Patents

Literature

218results about How to "Installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

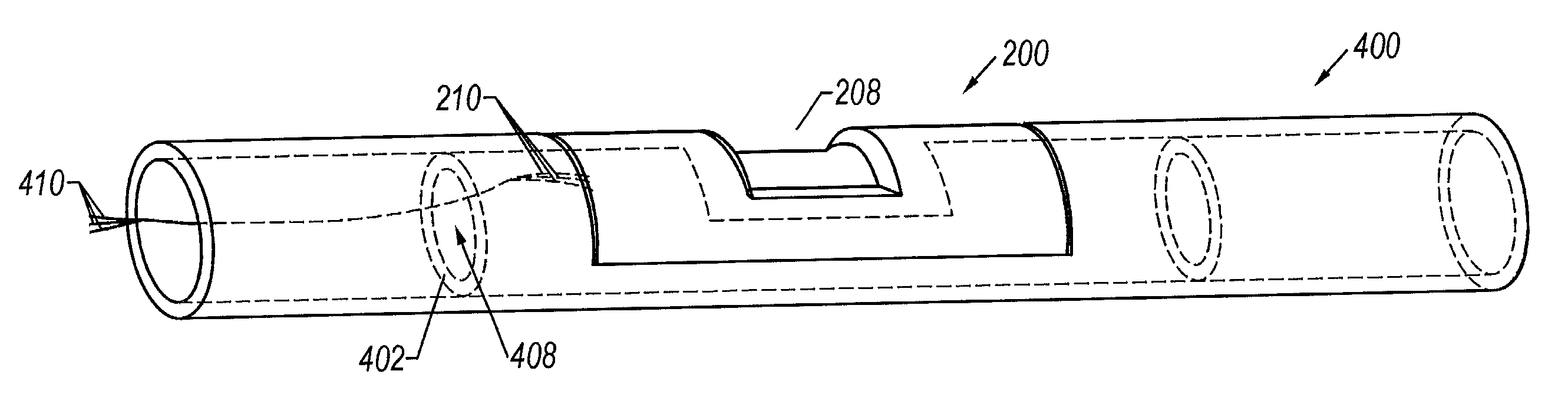

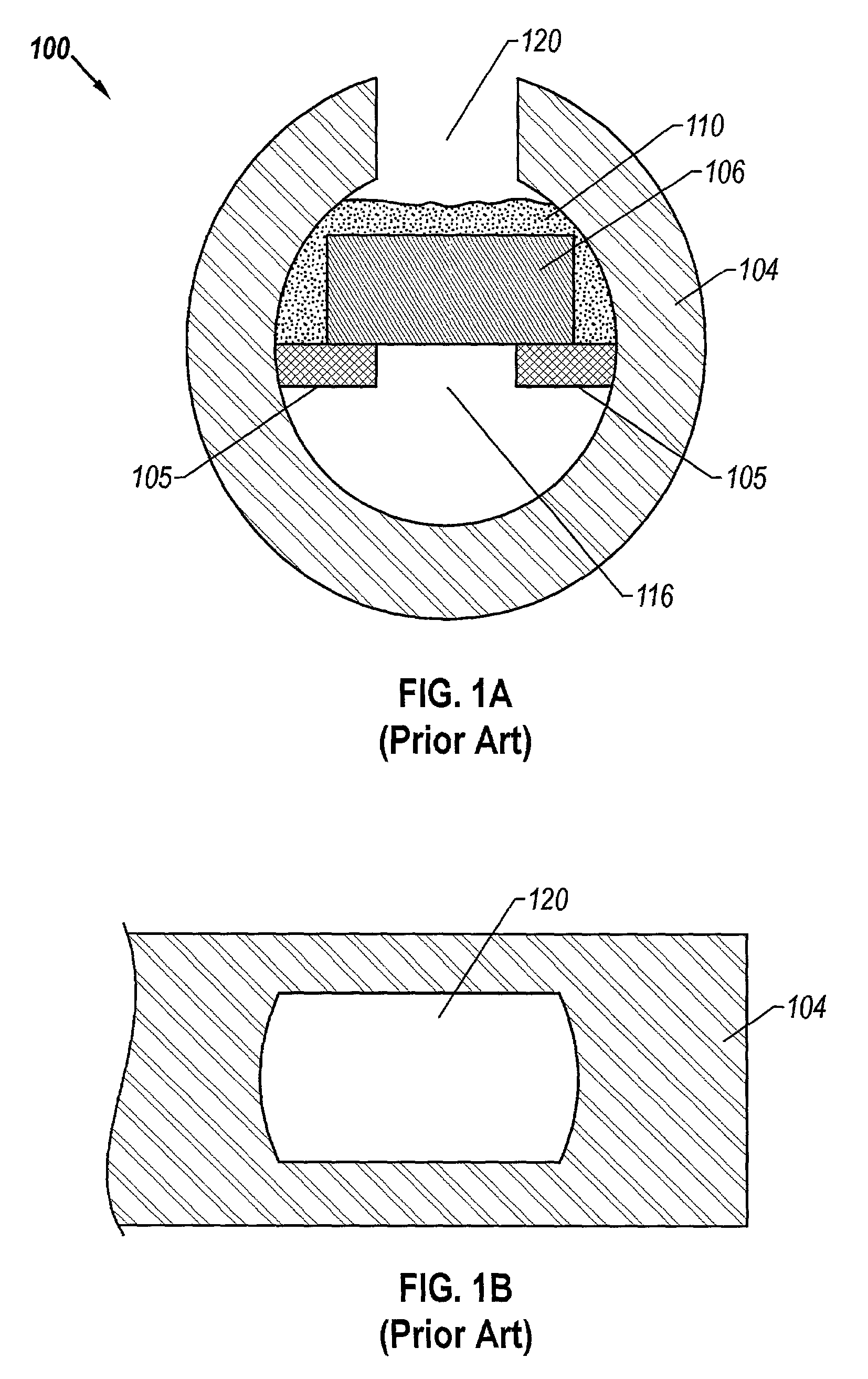

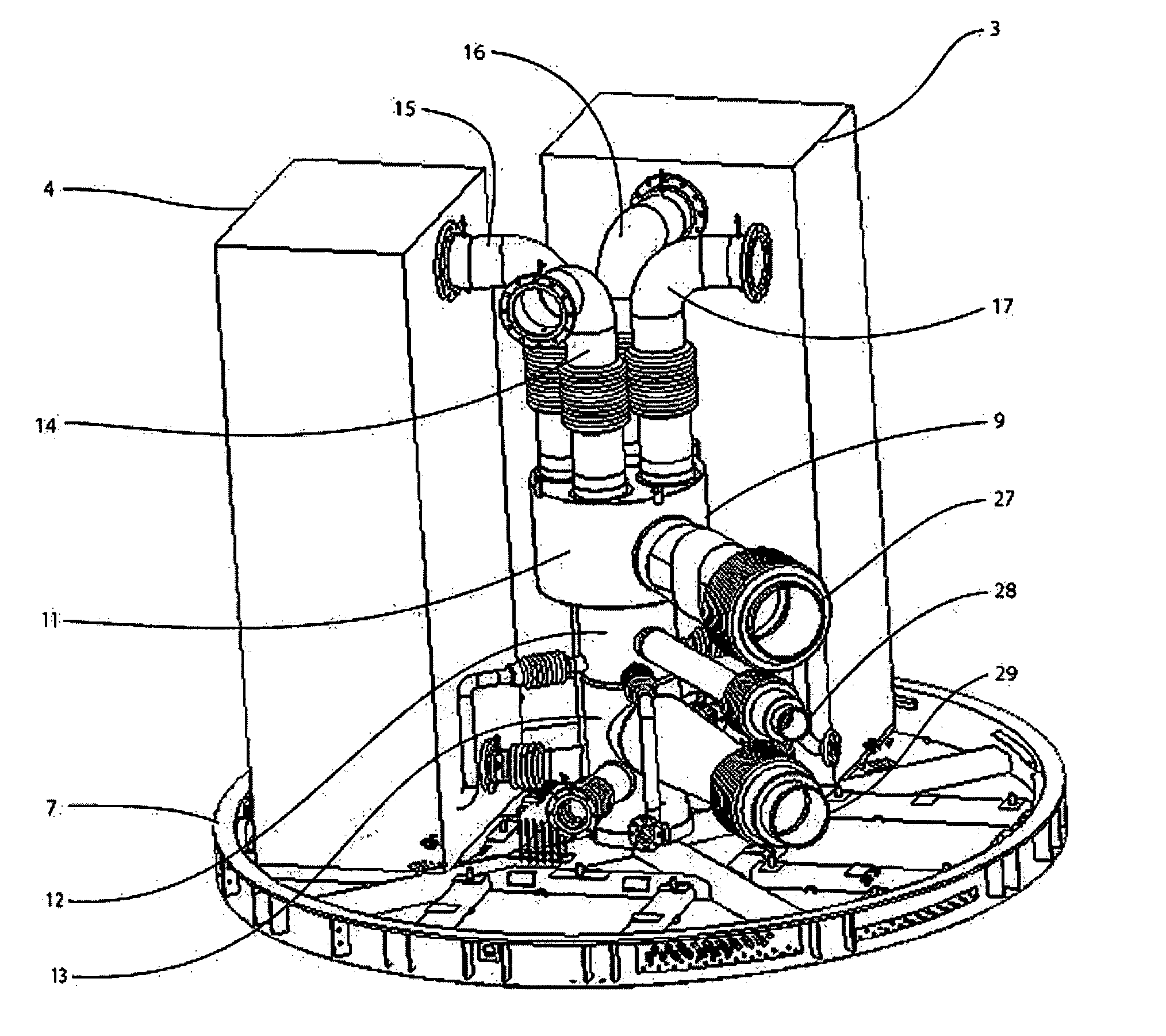

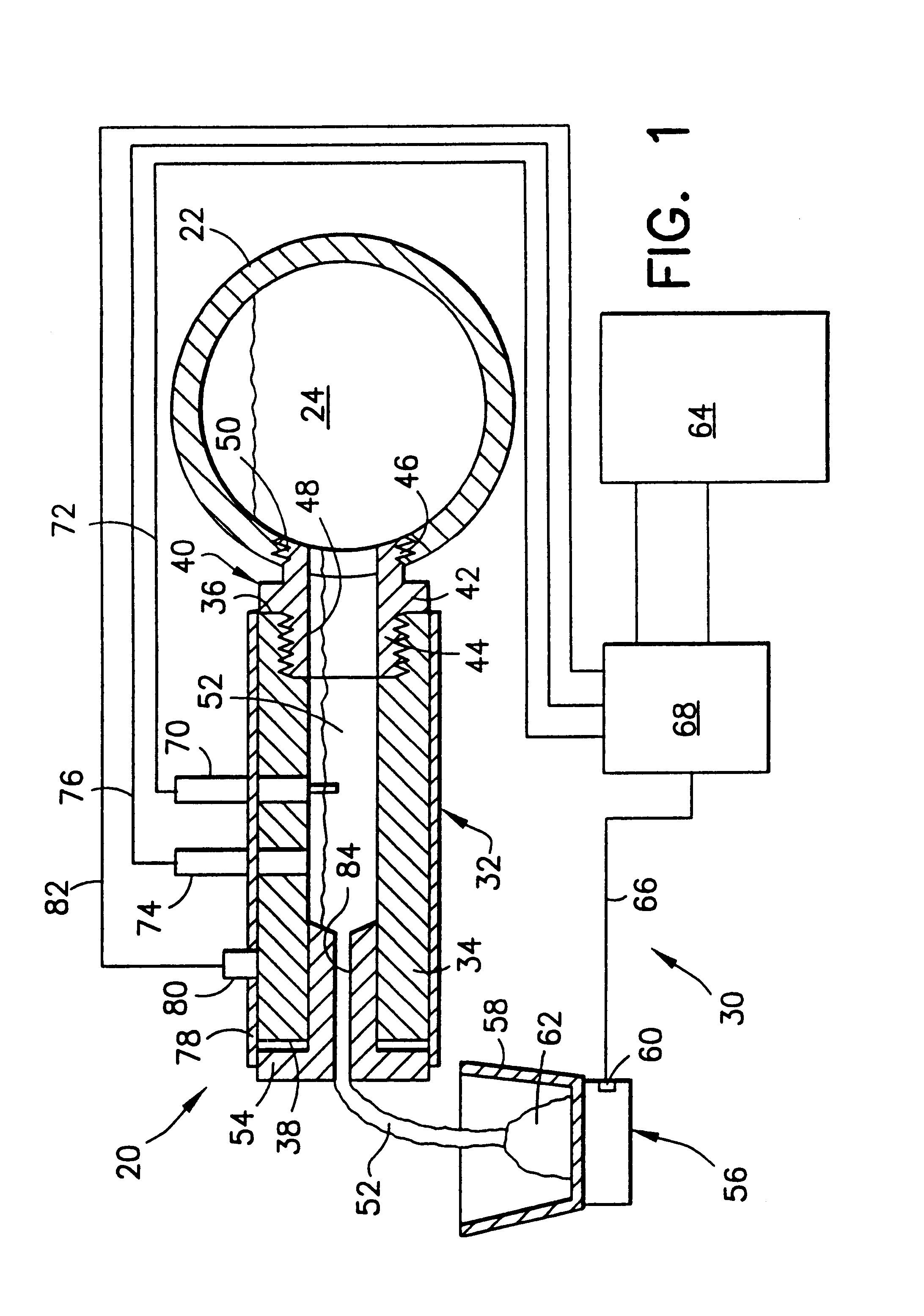

Catheter pressure transducer with pressure sensing module

InactiveUS6974422B1InstallationReduce manufacturing costCatheterDiagnostic recording/measuringTransducerPressure sense

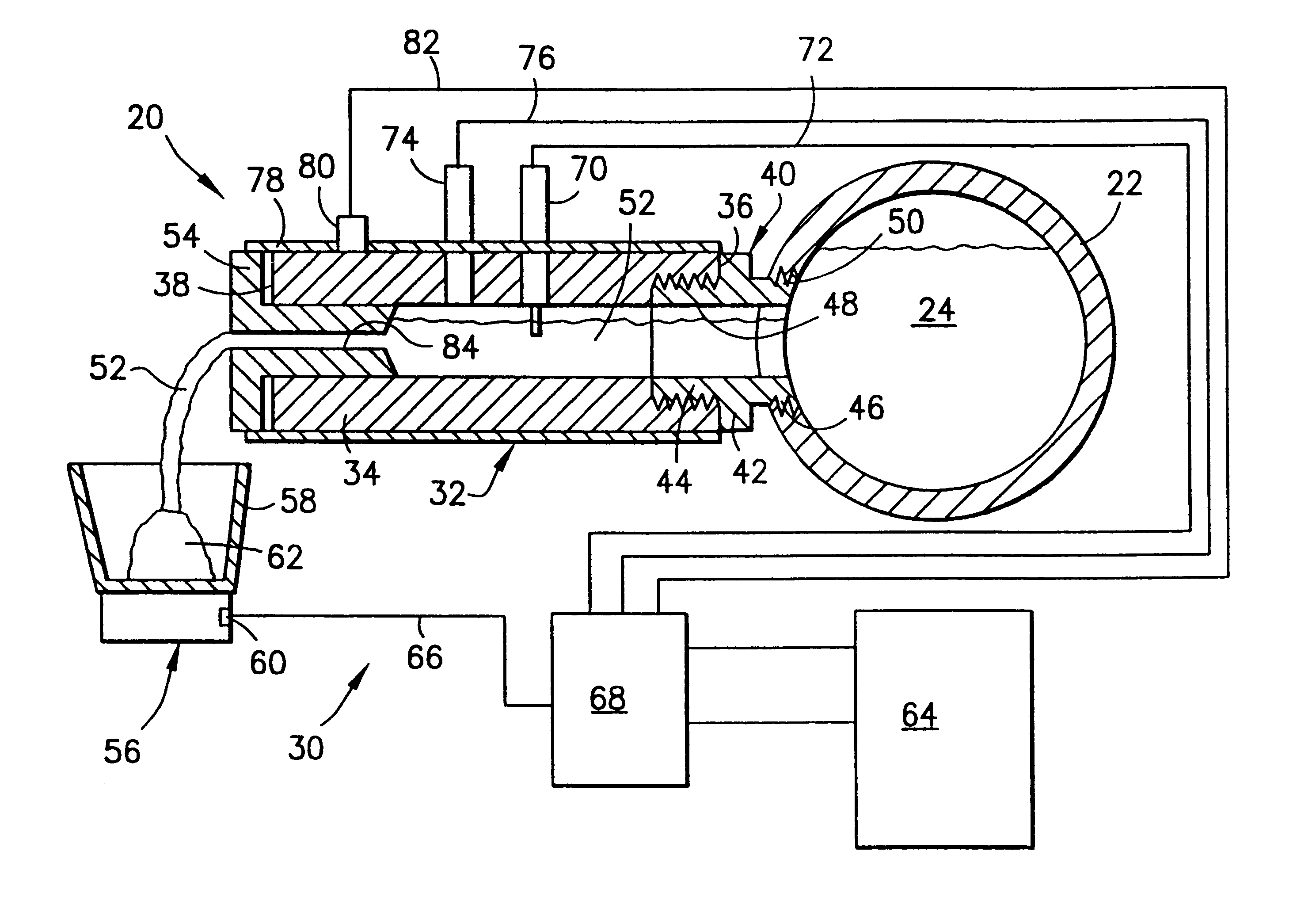

The present invention relates to a catheter pressure transducer having a pressure sensing module operable to provide a signal representative of pressure. The pressure sensor includes a sensing side and a pressure reference side. At least one signal transmission media is coupled to the sensor for transmitting the signal representative of pressure. A convex-shaped carrier is provided having a slot formed to expose the sensing side of the sensor. The convex-shaped carrier is adapted for receiving the sensor such that the sensing side of the sensor is adjacent the slot. A bonding material is provided for mounting the sensor to the carrier. The pressure sensing module provides ease of installation and manufacture because the module may easily be bonded and installed within a catheter.

Owner:MILLAR INSTR

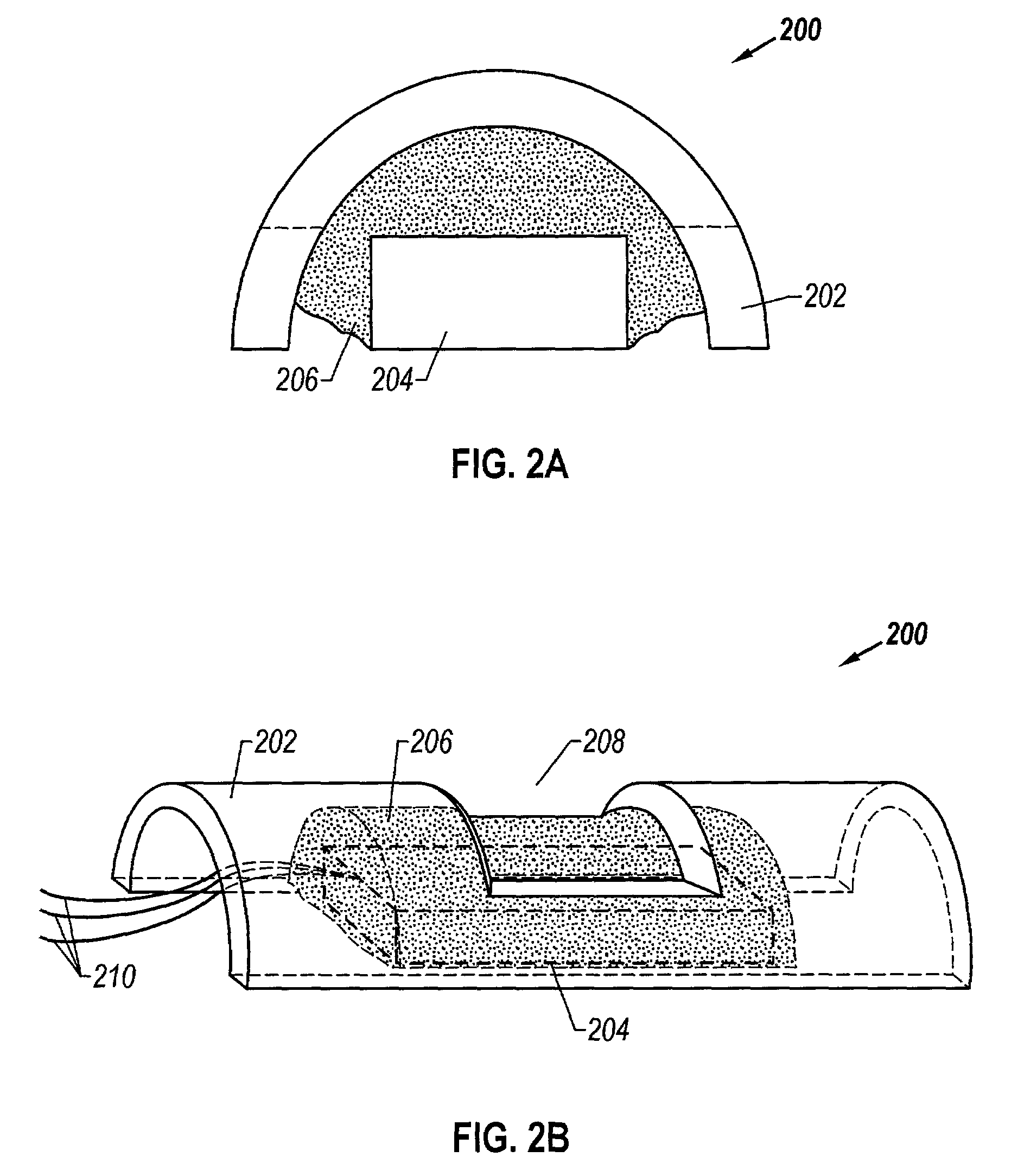

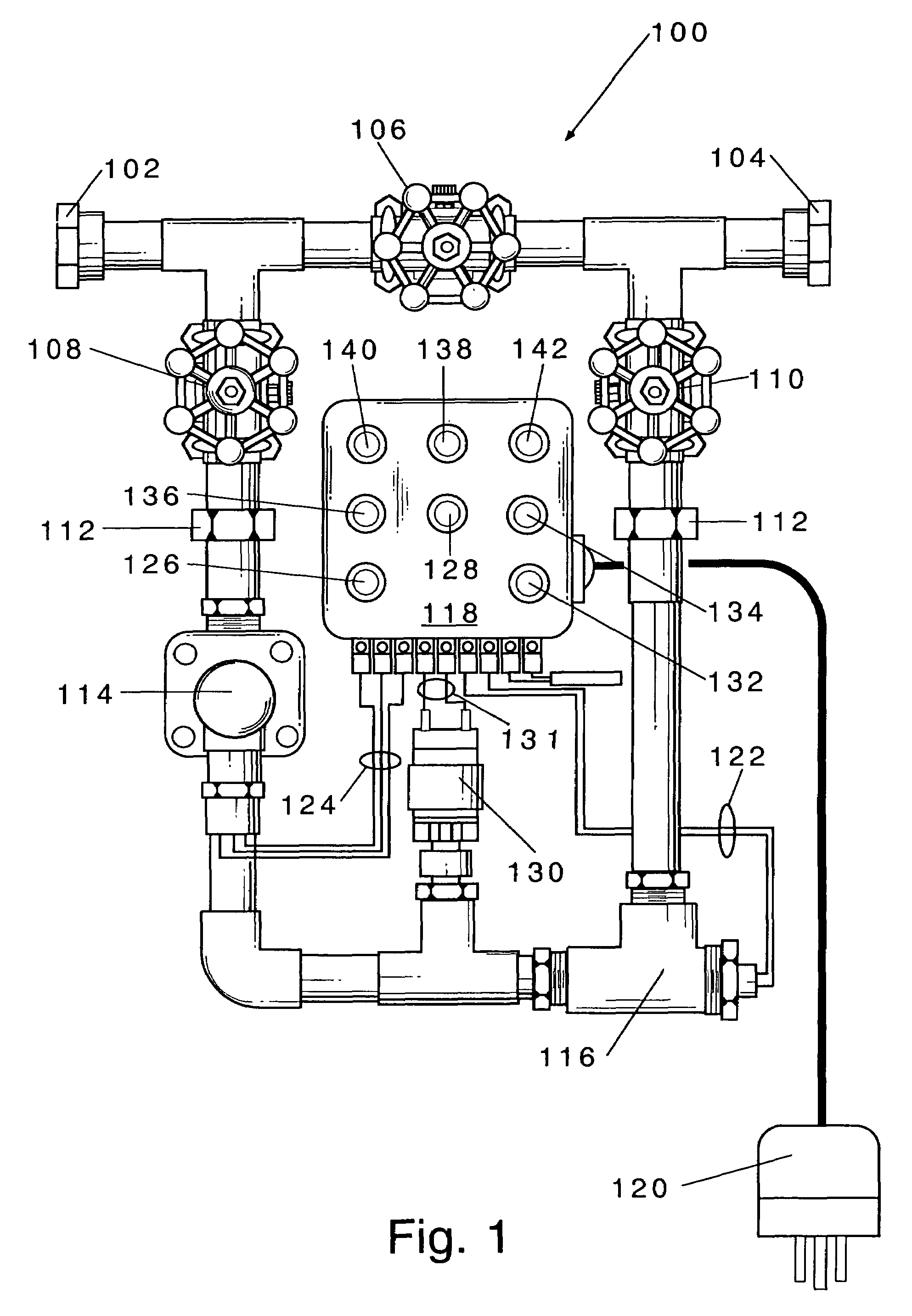

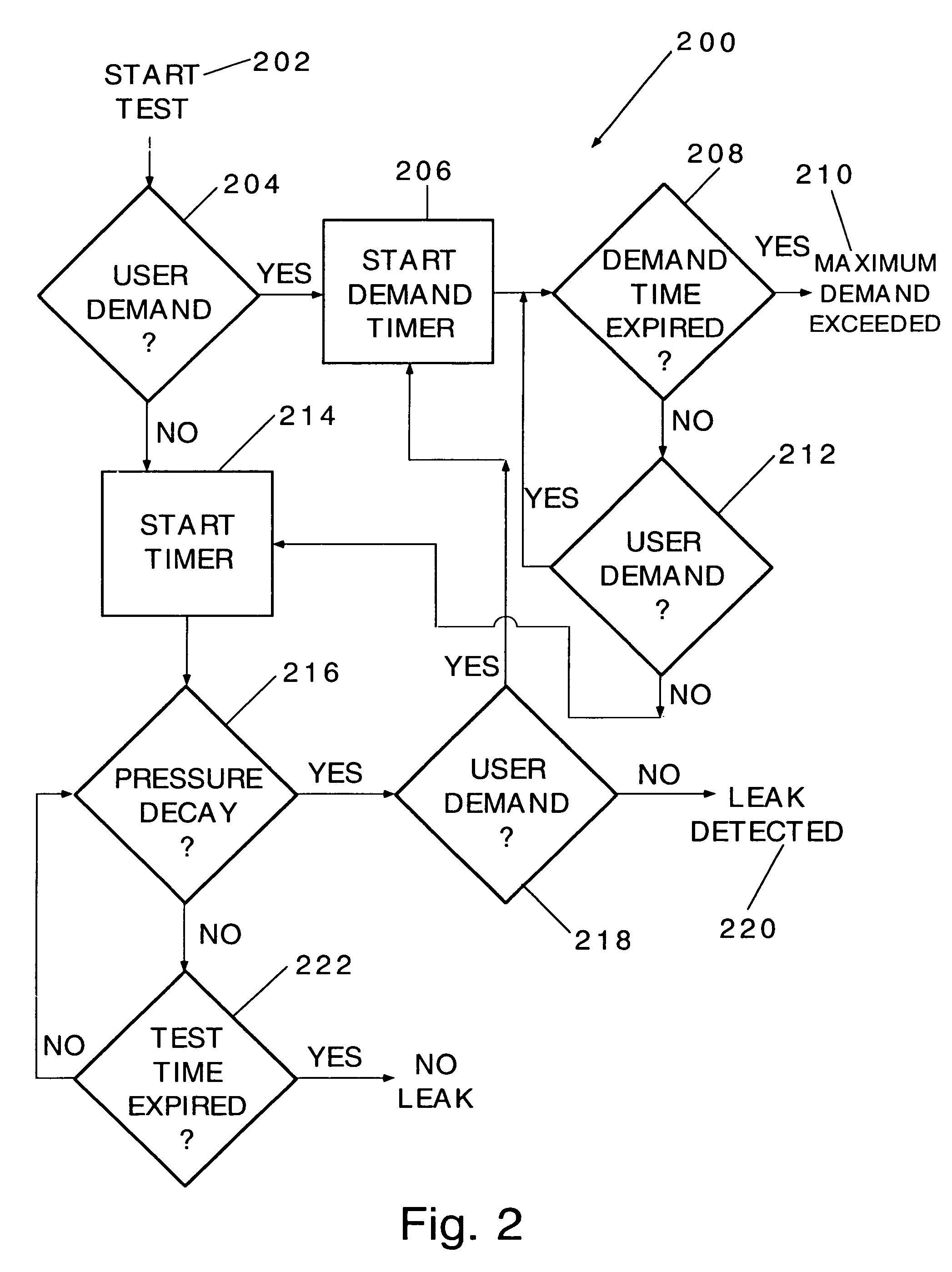

Leak detection and control

InactiveUS7574896B1Avoids complexity and uncertaintyImprove efficiencyMeasurement of fluid loss/gain rateRemote controlEngineering

Fluid leaks can be detected and controlled in a pressurized piping system. Apparatus for this includes control logic; in communication with the logic, a flow detector and / or a pressure detector, and a control valve. One or more of the following is or are provided also: the flow and pressure detectors are both present, and both as single units; the control logic, the flow and / or pressure detector(s) and the control valve are in close proximity to one another; and the control valve has a baseline condition of being shut off. A remote control device can remotely interact with the control logic. Pressure decay and / or flow properties can be employed. The fluid can be water as, for example, in a residential, commercial or institutional system.

