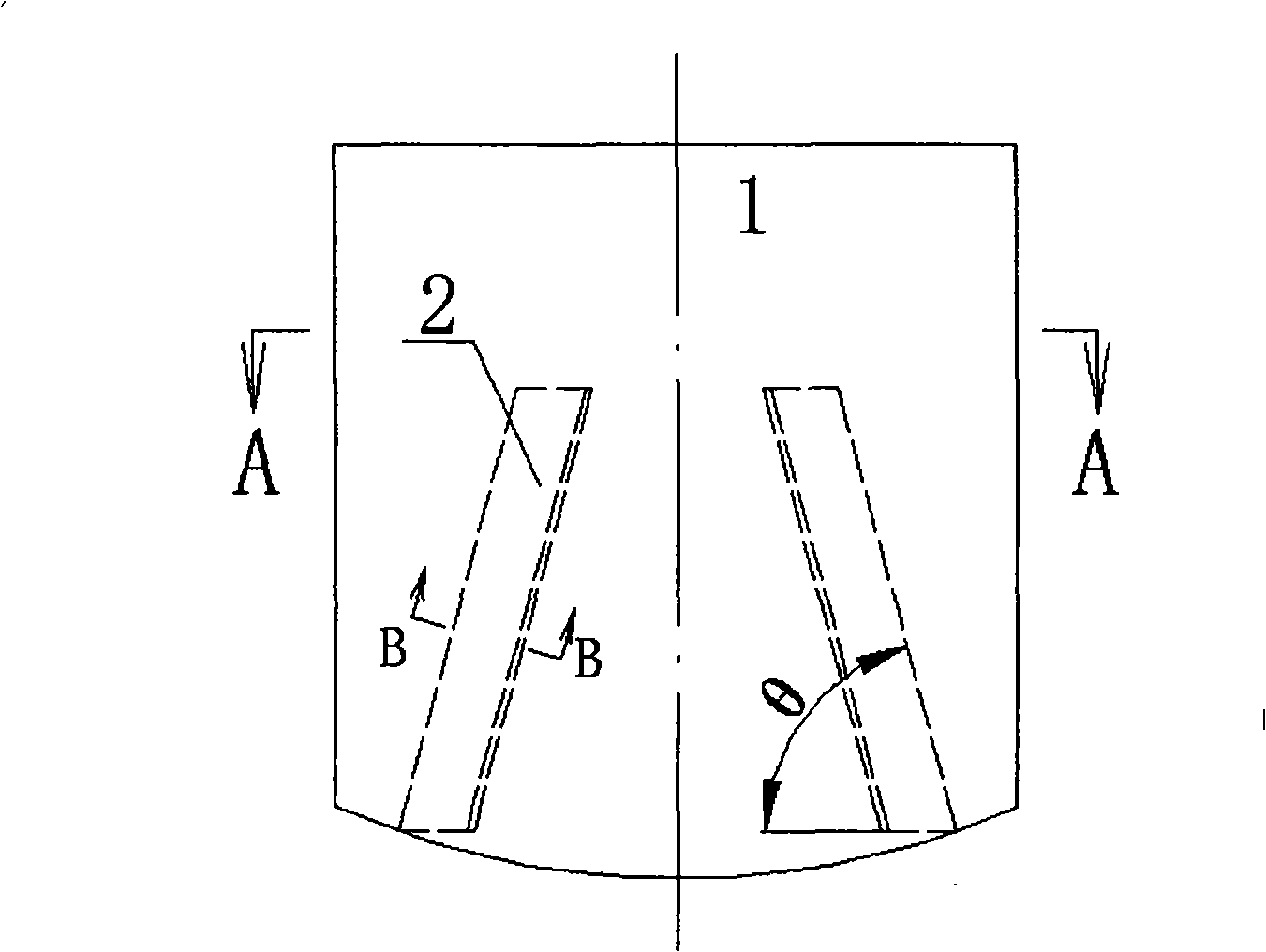

Radial fan-shaped magnetic focusing system for radial beam traveling-wave tube

The invention discloses a radial fan-shaped magnetic focusing system for a radial beam traveling-wave tube, and belongs to magnetic focusing systems in the technical field of vacuum electron devices. A magnetic field distributed in the radial direction is generated by the focusing system, and the direction of the magnetic field is divergent in the radial direction, so that a radial component of the magnetic field and a moving trajectory of a radial electron beam are consistent, and the focusing effect of the focusing system on the radial fan-shaped electron beam is improved. According to the technical scheme, the radial fan-shaped magnetic focusing system for the radial beam traveling-wave tube comprises a permanent magnet with the cross section shaped like a rectangle and a pole shoe with the cross section shaped like a T, the permanent magnet is shaped like a fan, and the pole shoe is shaped like a fan. Due to the fact that the permanent magnet and the pole shoe are both designed to be of a fan-shaped structure, the direction of the radial magnet field generated by the radial fan-shaped magnetic focusing system is in a radial mode, the direction of the radial magnetic field is matched with the moving trajectory of the electron beam which runs in a radial mode, and the focusing effect of the focusing system on the electron beam is significantly improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

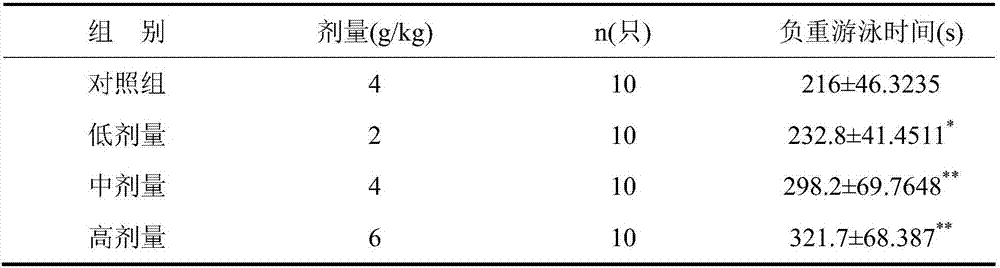

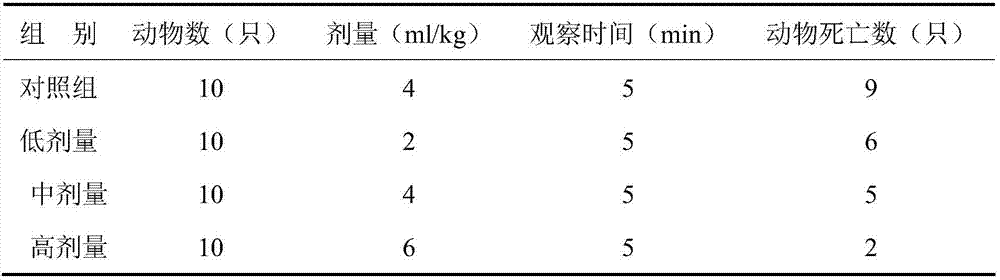

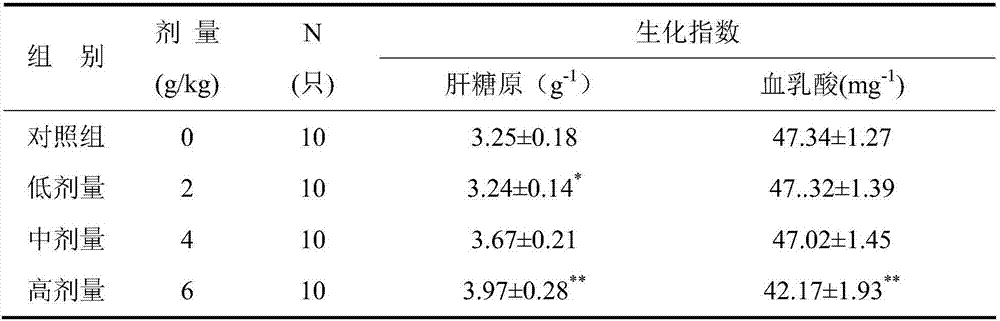

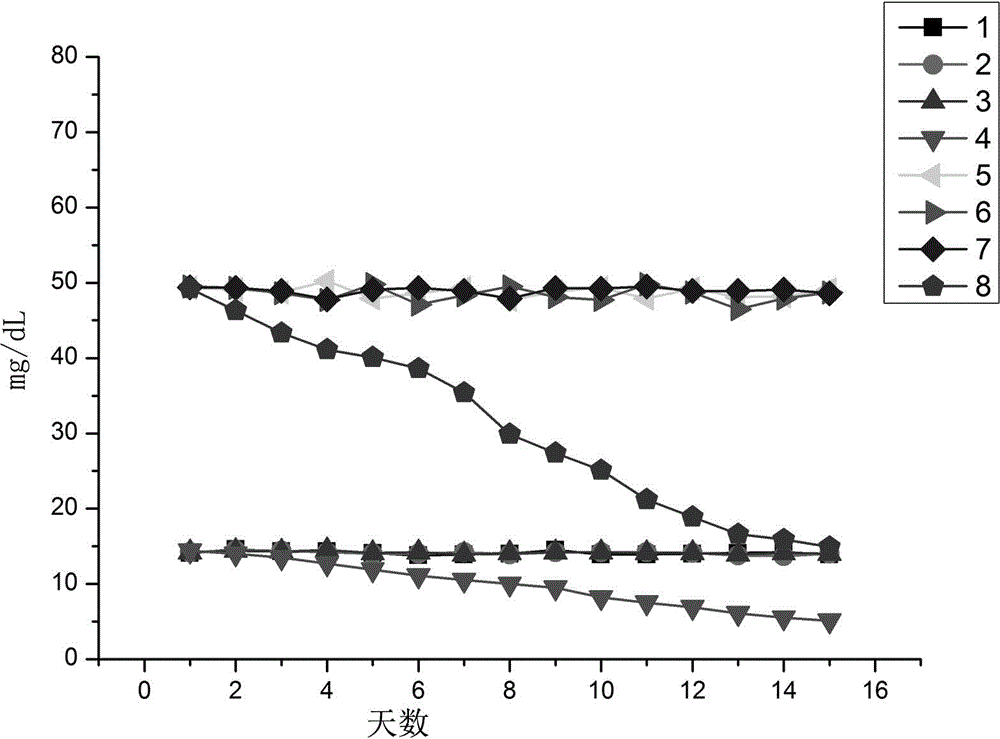

Preparation method for deer blood peptide and anti-fatigue effect of deer blood peptide

InactiveCN107164446AWorks well togetherHydrolysed protein ingredientsAntinoxious agentsFiltrationHydrolysis

The invention relates to a preparation method of deer blood peptide and its anti-fatigue effect, belonging to the field of medicine. Drying of deer blood: use a spray dryer, adjust the inlet temperature to 180°C, the outlet temperature to 80°C, and the speed to 26,000-30,000 rpm; deer blood protein hydrolysis: the concentration of deer blood protein is 3%, and alkaline protease is used for hydrolysis , The hydrolysis conditions are: temperature 53°C, time 5.5h, pH 9.5, enzyme amount 1272u / g; purification of deer blood peptide: membrane filtration and gel chromatography. In the present invention, the anti-fatigue experiment of mice is used to study the activity of the deer blood peptide. Animal experiments show that the polypeptide produced by the optimal hydrolysis process can significantly prolong the swimming time and low-pressure hypoxia tolerance of mice, the content of liver glycogen is significantly higher than that of the control group, and the content of blood lactic acid is significantly lower than that of the control group; It has good anti-fatigue effect.

