Waist support device of electric driver seat

A lumbar support and seat technology, applied in chairs, other seating furniture, stools, etc., can solve the problems of inconvenient moving back and forth, poor cushioning performance of rigid body supports, etc., to ensure durability and reliability, and improve service life. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

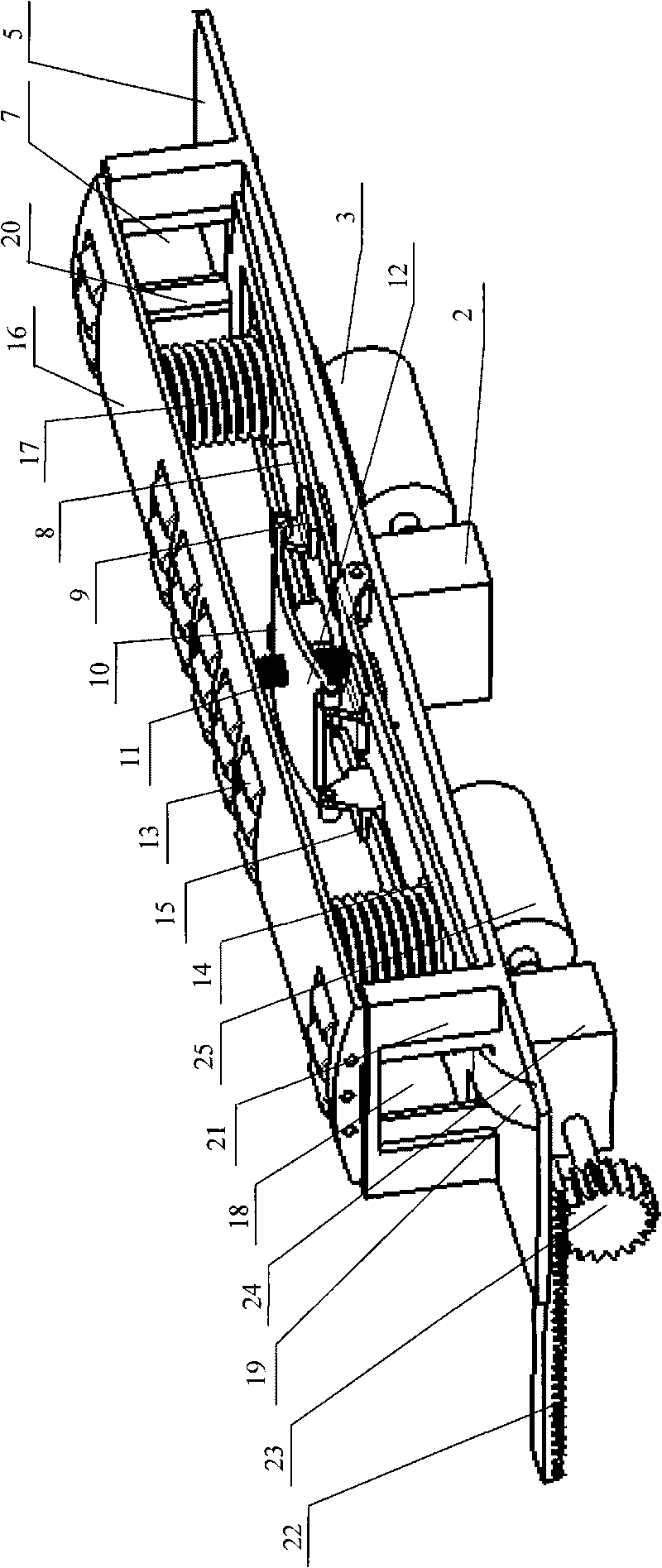

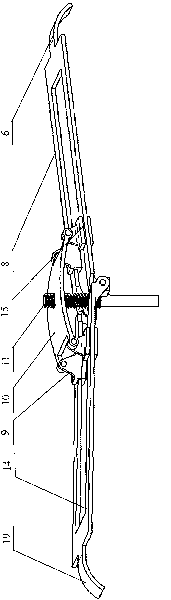

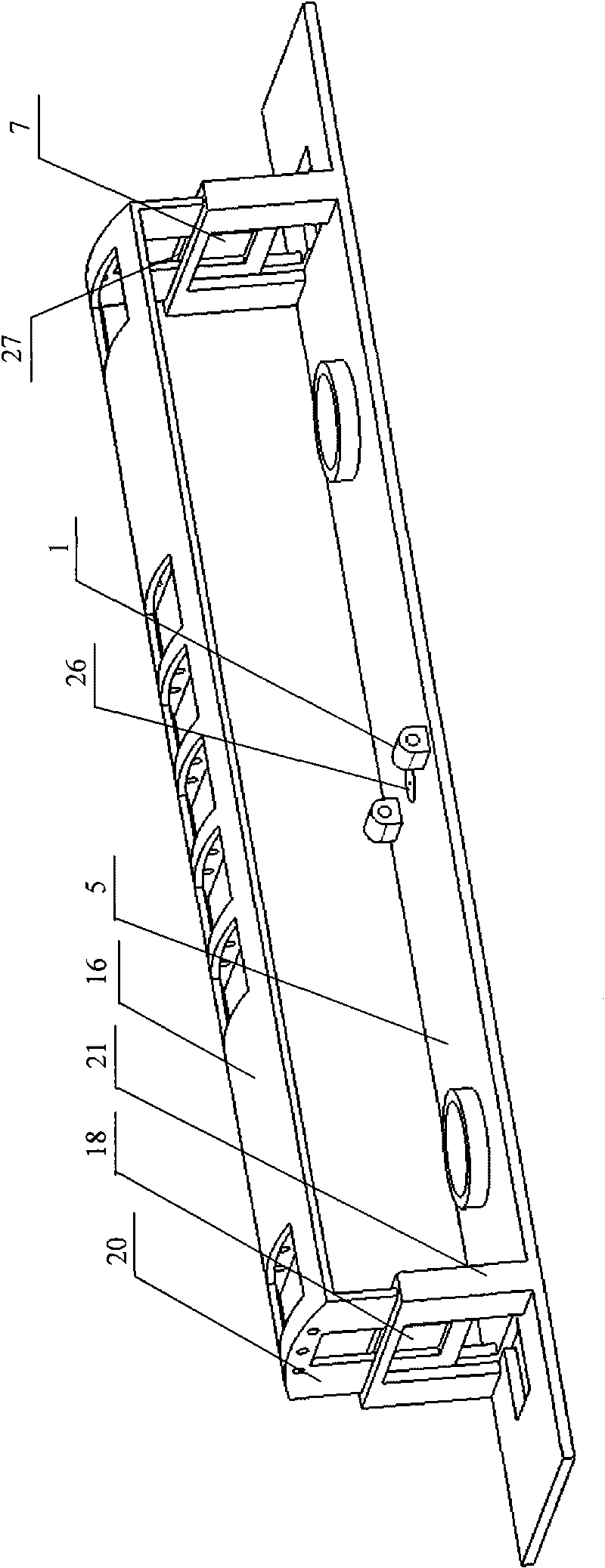

[0018] As shown in the figure, a lumbar support device for an electric driving seat includes a rear support plate 5 with a rising edge 21 and a front support plate 16 with a falling edge 20, and a chute is arranged in the rising edge 21 of the rear support plate 5 27, the falling edge 20 of the front support plate 16 is set in the chute 27 of the rising edge 21 of the rear support plate 5, the falling edge 20 of the front support plate 16 on the left side and the rising edge 21 of the rear support plate 5 A left through groove 18 is arranged on the top, and a right through groove 7 is arranged on the falling edge 20 of the front support plate 16 on the right side and the rising edge 21 of the rear support plate 5; Compression spring 17 and convexity adjustment transmission mechanism 12 are arranged, and described convexity adjustment transmission mechanism 12 comprises pressure plate 10, slide block 9, transmission screw rod 11 and left pull rod 14, right pull rod 8; The outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com