Owner:MICHIGAN AGUA TECH

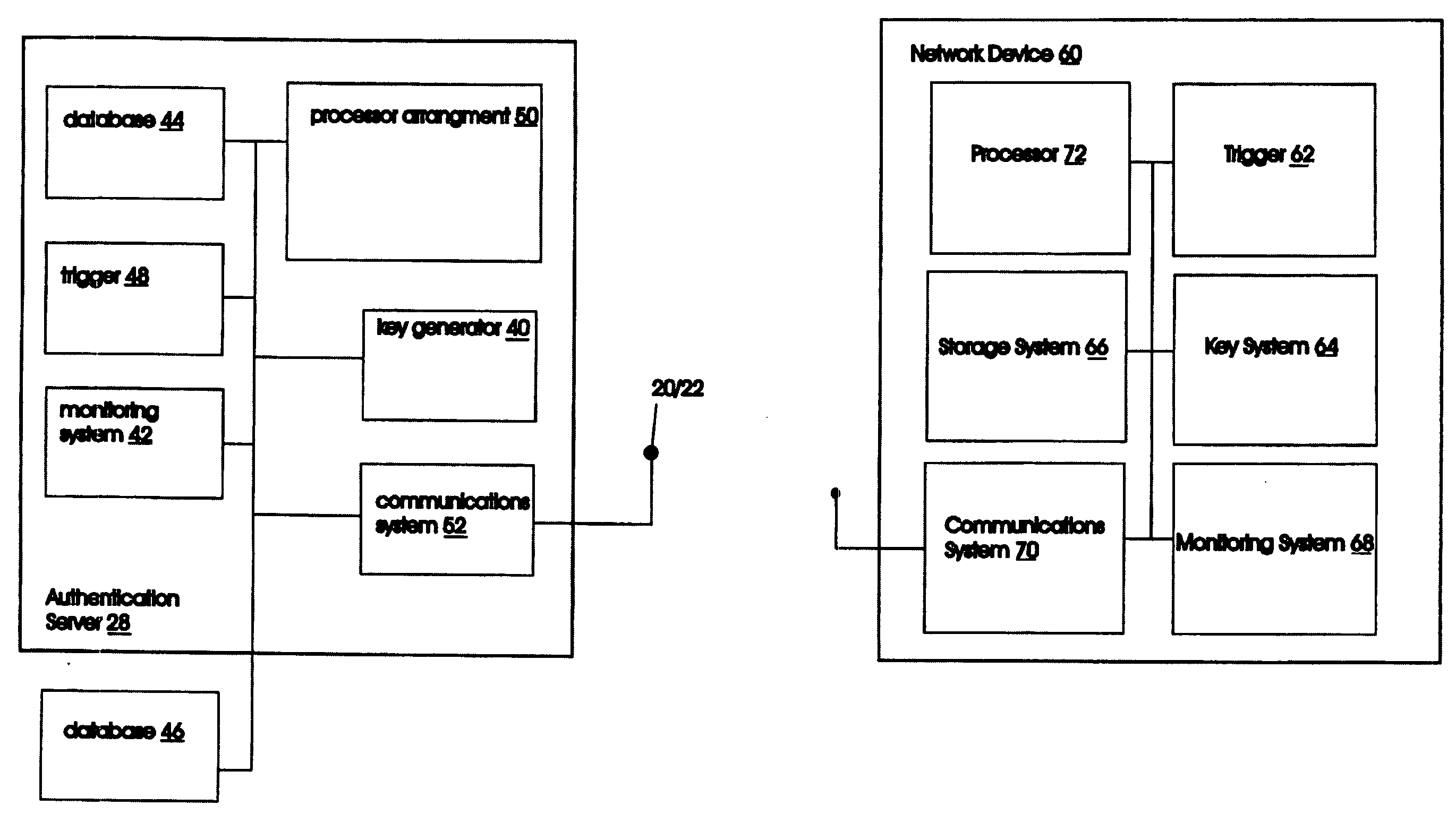

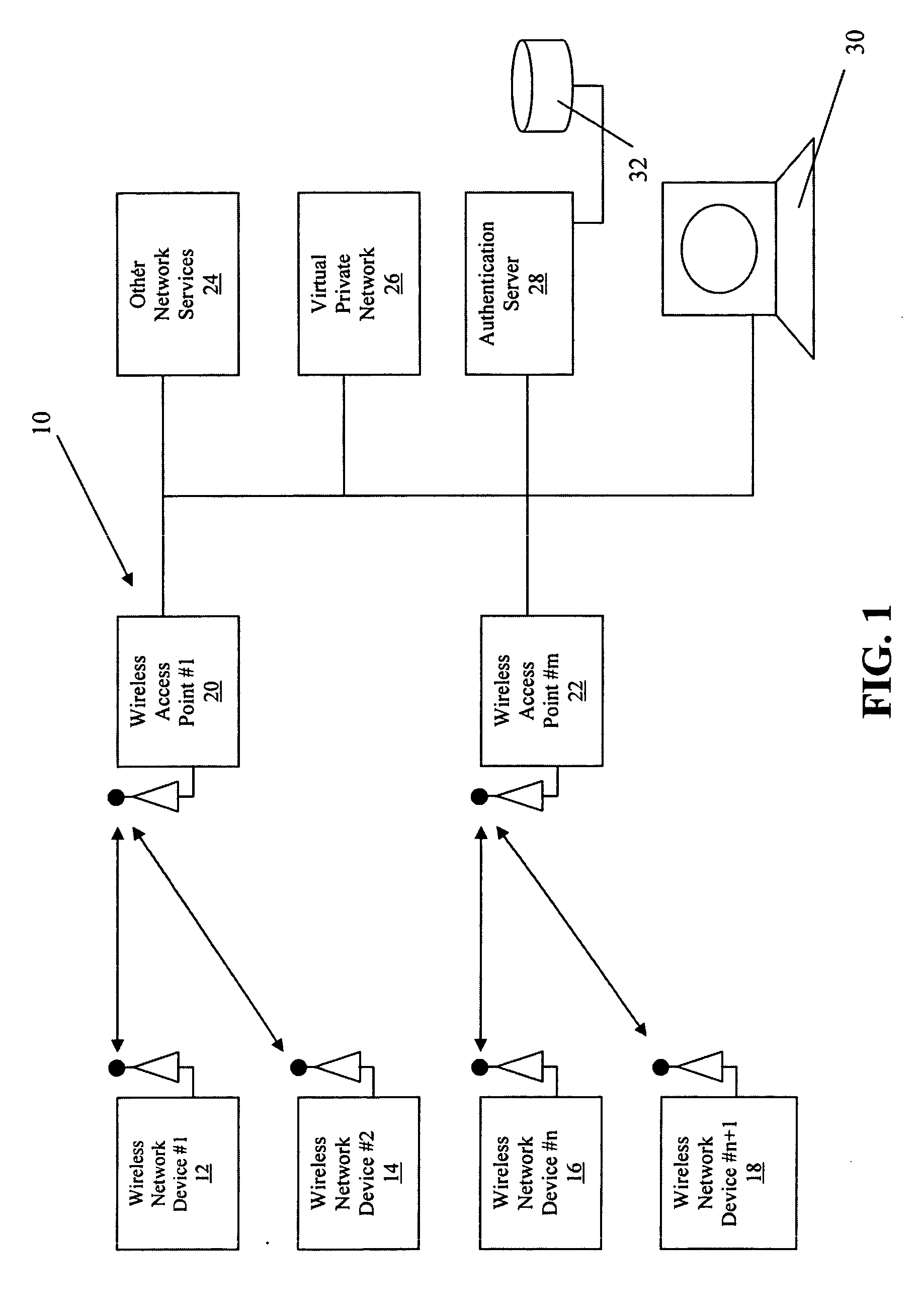

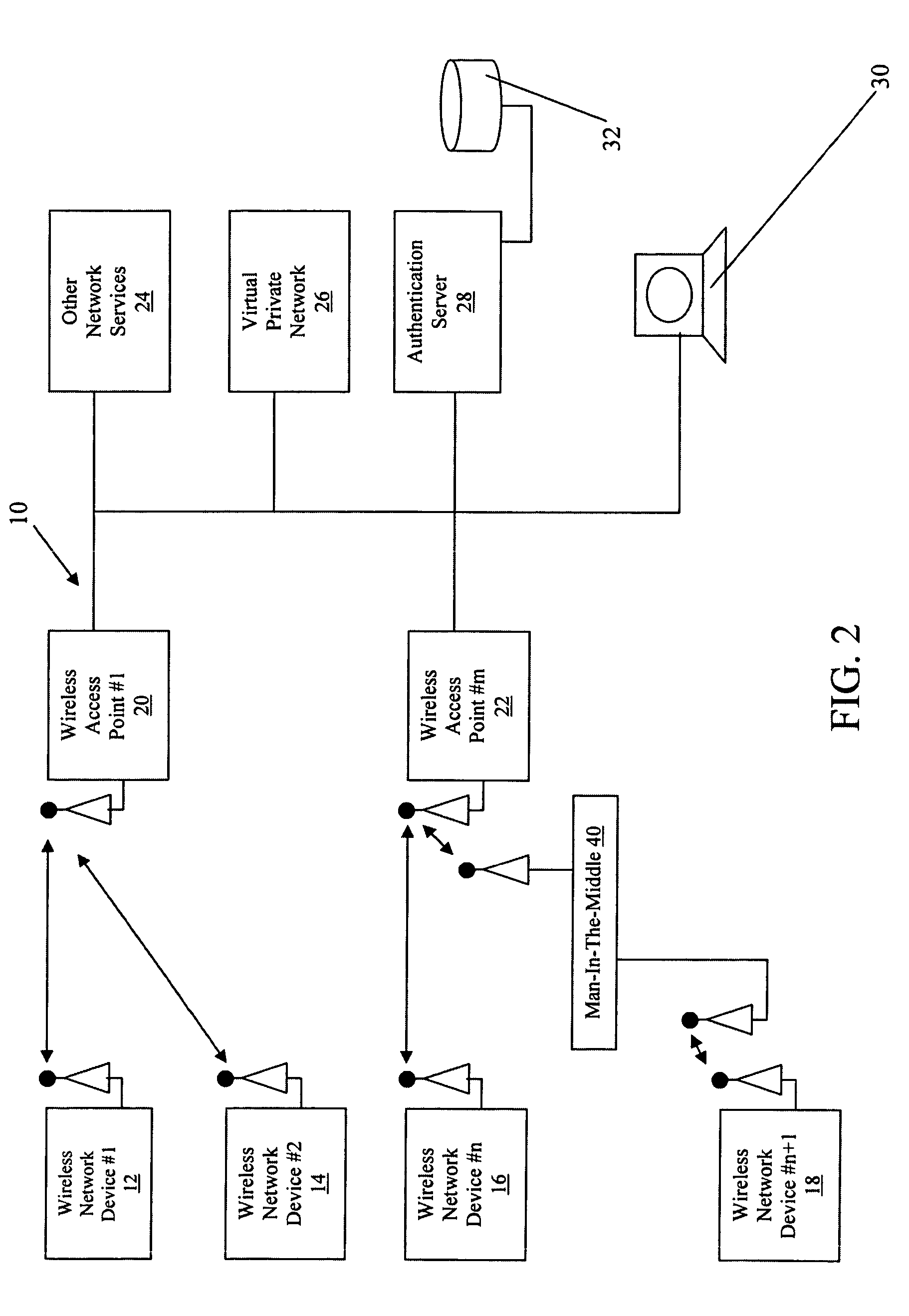

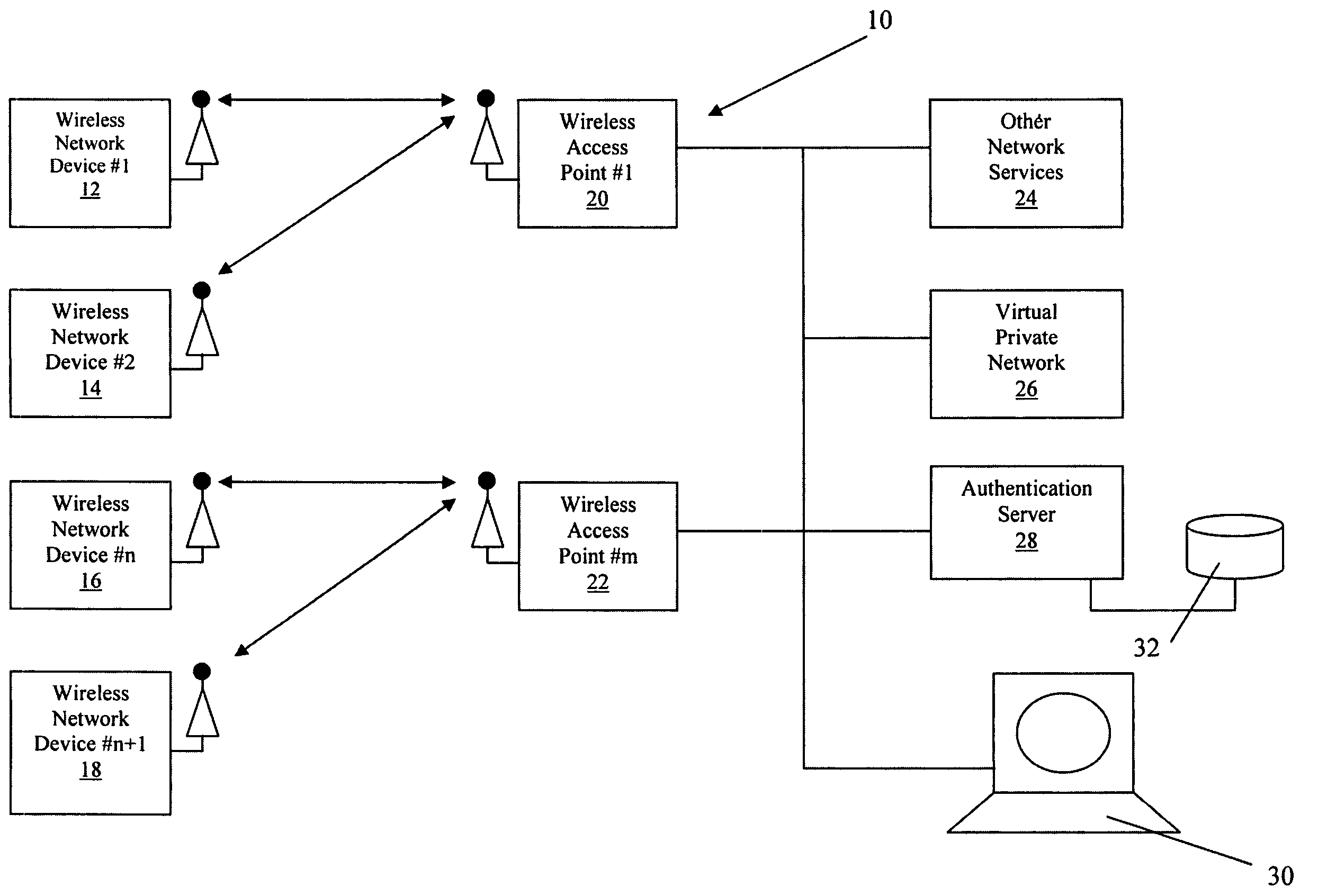

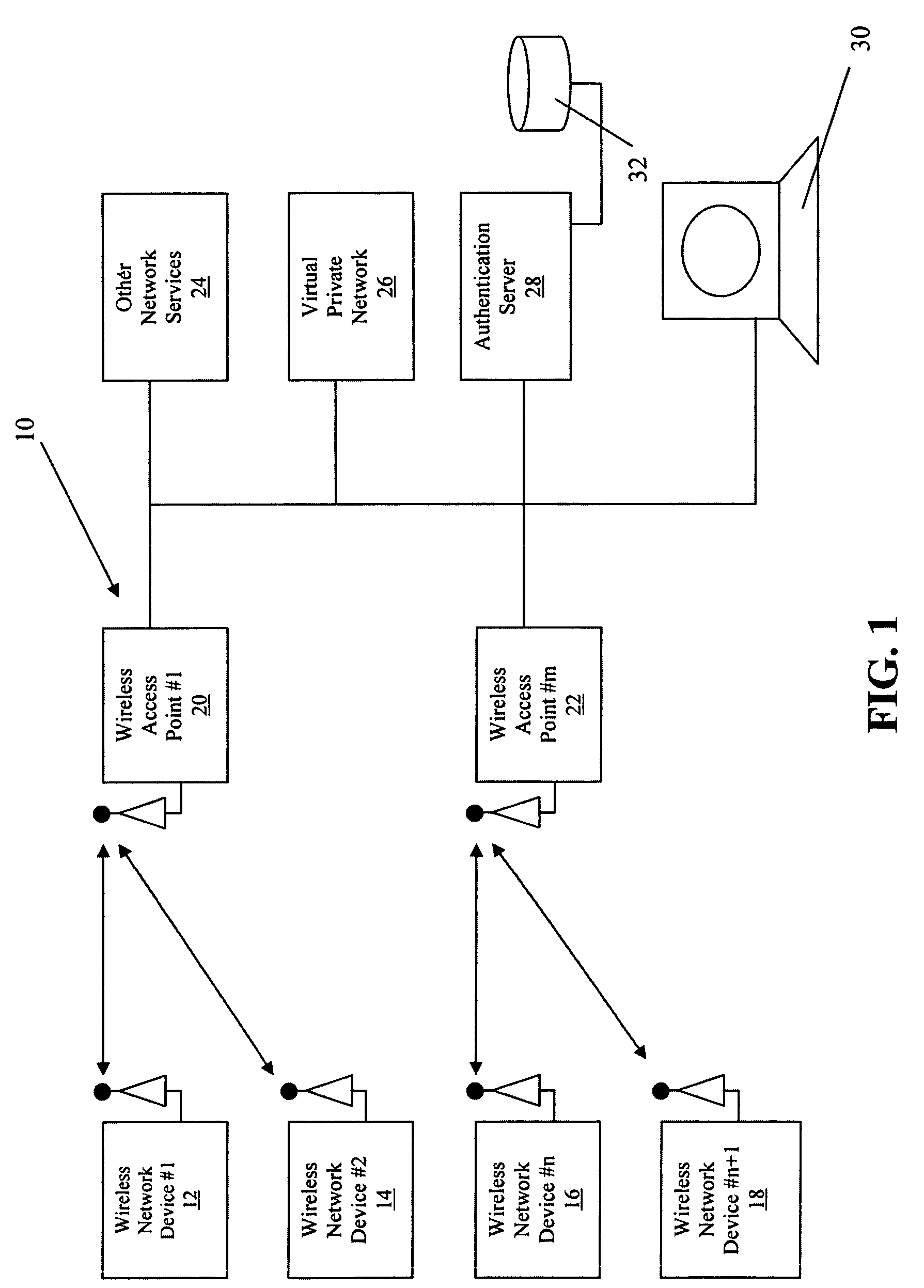

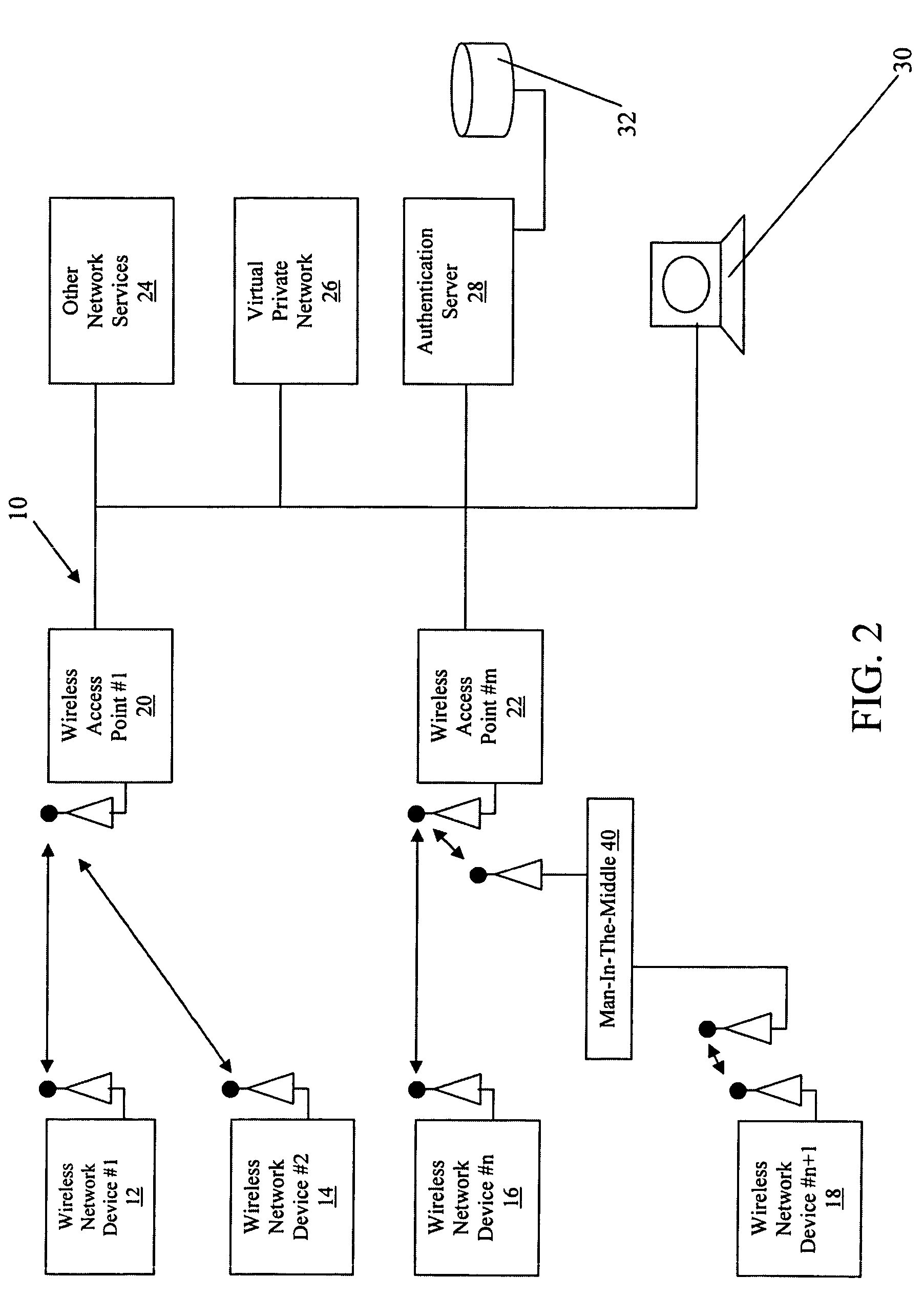

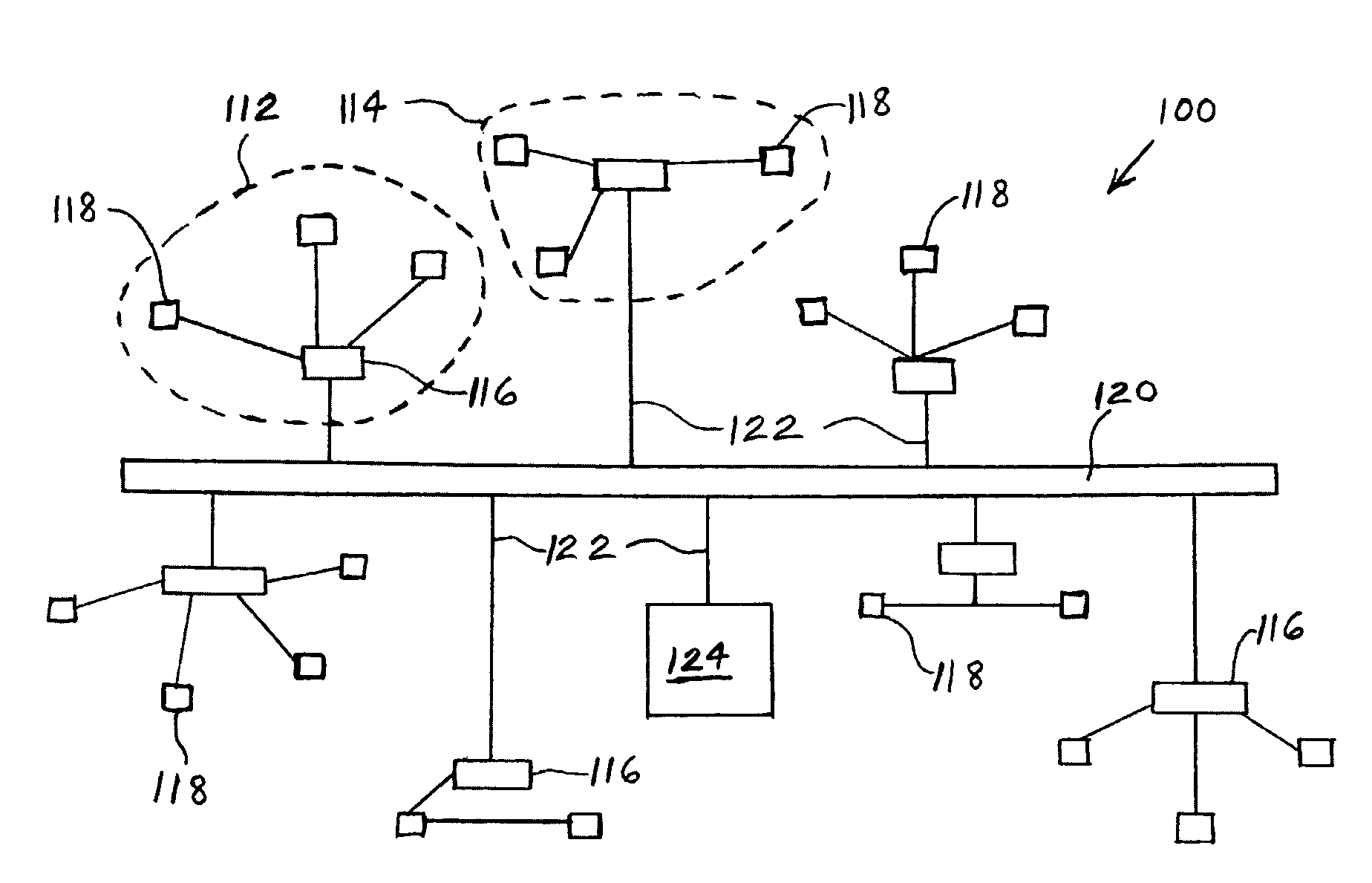

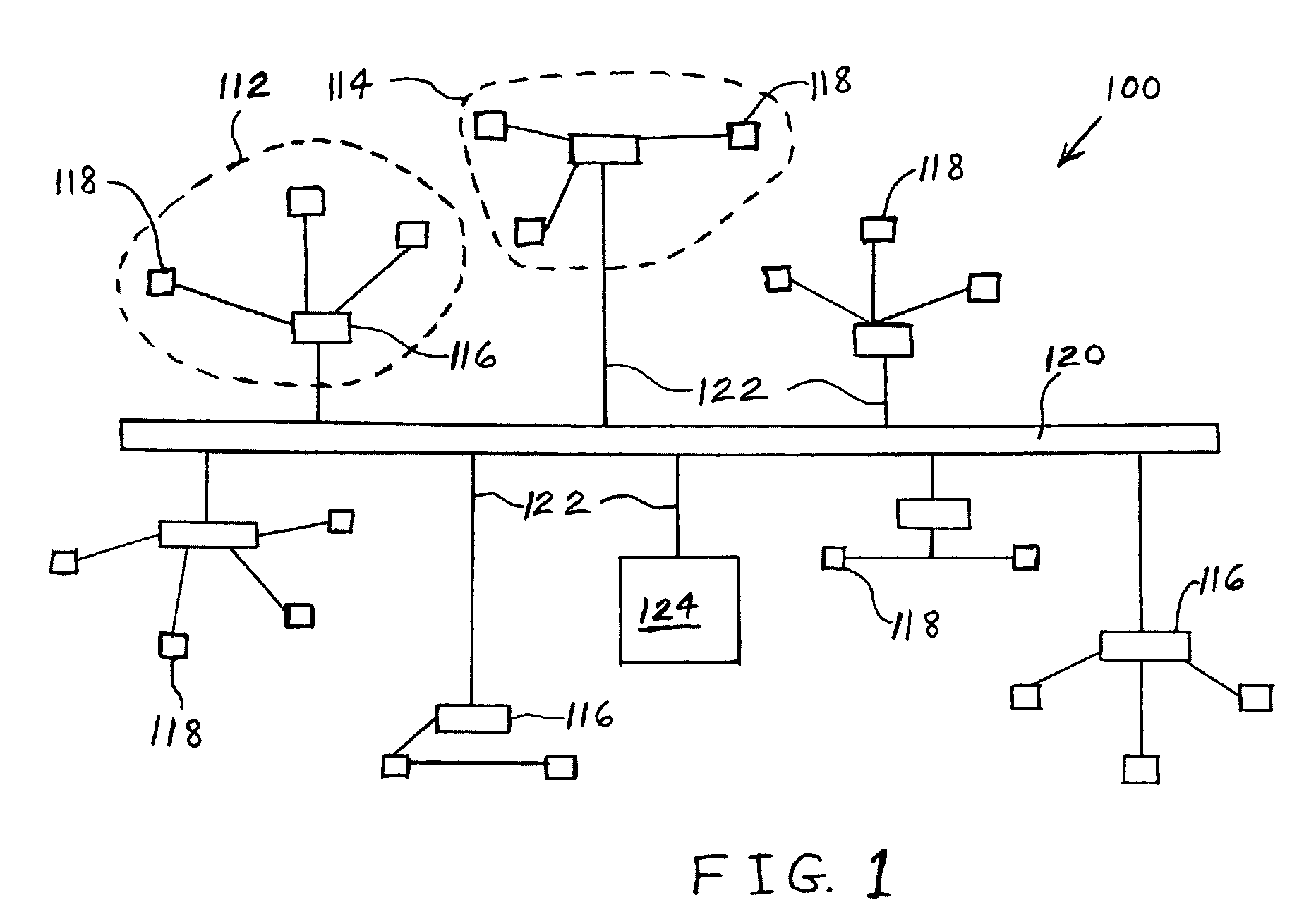

Enhanced shared secret provisioning protocol

InactiveUS20050010680A1Increase supplySimple processNetwork traffic/resource managementDigital data processing detailsWireless networkShared secret

An Enhanced Shared Secret Provisioning Protocol (ESSPP) provides a novel method and system for adding devices to a network in a secure manner. A registration process is launched at two network devices together within a predetermined time interval. These two devices then automatically register with each other. When two devices running ESSPP detect each other, they exchange identities and establish a key that can later be used by the devices to mutually authenticate each other and generate session encryption keys. With ESSPP, two ESSPP devices that are attempting to register with each other will only provision a key when they detect that they are the only two ESSPP devices on the wireless network running ESSPP. If additional devices running ESSPP are detected, the ESSPP protocol is either terminated or suspended.

Owner:MICROSOFT TECH LICENSING LLC

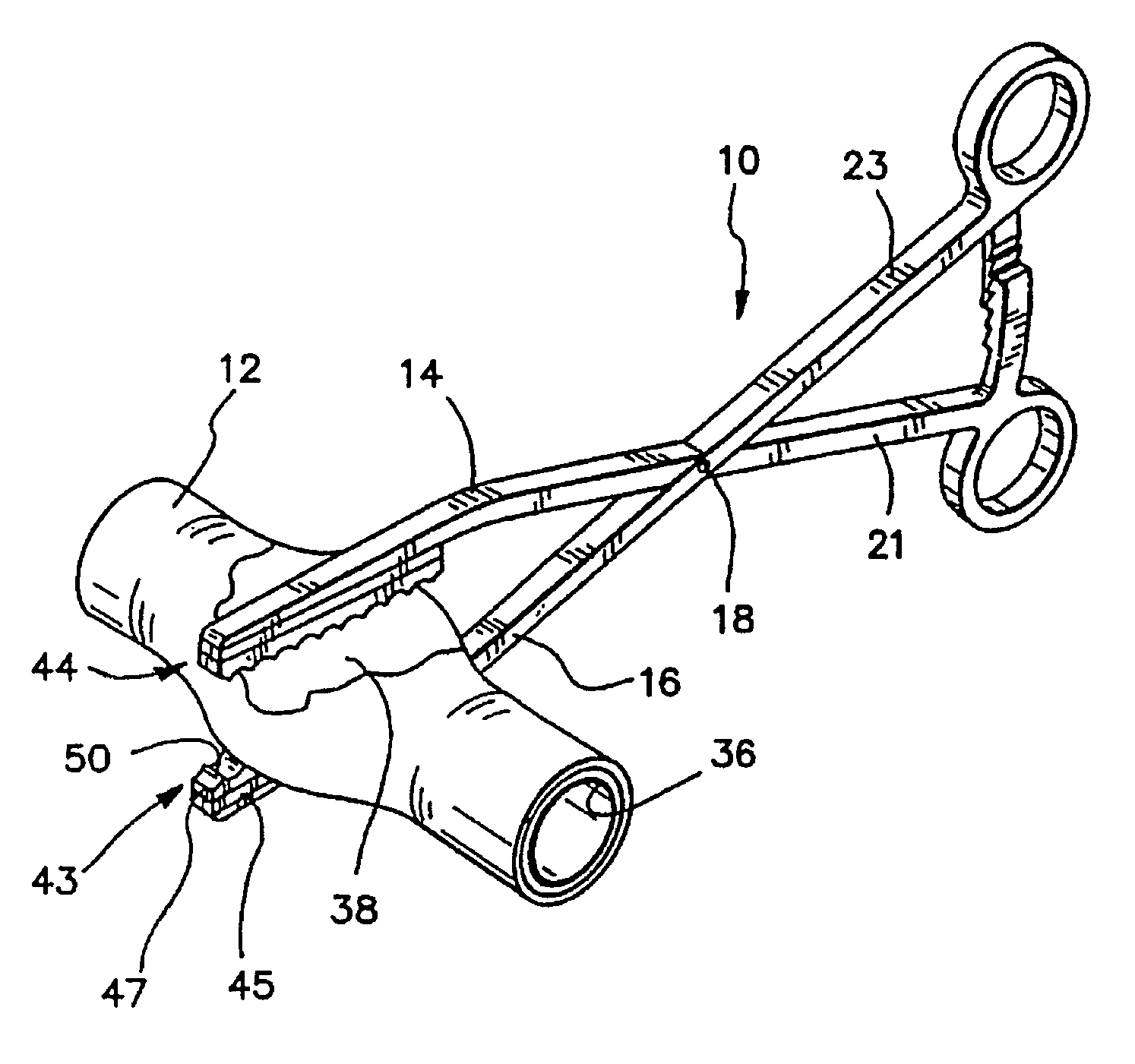

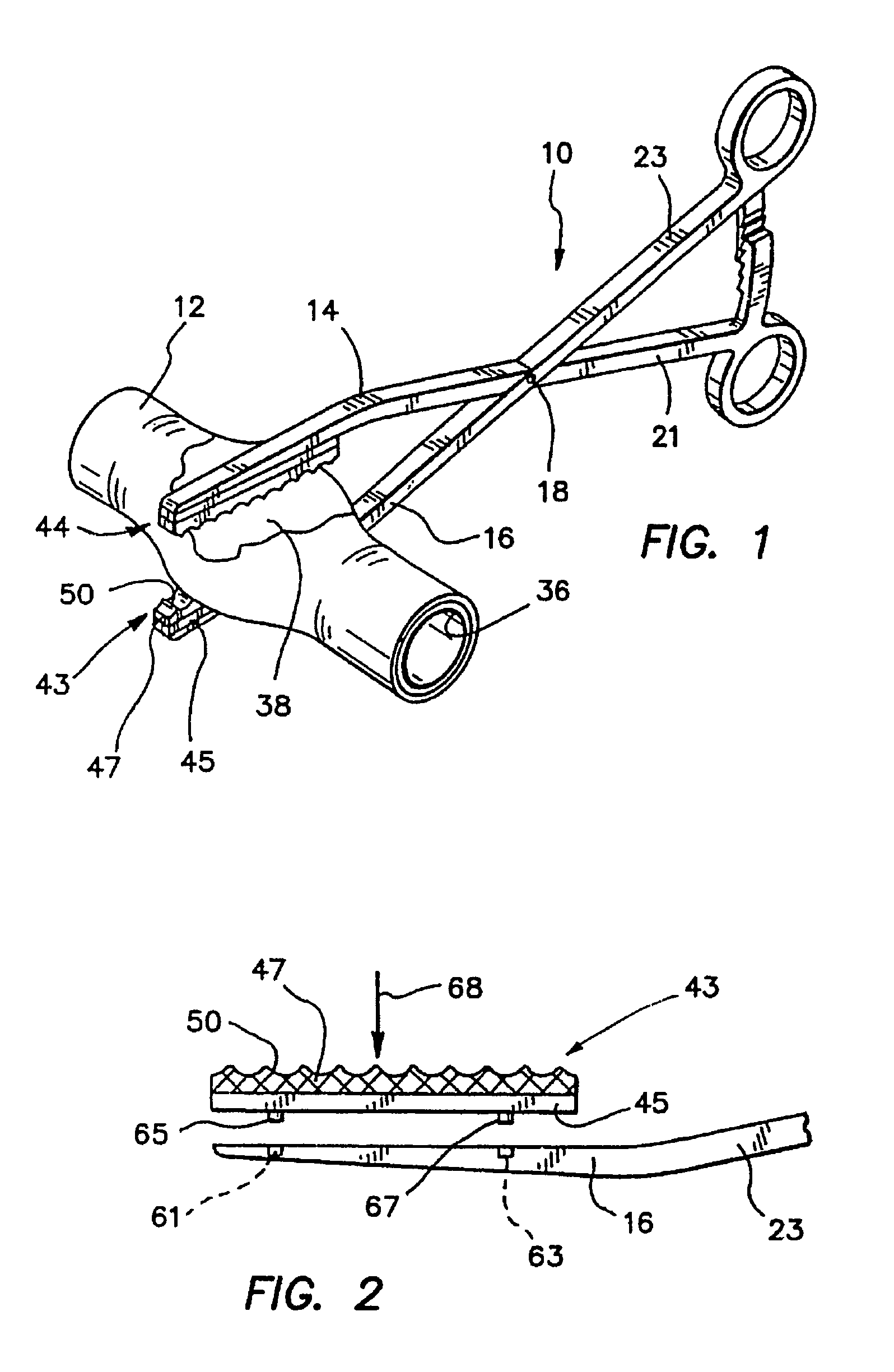

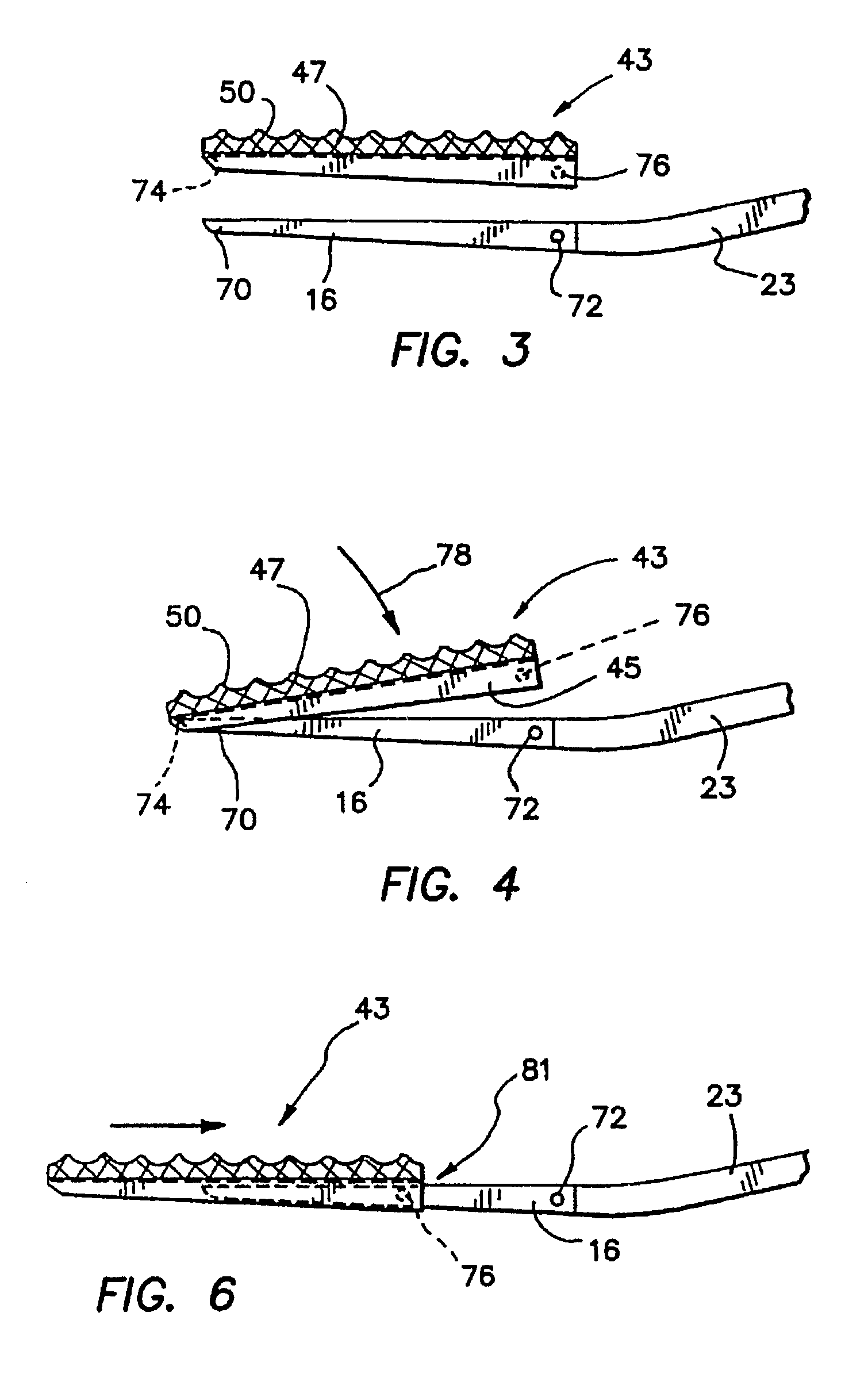

Peripheral vascular occlusion devices

InactiveUS20050240219A1Minimize trauma during surgeryInstallationSurgical forcepsWound clampsSurgery procedureBlood vessel

The invention relates to a surgical instrument for at least partially occluding a body conduit comprising a first jaw, a second jaw opposing the first jaw and moveable relative to the first jaw to occlude the conduit, and an insert being mounted by at least one of the first and second jaws with a length of the insert extending along at least one of the first and second jaws. One of the first and second jaws may further comprise a retention barb to provide a friction fit with the insert. The insert is flexible, disposable and may be formed by injection molding. The retention barb may be a three-sided or multiple-sided barb that is formed at the proximal end of at least one of the first and second jaws. The first and / or second jaws may be bent and / or curved. In another aspect, the insert comprises an outer wall and an inner wall for fitting over the jaw, and the inner wall further comprises a molded, rectangular raised ring formed at the proximal end to aid the retention of the insert over the retention barb of the jaw. The insert may be removed from the jaw by pulling the insert in a distal direction to overcome the friction fit of the retention barb. The insert may further include a soft tip covering the distal end of one of the jaws to minimize trauma during surgery. The distal ends of the jaw and the insert may be tapered to allow ease of installation and removal. In another aspect, the insert and jaws may be removably attached to one another in a snap-fit relationship where the jaws may include one or more holes and the insert may include one or more projections. It is appreciated that the holes and projections may vary in width, depth and height depending on application.

