Patents

Literature

148 results about "Shuttle box" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

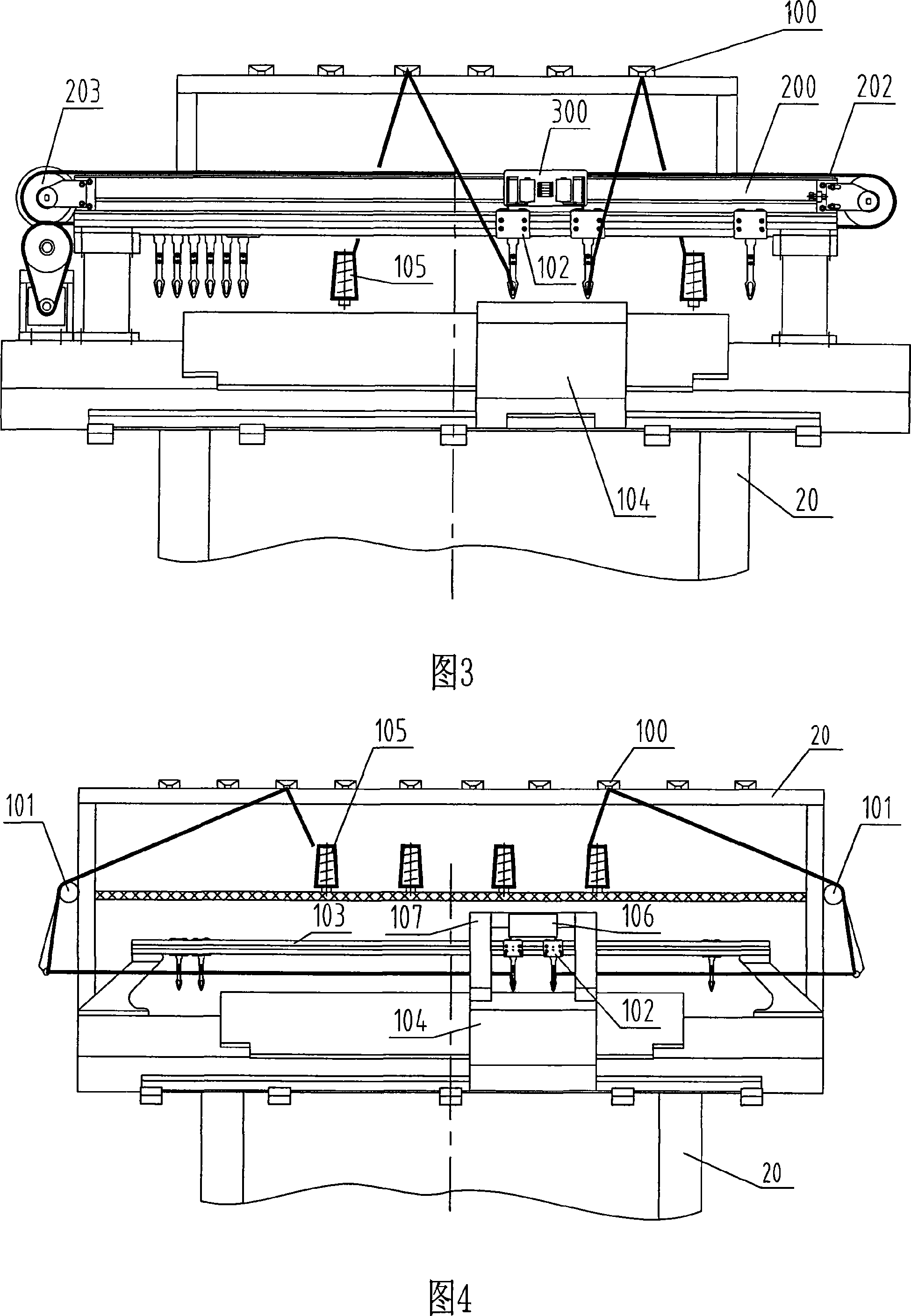

Automatic bottom line changing device of computer embroidery machine

InactiveCN101979747ASimplify spare parts requirementsHigh degree of automationBobbin-winding devicesEmbroidering machines apparatusReciprocating motionEngineering

