Patents

Literature

30results about How to "Implement automatic exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

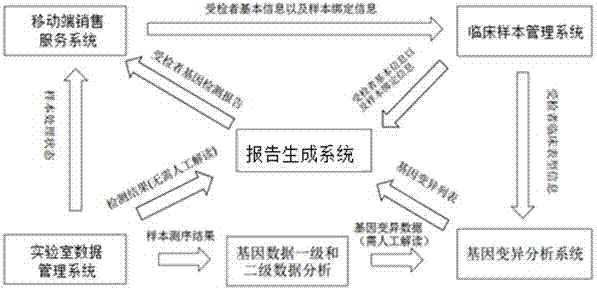

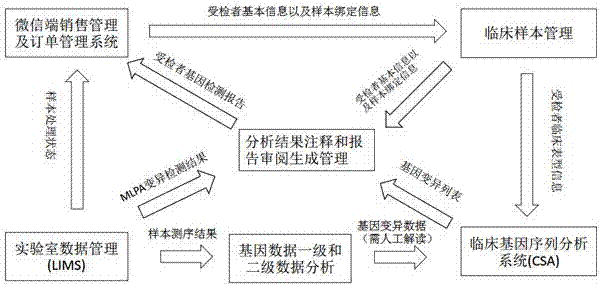

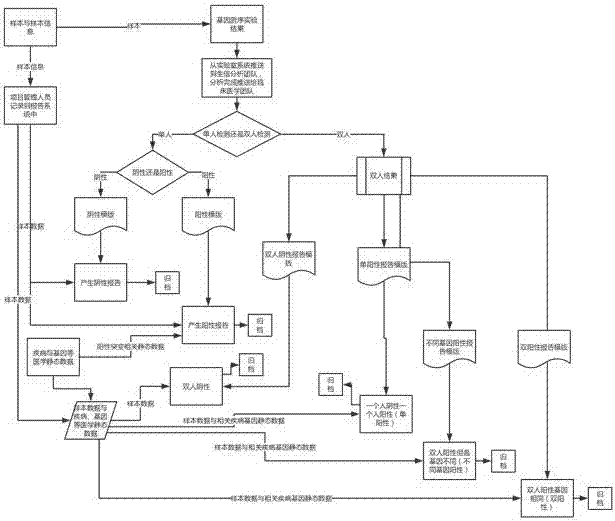

Gene detection product report system and method

InactiveCN107220885AImplement automatic exchangeGuaranteed accuracyProteomicsGenomicsBiologySpecific storage

The invention discloses a gene detection product report system comprising a mobile terminal sales service system which is used for the user to select a gene detection product and place an order to pay and is also used for acquiring basic information of the detected subject and sample binding information; a clinical sample management system which is used for receiving the basic information of the detected subject and the sample binding information from the mobile terminal sales service system; a laboratory data management system which is used for storing samples starting from order placing until the sequencing data are transferred to the specific storage position from a sequencer, wherein a report generation system generates a report to be stored in the laboratory data management system and pushed to the mobile terminal sales service system to be transmitted to the specific report receiver; and the report generation system which is used for receiving the basic information of the detected subject and the sample binding information from the clinical sample management system and the detection result from the laboratory data management system so as to generate the report. Automatic data exchange and centralized report management can be realized, and the report can be automatically generated according to the requirement so as to guarantee the accuracy of the report data.

Owner:MINGMA SHANGHAI BIOLOGICAL TECH CO LTD

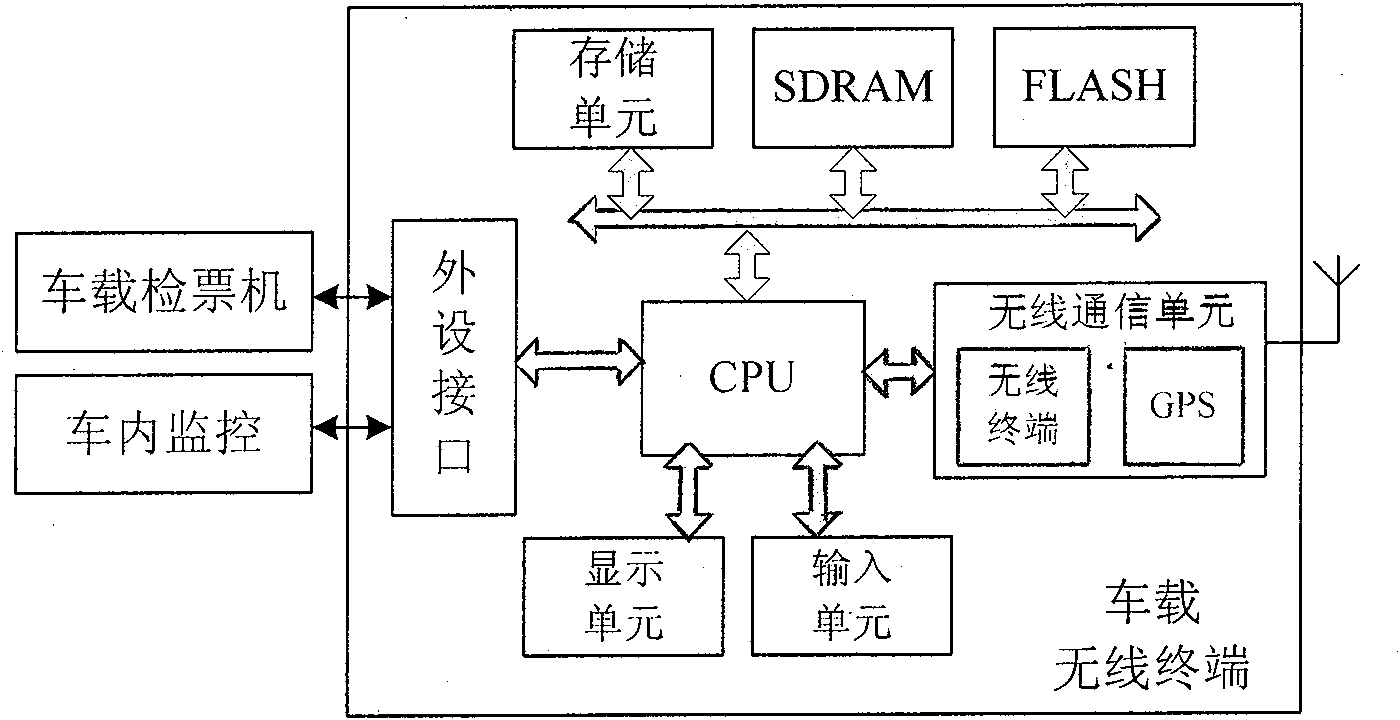

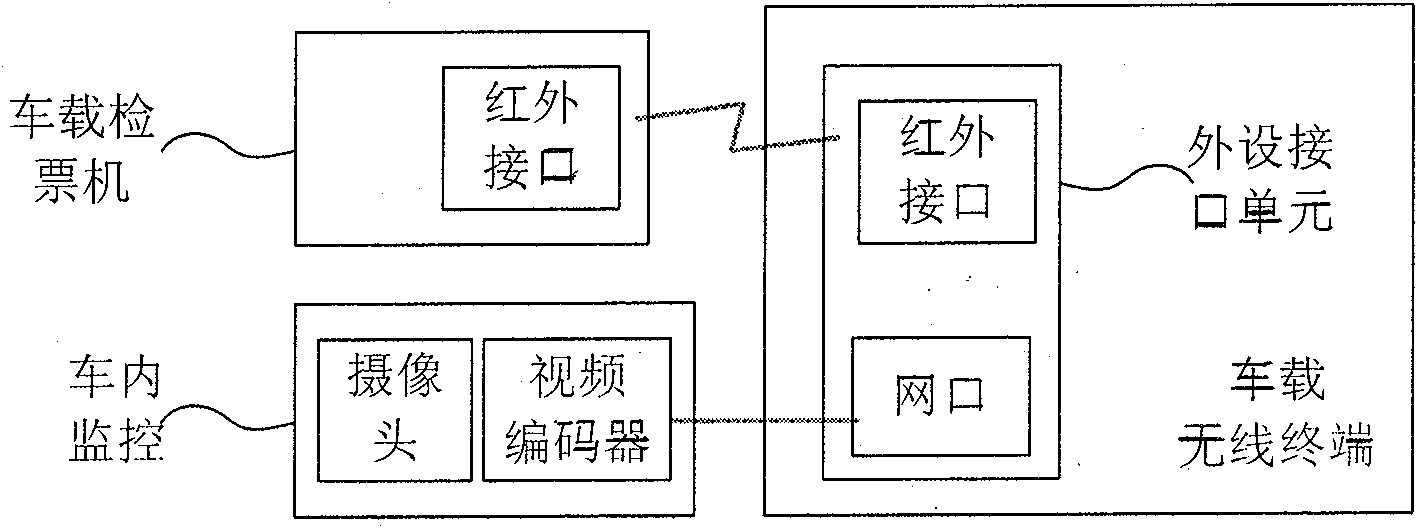

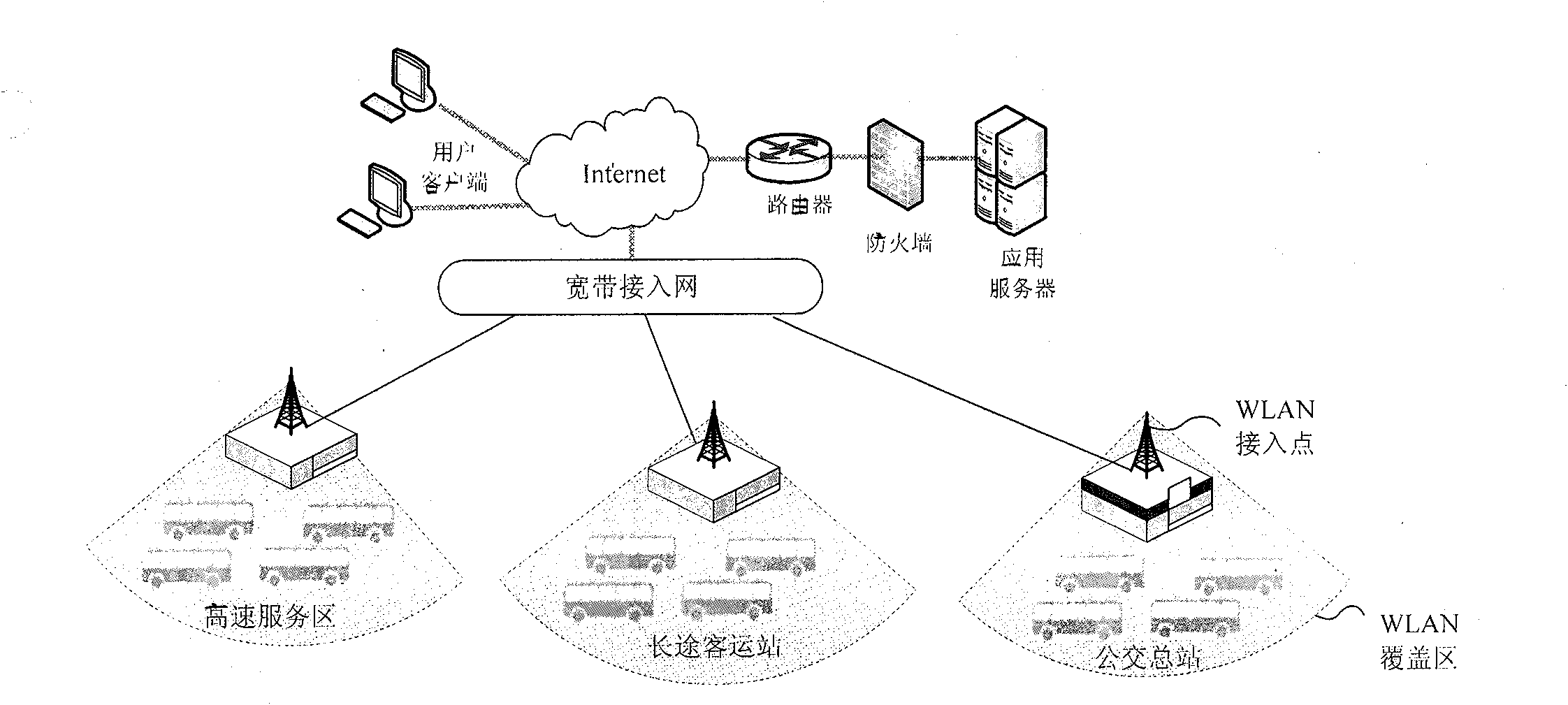

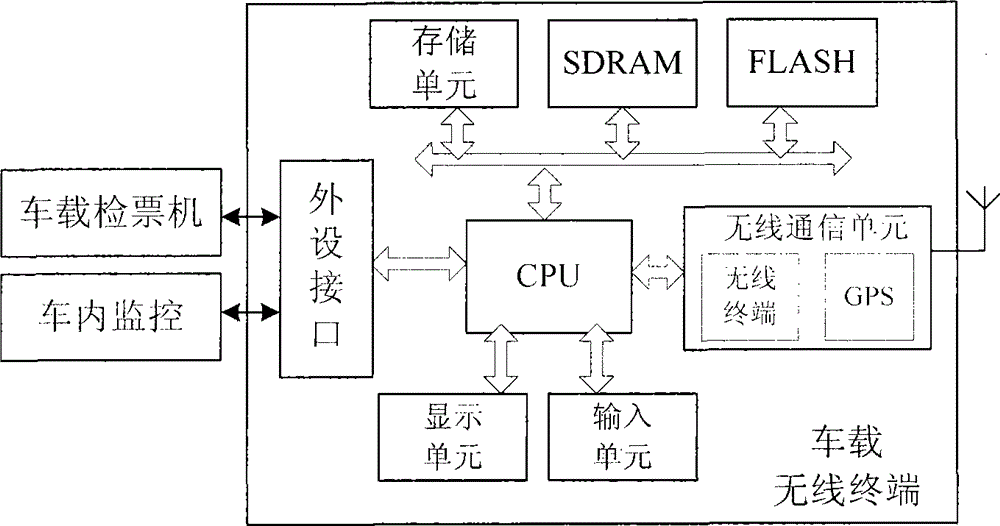

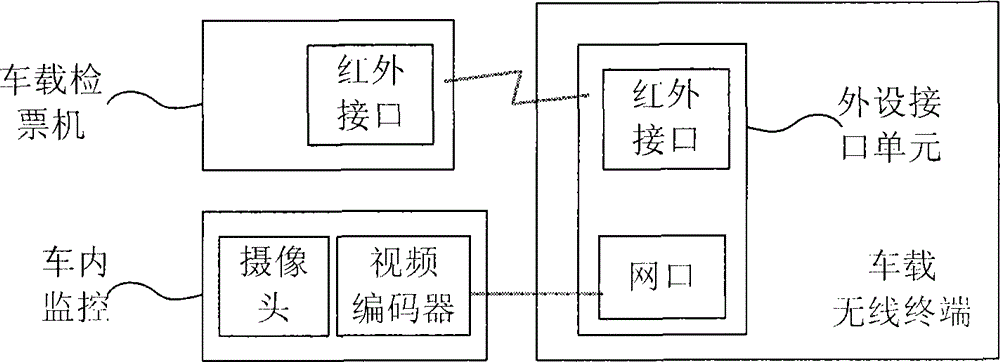

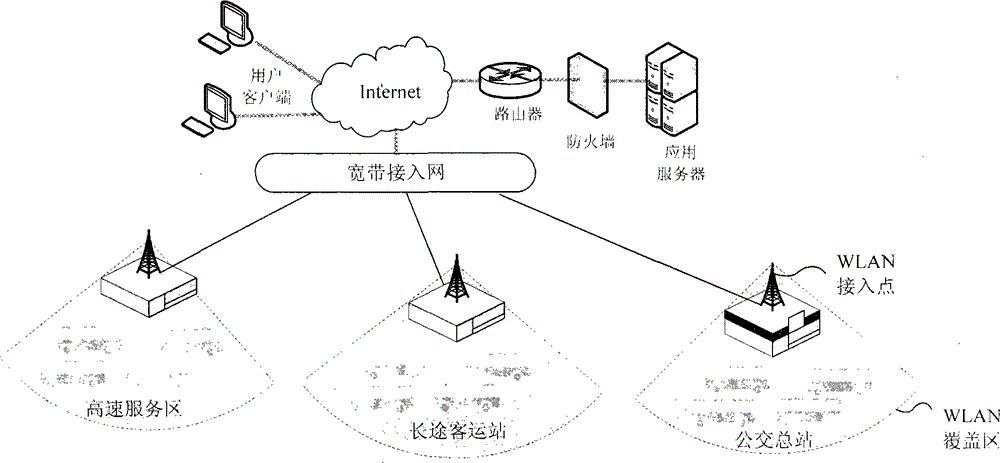

Vehicle wireless communication method and system

InactiveCN101998686AImplement automatic exchangeImprove economyTicket-issuing apparatusNetwork topologiesInternet networkData acquisition

The invention provides a method, a device and a system for realizing vehicle wireless communication. A vehicle wireless communication device is allocated on a vehicle and connected with other vehicle equipment through interfaces to support a first wireless network and a second wireless network; meanwhile, a background application subsystem connected with an Internet network is allocated; by implementing the method of the invention, the vehicle wireless communication device can automatically finish high-capacity data switching between the vehicle equipment and the background application subsystem through the first wireless network; and the vehicle wireless communication device transmits a state report and service data to the background application subsystem through the second wireless network when an emergency occurs. By applying the method and the system, vehicle ticket checker transaction data acquisition, centralized vehicle monitoring data uploading, periodic vehicle advertisement data downloading and updating and other vehicle data services can be more conveniently realized.

Owner:胡乐乐

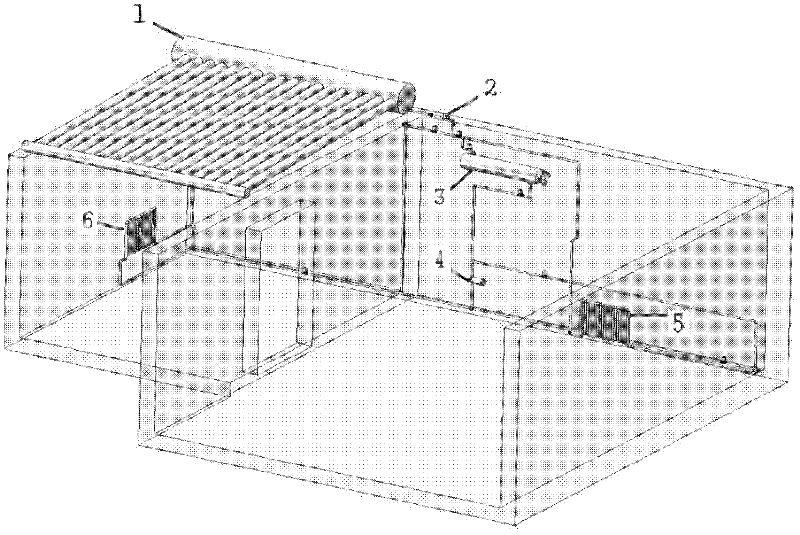

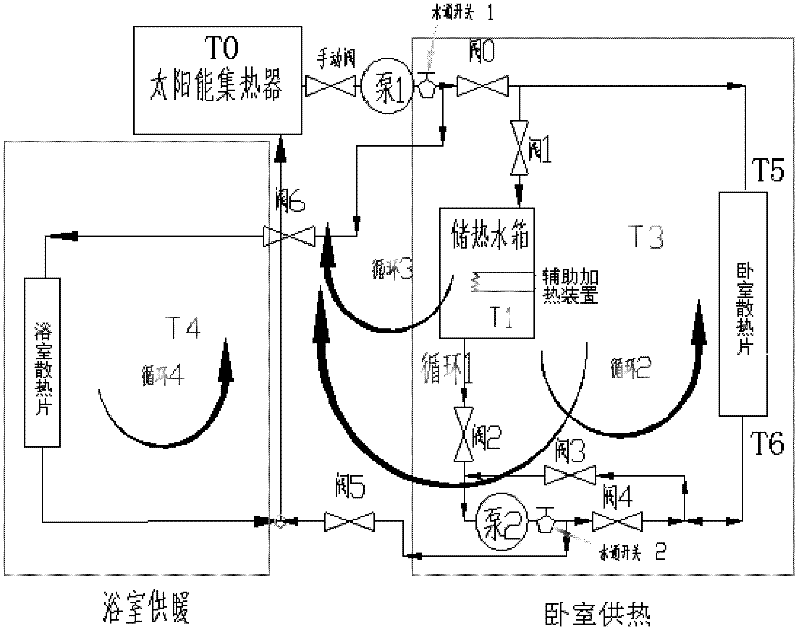

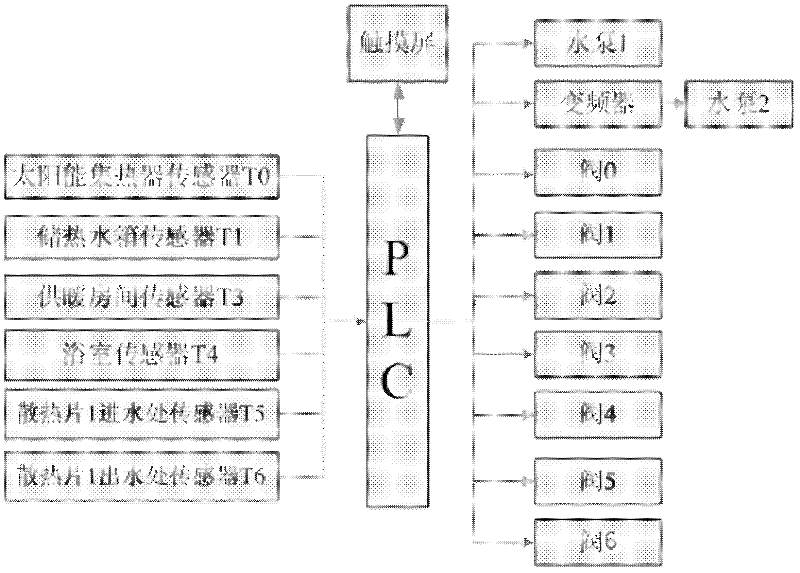

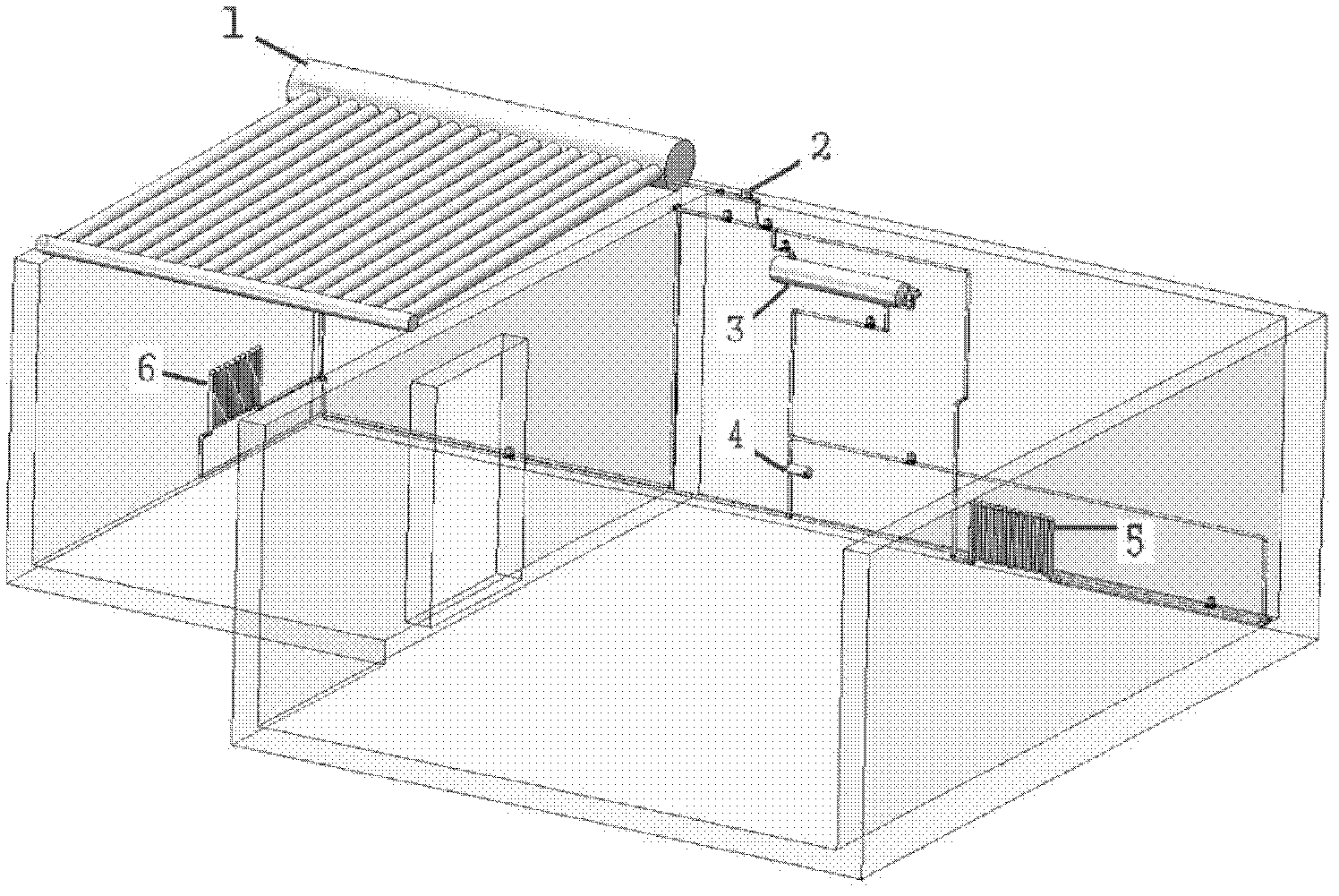

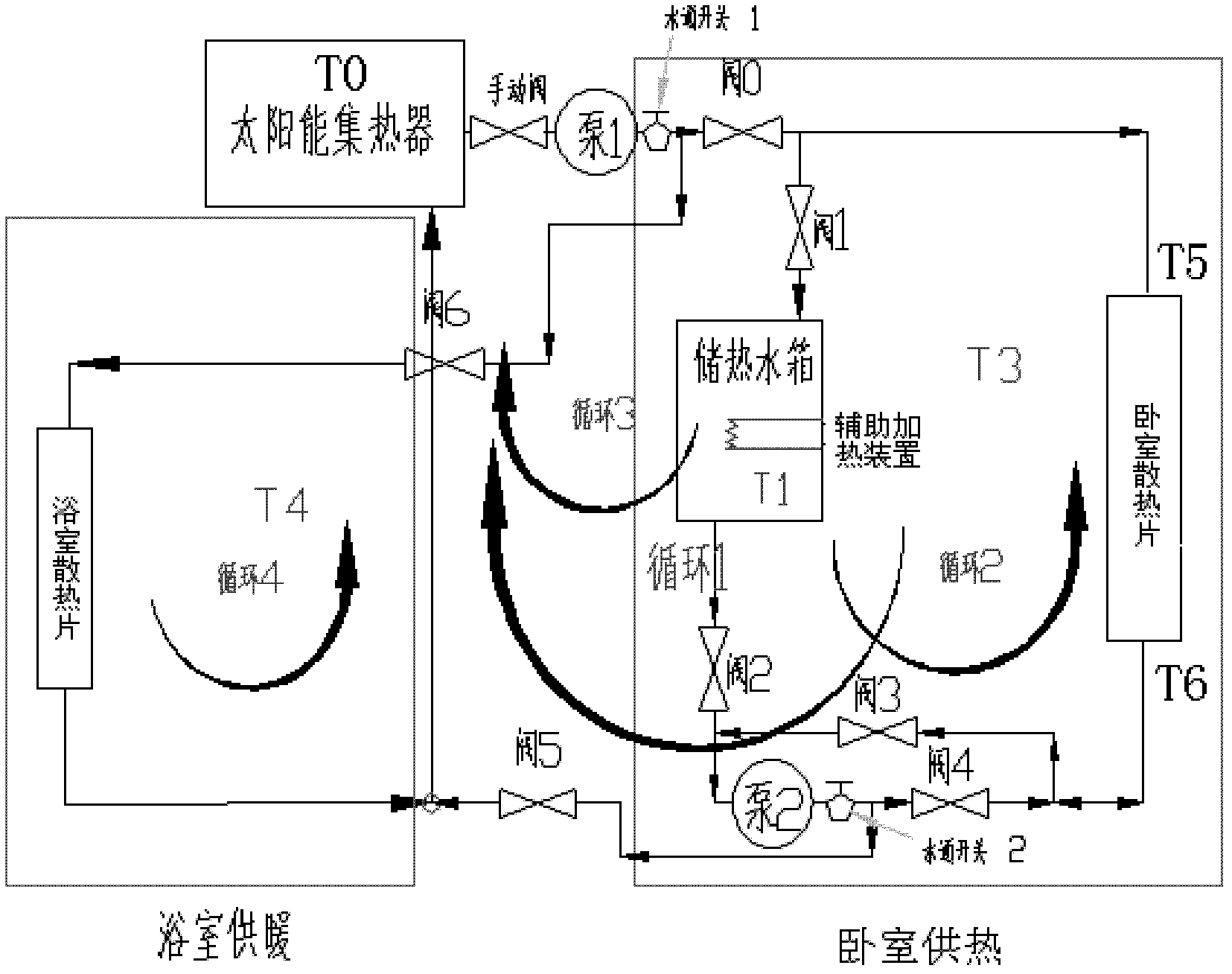

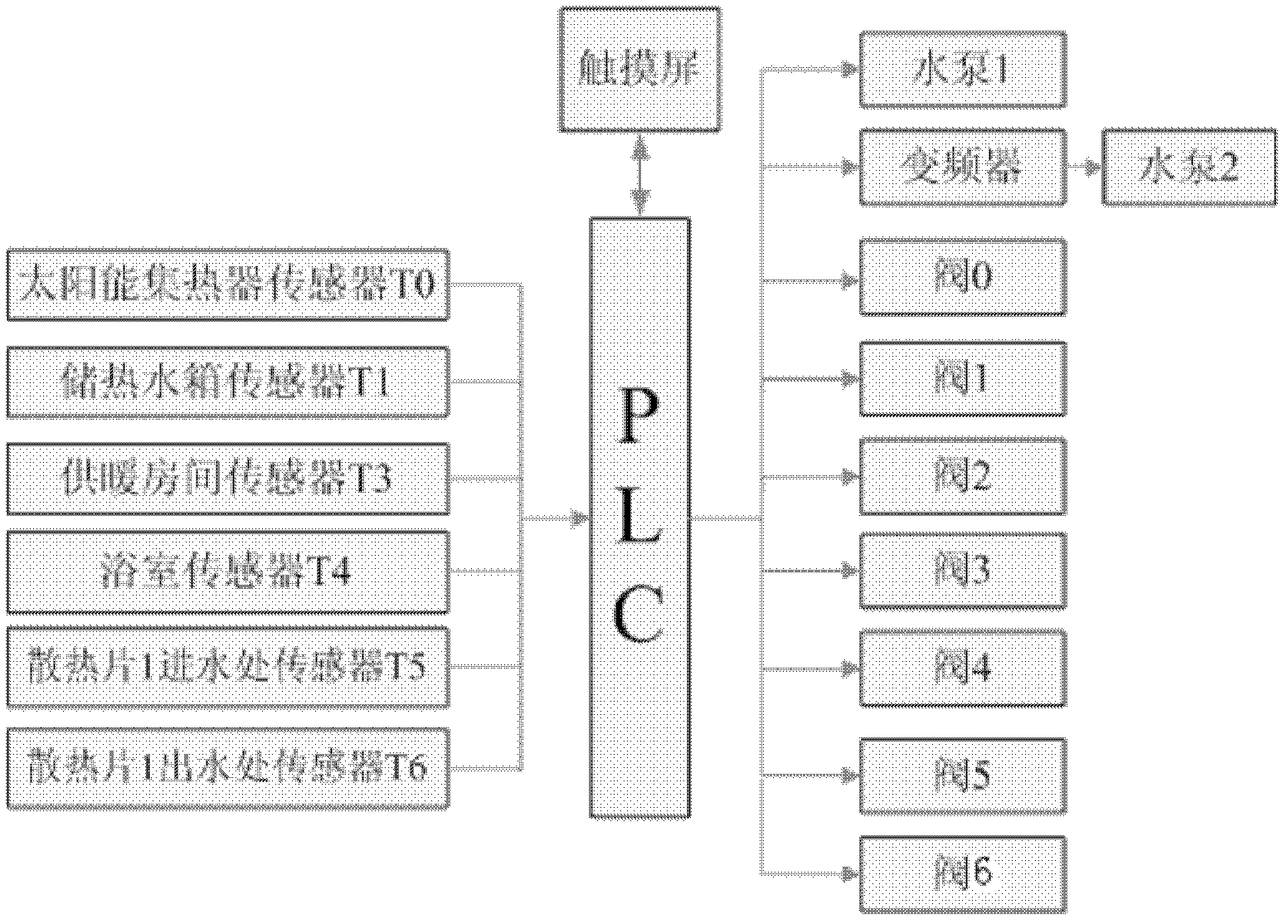

Solar heating control system and control method thereof

InactiveCN102644957AImprove utilization efficiencyReduce pollutionLighting and heating apparatusSpace heating and ventilation detailsControl systemEngineering

The invention discloses a solar heating control system and a control method thereof. The solar heating control system comprises a controller, a solar collector, a heat storage water tank with an auxiliary heating device, a first radiating fin, a second radiating fin, a first heating circulating pump and a second heating circulating pump. A sixth control valve is arranged between the first heating circulating pump and the second radiating fin , a zeroth control valve is arranged between the first heating circulating pump and the first radiating fin and between the first heating circulating pump and the heat storage water tank, a first control valve is arranged between the zeroth control valve and the heat storage water tank, a fifth control valve and a fourth control valve are respectively arranged between the second heating circulating pump and the solar collector and between the second heating circulating pump and the first radiating fin, a second control valve is arranged between the second heating circulating pump and the heat storage water tank, and a third control valve is arranged between the first radiating fin and the fourth control valve and between the second heating circulating pump and the second control valve. The solar collector, the heat storage water tank, a bedroom, a bathroom and the two outlets of the first radiating fin are respectively provided with a zeroth temperature sensor, a first temperature sensor, a second temperature sensor, a third temperature sensor, a fourth temperature sensor, a fifth temperature sensor and a sixth temperature sensor. The solar heating control system provided by the invention uses the solar collector and the auxiliary heating device for heating, the environment is protected and the energy is saved.

