Patents

Literature

124 results about "Protruding shoulders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

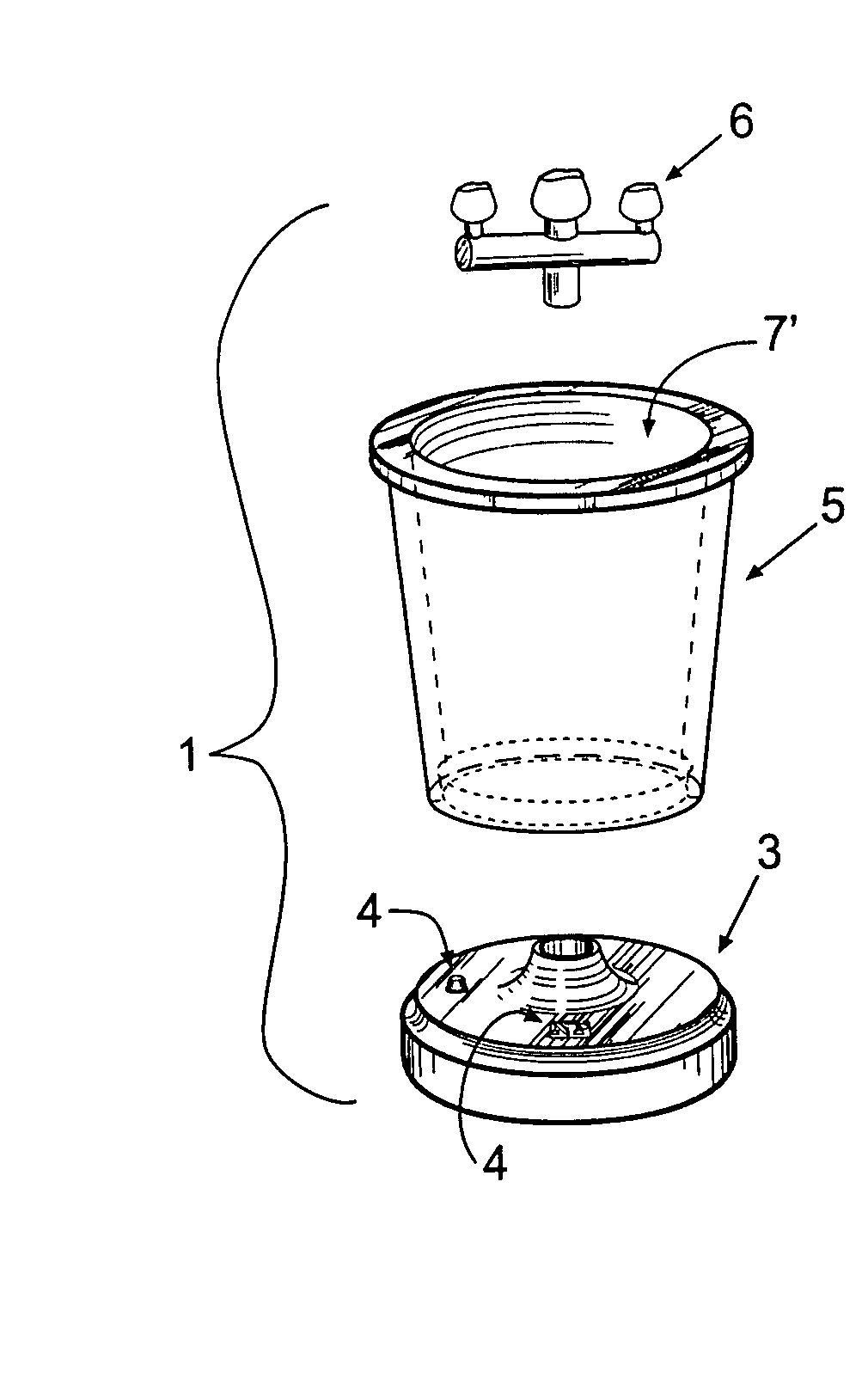

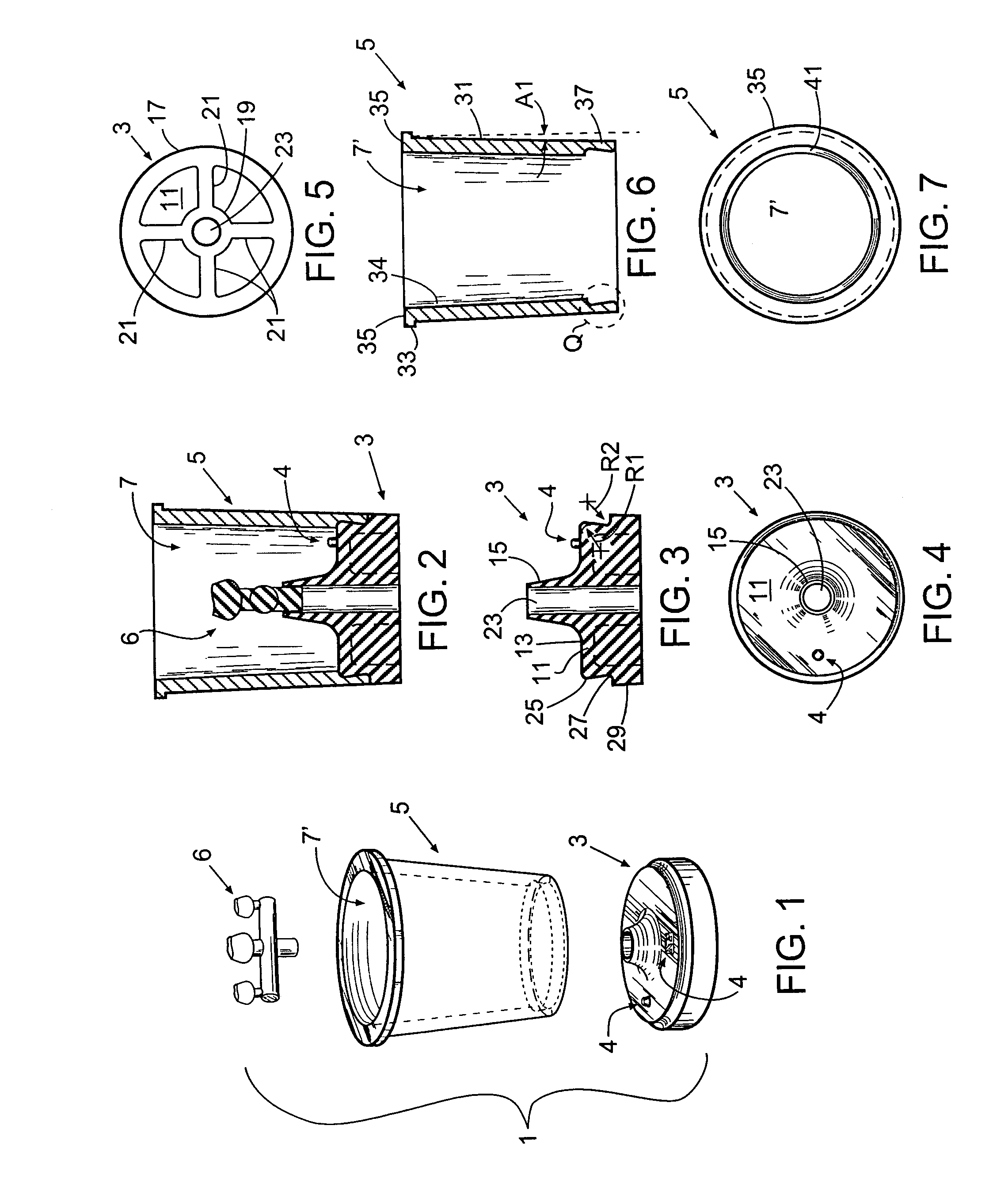

Casting ring

An apparatus comprising a casting ring and base sized and dimensioned to be coupled together to form a cavity having one or more walls comprising an inner surface of the casting ring, having a bottom comprising an upper surface of the base, and having a form receiving member portion of the base extending into the cavity. This embodiment includes an indicator forming portion sized and positioned to form an indicator on a mold produced by at least partially filling the cavity with investment and allowing the investment to harden. In some instances the casting ring may have a lower segment sized and dimensioned to surround and receive an upper segment of the base to couple the ring and base together, wherein, the casting ring latches onto an outwardly protruding shoulder of the base when the base and casting ring are coupled together.