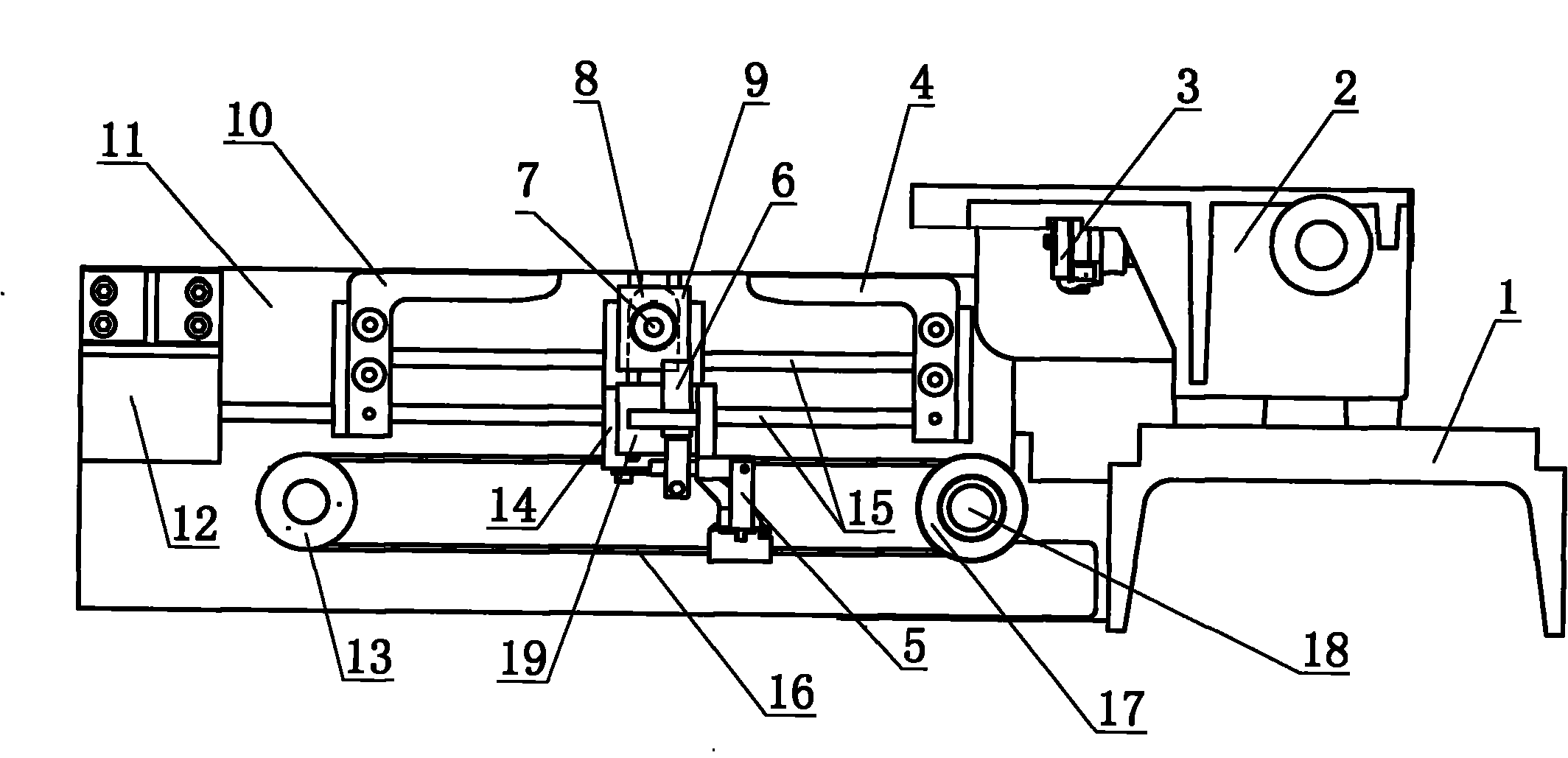

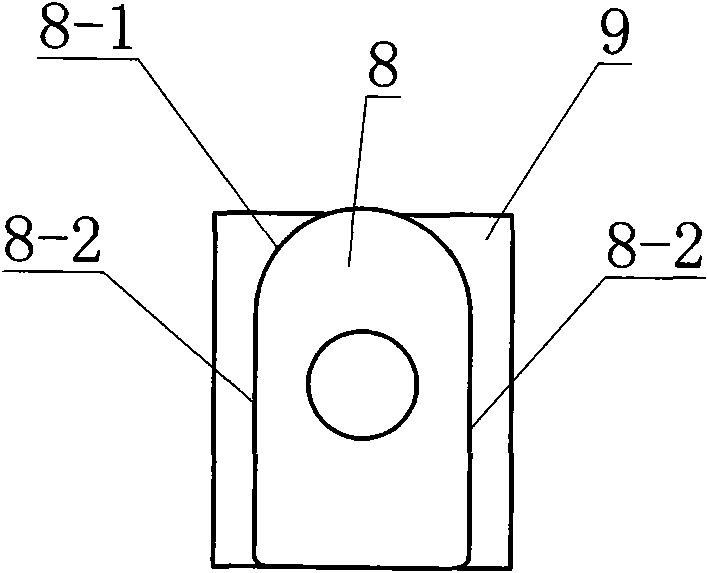

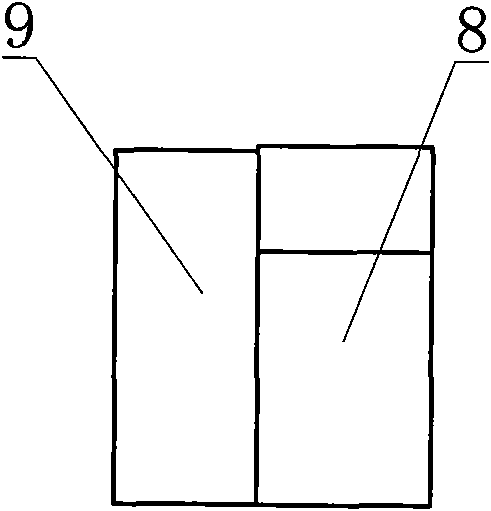

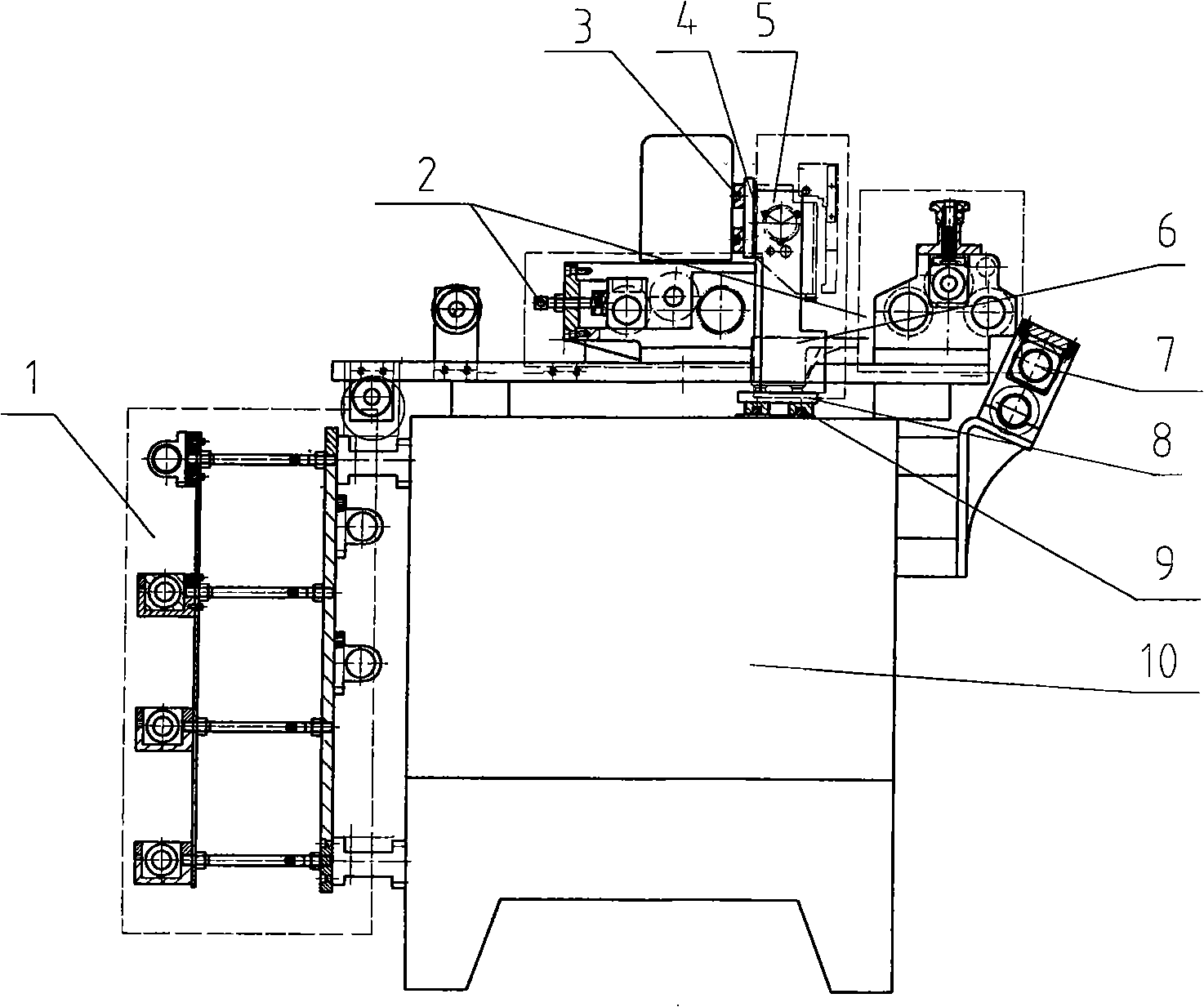

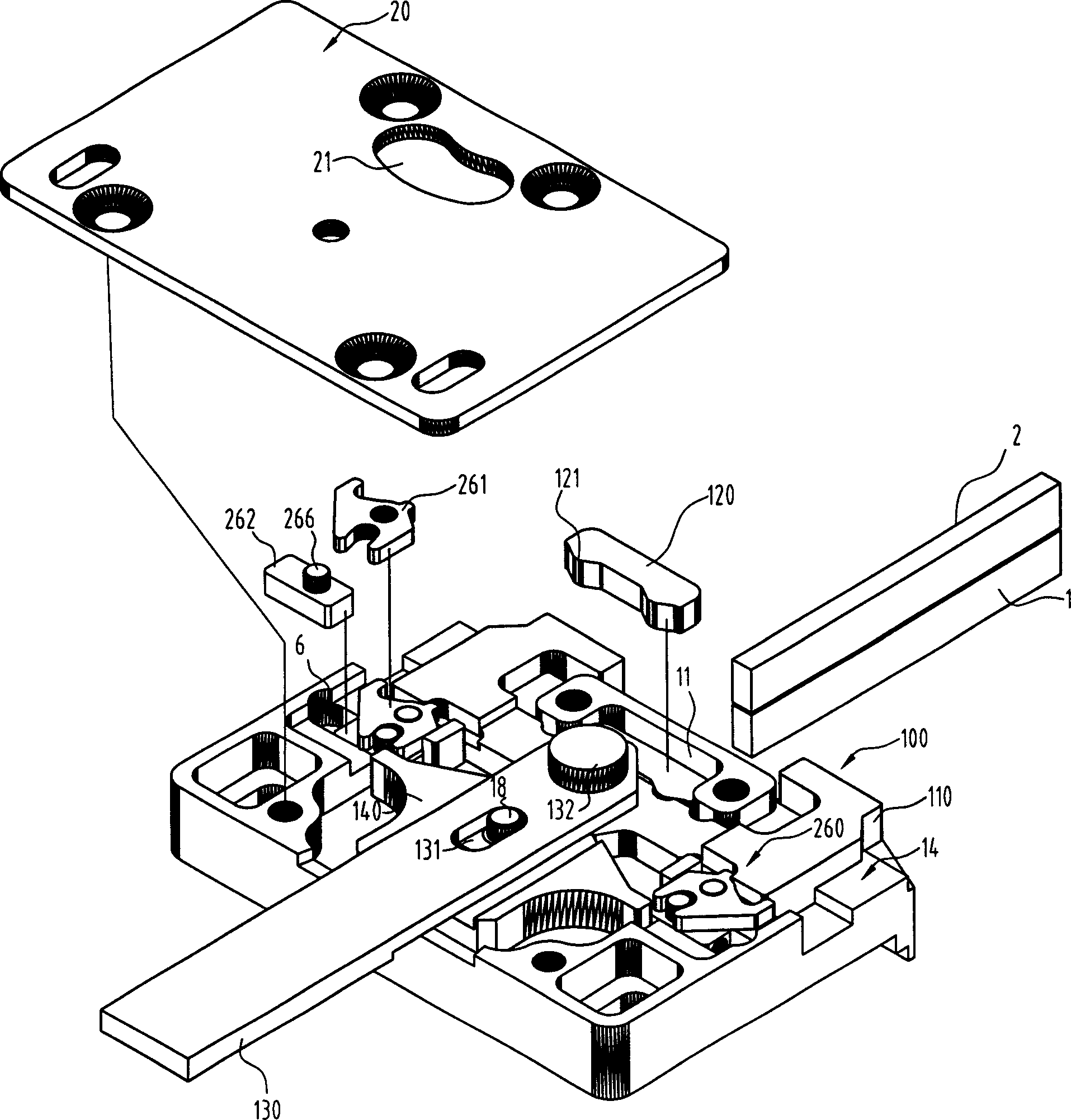

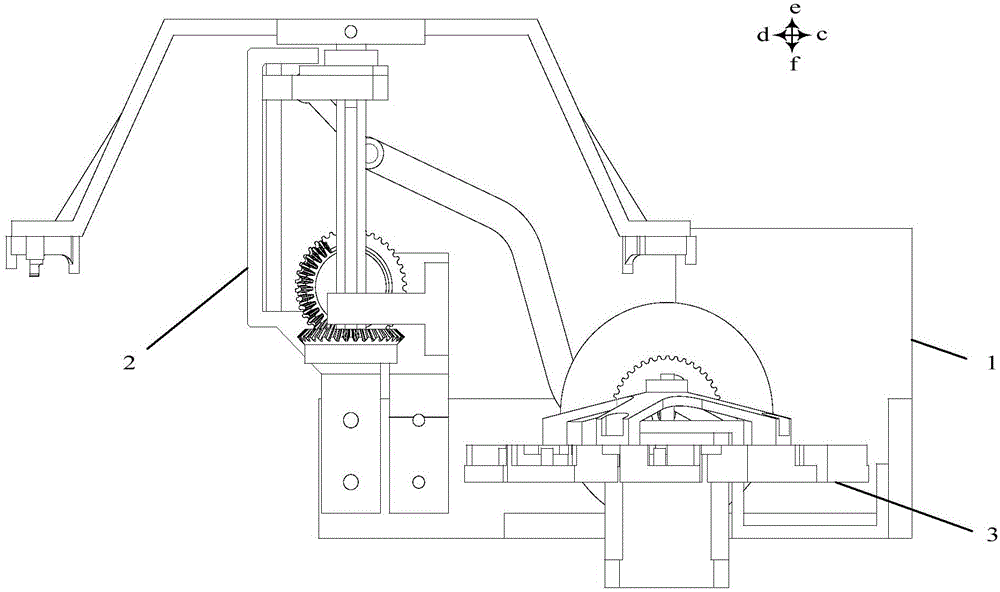

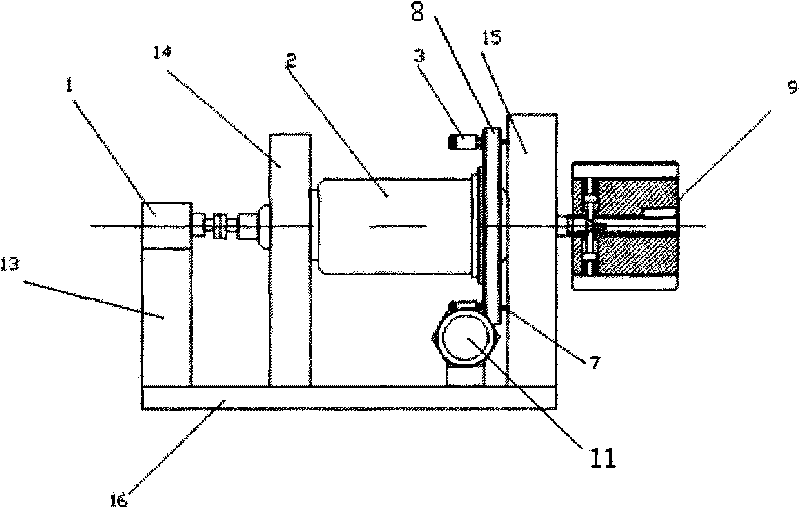

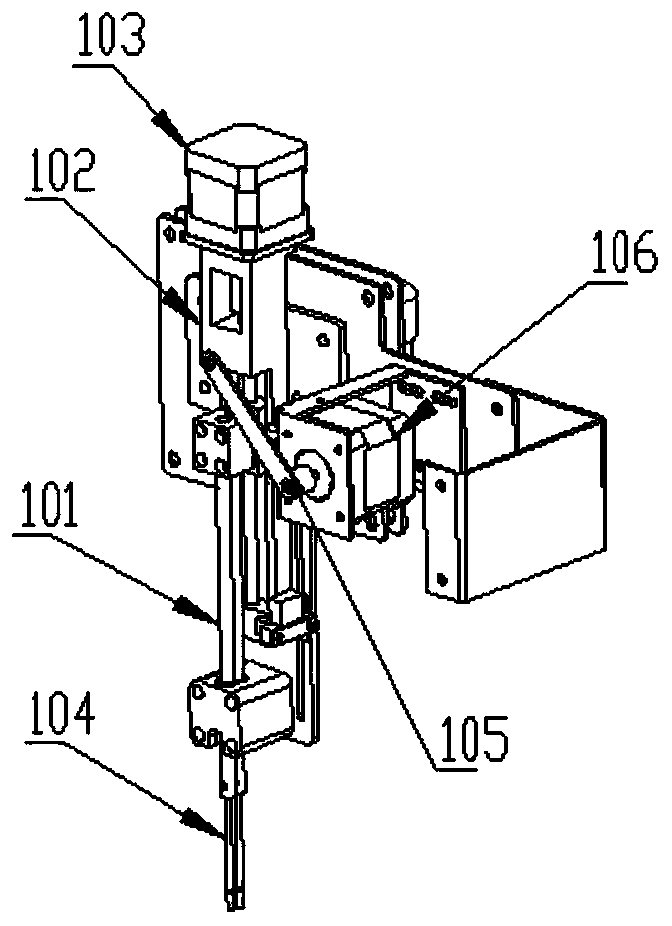

The invention discloses an automatic bottom line changing device of a computer embroidery machine, which can automatically change a shuttle peg of a bottom line rotating shuttle in a mechanical mode so as to further improve the production efficiency and the automation degree of the computer embroidery machine and lighten the labor intensity of workers. Therefore, a mounting plate is fixedly arranged on a machine frame; one end of the mounting plate is close to a rotating shuttle box, while the other end of the mounting plate is fixedly provided with a shuttle peg bin; two right angle type guide plates, which have the same shape and are opposite to each other, are arranged in the mounting plate; the outer side of the lower lateral surface of a horizontal section of the guide plate is provided with a sliding block; the upper part of the sliding block is provided with a rotary block and a positioning rotary block; the upper end face of the positioning rotary block is a semicircle surface, two lateral surfaces of the positioning rotary block are planes parallel to each other, and the positioning rotary block contact a limit track formed by the lower lateral surfaces of the horizontal sections of the two guide plates; a cylinder and a shuttle peg paw are vertically arranged on the left lower part of the rotary block; and the sliding block performs horizontal linear reciprocating motions with the help of a guide rod and a belt driving structure, thereby making the shuttle peg paw perform circular track motions between the shuttle peg box and the shuttle peg bin to realize the bottom line automatic changing.

