Feeding device of converter rotating chute

A technology of feeding device and chute, which is applied in the direction of manufacturing converters, etc., can solve the problems of inability to rotate the rotating cylinder, increase production and use costs, and difficulty in rotating the rotating cylinder, so as to reduce labor intensity of workers, improve work efficiency, and improve airtightness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

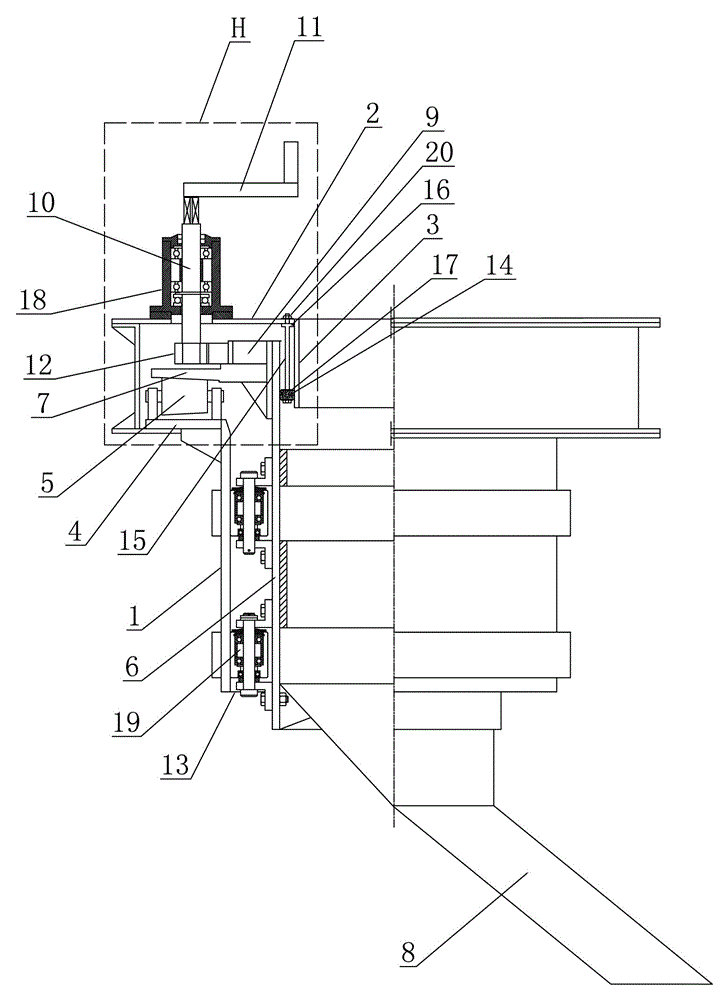

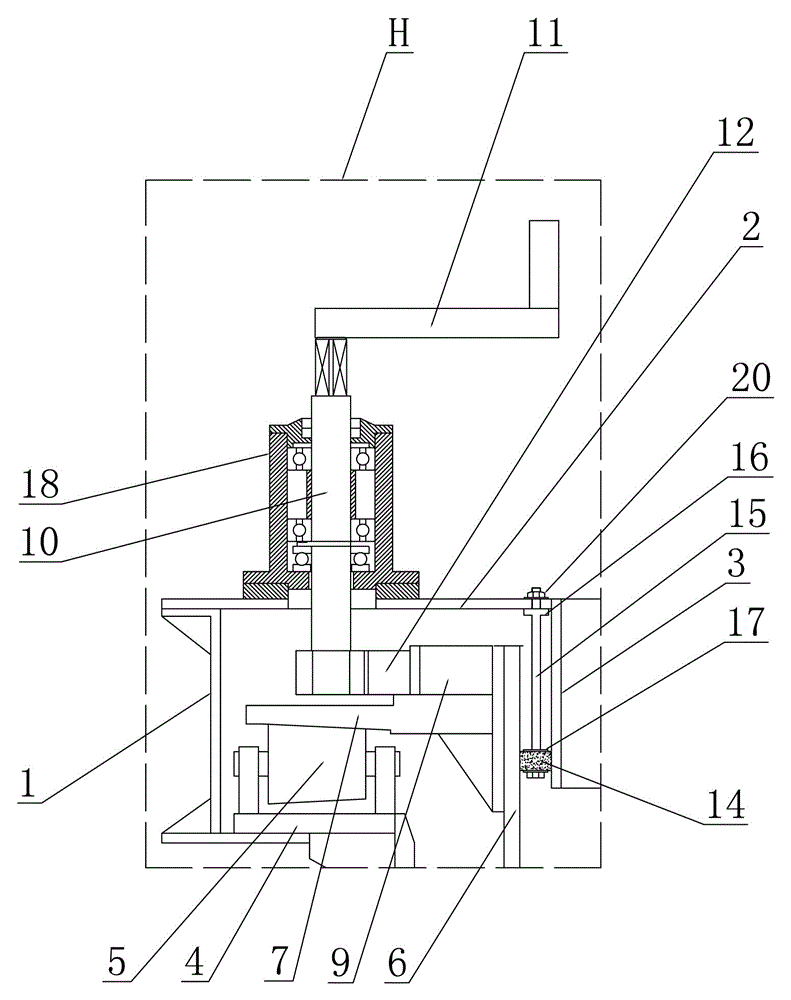

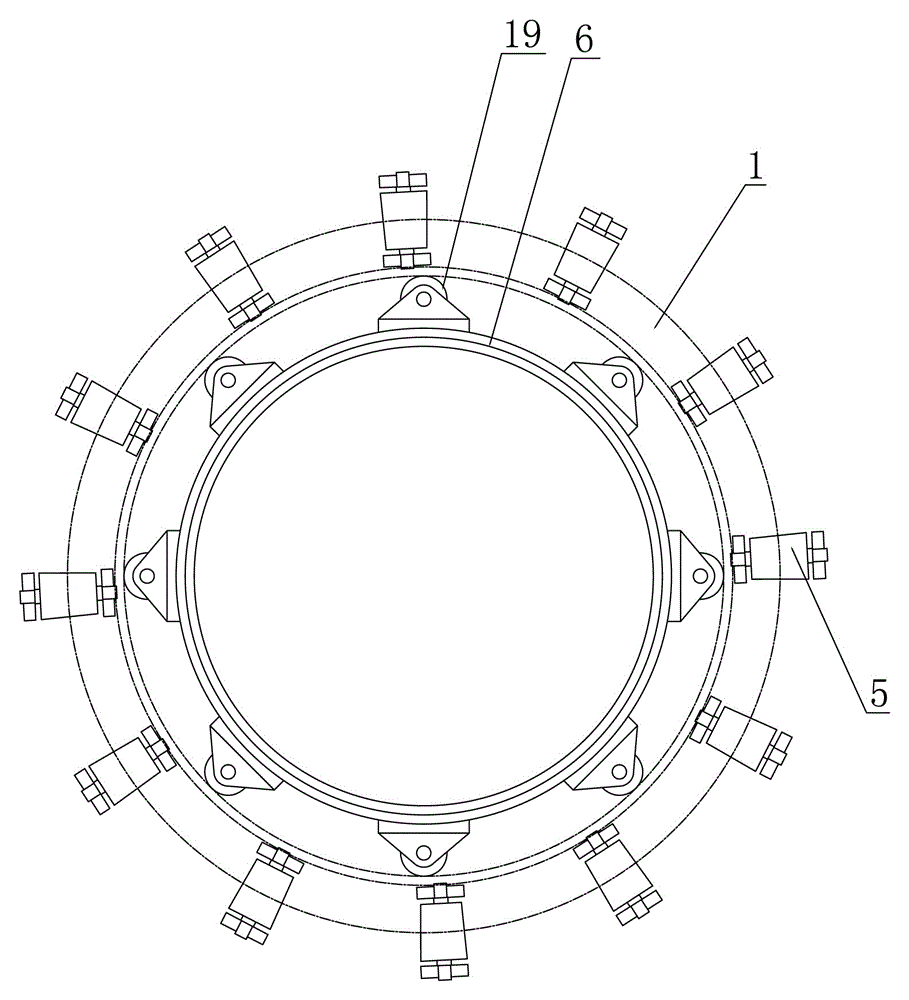

[0017] Such as figure 1 , figure 2 , image 3 As shown, the described converter rotary chute feeding device includes: an external fixed cylinder 1, a mounting plate 2 is arranged on the top cover of the external fixed cylinder 1, a feeding port is arranged at the center of the mounting plate 2, and at the feeding port The mounting plate 2 is provided with an inner fixing cylinder 3 sleeved in the outer fixing cylinder 1, an annular fixing seat 4 is arranged on the inner wall of the outer fixing cylinder 1, and on the annular fixing seat 4 along the outer fixing cylinder 1 A number of support rollers 5 are distributed at intervals in the circumferential direction, and the end faces of all the support rollers 5 jointly form a support platform. A rotating cylinder 6 is sleeved between the outer fixed cylinder 1 and the inner fixed cylinder 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com