Patents

Literature

79results about How to "Reasonable positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

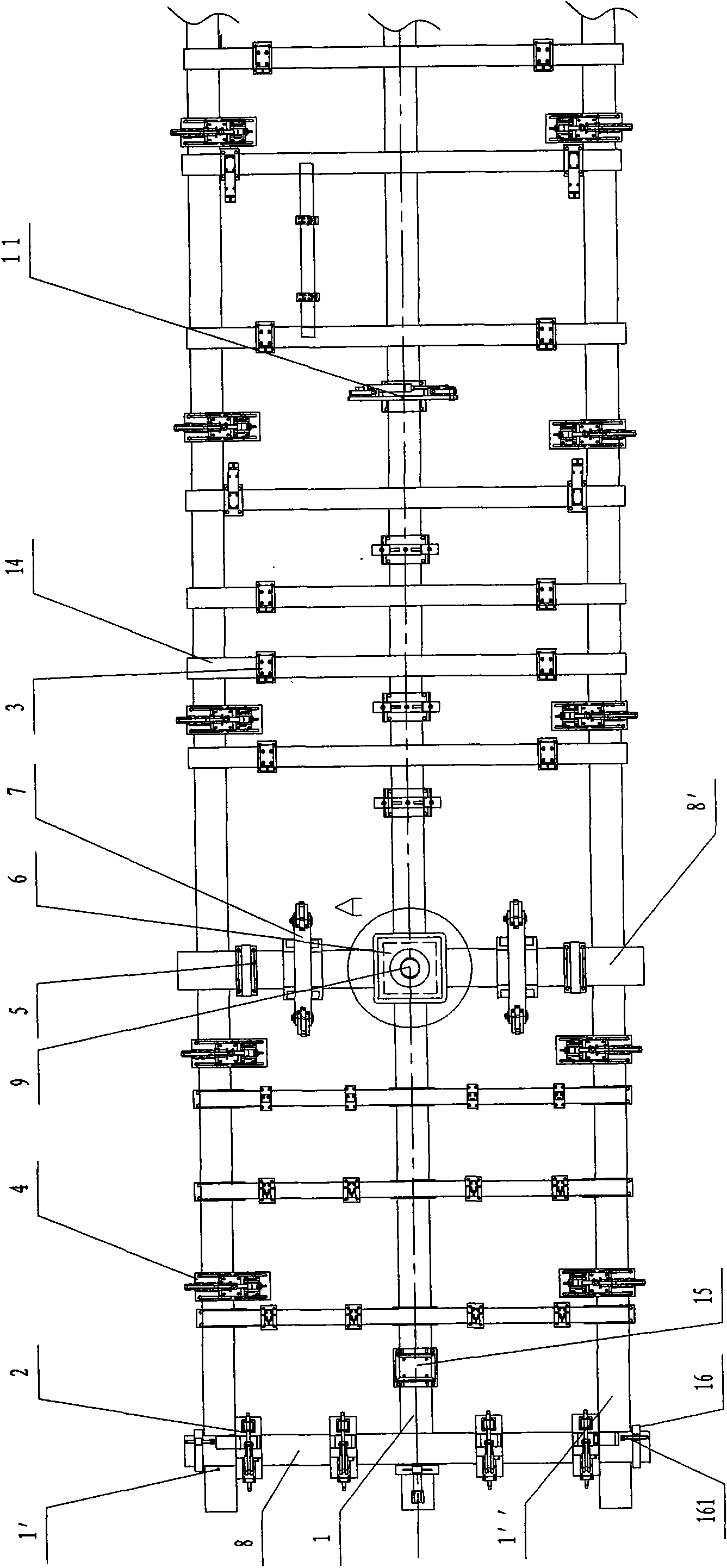

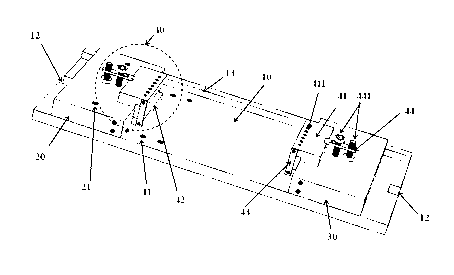

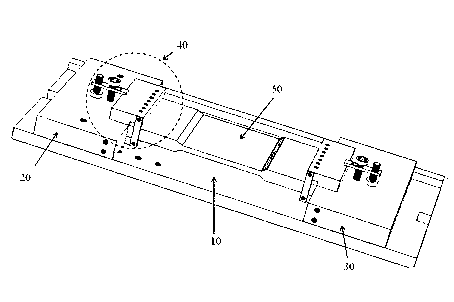

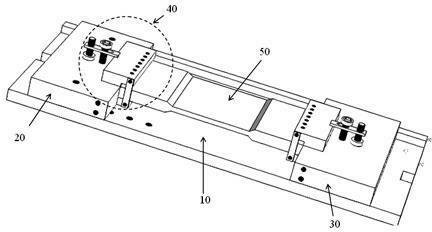

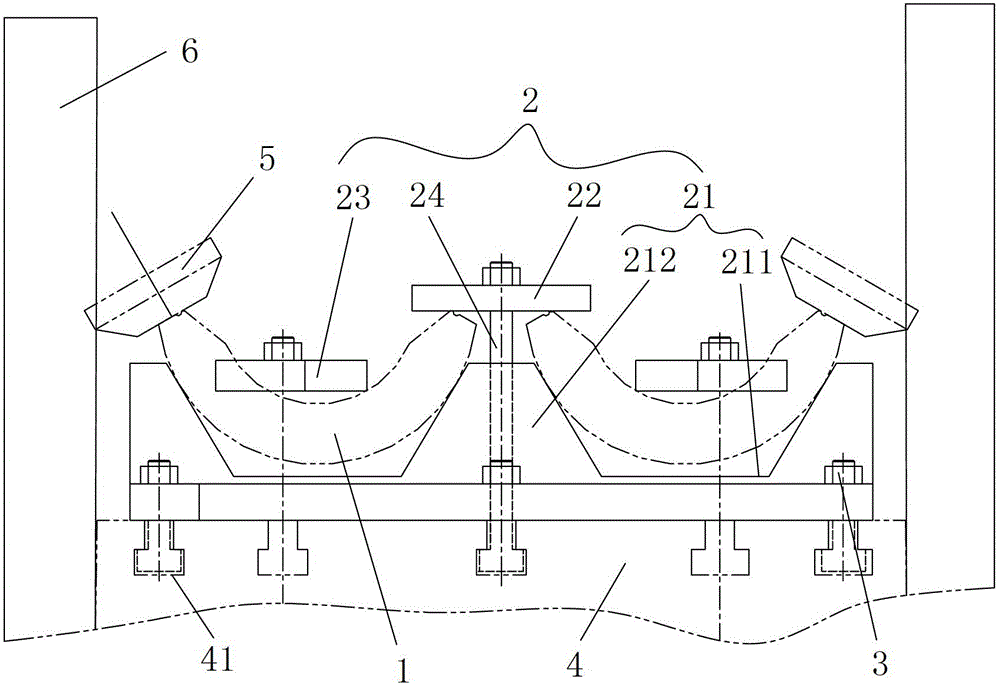

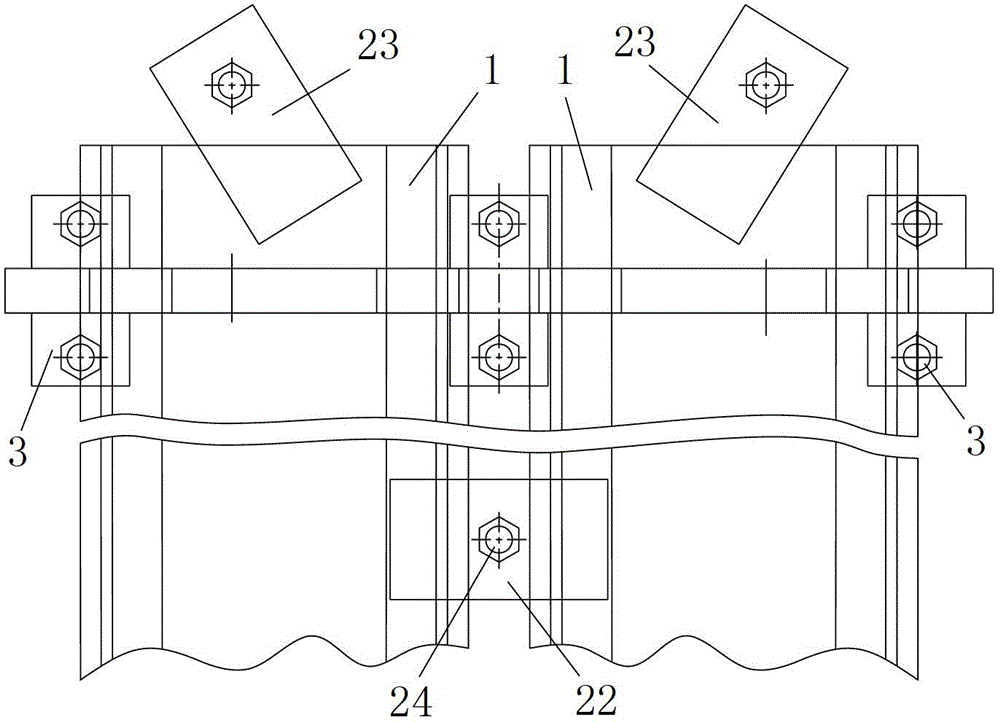

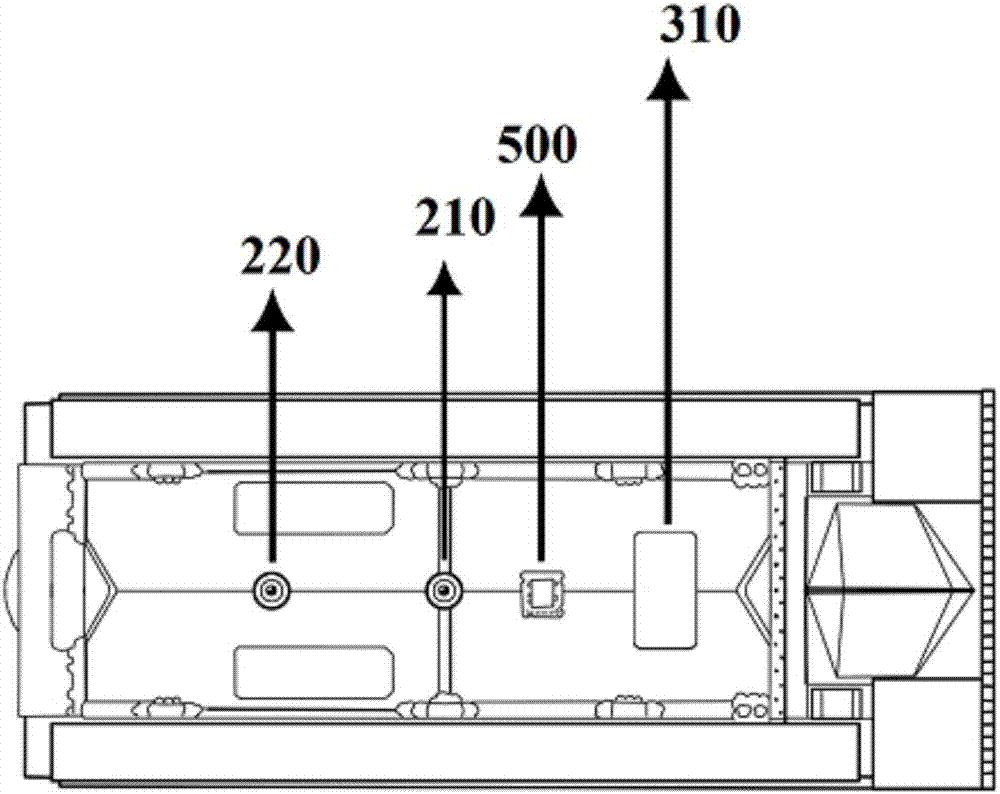

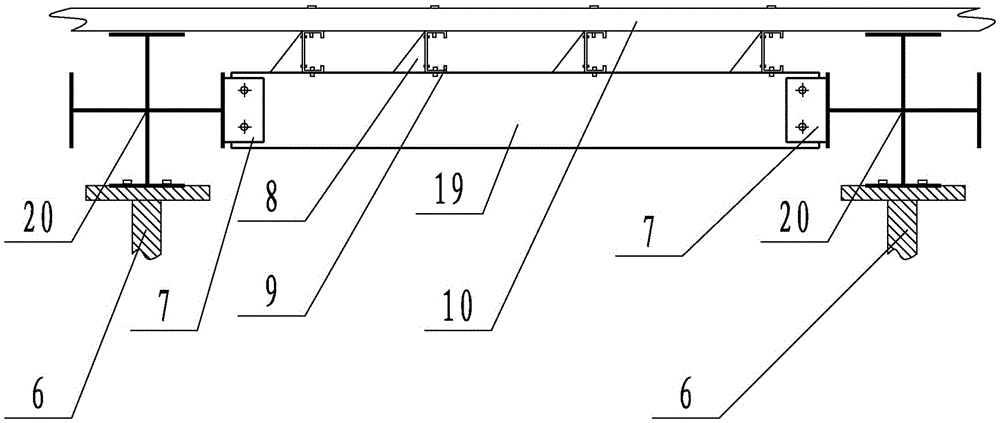

Production method of chassis of railway vehicle

ActiveCN102101219AReasonable positioningHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesLateral positioningBolster

The invention relates to a production method of a chassis of a railway vehicle, which comprises the following steps: opening an end beam positioning and clamping device, a side beam positioning and clamping device, a transverse centering device and a body bolster clamping device to the open positions; hoisting a side beam and an end traction and bolster mechanism in place; enabling the transversecentering device to act so as to center a traction beam; starting the end beam positioning and clamping device, and fixing an end beam in place and clamping; starting the body bolster clamping device; placing cross beams inside and outside a bolster; mounting a wire slot at the end part and the wire slot in the bolster; welding a cross beam downhand weld and a vertical weld, and welding a cover plate on a body bolster; retreating the end beam positioning and clamping device, the side beam positioning and clamping device, the transverse centering device and the body bolster clamping device; and using a clamping fixture for clamping. The lower planes of two upper center plates of an end traction and bolster and the lower plane of the end beam are fixed as reference for positioning the height of the end traction and bolster of the chassis, and positioning pins at center holes of the upper center plates and the transverse centering device are used for transverse positioning. The positioning way is reasonable, the artificial marking is not required, the positioning precision is high, and the production efficiency is high.

Owner:CRRC NANJING PUZHEN CO LTD

Method for preparing tooth implant locating guiding template

InactiveCN101239007AEliminate gapsEnsure safetyDental implantsDental prostheticsJaw boneBone structure

The invention relates to a method for producing a tooth plant positioning guiding template, comprising the following steps: (1) scanning the jaw bone of sufferers by multiple-layer helix CT to obtain the three dimensional anatomy structure information of the jaw bone; (2) establishing a three dimensional jaw bone model in CAD software; (3) measuring the bone structure of the plant area lack of tooth according to the three dimensional jaw bone model; (4) confirming the plant point, direction and depth of the dental implant according to the measuring result; (5) producing the positioning guiding template entity model based on dental face- bone face combination support type by applying photo-curing rapid forming technology; (6) having surface treatment to the positioning guiding template entity prototype. The advantage of the invention is that: a surgery positioning guiding template adopts a retention method of dental face-bone face combination support with accurate retention, high precision and convenient process.

Owner:SHANGHAI EAST HOSPITAL

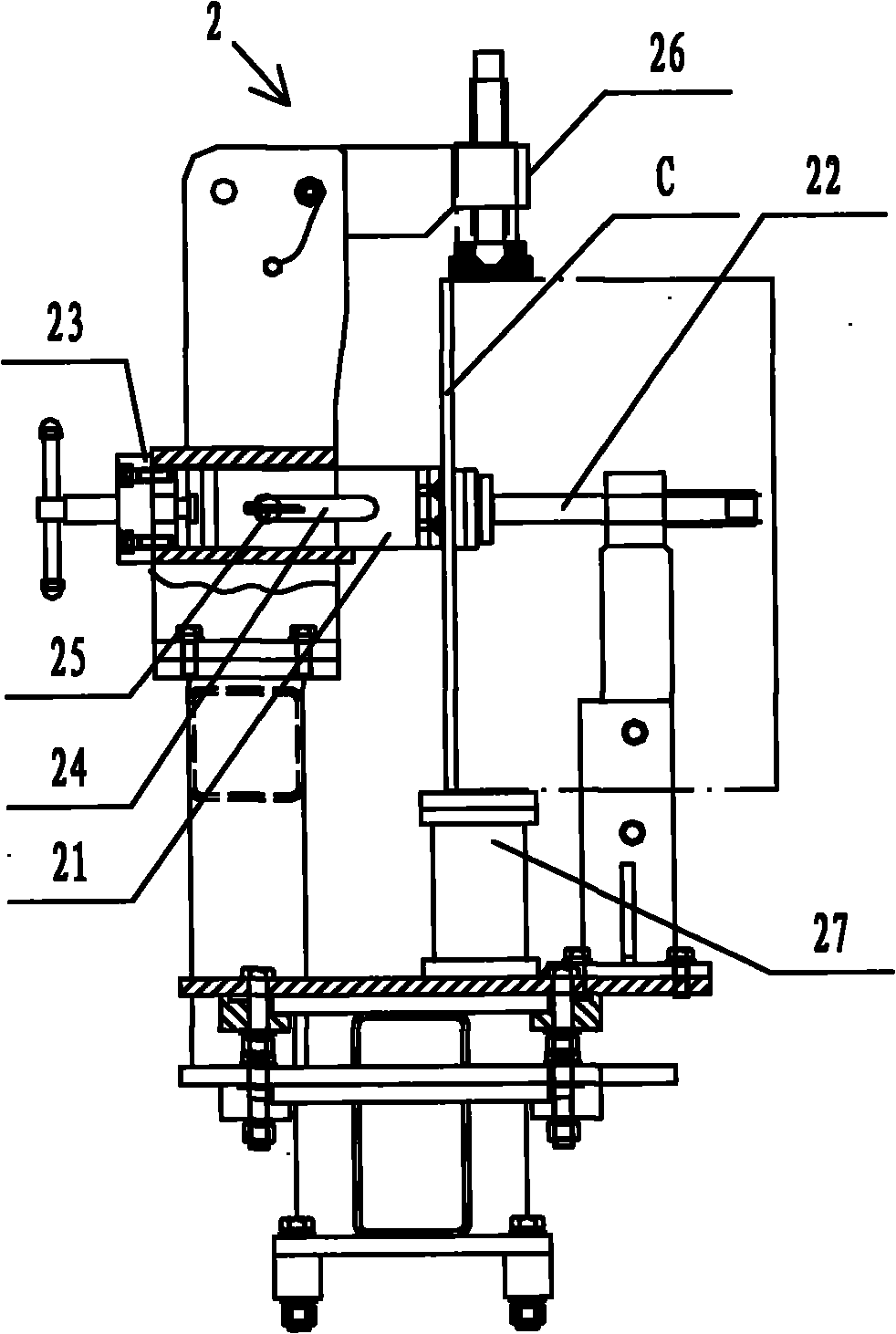

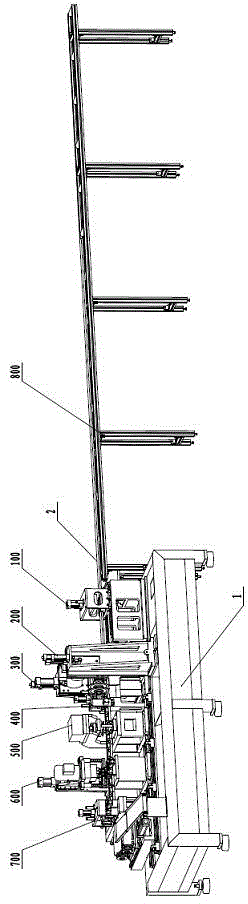

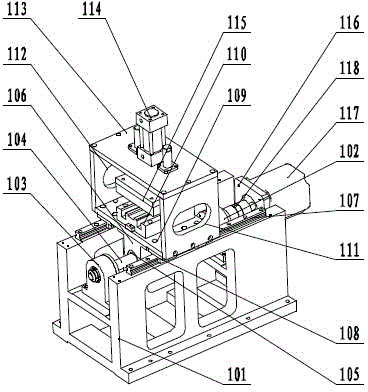

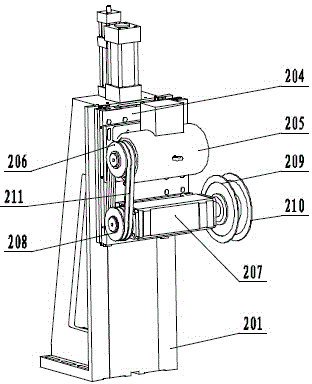

Hinge machining host and machining method

ActiveCN104647049AReasonable positioningScientific and reasonable conceptionMetal sawing devicesFeeding apparatusMotor drivePunching

The invention discloses a hinge machining host. The hinge machining host comprises a lathe bed, a control system and a hydraulic system; an automatic feeding device, a sawing device, a sawing compacting device, a punching device, a drilling device and a cutting device are arranged sequentially on the lathe bed along the feeding direction; the sawing device further comprises a front sawing device and a rear sawing device, the structure of the front sawing device is the same as the structure of the rear sawing device, the front and back sawing devices are arranged symmetrically front and back; a supporting device is arranged on the right side of the automatic feeding device; a service motor drives the feeding, the transmission precision is high; each station machines at the same time, the progresses are the same, and the machining efficiency is high. The invention further discloses a method for machining the hinge by the device disclosed by the invention; the method comprises the following steps: the feeding device compacts profiles and feeds; each station compacts the profiles; the sawing, punching, drilling and cutting devices machine the profiles at the same time; each station returns; the feeding device releases the profiles; the feeding device returns back to the initial position; the feeding device compacts the profiles again; each station looses the profiles; the feeding device feeds again; and then the next process is performed.