Owner:FOSHAN QICHUANG TECH DEV

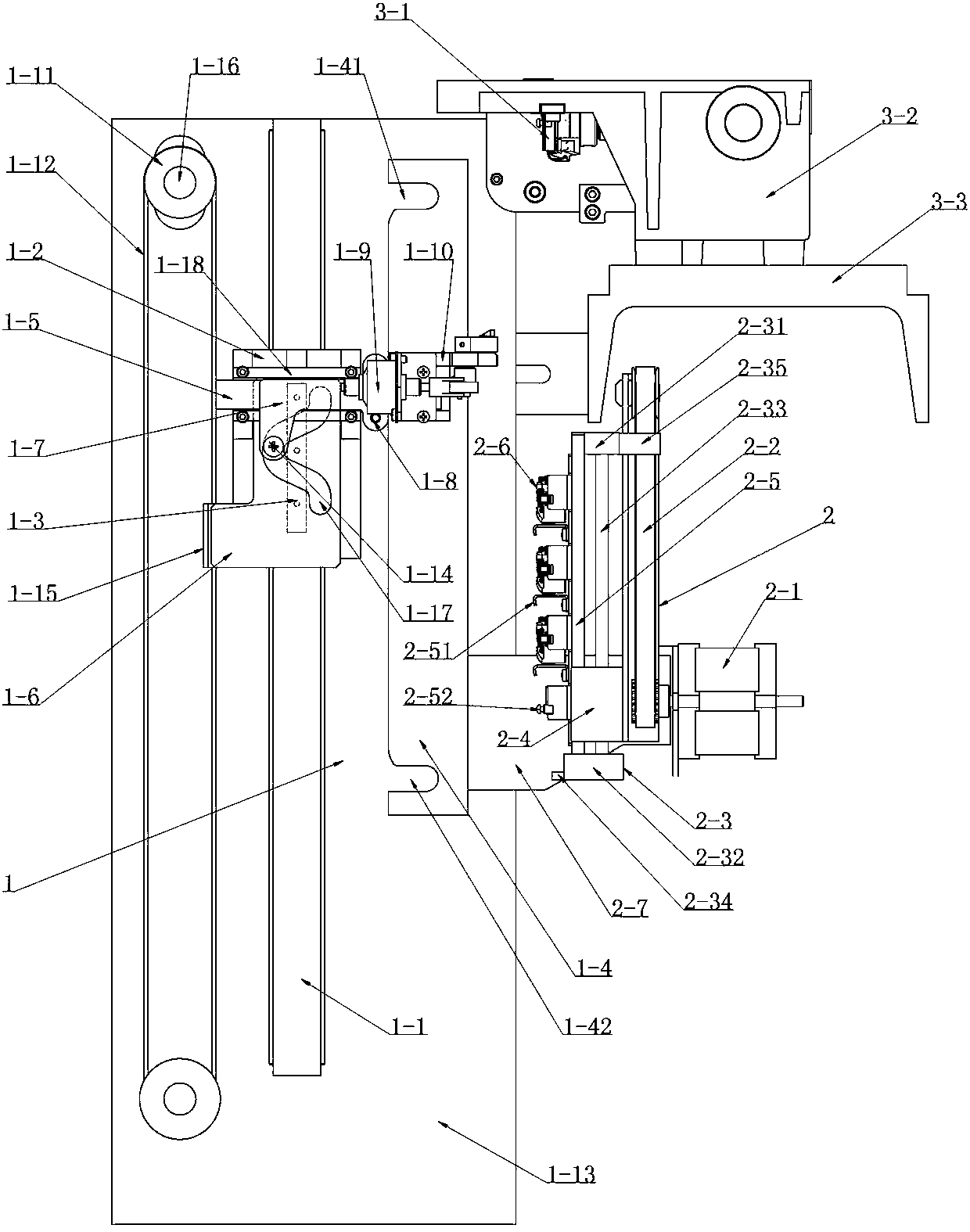

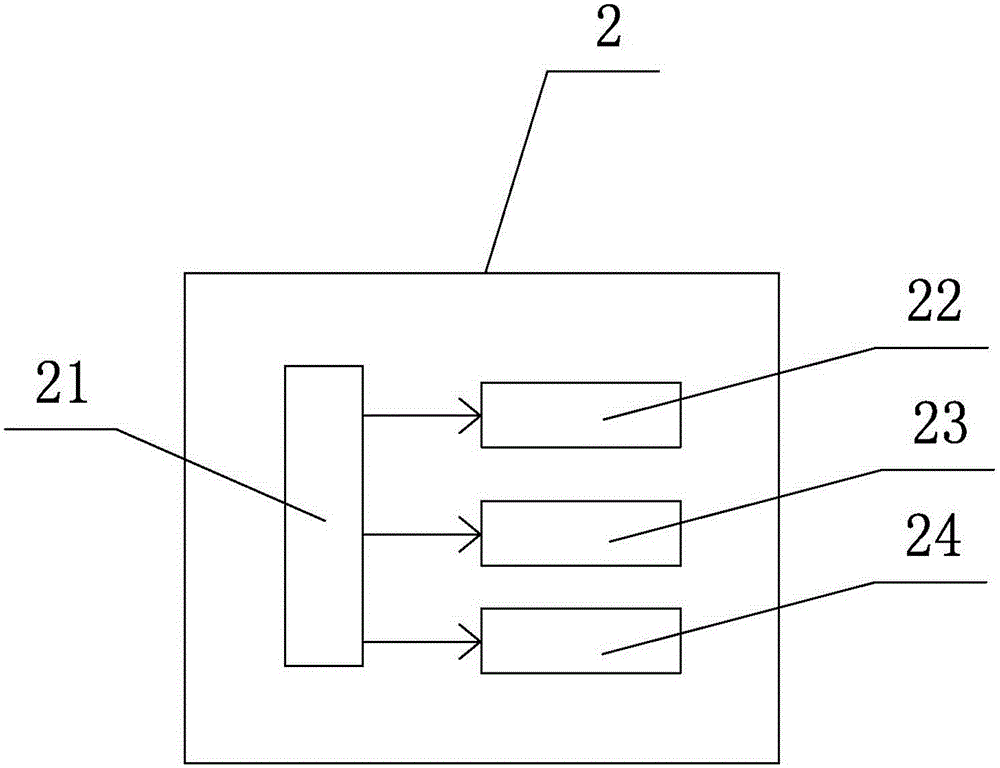

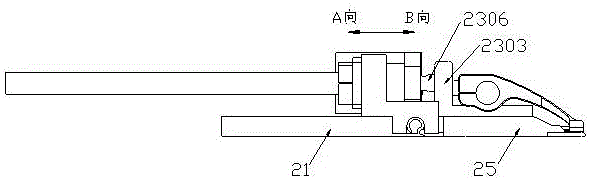

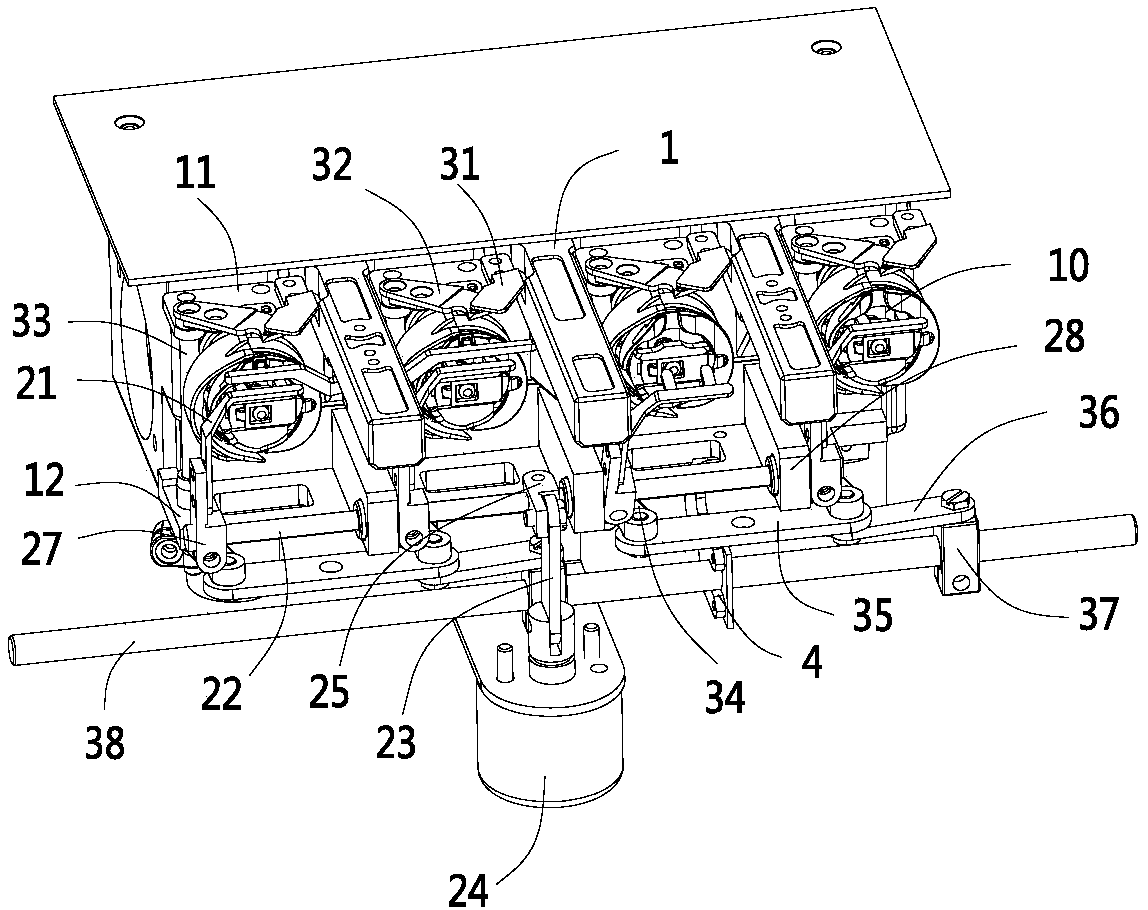

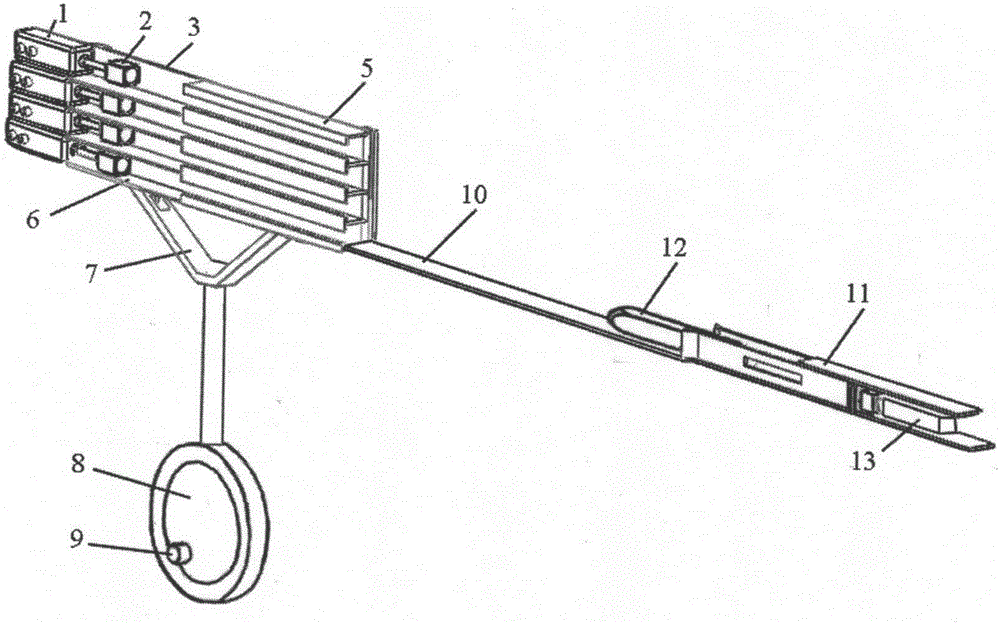

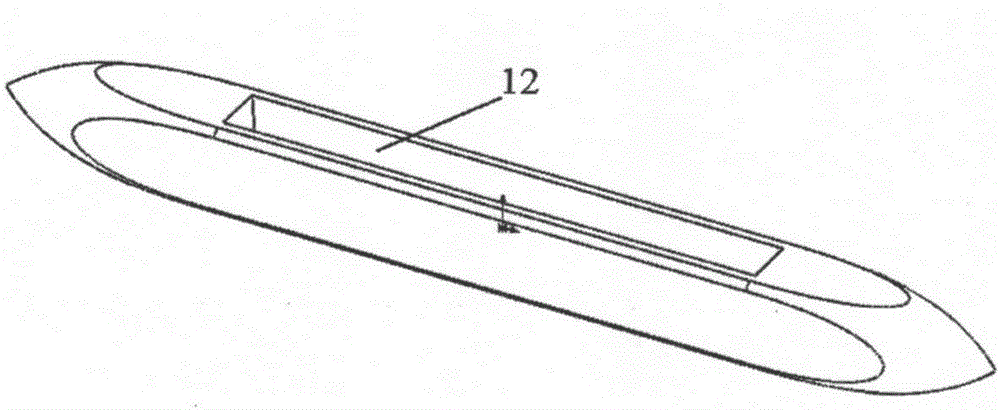

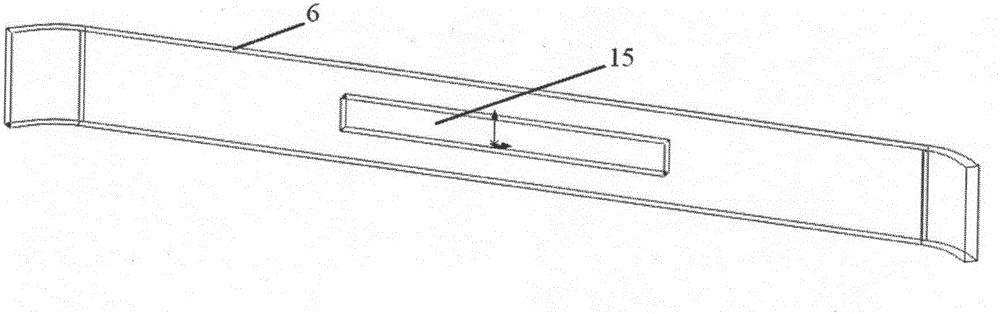

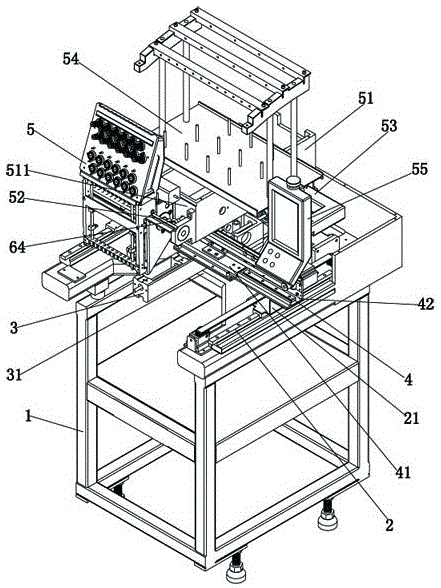

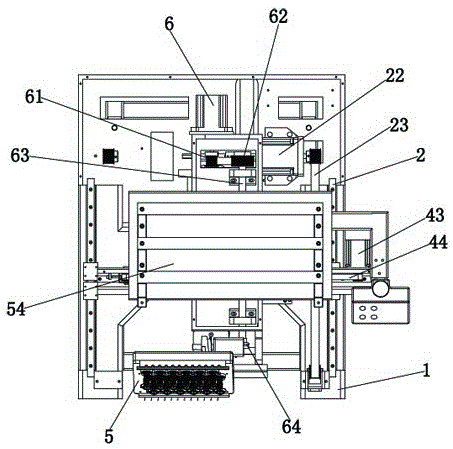

Automatic replacement device for multi-color bottom lines for computerized embroidery machine

ActiveCN103541165AShort strokeSingle actionEmbroidering machines apparatusTransmission beltControl engineering