Owner:ASAP

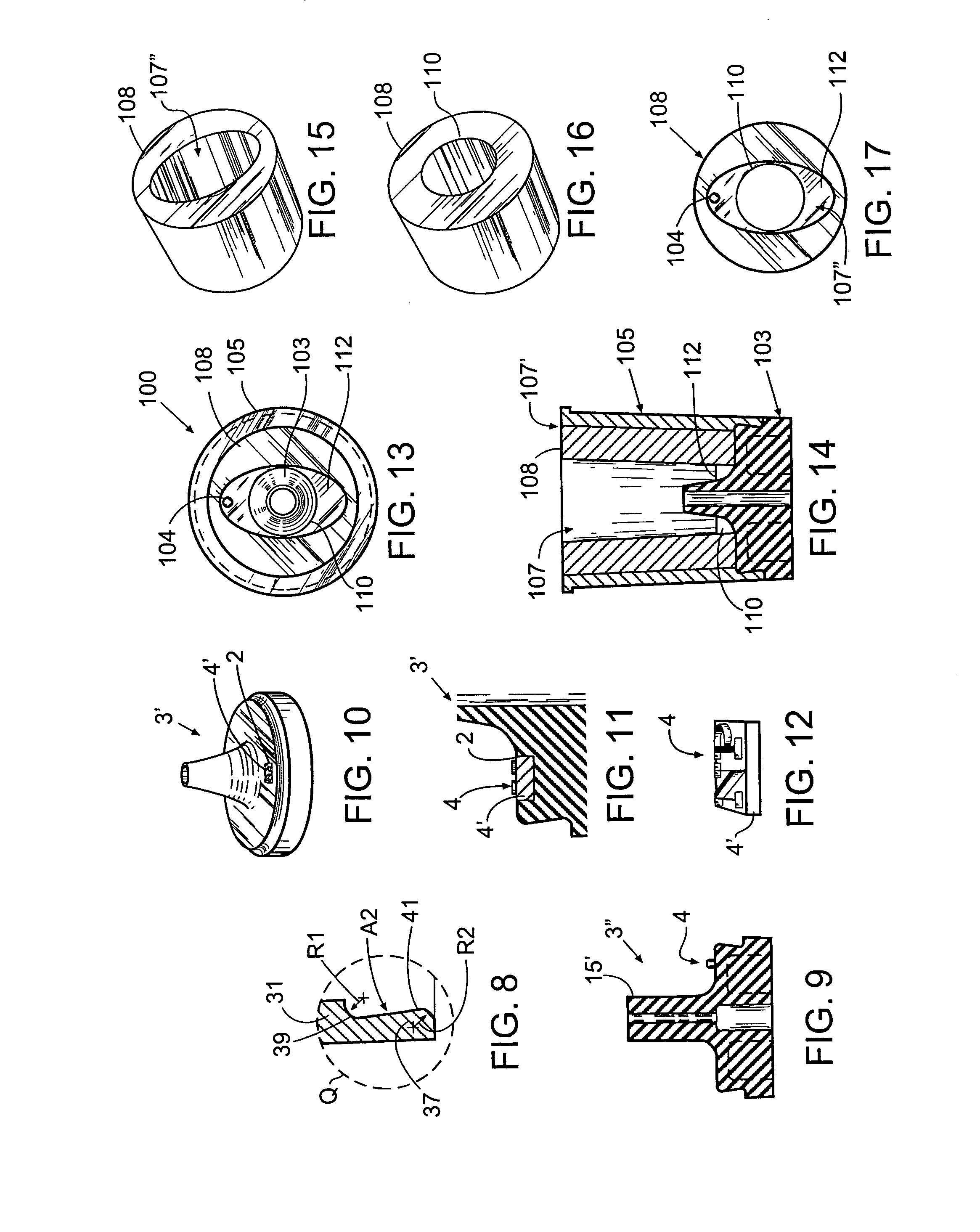

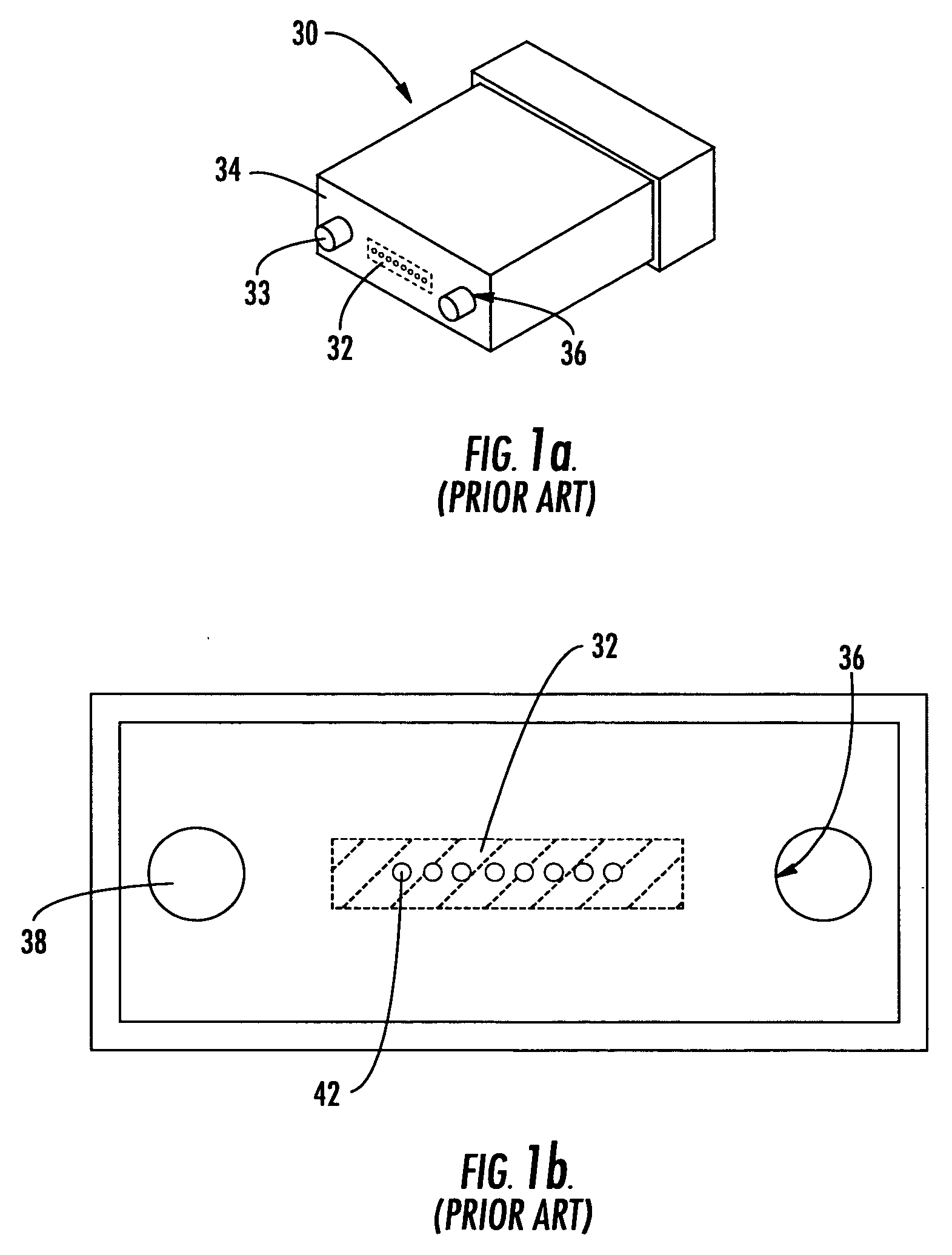

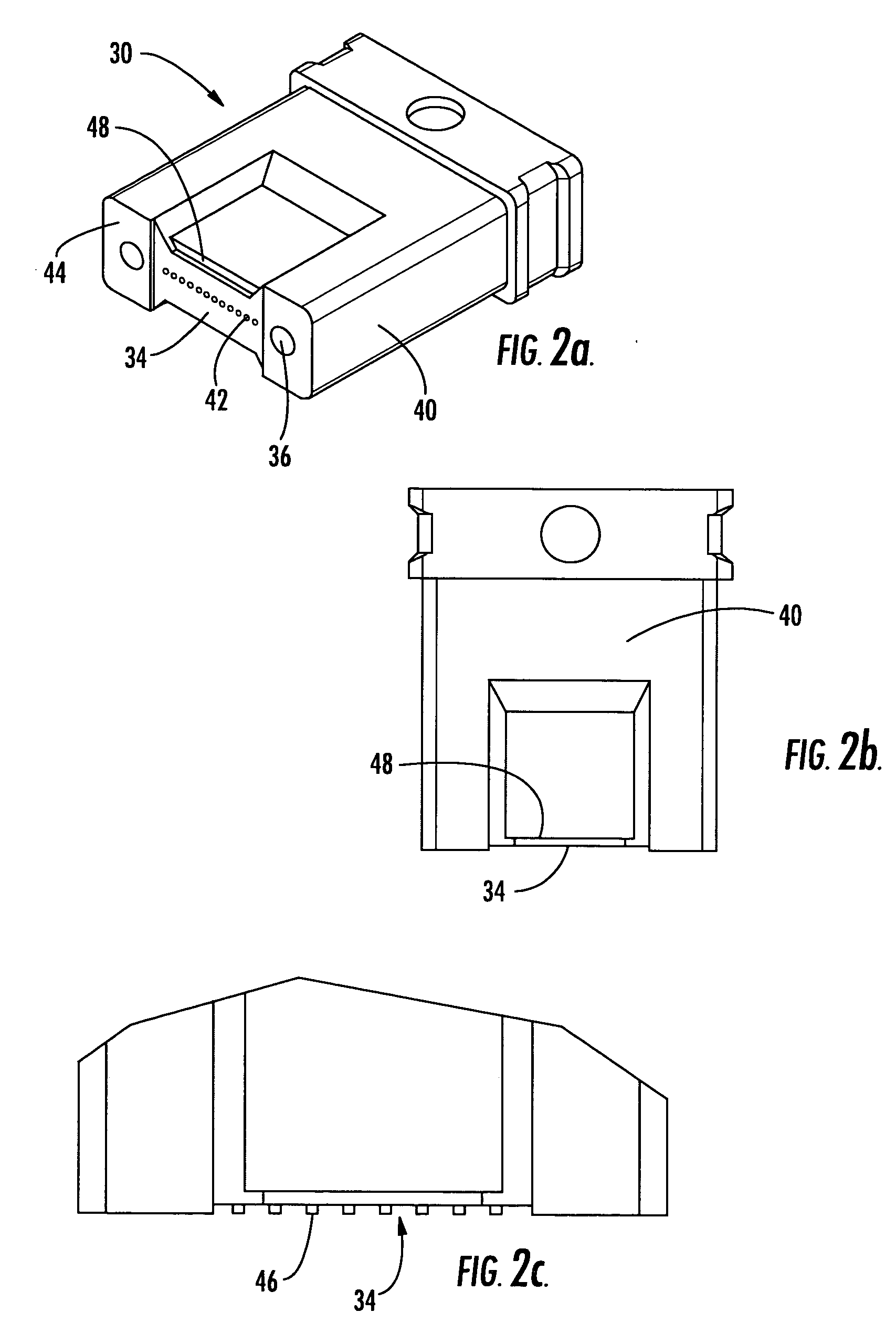

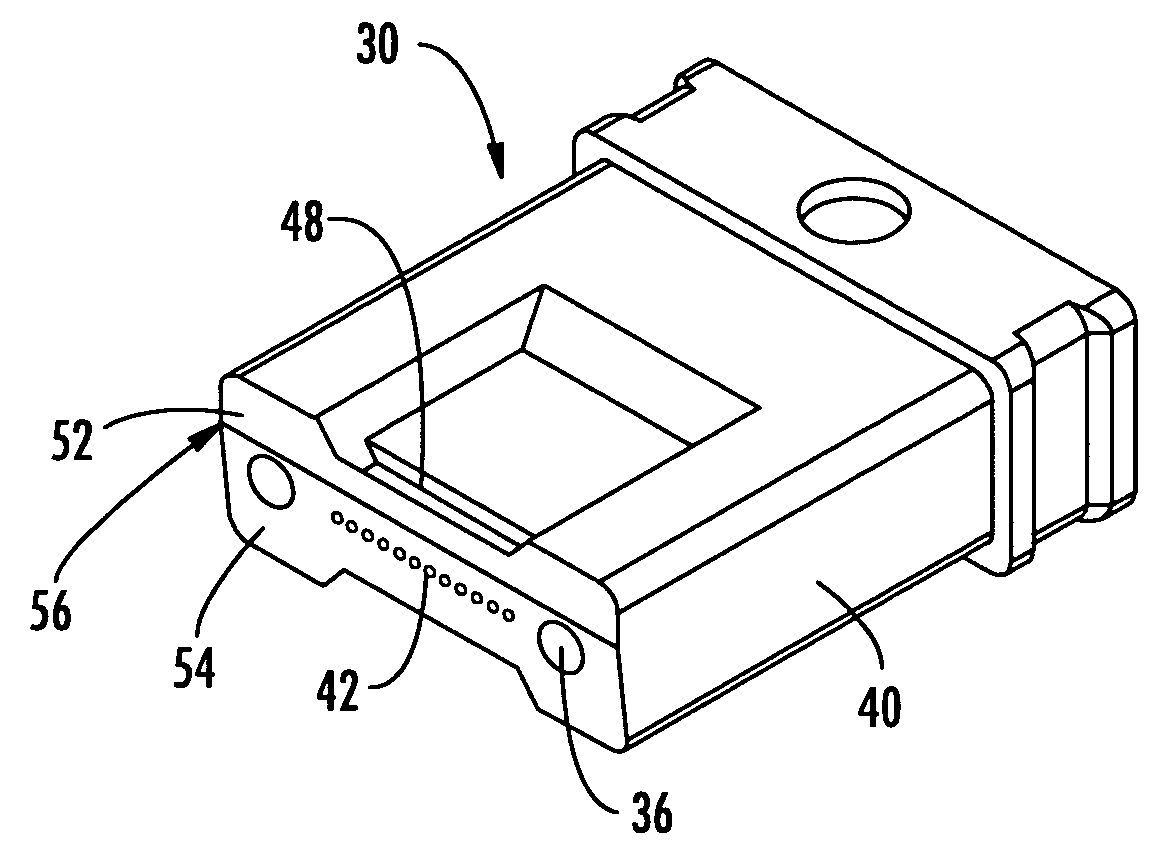

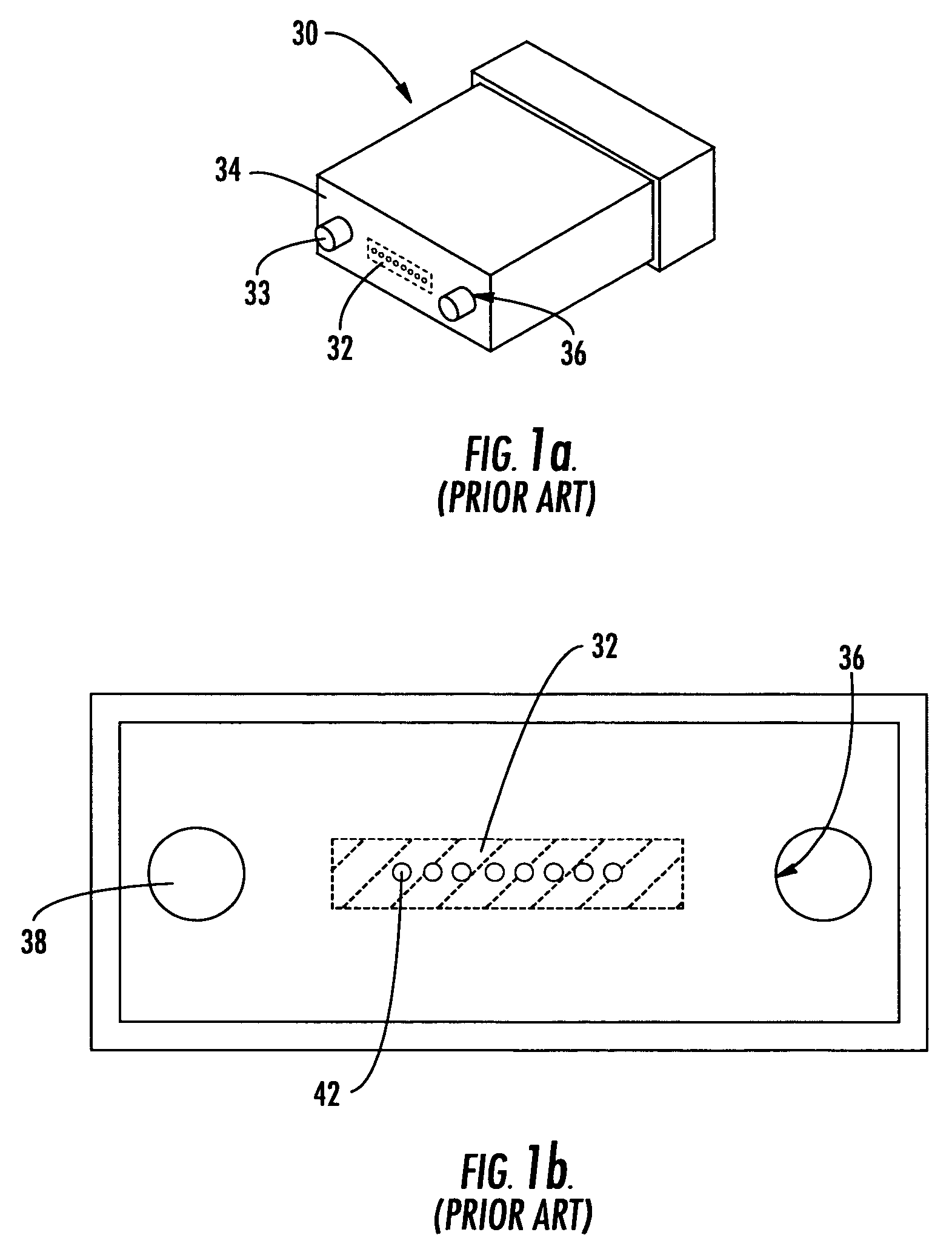

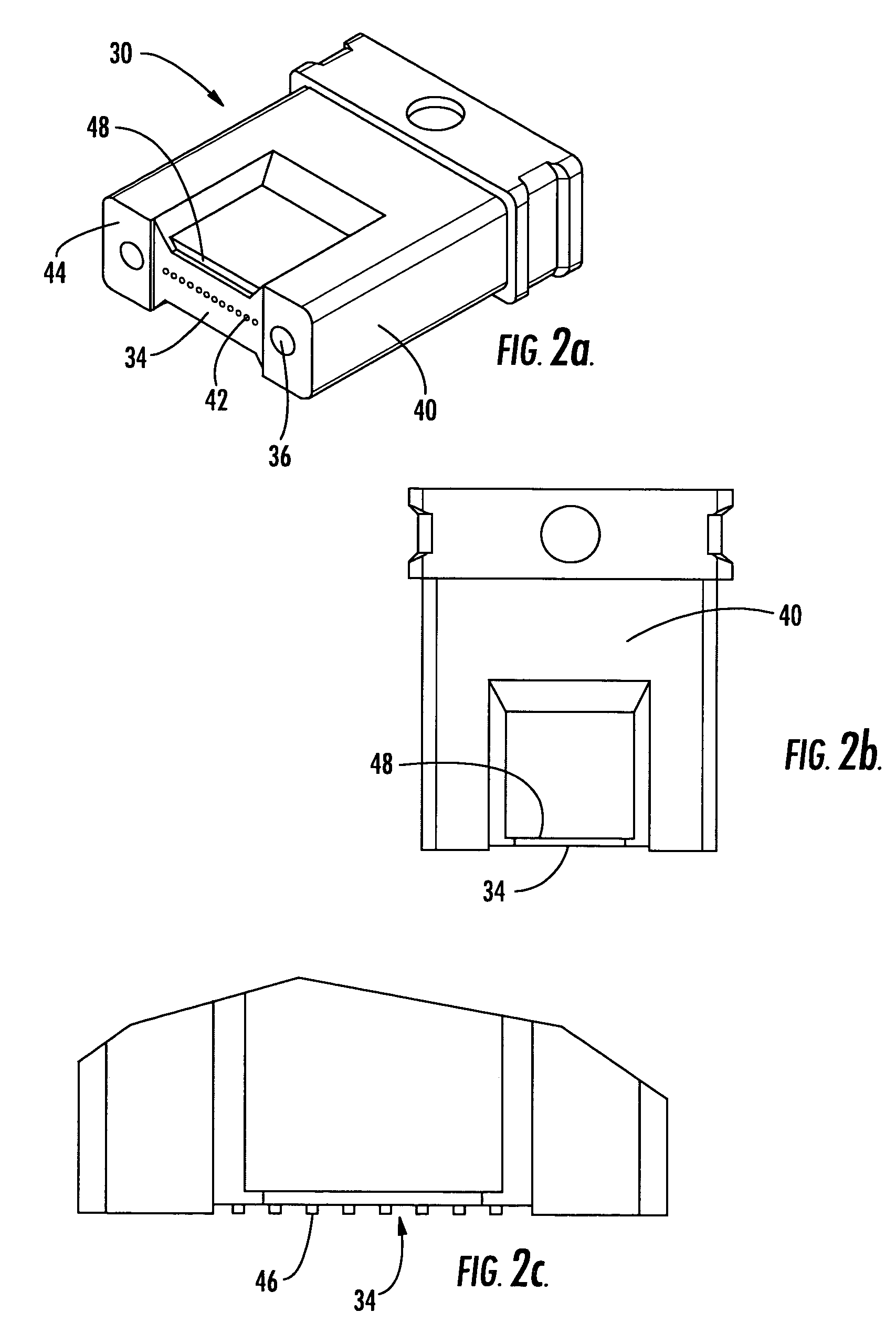

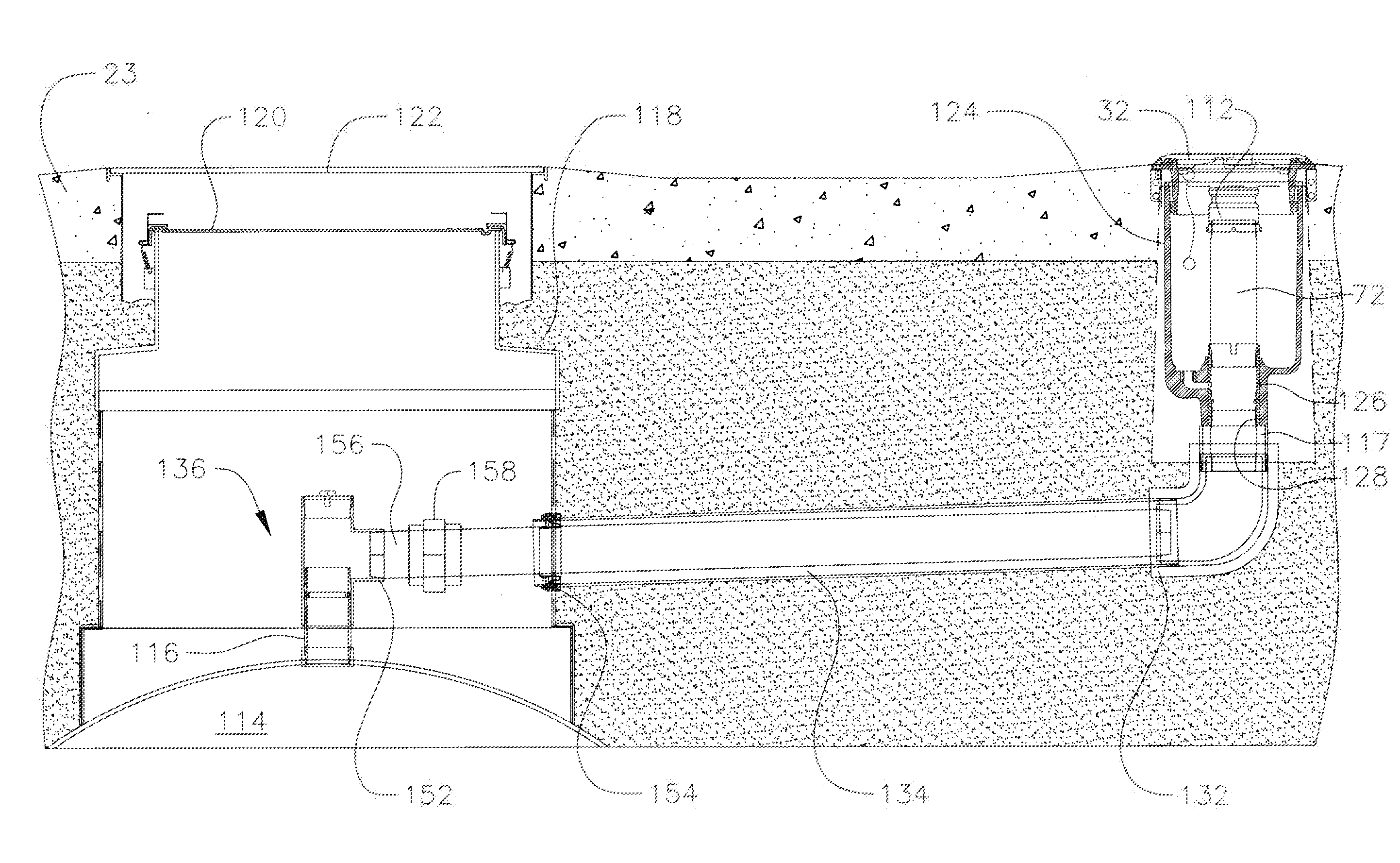

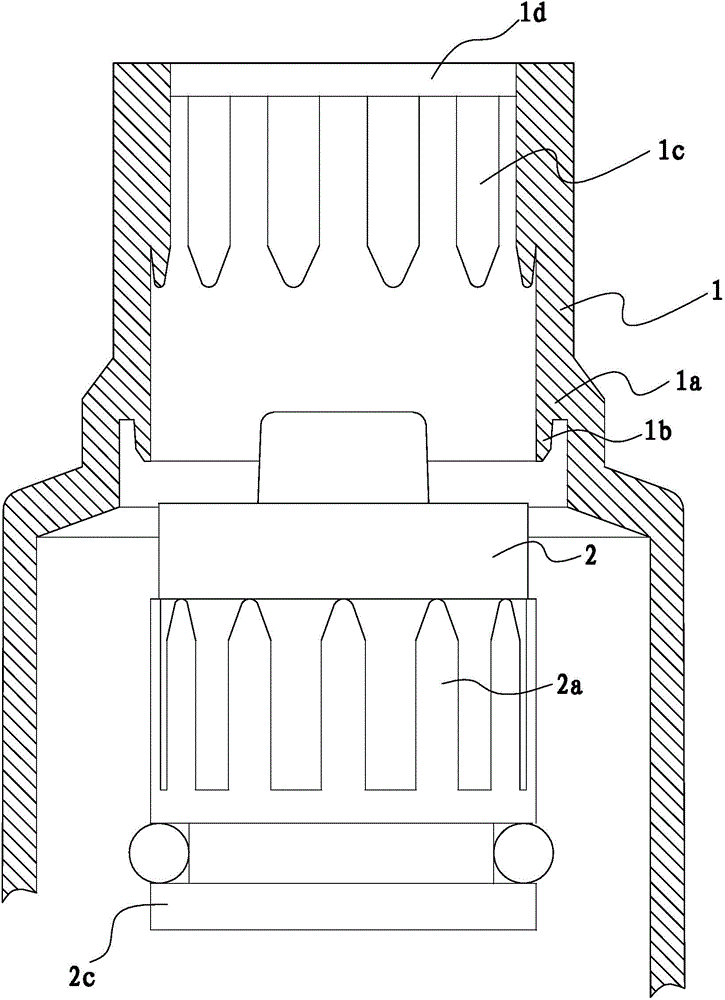

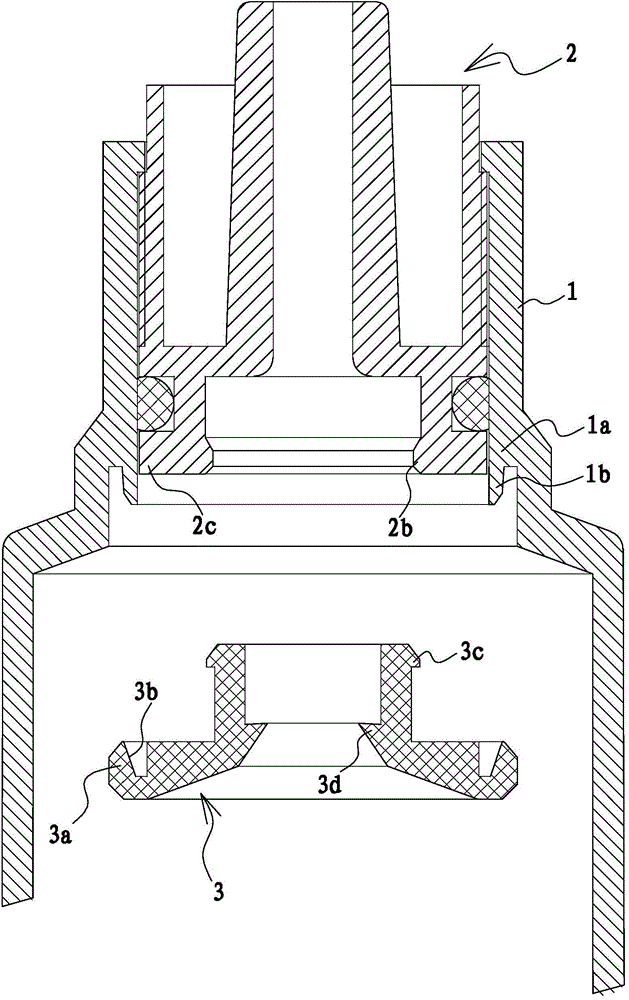

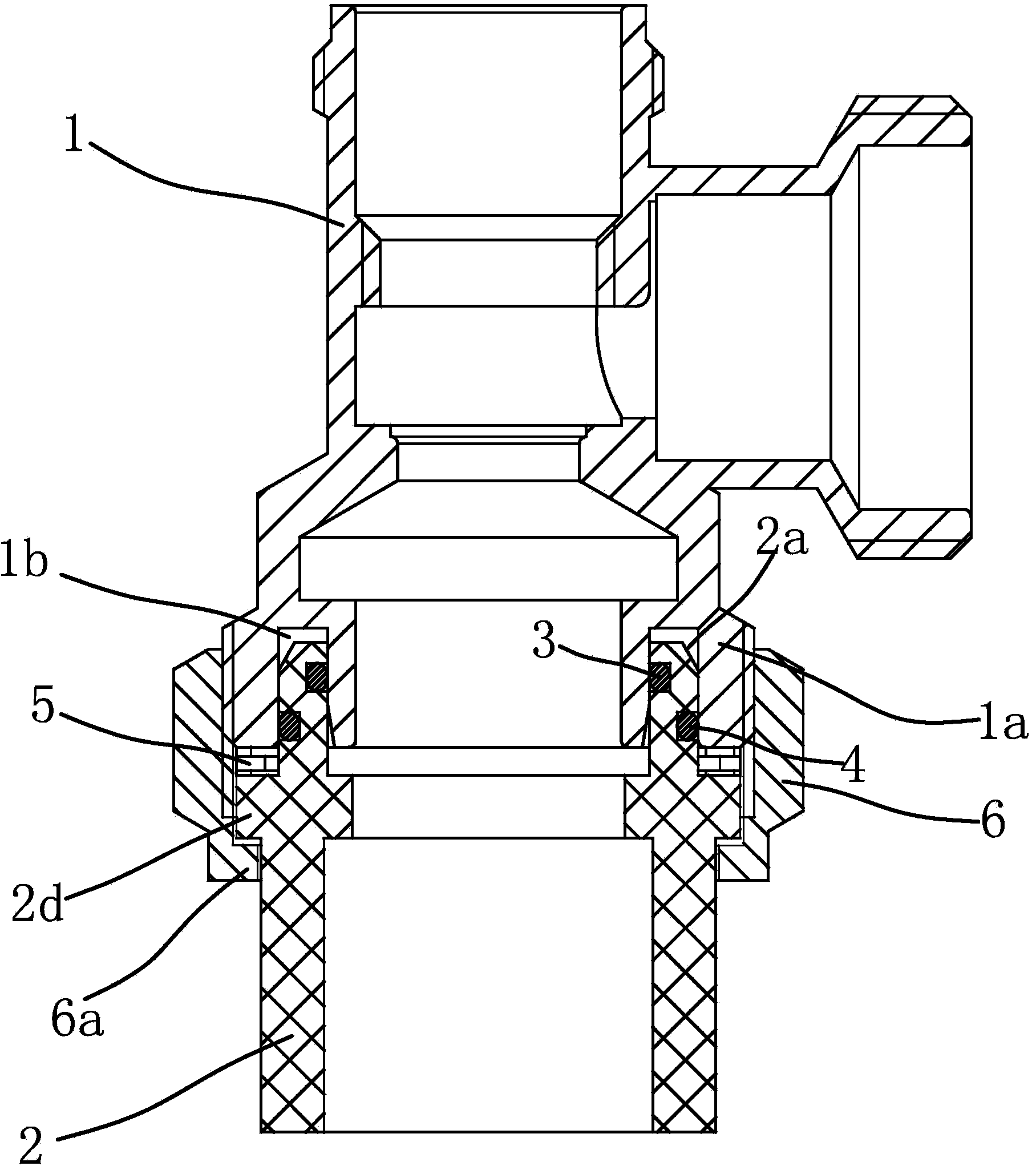

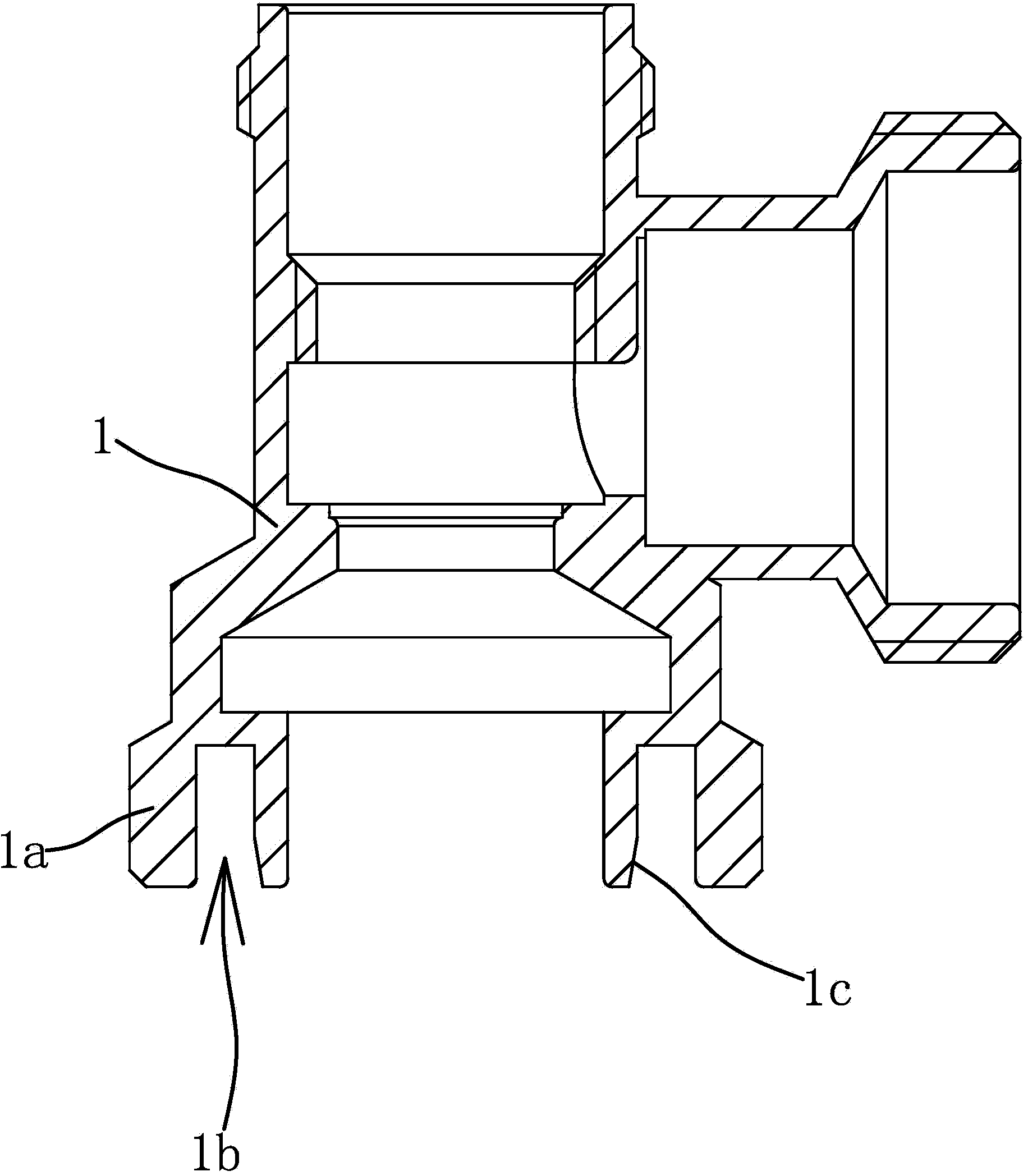

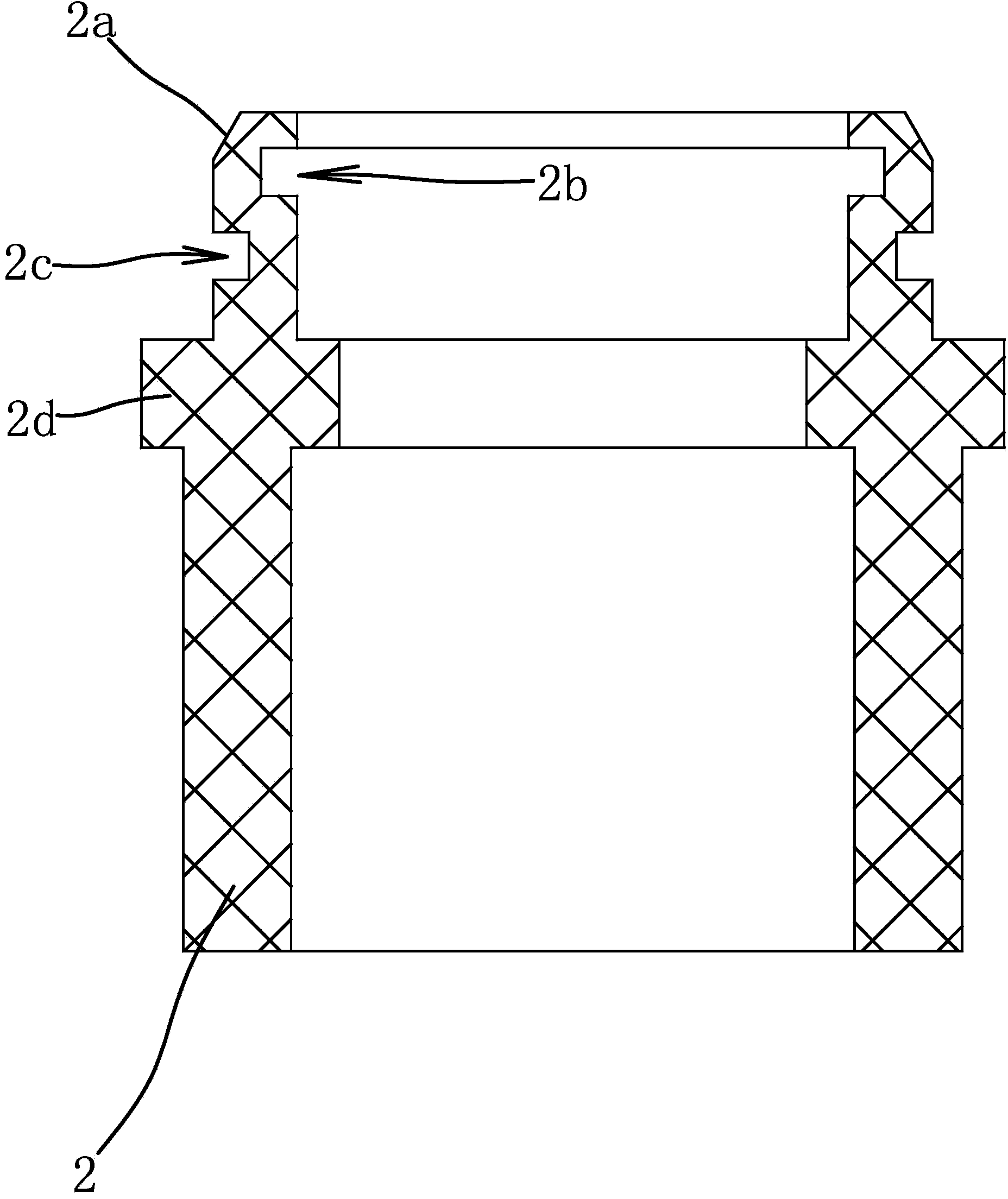

Molded ferrule with reference surface for end face geometry measurement

A ferrule comprising a molded ferrule body defining fiber bores, an end face of a connective end of the ferrule positioned about the fiber bores, and an integral reference surface for determining the angularity of the end face. The integral reference surface is not machined subsequent to a ferrule molding process and is accessible after assembly of the ferrule body into a connector body. A multi-fiber ferrule comprising a connective end defining an end face, a rear non-connective portion defining a protruding shoulder, and an integral reference datum positioned on a surface of the shoulder accessible for determining the angularity of a plane defined by the end face, wherein the integral datum is accessible when the ferrule is received within a connector body.