Owner:NANJING COLLEGE OF INFORMATION TECH

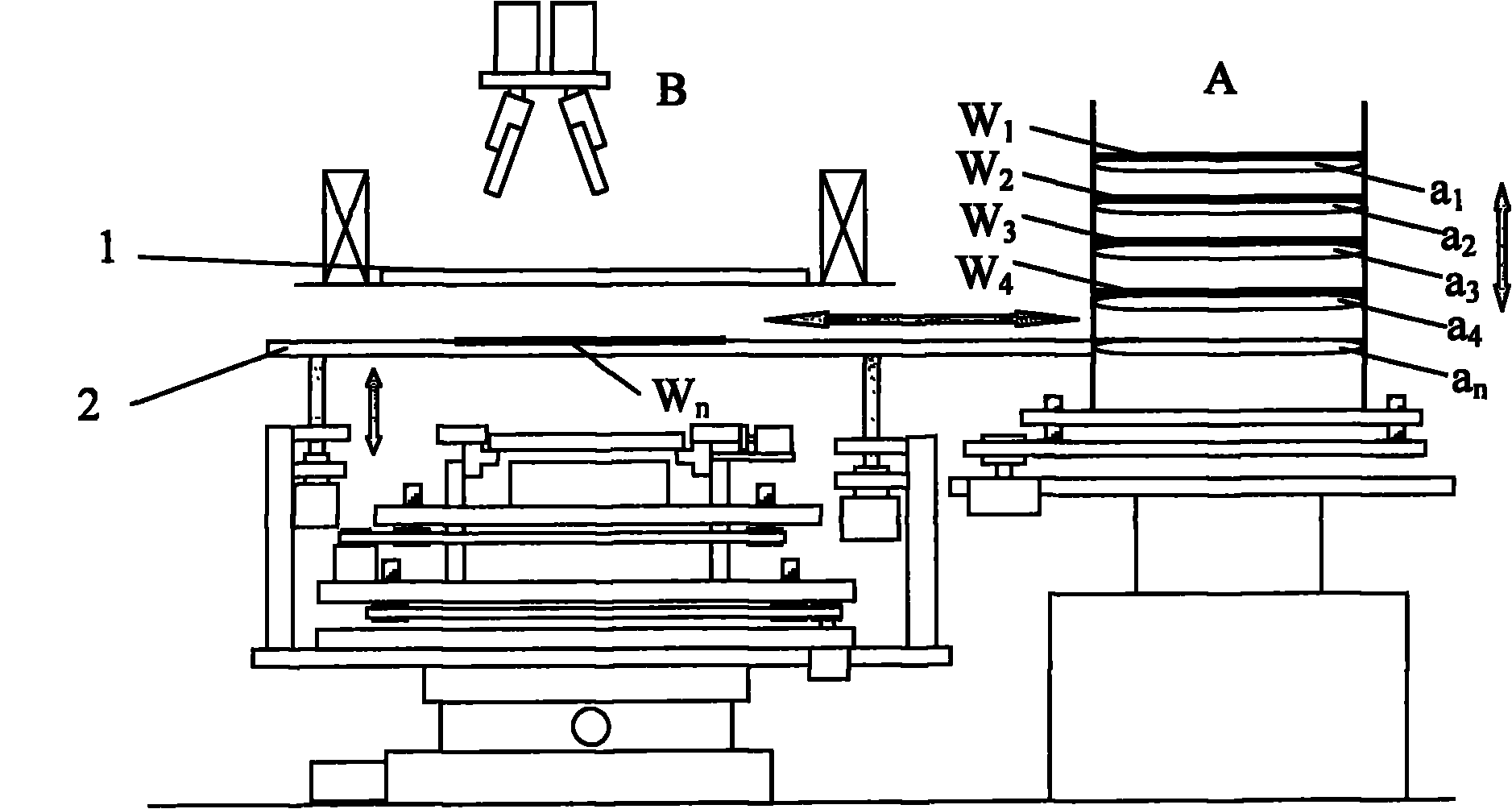

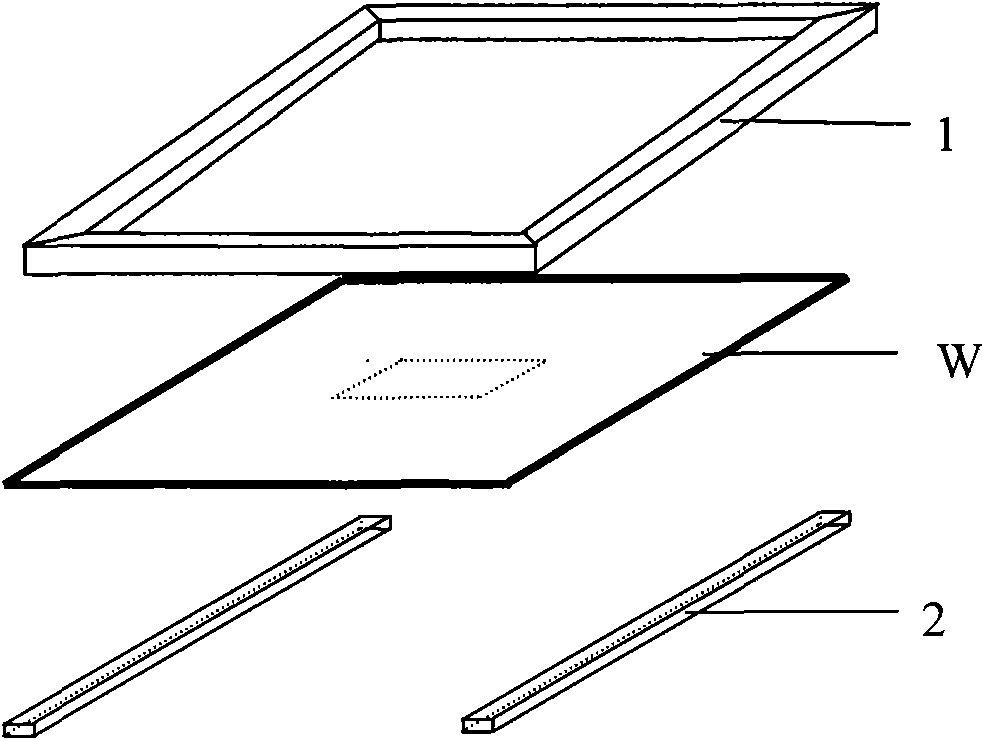

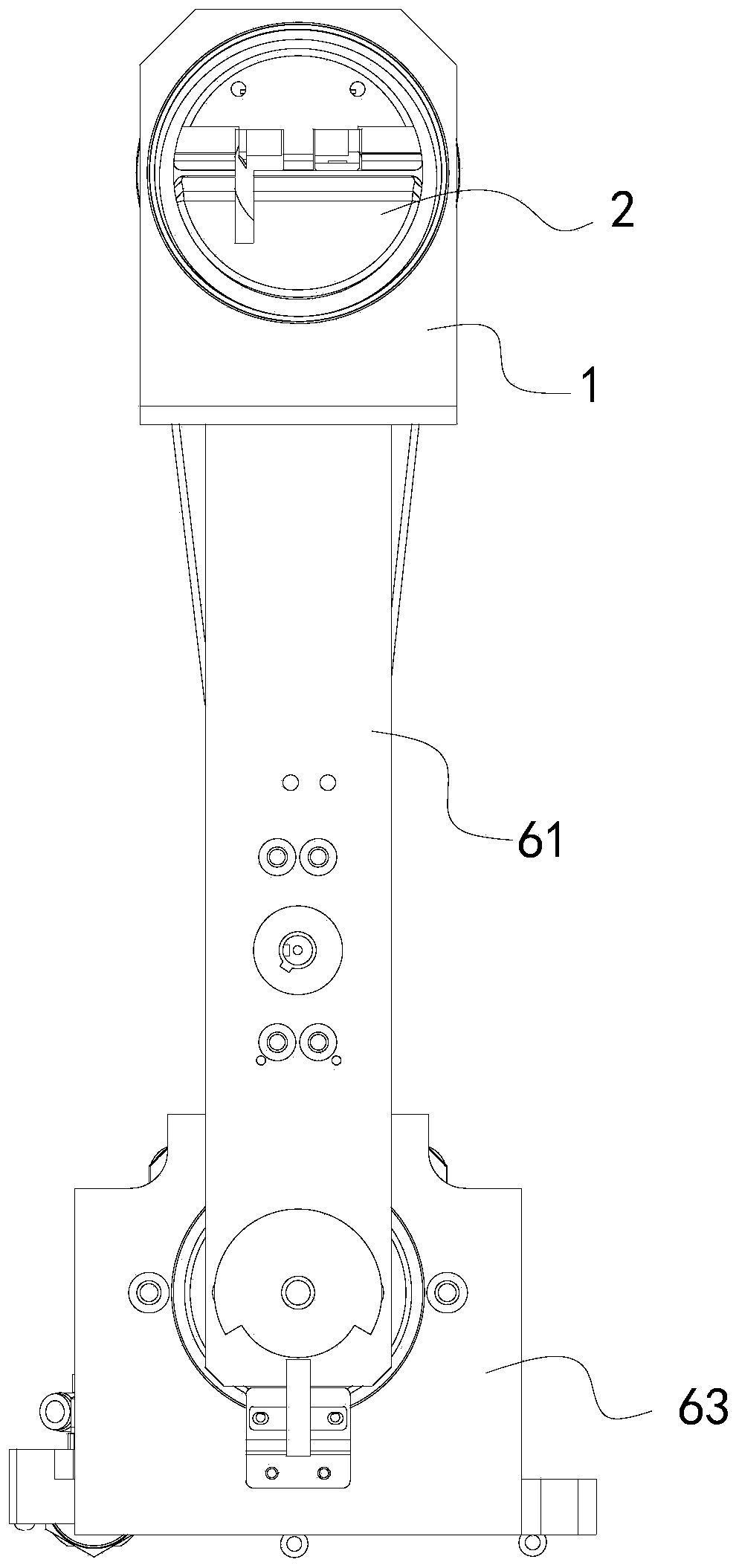

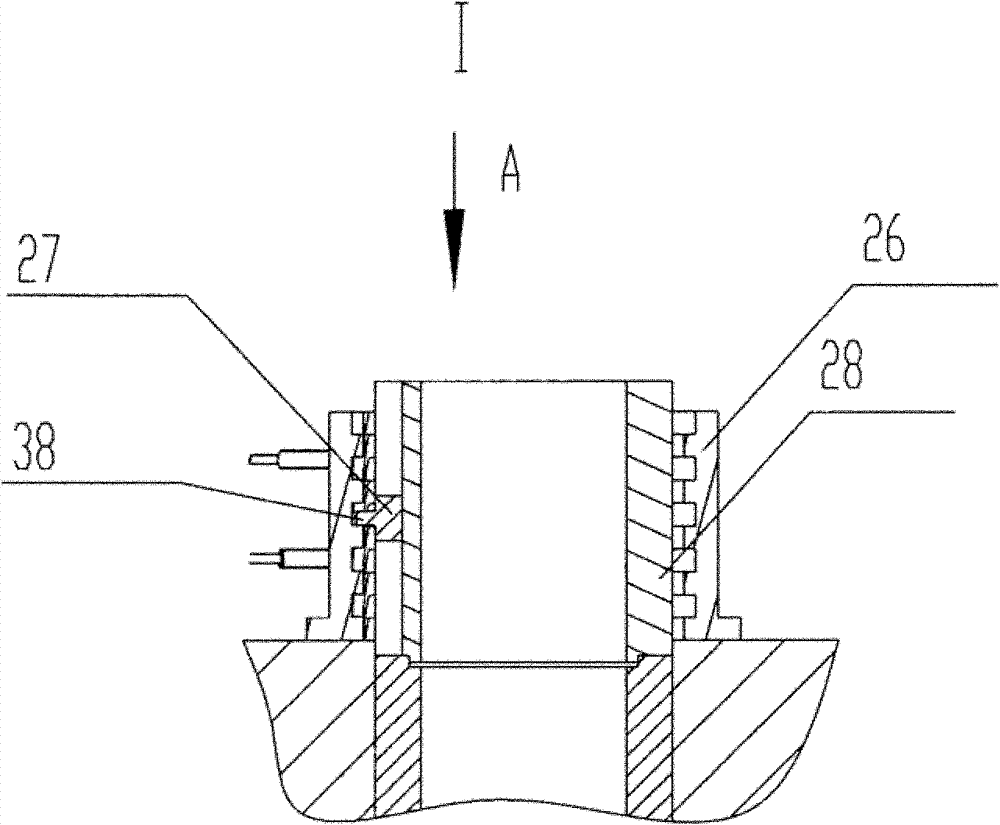

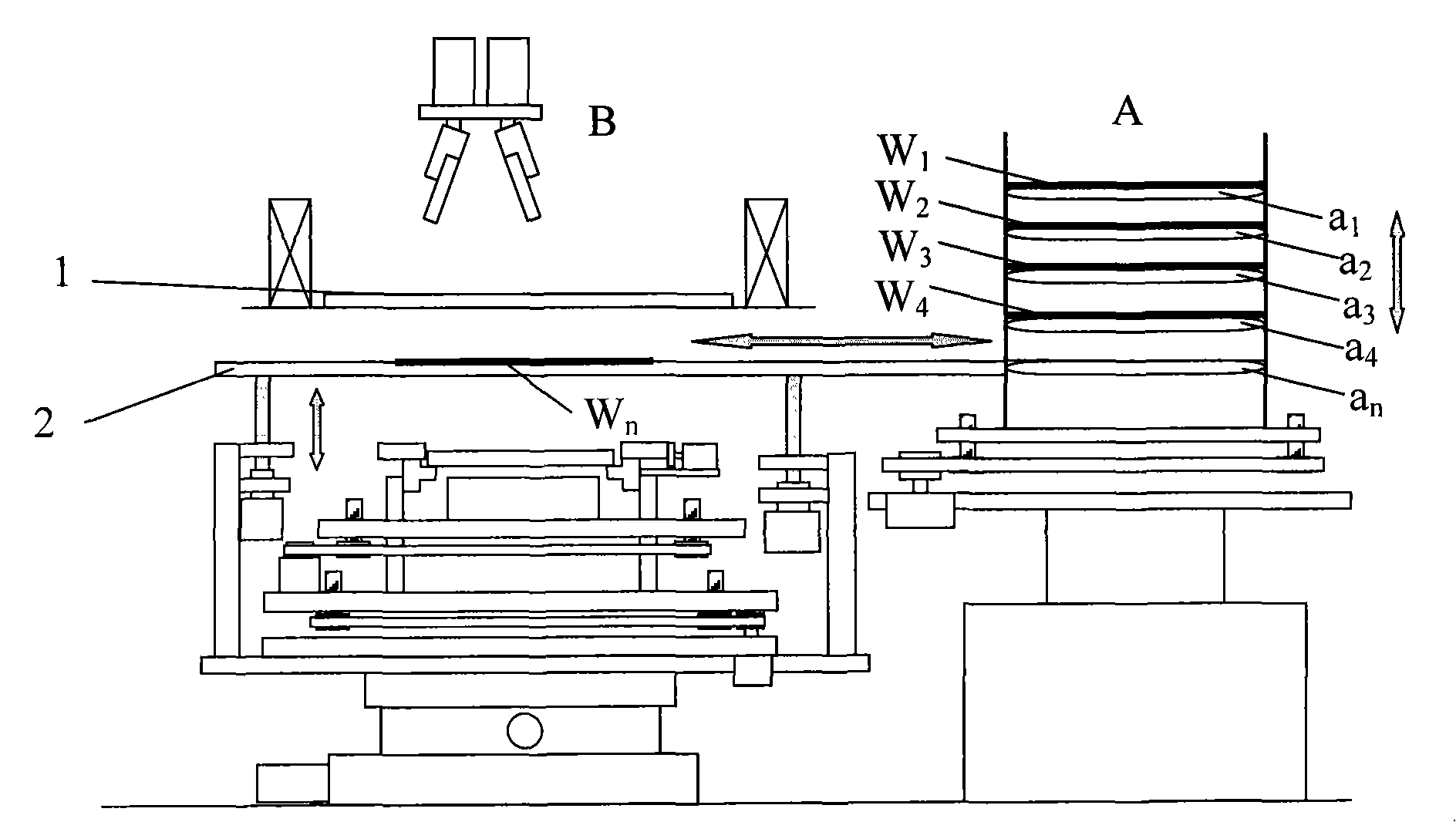

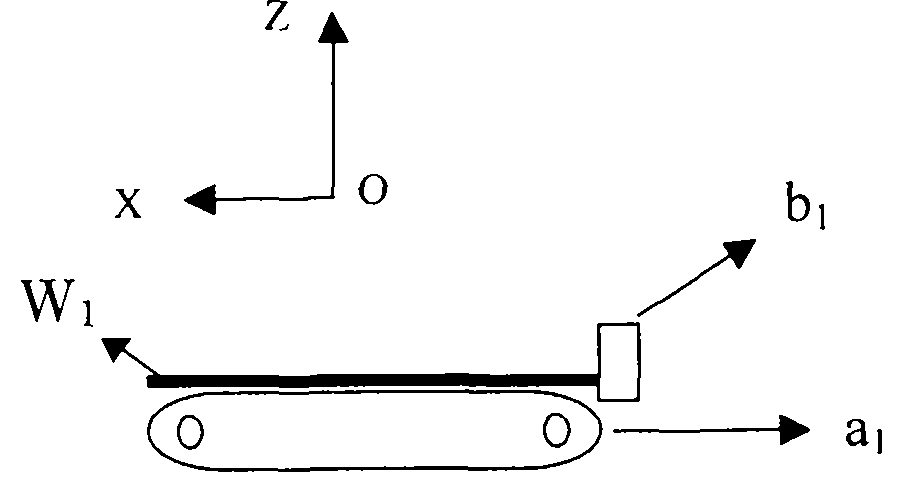

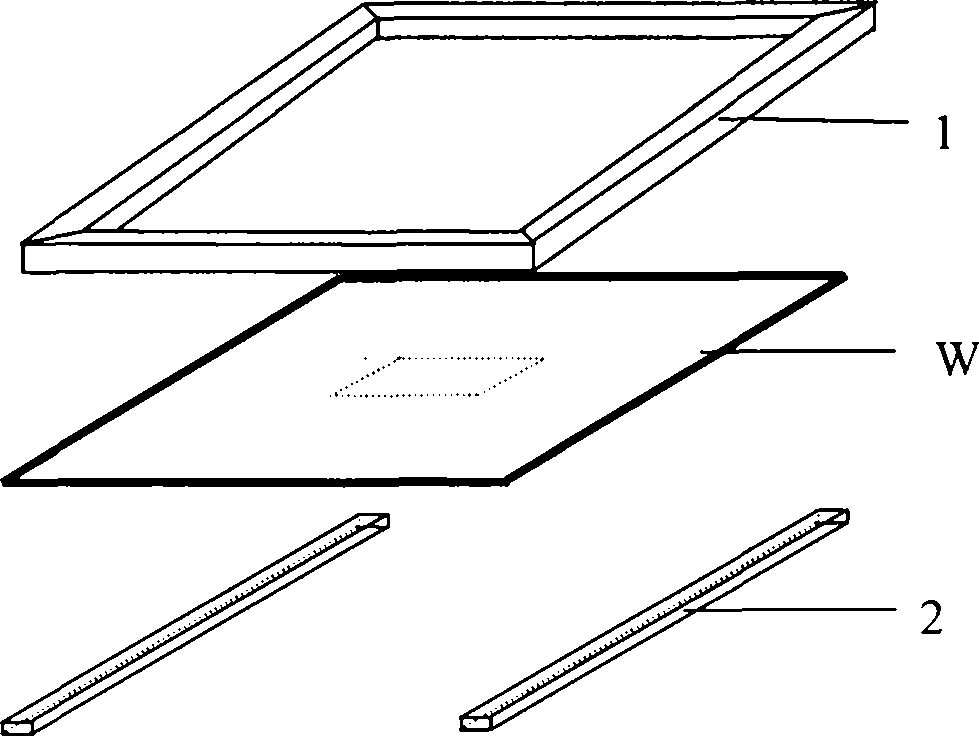

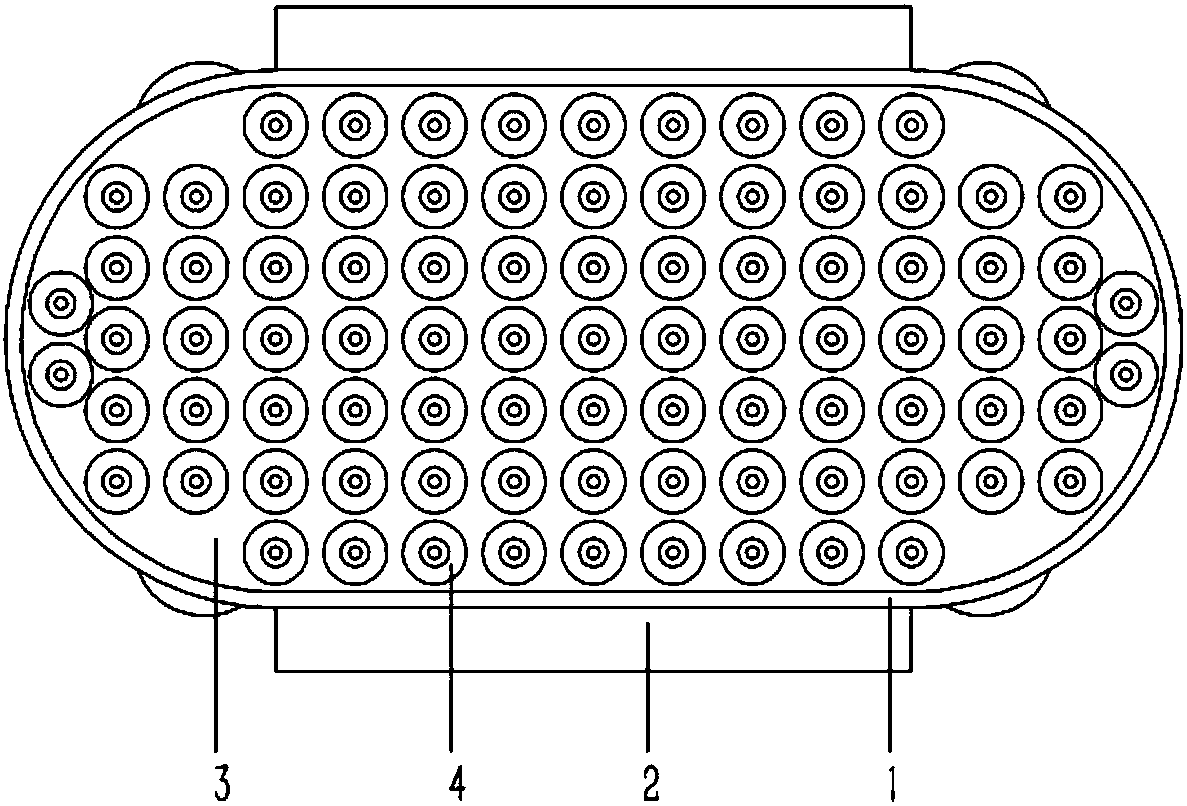

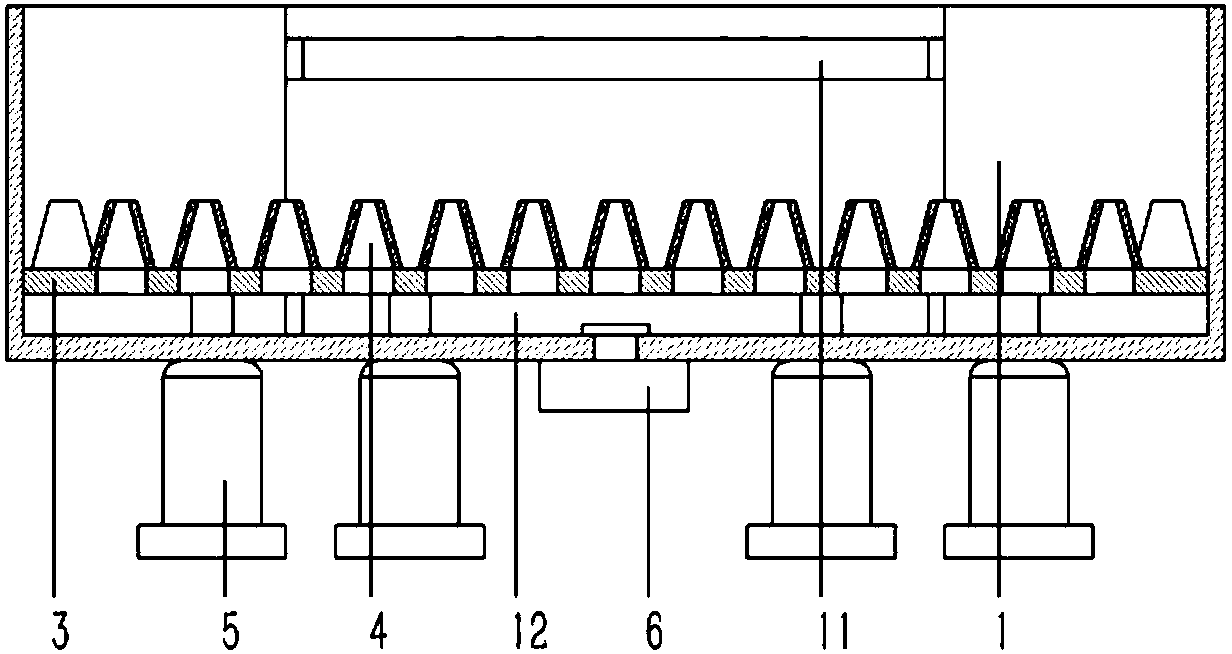

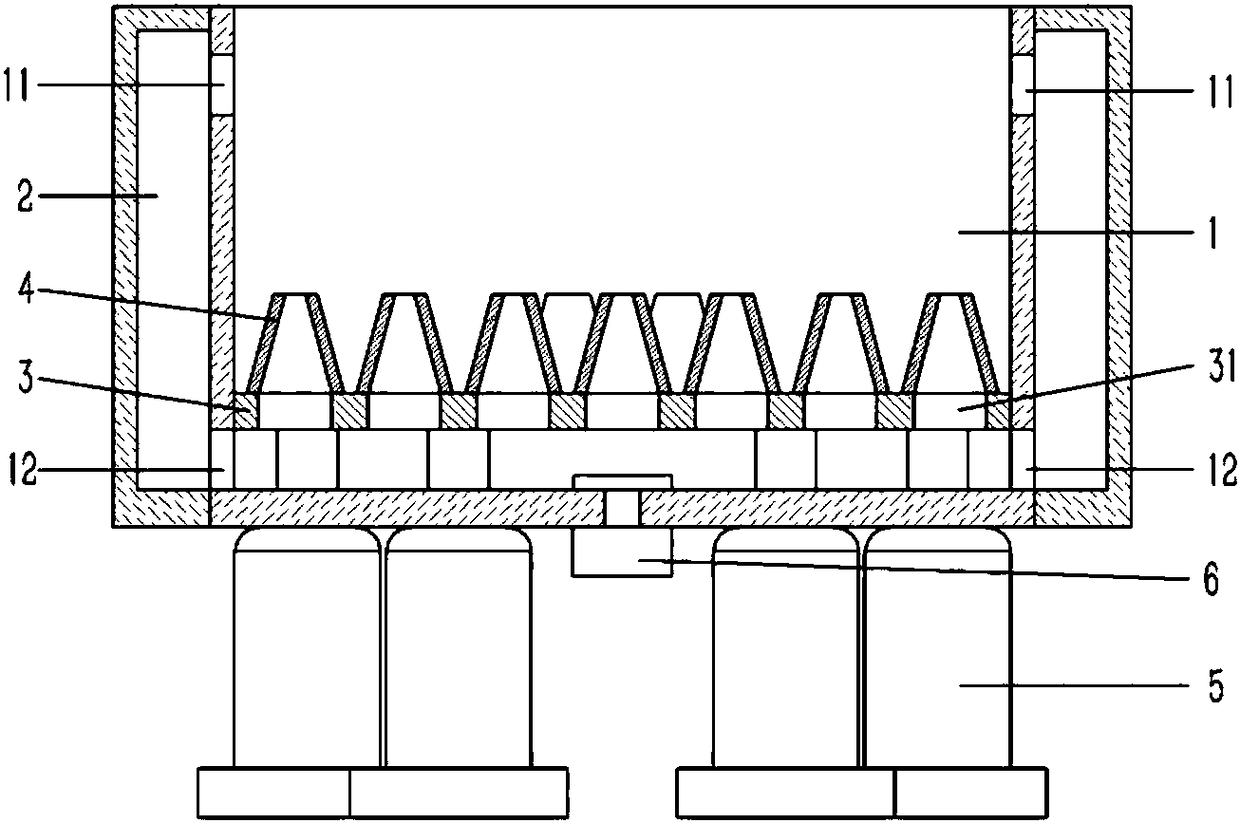

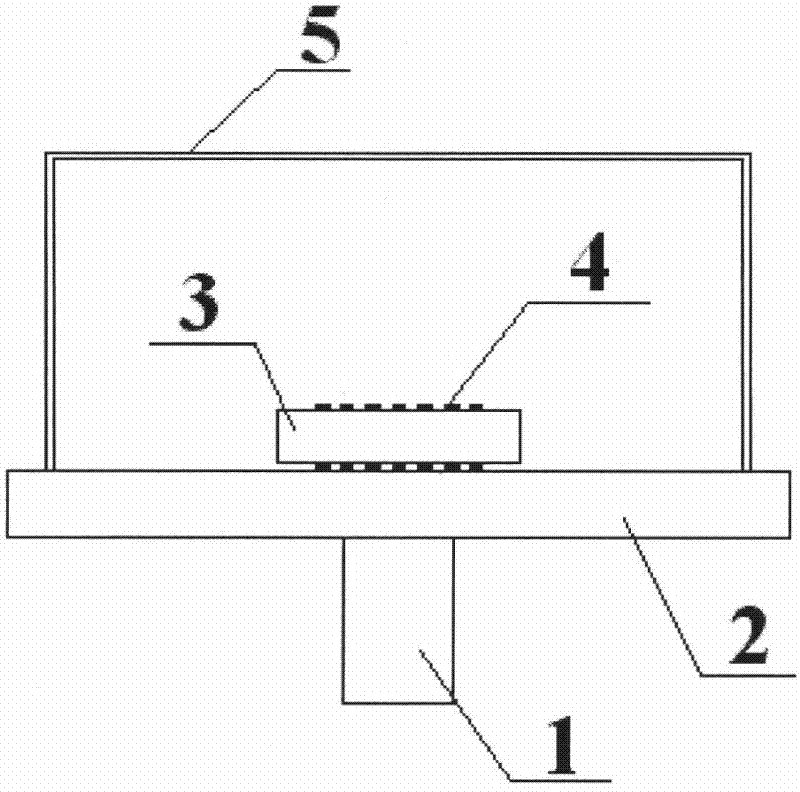

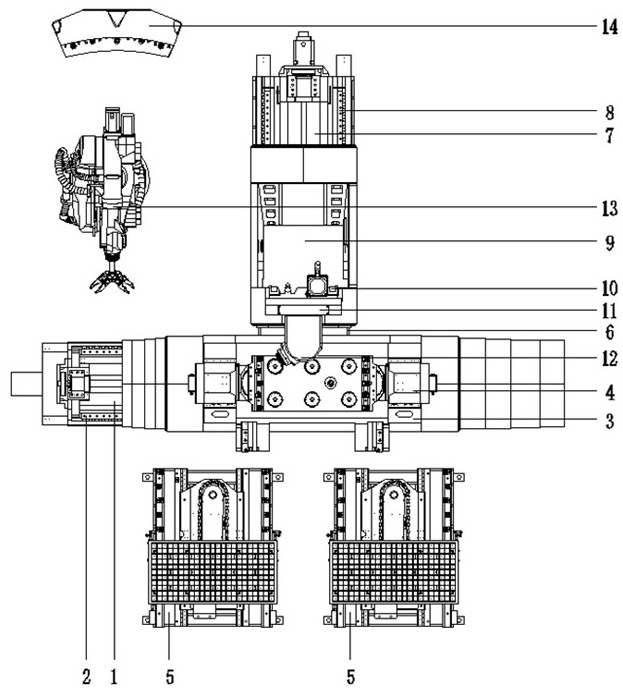

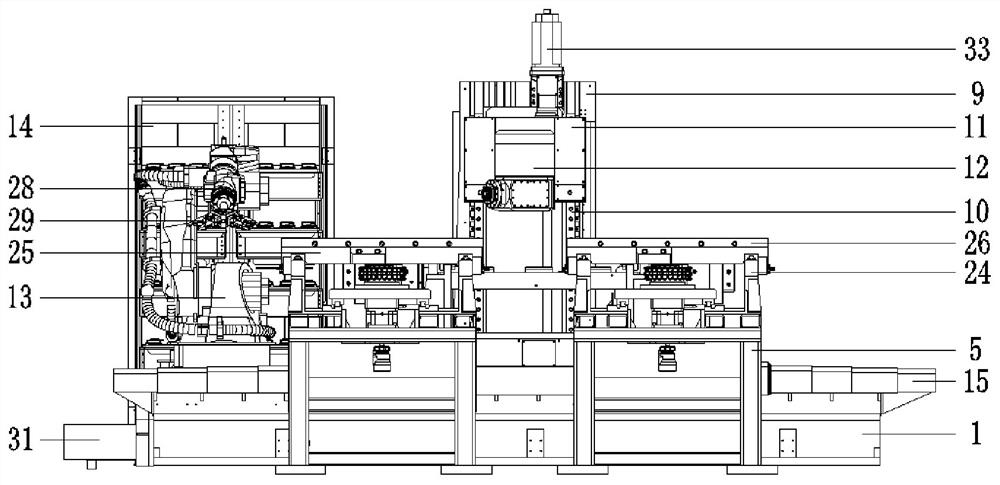

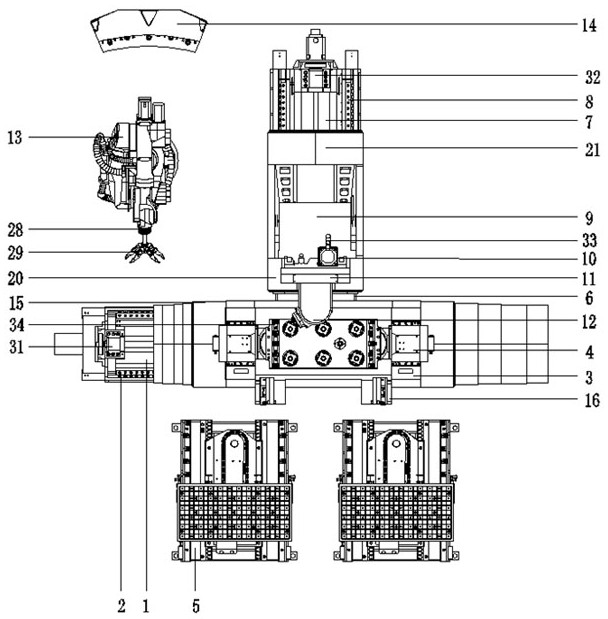

Screen printing machine and method for automatically exchanging screens

ActiveCN101850649AImprove work efficiencyImplement automatic exchangeScreen printersElectrical and Electronics engineeringPrinting press

The invention provides a screen printing machine and a method for automatically exchanging screens. The screen printing machine comprises a screen chamber, a workbench, a control device and a memory device, wherein the screen chamber is used for containing screens and exchanging screens with the workbench; the workbench is used for exchanging screens with the screen chamber and printing a substrate; the control device is used for controlling the automatic exchange of the screens; and the memory device is used for storing the corresponding relation between the substrate and each screen. The screen printing machine and the method for automatically exchanging screens provided by the invention, can realize the automatic exchange of screens, thereby greatly improving the working efficiency of the printing machine and saving the time and the cost.

Owner:PANASONIC CORP

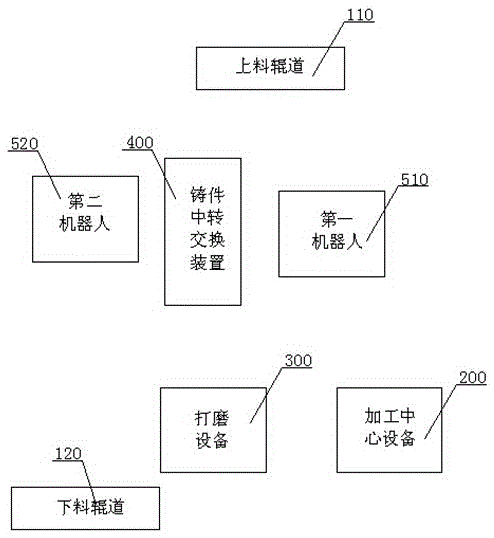

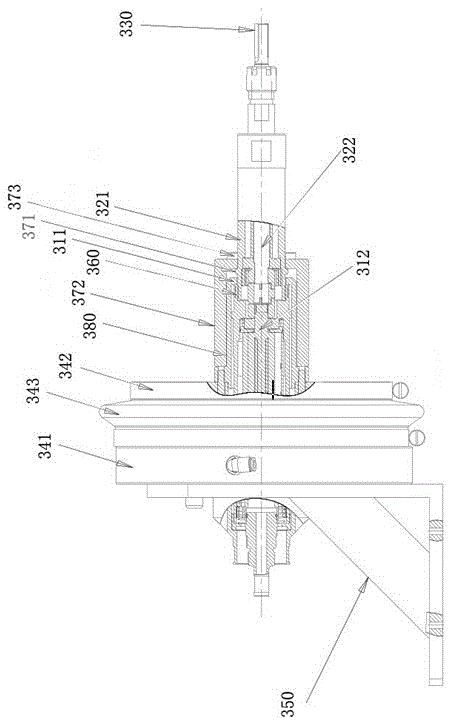

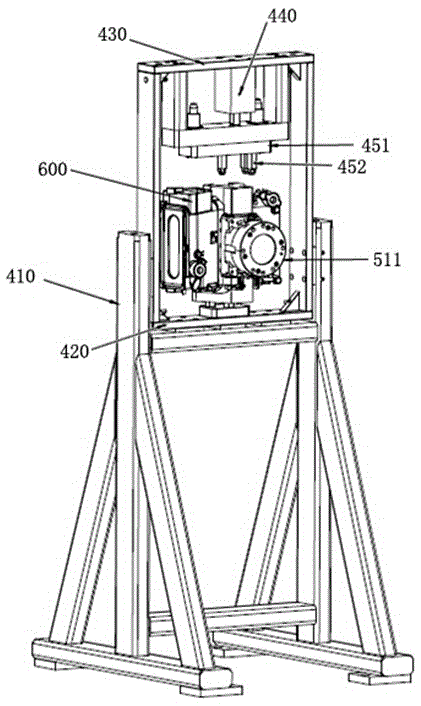

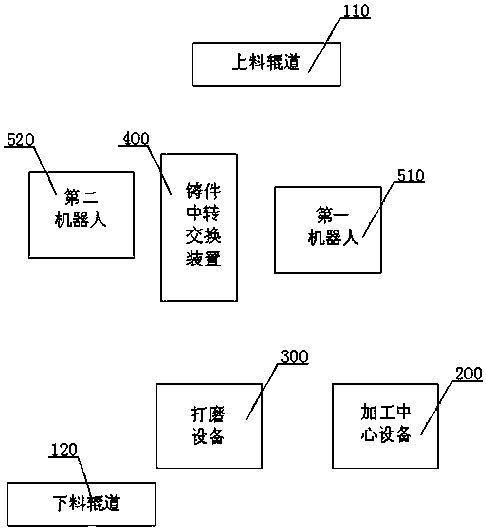

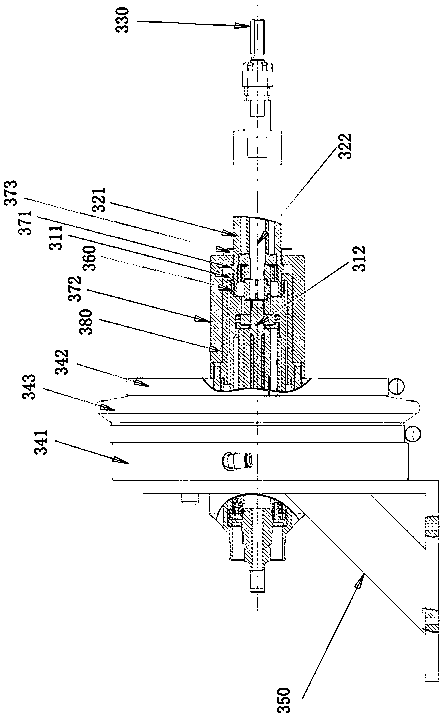

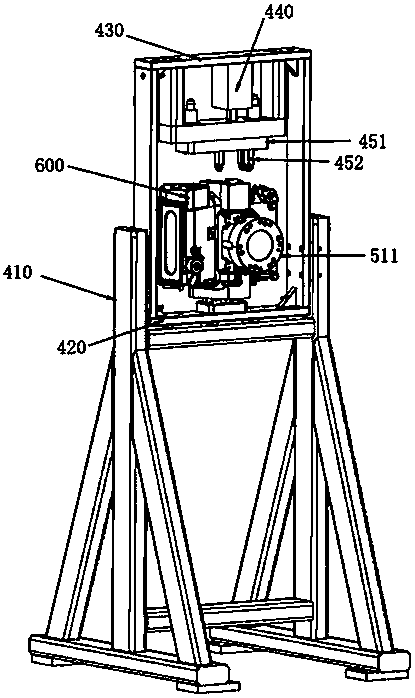

Casting cleaning unit and method

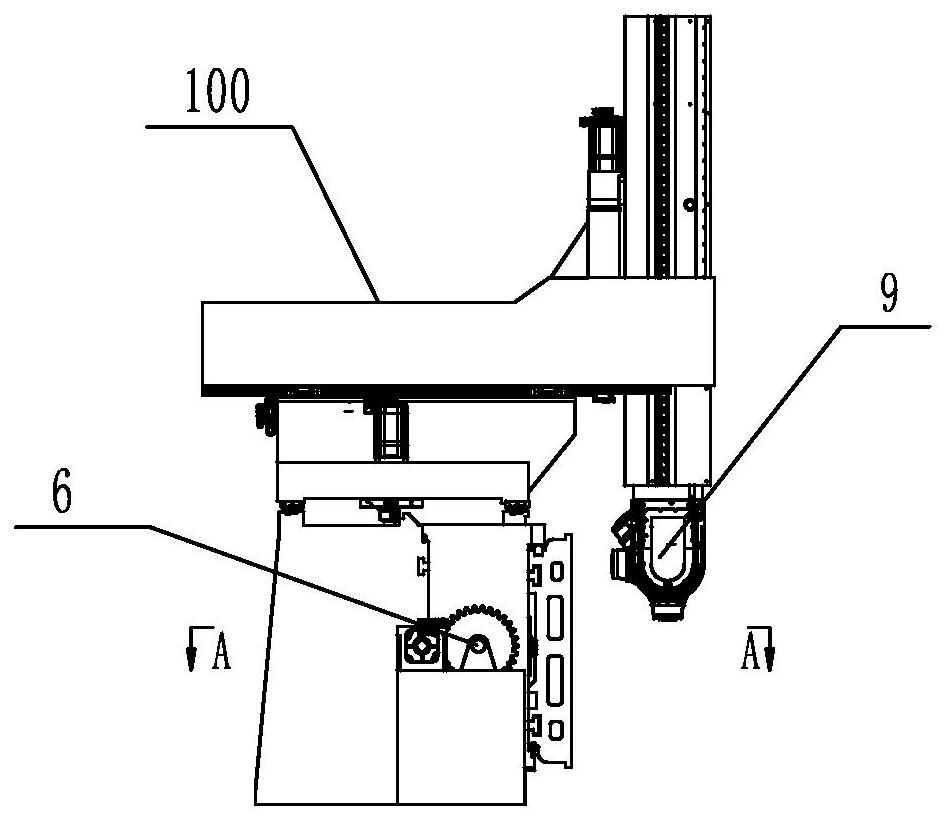

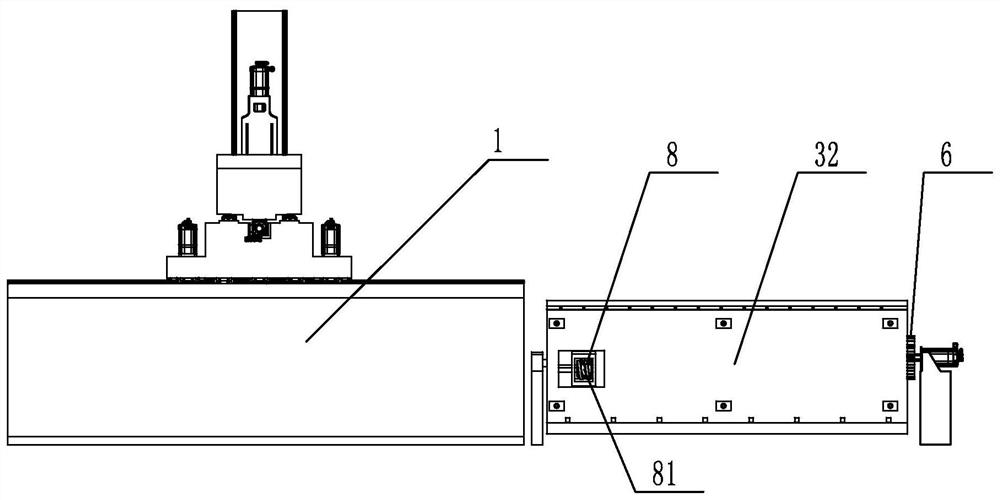

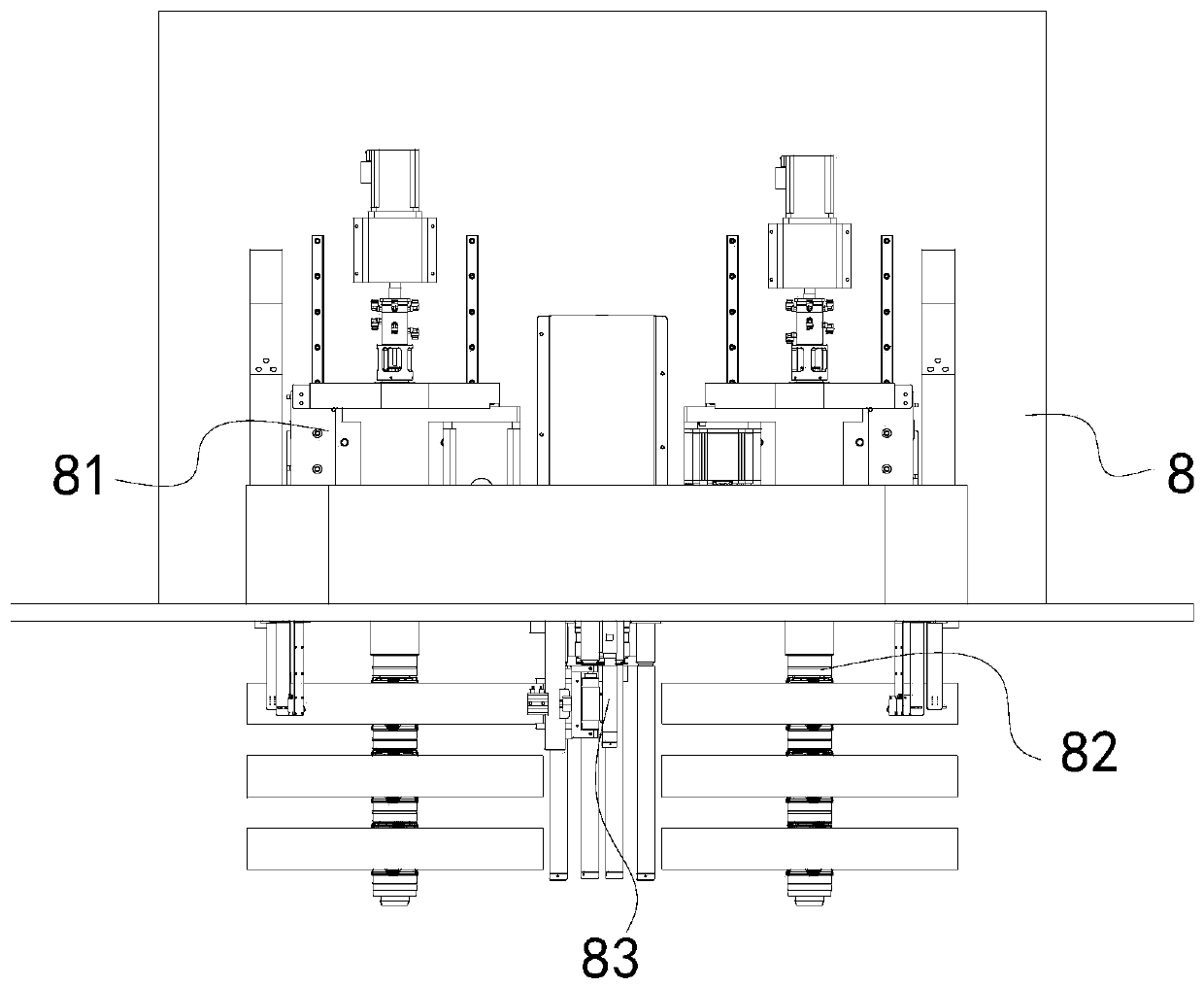

The invention discloses a casting cleaning unit which comprises a casting transit exchange mechanism. The casting transit exchange mechanism comprises a bottom support, an exchange platform, an upper support, a drive device and a positioning device. The positioning device comprises an installation plate and at least two ejecting rods. The installation plate is connected to the power output end of the drive device. The upper ends of the ejecting