Locknut for rotor of gas turbine and machining methods of locknut

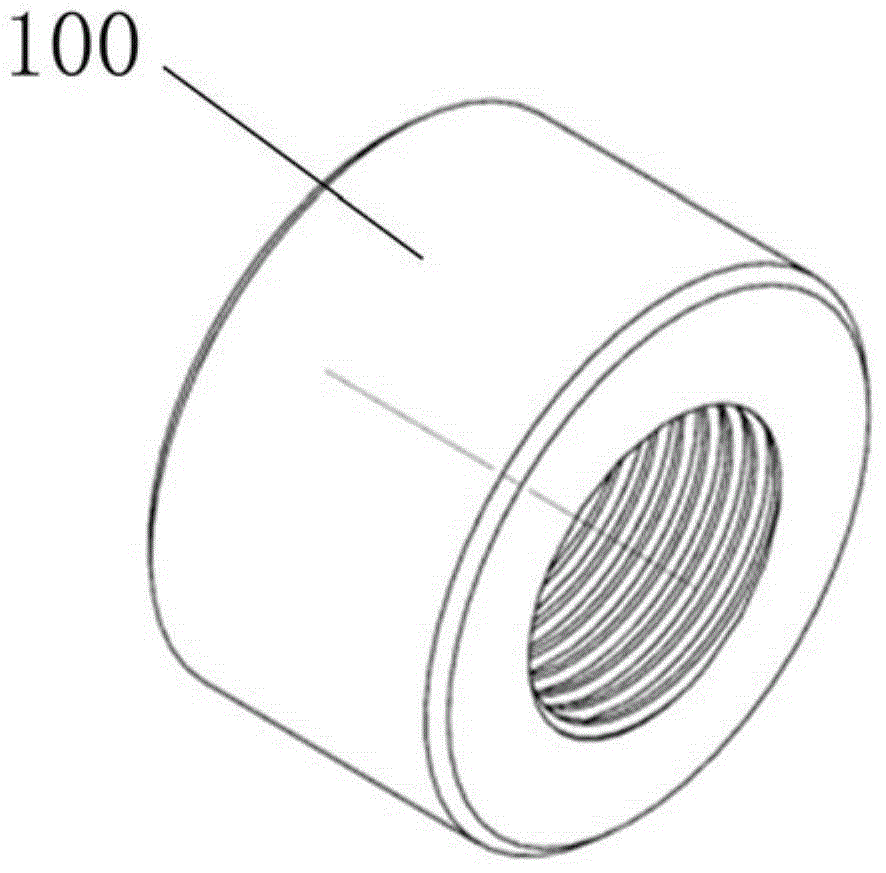

A technology of anti-loosening nuts and gas turbines, applied in the direction of nuts, screws, bolts, etc., can solve problems such as limited installation space, and achieve the effects of convenient installation and disassembly, good anti-loosening and self-locking effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

