Deep cavity injection mold achieving easy demolding

An injection mold and deep cavity technology, applied in the field of deep cavity injection molds, can solve the problems of high work intensity, damage to molds and operators, difficult air pins, etc., and achieve the effect of easy opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

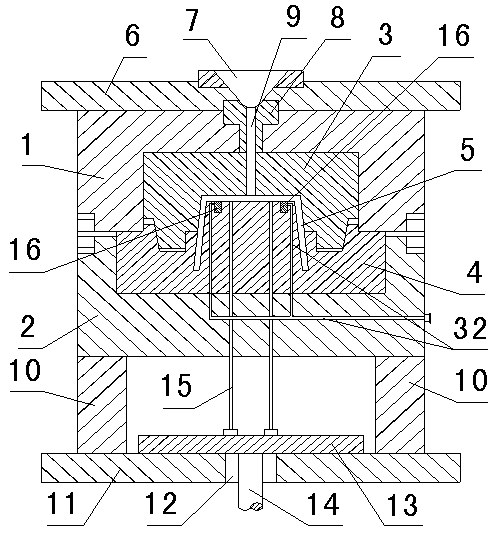

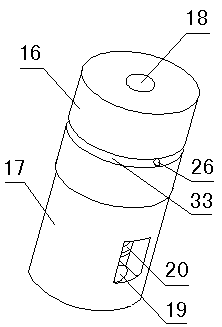

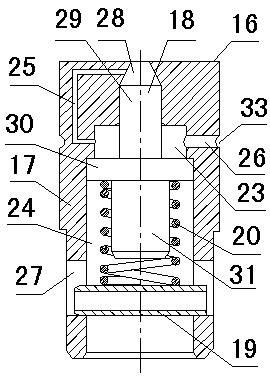

[0023] Such as Figure 1~5 As shown, an embodiment of the present invention, a deep cavity injection mold that is easy to demould, comprises adjacent fixed mold 1 and movable mold 2; The cavity surrounded by the lower mold core 4, the upper mold core 3 and the lower mold core 4 is a mold cavity 5 for injection molding; the fixed mold 1 is provided with a fixed mold seat plate 6, and a fixed mold seat plate 6 A gate 7 is arranged in the middle, and a sprue sleeve 8 is provided under the gate 7, and an injection runner 9 connecting the gate 7 and the mold cavity 5 is provided in the middle of the sprue sleeve 8 and the upper mold core 3; Die feet 10 are arranged on both sides below the mold 2, and a movable mold seat plate 11 is arranged under the mold foot 10. A perforation 12 is provided in the middle of the movable mold seat plate 11. A top plate 13 is arranged in the middle of the mold feet 10 on both sides. The main top of the injection molding machine The rod 14 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com