Owner:CORNING OPTICAL COMM LLC

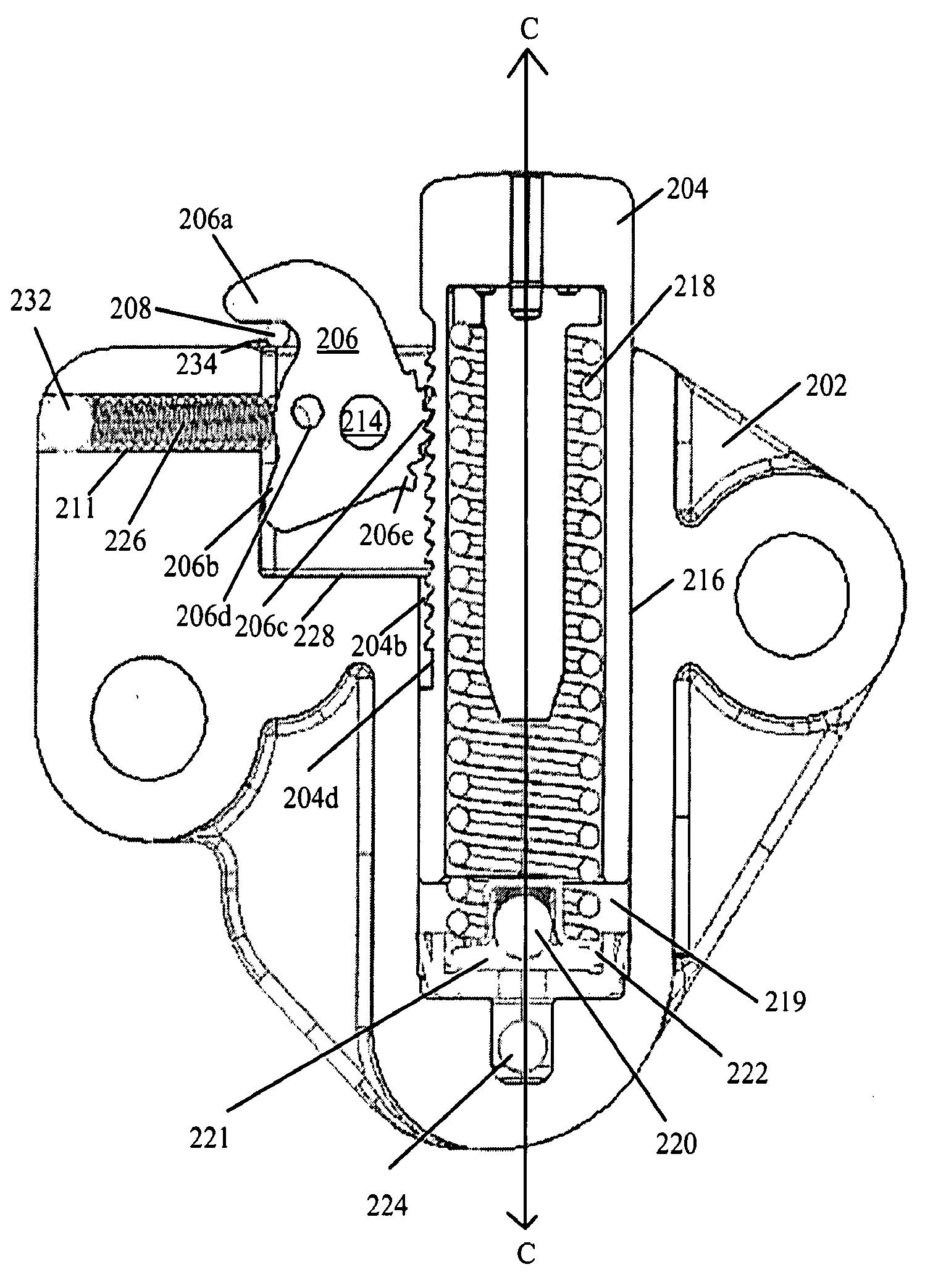

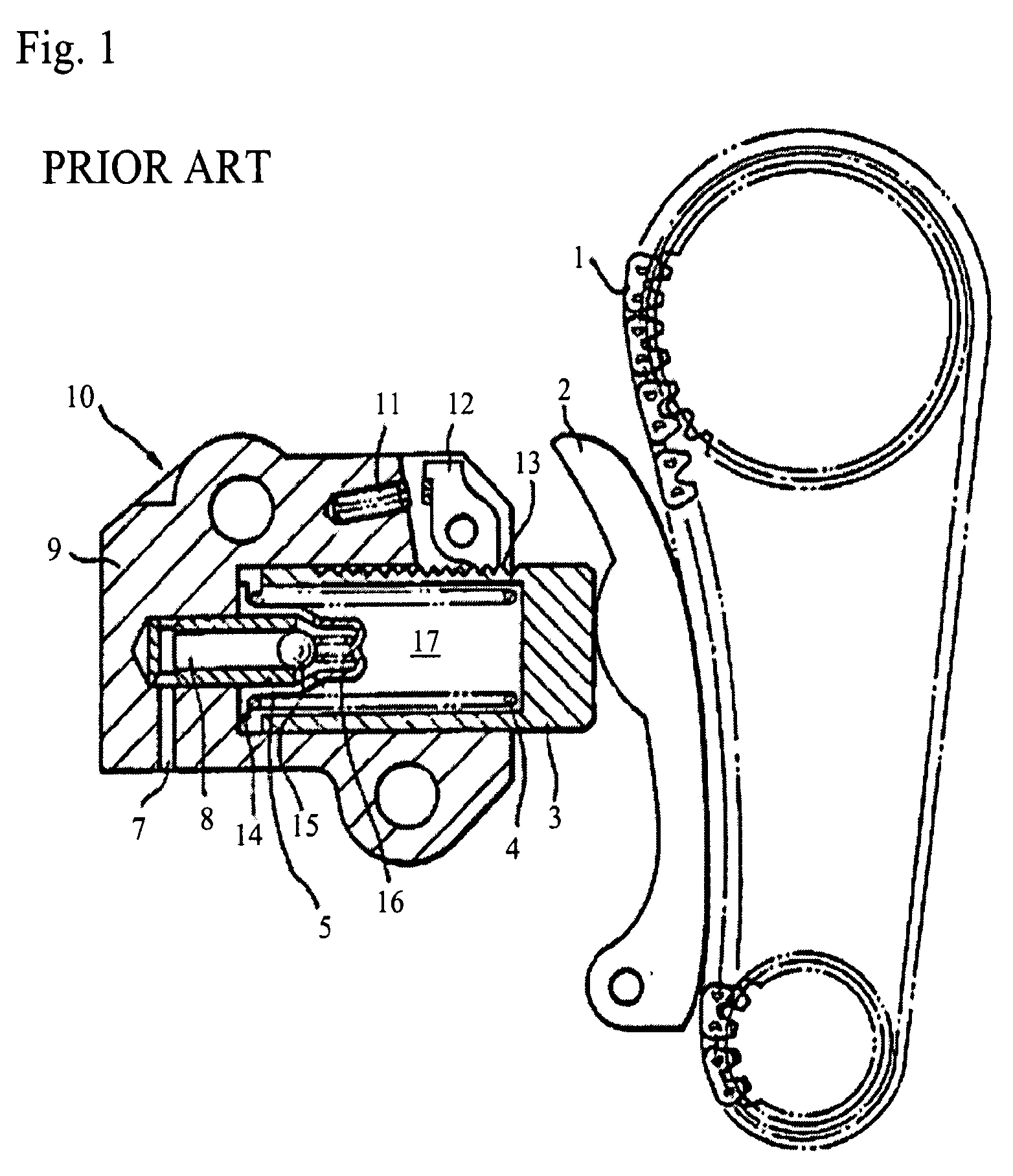

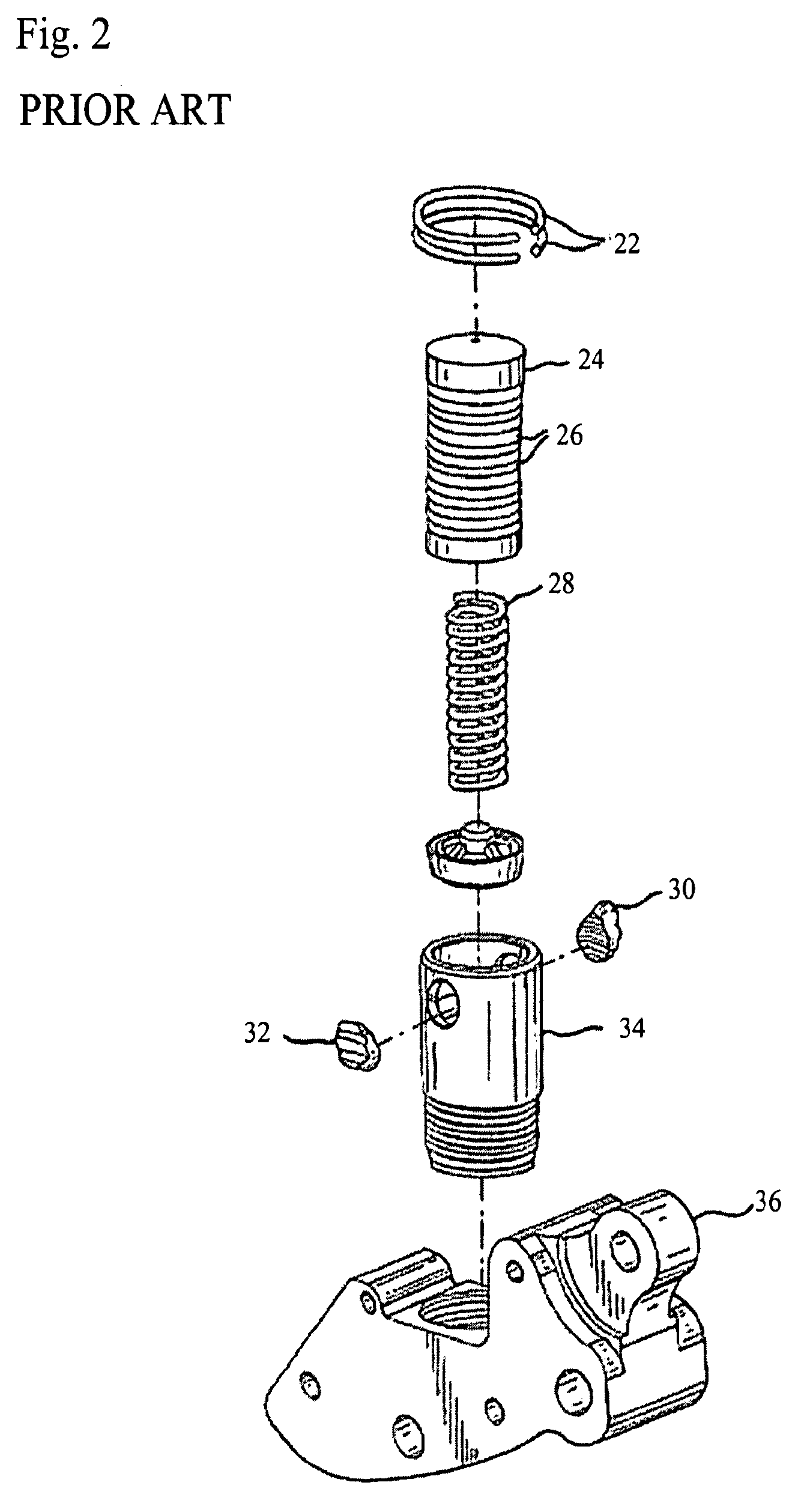

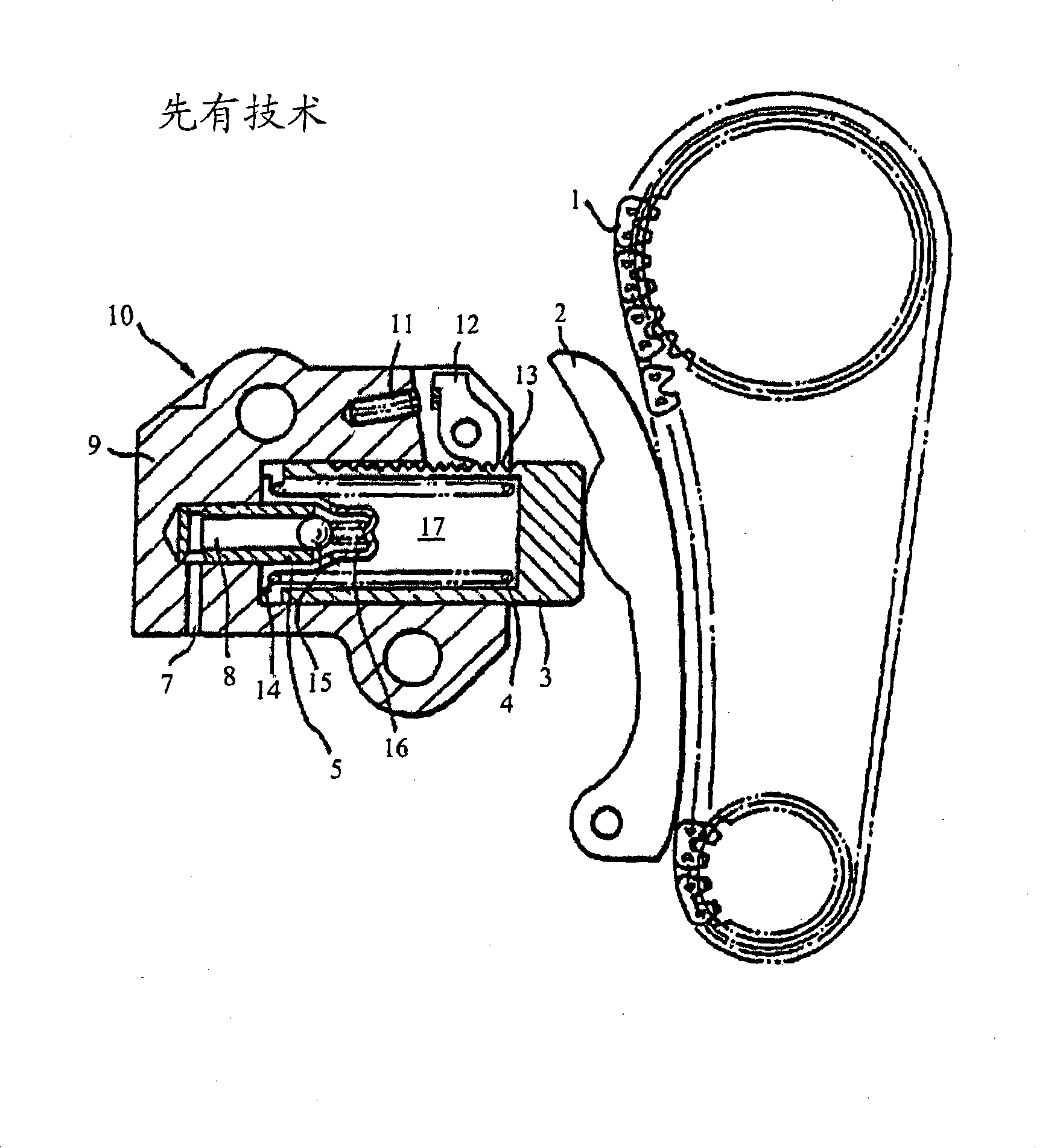

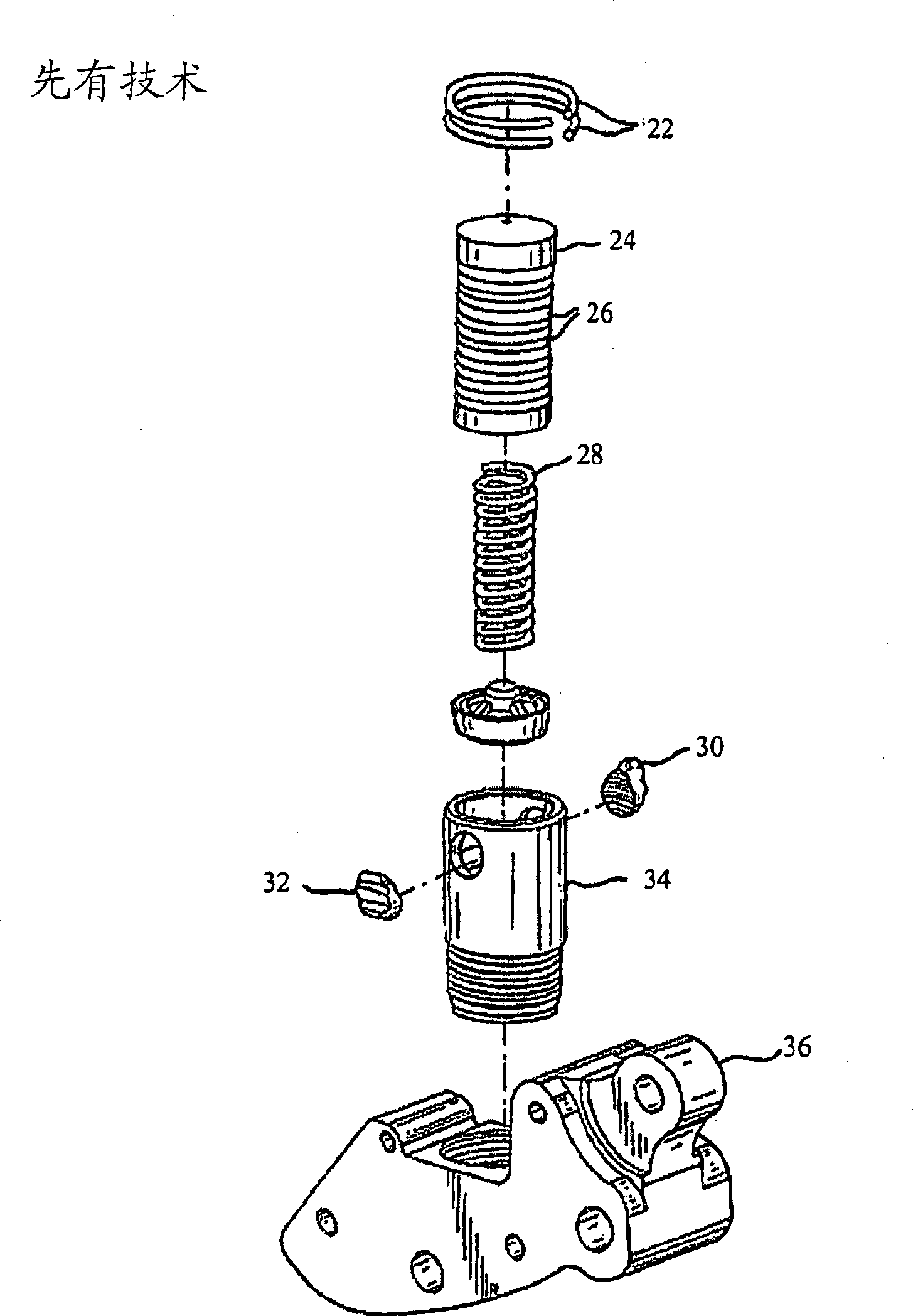

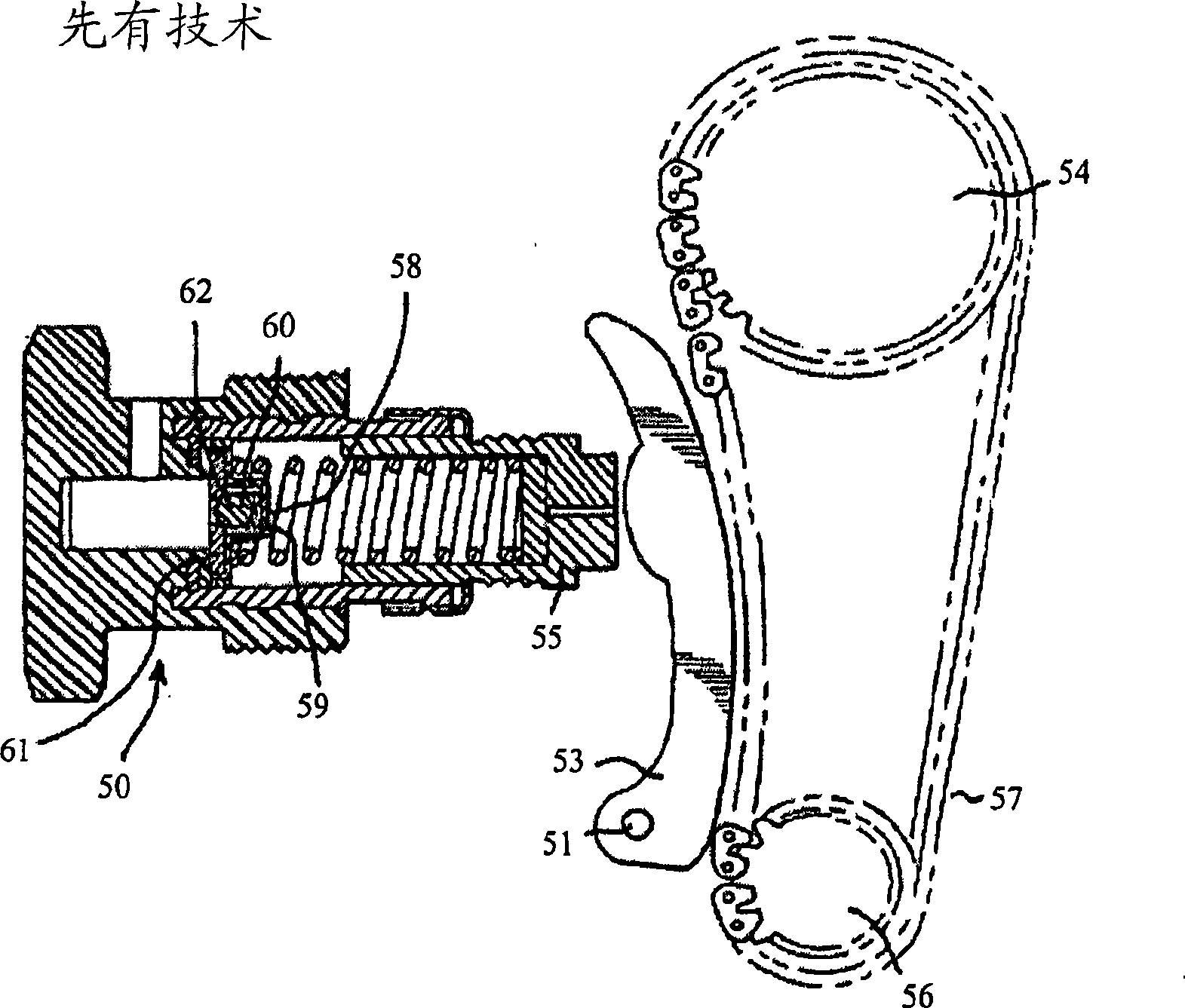

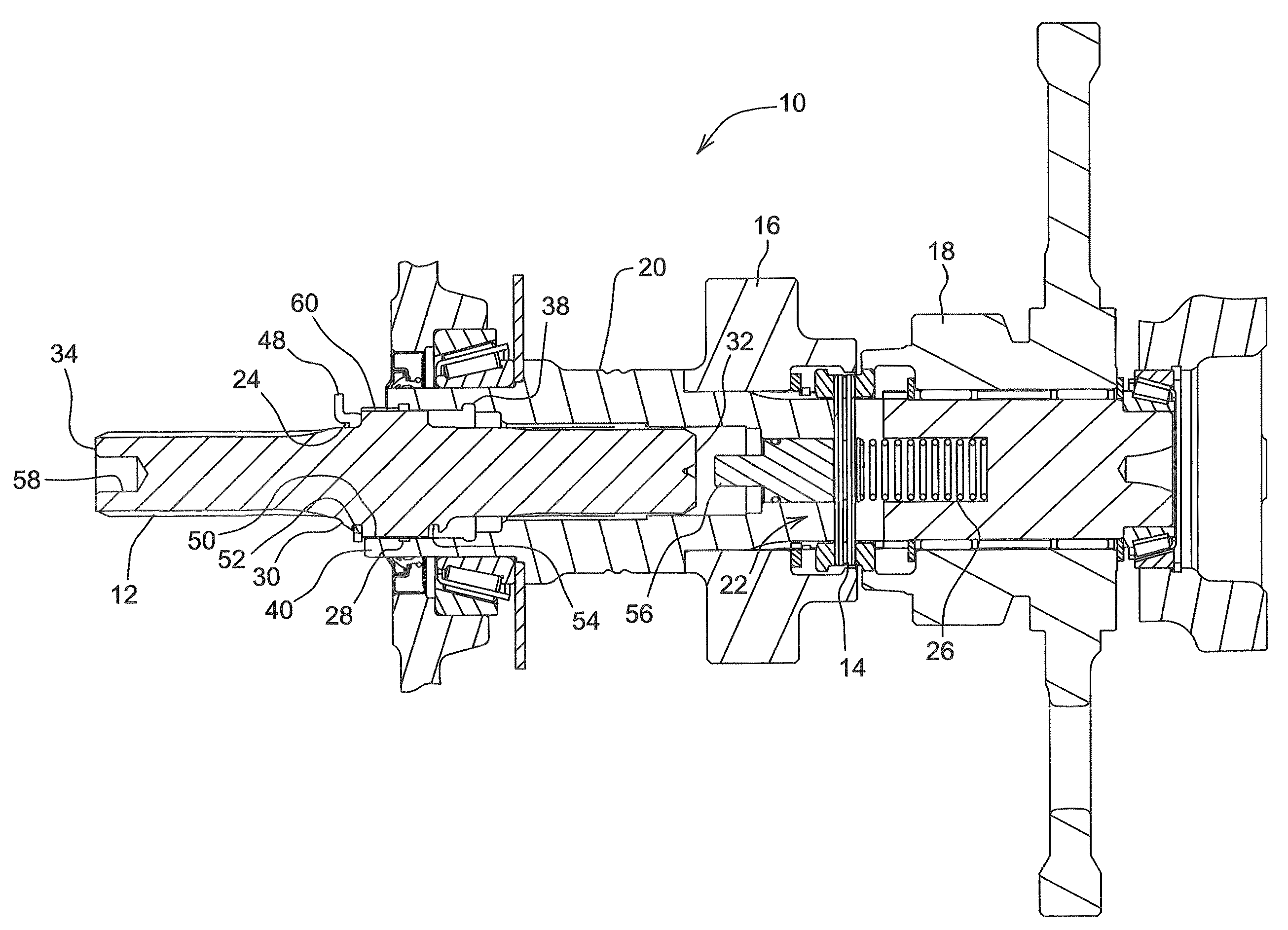

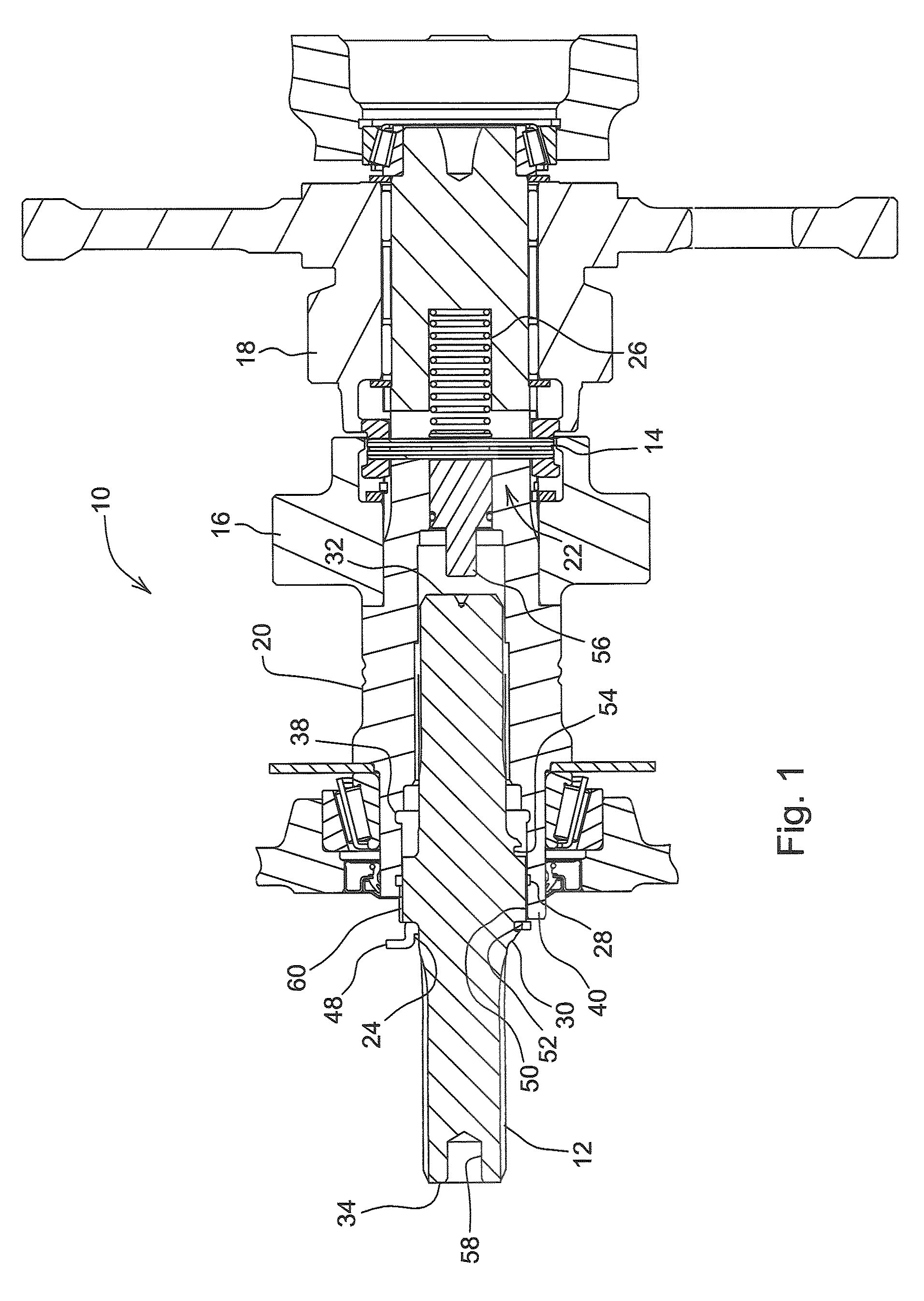

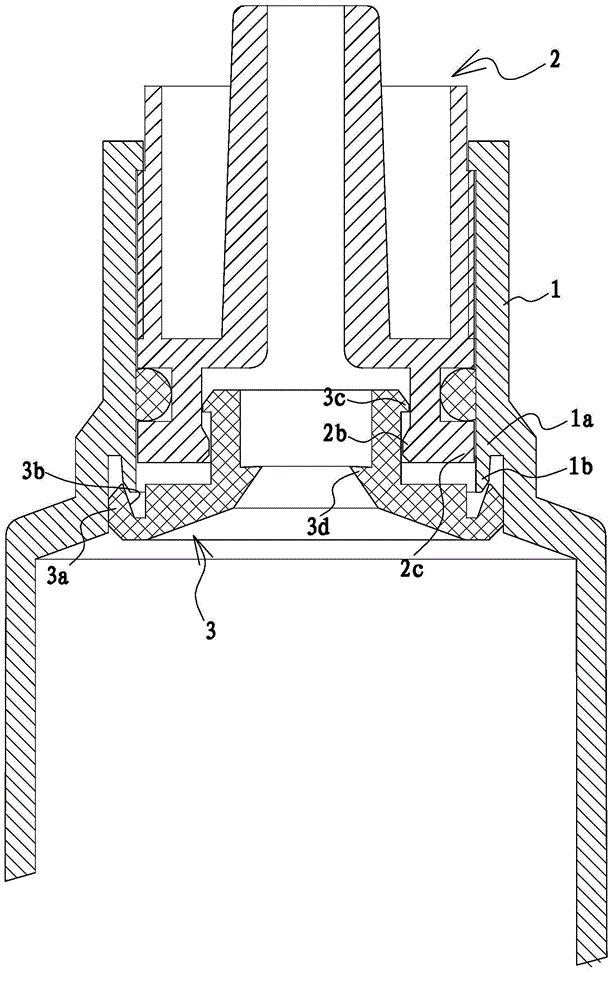

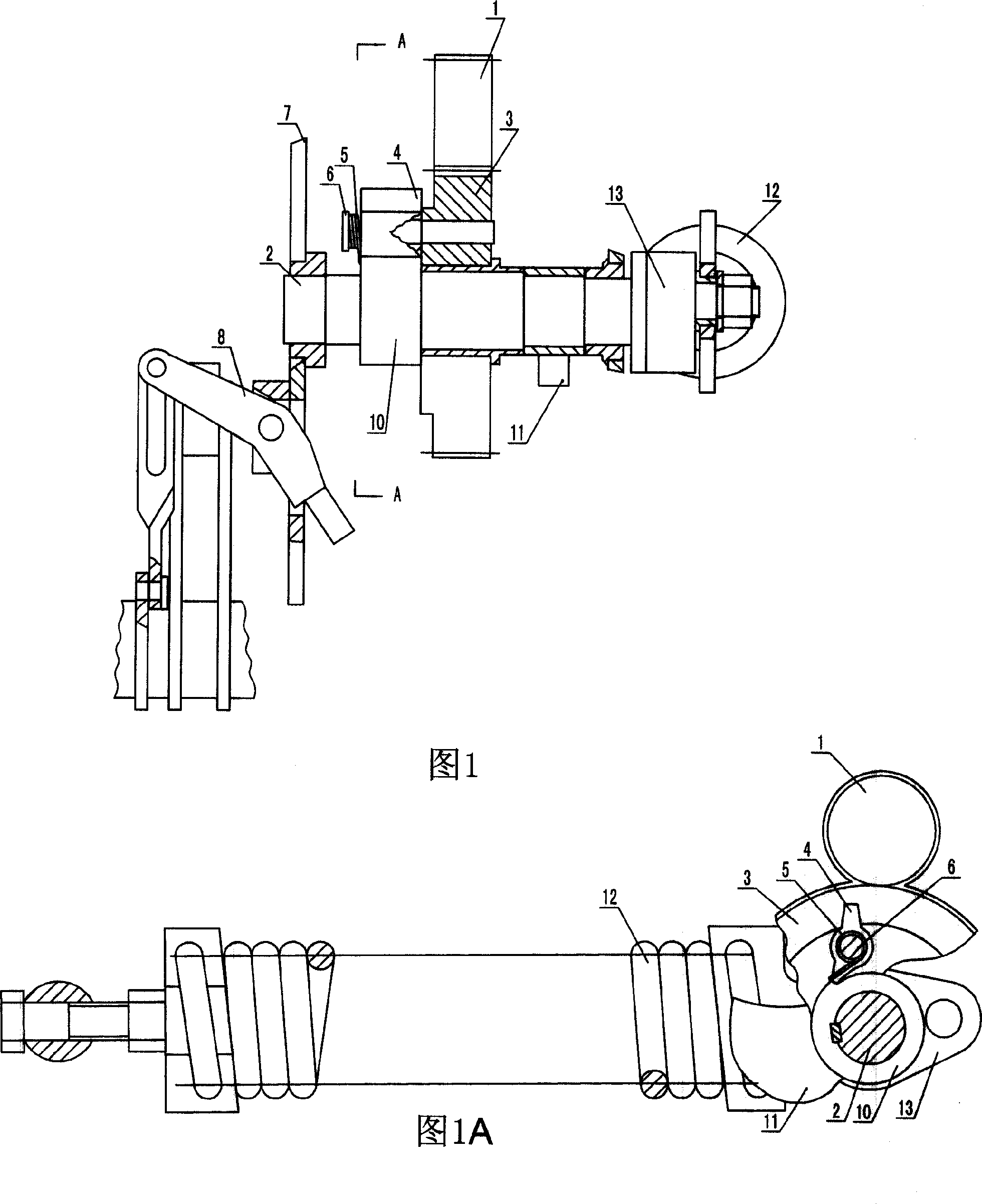

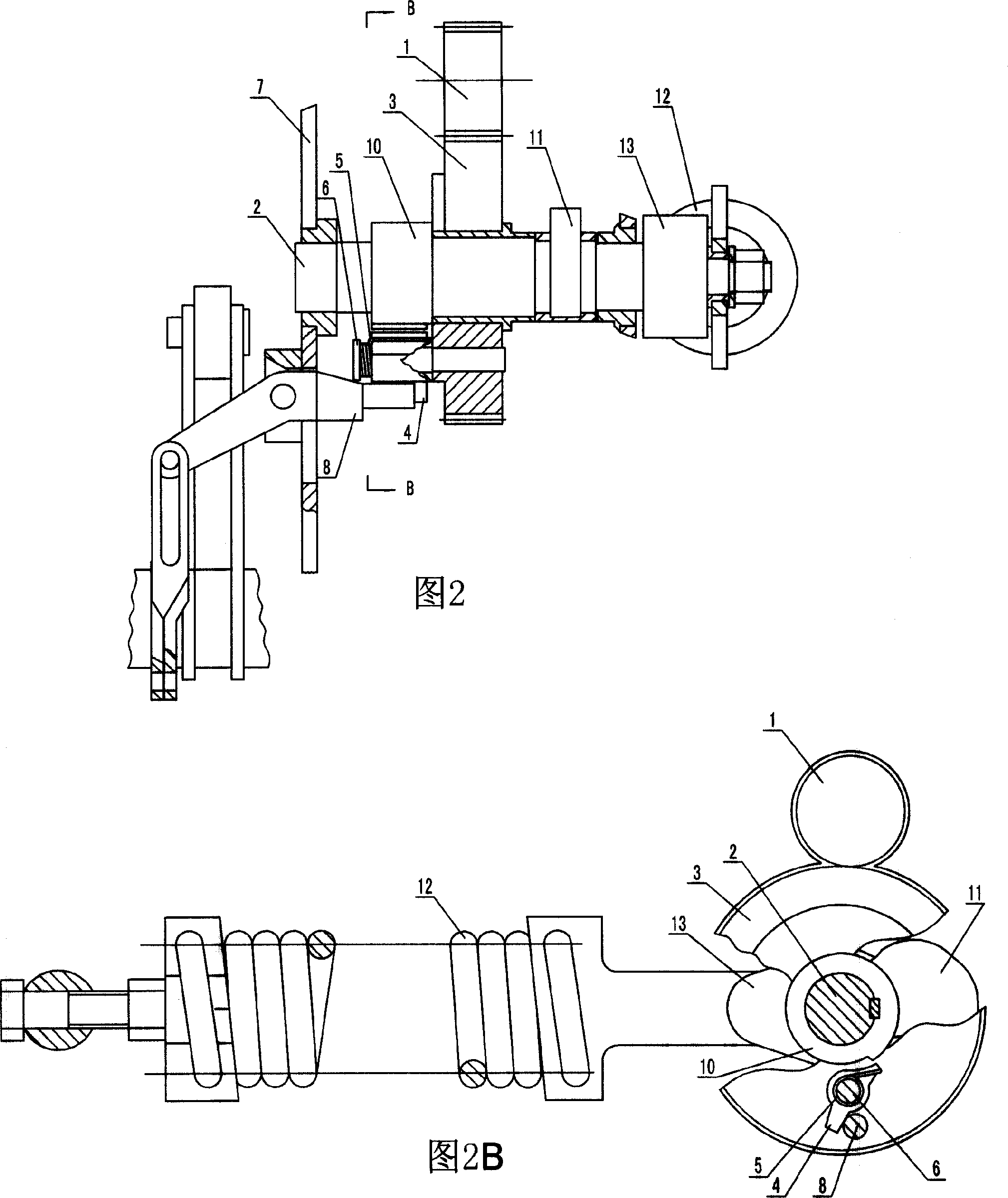

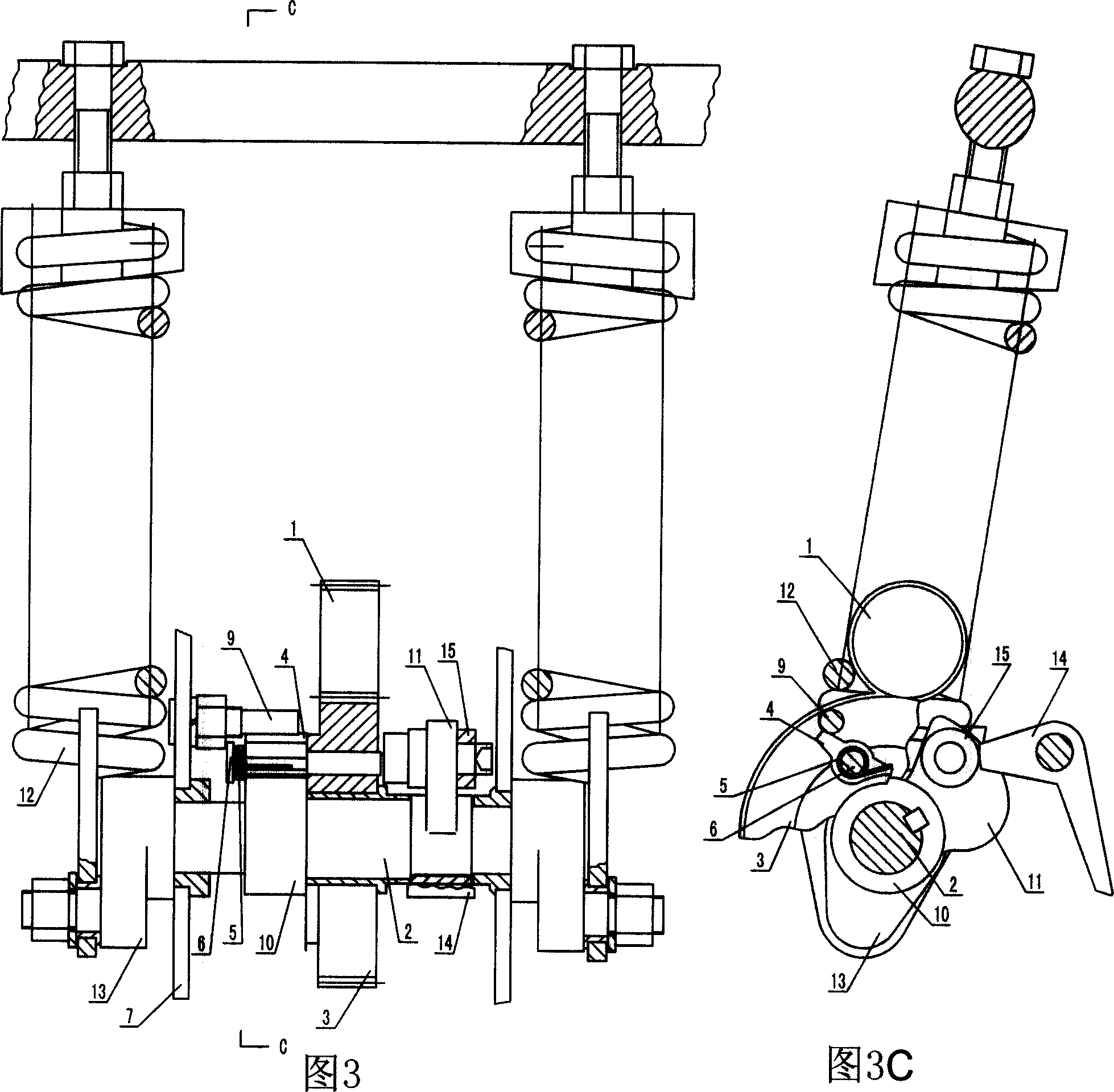

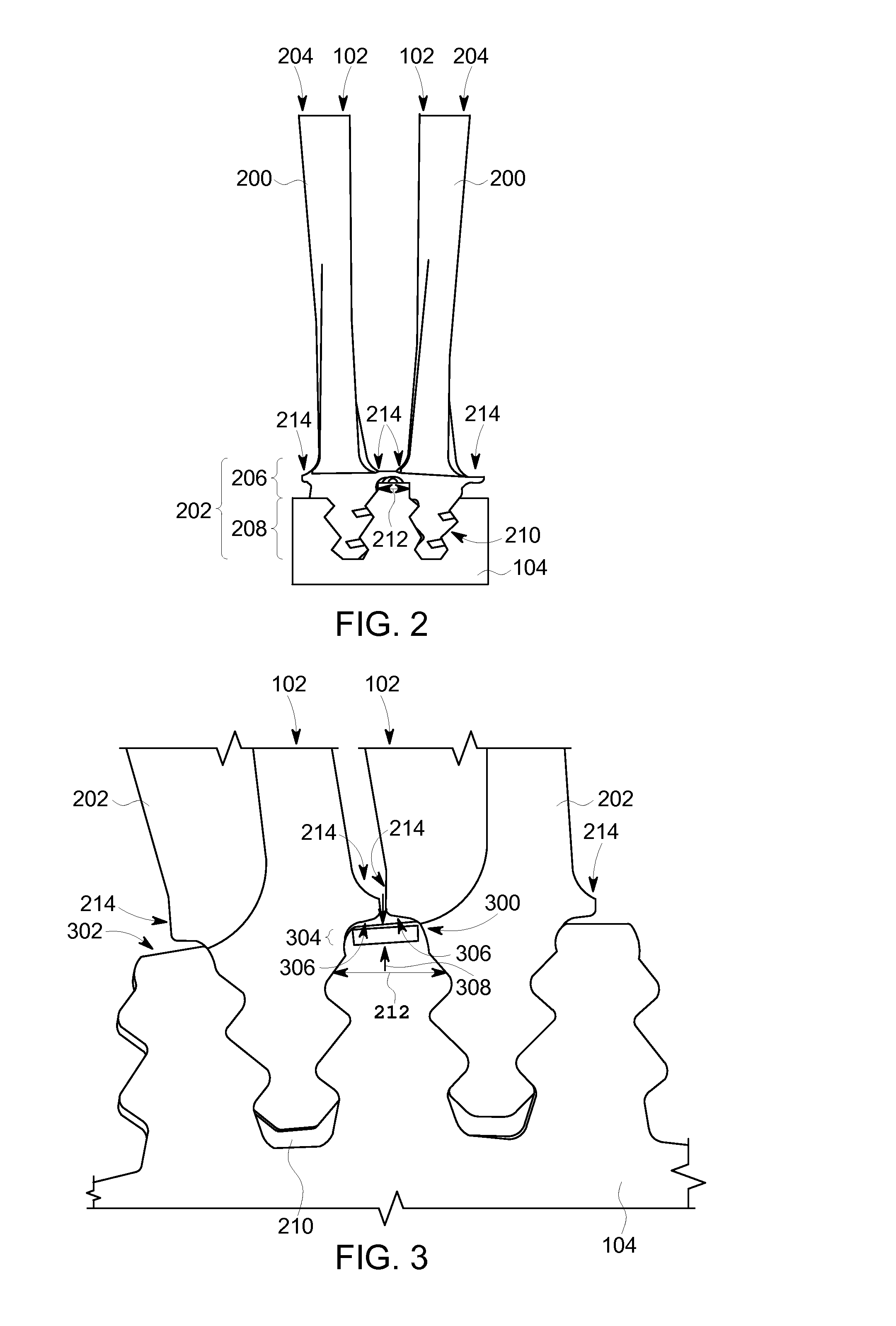

Ratcheting tensioner with a sliding and pivoting pawl

A tensioner with a piston is slidably received with a bore (216) of the housing and has a plurality of grooves (204b) formed on its outer circumference. A piston spring (226) biases the piston (204) in an outward direction from the bore. A pawl (206) is received by a cutout in the housing and is pivotally and slidably attached to the housing by a pin (208). The pawl has a first protruding shoulder (206a), a second shoulder (206b), a teeth portion (206c), and a hole (211) defined between the first protruding shoulder and the second shoulder. The pawl is biased toward the grooves formed on the outer circumference of the piston by a spring.