Owner:APPL MEDICAL RESOURCES CORP

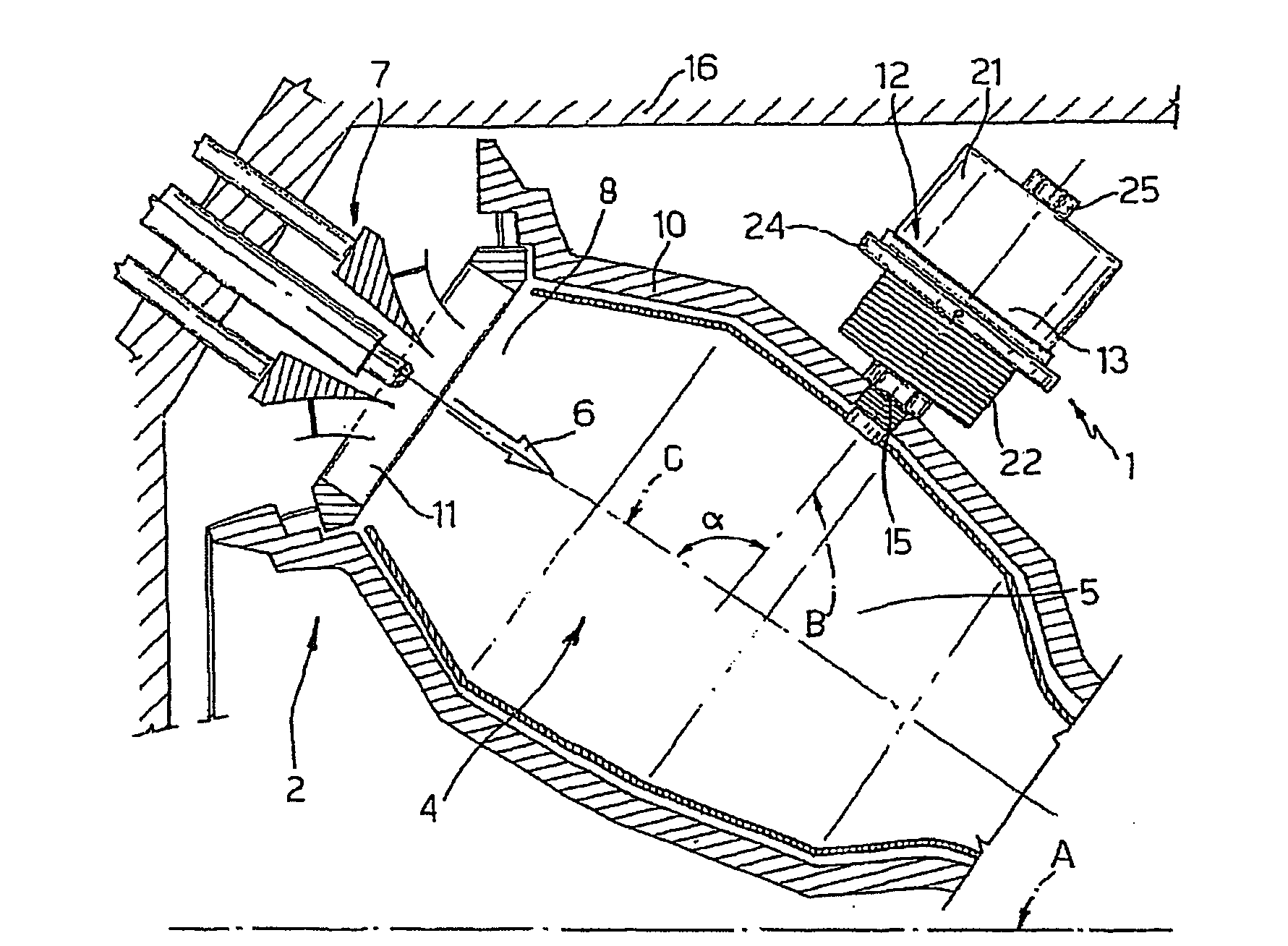

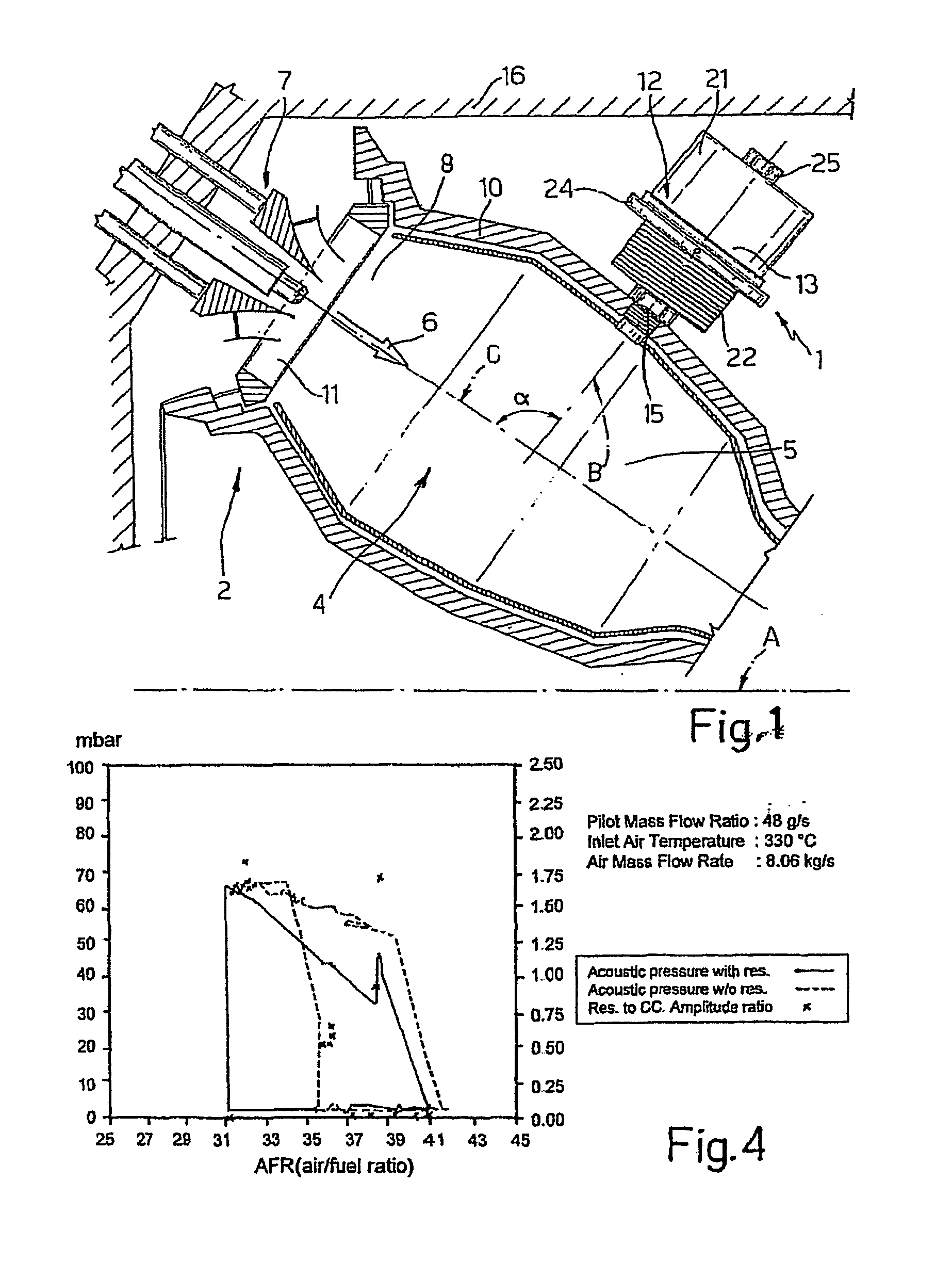

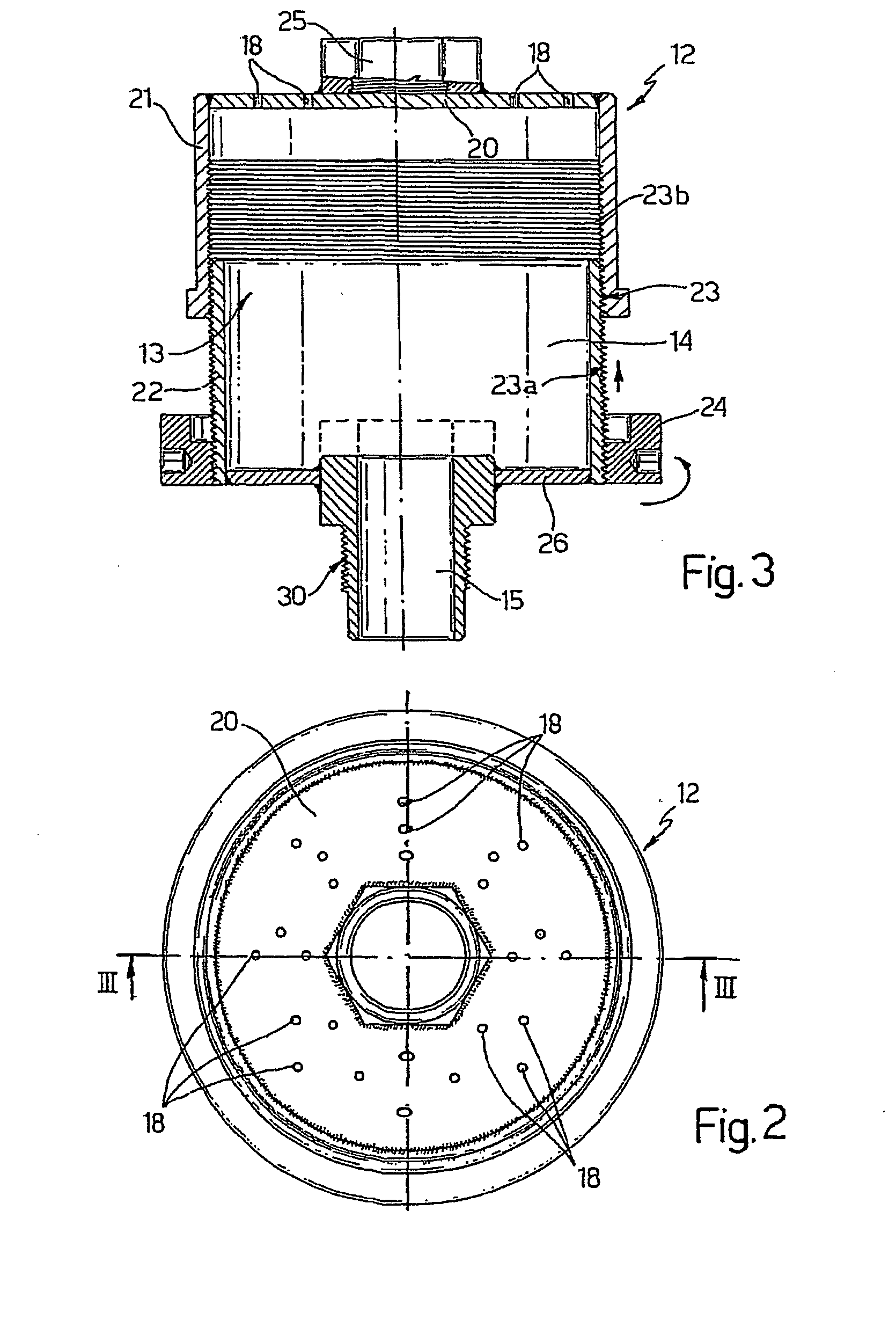

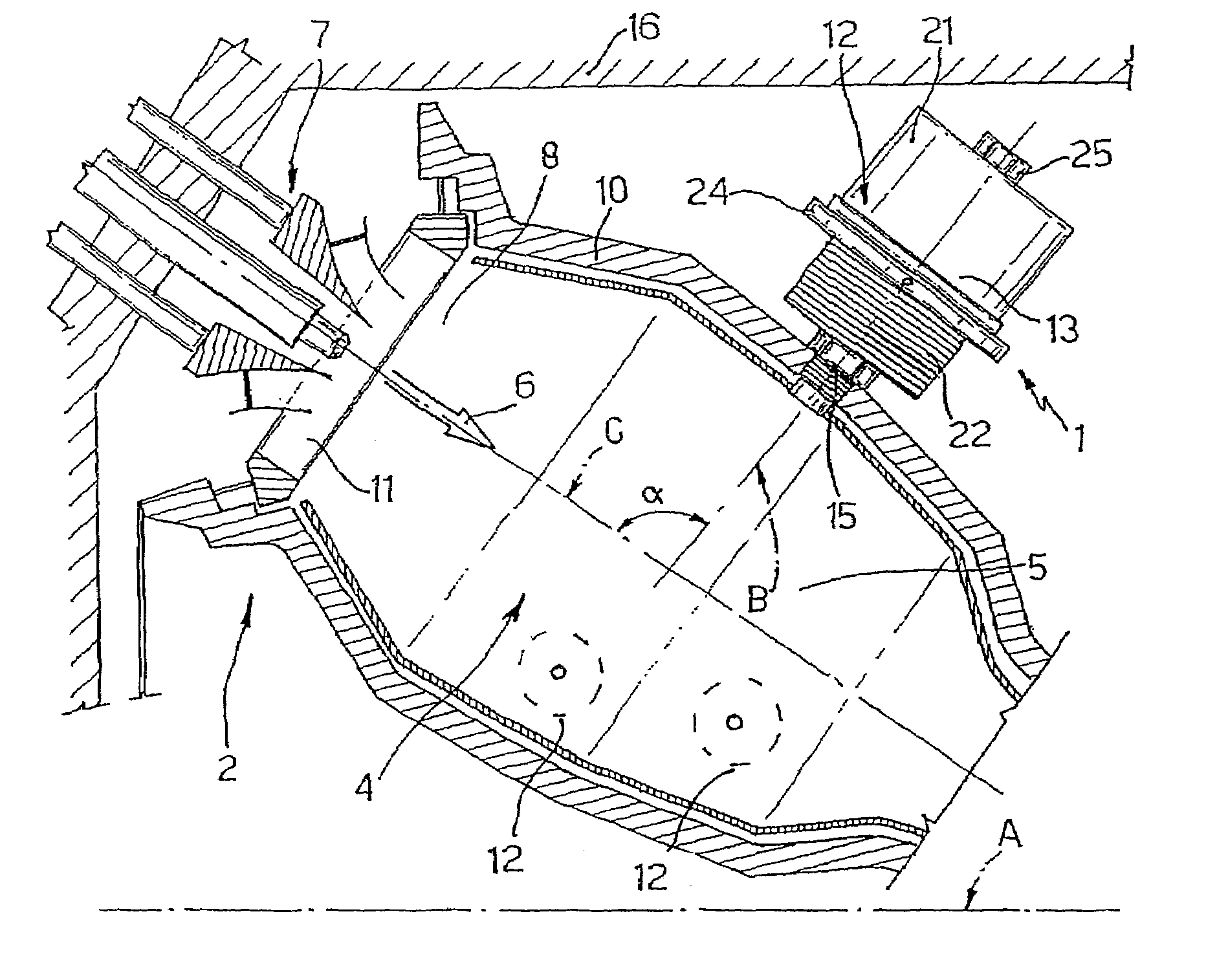

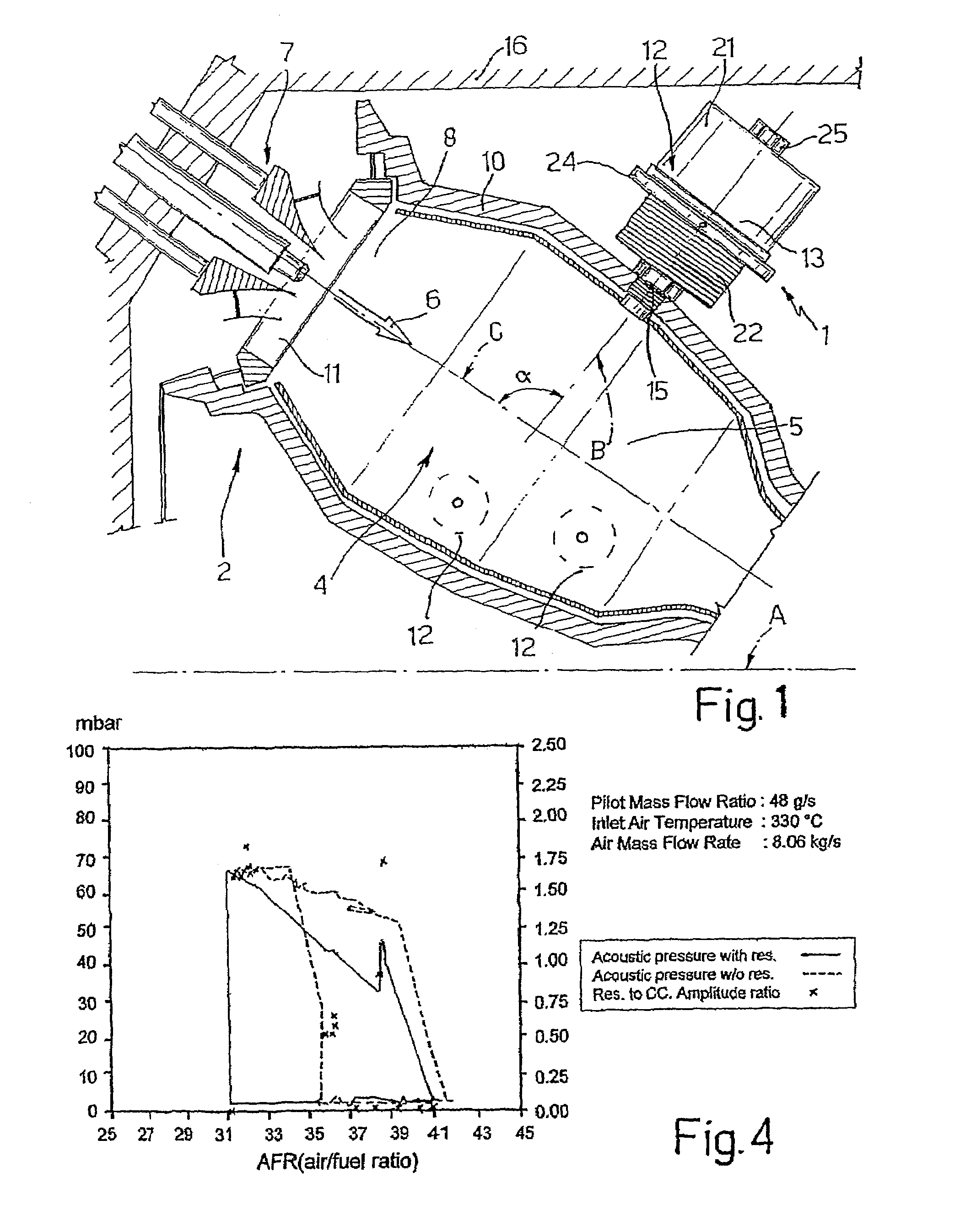

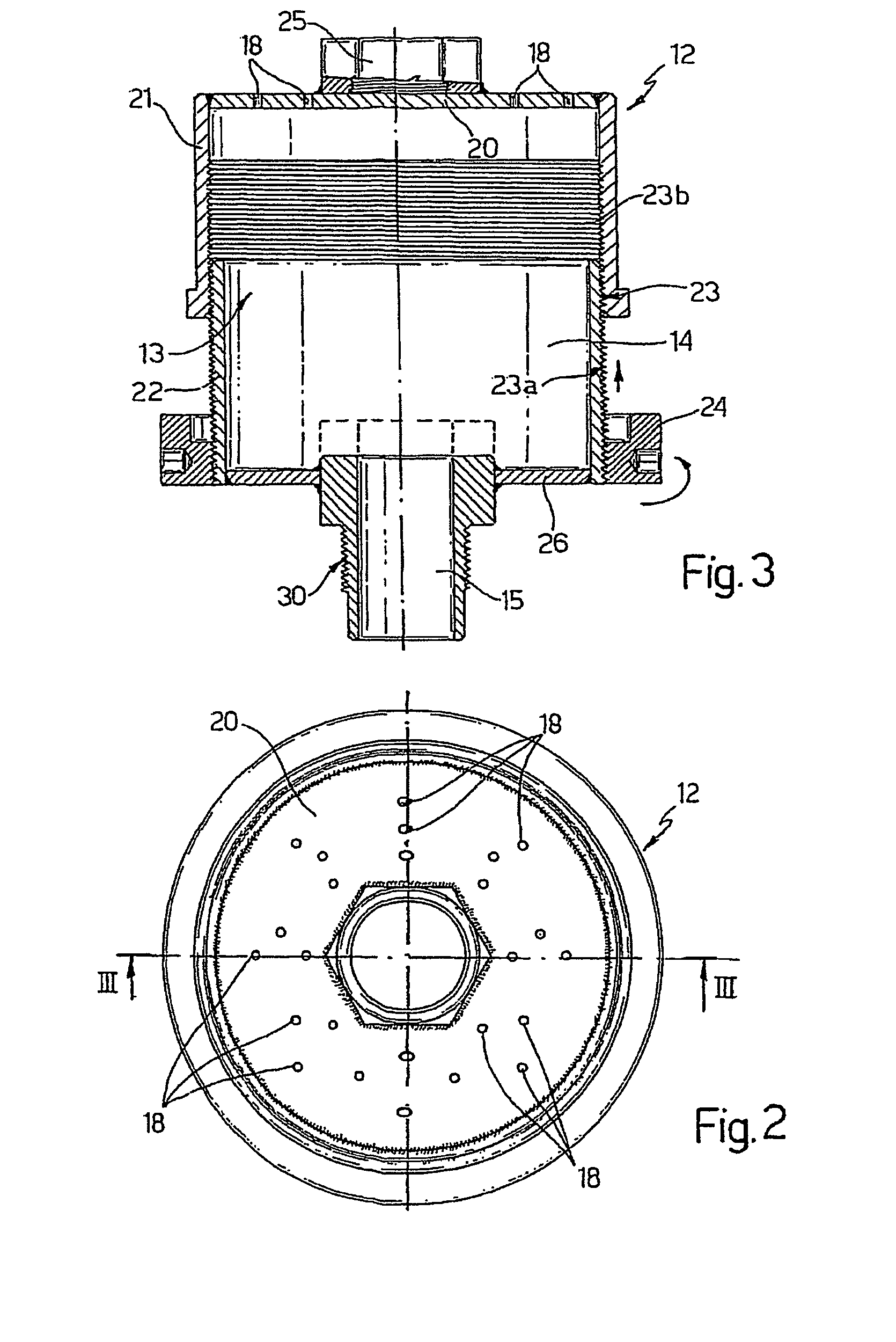

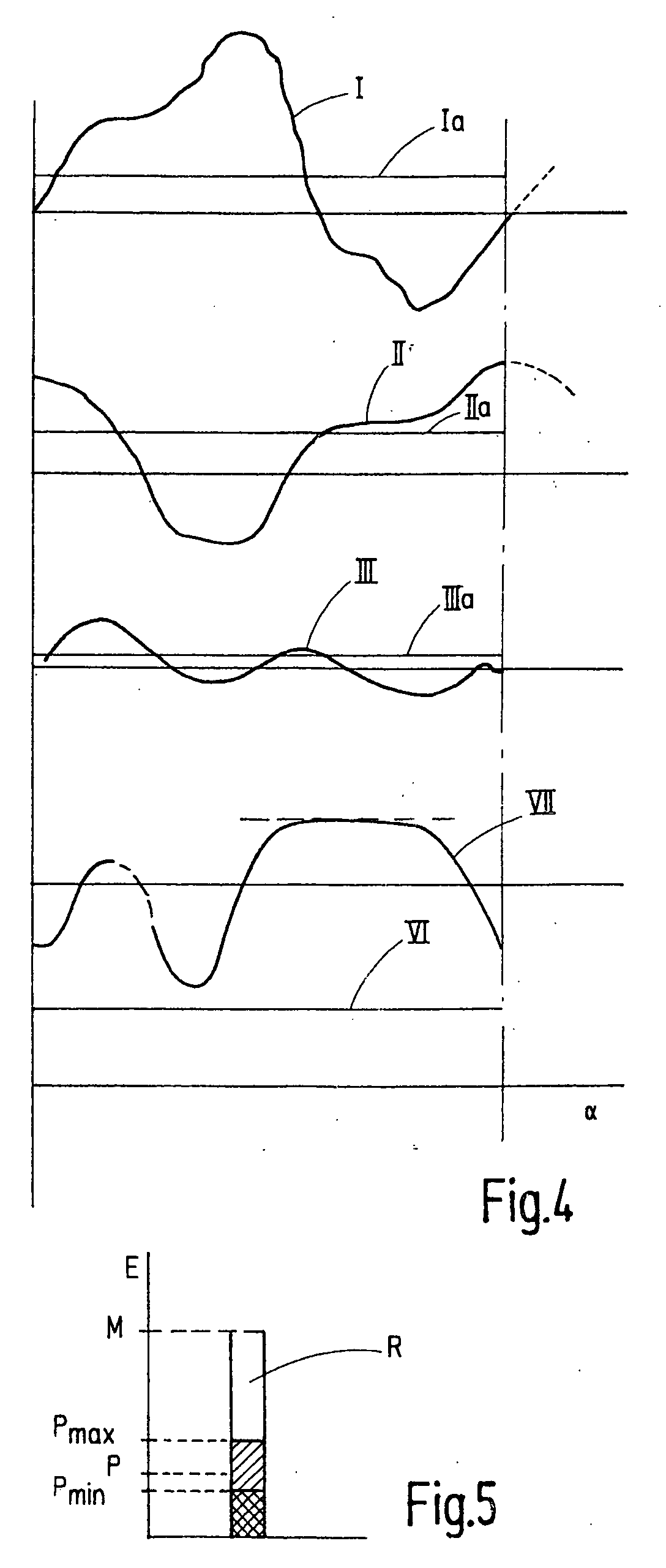

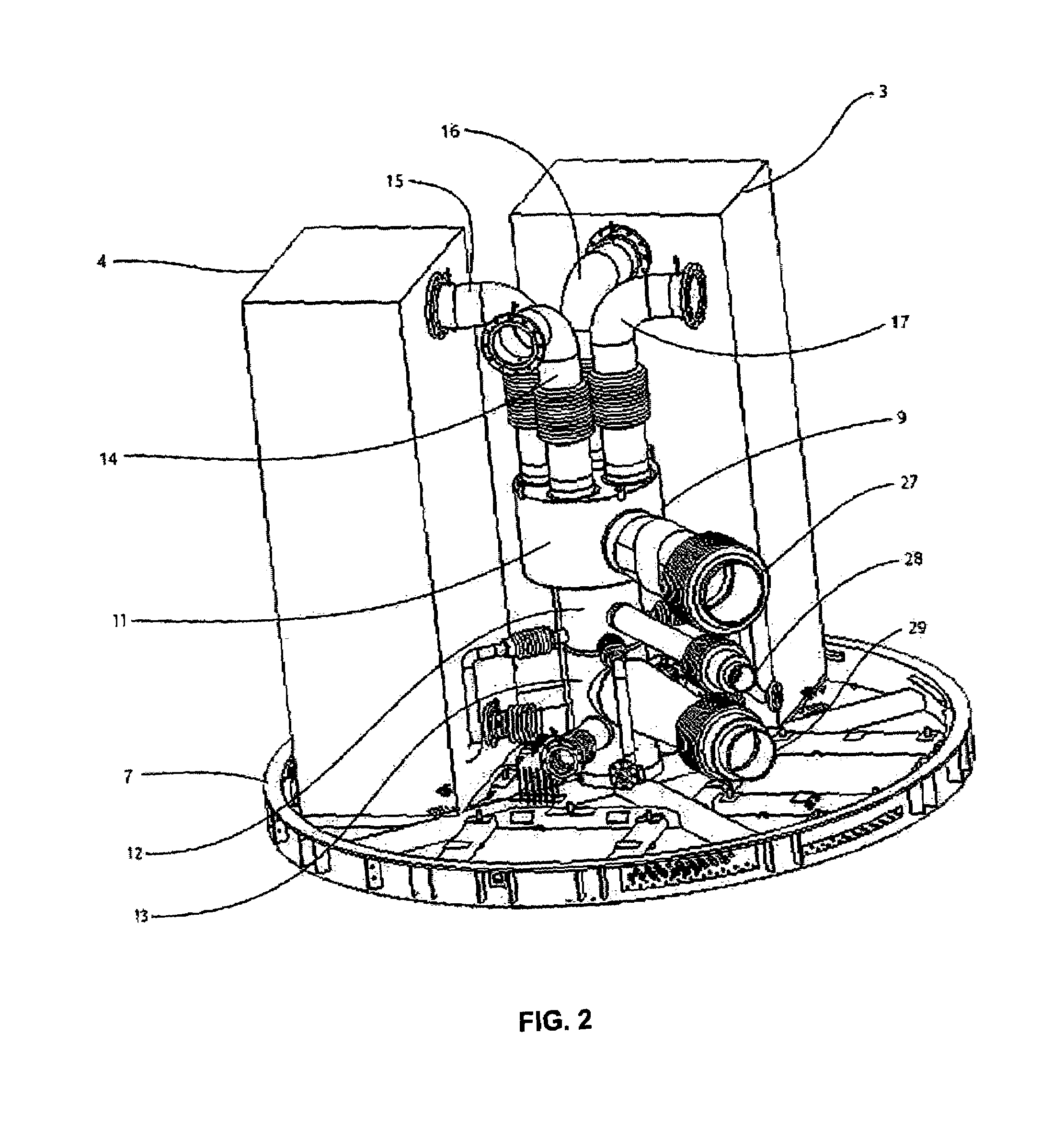

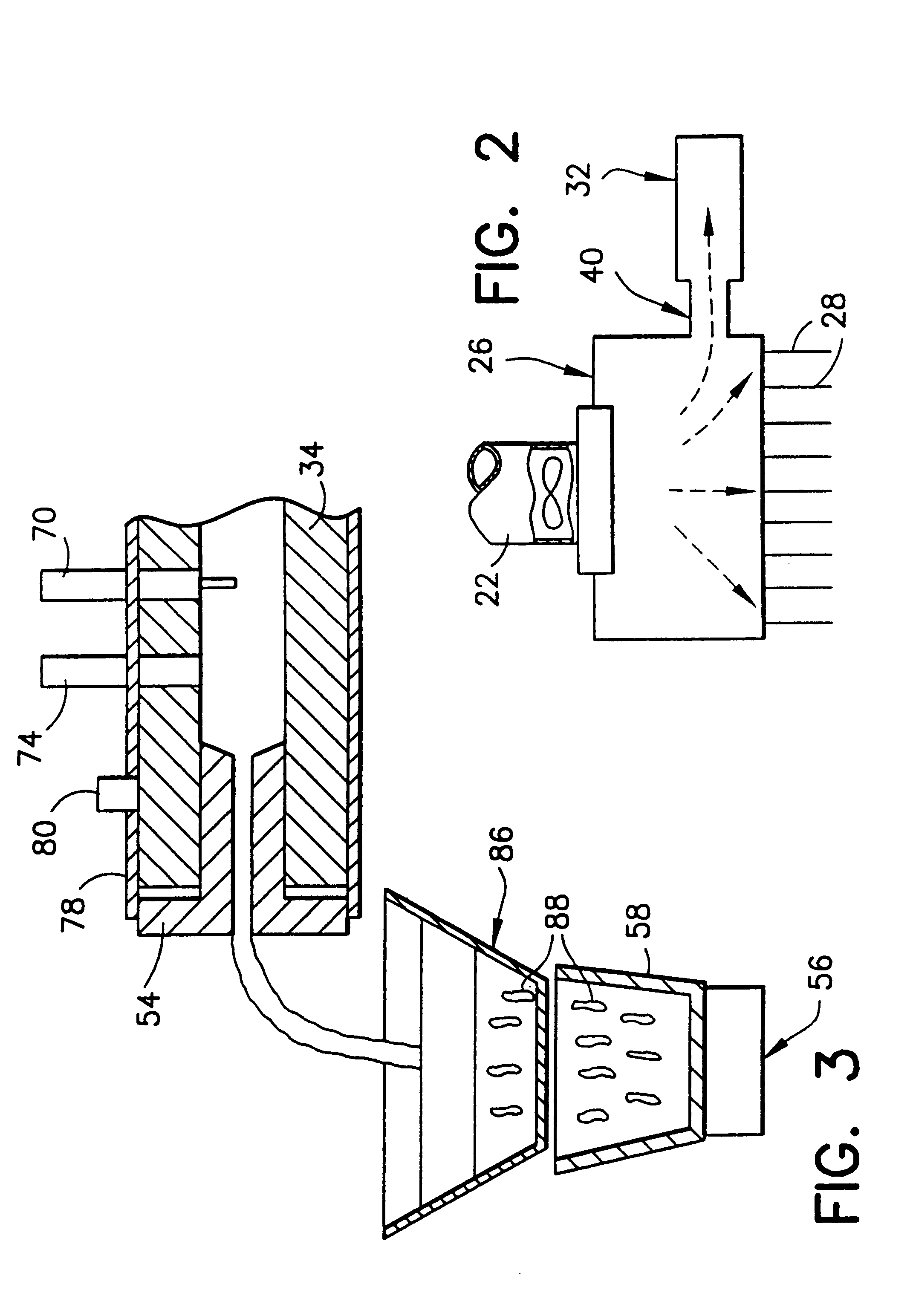

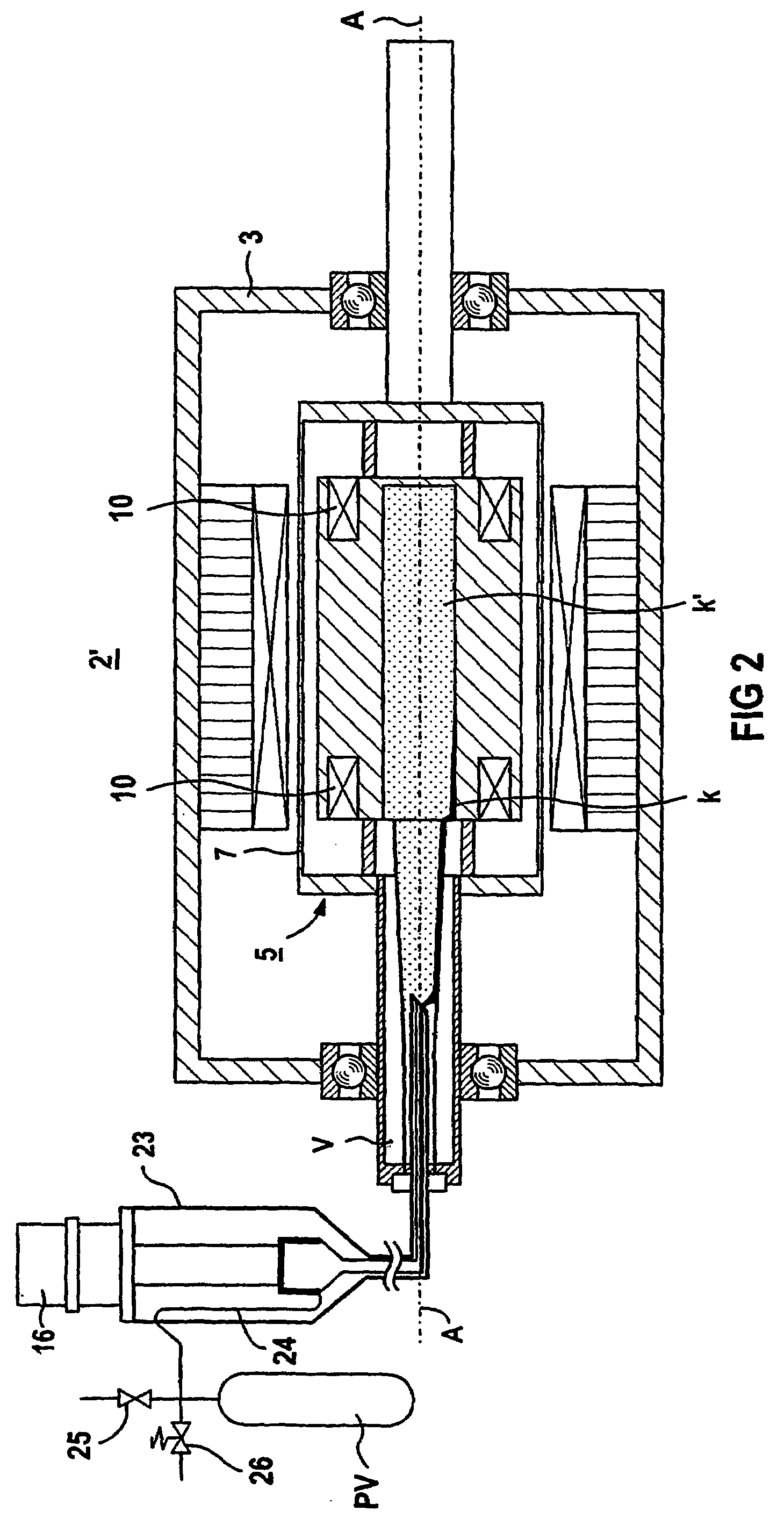

System for Damping Thermo-Acoustic Instability in a Combustor Device for a Gas Turbine

InactiveUS20080216481A1Improve reliabilityEasy to adjustContinuous combustion chamberGas turbine plantsCombustion chamberHelmholtz resonator

A system for damping thermo-acoustic instability in a combustor device for a gas turbine, the combustor device including at least one combustion chamber, in particular of an annular type, and at least one burner associated to the combustion chamber and mounted in a position corresponding to a front portion set upstream of the combustion chamber; the damping system including at least one Helmholtz resonator including a casing defining inside it a pre-set volume and a neck for hydraulic connection between the pre-set volume and the combustion chamber, the neck being connected to one side of the combustion chamber at a distance from the front upstream portion thereof provided with the at least one burner. The casing of the resonator includes structure which varies the pre-set volume within a pre-set range and structure which delivers a cooling fluid.

Owner:ANSALDO ENERGIA SPA

Enhanced shared secret provisioning protocol

InactiveUS7398550B2Increase supplySimple processNetwork traffic/resource managementRandom number generatorsNetwork Access DeviceShared secret

An Enhanced Shared Secret Provisioning Protocol (ESSPP) provides a novel method and system for adding devices to a network in a secure manner. A registration process is launched at two network devices together within a predetermined time interval. These two devices then automatically register with each other. When two devices running ESSPP detect each other, they exchange identities and establish a key that can later be used by the devices to mutually authenticate each other and generate session encryption keys. With ESSPP, two ESSPP devices that are attempting to register with each other will only provision a key when they detect that they are the only two ESSPP devices on the wireless network running ESSPP. If additional devices running ESSPP are detected, the ESSPP protocol is either terminated or suspended.

