Hinge machining host and machining method

A main machine and hinge technology, applied in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of high processing cost, difficult coordination of processing rhythm, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

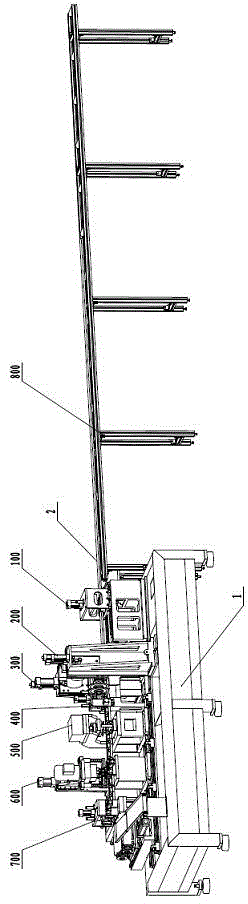

[0087] Such as figure 1 As shown, a hinge processing main engine includes a bed 1, a control system and a hydraulic system. The bed 1 is sequentially installed with an automatic feeding device 100, a sawing device, a sawing and pressing device 400, a stamping Device 500 , drilling device 600 and cutting device 700 .

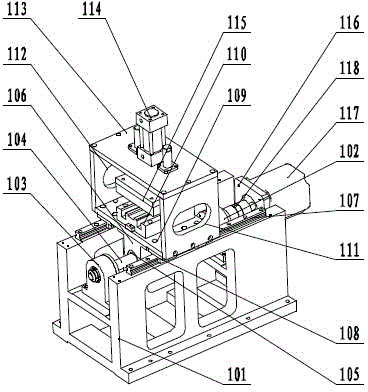

[0088] Such as figure 2 As shown, the automatic feeding device 100 includes a feeding base 101, a right screw seat 102 and a left screw seat 103 fixed on the feeding base 101, and is rotatably connected between the right screw seat 102 and the left screw seat 103 The leading screw 104, the screw nut 105 engaged with the leading screw 104, the screw nut 105 is fixed on the screw nut seat 106;

[0089] Two guide rails-107 are also fixed on the described feeding base 101, and 2 slide blocks-108 are slidably connected on each guide rail-107, and the bottom of the feed slide plate 109 is fixedly connected on 4 slide blocks-108, and the feed slide plate The top of ...

Embodiment 2

[0131] A method for processing a hinge using the hinge processing host, comprising the following steps:

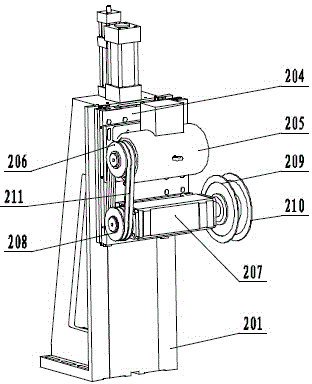

[0132] a) The control system starts the hydraulic system, starts the sawing motor 205, the drilling motor 606 and the cutting motor 705;

[0133] b) The control system controls the feeding and pressing cylinder 114 in the feeding device 100 to press the two profiles 2 symmetrically placed in the feeding backing plate 110, and the servo motor 117 drives the screw 104 to rotate and drives the feeding slide 109 to move for feeding ;

[0134] c) The control system controls the vertical compression cylinder 405 for sawing, the horizontal compression cylinder 407 before sawing, the horizontal compression cylinder 409 after sawing, the compression cylinder 624 before drilling, the compression cylinder 627 after drilling, and the vertical compression cylinder for cutting. The straight compression cylinder 721, the compression cylinder 723 before cutting and the compression cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com