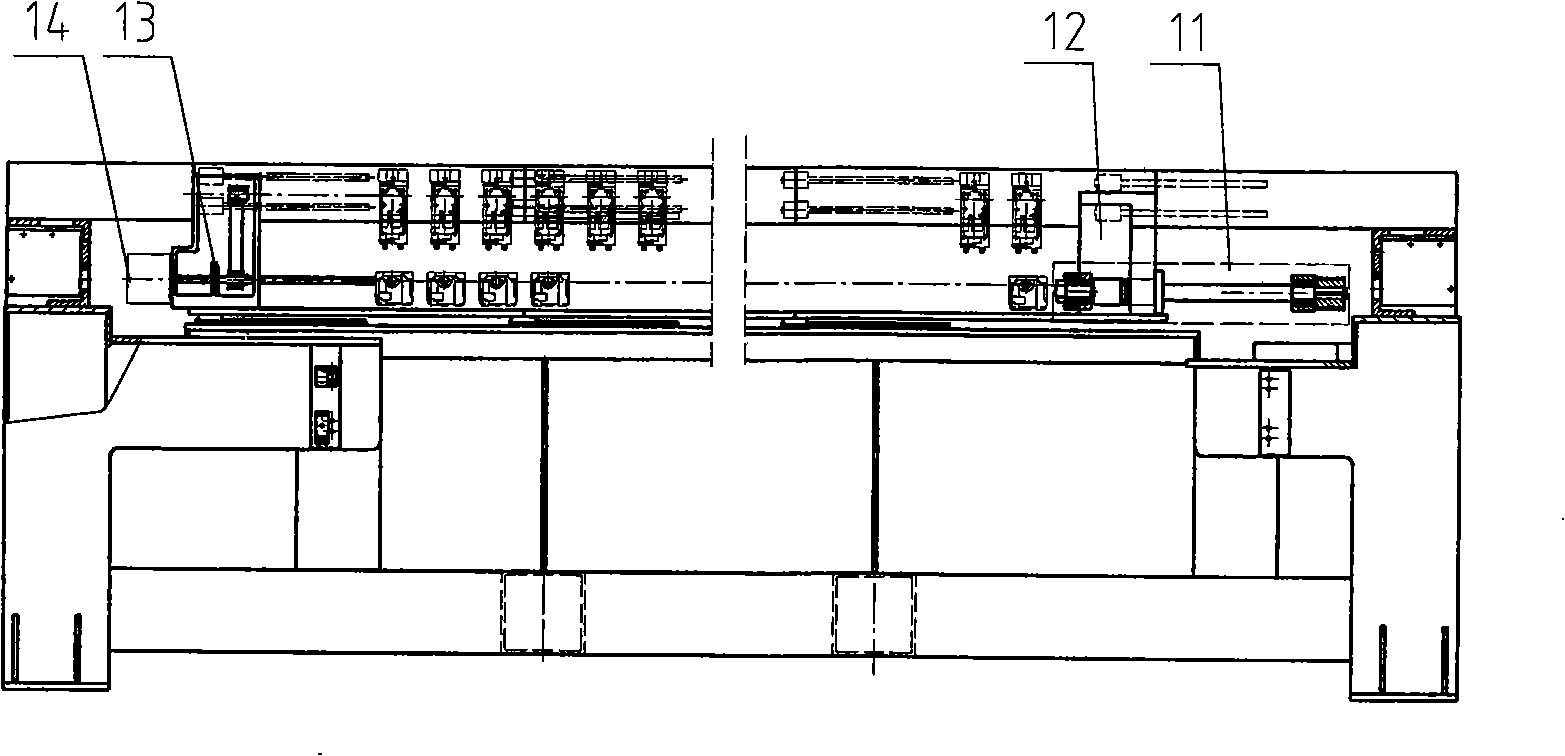

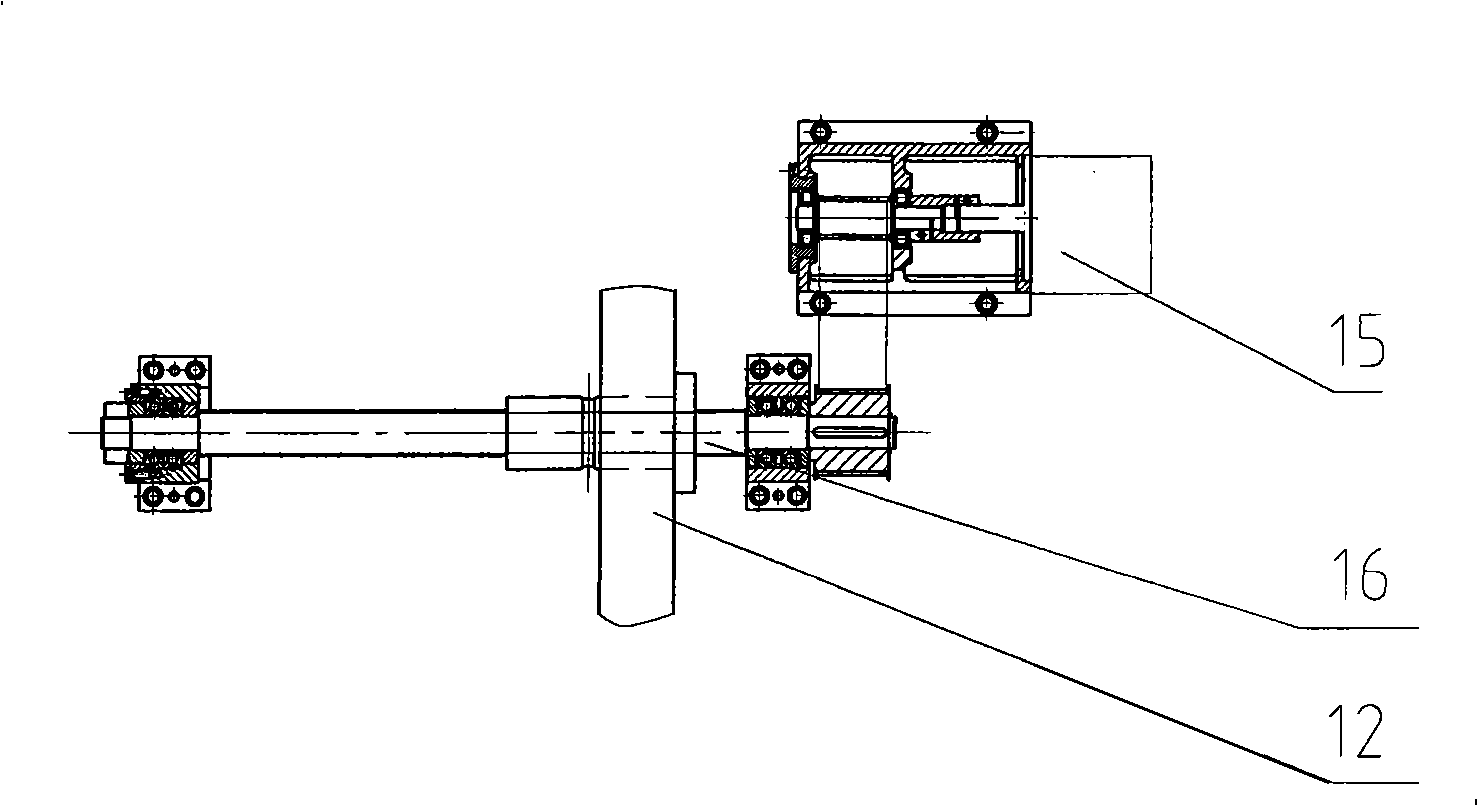

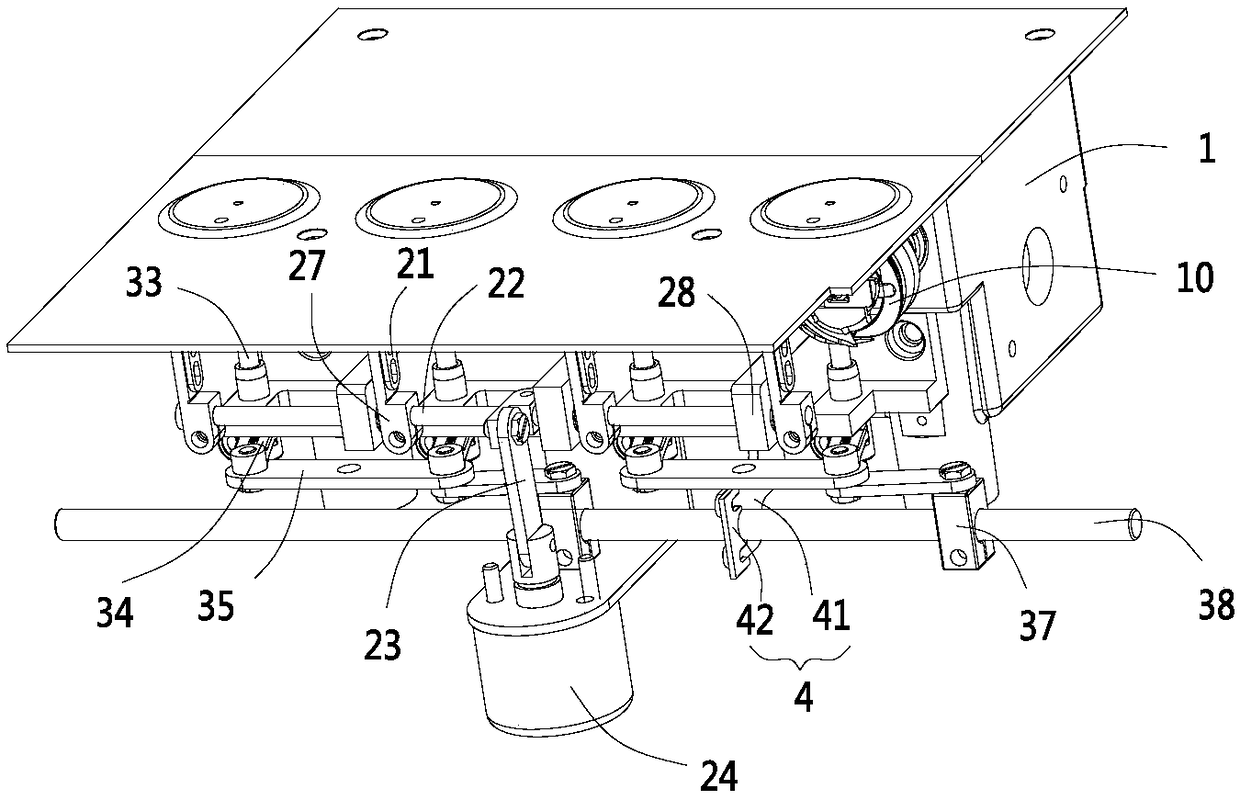

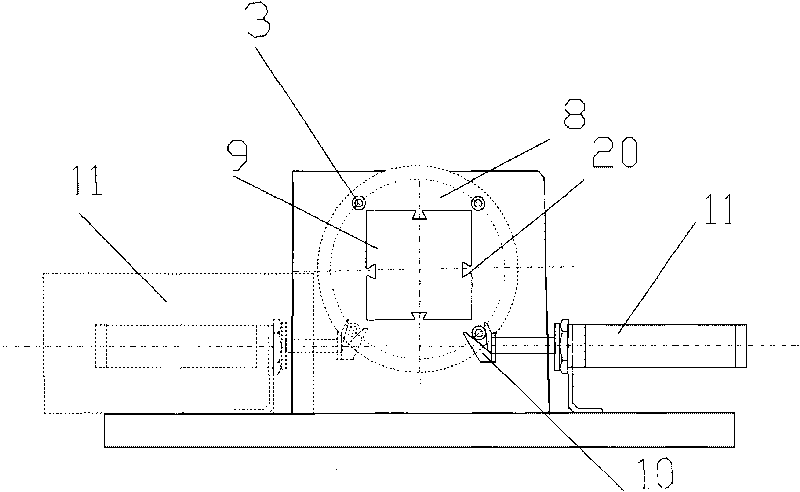

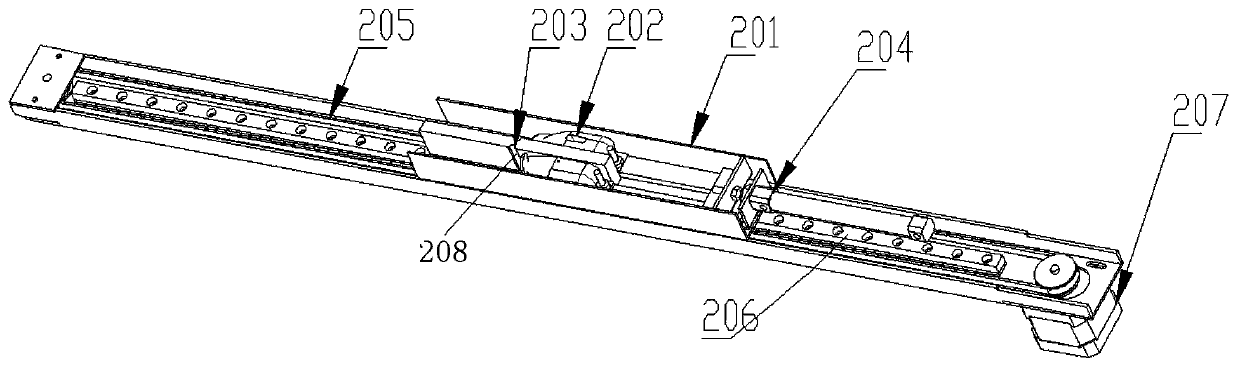

The invention relates to an automatic replacement device for multi-color bottom lines for a computerized embroidery machine. The device is provided with a transmission belt, a guide track and a position-limiting plate, which are parallel to each other, on a vertical mounting baseplate, a rotary shuttle box base equipped with a rotary shuttle box is fixedly arranged on a machine body of the embroidery machine, and the device is provided with a shuttle peg mobile access mechanism, which is in chimeric position-limiting sliding connection with the guide track through a pulley, fixedly connected with the transmission belt through a shuttle taking position-limiting plate and in contact connection with the left side edge of the position-limiting plate through a position-limiting shaft wheel respectively; the device is provided with a shuttle sending mechanism, a shuttle sending pulley seat is equipped with a shuttle sending pulley, as well as an upper driving mechanism and a lower driving mechanism thereof, the shuttle sending pulley is equipped with a split type standby shuttle row, and the shuttle sending pulley seat is fixed on the mounting baseplate through a mounting block. The device has simple structure, and can smoothly transmit a standby bottom line shuttle peg and correctly place on the rotary shuttle box, fully meet the requirements of replacing matching multi-color bottom lines of multi-color double-sided embroidery exceeding 10 colors, further improve the production efficiency of equipment and upgrade the quality grade of products.