Owner:吉林省金鹿药业有限公司

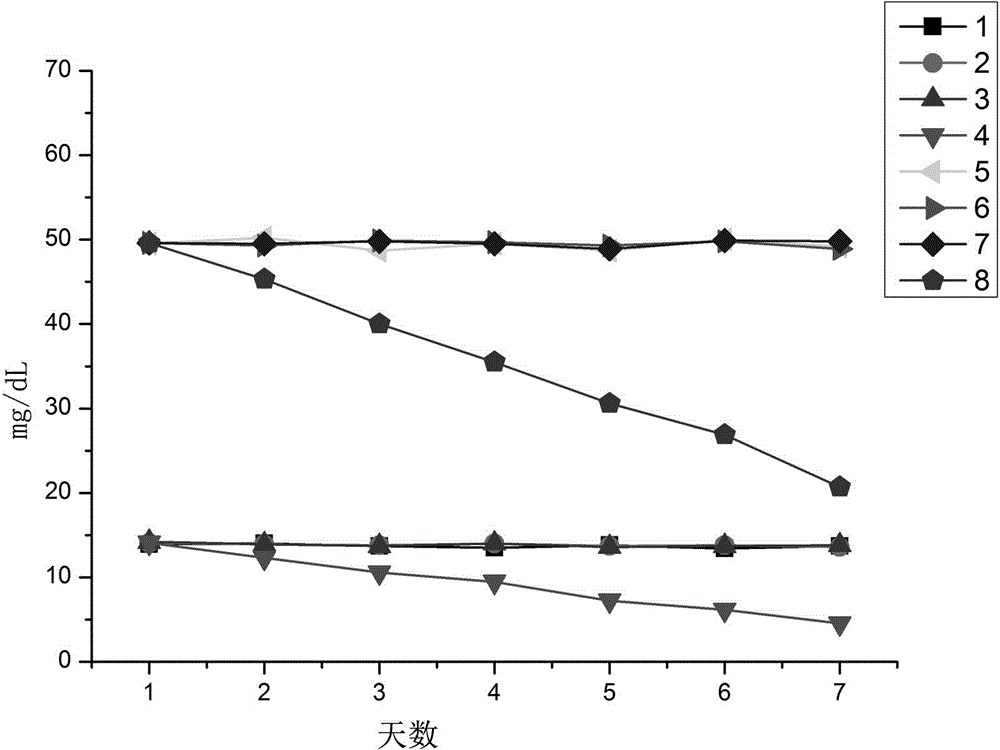

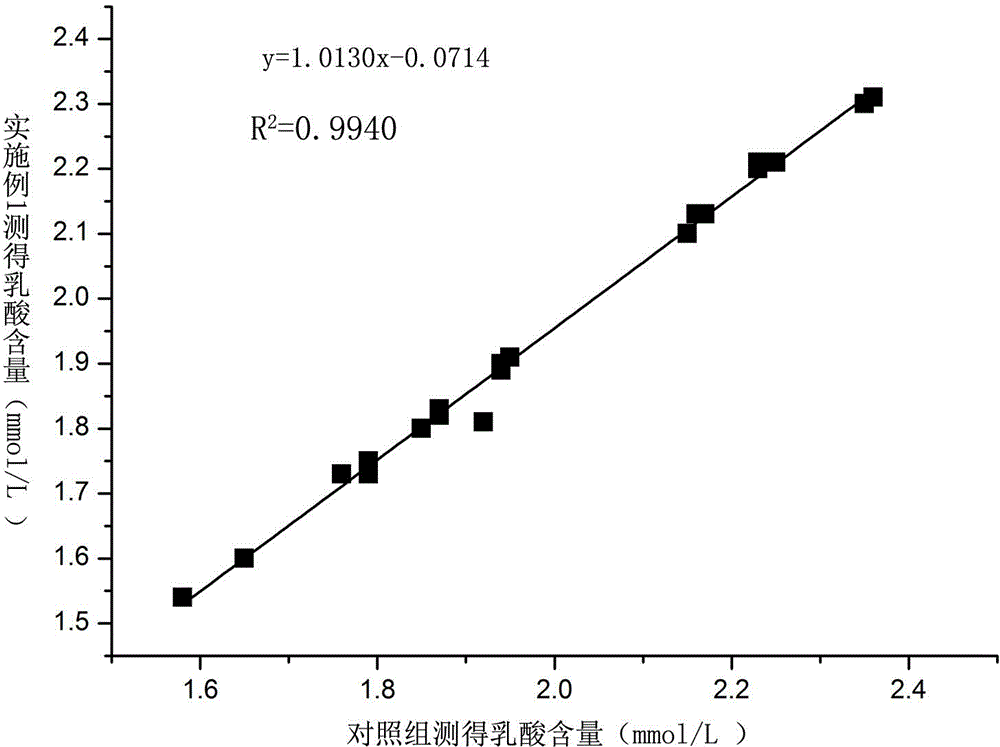

Strong-stability lactic acid detection reagent

ActiveCN104388530AEffectively get out of the wayNot easy to decomposeMicrobiological testing/measurementBiochemistryOrganic chemistry

The invention discloses a strong-stability lactic acid detection reagent, belonging to the technical field of clinical in-vitro detection. The strong-stability lactic acid detection reagent comprises two components, namely a reagent R1 and a reagent R2; substances in the reagent R1 and the reagent R2 are reasonably matched in use, so that the whole reagent system is in a stable state. Compared with a conventional lactic acid detection reagent, the strong-stability lactic acid detection reagent has a relatively excellent stability effect and is beneficial to the clinical popularization and use.

Owner:孟怡然 +1

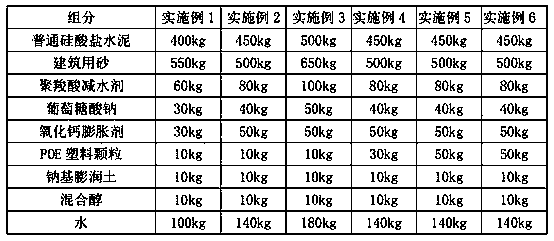

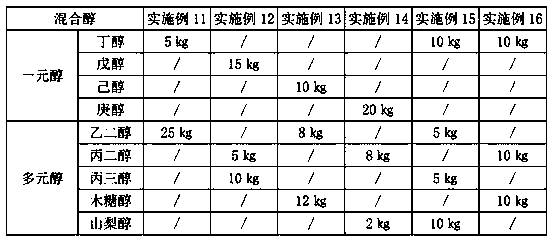

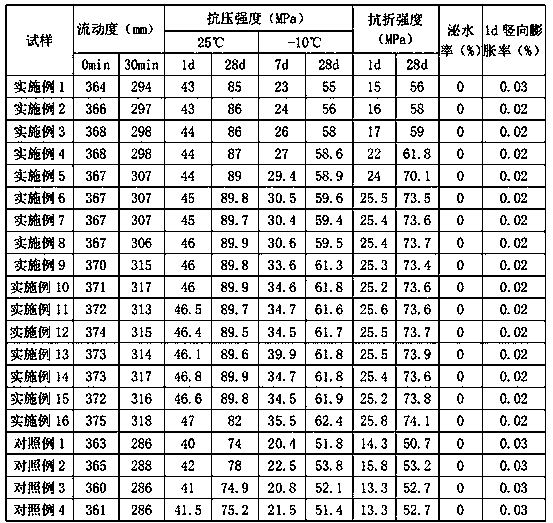

Grouting material for connection of prefabricated concrete member sleeves for prefabricated construction and preparation method thereof

ActiveCN109824320AImprove compression and impact resistanceAvoid crackingHigh intensityCompressive strength

The invention discloses a grouting material for the connection of prefabricated concrete member sleeves for prefabricated construction, and belongs to the technical field of cement based grouting materials. The grouting material comprises following components in parts by weight: 40 to 50 parts of silicate cement, 55 to 65 parts of building sand, 6 to 10 parts of water reducer, 3 to 5 parts of early strength agent, 3 to 5 parts of expanding agent, 1 to 5 parts of damping particles, 1 to 3 parts of bentonite, 1 to 3 parts of mixed alcohol, and 10 to 18 parts of water. The grouting material has the characteristics of excellent fluidity, high compressive strength and high rupture strength, maintains high strength at a low temperature, and is suitable for low temperature construction. The invention also discloses a preparation method of the grouting material. The preparation method has the advantages of simple steps and low raw material cost, and is suitable for popularization and application.

Owner:南京华致建设集团有限公司

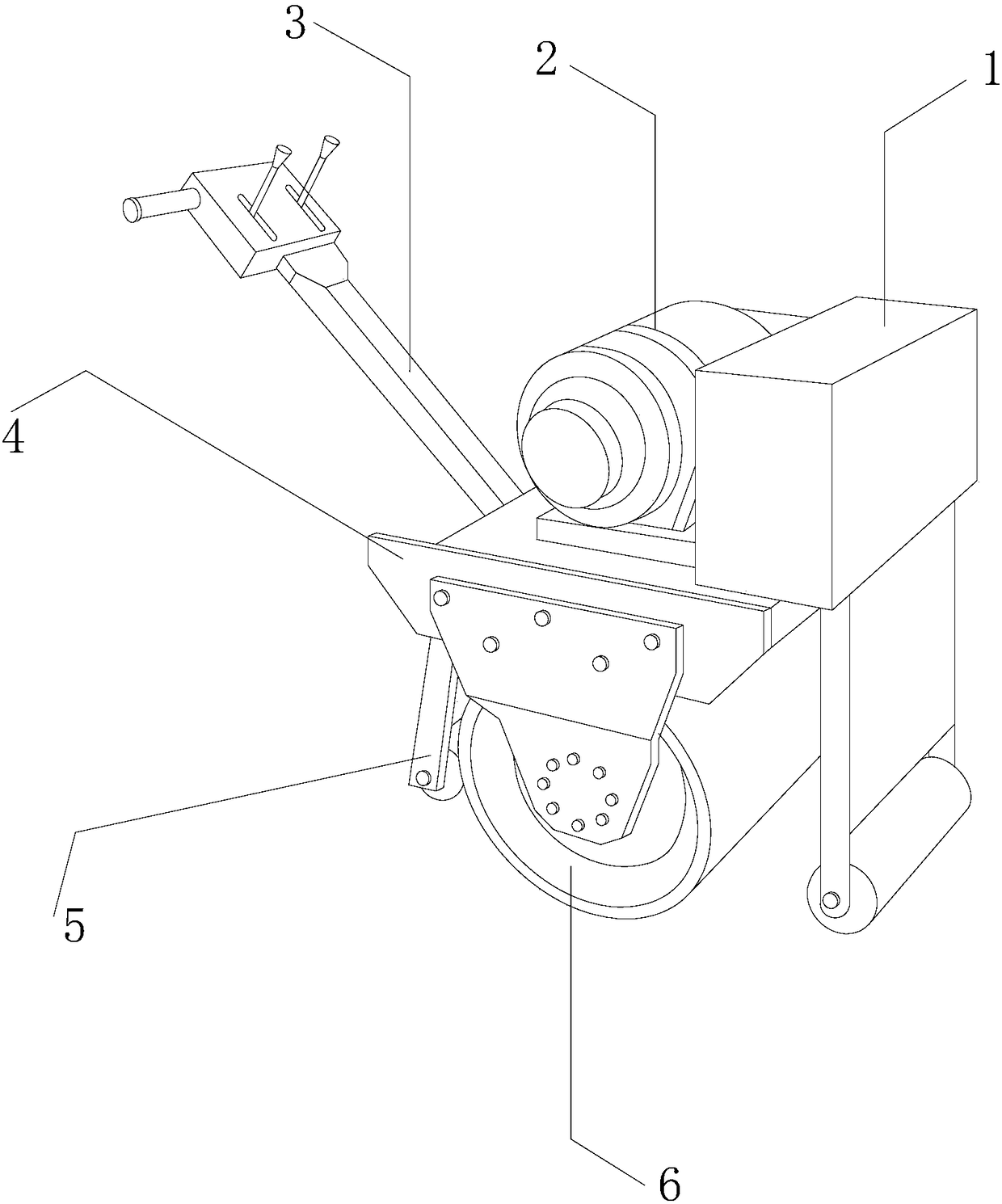

Concrete bulldozing device for building construction

The invention discloses a concrete bulldozing device for building construction. The concrete bulldozing device structurally comprises a bulldozing device body, an engine, a control push rod, a machinebody, a slurry-removing roller and a compacting-trowelling drum. The bulldozing device body and the control push rod are arranged at the front end and the rear end of the engine; the bulldozing device body is fixed to the machine body in a buckled mode; and the control push rod is connected with the engine and the bulldozing device body through wires. Accumulated concrete can be bulldozed by thebulldozing device body through control of the control push rod and then further compacted and trowelled through the compacting-trowelling drum, accordingly, the concrete laying efficiency is improved,and labor intensity is reduced; and slurry adheres to the surface of the compacting-trowelling drum in the rolling process, the slurry on the surface of the compacting-trowelling drum can be timely removed through a drum slurry-removing mechanism, and the effects of compacting and trowelling of the compacting-trowelling drum are improved advantageously.

Owner:莆田市拓凡达贸易有限公司

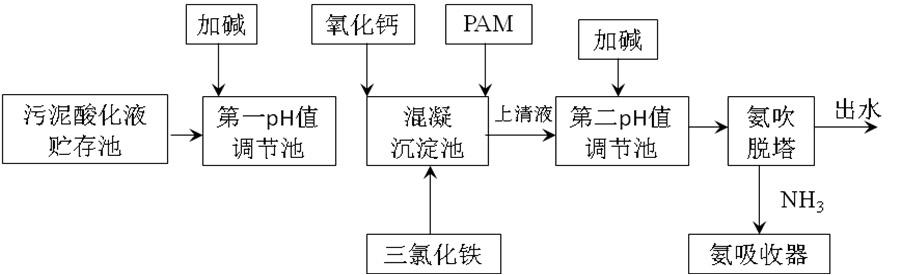

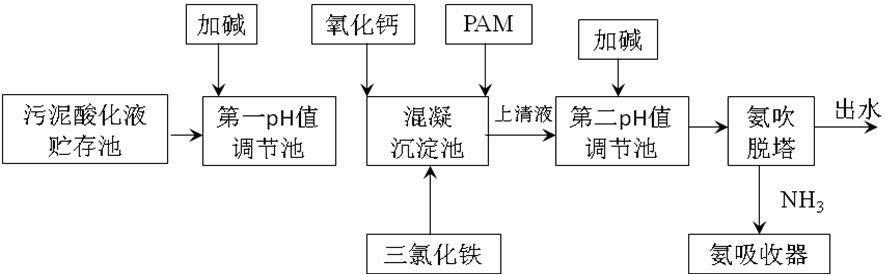

Method for removing nitrogen and phosphorus from sludge anaerobic acidification liquor

InactiveCN102531241AReduce negative impactNo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeSewage treatment

The invention belongs to the technical field of environmental protection, in particular to a method for removing nitrogen and phosphorus from a sludge anaerobic acidification liquor. The method comprises the following steps of: regulating the pH value of the acidification liquor to be 10-12 by using diluted NaOH, removing the phosphorus from the acidification liquor through coagulating sedimentation by using chemical reagents, namely CaO and FeCl3 coagulants and a coagulant aid polyacrylamide (PAM), and removing the nitrogen from the acidification liquor by using an ammonia stripping process. The method has a high effect of removing the nitrogen and the phosphorus from the acidification liquor. The acidification liquor treated by the method has high capacity of serving as a denitrification carbon source, and can serve as an additional carbon source for denitrification in sewage treatment plants.