Owner:济南天辰智能装备股份有限公司

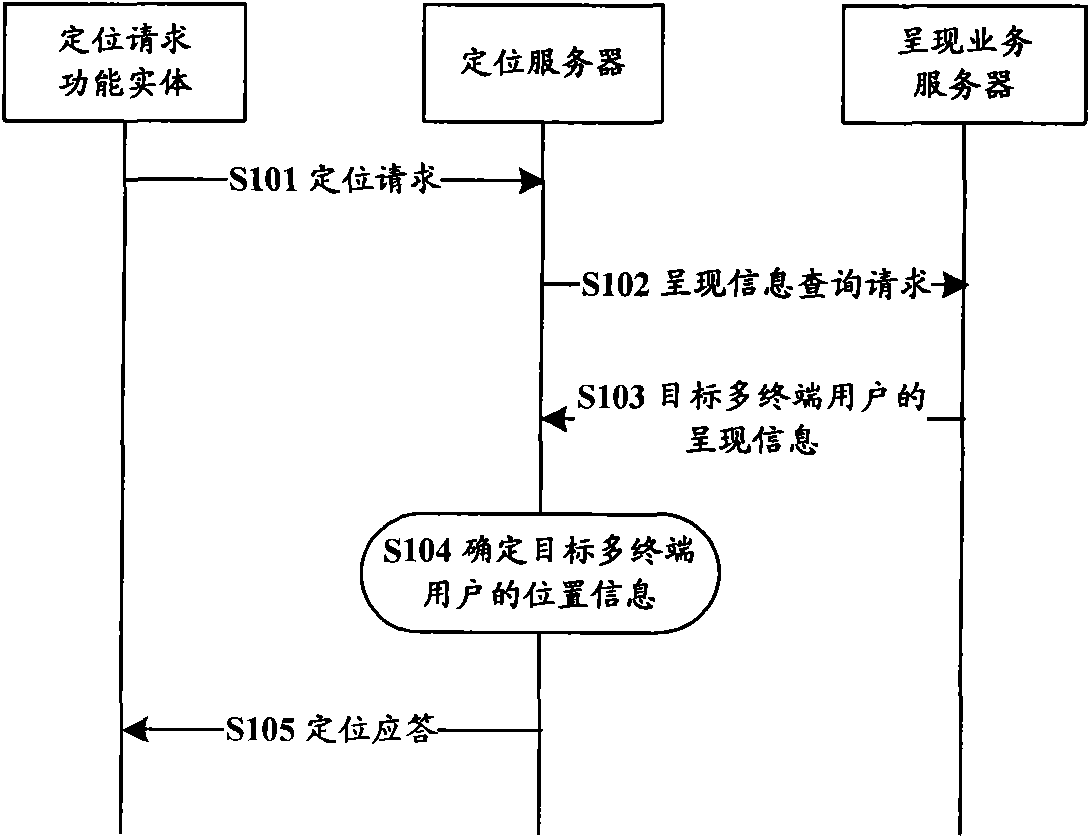

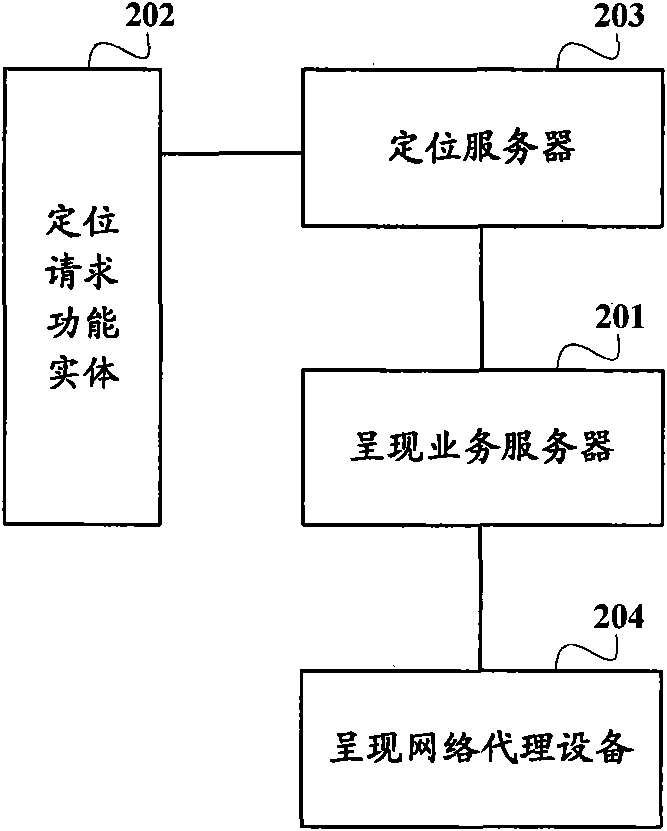

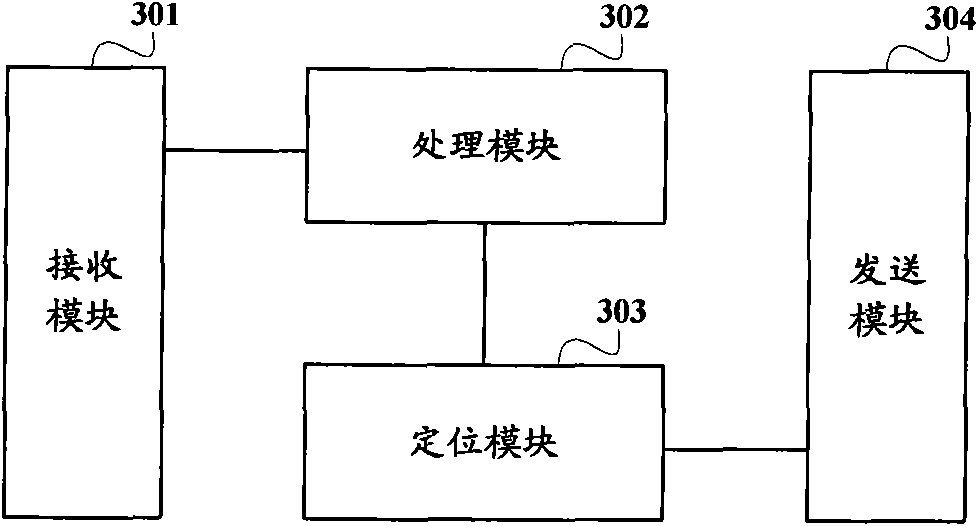

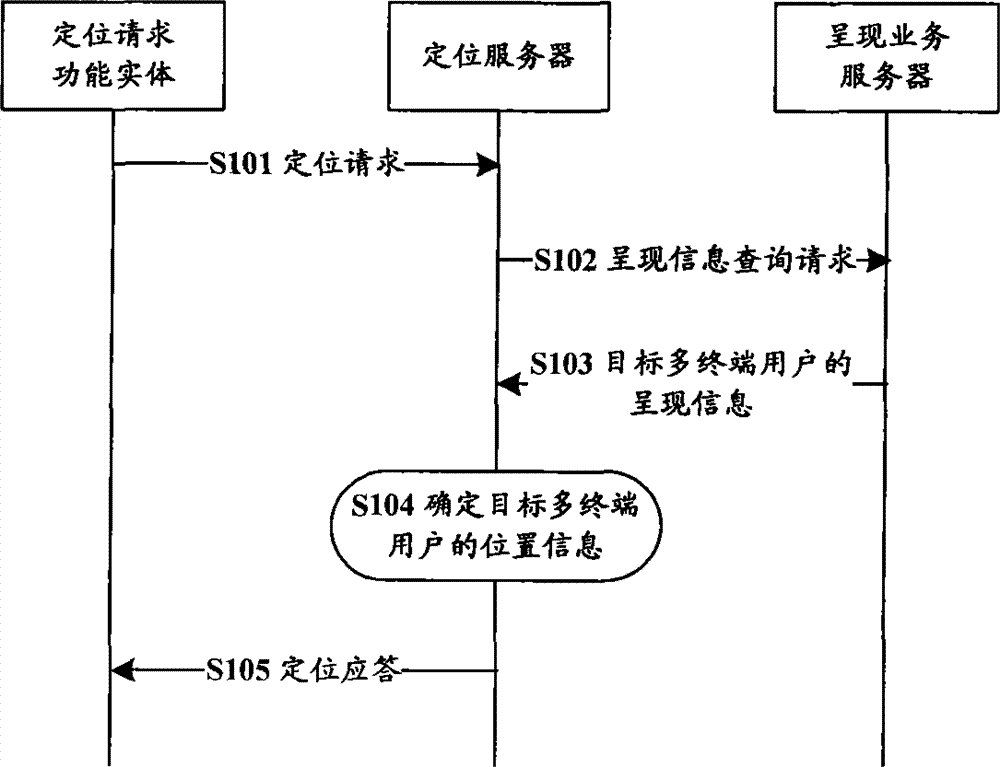

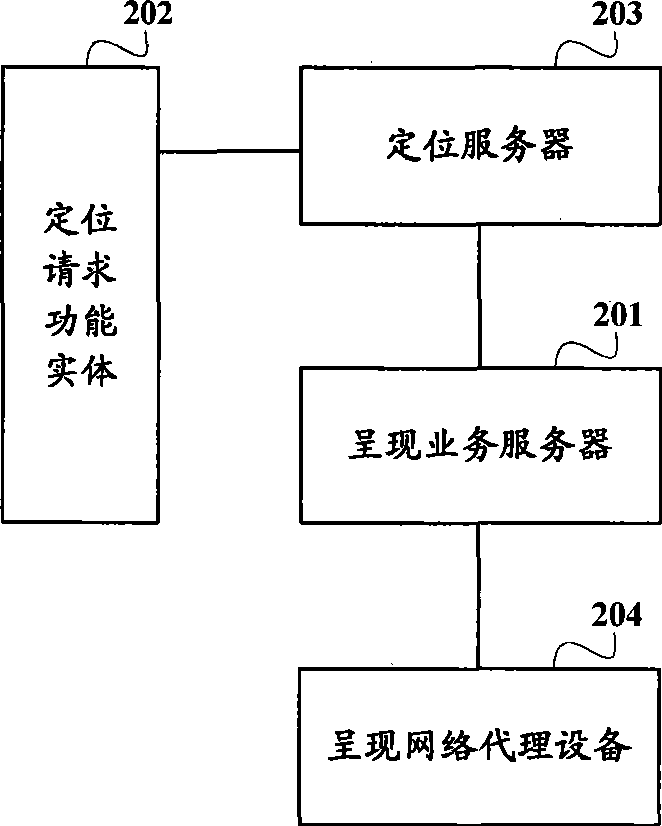

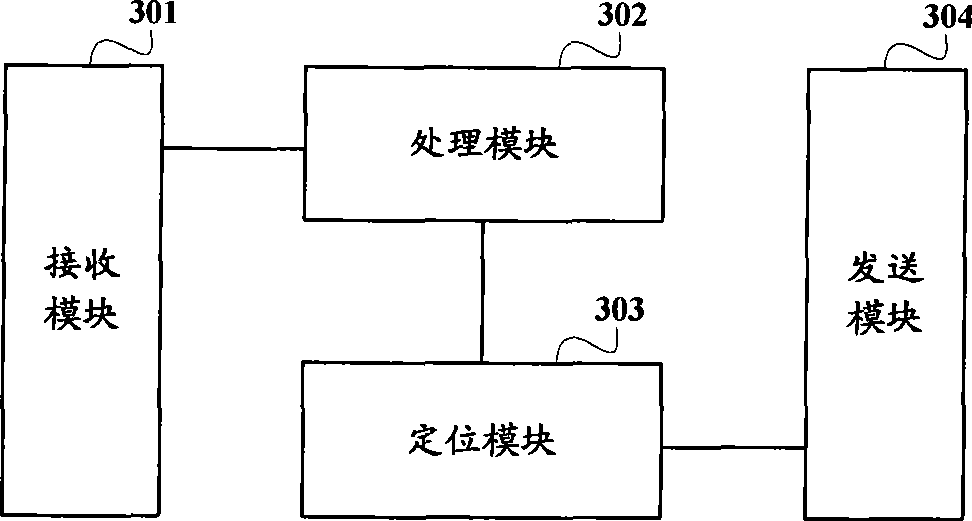

User positioning method, device and system

ActiveCN101686254AReasonable positioningEffective positioningTransmissionAccess networkPositioning technology

The invention relates to the communication field, in particular to a user positioning technology. The invention discloses a user positioning method, a device and a system, which are used for realizing reasonable and effective positioning to multiple terminal users. The user positioning method comprises the following steps: a positioning request is received and carries any identification information of the multiple terminal users of a target; a service server is inquired and presented according to the positioning request, and the presented information of the multiple terminal users of the target corresponding to the identification information is acquired, wherein the presented information comprises the terminal type of the online terminals and the information of the access network which isswitched in; and positioning information of the multiple terminal users of the target is determined according to the terminal type of online terminals and access network information, and positioning answer carried with the positioning information is returned.

Owner:CHINA MOBILE COMM GRP CO LTD

Machining tooling fixture for welding joint tensile sample and clamping and positioning method for machining tooling fixture

ActiveCN102699724AChange spacingAdjustable positionPositioning apparatusMetal-working holdersMachiningIndustrial engineering

The invention relates to a machining tooling clamp for a welding joint tensile sample and a clamping and positioning method for the welding joint tensile sample. A base is mounted on a milling machine. A sample to be machined is fixedly arranged between a fixed support block and a movable support block which are arranged in opposite positions on the base through two clamping parts of a sample clamping device; the space between the movable support block and the fixed support block can be changed by adjusting the position of the movable support block on the base so as to adapt to the length of the sample; after one surface of the sample is machined, the sample clamping device and the sample are taken out and turned and refixed between the movable support block and the fixed support block; and then the other surface of the sample is machined. Therefore, according to the machining tooling fixture and the clamping and positioning method disclosed by the invention, the machining work efficiency can be increased, the machining precision is ensured and the machining cost is greatly reduced simultaneously.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

