Transmission mechanism of self-suction tail door lock

A technology of transmission mechanism and tailgate lock, which is applied in the application of locks, power transmission/actuator characteristics, electric locks, etc., can solve the problems of large transmission force, complex structure, poor working reliability, etc., and achieve the reduction of transmission force, Simple and compact structure, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

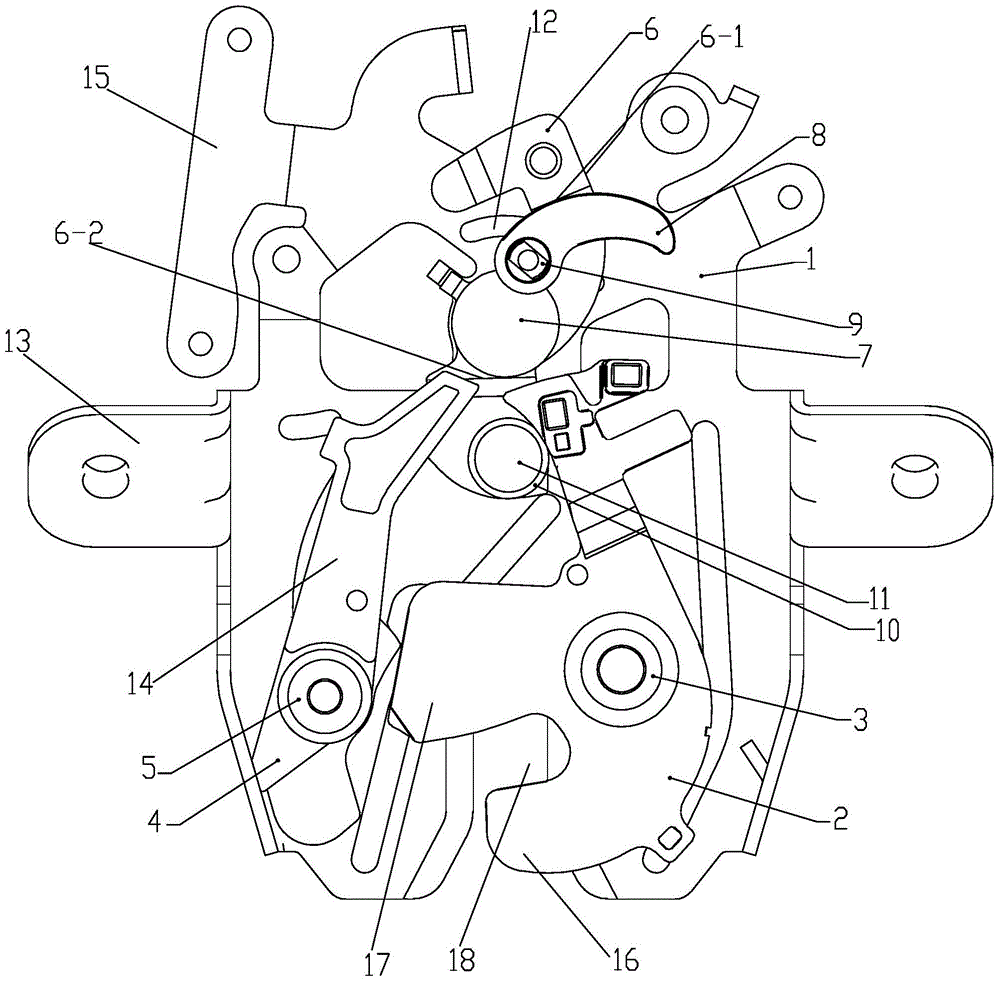

[0012] Such as figure 1 As shown, it includes base plate 1, ratchet 2, ratchet riveting shaft 3, pawl 4, pawl riveting shaft 5, transmission plate 6, first shoulder 6-1, second shoulder 6-2, transmission riveting shaft 7, Transmission rocker arm 8, transmission rocker shaft 9, transmission washer 10, transmission washer shaft 11, arc protrusion 12, mounting ear 13, push plate 14, connecting plate 15, first limit card arm 16, second limit Card arm 17, card slot 18, etc.

[0013] Such as figure 1 As shown, the present invention is a transmission mechanism of a self-priming tailgate lock, comprising a base plate 1, and a mounting ear 13 is respectively provided on both sides of the base plate 1 along the width direction, and a screw thread is provided on each mounting ear 13. hole.

[0014] Formed on the surface of one side of the base plate 1 are a drive plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com