Owner:FUDAN UNIV

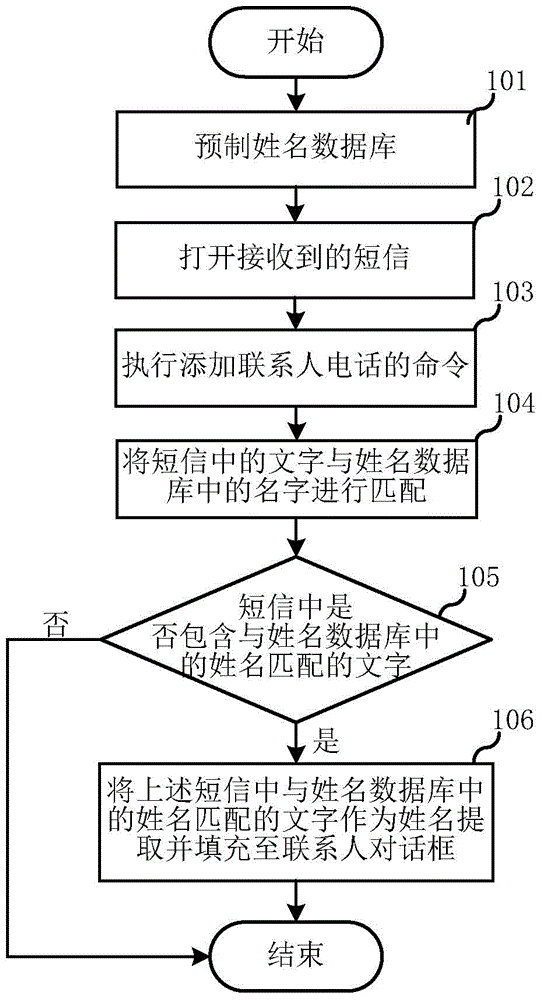

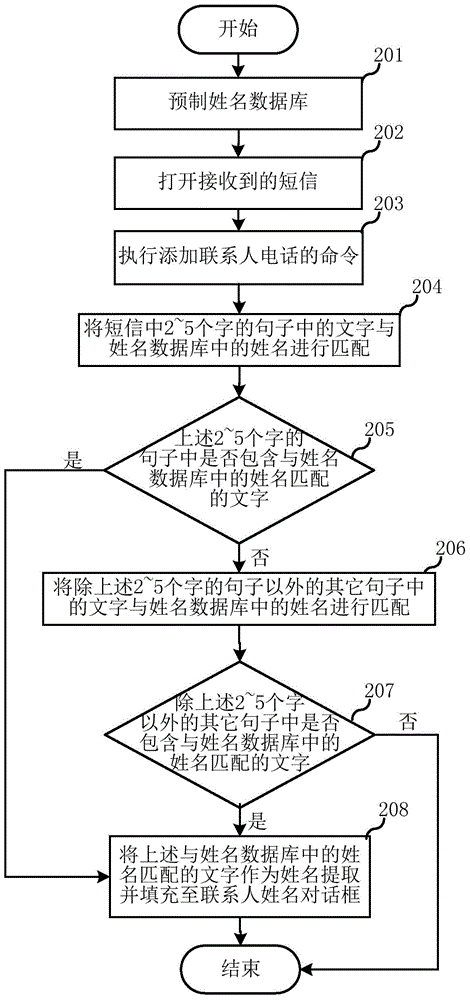

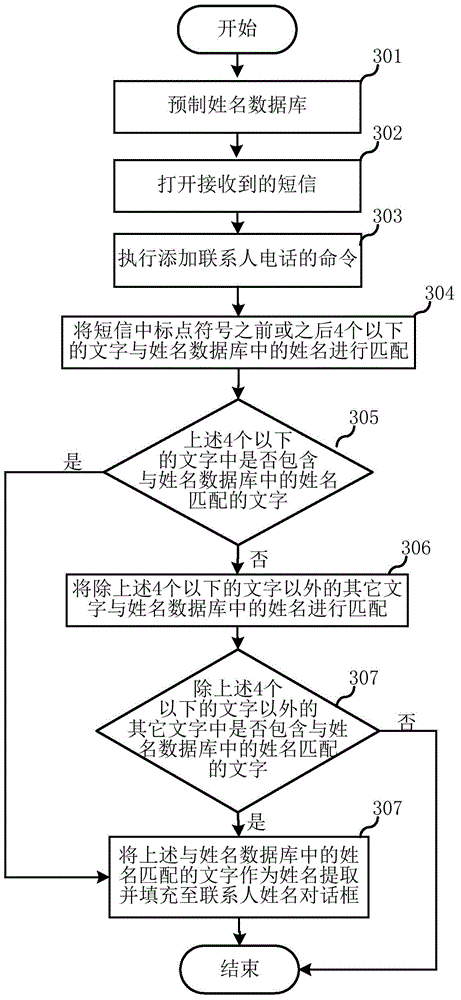

Method and device for automatically identifying and extracting a name in short message

The invention relates to the communication field and discloses a method and a device for automatically identifying and extracting a name in a short message. The method comprises steps that: a name database is pre-built; a received short message is opened; an instruction for adding a contact person telephone is carried out; matching of characters in the short message and names in the database is carried out; if a character in the short message is in matching with a name in the database, the character is taken as the name which is extracted and filled in a dialog box of the contact person name. Compared with the prior art, a user can successfully add numbers of contact persons without manually inputting contact person names after a number change short message is received.

Owner:SHANGHAI ZHUO YOU NETWORK TECH

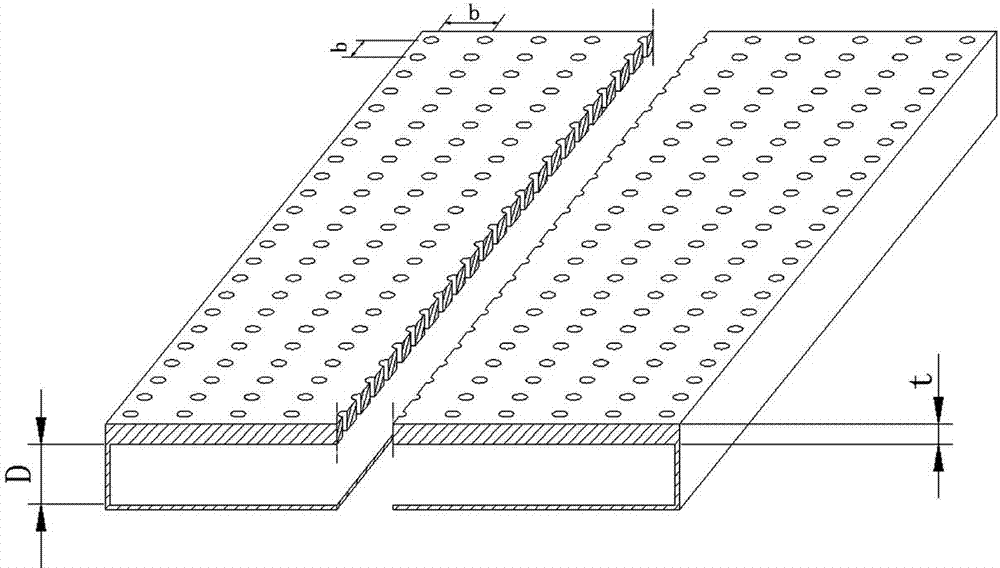

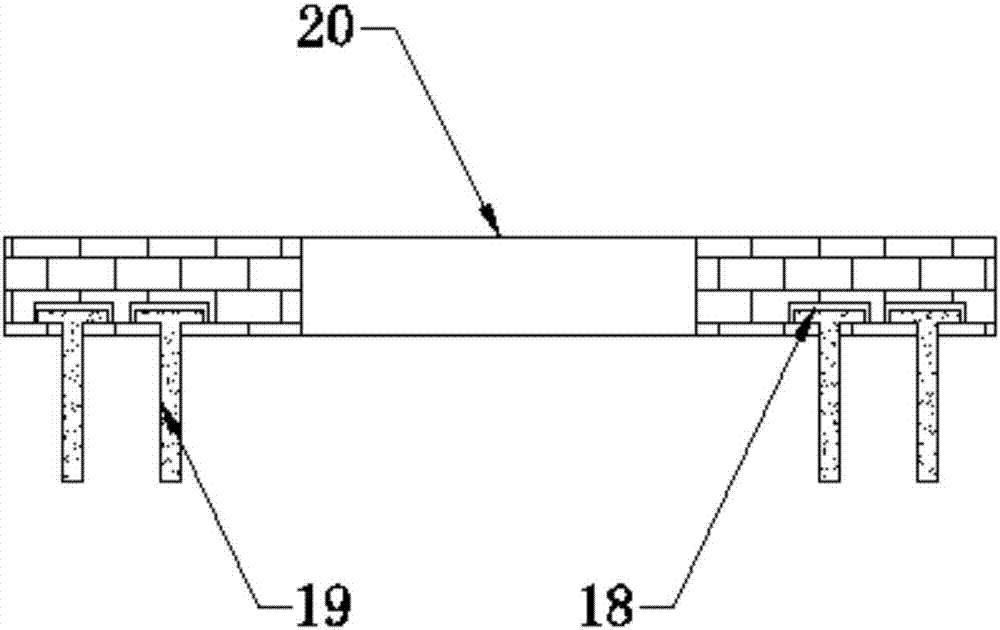

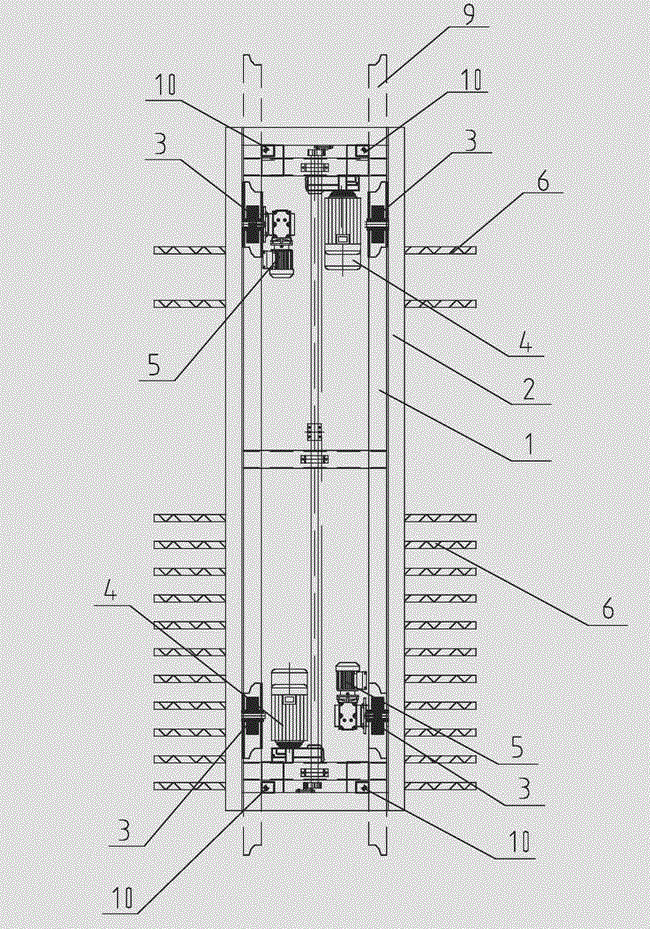

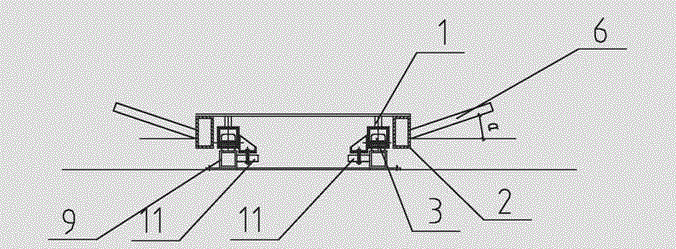

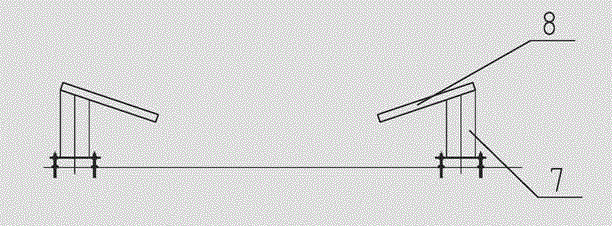

Comb tooth exchange transportation vehicle of self-stabilizing structure and vehicle parking fixing frame used cooperatively

The invention relates to a comb tooth exchange transportation vehicle of a self-stabilizing structure. The comb tooth exchange transportation vehicle comprises a bottom frame, a lifting frame capable of being lifted relative to the bottom frame, idler wheels used for driving the bottom frame to walk, a lifting drive device used for driving the lifting frame to be lifted, and an advancing drive device used for driving the idler wheels to roll. The front section and the rear section of the lifting frame are each provided with comb teeth which protrude in the direction of the left side and the direction of the right side of a vehicle body and are symmetrically distributed in parallel at intervals with the lifting frame as the center. The comb teeth gradually incline upwards from inside to outside from the connecting portion. The comb tooth exchange transportation vehicle overcomes the defect that an existing comb tooth exchange transportation vehicle and a vehicle parking fixing frame used cooperatively slide easily in the automobile transporting and parking processes, automobiles can be located in the transporting and parking processes, and not prone to shifting, an additional mechanical locating device is not needed, the production cost is greatly saved, the fault rate is reduced, use is easy, the transportation vehicle is environmentally friendly, and the efficiency and the safety of automobile transporting and parking are improved.