Owner:FOSHAN QICHUANG TECH DEV

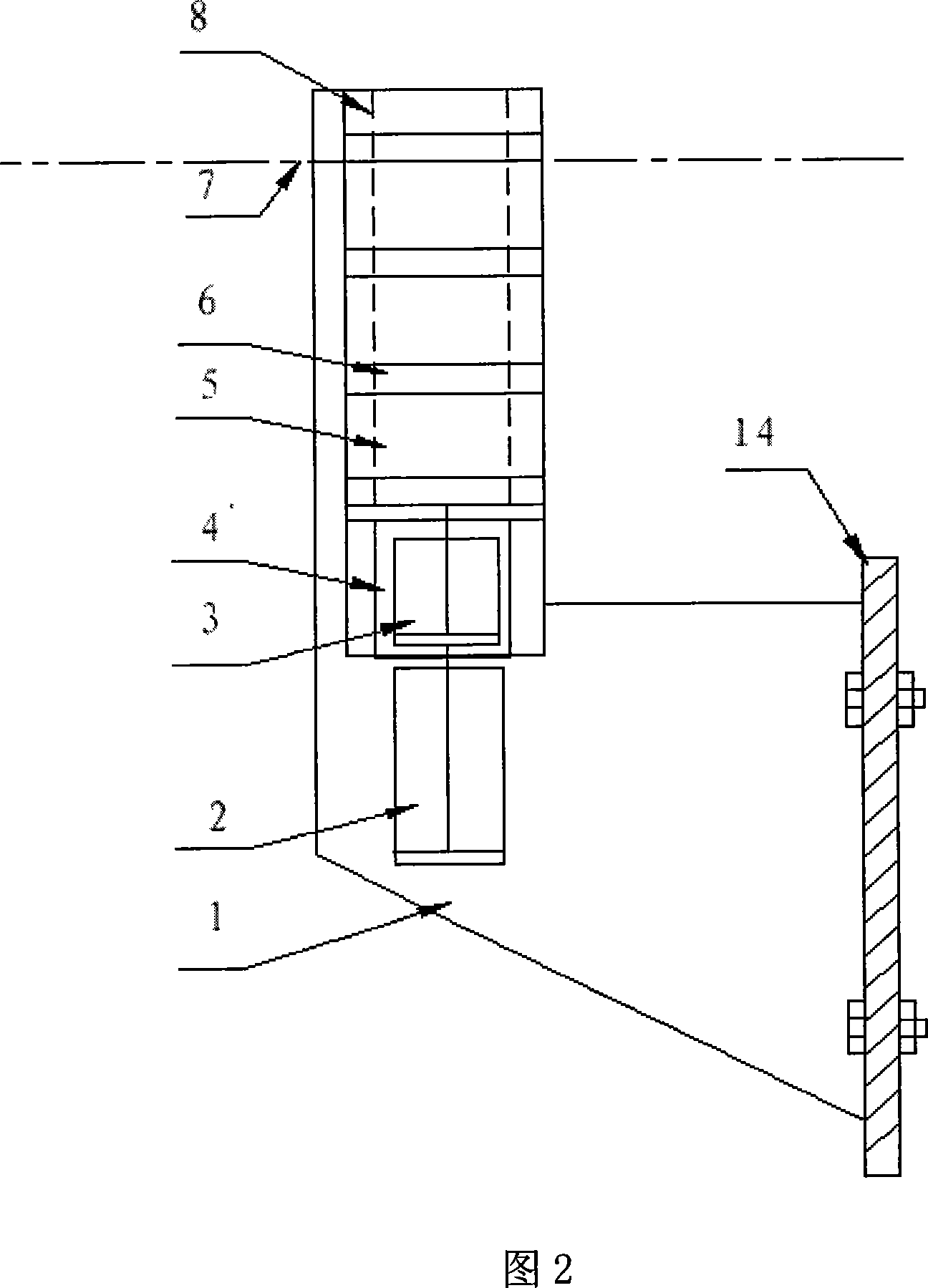

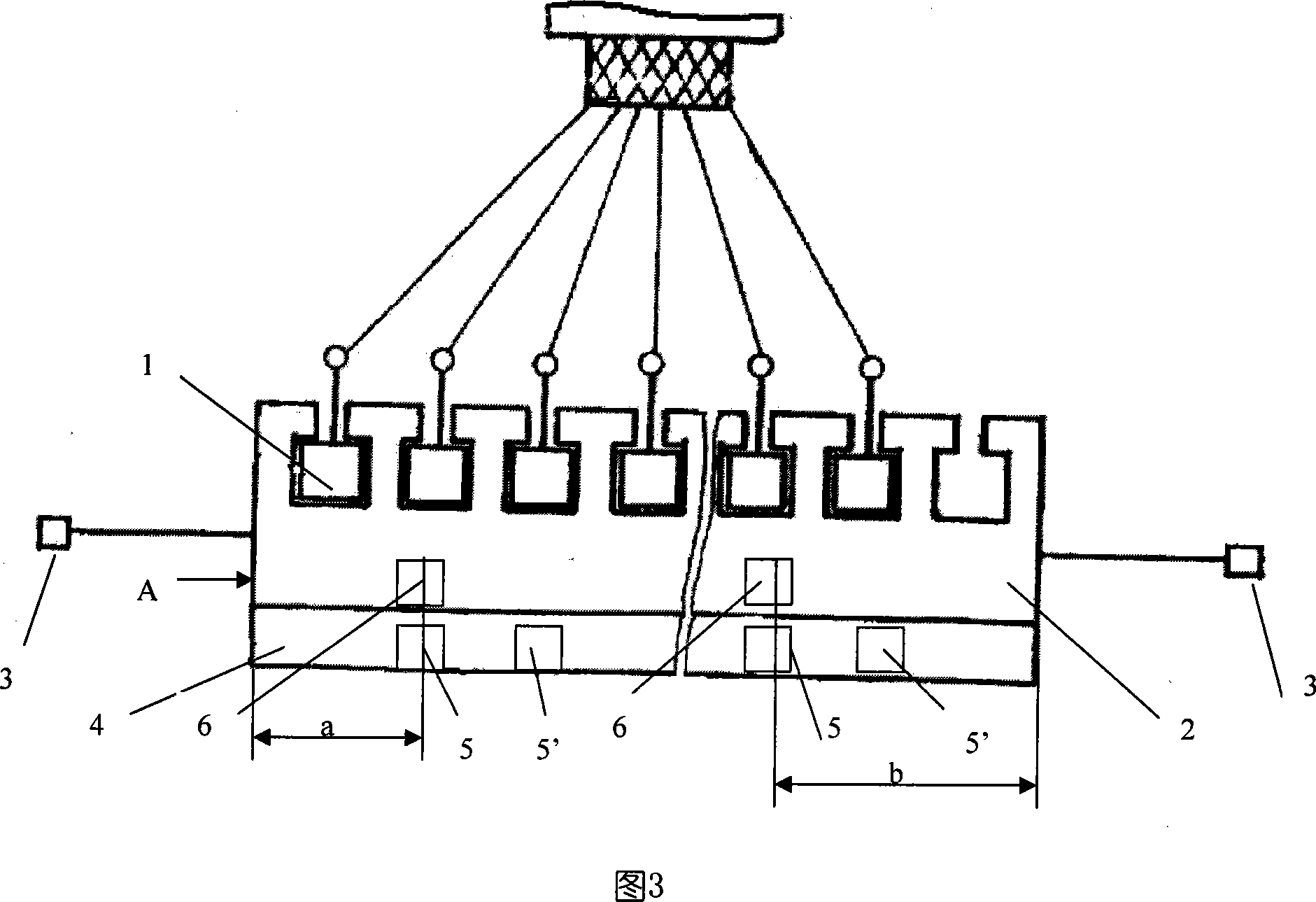

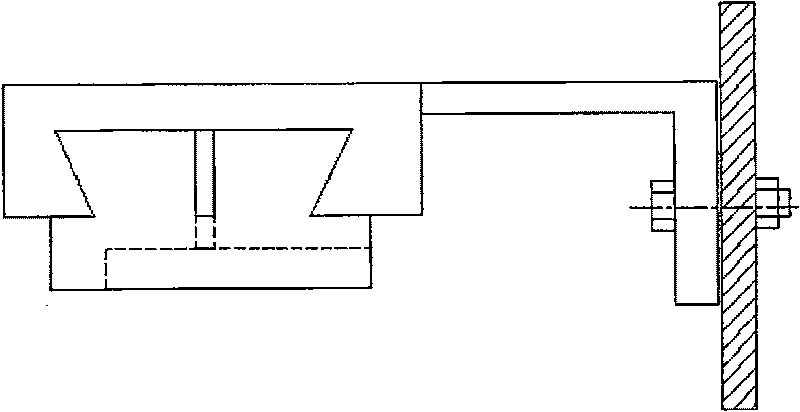

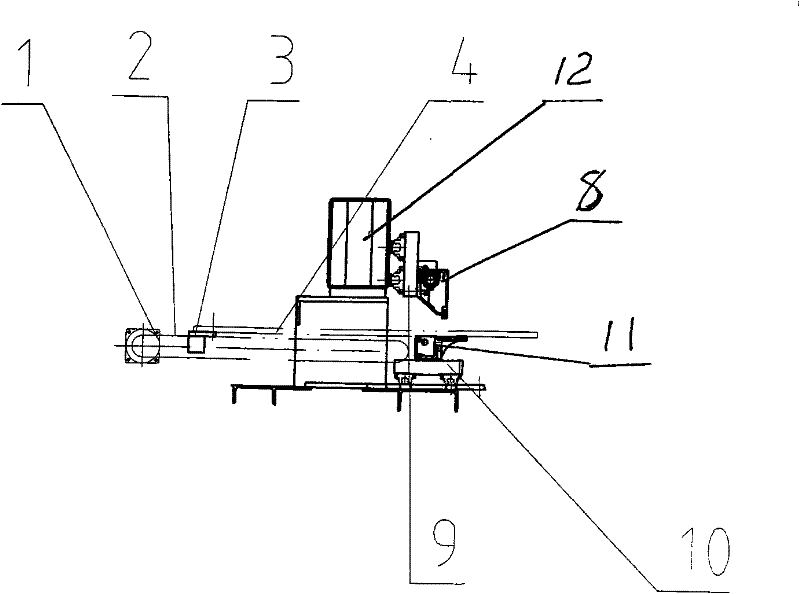

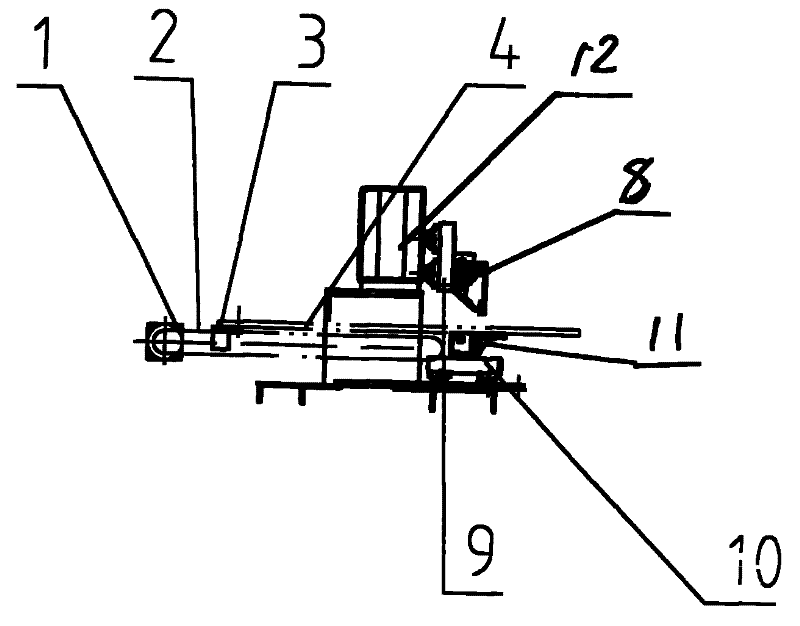

Rigid rapier loom 1 multiple 4 multi-shuttle box mechanism

The invention relates to a 1X4 multiple-shuttlebox device of the rigid rapier weaving machine including the stroke controller multiple-shuttlebox. The stroke controller is made up of the first air cylinder and second air cylinder. The multiple-shuttlebox is made up of shuttle storing box, active slipway and directional runner. The first air cylinder and directional runner are fixed on the supporting frame; the second air cylinder is fixed on the active slipway; the rut shuttle way is opened in shuttle storing box to make shuttle go and out. The boss at the shuttle box back and active slipway back are connected with the sliding slot. The active slipway lower is connected with the piston of first air cylinder; the second air cylinder piston is connected with the shuttle box bottom. The stroke of first air cylinder is 2 times than the second one. The invention can solve the problems that the abb is not continuously in ordinary rapier weaving machine and the low precision of 1X4 shuttle box, so it can lead in four lonely continuously abb and spin many kinds of pipe fabrics.

Owner:DONGHUA UNIV

Novel quilting embroidery machine

InactiveCN101319440AShorten the lengthImprove rigidityHem-stitch machinesMattress sewingElectric machineryAutomotive engineering

The invention discloses a novel quilting embroidery machine, consisting of a machine frame, as well as a charging system, a discharging system and two sets of rolling systems which are arranged on the machine frame. A servo motor realizes the front and rear rolling and synchronous rotation in a Y direction through a synchronous cog belt; a machine head component and a shuttle box component are also arranged on the machine frame; the machine head component is arranged on a connecting plate; a linear guide rail is arranged on the connecting plate; the shuttle box component is arranged on a shuttle box component connecting plate, and a shuttle box component linear guide rail is arranged on the connecting plate; a driving component is also arranged on the machine frame; the driving component comprises the servo motor, a lead screw and a driving-connecting block; the driving-connecting block is connected with the machine head component connecting plate and the shuttle box component connecting plate; the driving component realizes the movement of the machine in an X direction. The servo motor and a transmission box connected with the servo motor are also arranged on the machine frame; the transmission box connects the machine head component connecting plate with the shuttle box component connecting plate into a whole; the transmission box drives a needle bar of the machine head component to move up and down and also drives the shuttle box component to rotate. The machine is applicable to quilting embroidery machines.