Owner:MICROSOFT TECH LICENSING LLC

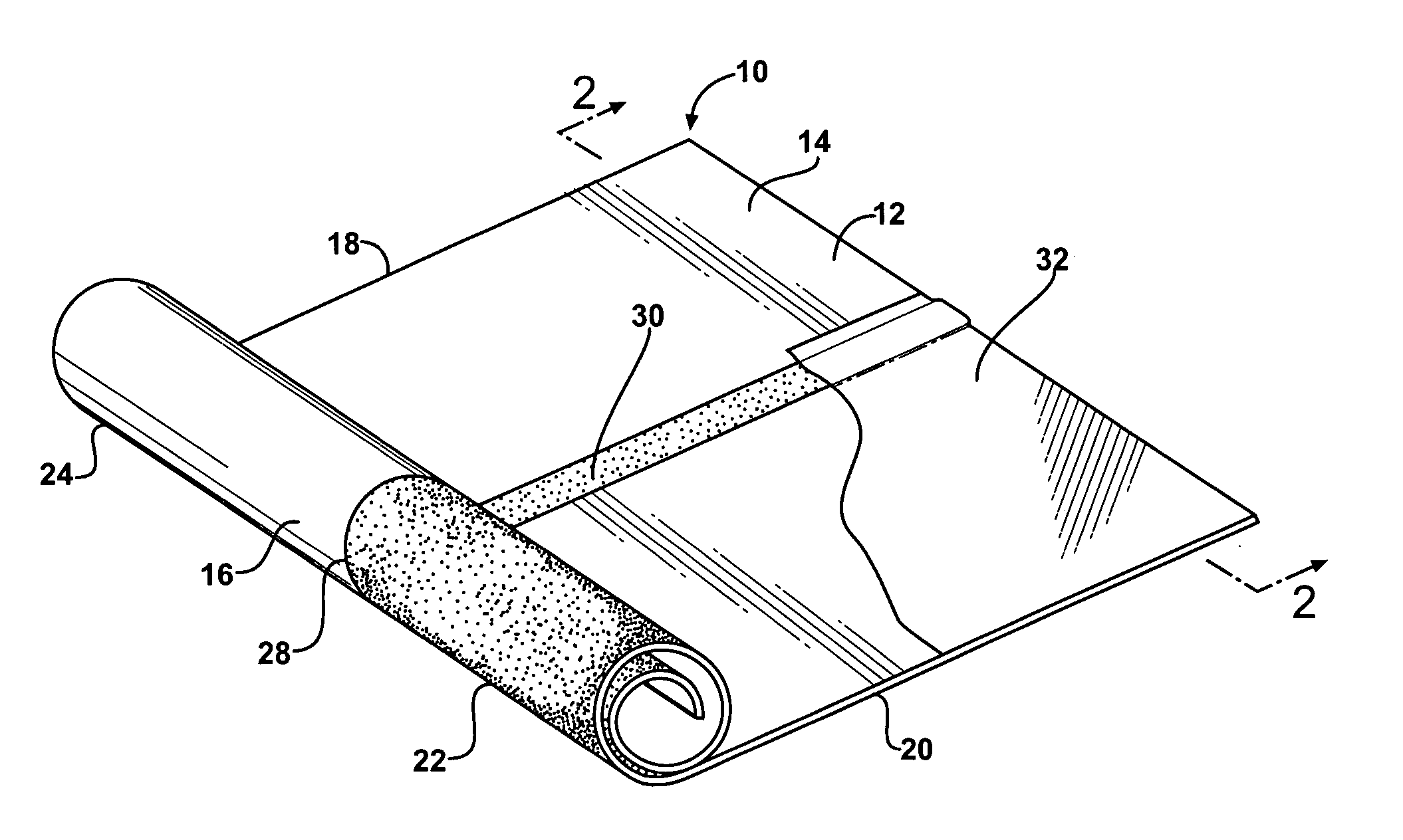

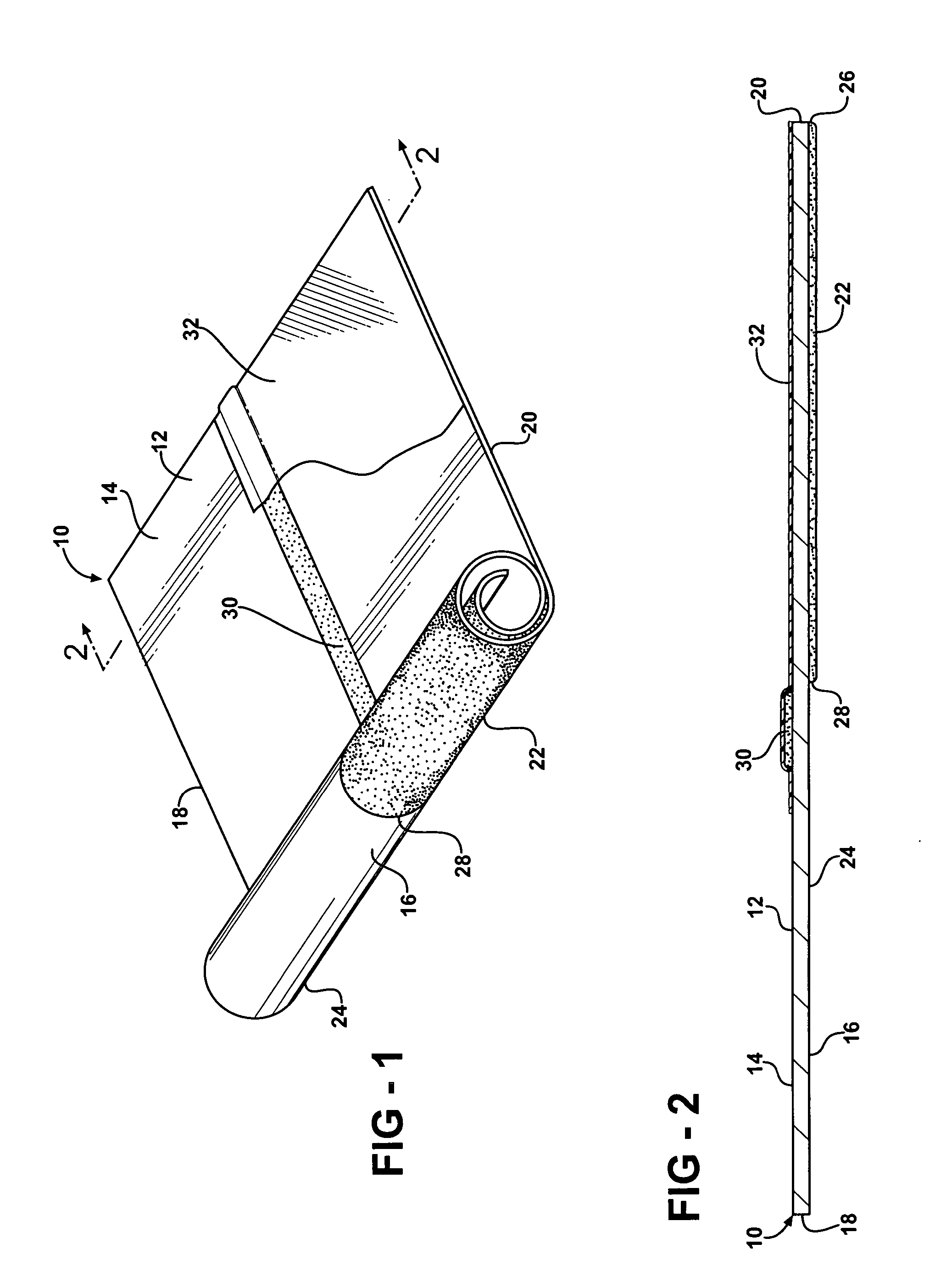

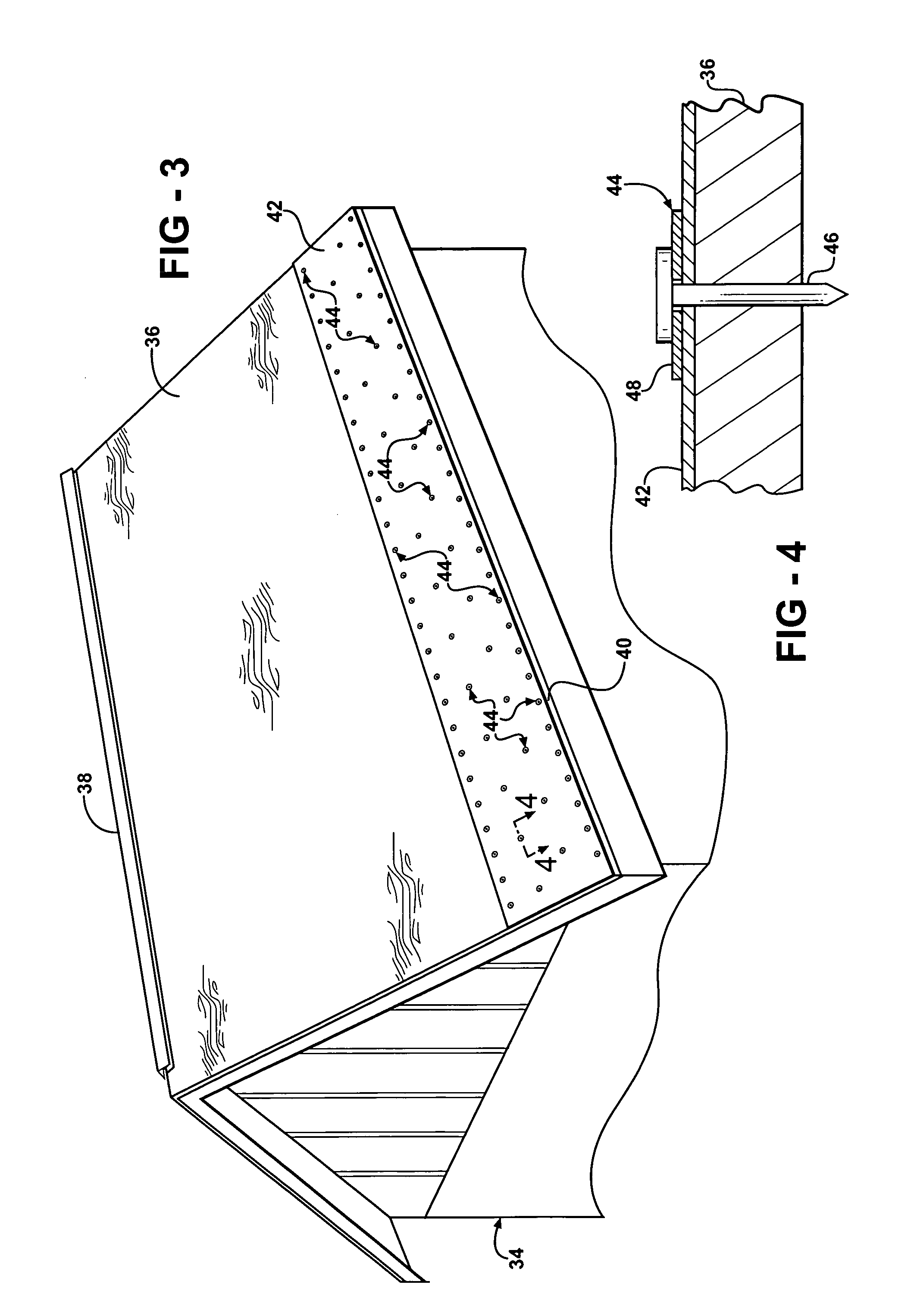

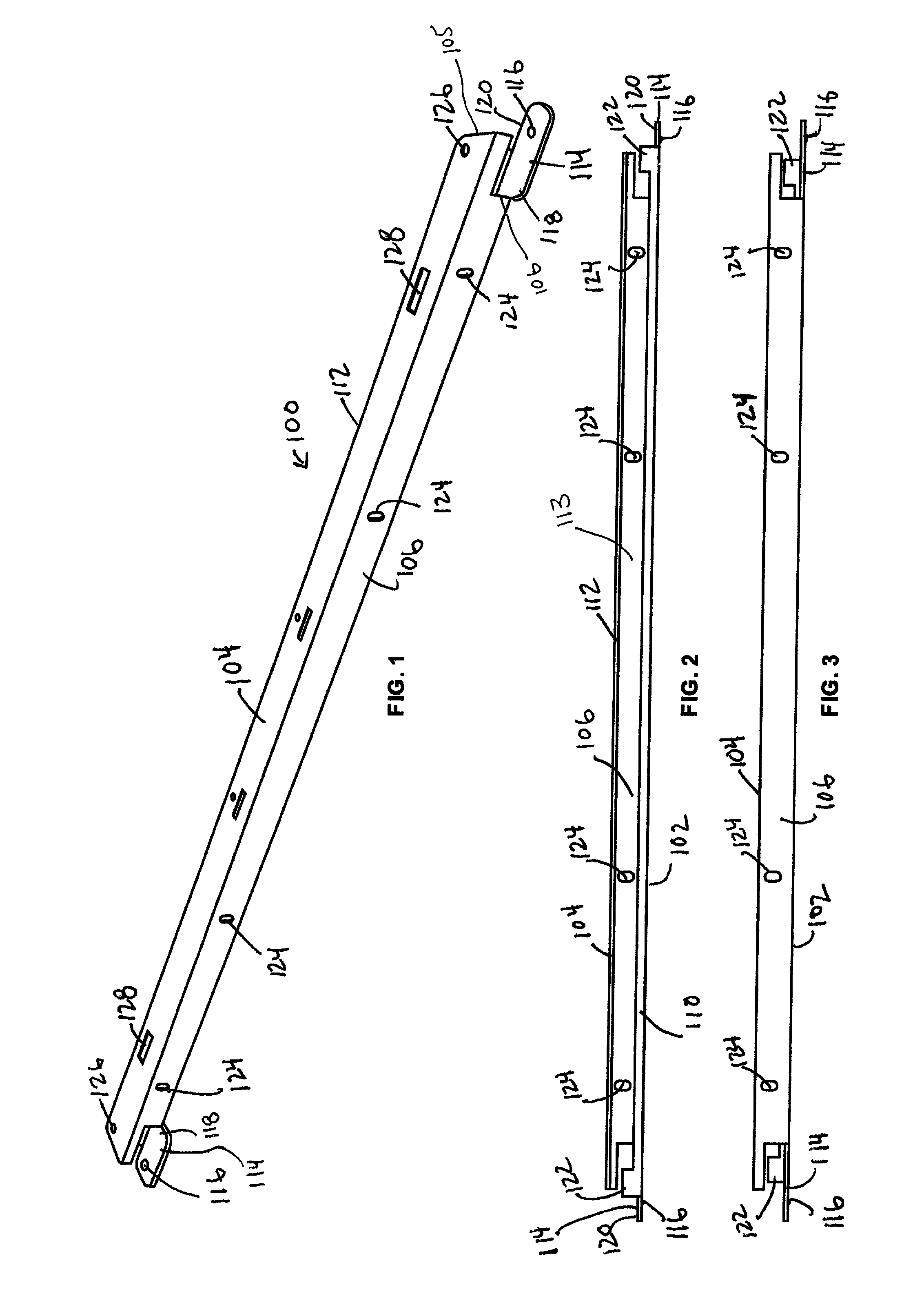

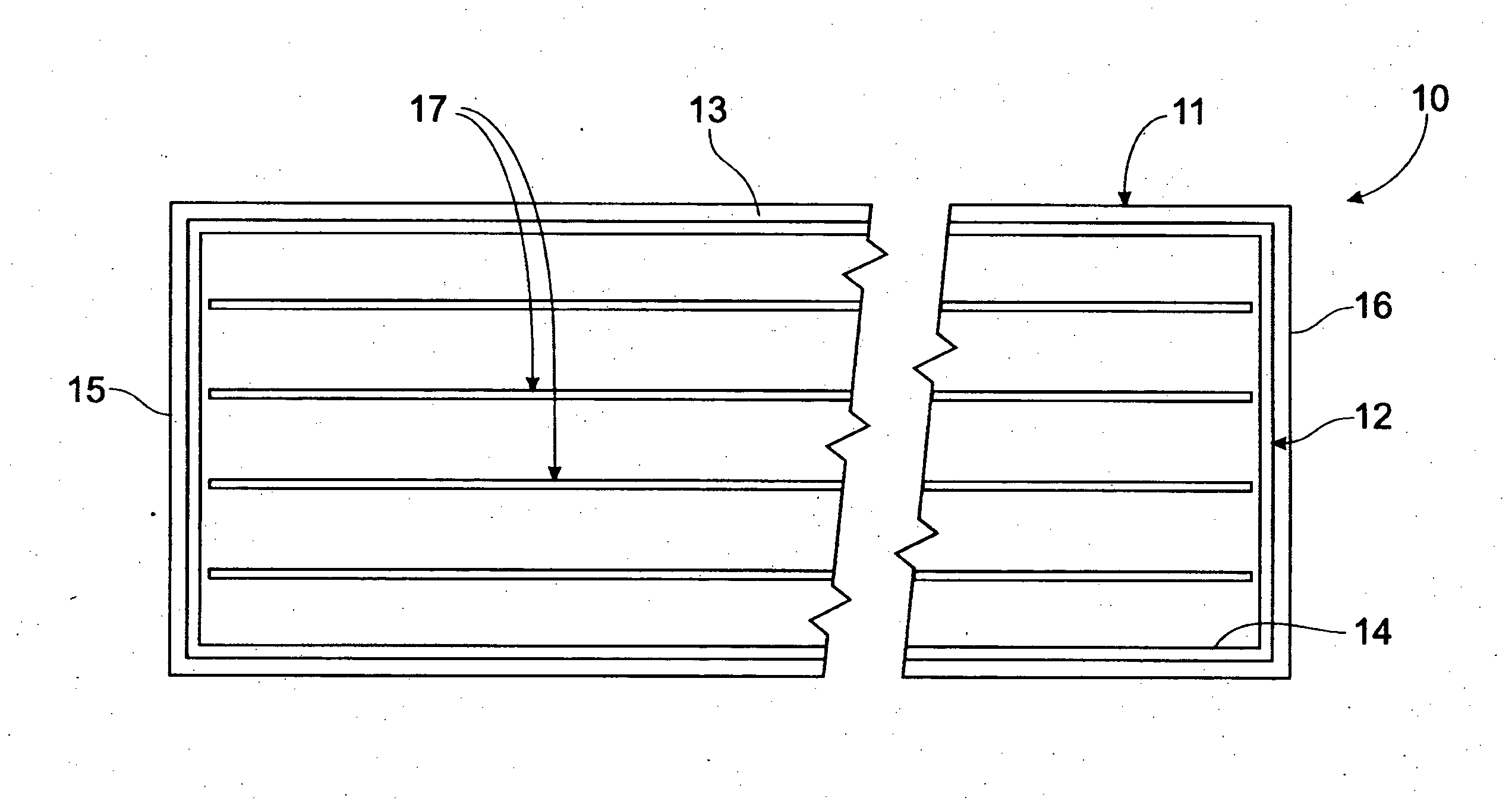

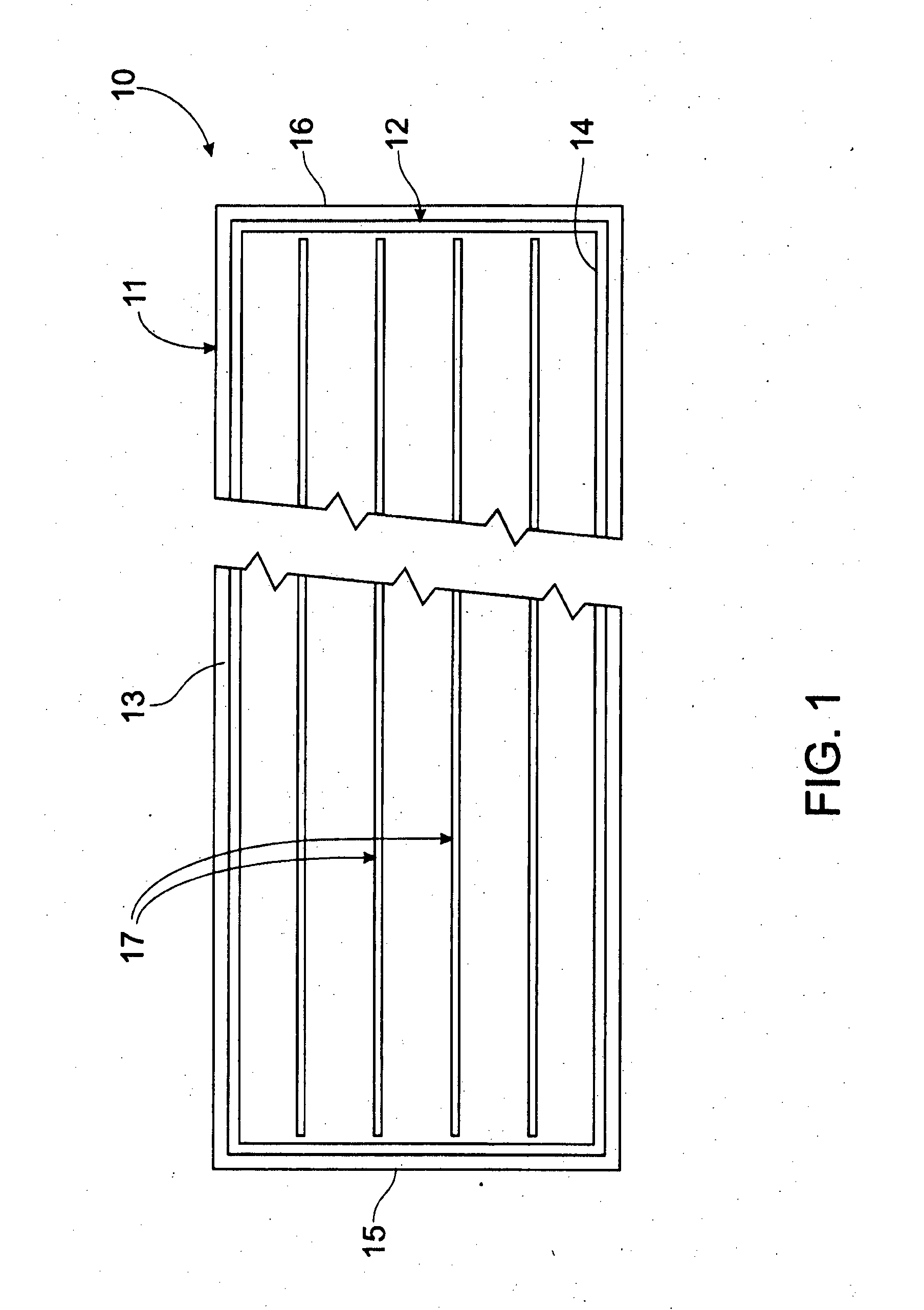

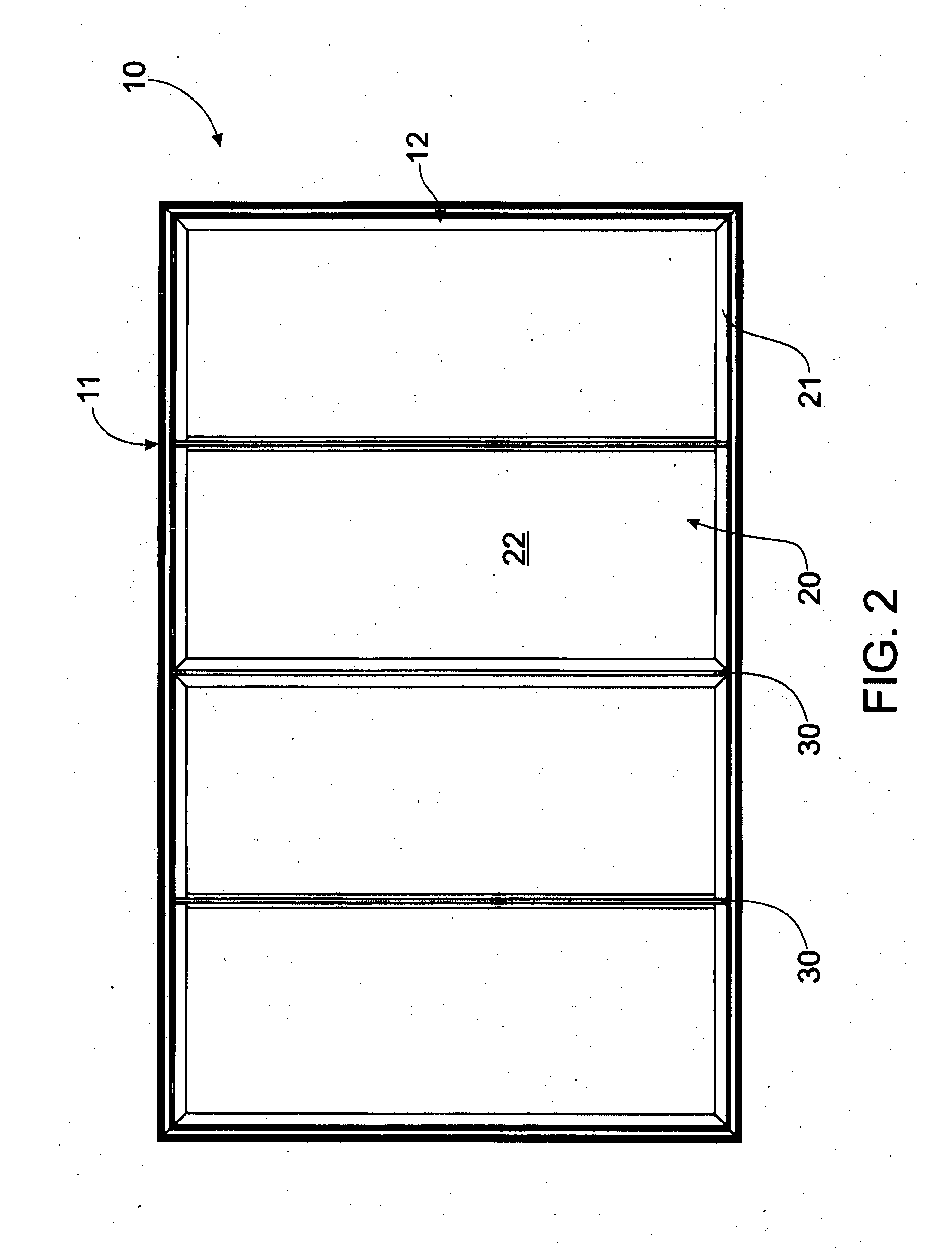

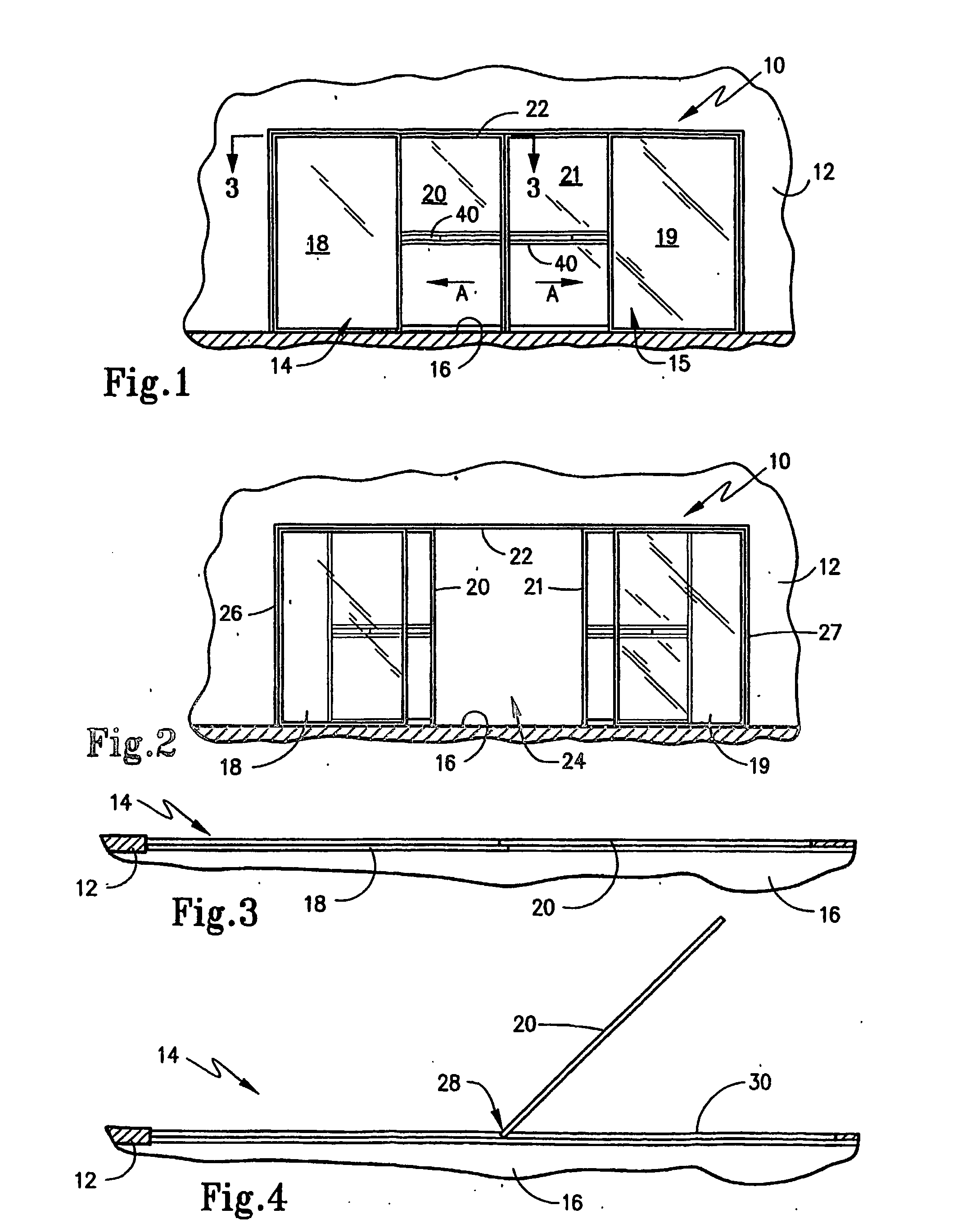

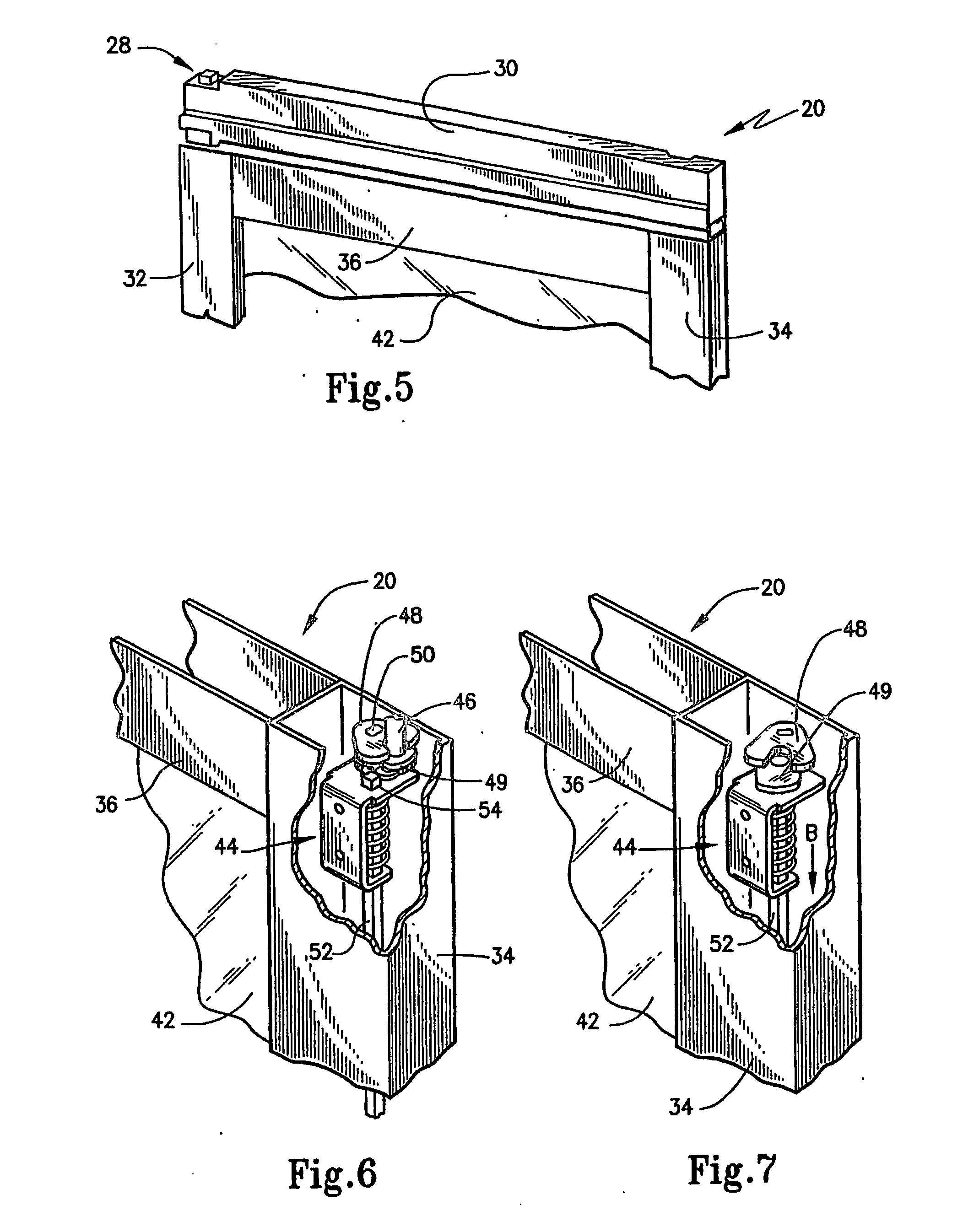

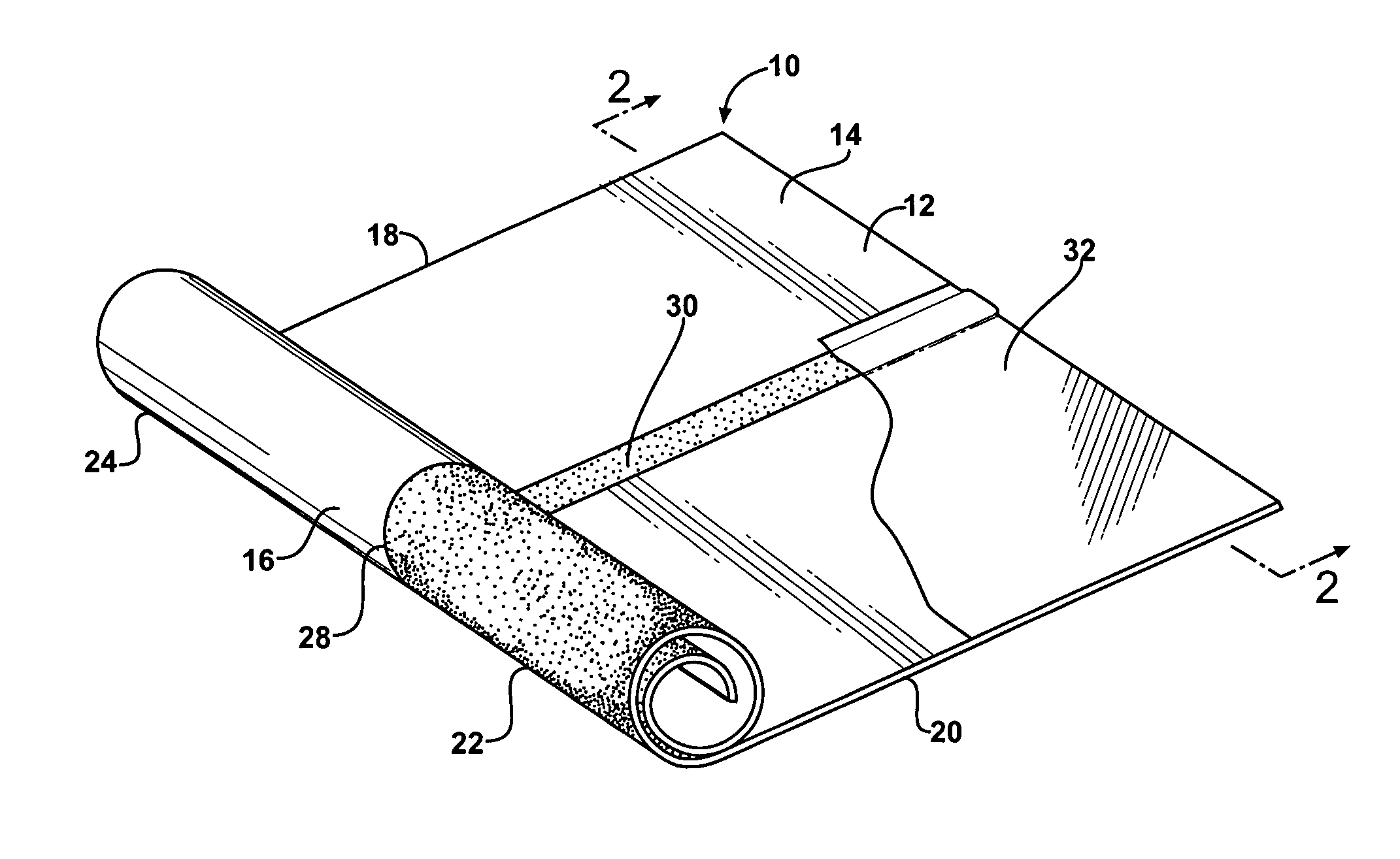

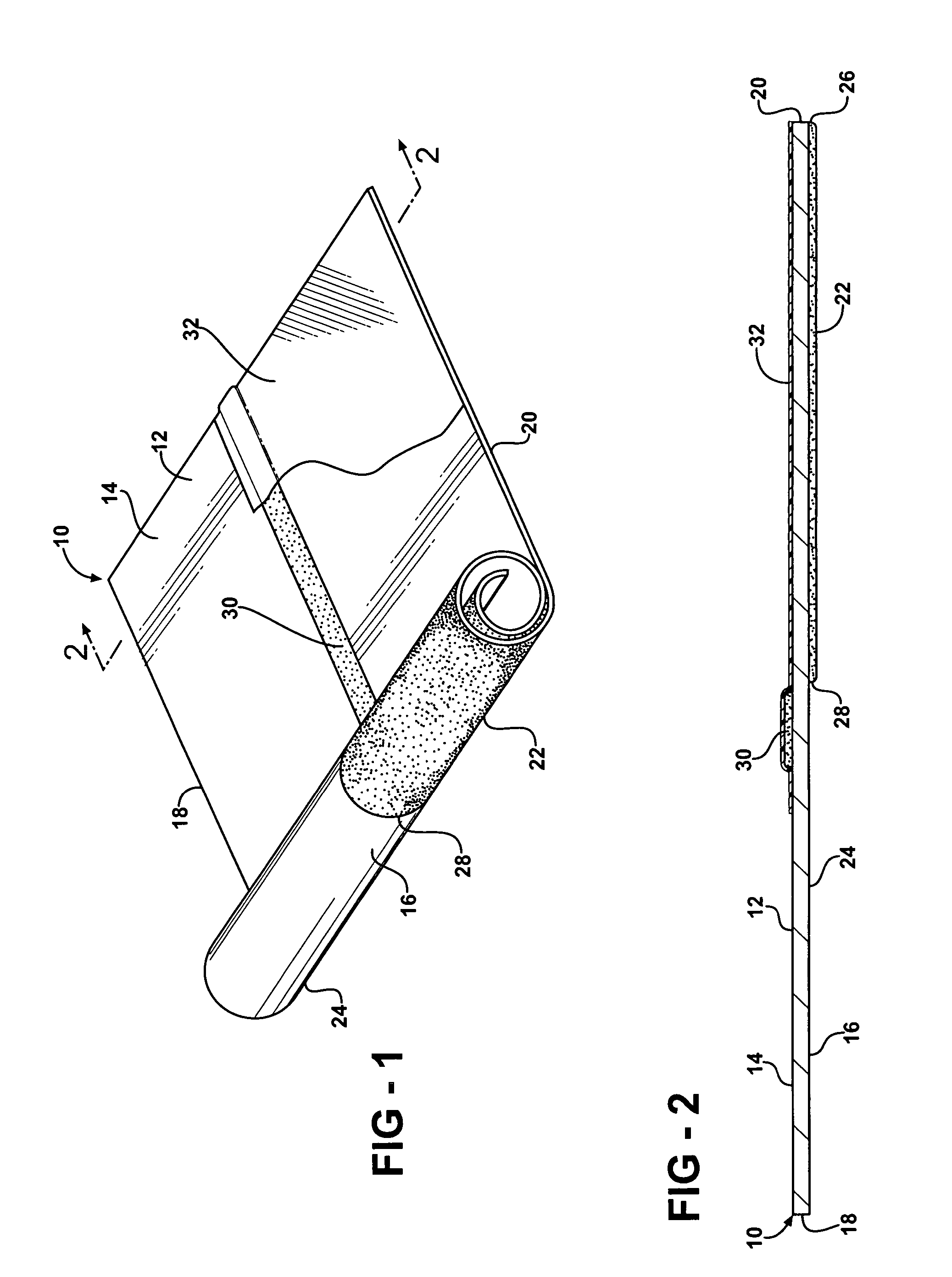

Roof underlayment

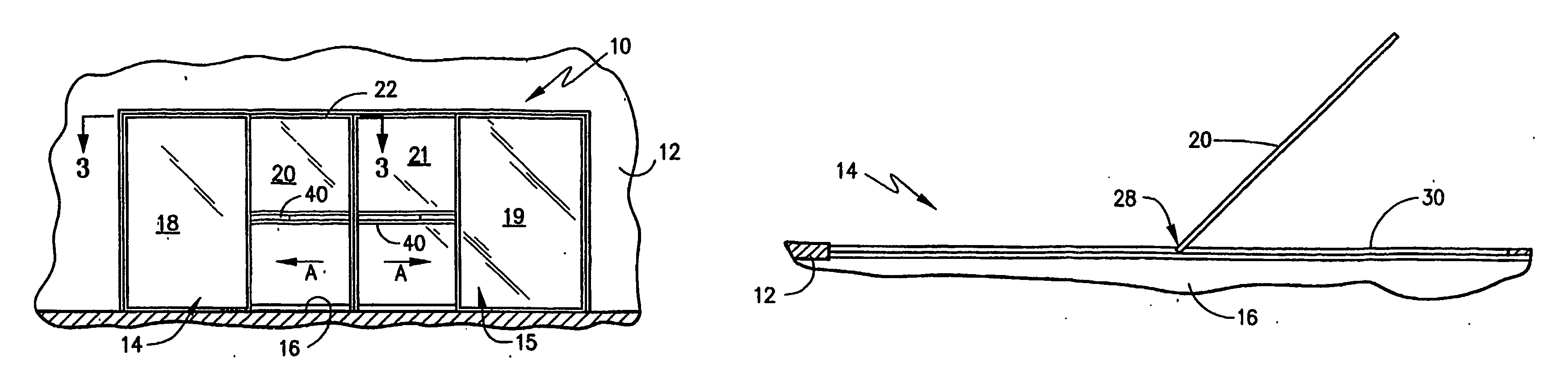

An underlayment sheet (10, 10′) is applied in overlapping courses to a roof deck (36) for establishing a weather-resistant membrane for use as a final exposed surface or below a roof covering (50). The underlayment sheet (10, 10′) has a bottom surface (16, 16′) to which a pressure sensitive adhesive section (22, 22′) is applied generally continuously along its length. A non-adhesive section (24, 24′) also extends the length of the bottom surface (16, 16′) adjacent its upper long edge (18, 18′) for providing a contact surface with the roof deck (36) which is devoid of any adhesive material. The non-adhesive section (24, 24′) is attached to the roof deck (36) using tin tags (44, 44′) or other mechanical fastening components. When subsequent underlayment sheets (10, 10′) are applied in overlapping courses, the adhesive sections (22, 22′) bond over the preceding underlayment sheet (10, 10′) to establish a water tight seal. The top surface (14) of the underlayment sheet (10) may include a supplemental bonding strip (30) which adheres directly to the adhesive section (22) of an overlying underlayment sheet (10) to establish a tenacious seal. The top surface (14′) may also be impregnated with a course granular material (52) to serve as a final, exposed surface for the roof in lieu of shingles or the like. If a future re-roofing operation is required, the subject underlayment system can be removed from the roof deck (36) without damaging or delaminating the roof deck (36) material.

Owner:T&S NEWCO

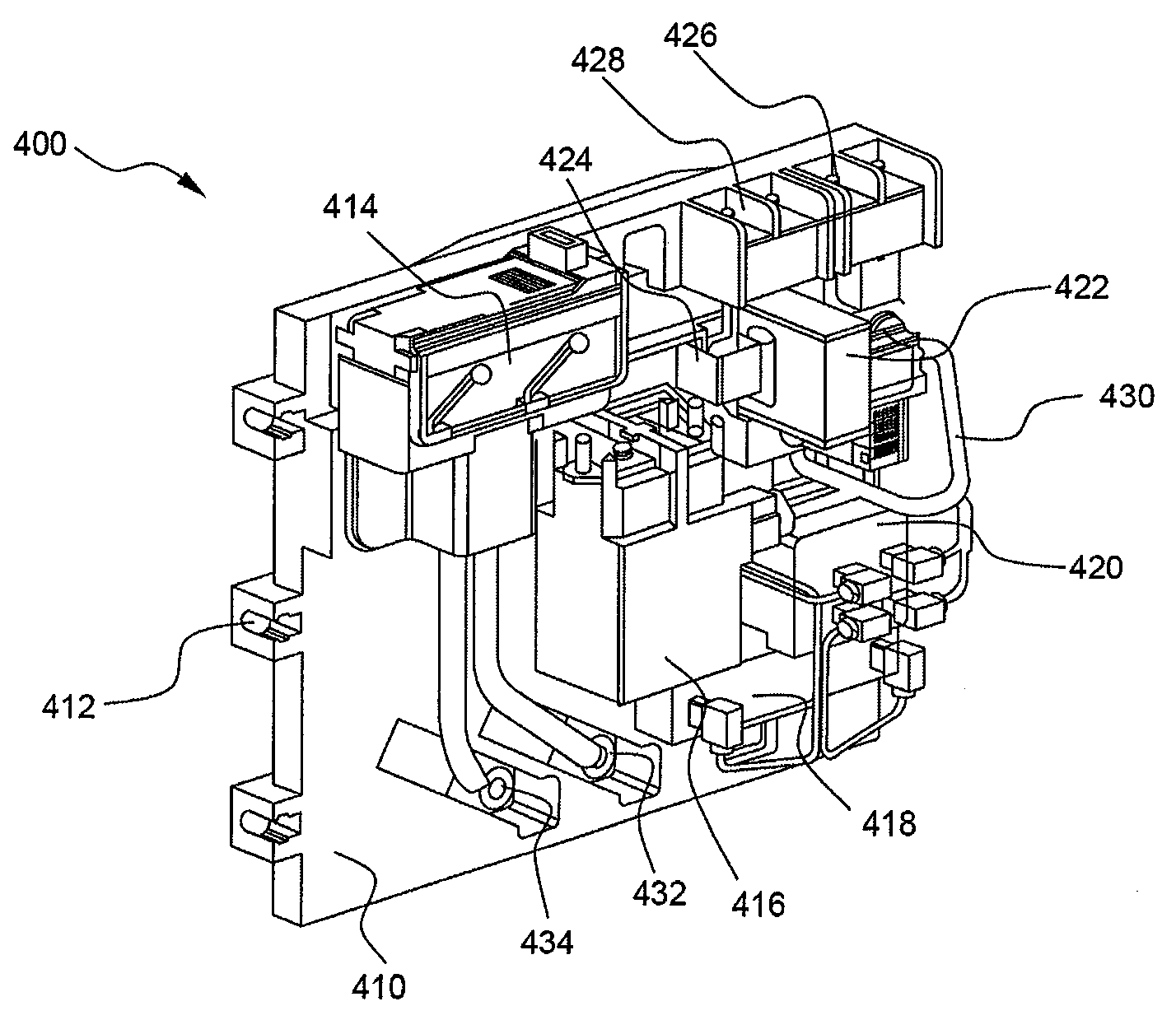

Power switching module for battery module assembly

ActiveUS20100141214A1Easy constructionImprove space utilizationBatteries circuit arrangementsRelay bases/casings/coversCouplingPower switching

Disclosed herein is a power switching module for a battery module assembly constructed in a structure in which a plurality of rectangular battery modules, each having a plurality of battery cells or unit modules connected in series to each other, are stacked in the width direction (the longitudinal direction) and the height direction (the transverse direction) by at least twos such that the rectangular battery modules generally constitute a hexahedral structure (hexahedral stack), outer edges of the hexahedral stack are fixed by a frame member, and input and output terminals of the rectangular battery modules are oriented such that the input and output terminals of the rectangular battery modules are directed toward one surface (a) of the hexahedral stack, wherein the power switching module comprises an insulative substrate mounted to the surface (a) of the hexahedral stack in a coupling fashion, elements mounted on the insulative substrate for controlling voltage and current during the charge and discharge of the rectangular battery modules, and connection members mounted on the insulative substrate for interconnecting the control elements.