Owner:李东泽

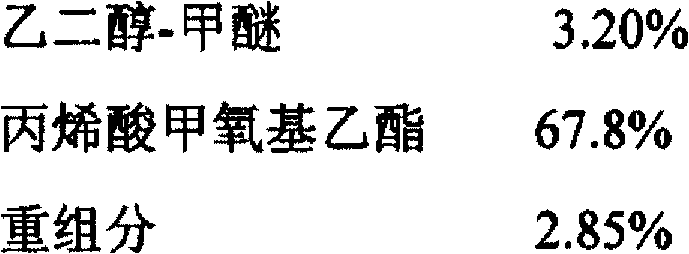

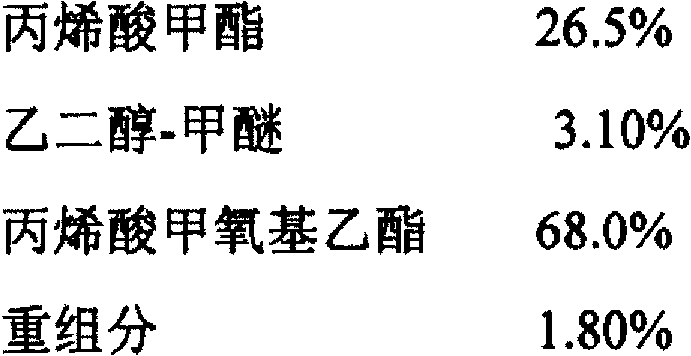

Method for preparing methoxyethyl acrylate and methoxyethyl methacrylate

ActiveCN102850217AHigh purityGood chromaPreparation by ester-hydroxy reactionOrganic compound preparationMethyl groupAzeotropic distillation

Disclosed is a method for preparing (methyl) methoxyethyl acrylate. The method includes that an integrated device with a reacting kettle on the lower portion and a rectifying tower on the upper portion is utilized, (methyl) methyl acrylate and glycol-methyl ether are used as raw materials, the raw materials are heated and reacted in the reacting kettle under the action of catalysts and polymerization inhibitors to generate the (methyl) methoxyethyl acrylate, and then the separation and purification are performed to obtain the product. According to the method, a reactive distillation and azeotropic distillation coupling technology is utilized, the reactive distillation and the azeotropic distillation are performed in the same tower, the equipment investment is reduced, the energy consumption is reduced, the material ratio is lowered, the reaction time is shortened, and the efficiency of a reactor is improved; an ester exchange process is utilized, so that the waste water can not be generated, and the highly purified (methyl) methoxyethyl acrylate can be obtained after separation; composite catalysts are utilized, so that the reacting efficiency is increased, the reaction time is shortened, and the quantity of generated polymers is lowered; and the novel polymerization inhibitors are utilized, so that the chromaticity of the product is improved.

Owner:苏州和创化学有限公司

Cassia seed scented tea for waist slimming

The invention provides a cassia seed scented tea for waist slimming. The scented tea comprises cassia seed, licorice and dried orange peel. In the scented tea, the cassia seed has the functions of gastrointestinal peristalsis promoting, removing of stubborn stool in the body, and blood fat and blood pressure reducing; the licorice has a cholesterol reducing function; and the dried orange peel has the functions of aid digesting, stomach qi eliminating and belly fat accumulation reducing, is mild in property, and can have a better effect after the mixing with mild-natured and slightly-cold herbal teas comprising the cassia seed, lotus leaf and the like, so the cooperation of the above three components can realize fat metabolism conditioning, waist fat decomposition accelerating, and timely eliminating of superfluous fats and water from the body.

Owner:NANTONG GOLDEN LAND GREEN FOOD

Hog house manure and dirt deodorant

InactiveCN109293184APromote reproductionBreed fastSpecific water treatment objectivesWaste water treatment from animal husbandryBacteroidesMicrobial agent

A hog house manure and dirt deodorant is characterized in that the hog house manure and dirt deodorant mainly comprises Bacillus lichogiformis, Bacillus subtilis, highly-active dry yeast, lactic acidbacteria and photosynthetic bacteria, wherein the number of effective viable bacteria in the Bacillus lichogiformis, Bacillus subtilis and photosynthetic bacteria is more than 200 millions / g. The Bacillus lichogiformis, Bacillus subtilis, highly-active dry yeast, lactic acid bacteria and photosynthetic bacteria are mixed to form a composite microbial agent, and the composite microbial agent concretely comprises 12.5 wt% of the Bacillus lichogiformis, 25 wt% of the Bacillus subtilis, 20 wt% of the lactic acid bacteria, 15-18 wt% of the highly-active dry yeast and 24-27 wt% of the photosyntheticbacteria. The deodorant further comprises bean cake powder used as a carrier together with the composite microbial agent, and the deodorant is prepared from 40 wt% of the composite microbial agent and 60 wt% of the bean cake powder, and is used for the deodorizing treatment of manure and dirt; and the optimal proportion of the highly-active dry yeast is 17.5%, and the optimal proportion of the photosynthetic bacteria is 25%.

Owner:邓州市汇海农业科技有限公司

Column plate downcomer for evenly distributing liquid stream

InactiveCN101306257AUniform initial distributionImprove efficiencyDistillation separationPistonInitial distribution

A column plate downcomer for evenly distributing liquid flow is mainly composed of a downcomer plate, a tower inner wall and a flow distribution plate, the tower inner and the flow distribution plate constitute the downcomer, the flow distribution plate is a group of metal sheets which are arranged between the downcomer plate and the tower inner wall with the different angles, the height H from the top end thereof to the top part of the downcomer is about one fourth to one second HT, the HT is the interval between the column plates, and the upper end surface uniformly divides the area of the downcomer into a plurality of channels with same or similar liquid flows, thereby effectively improving the initial distribution of the liquid in the downcomer; the lower end surface is tilted to the both sides of the downcomer to accelerate the flow of the liquid which is close to the side of the tower wall, thereby impelling the equal retention time of all flow channel regions on the column plates, minimizing the possibility of emerging a vortex cavity on the column plates, allowing the flow of the liquid on the column plates to show the ideal piston flow and further greatly improving the efficiency of the column plates.

Owner:NANJING UNIV

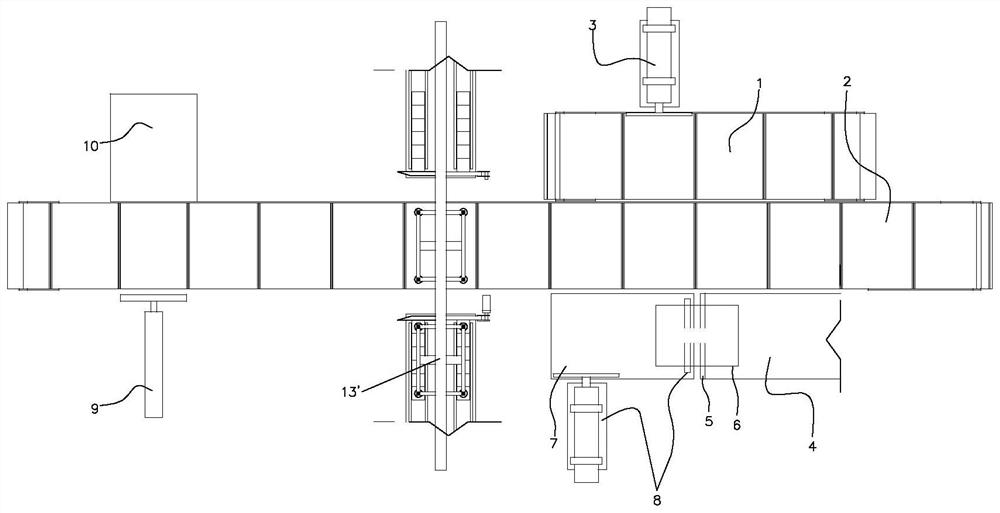

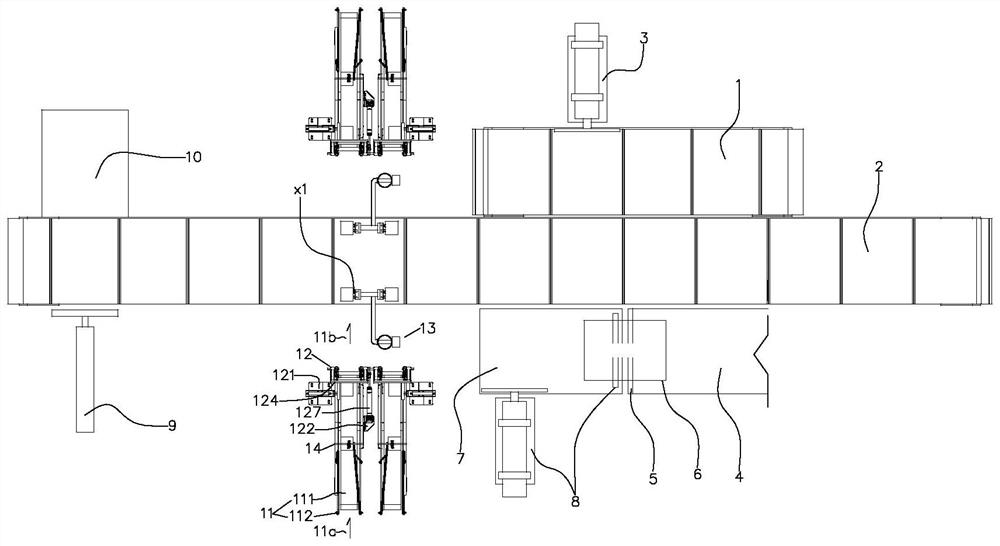

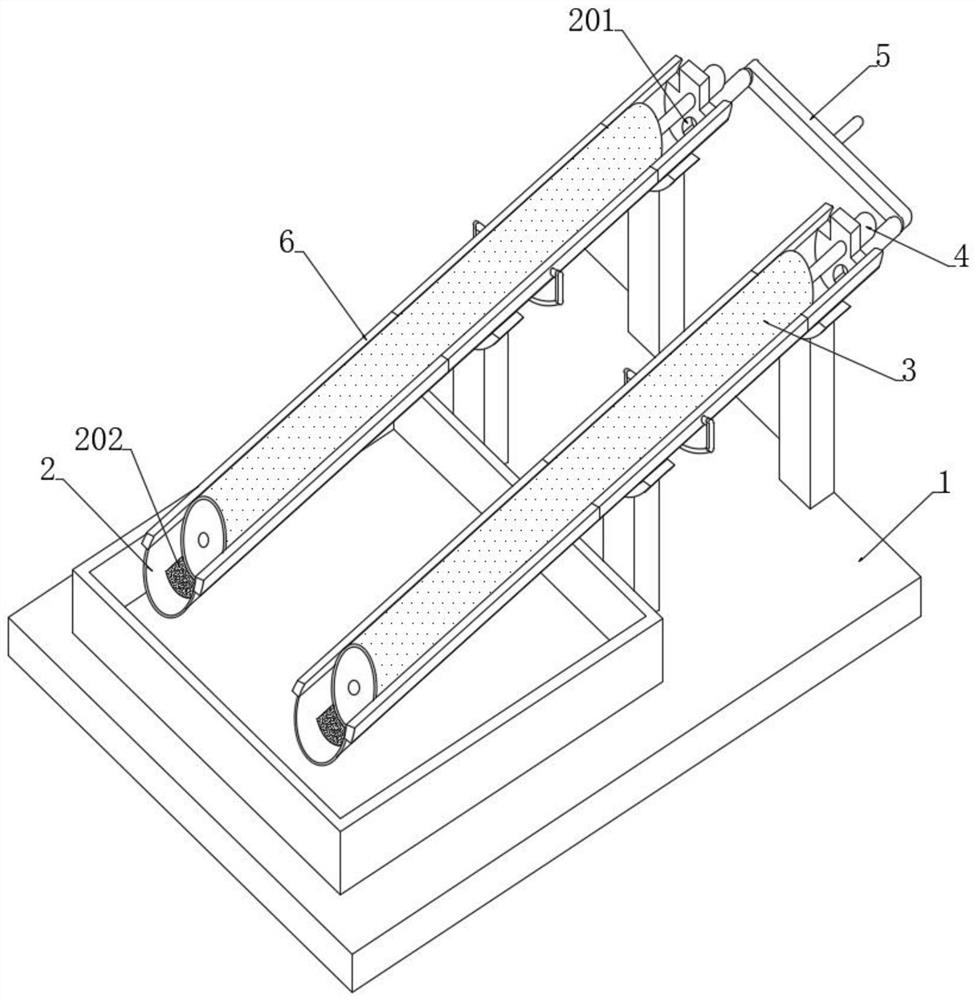

Special-shaped cigarette conveying device of tobacco packaging machine

ActiveCN114735296AHigh precisionAvoid the problem of adsorption transfer to the transfer beltWrapper twisting/gatheringFinal product manufactureCartonEngineering

