Rotary clutch

A clutch and rotary technology, applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of reducing the reliability of the spring operating mechanism and fatigue-resistant operation life, and the reliability, stability and durability of the clutch action. The effect of simple structure, strong adaptability, and stable and reliable action can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

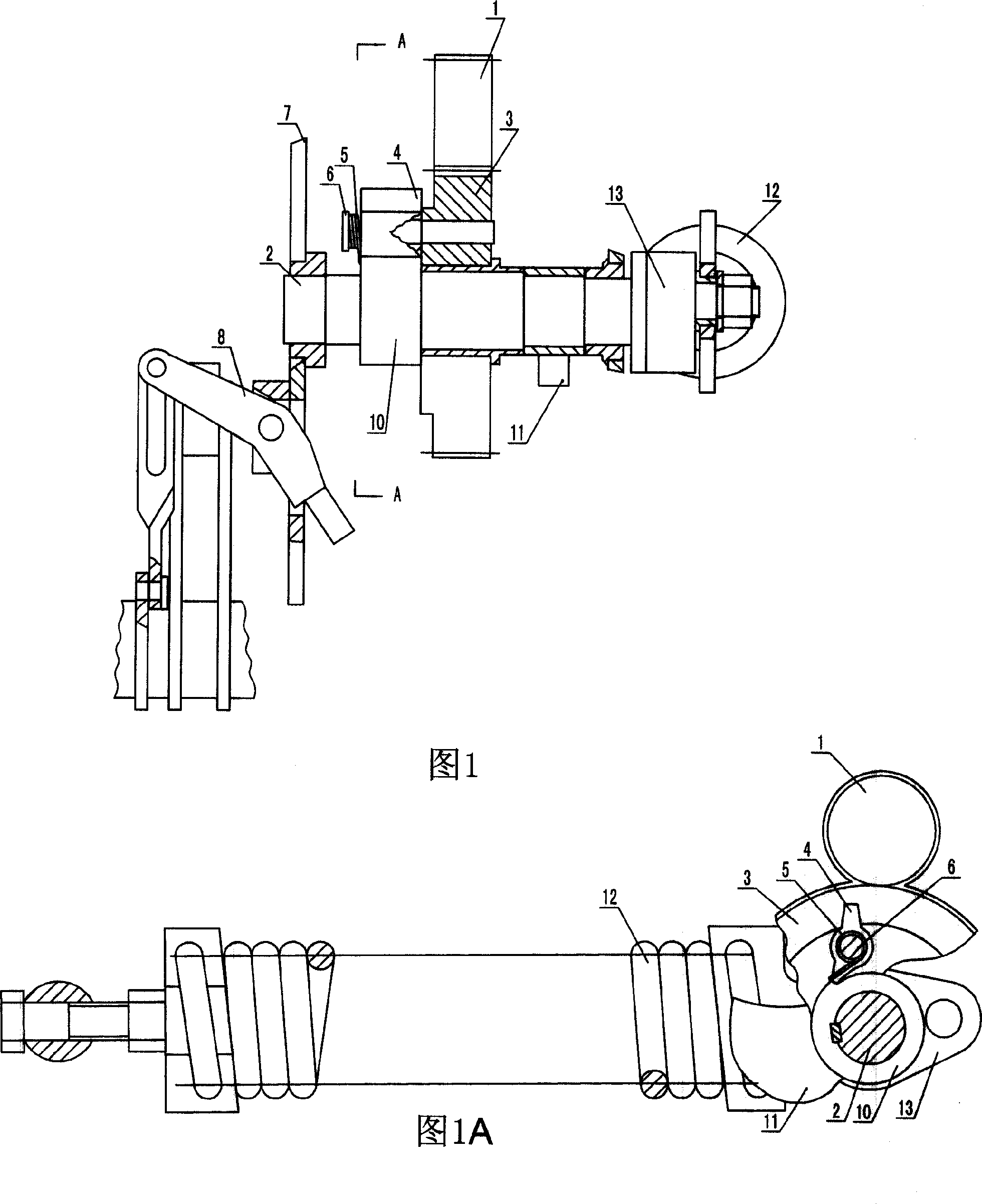

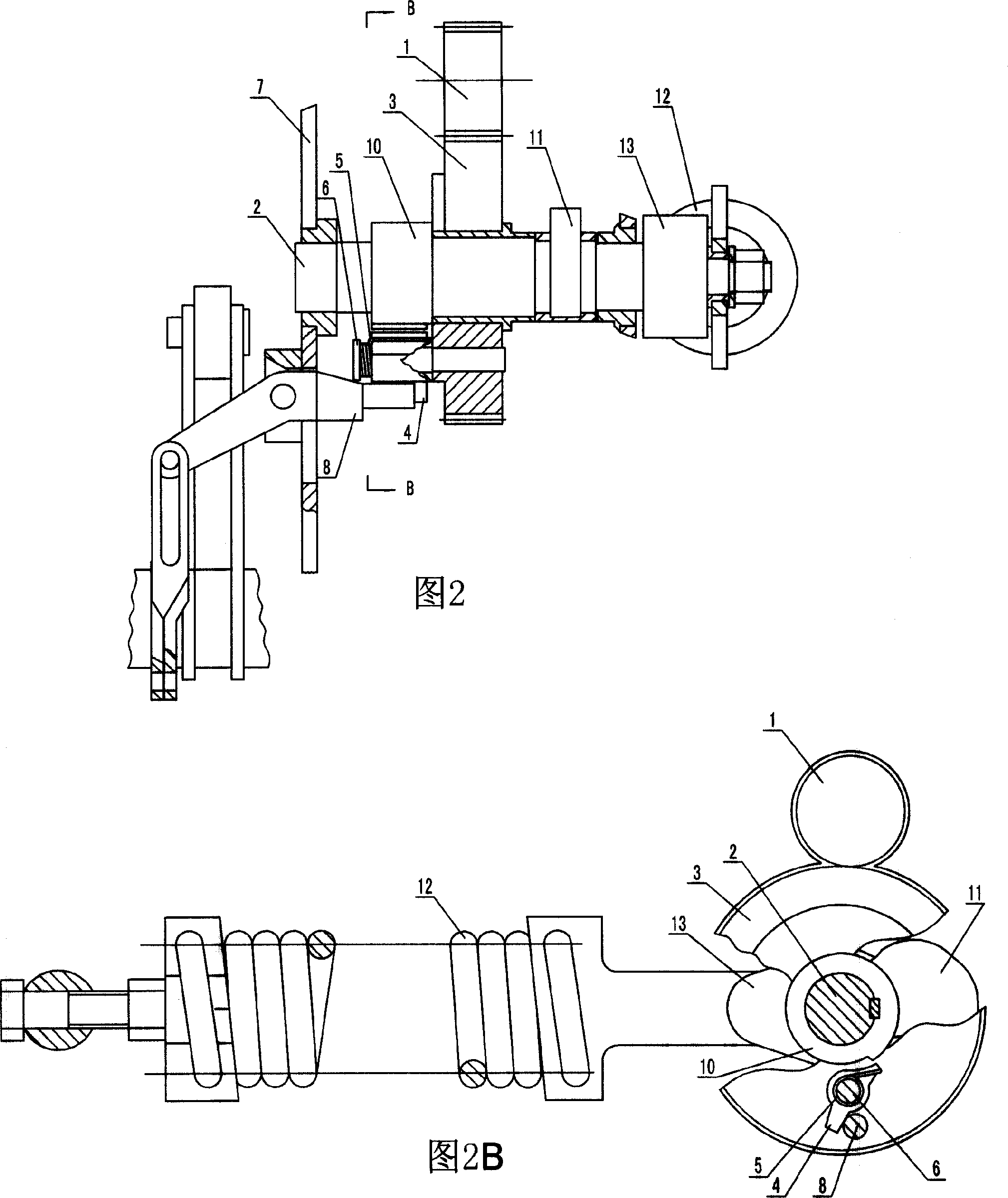