Owner:LG ENERGY SOLUTION LTD

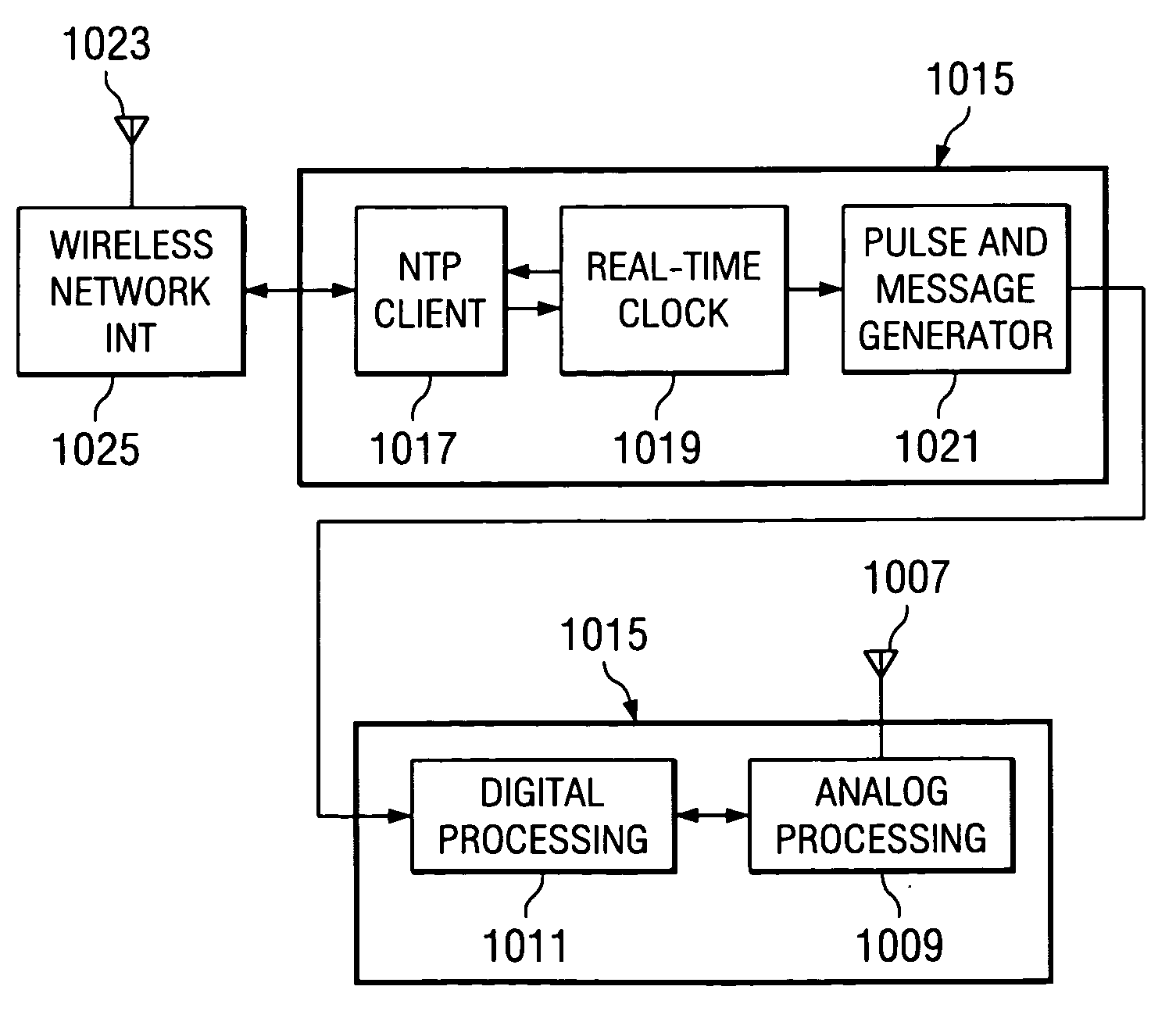

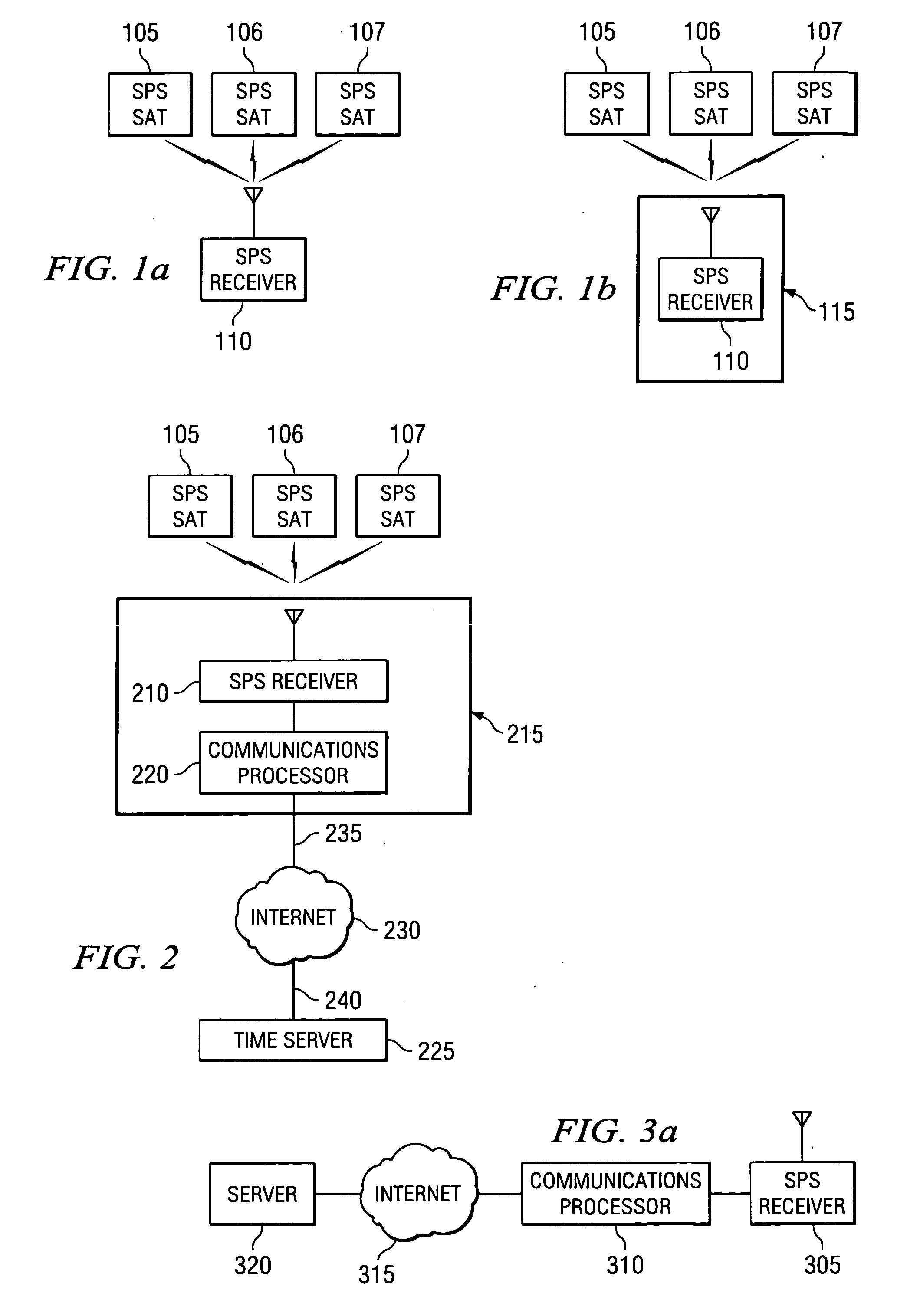

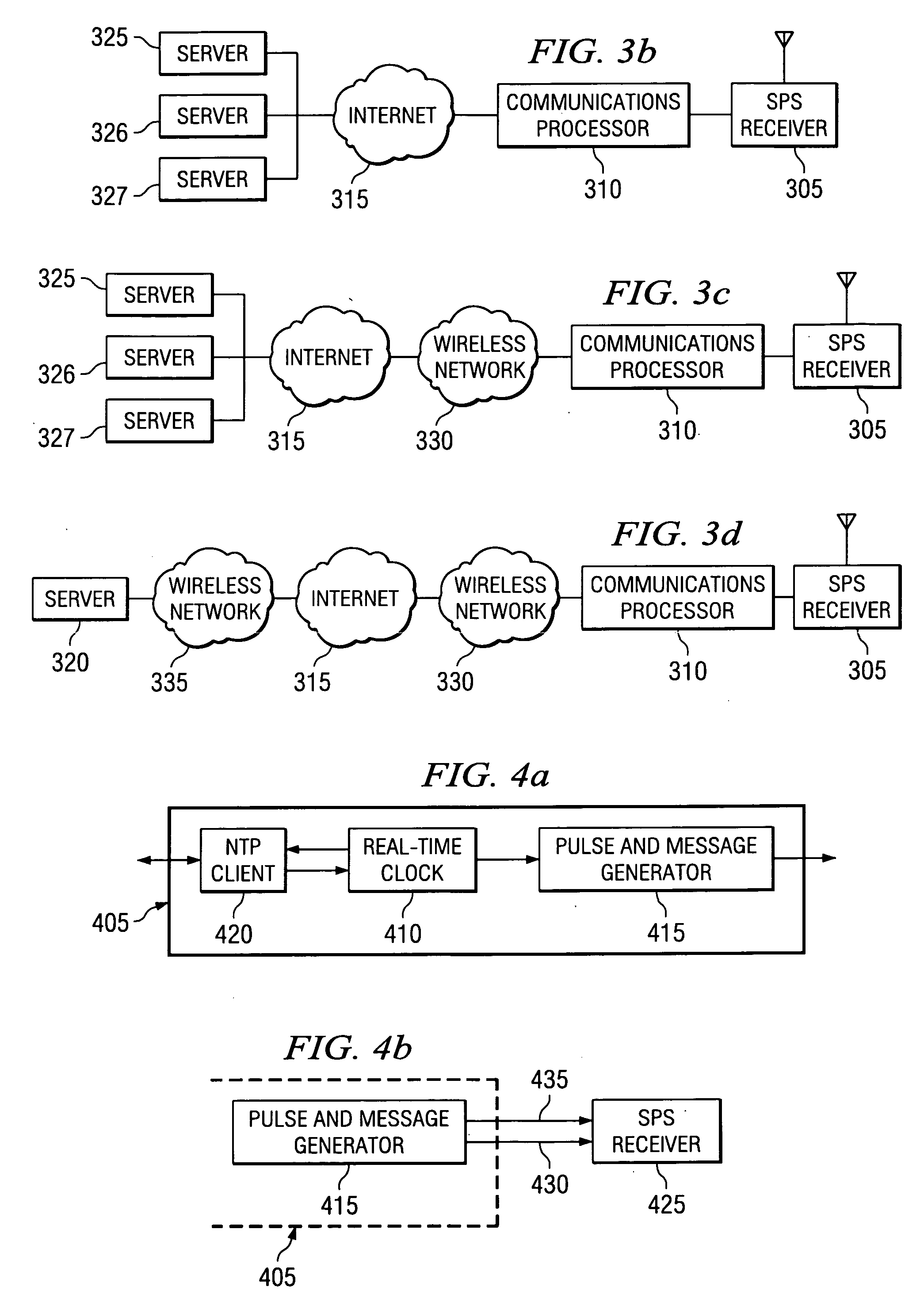

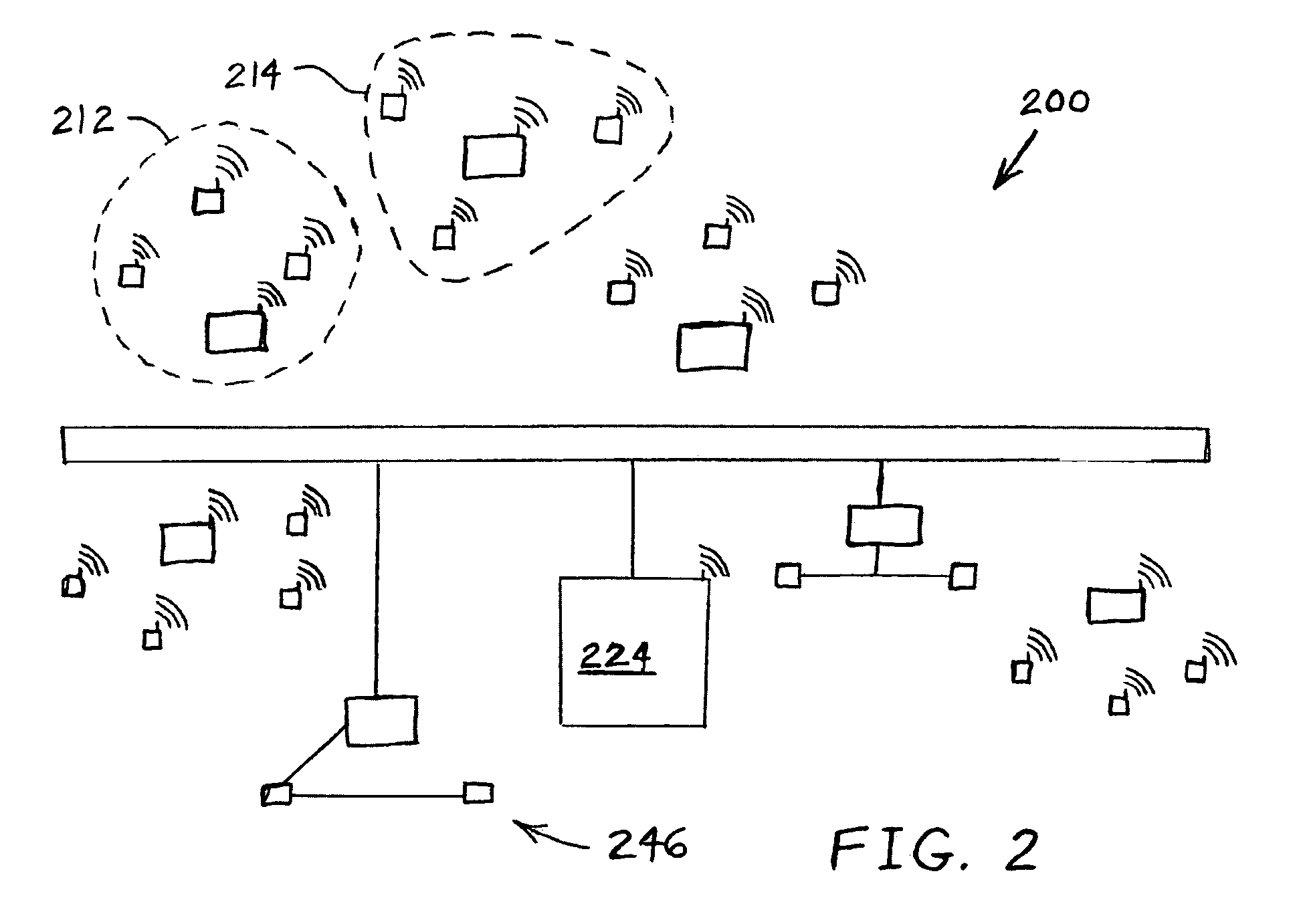

System and method for providing time to a satellite positioning system (SPS) receiver from a networked time server

InactiveUS20050078032A1Accurate time informationReadily availableSynchronous motors for clocksPosition fixationThe InternetPublic network

System and method for enabling signal acquisition in a satellite positioning system (SPS) when signals from SPS satellites are attenuated by the operating environment of a SPS receiver. A preferred embodiment comprises a communications server (for example, communications server 220) coupled to a SPS receiver (for example, SPS receiver 210) at one end and a time server (for example, time server 225) by a public network (for example, the Internet 230). Preferably, the communications server 220 is coupled to the Internet 230 via a wireless network to facilitate maximum mobility and flexibility. The communications server 220 queries the time server 225 for the current time and then provides the current time to the SPS receiver 210. The SPS receiver 210 makes use of the current time to assist it in signal acquisition.

Owner:TEXAS INSTR INC

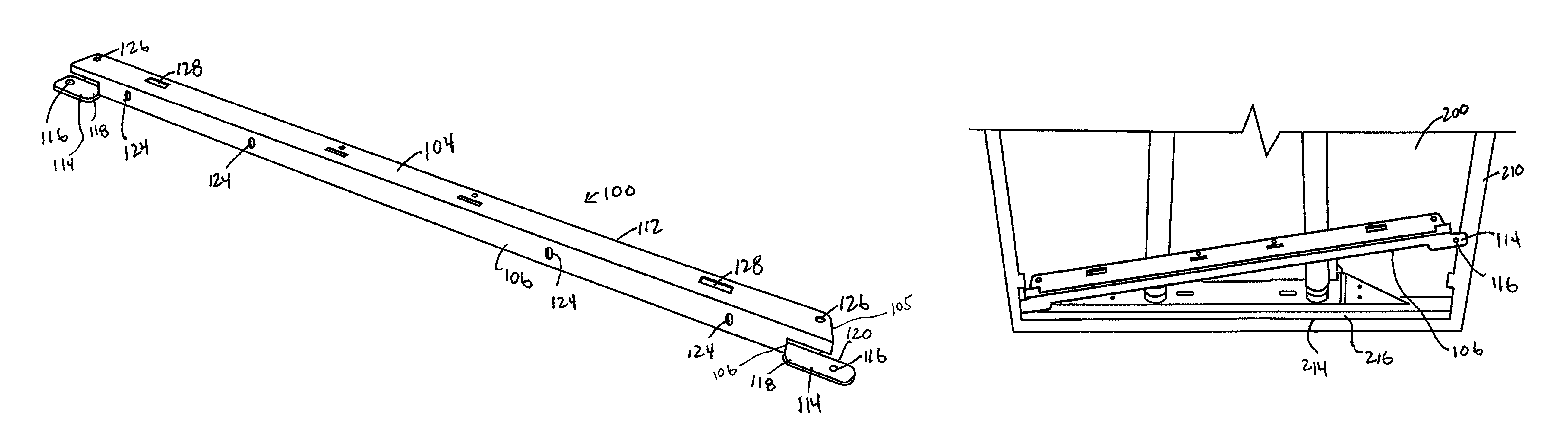

Bracket for a lighting fixture in a suspended ceiling

InactiveUS8083369B1InstallationLighting support devicesProtective devices for lightingEngineeringMechanical engineering

An adapter bracket which enables the installation of a door frame or louver into a recessed fixture that sits on a T-bar supported by a ceiling without having to custom design a hinge and latch system to match the original fixture or require the installation of a false frame that lifts the fixture. The brackets slide between the T-bar and the existing fixture. The bracket is also slightly wider than the T-bar opening. The door frame will keep the brackets spaced wide enough to ensure that the assembly would not fall out of the opening. The hinge and latch mechanism for the door frame is built into its end rails and latches onto the bracket to ensure the door frame is supported and held in position.

Owner:ALP LIGHTING & CEILING PROD INC

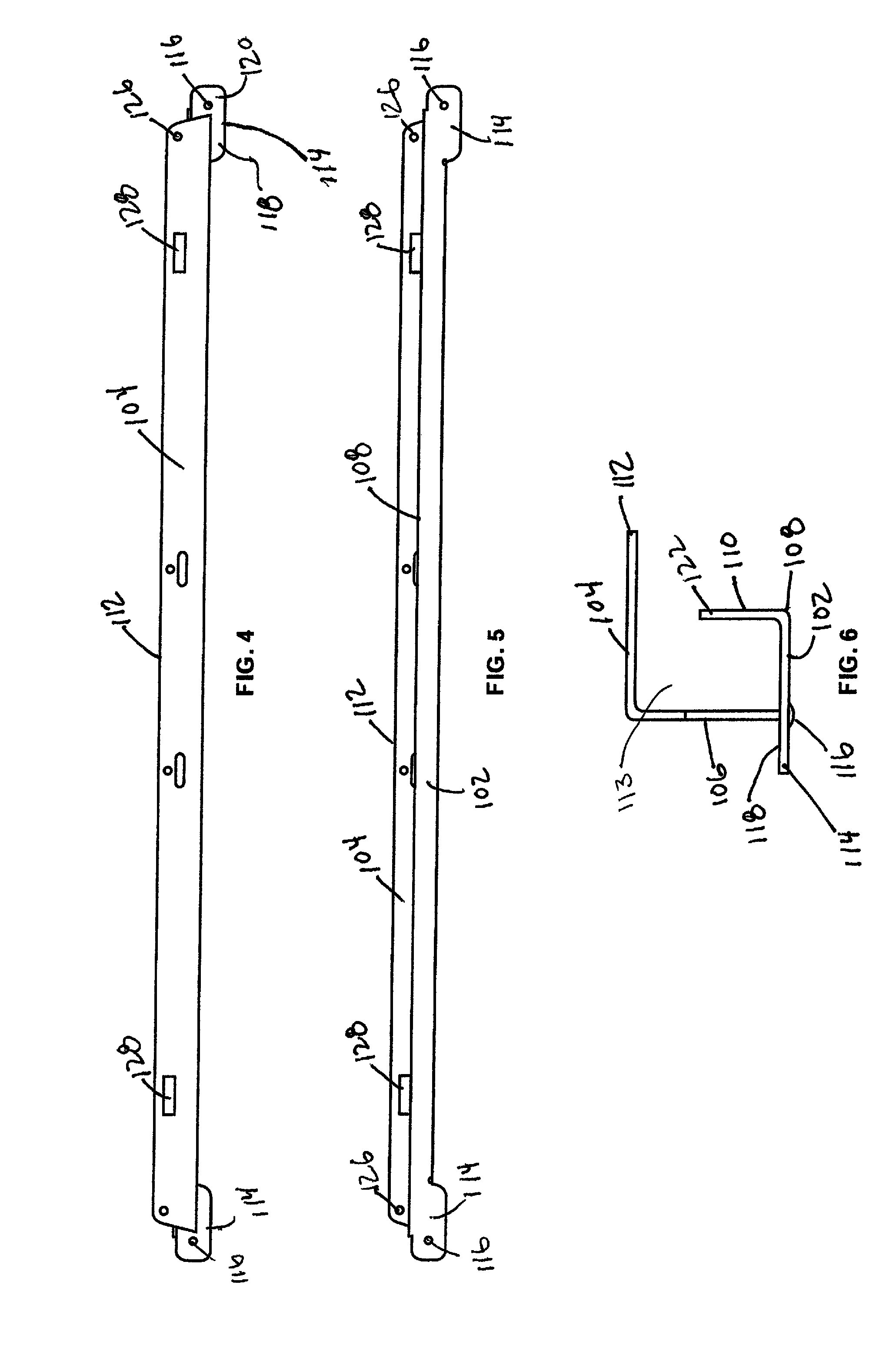

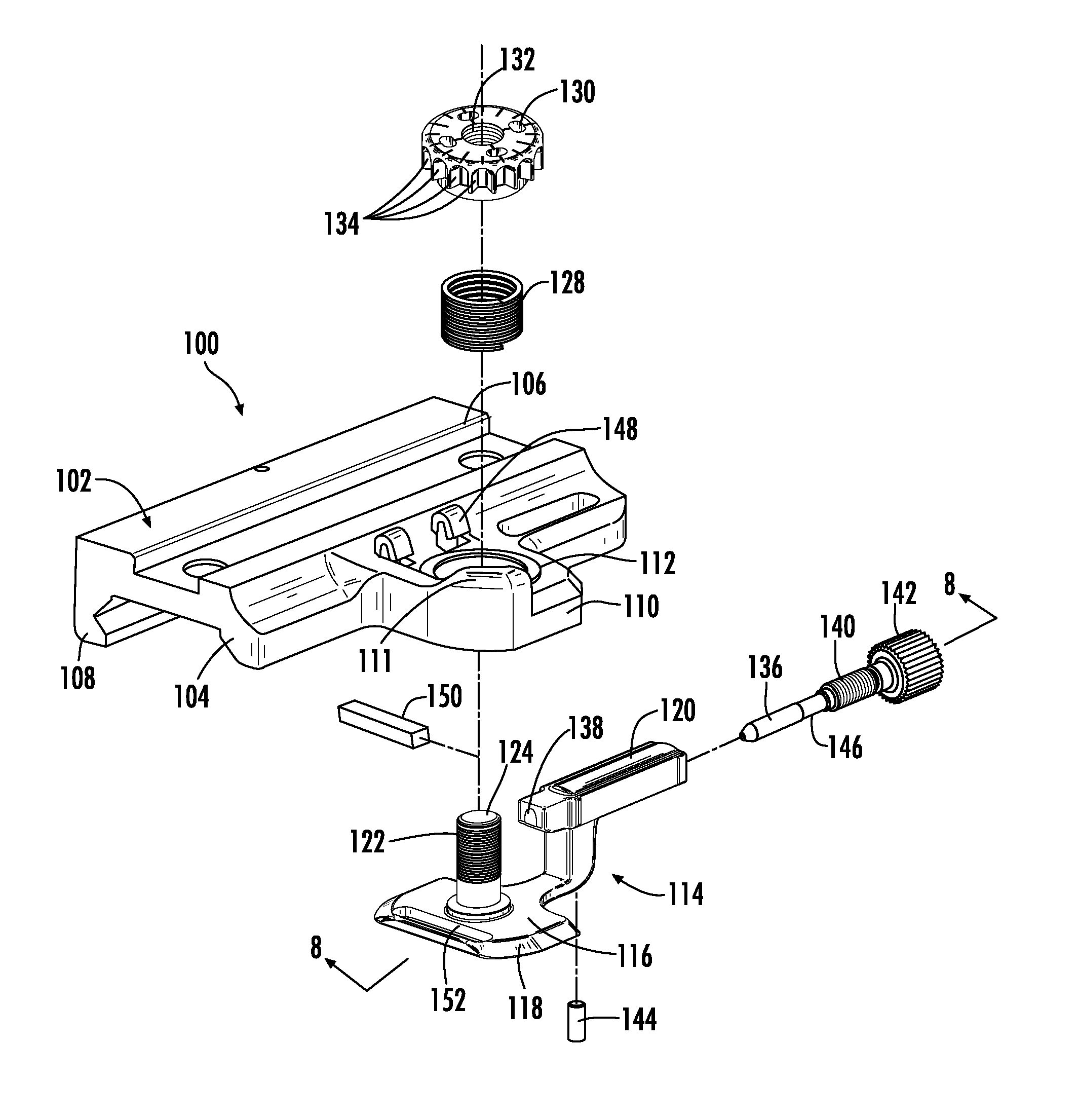

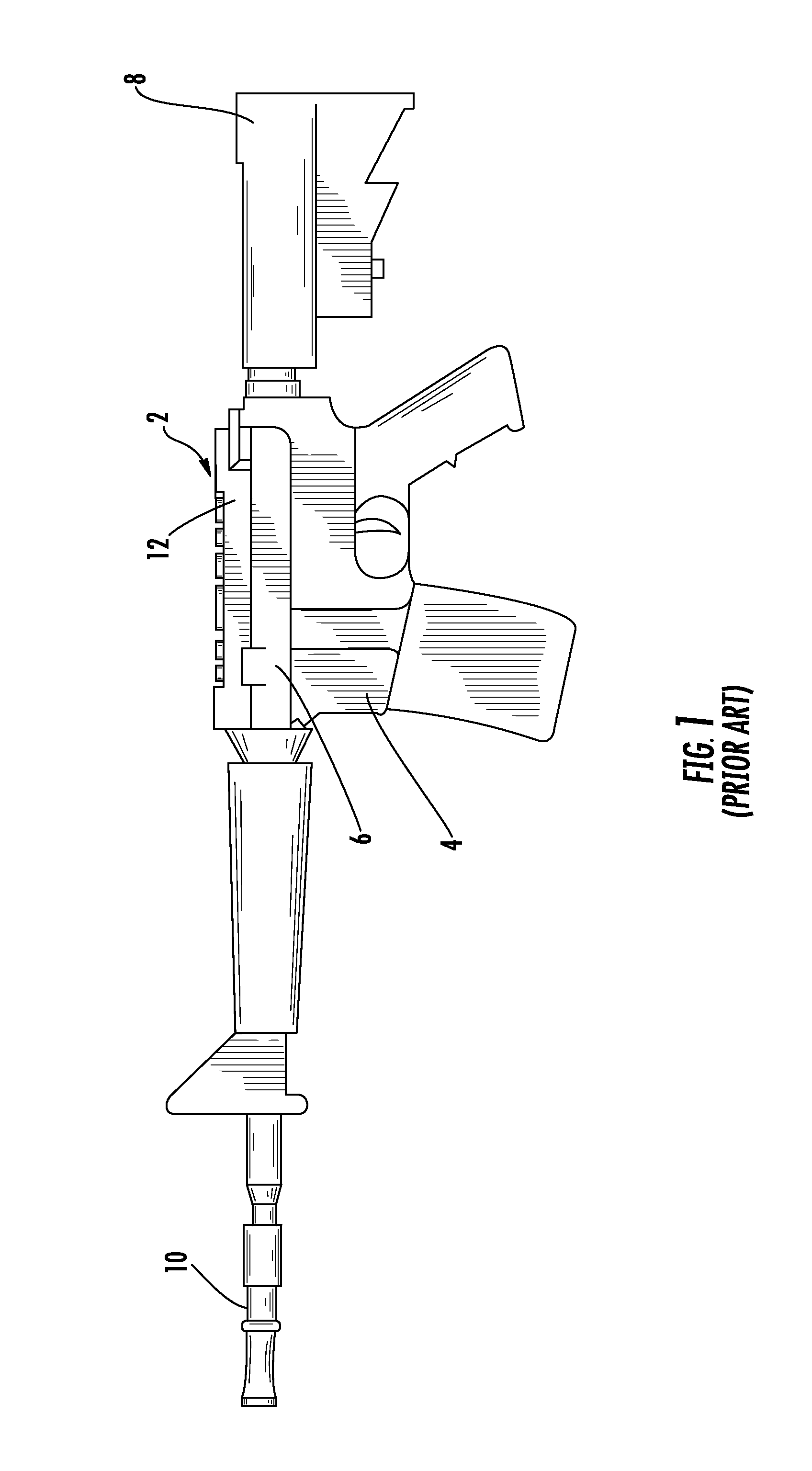

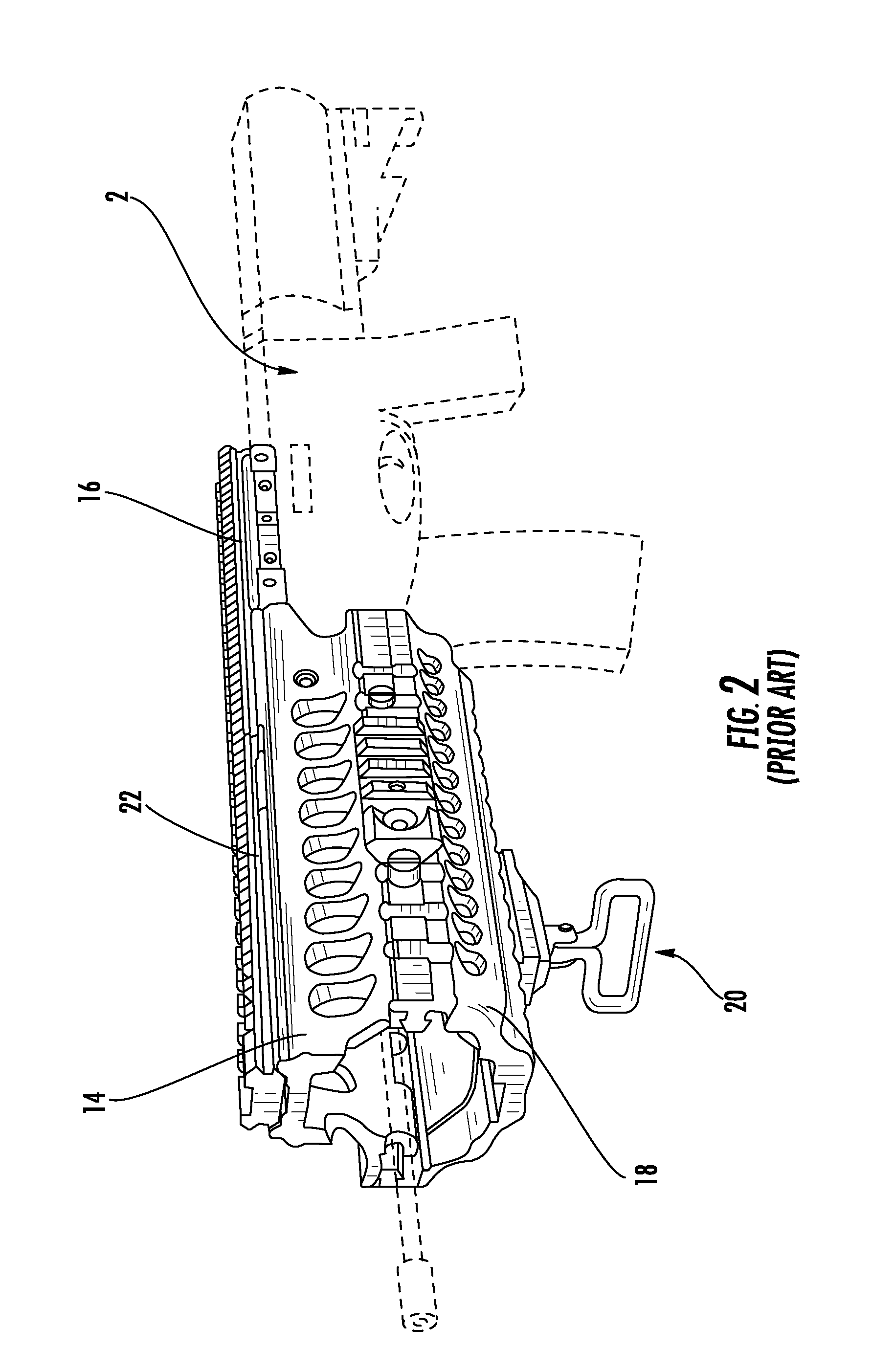

Buffered mounting assembly with magnetic foot

ActiveUS7886476B1Easy to assembleProtection wearSighting devicesRod connectionsInterface pointMechanical engineering

A mounting assembly for mounting accessories to a dovetail rail on a firearm is provided. The mounting assembly includes a main body having a lower portion with a first engagement member extending downwardly along one side thereof and a clamping assembly installed into the main body opposite the engagement member such that the clamping assembly can be engaged and disengaged with the dovetail rail to hold the mounting assembly on the dovetail rail. In addition, a buffer pad is provided between the clamping assembly and the interface point on the dovetail rail to protect the rail from wear. The clamping assembly includes a means for retracting the buffer pad when the clamping assembly is in the disengaged position, the retraction means preferably being magnetic. Such that the buffer pad is held out of the way when mounting or dismounting the mounting assembly.

Owner:SWAN RICHARD E

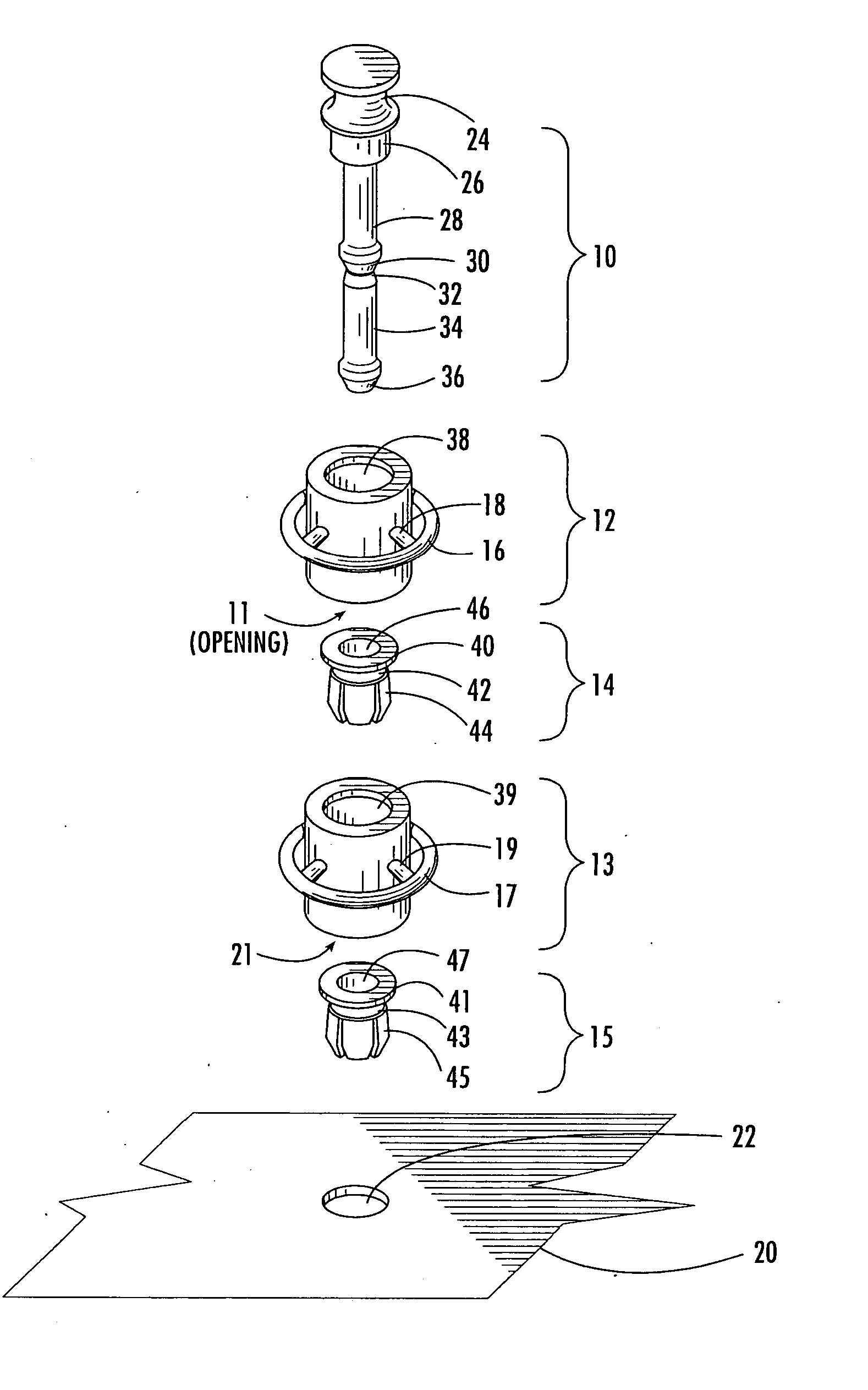

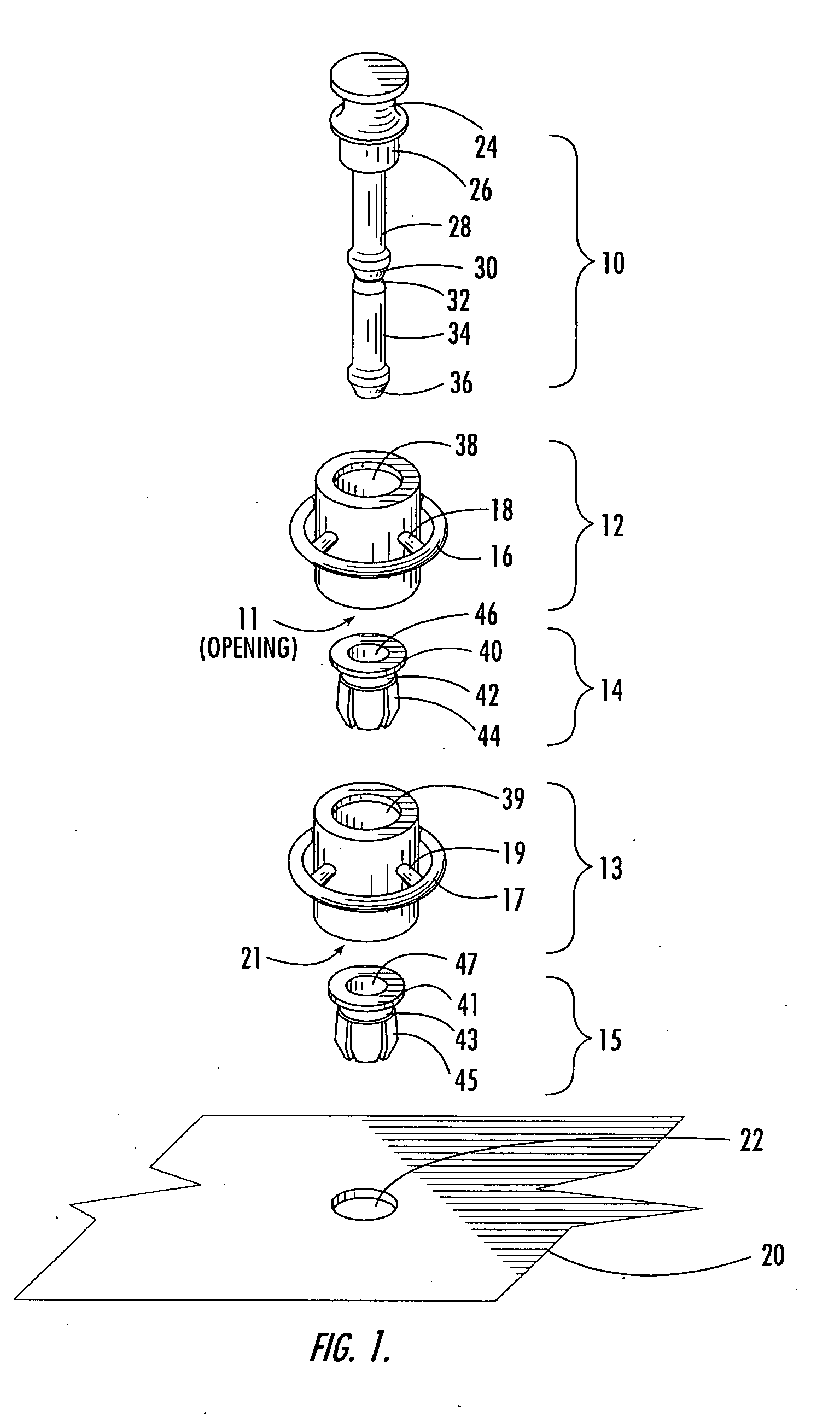

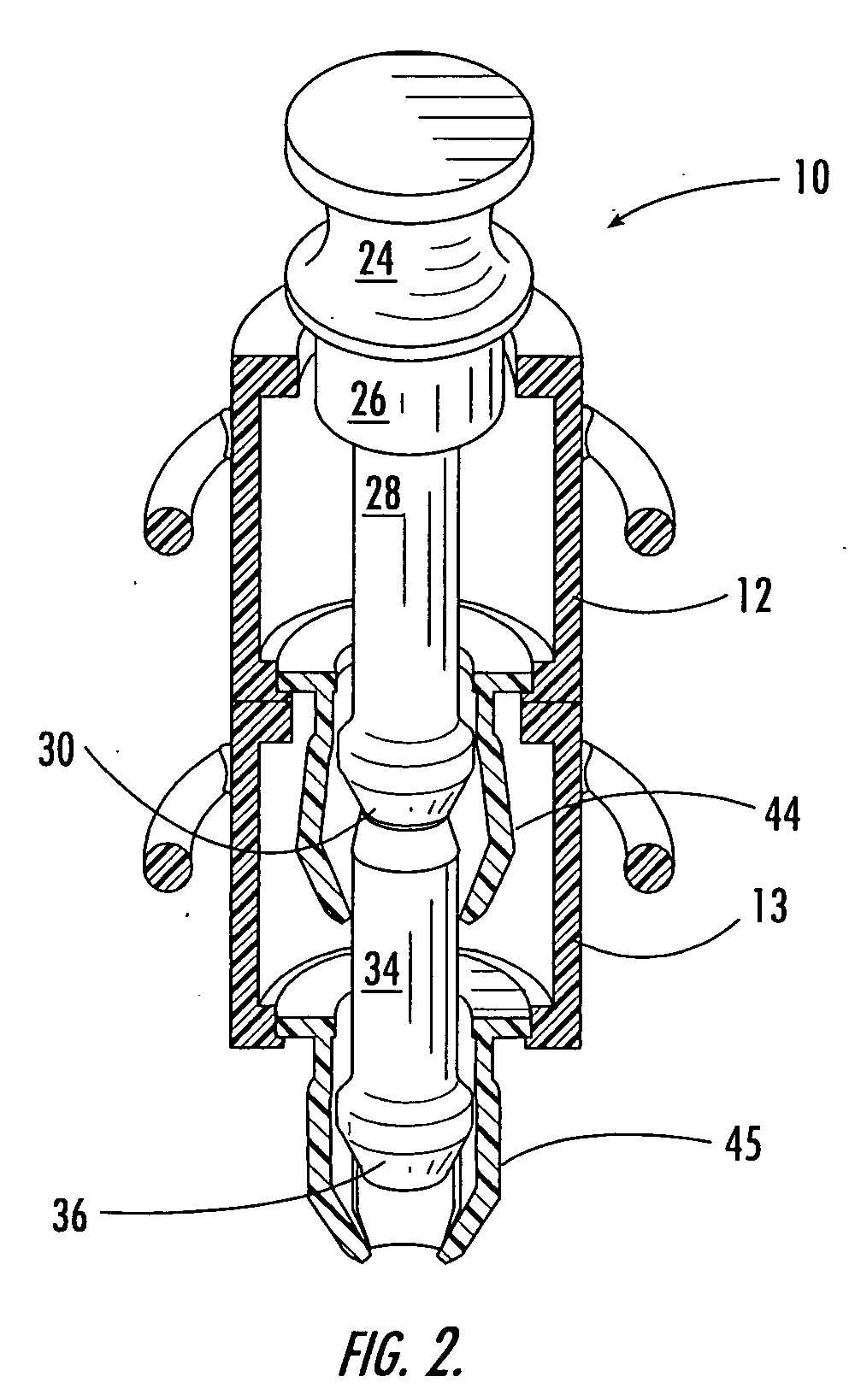

Quick release support post and associated method

A quick release support post and associated method are provided to attach a cable to a structure and later move the cable location without the need for many small parts and tools. Thus, cables and wires may be installed in hard-to-reach areas quicker and easier than with conventional clamps because no tools are required and an installer generally does not have to use both hands. Because the quick release support posts and associated method require only a hole in the structure for installation, there is no need for extra materials, and minimal weight is added to the structure during installation or movement. In addition, the quick release support posts and associated method of the present invention create efficient cable management systems because the support posts may be various lengths and cables may be grouped and secured to the support posts together, which makes trouble shooting and later moves much easier.

Owner:THE BOEING CO

System for damping thermo-acoustic instability in a combustor device for a gas turbine

InactiveUS7661267B2Improve reliabilityEasy to adjustContinuous combustion chamberGas turbine plantsCombustion chamberHelmholtz resonator

Owner:ANSALDO ENERGIA SPA

Internal Lighting for Refrigerated Display Cabinets

InactiveUS20130208447A1High degreeReduce obstaclesShow cabinetsFurnace componentsCold storeDisplay cabinet

Internal lighting for refrigerated display cabinets, chillers, cold rooms or freezers, has rearwardly-directed light assemblies incorporated in the rear faces of the vertical stiles (and / or top and bottom rails) of the door frames of the cabinet doors to illuminate the contents of the cabinets. The light assemblies may be provided in recesses, grooves or channels, and may comprise LED(s), lamps or lighting strips, connected to an electricity supply. Door switches can de-energise the light assemblies when the doors are open.

