Vibrating drilling machine

A vibratory drilling rig and sliding bearing technology, applied in vibratory drilling, sampling devices, etc., can solve the problems of large volume, complex structure, and high processing precision requirements of the audio frequency vibrating head, and achieve the effect of improving work efficiency and drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are the Some of the embodiments of the invention are not all of the embodiments, and the embodiments of the present invention are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

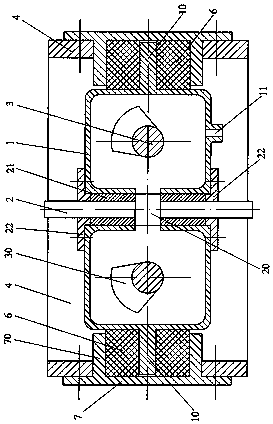

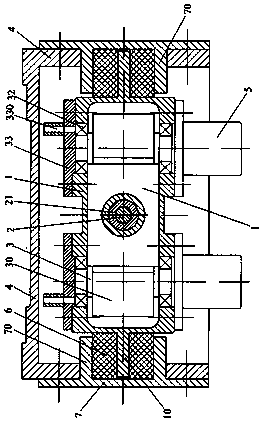

[0019] Such as Figure 1 to Figure 2 As shown, the vibration drill bit of the present invention includes a box body 1, a main shaft 2 passing through the middle of the box body 1 from top to bottom, two eccentric shafts 3 arranged horizontally in the box body 1 and symmetrical with respect to the main shaft 2, The sliding plate 4 arranged on the periphery of the box body 1 and the buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com