rods are connected to the installation plate. The lower ends of the ejecting rods are right opposite to the exchange platform. A robot system comprises a first robot and a second robot. The first robot is arranged on the feed side of the casting transit exchange mechanism. The second robot is arranged on the discharge side of the casting transit exchange mechanism. The casting cleaning unit is suitable for automatic unit product price multi-procedure conditions, reliable and stable in positioning, suitable for positioning castings of various types, and suitable for being shared by various product parts; the mechanism is simple in structure, low in manufacturing cost and high in cost performance. The invention further discloses a casting cleaning method.

Owner:SUZHOU MINGZHI TECH

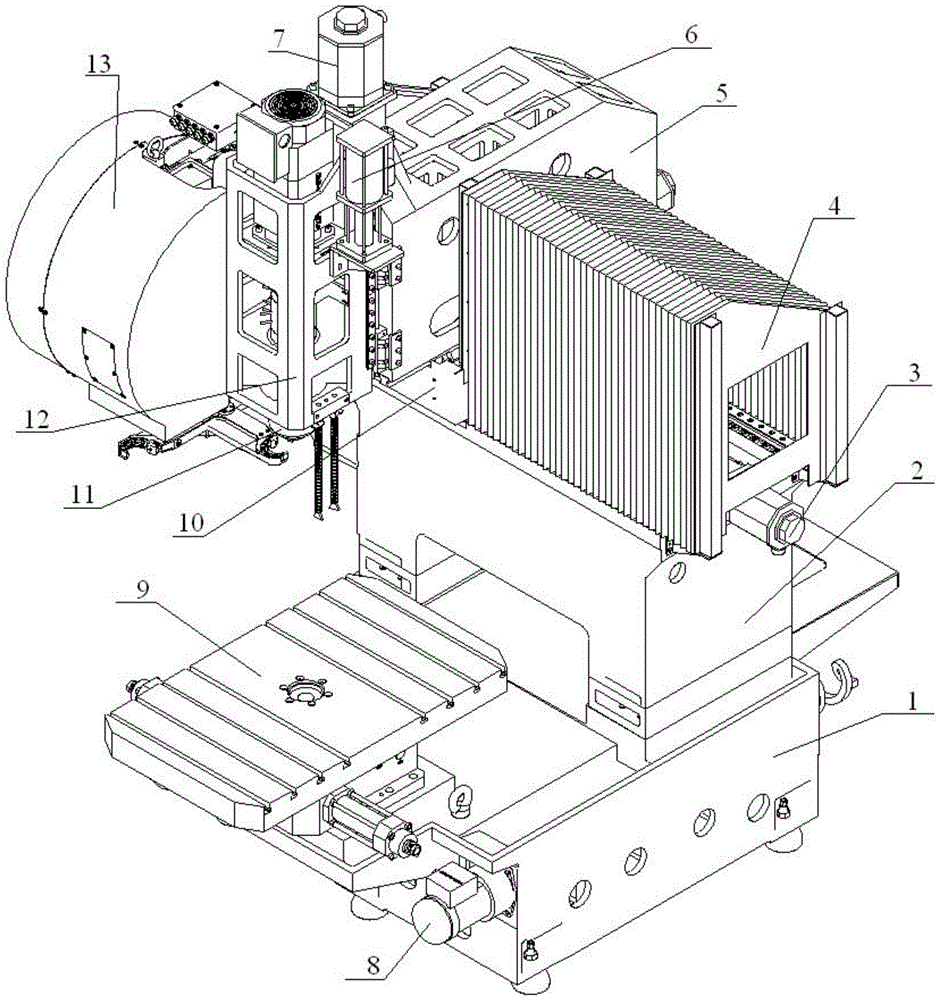

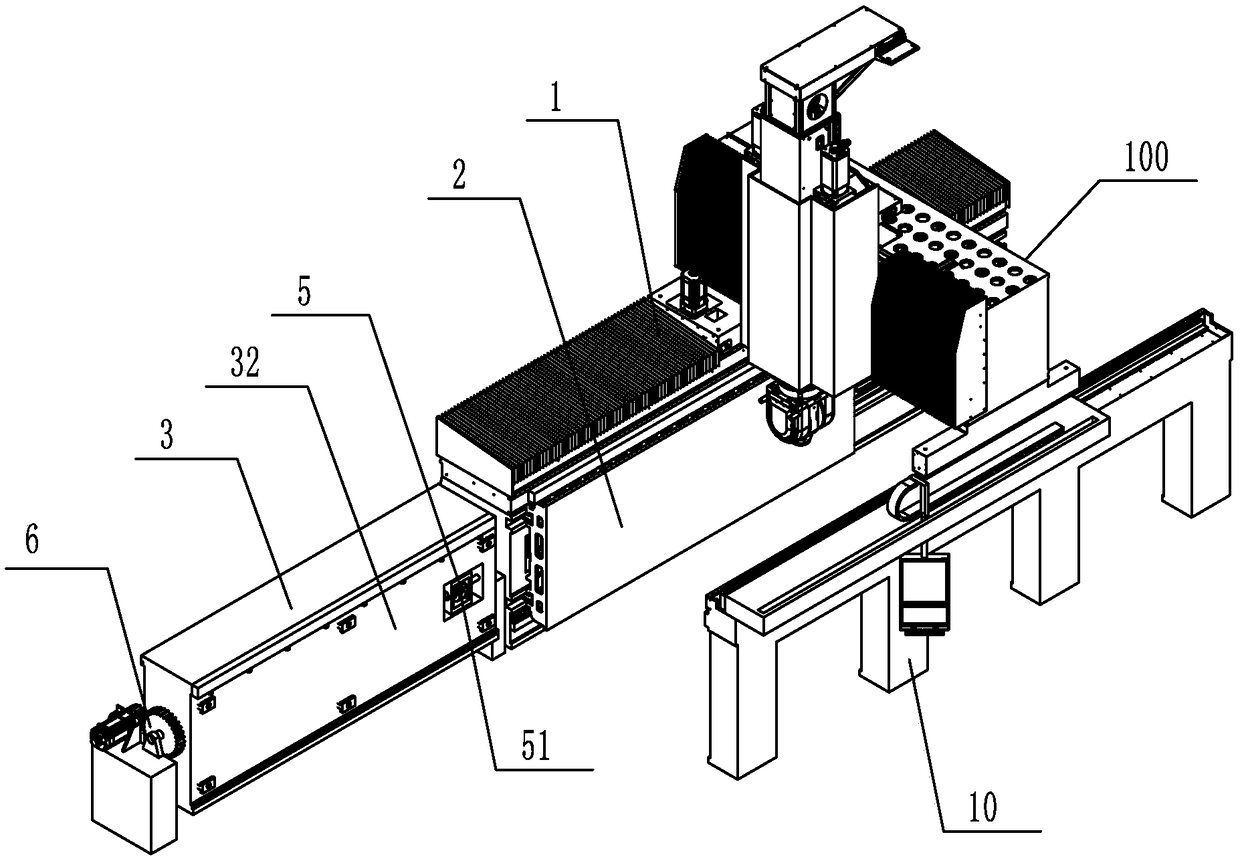

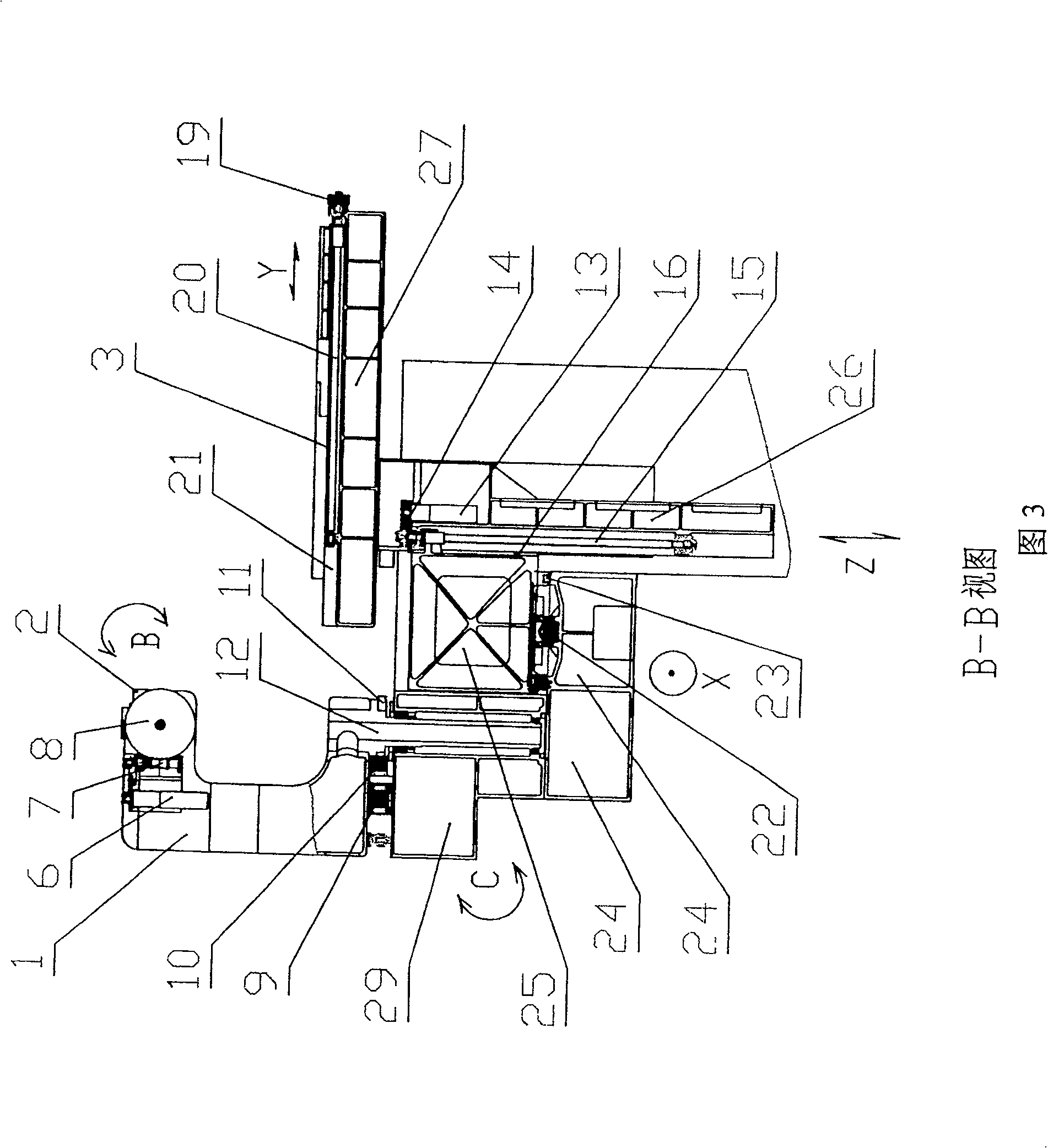

Vertical machining centre machine tool

InactiveCN104526364AImprove processing efficiencyImprove machining accuracyFeeding apparatusLarge fixed membersThree-dimensional spaceSlide plate

The invention discloses a vertical machining centre machine tool which comprises a base horizontally arranged on the ground. A lathe bed is arranged on the base, a workbench capable of doing horizontal progressive rotation is arranged on the side, on the lathe bed, of the base, a vertical column is arranged on one side of the lathe bed, a cross-shaped sliding plate horizontally arranged on the lathe bed is arranged at the connecting position of the vertical column and the lathe bed, and a spindle wrapping a spindle box is arranged on one side of the vertical column. The spindle box can vertically move along the vertical column in the Z-axis direction. The vertical column can horizontally move along the cross-shaped sliding plate in the Y-axis direction. The cross-shaped sliding plate can horizontally move along the lathe bed in the X-axis direction, and the vertical machining centre machine tool is provided with an automatic tool switching system. According to the technical scheme, the vertical machining centre machine tool can move in three-dimensional space, the automatic tool switching system achieves automatic tool switching of the machine tool, and machining efficiency and machining precision are improved. The defects that a workbench in the prior art participates in feeding motion under the condition of loads, the loads of the workbench are different, and the feeding speed and response time of the machine tool are influenced are overcome.