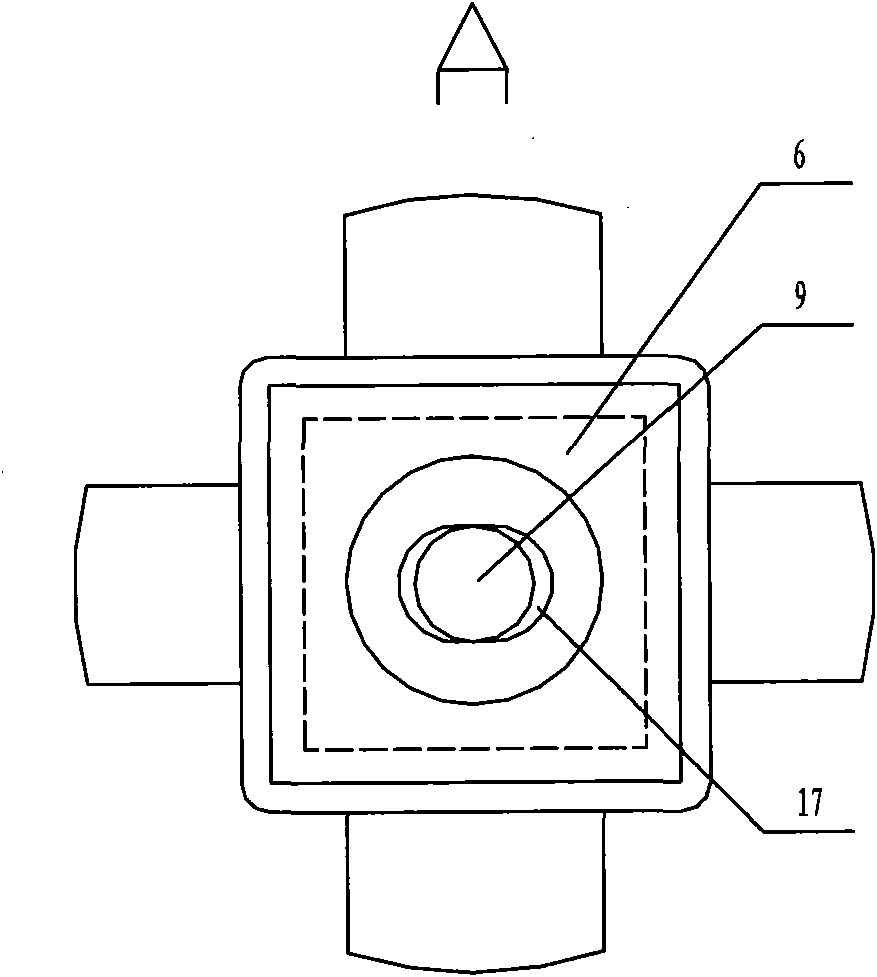

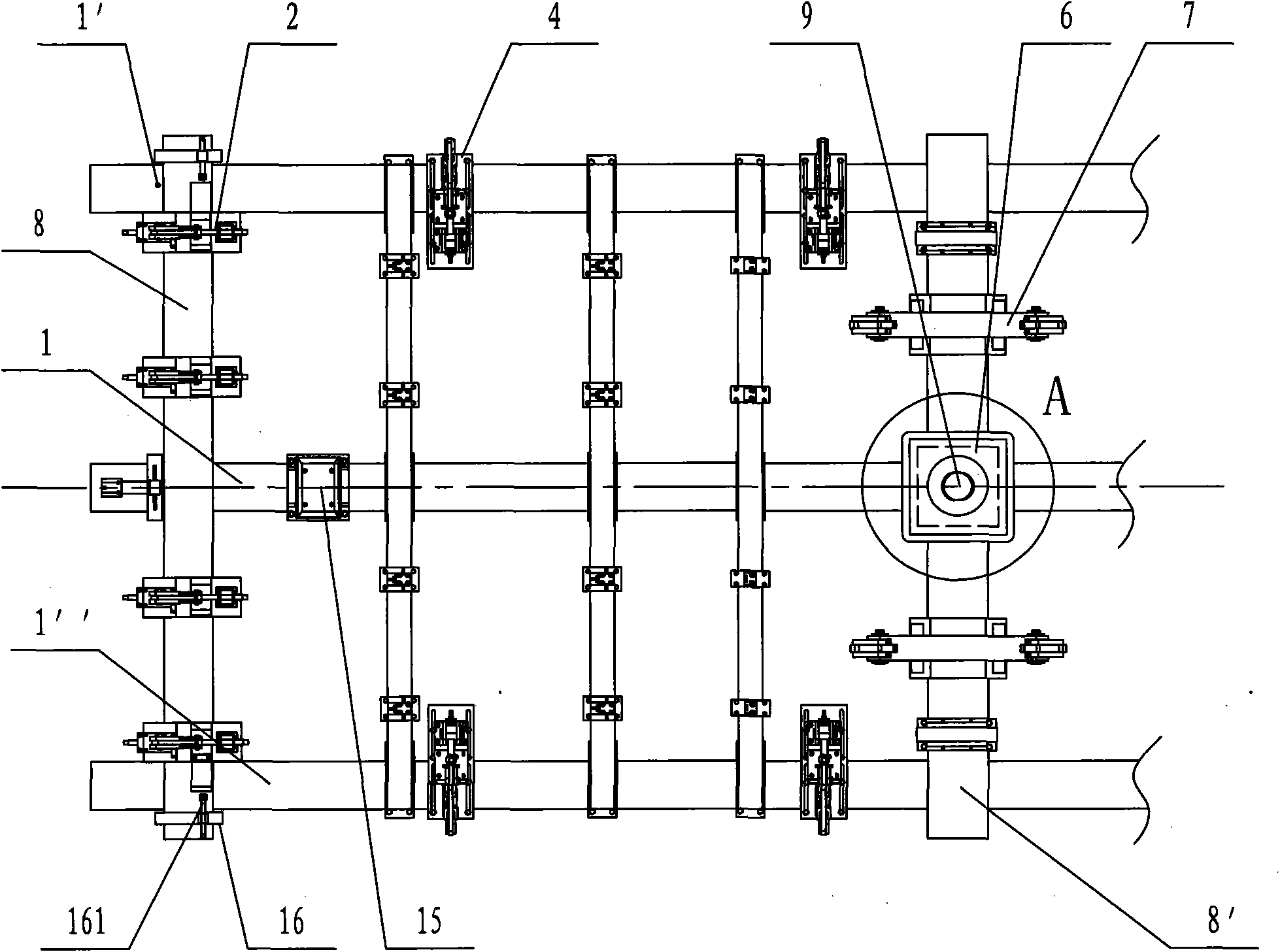

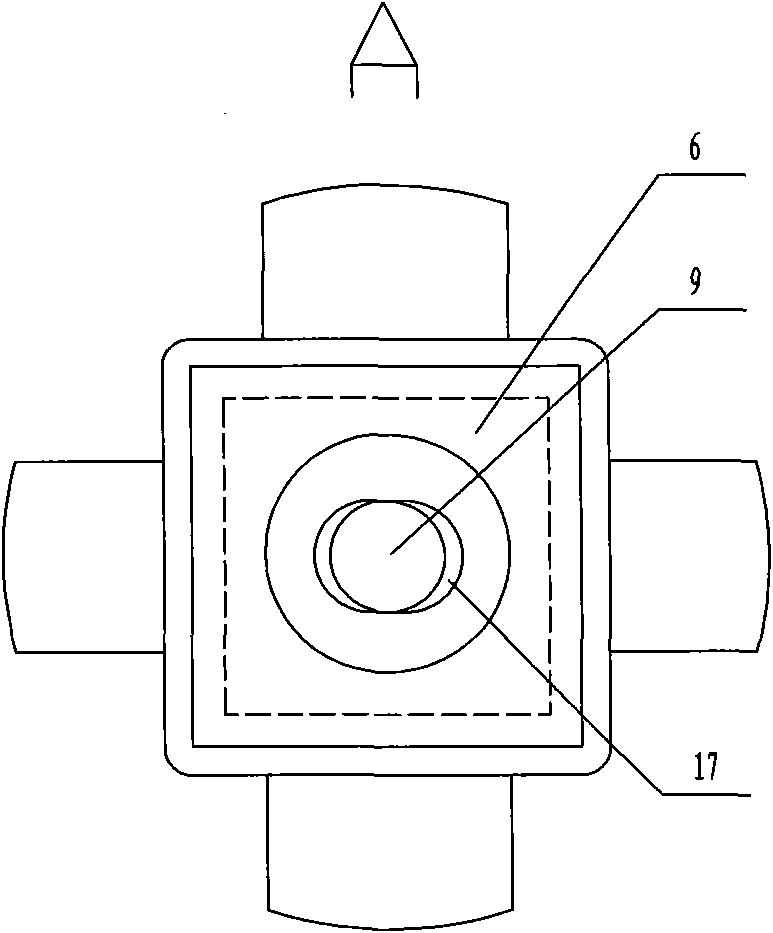

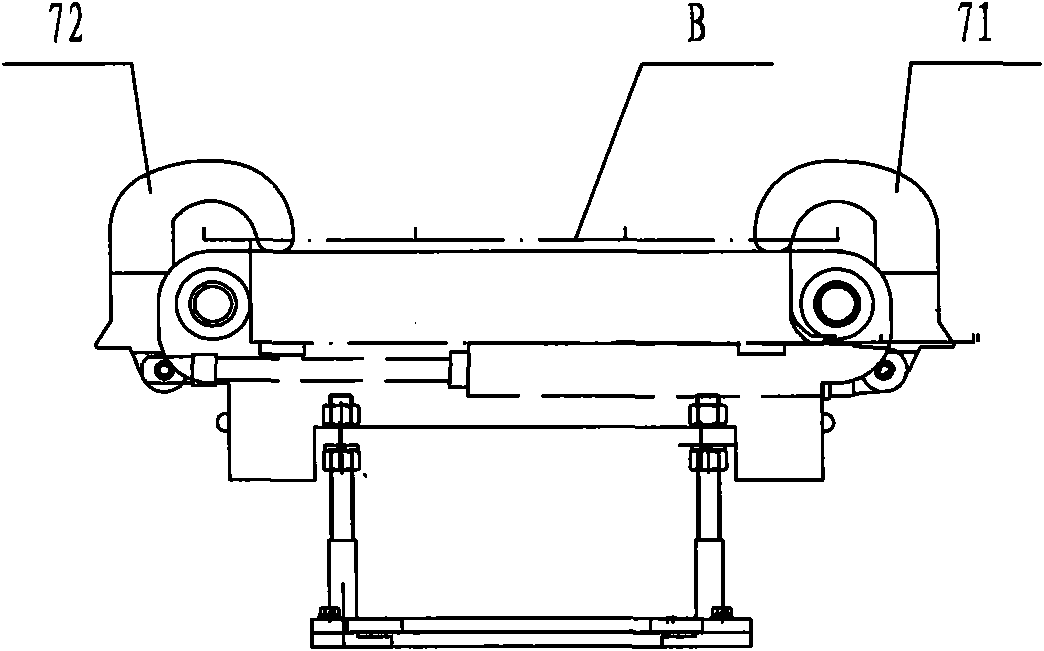

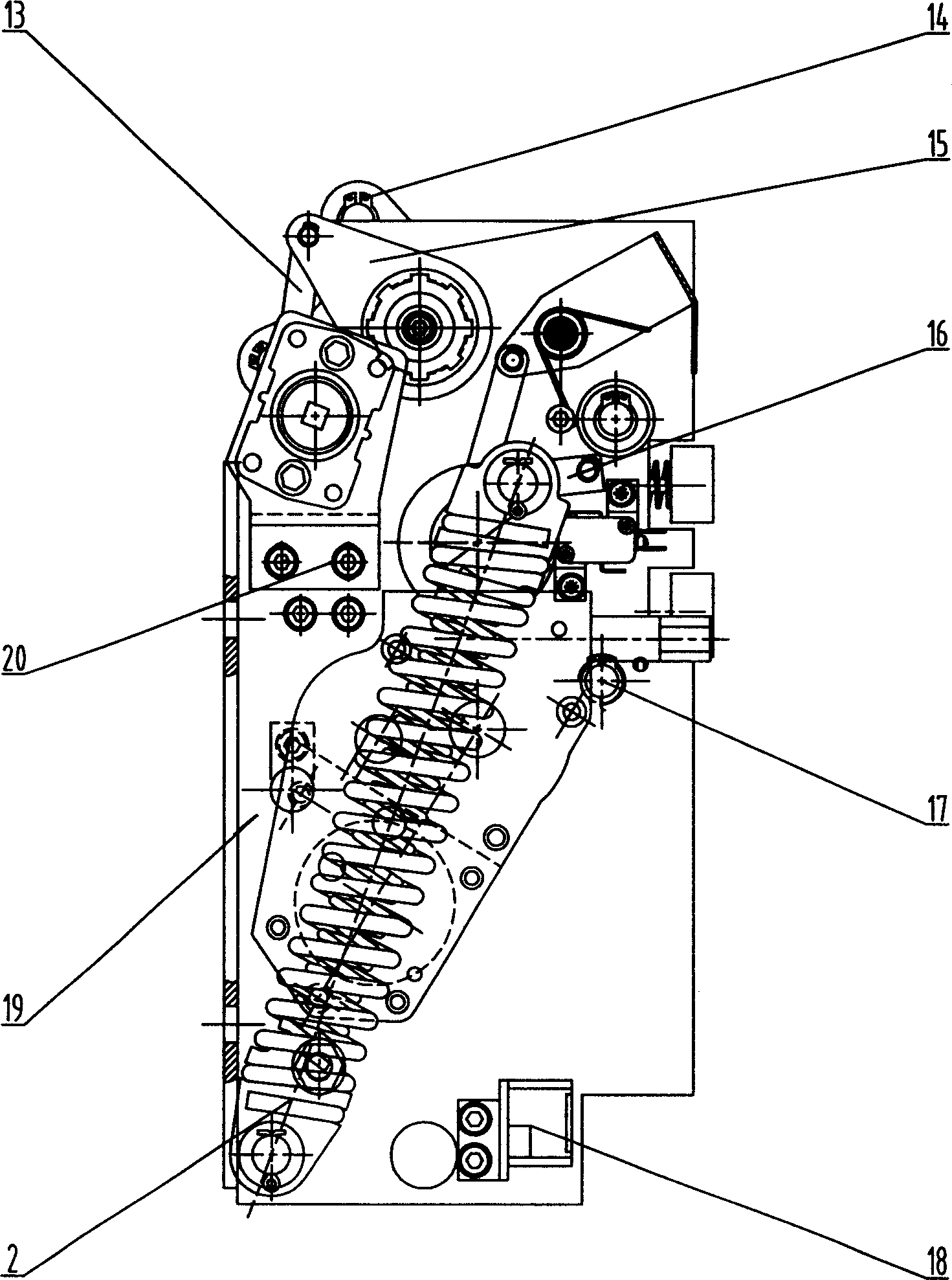

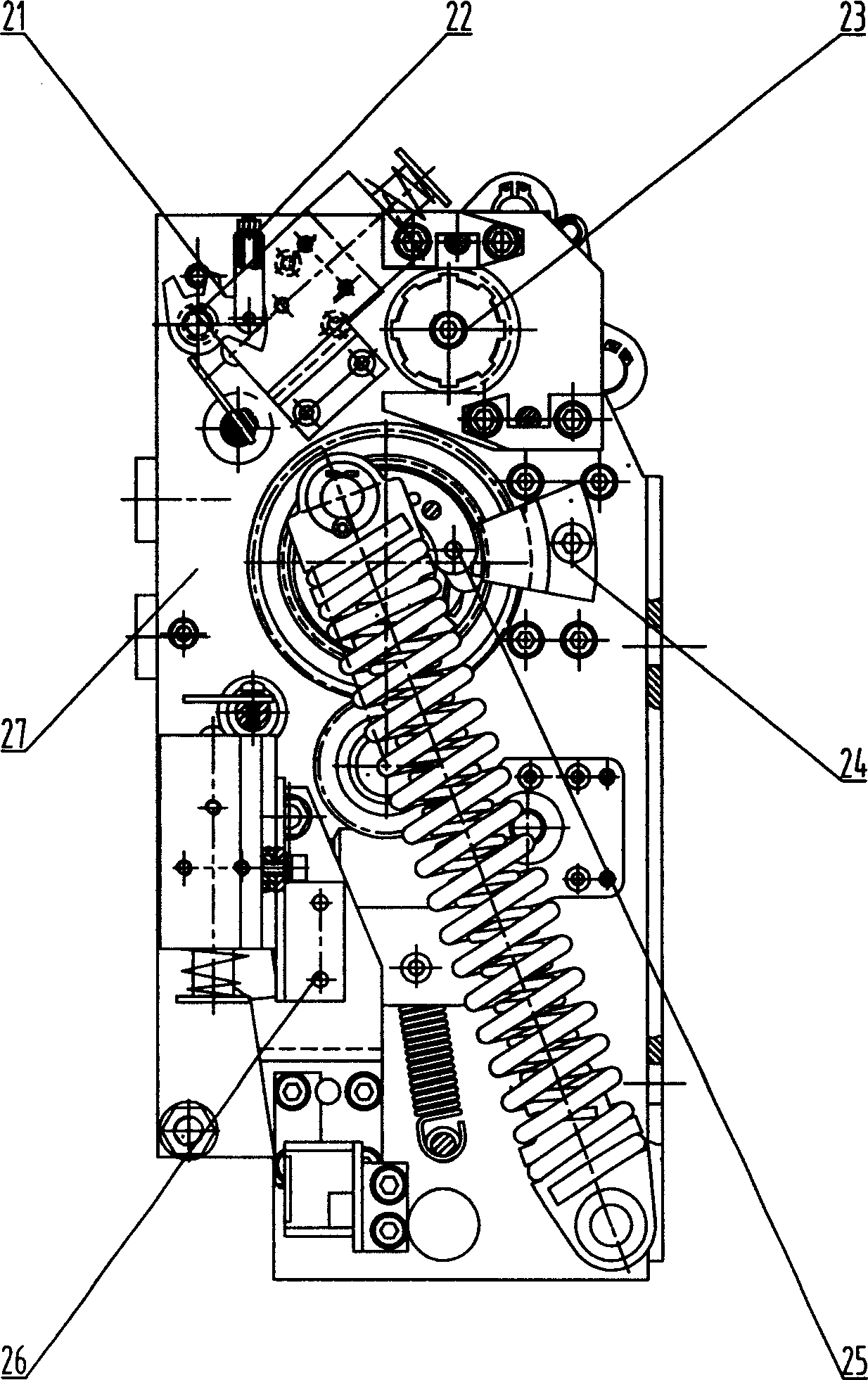

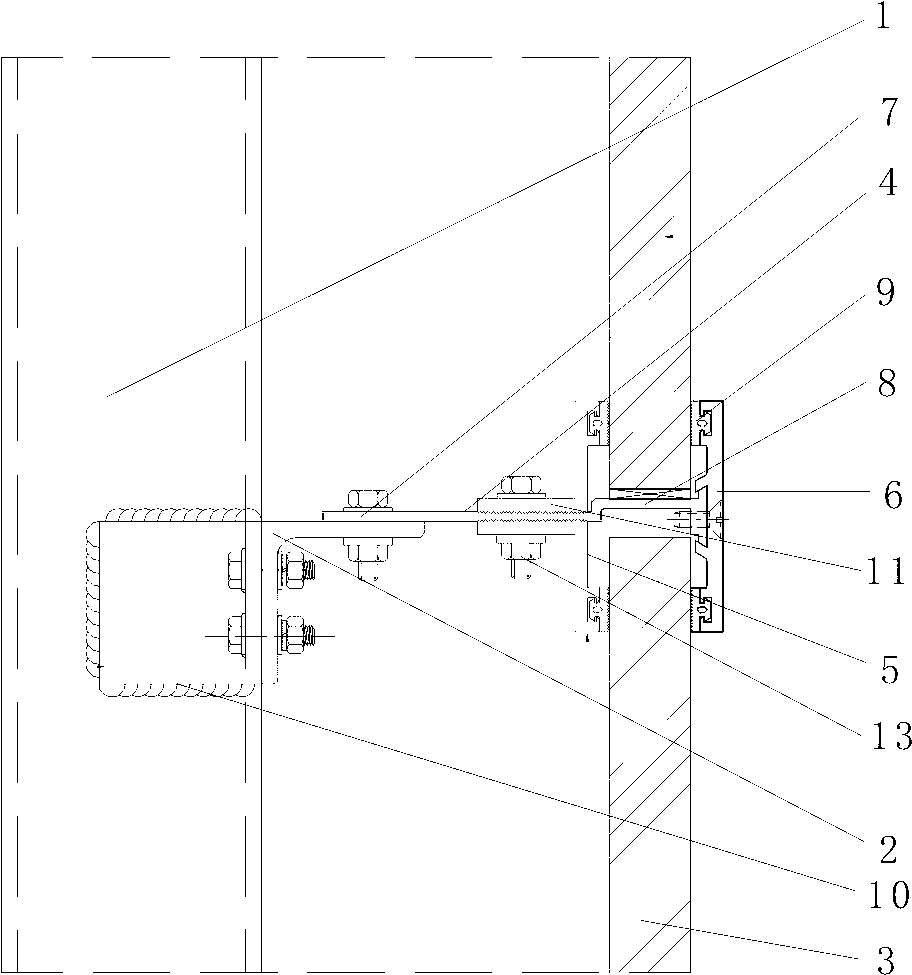

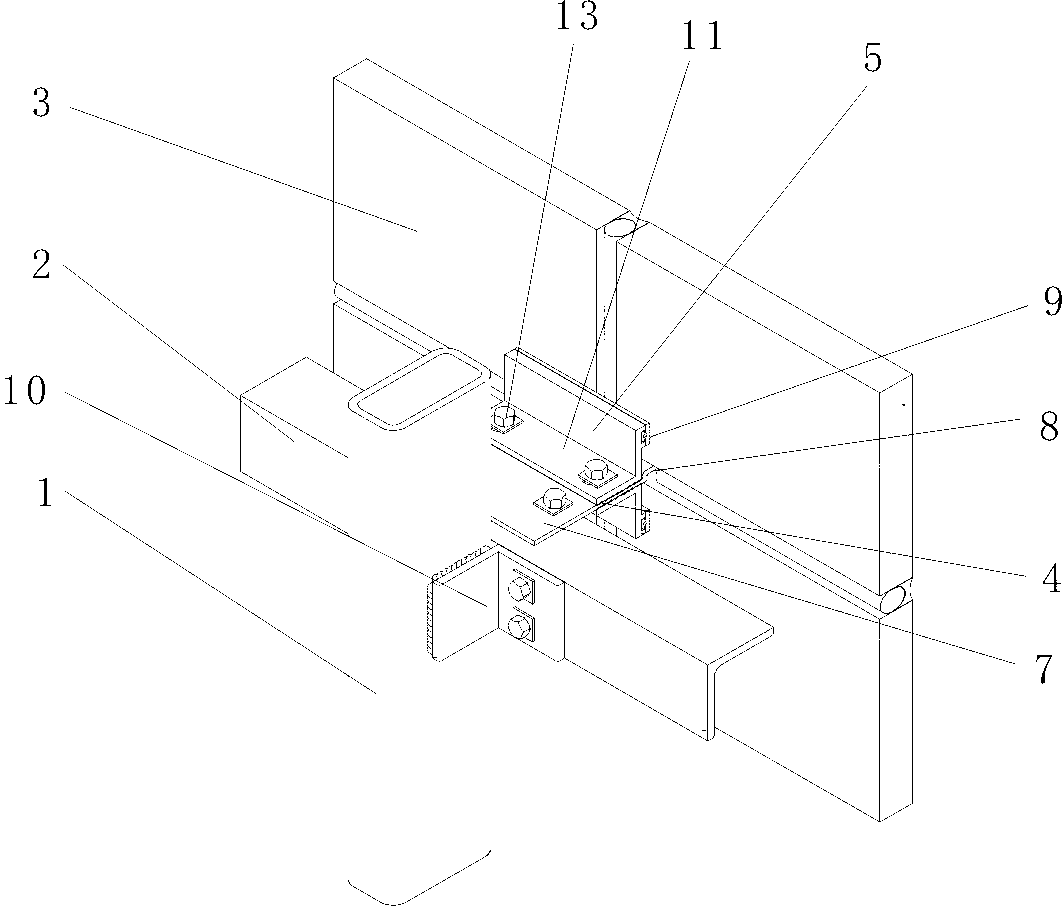

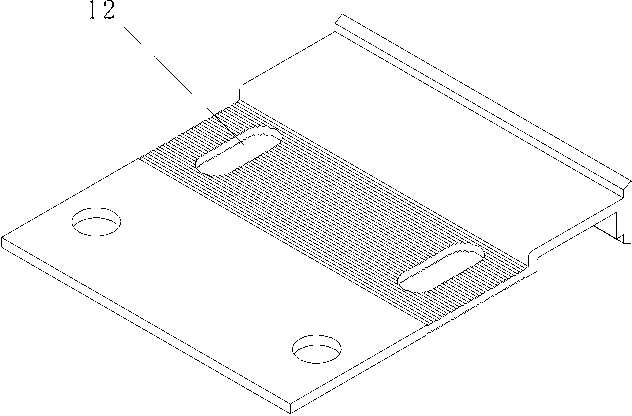

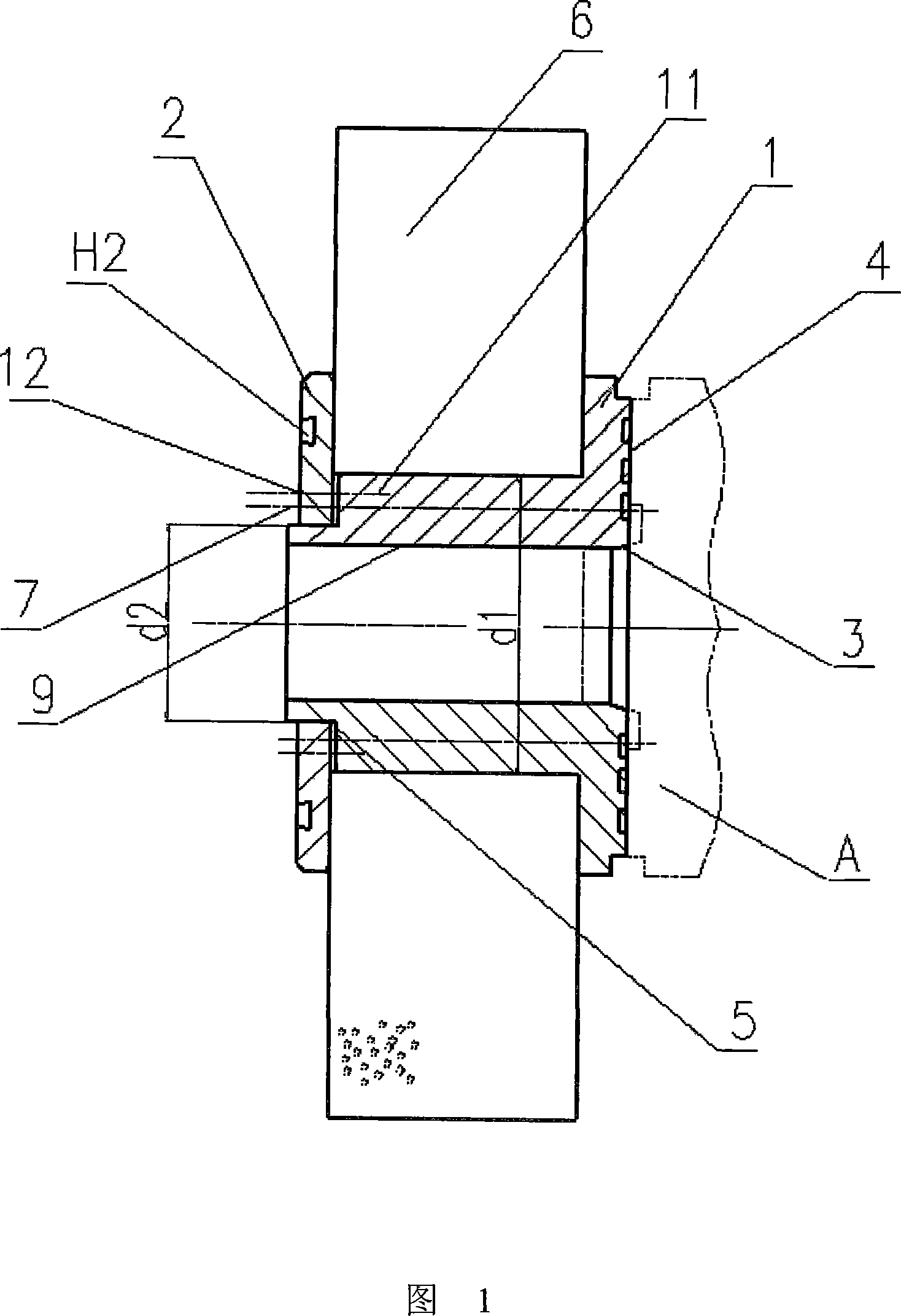

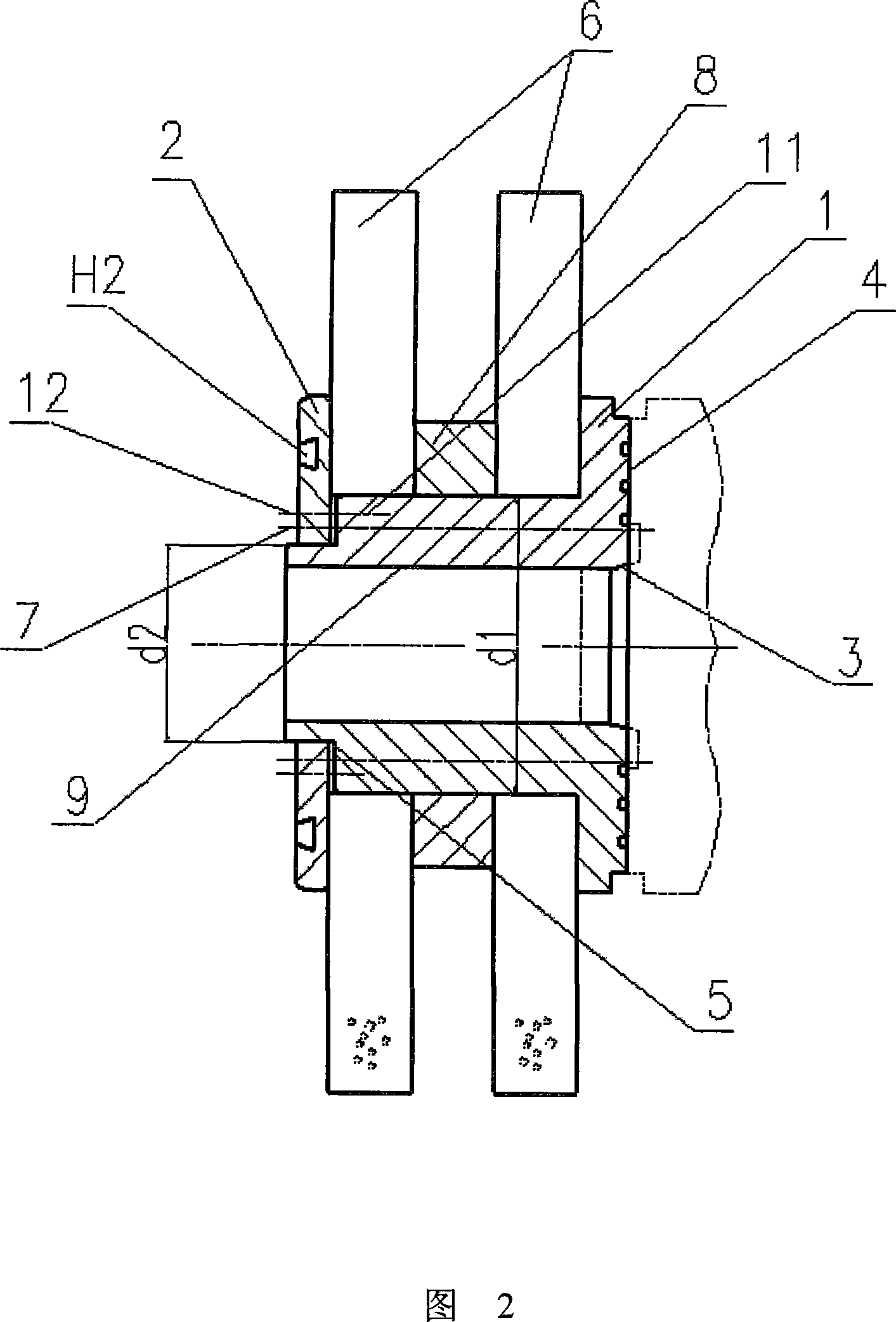

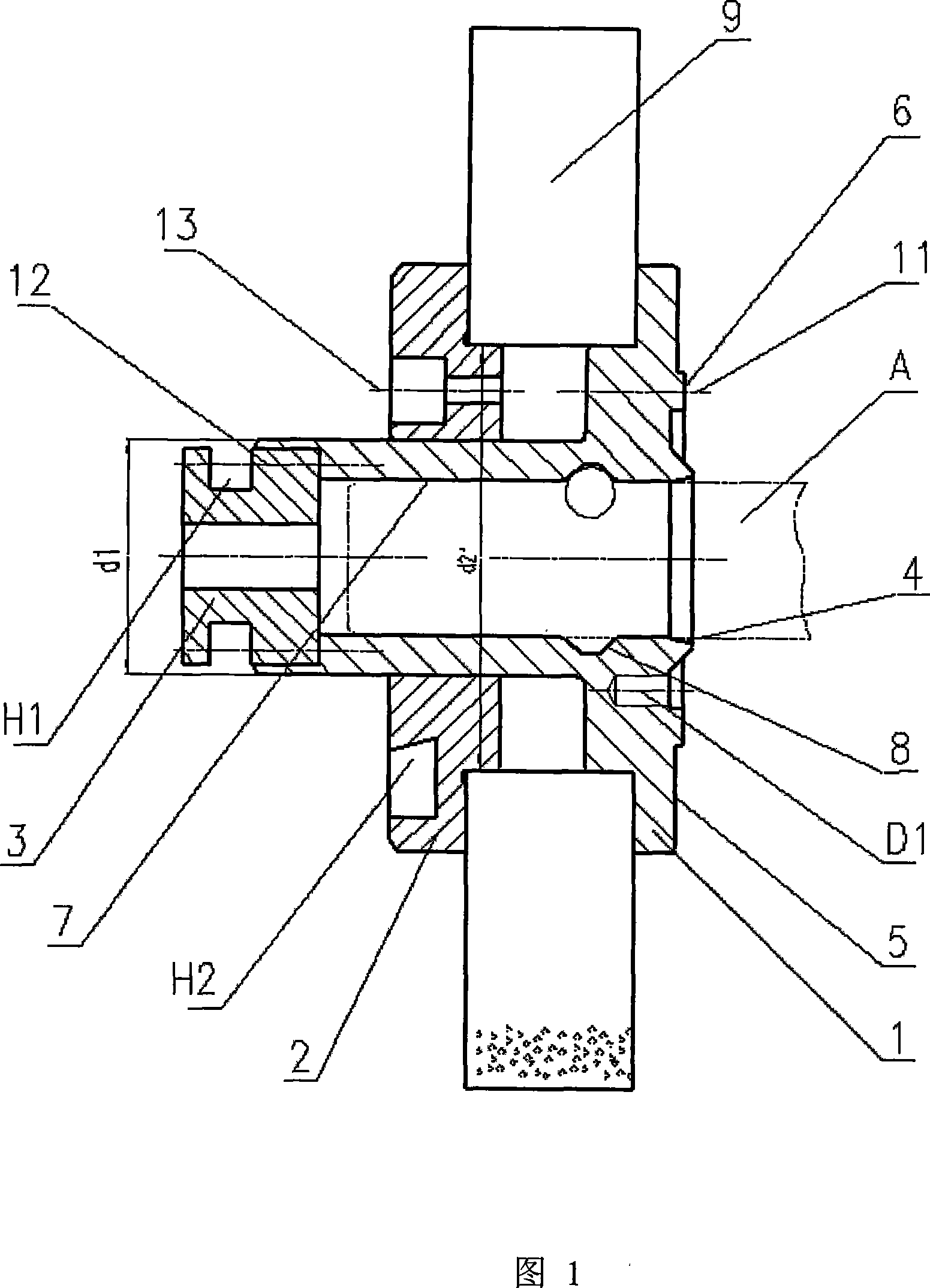

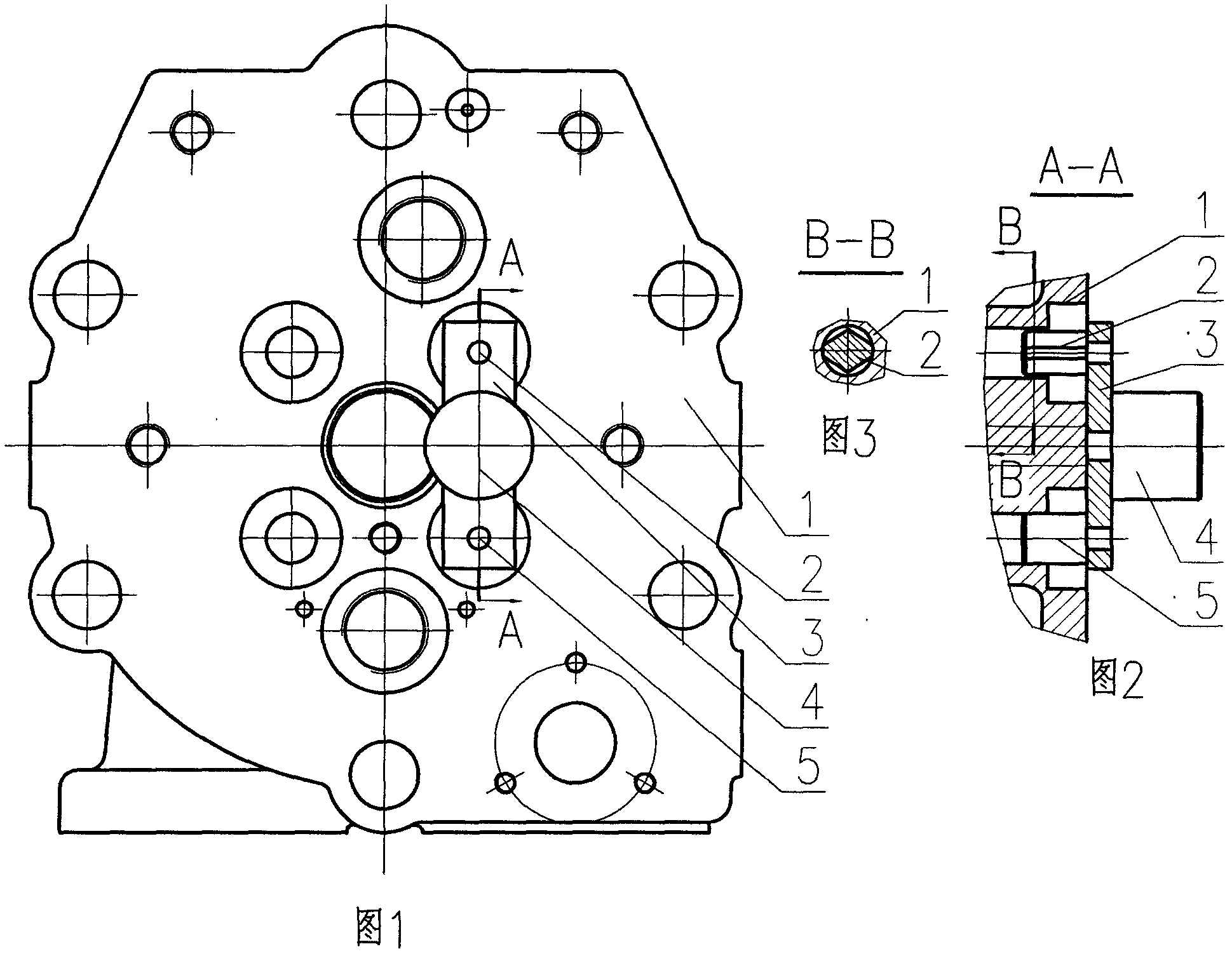

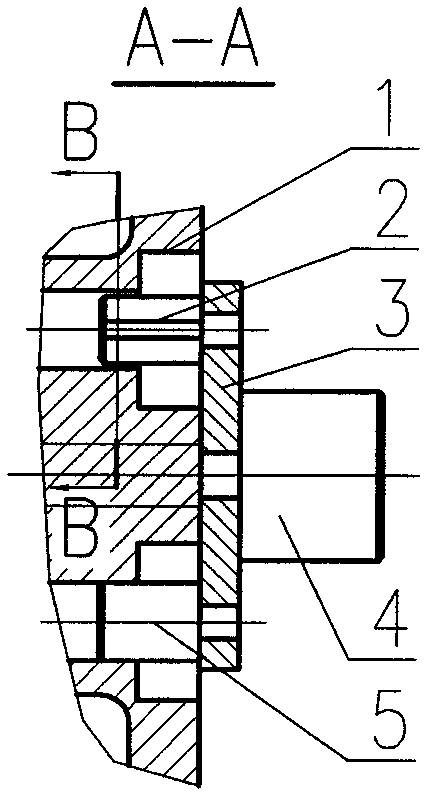

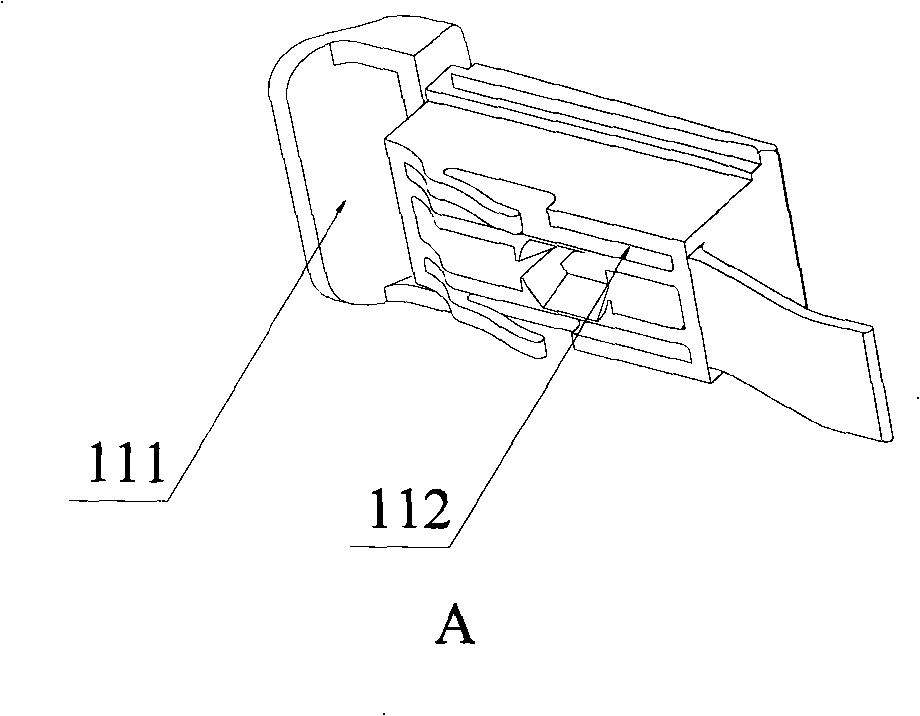

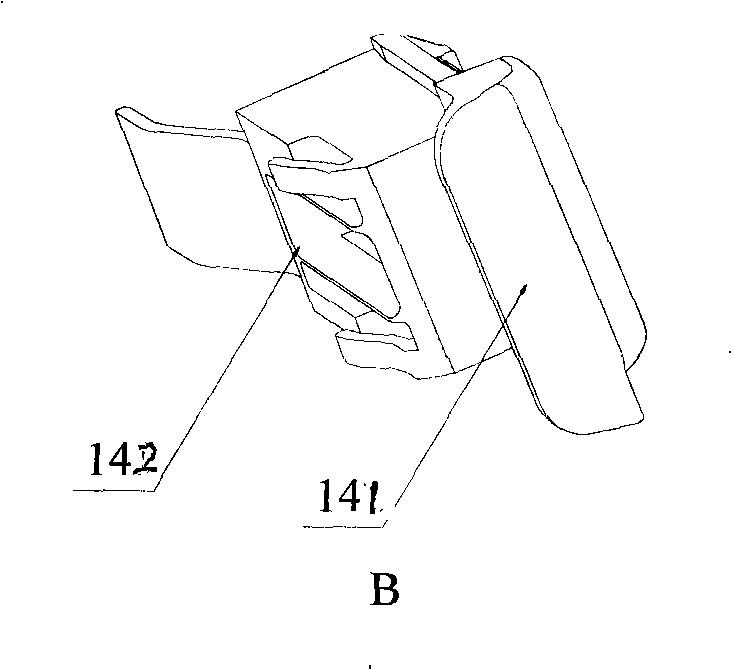

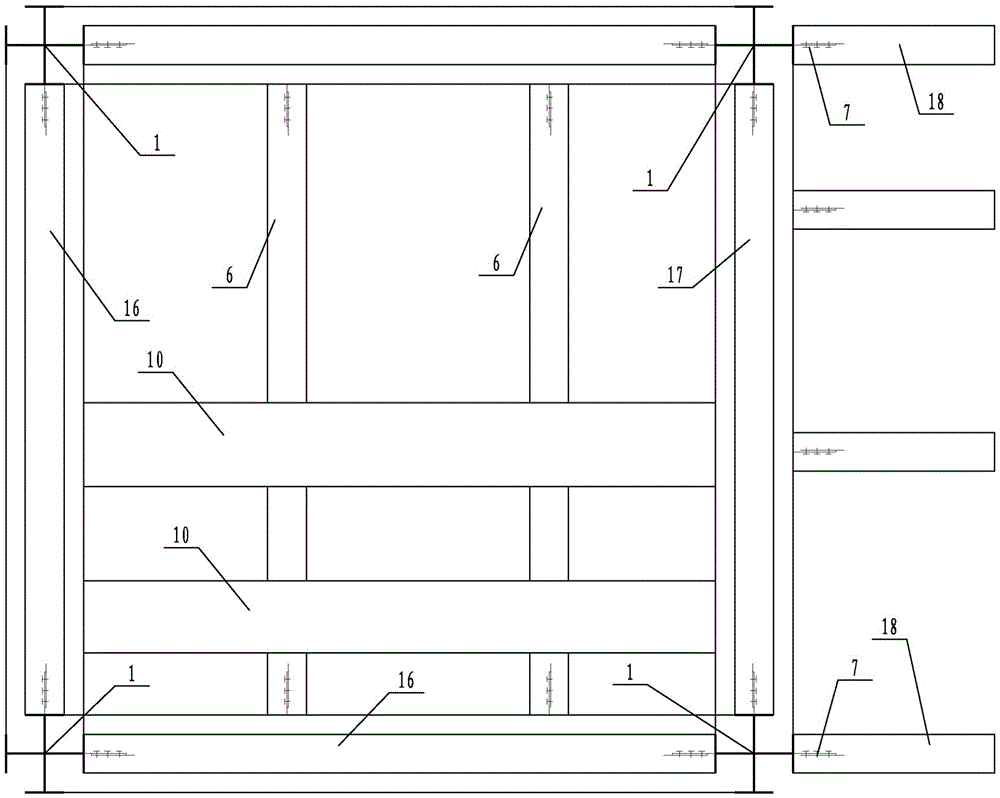

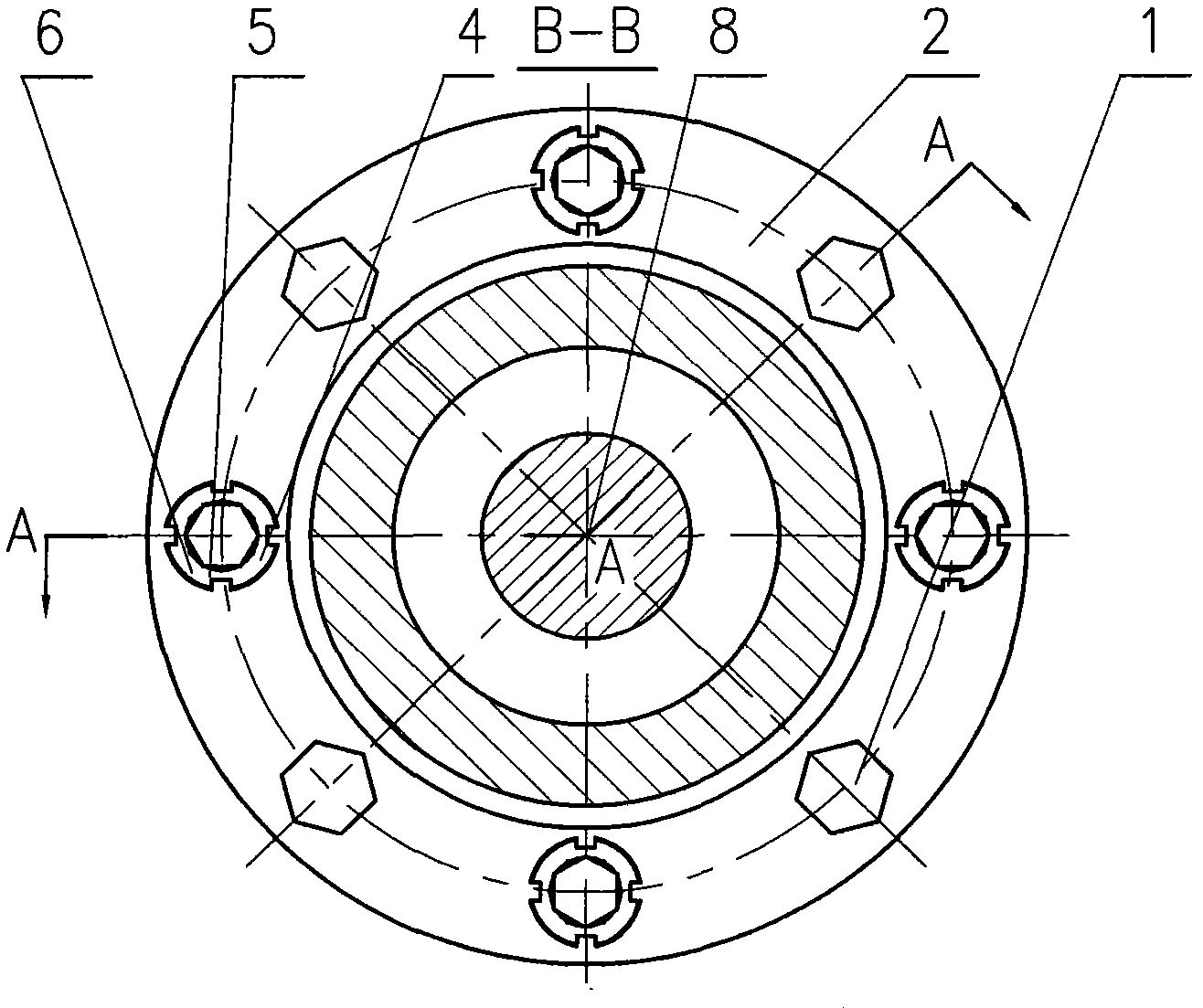

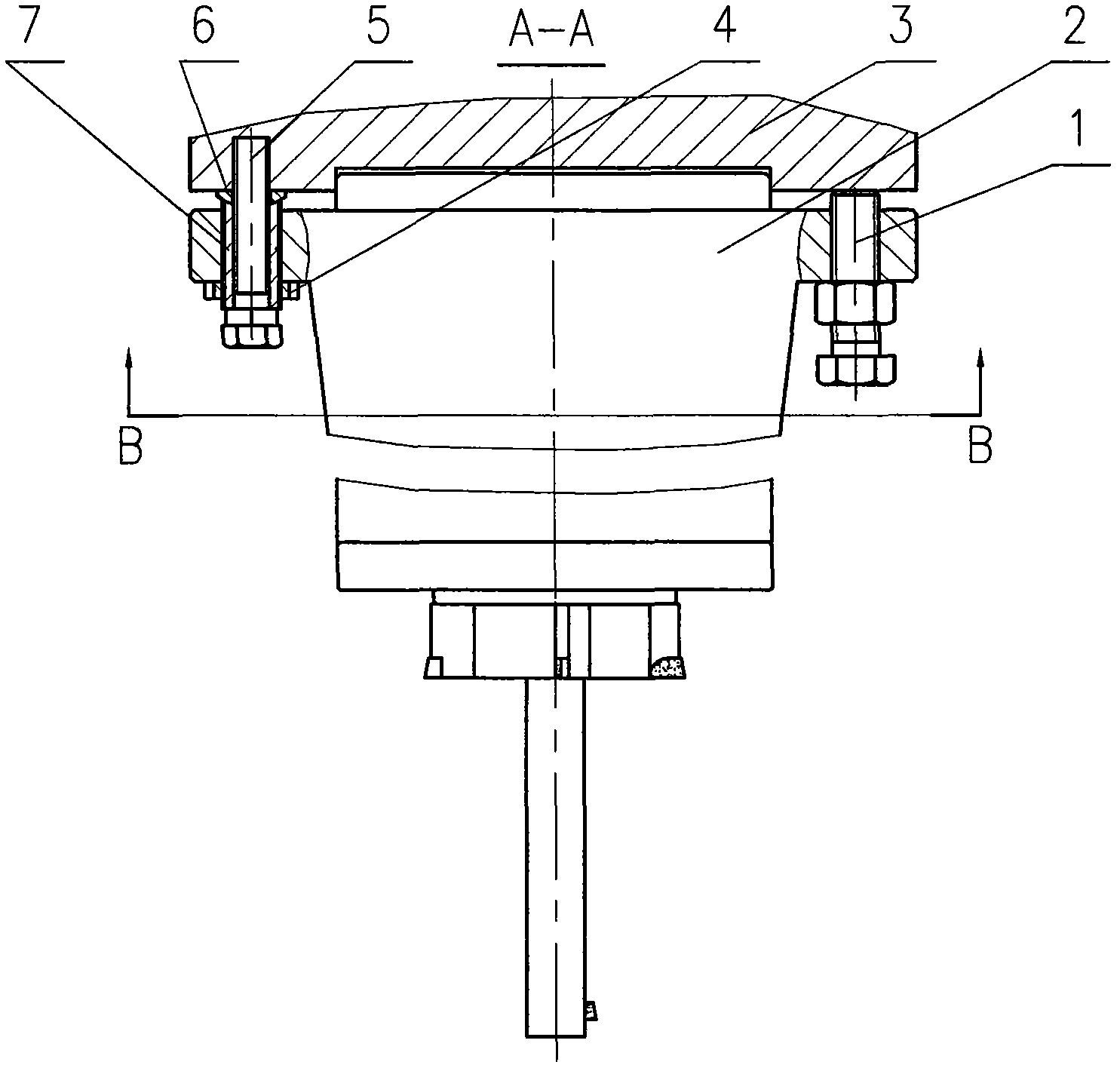

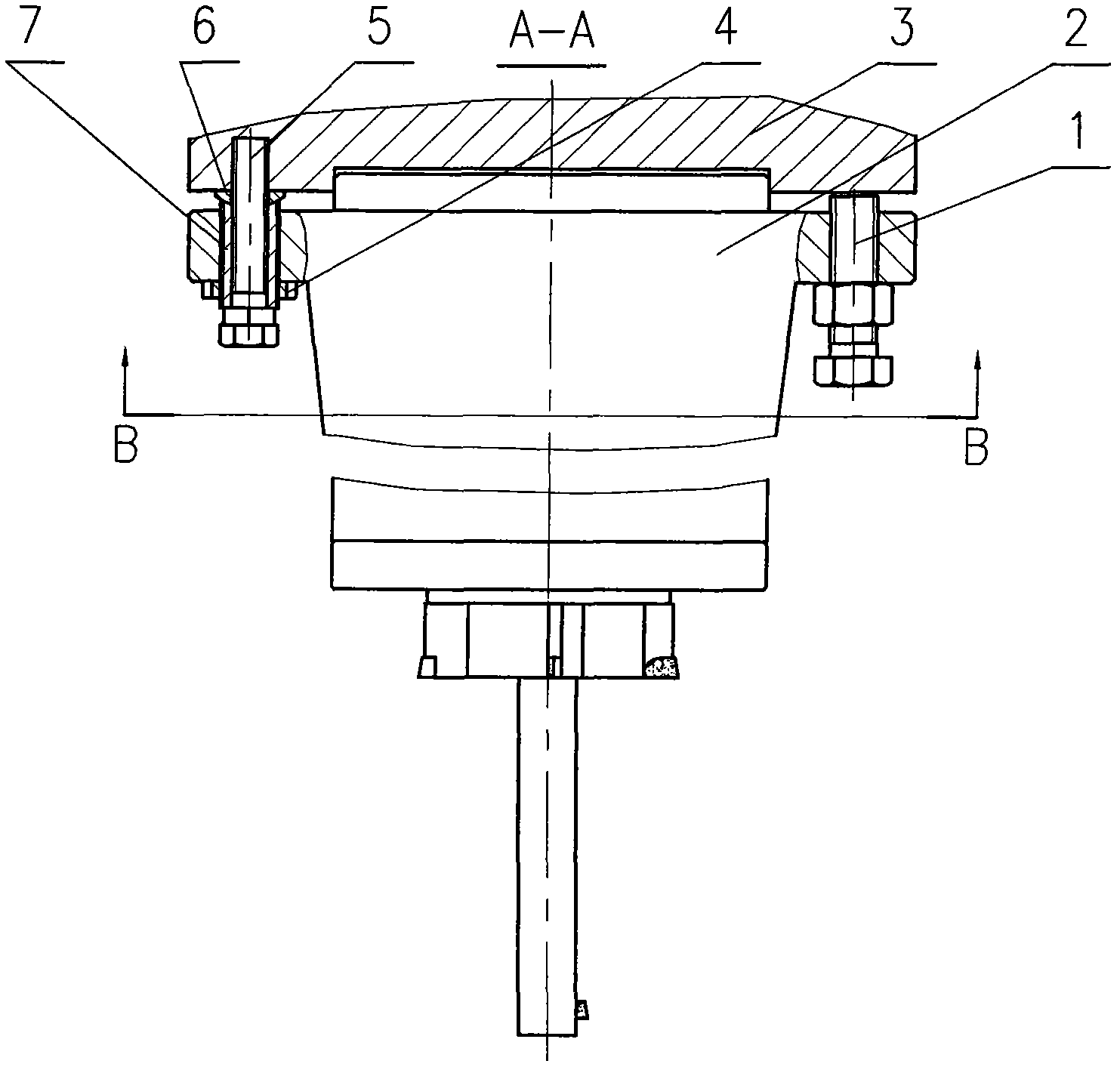

End traction and bolster positioning and clamping mechanism for chassis centered tyre

ActiveCN102091930AReasonable positioningHigh positioning accuracyMetal working apparatusBolsterEngineering

The invention discloses an end traction and bolster positioning and clamping mechanism for a chassis centered tyre, which comprises an end beam positioning and clamping device fixed on an outer end large crossframe, a horizontal centering device fixed on a middle longitudinal frame between inner and outer end large crossframes, and an upper center plate positioning surface arranged on the upper end face of the middle of the inner end large crossframe, wherein the upper center plate positioning surface is provided with an upper center plate central hole positioning pin positioned in the center line of the middle longitudinal frame; and the horizontal centering device takes the center line of a chassis towing beam as a positioning reference. For the chassis centered tyre, in the chassis end traction and bolster height positioning, lower planes of two upper center plates of the end traction and bolster and the lower plane of the end beam are taken as a reference, and in the horizontal positioning, the upper center plate central hole positioning pin and the horizontal centering device are used for positioning. Therefore, the positioning and clamping mechanism is reasonable in positioning mode without manual marking, high in positioning accuracy and high in production efficiency.

Owner:CRRC NANJING PUZHEN CO LTD

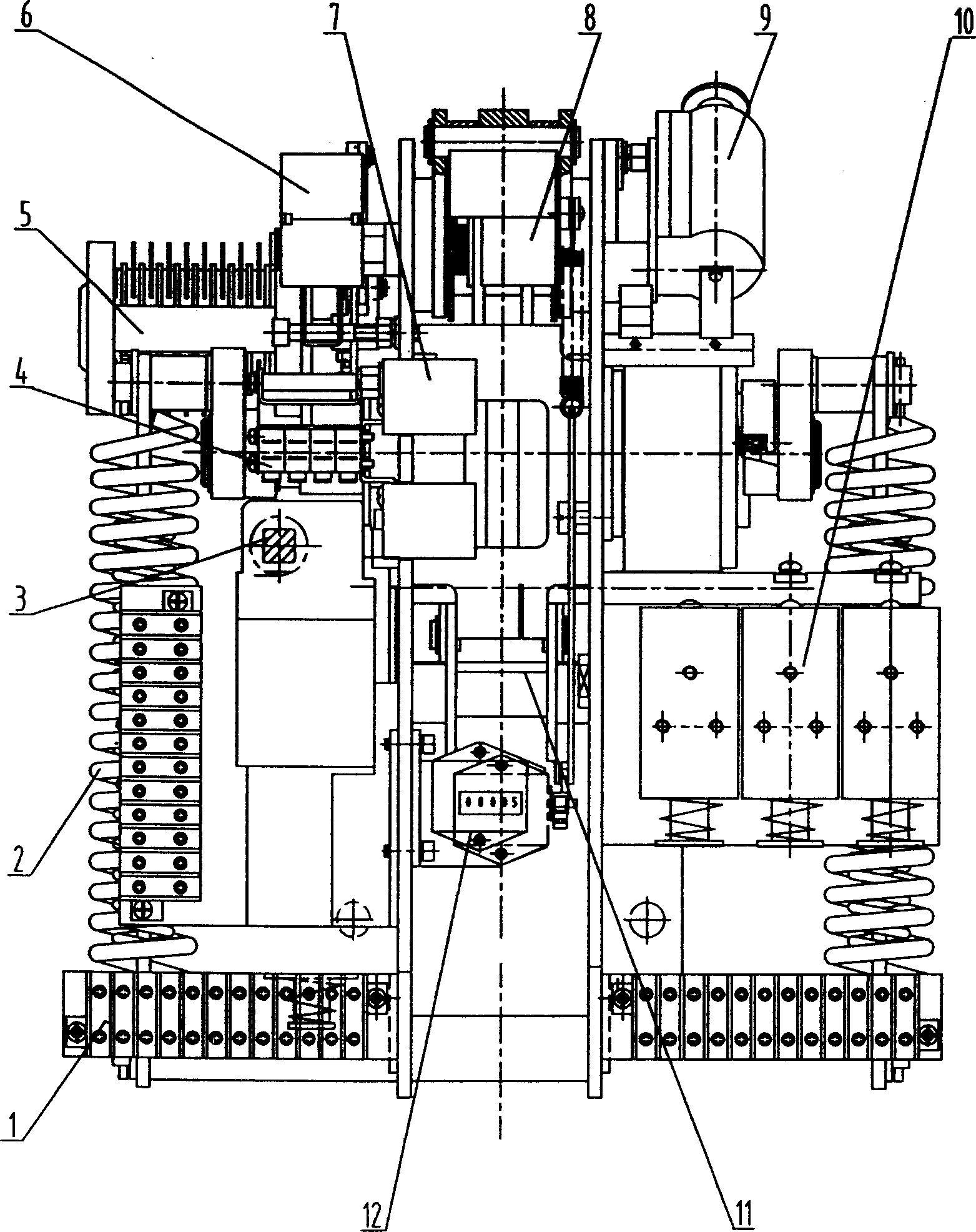

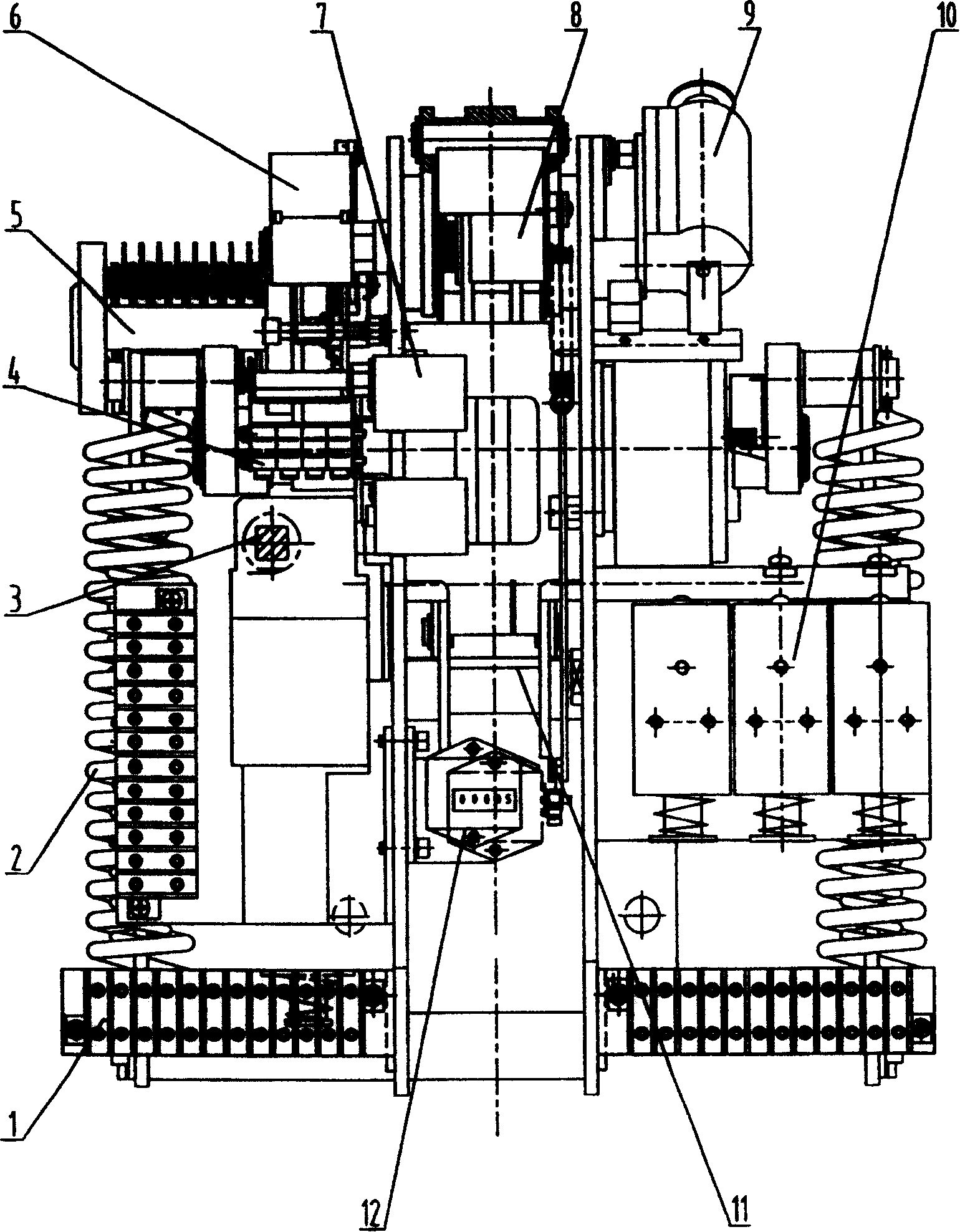

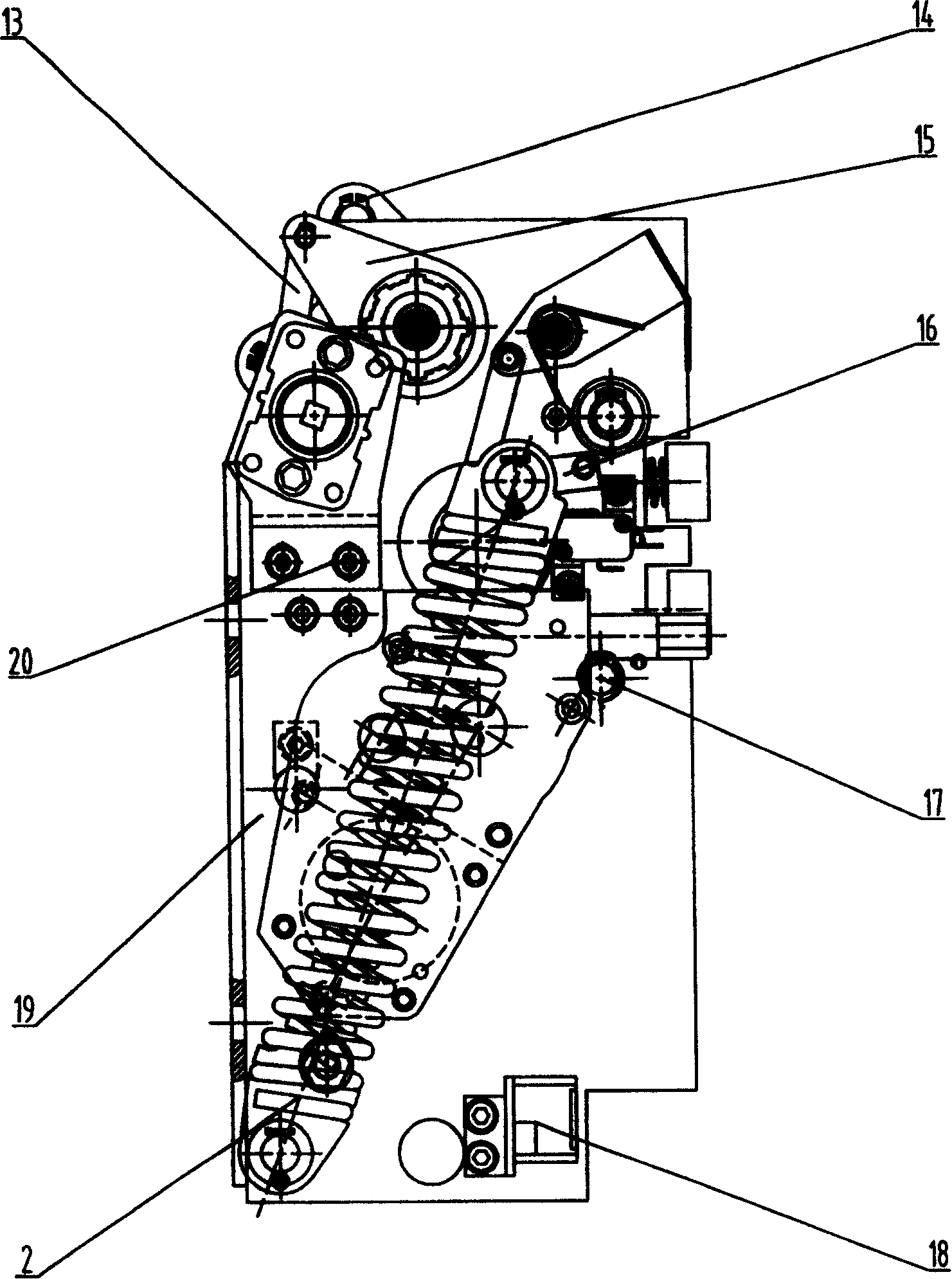

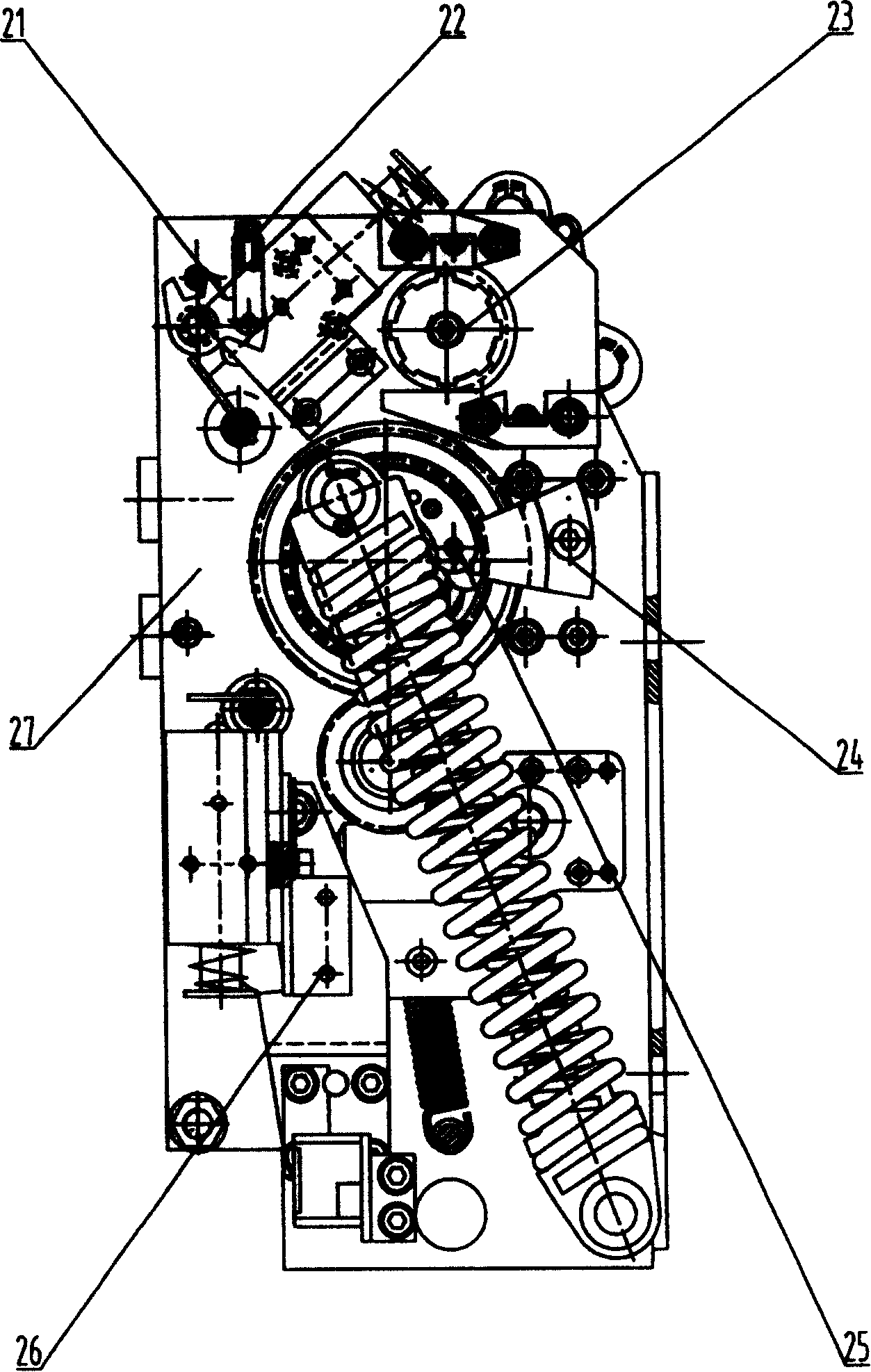

Small size spring operating mechanism for vacuum circuit breaker

InactiveCN1753123ACompact structureSafe and reliable operationHigh-tension/heavy-dress switchesAir-break switchesClutchFlywheel

