Automatic switching device for bottom-loading balance weights

An automatic exchange and dish-loading technology, which is applied to measuring devices, instruments, weighing, etc., can solve the problems of unrepeatable weight strength, high labor intensity, and turbulent airflow, so as to avoid manual weight exchange and improve measurement accuracy Degree, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

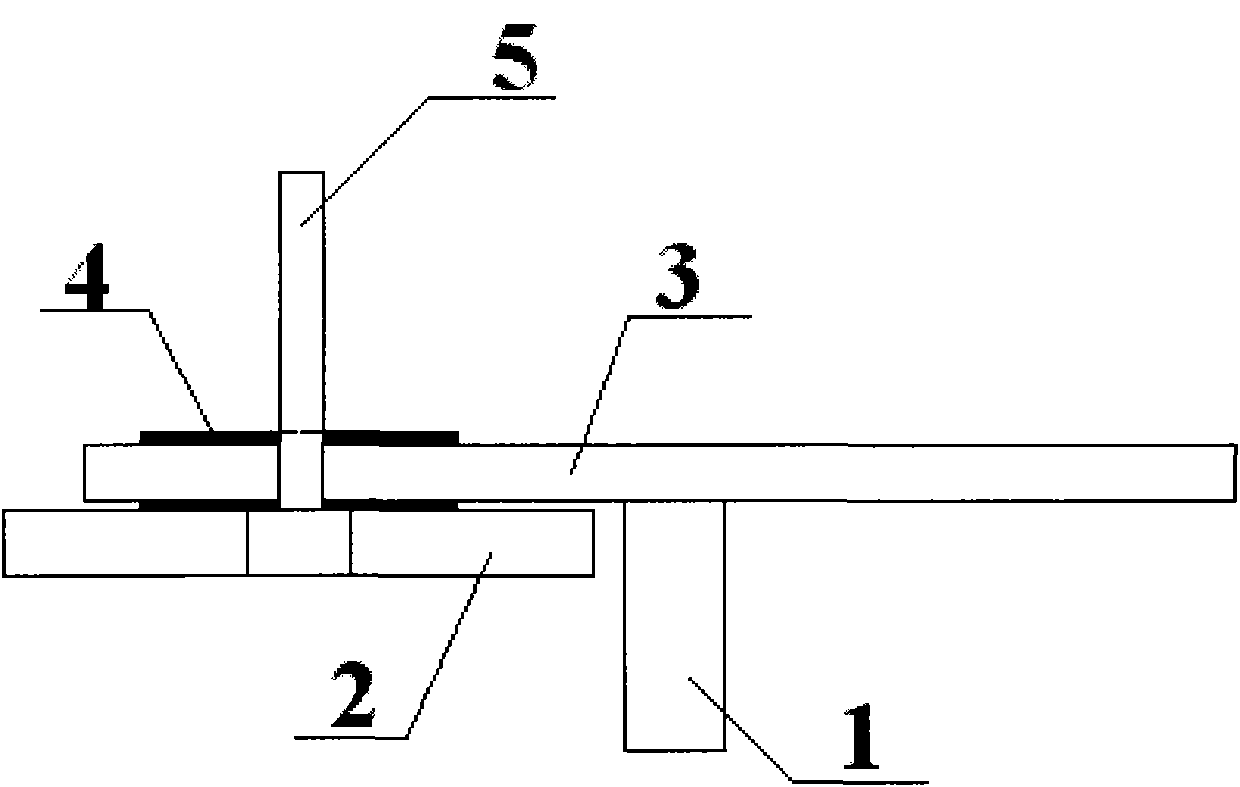

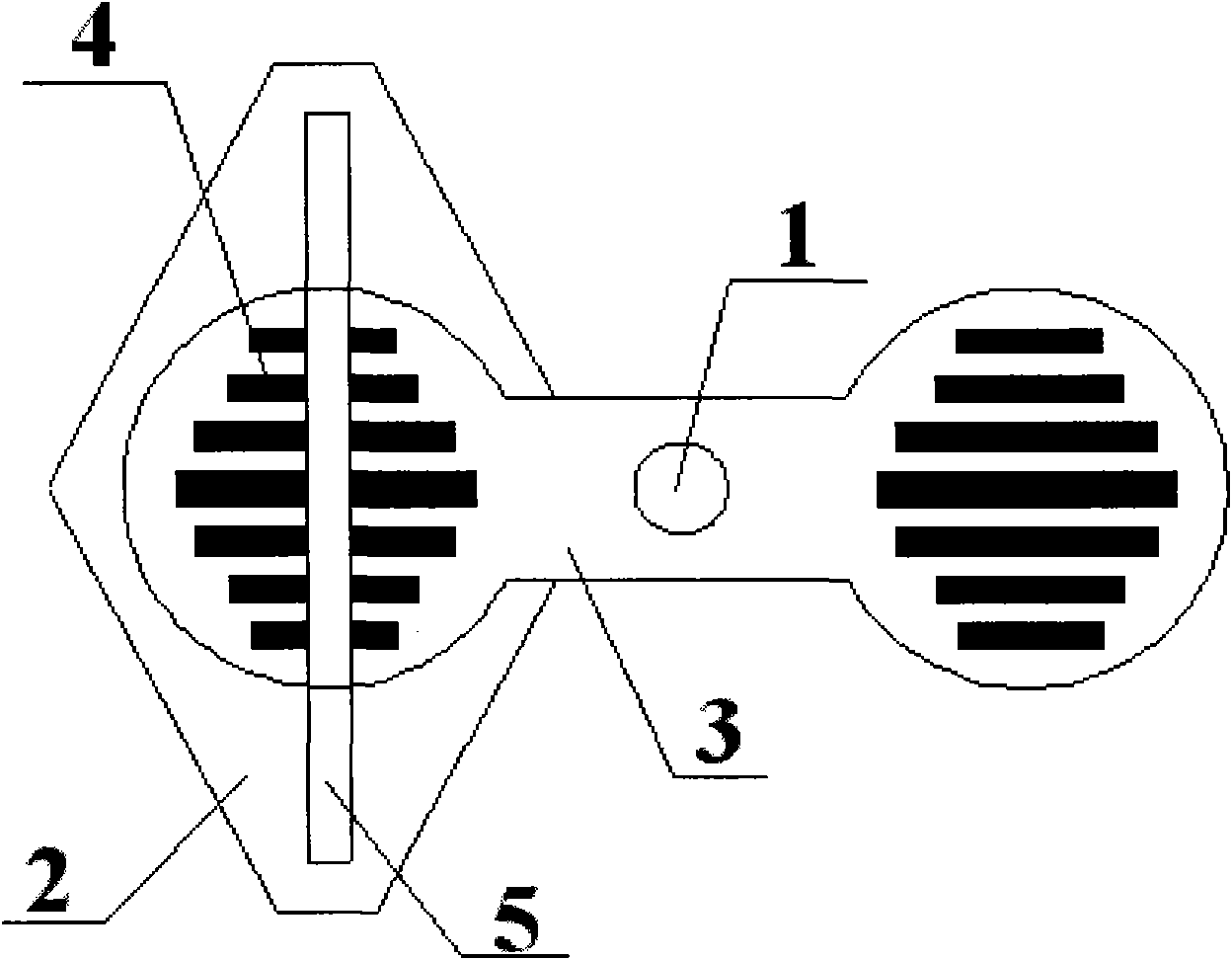

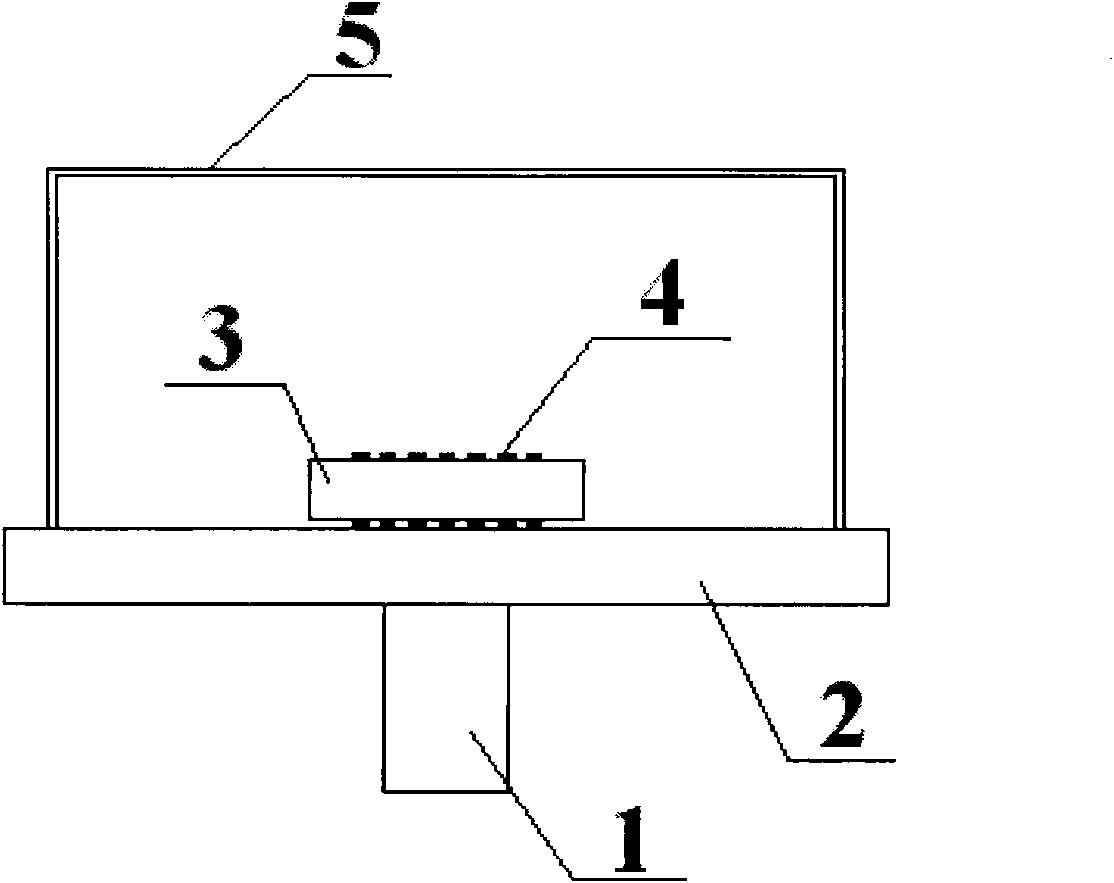

[0018] A kind of dish type balance weight automatic exchanging device of the present invention will be described in detail below in conjunction with accompanying drawings.

[0019] Such as figure 1 , 2 , Shown in 3 and 4, a kind of dish type balance weight automatic exchanging device of the present invention comprises turntable shaft 1, balance weighing pan 2, turntable 3, boss 4 and weighing beam 5. The turntable 3 is a rectangular stainless steel symmetrical structure in the middle of which two ends are identical discs. Below the center of symmetry of the turntable 3 is fixed a cylindrical stainless steel turntable shaft 1 with a smooth exterior. The lower part of the turntable shaft 1 is connected to a hydraulic drive device driven by a micro motor. Driven by the drive device, the turntable shaft 1 can slowly move up and down. Sliding, free and slow turning. Both ends of the turntable 3 are provided with seven rectangular through slots 6 of different sizes. Below a round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com