The invention relates to the field of packaging machinery, in particular to a special-shaped cigarette conveying device of a tobacco packaging machine, which comprises a first conveying belt, a transfer conveying belt, a first pushing device, a baffle plate, a parallel robot, a lifting platform, a second pushing device and a third pushing device, a paper box conveying belt, a positioning device, a transferring device and a pneumatic suction cup are arranged on one side of the transfer conveying belt, a third driving cylinder drives an extending hinge shaft to rotate through a rocker, the extending hinge shaft drives a blocking frame to rotate to the output end of the paper box conveying belt, and when a paper box conveyed by the conveying belt reaches the output end, the paper box is preliminarily positioned by the blocking frame; the carton positioning device has the advantages that the carton positioning device is high in precision, and the problem of difficulty in positioning the carton on the carton conveying belt is solved.

Owner:内蒙古自治区烟草公司包头市公司

Seasoned orange peel tea containing soluble dietary fibers

The present invention discloses a seasoned orange peel tea containing soluble dietary fibers, wherein seasoned orange peel and tea leaves are subjected to raw material extraction, and are matched with soluble dietary fibers, white sugar, citric acid and water to prepare the seasoned orange peel tea. The seasoned orange peel tea has functions of digestion aiding, gastric qi removing, and abdominal fat accumulation reducing. According to seasoned orange peel tea of the present invention, the warm-natured seasoned orange peel can be matched with obtuseleaf senna seed, lotus leaf and other herbs having medium and slightly cold natures so as to provide a good effect; and the seasoned orange peel tea contains the soluble dietary fibers so as to provide effects of intestine smoothing and constipation relieving.

Owner:NANTONG XIYUN TRADE

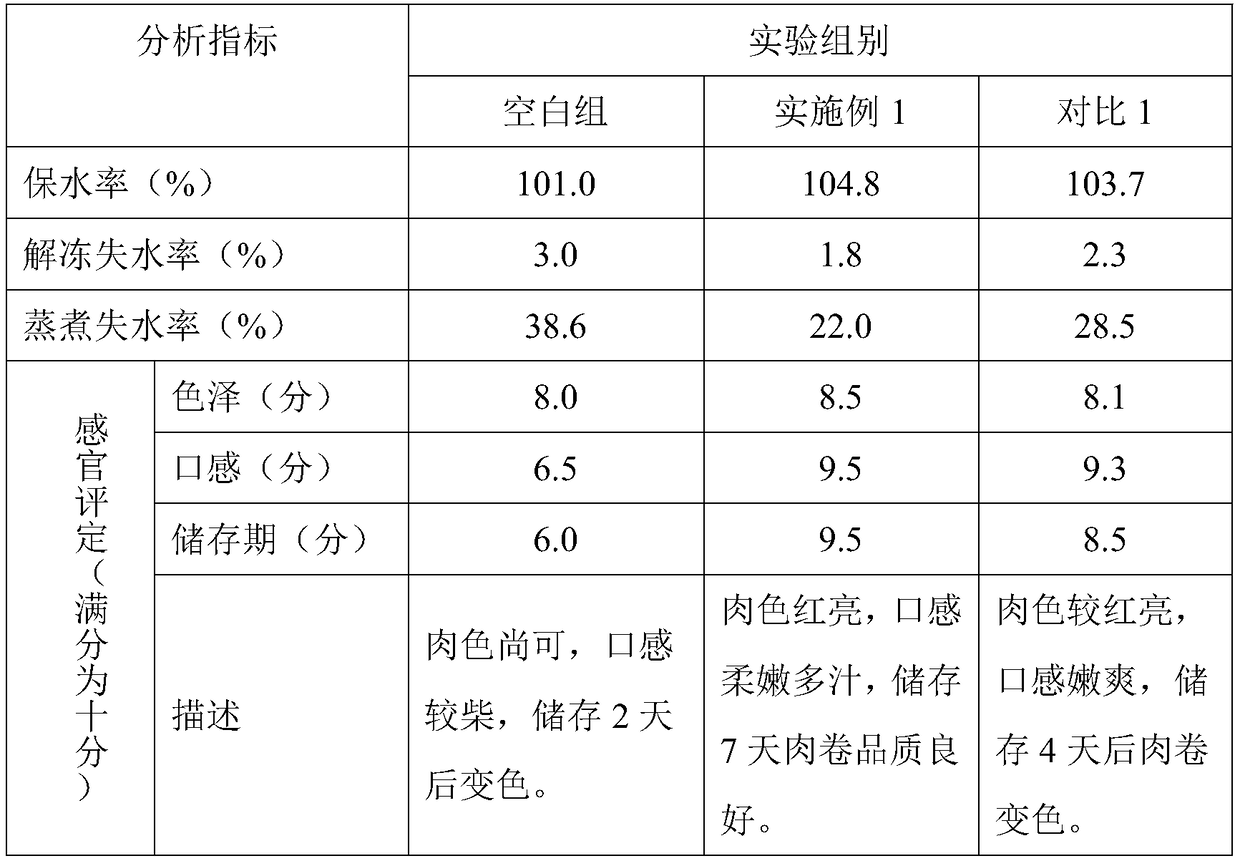

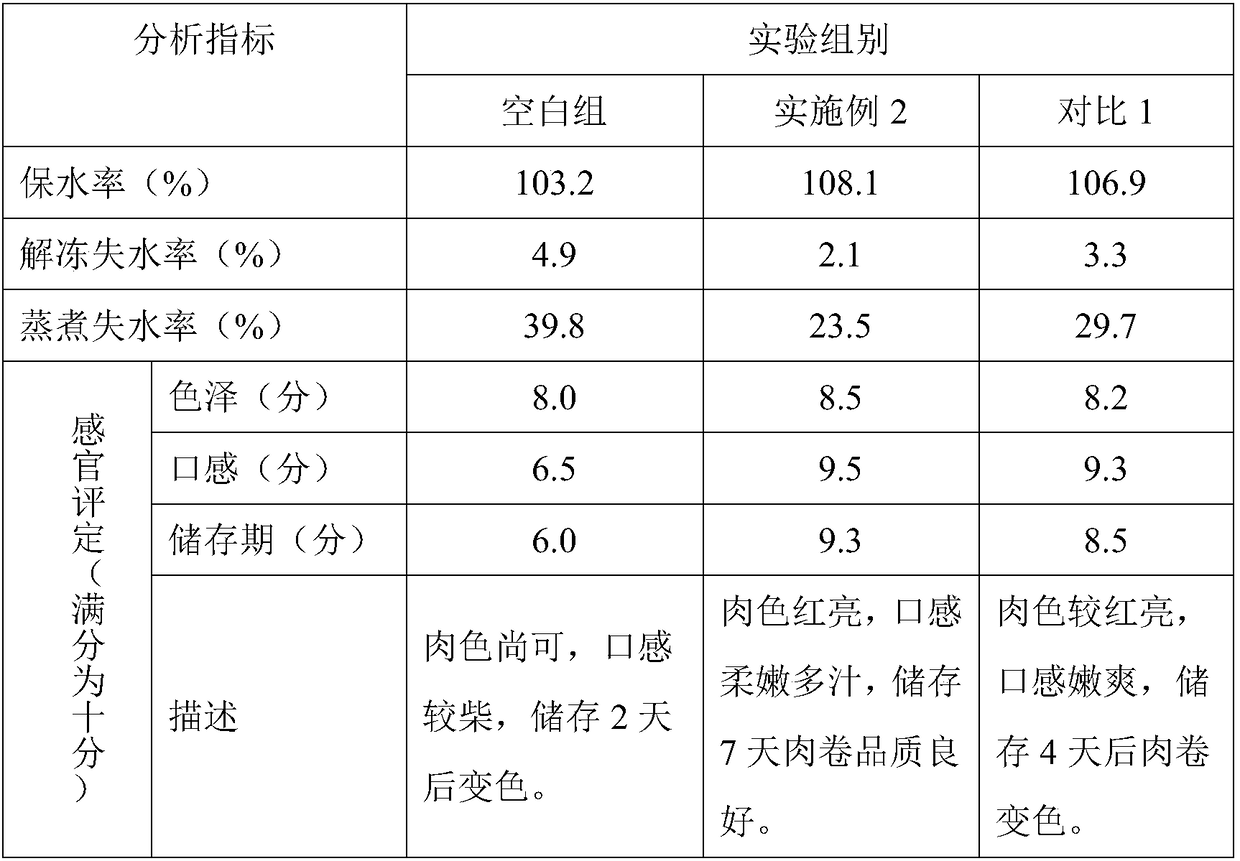

Beef roll food additive and using method thereof

The present invention discloses a product formula and a using method of a special three-in-one compound food additive with water retention, color protection and blackening prevention and for beef rolls. The product is composed of food-grade phosphate, carbonate, citric acid, salt, antioxidant and a small amount of food ingredients. The product is made into an aqueous solution, and a proper amountof the additive is added during rolling. The additive can effectively reduce the moisture loss of meat rolls, maintain the original taste and color of meat rolls, prolong the shelf life, integrate three functions into one, and avoid exceeding risks caused by the superposition use of a plurality of single-function compound food additives in the market.

Owner:湖北省兴发磷化工研究院有限公司

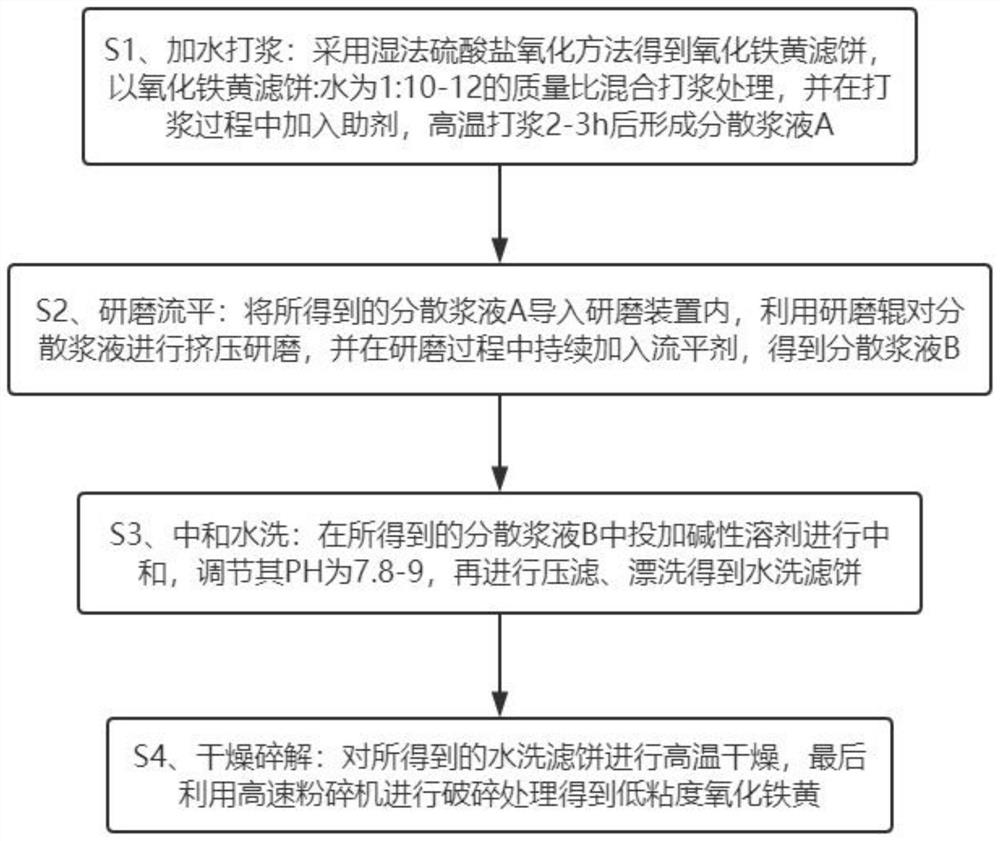

Production process of low-viscosity iron oxide yellow

InactiveCN112111180ALow viscosityReduce surface tensionCoatingsGrain treatmentsPhysical chemistrySlurry

The invention discloses a production process of low-viscosity iron oxide yellow, and belongs to the technical field of iron oxide yellow production. According to the process, water is added into an iron oxide yellow filter cake, pulping is conducted at high temperature, and an assistant is added in the high-temperature pulping process for dispersing to obtain dispersed slurry A, wherein the assistant is selected from one or more of a dispersion wetting agent and an active dispersing agent. In the process, the viscosity of the slurry is rapidly and effectively reduced and the surface characteristics of the slurry are changed in the pulping process through the assistant. Then the obtained dispersed slurry A is dispersed and ground by using a grinding device, a leveling agent is continuouslyand uniformly added in the grinding process, and grinding and leveling are performed to obtain dispersed slurry B, wherein the leveling agent is selected from one or more of acrylic acid leveling agents and organic silicon leveling agents, the wettability, smoothness and anti-blocking property of the slurry are effectively improved by utilizing leveling dispersion, and finally, the low-viscosity iron oxide yellow is prepared through filter pressing, rinsing, drying and crushing.