The invention is a miniaturized spring control mechanism, comprising main machine case, energy storage electric machine component, energy storage cam component, and drive link rod component, and its technical characters lie in that: there are mutually reverse free-wheeling clutches on the in-gear box segment of the output spindle in the energy storage electric machine component, the worm wheel of the worm gear free-wheeling clutch engages with the worm shaft of the socket handgrip, the gear of the gear of the gear free-wheeling clutch engages with the driving gear of the electric machine, the small gear arranged on the outside-gear box segment of the output spindle engages with the large gear mounted on the cam spindle, the inner circle of the large gear is provided with reverse stopping flywheel, hinged with the pawl on the flywheel, and the pawl is controlled by elastic pin and striking block to be inserted in or depart from the inner circle of the large gear. The invention has the characters of reasonable component distribution, compact structure, small bulk, etc.

Owner:姜全海

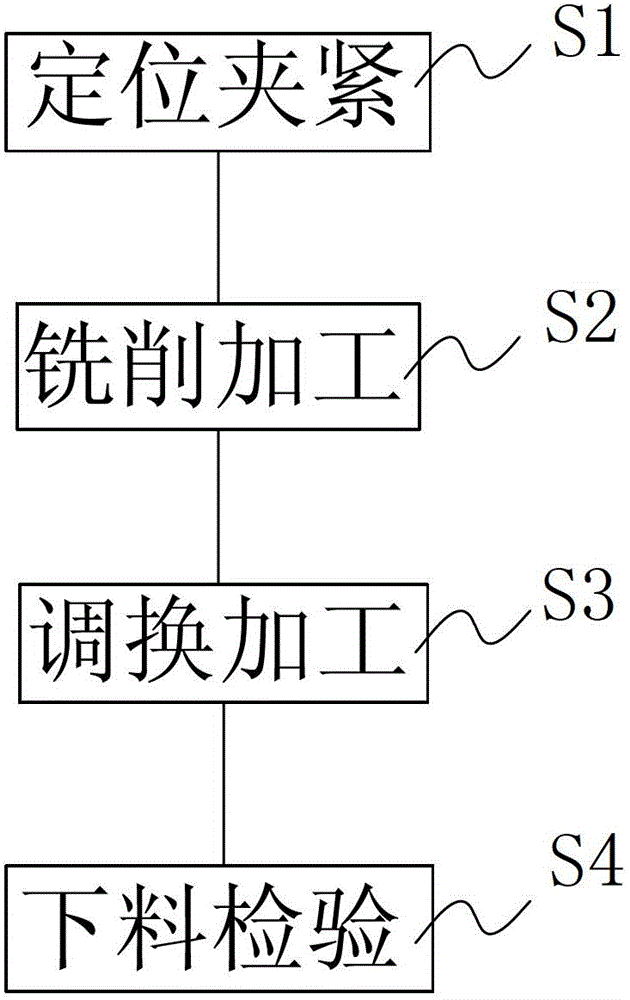

Semifocal chord pipe groove processing method and device

ActiveCN104148717AHigh dimensional accuracyQuality improvementMilling equipment detailsPositioning apparatusEngineering

The invention discloses a semifocal chord pipe groove processing method and device used for processing of a semifocal chord pipe groove or a curved surface groove of a self-elevating drilling platform; the device comprises a planer milling machine, a semifocal chord pipe processing fixture and a semifocal chord pipe processing cutter, the semifocal chord pipe processing fixture is installed on a working table of the planer milling machine, the work table is provided with a clamping groove for positioning the semifocal chord pipe processing fixture, and the semifocal chord pipe processing cutter comprises at least two sets of molding tools which are respectively used for processing of groove planes of the semifocal chord pipe groove and outer-side rounded slots. The method includes the following steps: positioning and clamping, to be more specific, at least two to-be-processed semifocal chord pipes are positioned and clamped in the semifocal chord pipe processing fixture; milling, to be more specific, the molding tools are used for respectively processing the groove planes on the outer side of the semifocal chord pipes and the outer-side rounded slots; exchange processing, to be more specific, the two semifocal chord pipes are exchanged, unprocessed parts in the semifocal chord pipes are processed by the above steps of positioning and clamping and milling; and material feeding, inspection and application for inspection.