Owner:BORGWARNER INC

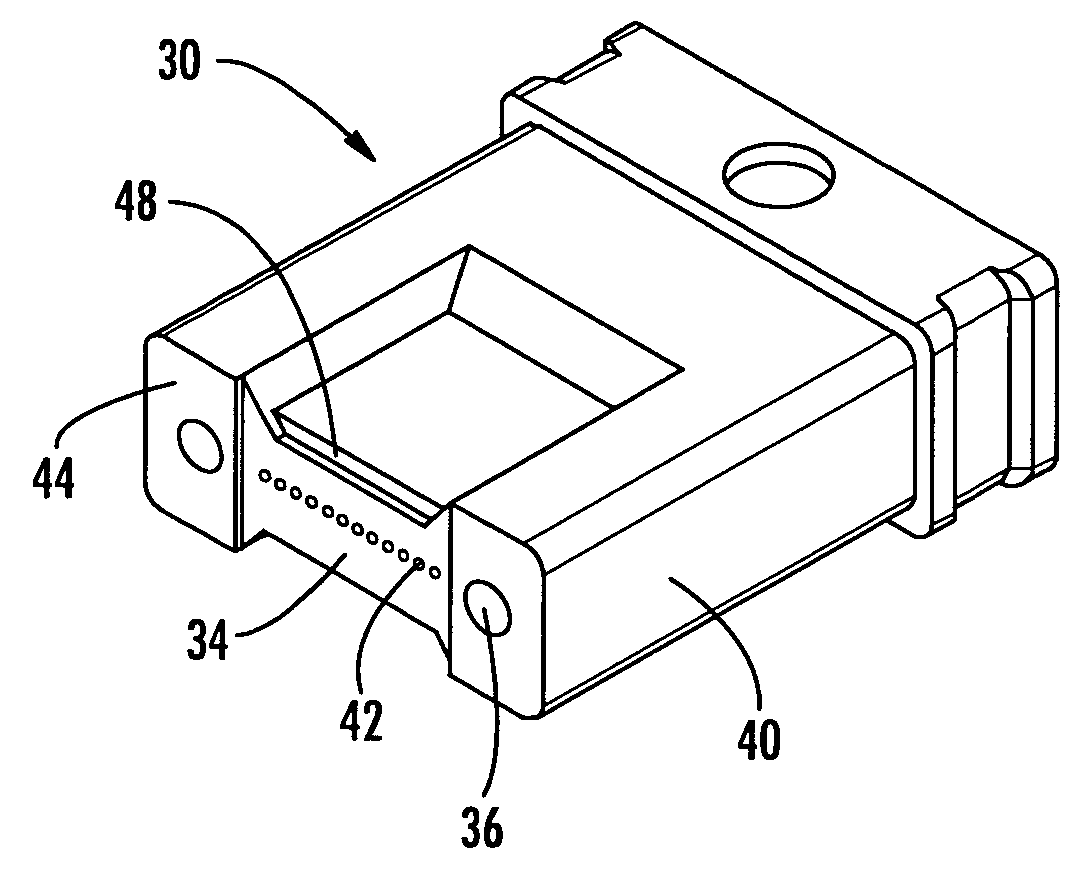

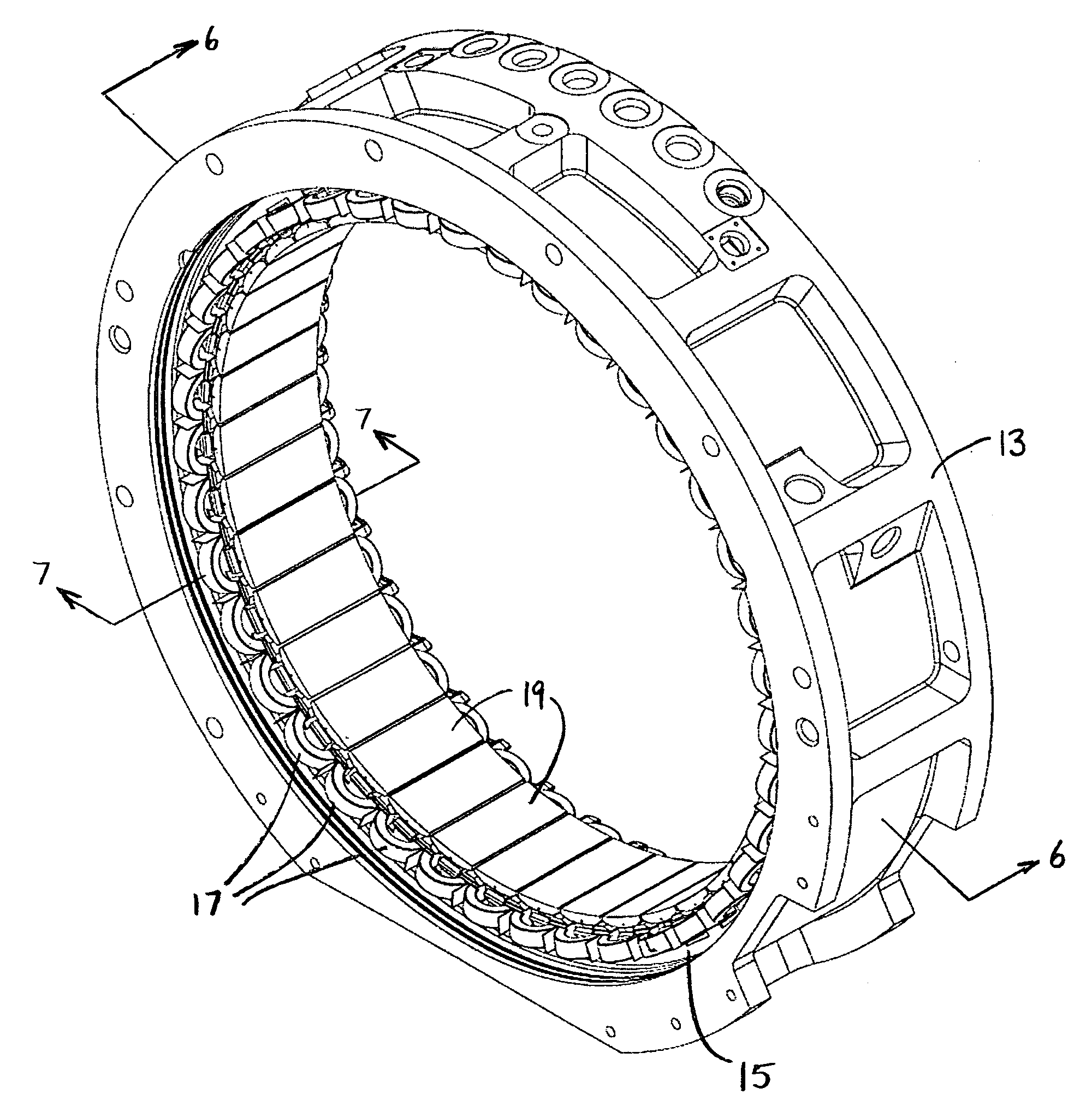

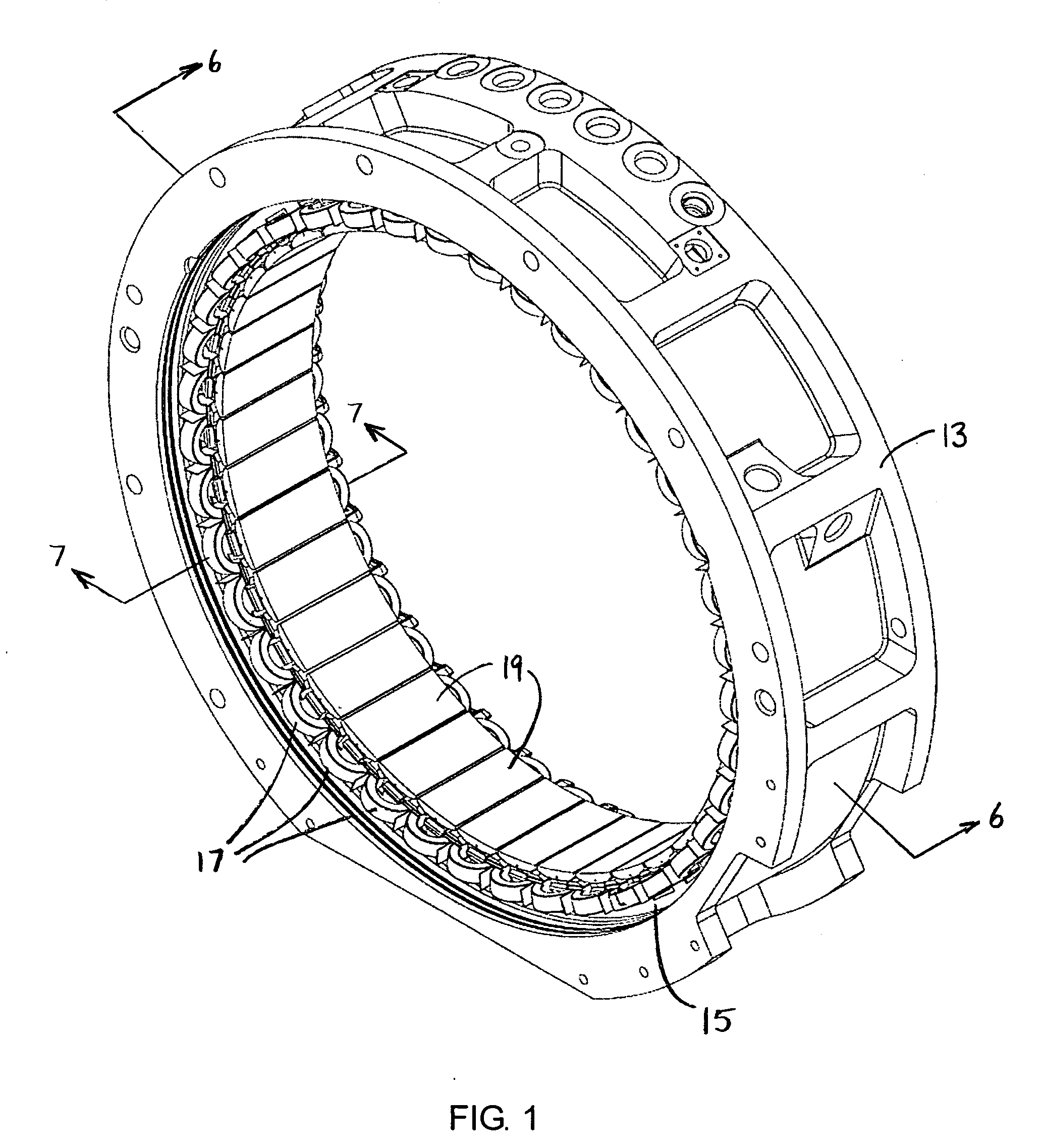

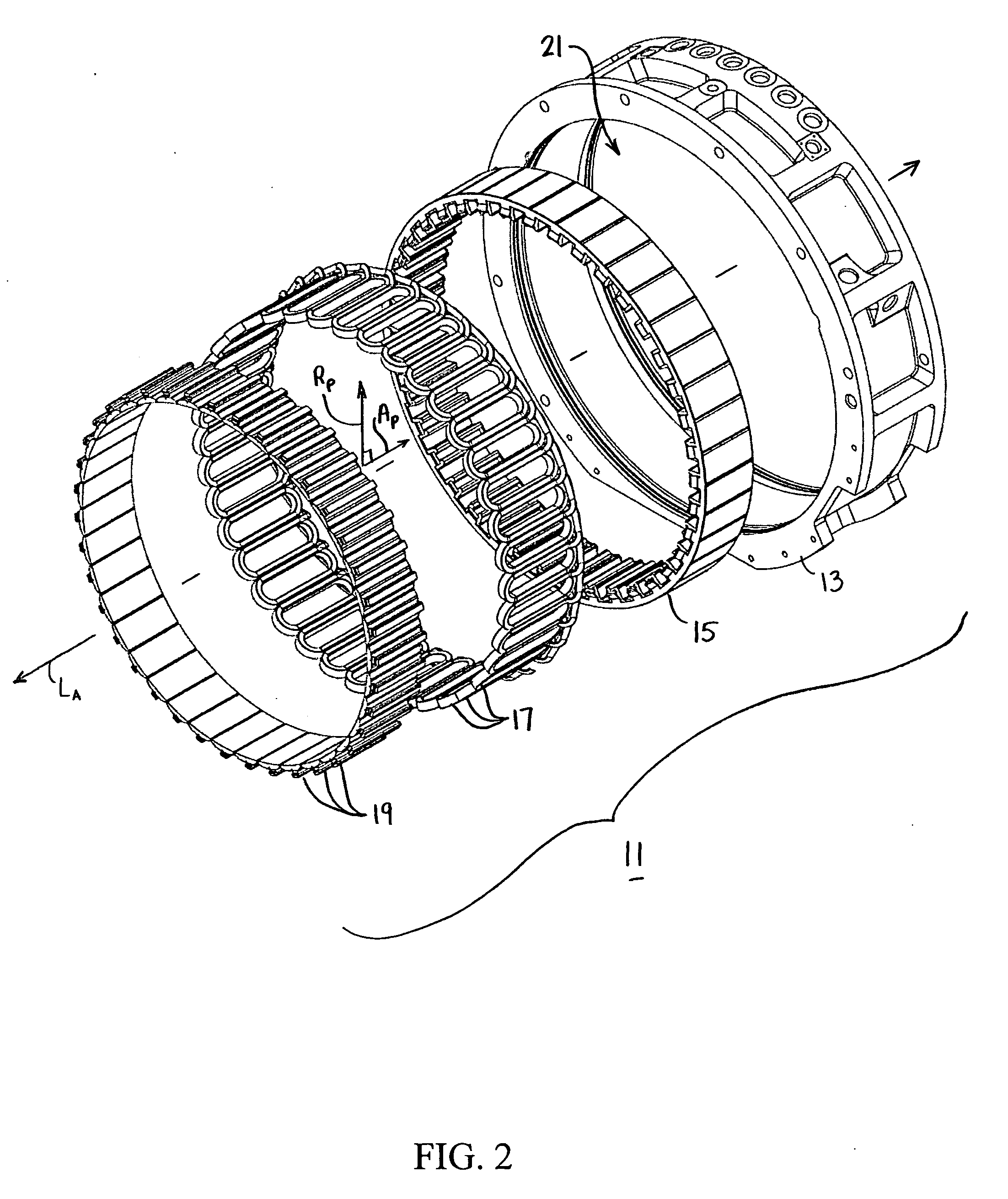

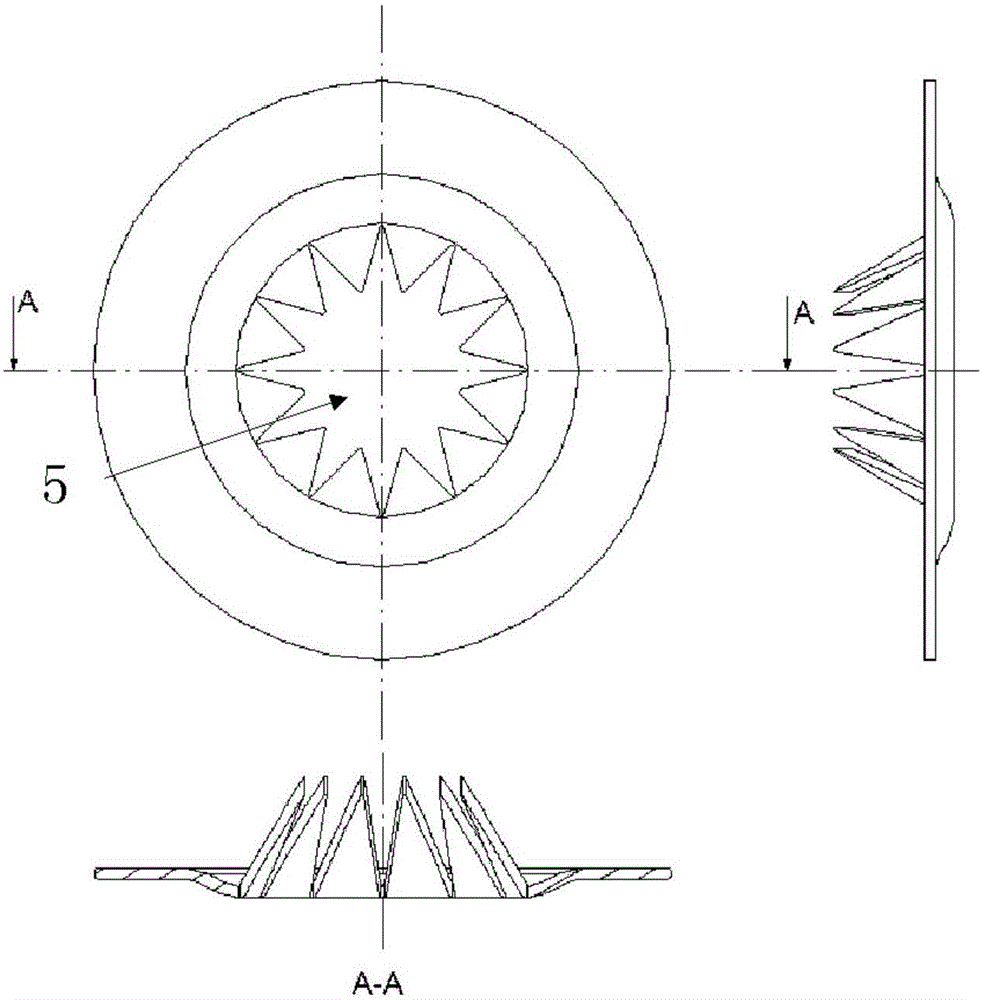

Attachment for a magnetic structure

InactiveUS20090026875A1Reduce mechanical stressMaximize contact areaWindingsMagnetic circuit stationary partsProtruding shouldersElectric machine

Attachments are removably coupled to the magnetic core of a rotating electric machine, the magnetic core being shaped to include a plurality of coil-receiving slots that are separated by radial teeth. Each attachment is constructed as a unitary member and includes a base and a stem, the stem being dimensioned for fitted insertion within a recess formed in the distal end of a corresponding tooth. The base includes a convex bottom wall, a flattened top wall and a pair of non-planar sidewalls. The stem is integrally formed on the top wall of the base and includes a front end, a rear end, a flattened top wall and a pair of opposing sidewalls. A longitudinal groove is formed into each of the pair of opposing sidewalls of the stem. An outwardly protruding shoulder designed for engagement by a retention plate is formed into the front and rear ends of the stem.

Owner:VESTAS WIND SYST AS

Molded ferrule with reference surface for end face geometry measurement

A ferrule comprising a molded ferrule body defining fiber bores, an end face of a connective end of the ferrule positioned about the fiber bores, and an integral reference surface for determining the angularity of the end face. The integral reference surface is not machined subsequent to a ferrule molding process and is accessible after assembly of the ferrule body into a connector body. A multi-fiber ferrule comprising a connective end defining an end face, a rear non-connective portion defining a protruding shoulder, and an integral reference datum positioned on a surface of the shoulder accessible for determining the angularity of a plane defined by the end face, wherein the integral datum is accessible when the ferrule is received within a connector body.

Owner:CORNING OPTICAL COMM LLC

Spill Containment Device

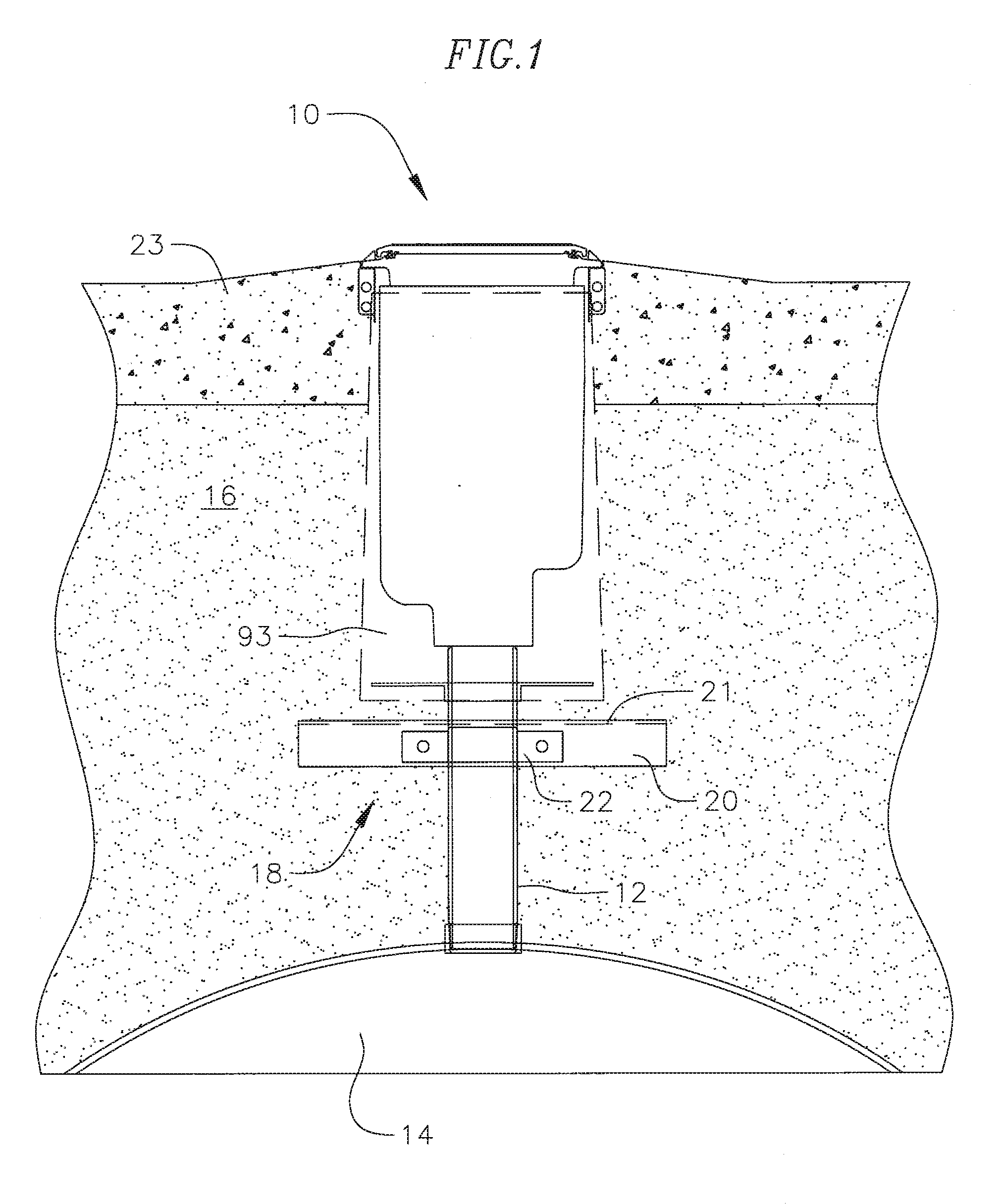

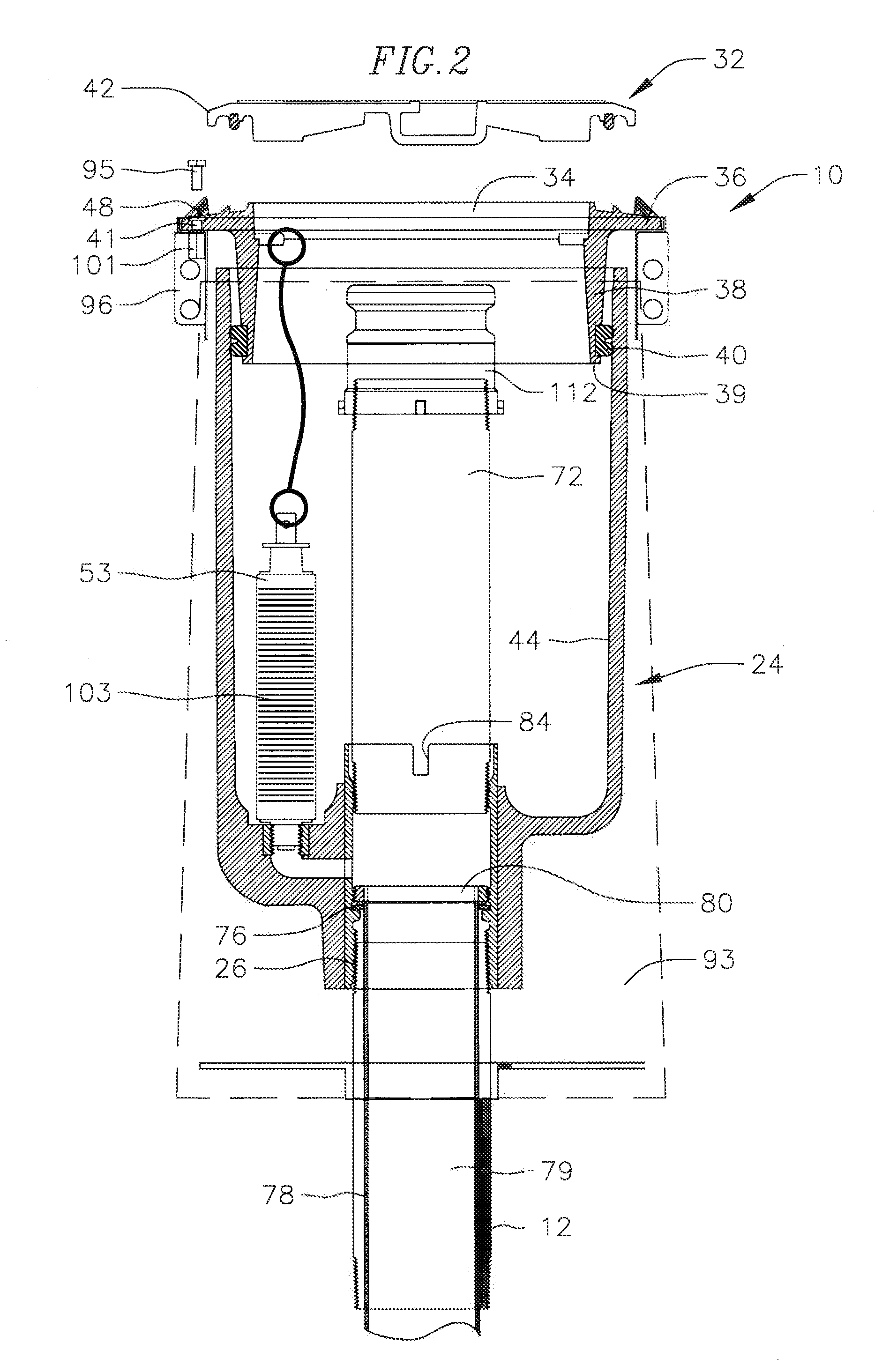

InactiveUS20080023075A1Other washing machinesLiquid transferring devicesVertical tubeProtruding shoulders

A spill containment device for a fluid storage tank filling system including a threaded riser pipe extending from a storage tank and a drop tube including a flange at one end with a conduit extending from the flange, through the riser pipe and into the storage tank. The spill containment device includes a tubular base having an inwardly protruding shoulder adapted to receive the flange of the drop tube, lower threads below the shoulder adapted to mate with the threaded riser pipe; and upper threads above the shoulder. A receptacle is attached to the tubular base, the receptacle having an open upper end. A threaded compression ring is provided, the threaded compression ring adapted to mate with the upper threads of the tubular base and attach the drop tube to the tubular base.

Owner:S BRAVO SYST

Ratcheting tensioner with a sliding and pivoting pawl

A tensioner with a piston is slidably received with a bore (216) of the housing and has a plurality of grooves (204b) formed on its outer circumference. A piston spring (226) biases the piston (204) in an outward direction from the bore. A pawl (206) is received by a cutout in the housing and is pivotally and slidably attached to the housing by a pin (208). The pawl has a first protruding shoulder (206a), a second shoulder (206b), a teeth portion (206c), and a hole (211) defined between the first protruding shoulder and the second shoulder. The pawl is biased toward the grooves formed on the outer circumference of the piston by a spring.

Owner:BORGWARNER INC

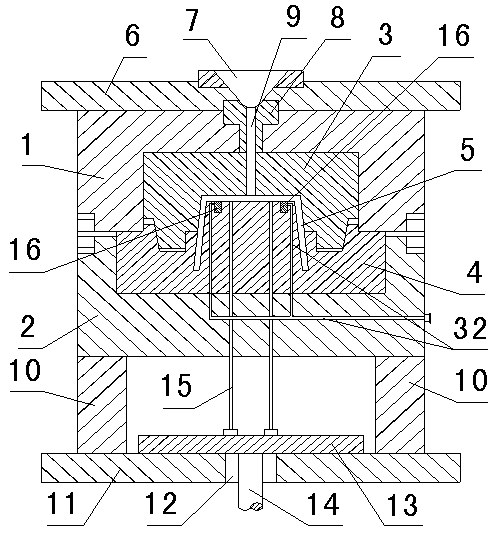

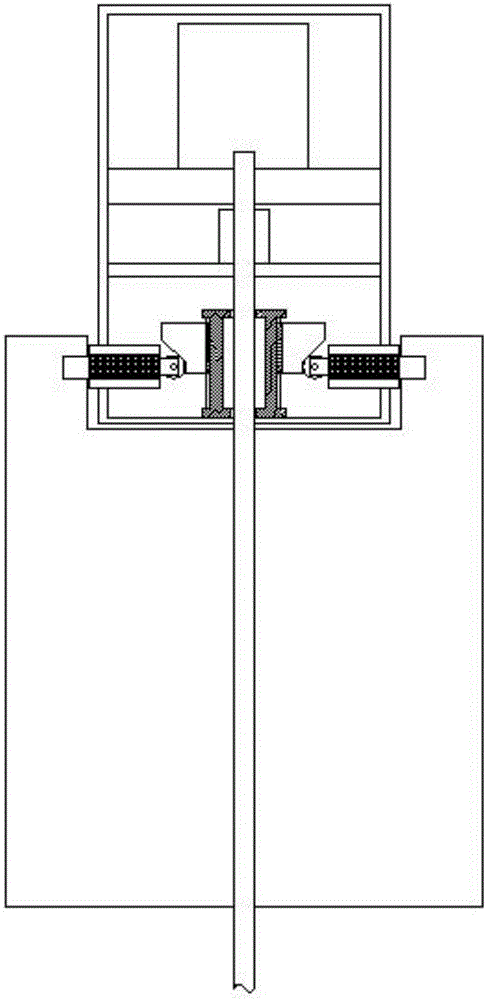

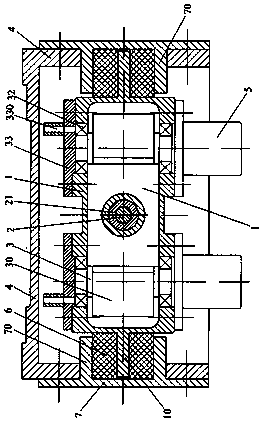

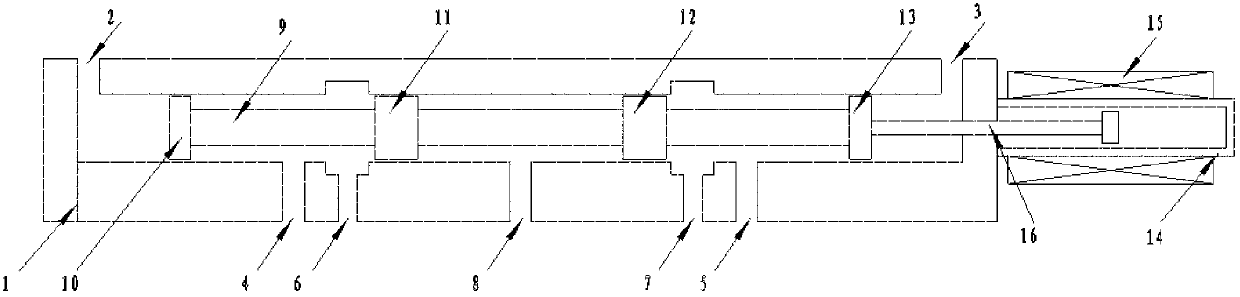

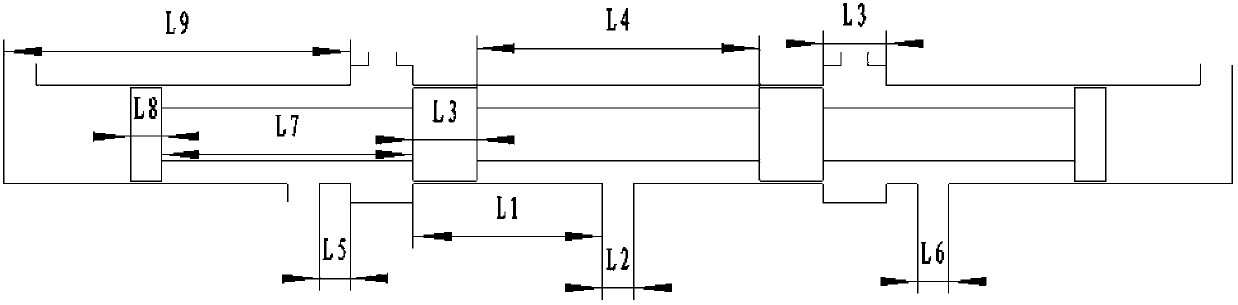

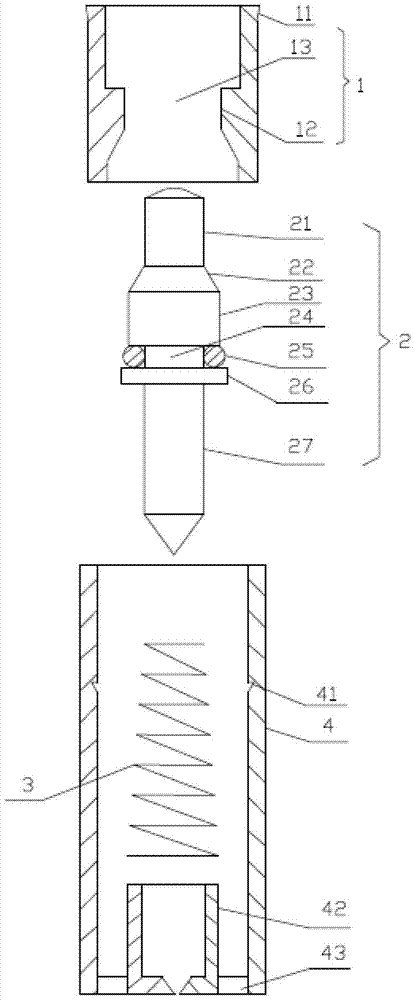

Deep cavity injection mold achieving easy demolding

The invention relates to a deep cavity injection mold achieving easy demolding. The deep cavity injection mold comprises a fixed mold, a moving mold, an upper mold core, a lower mold core, a mold cavity, a fixed mold seat plate, a sprue, a sprue sleeve, a glue injection runner, mold feet, a moving mold seat plate, an ejector plate and ejector rods. Air pins are arranged in the lower mold core, andeach air pin comprises a body with a through hole formed in the center, an ejector pin, a thrust pin and a spring. Each through hole is composed of a trapezoidal hole, a second hole, a third hole anda lower hole. An air guide hole communicating with the corresponding trapezoidal hole and third hole is formed in each body. An air inlet hole is formed in the inner wall of each third hole. A thrustpin hole is formed in the lower portion of each lower hole, and each thrust pin is inserted in the corresponding thrust pin hole. Each ejector pin is composed of an airtight segment, a guide segment,a protruding shoulder and a spring guide rod. Each spring is arranged on the outer portion of the corresponding spring guide rod in a sleeving manner, and the protruding shoulders are pushed towardsthe third holes so as to abut against the lower edges of the third holes. When the air pins of the deep cavity injection mold work, the ejector pins are opened inwards, opening is easy, an injection molded product and the mold are separated completely by compressed air, and the situation that the injection molded product is ejected to be white or be broken or deform cannot happen.

Owner:漳州市龙文区仁信工业设计有限公司

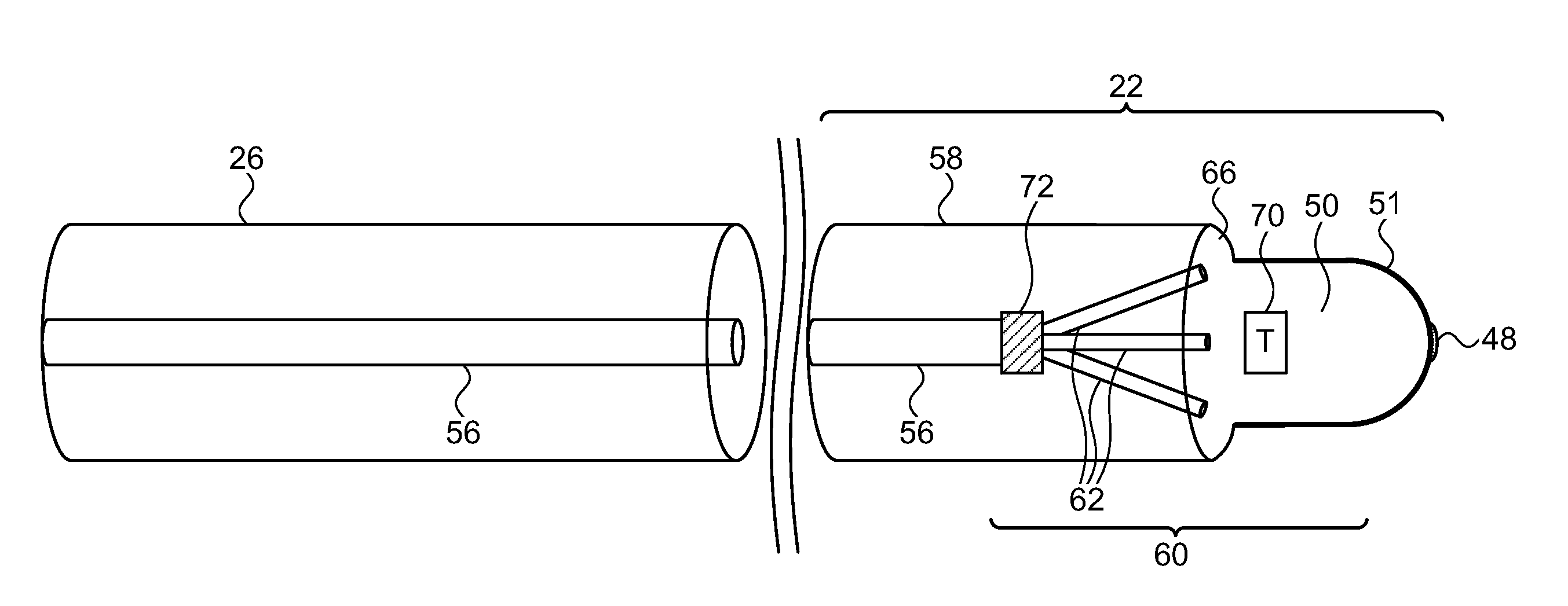

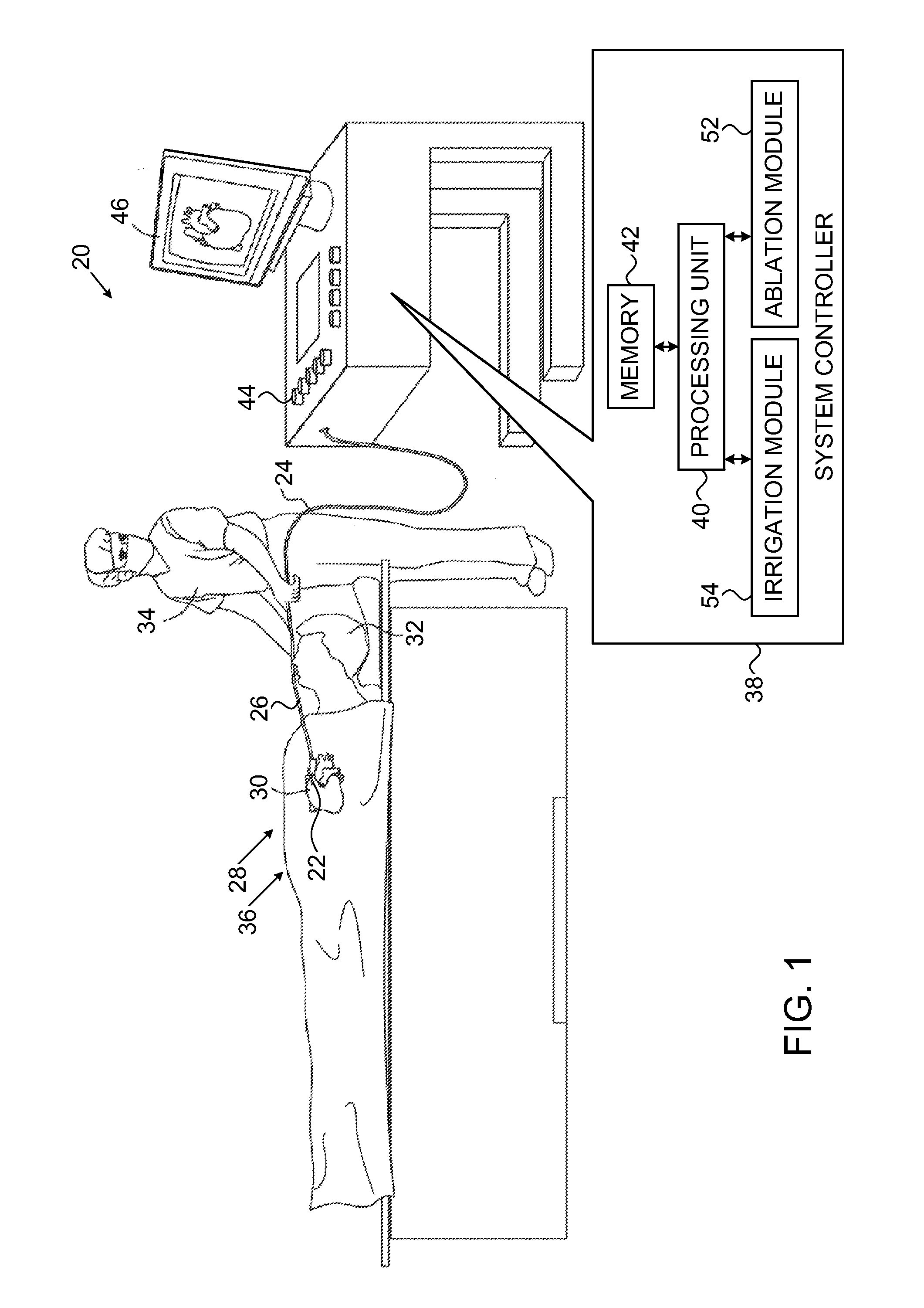

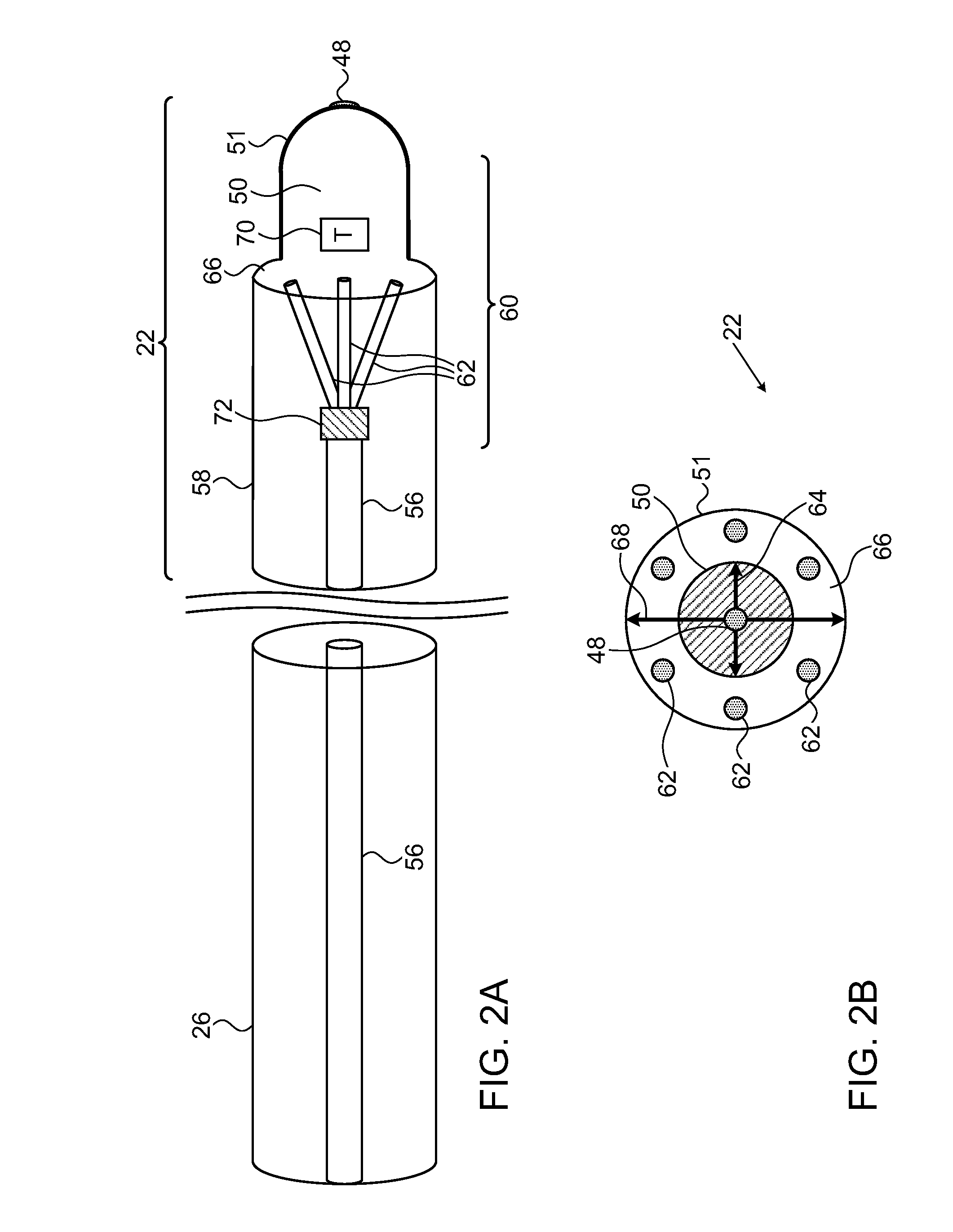

Catheter with spray irrigation

A medical probe, including a flexible insertion tube having a distal end for insertion into a body cavity, and a channel contained within the insertion tube and configured to convey a fluid to the distal end. A terminal member is fixed to the distal end of the insertion tube and includes a distal tip configured to be brought into contact with tissue in the body cavity, the distal tip having a first diameter, and a protruding shoulder surrounding the distal tip and having a second diameter, which is greater than the first diameter. The distal tip has one or more spray ports passing through the shoulder which are coupled to the channel so as to direct the fluid from the shoulder toward the tissue so as to irrigate the tissue.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