Owner:MASLEN TECH AUSTRALIA

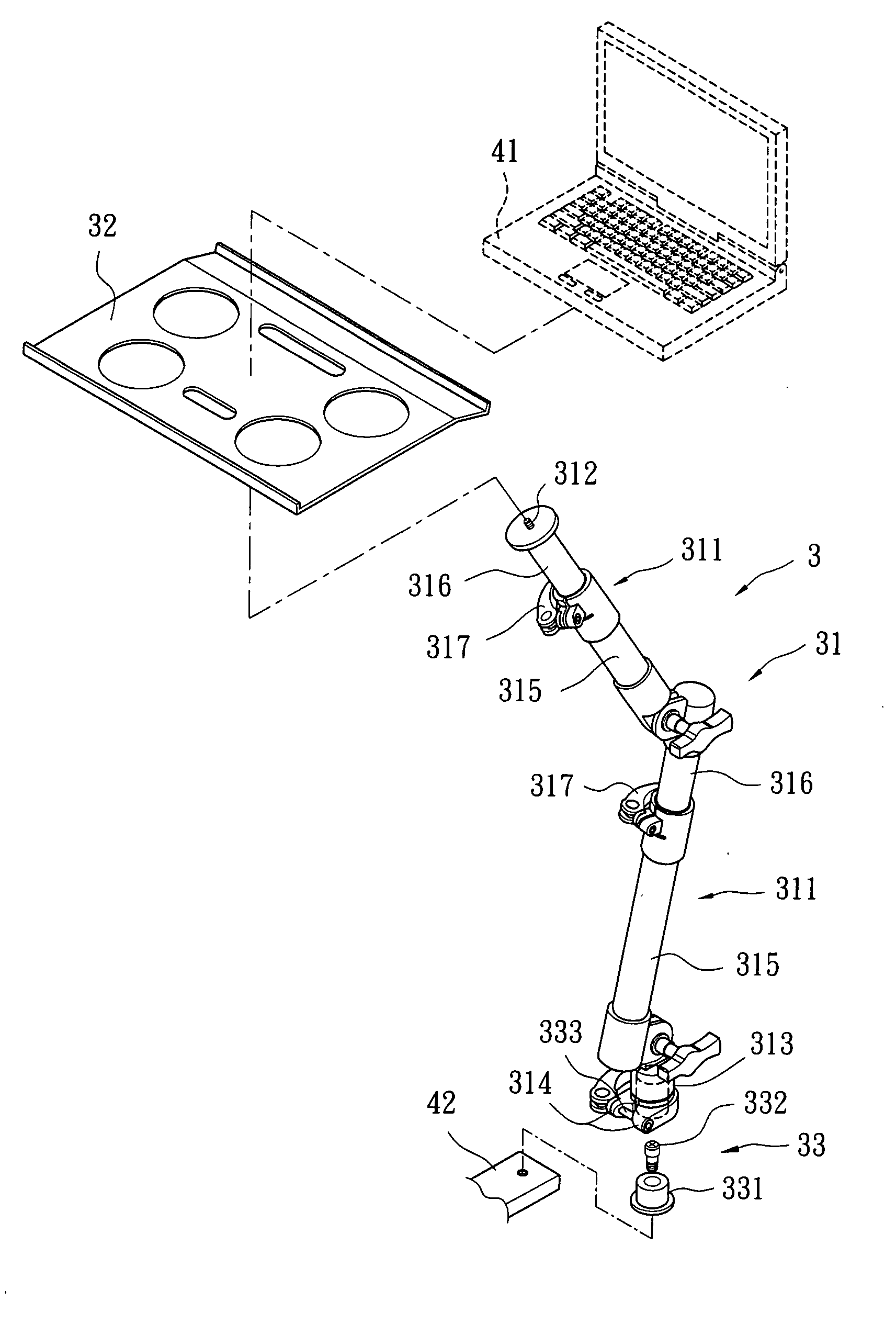

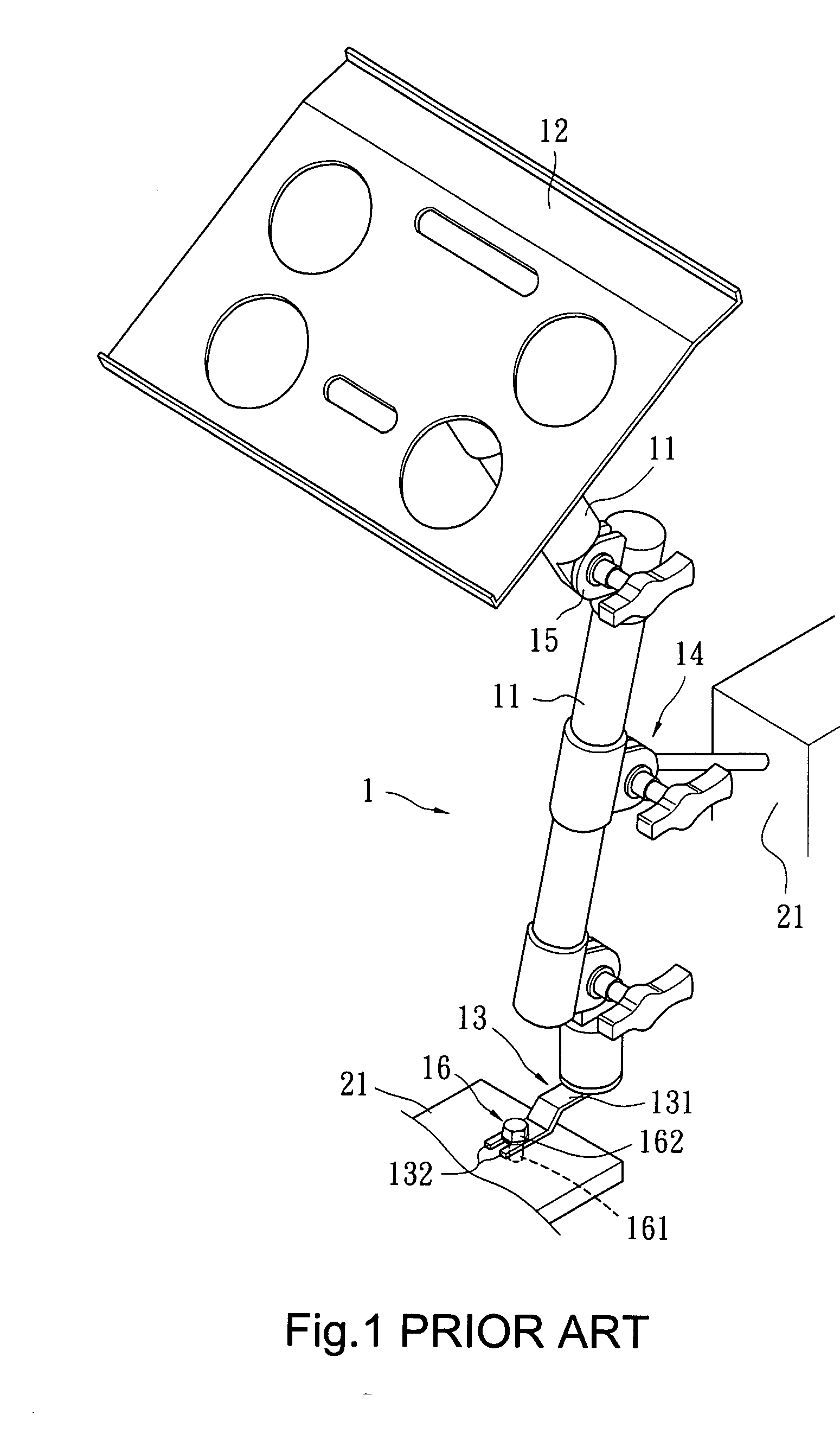

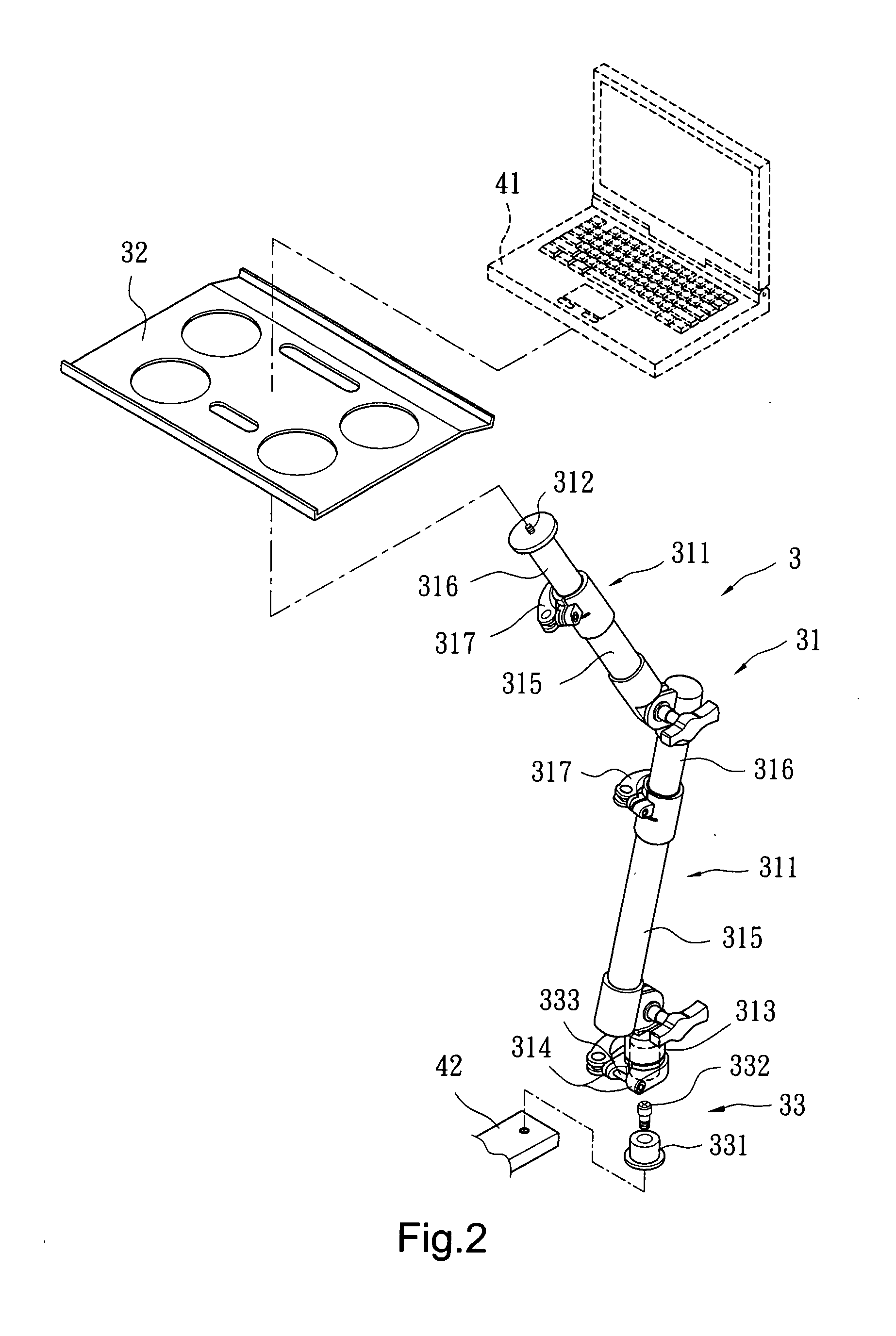

Multi-function supporting rack

InactiveUS20070295679A1Easy to assembleEasy to installStands/trestlesKitchen equipmentRack unitEngineering

A multi-function supporting rack includes a rack unit, a holding unit and a coupling unit. The rack unit has a fastening member at the top end and a hollow housing portion at the bottom end thereof. The holding unit is located on the fastening member to hold an article. The coupling unit has a latch member located in the housing portion and a connection member to couple the latch member and an equipment together. Such a design forms a greater supporting contact area between the latch member and the housing portion to provide an improved supporting effect. Moreover, once the latch member and the connection member are fastened to the equipment, the housing portion is coupled on the latch member. The finished assembly of the invention takes less space and installation is easier.

Owner:PIN ZUEN

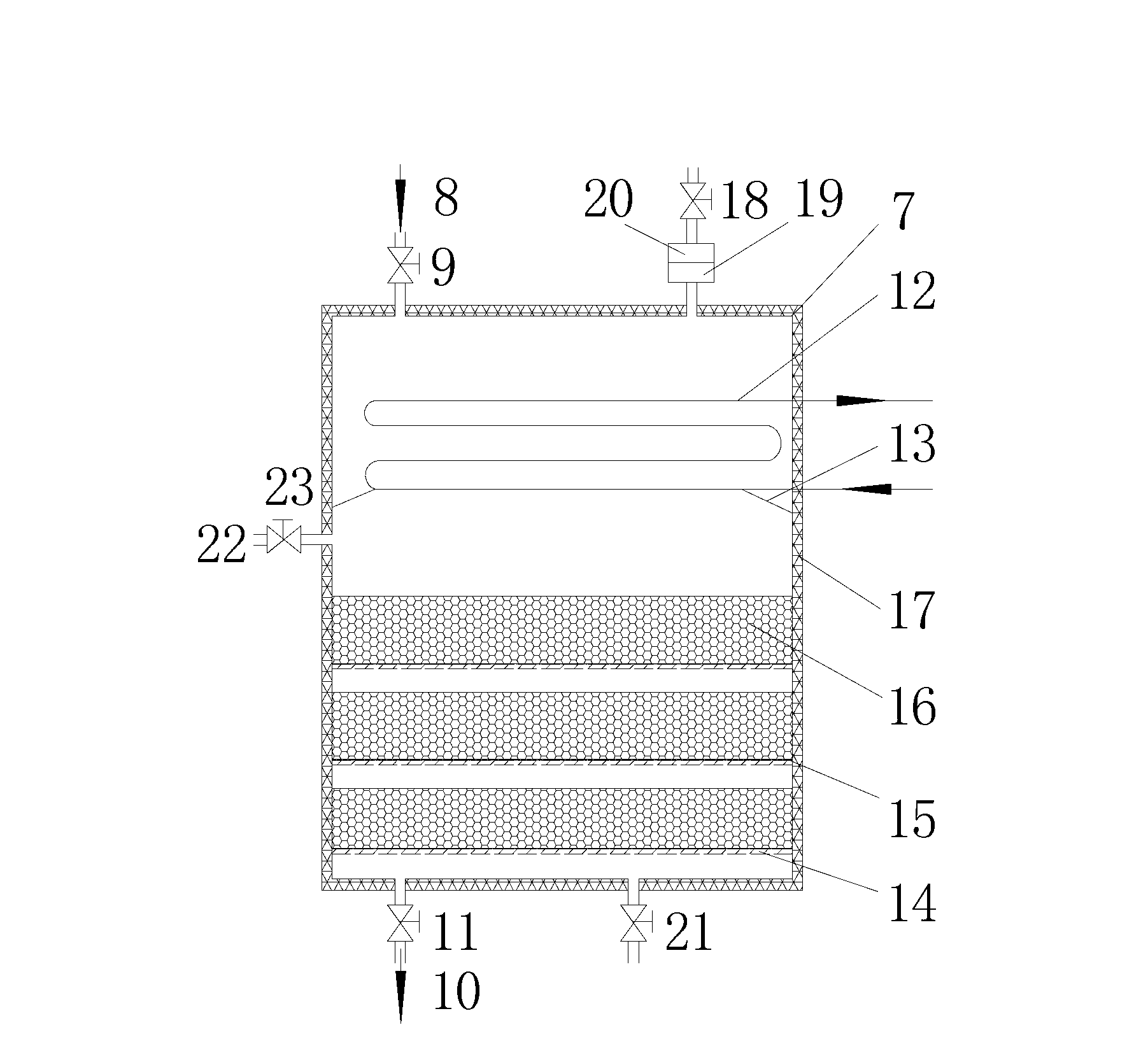

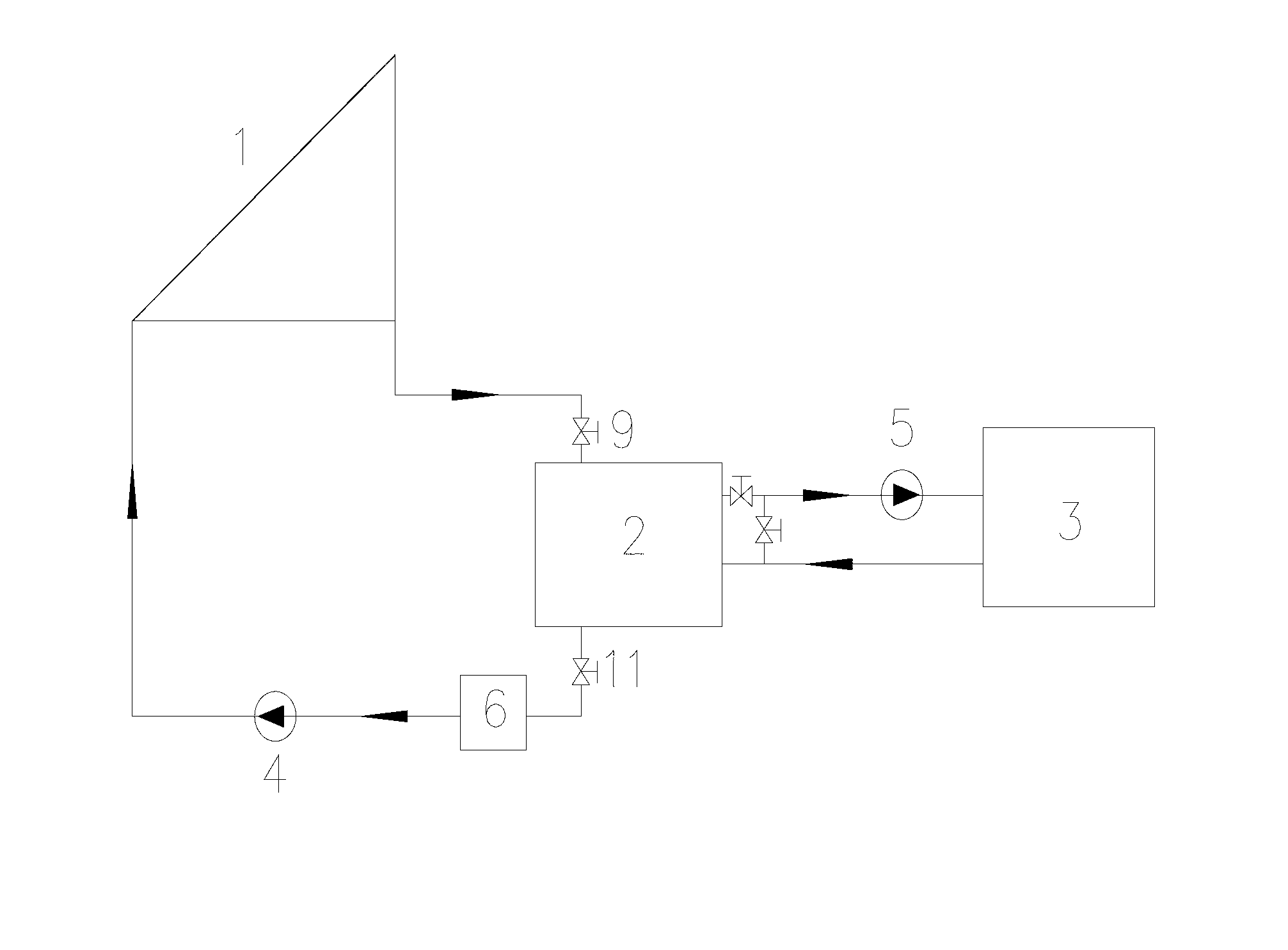

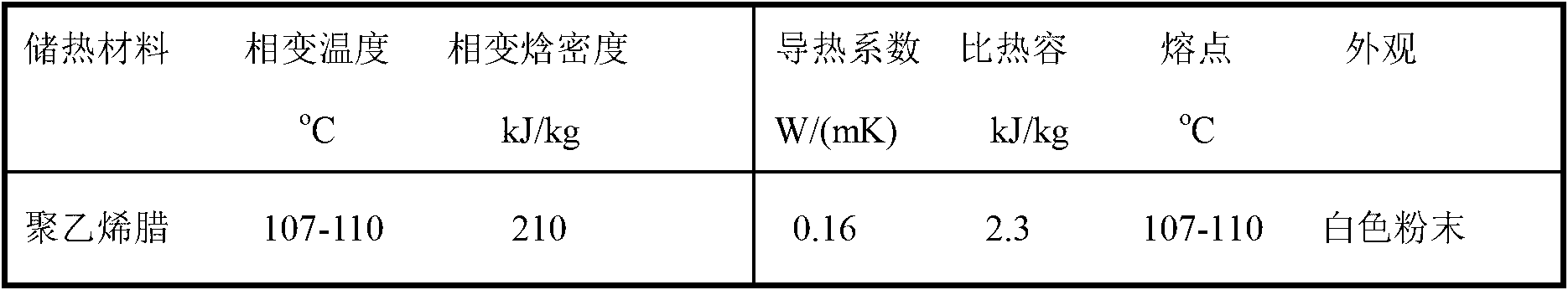

Phase-change heat transfer type intermediate temperature heat reservoir as well as manufacturing and application thereof

InactiveCN103017368AImprove heat transfer effectImprove heat transfer coefficientSolar heat devicesHeat storage plantsHeat conductingWater vapor

The invention discloses a phase-change heat transfer type intermediate temperature heat reservoir and an intermediate temperature solar air-conditioning system formed by the phase-change heat transfer type intermediate temperature heat reservoir. The phase-change heat transfer type intermediate temperature heat reservoir is a closed pressure container and comprises a box body, a plurality of ring frames, screens, heat accumulation layers and heat exchanging tubes, wherein the plurality of ring frames are respectively and horizontally fixed on the inner wall at the lower part of the box body, a plurality of screens are respectively arranged on each ring frame, the heat accumulation layers are respectively paved on each sieve screen, each heat accumulation layer is formed by mixing a composite phase-change heat accumulation material and grains of sand, the heat exchanging tubes are arranged in an inner cavity in the upper part of the box body, a tube cavity of each heat exchanging tube is isolated from the inside of the box body and is communicated with the outside of the box body, wherein a heat conducting device flows in the tube cavity, the intermediate temperature heat accumulation device takes water and water vapor as phase-change heat transfer working mediums, and the phase-change heat transfer mediums are directly evaporated or condensed on the surface of the granular composite phase-change heat accumulation material to realize phase-change heat exchange. The phase-change heat transfer type intermediate temperature heat reservoir and the intermediate temperature solar air-conditioning system have the advantages of excellent heat exchange capability, high solar utilization ratio, simple structure, easy manufacture and long service life.

Owner:SHANGHAI JIAO TONG UNIV +1

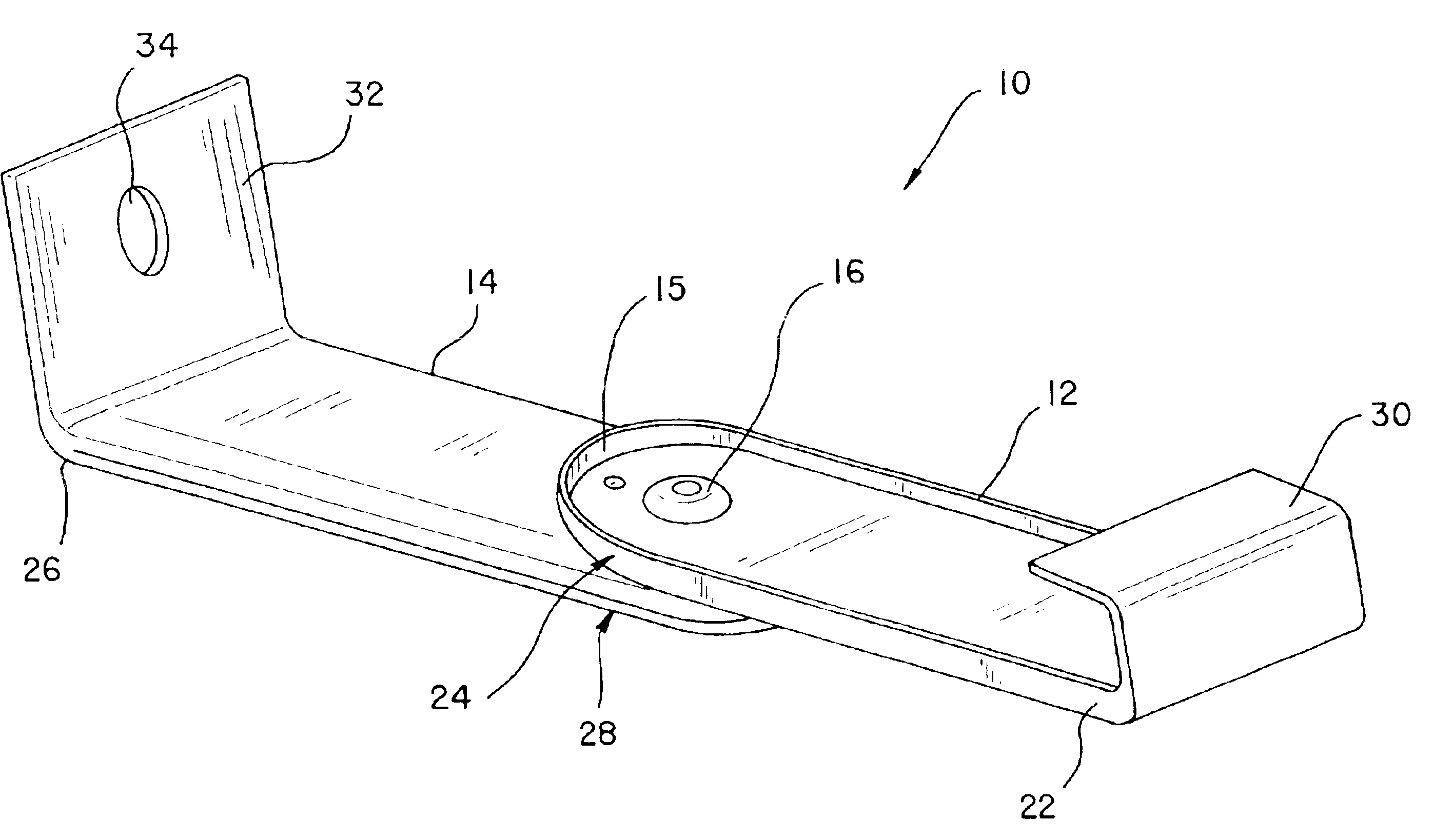

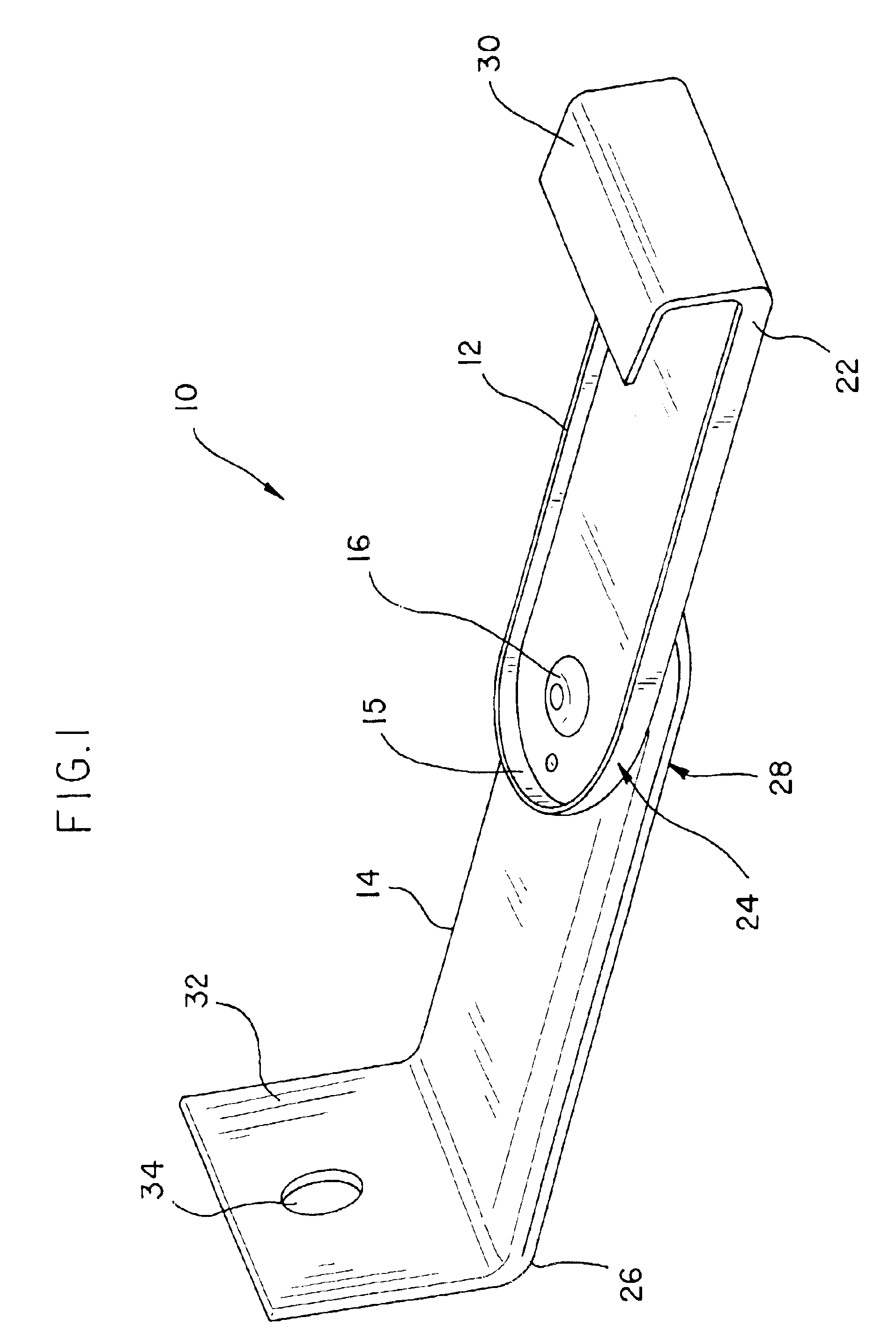

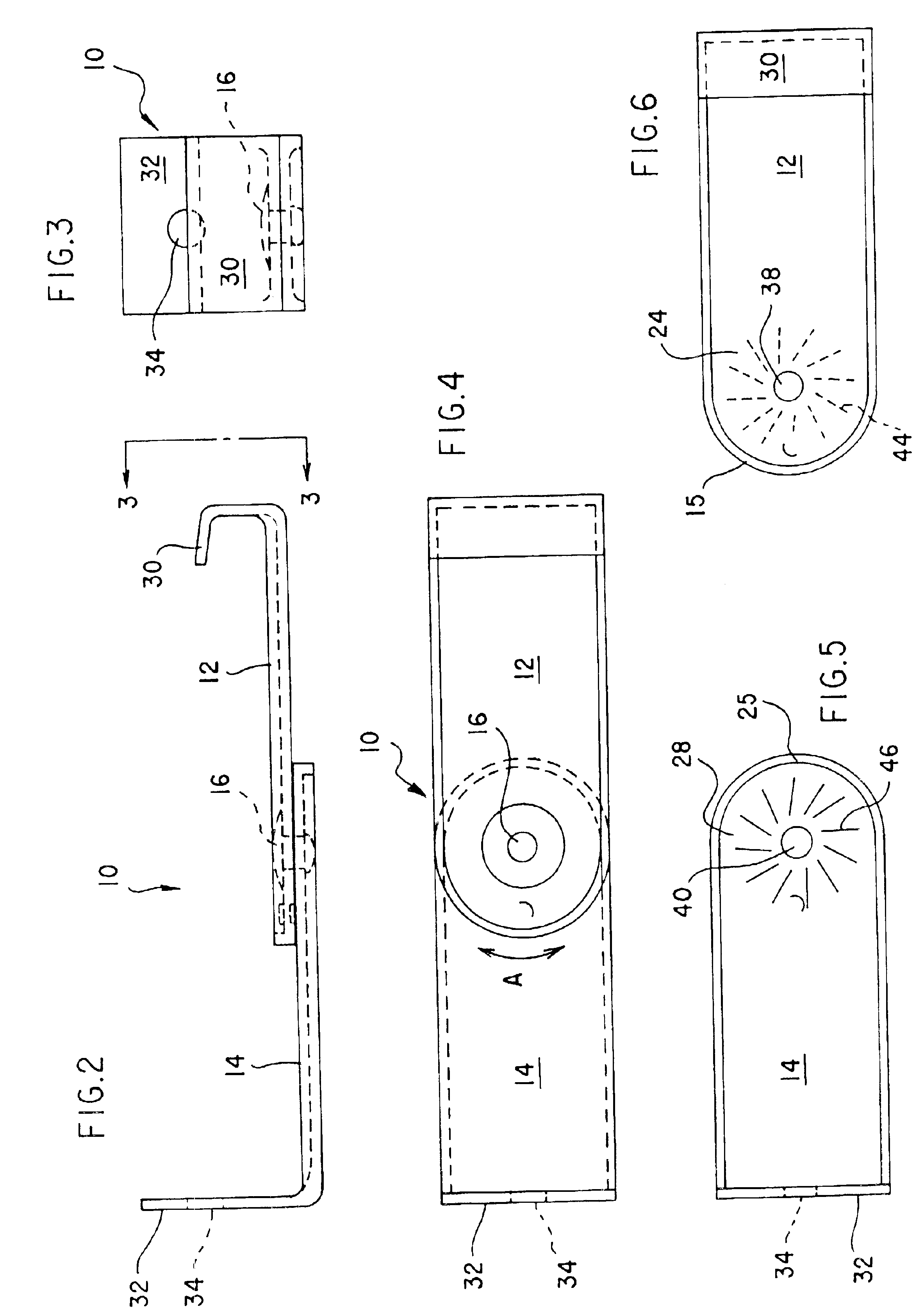

Swivelling gutter support and installation method

A swiveling gutter support or bracket is provided to be used to hang and support conventional existing gutters. The gutter support, when affixed to the gutter, keeps the gutter open as well as secured to the building sidewall. The gutter support has a first portion, an intermediate portion and a second portion. The first portion is adapted to be received within the gutter lip. The intermediate portion connects the first portion to the second portion and includes a swivel. In some configurations, especially using plastics, the first portion may be directly molded to the second portion, and the two portions would be able to rotate. The swivel connects the first portion to the second portion. The swivel also permits the second portion to rotate with respect to the first portion. Once rotated, the second portion aligns with the side of the house. An aperture is provided on the second portion structure. The aperture is adapted to receive a fastener such as a nail, screw or the like there through. The nail will pass through the second portion, through the flashing which is in contact with the building sidewall, and into the building sidewall securing the gutter support thereto. The swivelling gutter support may be made from metal, plastic or other material which has sufficient material properties.

Owner:WINKEL BRANDON J

Emergency release assembly and sliding door incorporating the same

InactiveUS20060150512A1Simple and reliable in constructionSimple and reliable in and operationBuilding locksWing suspension devicesReciprocating motionEmergency situations

An emergency release assembly for a door includes a latch mechanism to retain the door in a normally closed position yet releases to let the door move to an emergency open position. A release mechanism triggers the latch mechanism. The release mechanism has a reciprocating member that operates the latch mechanism. A push bar moves from an extended position through an intermediate position to a depressed position. A link member interconnects the push bar and the reciprocating member. When the push bar moves from the intermediate to the depressed position, it operates the reciprocating member to trigger the latch mechanism. A catch member operates to limit movement of the push bar between the intermediate and depressed positions but can be released to allow the push bar to move to the extended position. When the push bar is in the intermediate position, it is flush with the door muntin.

Owner:ADAMS RITE MFG CO

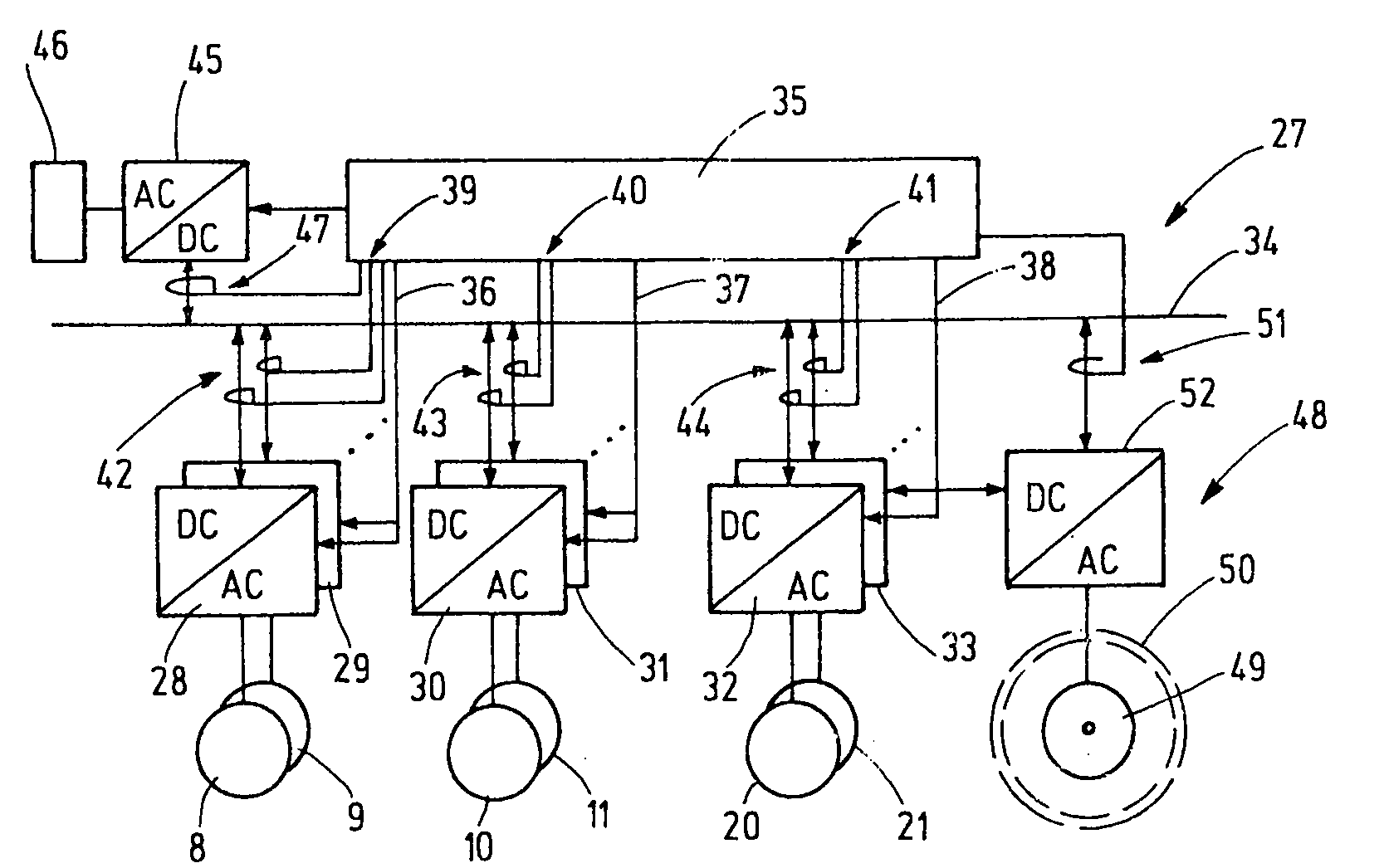

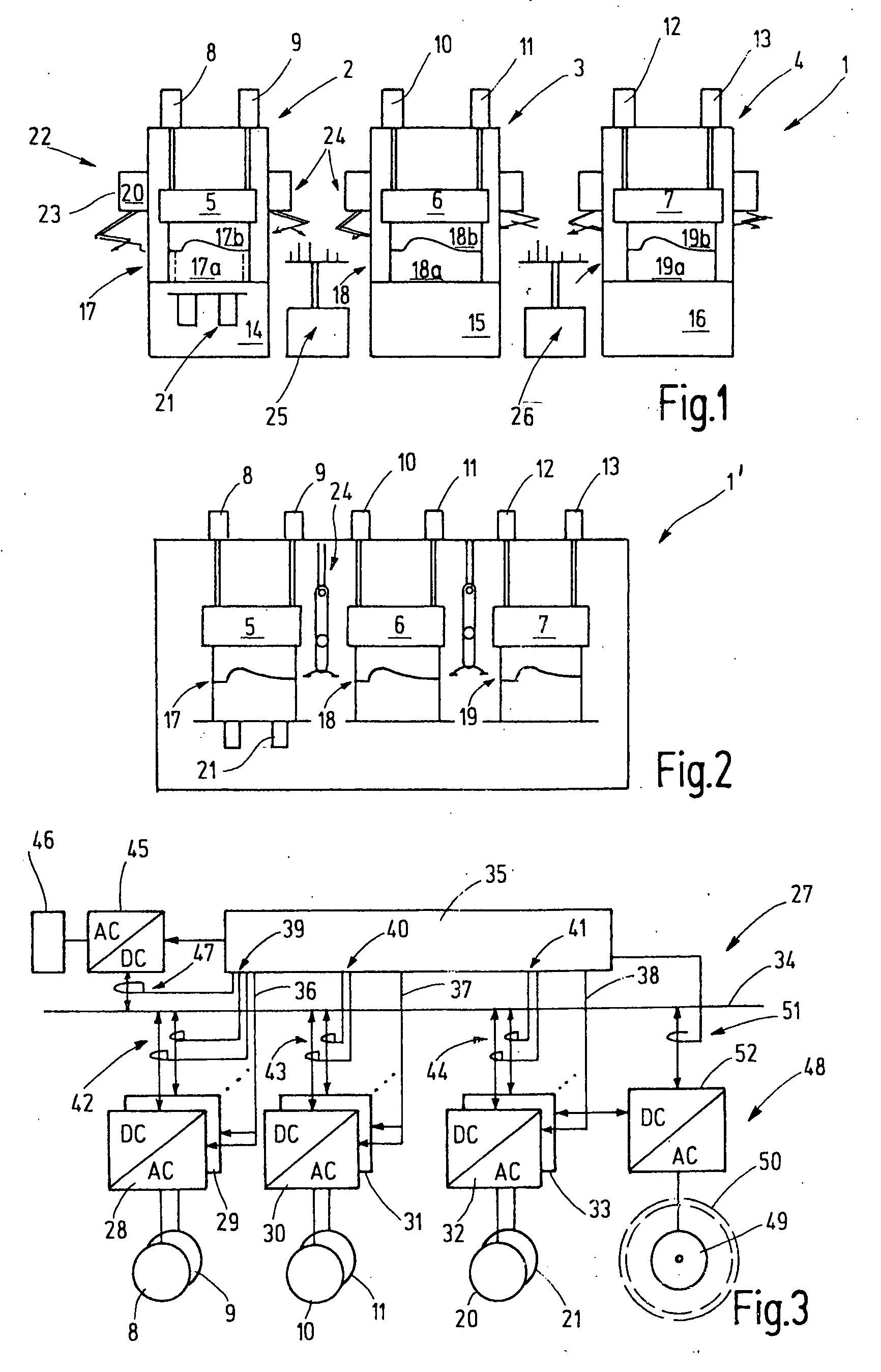

Servo-press with energy management

InactiveUS20080016940A1Arrangement be smallLow costDrop hammersMetal-working feeding devicesServo pressEnergy management system

In a press installation including a number of presses with servo-drives for operating the presses and auxiliary equipment such as workpiece handling devices wherein an energy management system is provided including a DC voltage intermediate circuit connected to a power supply grid via an AC / DC converter and to the servo-drives via servo-converters, a fly-wheel storage device is connected to the intermediate circuit for supplying energy thereto and recapturing energy therefrom under the control of a control arrangement which controls the flow of power between the intermediate circuit, the servo-drives, the fly-wheel storage device and the power supply grid.