Owner:YANTAI RAFFLES SHIPYARD +2

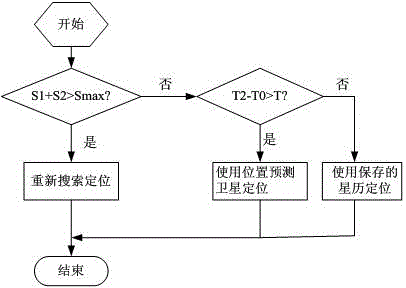

GPS positioning initialization method of vehicle-mounted navigation device

ActiveCN105527638AThe location information is accurateReasonable positioningSatellite radio beaconingIn vehicleSimulation

The invention provides a GPS positioning initialization method of a vehicle-mounted navigation device. The GPS positioning initialization method comprises the steps of: firstly, recording a latest ephemeris updating moment T0, a GPS terminal equipment turning-off moment T1, a restarting moment T2 and a running speed V of a vehicle, and then measuring a distance Smax that the vehicle runs during a period from an updating moment to a failure moment of an ephemeris; calculating a distance S2 that the vehicle runs during a period from a turning-off moment to a restarting moment of GPS terminal equipment and a distance S1 that the vehicle runs during a period from a latest ephemeris updating moment to a turning-off moment; and selecting different positioning methods according to a magnitude relation between S1+S2 and the Smax as well as a magnitude relation between T2-T0 and a ephemeris updating cycle T. The GPS positioning initialization method judges whether the ephemeris is valid based on timeliness and territoriality, adopts different positioning methods according to different judgment results, and avoids a large amount of time consumption caused by blindly using the single one of the positioning methods.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

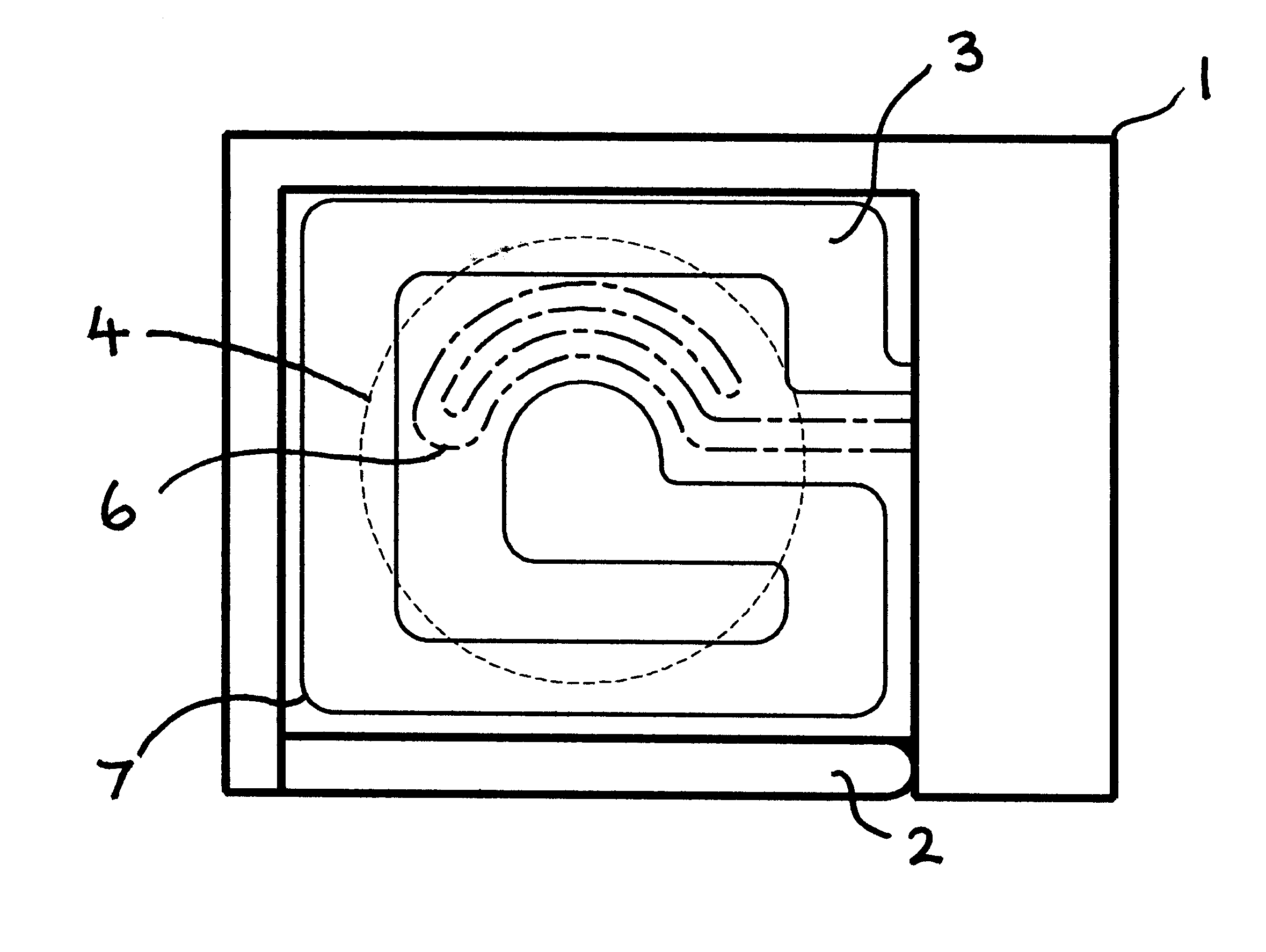

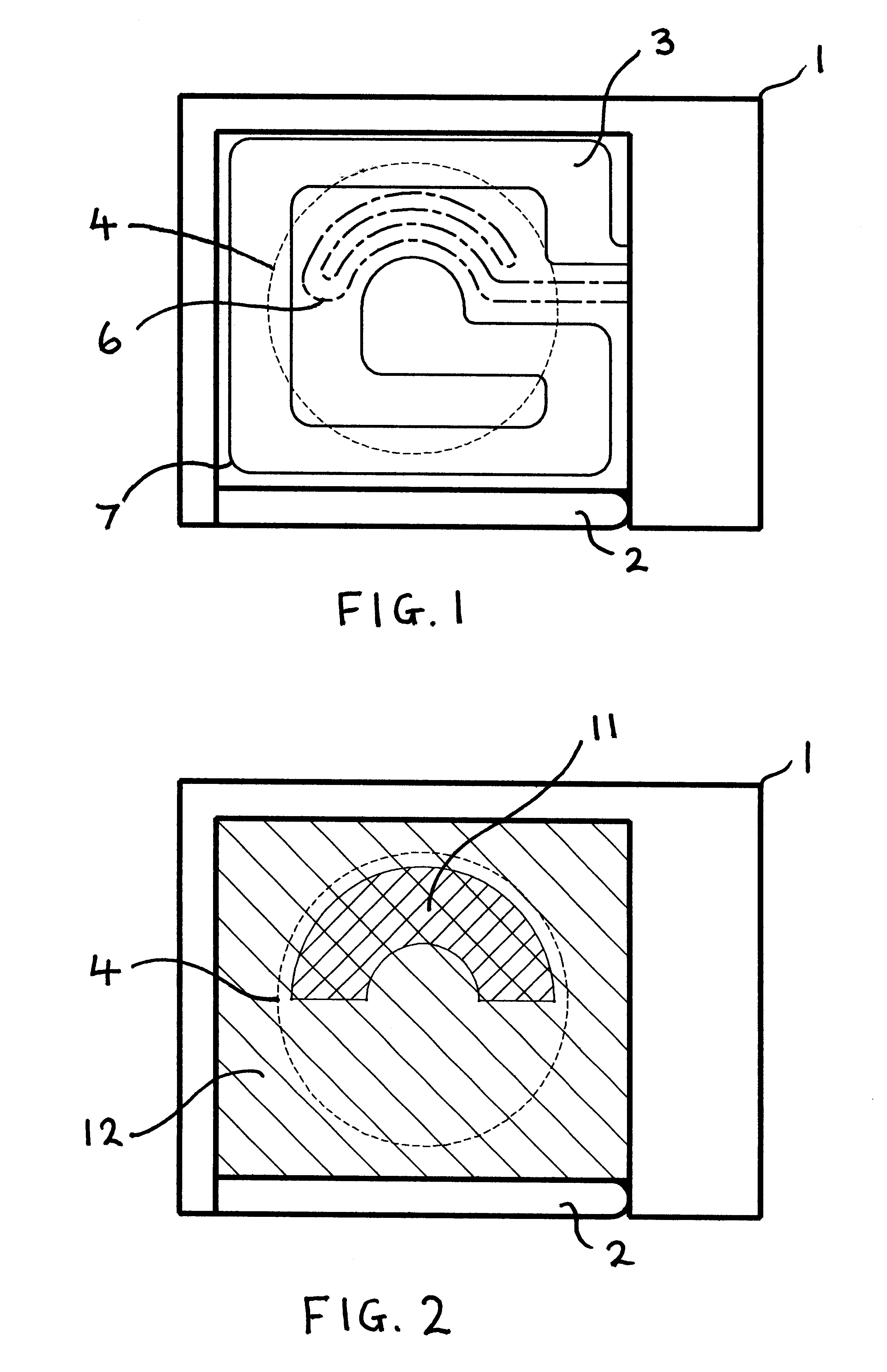

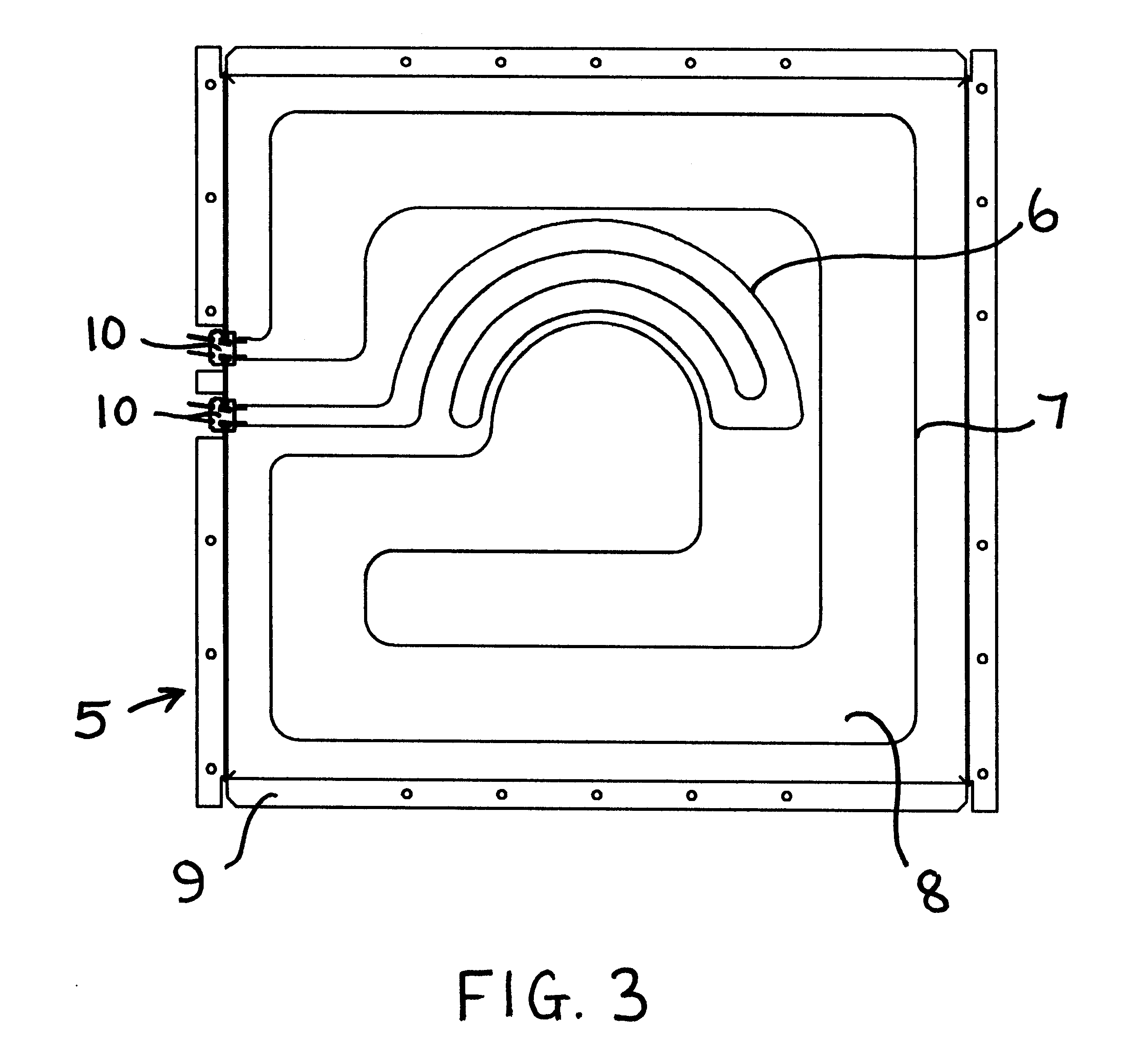

Radiant electric heater for a microwave oven

InactiveUS6323472B1Reduce power densityImprove functionalityDomestic stoves or rangesElectrical heating fuelMicrowave ovenPower density

A microwave oven (1) comprises an oven cavity (3) containing a rotatable turntable (4) for supporting one or more items to be heated. A radiant electric heater (5) is arranged for location above the turntable (4) and comprises at least one first heating element (6) and at least one second heating element (7). The at least one first heating element (6) overlies only a proportion of the total upper surface area of the turntable (4) such that, in operation, for each complete rotation of the turntable substantially all parts of the upper surface of the turntable are heated for substantially the same duration of time, the at least one first heating element (6) providing a first power density. The at least one second heating element (7), or a combination with the at least first heating element (6), overlies substantially the total upper surface area of the turntable (4), with the at least one second heating element operated alone, or an operating combination of the at least one second heating element (7) with the at least one first heating element (6), providing a second power density lower than the first power density.

Owner:CERAMASPEED

Small size spring operating mechanism for vacuum circuit breaker

InactiveCN100380553CMeet the use requirementsImprove performanceHigh-tension/heavy-dress switchesAir-break switchesGear wheelElectric machine

The invention is a miniaturized spring control mechanism, comprising main machine case, energy storage electric machine component, energy storage cam component, and drive link rod component, and its technical characters lie in that: there are mutually reverse free-wheeling clutches on the in-gear box segment of the output spindle in the energy storage electric machine component, the worm wheel of the worm gear free-wheeling clutch engages with the worm shaft of the socket handgrip, the gear of the gear of the gear free-wheeling clutch engages with the driving gear of the electric machine, the small gear arranged on the outside-gear box segment of the output spindle engages with the large gear mounted on the cam spindle, the inner circle of the large gear is provided with reverse stopping flywheel, hinged with the pawl on the flywheel, and the pawl is controlled by elastic pin and striking block to be inserted in or depart from the inner circle of the large gear. The invention has the characters of reasonable component distribution, compact structure, small bulk, etc.

Owner:姜全海

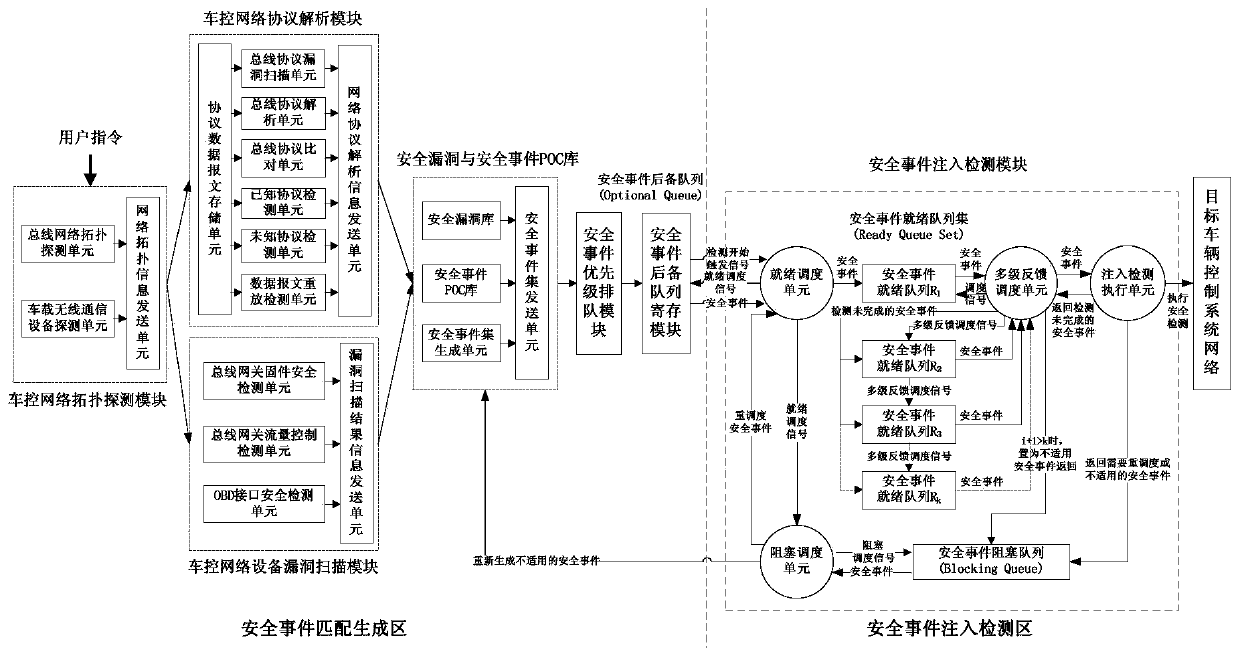

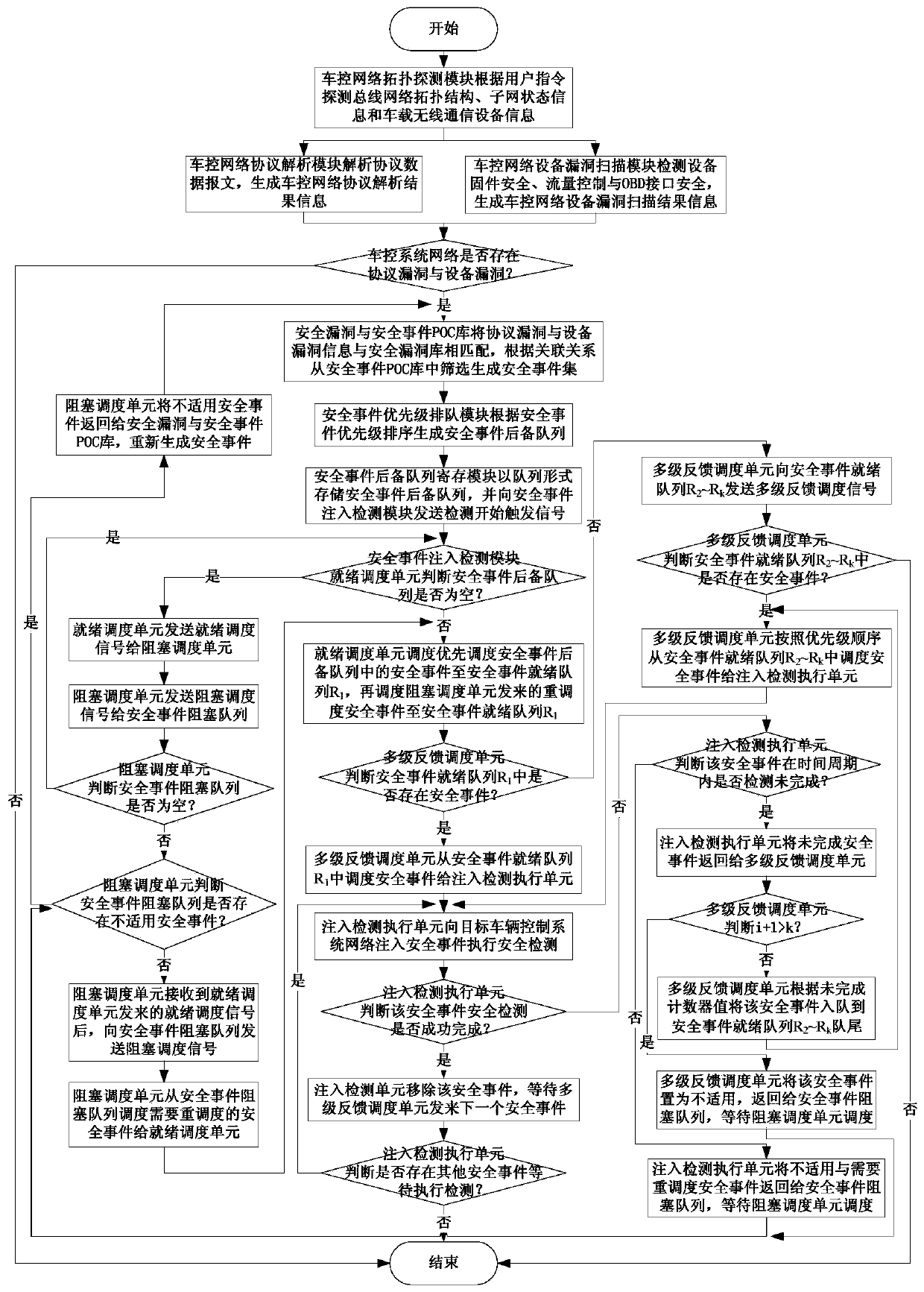

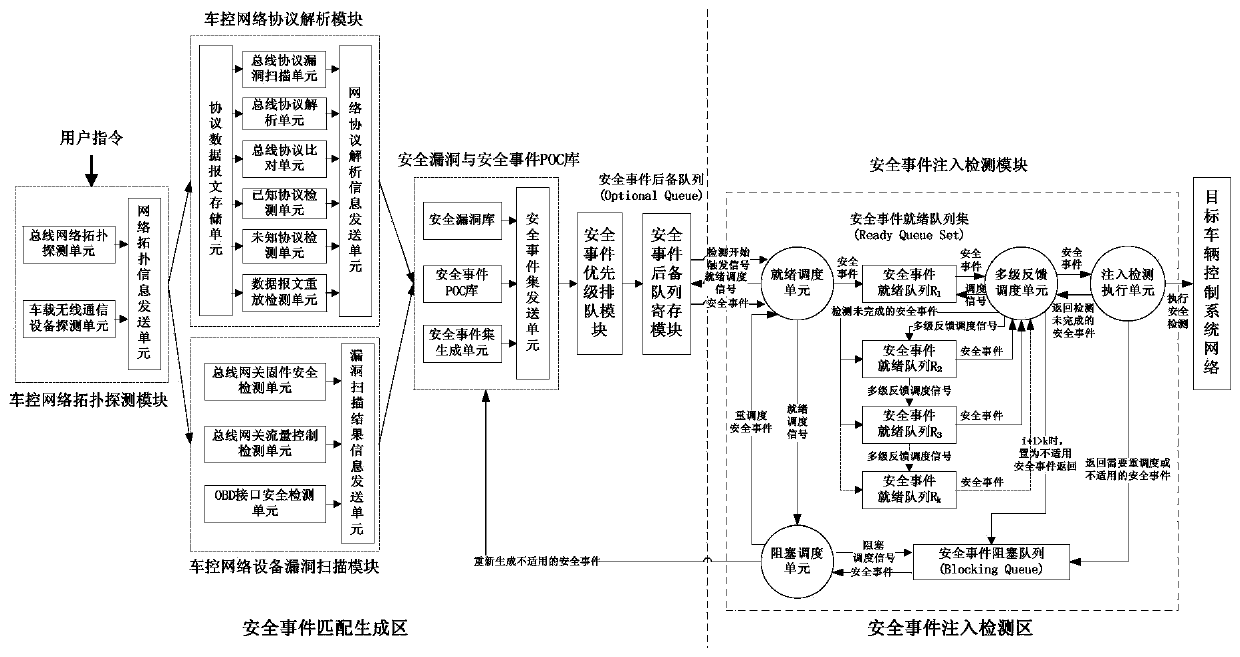

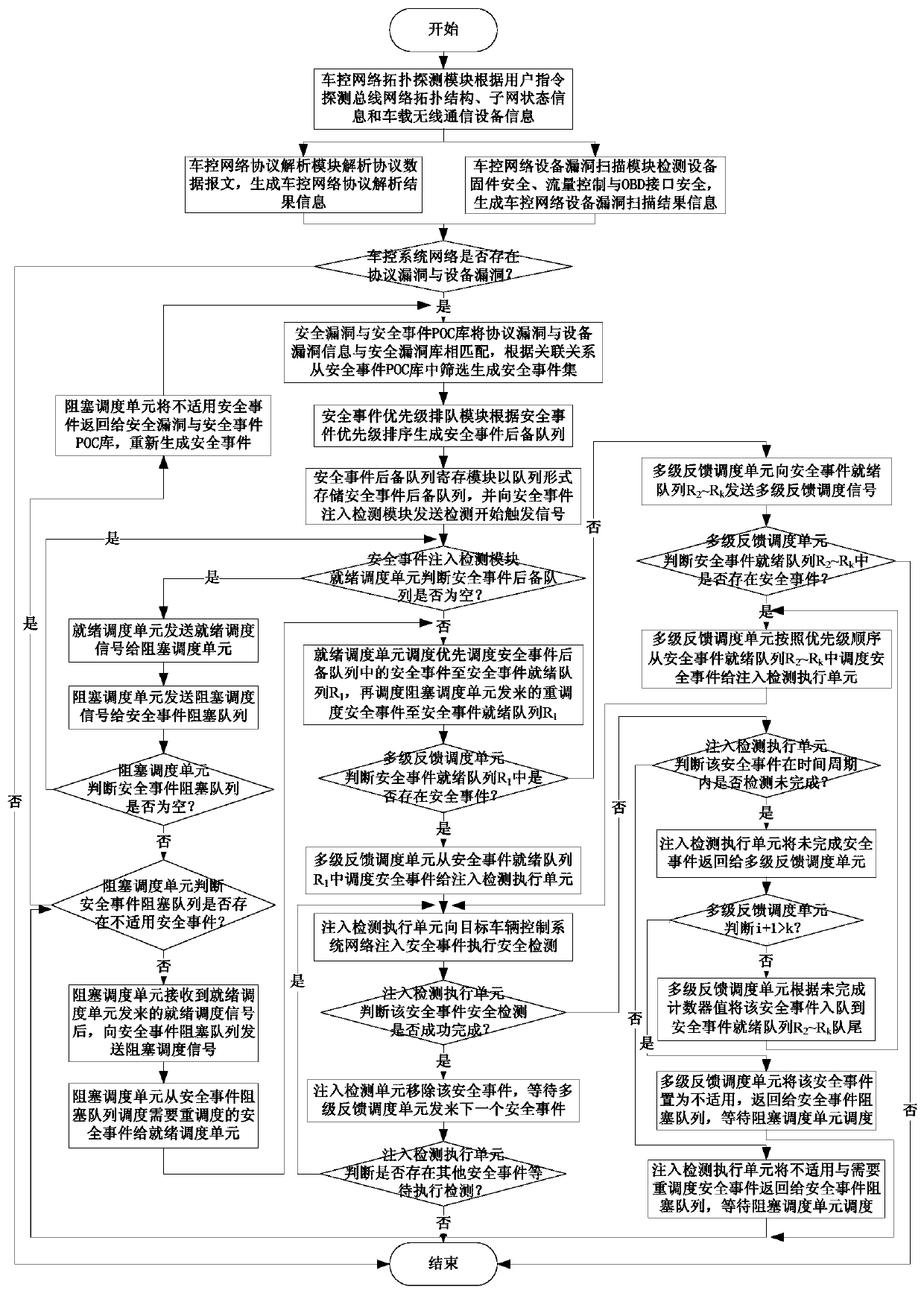

Vehicle control system network security detection method based on multi-stage feedback queue

ActiveCN110445810AQuick filterImprove automation and matchingData switching networksVulnerability scanningMultilevel feedback queue

The invention belongs to the technical field of vehicle control system network security detection, and particularly relates to a vehicle control system network security detection method based on a multi-stage feedback queue. The method is implemented based on a detection system, and the system comprises a vehicle control network topology detection module, a vehicle control network protocol analysis module, a vehicle control network equipment vulnerability scanning module, a security vulnerability and security event POC library, a security event priority queuing module, a security event backupqueue registration module and a security event injection detection module. According to the method, the security event queues for injection detection are sequentially generated, the security events are injected and detected by adopting a multi-stage feedback queue round-robin scheduling mechanism, security holes and vulnerabilities of the vehicle control network can be accurately positioned, and an autonomous and controllable network security detection target of the vehicle control system is achieved. The scheme is high in automation degree, the security event injection detection mechanism isreasonable, efficient and accurate, the detection scene conforms to the real attack behavior of an attacker, and the whole network security detection process is autonomous and controllable.