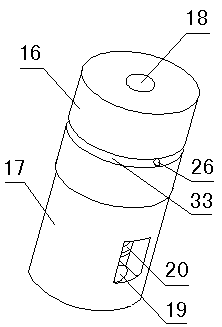

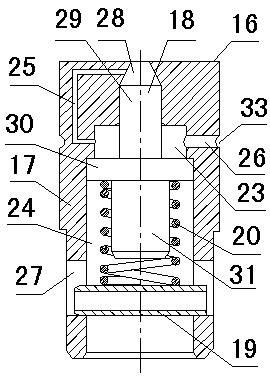

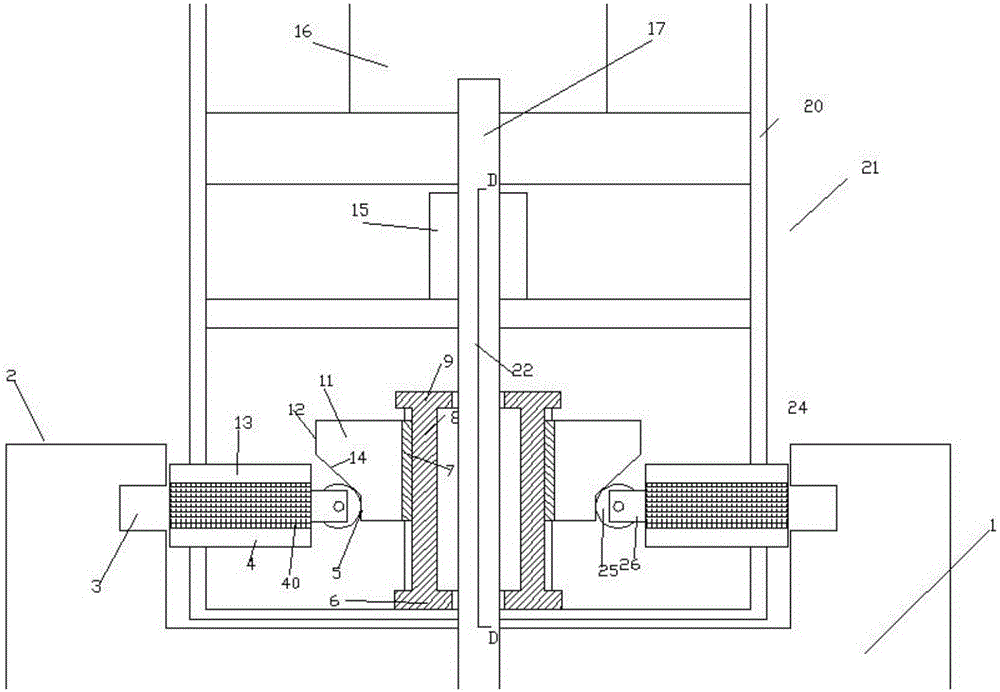

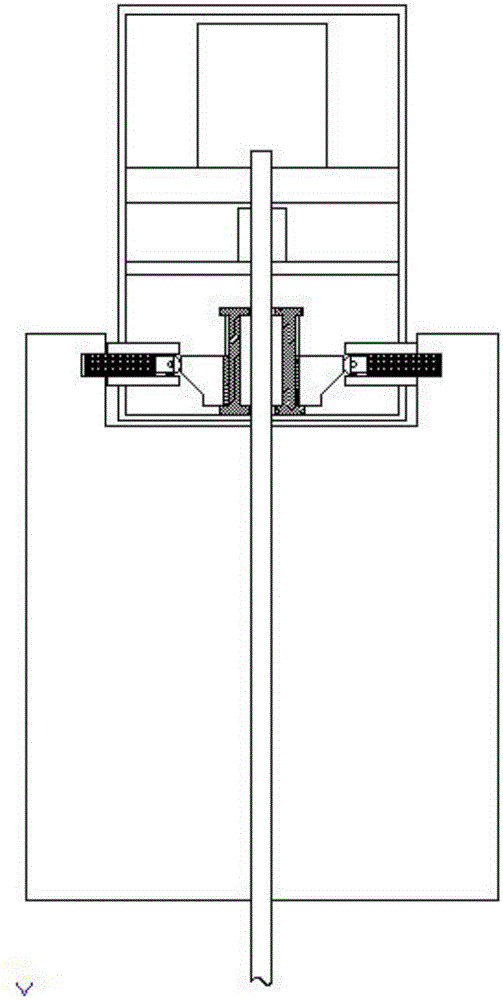

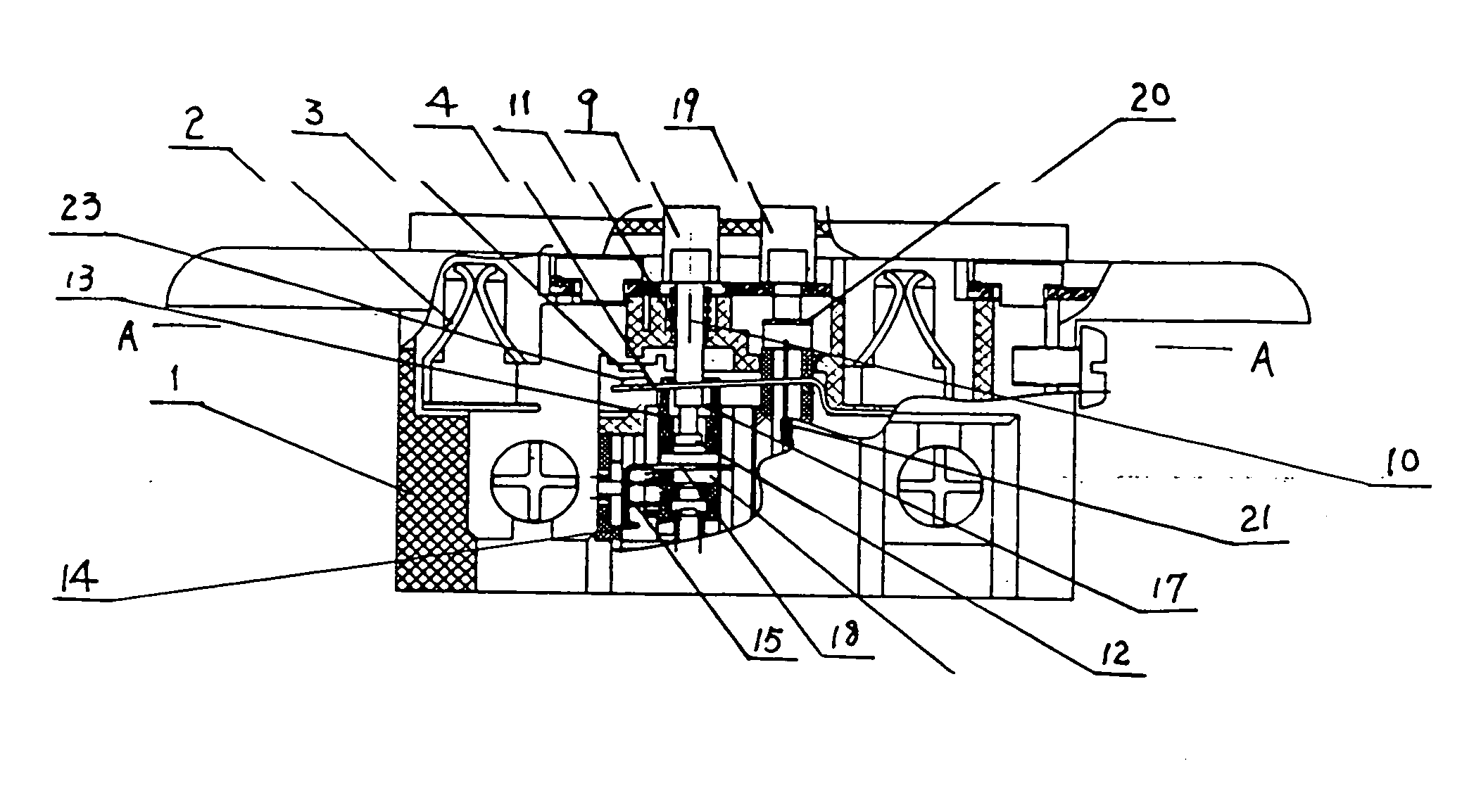

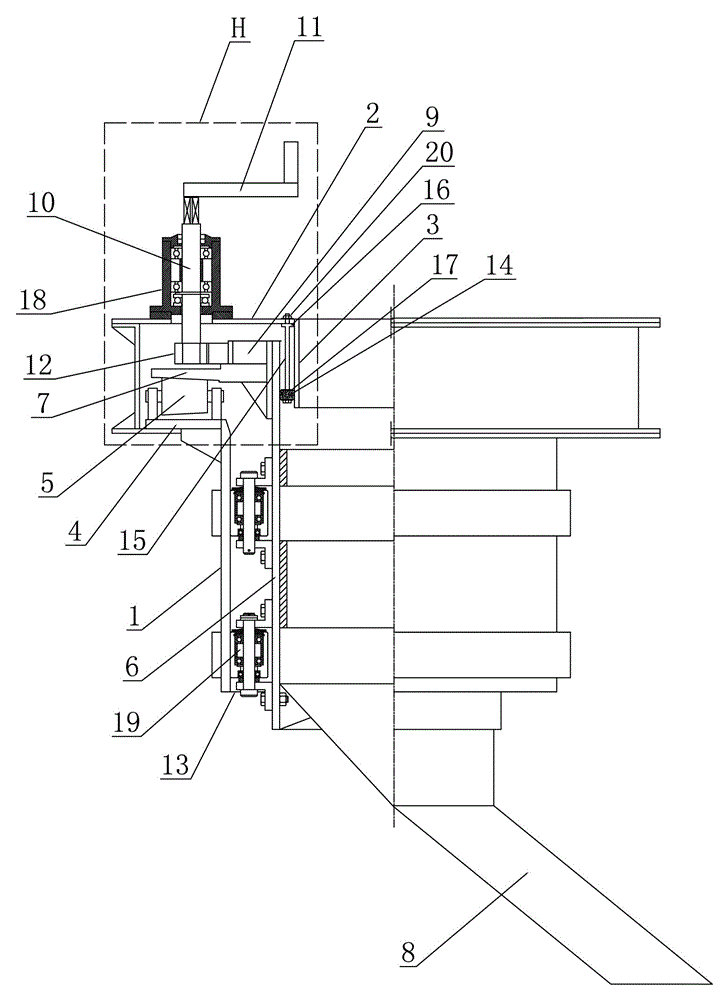

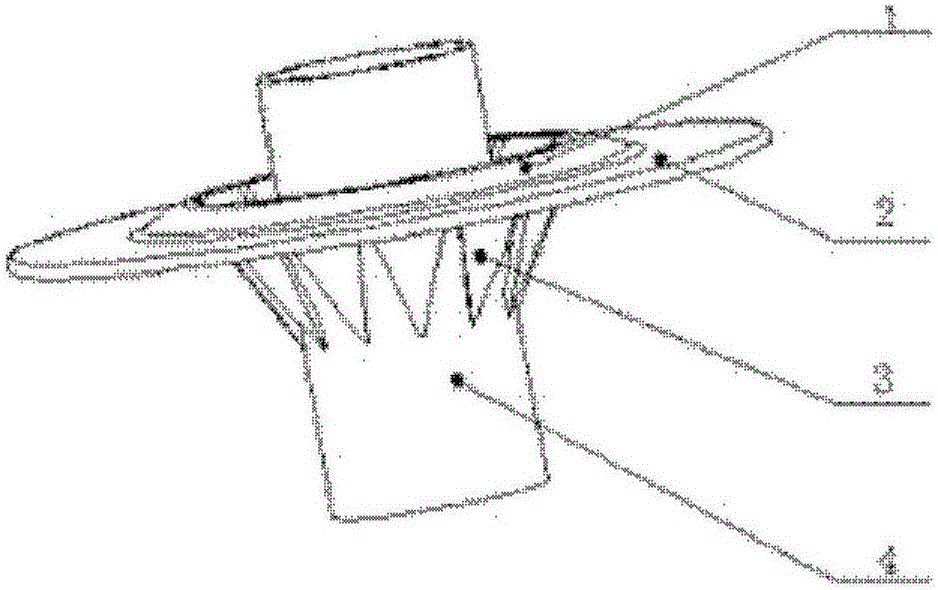

Application method of lift type door plank device using single screw to achieve automatic locking

InactiveCN105840036AReduce usageReduce distractionsBarrages/weirsPower-operated mechanismProtruding shouldersDrive motor

The invention discloses an application method of a lift type door plank device using a single screw to achieve automatic locking. The lift type door plank device comprises a door plank (1) and a door plank lift driving unit (21). The door plank lift driving unit (21) comprises a shell (20) which is fixed to a supporting substrate. A door plank lift driving motor (16) is fixed in the shell (20) and is in power connection with upper end of a door plank lift driving lead screw (17). The door plank lift driving lead screw (17) is in screw-thread fit with a screw hole in the door plank (1). The two sides of the upper edge of the door plank (1) are each provided with a protruding shoulder (2). The inner side faces of the two protruding shoulders (2) are provided with locking holes (3) which are open towards the middle of the door plank (1) and extend in the direction perpendicular to the door plank lift driving lead screw (17).

Owner:项智锋

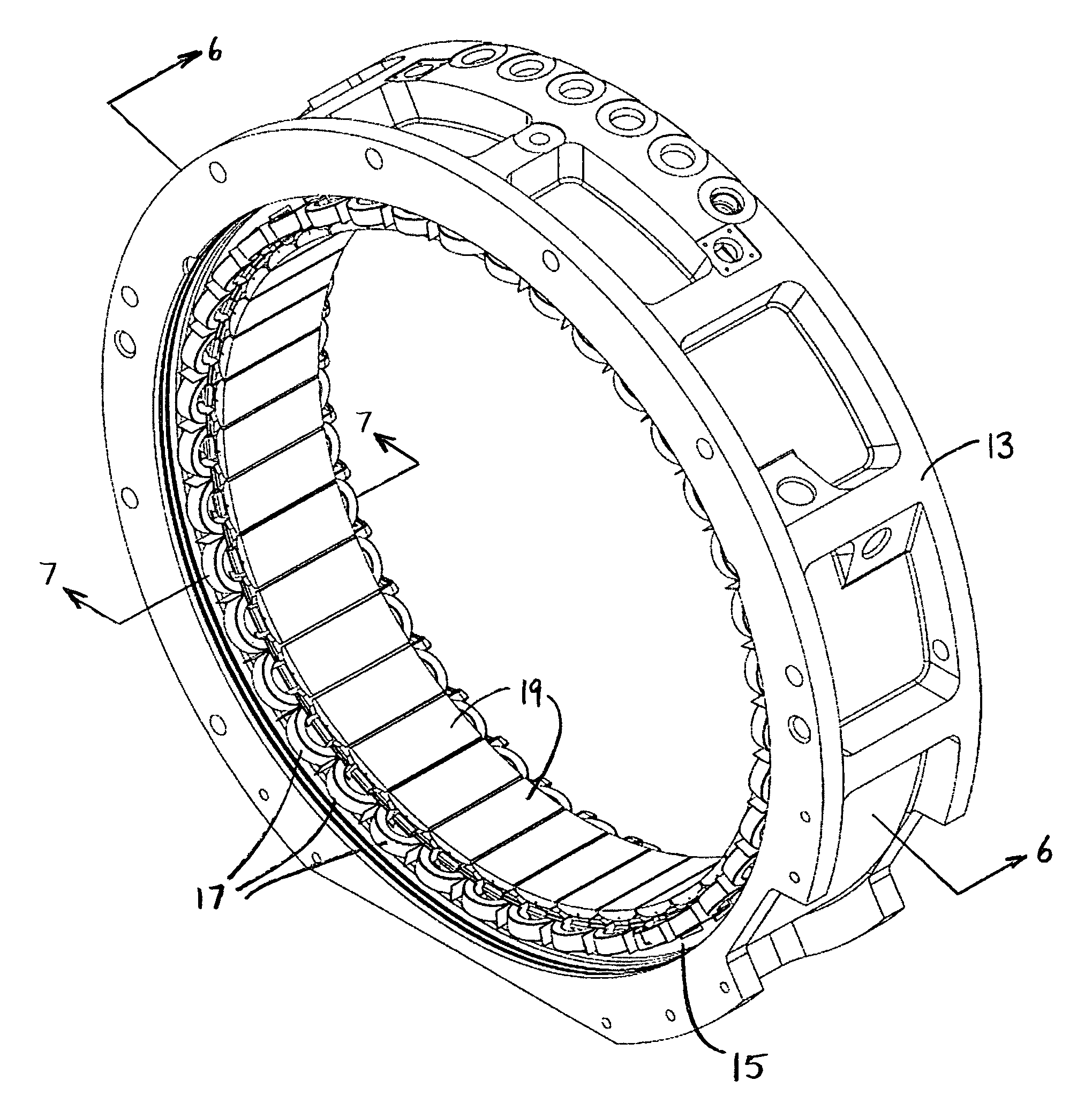

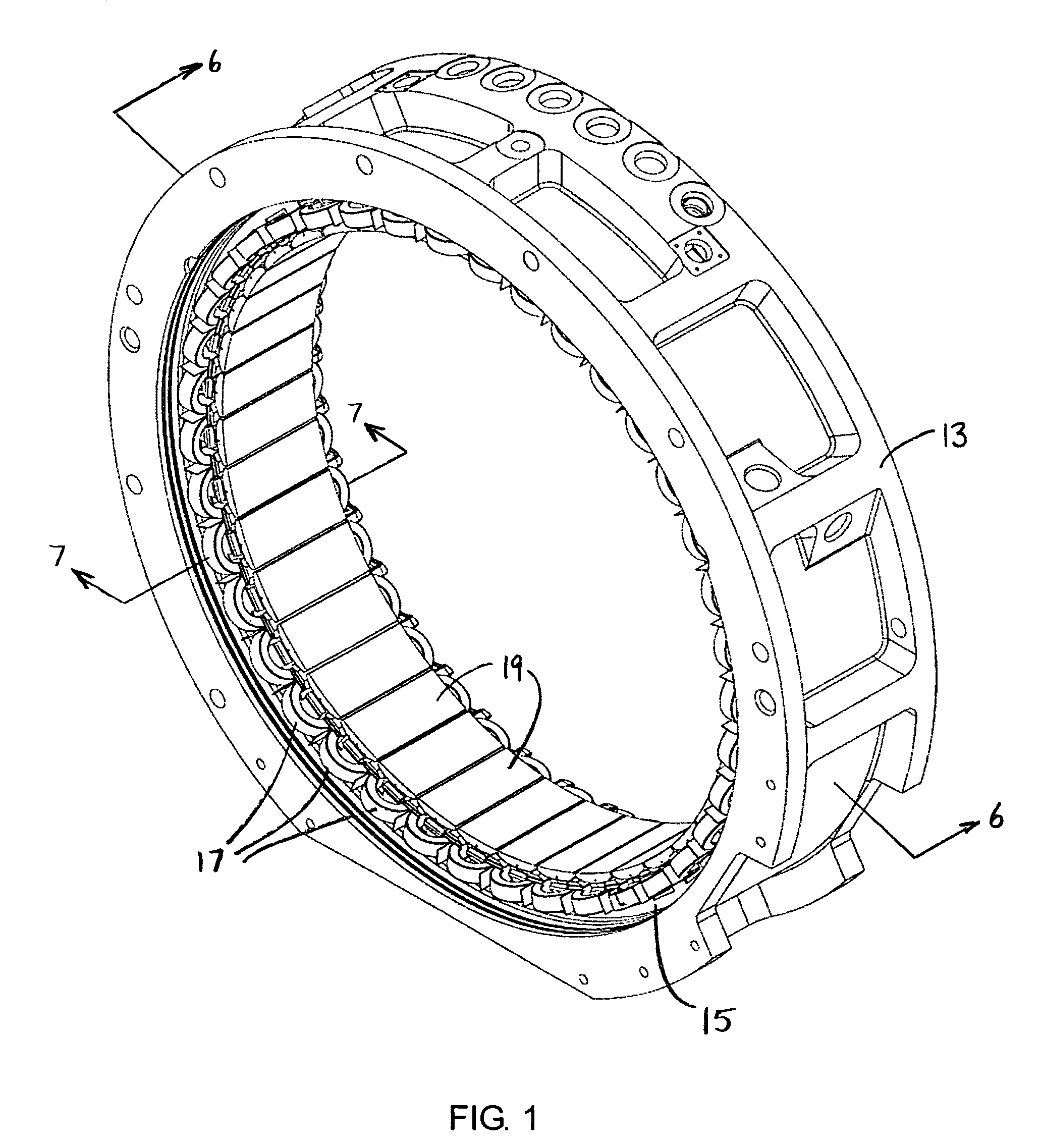

Pole tip attachment for a magnetic structure

InactiveUS7990015B2Reduce gapReduce mechanical stressWindingsMagnetic circuit stationary partsProtruding shouldersElectric machine

Attachments are removably coupled to the magnetic core of a rotating electric machine, the magnetic core being shaped to include a plurality of coil-receiving slots that are separated by radial teeth. Each attachment is constructed as a unitary member and includes a base and a stem, the stem being dimensioned for fitted insertion within a recess formed in the distal end of a corresponding tooth. The base includes a convex bottom wall, a flattened top wall and a pair of non-planar sidewalls. The stem is integrally formed on the top wall of the base and includes a front end, a rear end, a flattened top wall and a pair of opposing sidewalls. A longitudinal groove is formed into each of the pair of opposing sidewalls of the stem. An outwardly protruding shoulder designed for engagement by a retention plate is formed into the front and rear ends of the stem.

Owner:VESTAS WIND SYST AS

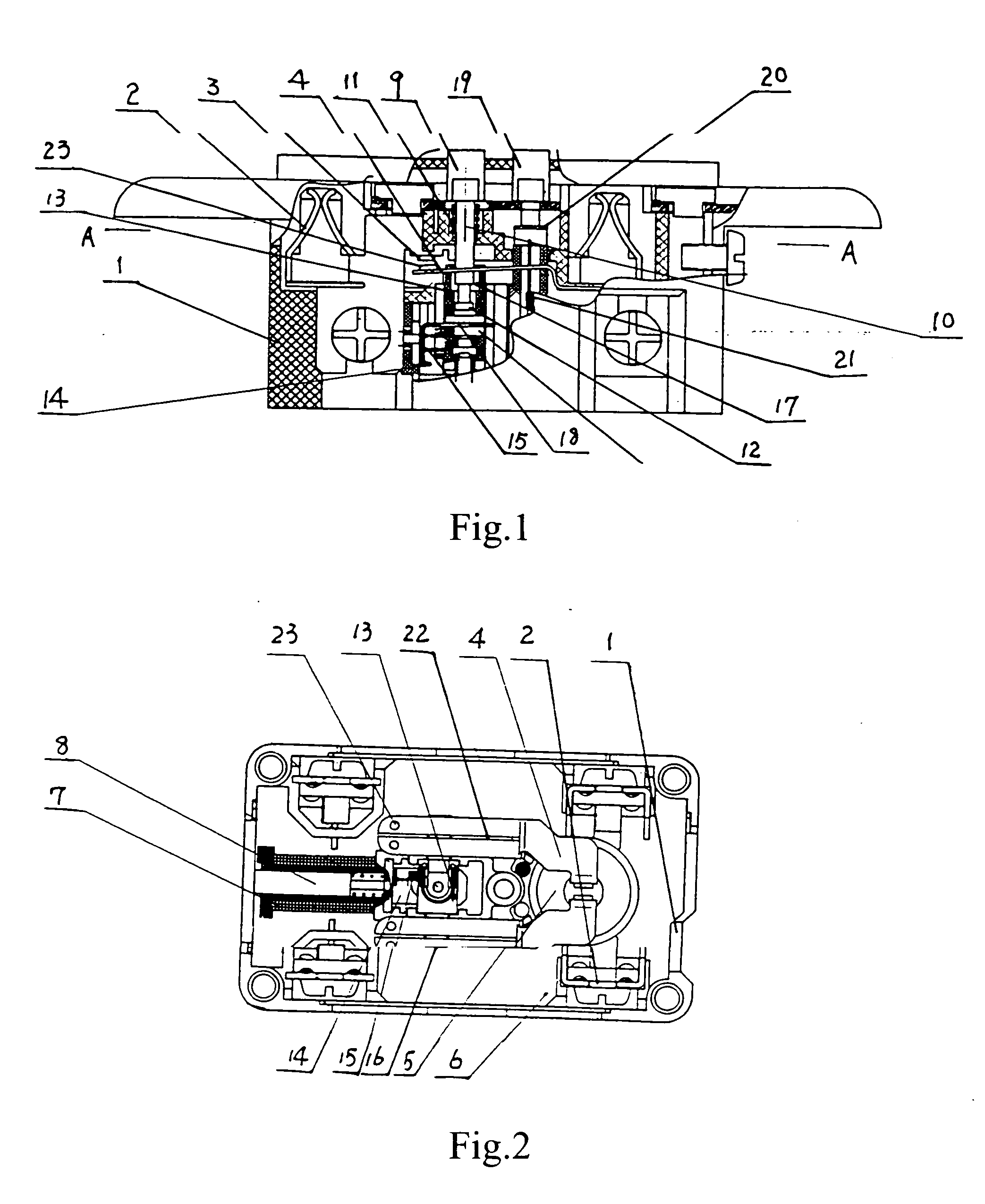

Electric leakage protection socket

InactiveUS20060119456A1Simple structureHigh sensitivityTwo pole connectionsCoupling device detailsElectricityState of art

This invention relates to an electric leakage protection socket, comprising a case in which a pin, a stationary contact chip, a movable contact chip, a magnetic ring, a circuit board, a trip coil, an iron core, a trip mechanism and a reset mechanism are installed; the reset spring is socketed outside the reset rod and the later forms a locating ring at its lower part; the trip mechanism comprises a sliding block, a self-locking plate and a spring, protruding shoulders are arranged on two sidewalls of the sliding block, a contact end of the movable contact chip is pressed against the protruding shoulder, a hole is axially machined on the sliding block, the lower part of the reset rod is inserted in the hole, the self-locking plate is in a shape of ‘7’ whose long edge passes through the transverse hole on the sliding block and has a locking hole matching to the locating ring, and one side of its short edge is pressed against the spring and another side adapts to the iron core. This invention overcome such shortcomings of existing technology as low safety, reliability and sensitivity and increase the sensitivity of the tripping of the electric leakage protection socket so that the equipment can be powered on only if it is started again after recovery of the electricity, with such advantages as simple structure, and convenient, safe and reliable operation.

Owner:YUAN KE

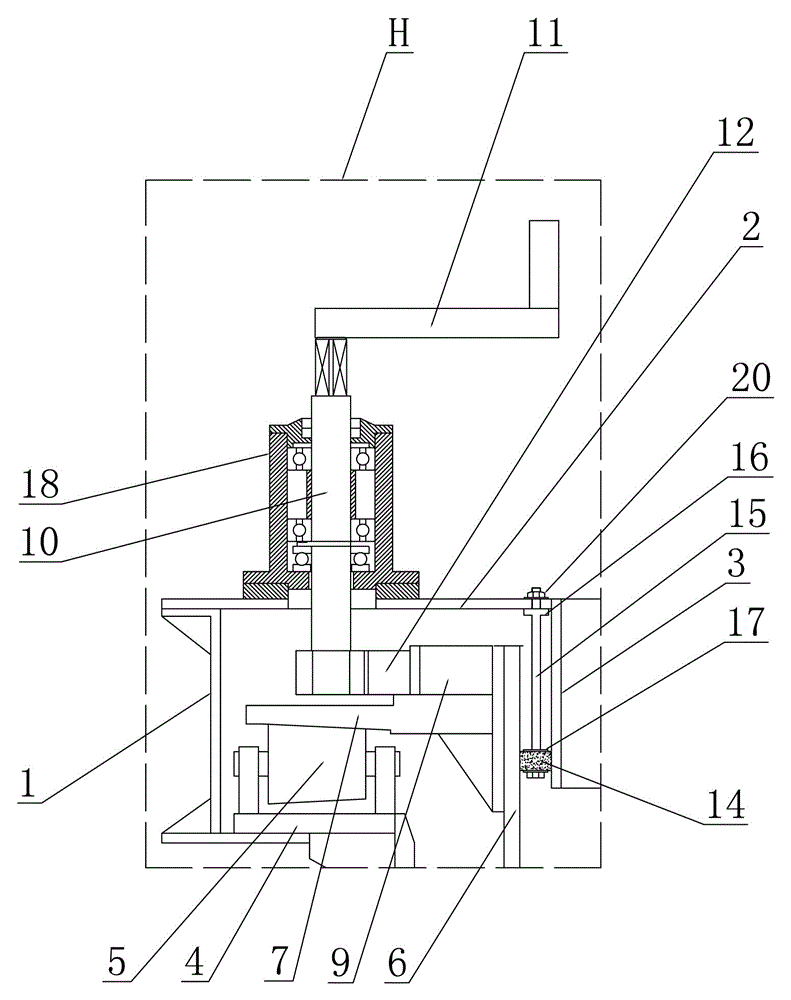

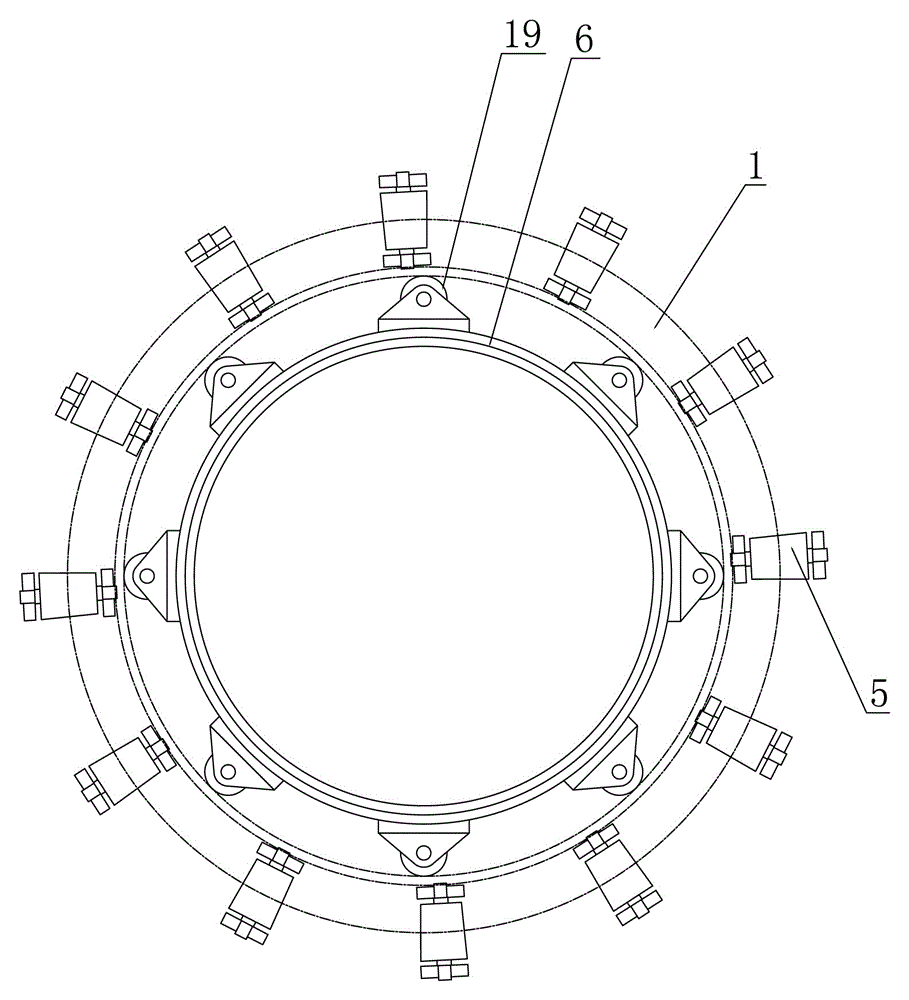

Vibrating drilling machine

InactiveCN108119063ANo pollution in the processNo disturbanceWithdrawing sample devicesVibration drillingProtruding shouldersSlide plate

The invention discloses a vibrating drilling machine which is arranged on a mast. The vibrating drilling machine comprises a box body, a spindle penetrating from top to bottom in the middle of the boxbody, two eccentric shafts, a sliding plate disposed on the periphery of the box body, and a buffer device connected between the sliding plate and the box body, wherein the two eccentric shafts are disposed in the box body in the horizontal direction and are symmetric with respect to the spindle. Each eccentric shaft is provided with an eccentric block, a protruding shoulder is formed at the middle of the spindle, the upper end of the spindle is connected with a rotating power head, the lower end of the spindle is connected with a drill rod and a sampler, the mast is provided with a sliding rail, and the sliding plate is disposed on the sliding rail. The vibrating drilling machine slides on the mast through a feeding oil cylinder and the sliding rail. The vibrating drilling machine can achieve effects of no pollution and no disturbance to the soil during sampling, and can also improve the drilling efficiency.