Owner:SCHULER PRESSEN GMBH & CO KG

Roof underlayment

An underlayment sheet (10, 10′) is applied in overlapping courses to a roof deck (36) for establishing a weather-resistant membrane for use as a final exposed surface or below a roof covering (50). The underlayment sheet (10, 10′) has a bottom surface (16, 16′) to which a pressure sensitive adhesive section (22, 22′) is applied generally continuously along its length. A non-adhesive section (24, 24′) also extends the length of the bottom surface (16, 16′) adjacent its upper long edge (18, 18′) for providing a contact surface with the roof deck (36) which is devoid of any adhesive material. The non-adhesive section (24, 24′) is attached to the roof deck (36) using tin tags (44, 44′) or other mechanical fastening components. When subsequent underlayment sheets (10, 10′) are applied in overlapping courses, the adhesive sections (22, 22′) bond over the preceding underlayment sheet (10, 10′) to establish a water tight seal. The top surface (14) of the underlayment sheet (10) may include a supplemental bonding strip (30) which adheres directly to the adhesive section (22) of an overlying underlayment sheet (10) to establish a tenacious seal. The top surface (14′) may also be impregnated with a course granular material (52) to serve as a final, exposed surface for the roof in lieu of shingles or the like. If a future re-roofing operation is required, the subject underlayment system can be removed from the roof deck (36) without damaging or delaminating the roof deck (36) material.

Owner:T&S NEWCO

Wireless Vehicle Communication Method Utilizing Wired Backbone

InactiveUS20090323578A1Fast communication speedImprove reliabilityFrequency-division multiplex detailsNetwork topologiesComputer networkElectronic communication

Owner:ROBERT BOSCH GMBH

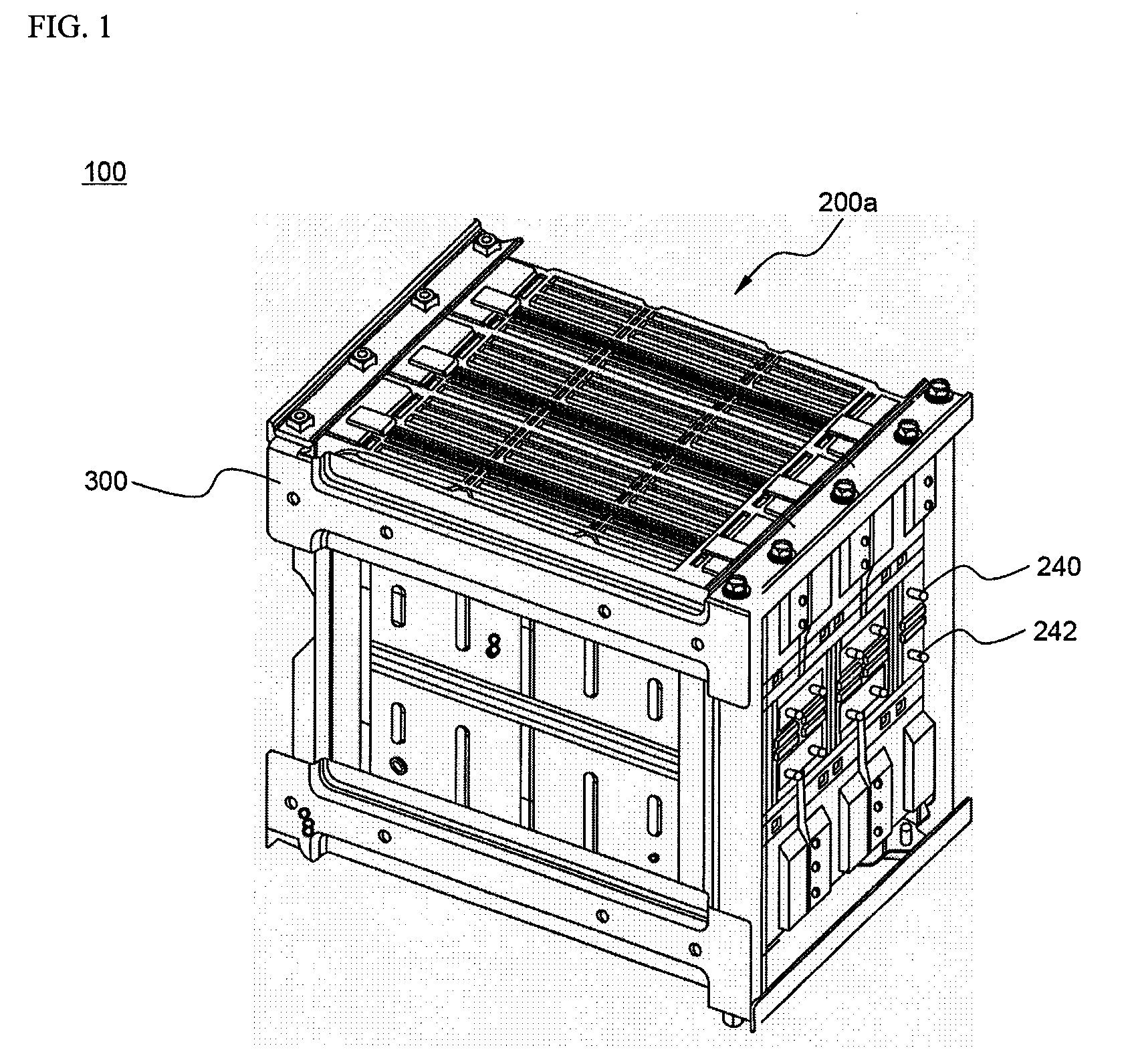

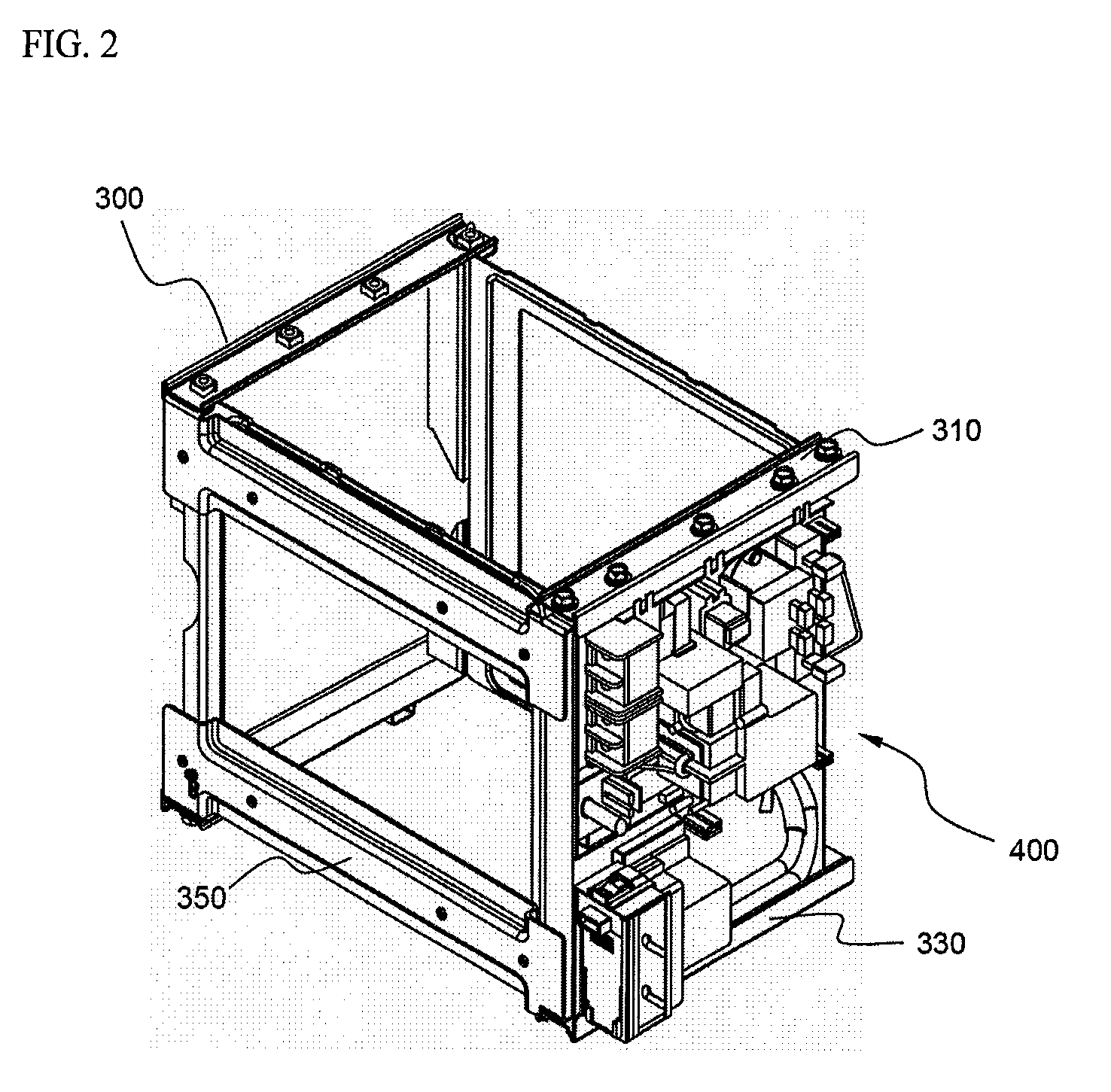

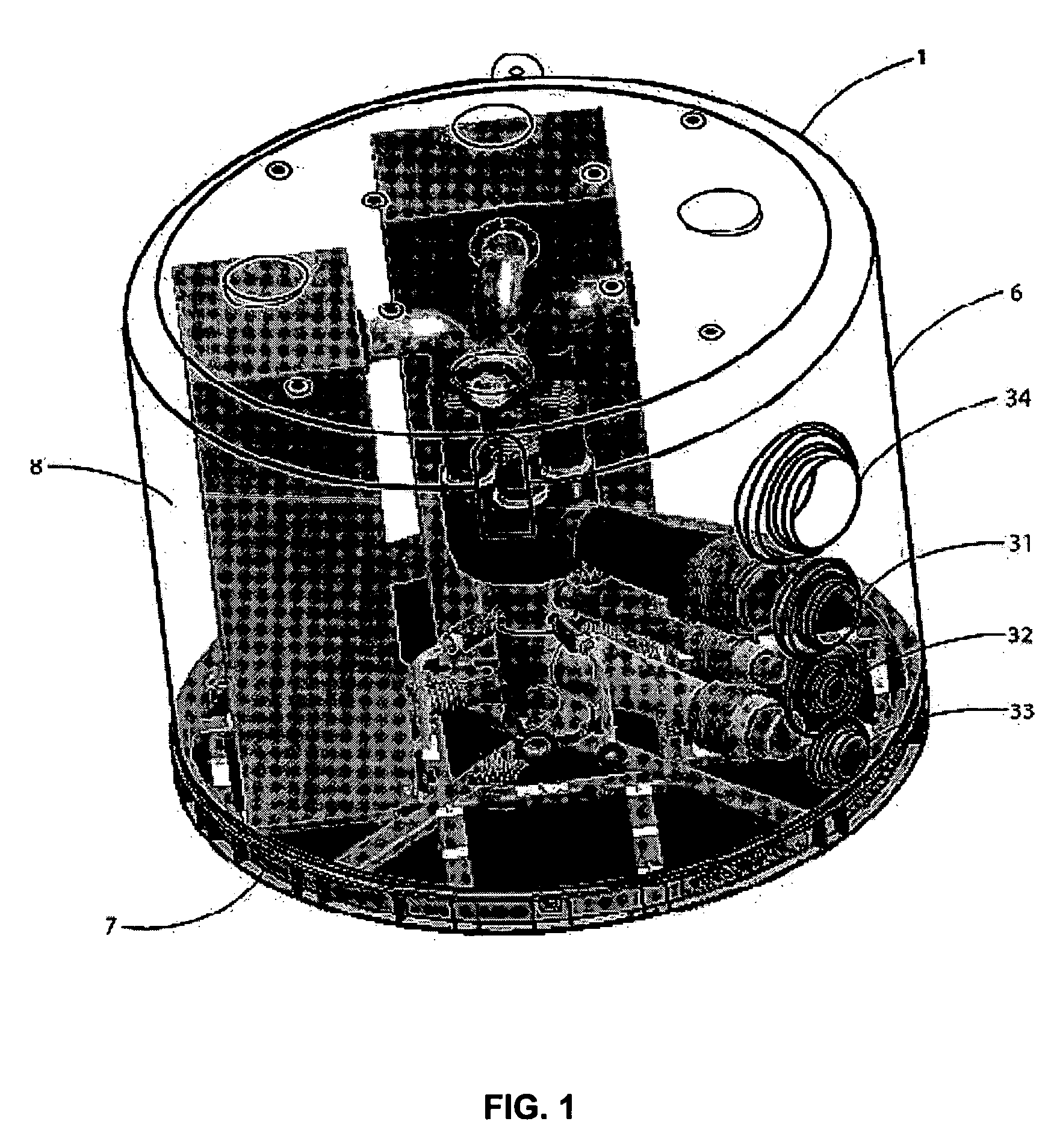

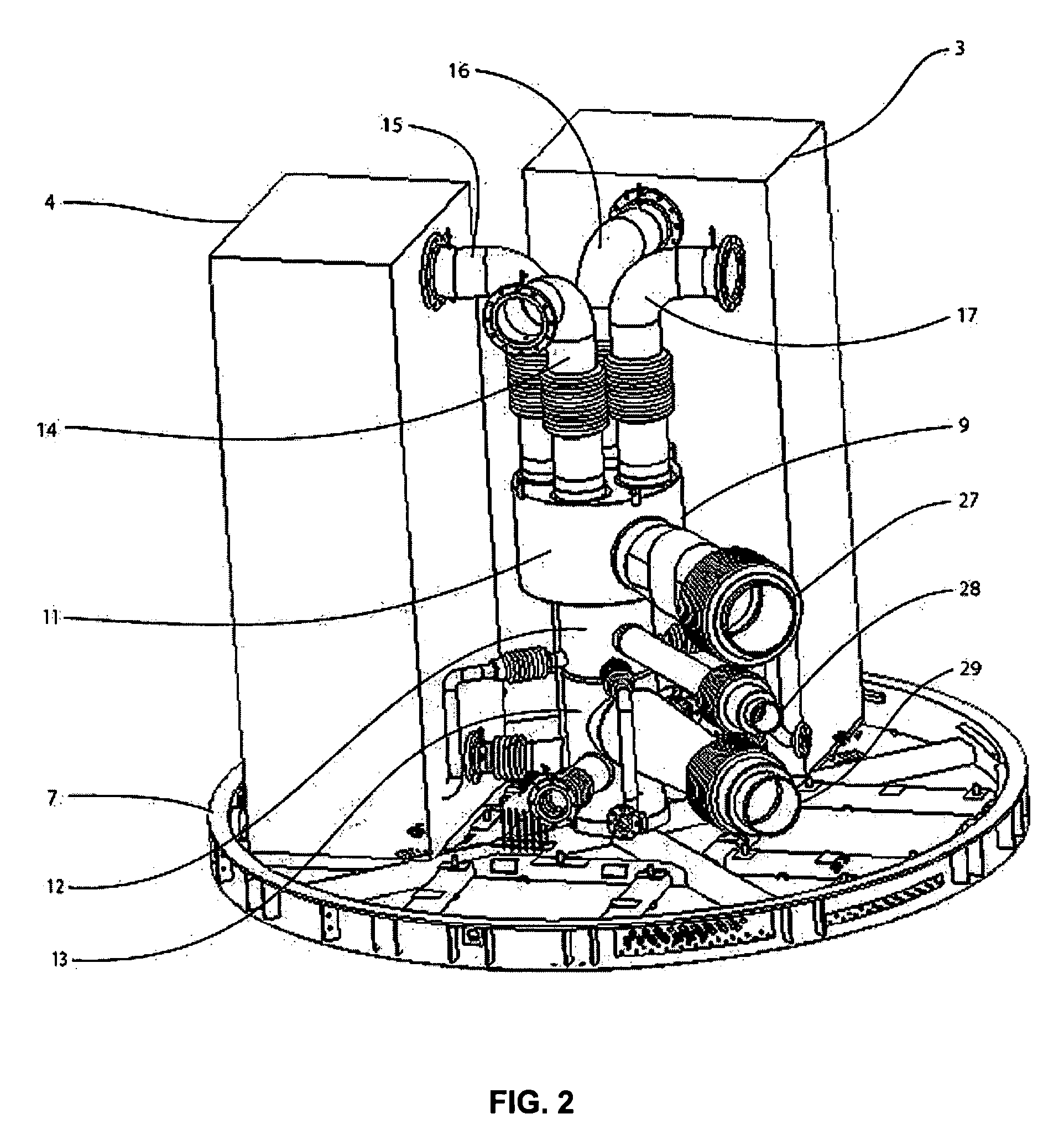

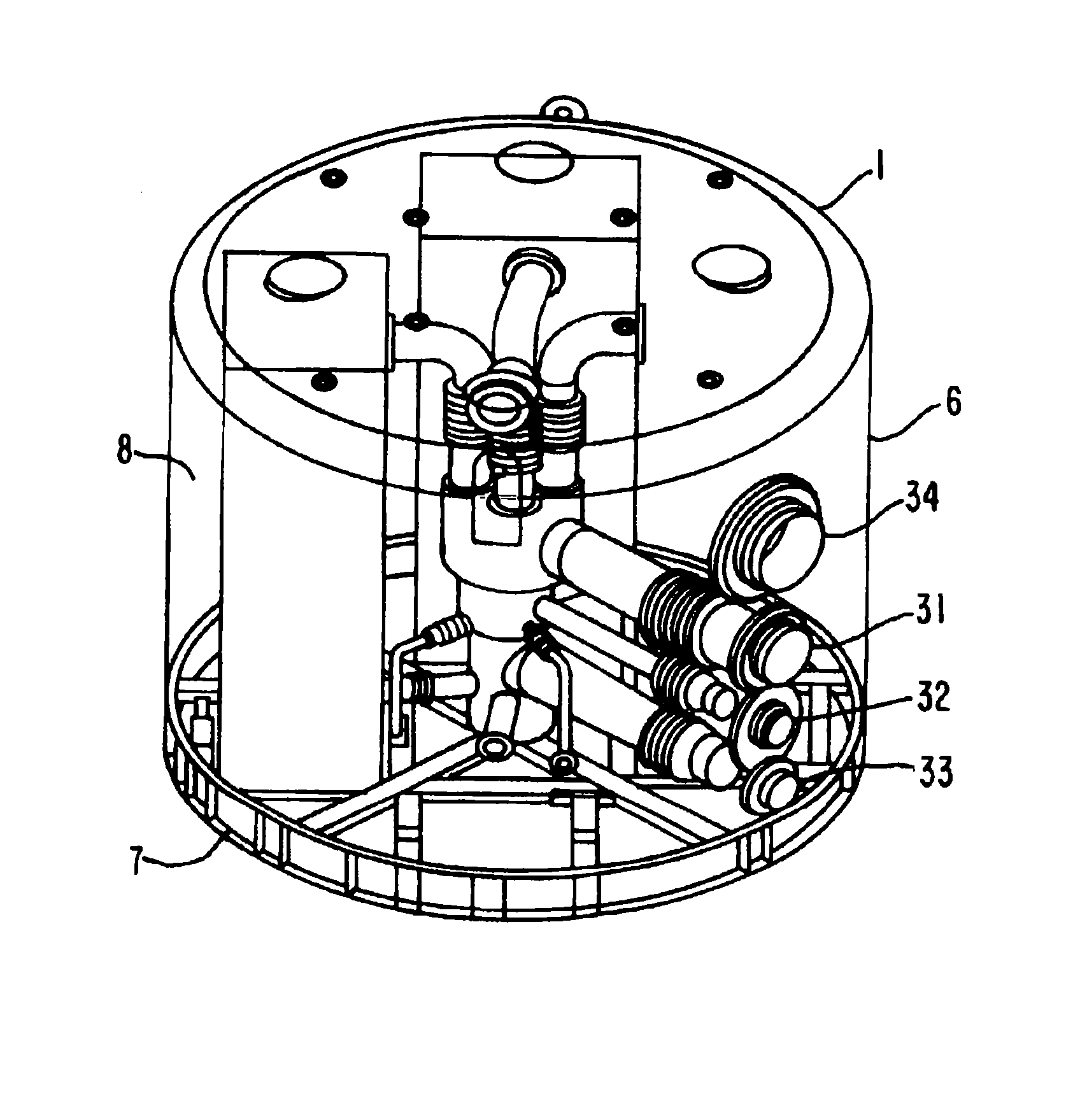

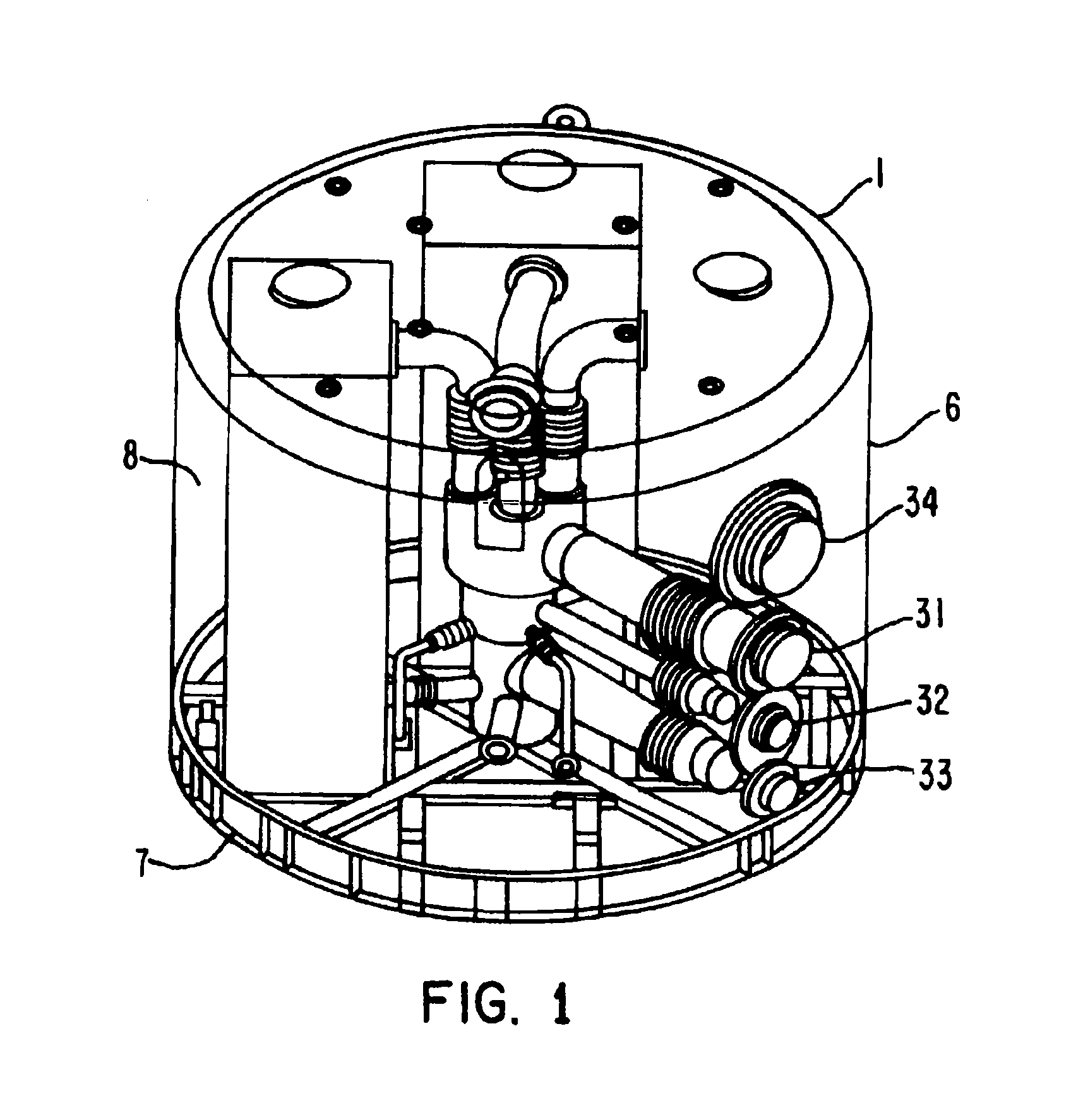

Modular fuel-cell stack assembly

InactiveUS20060035135A1Reduce needCompactnessFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A modular multi-stack fuel-cell assembly in which the fuel-cell stacks are situated within a containment structure and in which a gas distributor is provided in the structure and distributes received fuel and oxidant gases to the stacks and receives exhausted fuel and oxidant gas from the stacks so as to realize a desired gas flow distribution and gas pressure differential through the stacks. The gas distributor is centrally and symmetrically arranged relative to the stacks so that it itself promotes realization of the desired gas flow distribution and pressure differential.

Owner:FUELCELL ENERGY INC

Modular fuel-cell stack assembly

A modular multi-stack fuel-cell assembly in which the fuel-cell stacks are situated within a containment structure and in which a gas distributor is provided in the structure and distributes received fuel and oxidant gases to the stacks and receives exhausted fuel and oxidant gas from the stacks so as to realize a desired gas flow distribution and gas pressure differential through the stacks. The gas distributor is centrally and symmetrically arranged relative to the stacks so that it itself promotes realization of the desired gas flow distribution and pressure differential.

Owner:FUELCELL ENERGY INC

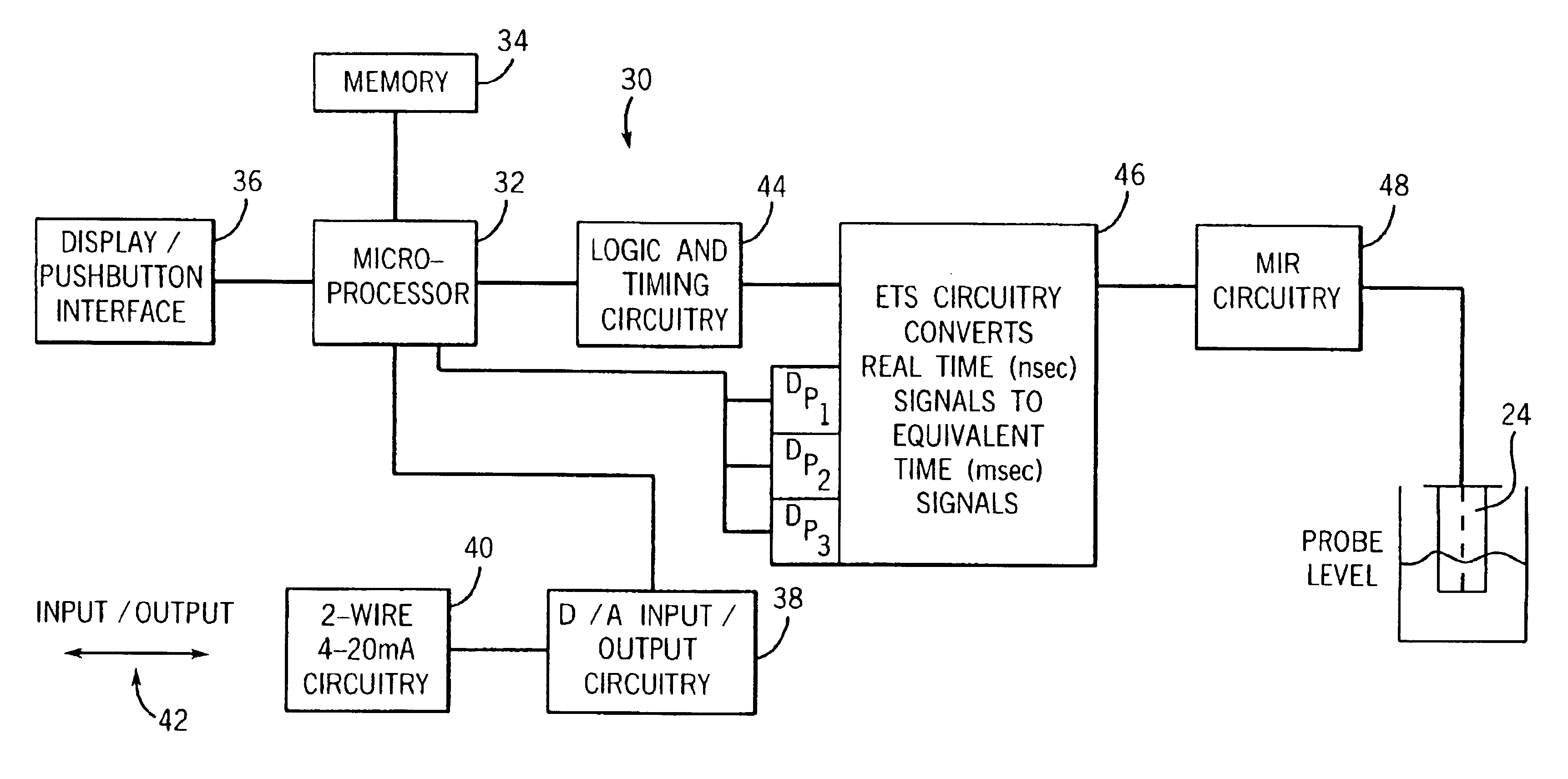

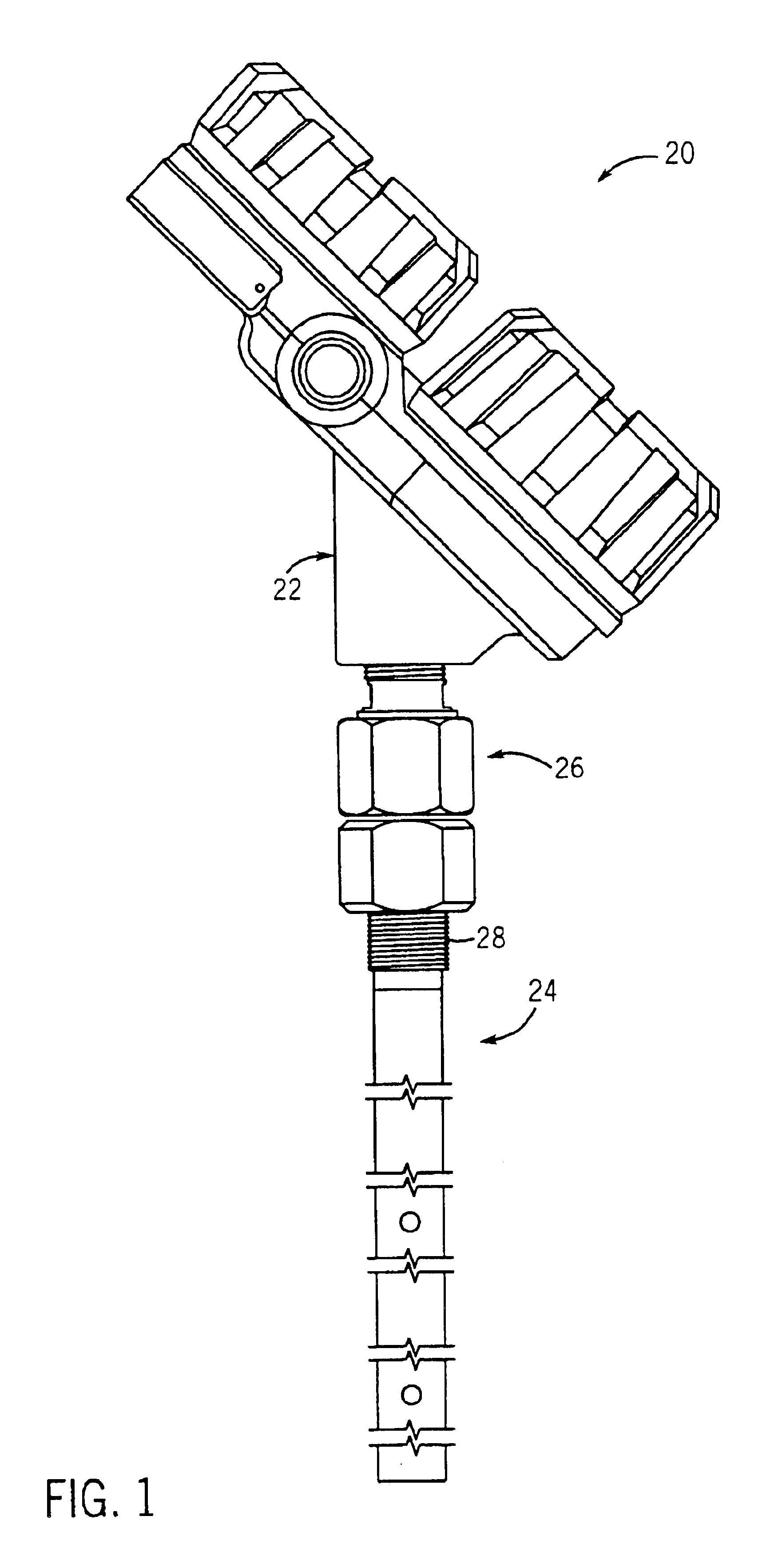

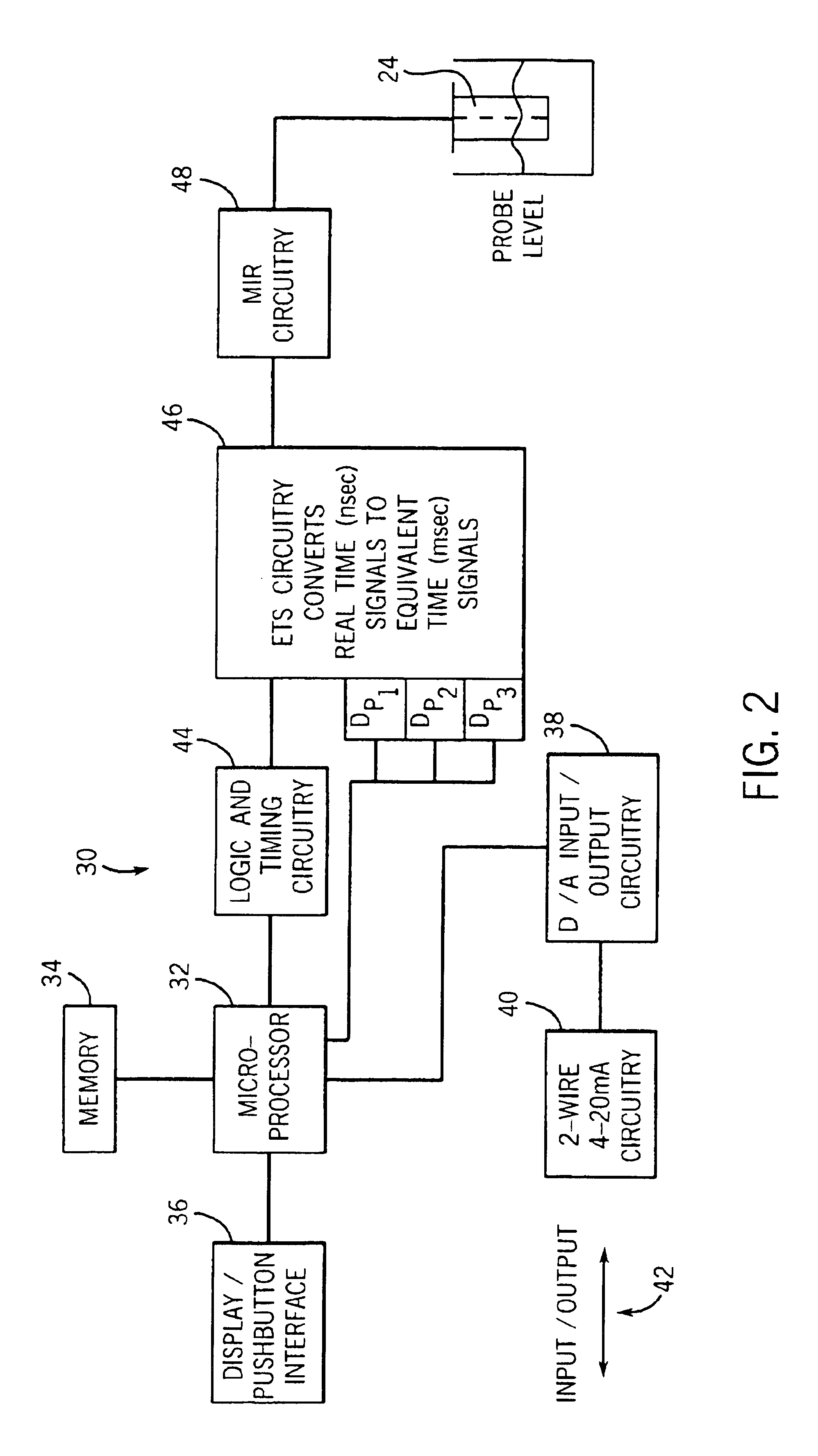

Time domain reflectometry measurement instrument

InactiveUS6906662B2Improved diagnostic and measurement featureInstallationResistance/reactance/impedenceMachines/enginesTime domainDielectric

A time domain reflectometry measuring instrument uses a microprocessor that provides added functionality and capabilities. The circuit electronics and probe are tested and calibrated at the factory. Installation and commissioning by the user is simple. The user installs the probe. The transmitter is attached to the probe. The user connects a standard shielded twisted pair to the electronics. Power is applied and the device immediately displays levels. A few simple parameters may need to be entered such as output characteristics and the process material dielectric constant.

