Patents

Literature

47results about How to "Reduce transmission force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

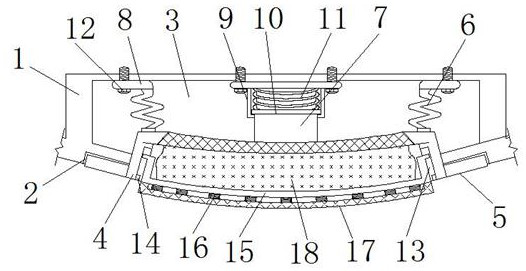

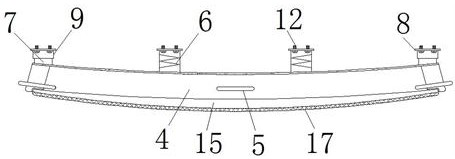

Protective material

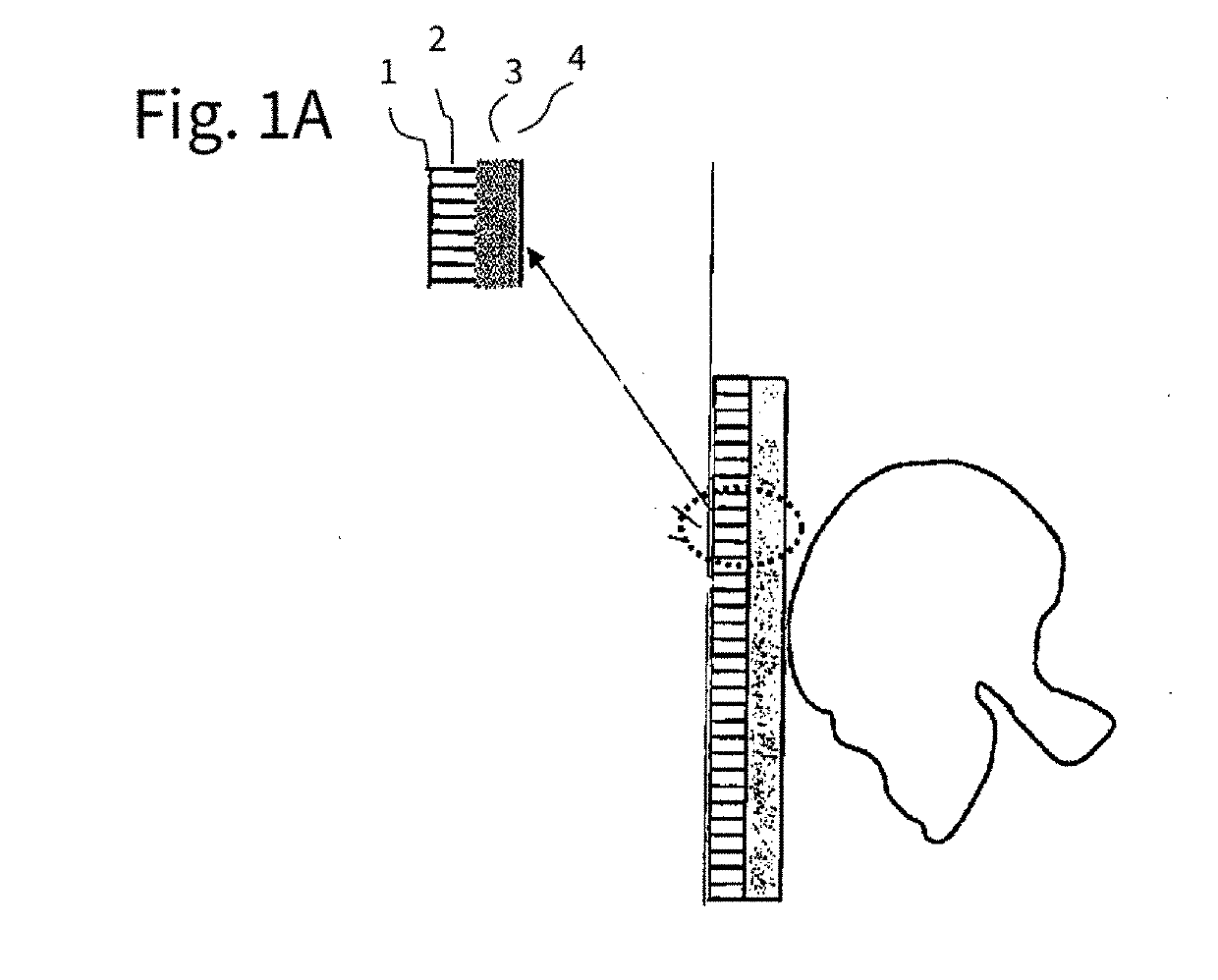

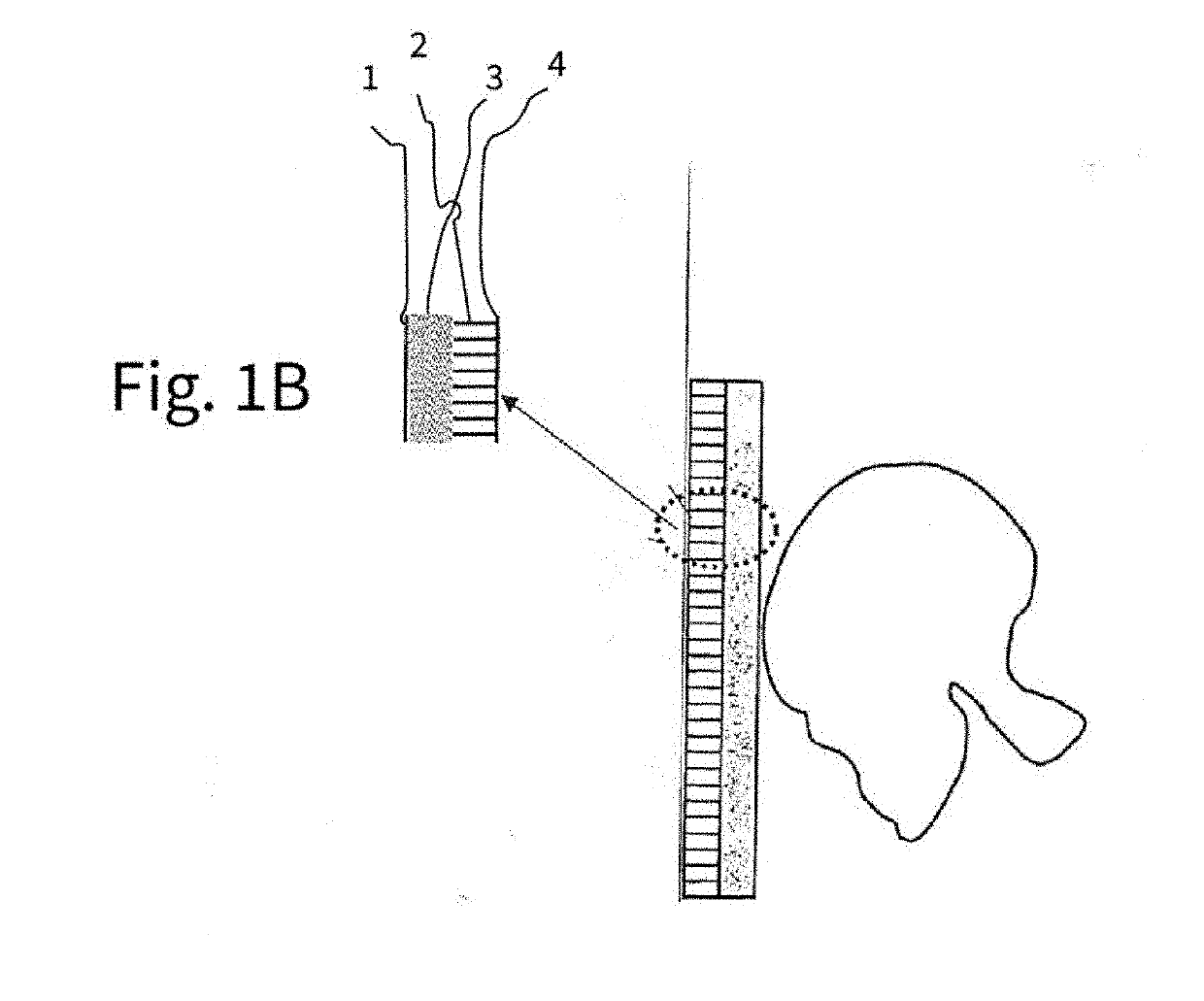

InactiveUS20130122256A1Reduce transmission forceReduce force transmissionLayered productsPedestrian/occupant safety arrangementFiberHouse building

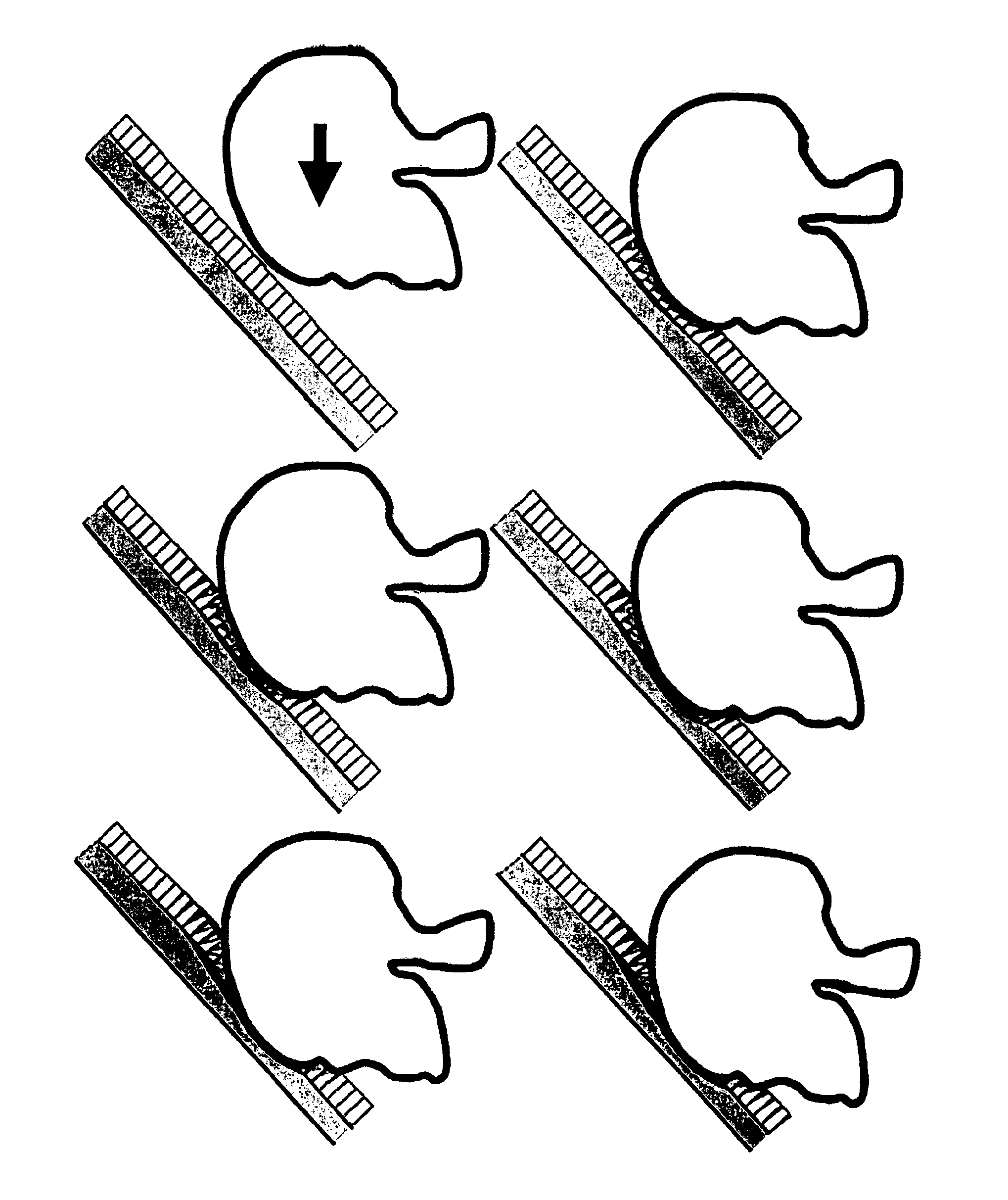

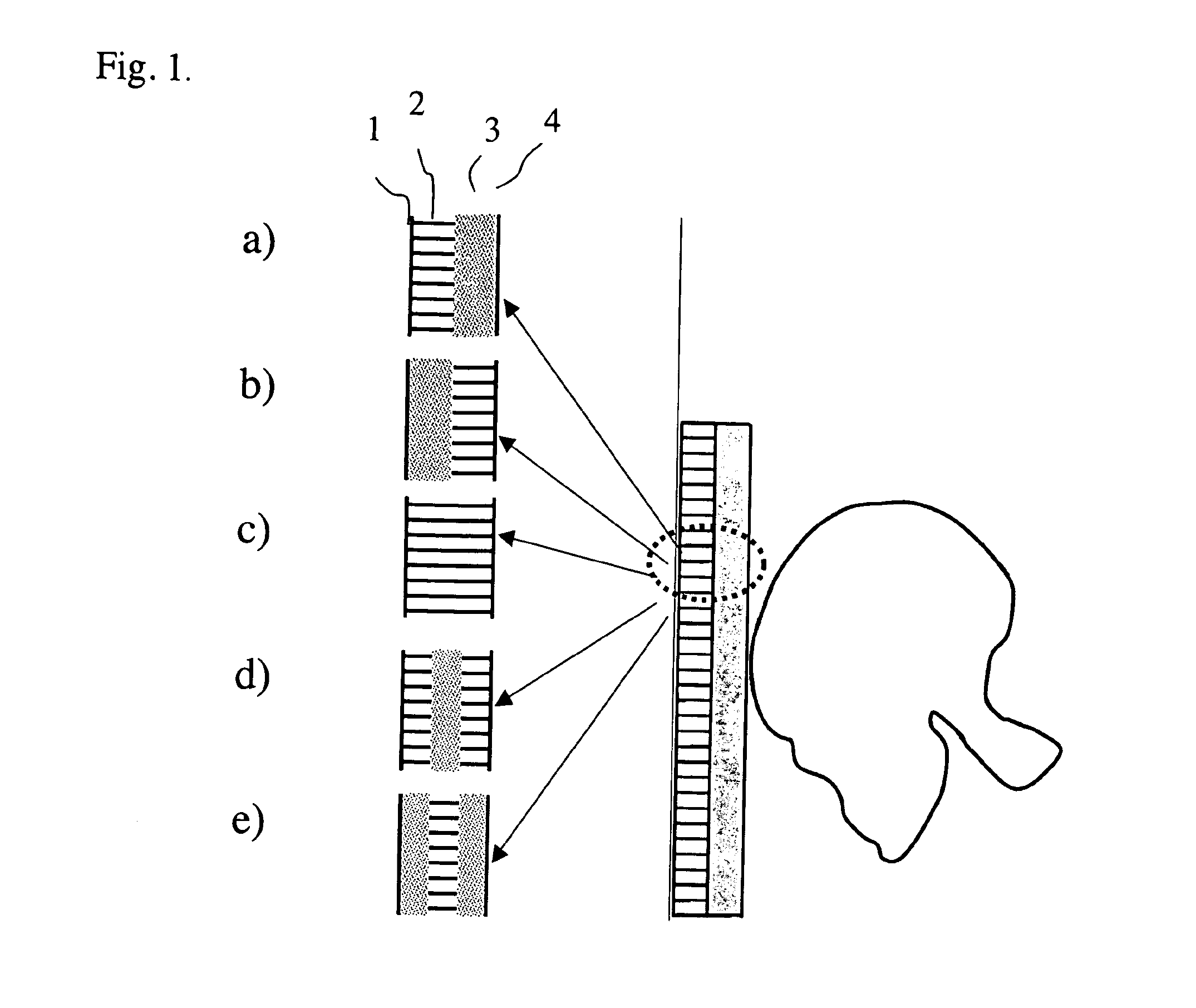

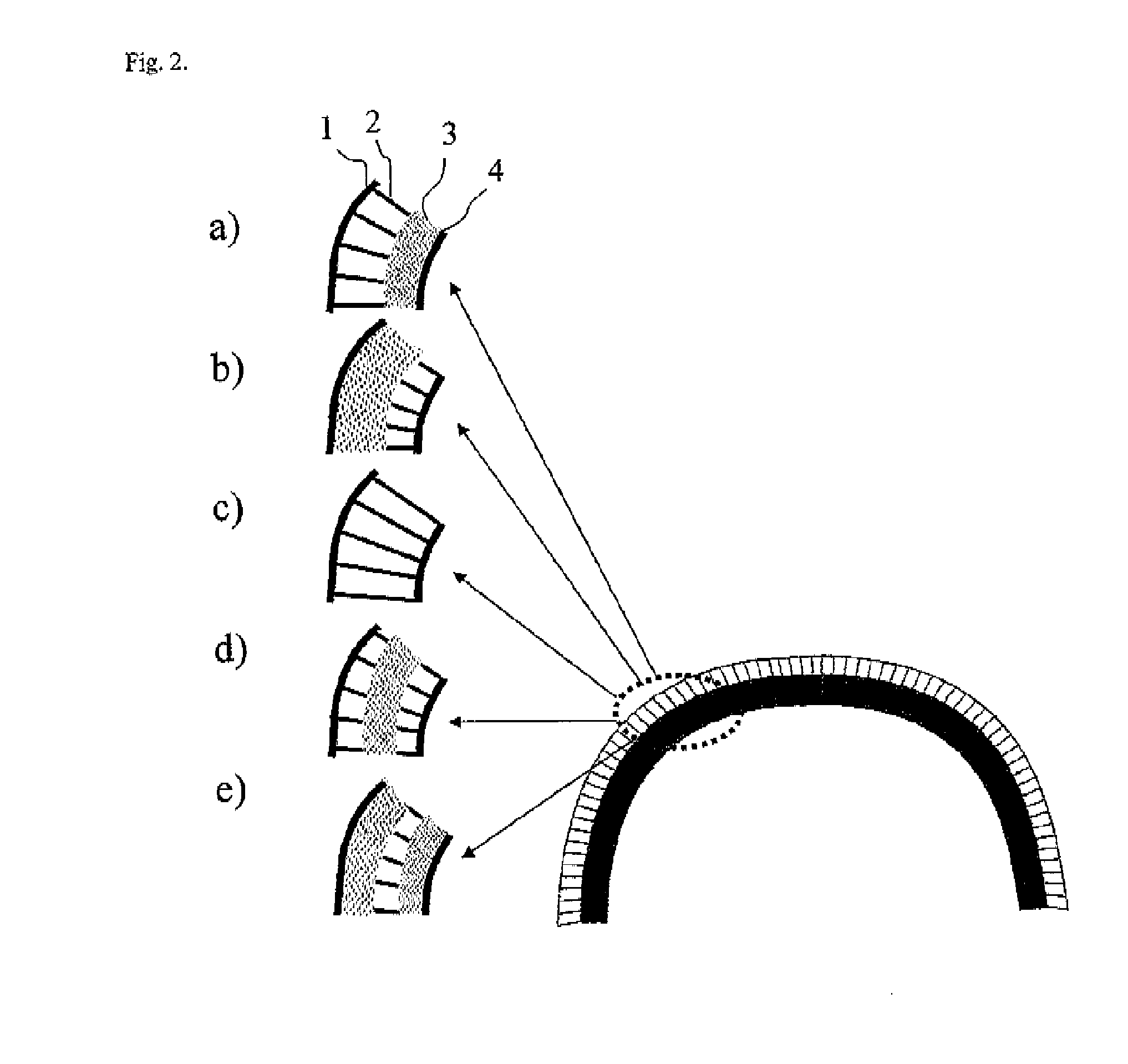

A protective material / structure is provided that reduces the risk of injury for a person after contact with said material / structure, and is based on a structure where an inner and outer shell can move relative to each other. The shells are separated by spikes or thin beams and the outer shell covers or envelops the spikes. The spikes or beams are constructed so that they permit displacement of the outer shell relative to the inner shell in the event of an oblique impact against the protective material / structure. The spikes or beams are designed to be thin / slim and can be made of flexible polymer materials such as plastics, rubber or fibers. This enables the spikes to give way after a tangential / rotational impact and thereby efficiently reduce the negative effects of such an impact on the brain. The material / structure can be used in e.g. helmets, vehicle interiors, vehicle exteriors, indoor house building material, boxing gloves and the like.

Owner:KLEIVEN SVEIN +1

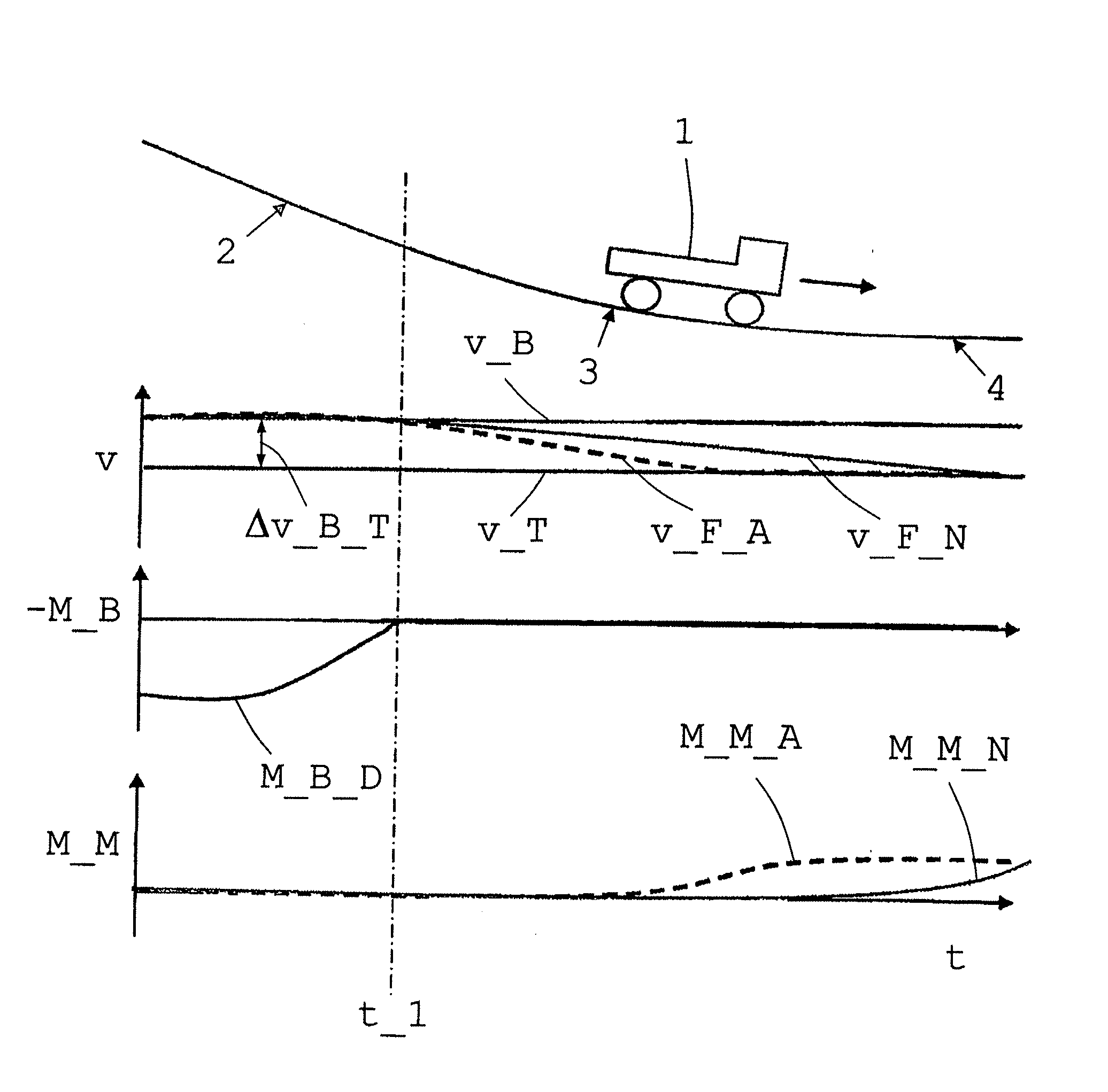

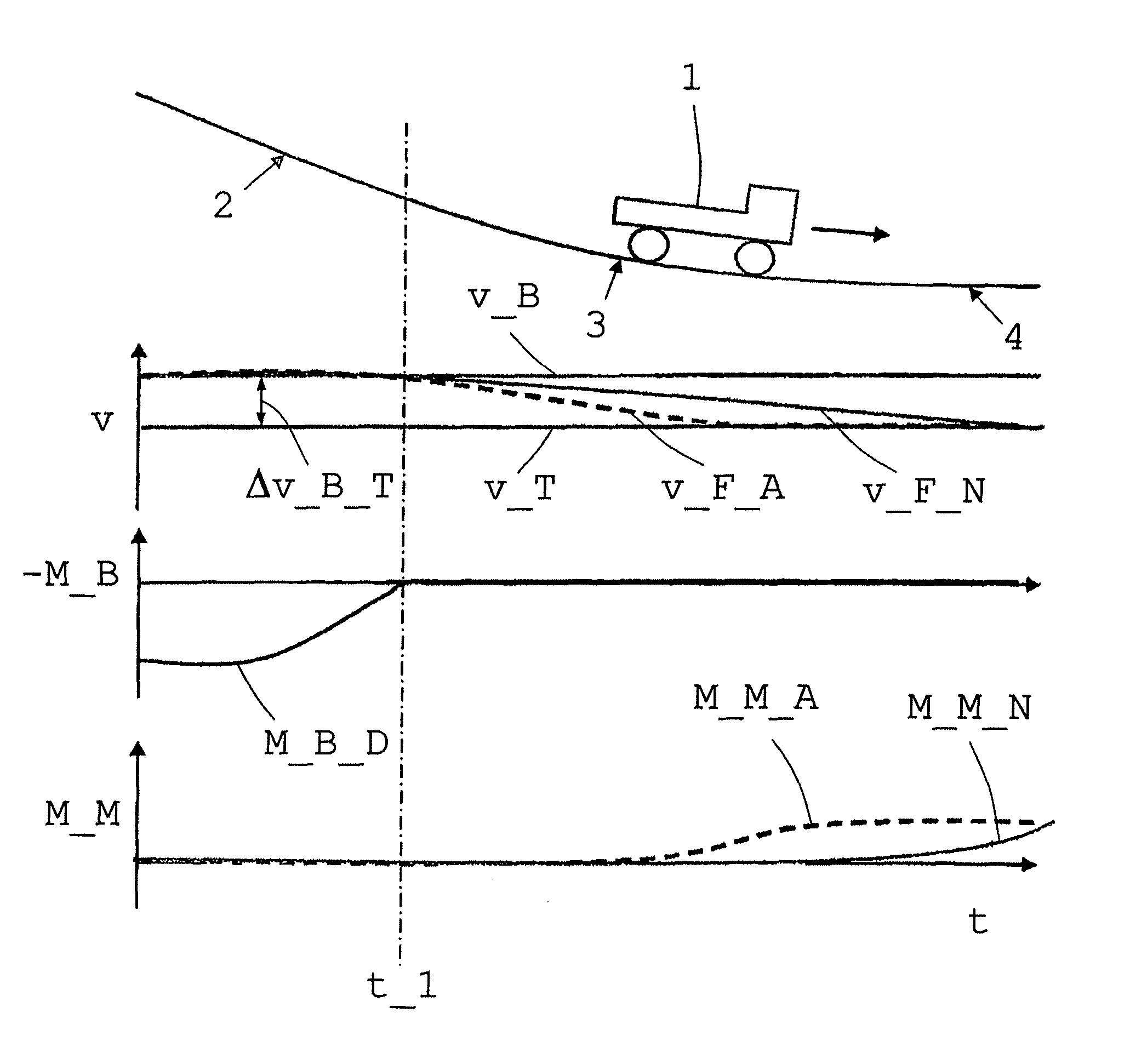

Method for controlling a rolling or coasting function of a vehicle

InactiveUS20120220422A1Reliably recognizePrevent unnecessary shifting into neutralRoad transportGearing controlAutomatic transmissionDrive motor