Owner:CHONGQING WNC INTELLIGENT EQUIP

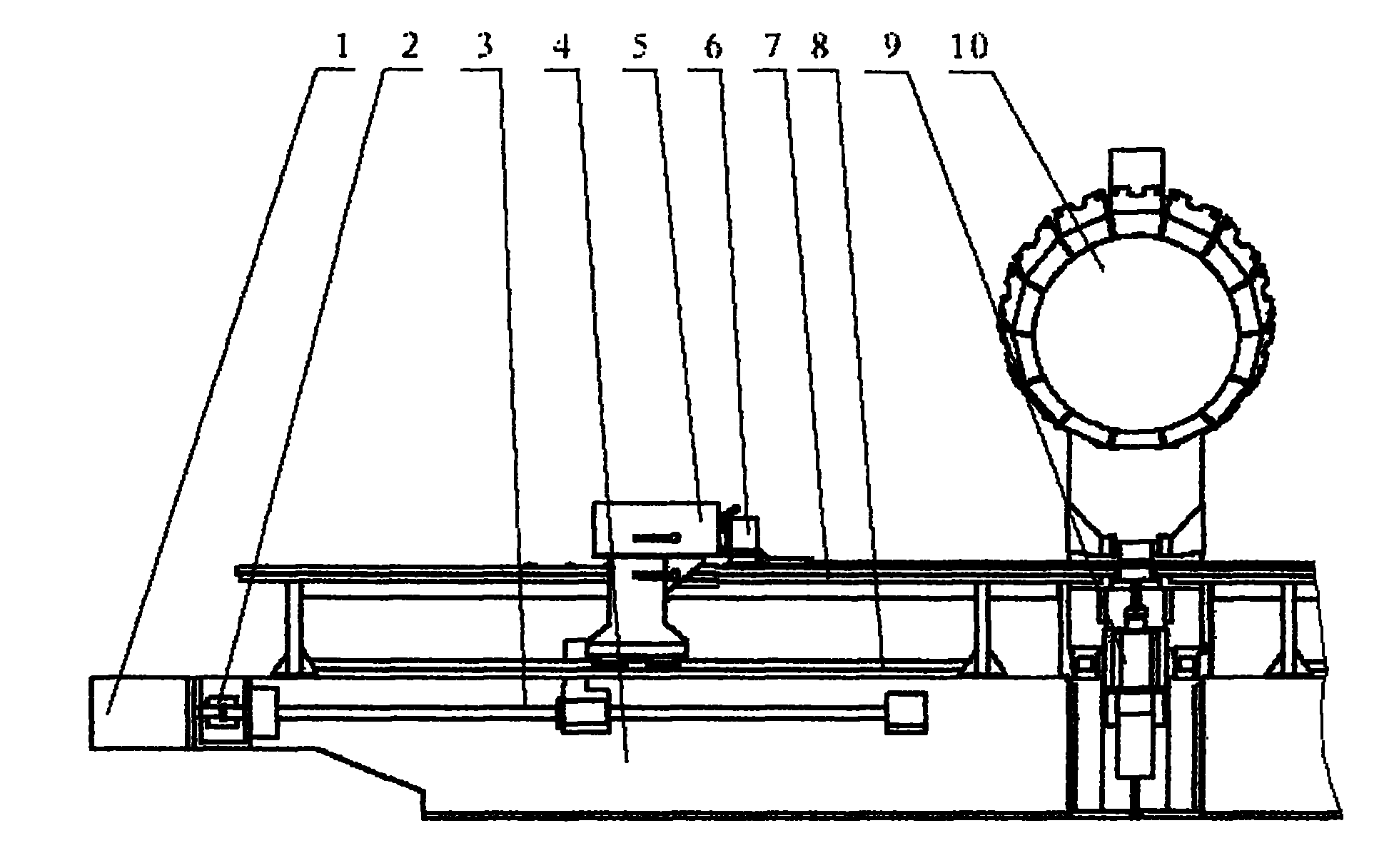

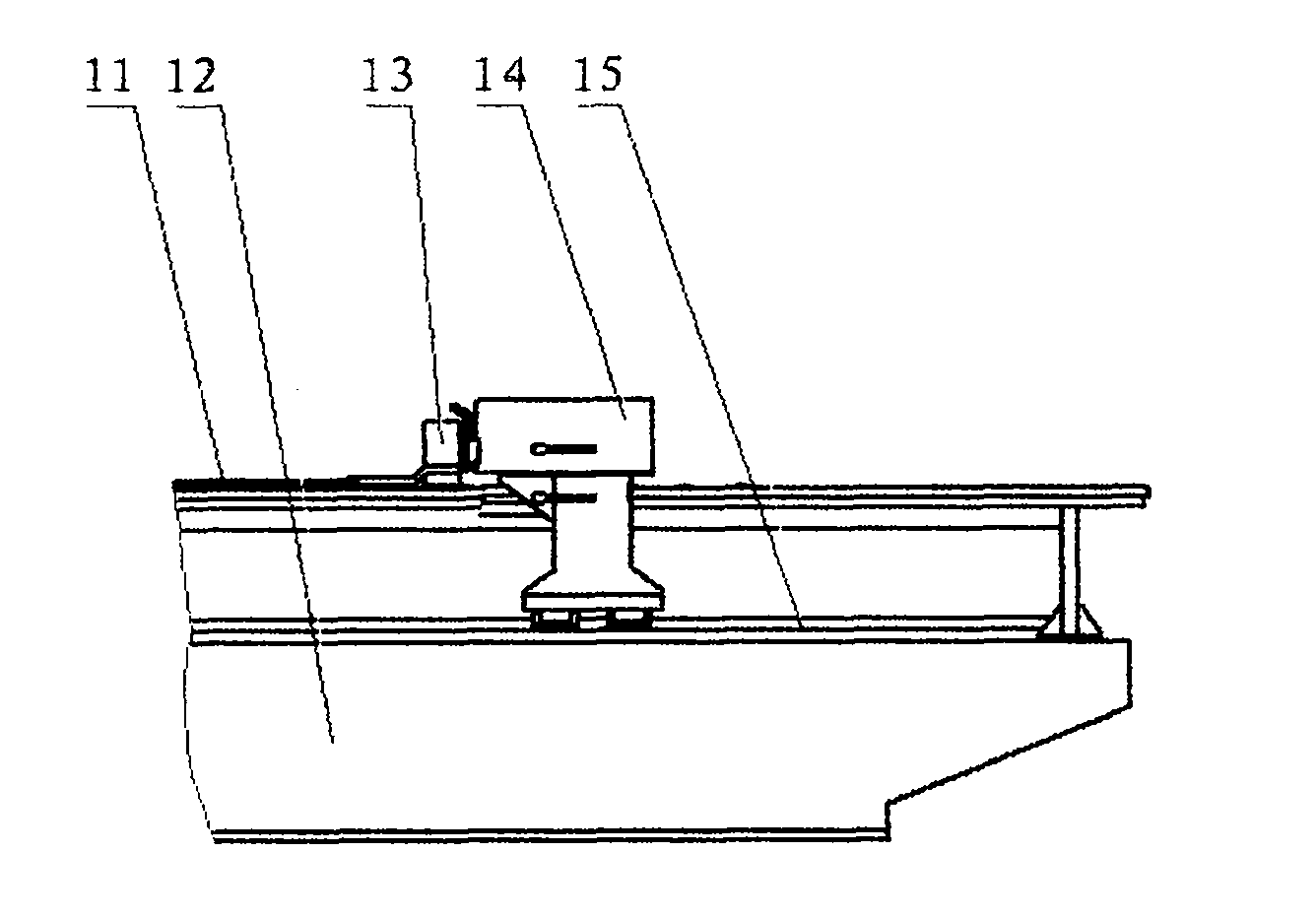

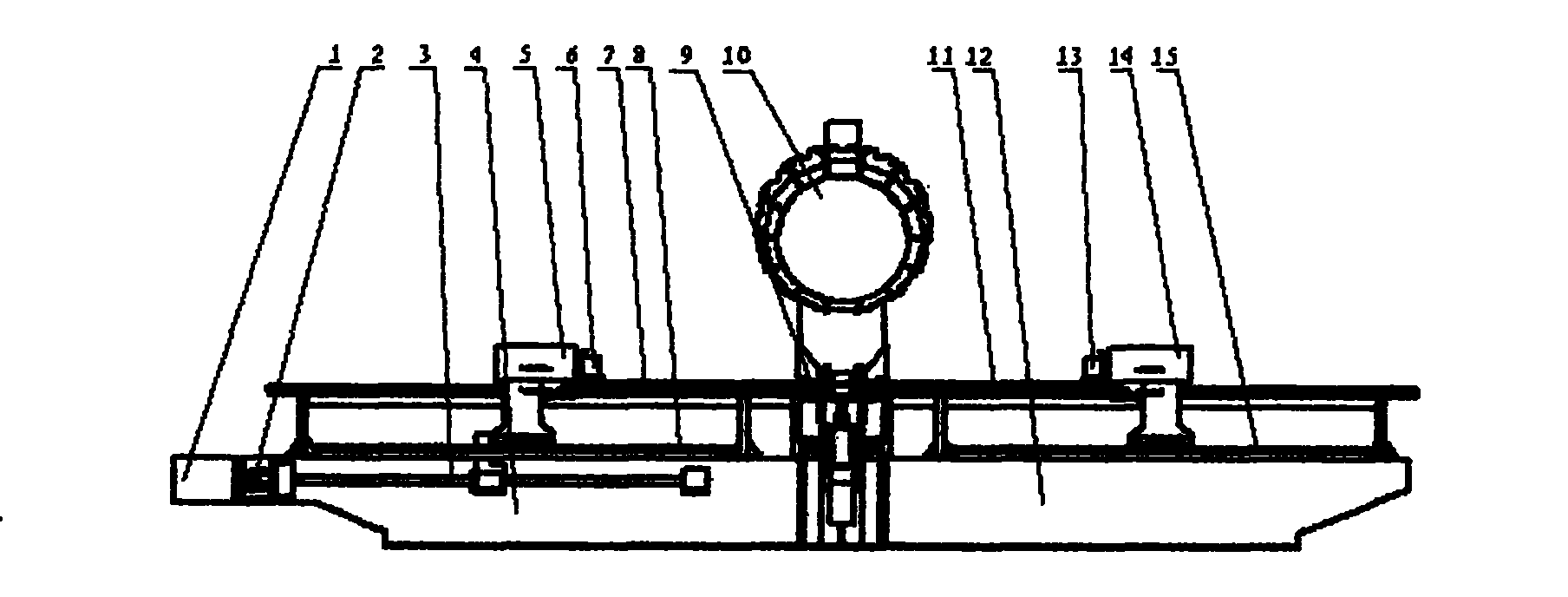

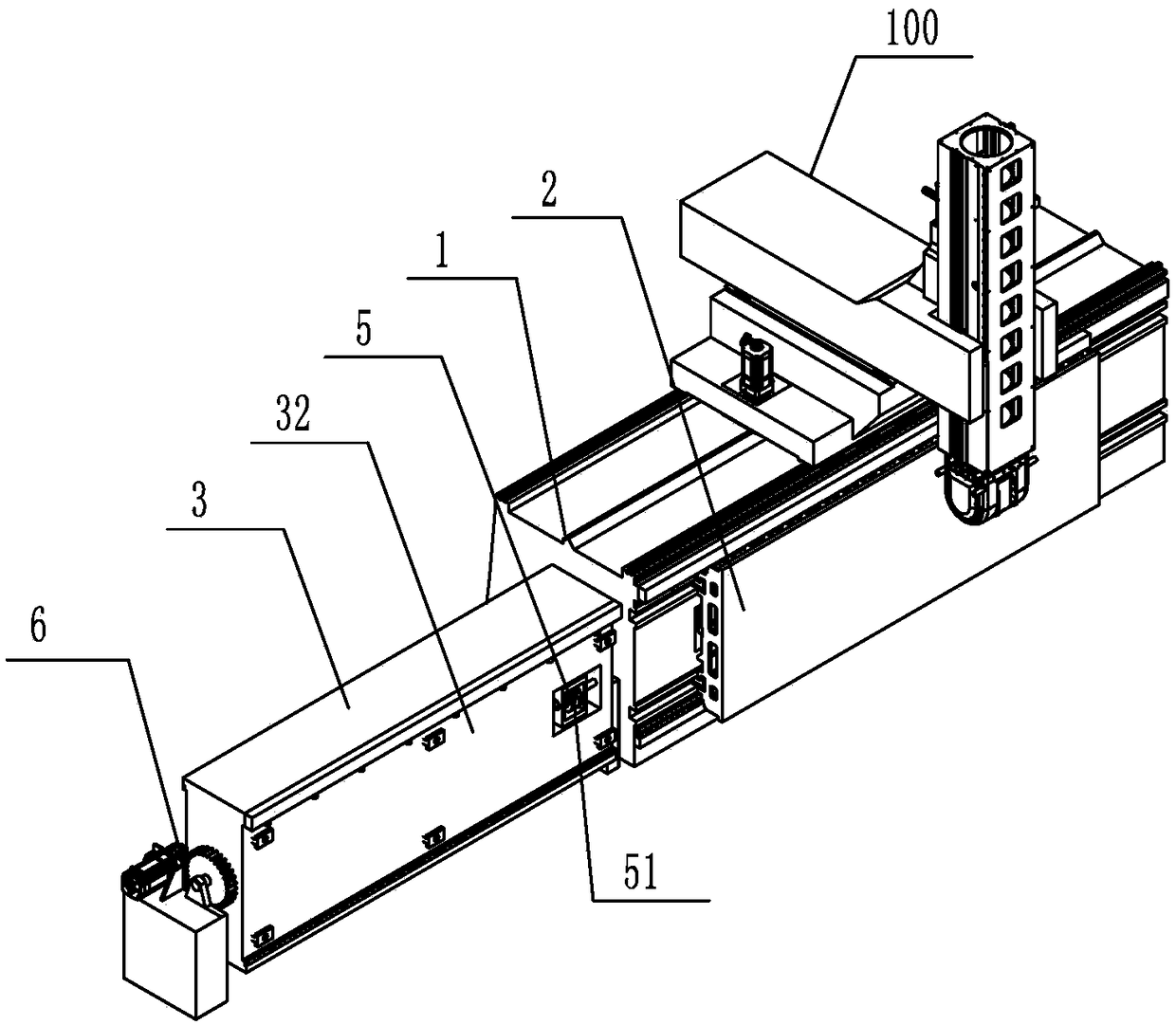

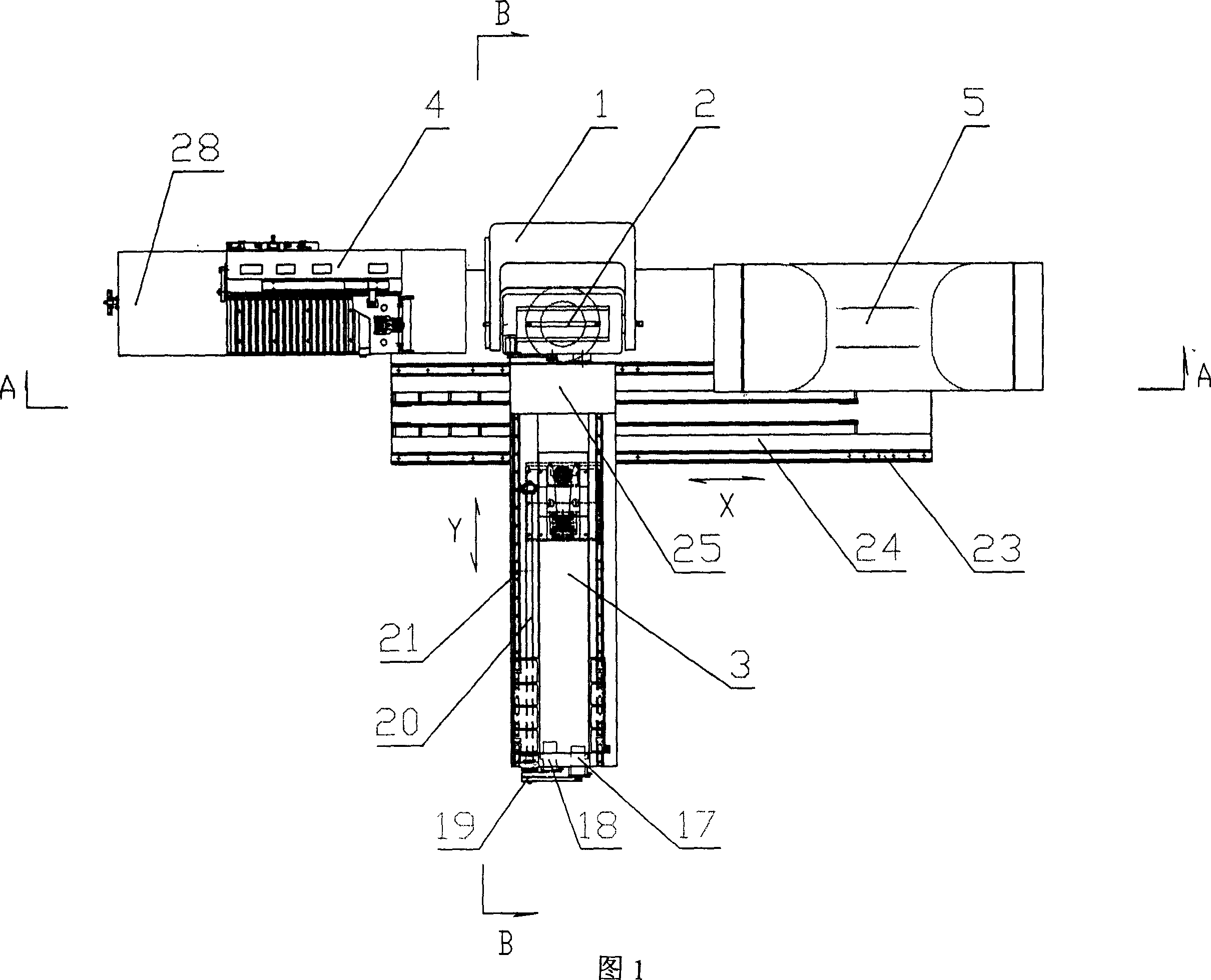

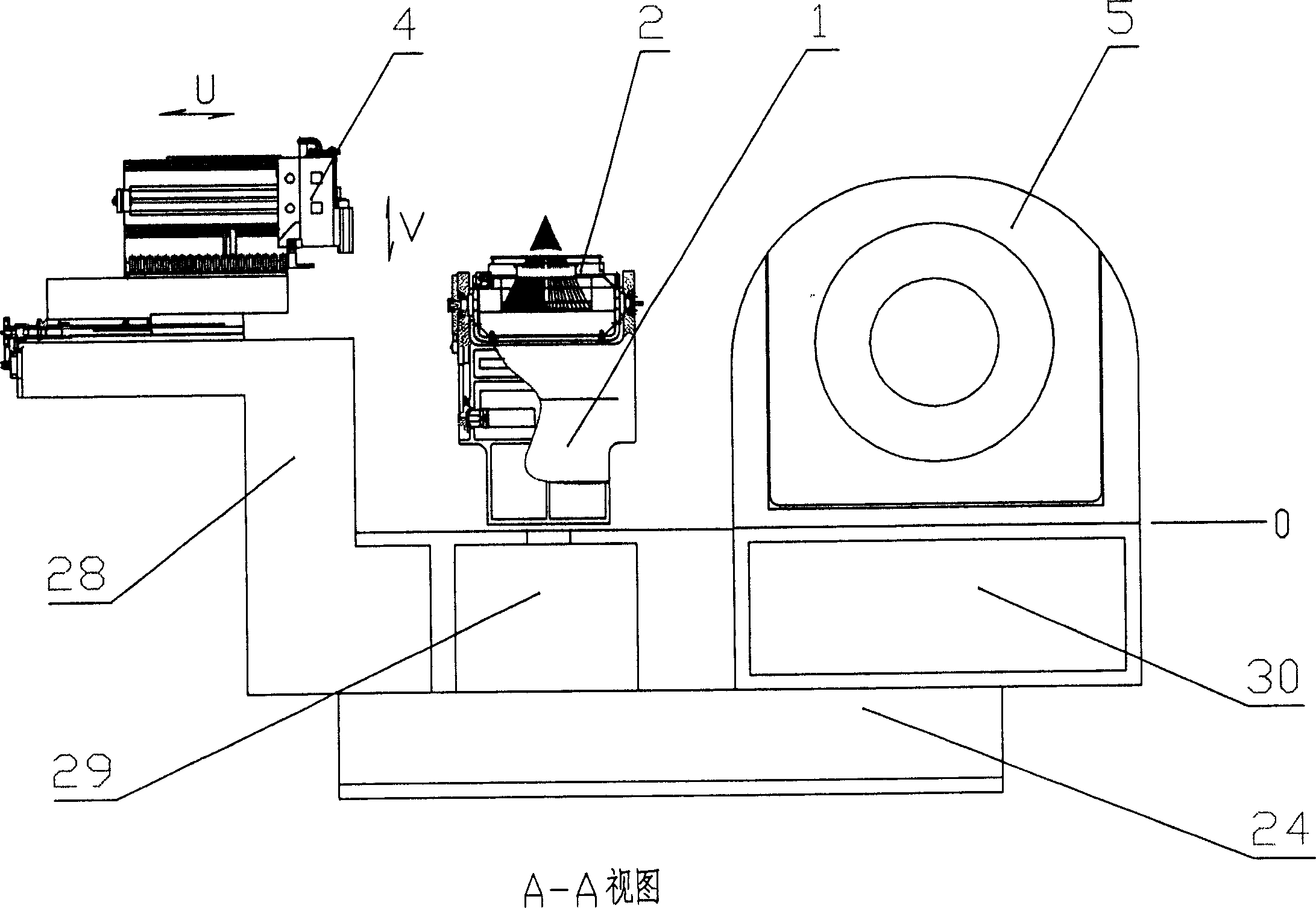

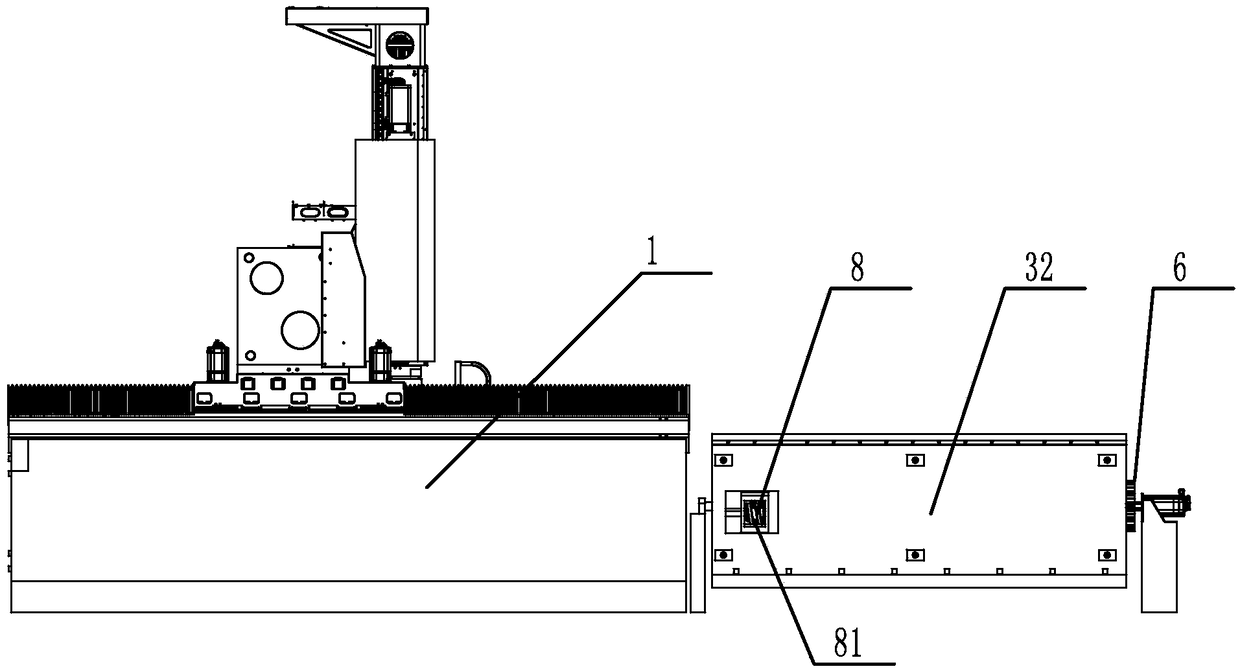

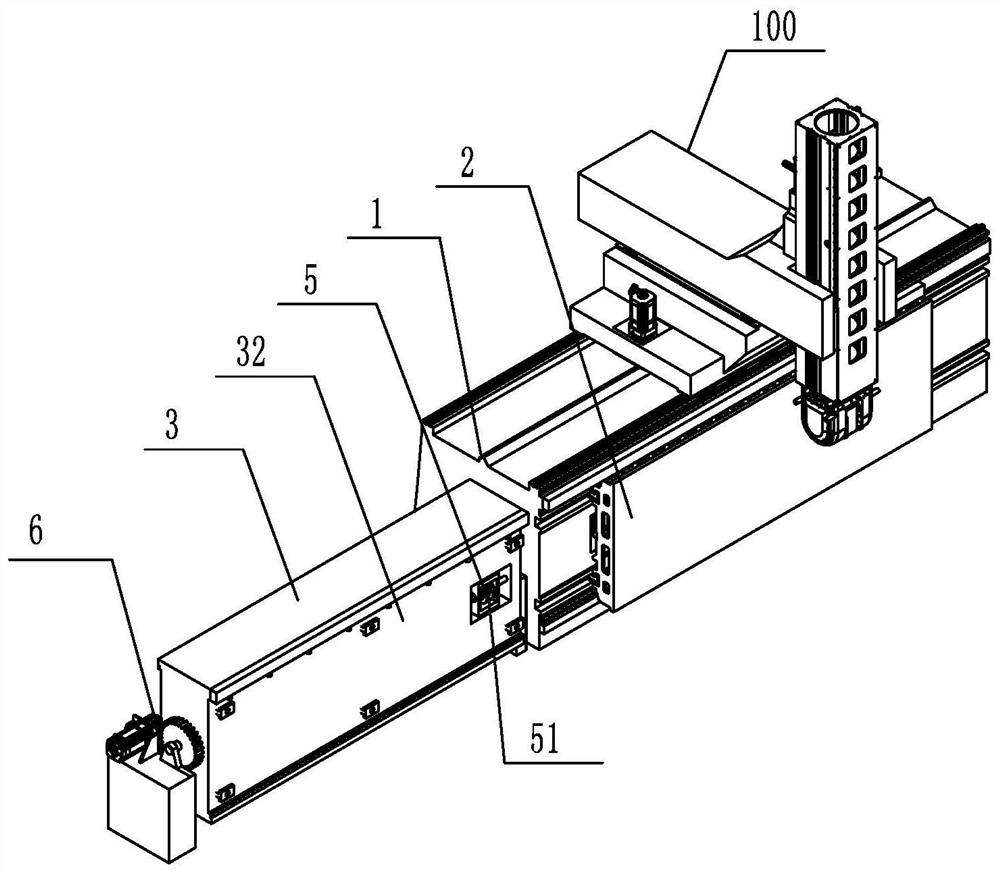

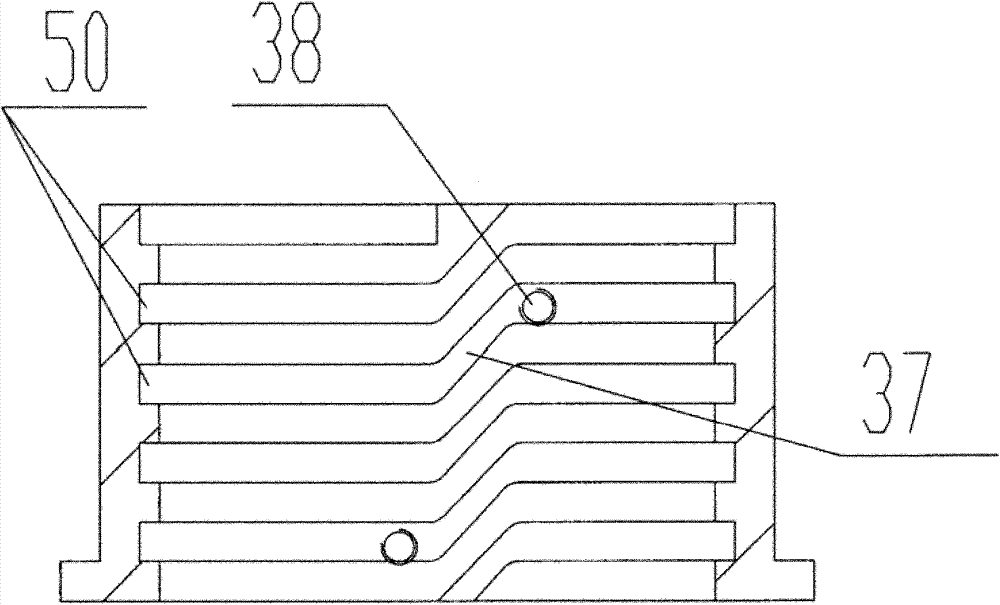

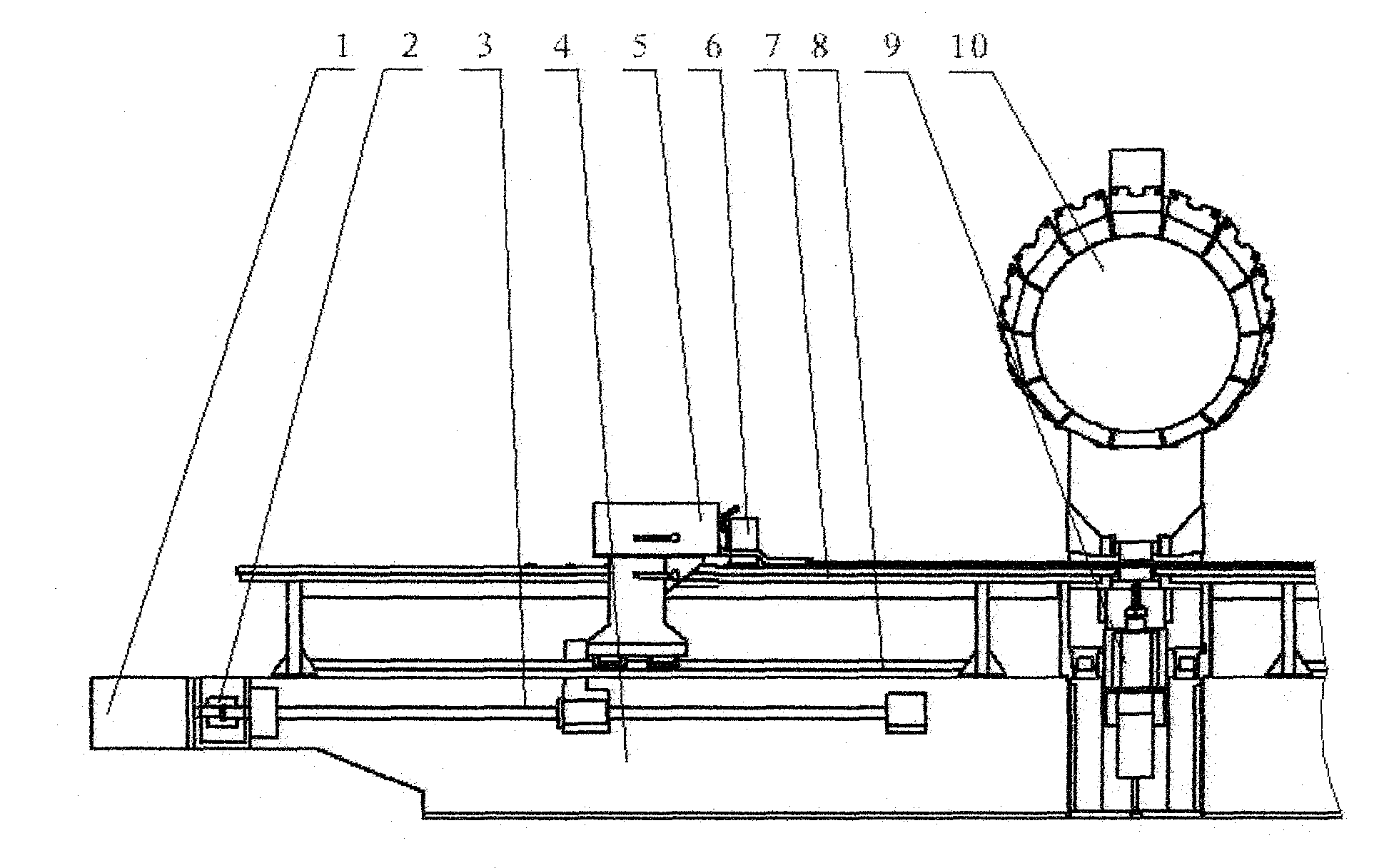

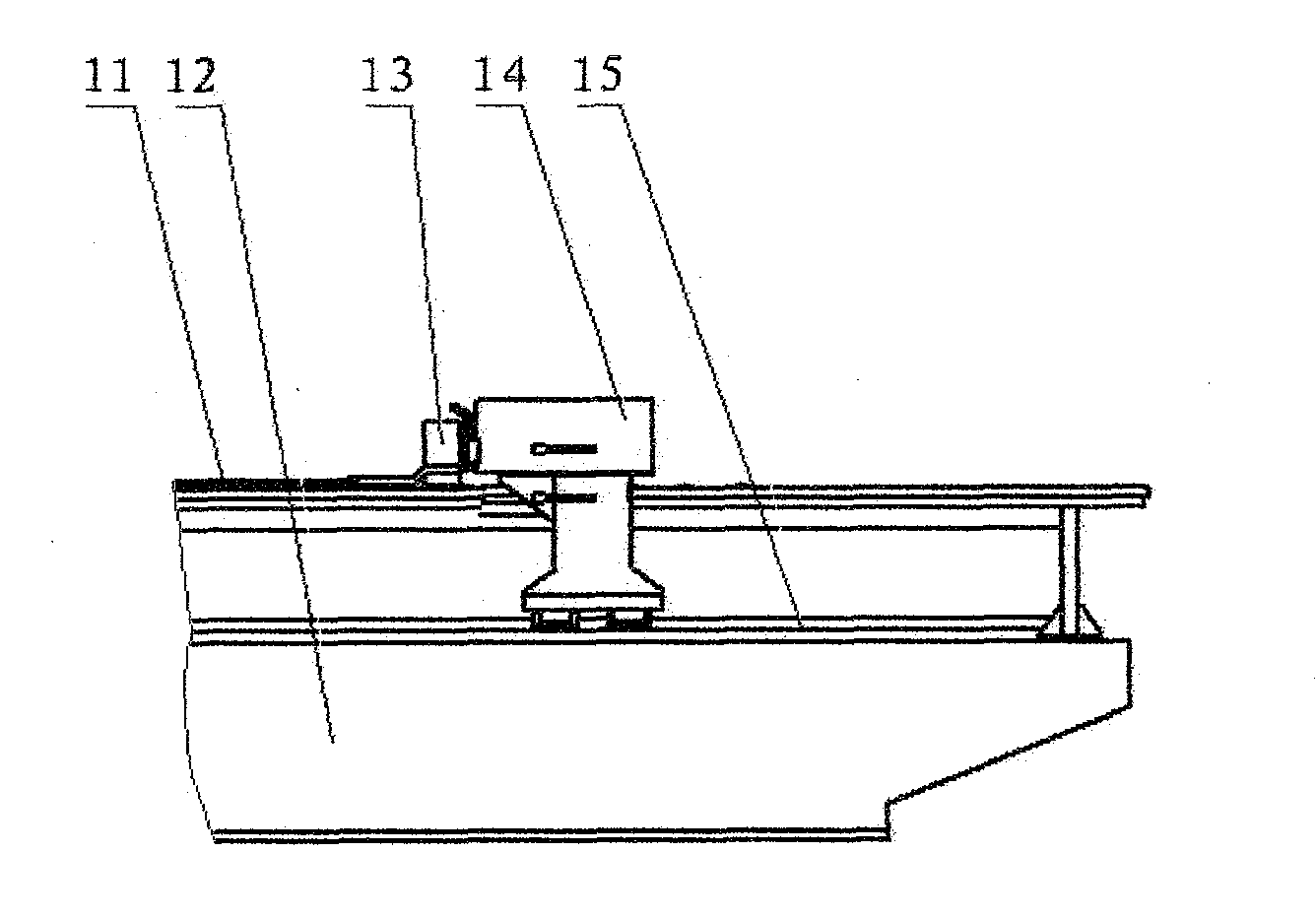

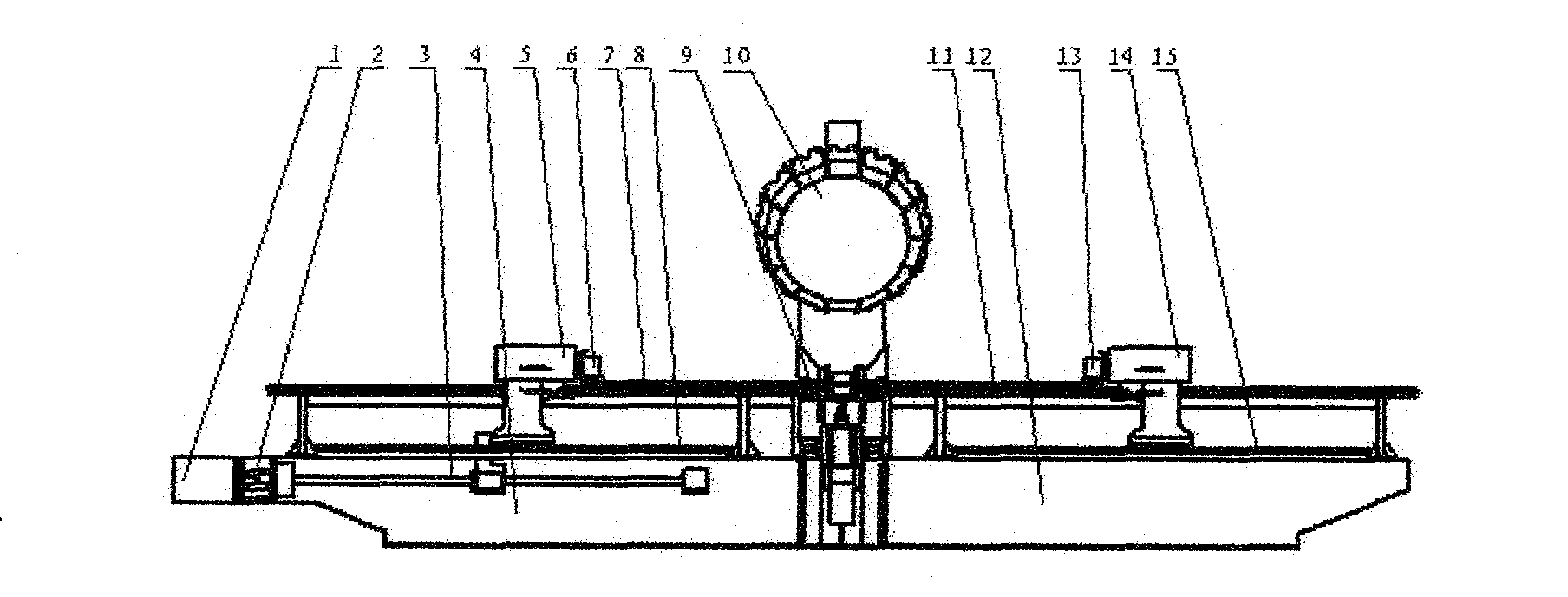

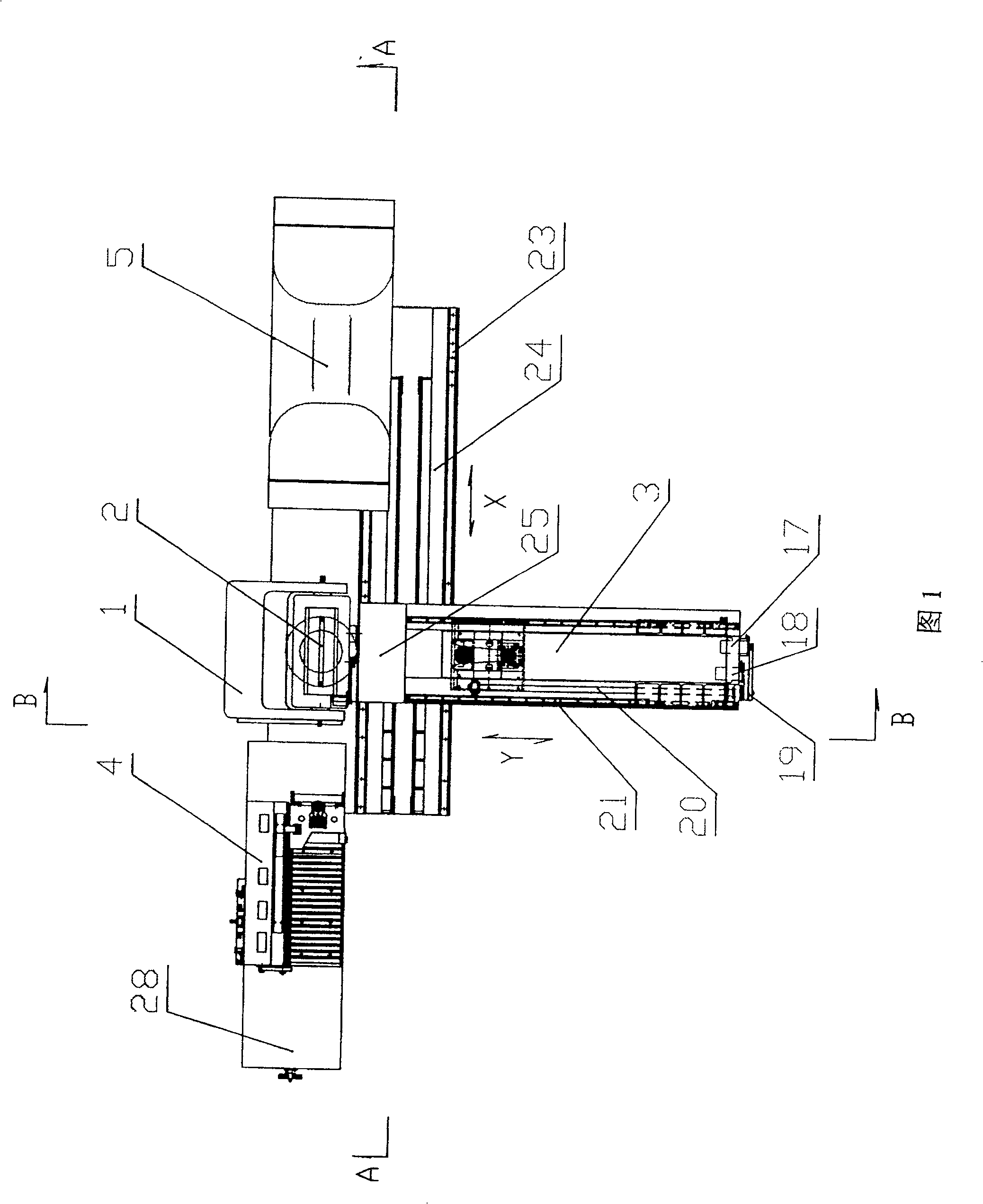

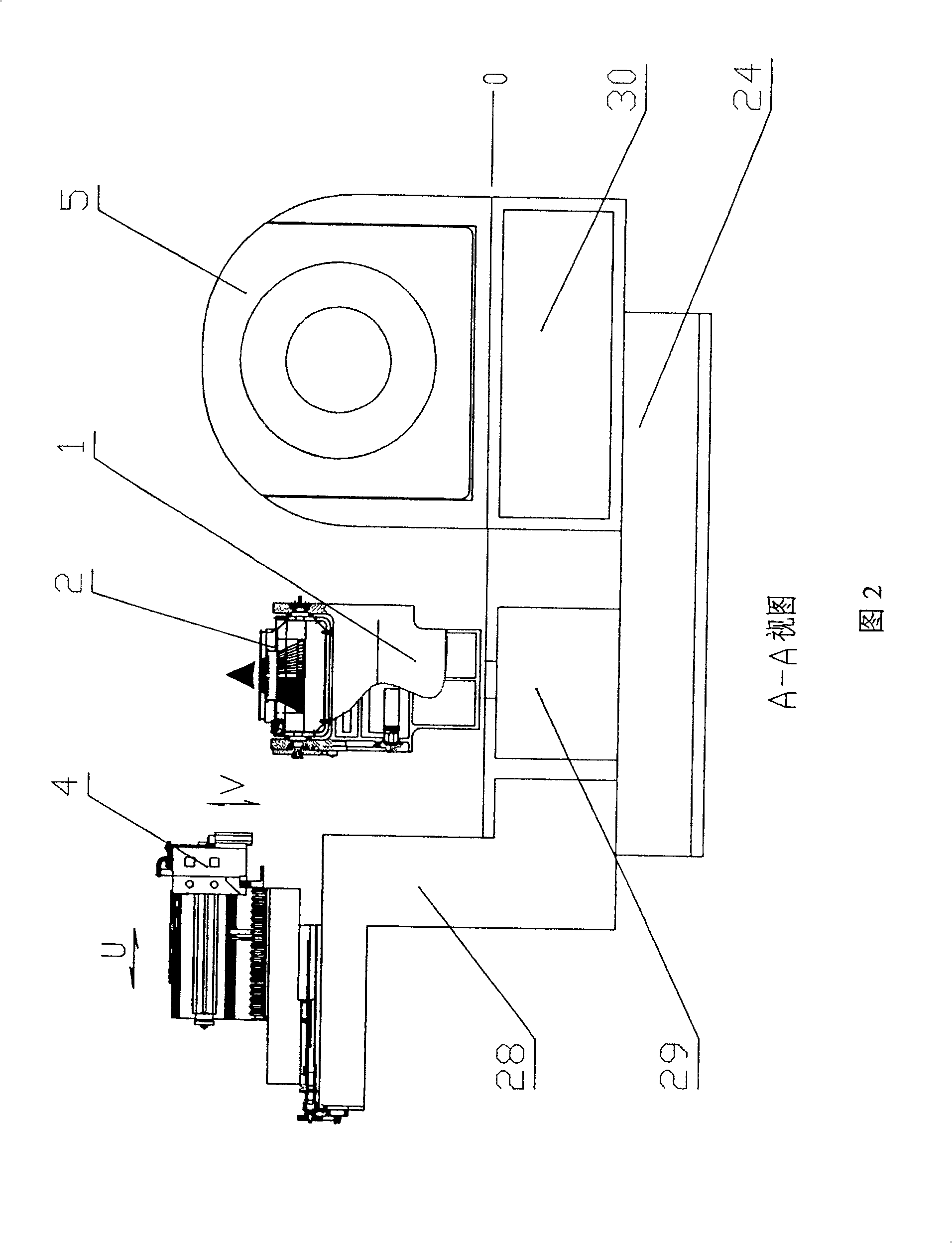

Flexible sheetmetal processing center

ActiveCN102430925AEasy to installImplement automatic exchangeOther manufacturing equipments/toolsMetal working apparatusEtchingElectrical control

The invention relates to a flexible sheetmetal processing center, belonging to sheetmetal processing equipment. The flexible sheetmetal processing center mainly comprises a motor and a servo motor, a main spindle box, a main spindle assembly, a screw rod component, a pedestal, crossbeams, a back-blading device, an upright column, a tool storage, a clamping assembly, a linear guide rail assembly, an electric control box and a base, wherein the main spindle box is arranged on the linear guide rail of the upright column and moves up and down to realize a Z-direction coordinate motion; the upright column is arranged on the linear guide rail