Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire treads/tread patterns, transportation and packaging, etc., can solve the problems of decreased drainage performance, difficulty in taking into account drainage performance and noise performance, etc., to maintain drainage performance, The effect of increasing the noise, increasing the reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

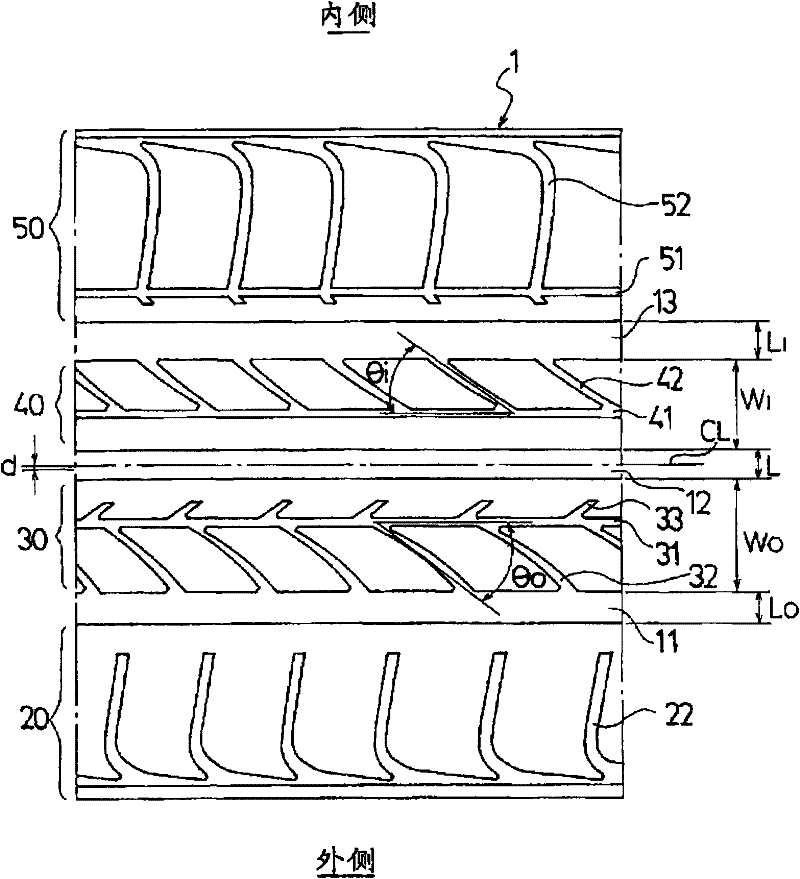

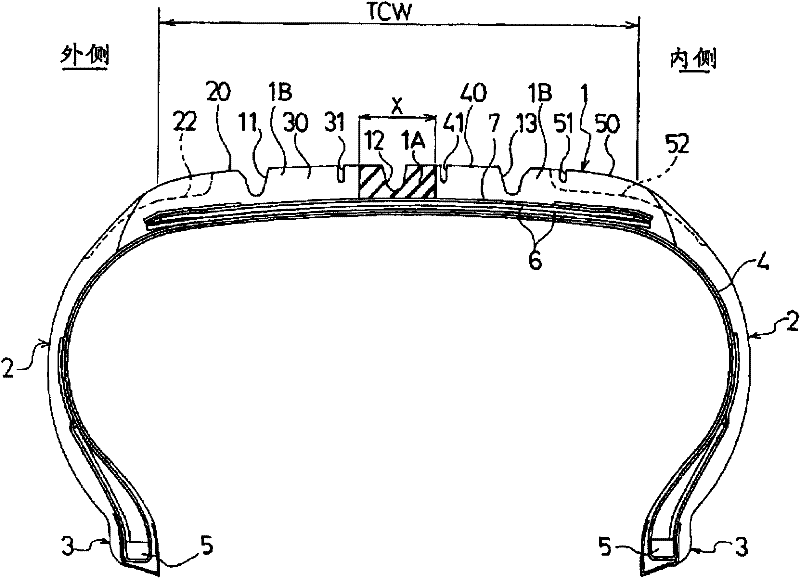

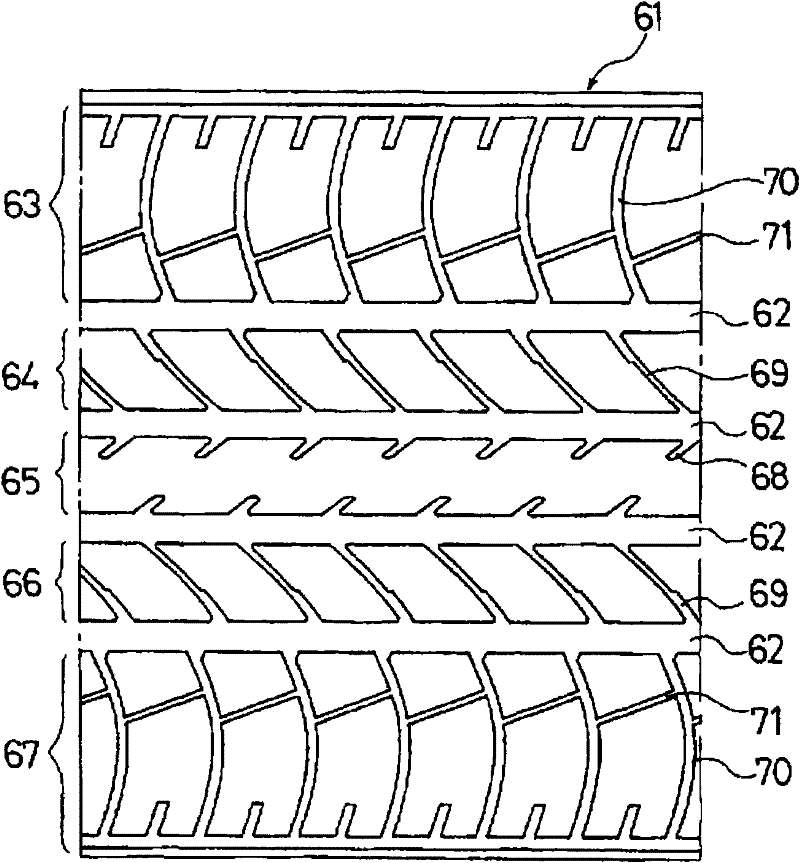

[0042] Make the tire of example 1~5, its tire size is 215 / 50R17, as figure 1 As shown, the pneumatic tire specifies the installation direction inside and outside of the tire when it is installed on the vehicle, wherein three main grooves extending in the tire circumferential direction are provided on the tread portion, and the center position of the central main groove is arranged from the tire equator to the vehicle. At the position offset on the outer side, these main grooves divide 4 rows of land portions, and at the same time, in the 2 rows of central land portions located at the tire equator on the tread portion, one thin groove extending in the tire circumferential direction and one thin groove extending from the thin groove to the A plurality of inclined grooves extending outward in the tire width direction, the width of the central land portion on the outer side of the vehicle is greater than the width of the central land portion on the vehicle inner side, and two rows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com