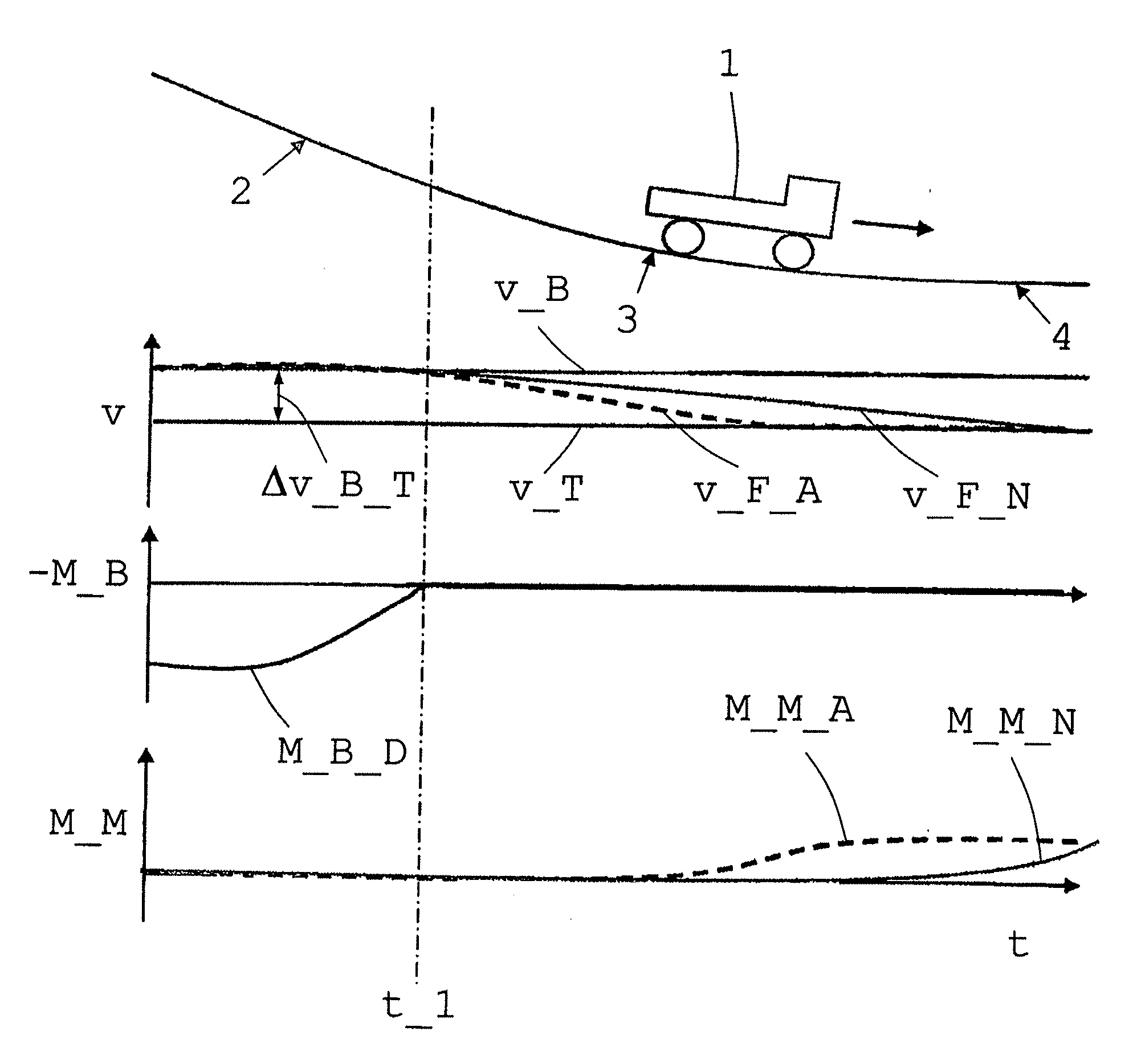

A method of controlling a rolling or coasting function of a vehicle with a drive train having a drive motor, an automatic or automated transmission, a controllable shifting means, a brake device and a drive speed control device. The vehicle speed is regulated by the drive speed control device and the braking device is activated, as needed, when driving on a downhill gradient section. To effectively and reliably use the rolling or coasting function in suitable driving situations, taking into account the influence of the driving speed control device, a rolling or a coasting condition for a downhill gradient taper is checked, when driving on the downhill gradient section, and, when the rolling or coasting condition is satisfied, the transmission controls interrupt the flow of power in the drive train before the vehicle entering a flat area, and / or before the driving speed control device generates an engine torque request.