Owner:陈桢铭

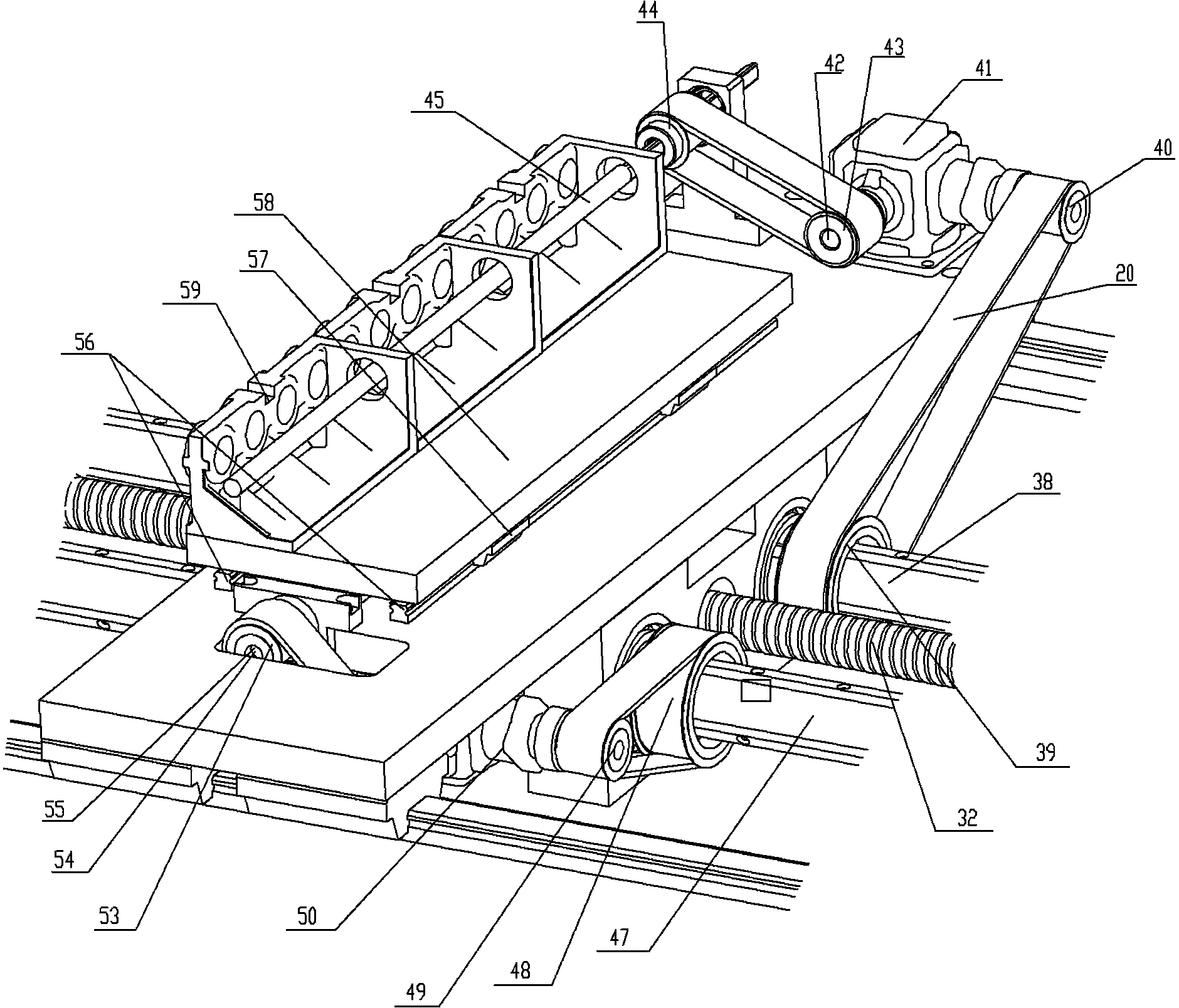

Multifunctional swinging type quilting and embroidering integration machine

ActiveCN103835083AHigh precisionNeedle spacing is smallAutomatic machinesNeedle barsMotor driveReciprocating motion

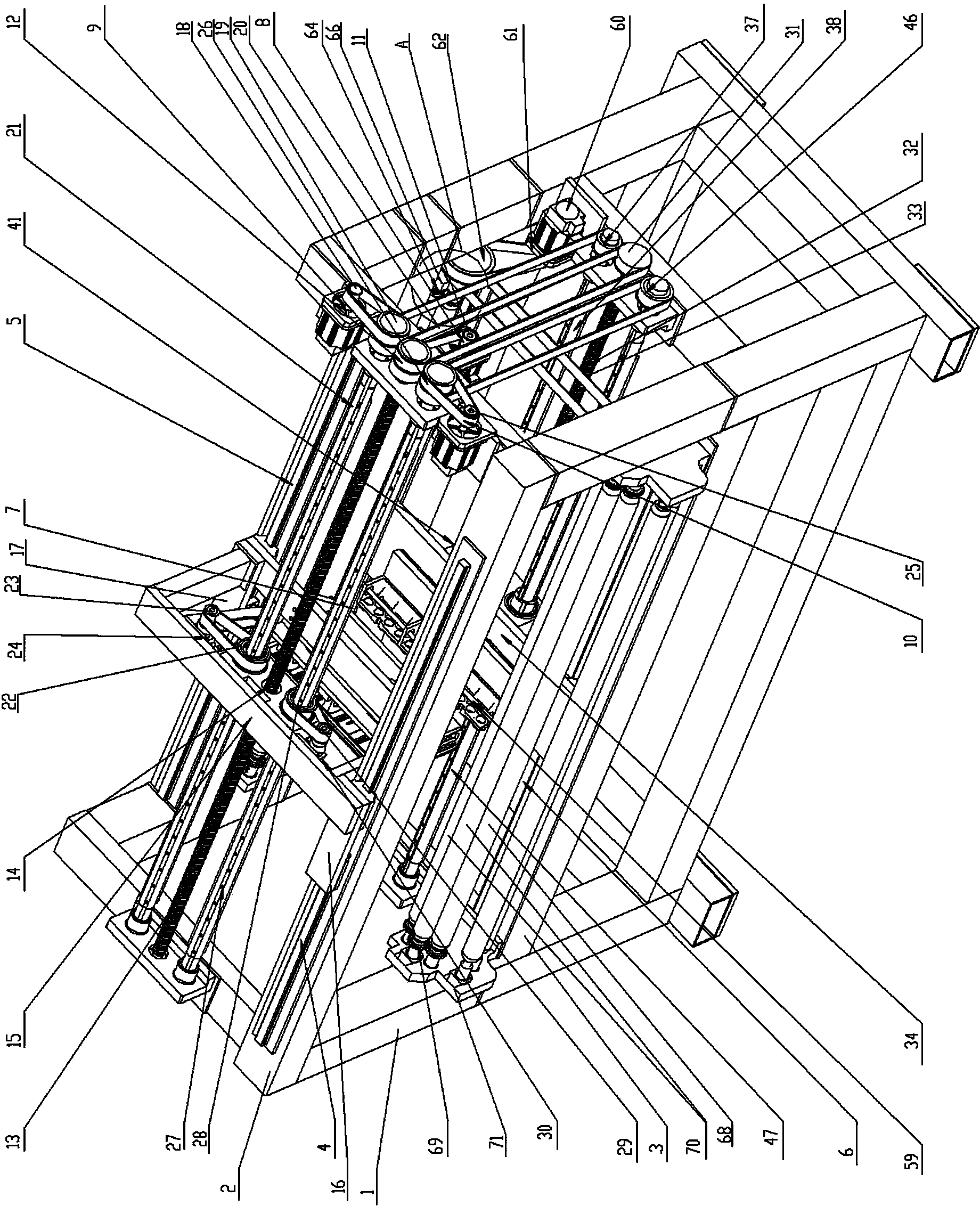

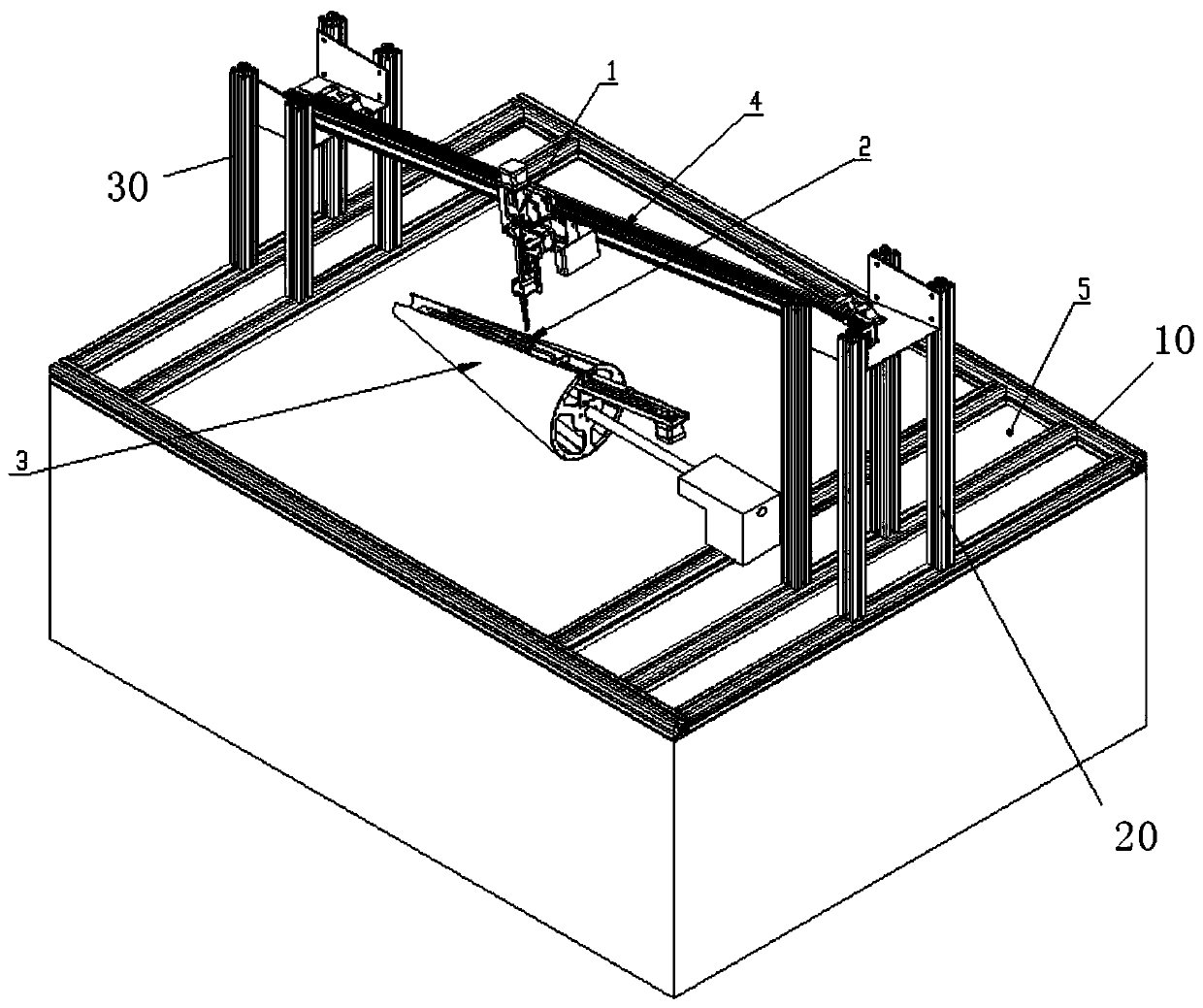

The invention discloses a multifunctional swinging type quilting and embroidering integration machine. The multifunctional swinging type quilting and embroidering integration machine comprises a rack, a machine head moving type working mechanism, a machine head swinging movement mechanism, a rotating shuttle box moving type working mechanism, a rotating shuttle box swinging movement mechanism and a cloth guiding mechanism, wherein a screw-rod servo motor drives the machine head moving type working mechanism and the rotating shuttle box moving type working mechanism to do synchronous X-direction movement on a linear guide rail I, a linear guide rail II, a linear guide rail III and a linear guide rail IV respectively; a moving servo motor drives the machine head moving type working mechanism and the rotating shuttle box moving type working mechanism to do X-direction movement; a swinging servo motor drives the machine head swinging movement mechanism and the rotating shuttle box swinging movement mechanism to do Y-direction reciprocating movement. The multifunctional swinging type quilting and embroidering integration machine has the advantages that infinitely-circulating quilting and embroidering are realized, the needle distance is short and can be set randomly, the adaptability to patterns is high, the accuracy of processed patterns is high and the application range is wide.