Owner:MAGNETROL INT

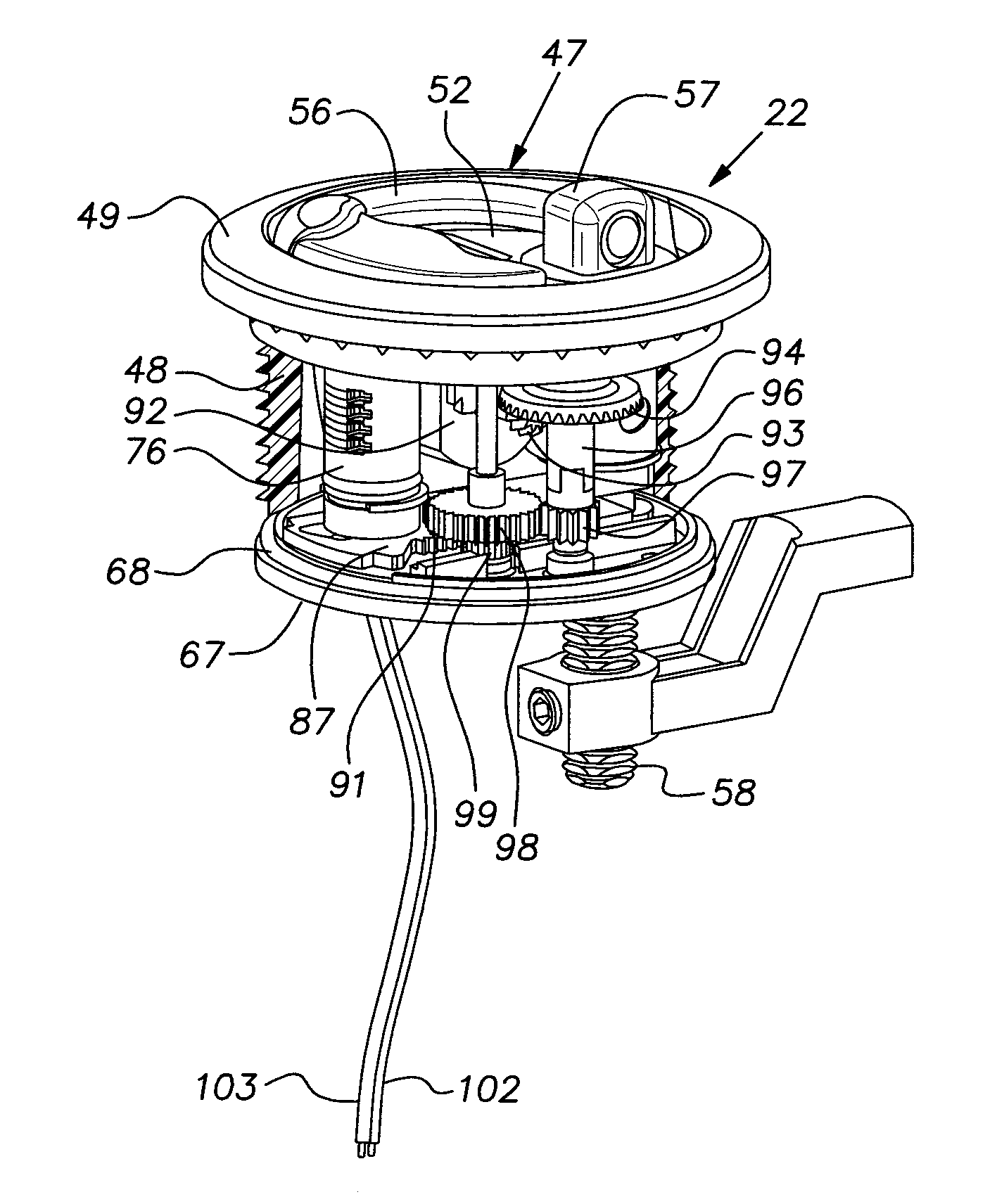

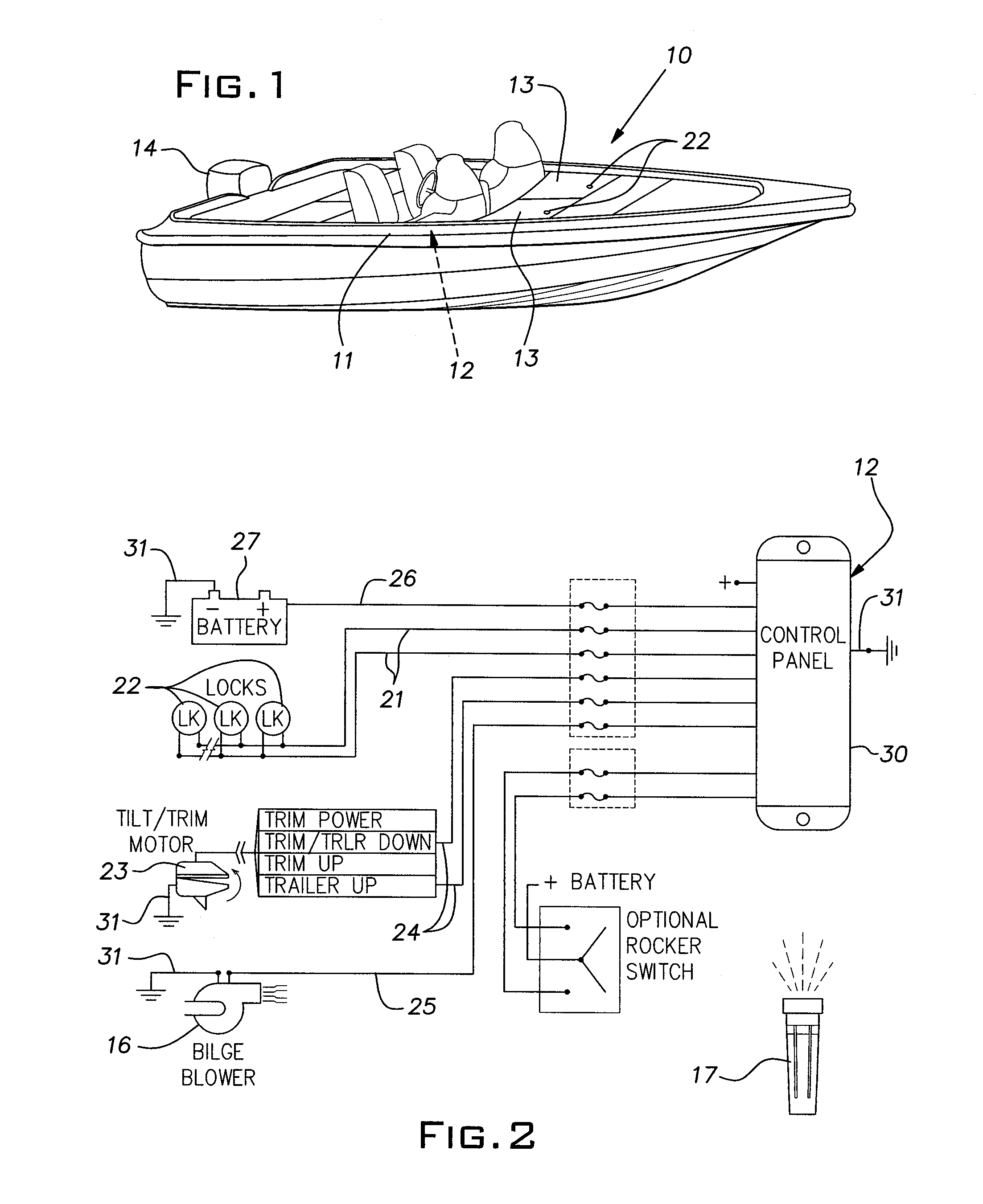

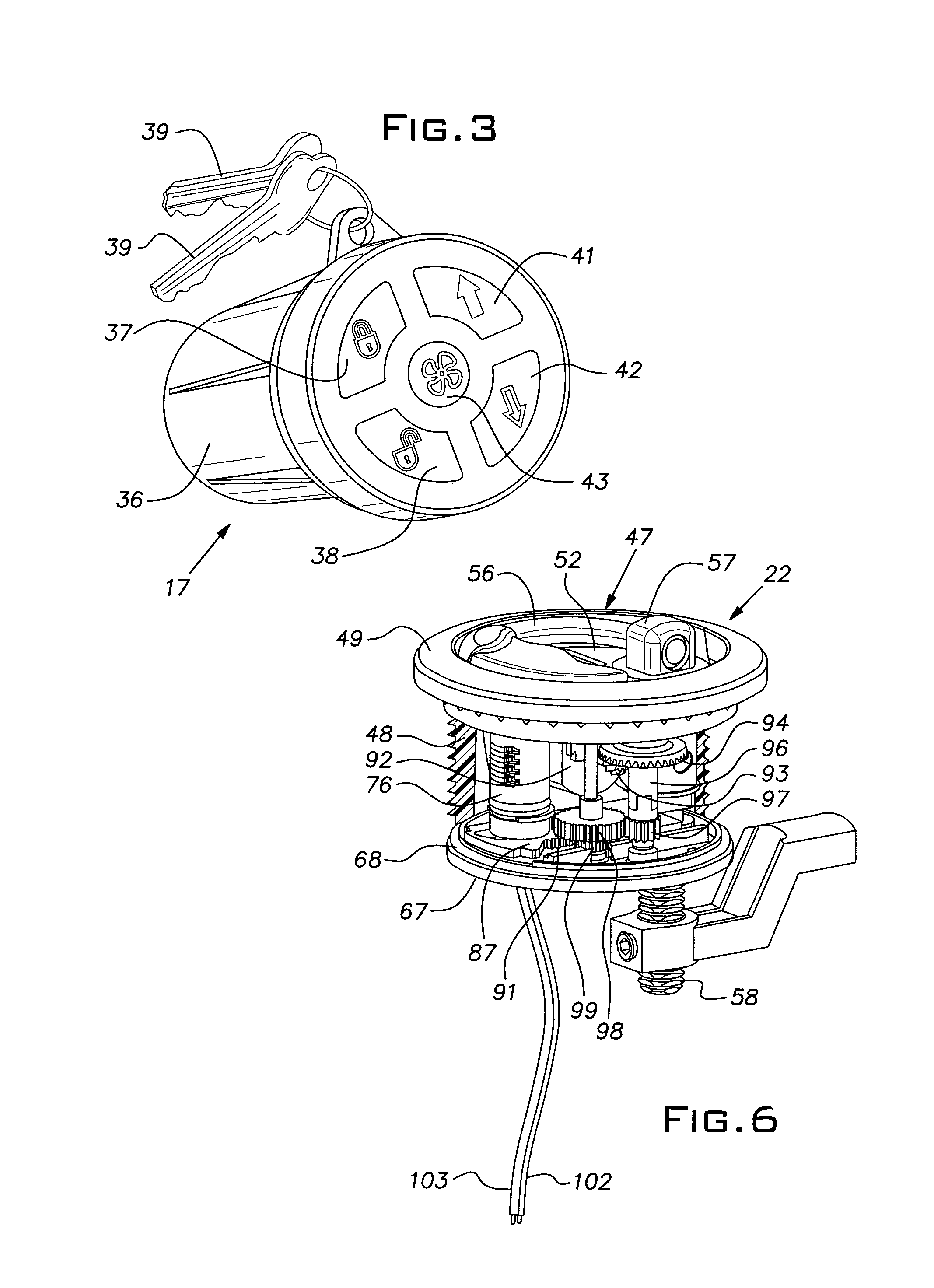

Remote control marine lock system

ActiveUS8272240B1Shorten the timeReduce effortAnti-theft cycle devicesWing handlesBilgeRadio reception

A system for simplifying launching and storage procedures for a recreational boat comprising a radio receiver / controller adapted to be permanently installed onboard the boat, a hand-held radio transmitter for sending a plurality of different signals to the receiver / controller, the receiver / controller including a plurality of separate control circuits, said circuits being connectable to a plurality of power-operated locks on the boat and a set of other electrically operated devices on the boat such as electric lights, an engine tilt actuator, and a bilge blower, the receiver / controller being arranged to be powered by an electrical power circuit serving electrically operated devices on the boat separate from those controlled by the transmitter and receiver / controller, the locks being integrated with manually operated latches and having a manual key override feature.

Owner:SCHILENS JAMES A

Scaleless on-line rheometer device

InactiveUS6405579B1Prevent heat lossIncreases flexibility and durabilityTailstocks/centresConfectioneryProduction rateControl system

A system for providing process control information, such as viscosity, concerning a polymer melt comprises a means containing a polymer melt under pressure; means for diverting a stream of the polymer melt directly from said containing means to and through an orifice of predetermined geometrical shape wherein the flow of said diverted portion to and through said orifice is unobstructed and directly dependent on the pressure of said main polymer melt wherein the cross sectional area is sized to permit the flow of said diverted melt polymer therethrough absence additional independent means acting on said diverted melt polymer for increasing flow through said orifice; temperature sensing means for measuring the temperature of the diverted melt stream and producing a resultant temperature signal; pressure sensing means for measuring the pressure of the diverted melt stream and producing a resultant pressure signal, said pressure signal being directly dependent on the pressure of polymer in said main polymer melt and the predetermined size of said orifice; means measuring or calculating the production rate of the extruder; and manufacturing control system means responsive to the temperature, pressure and production rate signals for determining process characteristics of the main polymer melt.

Owner:SABIC INNOVATIVE PLASTICS IP BV

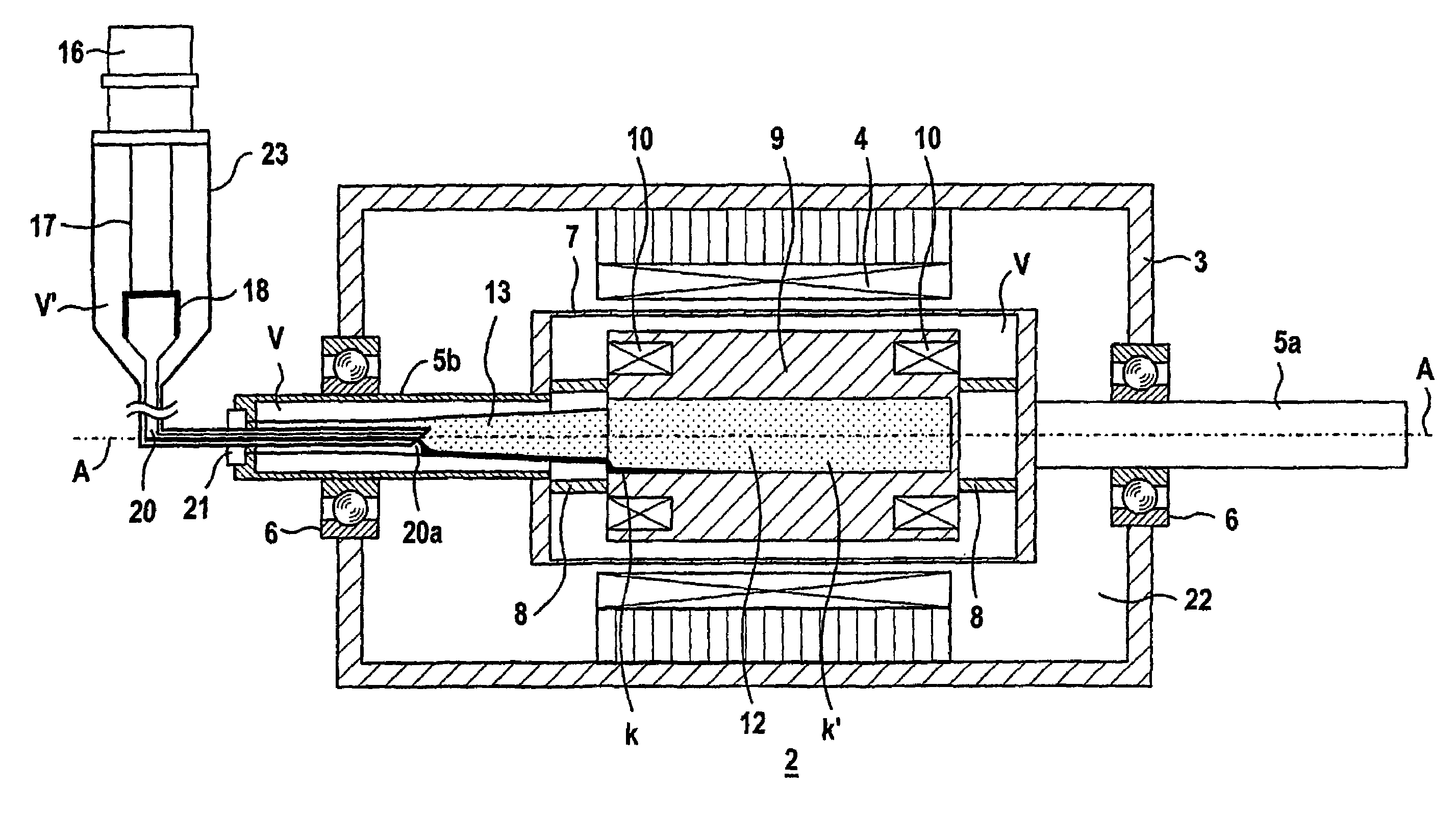

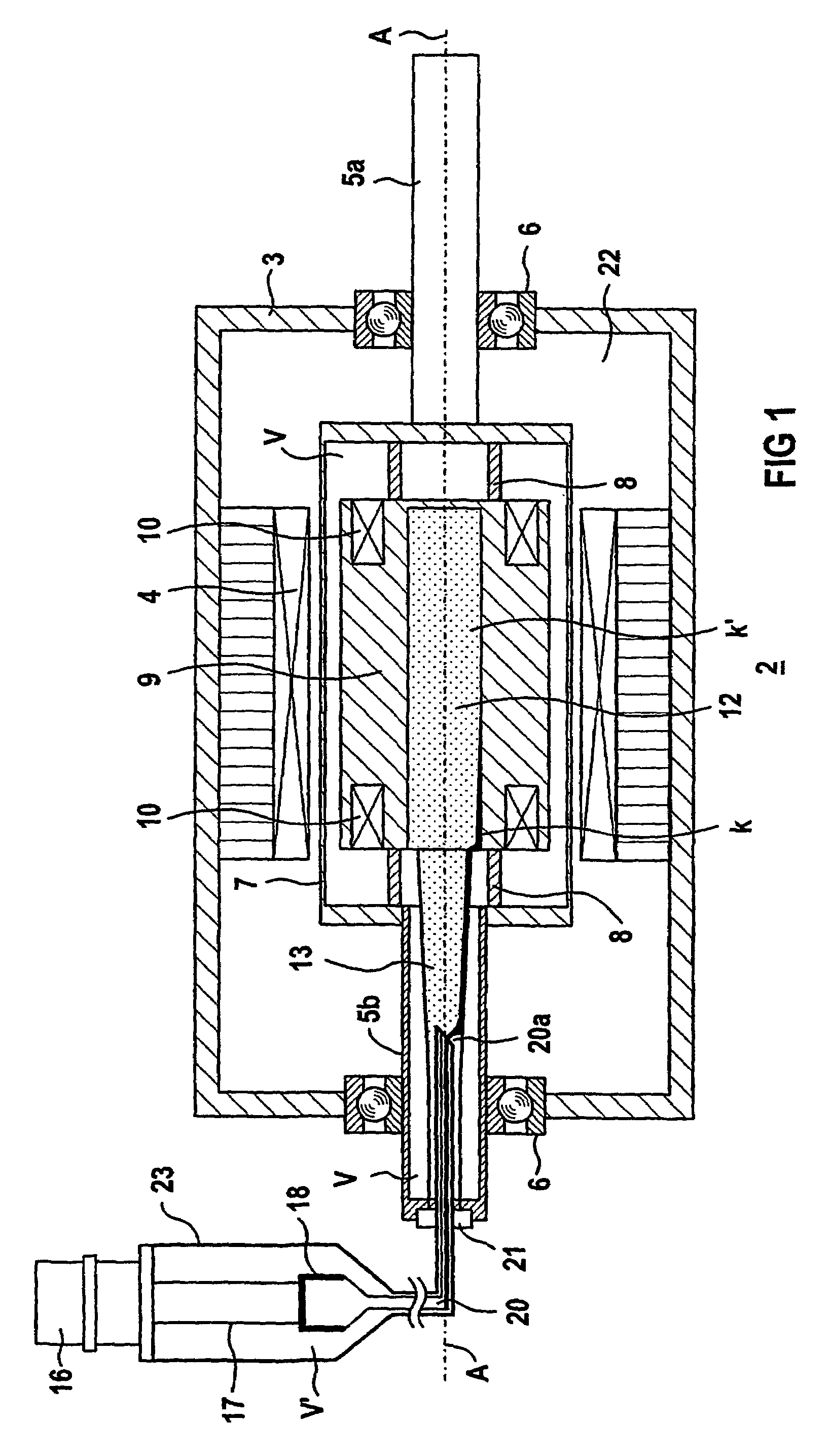

Superconducting device with a cooling-unit cold head thermally coupled to a rotating superconductive winding

InactiveUS7207178B2Reduce complexityMore reliableWindingsSuperconductors/hyperconductorsHeat conductingEngineering

The superconducting device has a rotor which is rotatable about an axis of rotation and is provided with a superconductive winding in a heat conducting winding carrier. The winding carrier has a central cooling agent cavity with a lateral cavity leading out of the winding carrier connected thereto. A cold head associated with a cooling unit is connected to a condenser unit which condenses the cooling agent. A fixed heat tube guiding the cooling agent is coupled to the condenser unit, protruding axially into the coorotating lateral cavity and is sealed in relation thereto.

Owner:SIEMENS AG

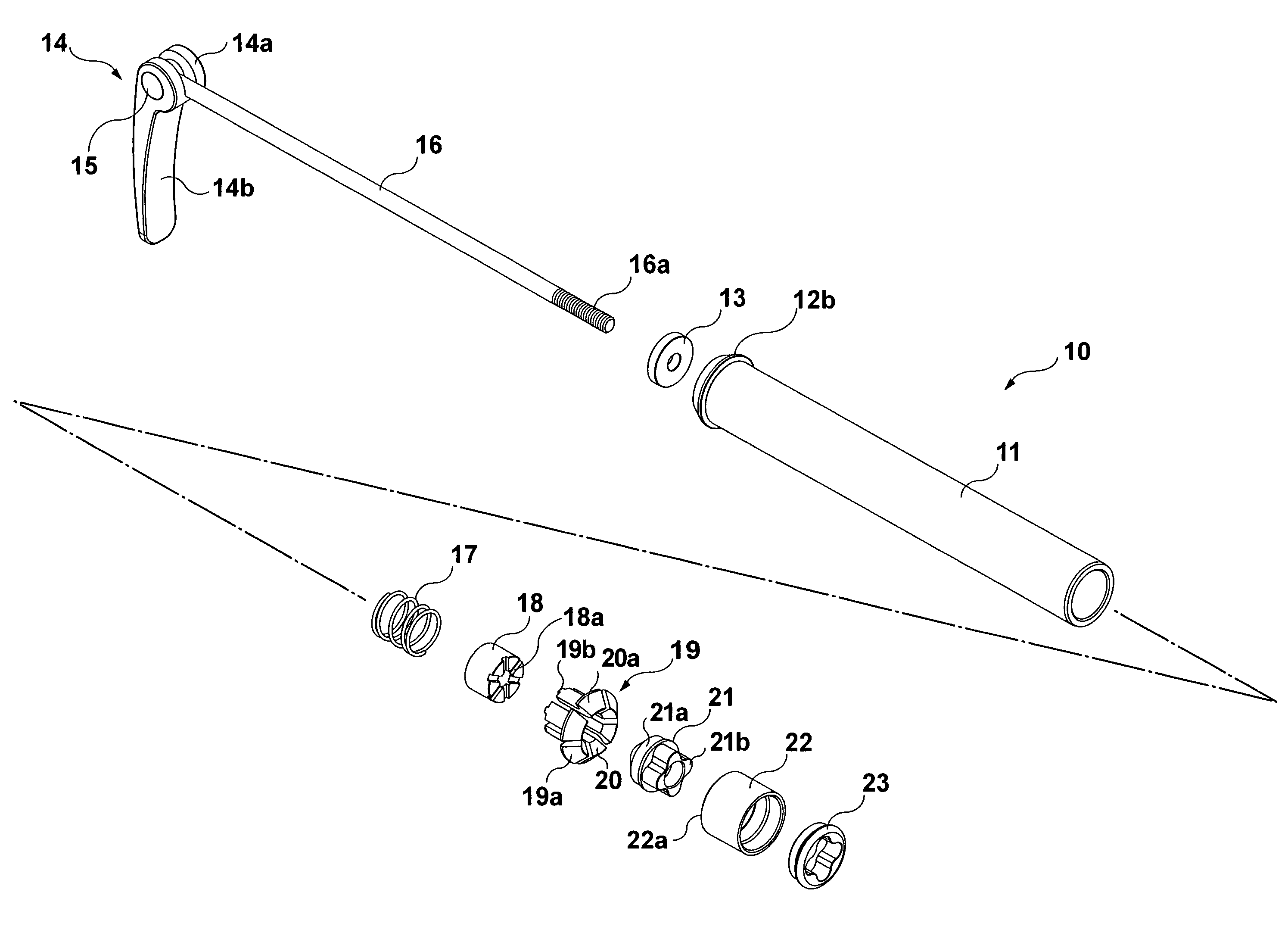

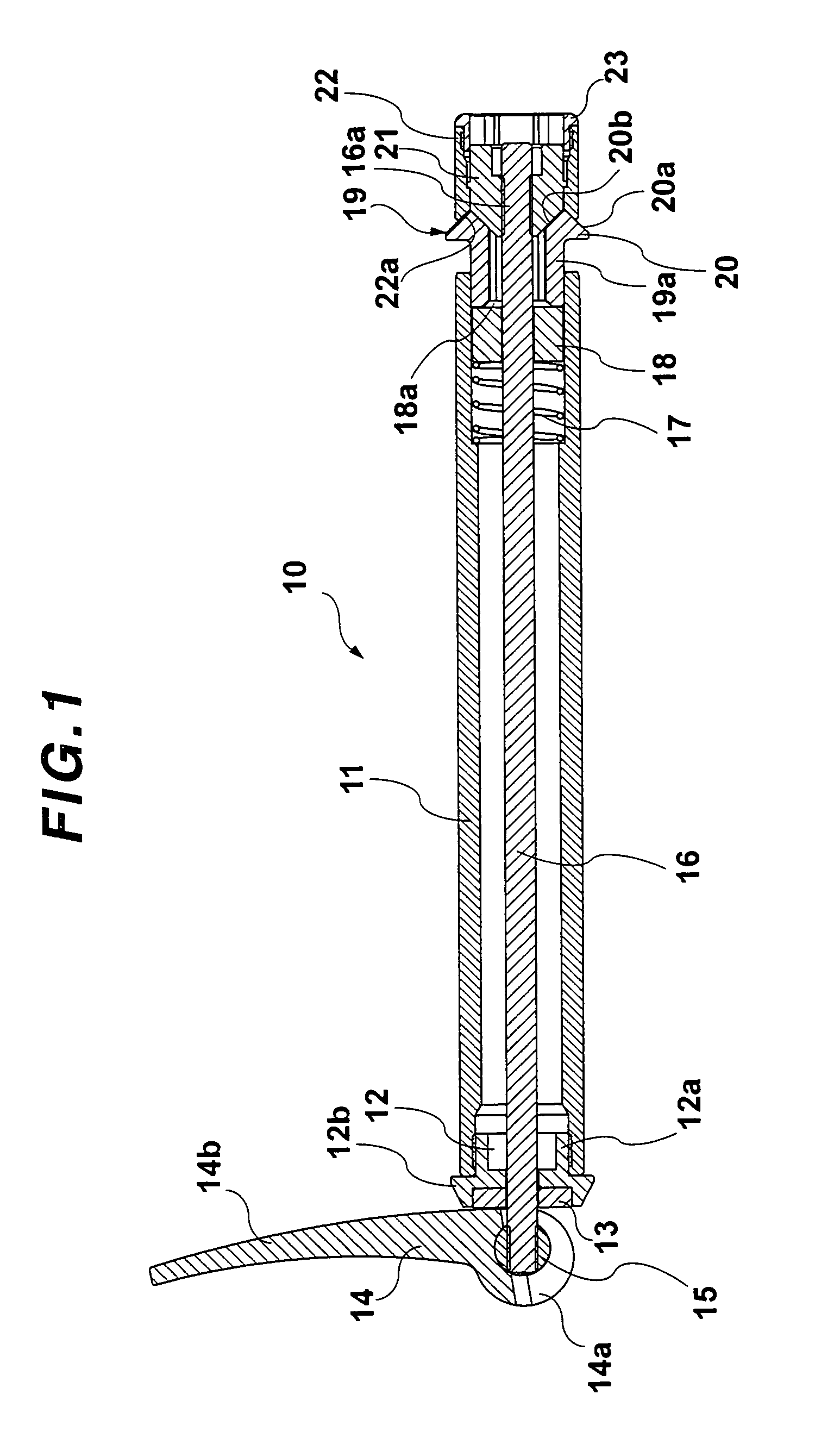

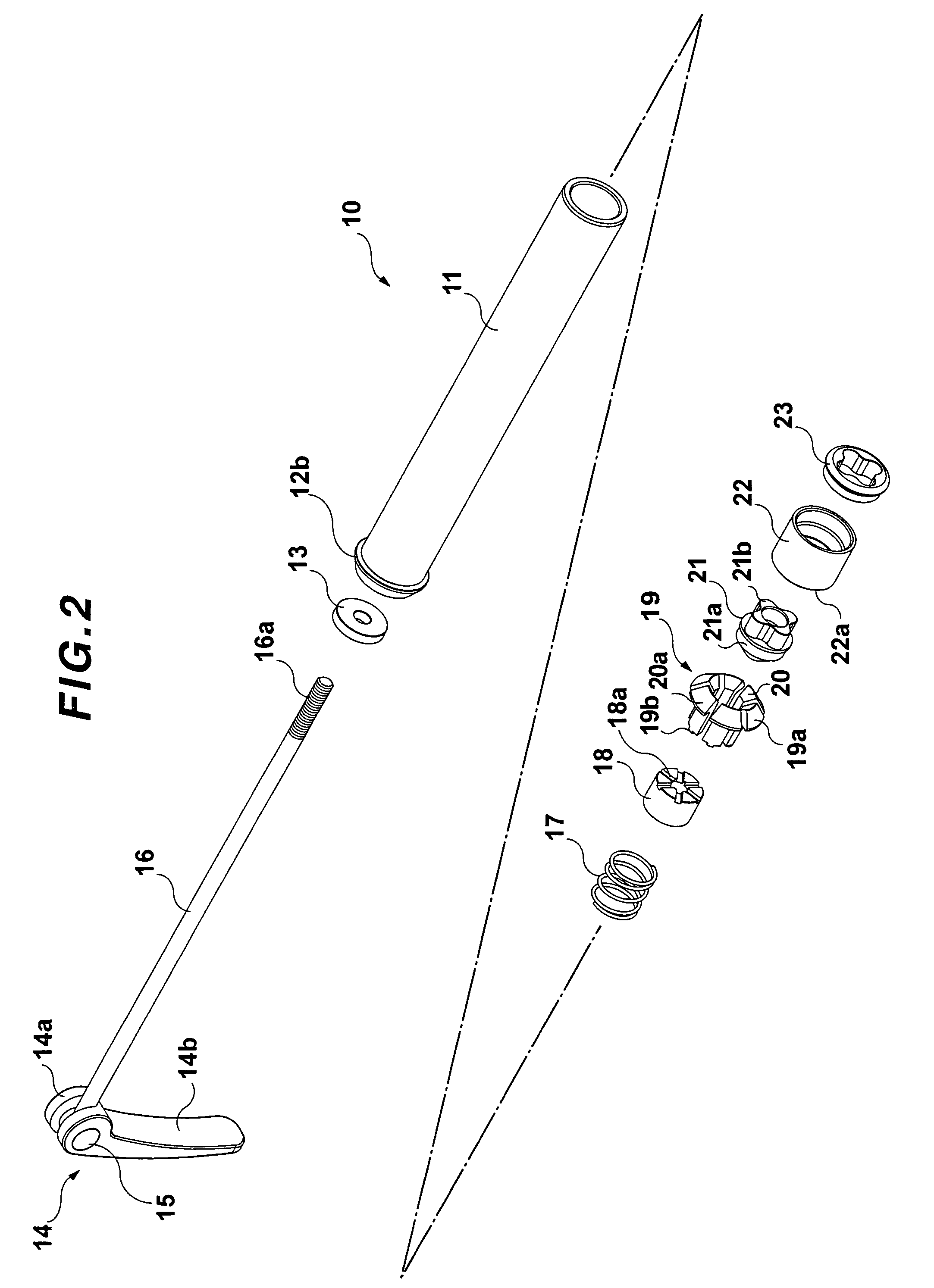

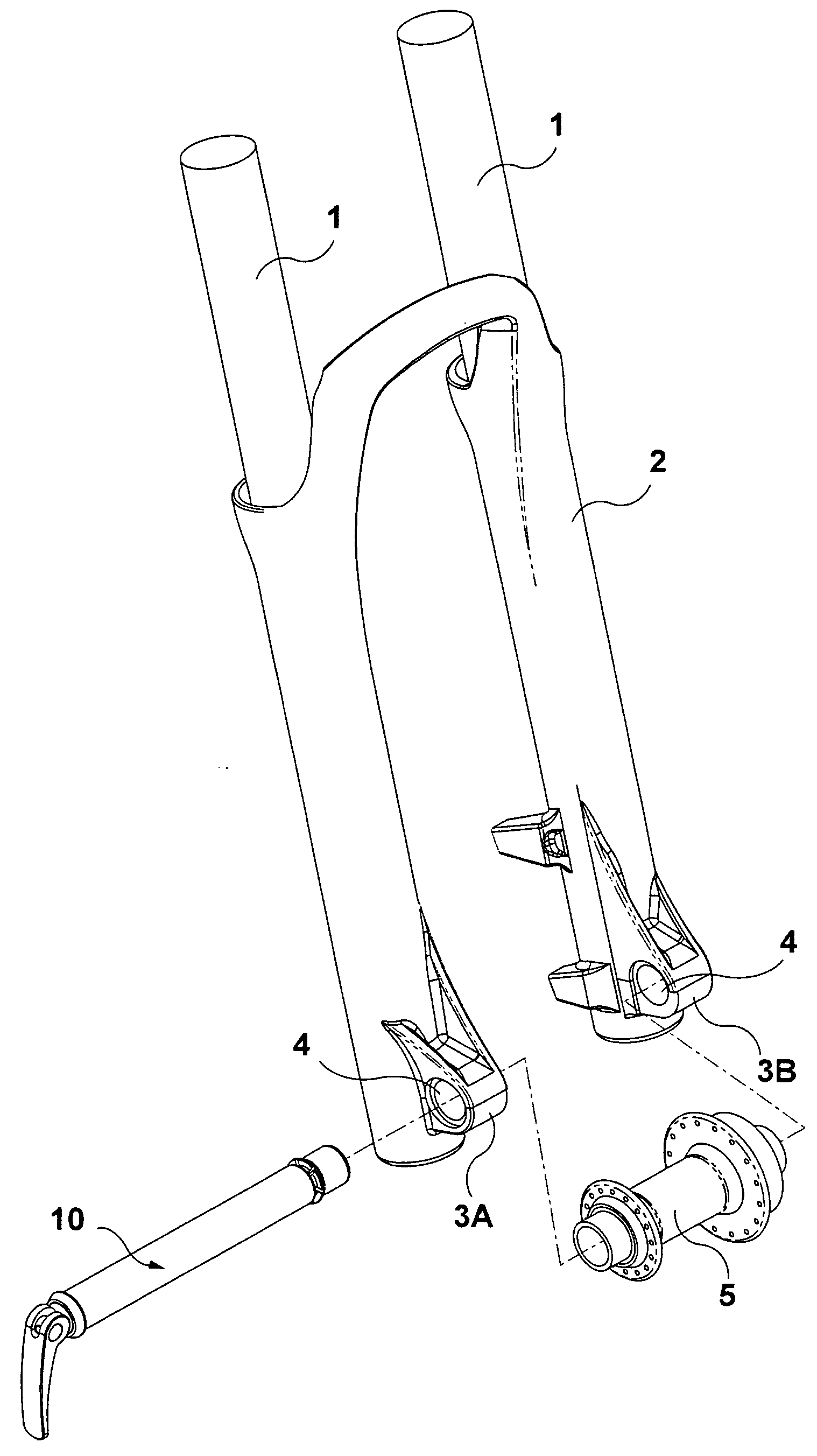

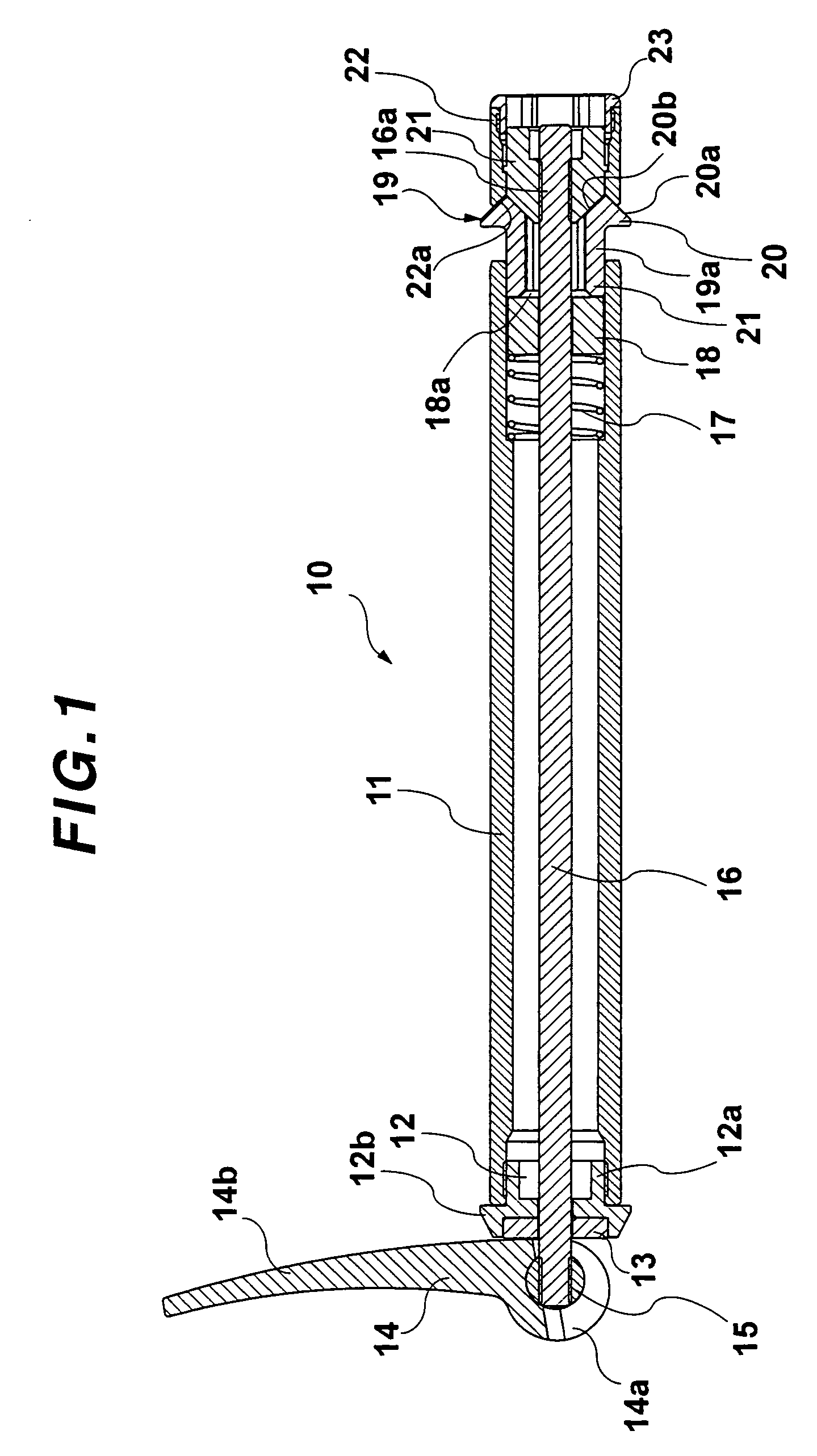

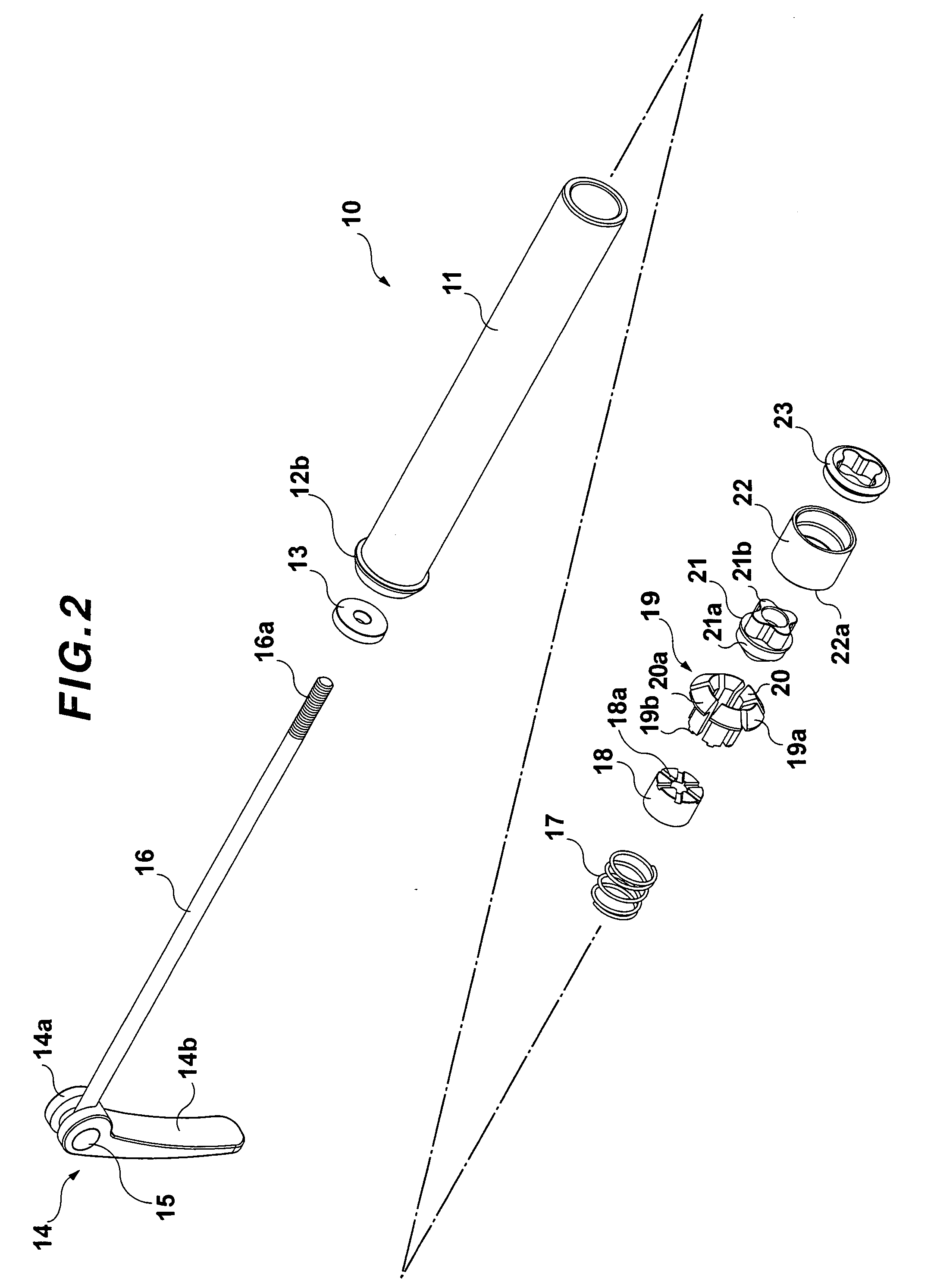

Quick release axle assembly

InactiveUS7735937B2InstallationImprove installation strengthAxle suspensionsRelease mechanismsEngineeringCollet

An axle assembly includes a first holding member, and a second holding member with a collet shape on a tubular body. The second holding member is inserted into a penetrating hole of a shaft mounting portion so as to reduce its diameter. The tubular body is directly inserted into the penetrating hole. When moving the fastening bar by operation of the cam lever, both holding members nip and hold the shaft mounting portion. While dismantling, a diameter shrinking part moves so as to reduce a diameter of the second holding member.

Owner:SAKAE ENG

Axle assembly

InactiveUS20090140571A1Simply perform mountingSimply dismantling workAxle suspensionsRelease mechanismsEngineeringWrench

An axle assembly is supplied capable of solving that troublesome mounting and dismantling works needing a wrench to screw fasten bolt. In the axle assembly, the present invention is to furnish nipping and holding member with collet shape on tubular body; to insert the nipping and holding member into penetrating hole of shaft mounting portion so as to shrink diameter; and to directly insert the tubular body into the penetrating hole. When moving fastening bar by operation of cam lever, both nipping and holding members nip and hold the shaft mounting portion. While dismantling, diameter shrinking part moves so as to make the nipping and holding member shrink diameter.

Owner:SAKAE ENG

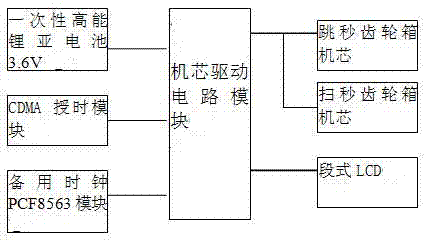

Control method of pointer type CDMA quartz clock

InactiveCN104749941AInstallationSuitable for engineering applicationsElectric windingRadio-controlled time-piecesComputer moduleCdma signal

The invention relates to a control method of a pointer type CDMA quartz clock, and belongs to the technical field of clock production and processing. According to the control method of the pointer type CDMA quartz clock provided by the invention, the pointer type clock is mainly subjected to timing by taking a precise satellite time provided by a CDMA mobile phone network signal which is wide in signal coverage and great in signal intensity as a standard time by virtue of a CDMA circuit module. The method does not severely require the geographic position of the quartz clock as that of a radio controlled clock. The position is random. Even if the clock is mounted in a building, the CDMA signal is also powerful, so that the defect that the radio controlled clock cannot receive weak signals or mistakenly decodes the signals is avoided effectively. Moreover, a receiving antenna is built in the quartz clock like that of a mobile phone, so that the clock is very easy to mount and suitable for various occasions such as domestic use and office. The CDMA circuit module provides the precise satellite time and the theoretical error of the provided time is nearly zero while the actual error does not exceed 5 milliseconds.

Owner:烟台钟表研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com