Owner:ZF FRIEDRICHSHAFEN AG

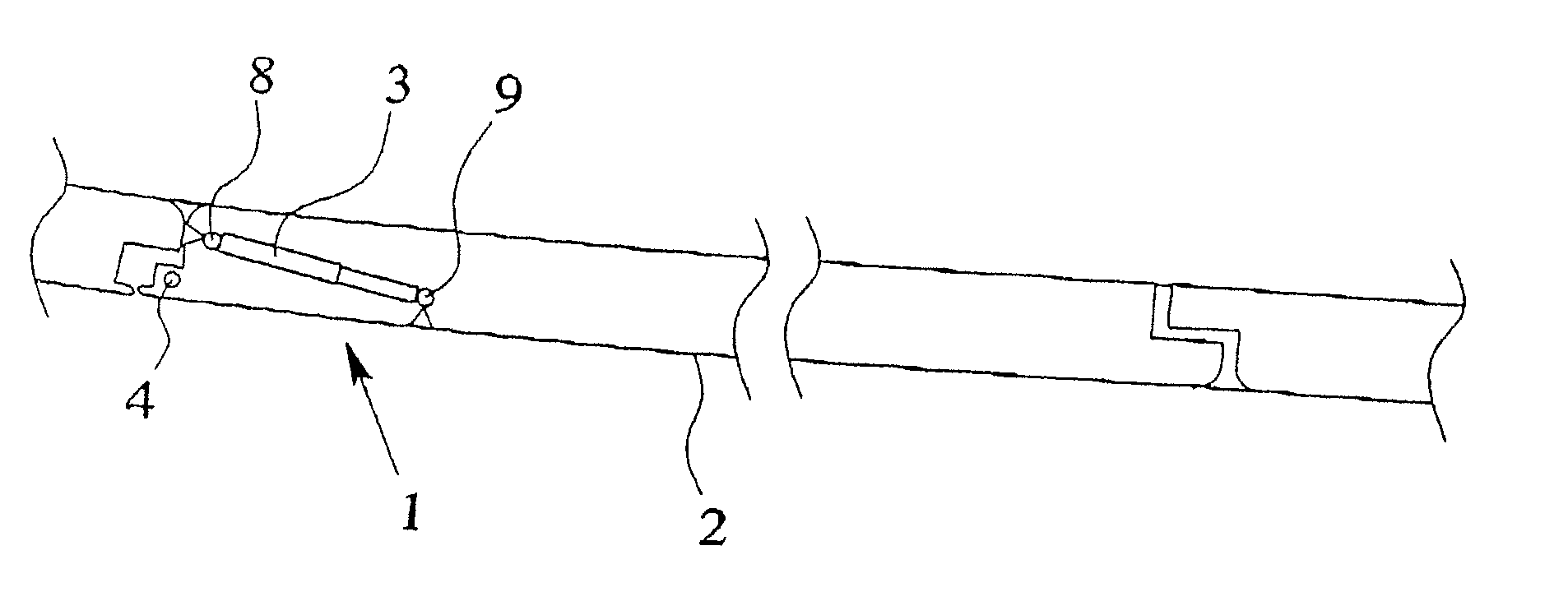

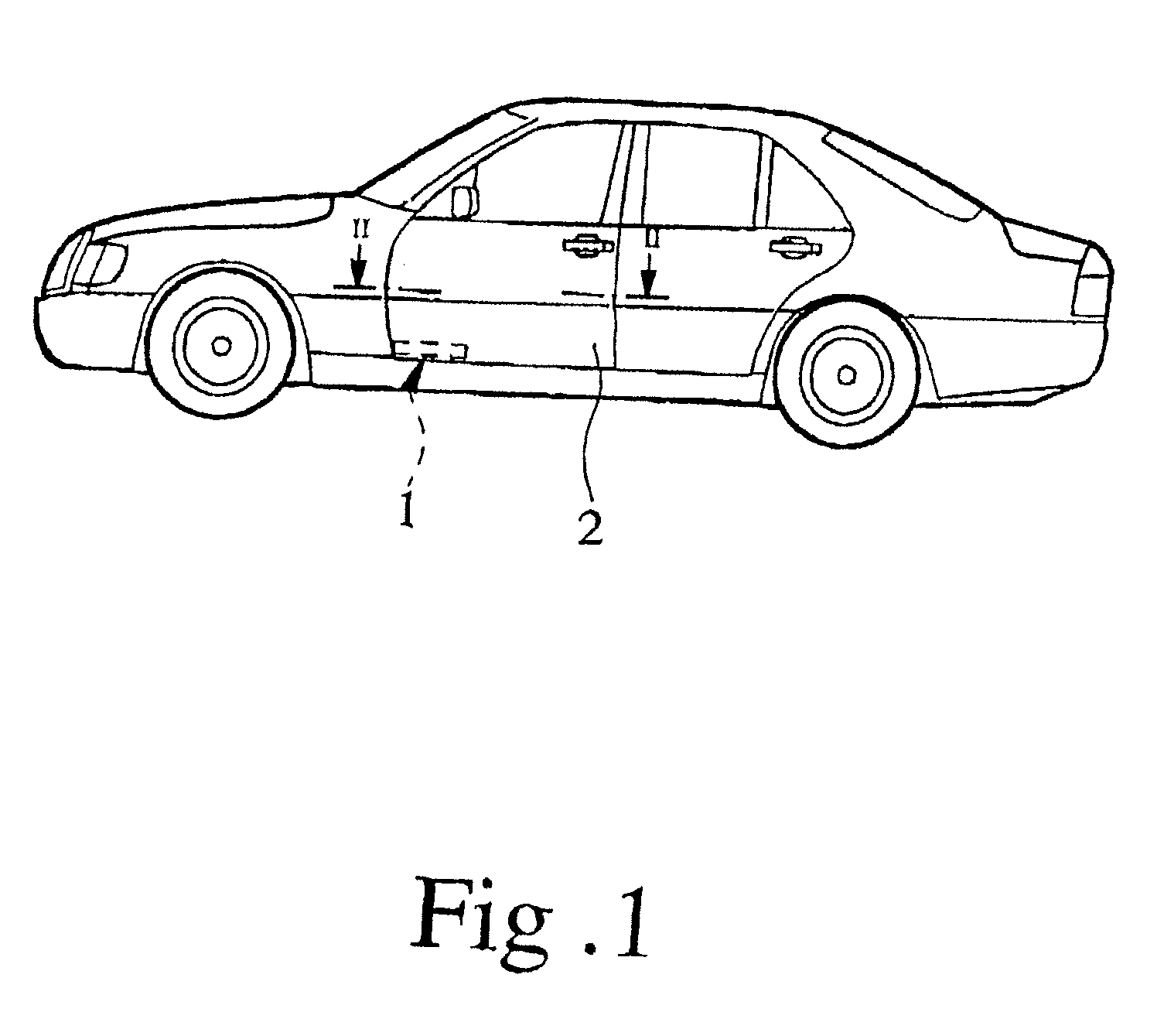

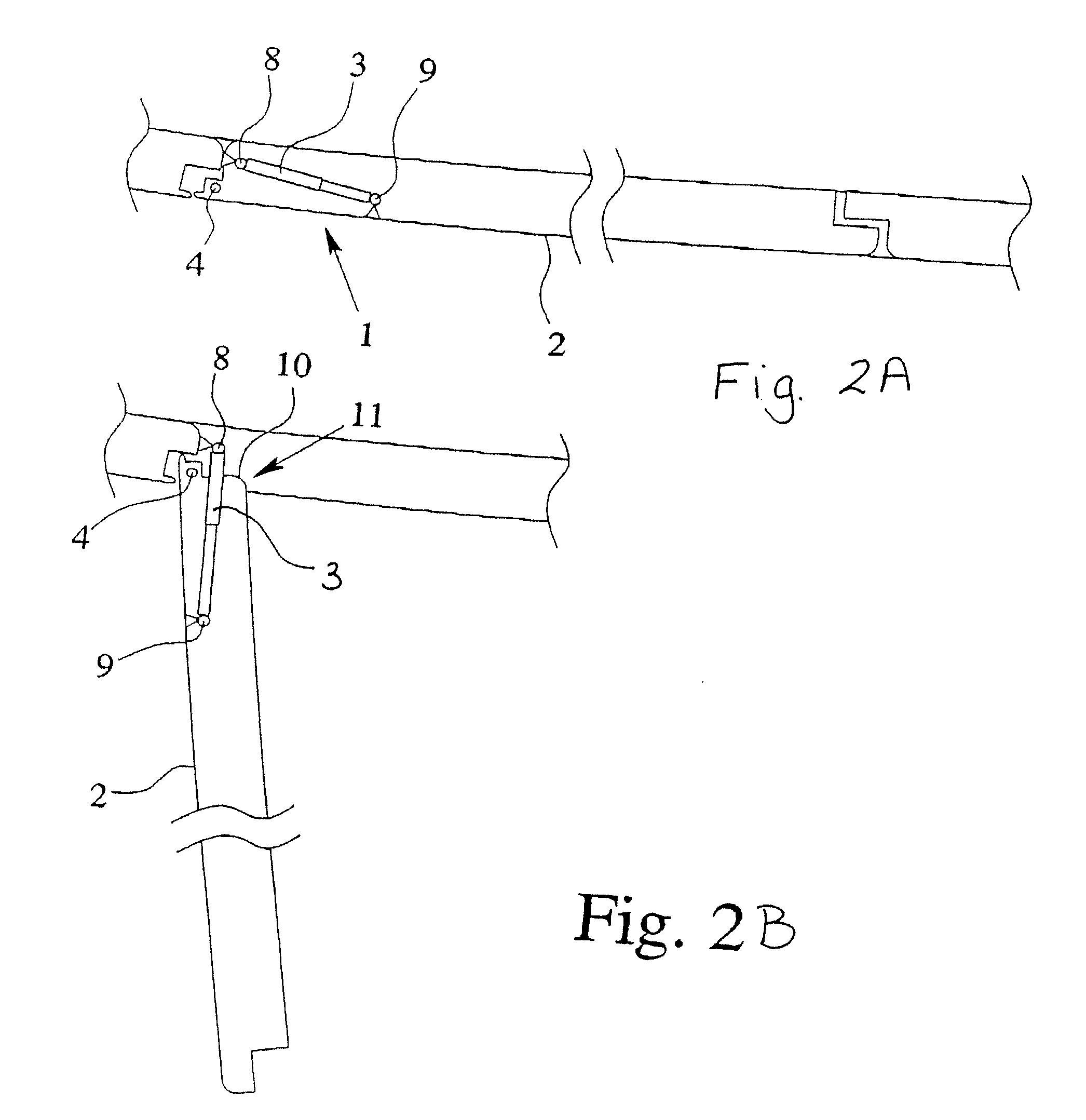

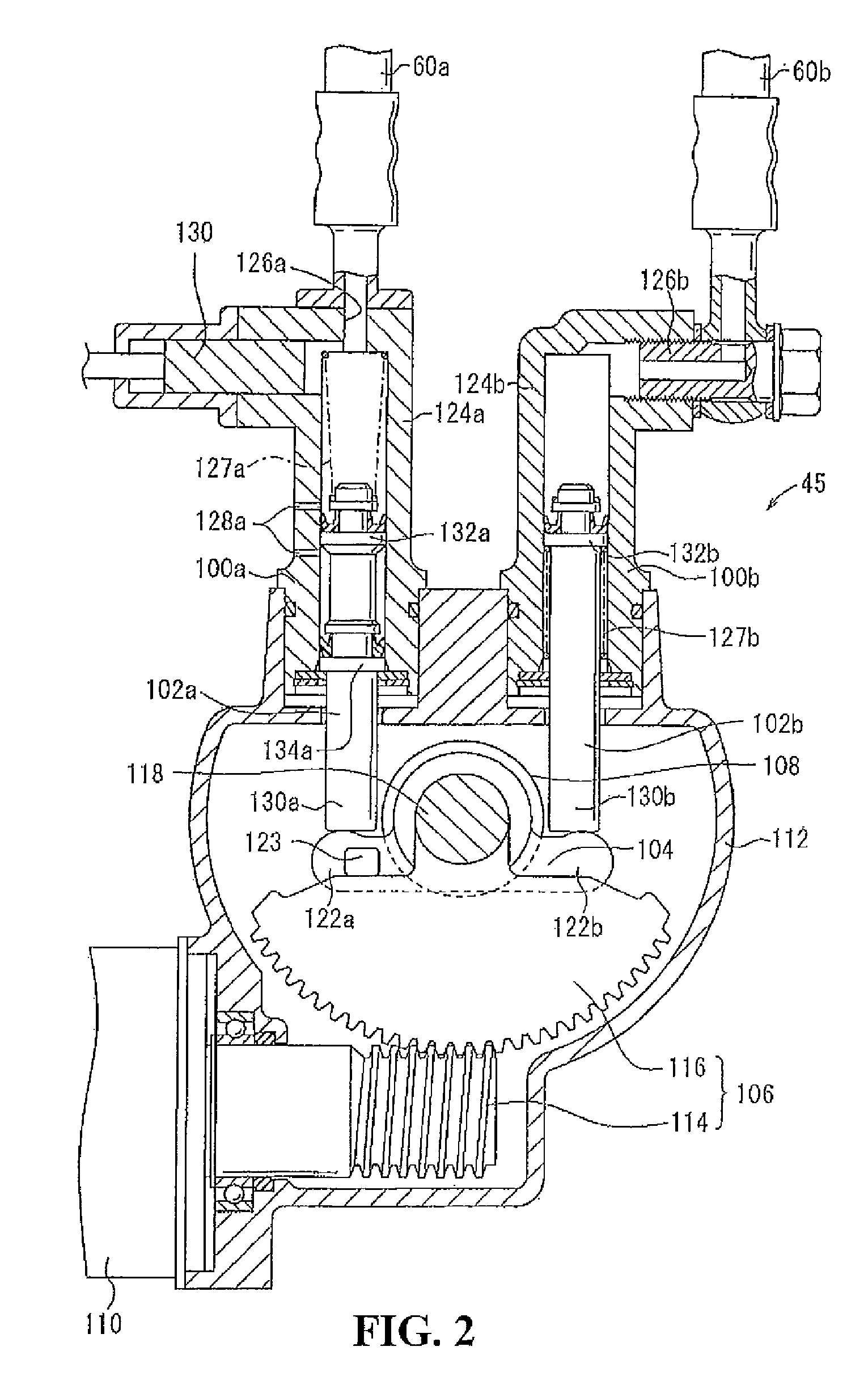

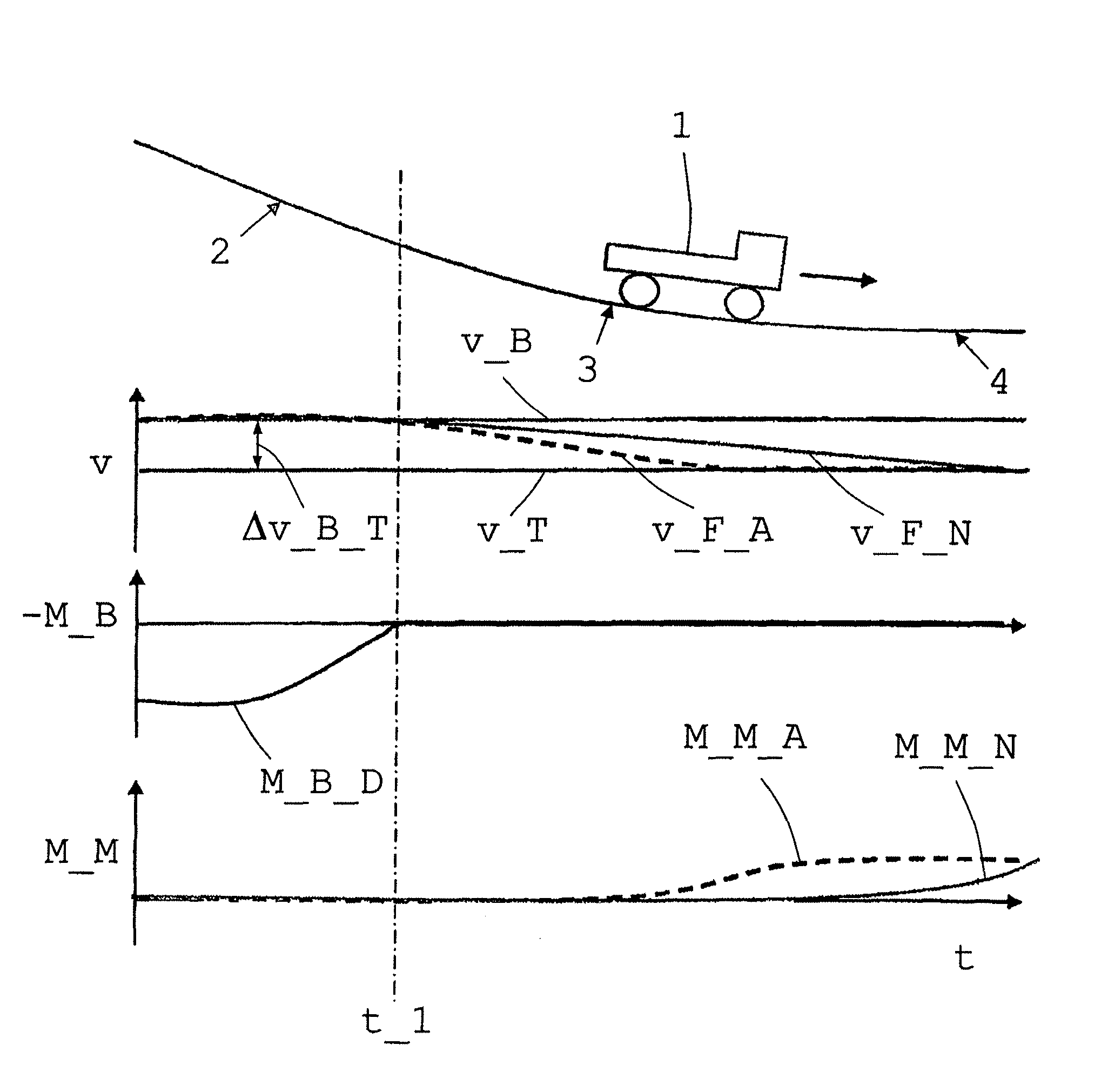

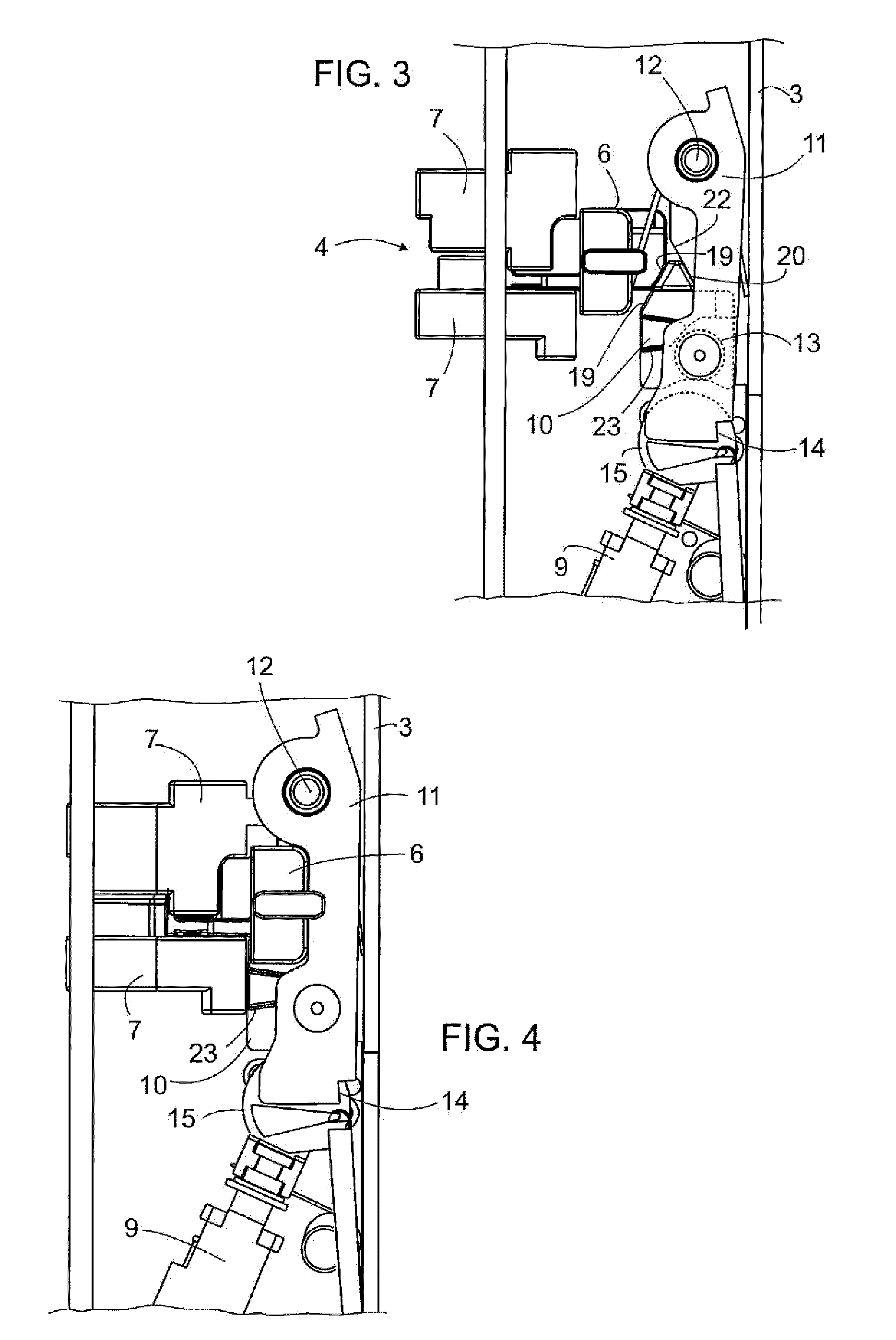

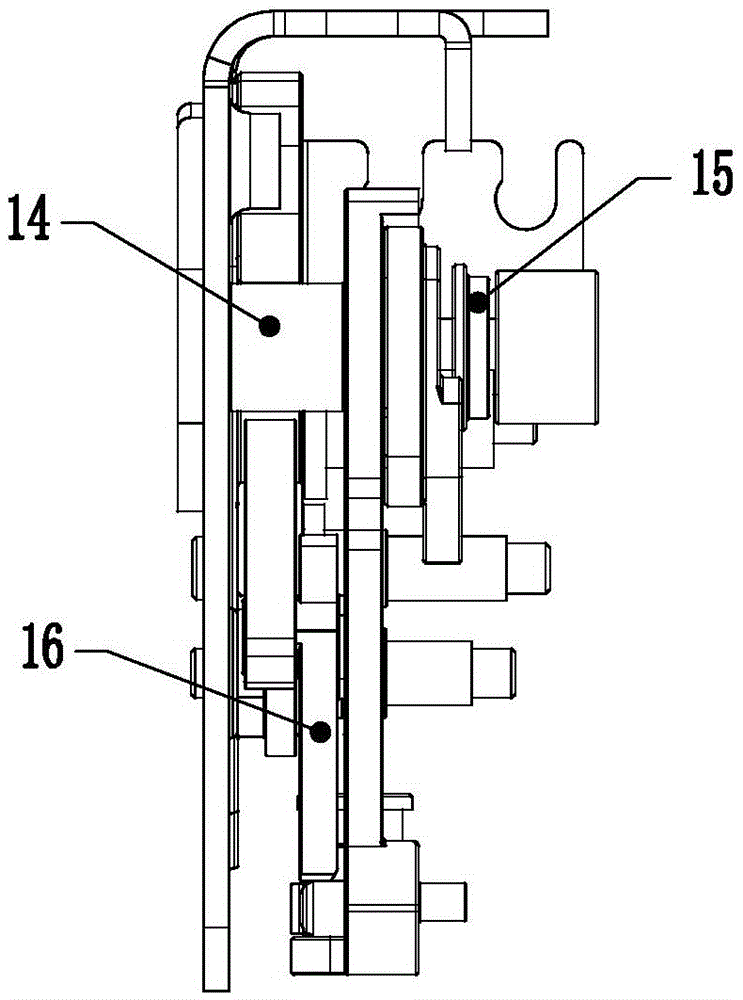

Drive arrangement for motorized movement of a motor vehicle door or the like

InactiveUS20070175099A1Easy to implementShorten the lengthMan-operated mechanismPower-operated mechanismEngineeringSelf locking

A drive arrangement is provided for motorized pivotal movement of a vehicle door. The drive has a self-locking motor unit, a gear connected downstream of the motor unit for producing linear drive movement, and a clutch connected therebetween. The clutch can be moved into an engaged state in which the motor unit for nominal operation is engaged to the vehicle door. When the motor unit is turned off, manual movement of the vehicle door is blocked. The clutch can be moved into a released state in which the motor unit is separated from the vehicle door in terms of drive engineering. The clutch can be moved into the intermediate engaged state with reduced transmission moment and force so that the vehicle door is kept in its current position at any time by self-locking of the motor unit, but can be moved by manual actuation with a minimum actuation force.

