Ferrule type grinding wheel chuck

A ferrule type and chuck technology, which is applied to the parts of grinding machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem that the grinding wheel chuck can not be freely exchanged with the grinding spindle of the machine tool, and cannot be installed and used And free exchange, time-consuming and labor-intensive problems, to achieve the effect of improving the automation of machine tools, reasonable positioning, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

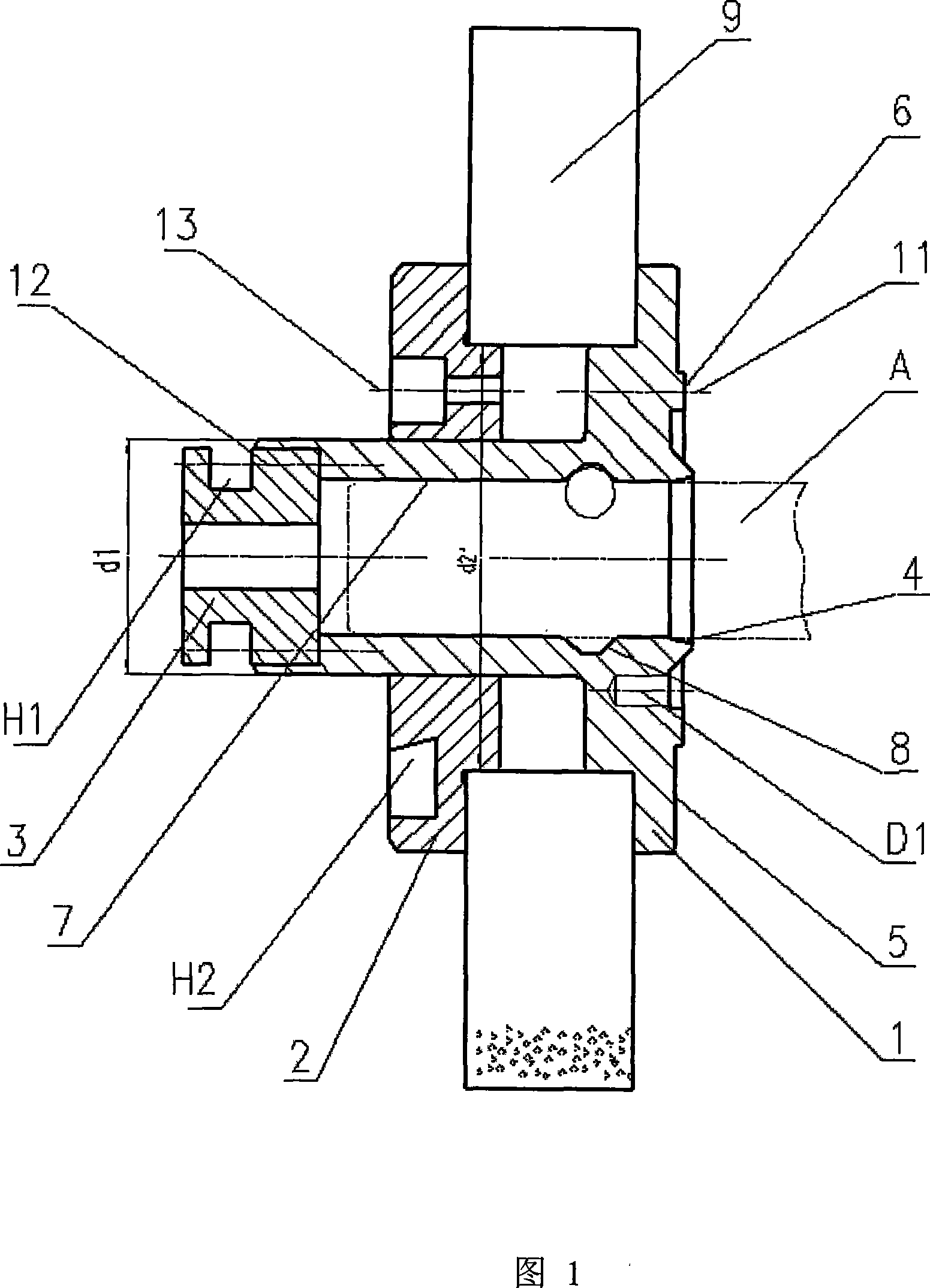

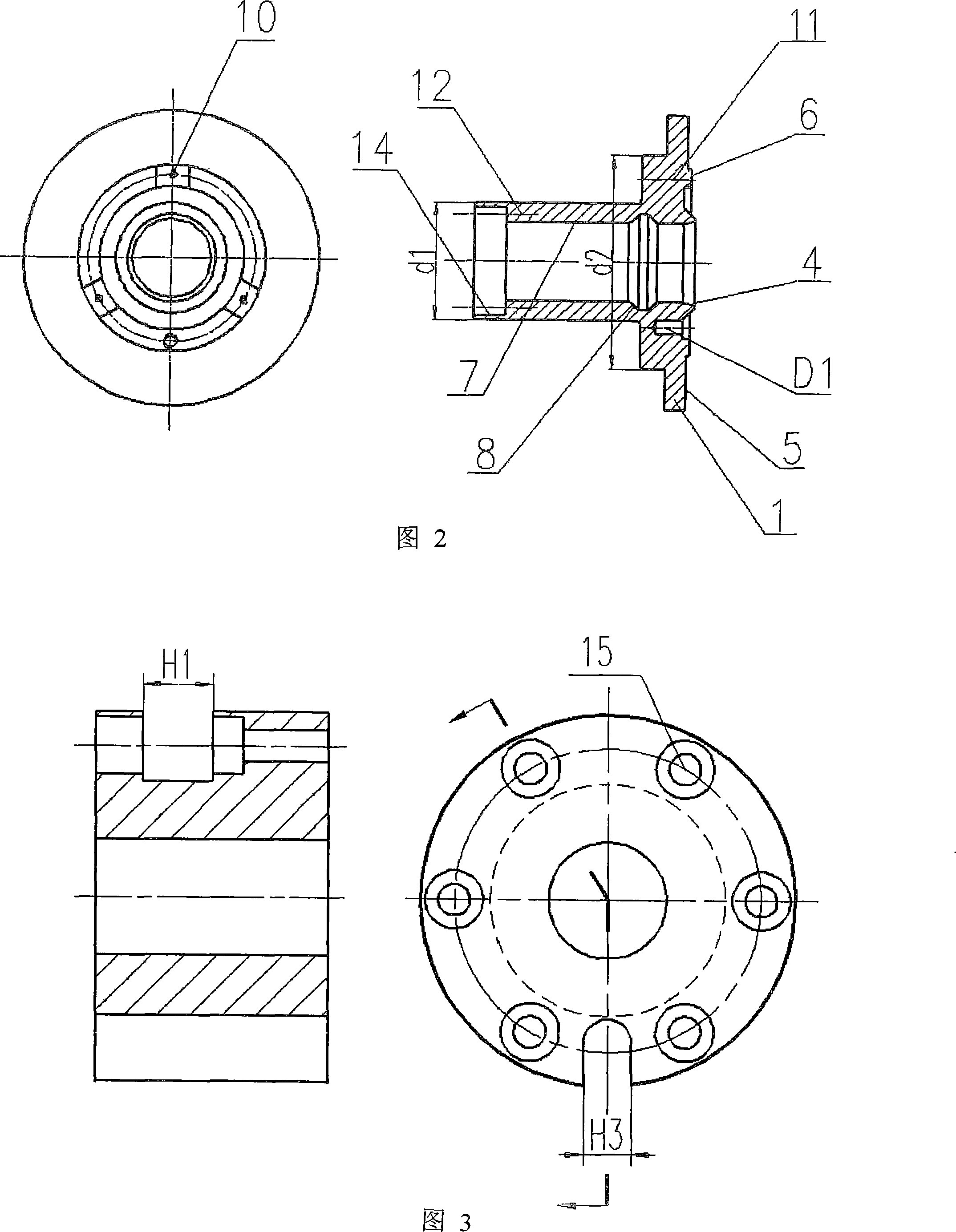

[0016] As shown in FIG. 1 , it is a ferrule-type grinding wheel chuck which is composed of a chuck body 1 , a pressing disc 2 and a ferrule 3 ; the grinding wheel 9 is installed on the chuck.

[0017] As shown in Figure 1 and Figure 2, the chuck body 1 has a cylindrical inner hole 7, and a clamping ring groove 8 connected with the main shaft tensioning mechanism A is arranged in the cylindrical inner hole, and the inclined surface of the clamping ring groove 8 is The angle is 45 degrees, and the groove width is 15mm, forming a point contact with the three positioning steel balls of the tensioning mechanism of the grinding head spindle; The inner cone of the cone body 4 is 45 degrees, and the large end size of the inner cone is 52mm. This small-sized cone is convenient for positioning and installation with the main shaft, and is convenient for machining. The left end of the cylindrical inner hole is provided with a counterbore 14 and 6 axial screw holes 12 that are matched and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com