Owner:北京京航计算通讯研究所

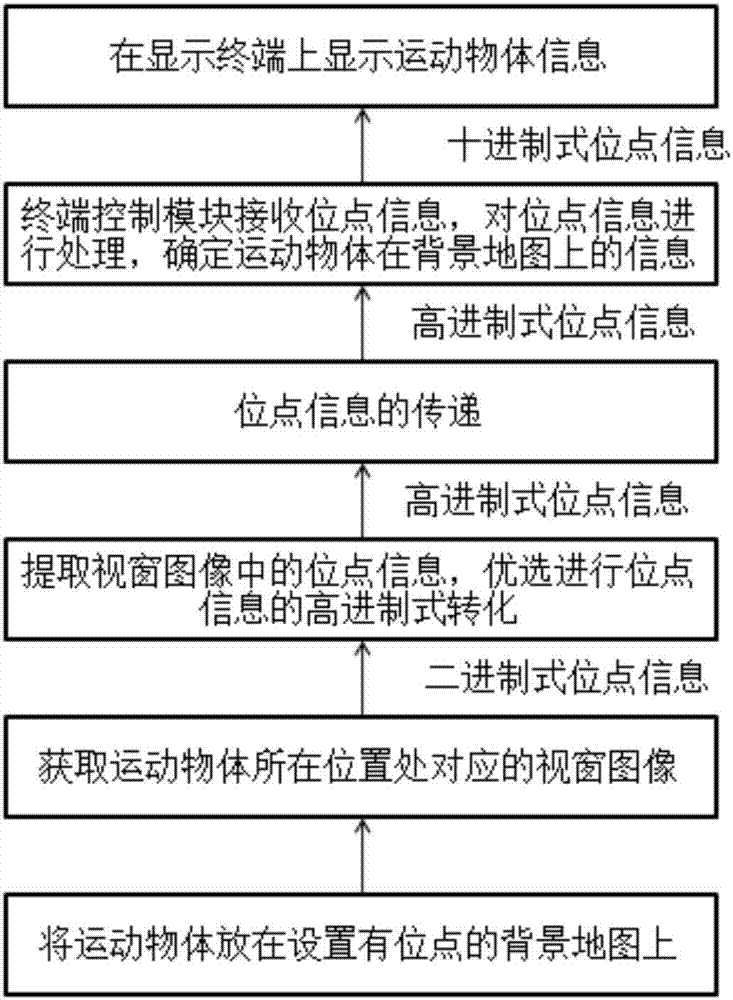

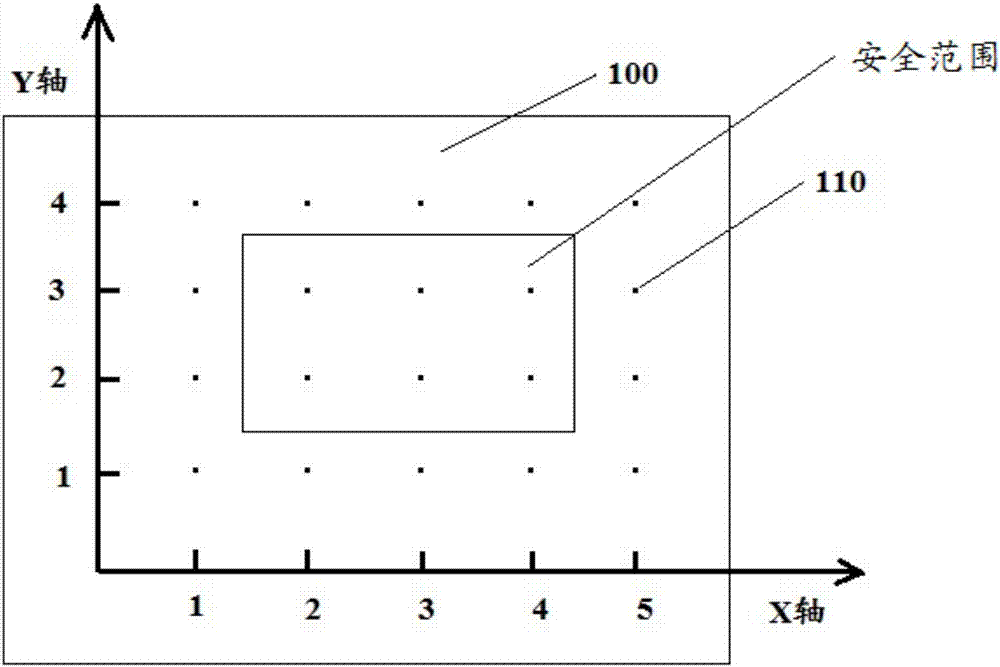

Method for rapidly and timely acquiring moving object information in augmented reality

InactiveCN106933355ASolve the problem of lagging in acquisitionEasy accessInput/output for user-computer interactionGraph readingComputer terminalAugmented reality

The invention discloses a method for rapidly and timely acquiring moving object information in augmented reality. The method comprises the steps of setting a plurality of sites which includes site information on a background map, and placing a moving object on the background map; acquiring a corresponding window image at the position of the moving object, extracting the site information and then transmitting the site information to a terminal control module on a display terminal; and processing the site information by the terminal control module, and determining the information of the moving object on the background map through the site information. The site information includes positional information of the sites, the real world and the positional information in the augmented reality are associated through the site information, the information of the moving object in the real world can be acquired rapidly, timely and exactly, and the locating on the display terminal is completed.

Owner:北京富龙飞科技有限公司

Stone curtain wall structure

The invention discloses a stone curtain wall structure which comprises a stand column, a beam, a connecting piece and stone face plates. The beam is fixed on the stand column. The connecting piece comprises a stone layer board, two fixed plates and a cover plate. The beam connecting end of the stone layer board is fixed with the beam. The stone face plate connecting end of the stone layer board is arranged below the connecting part of two adjacent stone face plates in a horizontal direction. The two fixed plates are respectively fixed on the upper side and the lower side of the stone layer board. The two fixed plates are parallel to the stone face plates and tightly abut against inner sides of the stone face plates. The cover plate is fixed on the end of the stone face plate connecting end of the stone layer board. The cover plate is parallel to the stone face plates and tightly abuts against outer sides of the stone face plates. According to the stone curtain wall structure, fixing between the connecting piece and the stone face plates is more reliable, machining of drilling or slotting is not needed on the stone face plates, safety of a stone curtain wall is guaranteed, and the stone curtain wall is convenient to install at the same time.

Owner:ZHEJIANG YASHA CURTAIN WALL

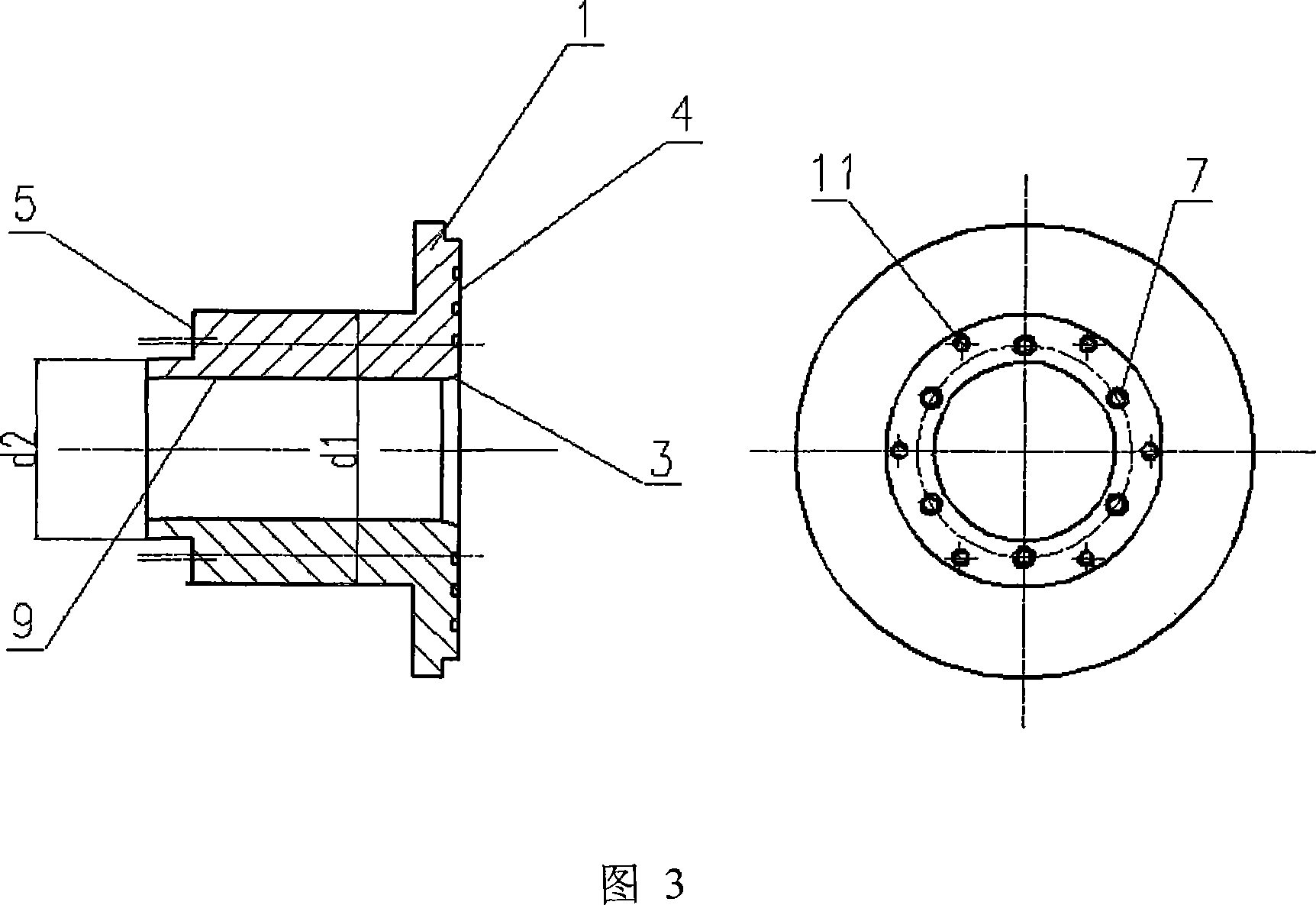

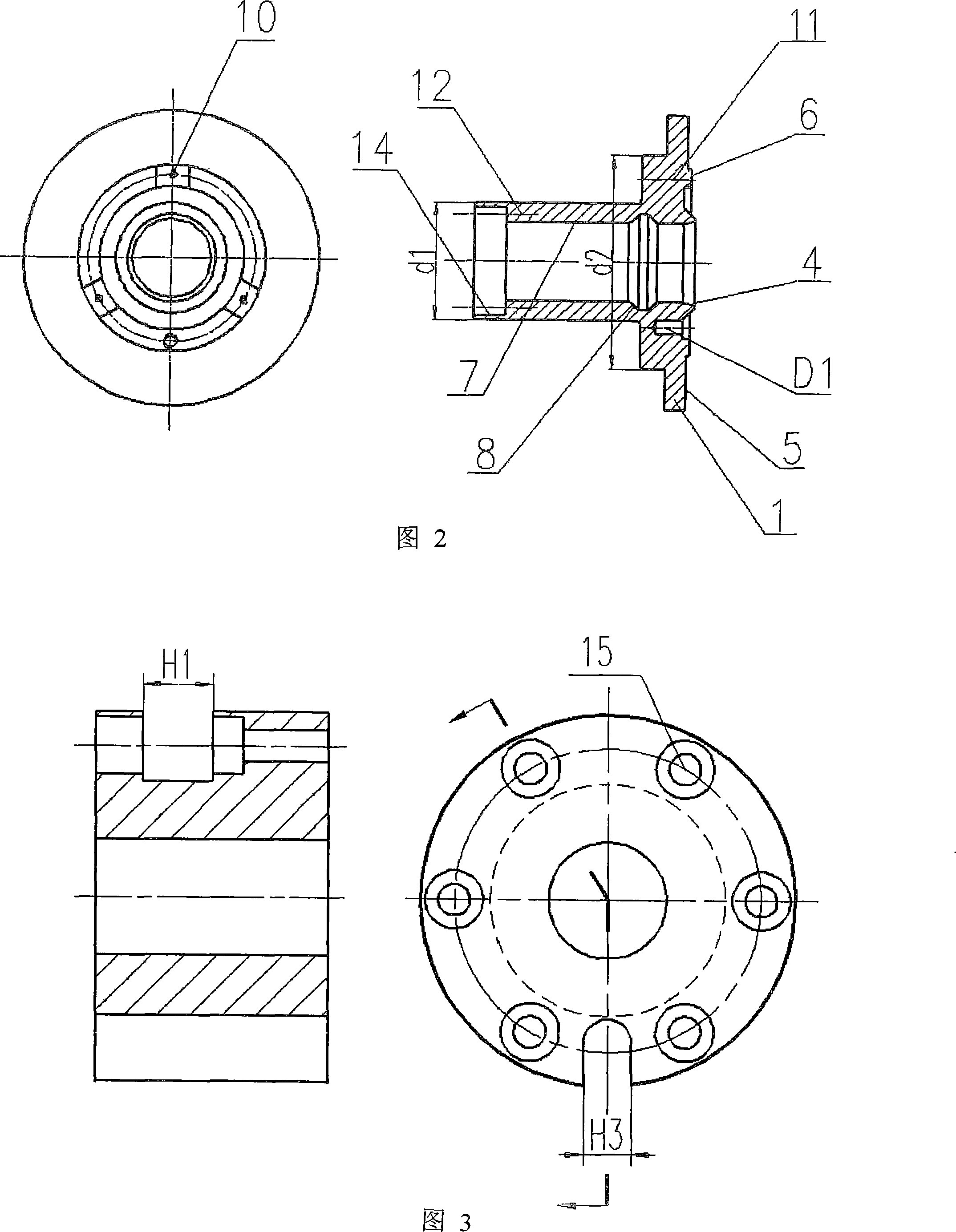

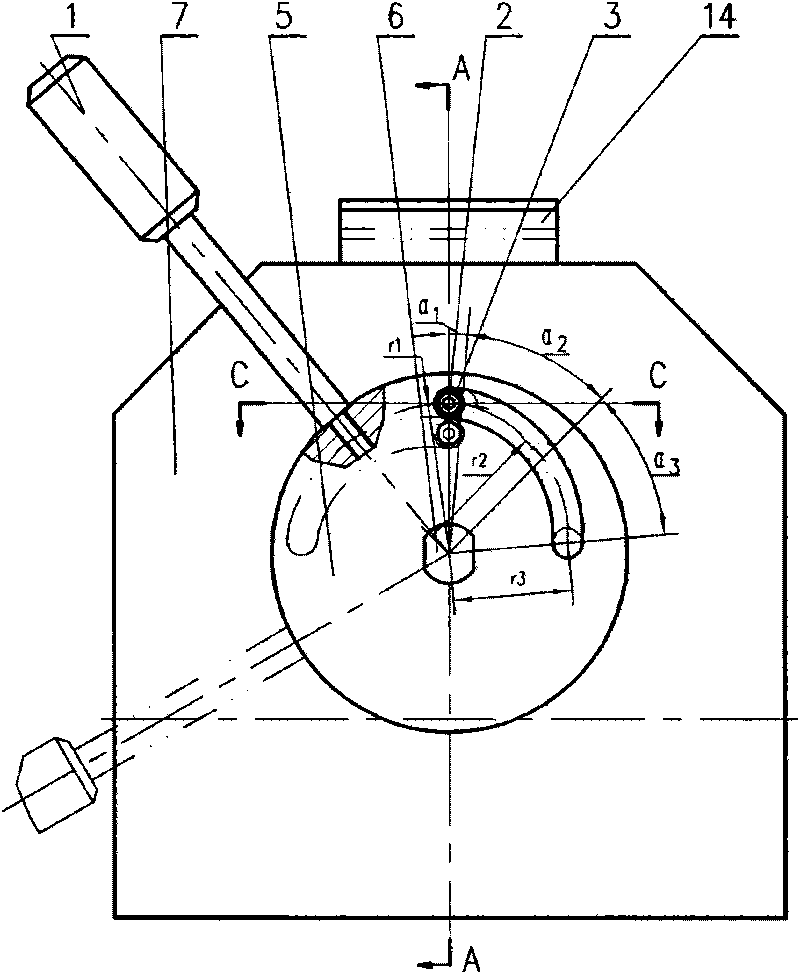

Grinding wheel chuck

ActiveCN101200051AEasy to processReasonable positioningGrinding wheel securing apparatusEngineeringCutting force

The invention discloses a novel grinding wheel chuck device of a grinder equipment, which is composed of a chuck body and a balance disk. The chuck body comprises an axial column inner hole and a joint surface which protrudes on the end surface and is composed of a plurality of circular rings; the joint part of the joint surface and the inner hole is provided with a short and micro inner cone matched with a grinding main shaft; a plurality of axial counterbore holes which are connected fixedly with the grinding main shaft through a bolt and a plurality of screw holes which are connected with the balance disk are arranged on the chuck body; the balance disk is enclosed on the chuck body and is provided with via holes corresponding to axial via holes on the chuck body and counter bores matched with the screw holes; a coattail type balance ring groove is arranged on the left side surface of the balance disk. Because the joint surface of the large end surface is connected with the end surface of the grinder main shaft directly, the contact rigidity is enhanced and the cutting force is increased. The invention is convenient to install and flexible to be used, so that the working efficiency of a machine tool is increased.

Owner:浙江杭机股份有限公司

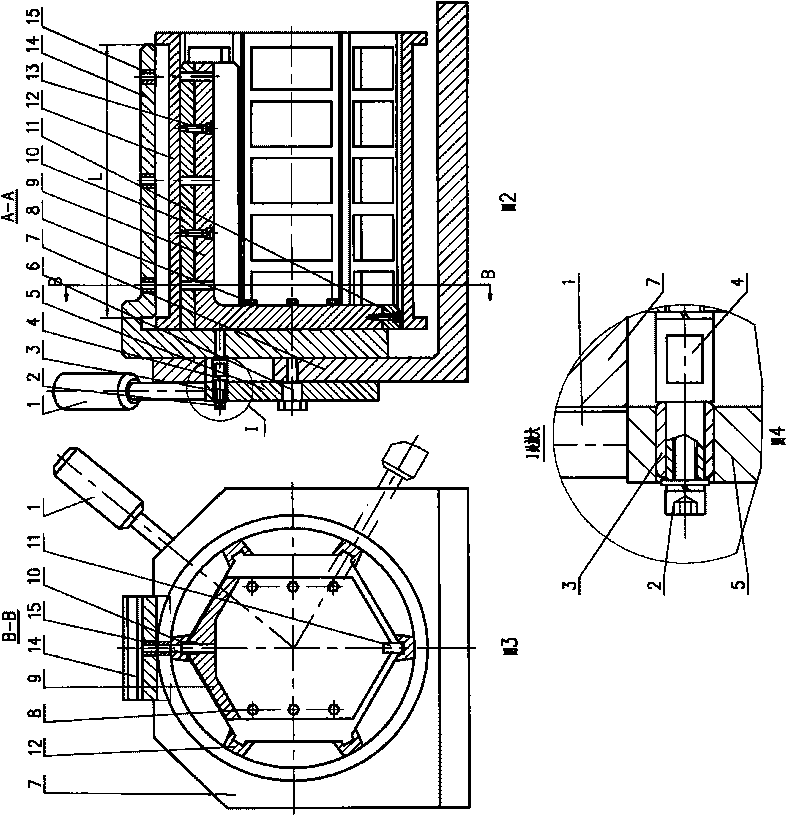

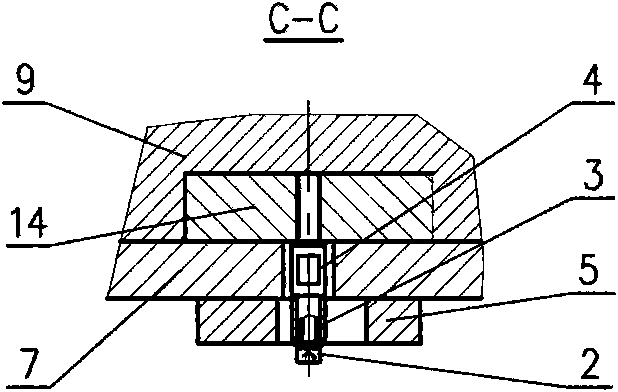

Ferrule type grinding wheel chuck

ActiveCN101200049AImplement automatic exchangeHigh degree of automationGrinding machine componentsMating connectionCounterbore

The invention discloses a ferrule type grinding wheel chuck device for a grinder equipment, which comprises a chuck body, a pressing disk sleeved out of the chuck body and a ferrule connected with the chuck body. The chuck body is provided with a column inner hole in which a clamping ring groove connected with a tension mechanism of a main shaft is arranged; the orifice at the right end of the inner hole is provided with an inner cone matched and connected with the end surface of a grinding head main shaft; the orifice at the left end of the inner hole is provided with a counter bore and a plurality of screw holes which are matched and connected with the ferrule; the large end surface of the chuck body is provided with a sealed joint surface and a plurality of connecting screw holes; the back of the large end surface is provided with a shoulder; the ferrule is provided with a positioning slot and a guiding groove which are matched and connected with a processing centre grinding wheel library or the other grinding equipment installation mechanism; the ferrule is provided with a counterbore hole matched with the screw holes of the chuck body; screw holes matched with the connecting screw holes on the chuck body are arranged on the pressing disk; a boss matched with the shoulder on the chuck body is arranged at the right side surface of the pressing disk. The labor strength is reduced and the labor and the time are saved with the invention, the grinding wheel chuck can be exchanged automatically, so that the producing efficiency and the advancement of the machine tool equipment are increased.

Owner:浙江杭机股份有限公司

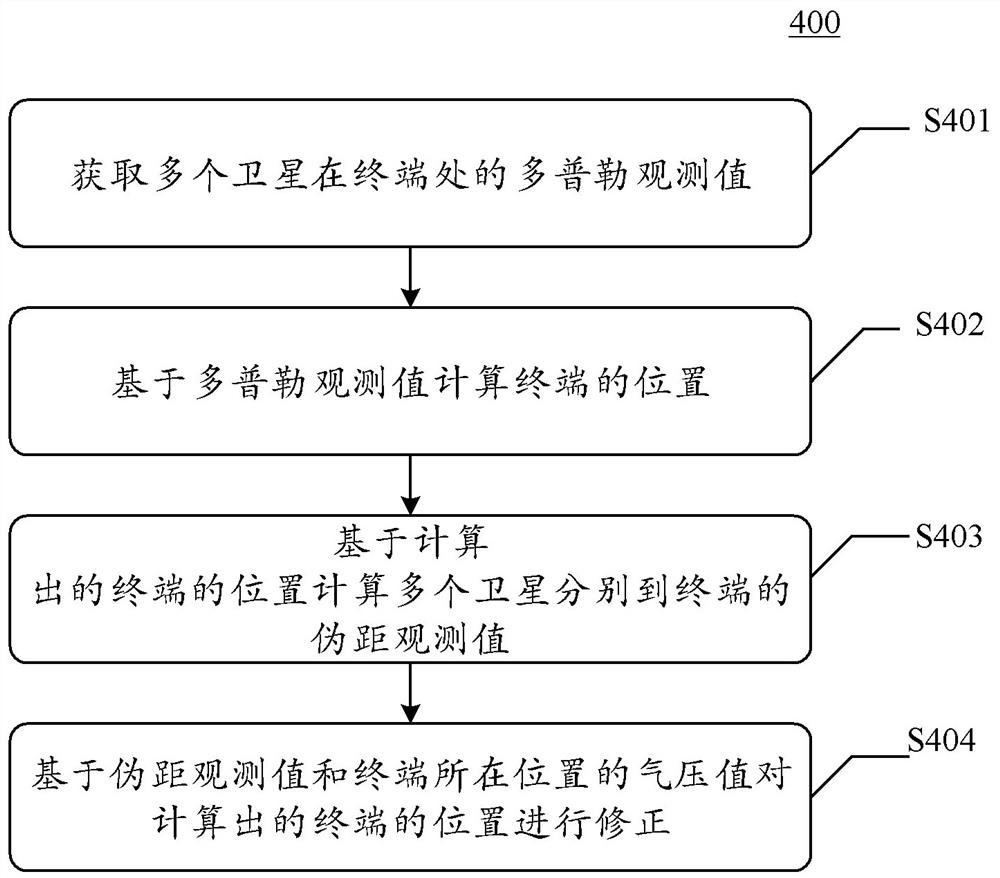

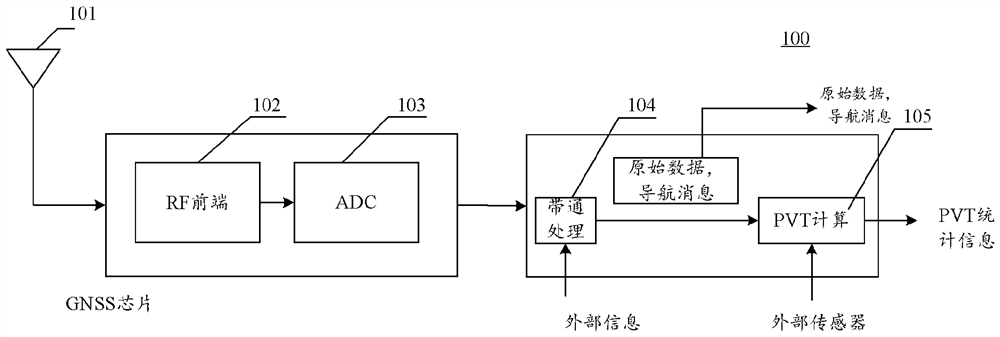

Method and device for positioning terminal and storage medium

ActiveCN112505735ARapid positioningReasonable positioningSatellite radio beaconingRemote sensingSatellite

Owner:TENCENT TECH (SHENZHEN) CO LTD

Cylinder head guide column drilling rectifying tool and application method

ActiveCN102601421AReasonable positioningHigh precisionBoring/drilling componentsCylinder headEngineering

Disclosed are an application method of a cylinder head guide column drilling rectifying tool. A diamond pin is mounted on the upper edge of a plate, an aligning column is mounted in the middle of the plate, a circular positioning pin is mounted on the lower edge of the plate, axes of the diamond pin, the aligning column and the circular positioning pin are positioned in the same plane and are parallel to each other, the diamond pin and the circular positioning pin are respectively mounted in valve guide pipe mounting holes of a cylinder head, and the distance from the axis of the diamond pin to the axis of the aligning column is equal to that from the axis of the circular positioning pin to the axis of the aligning column. The application method of the tool includes mounting the circular positioning pin in the lower valve guide pipe mounting hole, mounting the diamond pin in the upper valve guide pipe mounting hole, leading the aligning column to be coaxial with a spindle, and locating the spindle at a position a; mounting the circular positioning pin in the upper valve guide pipe mounting hole, mounting the diamond pin in the lower valve guide pipe mounting hole, leading the axis of the aligning column to be coaxial with the axis of the spindle of a boring mill, and locating the spindle at a position b; and shifting the spindle of the boring mill to a position between the position a and the position b, and drilling a guide column hole. The tool is reasonable in positioning and high in drilling precision.

