Upright and horizontal automatic exchange and automatic rotary type main shaft head

A technology of automatic exchange and automatic rotation, applied in the direction of driving devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of time-consuming and laborious, and achieve the effect of improving work efficiency and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

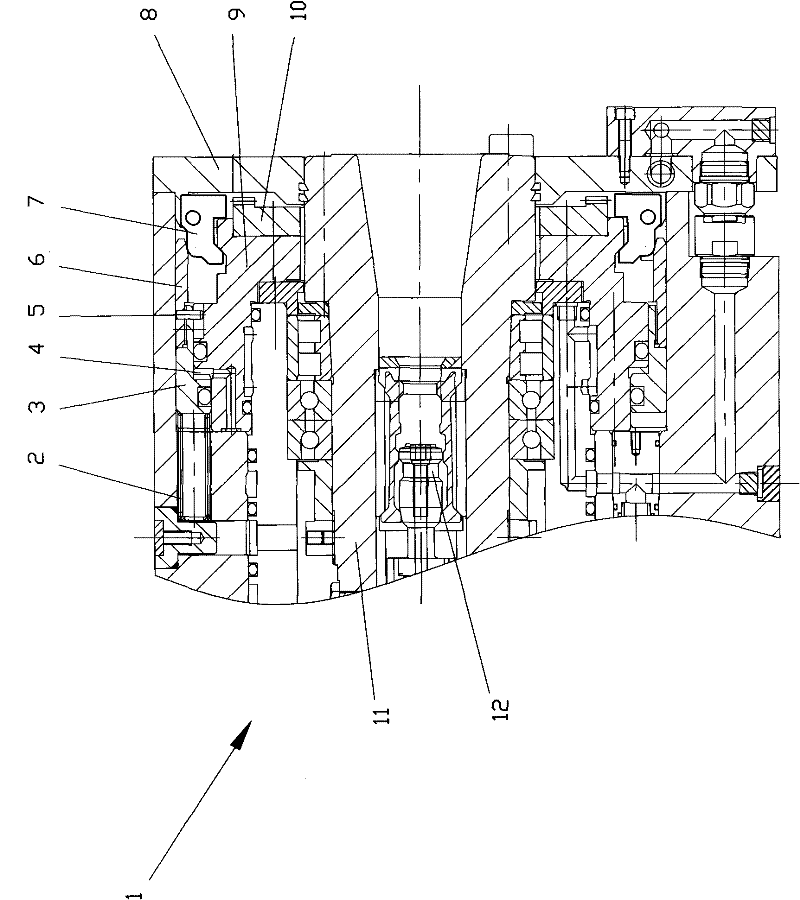

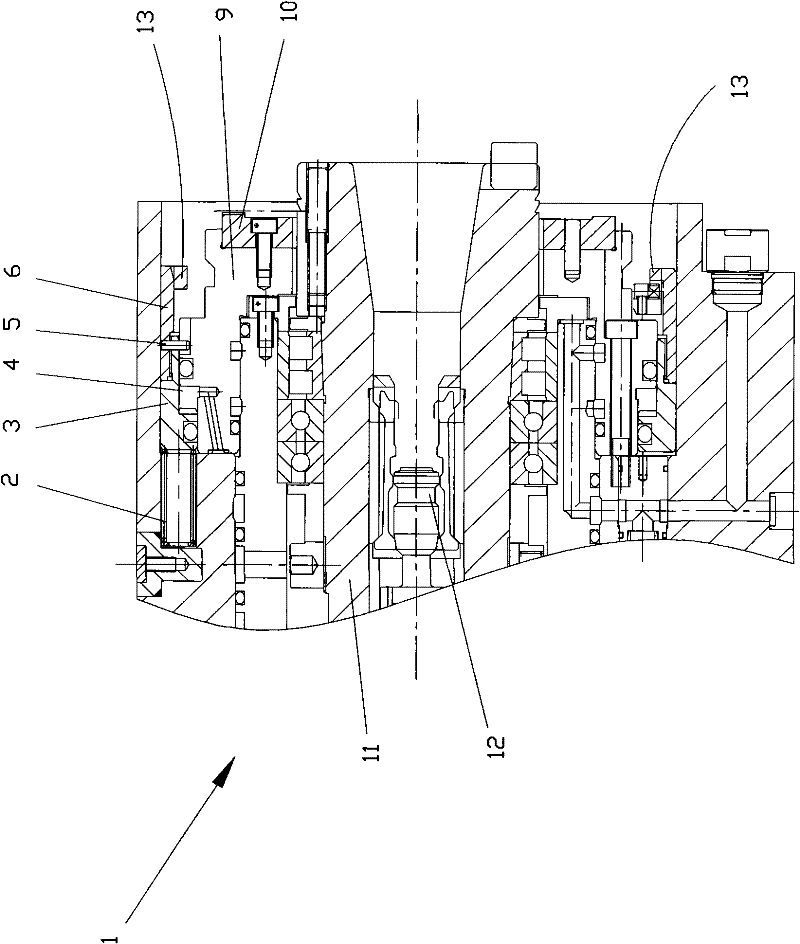

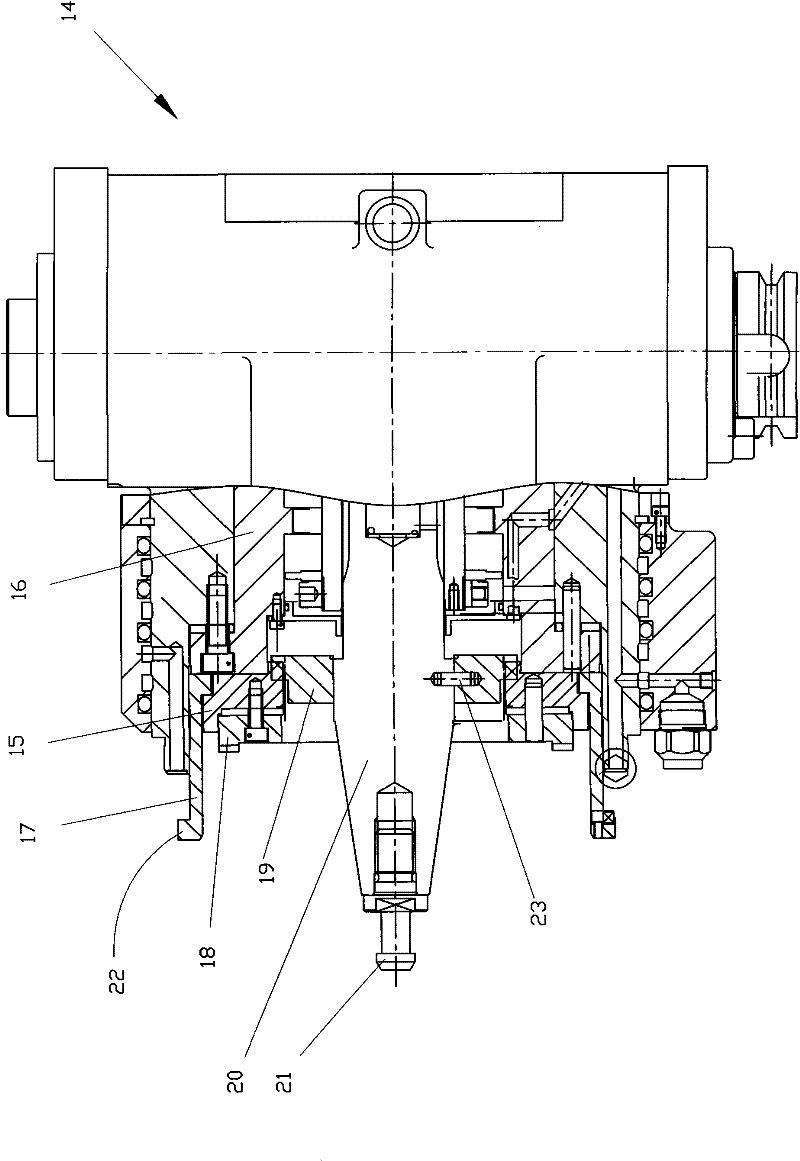

[0020] like figure 1 , 2 Shown: 1 is vertical shaft mechanism, vertical shaft body 9 is arranged in vertical shaft body 1, vertical shaft mechanism main shaft 11 is installed by bearing in the inboard of vertical shaft body 9, tensioning mechanism 12 is installed at the inner hole place of vertical shaft mechanism main shaft 11. The bottom inner hole of the main shaft 11 of the vertical shaft mechanism is tapered, and is used for combining with the main shaft in the tool holder or the horizontal shaft mechanism.

[0021] The bottom end of the vertical shaft body 9 is fixedly connected with a vertical shaft coupling tooth 10 by bolts, and the teeth portion on the vertical shaft coupling tooth 10 is arranged at the circumference near the outer side of the end surface.

[0022] Base plate 8 is sleeved at the bottom of vertical shaft mechanism main shaft 11, is connected with hanging claw 7 by rotating shaft on the side of base plate 8, and hanging claw 7 matches with the incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com