Carding machine

A carding and carding technology, applied in the field of carding machines, can solve the problems of reducing the service life of the toe surface of the flat plate, increasing the friction between the flat plate and the curved rail, etc. The effect of the combing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

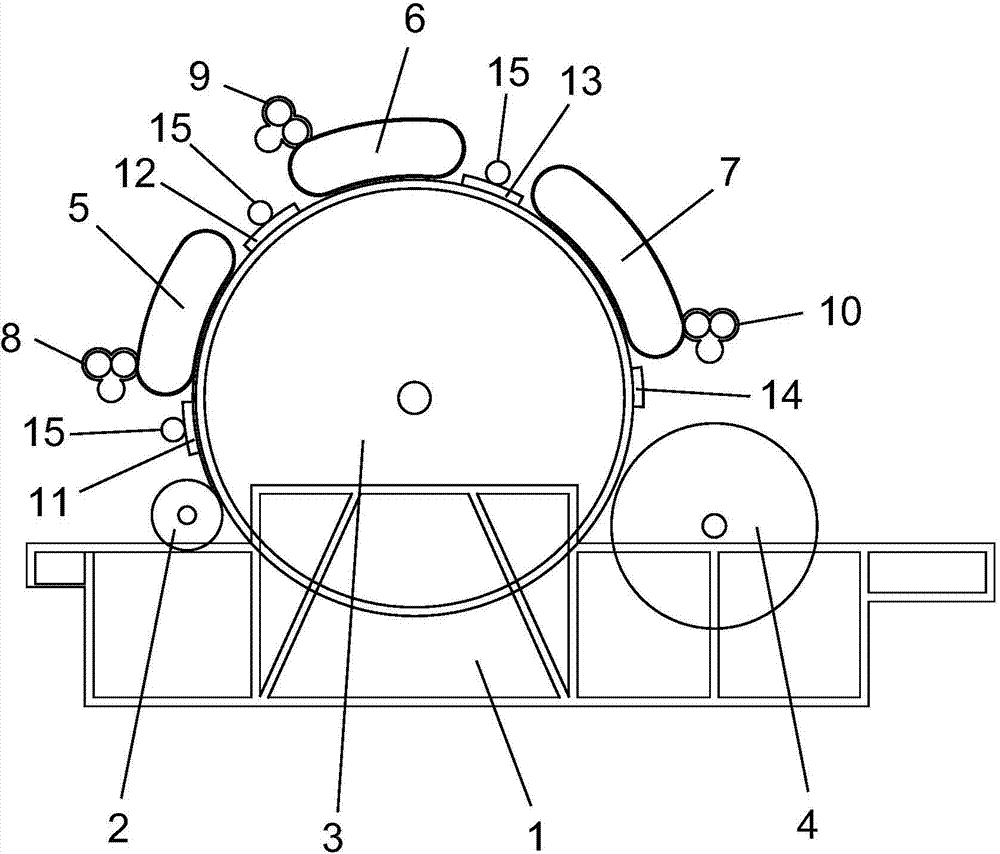

[0019] Carding machine of the present invention, as figure 1 Shown, comprise frame 1, on the frame 1, hair roller 2, cylinder 3 and doffer 4 are installed successively from front to back.

[0020] The top of the cylinder 3 corresponds to the frame 1, and the first carding area cover 5, the second carding area cover 6 and the third carding area cover 7 are installed sequentially from front to back, and the first carding area cover 5 and the second carding area Spaces are provided between the zone covers 6 and between the second carding zone cover 6 and the third carding zone cover 7 .

[0021] The first carding area cover plate 5, the second carding area cover plate 6 and the upper third carding area cover plate 7 are equipped with the first carding area cover plate cleaning device 8, the second carding area cover plate cleaning device 9 and the third carding area respectively. The area cover plate cleaning device 10 enables the three carding area cover plates to be cleaned in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com