Owner:HUZHOU MAILONG MACHINERY CO LTD

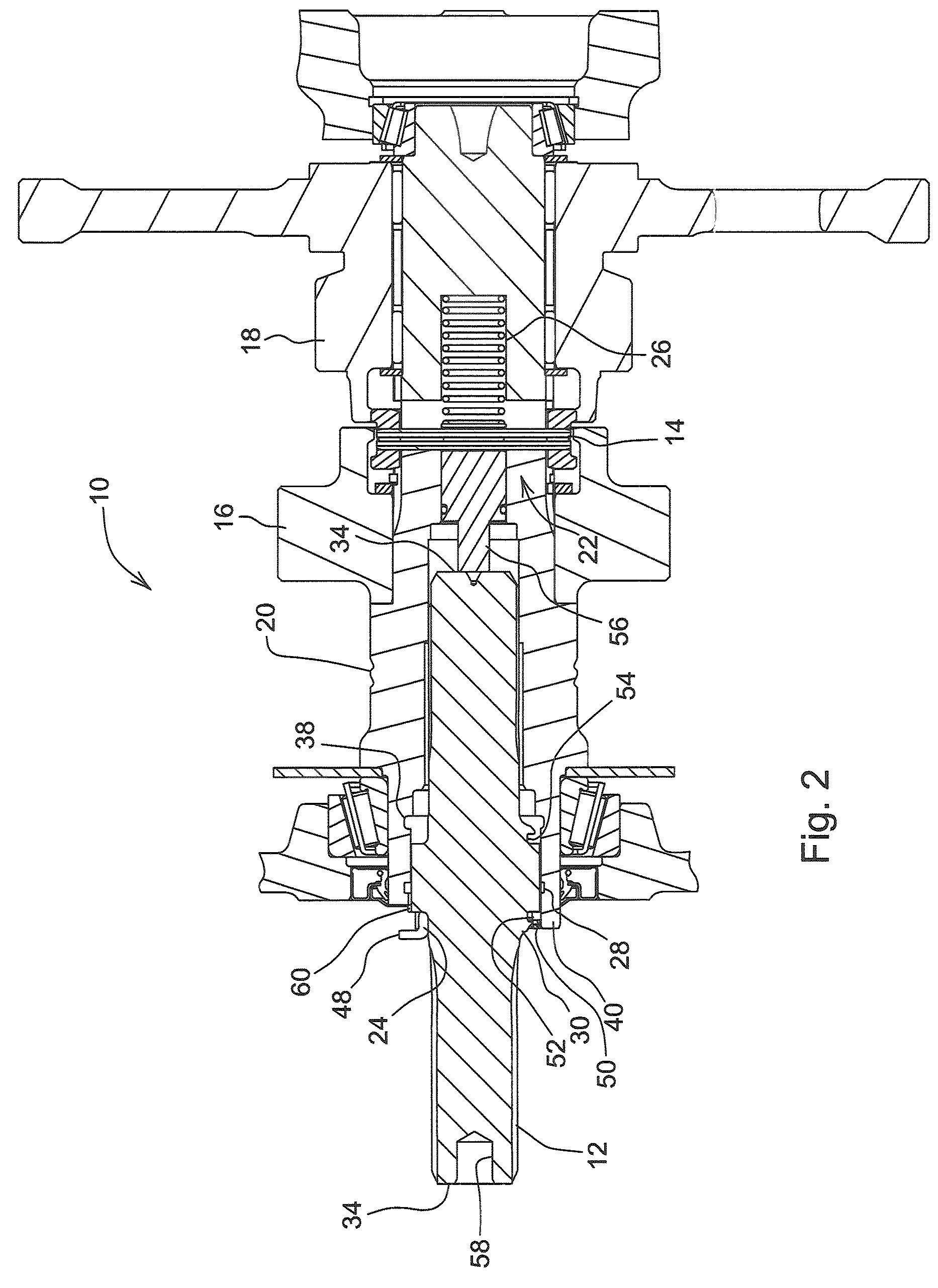

Two-speed PTO stub shaft exchange improvements

InactiveUS7874222B2Improve installationGood removal effectGearingInterengaging clutchesProtruding shouldersEngineering

A power take-off assembly for a work vehicle including an improved power take-off shaft for installation and removal. The power take off shaft is extended and a cut out section on the first end of the shaft is provided to engage an extended portion of a spring loaded mechanism. Once the cut out section securely fits over the extended portion, the spring loaded mechanism is prevented from axially moving in a rightward direction, thus enabling the spring to hold the gear collar in place to engage the high speed gear. The PTO stub shaft has an extended end with protruding shoulders which serve to capture the snap ring between the stub shaft and the output shaft so that when the stub is moved axially the shoulders will pull the snap ring into the groove on the output shaft which securely fastens the stub shaft. A cut-out section on the front end surface of the output shaft is also provided to allow clearance for the tool to squeeze the snap ring tabs during installation and removal.

Owner:DEERE & CO

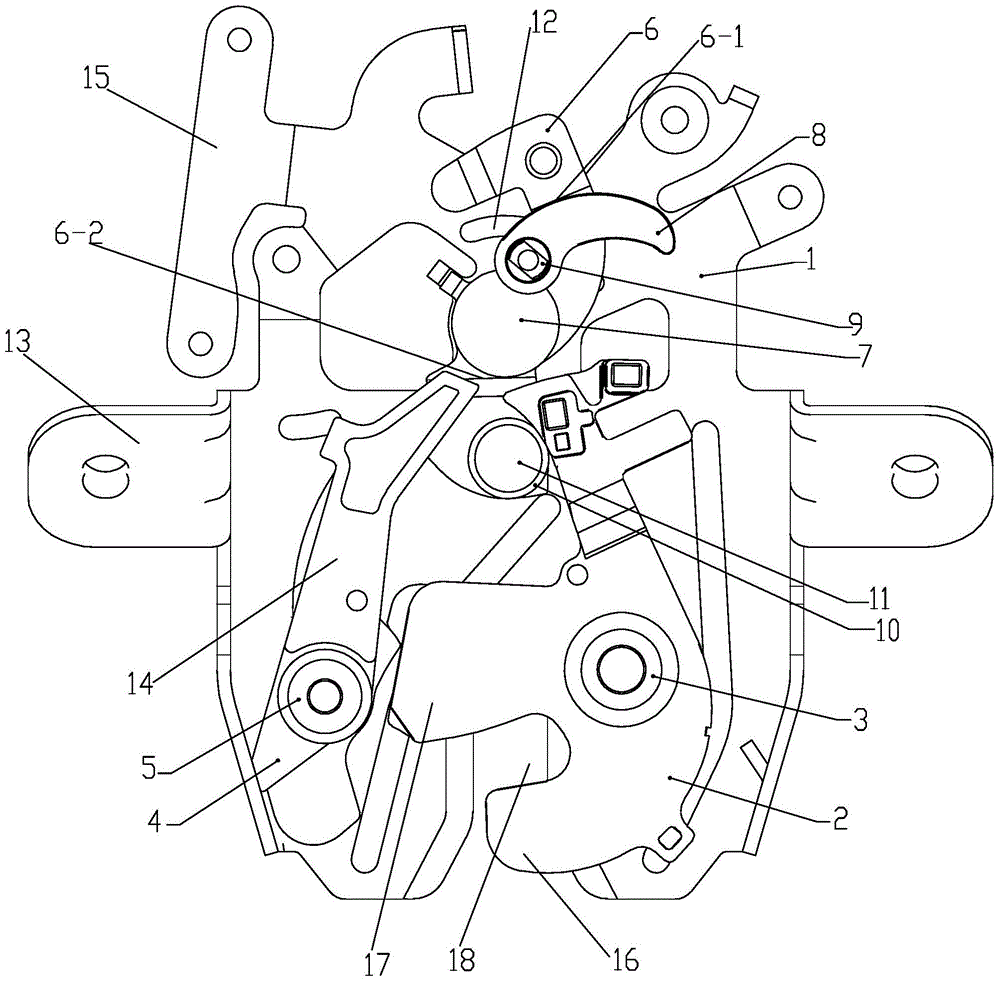

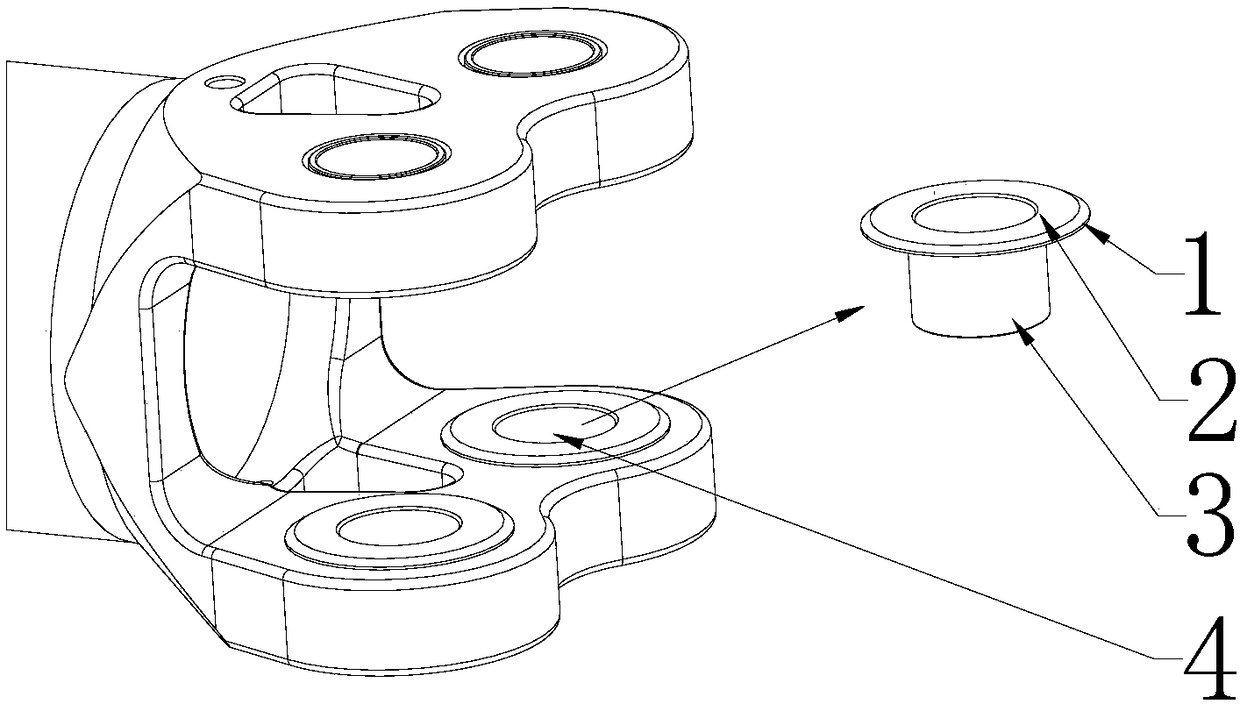

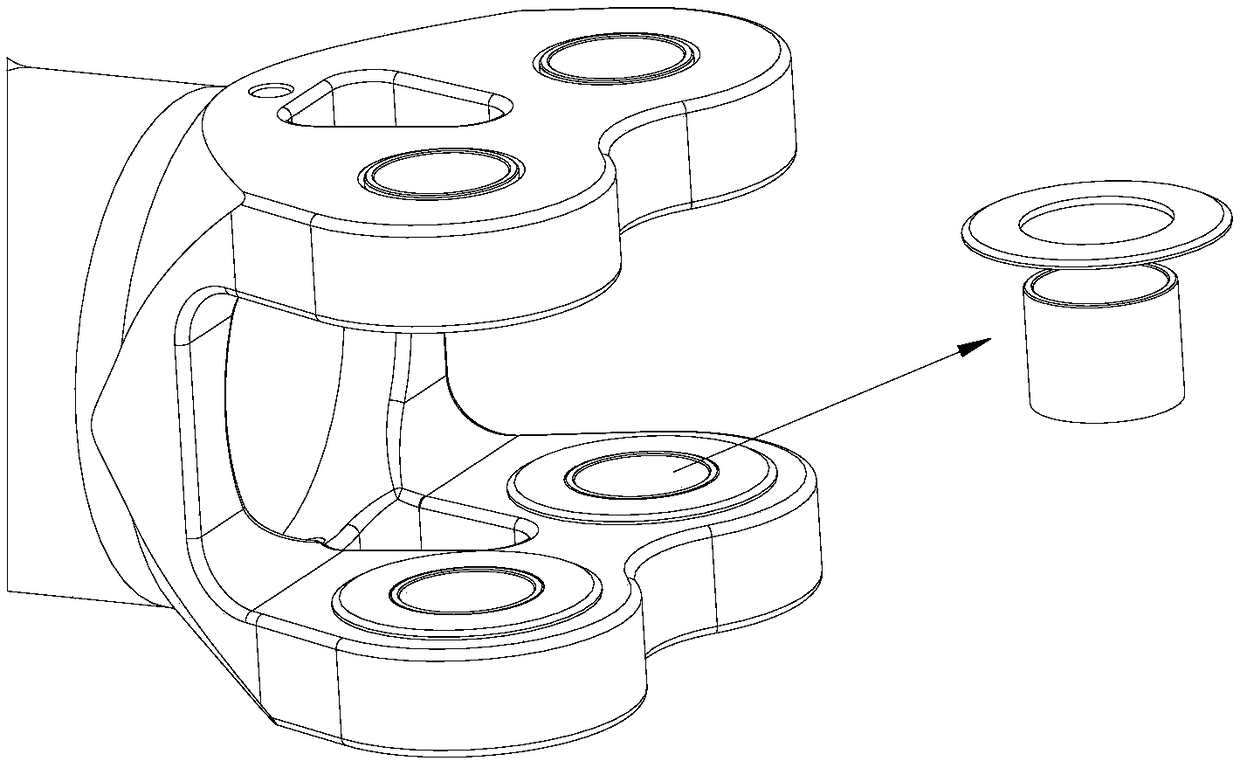

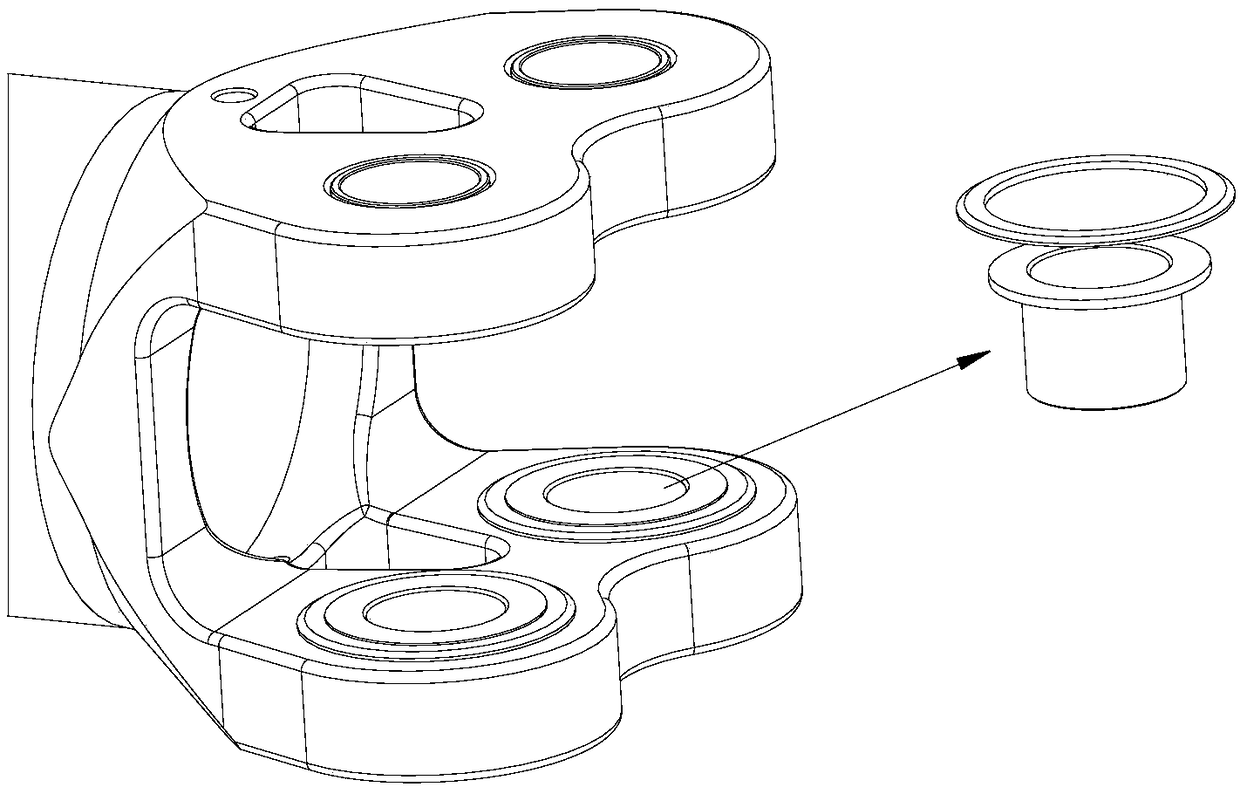

Transmission mechanism of self-suction tail door lock

ActiveCN104131747ASimple structureCompact structurePower transmission/actuator featuresElectrical locking actuatorsProtruding shouldersElectric machinery

The invention belongs to the field of automobile door lock systems, and particularly relates to a transmission mechanism of a self-suction tail door lock. The transmission mechanism of the self-suction tail door lock comprises a bottom plate, and a drive plate rivet shaft, a pawl rivet shaft and a ratchet wheel rivet shaft are formed on one side surface of the bottom plate. A drive plate is rotatably connected to the drive plate rivet shaft through a mounting hole formed in the end of the drive plate. An arc-shaped protrusion is arranged at the outer end, corresponding to the drive plate rivet shaft, of the bottom plate. A transmission rocker arm is rotatably connected to an external driving motor gear case through a transmission rocker arm shaft which is integrally connected at the end of the transmission rocker arm, and the outer side cambered surface of the transmission rocker arm abuts against a first protruding shoulder of the drive plate. A transmission gasket shaft is fixed on the inner side, corresponding to the drive plate rivet shaft, of the drive plate, and a transmission gasket is connected to the transmission gasket shaft in a rotating mode. The transmission mechanism of the self-suction tail door lock is simple and compact in structure, a connecting rod and cam structure is arranged on the bottom plate, driving force can be effectively lowered, the structure is simple, and the transmission efficiency and the transmission stability are greatly improved.

Owner:无锡忻润汽车安全系统有限公司

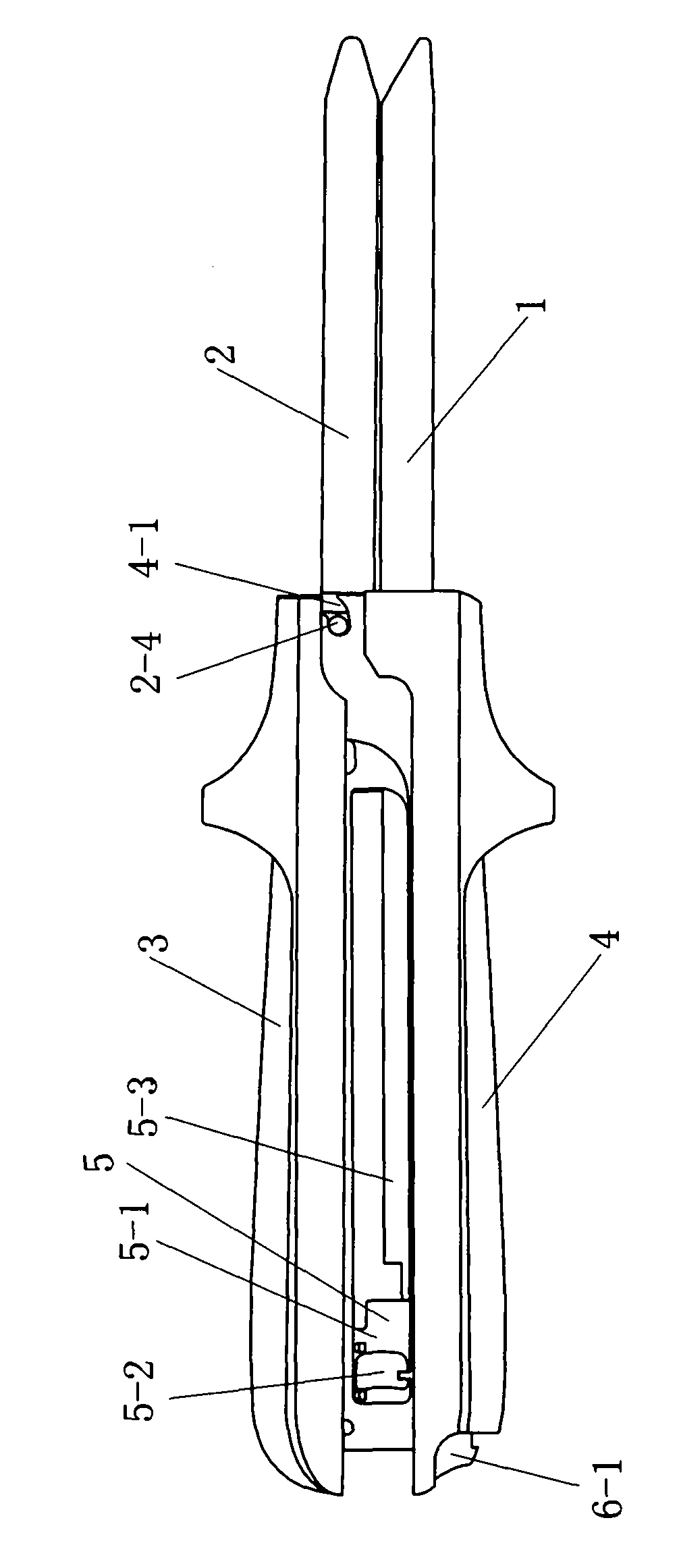

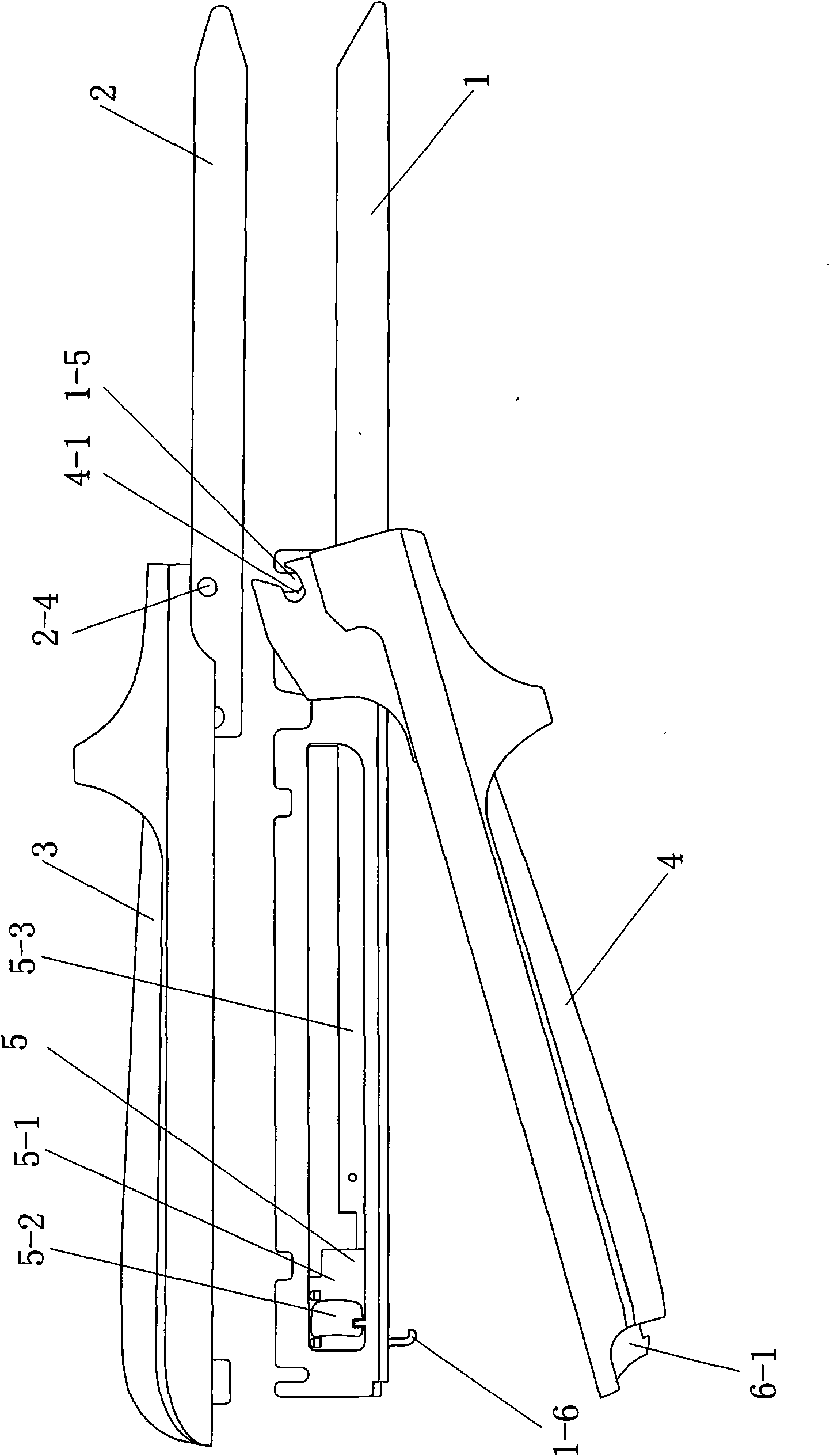

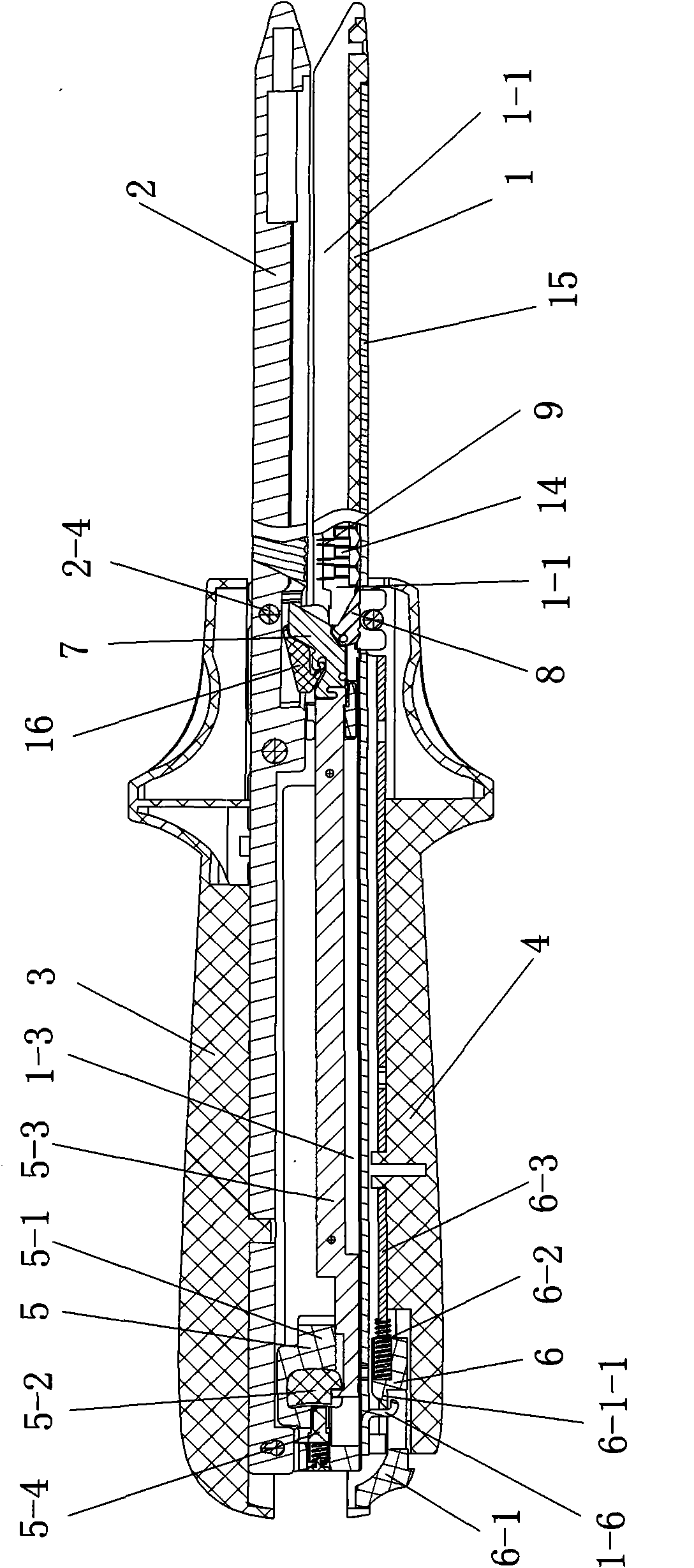

Linear type anastomat

ActiveCN101912287ALimit swingLimit left and right movementSurgical staplesProtruding shouldersEngineering

The invention discloses a linear type anastomat of a medical instrument. The linear type anastomat comprises a lower splint, a nail butting base, an upper handle, a lower handle, a percussion mechanism, an opening-closing mechanism and a cutting knife, wherein the upper handle is fixedly connected with the nail butting base; the lower handle is hinged with the nail butting base; the percussion mechanism is arranged on the lower splint and is matched with the lower splint in a slippage way; the opening-closing mechanism is arranged on the lower handle; the opening-closing mechanism can make the lower splint and the nail butting base mutually separated and closed; the head of the lower splint is provided with a nail bin; a nail pushing slice and a suture nail are arranged in the nail bin; the cutting knife is fixedly connected with the percussion mechanism and is matched with the lower splint in a slippage way; the nail pushing slice is fixedly connected with the percussion mechanism and is matched with the lower splint in a slippage way; the nail pushing slice can push out the suture nail in the nail bin; the percussion mechanism comprises a propelling block, a propelling handle, a propelling rod and a safety device; the lower splint is provided with two protruding shoulders; and a sliding groove is arranged between the two protruding shoulders. The linear type anastomat saves labor in the process of percussion, prevents the propelling handle from moving leftwards and rightwards and ensures smooth operations.