assembly of the base to realize a Y-direction coordinate motion; a universal rolling ball array is respectively arranged on a left support table and a right support table which are used for supporting sheetmetal parts needing to be processed; a left crossbeam assembly and a right crossbeam assembly can move in the longitudinal direction to form an X-direction coordinate motion; and through a W-direction motion of the back-blading part and a W-direction main spindle rotating motion, back-blading to burrs and chamfers can be automatically carried outon the bottom surface, therefore good manufacturability and high quality and efficiency of sheetmetal processing are achieved, and processing cost is reduced very remarkably. The flexible sheetmetal processing center disclosed by the invention is widely suitable for hole drilling, thread tapping, counter boring, burr back-blading at bottoms of holes, irregular hole milling and cutting and plate pattern etching and milling of the sheetmetal parts.

Owner:GUILIN GUANGLU MEASURING INSTR CO LTD

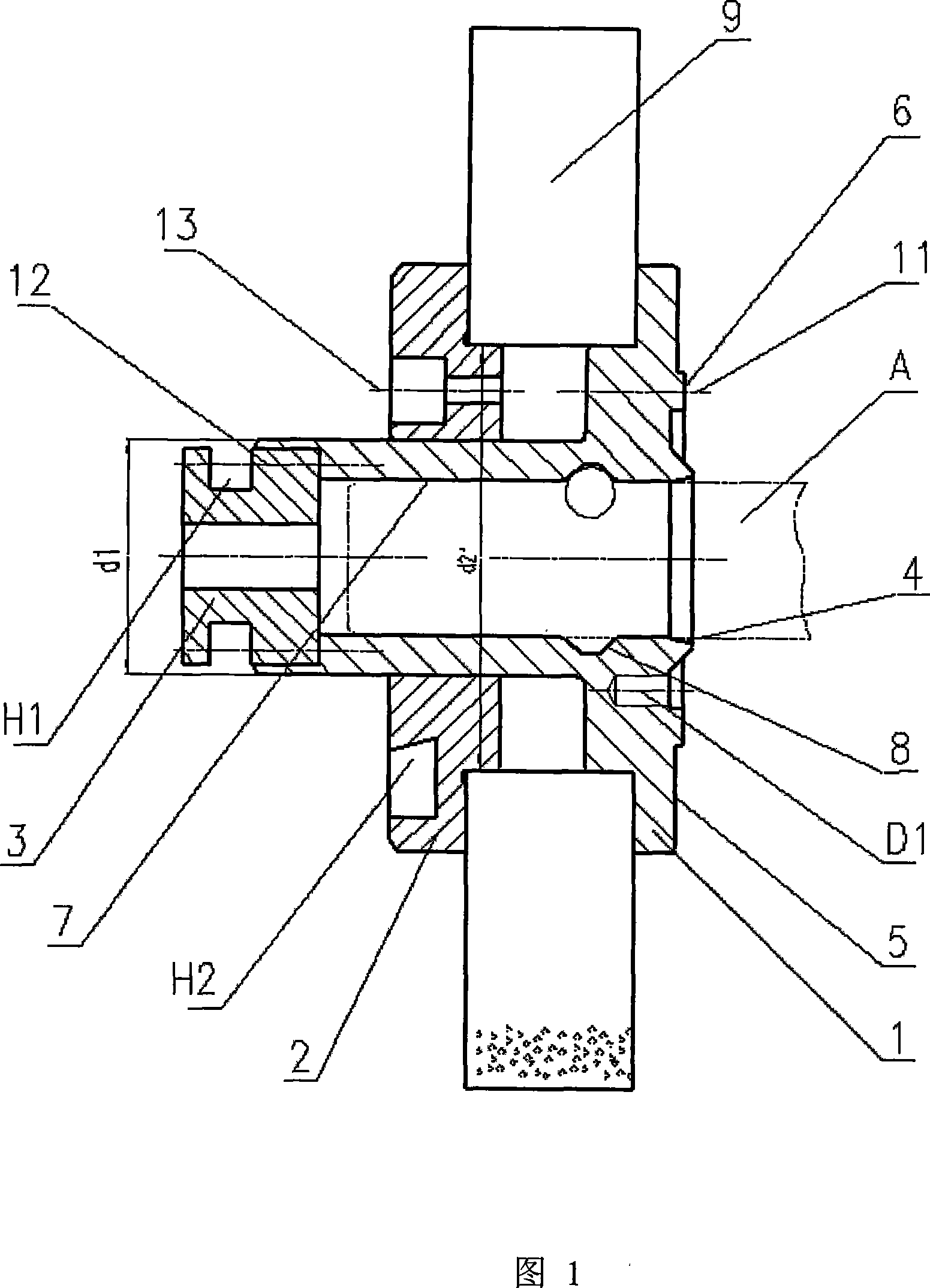

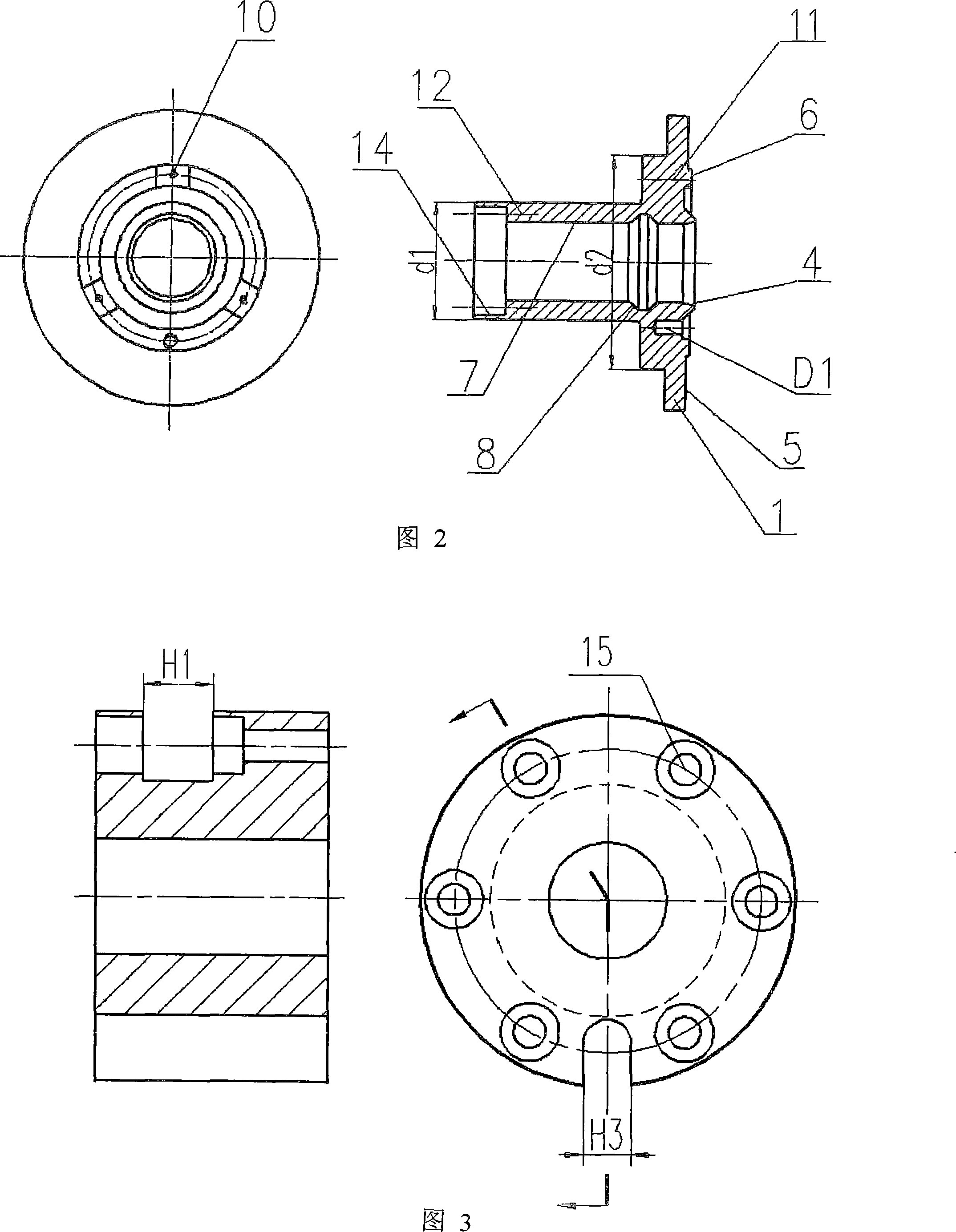

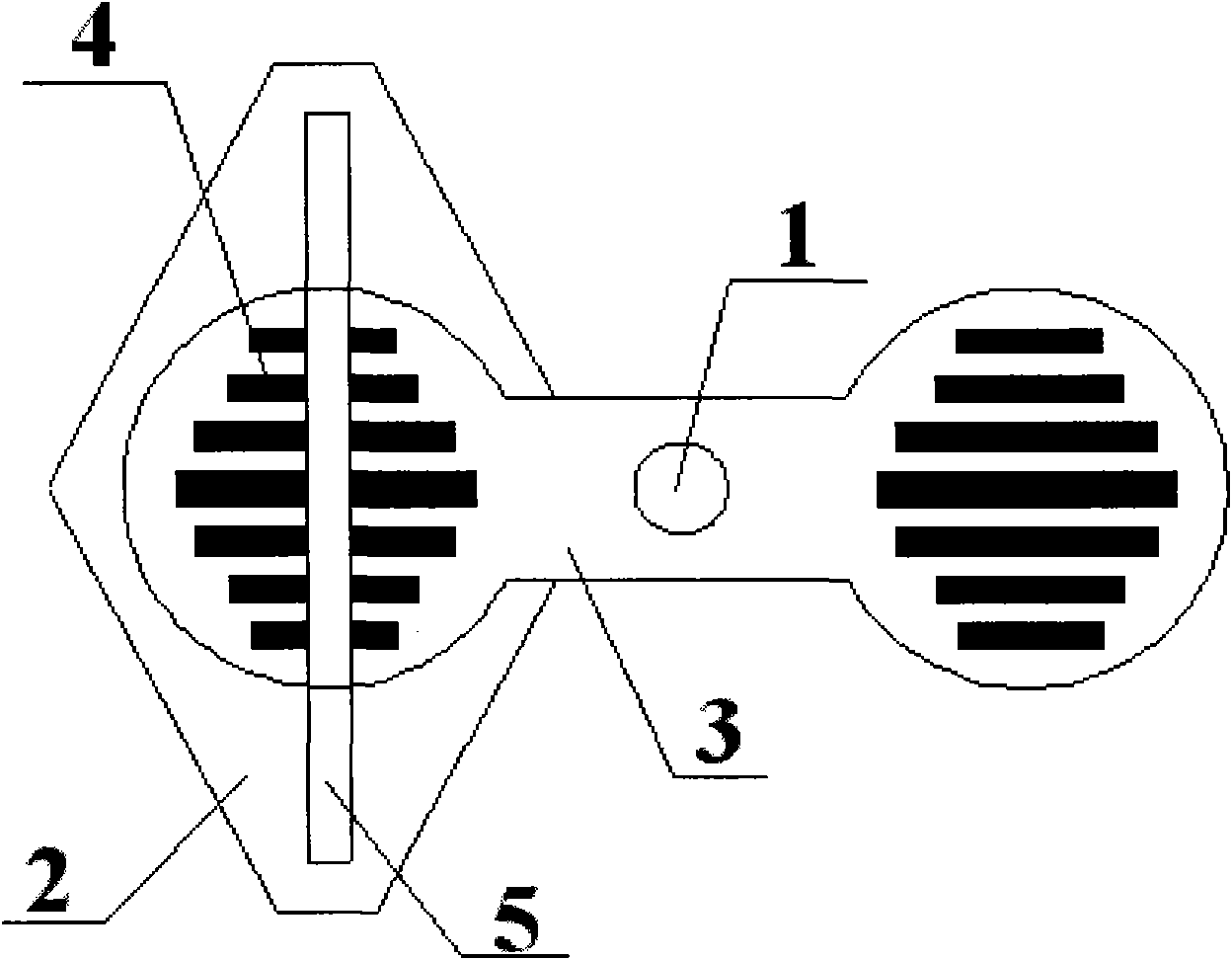

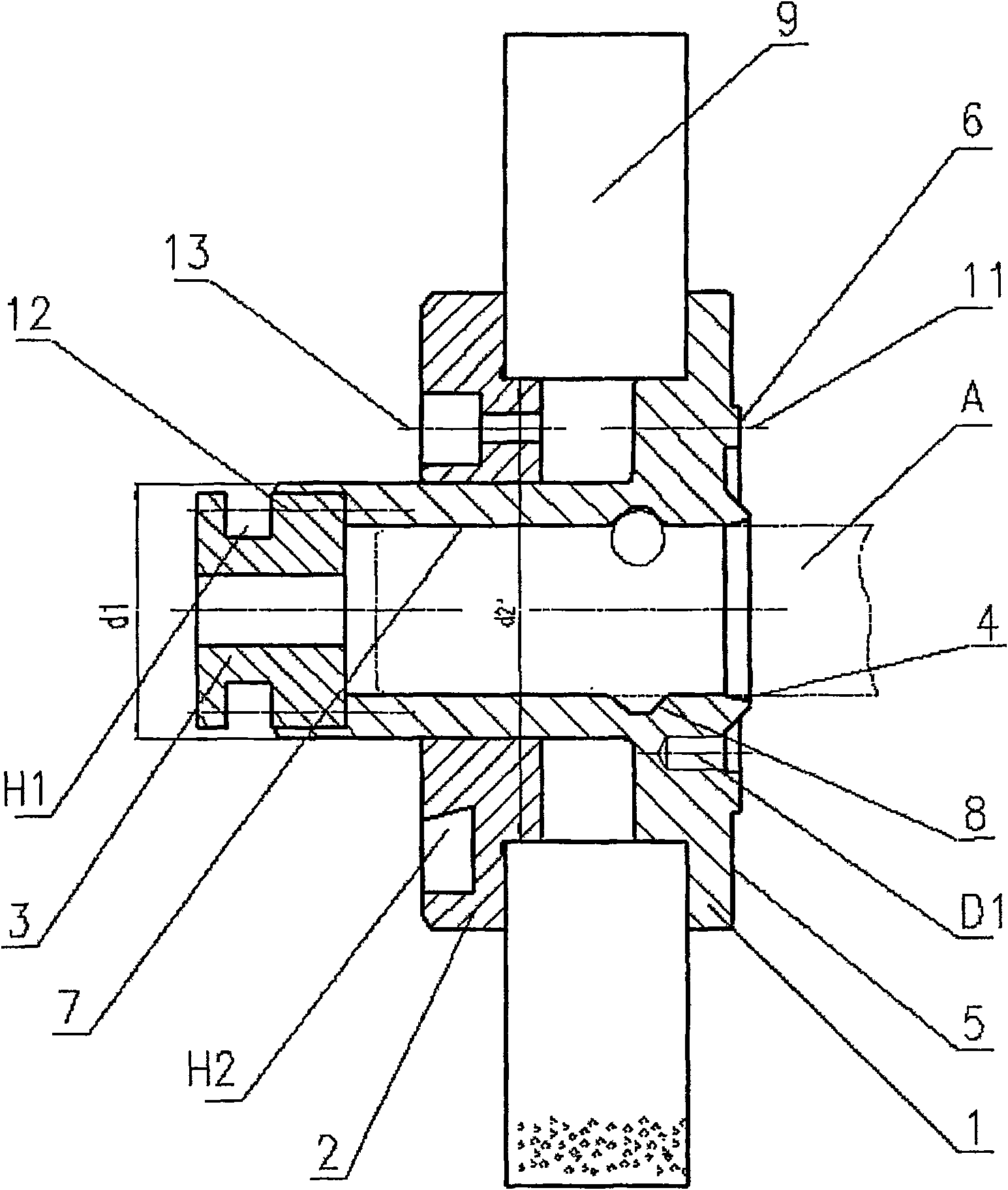

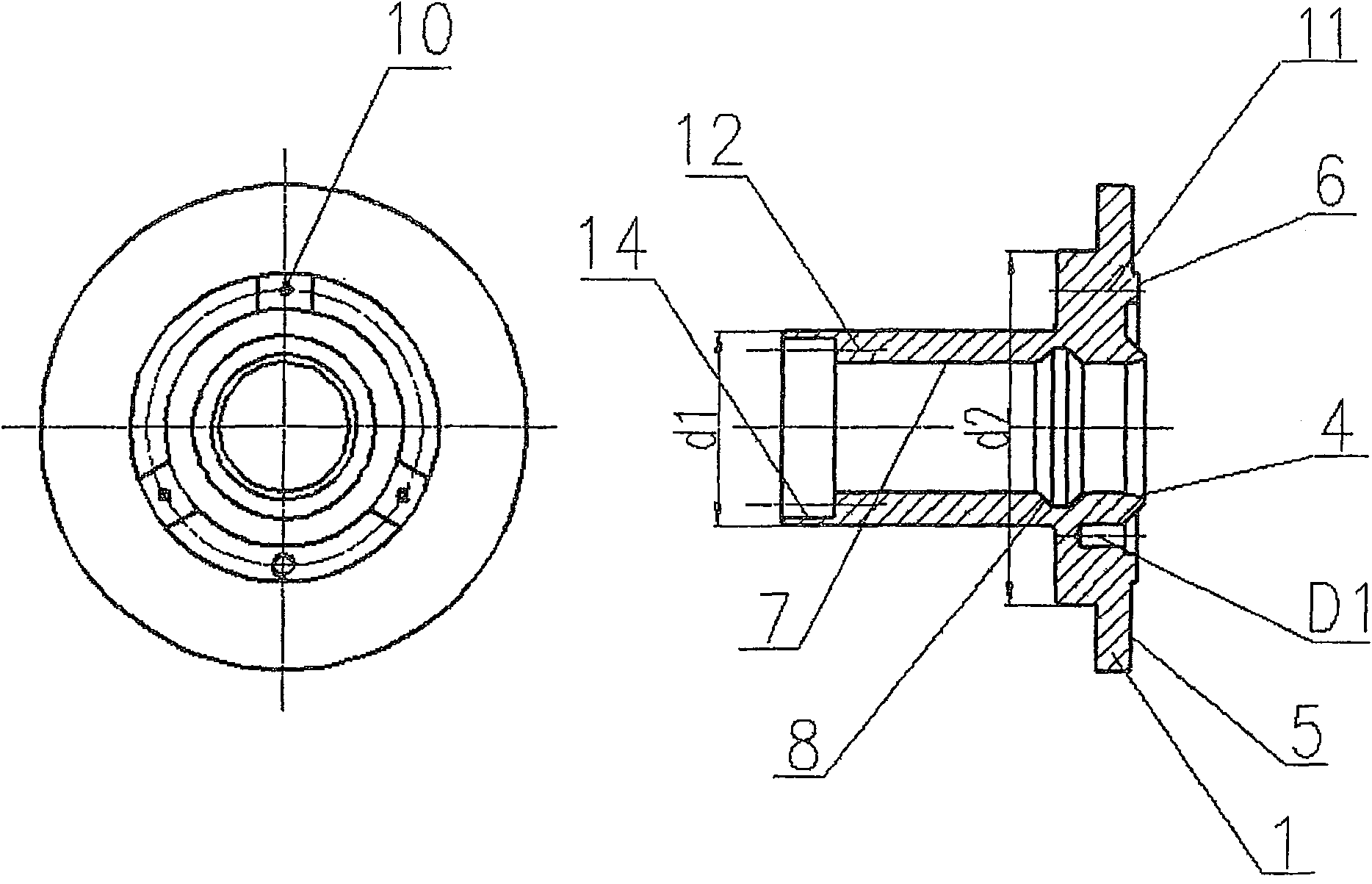

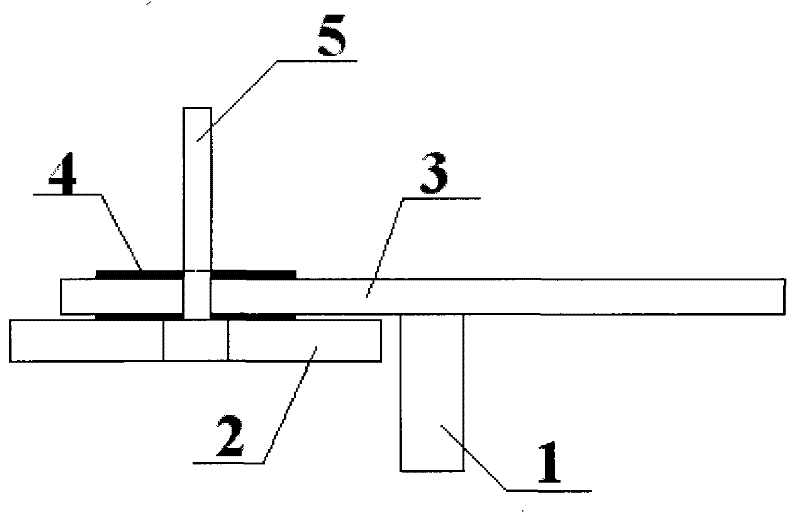

Ferrule type grinding wheel chuck

ActiveCN101200049AImplement automatic exchangeHigh degree of automationGrinding machine componentsMating connectionCounterbore