Owner:JIANGSU HIDA MARINE VALVE

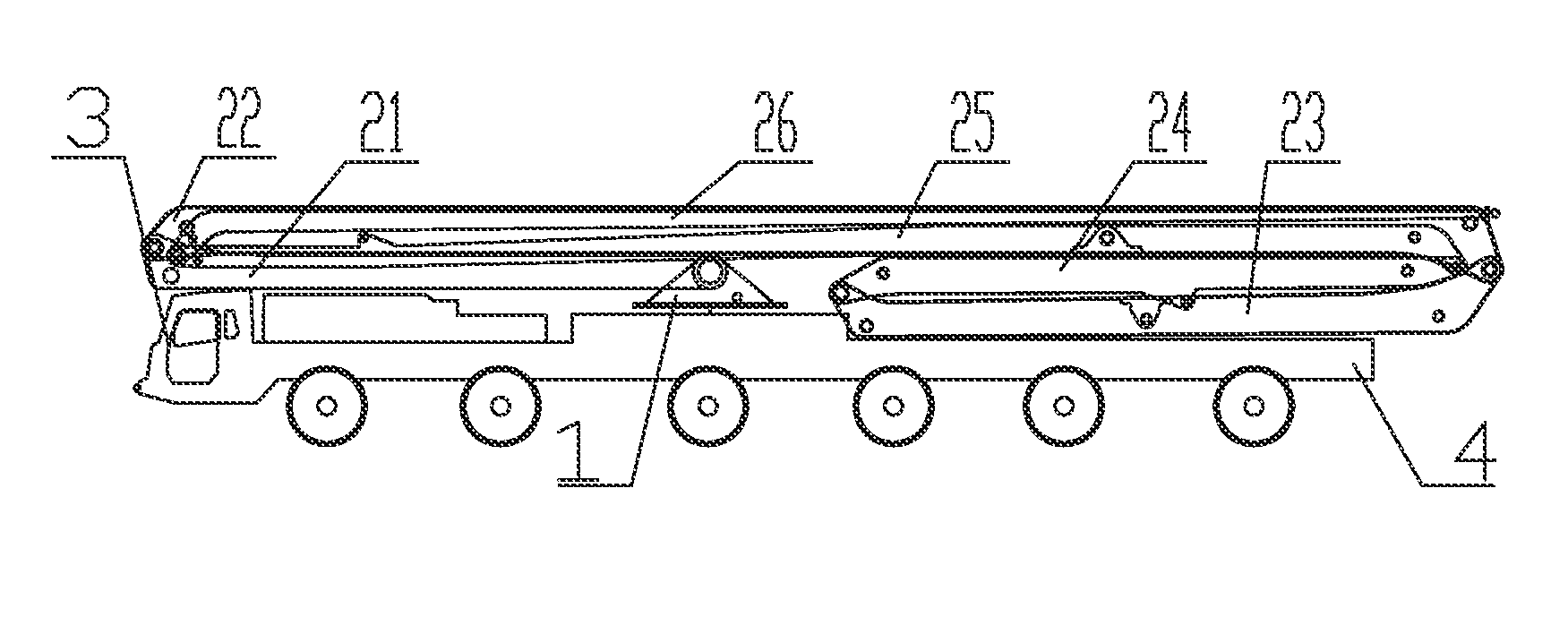

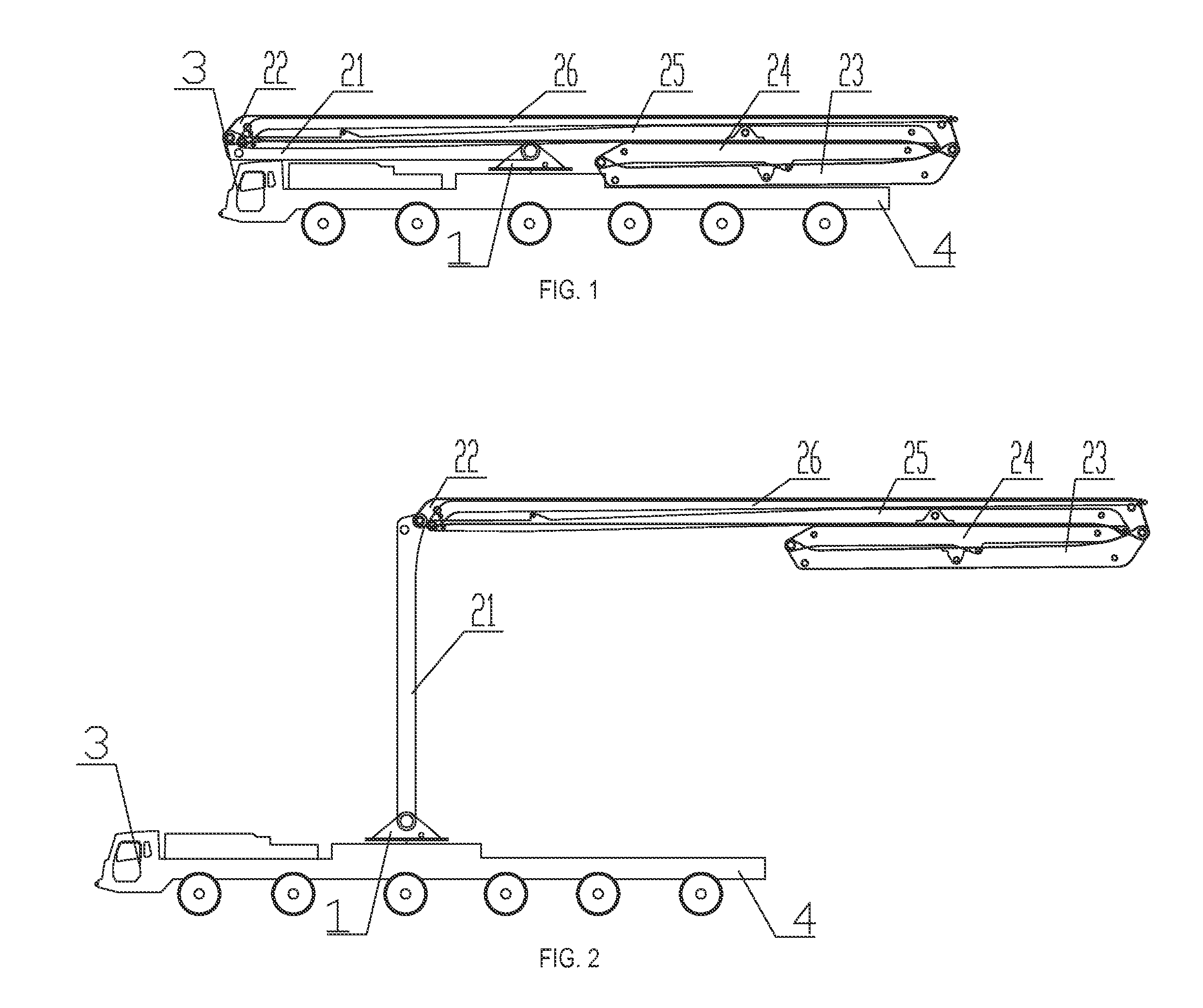

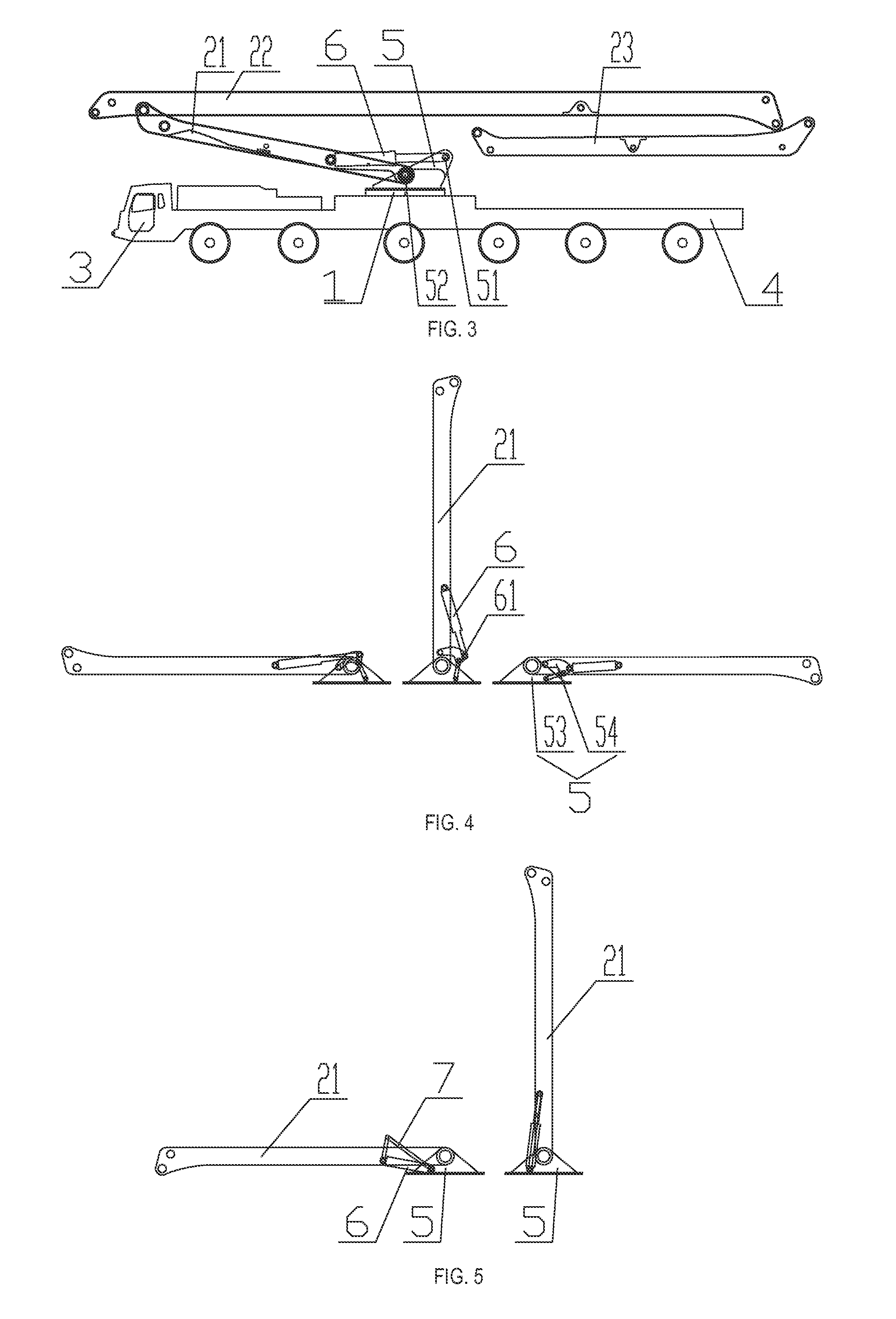

Boom apparatus and concrete pump vehicle having same

InactiveUS9394707B2Shorten the timeIncrease the maximum lengthBuilding material handlingWater supply installationEngineeringCantilever

In one aspect of the invention, a boom apparatus used for a concrete pump vehicle includes multiple booms, where the multiple booms comprise a first boom hinge-connected to a turntable of the concrete pump vehicle and a second boom hinge-connected to the first boom. When the boom apparatus is in a folded state, the first boom extends towards a cab of the concrete pump vehicle, and the second boom is further placed above the first boom. The invention also provides a concrete pump vehicle having the boom apparatus.

Owner:HUNAN SANY INTELLIGENT CONTROL EQUIP +1

Drill jig used for hole on central excircle of cylindrical part and provided with disks at two ends

The invention relates to a drill jig used for the hole on the central excircle of a cylindrical part and provided with disks at the two ends. A positioning plate seat is fixed on a bent plate, an upper positioning plate and a lower positioning plate are fixed in the groove of the positioning plate seat, and the vertical part of a drill plate is installed in the square hole formed by the groove of the positioning plate seat and the bent plate. A moving pin is fastened on the drill plate after penetrating the groove on the bent plate, and the roller on the moving pin is installed in the groove of an elevating master plate. The elevating master plate is installed on the bent plate through a wrist, and a handle is fastened on the elevating master plate. The drill jig is suited on the drill plate, and the length of the drill plate for installing the drill jig sleeve plate forms clearance fit with the inner surfaces of the two end disks of a rice screen shoe. A part is installed on the upper positioning plate and the lower positioning plate through the grooves at the upper part and the lower part of the inner cavity thereof. The upper positioning plate and the positioning plate seat are provided with holes coaxial with the inner hole of the drill jig sleeve, and the diameter of the holes is 0.4-0.7 mm larger than the inner hole of the drill jig sleeve. The drill jig has the advantages of reasonable positioning, convenient operation, high quality and efficiency, simple structure and low manufacturing cost.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

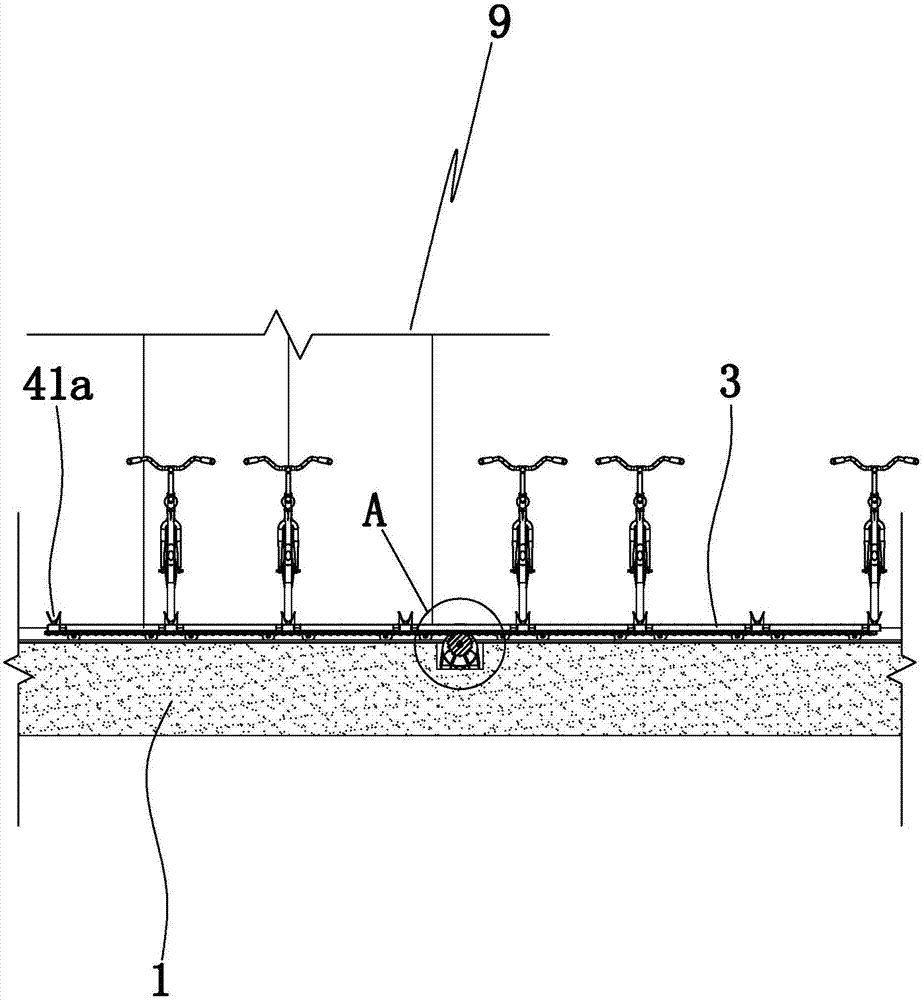

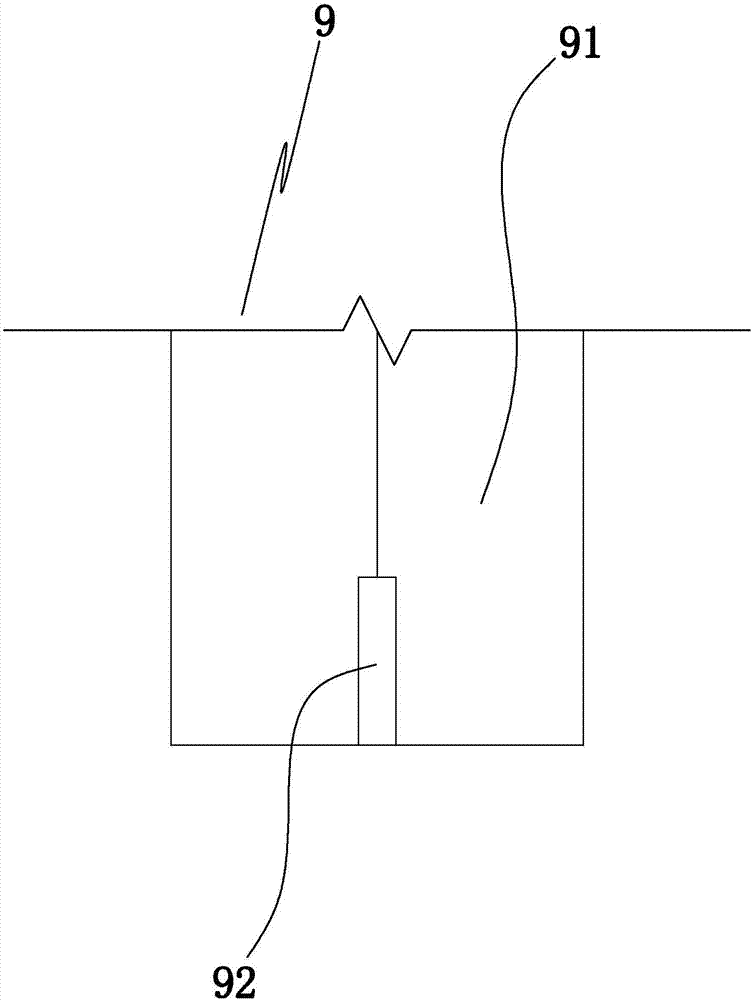

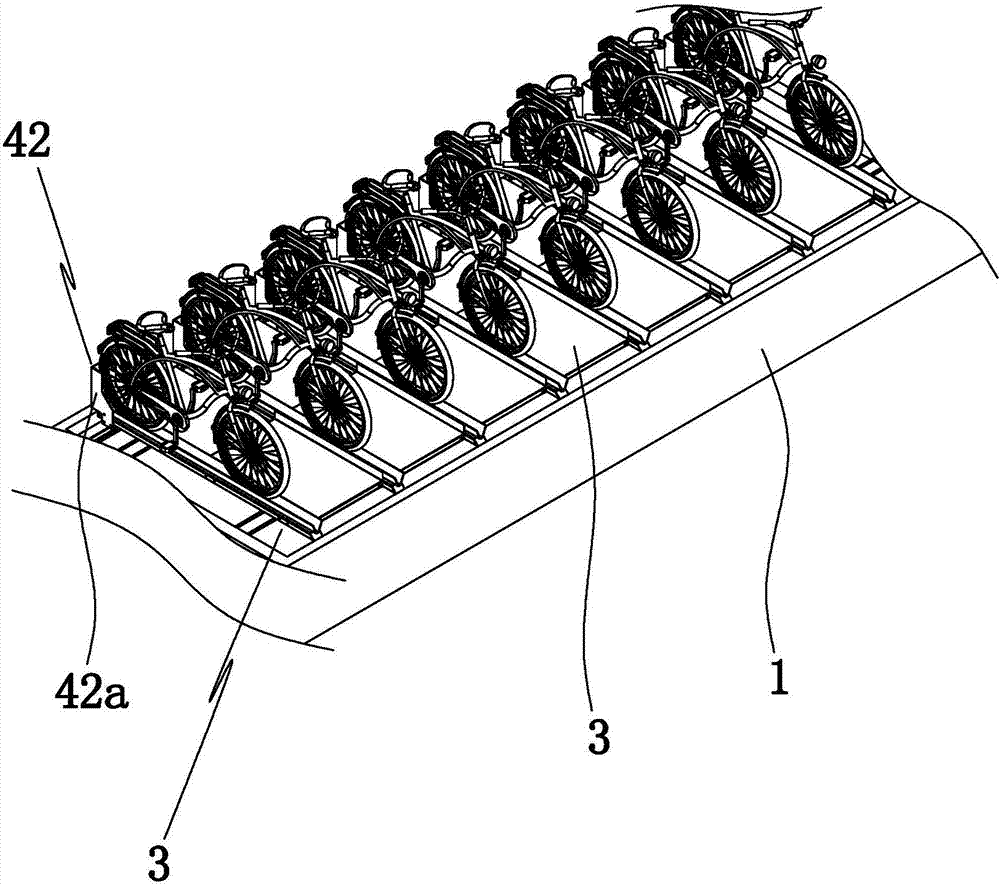

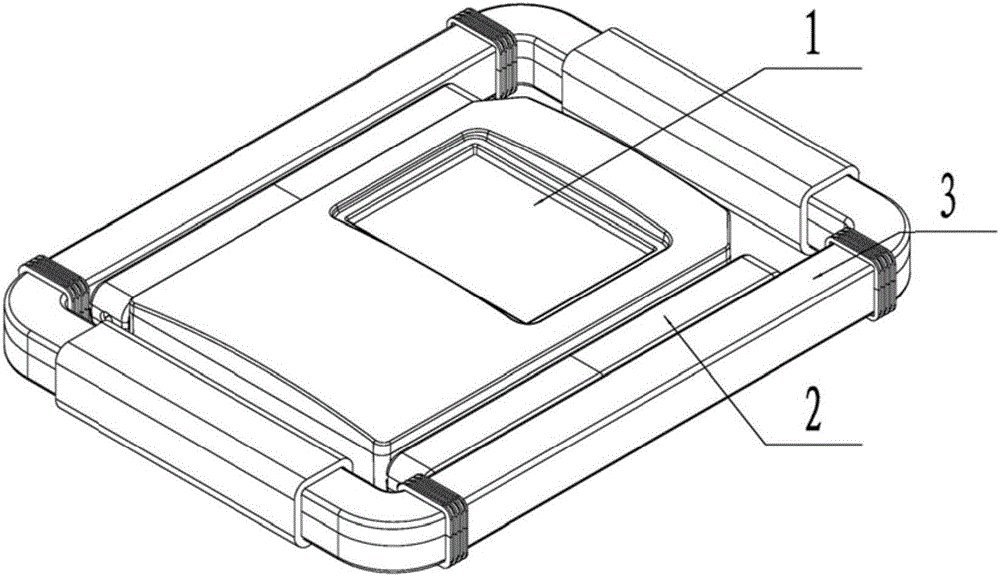

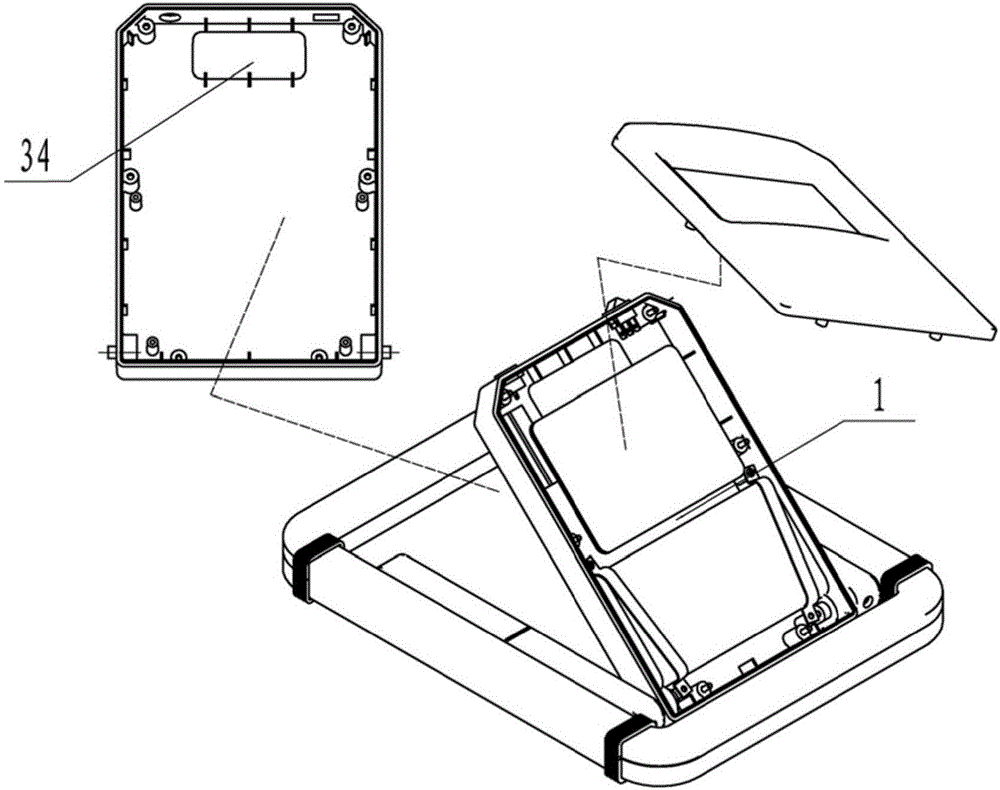

Cartridge holder type storing and taking structure

ActiveCN106907032APrecise positioningEasy accessAnti-theft cycle devicesCycle standsPush pullSlide plate

The invention discloses a cartridge holder type storing and taking structure. The cartridge holder type storing and taking structure comprises a foundation seat, power cylinders, cartridge holder guide rails, a main sliding plate and a position adjusting mechanism. The main sliding plate is provided with a plurality of bottom wheel frames and a plurality of wheel limiting structure bodies, each wheel limiting structure body comprises a wheel guide rail and a wheel push frame, each wheel push frame comprises two wheel clamping plates and a wheel limiting plate, a striker plate and two push-pull plates arranged in parallel are arranged on a piston rod of each power cylinder, transmission plates are arranged at the bottoms of the wheel push frames, and transmission through grooves for allowing the transmission plates to enter are formed between the corresponding two push-pull plates. The cartridge holder type storing and taking structure has the beneficial effects that multi-person-time and multi-vehicle-time parking can be simultaneously conducted, soon afterwards rotary storing is effectively achieved, more convenience is provided for users, in the rotary storing process, positioning is accurate, and it is guaranteed that the storing and taking process is safer; and the cartridge holder type storing and taking structure is provided with a positioning and locking structure body so that structural stability can be effectively promoted in the rotary storing process, the capacities of timely locking and timely automatic unlocking are achieved, the structure is reasonable, and the positioning and antitheft effects are good.

Owner:浙江慧源通服科技有限公司

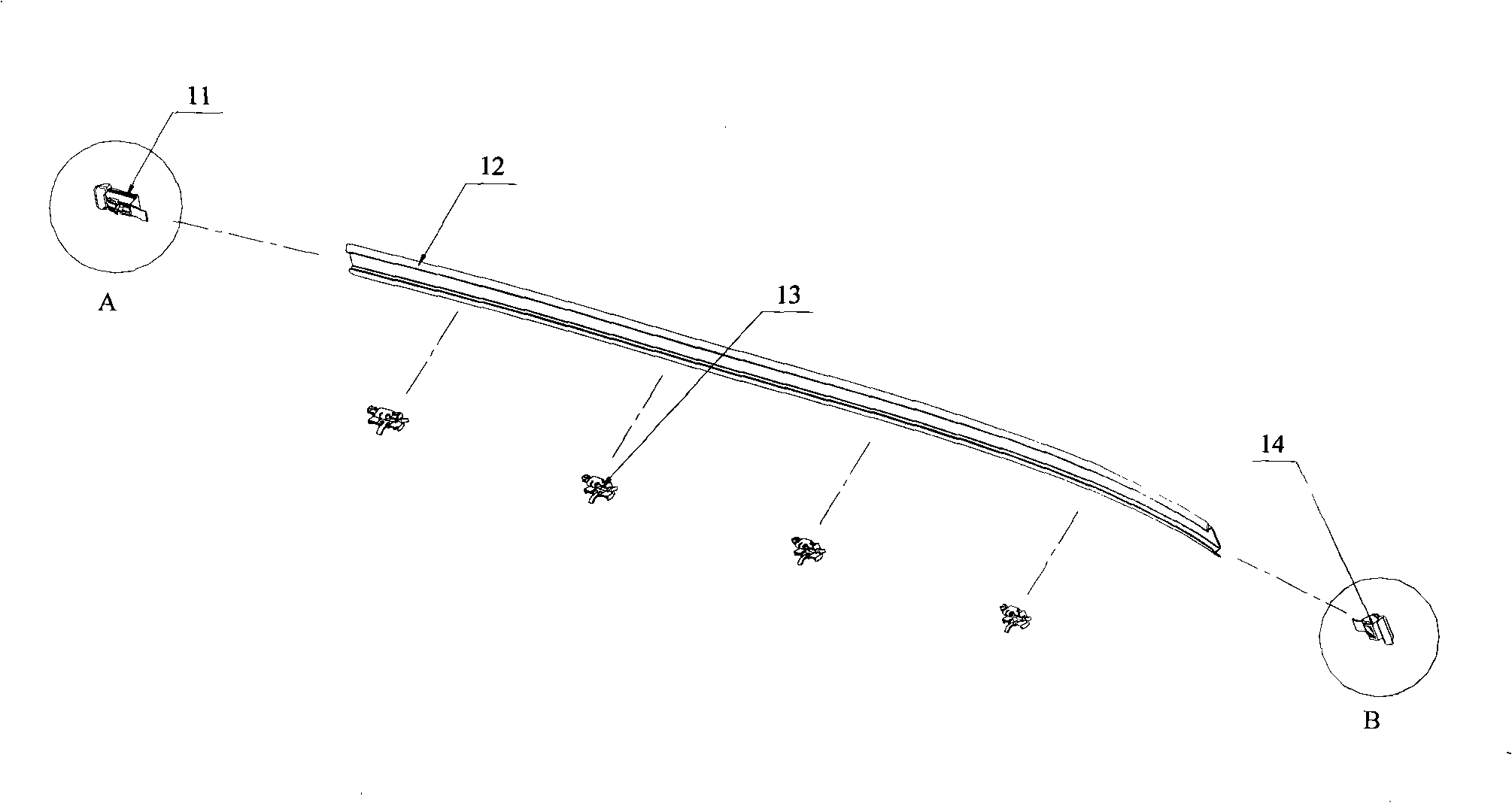

Decorative strip for sedan top cover

The invention relates to a sedan roof decorative strip, which comprises a decorative strip body and a clamp arranged in the middle of the body and matching with the flange of the roof; wherein a front positioning fastener is spliced in the front end of the decorative strip body, and a back positioning card is spliced in the back end; the front positioning card is clamped with the front rivet welded on the roof, thus realizing effective positioning of the roof decorative strips and eliminating the up-wrapping of the front end part; the back positioning card is clamped with the back rivet welded on the roof, thus eliminating the up-wrapping of the back end part of the roof. The decorative strip has reasonable positioning and stable installation, and eliminates the up-wrapping of the front and the back ends, and at the same time, simplifies the manufacture and assembly processes.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