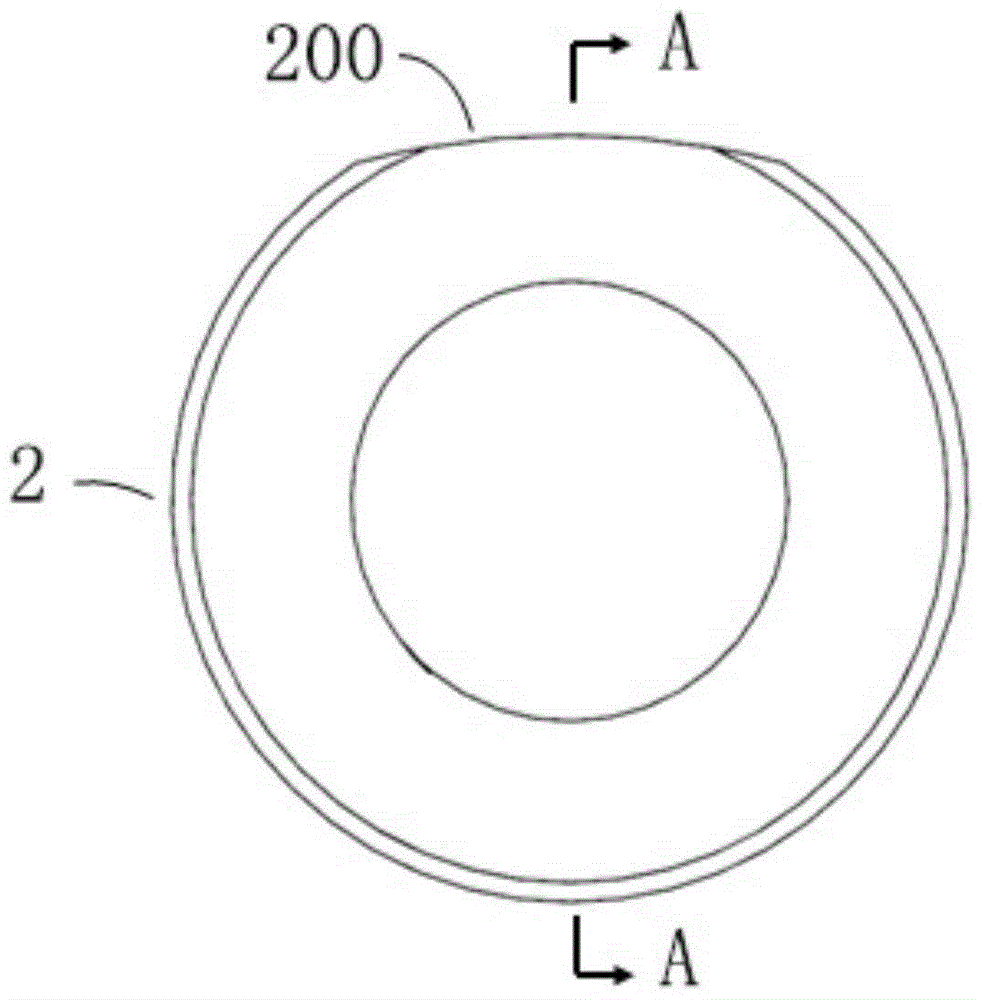

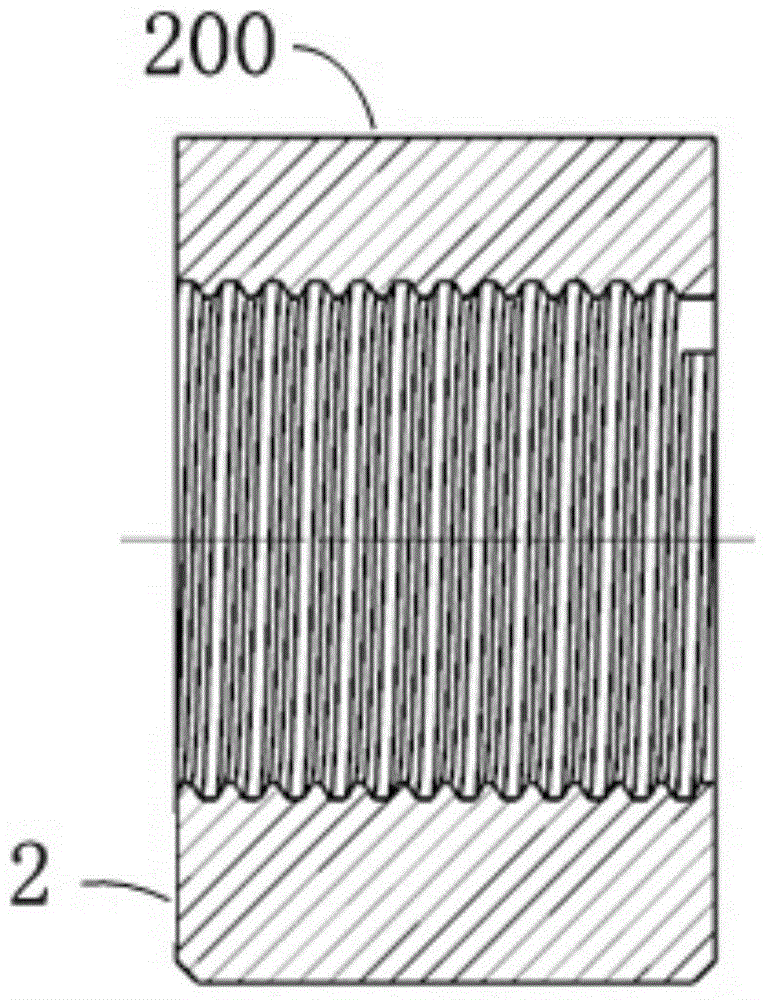

[0043] like Figure 5 and 6 As shown, the cross section of the recessed portion 200 is a convex arc or a concave arc. A transitional arc is provided at the joint between the concave portion 200 and the outer surface of the nut body 2 . During installation, put the locknut between two adjacent shoulders 10 at the end of the wheel 1, both shoulders 10 are ring-shaped, and the locknut is located between the two annular shoulders 10 In the groove, the concave portion 200 is matched with the outer shoulder 10, that is, the concave portion 200 is a convex arc, which has the same curvature as the inner wall of the outer shoulder 10; The loose nut is connected, and the other end is hydraulically stretched and pre-tightened, and then connected with an ordinary nut, and then the ordinary nut is tightened by a mechanical anti-loosening method to prevent falling off. Of course, the recessed part 200 can also be arranged at the place where it meets the inner shoulder 10, and the recesse...

Embodiment 2

[0045] like Figure 7 As shown, the present embodiment is basically the same as the first embodiment, the only difference is that the nut body 2 includes two recesses 200 that are not connected to each other. Preferably, one of the two concave portions 200 is a convex arc, and the other is a concave arc. That is to say, the two concave parts 200 on the nut body 2 are respectively matched with the shoulders 10 on both sides to achieve two anti-loosening effects, and the anti-loosening effect is better; the stress is dispersed, the nut body 2 is not easily deformed, and the anti-loosening effect is good. Preferably, the centers of the two recesses 200 are collinear with the center of the nut body 2 to facilitate processing.

[0046] This embodiment only provides the embodiment in which the concave portion 200 is an outer convex arc and an inner concave arc respectively, and the combination thereof also belongs to the protection scope of the present invention, for example, both ...

Embodiment 3

[0048] like Figure 8As shown, this embodiment is basically the same as the first or second embodiment, the only difference is that one end of the nut body 2 is provided with a stress relief groove 21, and the stress relief groove 21 is a closed annular sinker. That is, an annular groove is arranged at one end of the nut body 2, which is located between the thread of the nut body 2 and the outer surface, as a stress relief groove 21; Therefore, a stress relief groove 21 is provided on its outer side, so that these thread teeth can have a small deformation outward, so as to relieve the force on the thread teeth and prevent the thread teeth from being damaged.

[0049] Preferably, one end of the nut body 2 is opposite to the wheel disc 1 of the gas turbine rotor, and a gasket is provided at the end of the nut body 2 opposite to the wheel disc 1; Washers, spring washers, or a combination of two types of washers; when there is a rounded corner between the shoulder 10 and the whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com