Radial heavy load type roller linear guide rail pair

A linear guide pair, heavy-duty technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of small bearing capacity, inability to meet large CNC machine tools and mechatronic products, poor contact rigidity, etc. problems, to achieve the effect of easy assembly, good rigidity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

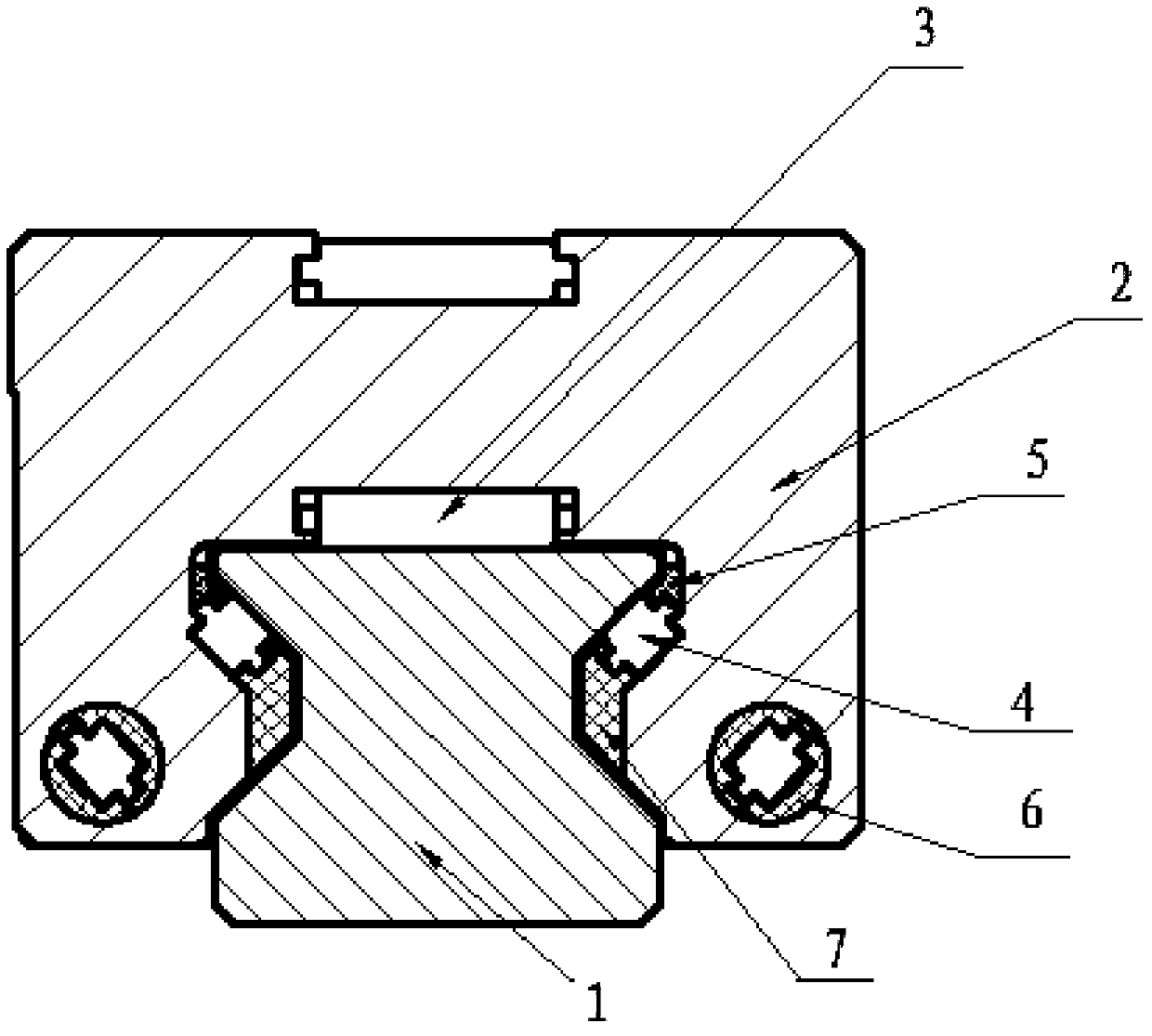

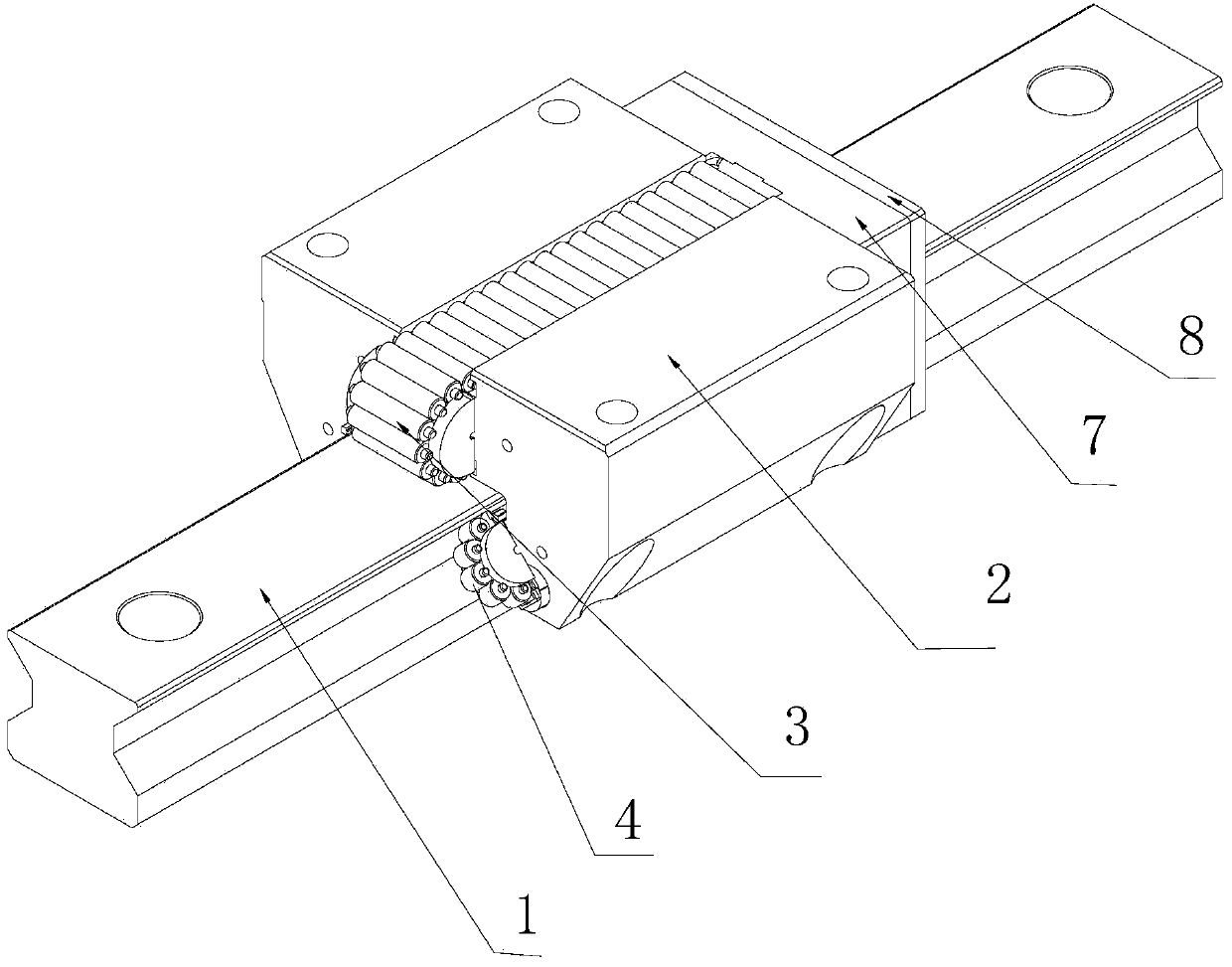

[0016] see Figure 1~2 As shown, the Figure 1~2 The structure of a radial heavy-duty roller linear guide pair provided by the embodiment of the present invention is shown. For ease of description, only parts related to the embodiments of the present invention are shown.

[0017] see Figure 1~2 , a radial heavy-duty roller linear guide pair, including a guide rail 1 and a slide seat 2, the upper part of the slide seat 2 is provided with a row of roller guide grooves and a row of upper raceways, and two rows of side rollers are symmetrically arranged on both sides. The roller 3 bearing the radial pressure load is set in the upper raceway, the roller 4 bearing the lateral pressure load is set in the side raceway through the cage 5, 6, and the rollers 3, 4 are both It is a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com