Owner:CHANGZHOU JIANRUIBAO MEDICAL DEVICES

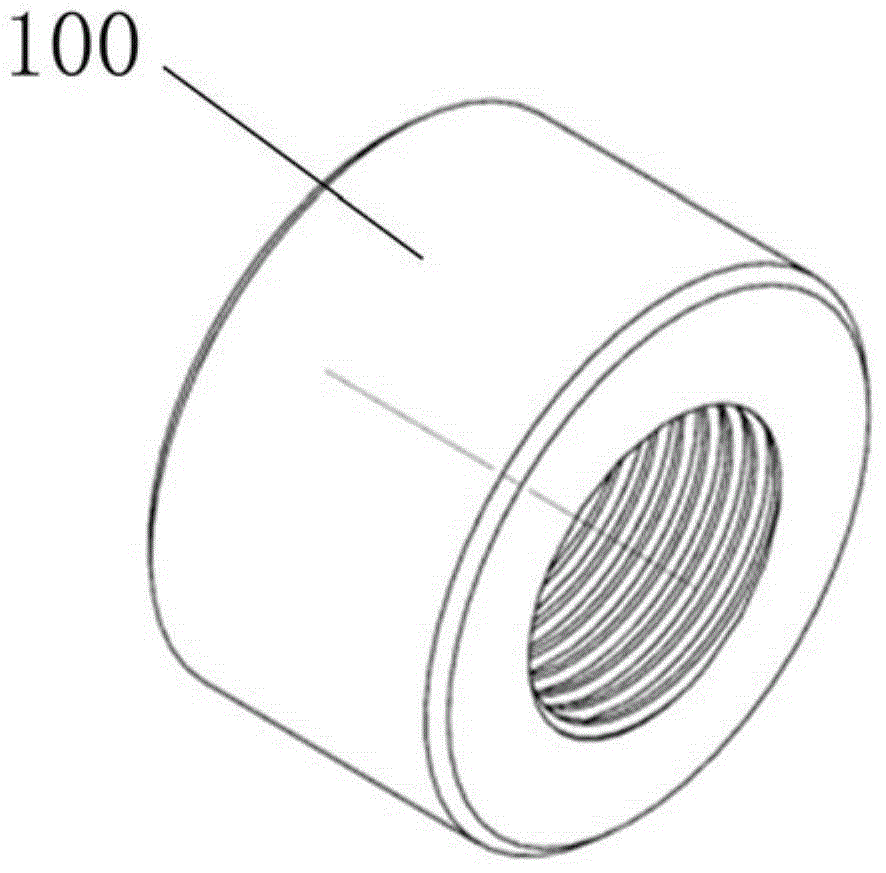

Locknut for rotor of gas turbine and machining methods of locknut

InactiveCN105275955APrevent self-rotationAchieve mechanical lockingNutsBoltsProtruding shouldersSelf locking

The invention belongs to the technical field of locknuts and discloses a locknut for a rotor of a gas turbine. The locknut comprises a recessed part arranged on the outer side face of a nut body, the distance between any point on the recessed part and the center of the nut body is smaller than the radius of the outer side face of the nut body, and the recessed part penetrates the whole nut body in the radial direction. Through the arrangement of the recessed part penetrating the whole nut body in the radial direction on the outer side of the nut body, the recessed part is matched with a protruding shoulder, and the locking function is achieved. The structure of an existing wheel disc is fully used, the structure is simple, assembly and disassembly are convenient, and the anti-looseness self-locking effect is good. The invention discloses two machining methods of the locknut. Multiple recessed parts can be machined at the same time through a tool rotary disc and linear cutting, and the recessed parts are not limited to the contour shape.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

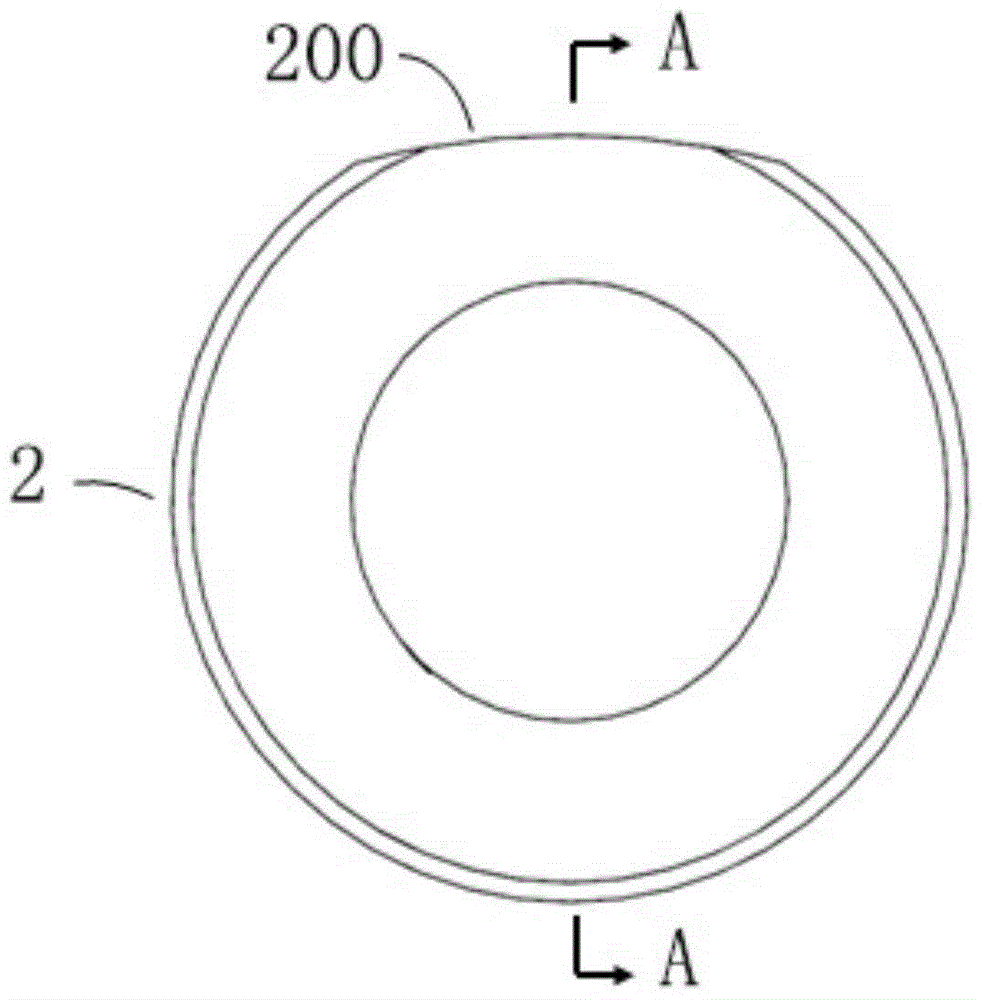

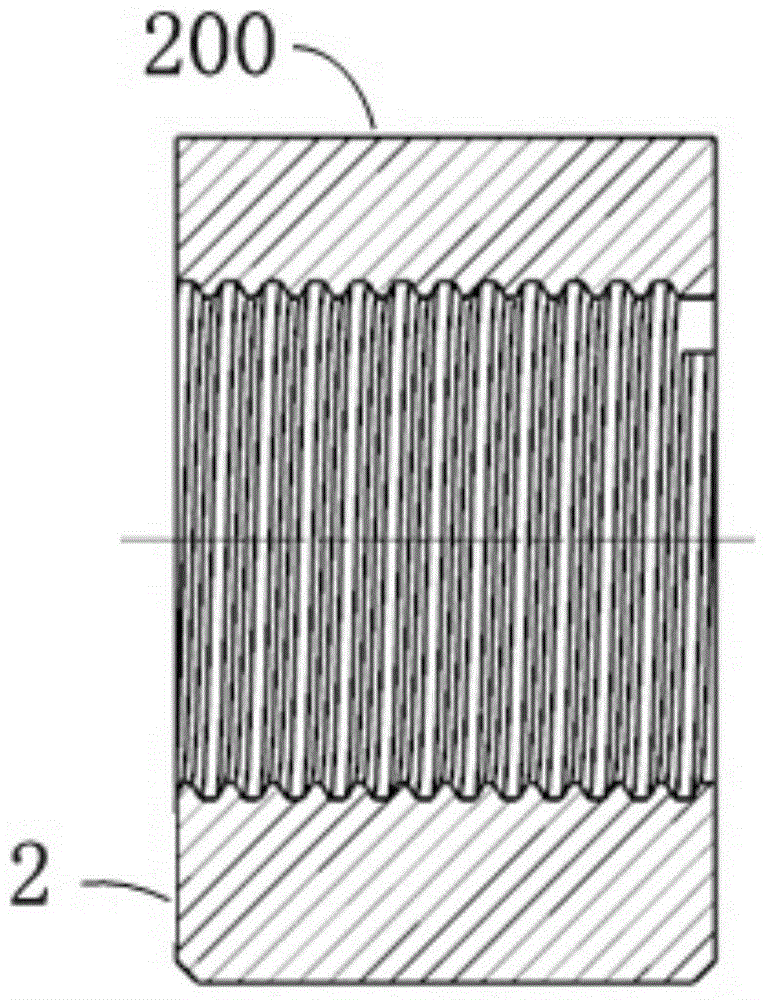

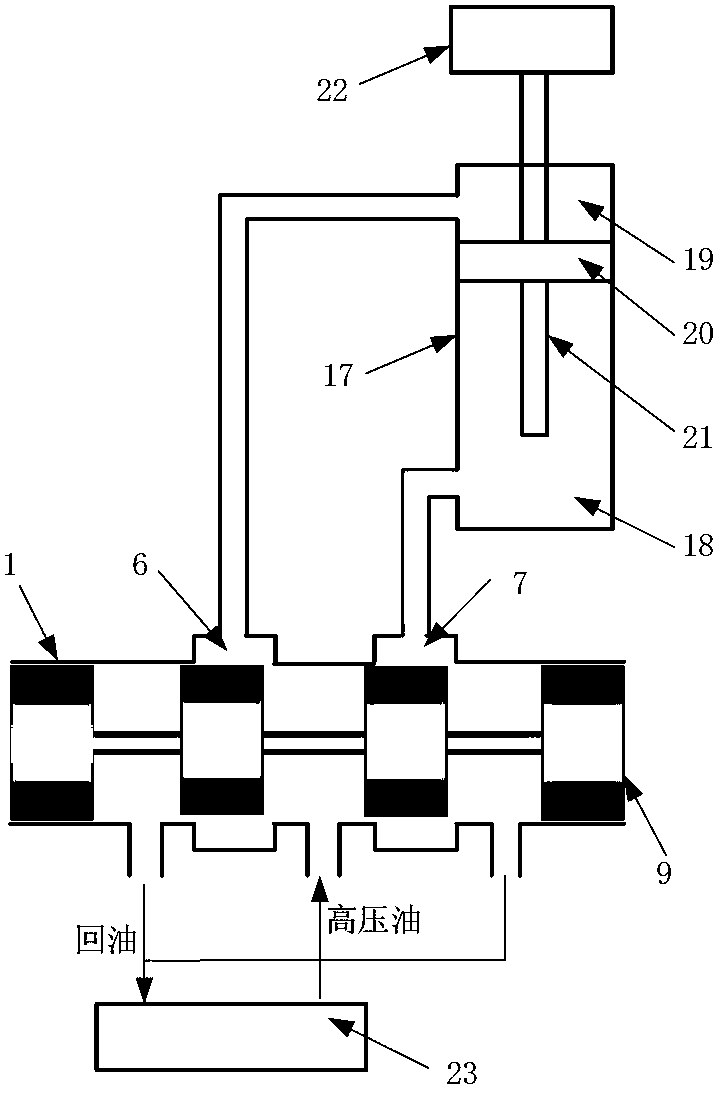

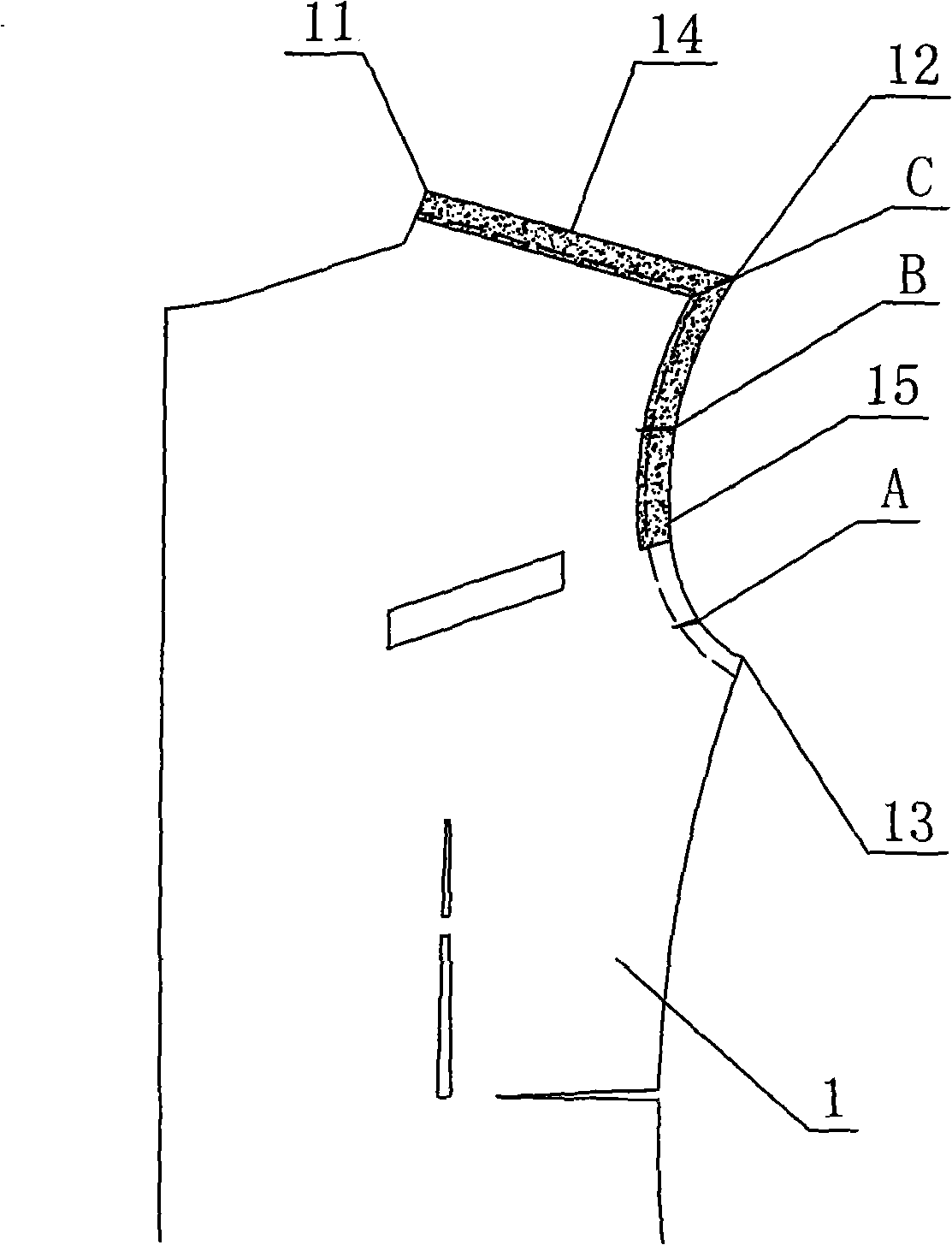

Energy-saving hydraulic valve with independently-controllable load throttle mouths and hydraulic valve control system

ActiveCN103133448AAchieve independent controlSave hydraulic energyServomotor componentsServomotorsProtruding shouldersControl system

The invention discloses an energy-saving hydraulic valve with independently-controllable load throttle mouths. A spool (9) of the hydraulic valve is provided with a displacement sensor (14). Two protruding shoulders (11 and 12) in the middle of the spool (9) and two load throttle mouths (6 and 7) satisfies the following conditions: when one of the protruding shoulder controls openness of one load throttle mouth, the other load throttle mouth is fully opened. No mutual interference occurs between the two load throttle mouths of the hydraulic valve, the two load throttle mouth can work independently, and energy-saving control of the hydraulic valve system is achieved.

Owner:北京海卓博尔科技有限公司

Limit mechanism of needle holder in retraction type safety syringe

ActiveCN104548283ACutting stabilityMedical devicesInfusion needlesProtruding shouldersSyringe needle

The invention provides a limit mechanism of a needle holder in a retraction type safety syringe, belongs to the technical field of medical apparatus and instruments, and solves the problem that the position of needle holder in an existing syringe is unstable. The limit mechanism comprises a first limit unit and a second limit unit, wherein the first limit unit is disposed between the syringe and the needle holder and used for limiting the needle holder from moving upwardly and the second limit unit is disposed between the syringe and the needle holder and used for limiting the needle holder from moving downwardly. A protruding shoulder is disposed on the inner lateral wall of the syringe. The lower side of the protruding shoulder is provided with a limit part which extends downwardly. The second limit unit comprises the limit part and an expansion part located in the syringe, wherein the expansion part is provided with an annular expansion portion, the expansion portion is located between the limit part and the lateral wall of the syringe and abutted against the limit part, and the limit part is bent inwardly and abutted against the needle holder. The limit mechanism has the advantages that the limit part which extends downwardly is disposed on the lateral wall of the syringe, so that the needle holder is stably limited in the syringe under the action of the expansion part.

Owner:湖北科莱德医疗器械有限公司

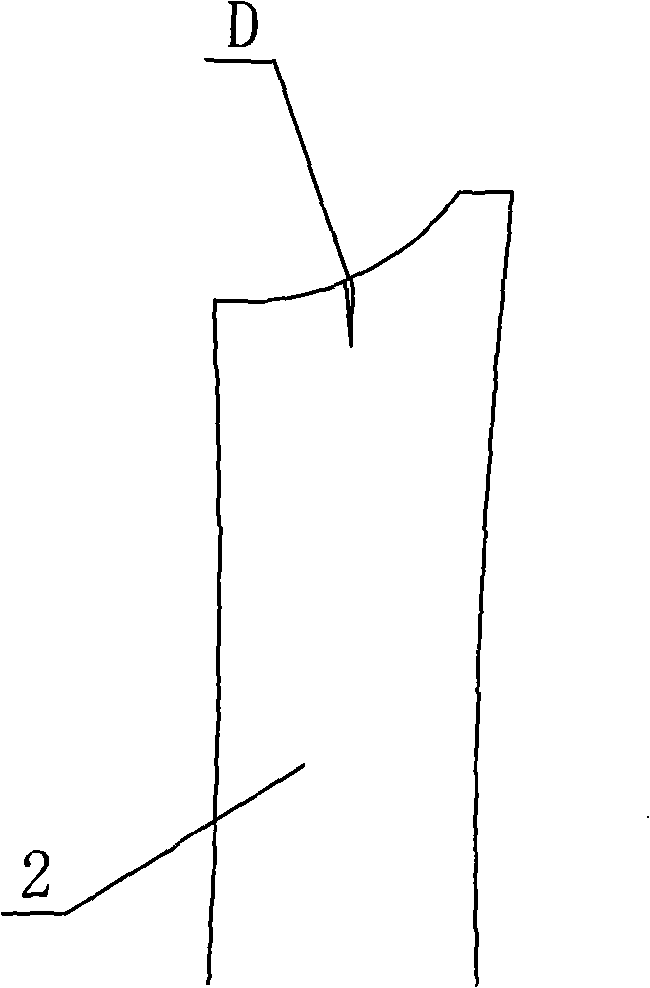

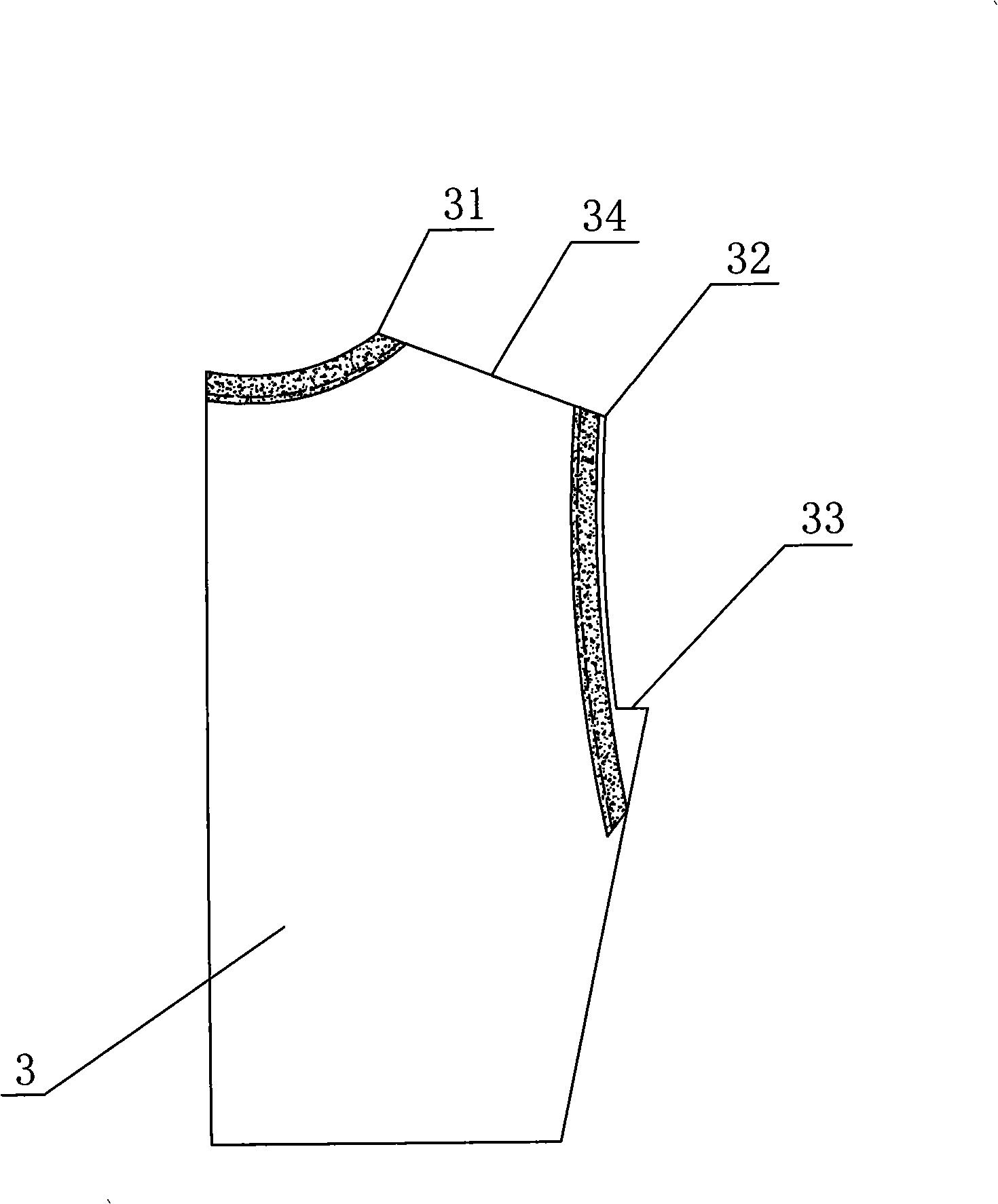

Method for processing uniforms without shoulder pad

InactiveCN101401667AEasy to stretchBody-fitting shoulder widthClothes making applicancesShoulder widthProtruding shoulders

The invention discloses a method for processing shoulder pad free Western style suit, which is characterized in that: firstly, a front piece, side pieces and a back pieces of the processed Western style suit to be processed are designed and tailored according to specific size, and shoulder oblique lines of the front piece and the back piece are smoothly sewed; front muffs are provided with shoulder-shaped moulds positioned on a binding wire vehicle, and knife holes of a chest lining and the front muffs are aligned and tightly bound; from edge jointed knife holes of the side pieces to second knife holes of the front muffs, lines are tightly bound in the inner part; the shoulder collar extension raw seam of the front piece is leveled with the knife holes of the chest lining, and is positioned on the part which is 0.2 to 0.3 cm below the low point of the front shoulder oblique lines, so that the inside-outside circular front protruding shoulder size is made, and the part which is 1.5 to 2.5 cm below the low point of the front shoulder oblique lines is flatly placed on the binding wire vehicle so as to make the protruding shoulders; and finally, the chest lining and the muffs are processed. For the Western style suit made by the processing method, the shoulder pads in the prior Western style suit are removed, the shoulder width of the Western style suit more fits the human body, a user wearing the Western style suit feels light and comfortable and does not have oppressing sensation; because the resistance is reduced, arms of the user can be extended more easily; moreover, the shoulder part of the Western style suit is still smooth and straight.

Owner:NINGBO YOUNGOR YINGCHENG UNIFORM

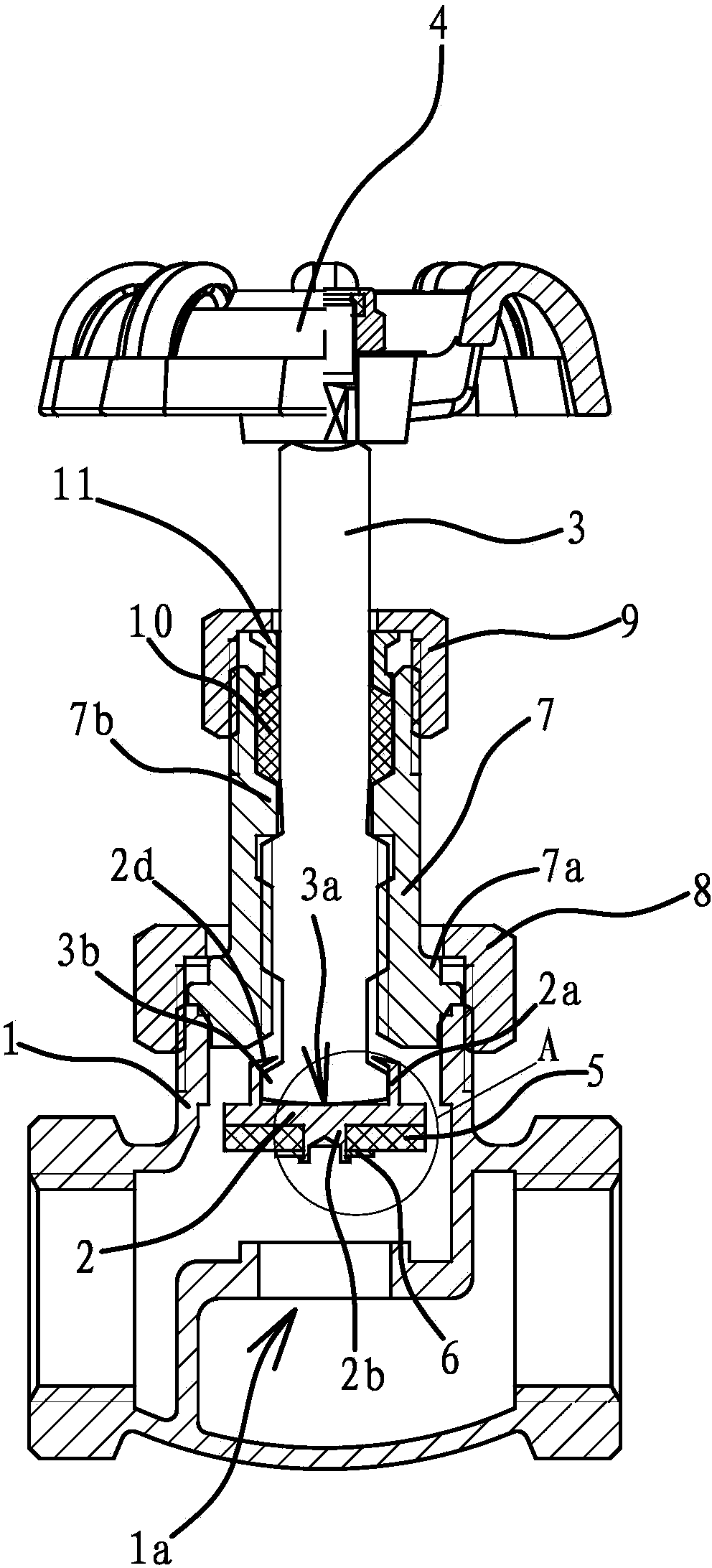

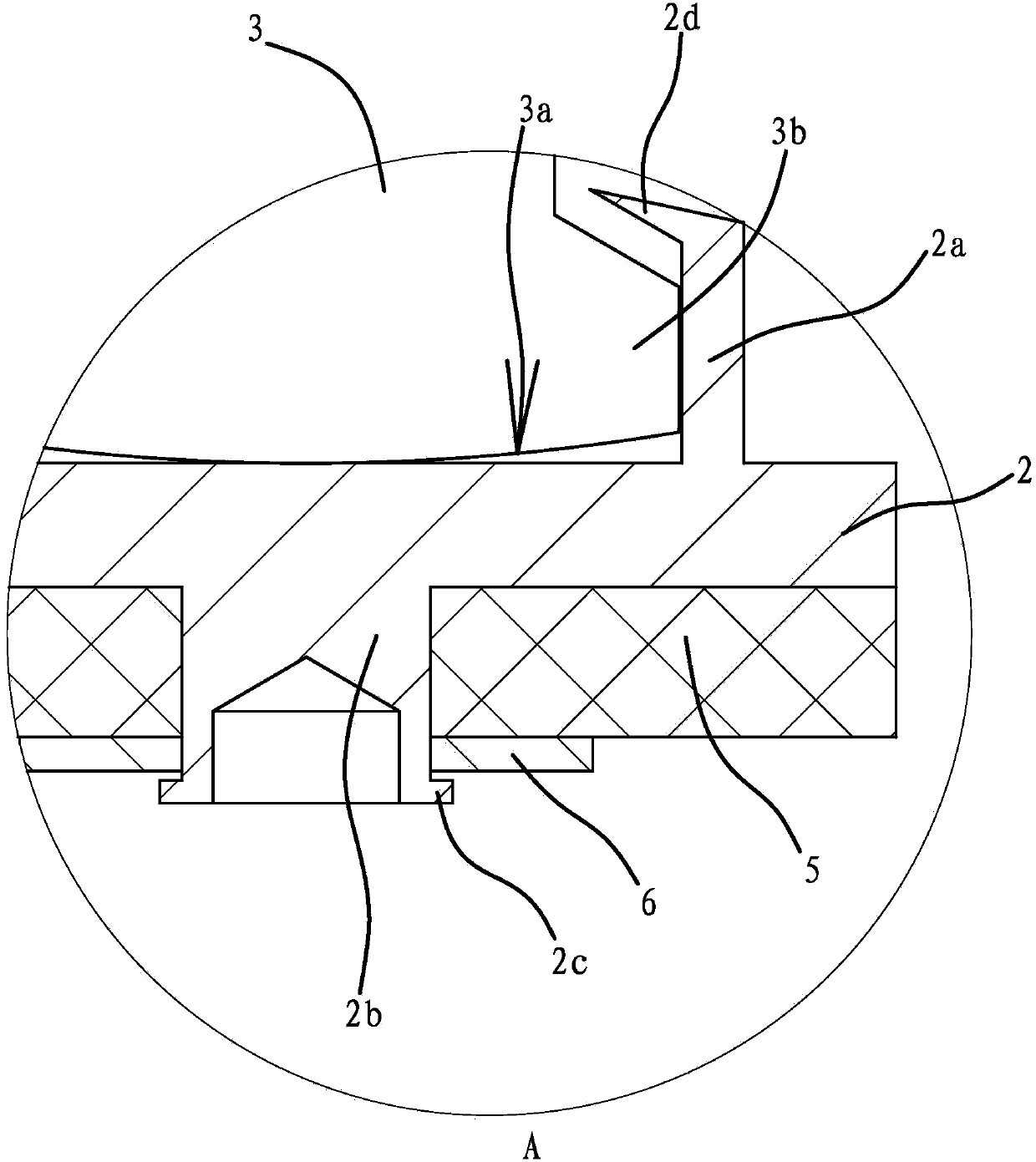

Stop valve

ActiveCN104006168AFirmly connectedImprove production efficiencySpindle sealingsLift valveProtruding shouldersEngineering

The invention provides a step valve, and belongs to the technical field of valves. The problem that connection between a valve rod and a valve clack of an existing stop valve is not firm enough is solved. The stop valve comprises a valve body, a valve clack and a valve rod, wherein the outer end of the valve rod extends out of the valve body and is connected with a handle, the valve clack is of a sheet shape, the inner end of the valve rod is provided with a protruding shoulder, the upper side face of the valve clack is provided with a protruding cylindrical connecting portion, the protruding shoulder is located in the connecting portion, the upper end of the connecting portion is provided with a bent portion which is bent inwards, the bent portion can abut against the upper end face of the protruding shoulder, and a sealing gasket is positioned on the lower side of the valve clack. The stop valve has the advantage that connection between the valve rod and the valve clack is firm.

Owner:ZHEJIANG DABLIN VALVE CO LTD

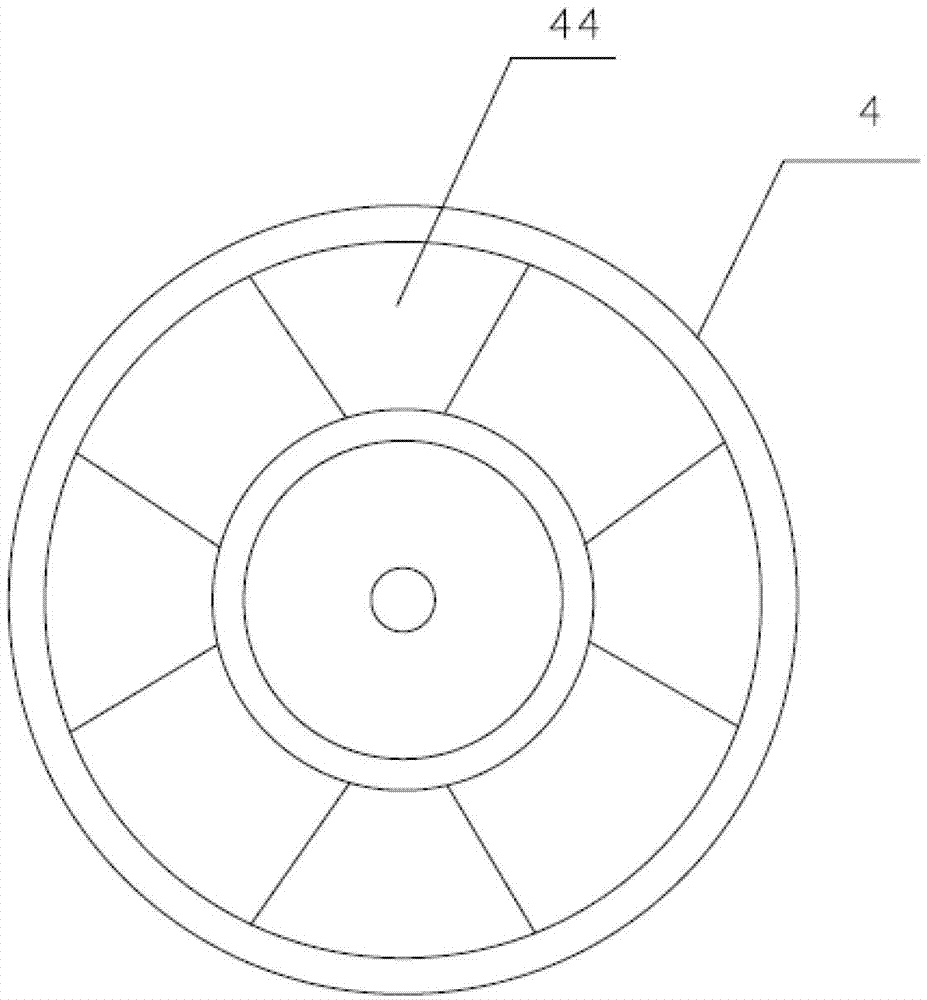

Feeding device of converter rotating chute

ActiveCN104988276AAvoid enteringAvoid stuck phenomenonManufacturing convertersProtruding shouldersArchitectural engineering

The invention discloses a feeding device of a converter rotating chute. The feeding device comprises an outer fixing cylinder with the top provided with an installation plate. A feeding port of the center of the installation plate is provided with an inner fixing cylinder, and an annular fixing seat is arranged on the inner wall of the outer fixing cylinder. The annular fixing seat is provided with a plurality of supporting rollers, and a supporting platform is formed by the supporting rollers. A rotating cylinder is arranged between the outer fixing cylinder and the inner fixing cylinder in a sleeved mode. The outer wall of the rotating cylinder is provided with an annular protruding shoulder, the bottom of the rotating cylinder is provided with the rotating chute, and the rotating cylinder is arranged on the supporting platform through the annular protruding shoulder of the rotating cylinder to be supported in the outer fixing cylinder. The bottom gap of the rotating cylinder and the outer fixing cylinder is sealed through an annular sealing plate. The outer wall of the rotating cylinder is provided with a gear ring, the installation plate is provided with a rotating shaft, the upper end of the rotating shaft is provided with a handle, the lower end of the rotating shaft is provided with a transmission gear meshed with the gear ring, and an annular high-temperature-resistance sealing piece is arranged between the rotating cylinder and the inner fixing cylinder. The annular high-temperature-resistance sealing piece is sealed and fixed between the rotating cylinder and the inner fixing cylinder through a detachable fixing mechanism. The feeding device has the advantage of being good in sealing performance.