Owner:YIXING YUXING IND & TRADE

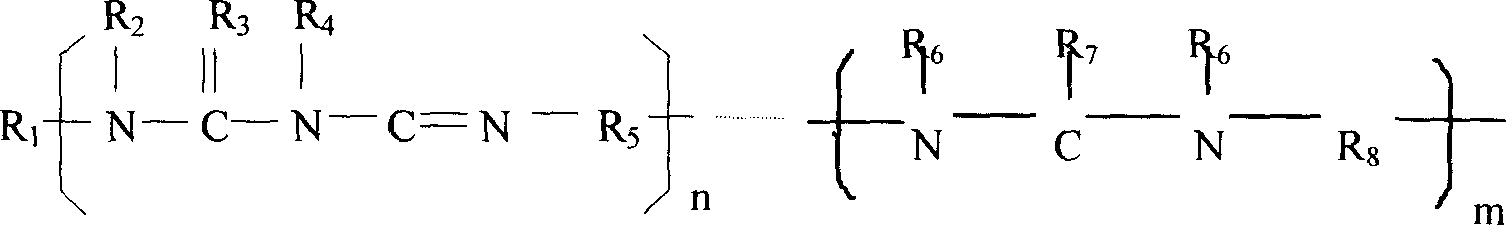

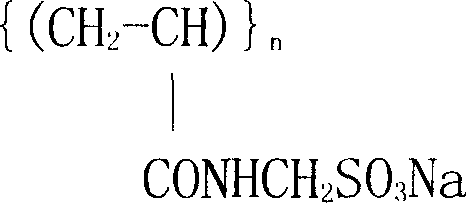

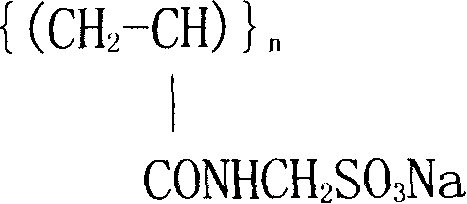

Polymer for sludge dewatering and preparation process thereof

ActiveCN101172748AEasy to operateEasy to handleSludge treatment by de-watering/drying/thickeningChemical industryPetroleum

The invention relates to a polymer for sludgy dehydration, colloidal water solution with sulfonated methyl polyarylamide as a main element obtained by using negative ion or non-ion polyacrylamide, formaldehyde, sodium bisulfite, and fresh water as raw materials, added with a small amount of auxiliary agent to react under a certain temperature. The invention has the advantages of simple technology and device, stable reaction process and easy operation. The polymer for sludgy dehydration can have better effect by being cooperated with the organic flocculant of Chinese patent 98121074.0 for using. Approved by the sludgy dehydration experiment of refinery, the polymer for sludgy dehydration of the invention has better disposal effect than exported agent under the condition of having same agent putting quantity. The filtrated solution through processing is basically lower than 2000mg / L, and the oil content is below 1000mg / L. The invention can be applicable for sewage and sludge processing in the fields of oil and chemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

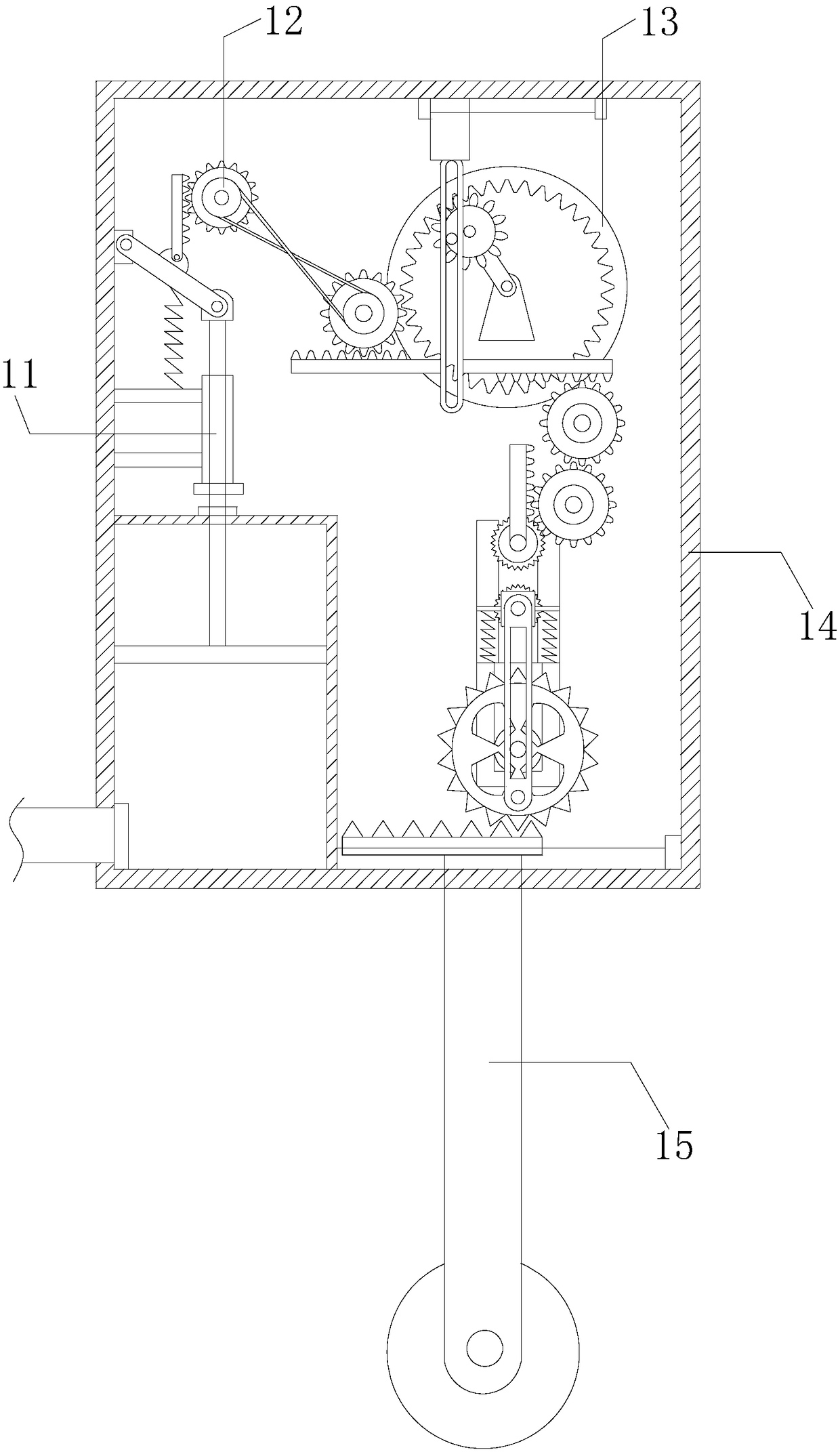

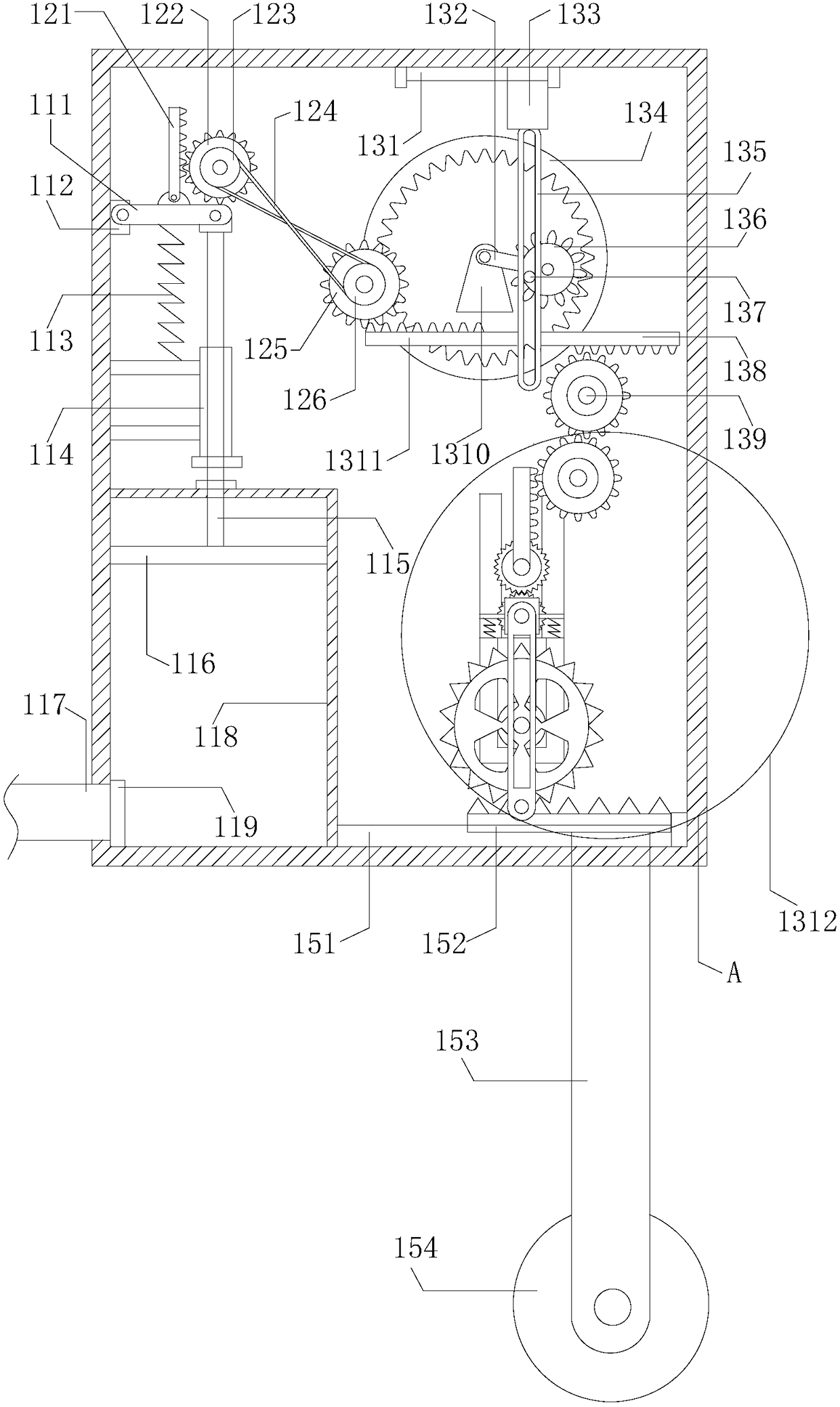

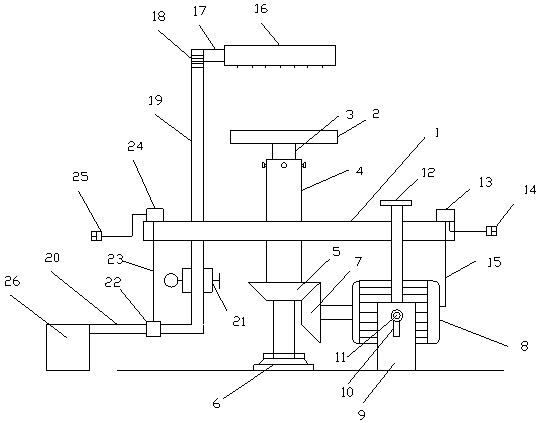

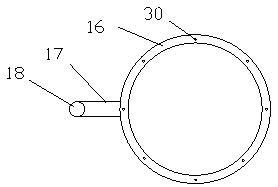

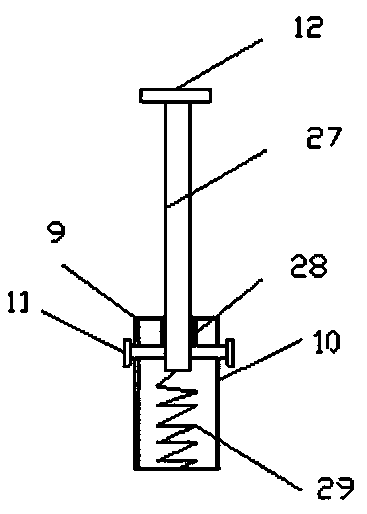

Adjusted and controlled type base body pulling device

InactiveCN109333752AEasy to controlAdjustable heightAuxillary shaping apparatusGear wheelEngineering

The invention belongs to the field of ceramic production, and relates to an adjusted and controlled type base body pulling device. The device comprises a rotary rotating disc used for carrying out base body pulling, a clutch mechanism used for driving the rotating disc and a spray structure connected with a water supply system. The rotating disc is of a circular operation rotary table and welded to the top end of a rotary shaft rod, the tail end of the rotary shaft rod is arranged in a bearing pedestal, the rotary shaft rod is provided with a driven bevel gear, the driven bevel gear is engagedwith a driving bevel gear, the driving bevel gear is arranged at the output end of a motor, the motor is driven by the clutch mechanism to do up-down motion, a spring is arranged in the clutch mechanism, a pedal plate is arranged upwards, the pedal plate is located on an operation table face and used for controlling up-down movement of a limiting convex rod, and the spray structure sprays water to the rotating disc through a spray ring located on the operation table face. All the parts are good in acting effect, the matched using effect is better, and the whole device has the good operation effect of saving time and labor.