Owner:BROSE SCHLIESSSYSTEME GMBH & CO KG

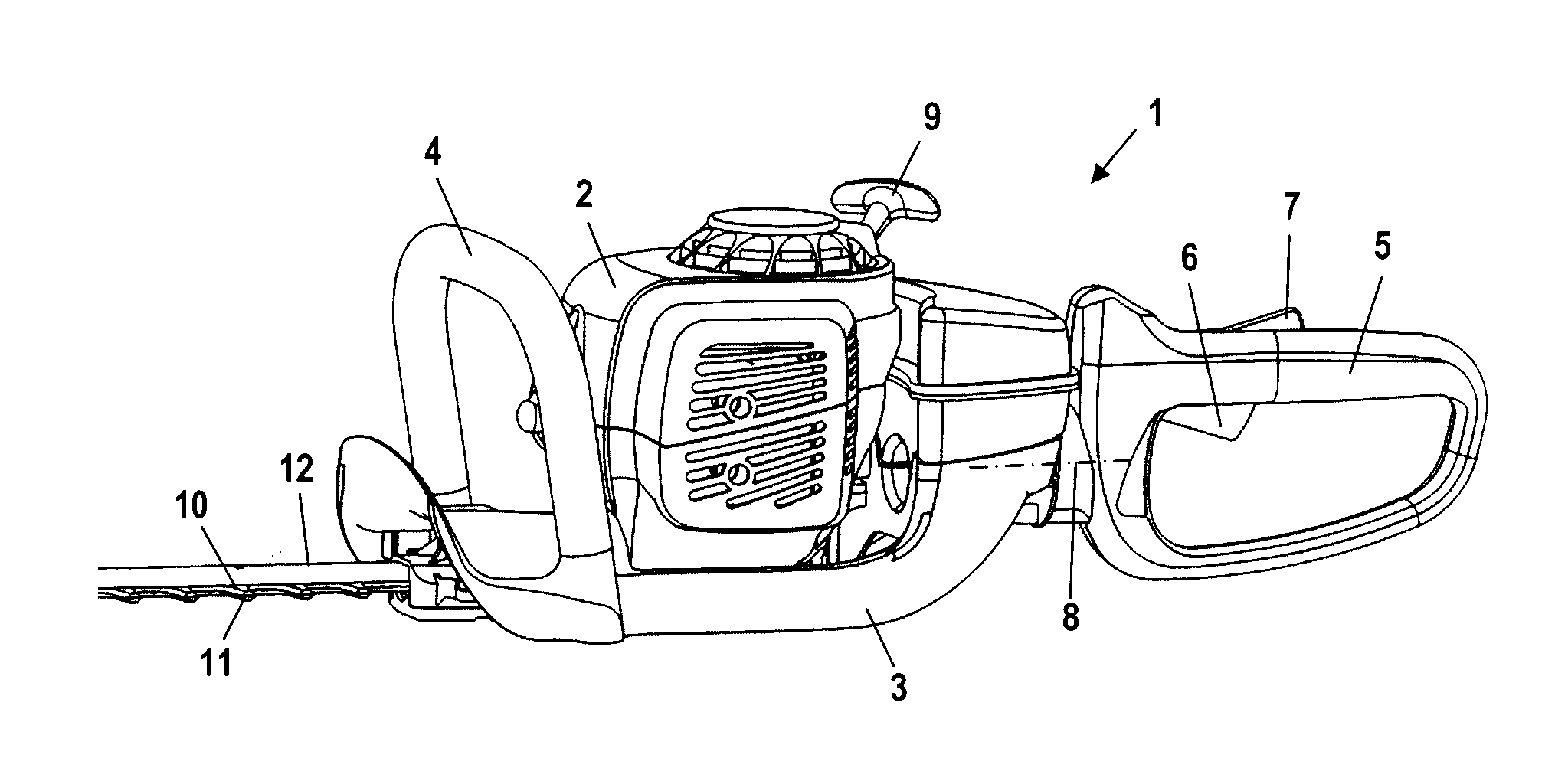

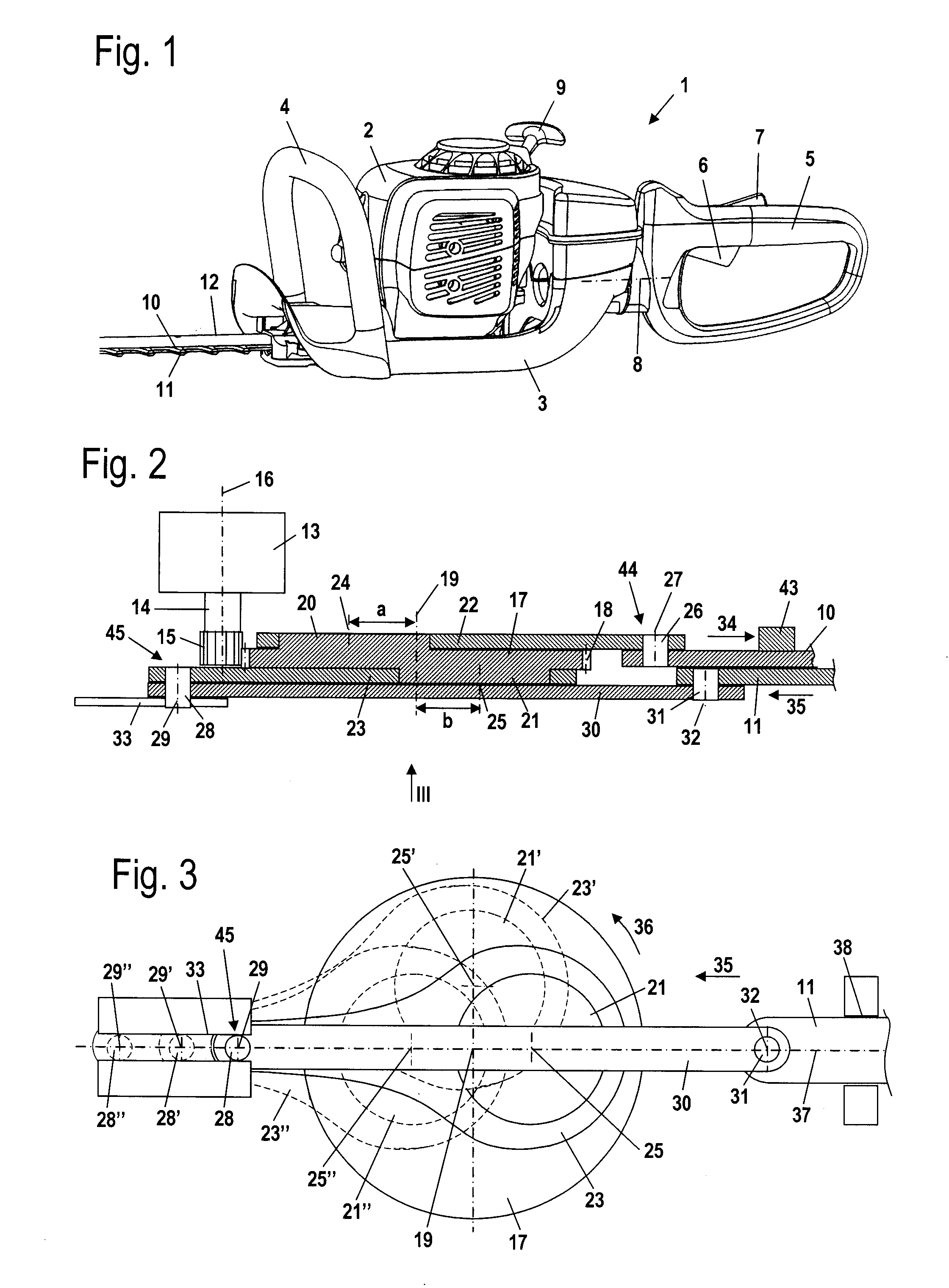

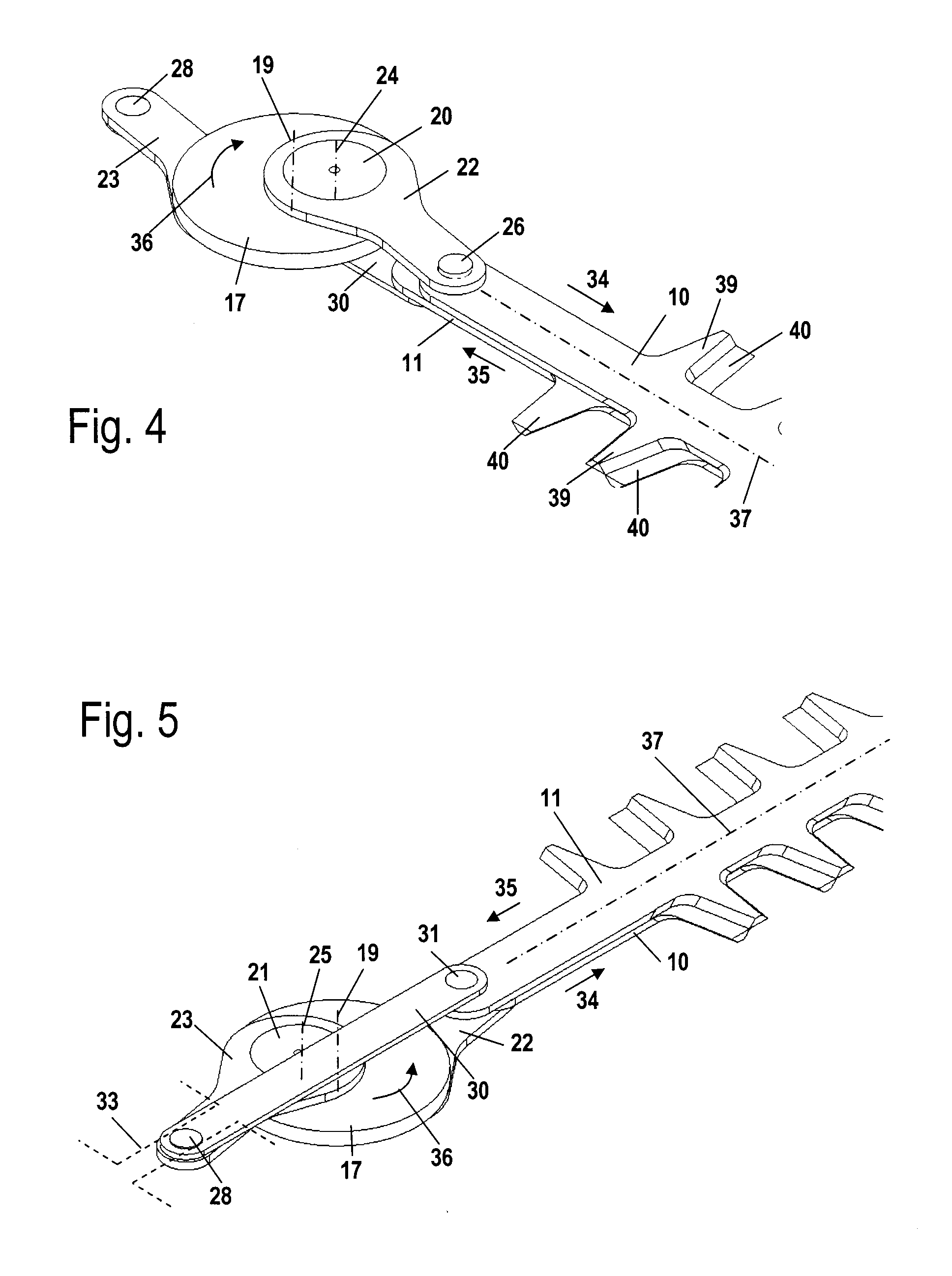

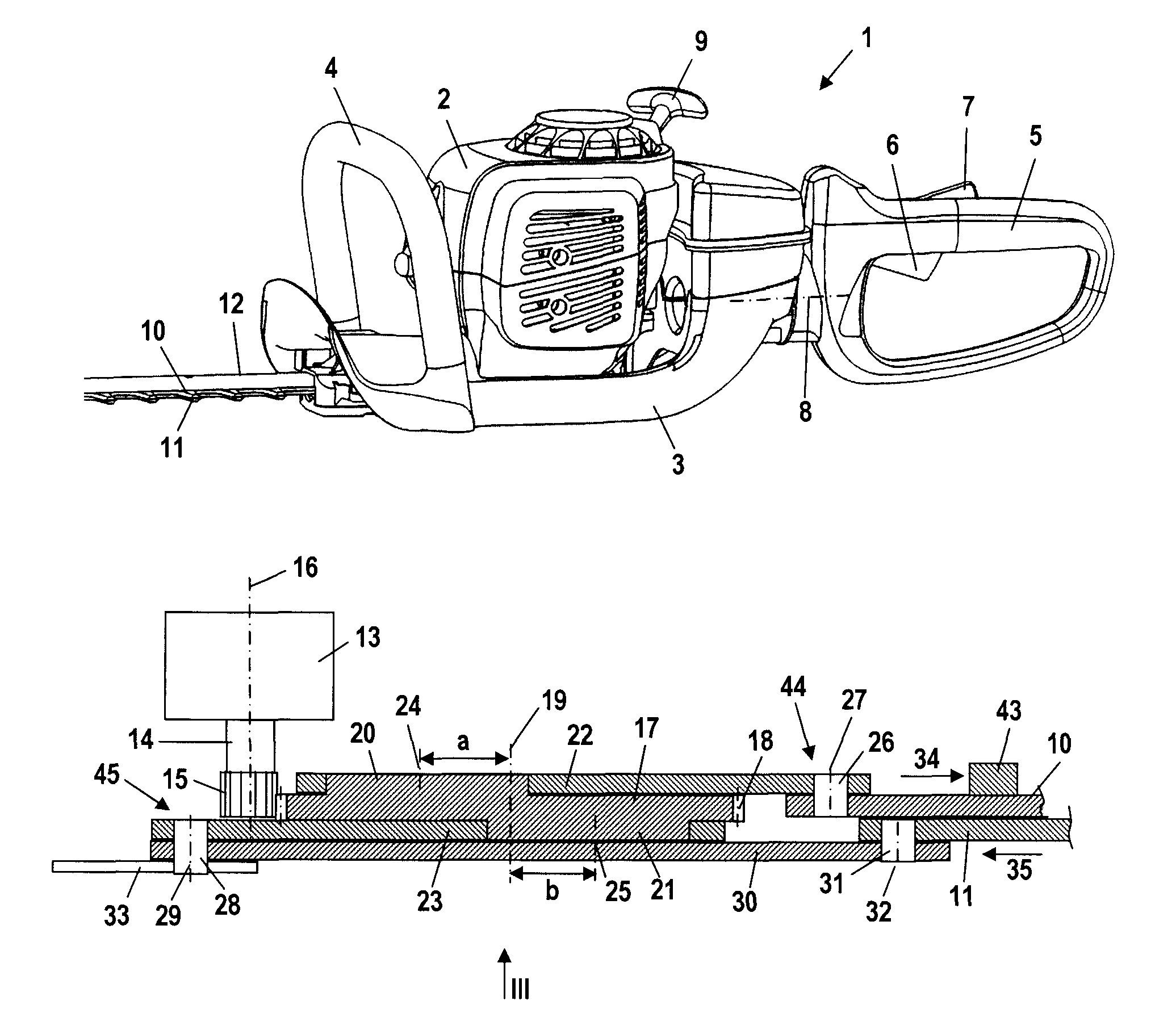

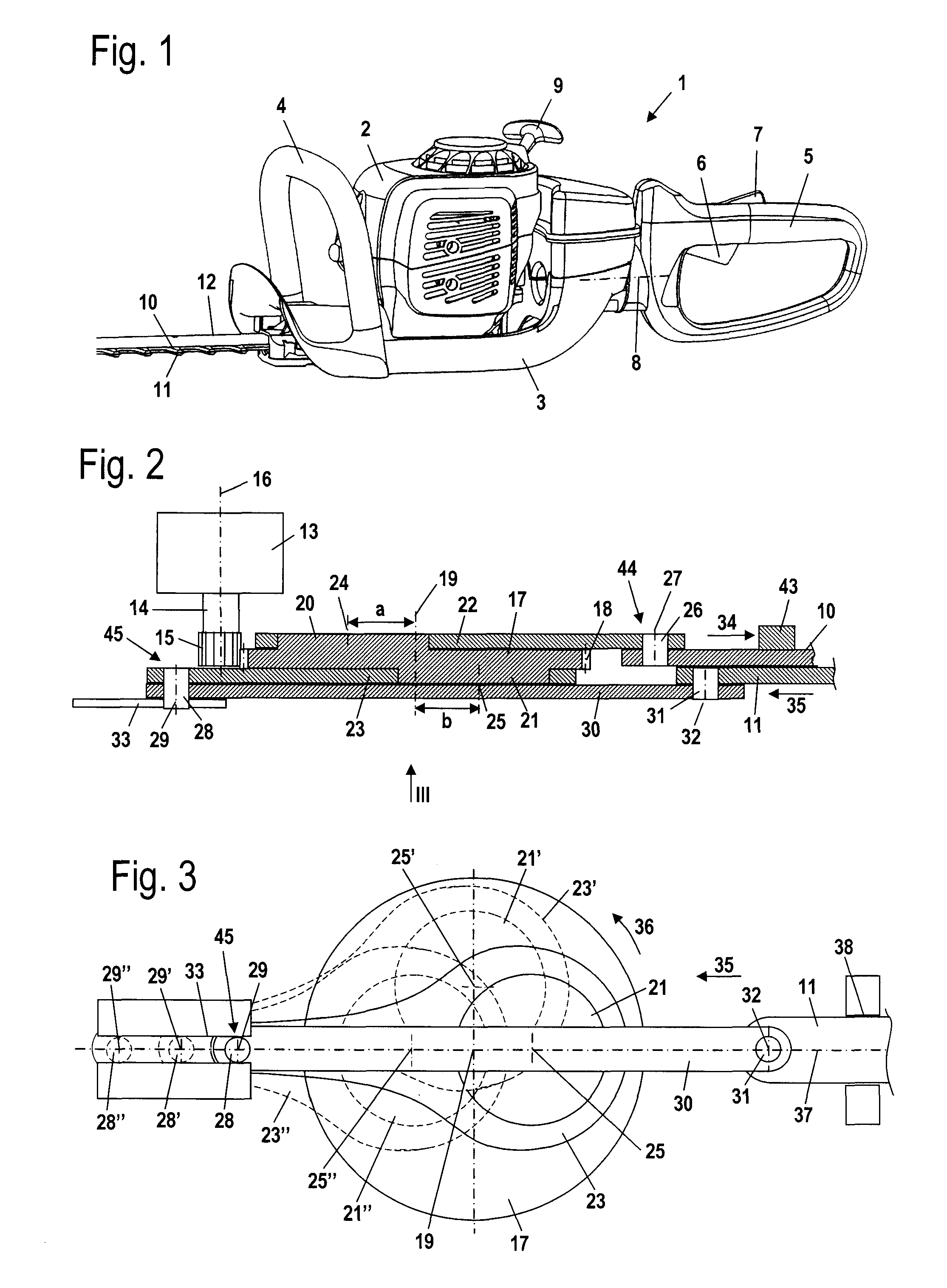

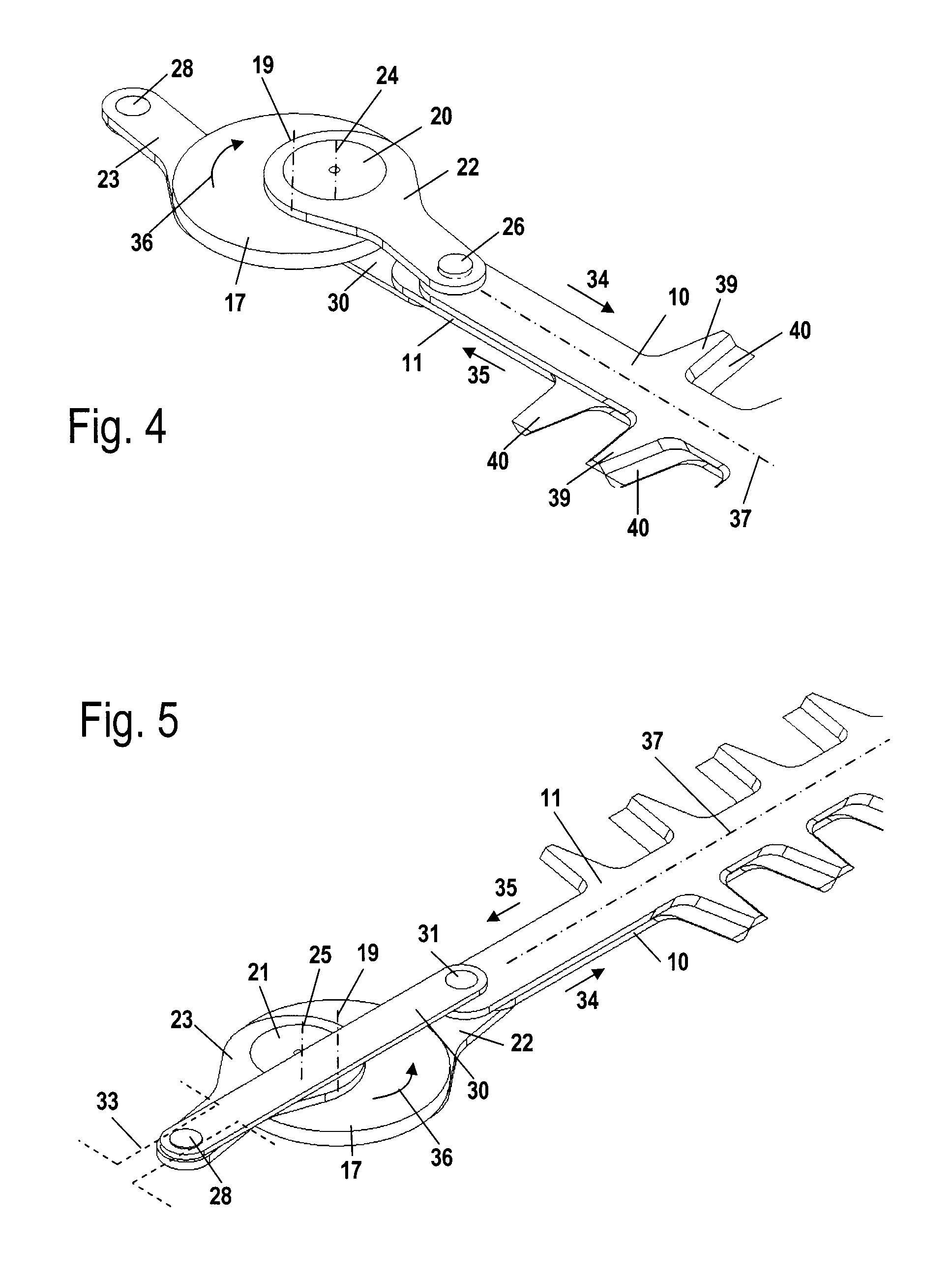

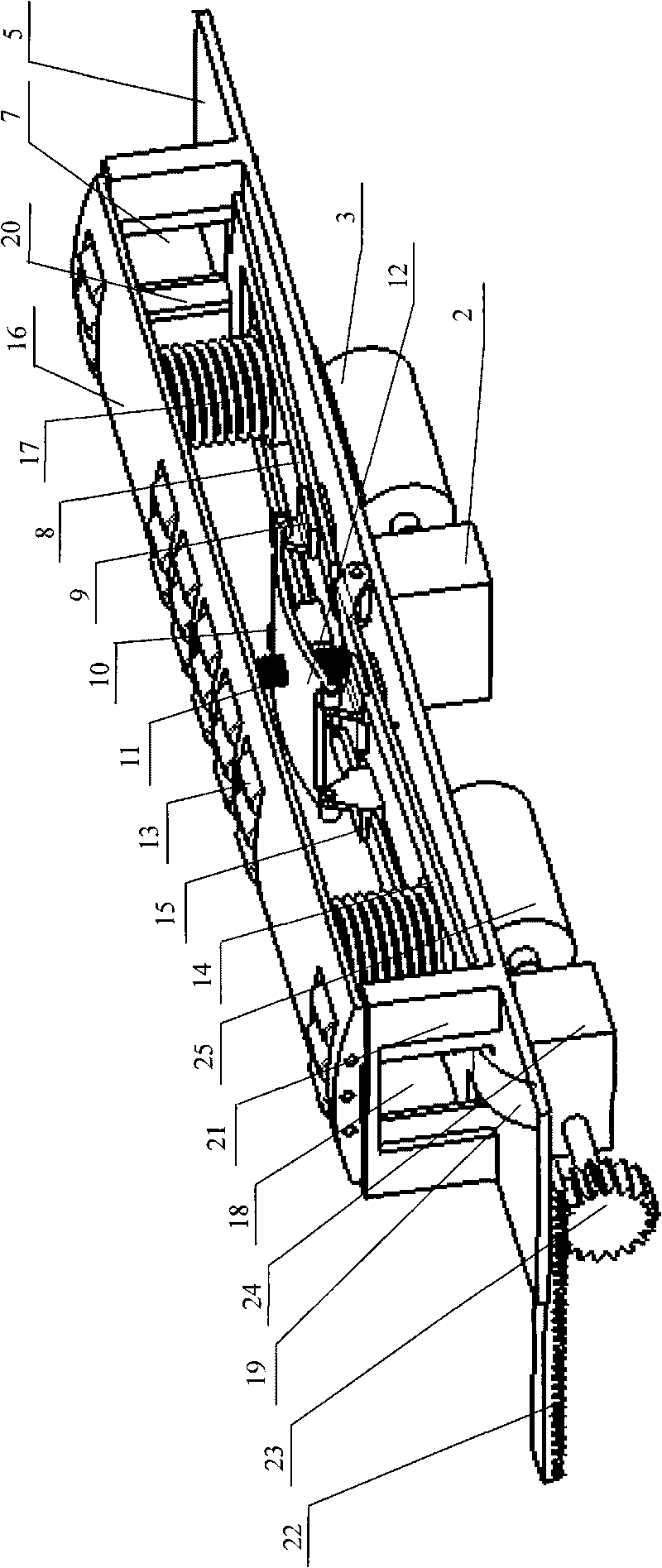

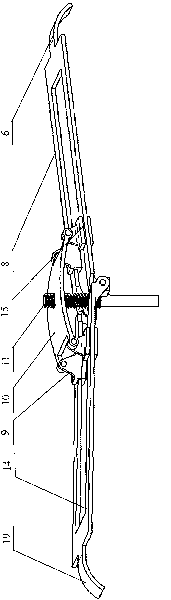

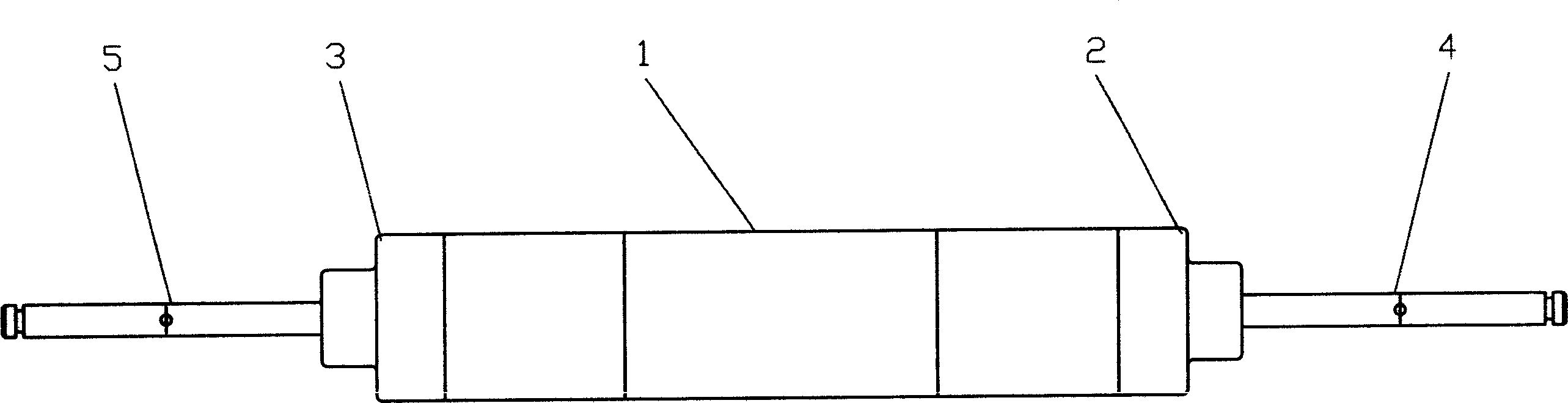

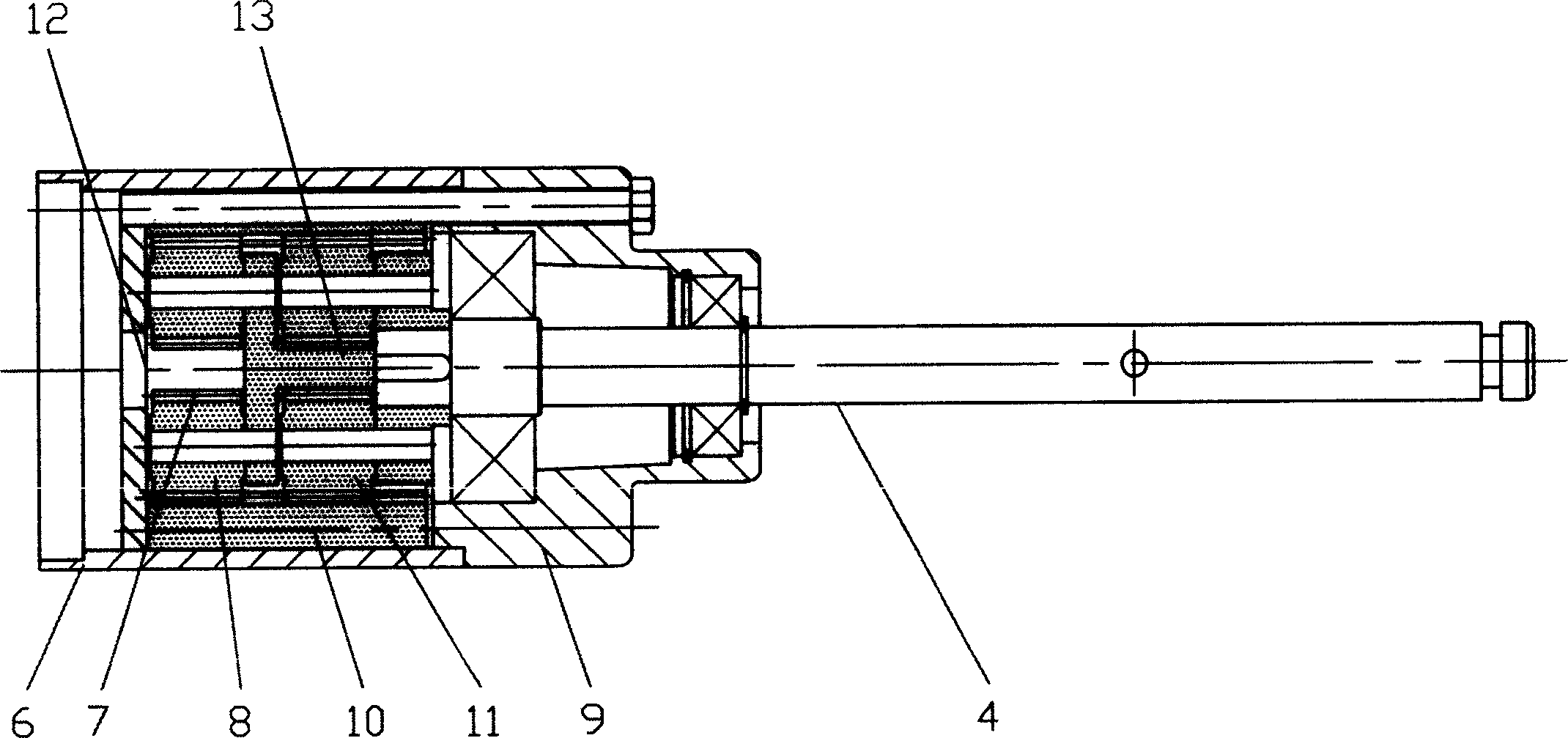

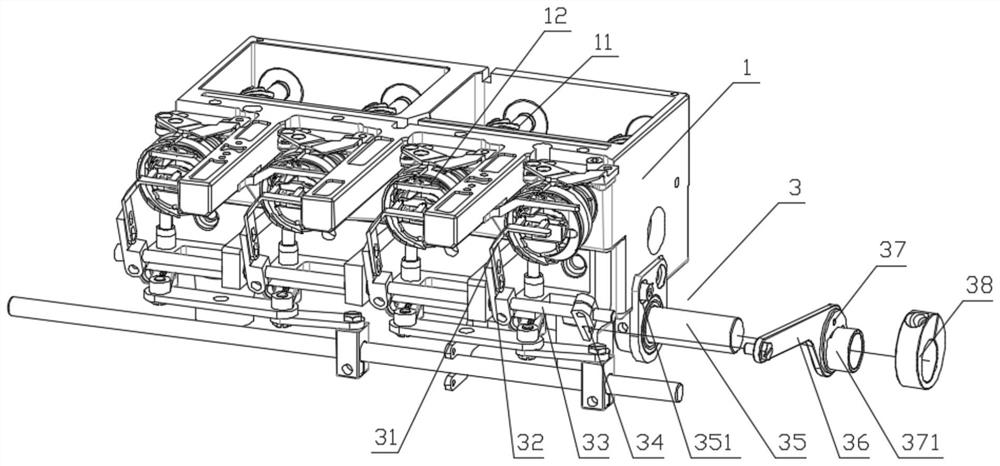

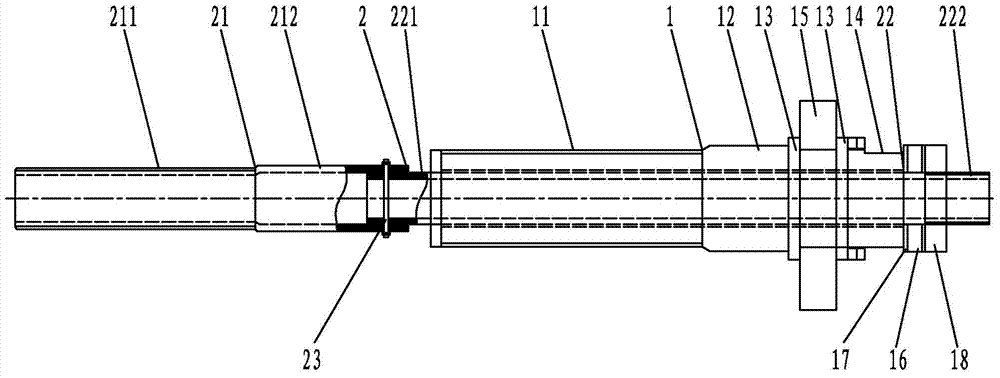

Power Tool

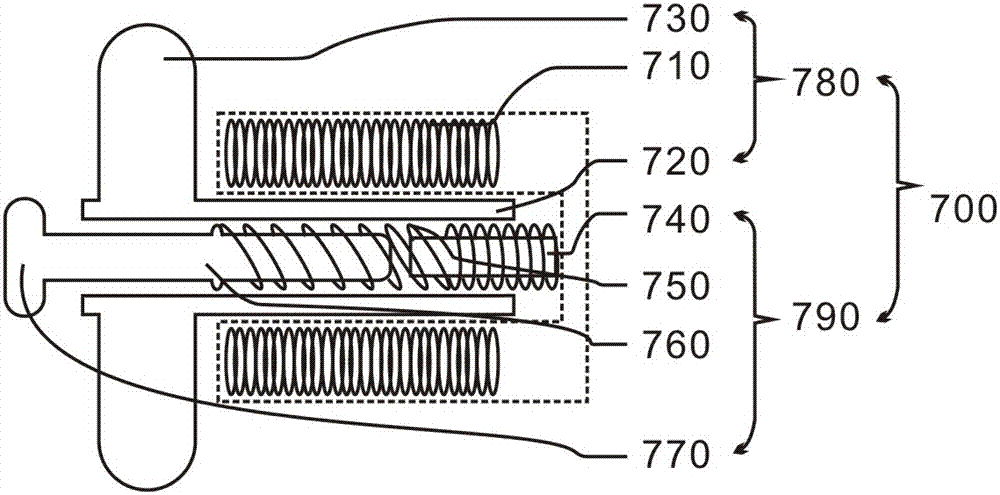

ActiveUS20100146796A1Reduce vibrationPrevent lateral deviationCuttersCutting implementsDrive motorEngineering

A power tool has a drive motor and first and second tool members driven reciprocatingly by the drive motor in opposite directions, respectively. The first tool member is driven by a first connecting rod and the first connecting rod is connected to the first tool member by a first pivot joint arranged on the first connecting rod. The second tool member is driven by a second connecting rod and the second connecting rod is connected to the second tool member by a second pivot joint arranged on the second connecting rod. The first pivot joint is arranged on an end of the first connecting rod which end is facing the tool members. The second pivot joint is arranged on an end of the second connecting rod which end is facing away from the tool members.

Owner:ANDREAS STIHL AG & CO KG

Power tool

ActiveUS8397389B2Reduce resultReduce transmission forceCuttersCutting implementsDrive motorEngineering

A power tool has a drive motor and first and second tool members driven reciprocatingly by the drive motor in opposite directions, respectively. The first tool member is driven by a first connecting rod and the first connecting rod is connected to the first tool member by a first pivot joint arranged on the first connecting rod. The second tool member is driven by a second connecting rod and the second connecting rod is connected to the second tool member by a second pivot joint arranged on the second connecting rod. The first pivot joint is arranged on an end of the first connecting rod which end is facing the tool members. The second pivot joint is arranged on an end of the second connecting rod which end is facing away from the tool members.