The invention discloses a ferrule type grinding wheel chuck device for a grinder equipment, which comprises a chuck body, a pressing disk sleeved out of the chuck body and a ferrule connected with the chuck body. The chuck body is provided with a column inner hole in which a clamping ring groove connected with a tension mechanism of a main shaft is arranged; the orifice at the right end of the inner hole is provided with an inner cone matched and connected with the end surface of a grinding head main shaft; the orifice at the left end of the inner hole is provided with a counter bore and a plurality of screw holes which are matched and connected with the ferrule; the large end surface of the chuck body is provided with a sealed joint surface and a plurality of connecting screw holes; the back of the large end surface is provided with a shoulder; the ferrule is provided with a positioning slot and a guiding groove which are matched and connected with a processing centre grinding wheel library or the other grinding equipment installation mechanism; the ferrule is provided with a counterbore hole matched with the screw holes of the chuck body; screw holes matched with the connecting screw holes on the chuck body are arranged on the pressing disk; a boss matched with the shoulder on the chuck body is arranged at the right side surface of the pressing disk. The labor strength is reduced and the labor and the time are saved with the invention, the grinding wheel chuck can be exchanged automatically, so that the producing efficiency and the advancement of the machine tool equipment are increased.

Owner:浙江杭机股份有限公司

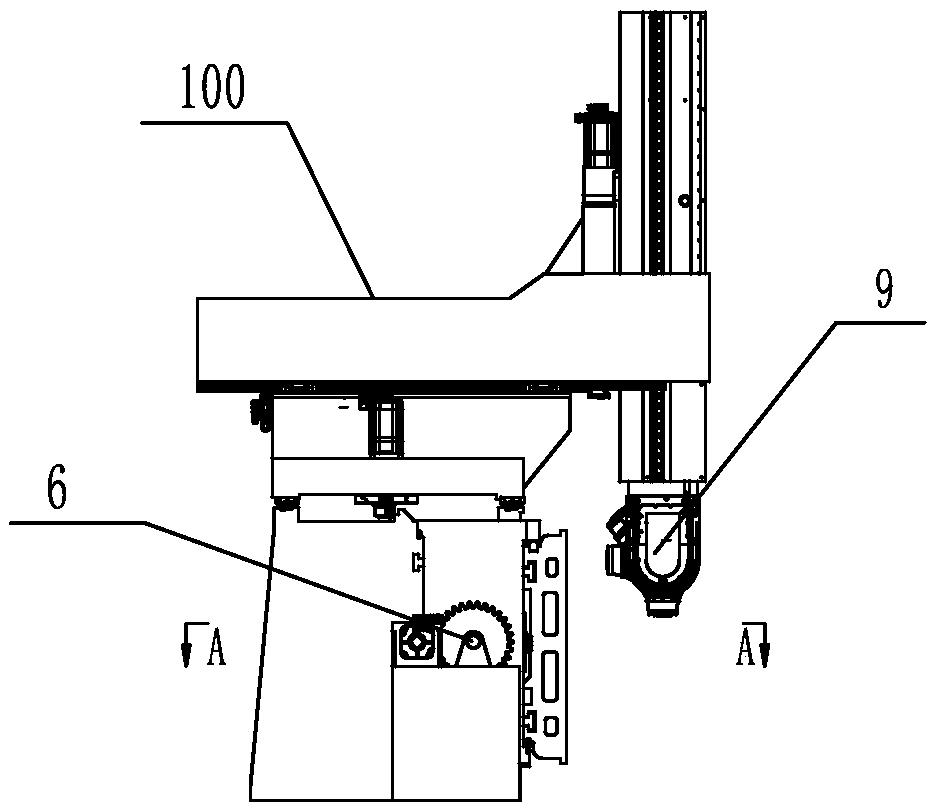

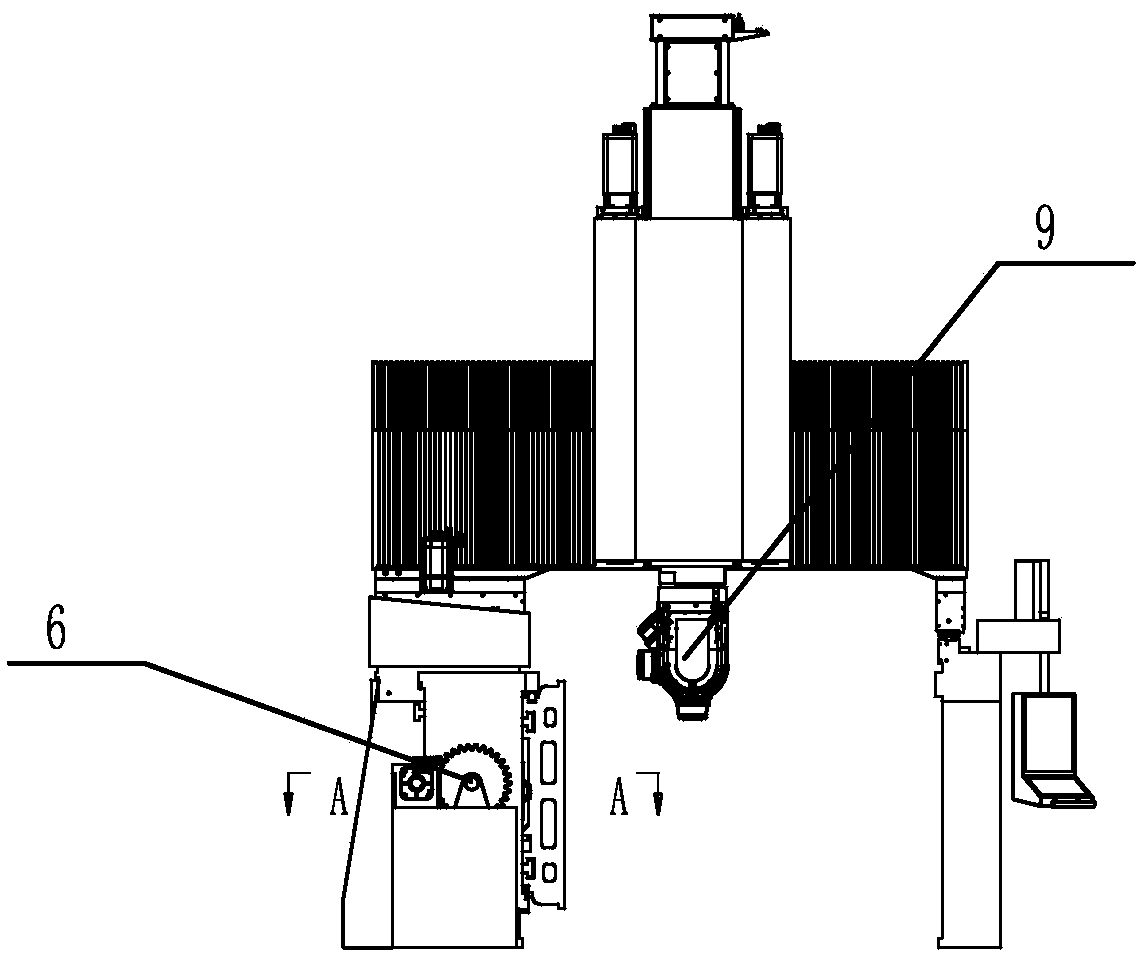

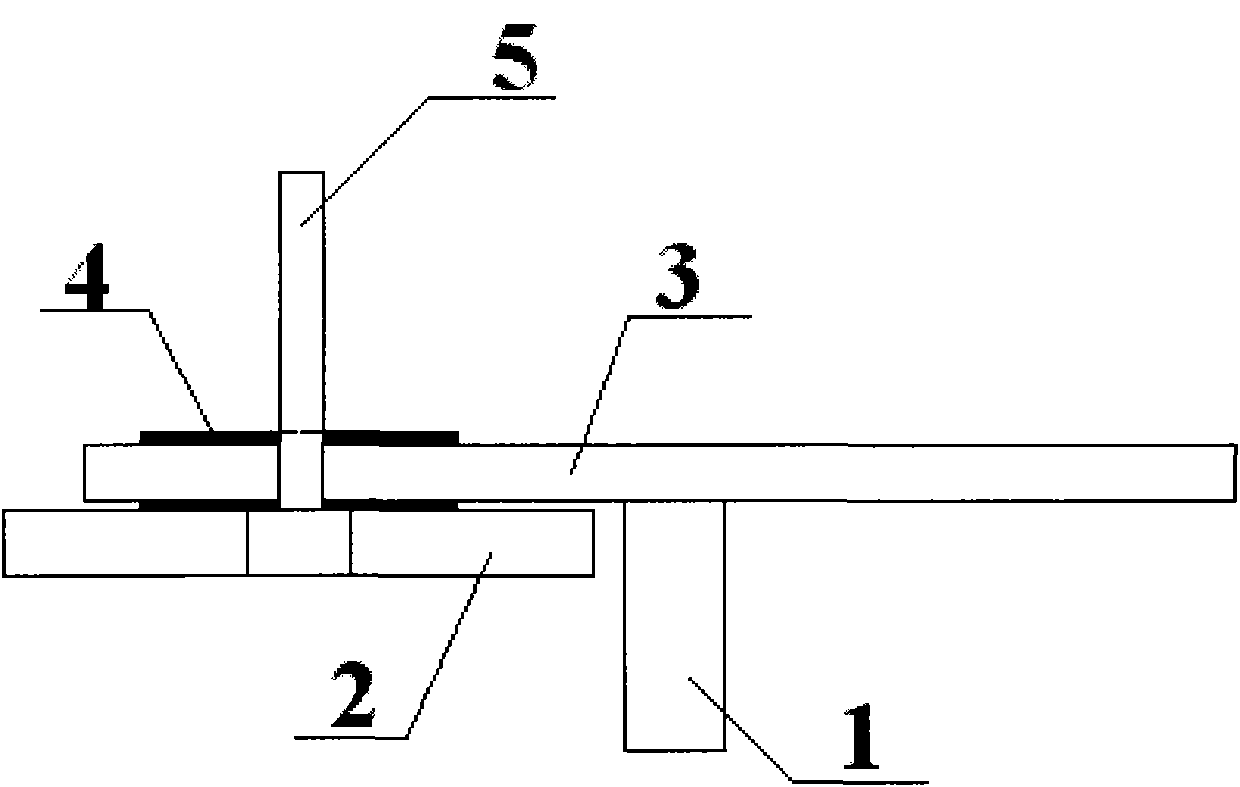

Method and plate flipping milling machine for achieving five-axis single-wall horizontal plate flipping milling

ActiveCN109262031ASimple structureLow costMilling machinesLarge fixed membersMachine toolManufacturing line

The invention discloses a method and a plate flipping milling machine for achieving five-axis single-wall horizontal plate flipping milling. The milling machine comprises a single side wall, a workingtable, a flipping table, and a first driving unit and a second driving unit for driving the working table to perform position switch between the flipping table and the single side wall, wherein the first driving unit and the second driving unit are respectively arranged on the single side wall and the flipping table, a third driving unit for driving the flipping table to flip is arranged at the flipping table position, the working table is subjected to position switch between the flipping table and the single side wall through a sliding channel, and the single side wall and the flipping tableare respectively provided with a locking mechanism for locking the working table. According to the present invention, the horizontal processing is beneficial to efficient chip discharge so as to improve the processing efficiency, reduce the cutter wear, and greatly reduce the time for cleaning chips; and on the basis of the single side wall, the automatic exchange of the working table is achieve,and the automation function of the machine is increased, or the fully automatic production line is formed through expanding so as to further improve the production efficiency.

Owner:KEDE NUMERICAL CONTROL CO LTD

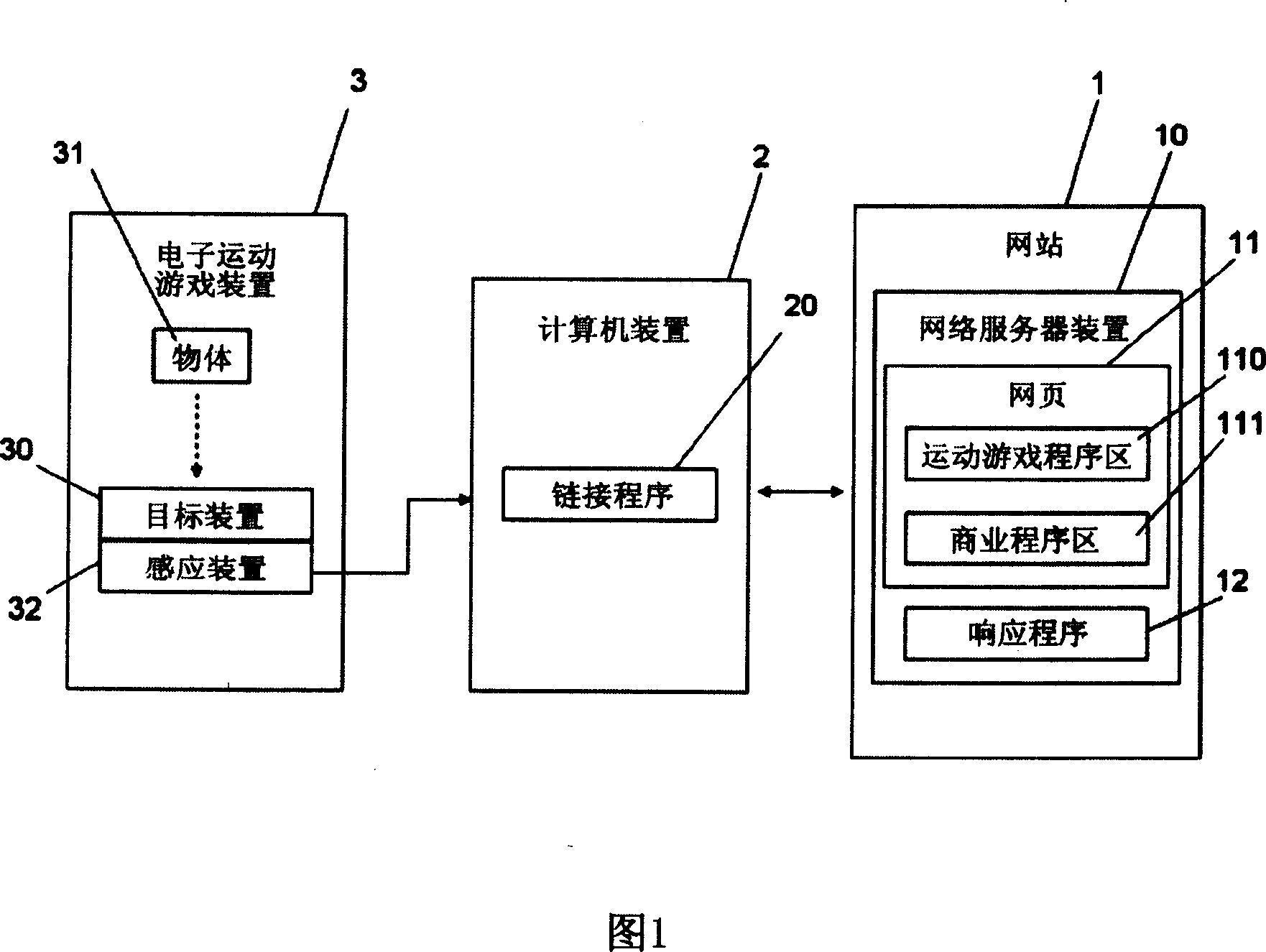

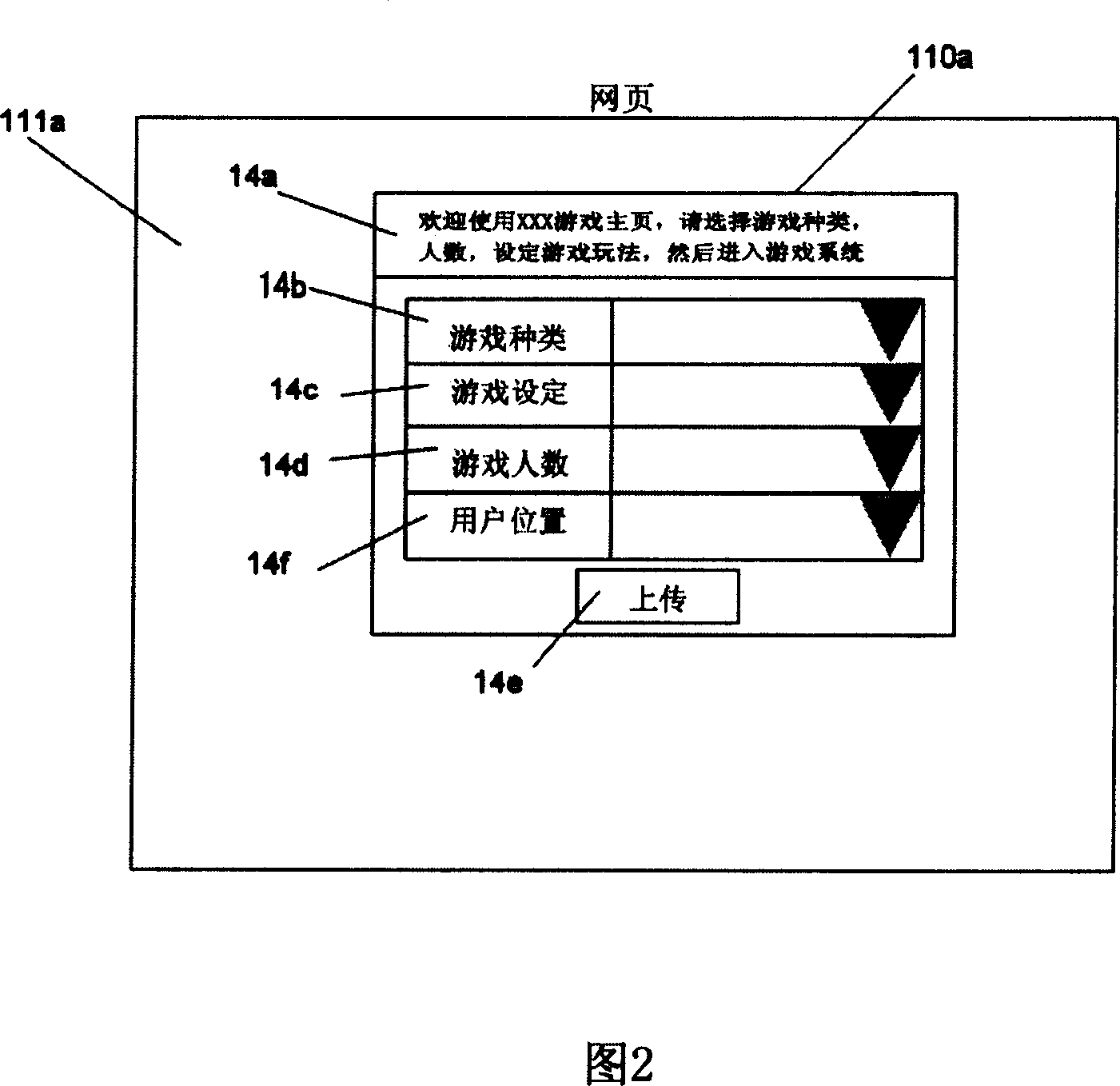

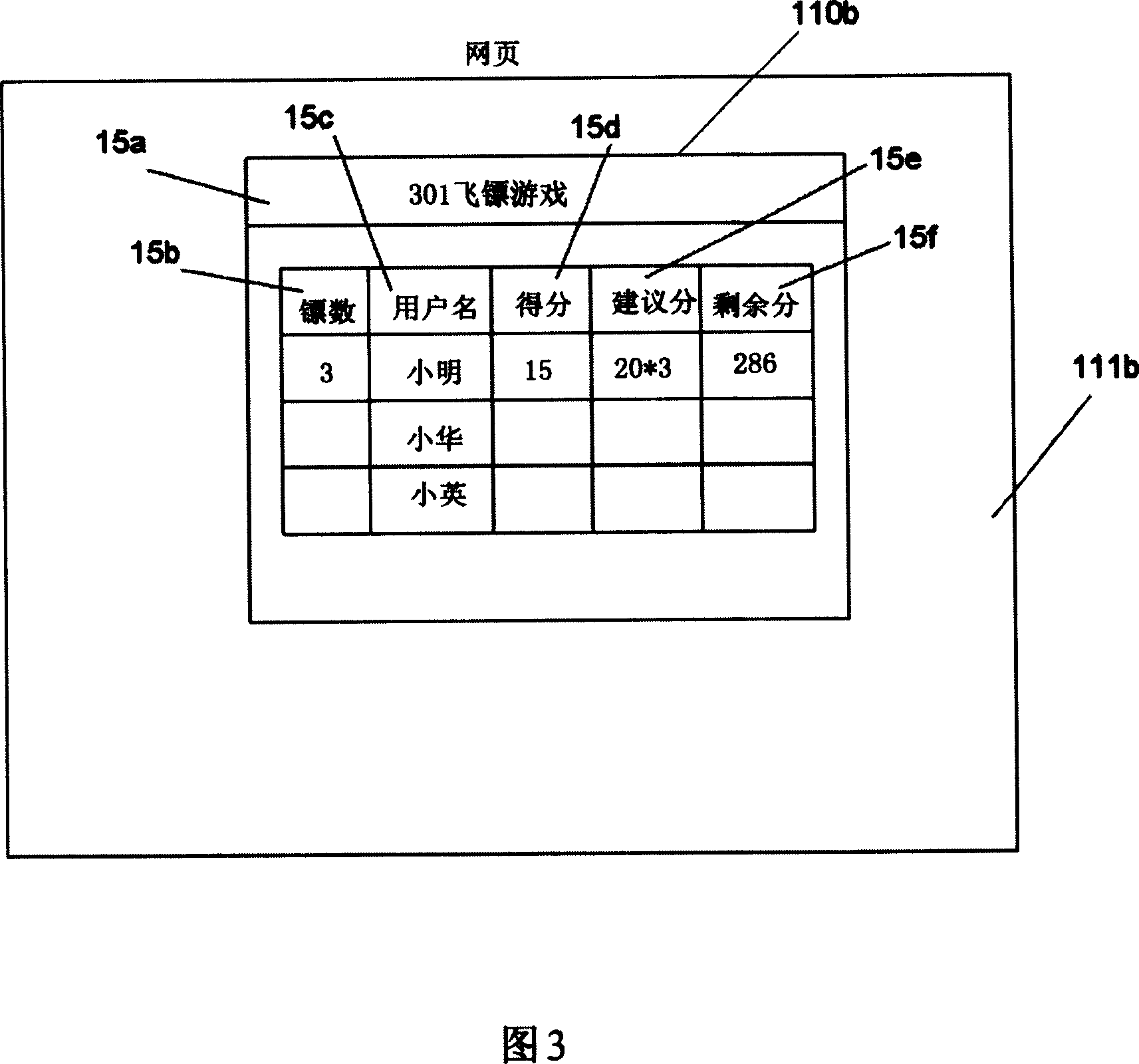

Electron motion game system based on network and method thereof

The invention discloses an internet electronic sports game system and a method of the system, which includes a website, a computer device and an electronic sports game device; the computer device can upload a piece of set data from a webpage of a server device on the website to the server device; a response program in the server device receives the set data, and respond the corresponding webpage to the computer device according to the set data; the corresponding web page is provided with a sports game program area and a commercial program area; the sports game program area provides corresponding sports games according to the set data, controls the sports games to run according to the signal, and displays the progress of the sports games; the commercial program area publishes at least a piece of advertisement. The system the and method can not only provide entertainment and sports for the users, but also increase the browse rate of the website, so as to initiatively promote commodities or services.

Owner:邵学悌 +1

Gamma ray therapeutic device

InactiveCN1663635AReduce volumeImplement dynamic focusX-ray/gamma-ray/particle-irradiation therapyCoronal planeTherapeutic Devices

The invention discloses a gamma-rays therapeutic equipment, comprises the foundation fixed under the ground, above the function, the collimator foundation, framework foundation and CT engine base are assembled left-right. The framework can do 200 degree Centigrade axial rotary motion, the irradiation unit can make 200 degrees Centigrade B axial rotating motion. Both the rotating motion are superposed can result in the focal point of the radioactive source rays move on the most of the spherical surface., and realize ''dynamic focal point''. The treatment bed not only can lift fore-and-aft or upper-and-lower, to realize the cross-section or coronal section scan of patients, but also can move left-right, to realize the real-time detection change between gamma-rays treatment and roentgen rays. The real-time detection is good for patients to accomplish one time treatment. The synchronism can make position fixed check and treatment, eliminate the accumulated error of twice position fix, improve the therapeutic precision. This is the so-called ''check on-line''. Increasing the collimator data base, the collimators there changes with the collimators in irradiation unit automatically.

Owner:杭州威力克机电设备有限公司

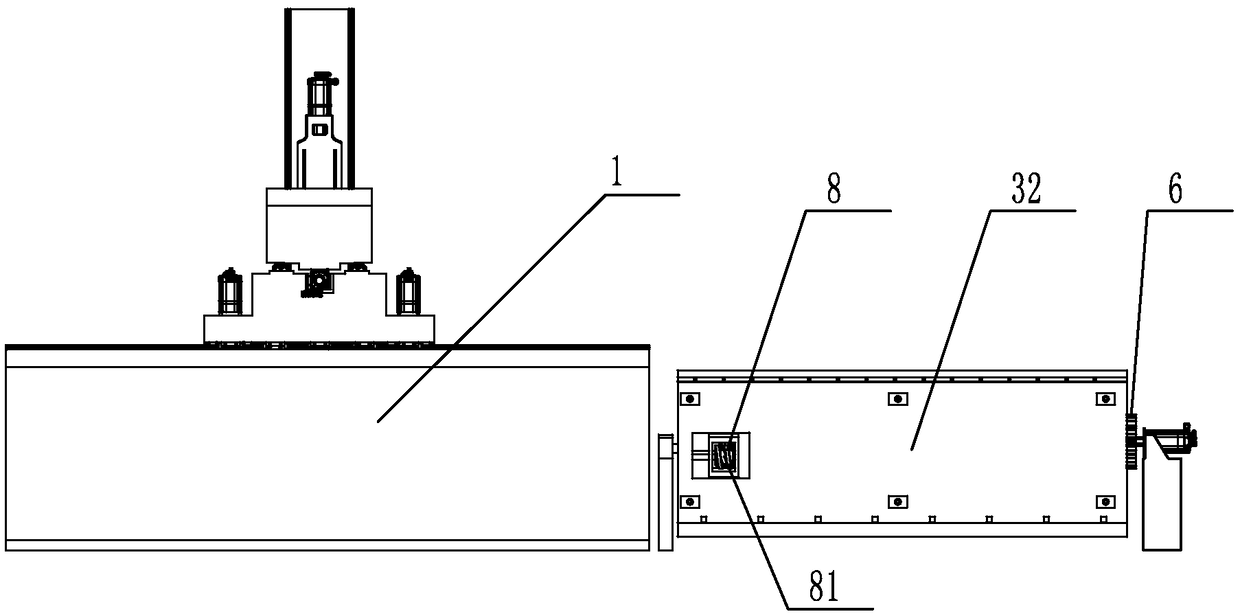

Method and plate flipping milling machine for achieving five-axis gantry horizontal plate flipping milling

PendingCN109262032AImproved accuracy and stabilityImprove structural rigidityMilling machinesLarge fixed membersProduction lineBridge type

The invention discloses a method and a plate flipping milling machine for achieving five-axis gantry horizontal plate flipping milling. The milling machine comprises a gantry side wall, a working table, a flipping table, and a first driving unit and a second driving unit for driving the working table to perform position switch between the flipping table and the gantry side wall, wherein the firstdriving unit and the second driving unit are respectively arranged on the gantry side wall and the flipping table, a third driving unit for driving the flipping table to flip is arranged at the flipping table position, the working table is subjected to position switch between the flipping table and the gantry side wall through a sliding channel, and the gantry side wall and the flipping table arerespectively provided with a locking mechanism for locking the working table. According to the present invention, the horizontal processing is beneficial to efficient chip discharge so as to improve the processing efficiency, reduce the cutter wear, and greatly reduce the time for cleaning chips; and on the basis of the bridge type gantry, the automatic exchange of the working table is achieve, and the automation function of the machine is increased, or the fully automatic production line is formed through expanding so as to further improve the production efficiency.