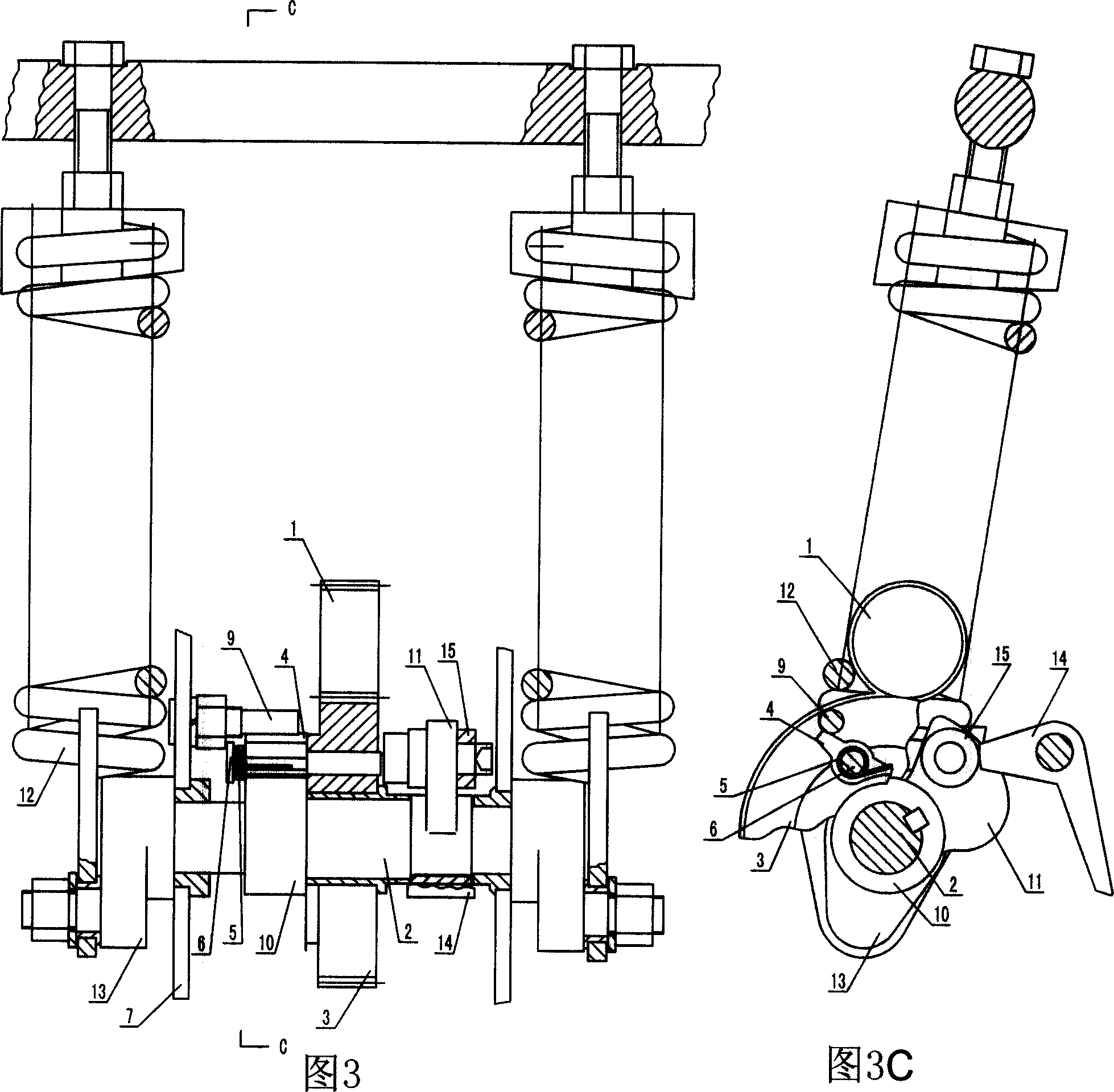

[0021] 1 to 4D are structural schematic diagrams of a rotary clutch. The rotary clutch includes a small gear 1, a main shaft 2 and a large gear 3. The main shaft 2 is equipped with a large gear 3, and the large gear 3 meshes with the pinion 1. The pin shaft 6 of the spring 5 is fixed with a convex sleeve 10 on the main shaft 2 corresponding to the top block 4, and the convex sleeve 10 is shaped on a convex shoulder to match the end of the top block 4; a cam 11 is fixed in the middle of the main shaft 2, and the main shaft 2 The end is fixed with the energy storage crank arm 13 that pulls the energy storage spring 12 and rotates synchronously with the main shaft 2; the side plate 7 is provided with a contact block with energy storage and closing self-locking protection functions.

[0022] One is that as shown in Figures 1 to 2B, the stopper is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com