Owner:JIANGSU YONGGANG GROUP CO LTD

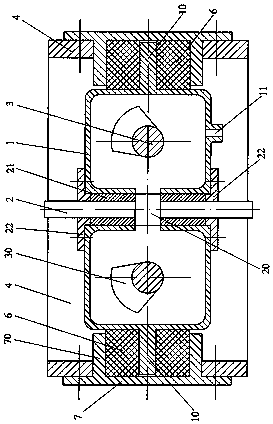

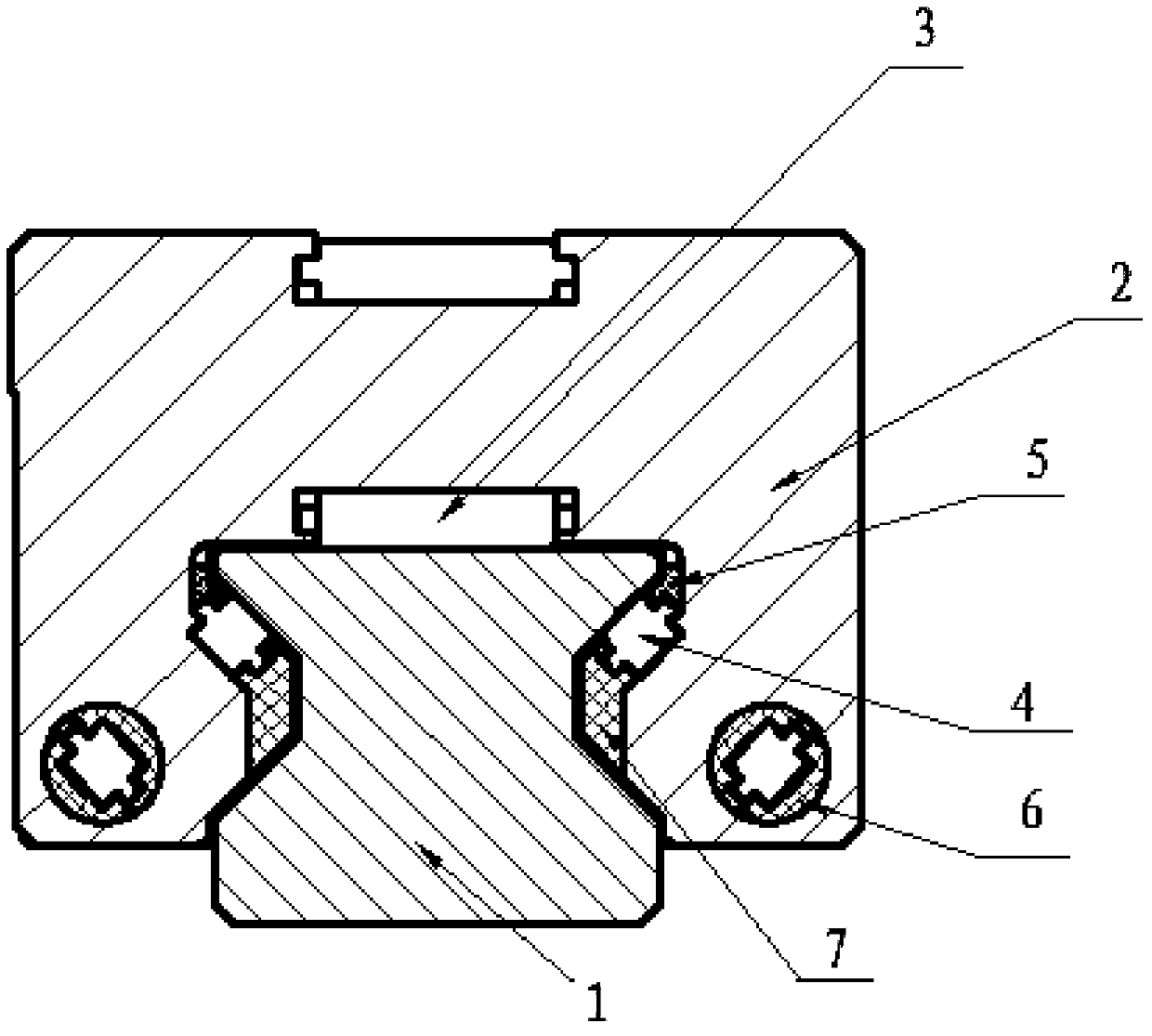

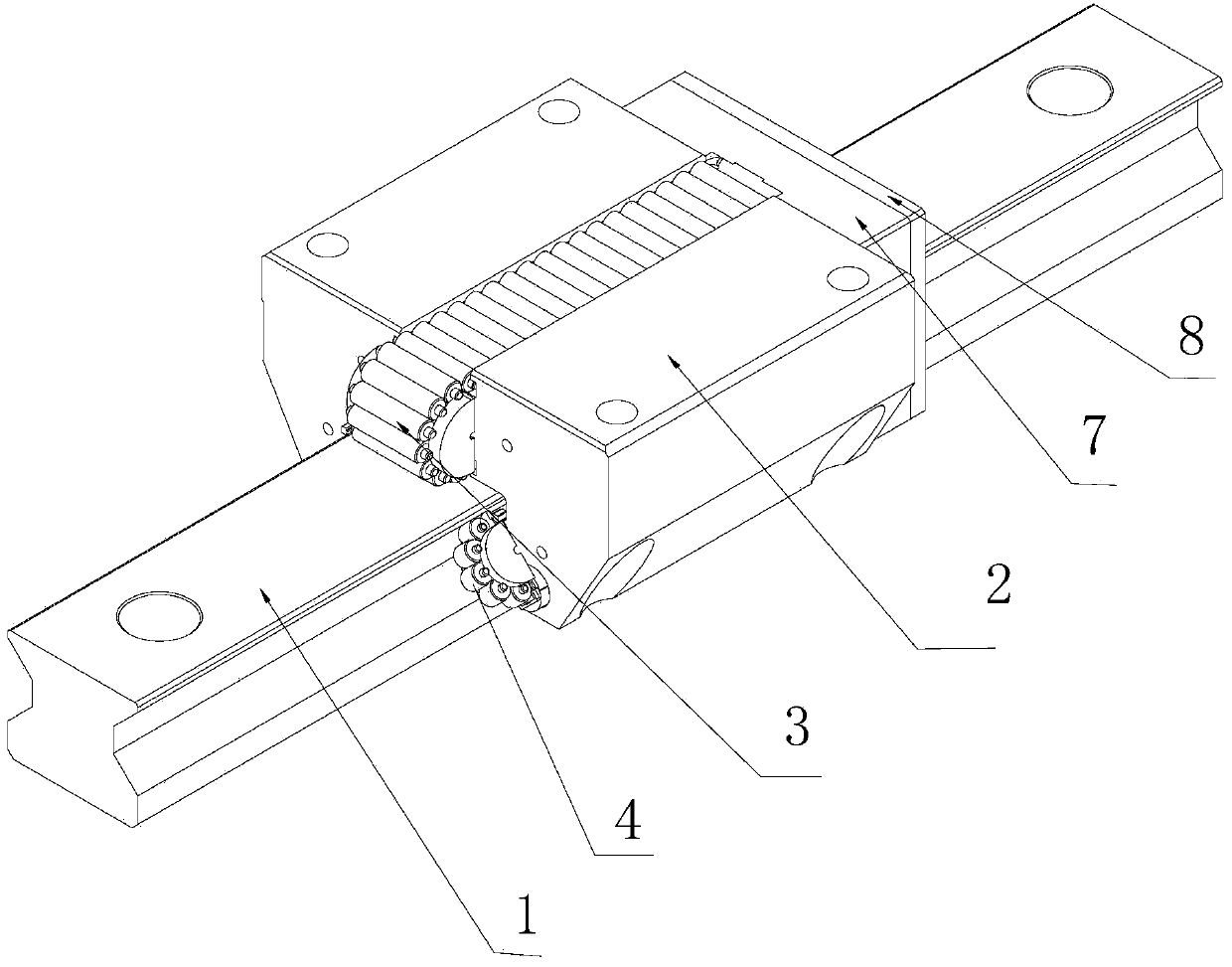

Radial heavy load type roller linear guide rail pair

InactiveCN103433754AIncrease contact stiffnessReduce wearLarge fixed membersProtruding shouldersHeavy load

The invention belongs to the technical field of linear guide rail pairs, and particularly relates to a radial heavy load type roller linear guide rail pair. The radial heavy load type roller linear guide rail pair comprises a guide rail and a sliding base. The upper portion of the sliding base is provided with a row of a roller guide groove and a row of an upper roller path, and two rows of lateral roller paths are symmetrically arranged on the two sides of the sliding base; rollers bearing radial pressure loads are arranged in the upper roller path, rollers bearing lateral pressure loads are arranged in the lateral roller paths through retainers, each roller is a circular cylinder with protruding shoulders at the two ends, and the rollers are in linear contact with the roller path face of the upper roller path and the roller path faces of the lateral roller paths. The rollers stably move in the roller paths and can bear acting force in all directions, abrasion of contact surfaces of the rollers and the roller paths is low, and thus the service life of the radial heavy load type roller linear guide rail pair is long. Compared with a traditional product, contact rigidity of the radial heavy load type roller linear guide rail pair is increased to about 5 times, and bearing capacity is increased to about 10 times.

Owner:TIANJIN TAIRUI BEARING TECH DEV

Structure and assembling technology of propeller blade connecting joint

InactiveCN108069031AMeet the requirements of force transmissionPrevent slippingAircraft assemblyRotocraftProtruding shouldersPropeller

The invention belongs to the technical field of structural design and assembling technologies of main propeller hubs of helicopters, and particularly relates to a structure and assembling technology of a propeller blade connecting joint. At present, one structure is to assemble and mount a lining with a large protruding shoulder into a hole through the temperature difference, the other structure is to assemble and mount a straight lining into the hole through the temperature difference, and then a large gasket is bonded to the hole end face through an adhesive agent. The linings of the two connecting joints adopt the mode of temperature difference assembly, initial damage of the inner surface of the hole has uncertainty, binding force of the hole and the lining is small, and the hole and the lining are prone to generating fretting wear after the hole is subjected to force. According to the structure of the propeller blade connecting joint, a lining is mounted in a connecting hole, thelining is provided with a protruding shoulder, the lining is mounted in the connecting hole through a secondary extruding strengthening method, the lining is used for transmitting the force, and the width of the protruding shoulder of the lining is smaller than 10 mm; and a guiding gasket is arranged on the periphery of the protruding shoulder, the easily occurred problem of sliding of the liningcan be avoided, and meanwhile, the problem of upwarp by excessively extruding strengthening assembly of the protruding shoulder is solved.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

Rotary clutch

InactiveCN101013634ANot easy to damageImprove adaptabilitySwitch power arrangementsHigh-tension/heavy-dress switchesProtruding shouldersGear wheel

The invention discloses one rotation clutch, which comprises small gear and main axis and large gear, wherein, the main axis matches large gear and the large gear meshes with small one. The actions comprise the following steps: large gear end is fixed with top block and torque bolt; the main axis relative to top block is fixed with protruding cover to process protruding shoulder and top block; the main axis is fixed with protruding wheel and one pulling memory spring arm; the side board is set with memory and clutch automatic protection block part.

Owner:冯保明 +2

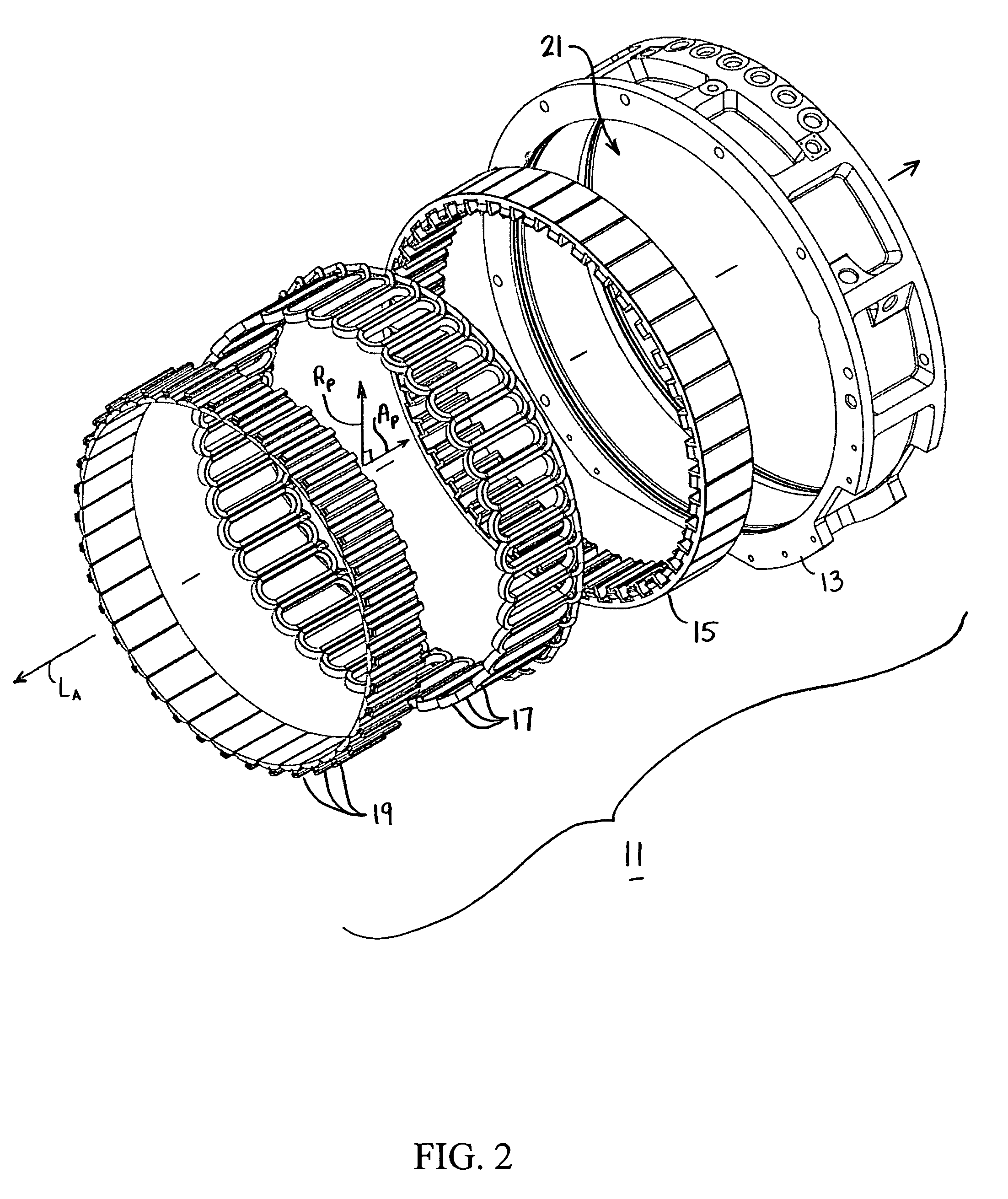

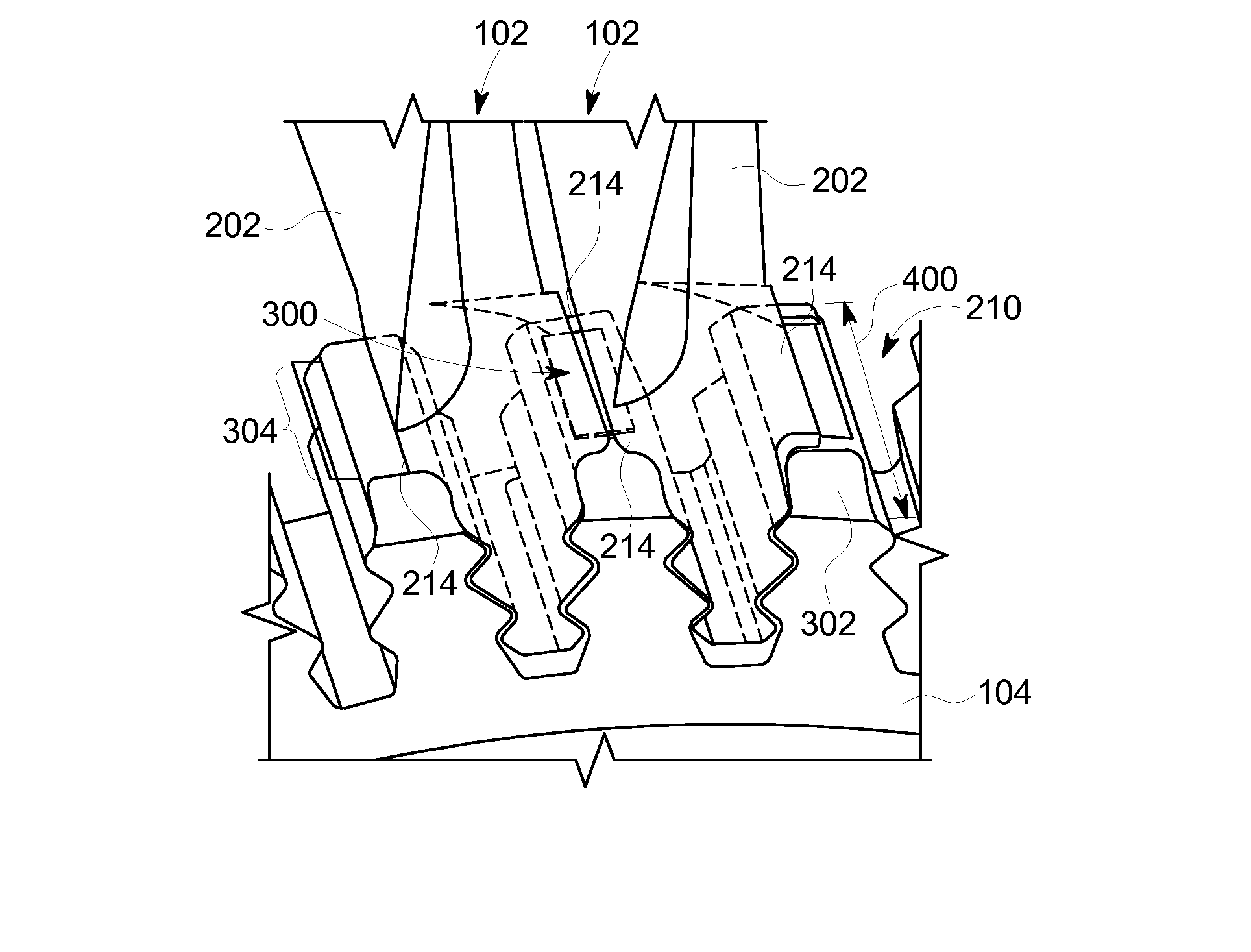

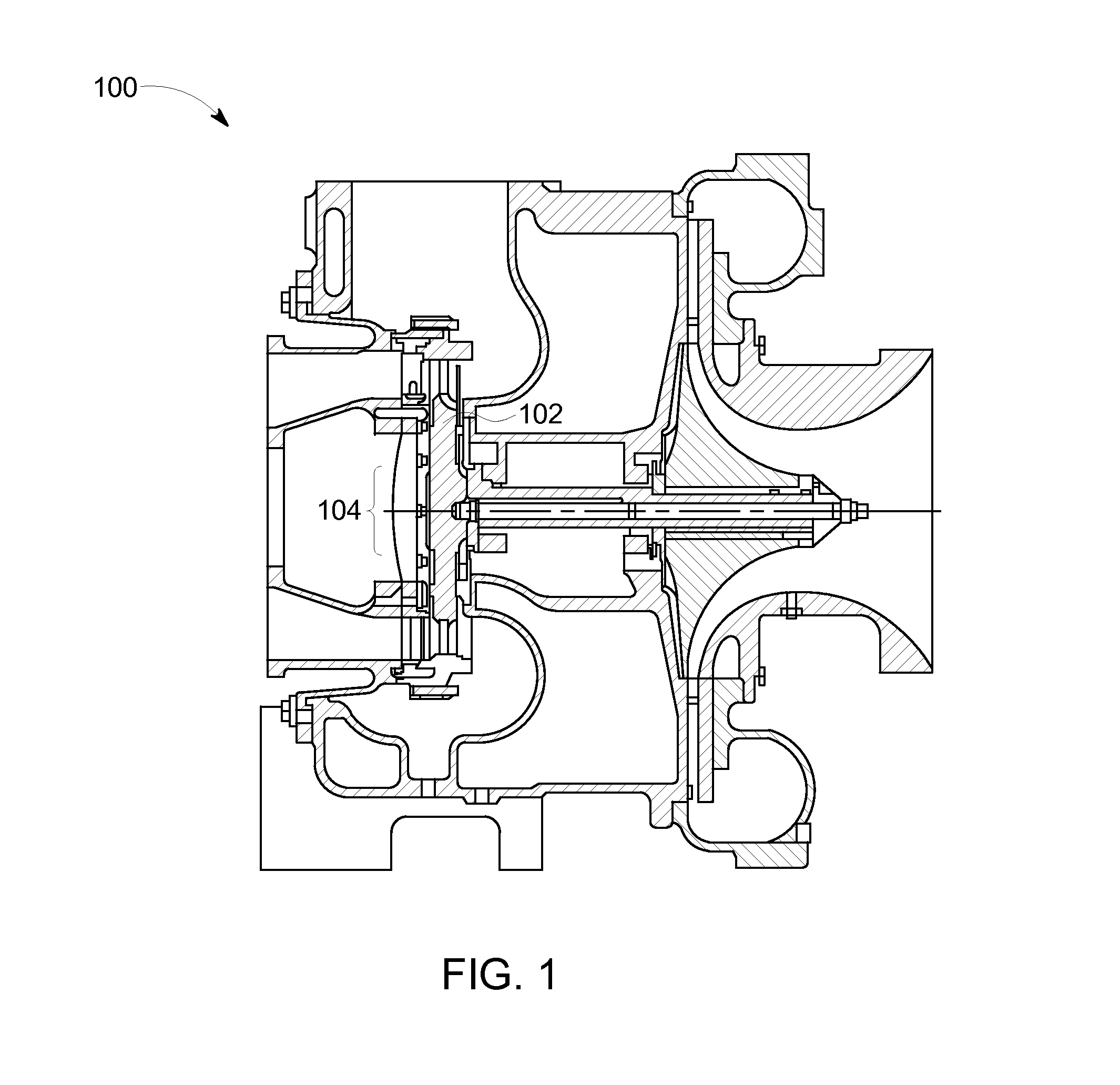

Underplatform damping members and methods for turbocharger assemblies

ActiveUS20170037734A1Reduce vibrationInternal combustion piston enginesEngine fuctionsProtruding shouldersTurbocharger

Damping members for turbocharger assemblies, methods for providing turbocharger assemblies, and turbocharger assemblies are described herein. The damping members include bodies having shapes to fit between a recess extending into a rotor disk of a turbocharger and laterally protruding shoulders of platforms in neighboring blades of the turbocharger. The bodies dampen vibrations of the blades during rotation of the blades. The damping members may include a variety of shapes, such as a sheet, a wedge, a tapered pin, a cylindrical pin, a bent sheet, or another shape.

Owner:GE GLOBAL SOURCING LLC

Structure for connecting valve body with connector in steam heat valve

ActiveCN104061383AConnect smoothlySmooth connectionJoints with sealing surfacesValve housingsProtruding shouldersEngineering

The invention provides a structure for connecting a valve body with a connector in a steam heat valve, and belongs to the technical field of valves, wherein the structure solves the problem that insertion bending easily occurs when a movable connector and a valve body of an existing steam heat valve are connected. According to the structure, a cavity is formed inside the valve body, the valve body is provided with a connecting end communicated with the cavity, the structure comprises a connector inner end, a locking nut and an annular groove formed in the end face of the connecting end, the connector inner end is cylindrical, the connector inner end is inserted into the annular groove, the inner side of the locking nut is provided with a protruding blocking edge, the locking nut is connected with the connecting end in a threaded mode, the outer side of a connector outer end is provided with an annular protruding shoulder, and the blocking edge abuts against the annular protruding shoulder so that the connector inner end can be fixed in the annular groove in a sealed mode. The structure for connecting the valve body with the connector in the steam heat valve has the advantage that the connector can be stably inserted into the valve body.

Owner:玉环大众气动工具有限公司

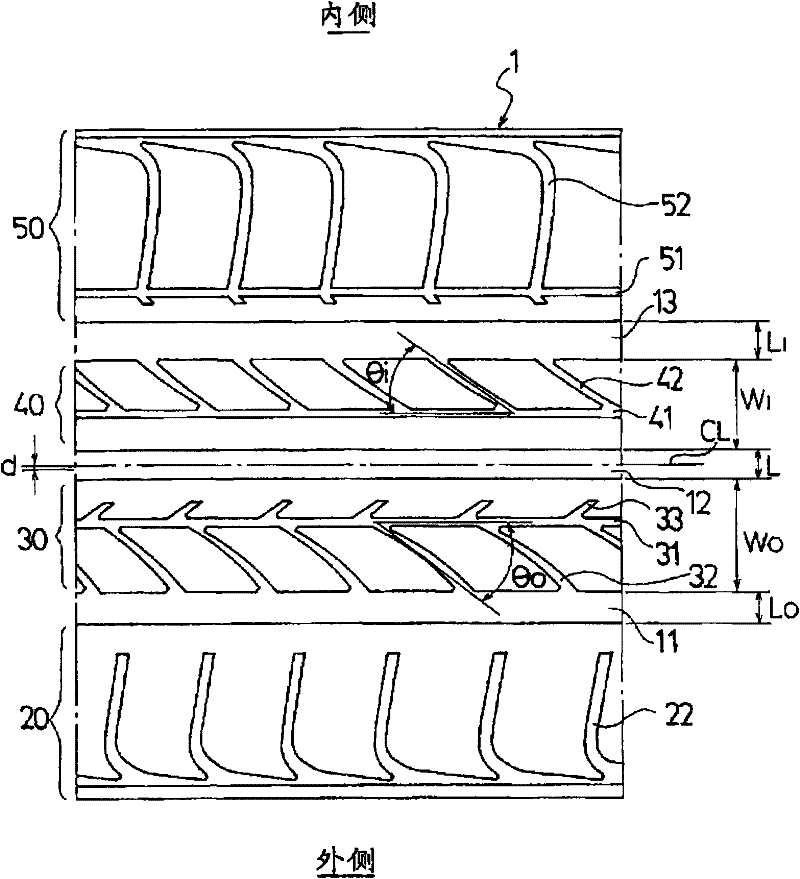

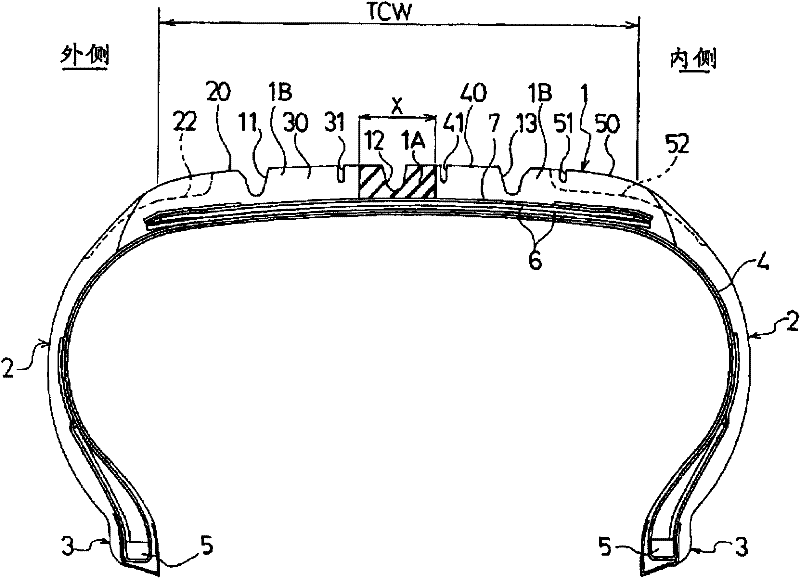

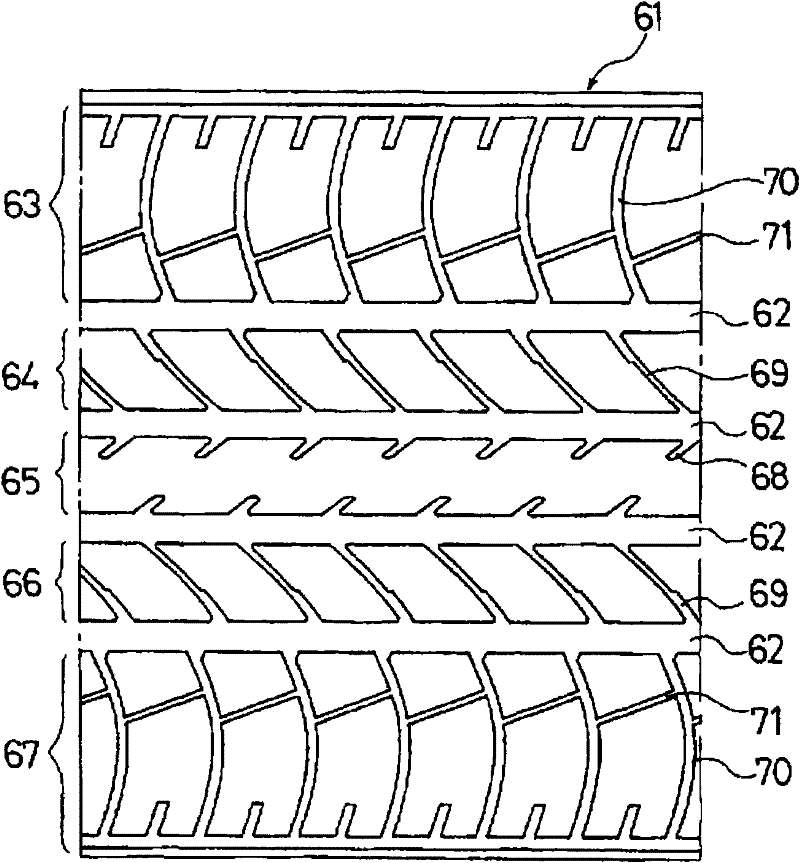

Pneumatic tire

InactiveCN102049977AReduce noiseImprove and reduce effectTyre tread bands/patternsProtruding shouldersEngineering

The invention discloses a pneumatic tire, wherein the inner and outer installation direction of the tire is assigned when installed on a vehicle.The tire is equipped with three main grooves (11-13) running into a running surface section (1) in a tire circumferential direction.The central position of the central main groove (12) is configured to offset outward from the tire equator (CL).The main grooves (11-13) divide the running surface section into four protruding shoulder surface sections (20-50) and two middle protruding surface sections (30, 40). Angled grooves (32, 42) run from narrow grooves (31, 41, 51) to an outer side in a tire width direction. Lug grooves (22, 52) run into the shoulder surface sections (20, 50) in the width direction and are not connected to the main grooves (11, 13), where the shoulder surface sections are located on shoulder sides of the running surface section.

Owner:YOKOHAMA RUBBER CO LTD

One-way valve

Owner:闽侯福怡塑料制品有限公司

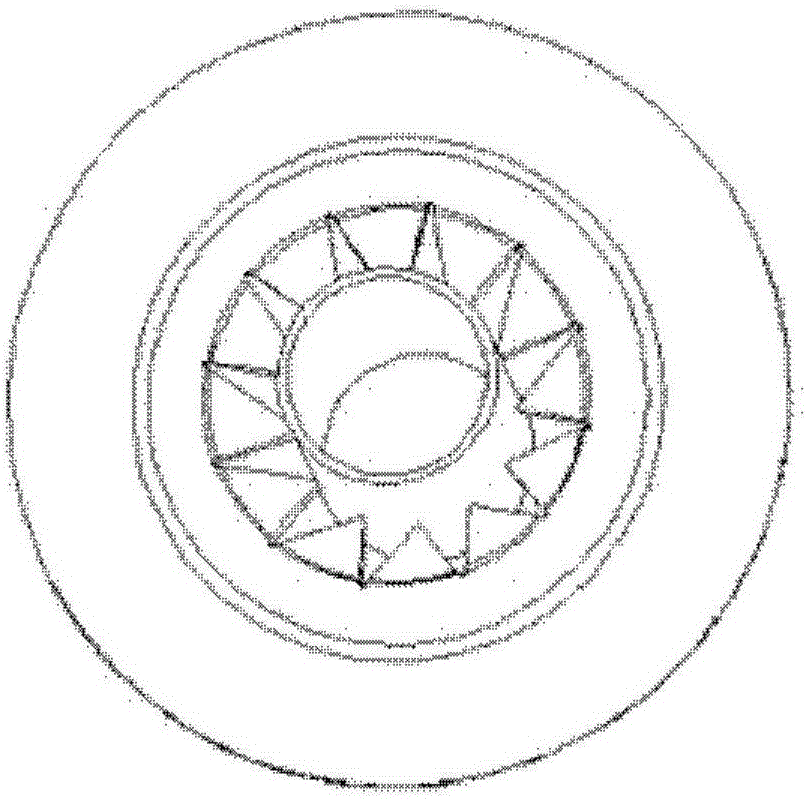

Multi-channel outside-pipe falling film liquid distributor and heat exchange device

ActiveCN105797410APlay the role of liquid separationEvenly distributedEvaporator accessoriesProtruding shouldersEngineering

The invention provides a multi-channel outside-pipe falling film liquid distributor and a heat exchange device.The multi-channel outside-pipe falling film liquid distributor is provided with a protruding shoulder, liquid can uniformly enter each overflow hole and from a liquid film on the outer wall of each falling film pipe after passing through liquid guide teeth of the overflow holes, and the protruding shoulder plays a liquid distribution effect so that the liquid can be uniformly distributed to the falling film pipes.The protruding shoulder is connected with the liquid guide teeth, the liquid guide teeth play a uniform liquid distribution effect on the falling film pipes, and the liquid reaches the outer walls of the falling film pipes along the liquid guide teeth and forms the uniform and stable liquid films on the outer walls of the falling film pipes along a main liquid flowing channel.The liquid distributor further has a settlement effect, and residues in the liquid can bee discharged out along the main liquid flowing channel to be prevented from blocking a liquid channel.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com