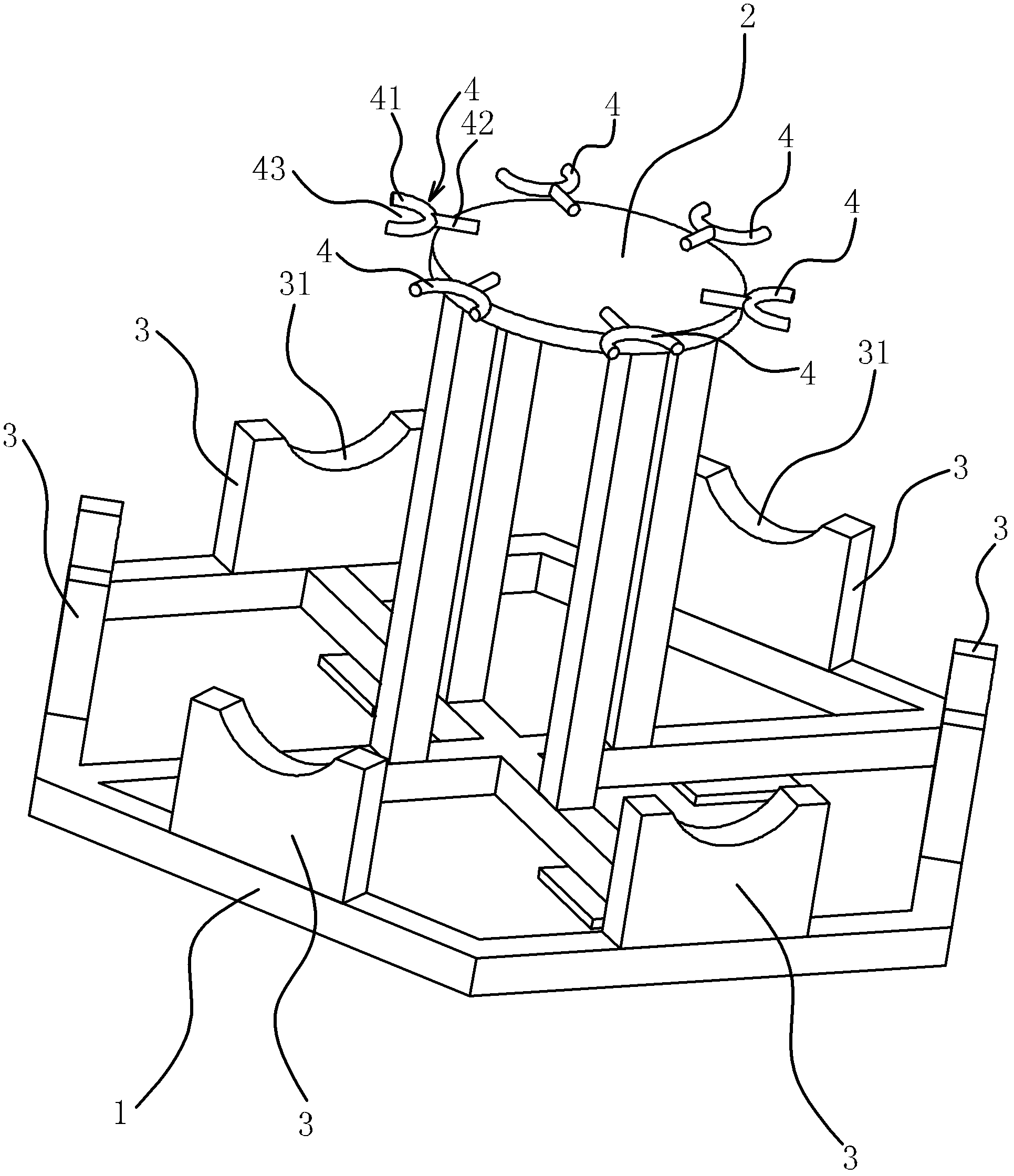

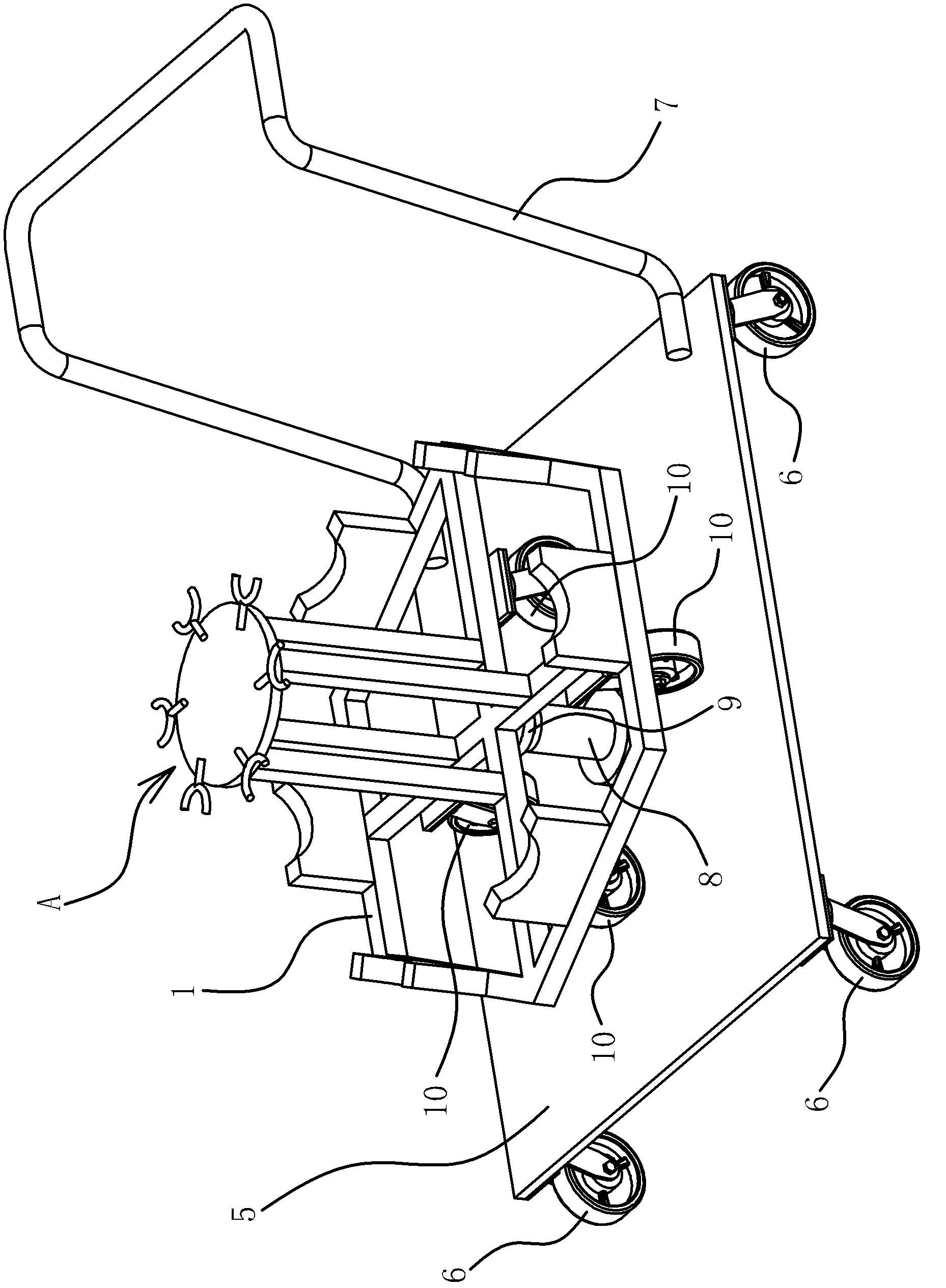

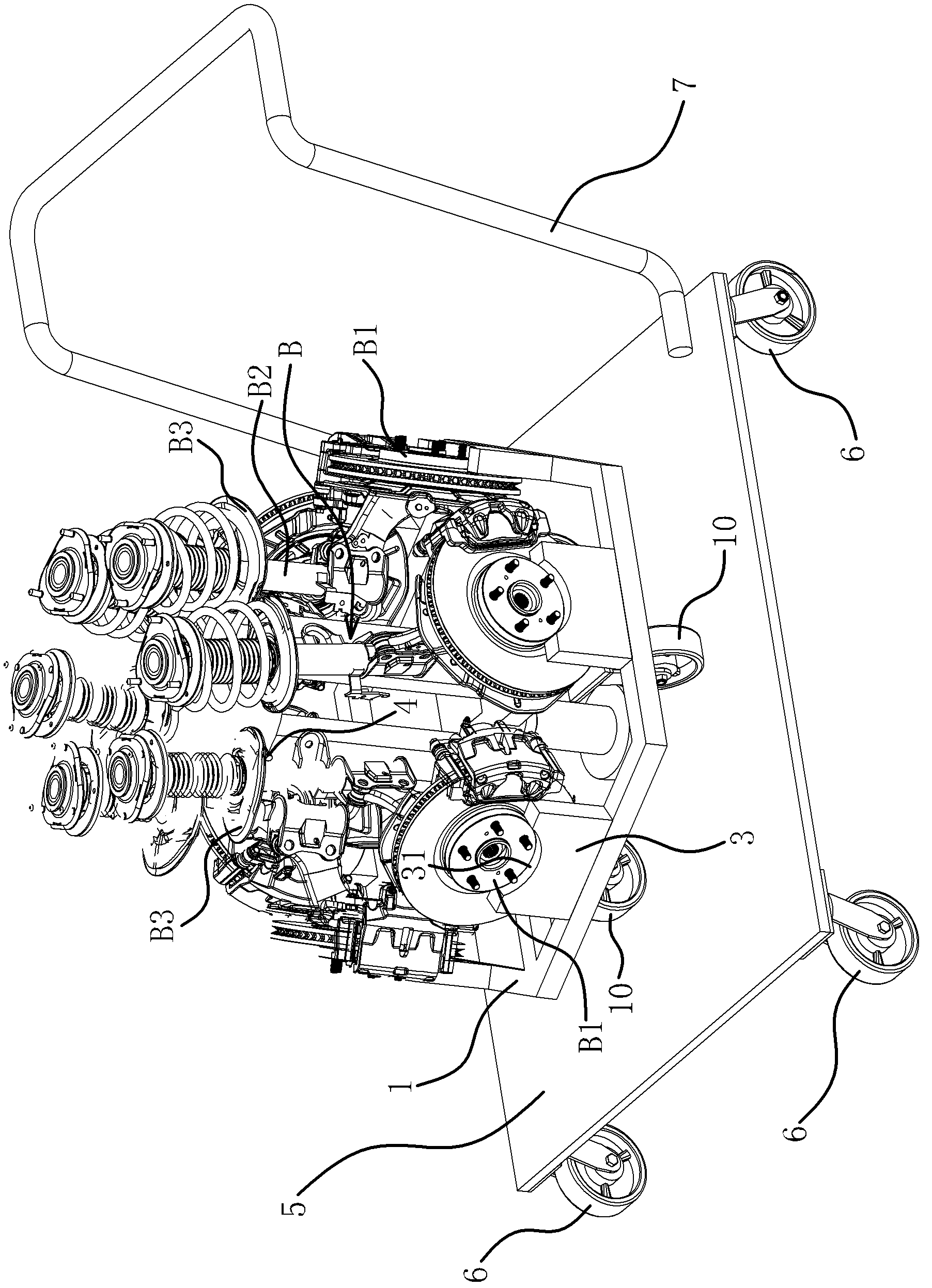

Supporting device of brake with shock absorber assembly and trolley with supporting device

ActiveCN102490773AAvoid damageImprove efficiencyHand carts with multiple axesPush and pullSteering wheel

The invention provides a supporting device of a brake with a shock absorber assembly and a trolley with the supporting device, belonging to the technical field of automobiles. The supporting device and the trolley solve the problem that the traditional brake with the shock absorber assembly is free from fixed placing position and good transportation in the process of transporting and storing. The supporting device of the brake with the shock absorber assembly comprises a horizontally arranged chassis and a vertically arranged side frame, wherein the lower part of the side frame is fixedly connected with the chassis; a positioning structure I for positioning the brake is arranged on the chassis, and a positioning structure I for positioning the shock absorber is arranged on the side frame. The trolley with the supporting structure comprises a plate-shaped trolley body, wherein the bottom part of the trolley body is connected with a plurality of steering wheels I; and a push-and-pull rod is fixed on one side of the trolley body. The supporting device of the brake with the shock absorber assembly and the trolley with the supporting device, provided by the invention, have the advantages of stable location on the brake with the shock absorber assembly, and convenience for transporting and placing of the brake with the shock absorber assembly.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

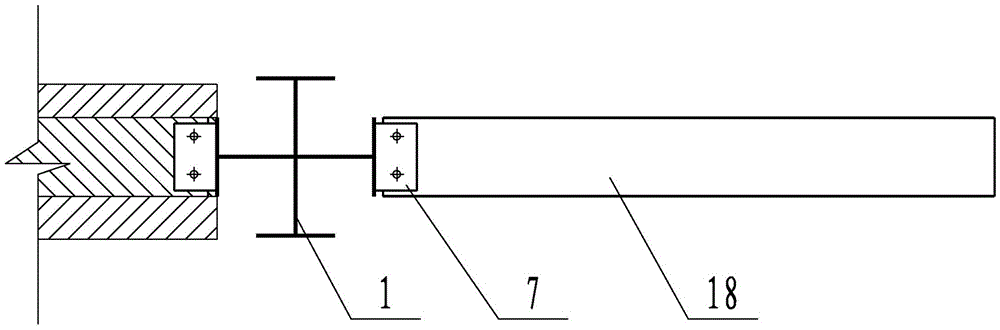

Floor system adopting cross-shaped beams

The invention relates to a floor system adopting cross-shaped beams. The floor system comprises two first cross-shaped steel beams which are in parallel mutually, two mutually parallel second cross-shaped steel beams which are in parallel mutually, first cross-shaped steel structural beam columns arranged between one ends of the first cross-shaped steel beams and the end parts of the adjacent second cross-shaped steel beams, H-shaped steel beam keels arranged between the two first cross-shaped steel beams, two second cross-shaped steel structural beam columns respectively arranged at the upper ends of the corresponding H-shaped steel beam keels, a connection beam arranged between the two second cross-shaped steel structural beam columns, prefabricated decorative sheets arranged on the upper end faces of the two second cross-shaped steel structural beam columns, floor C-shaped beams arranged between the lower surfaces of the prefabricated decorative sheets and the upper end of the connection beam, and reinforcing ribs arranged at one sides of the corresponding floor C-shaped beams. The floor system is compact in structure, reasonable in design, convenient to assemble, accurate to position, low in cost, safe and reliable; raw materials are saved; the floor system is reasonable in structure.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

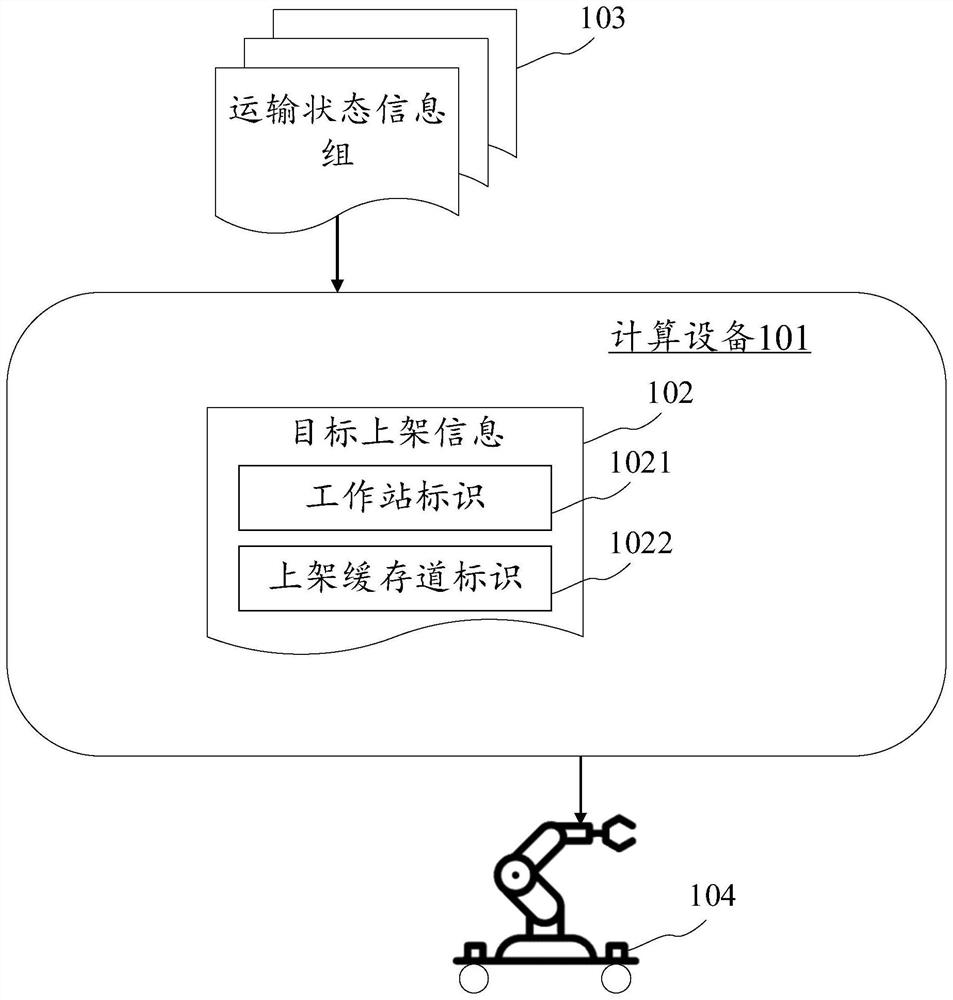

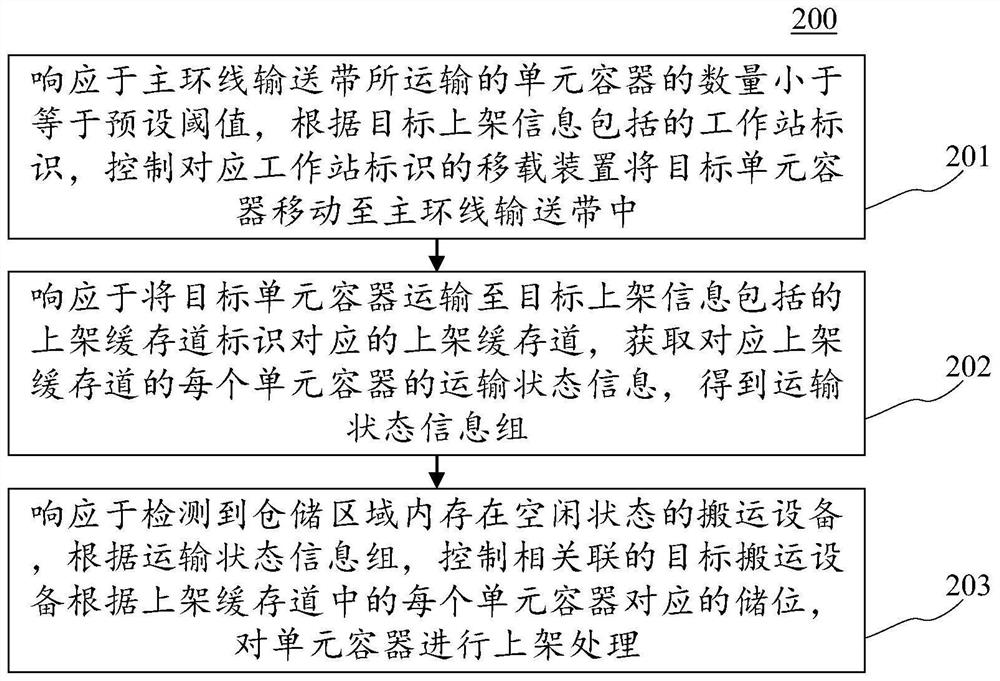

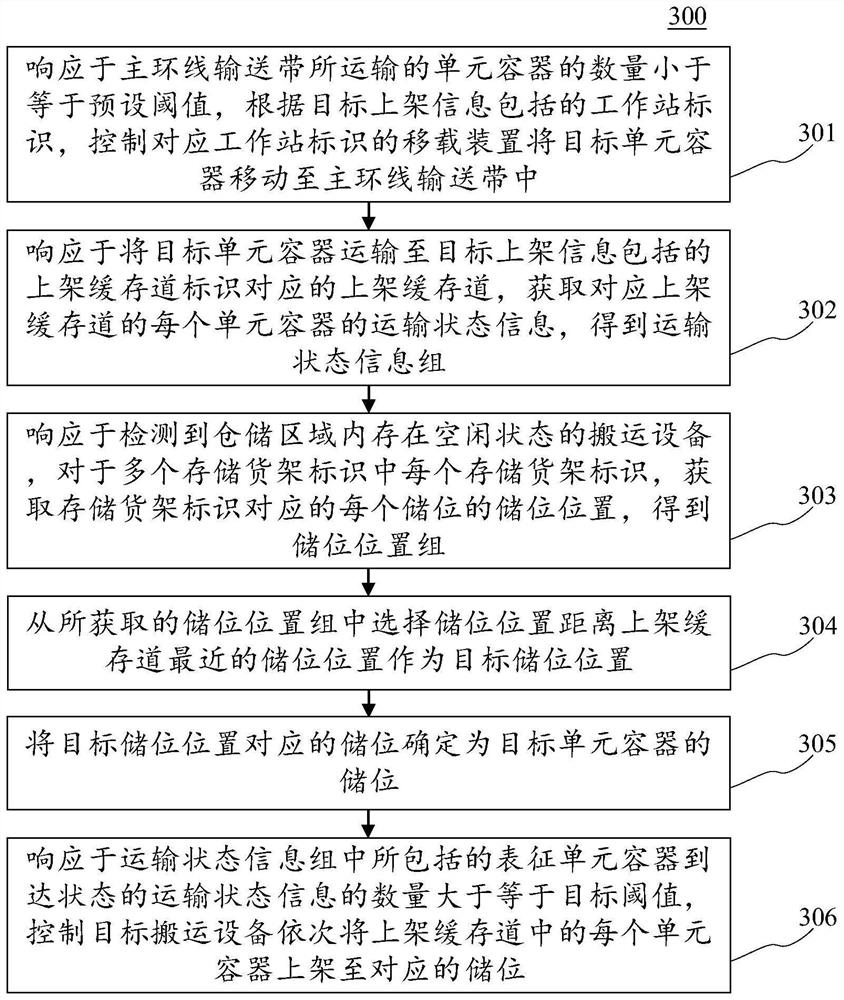

Container racking method, device and system, electronic equipment and computer readable medium

The embodiment of the invention discloses a container racking method, device and system, electronic equipment and a computer readable medium. A specific embodiment of the method comprises the following steps: controlling a transfer device corresponding to a workstation identifier to move a target unit container into a main loop line conveying belt according to the workstation identifier included in target racking information; in response to transportation of the target unit container to a shelving cache channel corresponding to a shelving cache channel identifier included in the target shelving information, obtaining transportation state information of each unit container corresponding to the shelving cache channel, and obtaining a transportation state information group; and in response to detecting that the carrying equipment in the idle state exists in the storage area, controlling the associated target carrying equipment to carry out racking treatment on the unit containers according to the storage position corresponding to each unit container in the racking cache channel according to the transportation state information group. According to the embodiment, waste of carrying resources is reduced, and the waiting time of carrying equipment is shortened.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

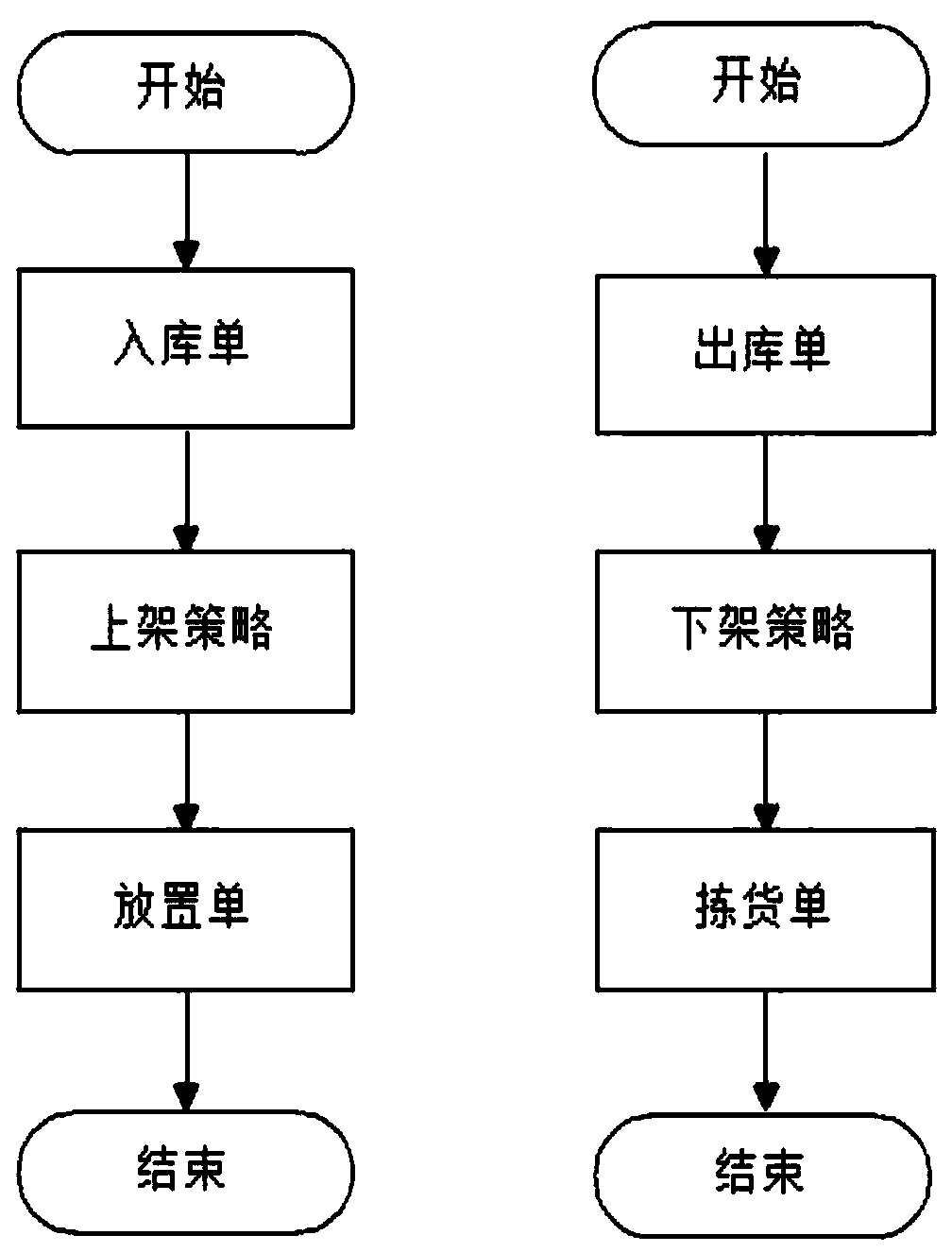

Management and use method of third-party logistics storage location

InactiveCN110443537AImprove work efficiencyImprove efficiencyResourcesLogisticsThird partyLogistics management

The invention relates to third-party logistics, and particularly relates to a management and use method of a third-party logistics storage location. The method comprises: designing a shelf loading strategy and a shelf unloading strategy of the goods; generating a warehouse-in list and a warehouse-out list; according to the warehouse-in list and the warehouse-out list in the S2 and the shelving strategy and the unshelving strategy in the S1, generating a corresponding placement list and a corresponding picking list; associating the loading strategy with the attributes of the goods; specifying the type of goods stored in each storage location; associating the off-shelf strategy with the warehouse; setting an off-shelf strategy of each warehouse; wherein the unshelving strategy comprises a strategy of setting first and then zero, a strategy of setting first and then zero and a strategy of shelving, the unshelving strategy is dynamically added according to business development, a pluralityof warehouse-in lists are combined according to specifications, batches and quantity of warehouse-in list goods before a placement list is generated, and a plurality of warehouse-out lists are combined according to specifications, batches and quantity of warehouse-out list goods before a picking list is generated. According to the technical scheme provided by the invention, the defect that a third-party logistics storage location management and use method can not be reasonably used can be effectively overcome.

Owner:上海安茁信息技术有限公司

Axis adjustment method of boring head

InactiveCN102658387AReasonable positioningEasy to operateDrilling/boring measurement devicesEngineeringStructural engineering

The invention discloses an axis adjustment method of a boring head. According to the axis adjustment method, the rotation axis of a main shaft of the boring head and the feeding movement direction of the boring head can be conveniently adjusted to be parallel. A large hole in the upper part of a component is bored by using a boring cutter on the main shaft; a dial gauge is arranged on the main shaft of the boring head, so that a measuring head of the dial gauge is arranged at the position of the boring cutter of a small hole on the lower part of the bored component on the main shaft; the measuring head of the dial gauge is pressed on the wall of the large hole in the upper part of the bored component; the main shaft is turned, and the measured value of the dial gauge is zero though four adjusting screw barrels on a disc on the upper edge of the boring head body; the connection of the boring head and a stand is adjusted for many times by using the method, so that the adjusting screw barrels are fixed to the boring head body by using locking nuts after the rotation axis of the main shaft of the boring head is parallel to the feeding movement direction of the boring head, and long bolts penetrate through the locking nuts and spherical washers to fix the boring head body to the stand; studs of short bolts are arranged in four small screw holes in the disc on the upper edge of the boring head body; and after the upper end faces of the studs of the short bolts are tightly pressed against the lower surface of the stand, each short bolt is locked by using the nut. The adjustment method has the advantages of rationality in positioning, easiness in operation and capability of quickly adjusting the parallelism of the rotation axis of the main shaft of the boring head and the feeding movement direction of the boring head to be within the required accuracy of machined components.

Owner:陈硕

User positioning method, device and system

ActiveCN101686254BReasonable positioningEffective positioningTransmissionAccess networkComputer terminal

Owner:CHINA MOBILE COMM GRP CO LTD

Foldable outdoor LED projector lamp

ActiveCN106051636AAvoid exposureAvoid wear and tearLighting support devicesSemiconductor devices for light sourcesEngineeringProjector

The invention relates to a foldable outdoor LED projector lamp. The foldable outdoor LED projector lamp comprises a lamp body, a base frame and movable arms, wherein the two ends of each movable arm are correspondingly hinged to the lamp body and the base frame. The movable arms can rotate relative to the lamp body, can extend and contract relative to the lamp body and can rotate relative to the base frame and / or extend and contract relative to the base frame. The foldable outdoor LED projector lamp is reasonable in structure, convenient to use, capable of being fixed at any position, wide in adjustable range, big in angle, high in flexibility and low in cost.

Owner:ZHEJIANG LIPER LIGHTING TECH CO LTD

Vehicle control system network security detection system based on multi-stage feedback queue

ActiveCN110430223APrecise positioningHigh degree of automationTransmissionMultilevel feedback queueControl system

The invention belongs to the technical field of vehicle control system network security detection, in particular to a vehicle control system network security detection system based on multistage feedback queues. The system comprises a vehicle control network topology detection module, a vehicle control network protocol analysis module, a vehicle control network equipment vulnerability scanning module, a security vulnerability and security event POC library, a security event priority queuing module, a security event backup queue registration module and a security event injection detection module. The security event queues for injection detection are sequentially generated, and the security events are injected and detected by adopting a multi-stage feedback queue round-robin scheduling mechanism, so that the security vulnerabilities and vulnerabilities of the vehicle control network can be positioned more reasonably, efficiently and accurately, and the autonomous and controllable networksecurity detection target of the vehicle control system is achieved. The scheme is high in automation degree, the security event injection detection mechanism is reasonable, efficient and accurate, the detection scene conforms to the real attack behavior of an attacker, and the whole network security detection process is autonomous and controllable.

Owner:北京京航计算通讯研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com