Owner:ANDREAS STIHL AG & CO KG

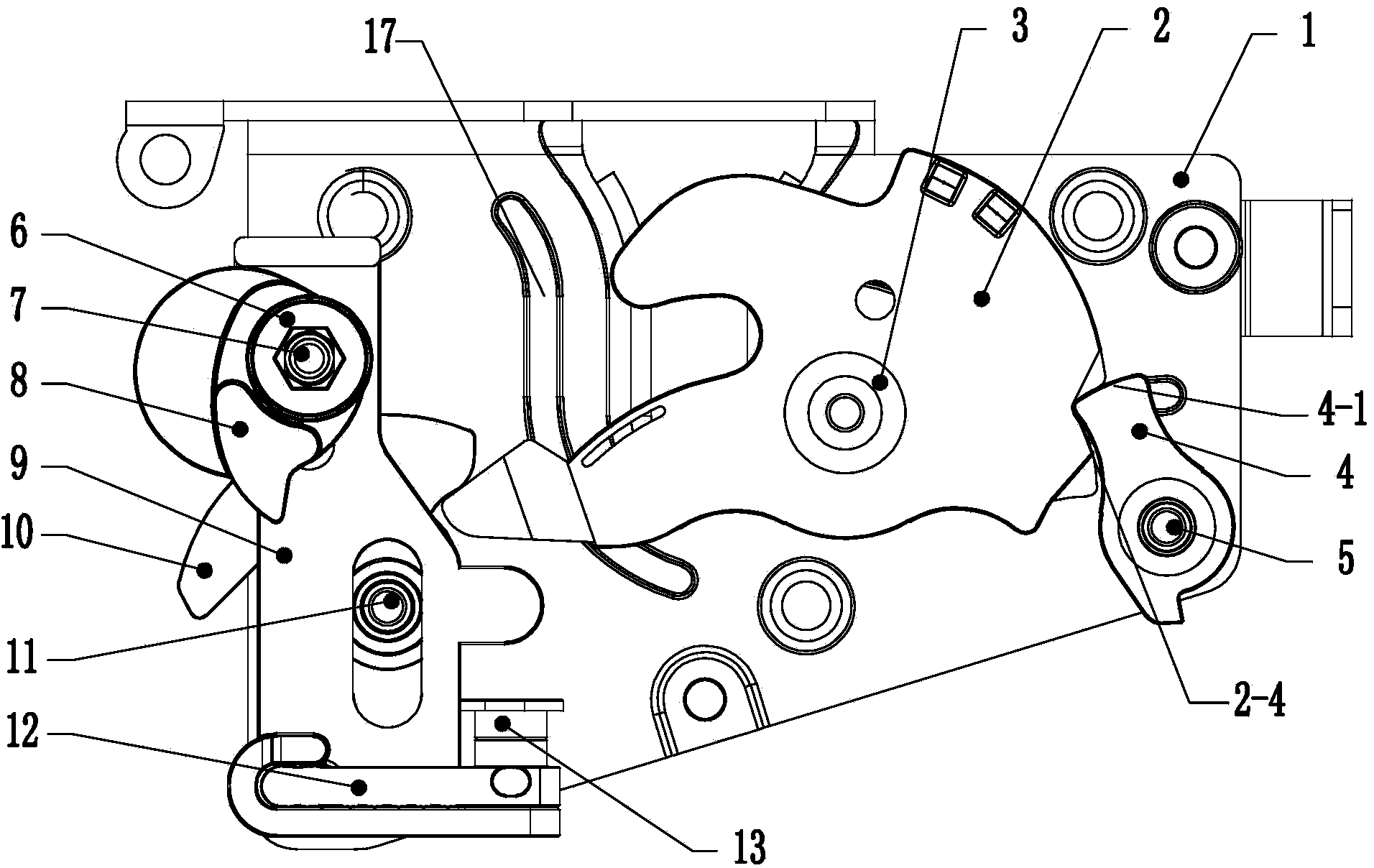

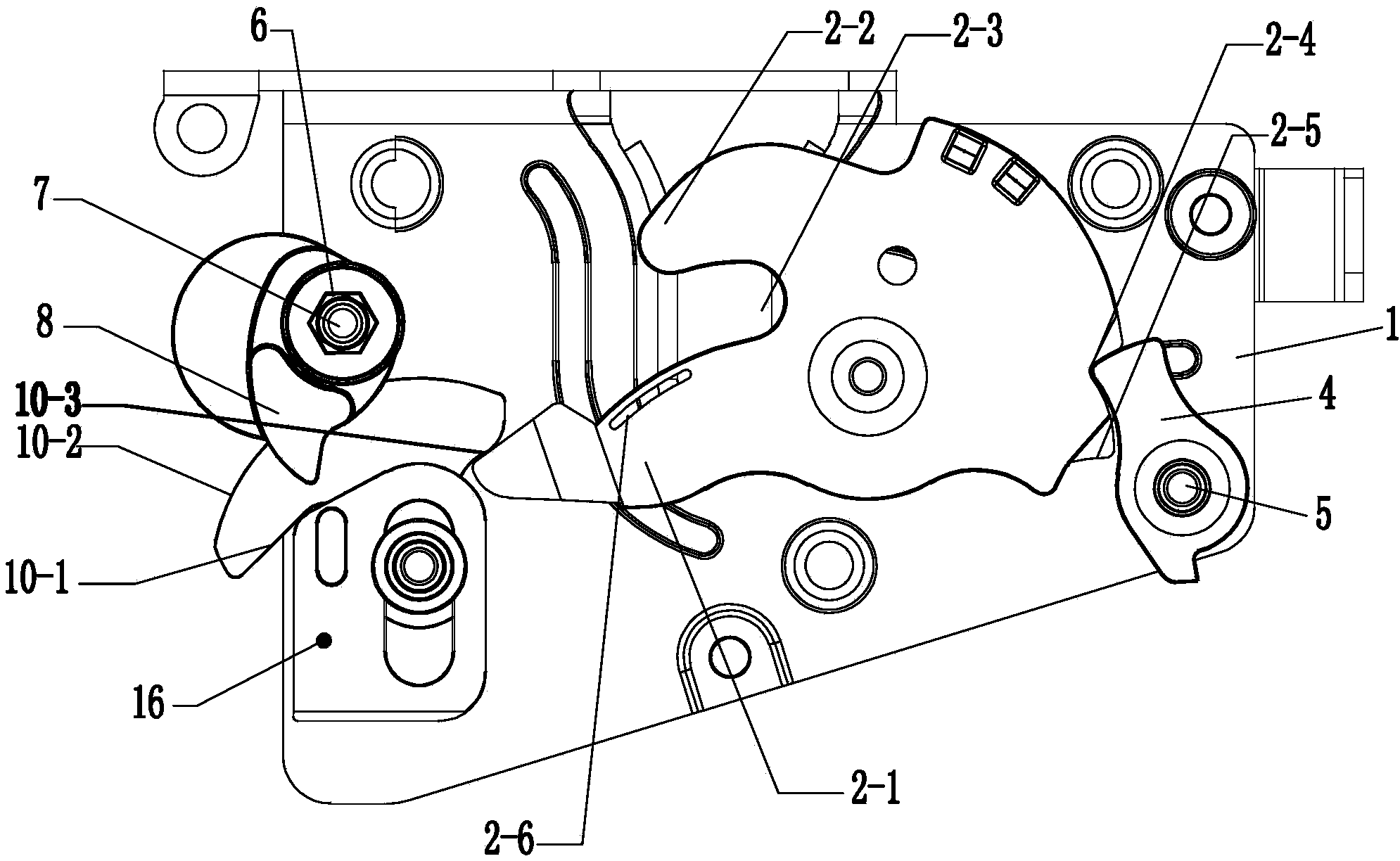

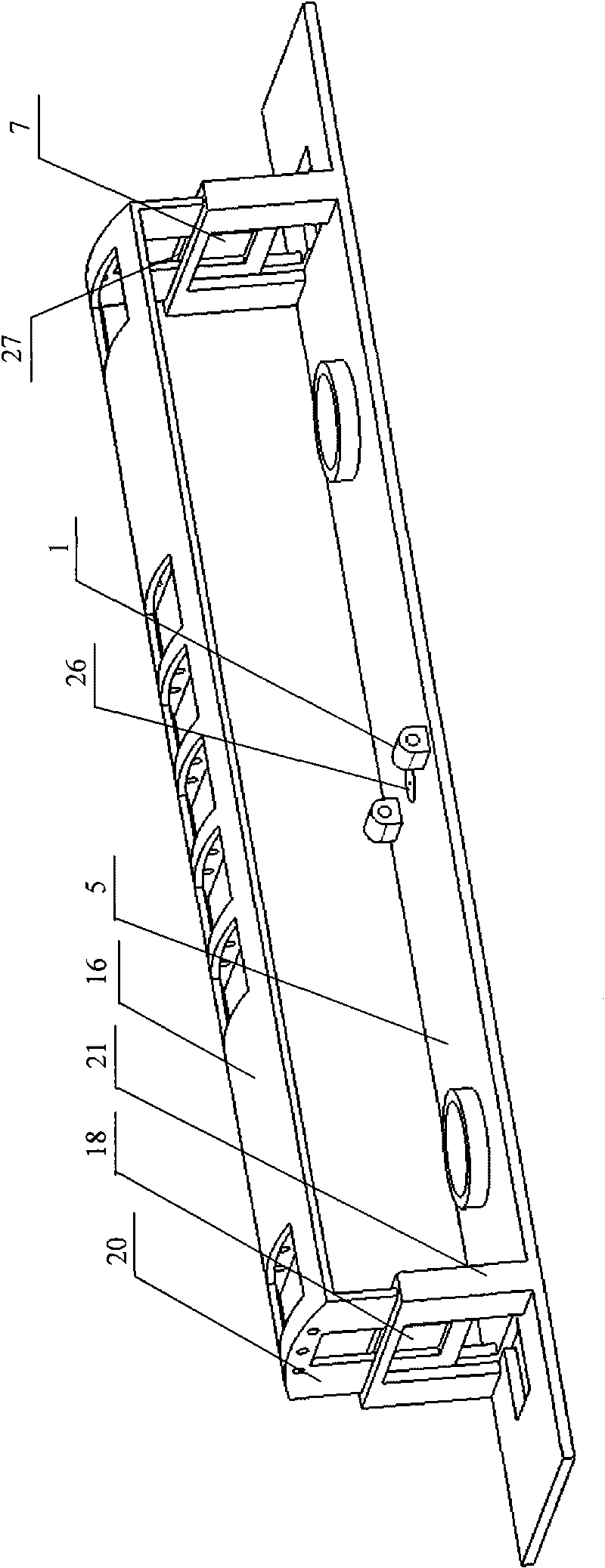

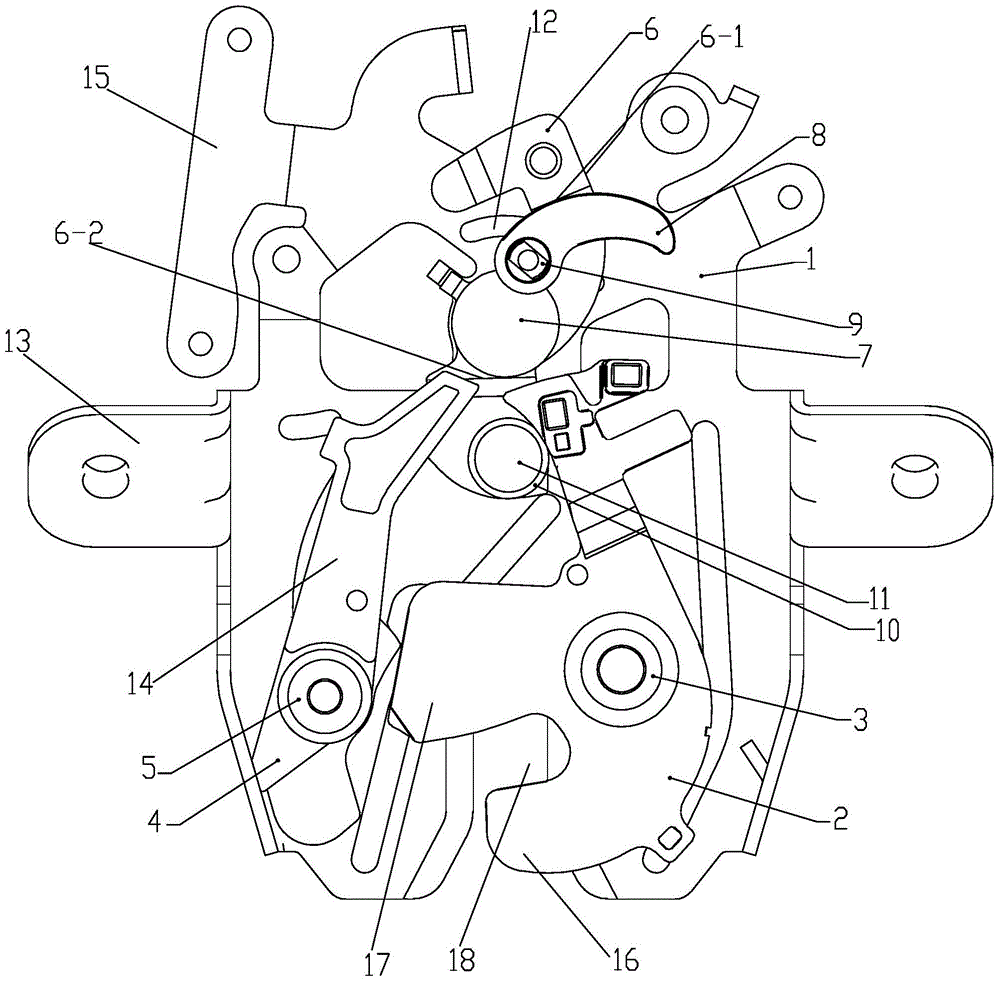

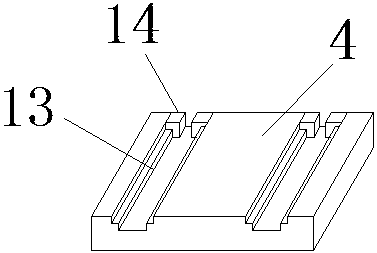

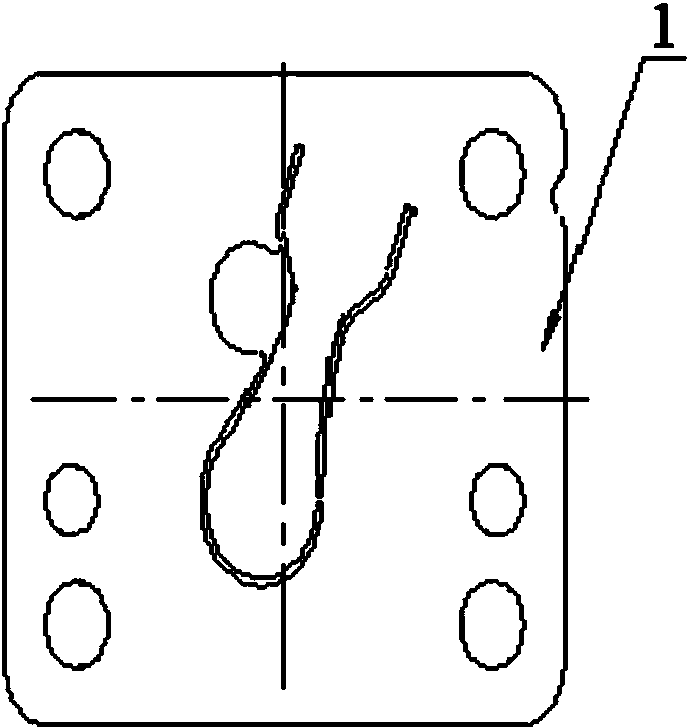

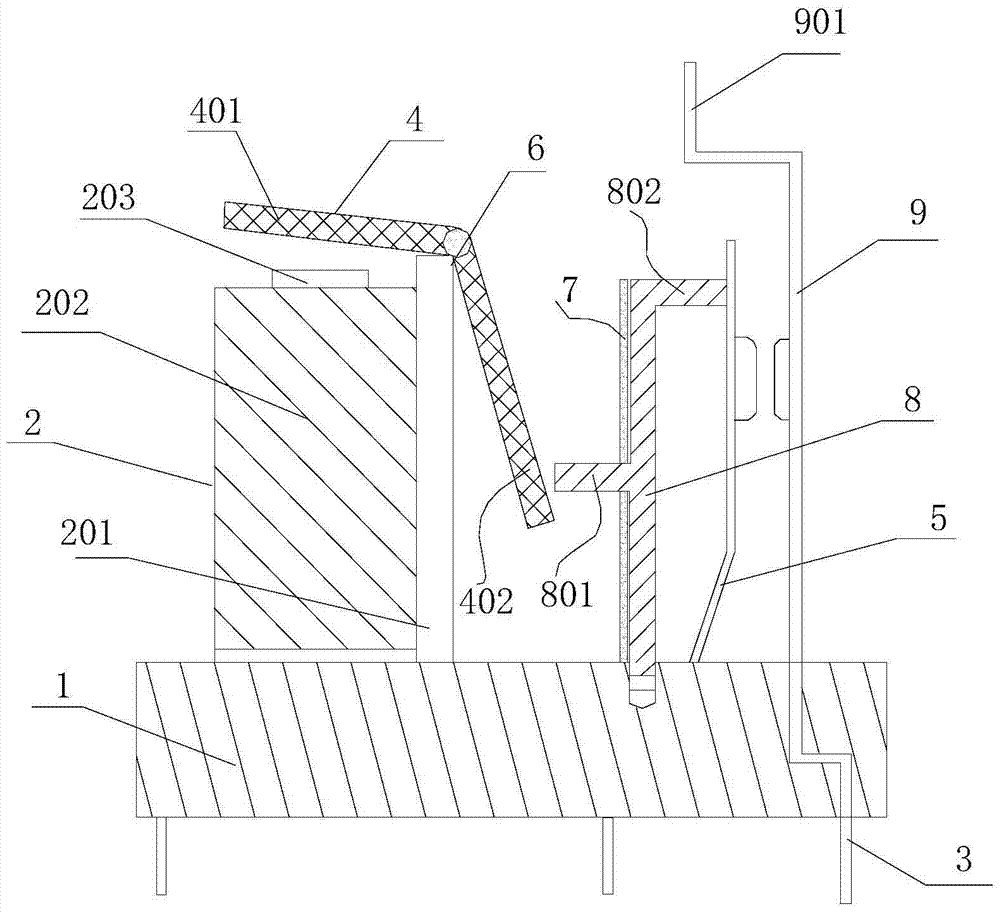

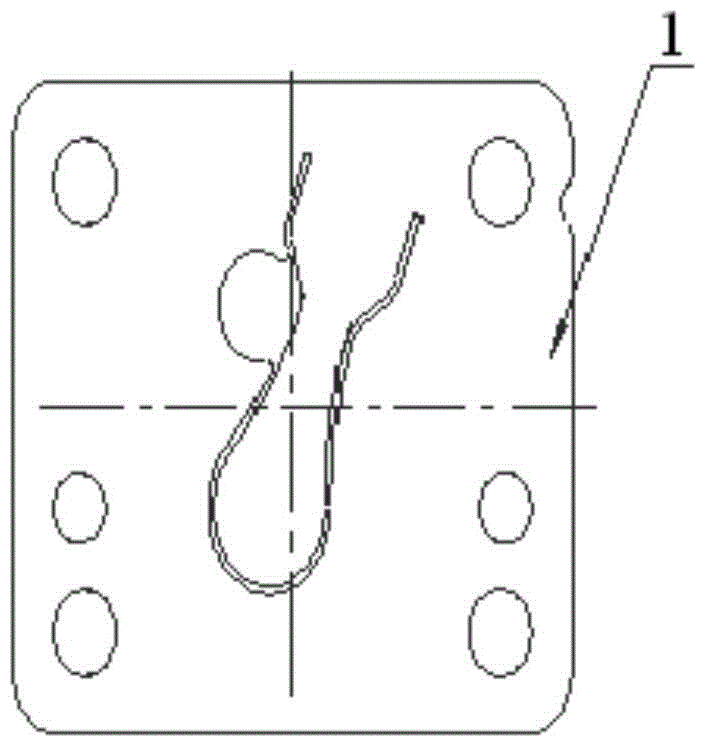

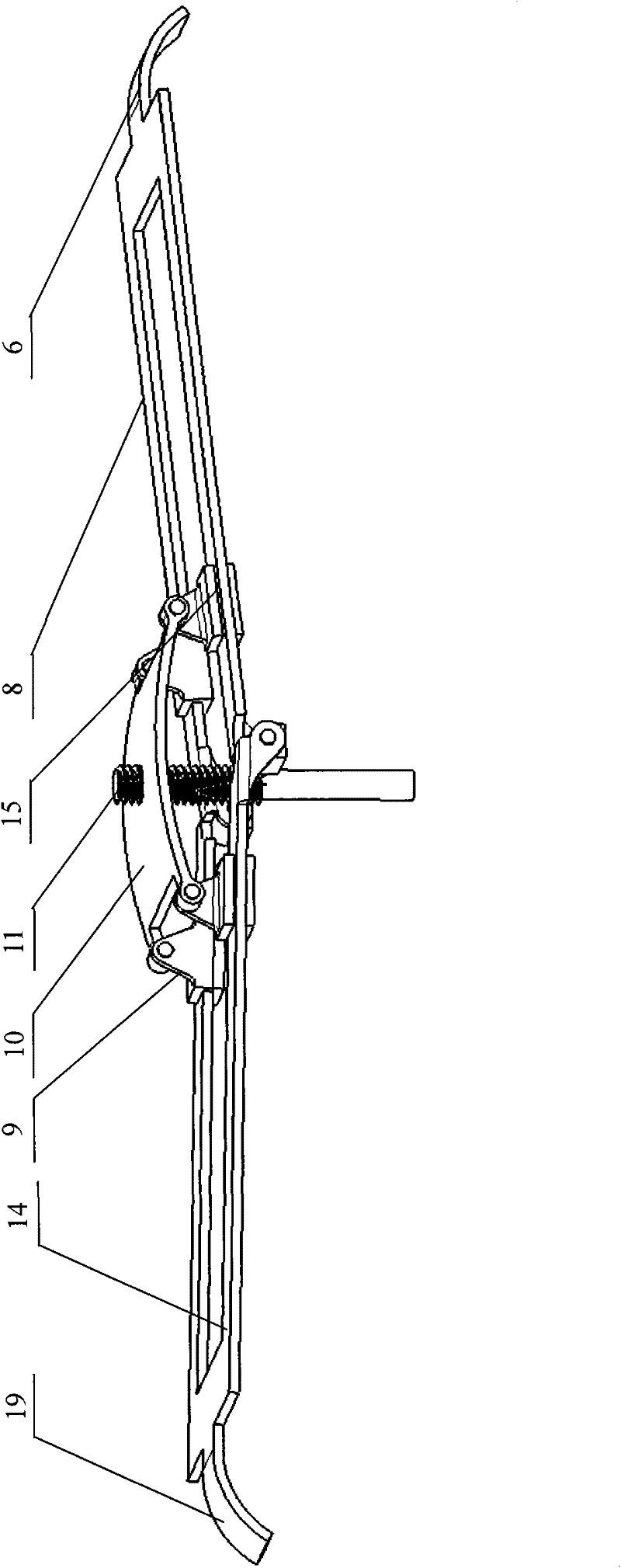

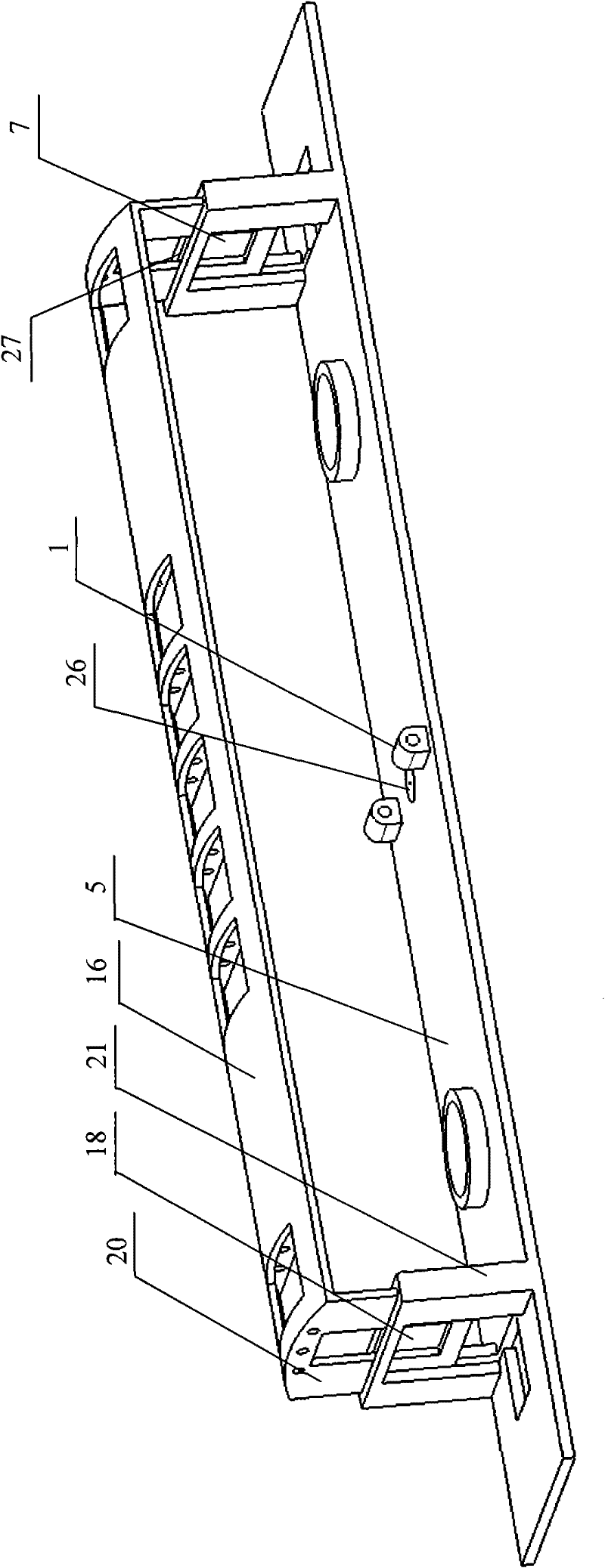

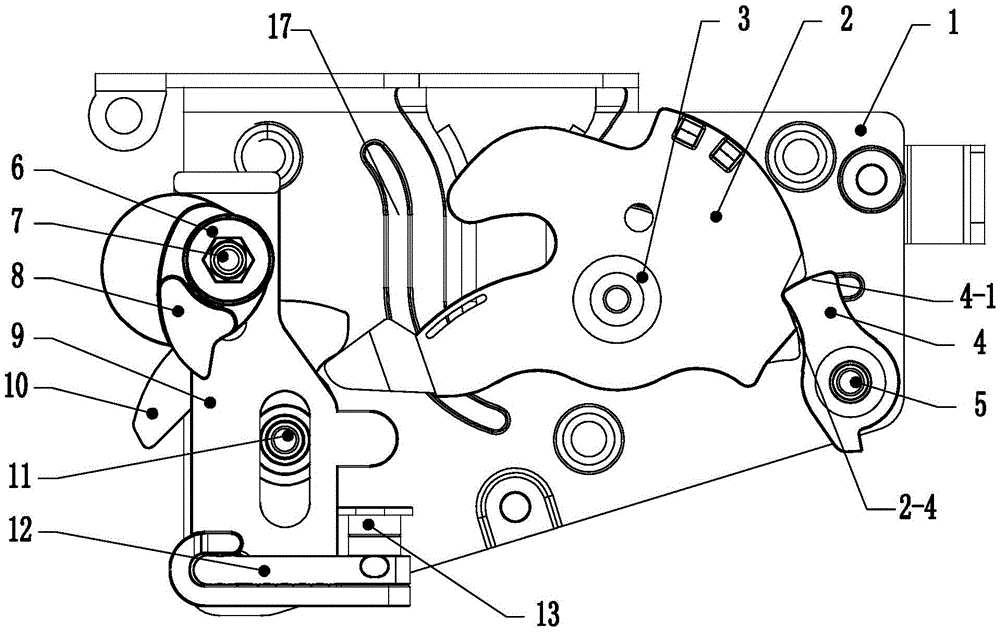

Side door lock transmission mechanism

The invention belongs to the field of automobile door lock systems, and particularly relates to a side door lock transmission mechanism. The mechanism comprises a baseplate, wherein a ratchet wheel riveting shaft and a ratchet pawl riveting shaft are fixed on the baseplate; a ratchet wheel is rotationally connected onto the ratchet wheel riveting shaft; the ratchet pawl is rotationally connected onto the ratchet pawl riveting shaft; the front part pawl end of the ratchet pawl is propped against the locking meshing cambered surface of the ratchet wheel; a transmission shaft is rotationally arranged at the end part on the side of the baseplate away from the ratchet pawl riveting shaft; a transmission cam is connected onto the transmission shaft in an interference fitting manner; a sliding block positioning shaft is arranged at the lower part, corresponding to the transmission shaft, of the baseplate. The mechanism is simple and compact in structure, can reduce the transmission force effectively through the arrangement of a connecting rod sliding block cam on the base plate, is simple in structure, and can improve the transmission efficiency and the transmission stability greatly.

Owner:无锡忻润汽车安全系统有限公司

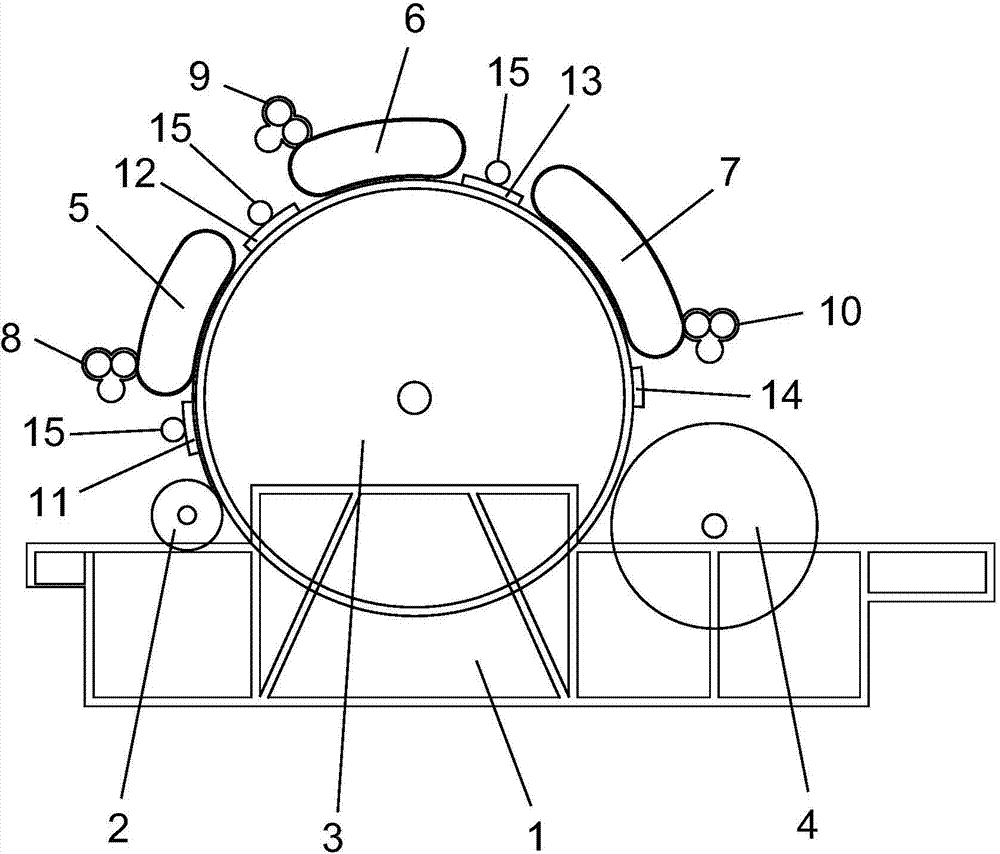

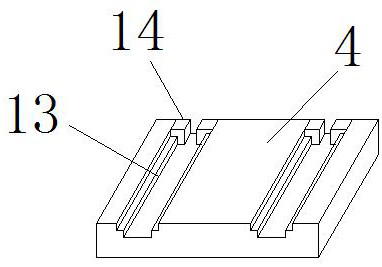

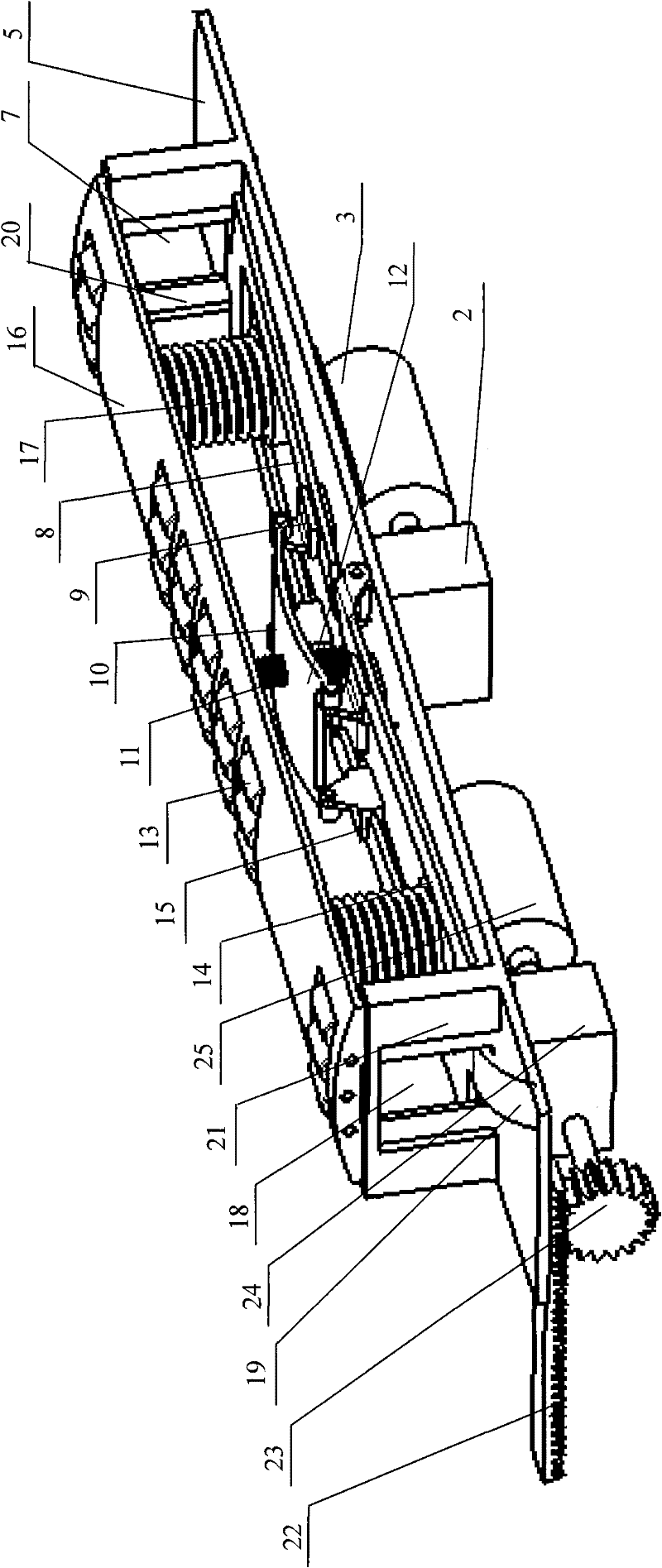

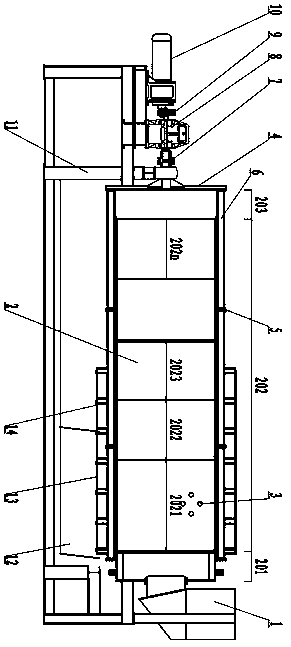

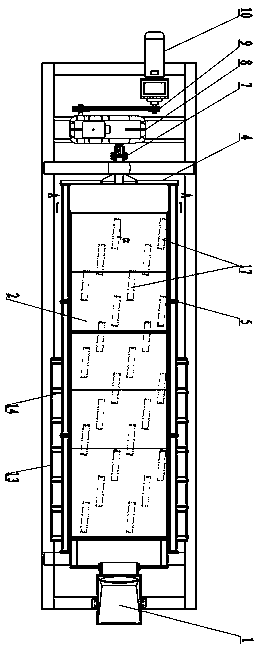

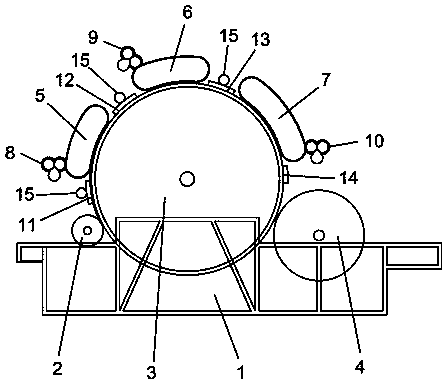

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are sequentially arranged on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are sequentially arranged on the top of the cylinder from front to back and correspond to the rack; partitions are respectively arranged between the first carding region cover plate and the second carding region cover plate and between the second carding region cover plate and the third carding region cover plate; the carding machine is provided with the three carding cover plates, so that three carding regions are formed; the first carding region is mainly used for clearing up and combing fibers smoothly and initially discharging impurities and short fibers; the second carding region is further used for clearing up and combing the fibers smoothly and initially discharging the impurities and the short fibers; the third carding region is mainly used for precisely combing the fibers and discharging the impurities and the short fibers further; each carding region cover plate is provided with a cover plate cleaning device; the cover plate cleaning devices can clean independently; and the cleaned carding cover plates can be used for combing operation rapidly and efficiently. The carding machine is provided with the three carding cover plates, the radian of each carding cover plate is reduced, the carding cover plates can be cleaned as soon as possible, the cleaning efficiency of the cover plates is improved further, and the carding effect is guaranteed.

