Door lock

a door lock and lock body technology, applied in the field of door locks, can solve the problems of affecting the operation of the lock, imposing a great force between the striker plate and the bolt, and the force conveyed from the actuator to the lock can be quite great, so as to reduce the electrical energy needed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

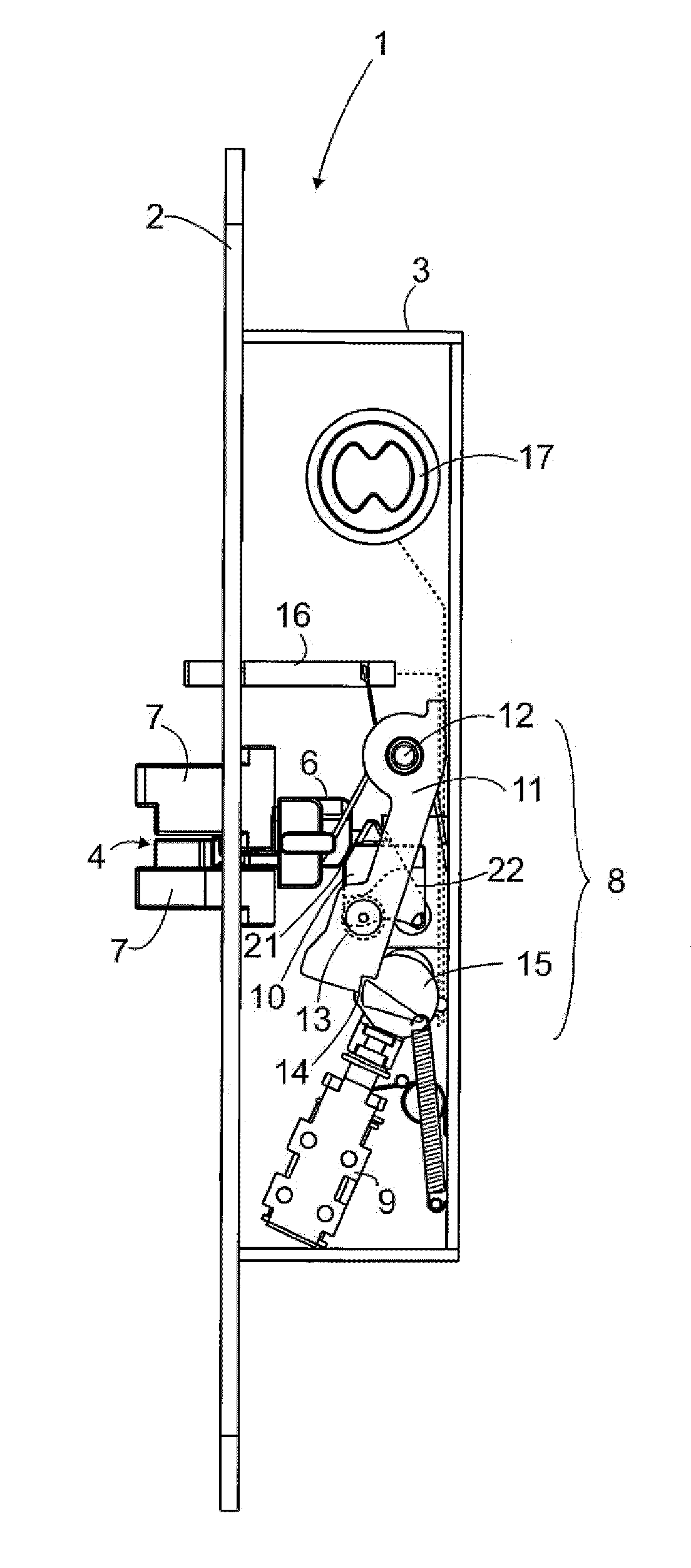

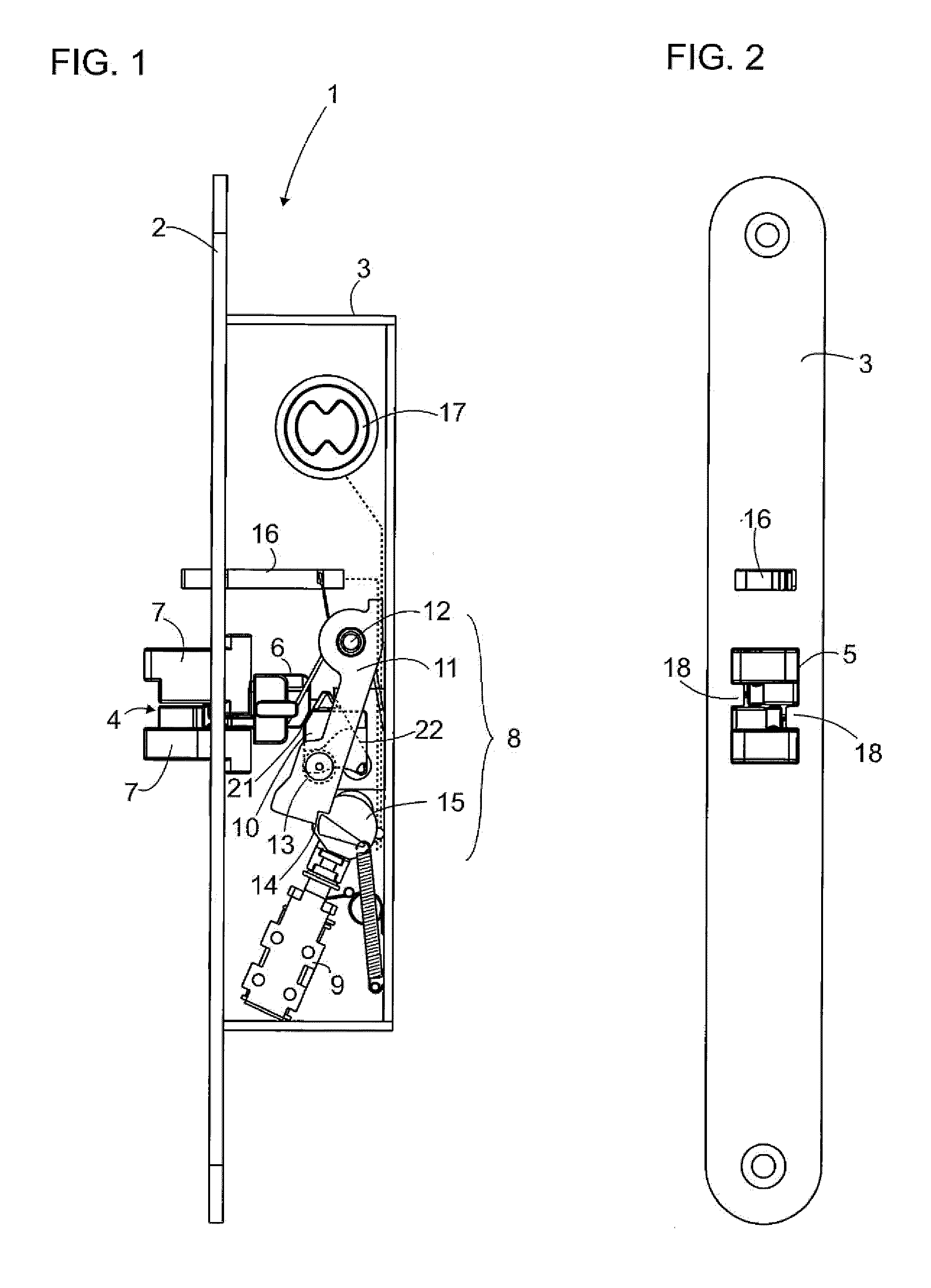

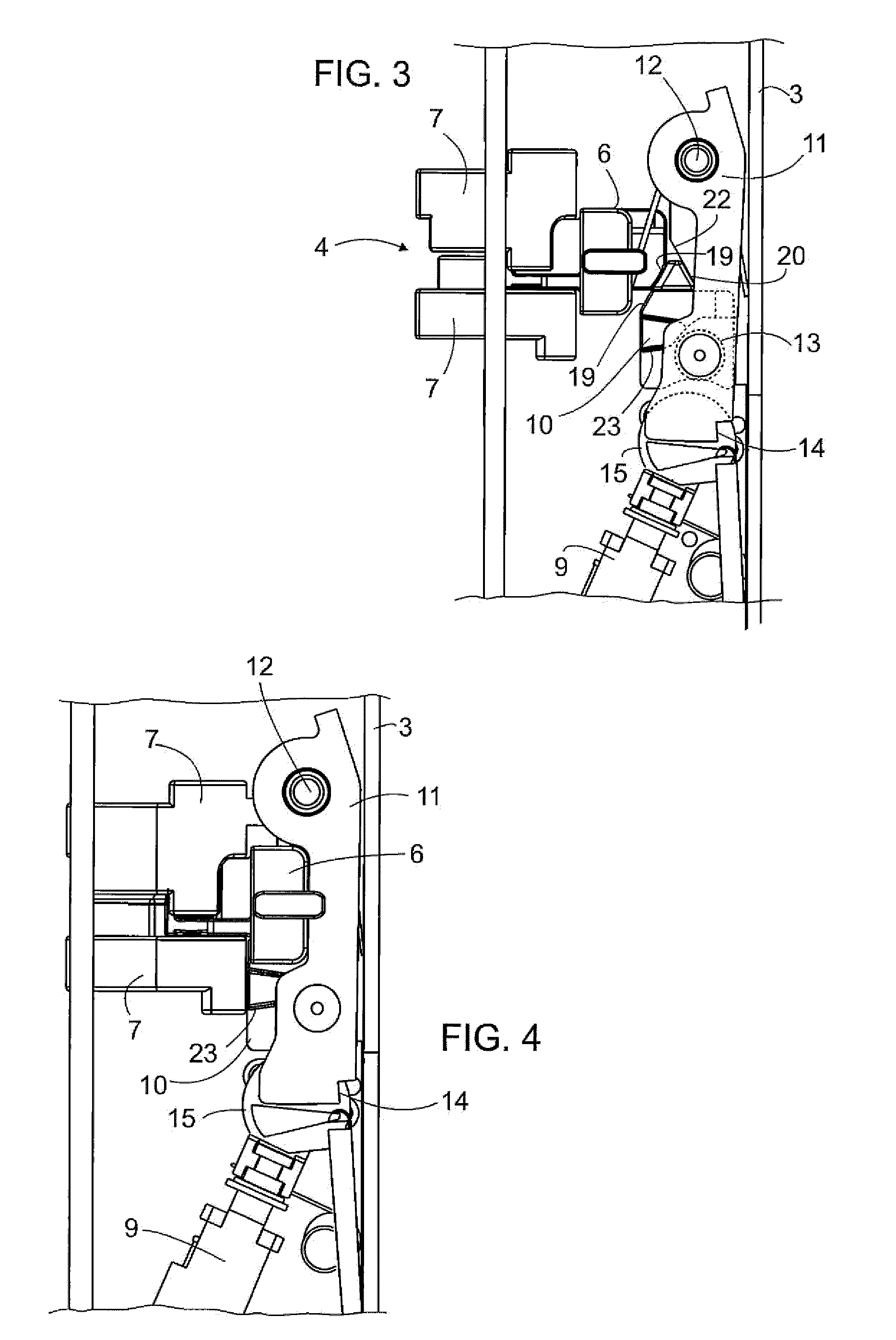

[0020]FIG. 1 illustrates an example of a door lock 1 according to the invention. The door lock comprises a lock body 3 fitted with a front plate 2; the lock body has a dual-action bolt 4 that can be moved with reciprocal linear motion between a withdrawn position and a locking position protruding out from the lock body through the bolt opening 5 (FIG. 2) in the front plate 2. The bolt 4 comprises a body part 6, and in the embodiment of FIG. 1, two bolt pieces 7. The bolt 4 is spring-loaded towards said protruding position. The door lock 1 further comprises deadbolting means 8 that can be moved to a deadbolting position in which they prevent the dual-action bolt from being moved from the protruding position to the withdrawn position in the lock body 3. The lock of this embodiment also comprises a solenoid 9 for controlling the deadbolting means.

[0021]The door lock usually also comprises other control means for controlling the deadbolting means. The lock may have an auxiliary bolt 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com