Owner:禹州市锦丰源瓷业有限公司

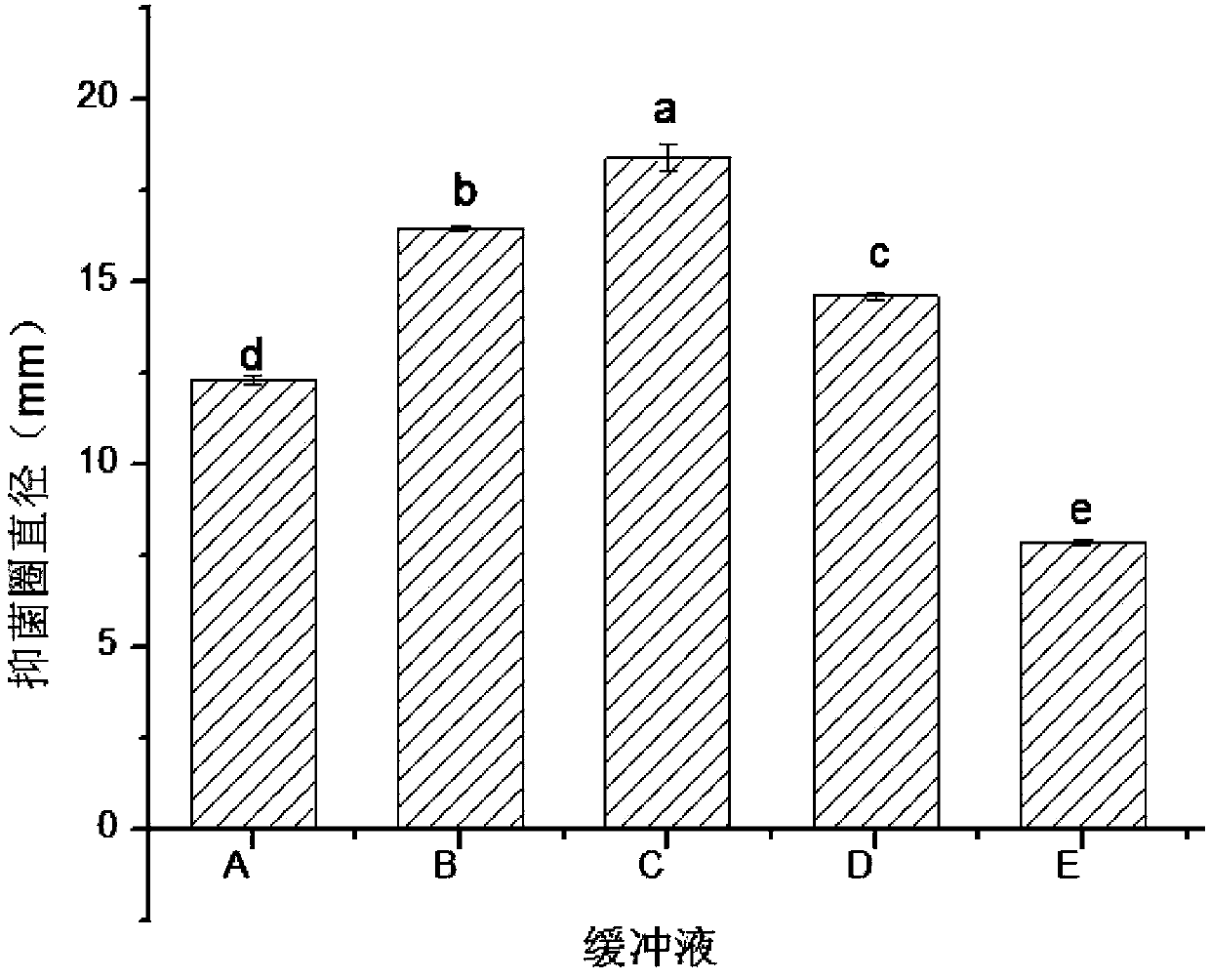

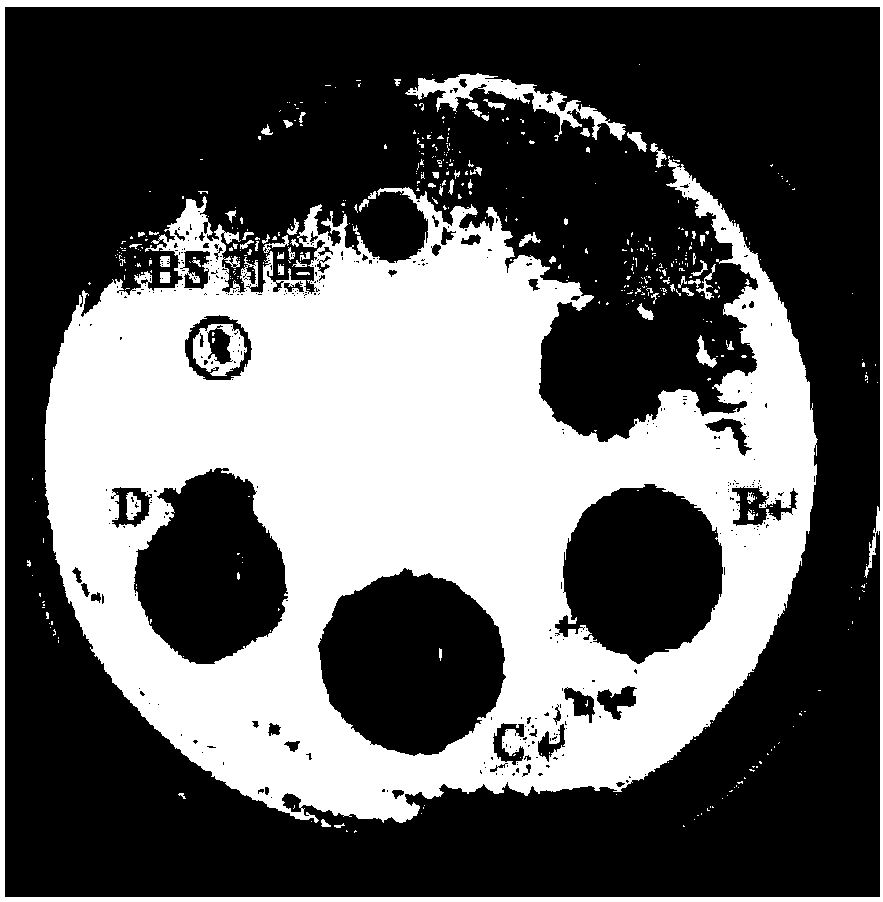

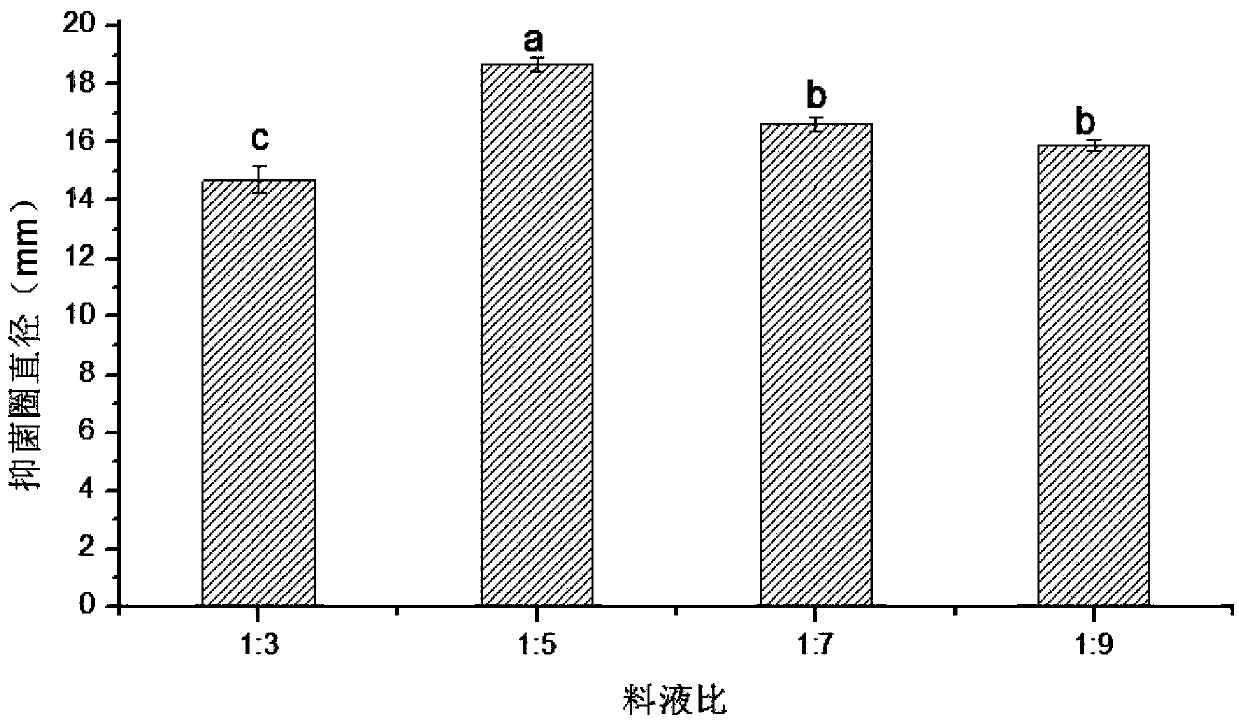

Chili antibacterial peptide extraction and purification method

ActiveCN108586570AGood extraction conditionsBroad antibacterial spectrumPeptide preparation methodsPurification methodsSpore germination

The invention discloses an optimized chili antibacterial peptide extraction and purification method. Particularly, an inventor acquires the best conditions of chili antibacterial peptide extraction byresearching the influence of different extracting liquid, solid-liquid ratios, extracting time and ammonium sulfate saturability on chili seed antibacterial peptide extraction, and further, components with good antibacterial effects are selected after ultrafiltration and crude separation and subjected to Sephadex gel filtration chromatography to obtain an electrophoresis pure antibacterial peptide sample. The extraction and purification method is simple, the antibacterial effect of an extracted antibacterial peptide is improved by 50.32% as compared with the antibacterial effect before optimization, the antibacterial peptide has a wide antibacterial spectrum, particularly has a strong inhibiting effect on Aspergillus flavus, can effectively inhibit Aspergillus flavus spore germination andmycelial growth and can further inhibit absorption and utilization of nutrient substances in a culture medium by the Aspergillus flavus. The antibacterial peptide extracted by the method is used as acorn mildew preventive, corn quality can be effectively kept, the service life is prolonged, and the antibacterial peptide is better in effect when being used with other mildew preventives.

Owner:SOUTHWEST UNIVERSITY

Novel cartridge valve regulation device

InactiveCN103899774AWorks well togetherHigh strengthOperating means/releasing devices for valvesLift valveMechanical engineeringEngineering

The invention relates to a novel cartridge valve regulation device comprising an oil circuit plate. A cover plate is arranged at one end of the oil circuit plate, the cover plate and the oil circuit plate are fixedly connected, a large-diameter mounting hole is formed at the outward end of the cover plate, a medium-diameter mounting hole is formed in the rear of the large-diameter mounting hole, a small-diameter mounting hole is formed in the rear of the medium-diameter mounting hole, a cartridge valve is arranged between the oil circuit plate and the cover plate, one end of a regulation lever is arranged in the cartridge valve while the other end of the same is arranged in the small-diameter mounting hole, and a regulating screw is arranged in the large-diameter mounting hole and the medium-diameter mounting hole. Processing difficulty is lowered greatly, the novel cartridge valve regulation device is easy to mount and reasonable in structure, and strength of the regulating lever is high.