Owner:KEDE NUMERICAL CONTROL CO LTD

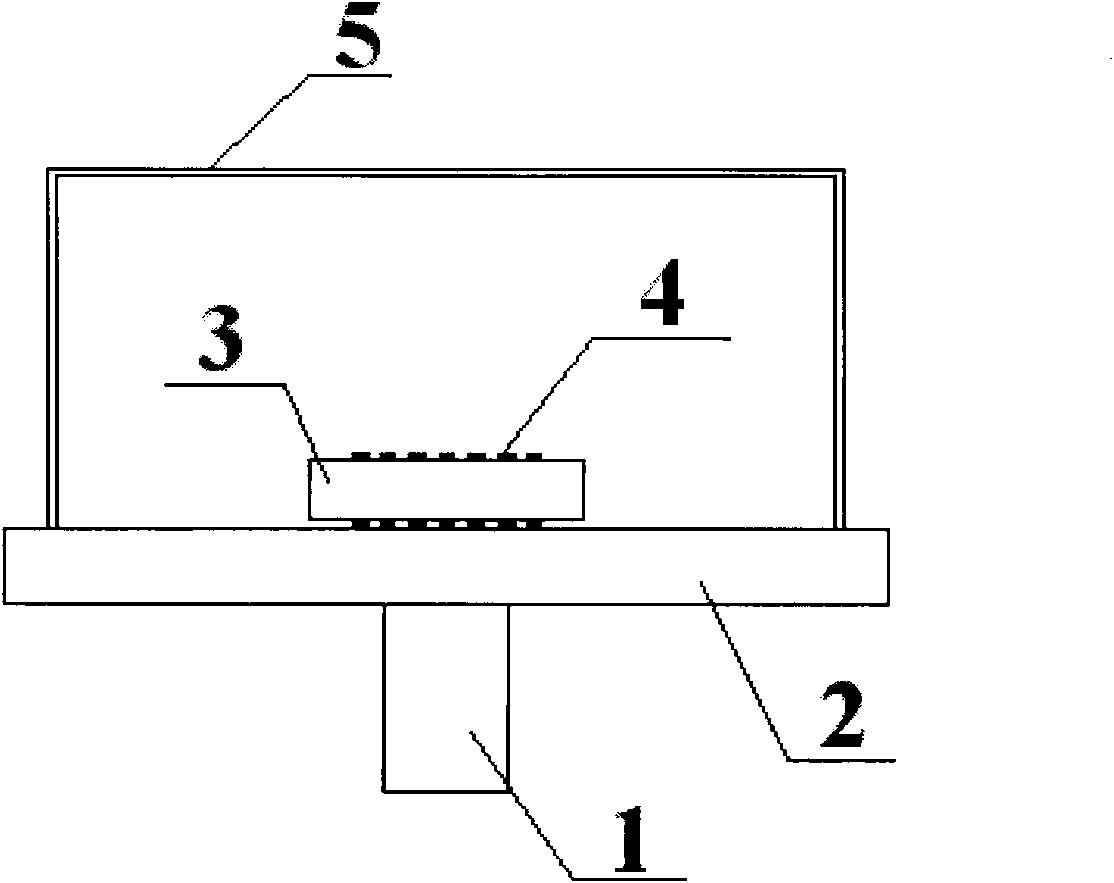

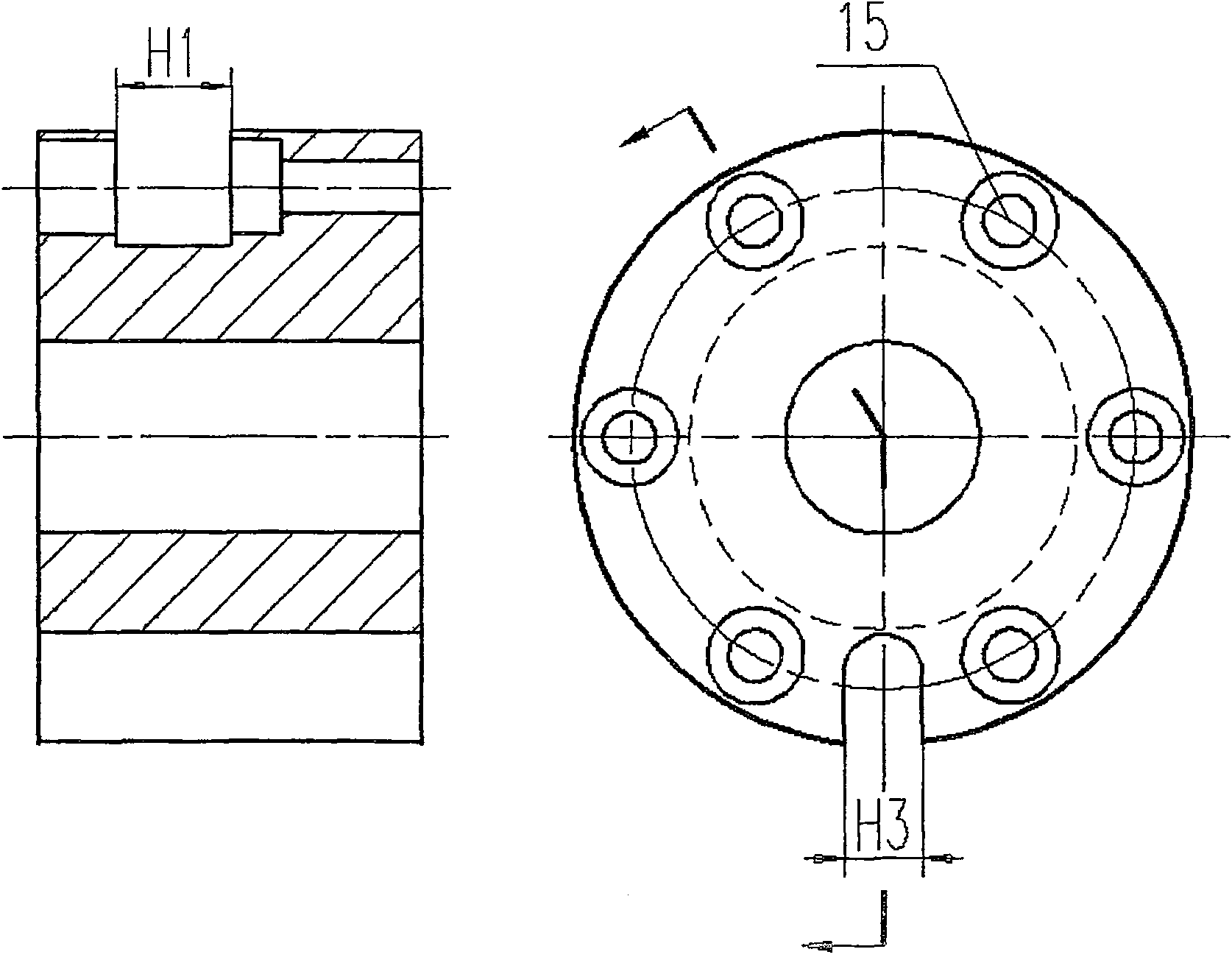

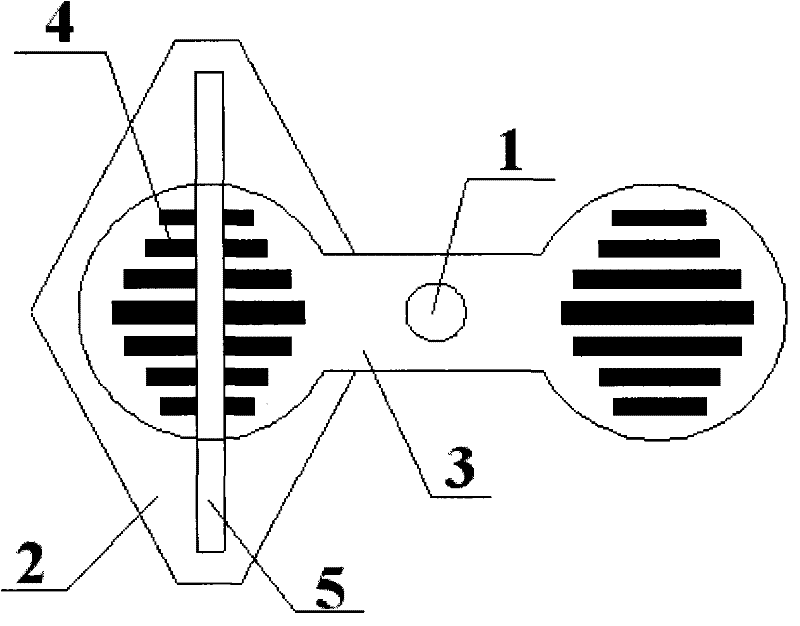

Automatic switching device for bottom-loading balance weights

ActiveCN101893473AAvoid manual exchangeImplement automatic exchangeWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCircular discEngineering

The invention discloses an automatic switching device for bottom-loading balance weights. The device comprises a rotary disc rotating shaft, a balance scale pan, a rotary disc, a lug boss and a weigh beam, wherein the two ends of the rotary disc are provided with circular discs with grooves and the middle parts of the circular discs are connected through a rectangular block so as to form a symmetric structure; a cylindrical rotary disc rotating shaft capable of lifting and rotating is connected below the symmetric centre of the rotary disc; the balance scale pan is positioned below one circular disc end of the rotary disc and provided with the lug boss which passes through the grooves on the circular discs of the rotary disc; the height of the lug boss is slightly greater than the thickness of the rotary disc; and the balance scale pan is connected with the weigh beam. Because the device realizes automatic switching during the measurement, the operation such as manual switching of weights, opening and closing of a balance housing and the like are prevented and the measurement accuracy is greatly improved; and by using the balance with automatically switched weights, the number of division reaches 2*10<7>.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

A vehicle wireless communication method and system

InactiveCN101998686BImplement automatic exchangeImprove economyTicket-issuing apparatusNetwork topologiesInternet networkIn vehicle

Owner:胡乐乐

A method for realizing five-axis single-wall horizontal flip milling and a flip milling machine

ActiveCN109262031BSimple structureLow costMilling machinesLarge fixed membersProcess engineeringTurbine

The invention discloses a method for realizing five-axis single-wall horizontal turning plate milling and a turning plate milling machine. The milling machine includes a single side wall, and also includes a workbench, a turntable, and is used to drive the workbench between the turntable and the single side wall. The first drive unit and the second drive unit for position conversion between them, the first drive unit and the second drive unit are respectively arranged on the single side wall and the overturn platform, and the overturn platform is also provided with a The third drive unit, the workbench performs position conversion between the overturning platform and the single-side wall through the slideway, and the single-side wall and the overturning platform are both provided with locking mechanisms for locking the workbench. The horizontal processing of the present invention is conducive to efficient chip removal, improves processing efficiency, reduces tool wear, greatly reduces the time for cleaning chips, and realizes automatic exchange of workbenches on the basis of a single side wall, increasing the automation function of the machine tool, or expanding to Fully automatic production line to further improve production efficiency.

Owner:KEDE NUMERICAL CONTROL CO LTD

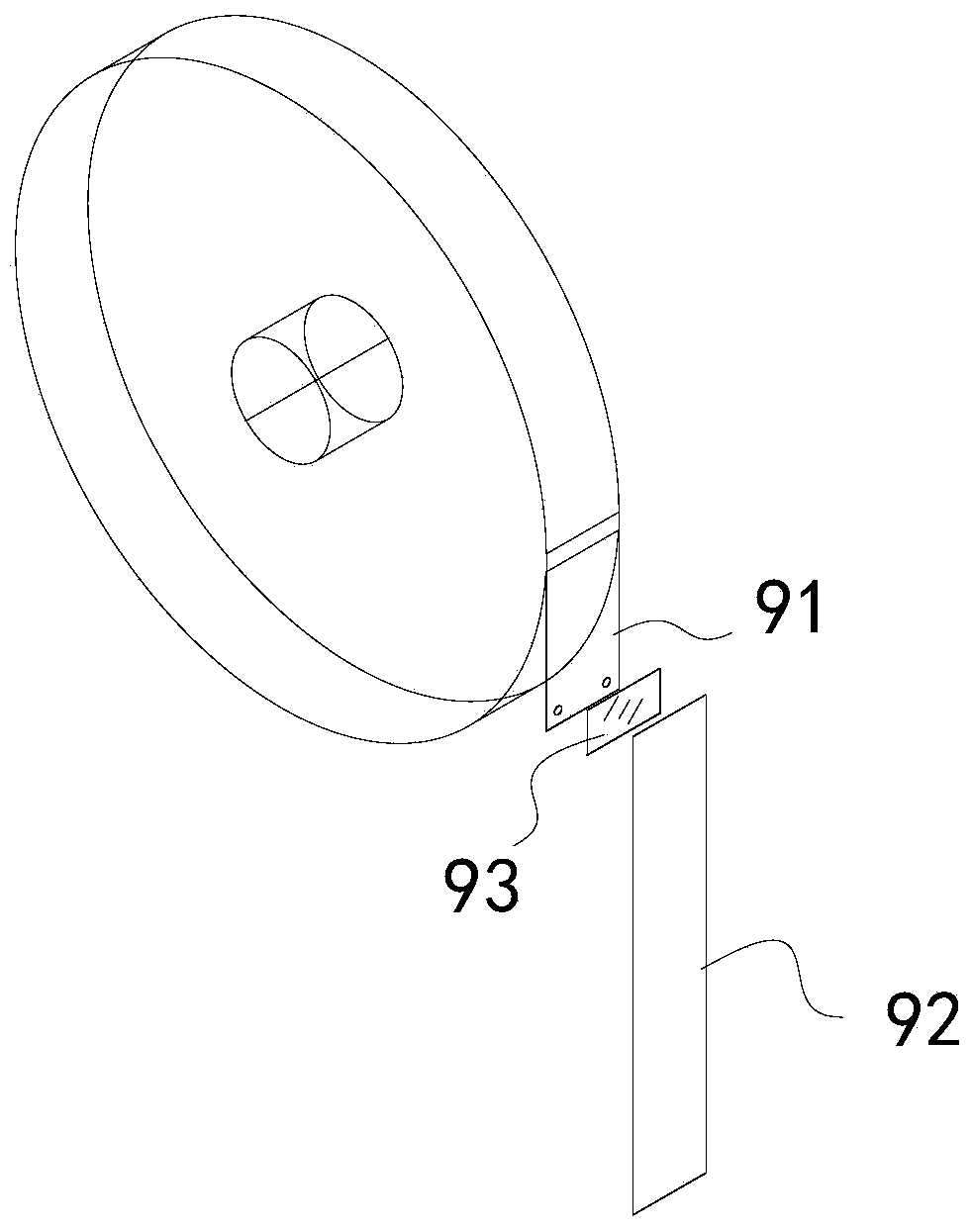

Automatic coil change device for coiled materials

PendingCN110002259AImplement automatic exchangeAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

Owner:DONGGUAN ARECONN PRECISION MACHINERY

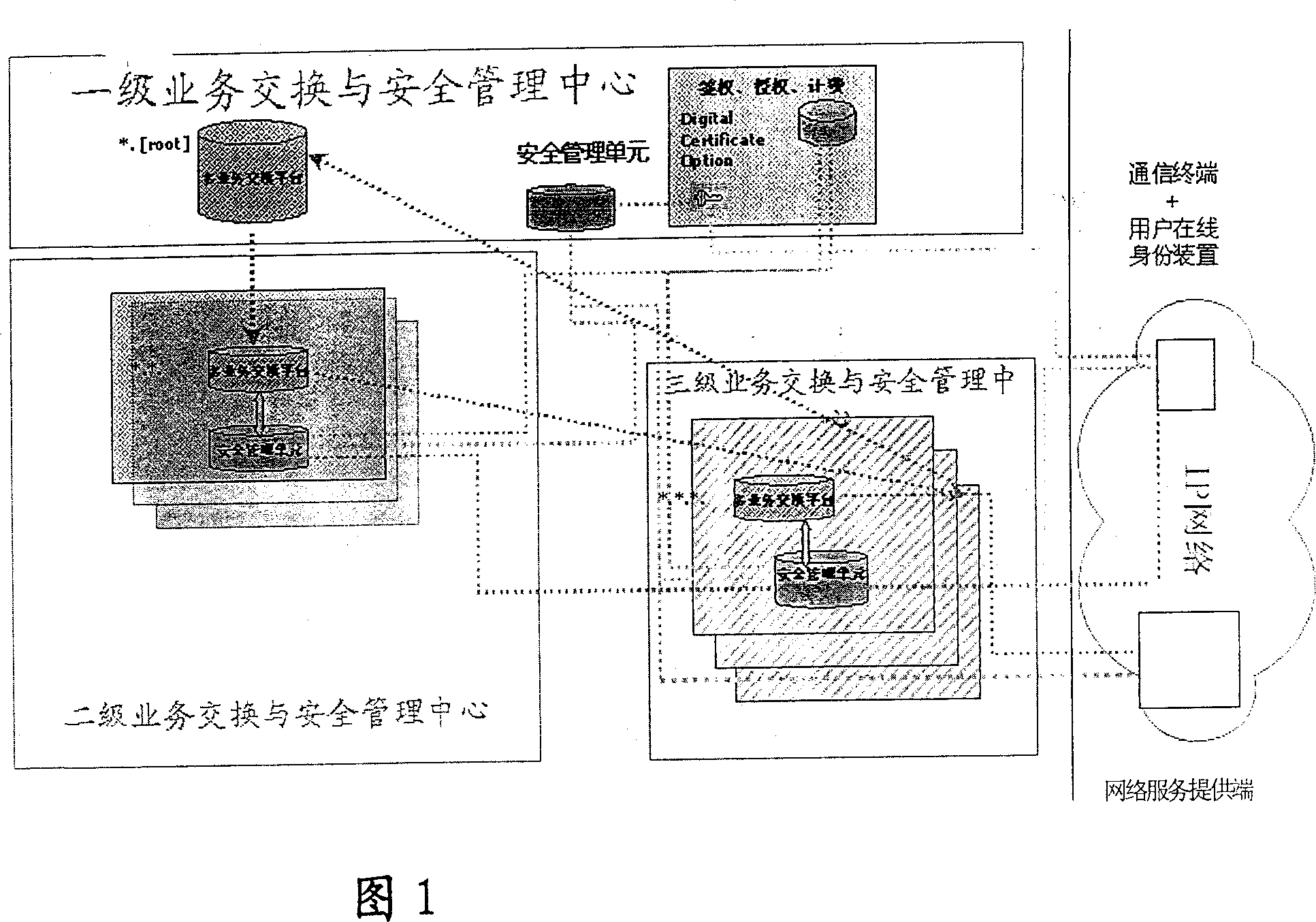

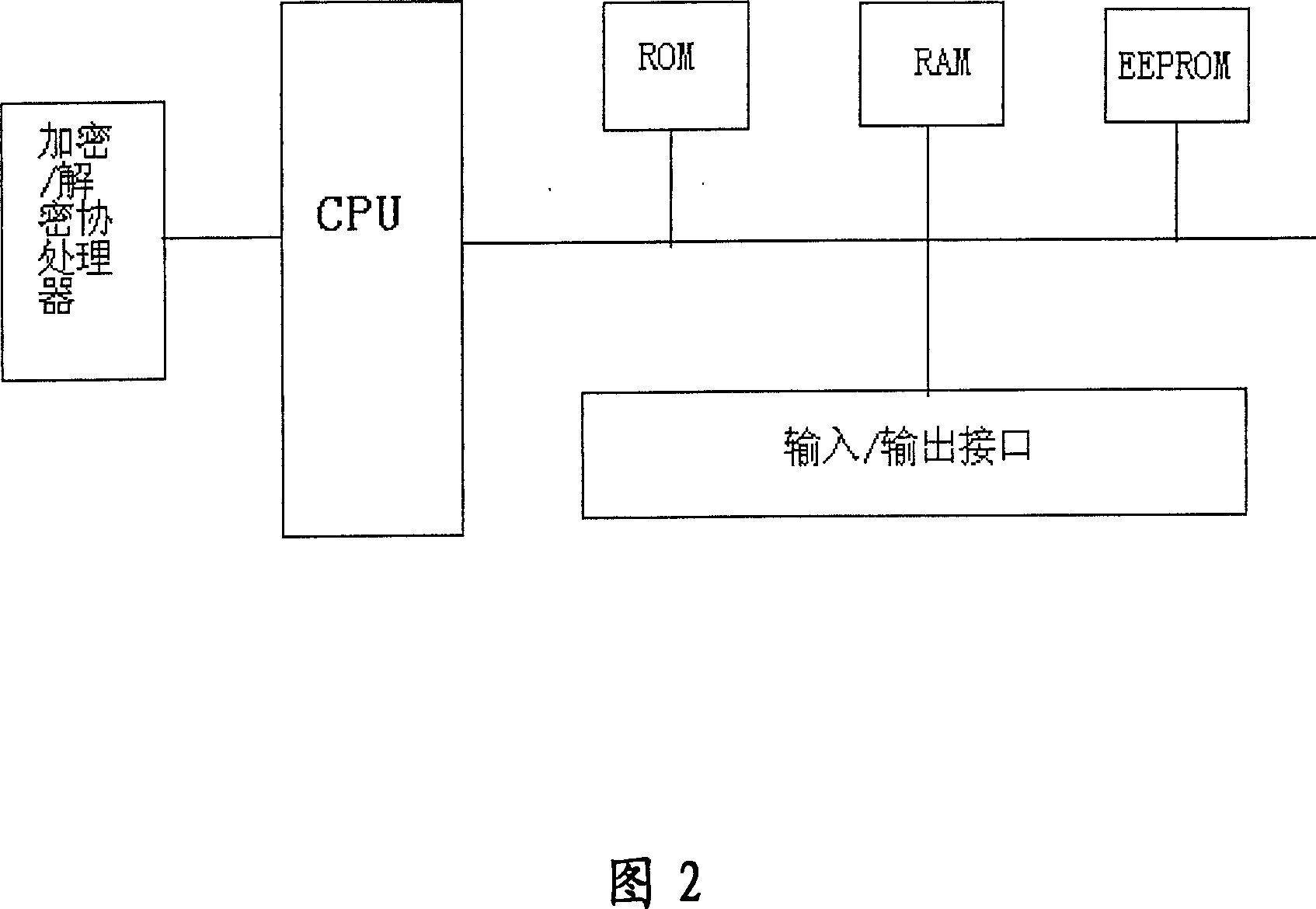

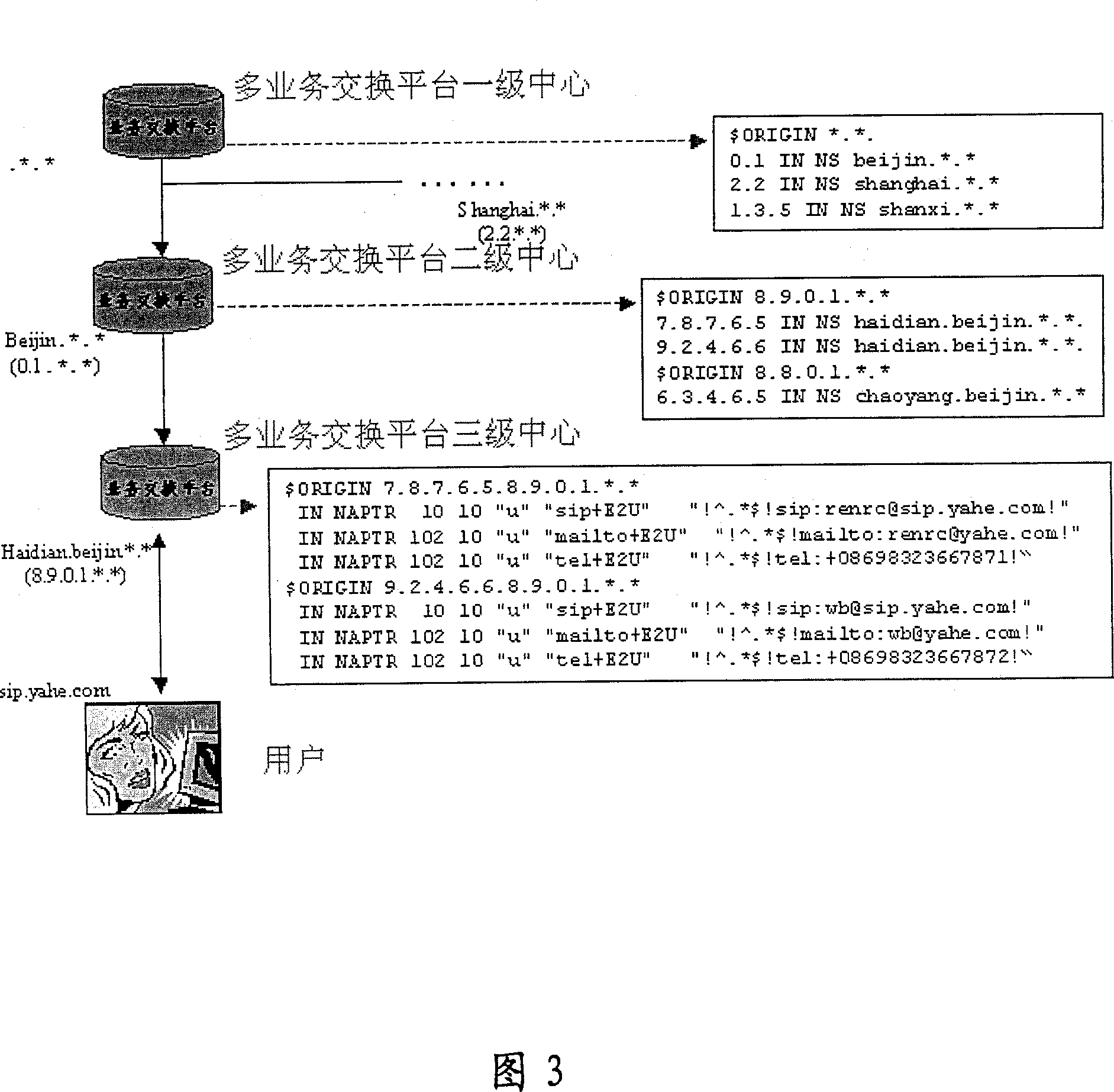

Multiple service exchange method and system based on IP network user identification

InactiveCN100349400CEnable two-way communicationImplement automatic exchangeUser identity/authority verificationService providerInternet service provider

The invention provides a multiple service exchange method and system based on IP network user identification, wherein communication terminals, a multiple service exchange platform and a network service provider are coupled with the IP network respectively, and an online identification device is employed as the initiating party and receiving party of the services, a safety identification administration unit is employed for secrecy administration, the user information is stored in the said online identification device and multiple exchange platform, the network service provider business information is also stored in the multiple service platform.

