High-precision fixed beam type digital control plane milling and boring machine

A fixed-beam type, high-precision technology, used in large-scale fixed members, maintenance and safety accessories, driving devices, etc., can solve problems such as reducing output torque, affecting machining accuracy, and generating vibration, improving accuracy and accuracy stability, The effect of improving cutting vibration resistance and increasing contact rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

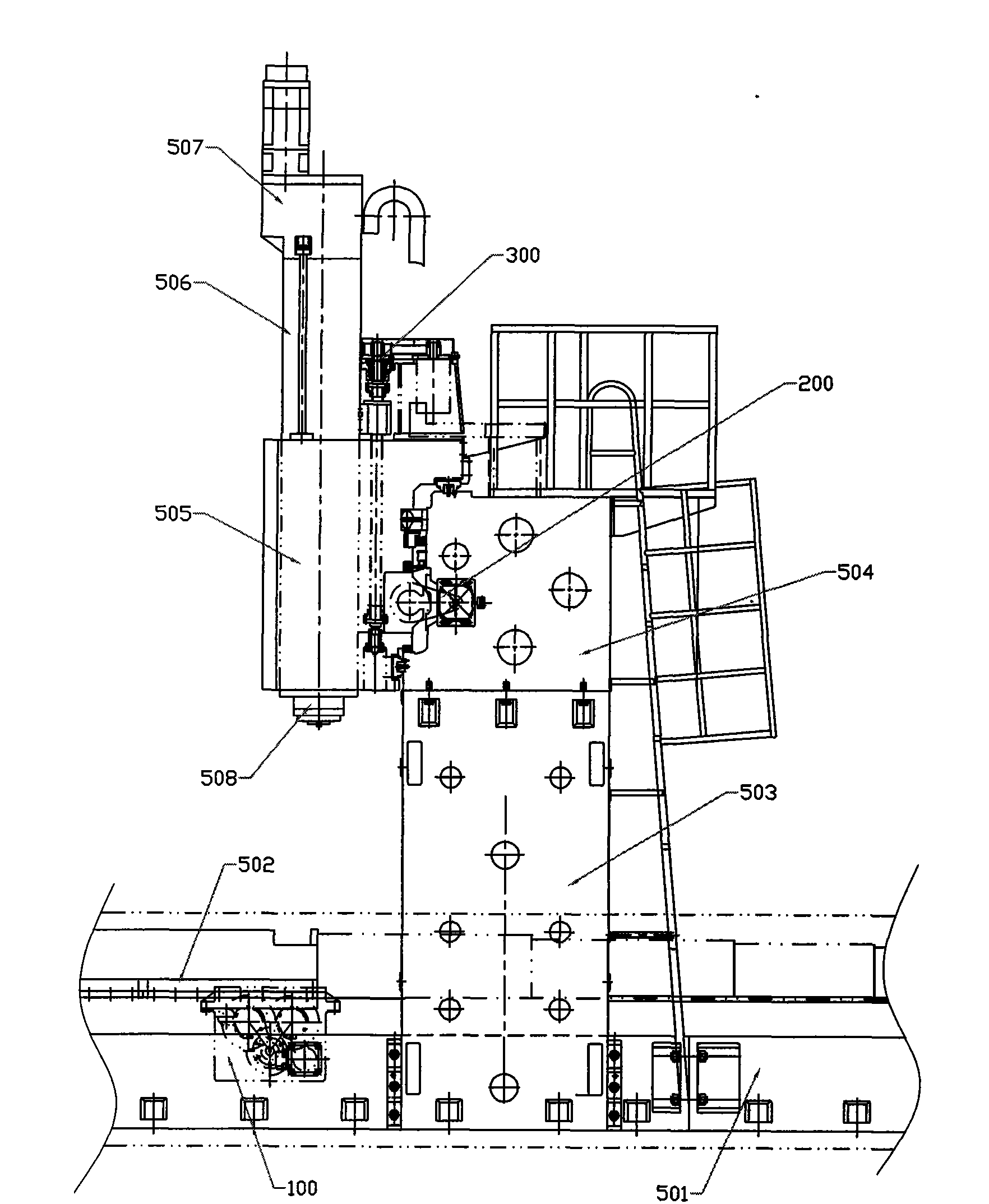

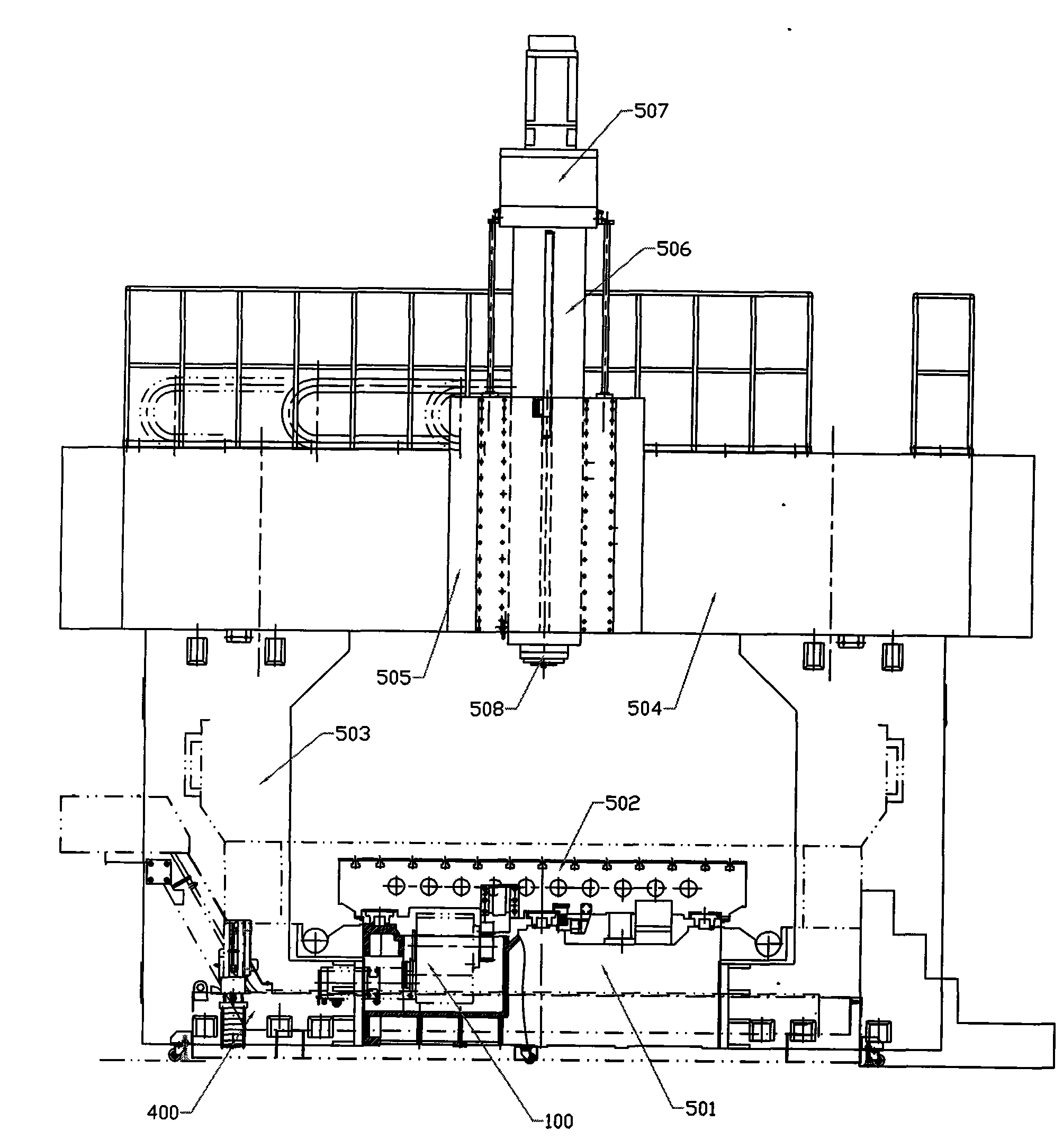

[0030] refer to figure 1 , figure 2 , this high-precision fixed-beam CNC gantry boring and milling machine mainly includes a bed 501, a worktable 502, a column 503, a beam 504, a carriage 505, a ram 506, an X-axis guide rail and Its transmission system, the Y-axis guide rail and its transmission system arranged between the beam 504 and the carriage 505, the Z-axis guide rail and its transmission system arranged between the carriage 505 and the ram 506, and the Main shaft gearbox 507 and main shaft 508, as well as electrical control device, lubricating device, hydraulic device, cooling and chip removal system 400, etc. in:

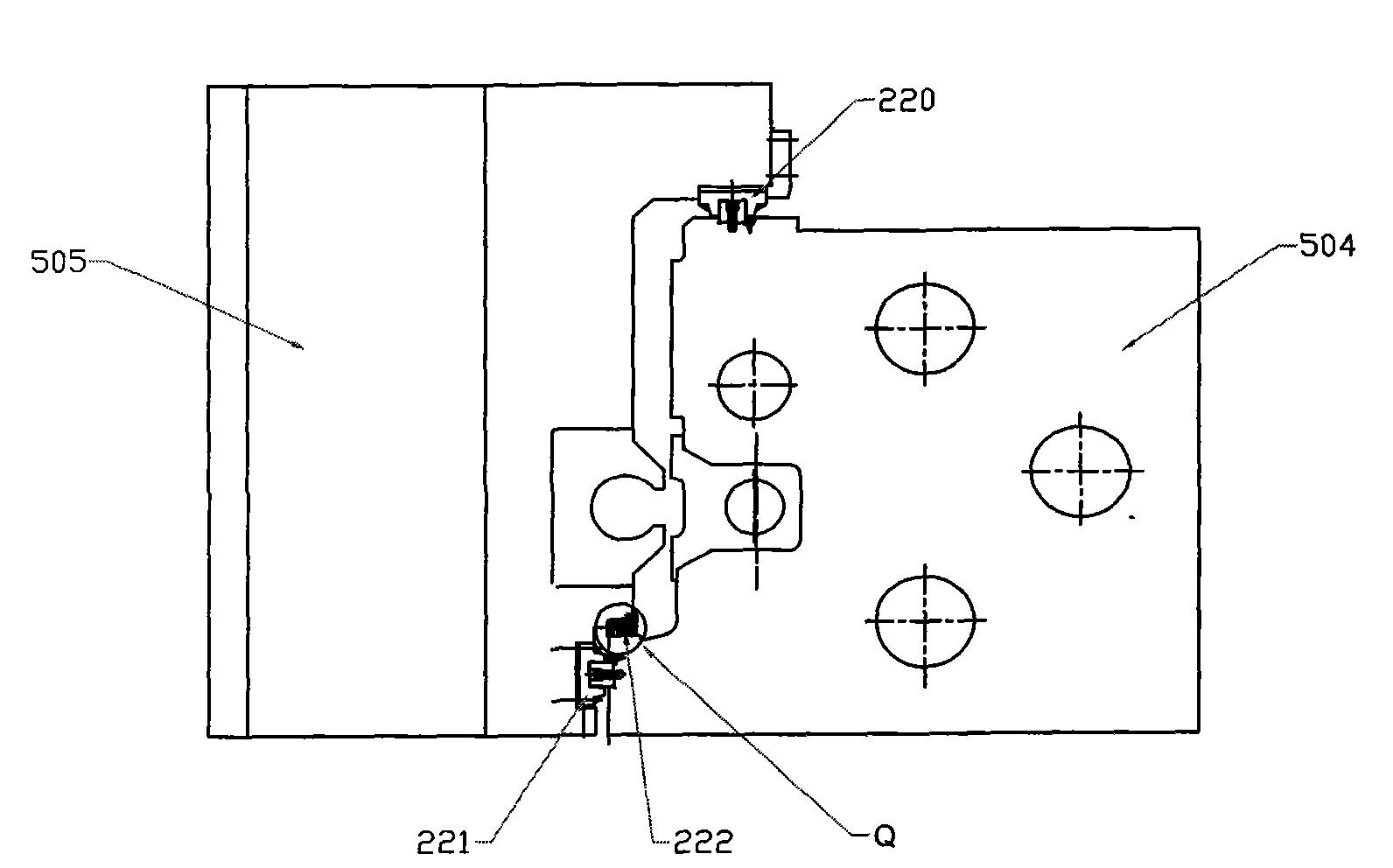

[0031]refer to Figure 3-Figure 7 , the Y-axis guide rail device includes a main guide rail 220 and a side guide rail 221, the main guide rail and the side guide rails are linear rolling guide rails, and a set of sliding pairs 222 parallel to the linear rolling guide rails are set above the side guide rails 221, and the sliding pair 222 consists of The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com