Owner:QINGDAO HUANUO MACHINERY

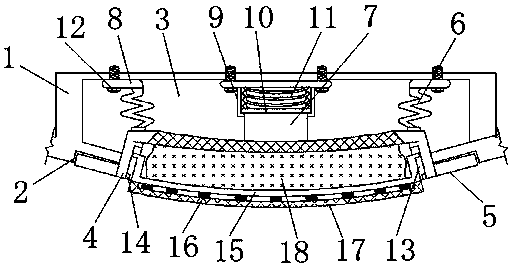

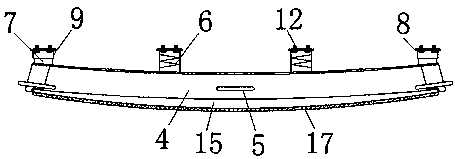

Waist support device of electric driver seat

InactiveCN101758784APrecise and continuous adjustmentHas a buffering effectBack restsStoolsEngineeringScrew thread

The invention relates to a waist support device of an electric driver seat, which belongs to a fitting of an electric driver seat. The waist support device comprises a rear support plate with an ascending edge and a front support plate with a descending edge. The descending edge is arranged in a slide groove of the ascending edge. The descending edge and the ascending edge are provided with through grooves. A compression spring and a convexity adjusting driving mechanism are arranged between the front support plate and the rear support plate. A pull hook is arranged at the outer end of a pull rod of the convexity adjusting driving mechanism, and is arranged in the through groove. The inner end of the pull rod is hinged with a fixed hinge seat which is arranged on the rear support plate. The lower end of a driving screw rod is connected with the output end of a convexity adjusting gearbox through a through hole at the middle part of the rear support plate, and the input end of the convexity adjusting gearbox is connected with a convexity adjusting motor. A pressure plate with threads is arranged outside the driving screw rod. Both ends of the pressure plate are respectively provided with a slide block which is provided with a groove relative to the pull rod. A position adjusting motor is arranged at the outside of the rear support plate, and is connected with a gear through the gearbox. The gear is meshed with a gear rack.

Owner:NORTHEASTERN UNIV

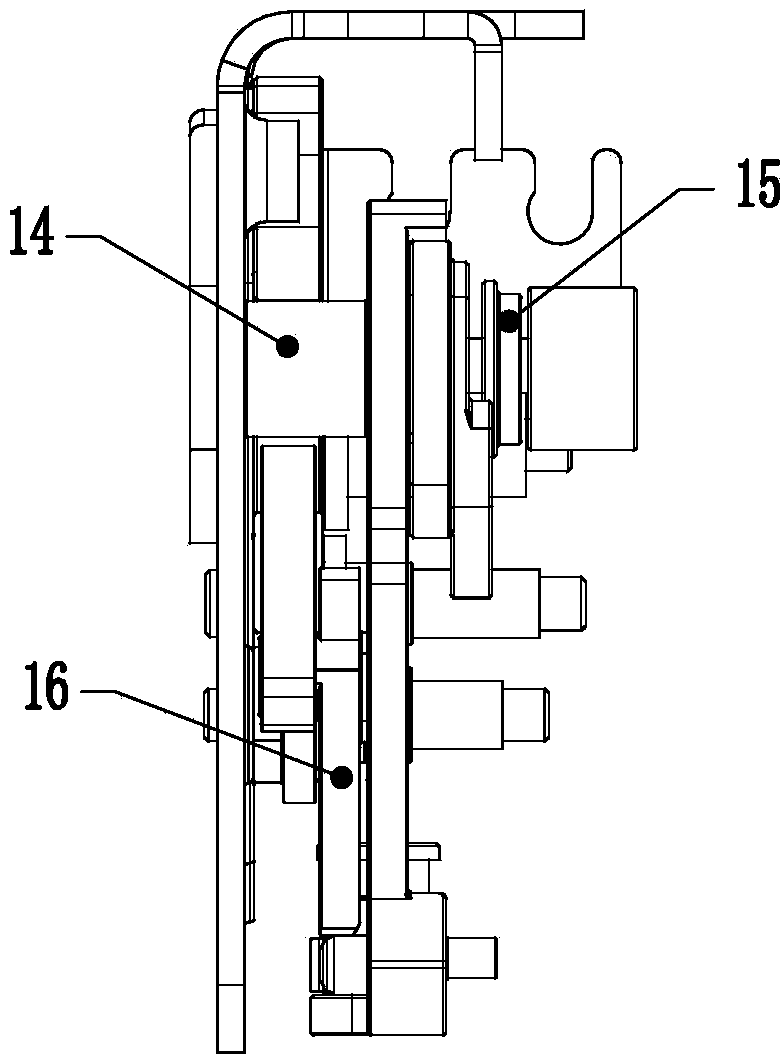

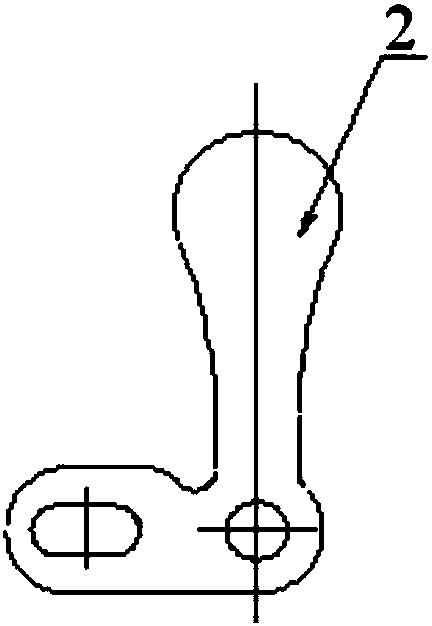

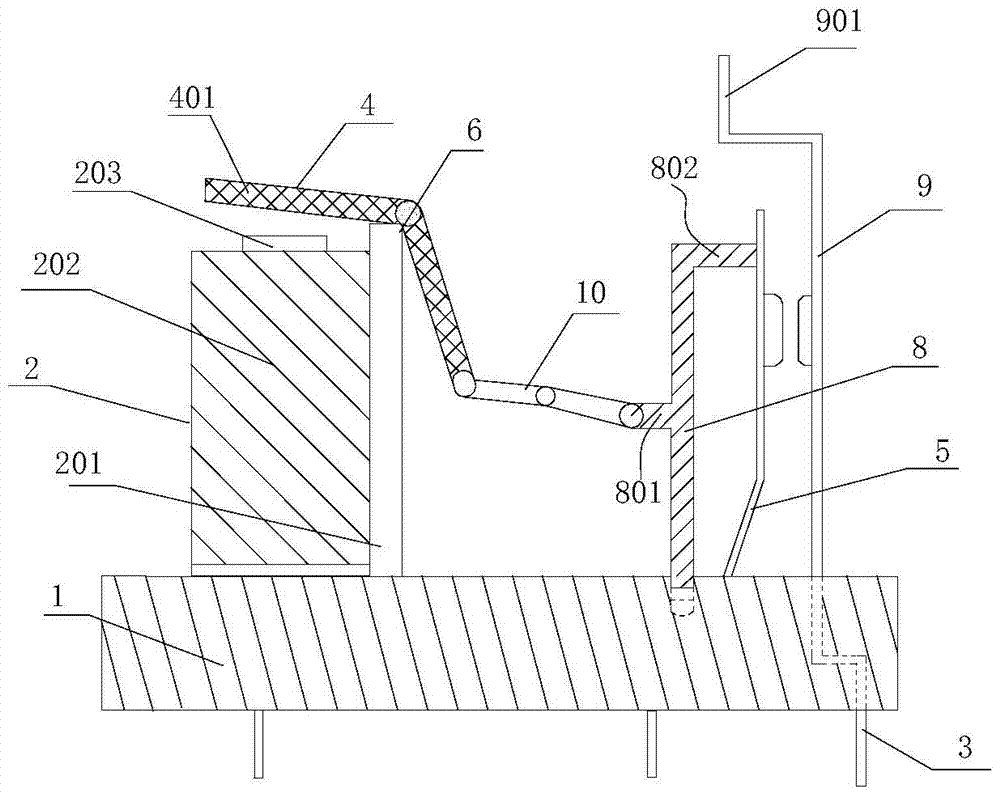

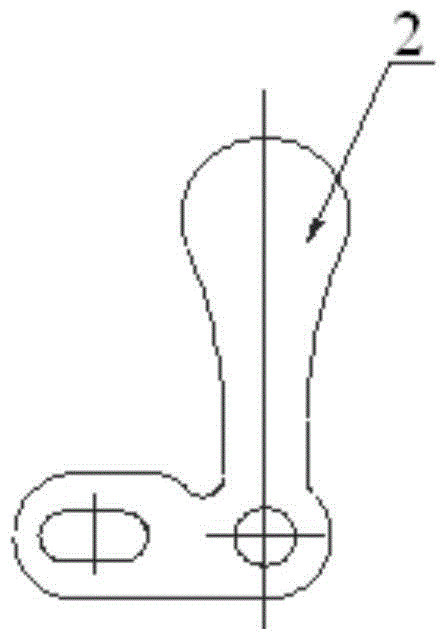

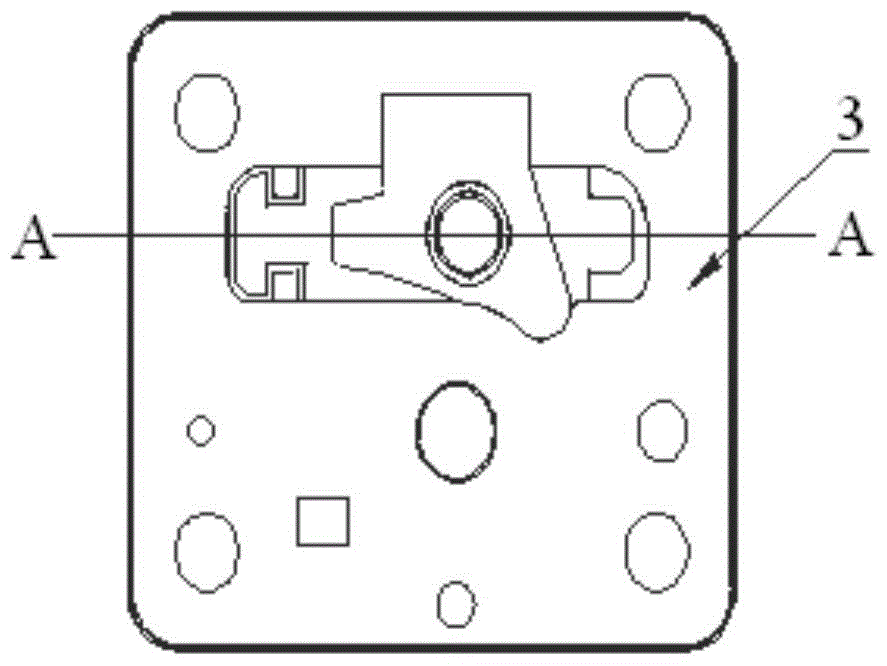

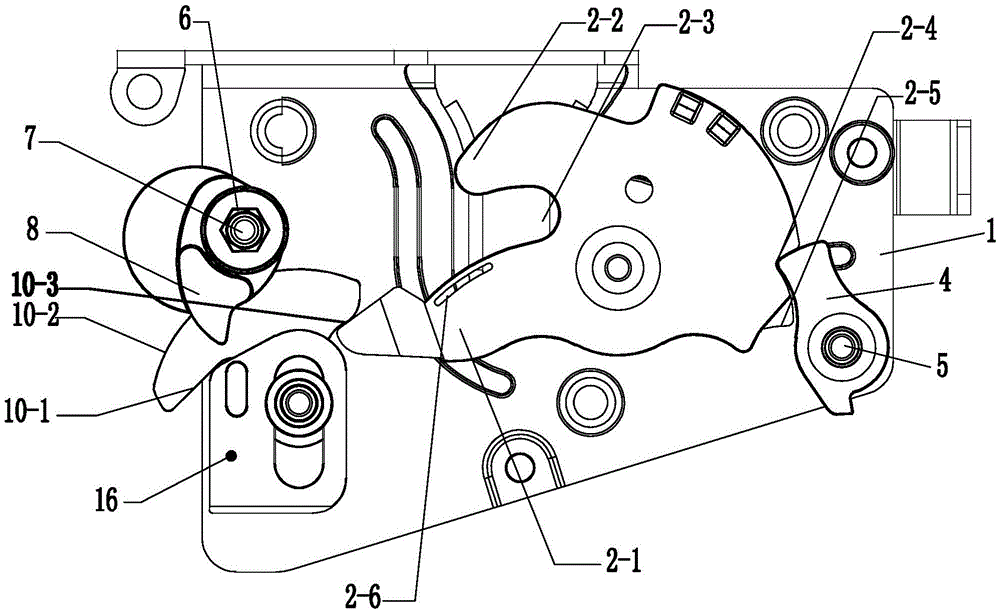

Transmission mechanism of self-suction tail door lock

ActiveCN104131747ASimple structureCompact structurePower transmission/actuator featuresElectrical locking actuatorsProtruding shouldersElectric machinery

The invention belongs to the field of automobile door lock systems, and particularly relates to a transmission mechanism of a self-suction tail door lock. The transmission mechanism of the self-suction tail door lock comprises a bottom plate, and a drive plate rivet shaft, a pawl rivet shaft and a ratchet wheel rivet shaft are formed on one side surface of the bottom plate. A drive plate is rotatably connected to the drive plate rivet shaft through a mounting hole formed in the end of the drive plate. An arc-shaped protrusion is arranged at the outer end, corresponding to the drive plate rivet shaft, of the bottom plate. A transmission rocker arm is rotatably connected to an external driving motor gear case through a transmission rocker arm shaft which is integrally connected at the end of the transmission rocker arm, and the outer side cambered surface of the transmission rocker arm abuts against a first protruding shoulder of the drive plate. A transmission gasket shaft is fixed on the inner side, corresponding to the drive plate rivet shaft, of the drive plate, and a transmission gasket is connected to the transmission gasket shaft in a rotating mode. The transmission mechanism of the self-suction tail door lock is simple and compact in structure, a connecting rod and cam structure is arranged on the bottom plate, driving force can be effectively lowered, the structure is simple, and the transmission efficiency and the transmission stability are greatly improved.

Owner:无锡忻润汽车安全系统有限公司

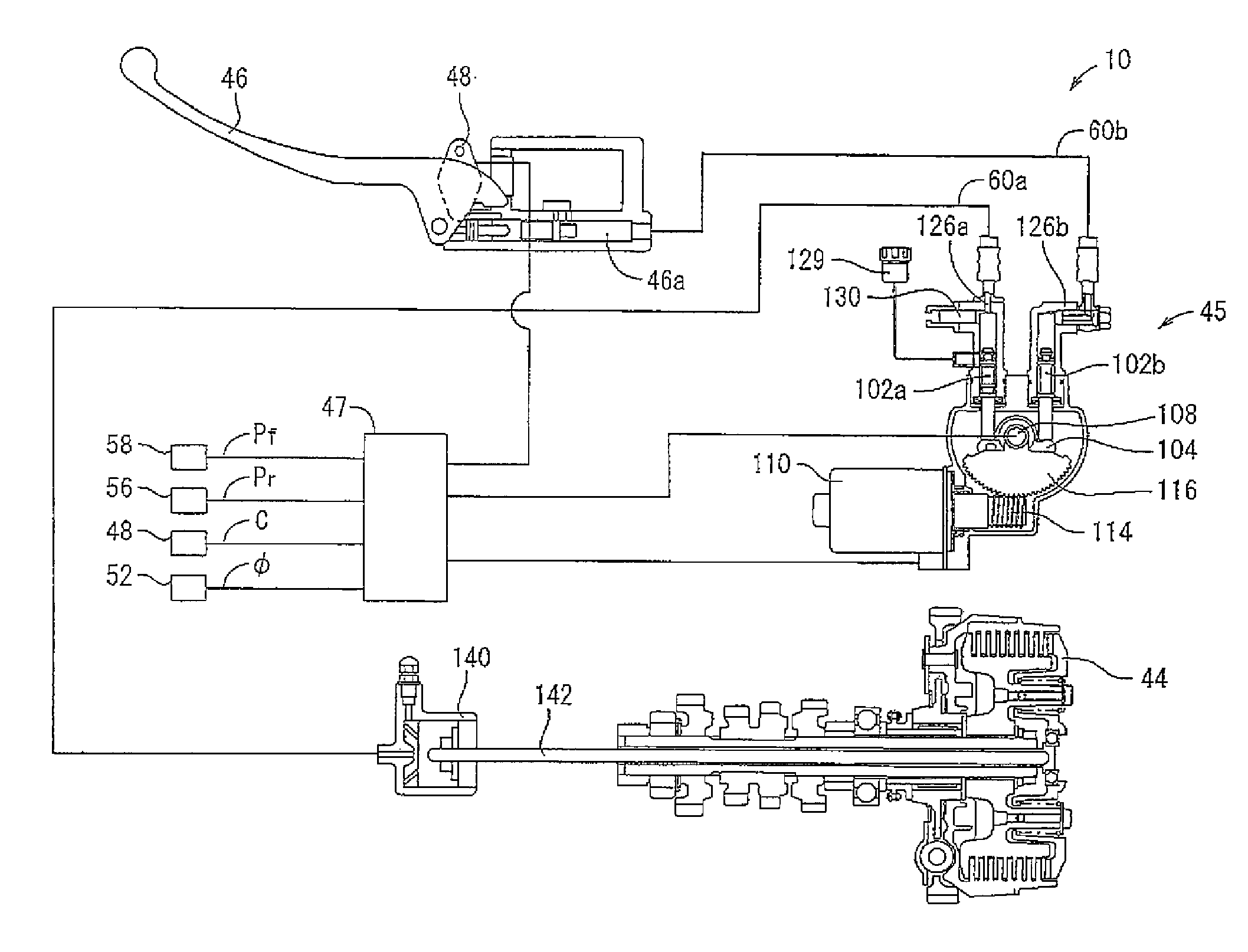

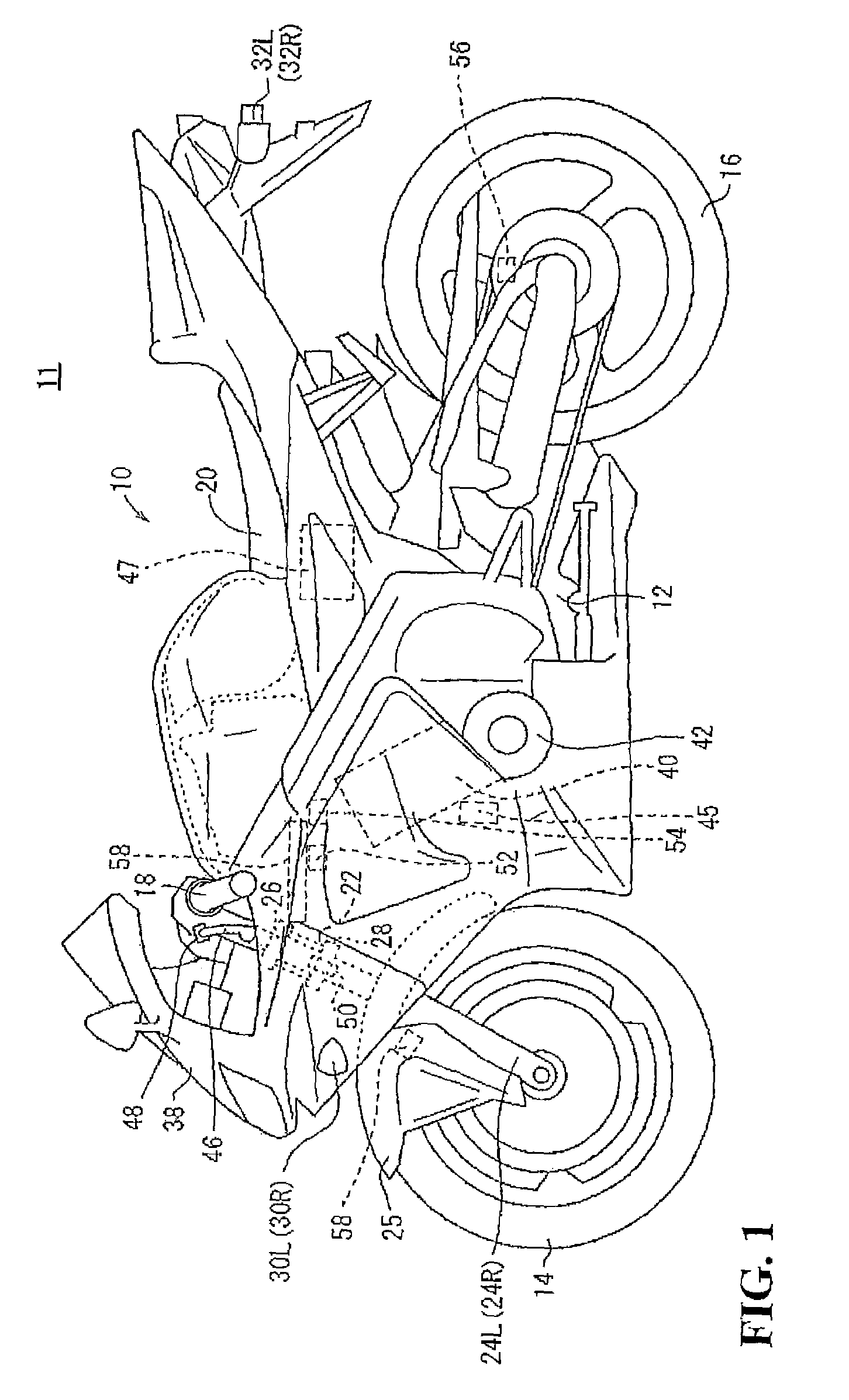

Clutch control system for saddle riding type vehicle

ActiveUS8147381B2Reduce transmission forceReduce outputClutchesAnalogue computers for trafficClutch controlGrip force

A grip force of a driving wheel is maintained by identifying an actual condition of a motorcycle and controlling a clutch in a timely manner. A clutch control system includes a clutch, an actuator unit causing the clutch to engage or disengage, a rear wheel speed sensor, a front wheel speed sensor, a clutch lever sensor and a controller controlling a control motor based on a rear wheel speed and a front wheel speed. When the rear wheel speed is lower than the front wheel speed and an absolute value of a difference between the rear wheel speed and the front wheel speed is greater than a threshold value, the control motor is driven so as to reduce a transmission force of the clutch. When an operational amount of the clutch lever is greater than a threshold value, processing to reduce the transmission force of the clutch is suspended.

