Drill jig used for hole on central excircle of cylindrical part and provided with disks at two ends

A technology of parts and cylinders, applied in the field of mechanical processing equipment, to achieve the effect of simple structure of drilling jig, low manufacturing cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

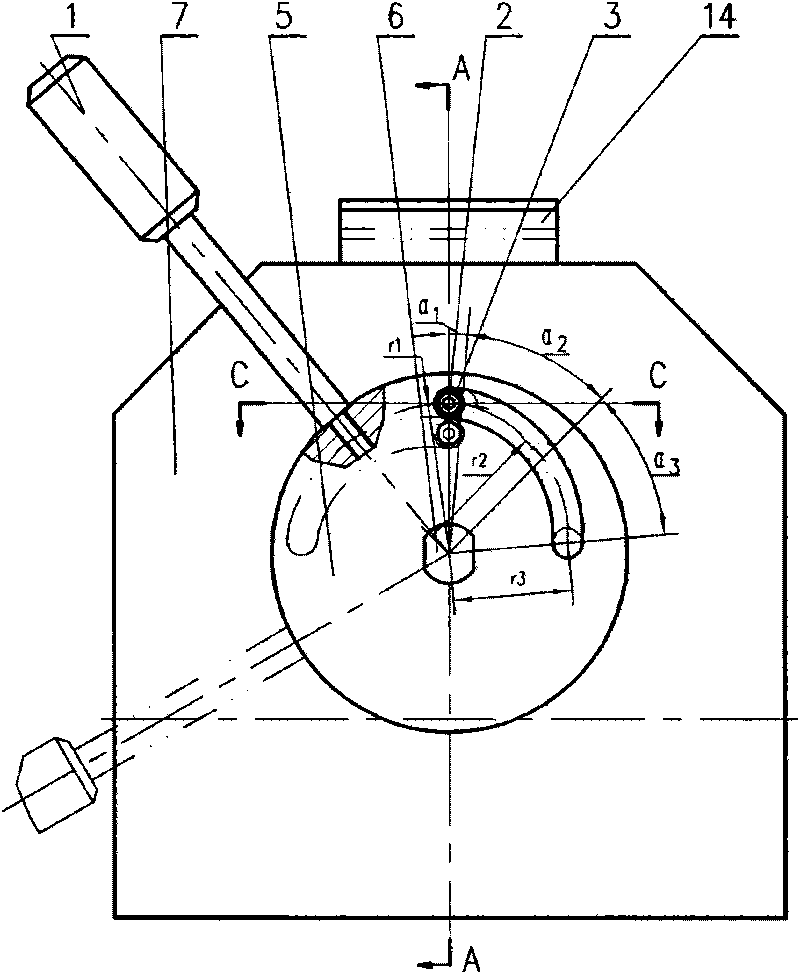

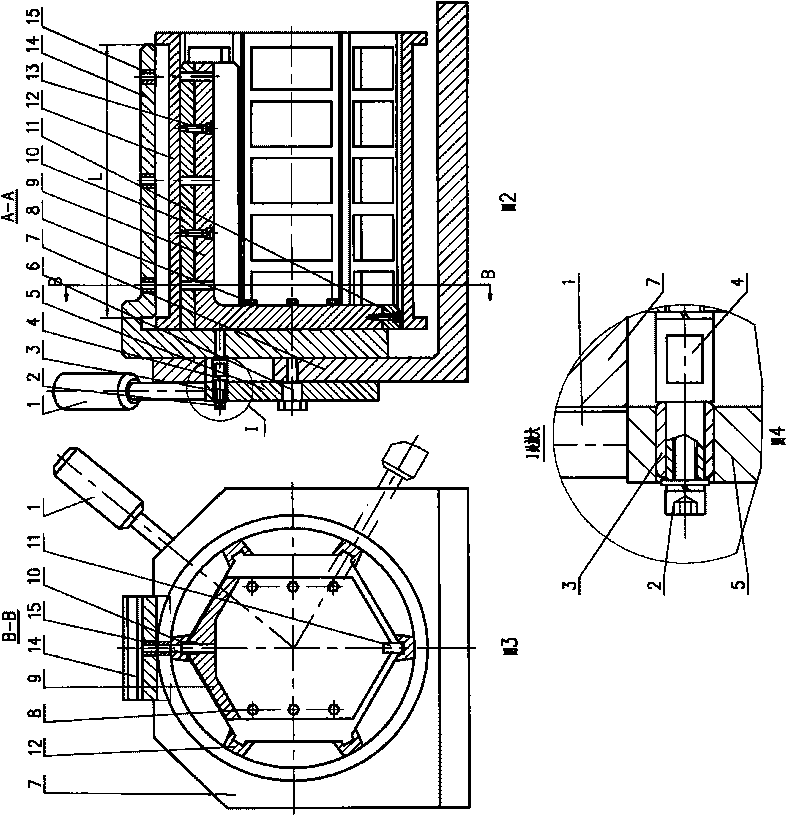

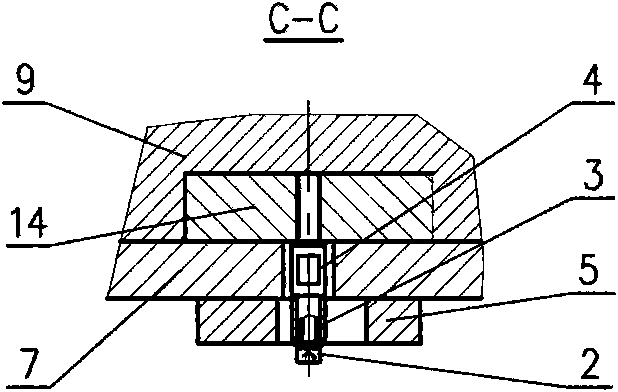

[0015] Accompanying drawing is the drilling template of the upper hole in the outer circle in the middle of the cylindrical parts with discs at the two ends of the processing 6NF series jet rice milling machine rice sieve frame (12). Because the holes to be drilled on the outer circle of the middle rib of the rice sieve frame (12) are matched with the studs on the bead, and the bead is installed in the groove of the rice sieve frame (12) inner cavity, so the position of the drill cover (15) Should take the groove of rice sieve frame (12) inner cavity as positioning datum, consider the depth of meter sieve frame (12) inner cavity groove is shallower, do auxiliary positioning with the groove of 180 ° direction under it. So when drilling, the rice sieve frame (12) is installed on the upper positioning plate (10) and the lower positioning plate (11) by the groove up and down in its inner chamber, and the hole of a groove is drilled and the rice sieve frame (12) is replaced. Go to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com