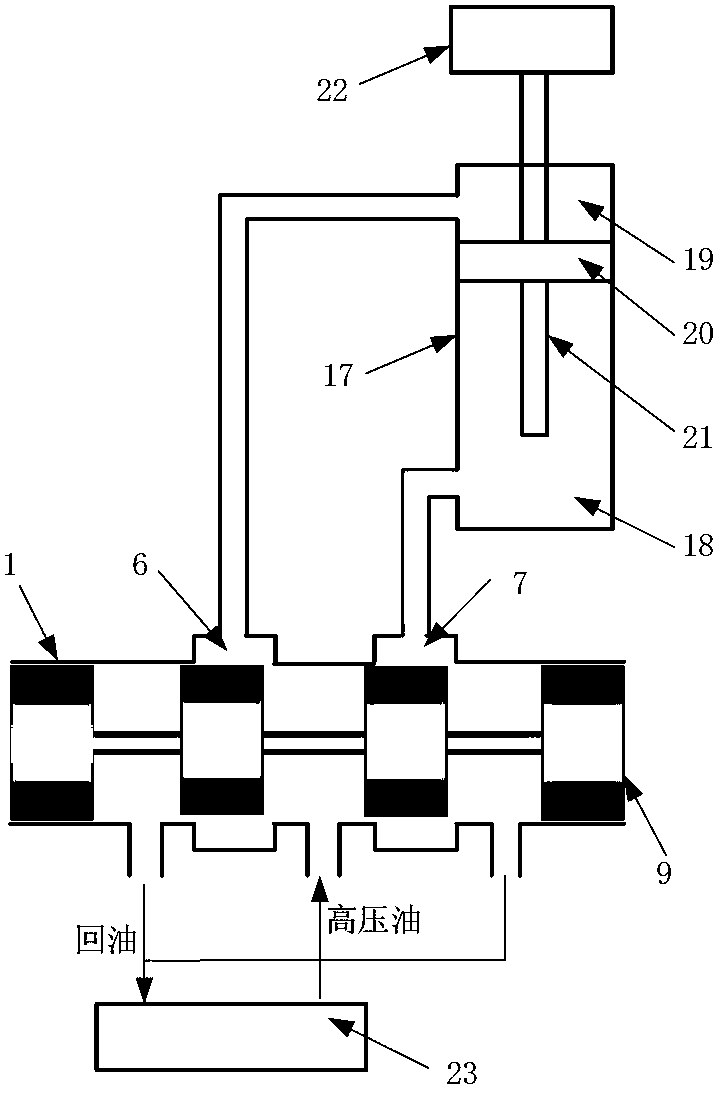

Energy-saving hydraulic valve with independently-controllable load throttle mouths and hydraulic valve control system

An independent control and throttling technology, applied in fluid pressure actuators, servo motors, servo motor components, etc., can solve problems such as waste, achieve low energy consumption, optimize the valve core structure, and save hydraulic energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

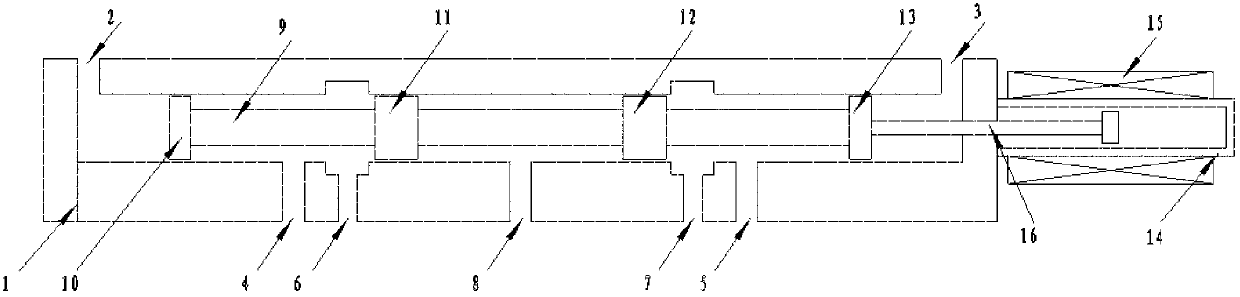

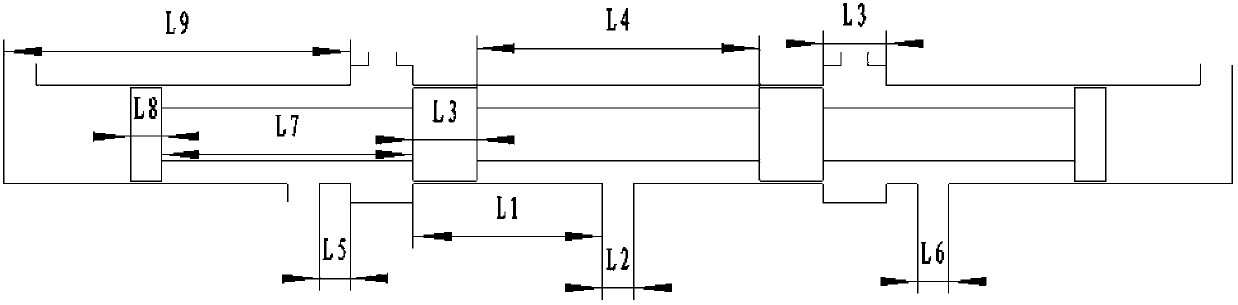

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0037] The structure of the hydraulic valve with independent control of the load throttle port proposed by the present invention is as attached figure 2 As shown, it includes a hydraulic valve body 1 , a valve core 9 and a displacement sensor 14 .

[0038] A left control port 2 and a right control port 3 are designed on the hydraulic valve body 1, and the valve core 9 can be controlled to slide left and right in the valve body 1 by passing hydraulic oil with a certain pressure into the two control ports. When the pressure in the left control port 2 is higher than the pressure in the right control port 3, the spool 9 moves to the right under the action of the pressure difference, otherwise the spool 9 moves to the left, when the pressures in the two control ports are equal , the spool 9 stops moving.

[0039] A first load throttle 6 and a second load thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com