Owner:HONDA MOTOR CO LTD

Motor vehicle

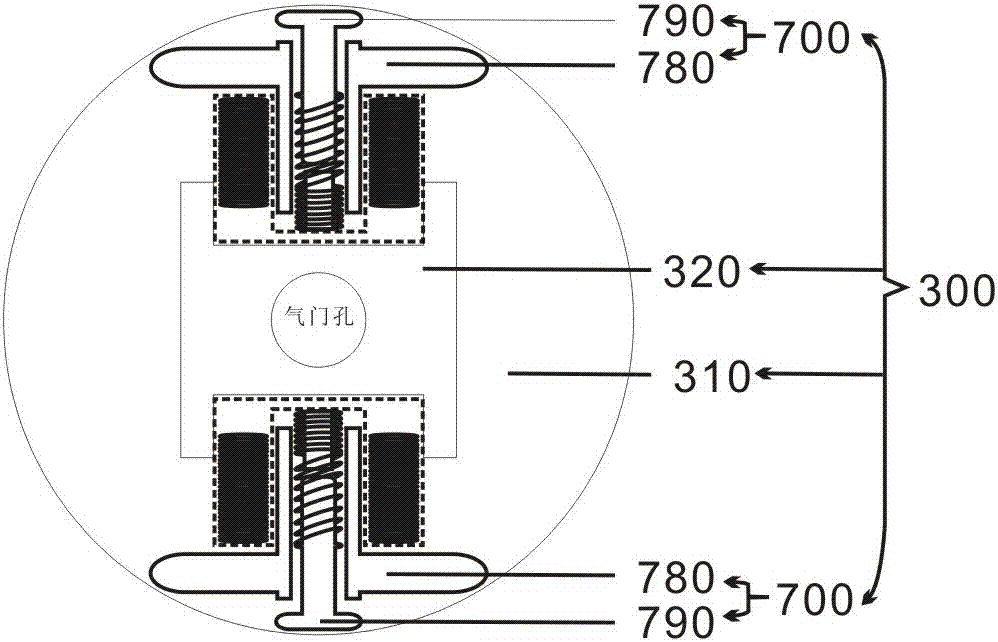

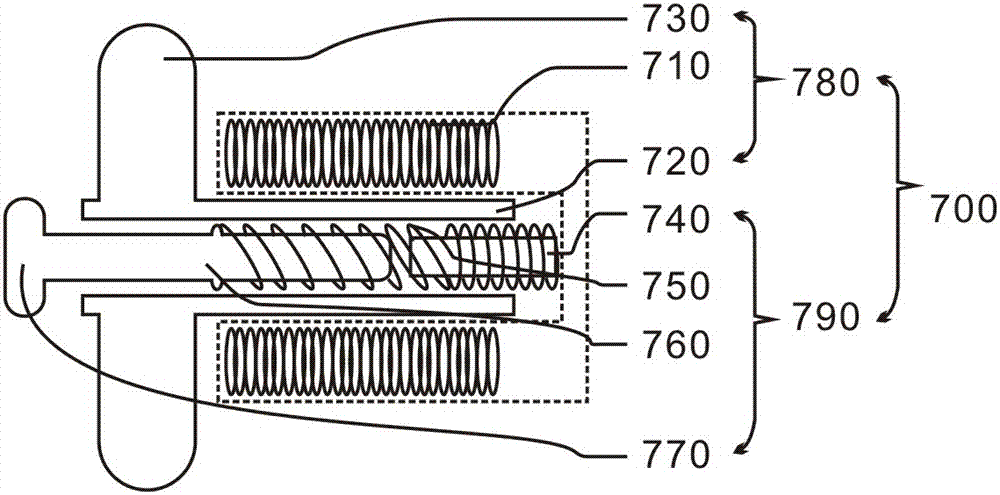

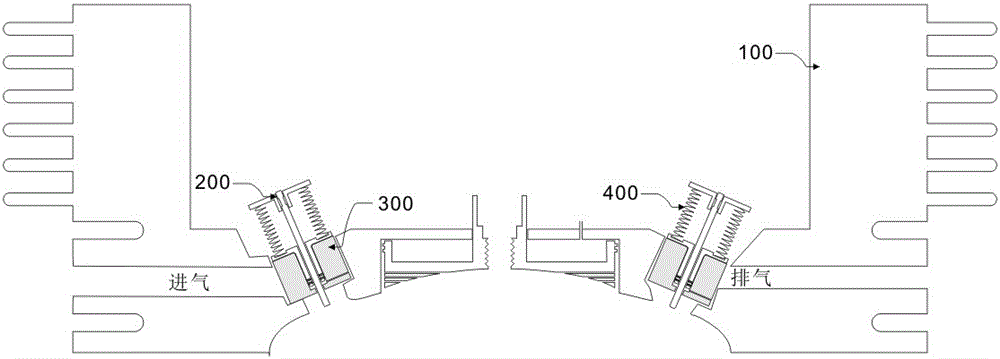

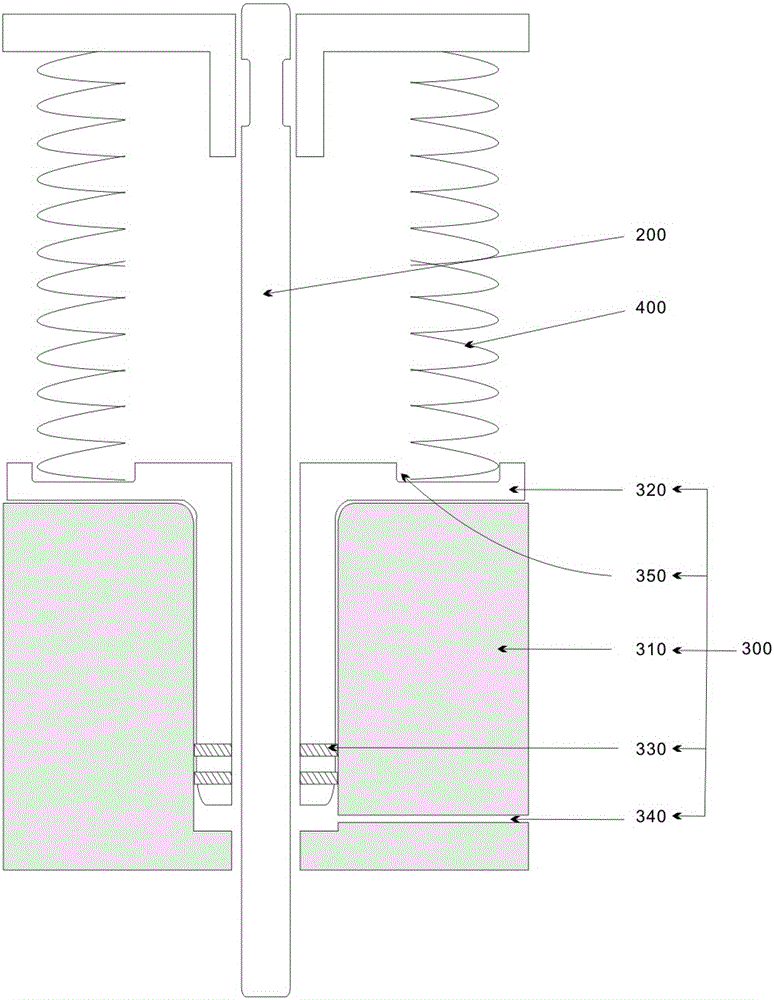

InactiveCN106948896ARelieve stressExtended service lifeValve arrangementsMachines/enginesCylinder headEngineering

The invention proposes a motor vehicle, comprising: an engine, and a cylinder head installed on the engine, one end of the valve spring withstands the pressure plate of the valve spring, and the other end withstands the lifting seat, and the lifting seat is installed on the cylinder head. On the valve seat; there is a balance weight and at least one lifter inside the lifting seat. Wherein, adjusting the pressure of the inner spring of the valve includes adjusting the electric control connected with the lifter. Includes electrical control that adjusts to the lifter based on engine speed. Adjust the pressure of the valve inner spring when the engine speed is high and adjust the pressure of the valve inner spring to be small when the engine speed is low. Realize increasing the pressure of the inner spring of the valve when the engine speed is high and reducing or canceling the pressure of the inner spring of the valve when the engine speed is low.

Owner:NANAN FENGZHOU GAOJIE MOTORCYCLE ENERGY SAVING PRACTICAL TECH PROD SALES CENT

Method for controlling a rolling or coasting function of a vehicle

InactiveUS8939870B2Reliably recognizePrevent unnecessary shifting into neutralRoad transportGearing controlAutomatic transmissionDrive motor

A method of controlling a rolling or coasting function of a vehicle with a drive train having a drive motor, an automatic or automated transmission, a controllable shifting means, a brake device and a drive speed control device. The vehicle speed is regulated by the drive speed control device and the braking device is activated, as needed, when driving on a downhill gradient section. To effectively and reliably use the rolling or coasting function in suitable driving situations, taking into account the influence of the driving speed control device, a rolling or a coasting condition for a downhill gradient taper is checked, when driving on the downhill gradient section, and, when the rolling or coasting condition is satisfied, the transmission controls interrupt the flow of power in the drive train before the vehicle entering a flat area, and / or before the driving speed control device generates an engine torque request.

Owner:ZF FRIEDRICHSHAFEN AG

Motor with two-end output

Owner:许晓华

Supporting accessory enabling vehicle to reduce collision injury

ActiveCN109278696AReduce collision damageReduced effectPedestrian/occupant safety arrangementEngineering

The invention discloses a supporting accessory enabling a vehicle to reduce collision injury. The supporting accessory comprises a vehicle body, a fixing baffle, a blocking plate, and a contact plate.A positioning groove is formed in the vehicle head shell of a vehicle body. A mounting cavity is reserved in the vehicle head shell of the vehicle body. Positioning frange plates are fixedly connected to the edges of the top of the fixing baffle. The bottom of the fixing baffle is mounted in an inner cavity. The column end of a fixing column is arranged in a positioning shell. Positioning bottomplates are fixedly mounted at the ends of the positioning shell and a connecting piece. A sliding groove is formed in the inner wall of the fixing baffle. The end of the blocking plate is arranged inthe sliding groove. The contact plate is located outside the blocking plate. A fixing groove is formed in the edge of the outer side of the blocking plate. According to the supporting accessory enabling the vehicle to reduce the collision injury, multiple collision force weakening between a vehicle and a victim is achieved, and therefore the force and reactive force between the victim and the vehicle are greatly reduced, and the impact damage to the victim is reduced.

Owner:平邑现代中药产业园有限公司

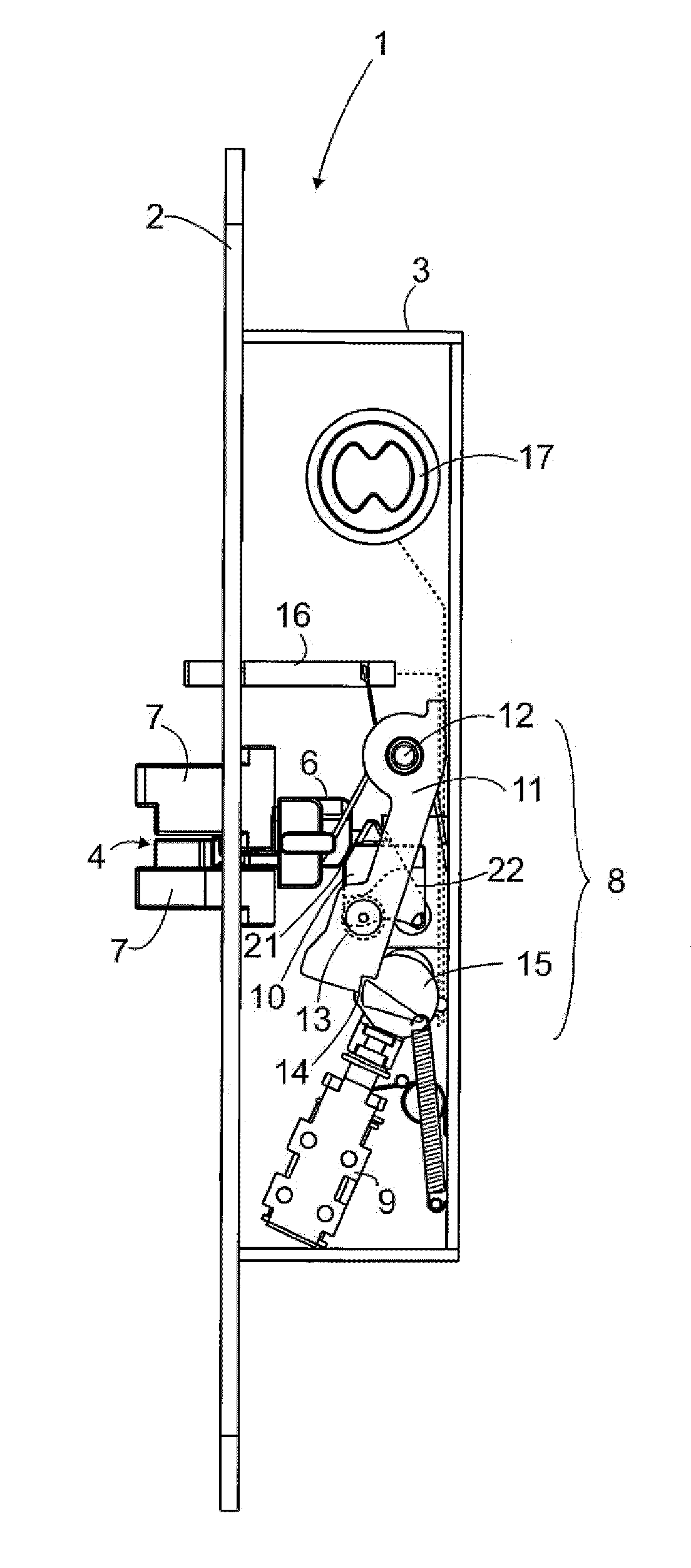

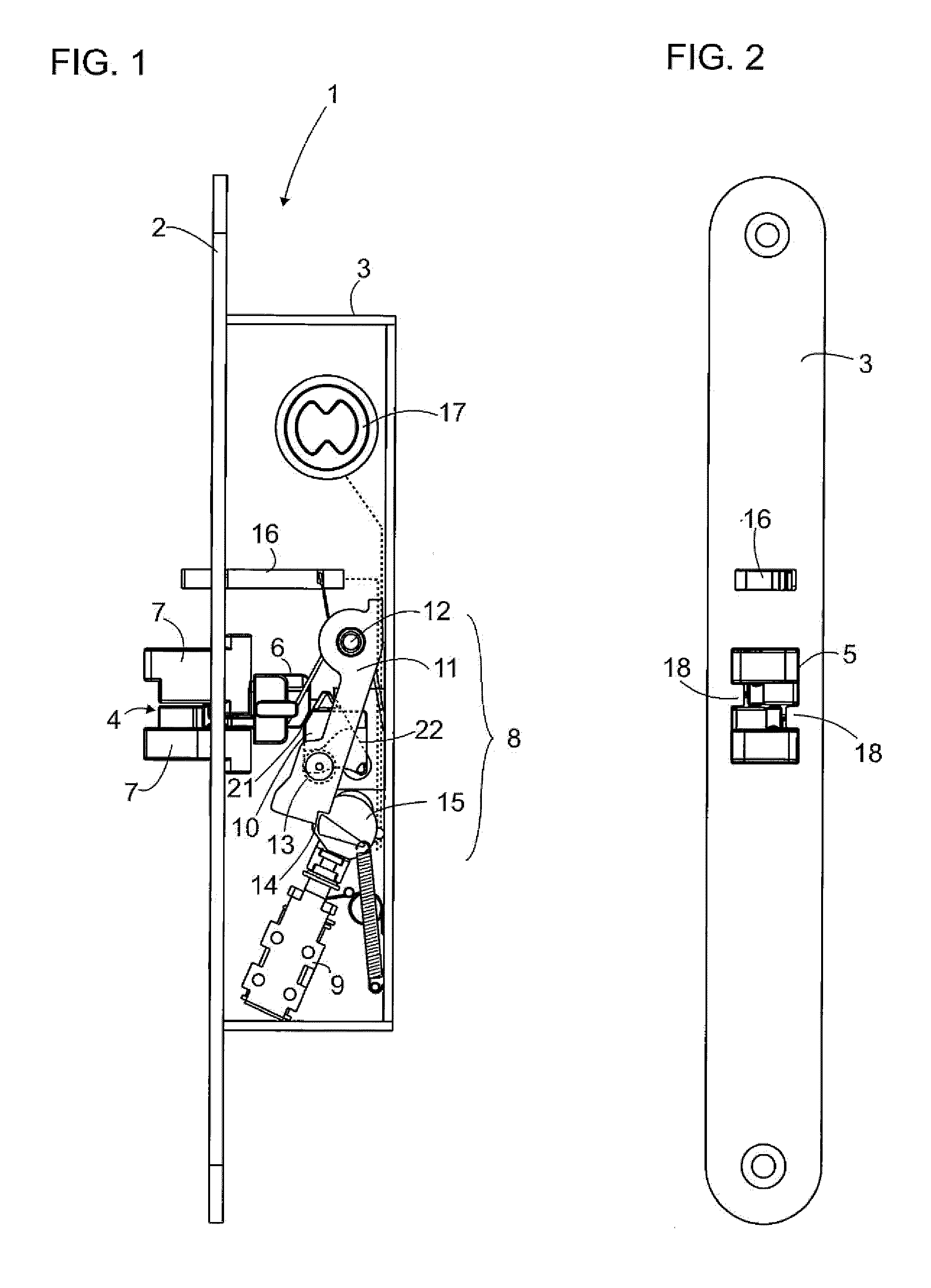

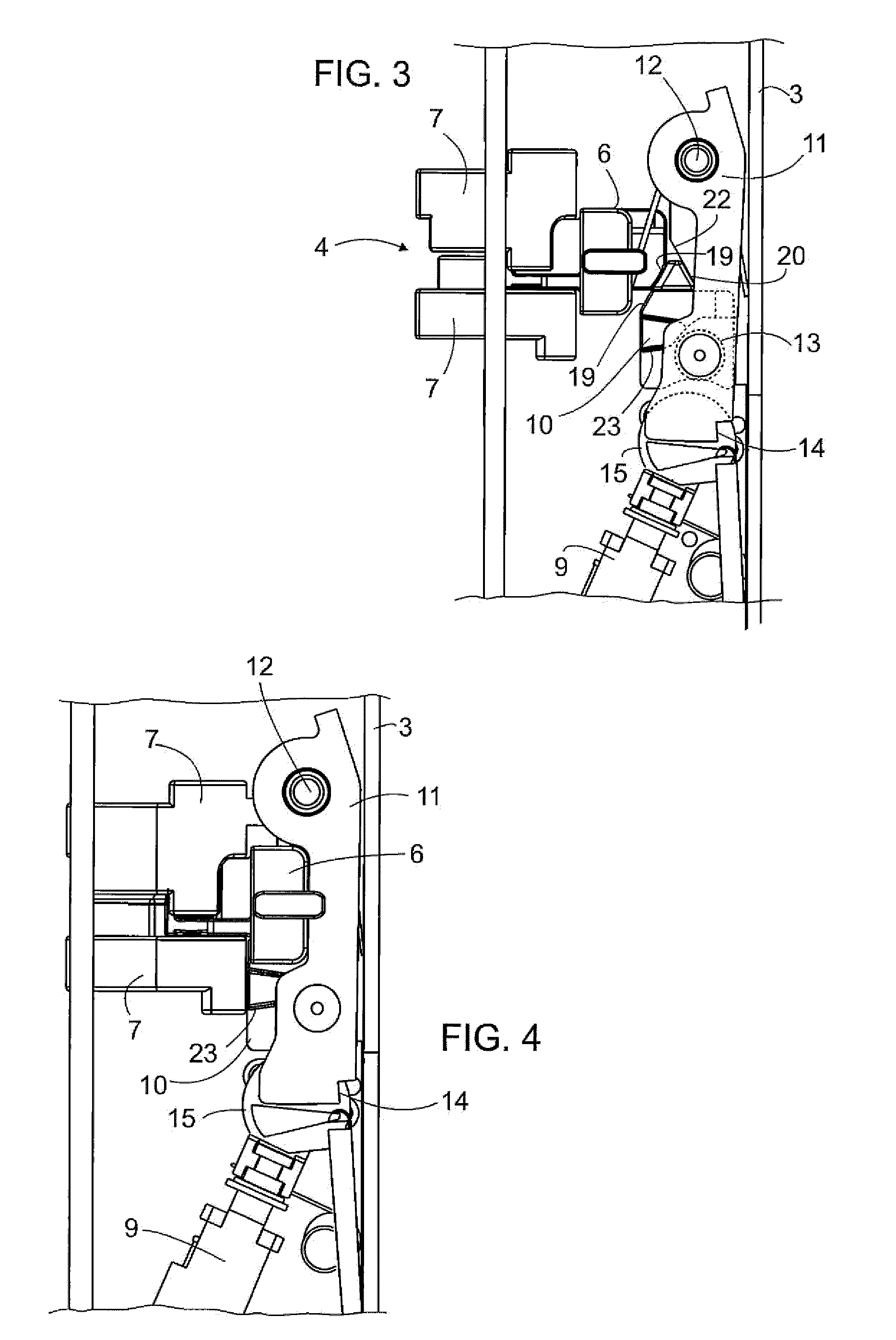

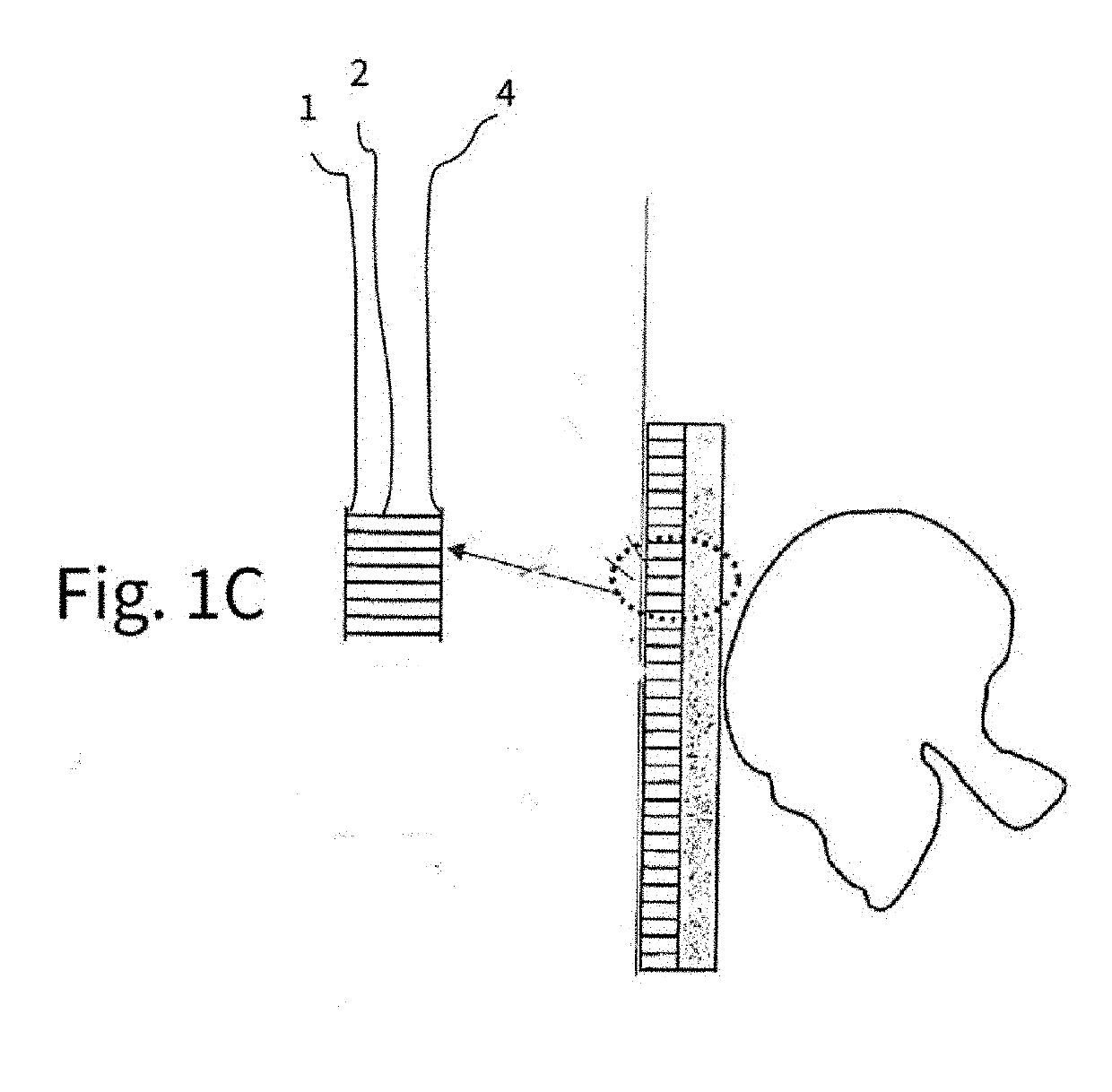

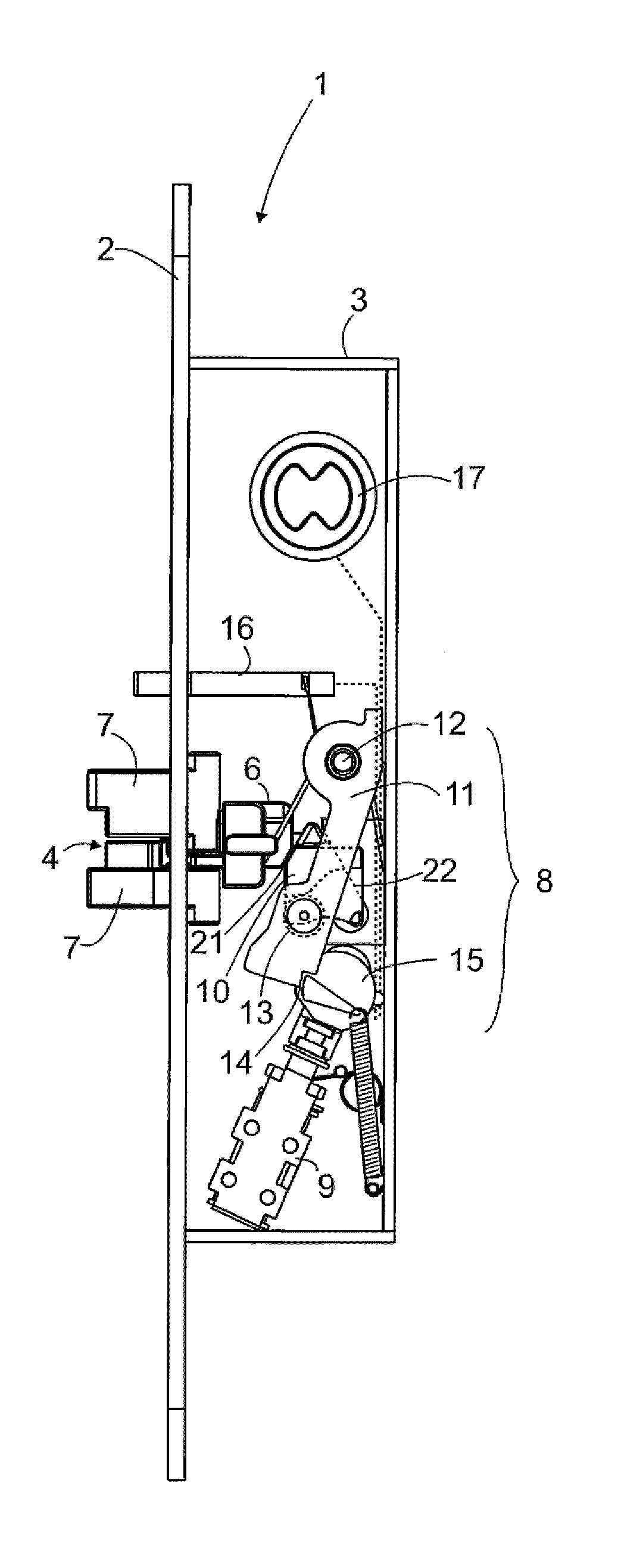

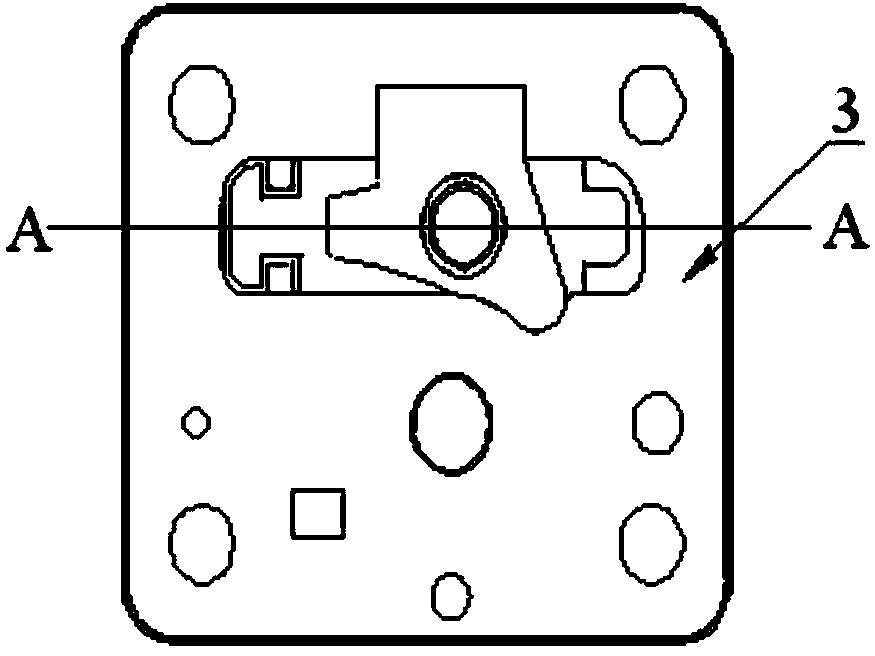

Door lock

ActiveUS20100045050A1Reduce electrical energyGuaranteed uptimeNon-mechanical controlsConstruction fastening devicesEngineeringMechanical engineering

