End traction and bolster positioning and clamping mechanism for chassis centered tyre

A technology for positioning, clamping and chassis, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of affecting the assembly efficiency of steel structure chassis components, the inconsistency of design benchmarks and process benchmarks, and affecting the installation of bolsters and other components Accuracy and other issues, to achieve good market prospects, simple and reliable structure, and reasonable positioning methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

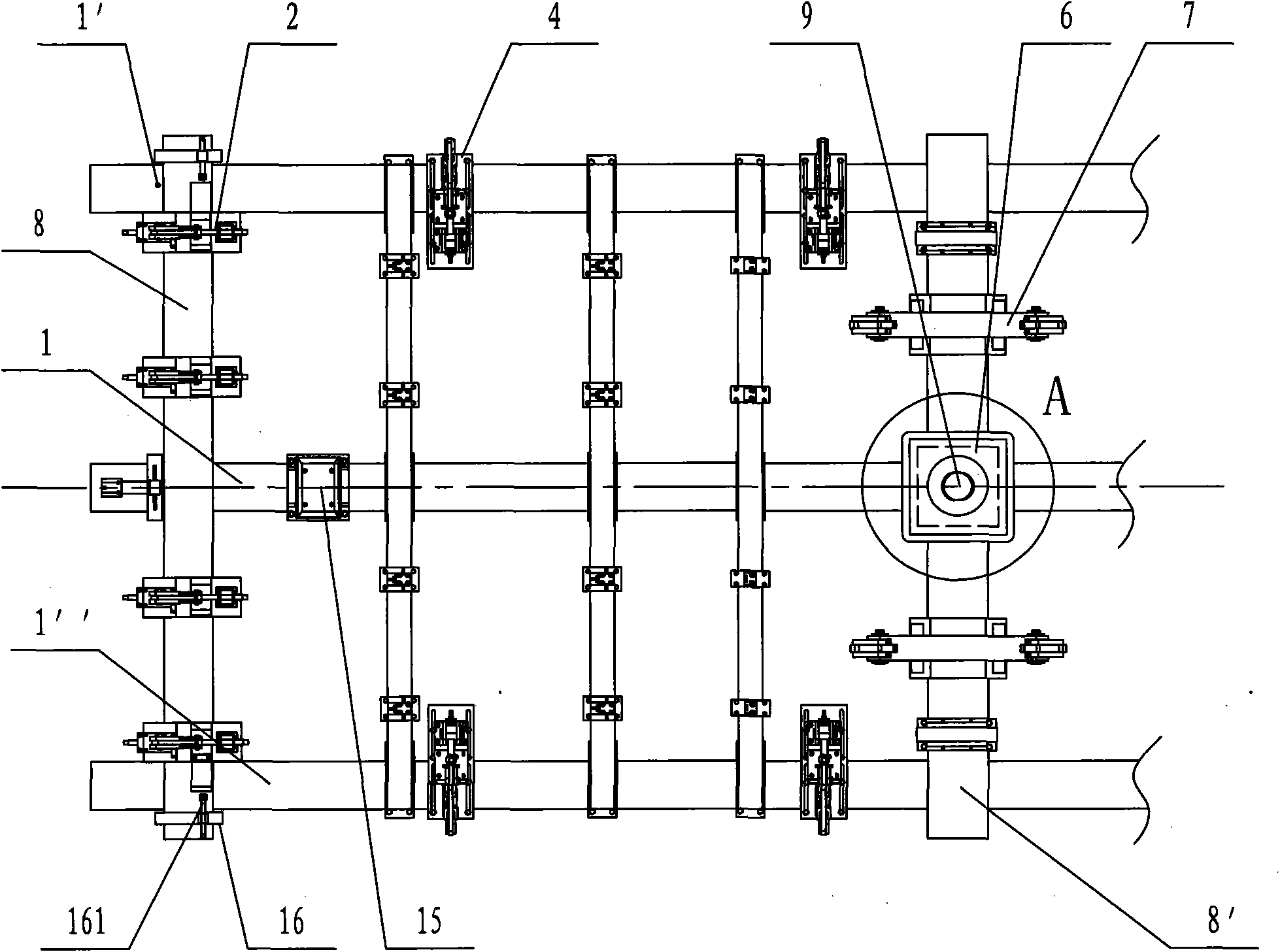

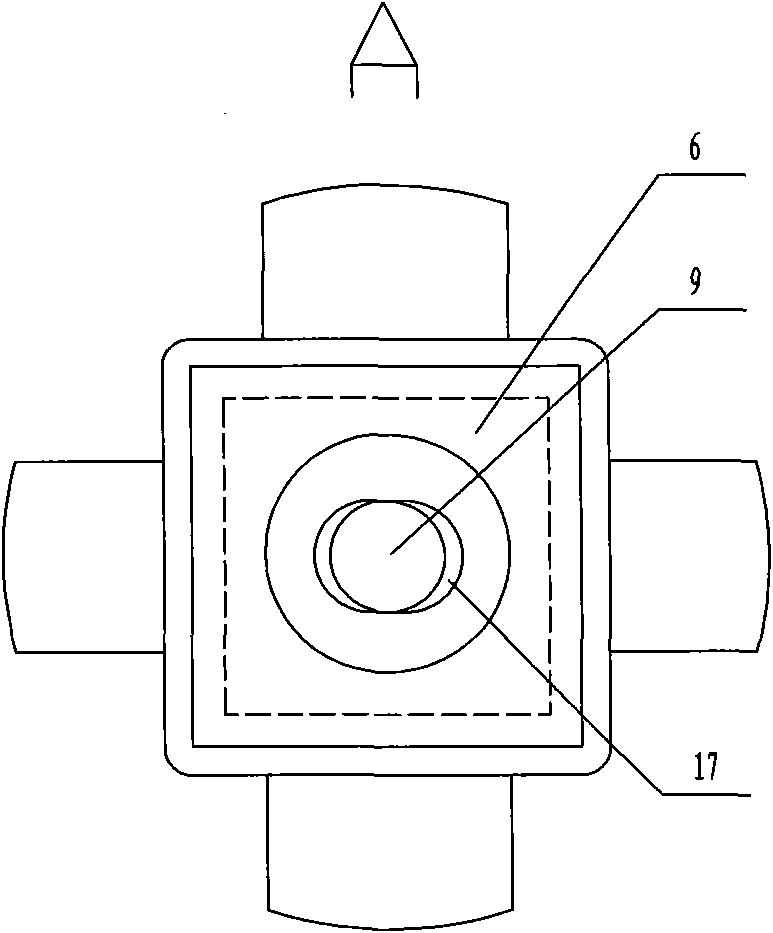

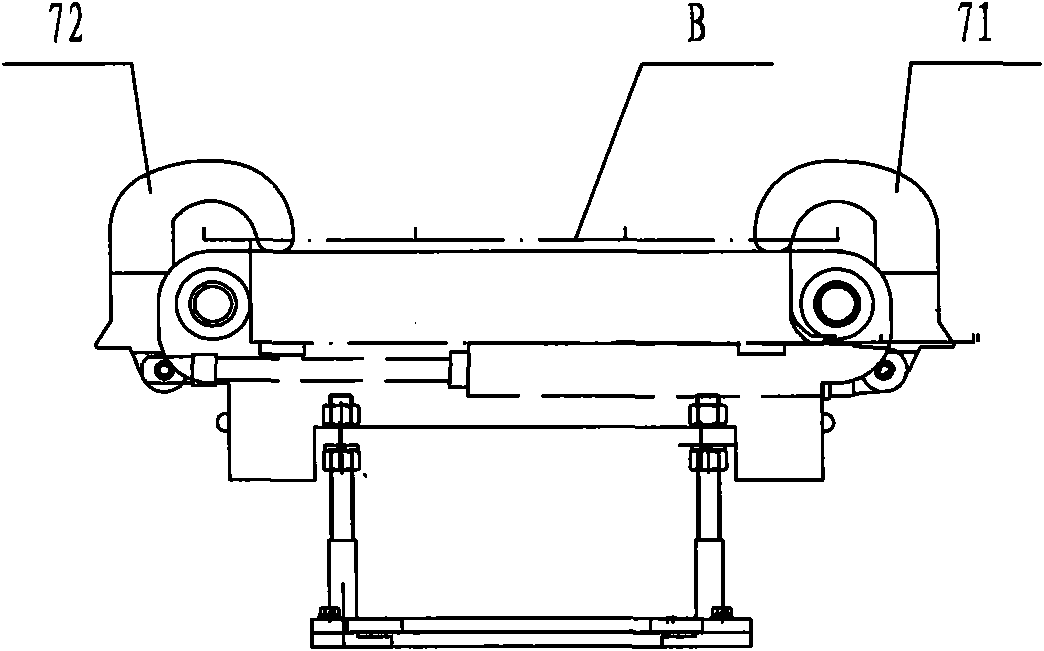

[0023] Such as figure 1 Shown is the positioning and clamping mechanism of the end-leading pillow for the underframe formal tire of the present embodiment, the main structure of the underframe formal tire is composed of three longitudinal beams 1, 1 ', 1 ", and four heel large horizontal frames 8, 8 ' (in the figure Only draw the left part of the bottom frame for the tire, and the right part is symmetrical with it), the upper end faces of the longitudinal frames 1, 1', 1" are located in the same horizontal plane (the flatness is about 1mm), and the large horizontal frames 8, 8' It is perpendicular to the vertical frames 1, 1', 1" and can be moved and positioned arbitrarily on the vertical frames 1, 1', 1". Two large horizontal frames 8 are located at the outer ends and bottoms of the vertical frames 1, 1', 1". The frame end beams correspond, and the other two large horizontal frames 8 ' are located at the longitudinal frames 1, 1 ', 1 " and correspond to the corbel beams on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com