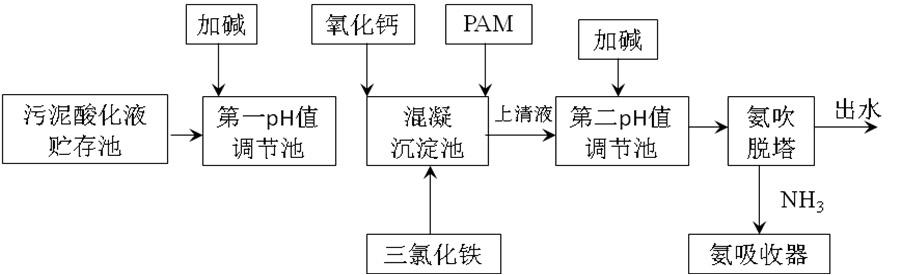

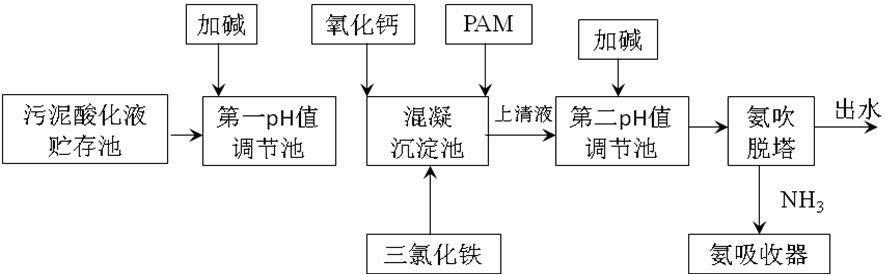

Method for removing nitrogen and phosphorus from sludge anaerobic acidification liquor

A technology of anaerobic acidification and sludge acidification, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of easy release under anaerobic conditions, sludge production Large and other problems, to achieve the effect of low cost, reduced negative impact, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The remaining sludge from a sewage treatment plant in the south is taken from the supernatant after anaerobic fermentation. The acidified liquid first enters the storage tank for adjustment and stabilization, and then enters the first pH value adjustment tank. In the first pH adjustment tank Add 30% NaOH to adjust the pH value to about 11, stir well and make it fully mixed. Then enter the coagulation sedimentation tank, first add CaO with a molar concentration equivalent to 1.6 times the total phosphorus concentration, mix at a medium speed (150r / min) for 10min for chemical precipitation reaction; then add FeCl 3 70mg / L, stirring rapidly (300r / min) for 1min, then adding coagulant PAM0.5mg / L, stirring slowly (60r / min) for 15min, and then standing for 45min for precipitation. The precipitated supernatant enters the second pH adjustment tank, and NaOH is added to adjust the pH value to about 11, and then flows into the ammonia stripping tower, and the gas-liquid ratio of t...

Embodiment 2

[0025] The dewatered sludge from a sewage treatment plant is taken from the supernatant after anaerobic fermentation. The acidified liquid first enters the storage tank for adjustment and stabilization, and then enters the first pH value adjustment tank, and in the first pH adjustment tank, add 30% NaOH to adjust the pH value to about 11, stir well and make it fully mixed. Then enter the coagulation sedimentation tank, first add CaO with a molar concentration equivalent to 2 times the total phosphorus concentration, mix at a medium speed (200r / min) for 15min for chemical precipitation reaction; then add FeCl 3100mg / L, stir rapidly (500r / min) for 3min, then add coagulant PAM1mg / L, stir slowly (60r / min) for 30min, and then stand for 60min for precipitation. The precipitated supernatant flows into the second pH adjustment tank, adjusts the pH to about 11, and then enters the ammonia stripping tower, adjusting the gas-liquid ratio of the ammonia stripping tower to 4500, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com