Owner:ABLOY OY

Protective material

InactiveUS20190232601A1Reduce force transmissionLittle strengthLayered productsPedestrian/occupant safety arrangementFiberEngineering

A protective material / structure is provided that reduces the risk of injury for a person after contact with said material / structure, and is based on a structure where an inner and outer shell can move relative to each other. The shells are separated by spikes or thin beams and the outer shell covers or envelops the spikes. The spikes or beams are constructed so that they permit displacement of the outer shell relative to the inner shell in the event of an oblique impact against the protective material / structure. The spikes or beams are designed to be thin / slim and can be made of flexible polymer materials such as plastics, rubber or fibers. This enables the spikes to give way after a tangential / rotational impact and thereby efficiently reduce the negative effects of such an impact on the brain.

Owner:KLEIVEN SVEIN +1

Door lock

ActiveUS8366157B2Reduced Power RequirementsReduce transferNon-mechanical controlsConstruction fastening devicesEngineeringMechanical engineering

Owner:ABLOY OY

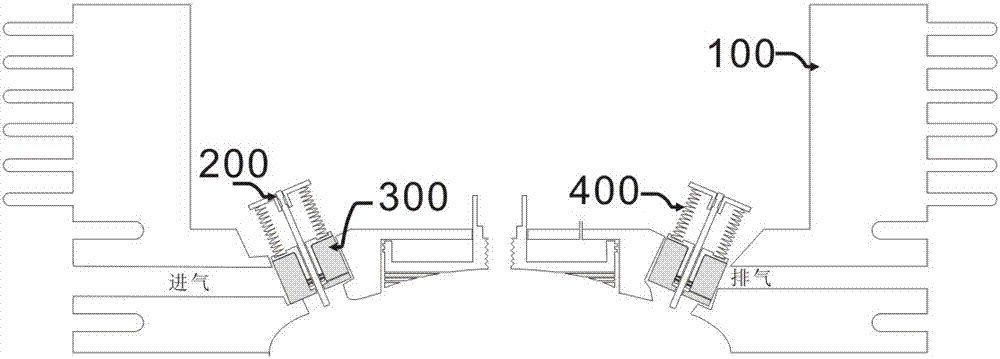

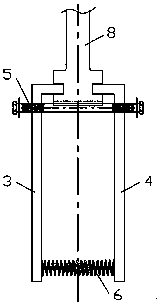

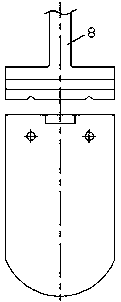

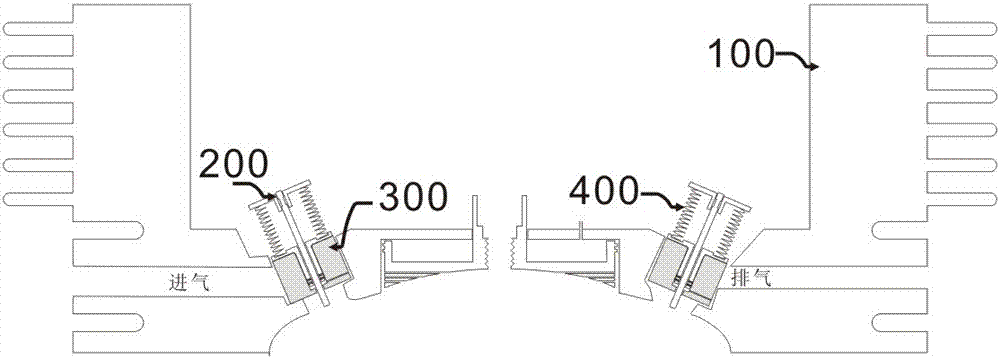

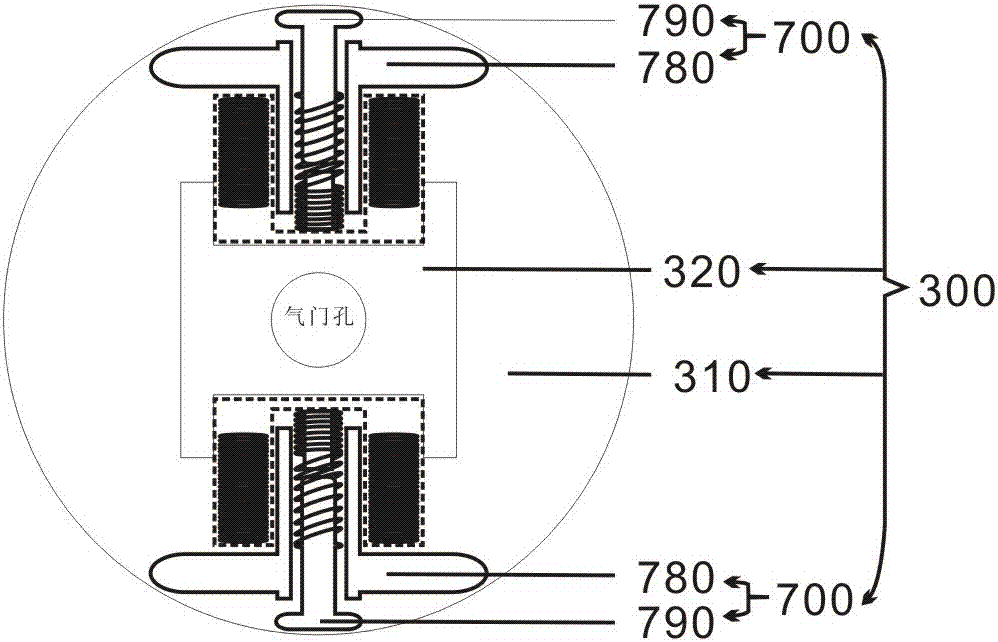

Efficient low-noise reciprocating piston type refrigerator compressor and manufacturing process thereof

ActiveCN103925193AReduce reaction forceEasy to liftPositive displacement pump componentsPositive-displacement liquid enginesEnvironmental resistanceLow noise

The invention discloses an efficient low-noise reciprocating piston type refrigerator compressor. The efficient low-noise reciprocating piston type refrigerator compressor comprises an air suction valve slice, an exhaust valve slice and a valve plate, wherein the compressor operates back and forth in the manner that a motor drives a crankshaft and the crankshaft drives a piston, and a coating is arranged on the surface of either the air suction valve slice or the exhaust valve slice; or the surfaces of the air suction valve slice and the exhaust valve slice are respectively provided with a coating; the coatings are made of polytetrafluoroethylene or PEEK engineering plastics. In addition, the invention further relates to the manufacturing process of the refrigerator compressor. By means of the technical scheme, the noise of the valve slices of the compressor is largely lowered, fatigue strength is improved, the gas transmission coefficient of the compressor is increased, and therefore the refrigerating capacity is increased. The effect of eliminating the exhaust pulse of the compressor is good, and pressure loss is reduced, so that the gas transmission coefficient is increased. The noise of the compressor is lowered, the energy efficiency ratio of the compressor is improved, and the purposes of saving energy and protecting the environment are achieved.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

an electromagnetic relay

Owner:XIANNING POWER SUPPLY COMPANY OF STATE GRID HUBEIELECTRIC POWER +1

A support accessory capable of reducing collision damage for automobiles

ActiveCN109278696BReduce collision damageReduced effectPedestrian/occupant safety arrangementStructural engineeringMechanical engineering

The invention discloses a supporting accessory capable of reducing collision damage for an automobile, which comprises a car body, a fixed baffle, a barrier and a contact plate. A positioning groove is opened on the front shell of the car body, and the inside of the front shell of the car body is pre-set. An installation inner cavity is left, the top edge of the fixed baffle is fixedly connected with a positioning flange, the bottom of the fixed baffle is arranged in the installation inner cavity, and the column end of the fixed column is arranged in the positioning shell, Both the positioning shell and the ends of the connector are fixedly equipped with a positioning bottom plate, and a chute is opened on the inner wall of the fixed baffle, and the end of the baffle is arranged in the chute, and the contact plate is located on the baffle. On the outer side of the baffle, a fixing groove is opened at the outer edge of the baffle. The car can reduce the support accessories of collision damage, realize the multiple collision force weakening between the car and the hit person, thereby greatly reducing the force and reaction force between the bumped person and the car, and reducing the impact of the bumped person harm.

Owner:平邑现代中药产业园有限公司

High-efficiency and low-noise reciprocating piston refrigerator compressor and its manufacturing process

ActiveCN103925193BStable high temperature resistanceHigh melting pointPositive displacement pump componentsPositive-displacement liquid enginesLow noiseExhaust valve

The invention discloses an efficient low-noise reciprocating piston type refrigerator compressor. The efficient low-noise reciprocating piston type refrigerator compressor comprises an air suction valve slice, an exhaust valve slice and a valve plate, wherein the compressor operates back and forth in the manner that a motor drives a crankshaft and the crankshaft drives a piston, and a coating is arranged on the surface of either the air suction valve slice or the exhaust valve slice; or the surfaces of the air suction valve slice and the exhaust valve slice are respectively provided with a coating; the coatings are made of polytetrafluoroethylene or PEEK engineering plastics. In addition, the invention further relates to the manufacturing process of the refrigerator compressor. By means of the technical scheme, the noise of the valve slices of the compressor is largely lowered, fatigue strength is improved, the gas transmission coefficient of the compressor is increased, and therefore the refrigerating capacity is increased. The effect of eliminating the exhaust pulse of the compressor is good, and pressure loss is reduced, so that the gas transmission coefficient is increased. The noise of the compressor is lowered, the energy efficiency ratio of the compressor is improved, and the purposes of saving energy and protecting the environment are achieved.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

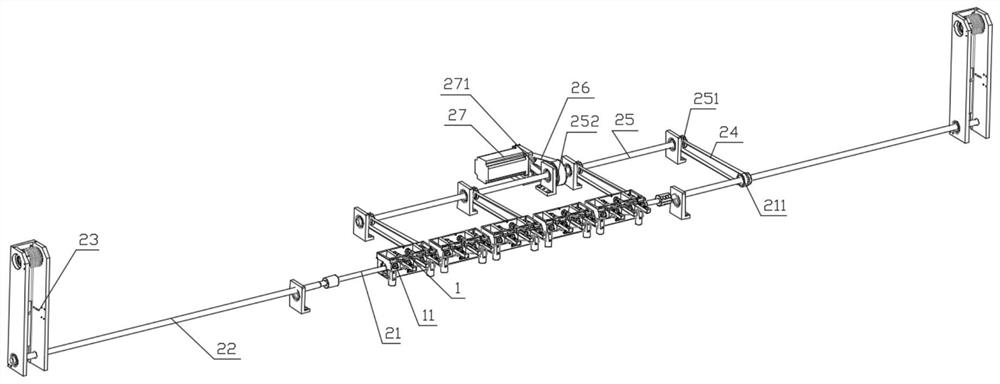

Multi-head embroidery machine shuttle box assembly with thread buckling mechanism, and embroidery machine

InactiveCN112760848ARealize multi-point transmissionAvoid attenuationEmbroidering machines apparatusElectric machineryEngineering

The invention discloses a multi-head embroidery machine shuttle box assembly with a thread buckling mechanism and an embroidery machine. The multi-head embroidery machine shuttle box assembly comprises a plurality of shuttle boxes arranged side by side, a multi-head rotating shuttle lower shaft driving mechanism and the thread buckling mechanism, wherein the multi-head rotating shuttle lower shaft driving mechanism comprises a lower shaft and an auxiliary shaft arranged in parallel with the lower shaft, two ends of the lower shaft are correspondingly in transmission connection with the two up-down shaft transmission boxes, the auxiliary shaft is driven by an auxiliary shaft motor, at least one transmission assembly synchronously driving the lower shaft to rotate with the up-down shaft transmission boxes is arranged between the auxiliary shaft and the lower shaft in the axial direction, The thread buckling mechanism comprises a thread buckling driving rotating shaft which is rotationally arranged and is parallel to a thread buckling shaft, the thread buckling driving rotating shaft is connected with an eccentric wheel, the eccentric wheel is connected with the thread buckling shaft through a connecting rod, and the thread buckling driving rotating shaft is driven by a thread buckling driving motor or a lower shaft. The rotating amplitude of the lower shaft in the length direction cannot have too large deviation, transmission force is prevented from being attenuated in the direction of the lower shaft, and thread buckling of a plurality of rotating shuttles can be solved.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

Waist support device of electric driver seat

InactiveCN101758784BPrecise and continuous adjustmentHas a buffering effectBack restsStoolsEngineeringScrew thread

The invention relates to a waist support device of an electric driver seat, which belongs to a fitting of an electric driver seat. The waist support device comprises a rear support plate with an ascending edge and a front support plate with a descending edge. The descending edge is arranged in a slide groove of the ascending edge. The descending edge and the ascending edge are provided with through grooves. A compression spring and a convexity adjusting driving mechanism are arranged between the front support plate and the rear support plate. A pull hook is arranged at the outer end of a pullrod of the convexity adjusting driving mechanism, and is arranged in the through groove. The inner end of the pull rod is hinged with a fixed hinge seat which is arranged on the rear support plate. The lower end of a driving screw rod is connected with the output end of a convexity adjusting gearbox through a through hole at the middle part of the rear support plate, and the input end of the convexity adjusting gearbox is connected with a convexity adjusting motor. A pressure plate with threads is arranged outside the driving screw rod. Both ends of the pressure plate are respectively provided with a slide block which is provided with a groove relative to the pull rod. A position adjusting motor is arranged at the outside of the rear support plate, and is connected with a gear through thegearbox. The gear is meshed with a gear rack.

Owner:NORTHEASTERN UNIV LIAONING

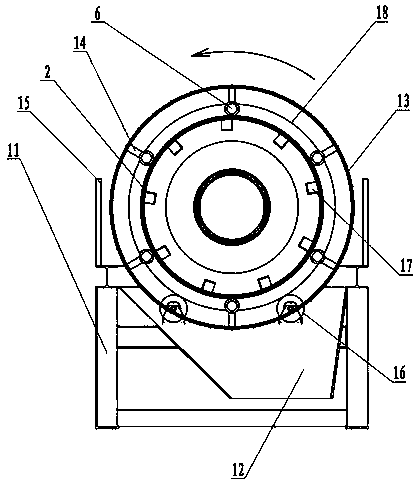

A high-efficiency and environment-friendly cylindrical sieve washing machine

ActiveCN106391291BDoes not affect lifeReduce transmission energy consumptionSievingScreeningPulp and paper industryEnvironmentally friendly

The invention relates to the field of screening equipment, in particular to a high-efficiency environment-friendly cylinder screening and washing machine. The cylinder screening and washing machine comprises a drum with a feeding hopper, a collecting hopper located at the bottom of the drum, and a drive device. The drum comprises an inner barrel body and inner barrel panels at the two ends. The feeding hopper is arranged at one end of the inner barrel body. The inner barrel body is connected with the drive device through the inner barrel panel away from the end with the feeding hopper. The inner barrel body is divided into a feeding section, a screening section and a discharging section, and the screening section of the inner barrel body is provided with screening holes. The area of the inner barrel panels is larger than the cross section area of the inner barrel body. A plurality of clamping rings are further arranged on the outer side of the inner barrel body, and the plane of each clamping ring is perpendicular to the axial direction of the inner barrel body. The clamping rings are further provided with supporting rods which are parallel to the inner barrel body and are connected with the inner barrel panels at the two ends. The supporting rods are very close to the outer side of the inner barrel body and are evenly distributed in the radial direction of the clamping rings. The high-efficiency environment-friendly cylinder screening and washing machine can achieve integration of screening and washing and can also achieve multi-stage screening, a drum body is easy to replace, the service life of the screening and washing machine is effectively prolonged, and the investment cost is reduced.

Owner:樊日宏 +1

Side door lock drive mechanism

The invention belongs to the field of automobile door lock systems, and specifically relates to a side door lock transmission mechanism, which includes a bottom plate, on which a ratchet riveting shaft and a pawl riveting shaft are fixed, and the ratchet is rotatably connected to the ratchet riveting shaft. The claw is rotatably connected to the ratchet riveting shaft, and the front claw end of the ratchet leans against the locking and engaging arc surface of the ratchet wheel; a drive shaft is arranged on the end of the bottom plate away from the ratchet riveting shaft to rotate. The cam is connected to the transmission shaft with an interference fit, and a slider positioning shaft is arranged on the bottom plate corresponding to the bottom of the transmission shaft. The structure of the product of the present invention is simple and compact, and the transmission force can be effectively reduced by setting the connecting rod slider cam structure on the bottom plate, the structure is simple, and the transmission efficiency and transmission stability are greatly improved.

Owner:无锡忻润汽车安全系统有限公司

Seeder adjustment lead screw

InactiveCN103947340BEasy to adjustSimple structureFertiliser and seeding apparatusBall bearingAgricultural engineering

The invention relates to an adjustment screw rod of a sowing machine, belonging to the technical field of agricultural machinery, and aiming at solving the problems that the existing adjustment screw rod of the sowing machine is inconvenient and inaccurate to adjust, and adjustment needs a high driving force. According to the adjustment screw rod of the sowing machine, an outer shaft sleeve comprises a shaft sleeve thread part, a shaft sleeve polish rod part, two installation locating rings and a milling flat part, wherein the shaft sleeve thread part, the shaft sleeve polish rod part and the milling flat part are manufactured into a whole on the same axis from left to right; the two installation locating rings are fixed on the shaft sleeve polish rod part in parallel in the horizontal direction; a support seat is arranged between the two installation locating rings; the right side of the screw rod is inserted into the outer shaft sleeve, and the right end of the screw rod penetrates outside the outer shaft sleeve; a ball bearing is connected with the part, penetrating outside the outer shaft sleeve, of the right end of the screw rod; two gaskets are respectively arranged on the two sides of the ball bearing; the ball bearing and the gaskets are locked on the end surface of the right side of the milling flat part by lock nuts which are arranged on the right sides of the ball bearing and the gaskets. The adjustment screw rod is used for the sowing machine.

Owner:东方城居房屋管理服务有限公司

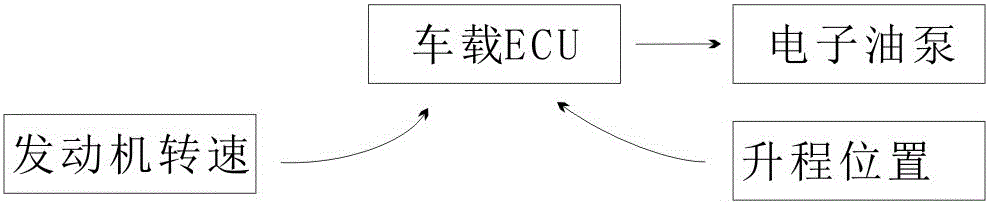

Spring pressure plan based on engine rotation speed

InactiveCN106837462ARelieve stressExtended service lifeMachines/enginesLift valveIdle speedEngine valve

The invention provides a system and method for controlling an engine valve spring. The method comprises the steps that the pressure of the valve spring is adjusted on the basis of the engine rotation speed, valve spring pressure adjustment comprises adjustment on electric control connected with an oil pump, the oil pump controls the lift of a base, and lift control is conducted on the basis of the oil supply amount of the oil pump to the base. For example, when the engine rotation speed is changed to 2,000 r / min from the idle speed which is 700 r / min, a piston is pushed through oil pumping of the oil pump to be pushed to move upwards from the start point, the valve spring pressure is increased, and the valve reset speed becomes high.

Owner:NANAN GAOJIE ELECTRONICS TECH

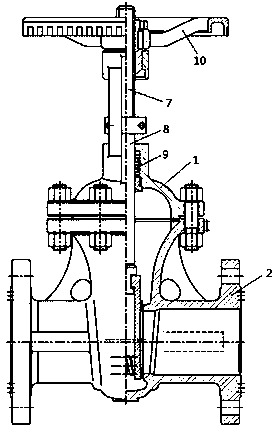

Sluice valve with high sealing property

InactiveCN109139953AImprove sealingMake up for angular deviationSpindle sealingsSlide valveTorque transmissionSluice

The invention discloses a sluice valve with high sealing property. The sluice valve with high sealing property comprises a valve rod, a valve bonnet, a valve seat and a flashboard. The valve rod and the flashboard which are fixedly connected are sealed in the valve seat by the valve bonnet. The flashboard is driven to move up and down by the valve rod, and the valve seat is started and stopped bythe valve rod. The flashboard is of a dual-flashboard structure composed of a left flashboard and a right flashboard. Upper portions of the left flashboard and the right flashboard are fixed through bolts, and inner sides of lower portions of the left flashboard and the right flashboard are in elastic support through springs. According to the dual-flashboard structure of the sluice valve, angle limiting adjustment of the upper portions are achieved through bolts, and adjustment support of the lower portions are achieved through springs. Pressing force is added by the springs. Pushing and pressing type sealing is formed. Good sealing property on a sealing surface between the flashboard and the valve seat is always kept. A novel type nonmetal sealing filler is adopted, sealing property of the valve bonnet is improved, and meanwhile, polished rod transmission force can also be reduced. A sectional type fixing method is adopted by the valve rod; a former form of spiral rising is changed into a form of straight rising; and torque transmission is changed into stretching sliding transmission. According to the sluice valve with the high sealing property, possibility that the valve rod bends is directly eliminated; and failure of a valve in an existing design is effectively and completely eradicated.

Owner:自贡诚鑫阀门有限公司

Setting method for valve pressure

InactiveCN106968806ARelieve stressExtended service lifeInternal combustion piston enginesOutput powerElectric machineControl theory

Owner:NANAN FENGZHOU GAOJIE MOTORCYCLE ENERGY SAVING PRACTICAL TECH PROD SALES CENT

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are successively mounted on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are successively mounted on the top of the cylinder from front to back and correspond to the rack; a gap is formed between the first carding region cover plate and the second carding region cover plate; and a gap is also formed between the second carding region cover plate and the third carding region cover plate. The carding machine is provided with the three carding cover plates, three carding regions are formed, the first carding region has main effects of neatening, smoothly carding fibers and preliminarily discharging impurities andlower piles, the second carding region is further used for neatening, carding the fibers and preliminarily discharging the impurities and the lower piles, the third carding region has main effects ofprecisely carding and further discharging the impurities and lower piles, each of the three carding region cover plates is provided with a cover plate cleaning device, the three carding region cover plates can be cleaned independently, and after being cleaned, the carding cover plates can be rapidly and efficiently used in carding operation. The carding machine is divided into three portions, radian occupied by each carding cover plate is also reduced, the carding cover plates can be cleaned as quickly as possible, the cover plate cleaning efficiency is further improved, and a carding effect is ensured.

Owner:乐陵市佳和纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com