Stop valve

A globe valve and disc technology, applied in the field of globe valves, can solve problems such as the relative axial movement of the valve stem and the valve disc, and the insufficient connection between the valve stem and the valve disc, so as to achieve good sealing effect, firm positioning and high manufacturing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

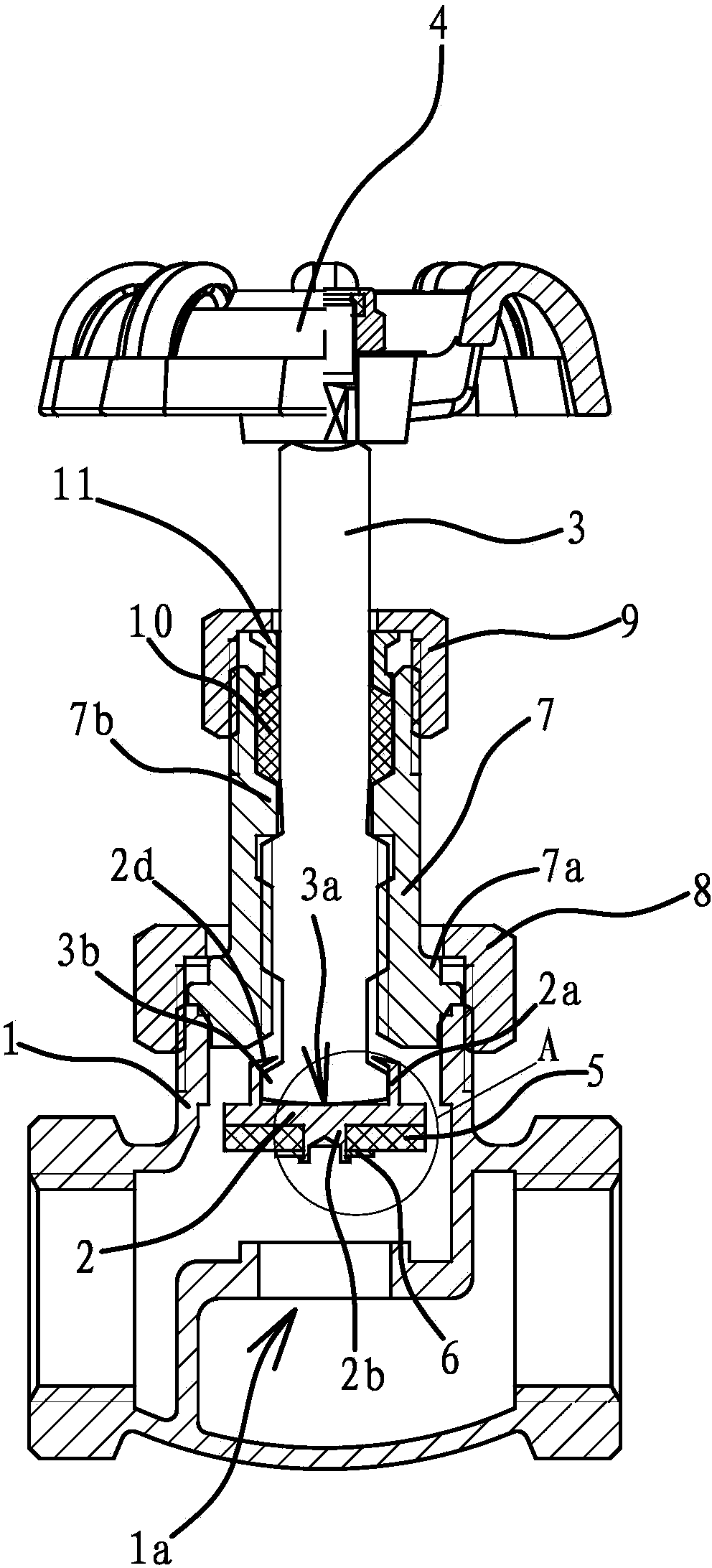

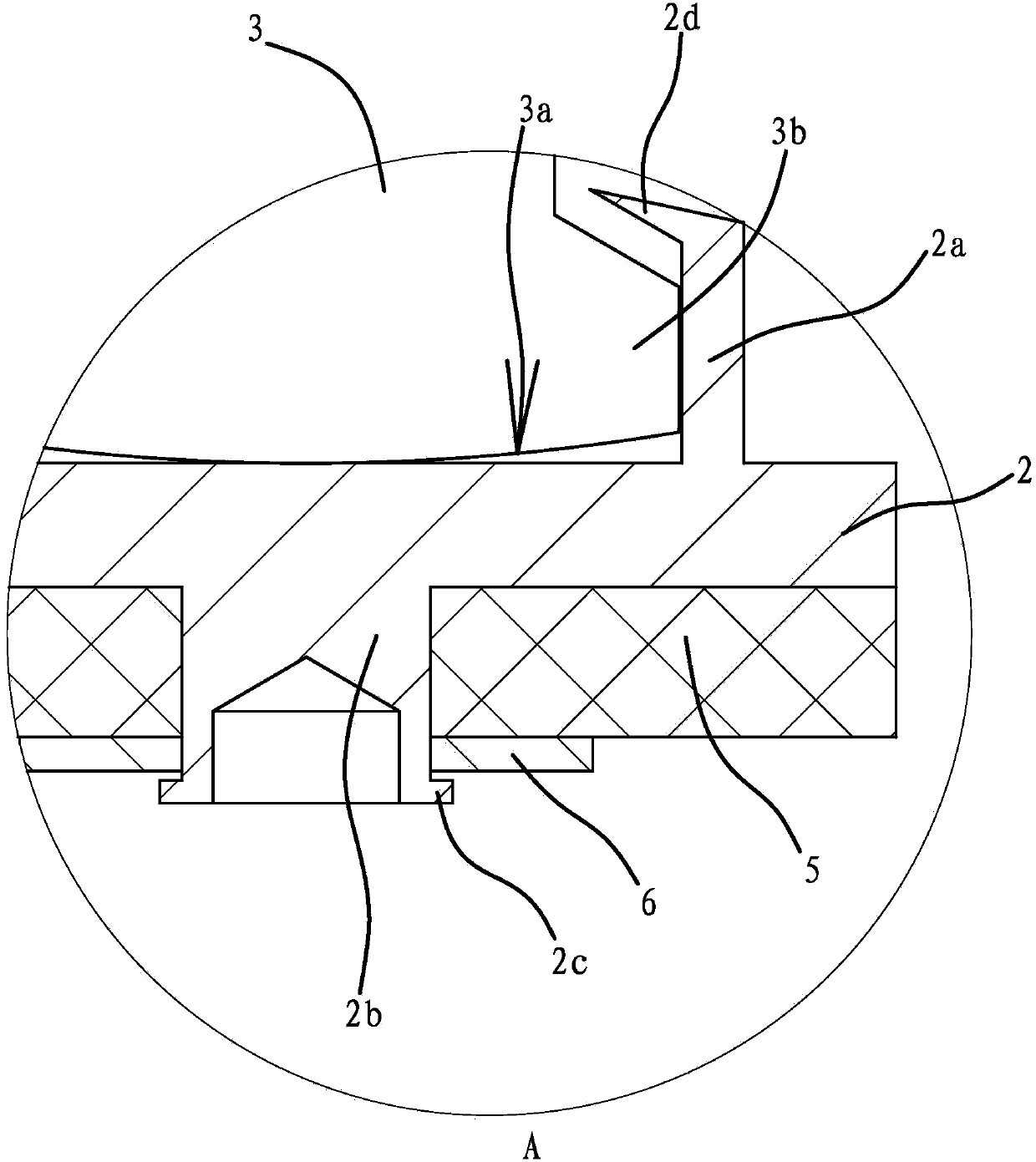

[0028] Such as figure 1 and 2 As shown, a shut-off valve includes a valve body 1, a valve disc 2 and a valve stem 3. The outer end of the valve stem 3 protrudes from the valve body 1 and is connected with a handle 4. The valve disc 2 is in the shape of a sheet, and the valve stem 3 The inner end of the valve disc 2 has a shoulder 3b, and the upper side of the valve disc 2 has a protruding and cylindrical connecting portion 2a, the shoulder 3b is located in the connecting portion 2a, and the upper end of the connecting portion 2a is a bending portion 2d bent inward. , the upper end surface of the shoulder 3b matches the bent portion 2d and the bent portion 2d can abut against the upper end surface of the shoulder 3b, the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com