Owner:YIXING JIACHEN DIE CASTING MACHINE MFG

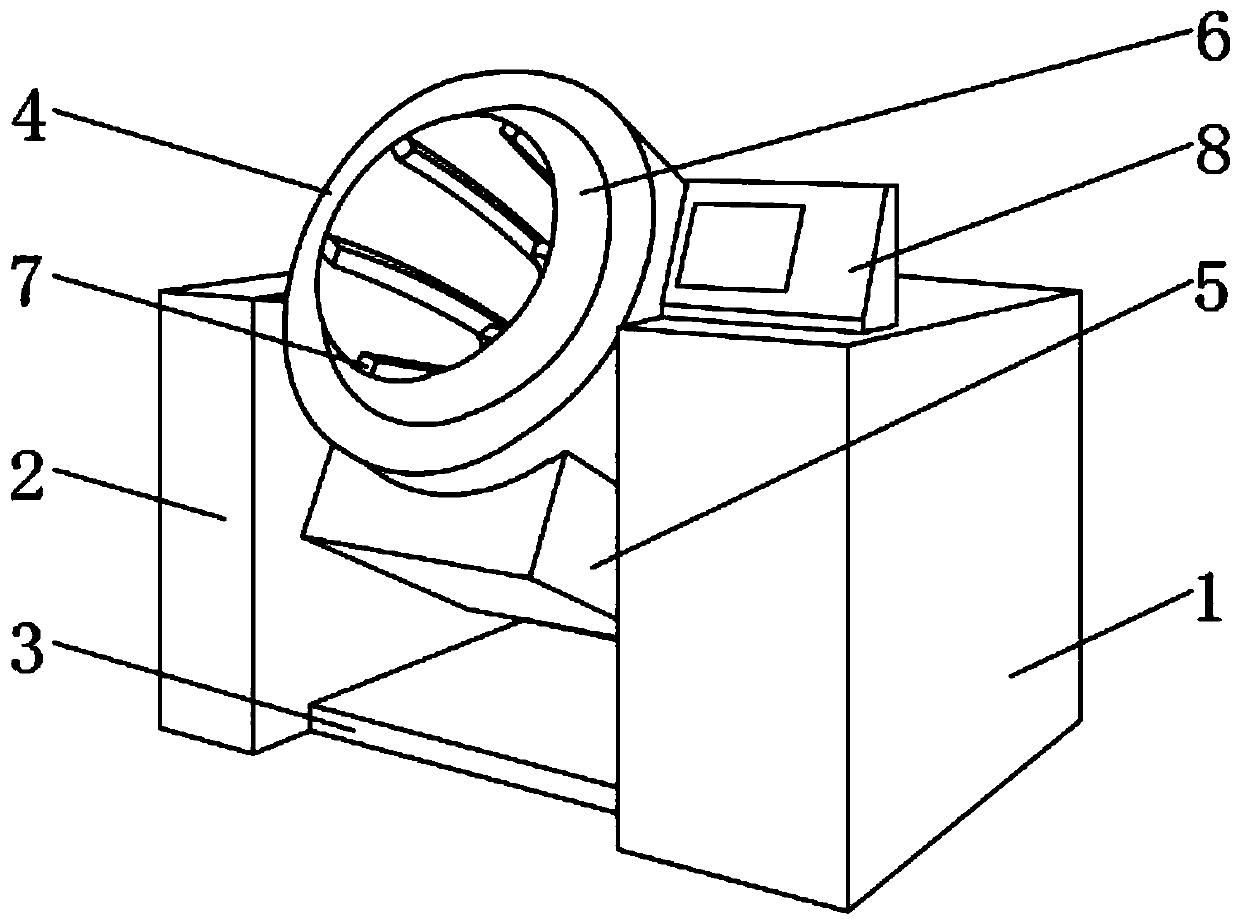

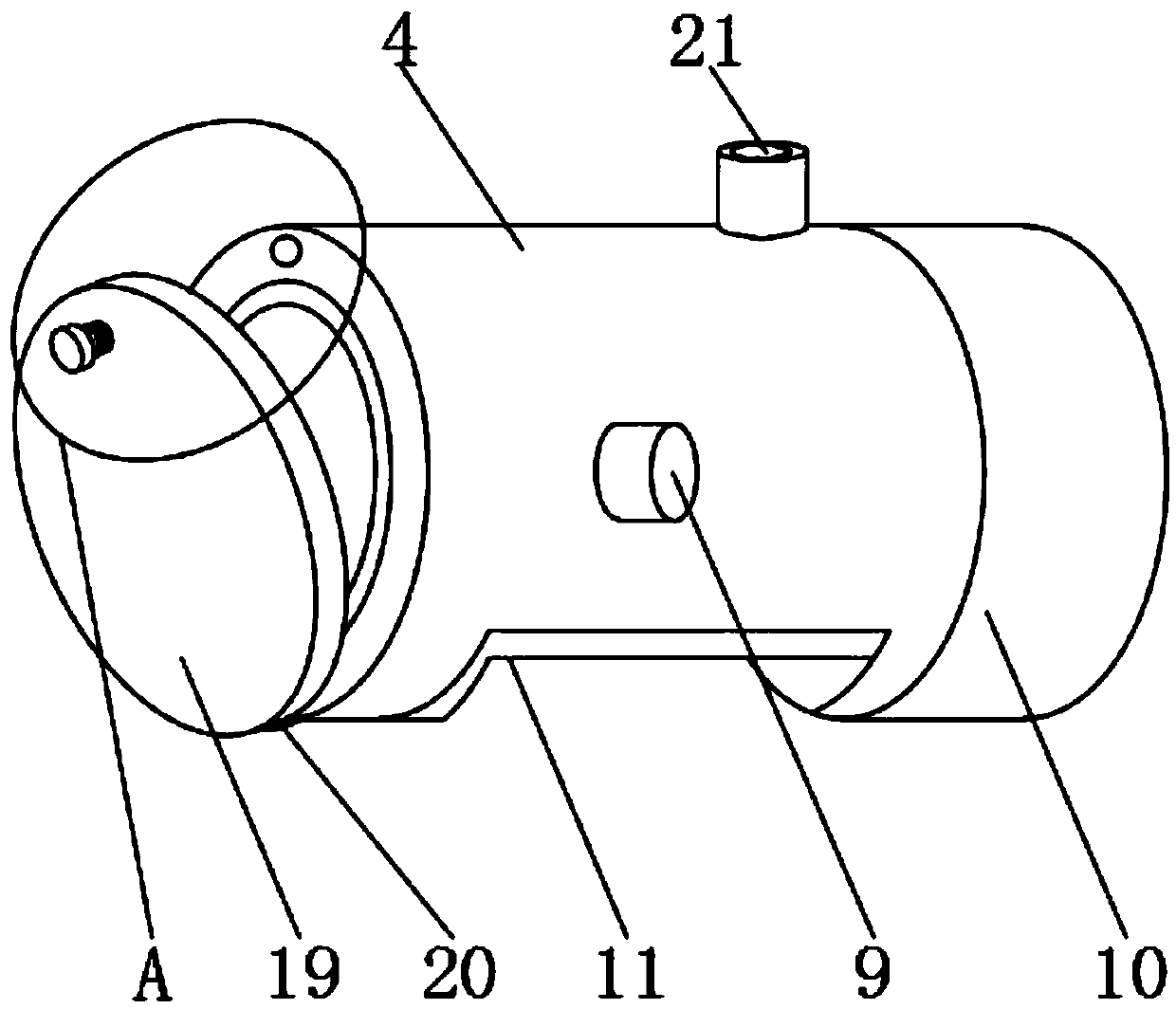

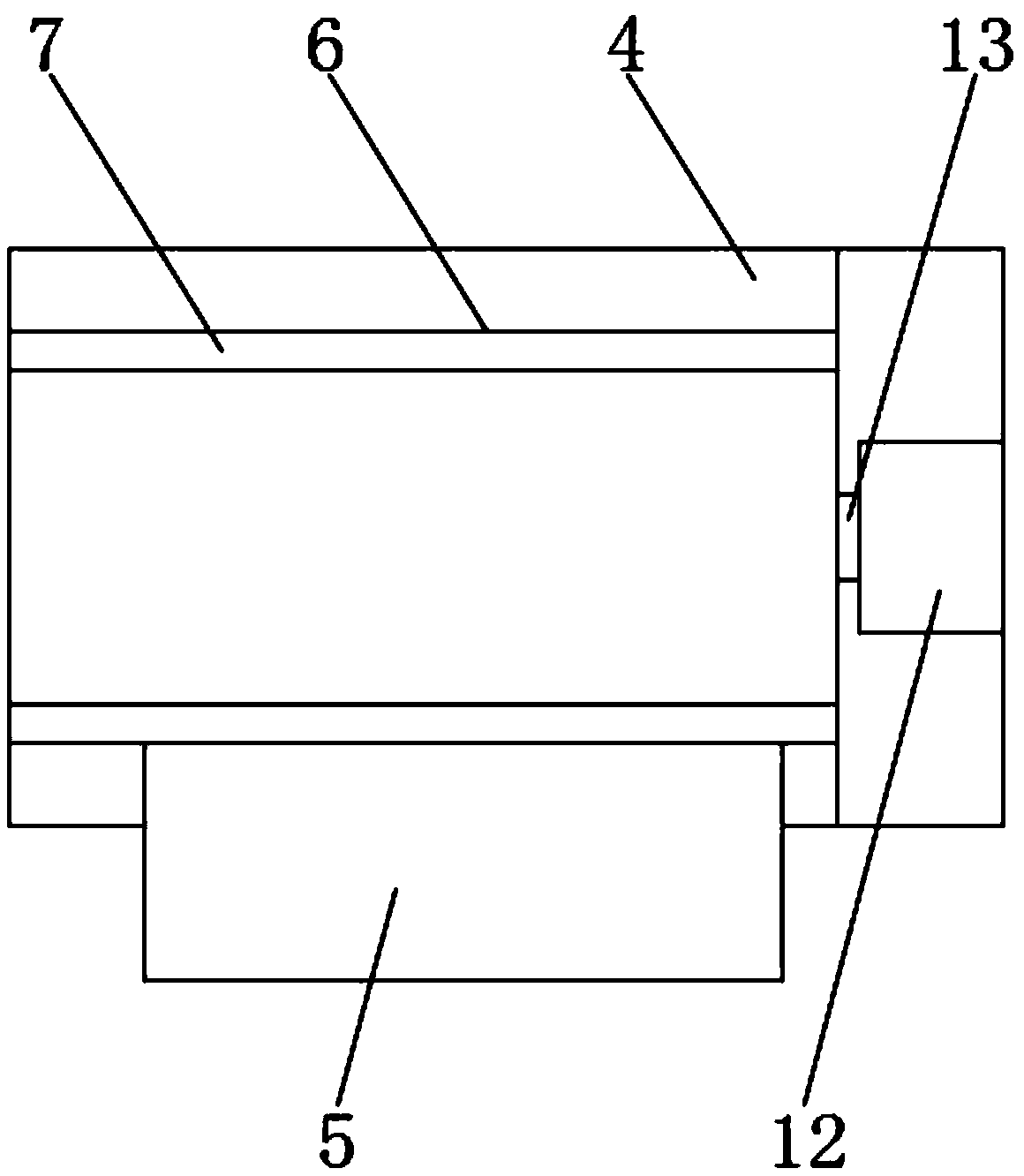

Tea enzyme deactivation machine

PendingCN109527128AHeating evenlyAvoid burning phenomenonPre-extraction tea treatmentAutomatic controlAgricultural engineering

The invention discloses a tea enzyme deactivation machine. The tea enzyme deactivation machine comprises an electric cabinet, a connecting plate is fixedly mounted on one side at the bottom end of theelectric cabinet, a pedestal box is fixedly mounted on one side of the connecting plate, the electric cabinet, the pedestal box and the connecting plate compose a support pedestal, and a shell is disposed between the electric cabinet and the pedestal box. The tea enzyme deactivation machine provided by the invention can achieve uniform heating of a rotating inner cylinder and avoids the over-baking phenomenon caused by intensive heating of the inner cylinder, the tea in the rotating inner cylinder can turn over under the obstruction of stirring ribs, thus realizing front and back baking of tea, being conducive to all-around enzyme deactivation of tea, avoiding hardening phenomenon, and improving the work efficiency. The tea enzyme deactivation machine can achieve rotation control of the shell up and down, is convenient for feeding and discharging, and realizes automatic control of the shell and inner cylinder turnover. By adjusting different angles, the tea enzyme deactivation machinecan be used cooperatively with a heating box to achieve a better effect, has certain practicability, and brings better application prospects.

Owner:安徽金满盈农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com