Owner:速位隆通(北京)科技有限公司

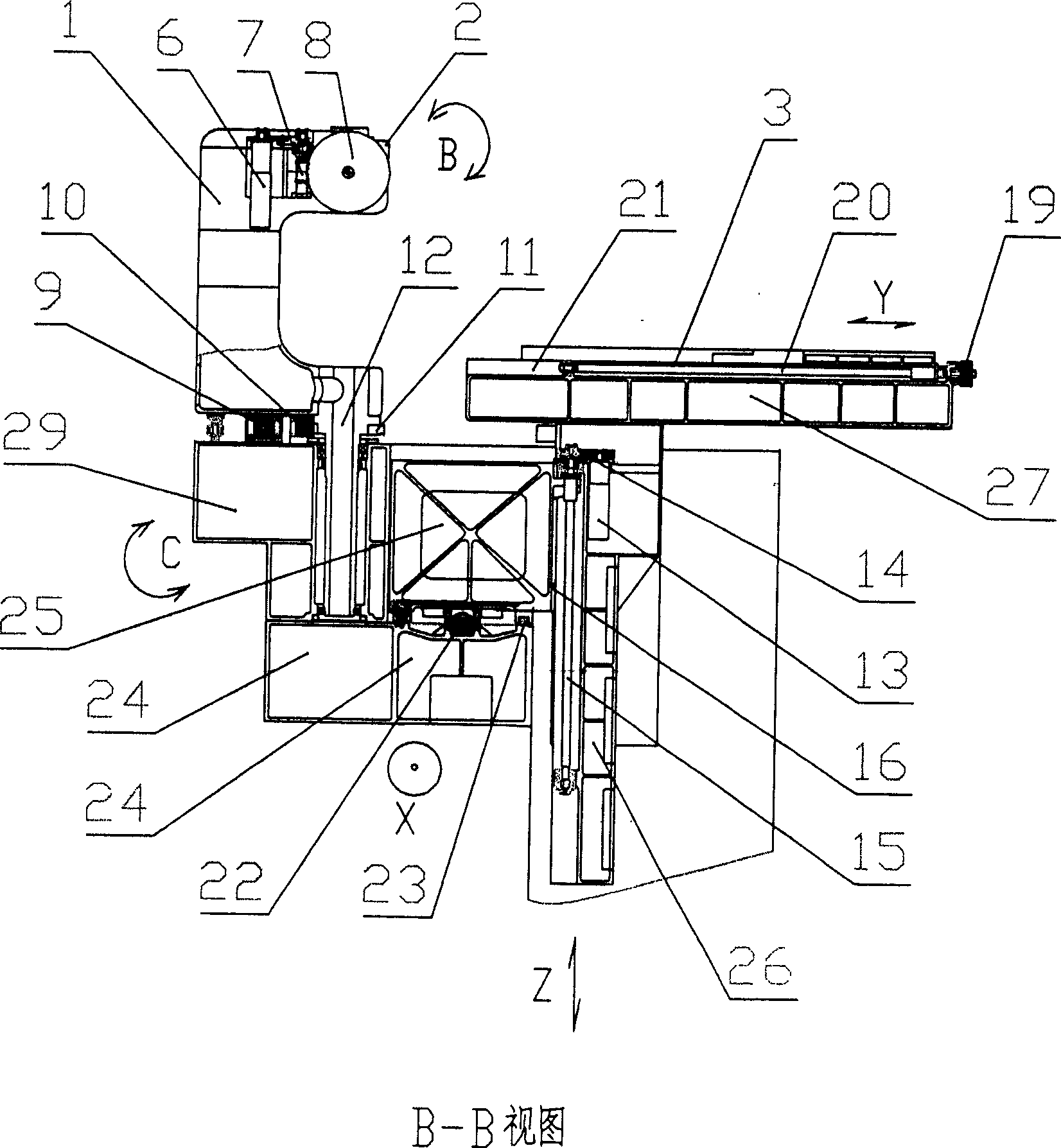

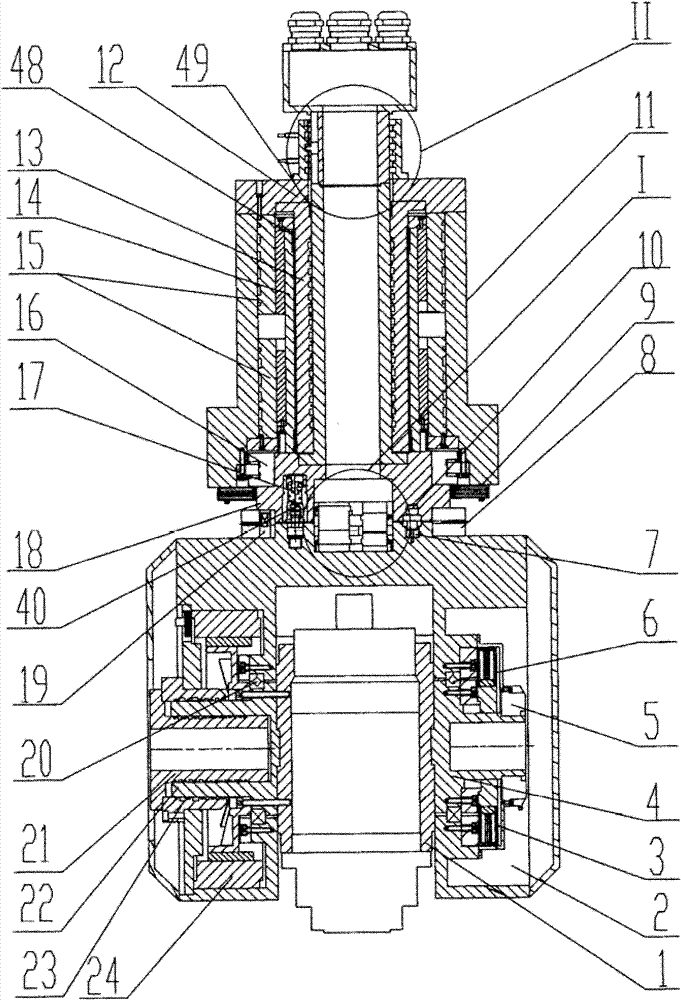

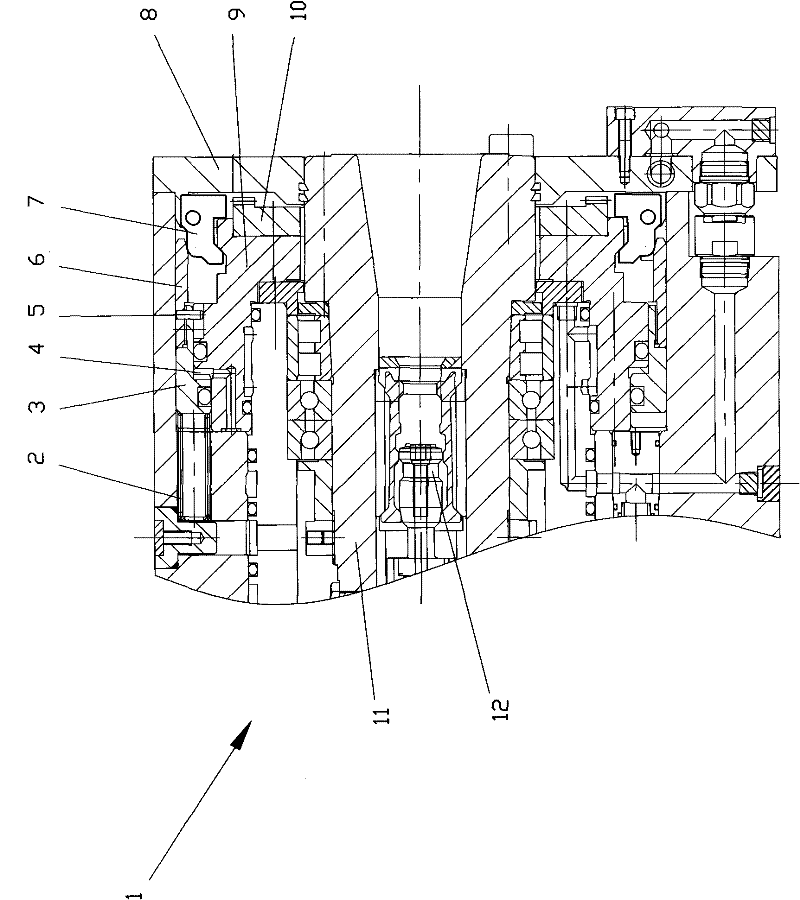

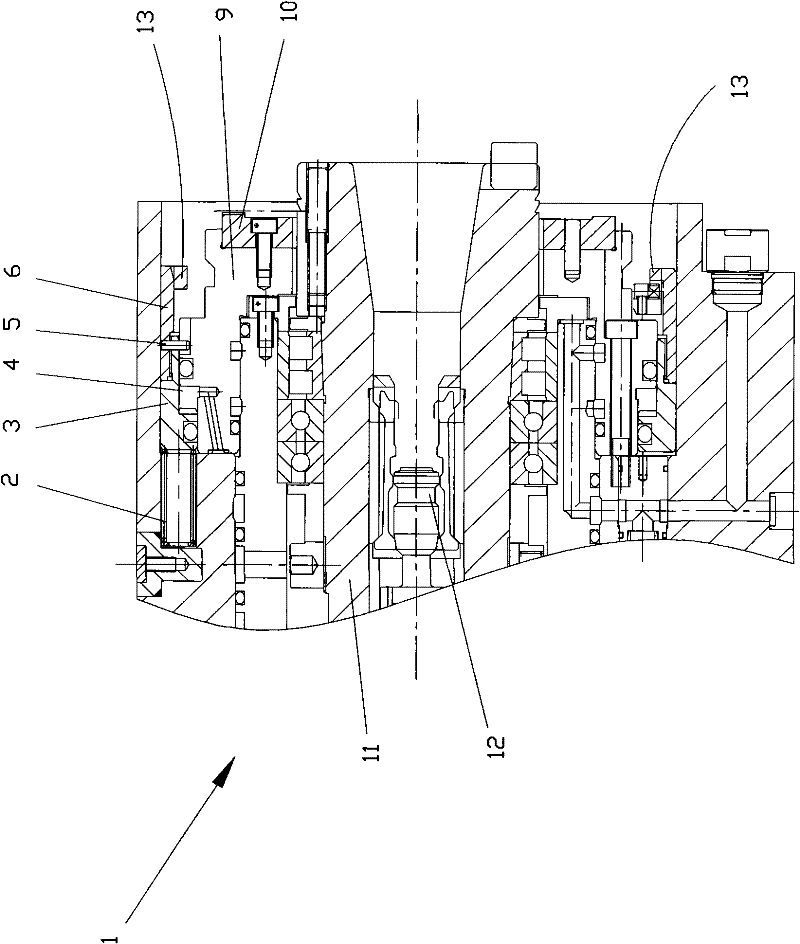

Double-swing cutter head driven by alternating-current permanent-magnet synchronous inner rotor torque motor

ActiveCN102069409BImplement automatic exchangeImprove adaptabilityLarge fixed membersDriving apparatusNumerical controlTorque motor

The invention belongs to the field of machine tools, in particular to a double-swing cutter head driven by an alternating-current permanent-magnet synchronous inner rotor torque motor. The double-swing cutter head is divided into an upper part and a lower part by an end-toothed disc, wherein the upper part is a shaft C which can rotate around a vertical shaft, the lower part is a shaft A which can swing around the vertical shaft, and the shaft A and the shaft C are respectively connected by an exchangeable interface; a spindle box of the shaft A, a spindle-box support shaft, and an inner rotor of the torque motor are connected to a box body of the shaft A by bearings; the box body of the shaft A is equipped with an outer rotor of the torque motor; the cutter head is connected with the shaft C by a hydraulic pulling claw through the positioning of the end-toothed disc, and the exchange of the shaft A is realized by the pulling claw through hydraulic control; and the torque motor on the shaft C transmits twisting moments by the end-toothed disc so as to realize the peripheral rotation of the shaft A, and the swing of the spindle box is realized by the torque motor on the shaft A. By using the double-swing cutter head provided by the invention, the problems that the traditional mechanically operated double-swing is large in additional rotation inertia and complicated in installation and has a transmission clearance, and the like caused by excessive middle transmission links are solved, therefore, the double-swing cutter head provided by the invention can be widely applied to high-grade numerical control machining centers subjected to surface machining.

Owner:沈阳机床中捷友谊厂有限公司

Ferrule type grinding wheel chuck

ActiveCN100563929CImplement automatic exchangeHigh degree of automationGrinding wheel securing apparatusMating connectionCounterbore

The invention discloses a ferrule type grinding wheel chuck device for a grinder equipment, which comprises a chuck body, a pressing disk sleeved out of the chuck body and a ferrule connected with the chuck body. The chuck body is provided with a column inner hole in which a clamping ring groove connected with a tension mechanism of a main shaft is arranged; the orifice at the right end of the inner hole is provided with an inner cone matched and connected with the end surface of a grinding head main shaft; the orifice at the left end of the inner hole is provided with a counter bore and a plurality of screw holes which are matched and connected with the ferrule; the large end surface of the chuck body is provided with a sealed joint surface and a plurality of connecting screw holes; the back of the large end surface is provided with a shoulder; the ferrule is provided with a positioning slot and a guiding groove which are matched and connected with a processing centre grinding wheel library or the other grinding equipment installation mechanism; the ferrule is provided with a counterbore hole matched with the screw holes of the chuck body; screw holes matched with the connecting screw holes on the chuck body are arranged on the pressing disk; a boss matched with the shoulder on the chuck body is arranged at the right side surface of the pressing disk. The labor strength is reduced and the labor and the time are saved with the invention, the grinding wheel chuck can be exchanged automatically, so that the producing efficiency and the advancement of the machine tool equipment are increased.

Owner:浙江杭机股份有限公司

Solar heating control system and control method thereof

InactiveCN102644957BImprove utilization efficiencyReduce pollutionSolar heat devicesSpace heating and ventilation detailsControl systemEngineering

Owner:NANJING COLLEGE OF INFORMATION TECH

Screen printing machine and method for automatically exchanging screens

ActiveCN101850649BImprove work efficiencyImplement automatic exchangeScreen printersEngineeringPrinting press

Owner:PANASONIC CORP

Flexible sheetmetal processing center

ActiveCN102430925BEasy to installImplement automatic exchangeOther manufacturing equipments/toolsMetal working apparatusEtchingElectrical control

The invention relates to a flexible sheetmetal processing center, belonging to sheetmetal processing equipment. The flexible sheetmetal processing center mainly comprises a motor and a servo motor, a main spindle box, a main spindle assembly, a screw rod component, a pedestal, crossbeams, a back-blading device, an upright column, a tool storage, a clamping assembly, a linear guide rail assembly, an electric control box and a base, wherein the main spindle box is arranged on the linear guide rail of the upright column and moves up and down to realize a Z-direction coordinate motion; the upright column is arranged on the linear guide rail assembly of the base to realize a Y-direction coordinate motion; a universal rolling ball array is respectively arranged on a left support table and a right support table which are used for supporting sheetmetal parts needing to be processed; a left crossbeam assembly and a right crossbeam assembly can move in the longitudinal direction to form an X-direction coordinate motion; and through a W-direction motion of the back-blading part and a W-direction main spindle rotating motion, back-blading to burrs and chamfers can be automatically carried out on the bottom surface, therefore good manufacturability and high quality and efficiency of sheetmetal processing are achieved, and processing cost is reduced very remarkably. The flexible sheetmetal processing center disclosed by the invention is widely suitable for hole drilling, thread tapping, counter boring, burr back-blading at bottoms of holes, irregular hole milling and cutting and plate pattern etching and milling of the sheetmetal parts.

Owner:GUILIN GUANGLU MEASURING INSTR CO LTD

An open microalgae cultivation pond

ActiveCN106281970BImplement automatic exchangeFully photosynthesizedBioreactor/fermenter combinationsBiological substance pretreatmentsWater dischargeEngineering

Owner:中义(北京)健康研究院

Gamma ray therapeutic device

InactiveCN100420496CReduce volumeImplement dynamic focusX-ray/gamma-ray/particle-irradiation therapyCoronal planeTherapeutic Devices

The invention discloses a gamma-rays therapeutic equipment, comprises the foundation fixed under the ground, above the function, the collimator foundation, framework foundation and CT engine base are assembled left-right. The framework can do 200 degree Centigrade axial rotary motion, the irradiation unit can make 200 degrees Centigrade B axial rotating motion. Both the rotating motion are superposed can result in the focal point of the radioactive source rays move on the most of the spherical surface., and realize ''dynamic focal point''. The treatment bed not only can lift fore-and-aft or upper-and-lower, to realize the cross-section or coronal section scan of patients, but also can move left-right, to realize the real-time detection change between gamma-rays treatment and roentgen rays. The real-time detection is good for patients to accomplish one time treatment. The synchronism can make position fixed check and treatment, eliminate the accumulated error of twice position fix, improve the therapeutic precision. This is the so-called ''check on-line''. Increasing the collimator data base, the collimators there changes with the collimators in irradiation unit automatically.

Owner:杭州威力克机电设备有限公司

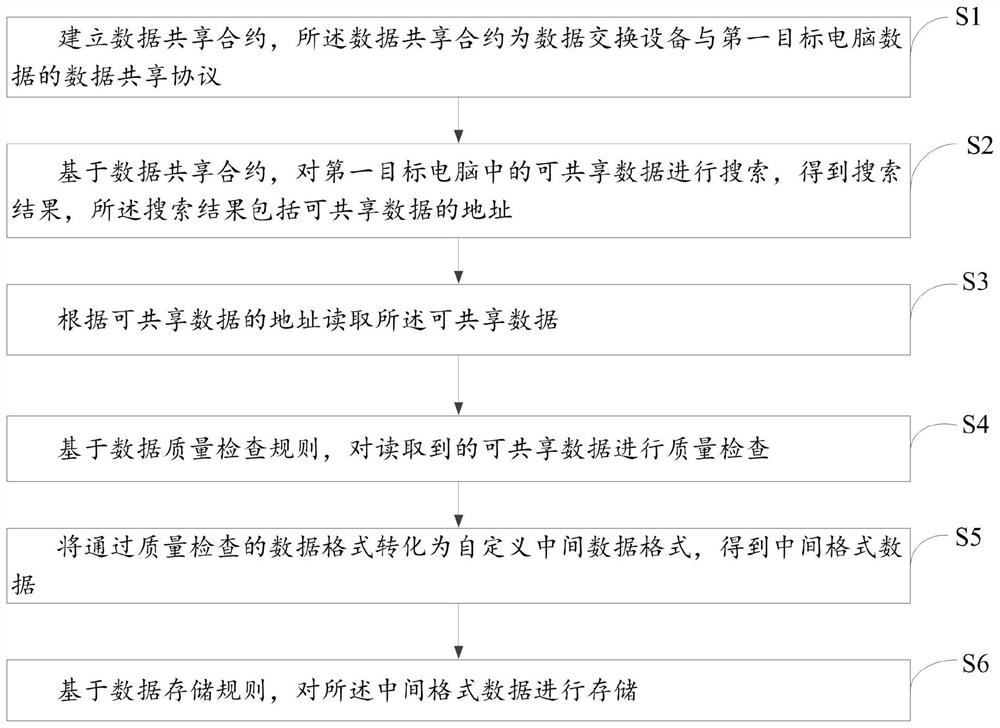

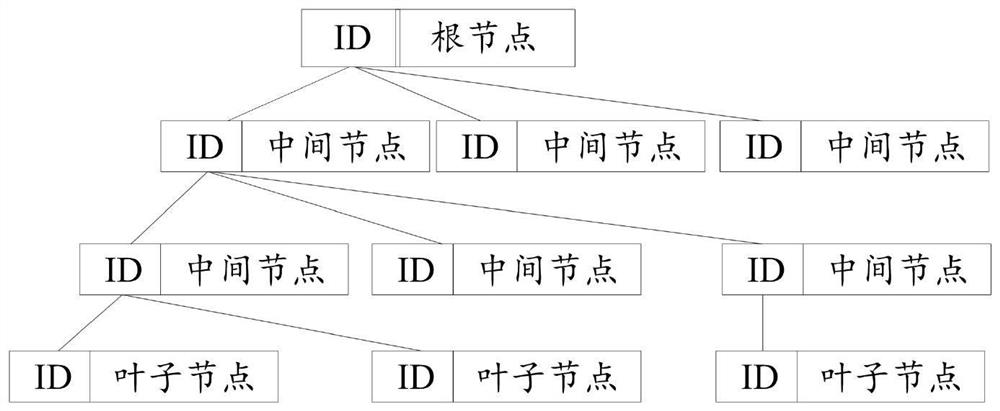

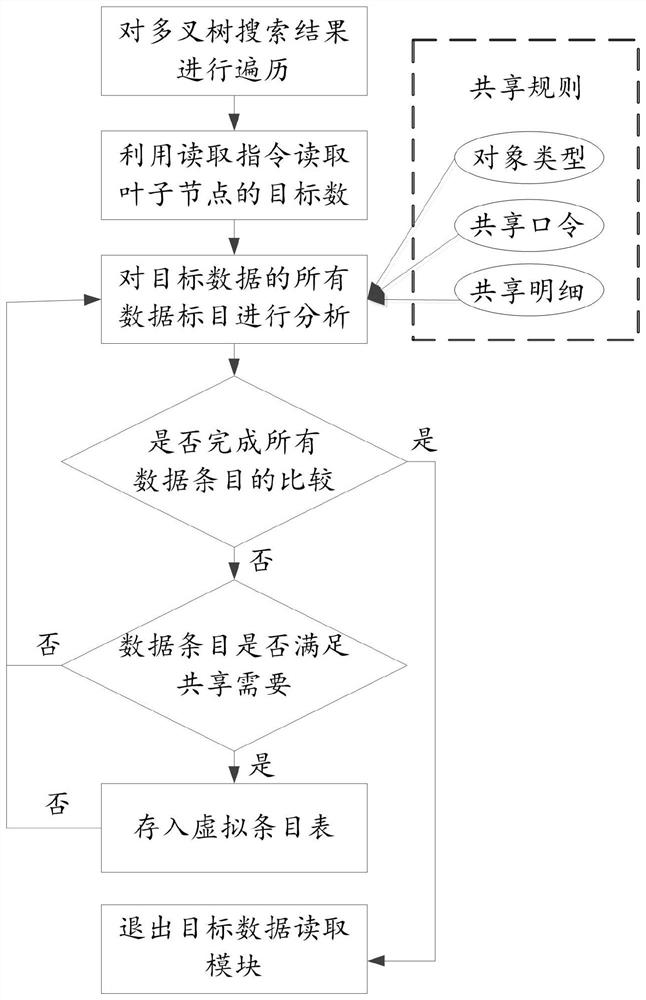

Stand-alone data exchange method and equipment

ActiveCN113157681AImplement automatic exchangeEasy to moveDatabase queryingDatabase management systemsOriginal dataSoftware engineering

The invention provides a stand-alone data exchange method and equipment, and the equipment is used for obtaining data in a first target computer when the equipment is plugged with the first target computer: building a data sharing contract to form a data sharing protocol between the data exchange equipment and the first target computer, searching the first target computer, and transmitting the searched data to the first target computer; and extracting sharable data in the first target computer, and performing quality detection, format conversion and storage. When the equipment is plugged with a second target computer, transmitting shared data extracted from the first target computer to the second target computer; establishing a data utilization electronic protocol for defining a data exchange relationship between the data exchange equipment and the second target computer; and fusing the shared data extracted from the first target computer with the original data in the second target computer. And automatic exchange of data between the first target computer and the second target computer is realized. Data sharing between the two non-networked computers is achieved through the data exchange device, operation is convenient, and efficiency is high.

Owner:AGRI INFORMATION INST OF CAS

A casting cleaning unit and cleaning method

The invention discloses a casting cleaning unit which comprises a casting transit exchange mechanism. The casting transit exchange mechanism comprises a bottom support, an exchange platform, an upper support, a drive device and a positioning device. The positioning device comprises an installation plate and at least two ejecting rods. The installation plate is connected to the power output end of the drive device. The upper ends of the ejecting rods are connected to the installation plate. The lower ends of the ejecting rods are right opposite to the exchange platform. A robot system comprises a first robot and a second robot. The first robot is arranged on the feed side of the casting transit exchange mechanism. The second robot is arranged on the discharge side of the casting transit exchange mechanism. The casting cleaning unit is suitable for automatic unit product price multi-procedure conditions, reliable and stable in positioning, suitable for positioning castings of various types, and suitable for being shared by various product parts; the mechanism is simple in structure, low in manufacturing cost and high in cost performance. The invention further discloses a casting cleaning method.

Owner:SUZHOU MINGZHI TECH

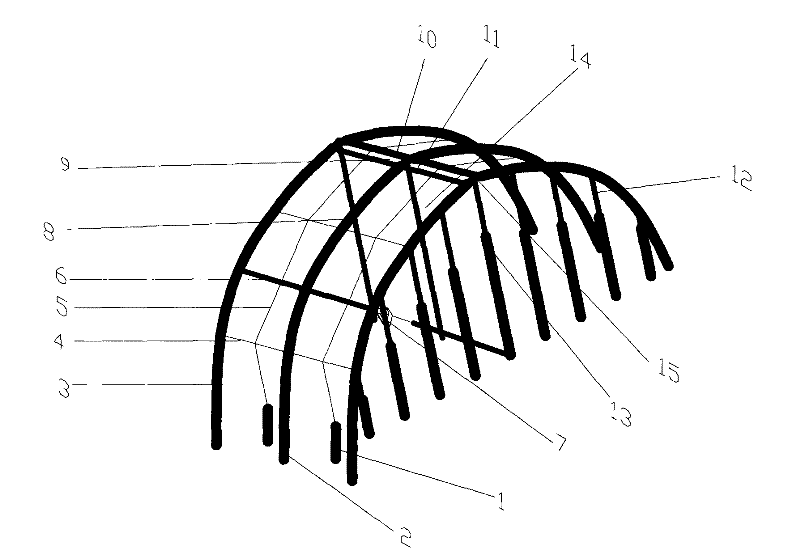

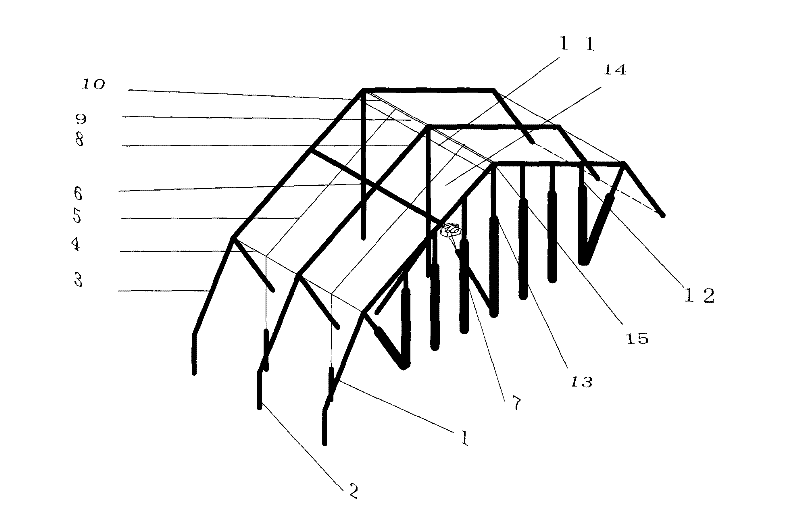

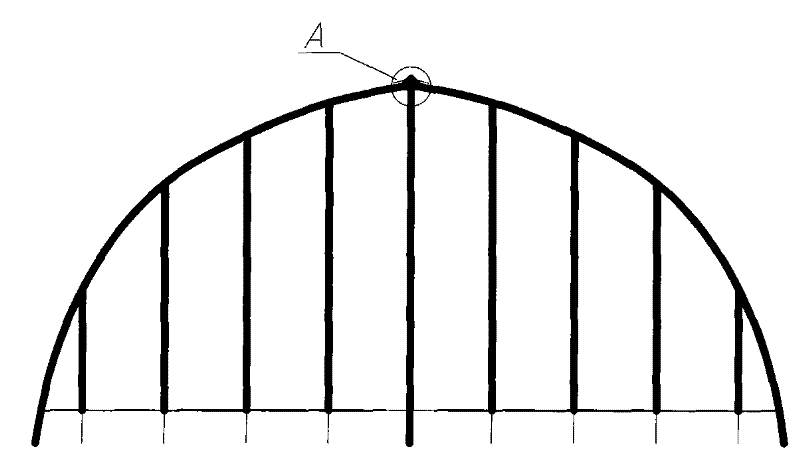

Anti-pneumatic film type fruit tree rainproof facility

InactiveCN102144512BImplement automatic exchangeStrong wind and rain resistancePlant protective coveringsInternal pressureFruit tree

The invention discloses an anti-pneumatic film type fruit tree rainproof facility. The facility consists of wire pressing ground anchors, wire supporting ground anchors, boundary stay bars, longitudinal bracing wires, film pressing wires, a roll-up unit scroll, an electric roll-up unit, an arch bar or film supporting wire, a rainproof ventilation plastic film, a top ridge, a film fixing clamping groove, boundary struts, middle spines, a rainproof covering plastic film, and a plastic clamp; and the facility has a bar and cable combined structural system combining rigidity and flexibility. The anti-pneumatic film type fruit tree rainproof facility can realize the automatic exchange of air inside and outside the facility, the air inside the facility automatically jacks up the rainproof ventilation plastic film to exhaust when the internal pressure of the air is greater than the external pressure, and the rainproof ventilation plastic film droops due to the action of gravity to recover the original shape when the internal pressure and the external pressure are balanced; years of experiments show that the facility can safely stand the test of high wind and heavy rain in northern autumn; and the facility has the characteristics of rainproofness, high ventilation efficiency, no building pollution, simple construction, sturdiness and durability, convenience in use and the like.

Owner:SHANXI AGRI UNIV

Automatic switching device for bottom-loading balance weights

ActiveCN101893473BAvoid manual exchangeImplement automatic exchangeWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCircular discEngineering

The invention discloses an automatic switching device for bottom-loading balance weights. The device comprises a rotary disc rotating shaft, a balance scale pan, a rotary disc, a lug boss and a weigh beam, wherein the two ends of the rotary disc are provided with circular discs with grooves and the middle parts of the circular discs are connected through a rectangular block so as to form a symmetric structure; a cylindrical rotary disc rotating shaft capable of lifting and rotating is connected below the symmetric centre of the rotary disc; the balance scale pan is positioned below one circular disc end of the rotary disc and provided with the lug boss which passes through the grooves on the circular discs of the rotary disc; the height of the lug boss is slightly greater than the thickness of the rotary disc; and the balance scale pan is connected with the weigh beam. Because the device realizes automatic switching during the measurement, the operation such as manual switching of weights, opening and closing of a balance housing and the like are prevented and the measurement accuracy is greatly improved; and by using the balance with automatically switched weights, the number of division reaches 2*10<7>.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

Five-axis linkage turning plate machining center and application thereof

PendingCN113305589AImplement automatic exchangeAchieve positioningLarge fixed membersPositioning apparatusStructural engineeringMachine tool

The invention belongs to the field of horizontal machine tool machining centers, and relates to a five-axis linkage turning plate machining center and application thereof. The five-axis linkage turning plate machining center comprises a transverse lathe bed, a Y-axis driving mechanism is connected to the left side end face of the transverse lathe bed, a Y-direction sliding rail is arranged at the top of the transverse lathe bed, a swing table supporting plate is arranged on the Y-direction sliding rail, and a swing table structure is connected to the top of the swing table supporting plate. A workbench automatic exchange station is arranged on one side of the transverse lathe bed, the other side of the transverse lathe bed is fixedly connected with a longitudinal lathe bed through a connecting support, a Z-direction sliding rail is arranged at the top of the longitudinal lathe bed, a stand column is connected to the Z-direction sliding rail, a Z-axis driving mechanism is arranged on the left side of the stand column and fixedly connected to the upper end face of the longitudinal lathe bed, and an X-direction sliding rail is fixedly connected to the front end face of the stand column. An X-axis driving mechanism is arranged on the upper end face of the stand column, the X-direction sliding rail is movably connected with a spindle box, and the spindle box is fixedly connected with a single swing head. A robot tool changing mechanism and a tool magazine wall assembly are arranged on one side of the longitudinal lathe bed. Five-axis linkage machining is achieved, and potential safety hazards caused by the fact that a machine tool suddenly powers off, and swing heads droop in an existing horizontal machining center are eradicated.

Owner:沈阳中捷航空航天机床有限公司

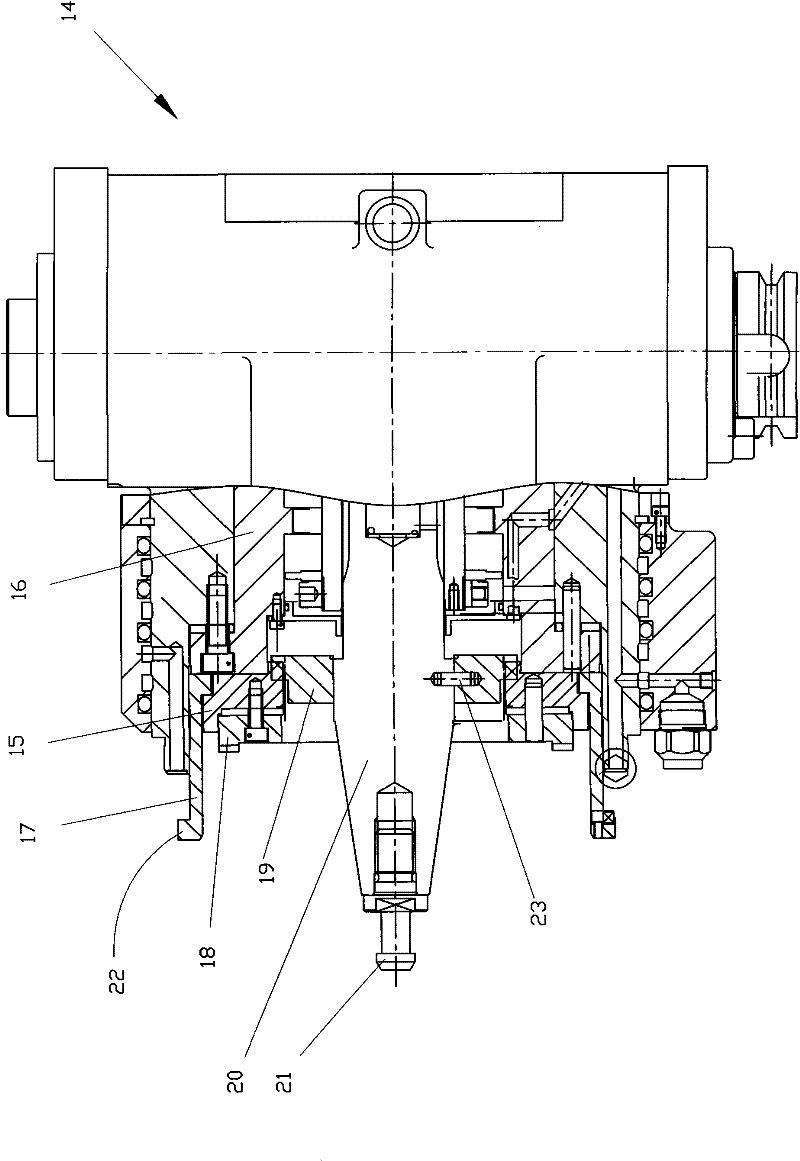

Upright and horizontal automatic exchange and automatic rotary type main shaft head

InactiveCN101602173BImprove work efficiencyReduce processing costsDriving apparatusPistonEngineering

The invention relates to an upright and horizontal automatic exchange and automatic rotary type main shaft head. An upright shaft mechanism is provided with an upright shaft body, the inner side of the upright shaft body is provided with a main shaft, and an inner hole of the main shaft is provided with a tightening mechanism; a horizontal shaft mechanism is provided with a horizontal shaft body,the inside of the horizontal shaft body is provided with a main shaft of the horizontal shaft mechanism, and the end head of the main shaft is provided with a horizontal shaft tightening end head which is matched with the tightening mechanism; the bottom end of the main shaft of the upright shaft mechanism is provided with a bottom plate, the bottom plate is connected with a hanging jaw, and the inner side of the hanging jaw is matched with an inclined hanging face on the upright shaft body; the outer side of the upright shaft body is provided with a piston, one side of the piston is connected with an abutting hanger body which is matched with the hanging jaw, the inner side of the end part of the abutting hanger body is provided with inner hangers which are inwards arranged at intervals,and the other side of the piston is provided with a spring; an upright shaft combination tooth is fixed on the end surface of the upright shaft body; the end part of the horizontal shaft body is provided with a horizontal shaft tightening component provided with end hooks, and the end hooks are matched with the inner hangers; and the end part of the horizontal shaft body is fixed with a horizontal shaft combination tooth which is matched with the upright shaft combination tooth and a horizontal shaft inner tooth which is matched with a horizontal shaft rotation tooth fixed on the main shaft of the horizontal shaft mechanism. The invention can carry out upright and horizontal exchange, is timesaving and laborsaving and has high work efficiency and low processing cost of a workpiece.

Owner:DALIAN HUAGEN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com