Owner:JIANGSU DADAO MACHINE GROUP

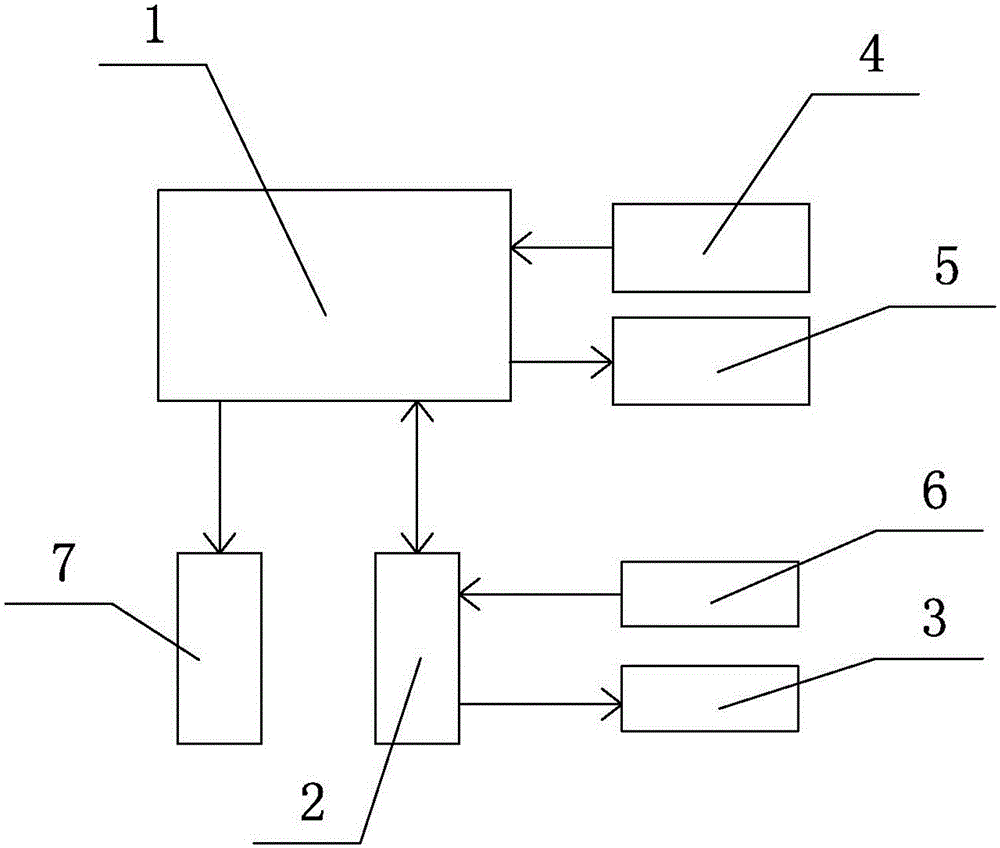

Visual scare connection automatic training apparatus

InactiveCN104996311AWon't hurtNo electromagnetic interferenceDiagnostic recording/measuringSensorsMicrocontrollerVideo monitoring

The invention relates to the field of research on animal visual scare memory, and especially relates to a visual scare connection automatic training apparatus. According to the invention, a master control unit designs a stimulation scheme and sends a control instruction, and a microcontroller, according to the instruction of the master control unit, controls a gas punishment unit to work; the gas punishment unit punishes an animal disposed in a shuttle box by spraying a gas in the shuttle box; a video monitor is used for monitoring the action of the animal disposed in the shuttle box in real time; and a visual stimulation display unit is used for displaying visual stimulation information according to the instruction of the master control unit. According to the invention, visual scare memory connection is realized by use of an animal Pavlov's conditioning principle, punishment is carried out by use of the high-pressure gas, anti-interference real-time signal acquisition is realized in a training process, at the same time, electromagnetic noise is eliminated, damage is not brought to the animal either, and the time for a subject to establish scare connection conditioning is shortened.

Owner:ZHENGZHOU UNIV

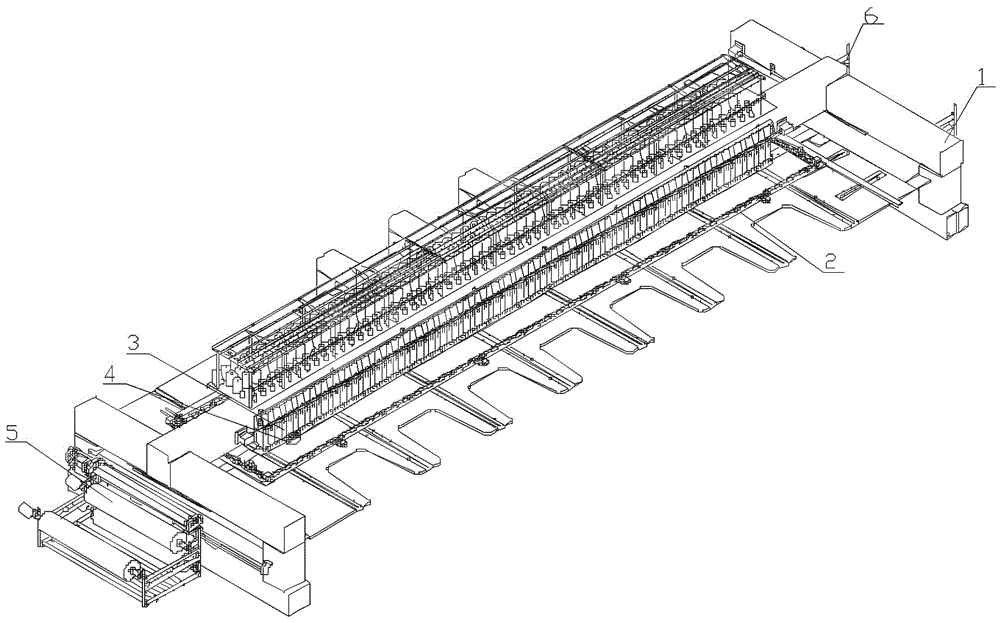

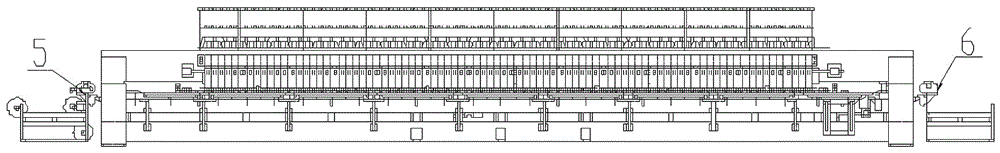

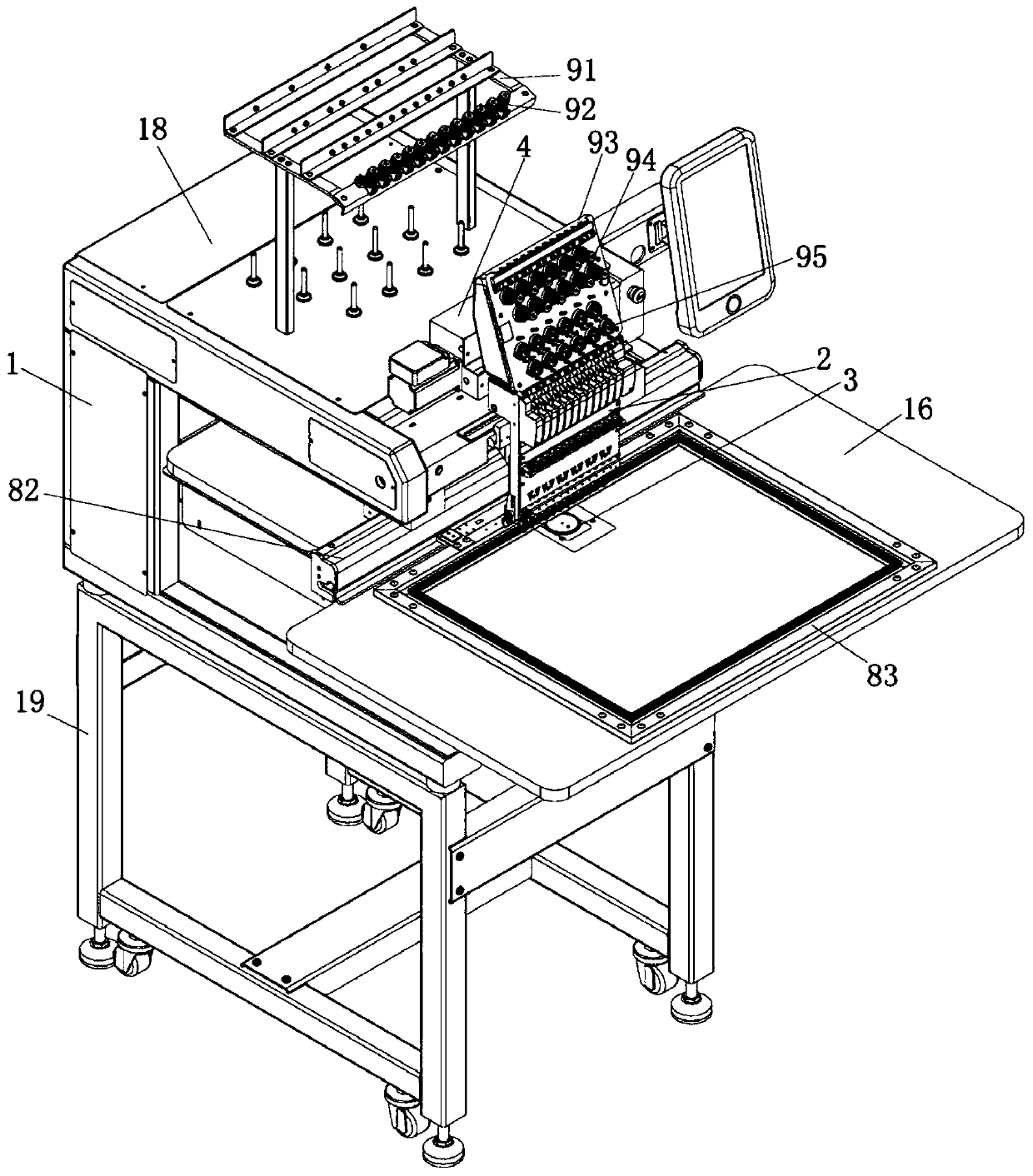

Embroidery processing center

ActiveCN106012357AImprove stabilityQuality improvementPressersMattress sewingEngineeringMechanical engineering

The invention discloses an embroidery processing center which comprises a rack structure, an embroidery frame structure, an embroidery mechanism and a feeding and discharging mechanism. The feeding and discharging mechanism comprises a fabric feeding device and a fabric discharging device located at the left end and the right end of a crossbeam of the rack structure, the embroidery frame structure comprises a movable frame and a fabric clamping device and a fabric tensioning device installed on the movable frame, the embroidery mechanism comprises multiple machine head assemblies and rotary shuttle box assemblies corresponding to the lower portions of the machine head assemblies, the machine head assemblies are installed on the crossbeam of the rack structure, and the embroidery frame structure is arranged on a platen under the crossbeam. The fabric feeding device inputs an embroidery fabric into an embroidery region, the embroidery fabric enters the movable frame and is clamped by the fabric clamping device, the embroidery fabric in the embroidery region is in a tensioned state under the effect of the fabric tensioning device, meanwhile an embroidery process is completed through the embroidery mechanism, and finally a finished product fabric with embroidered patterns is output by the fabric discharging device. Embroidering, quilting seaming and seaming embroidering integrated functions are integrally controlled by a computer, various single-layer or multi-layer fabrics required for embroidering, quilting seaming and seaming embroidering are operated in the same device, and embroidering processing is completed through one program command.

Owner:JIANGSU DADAO MACHINE GROUP +1

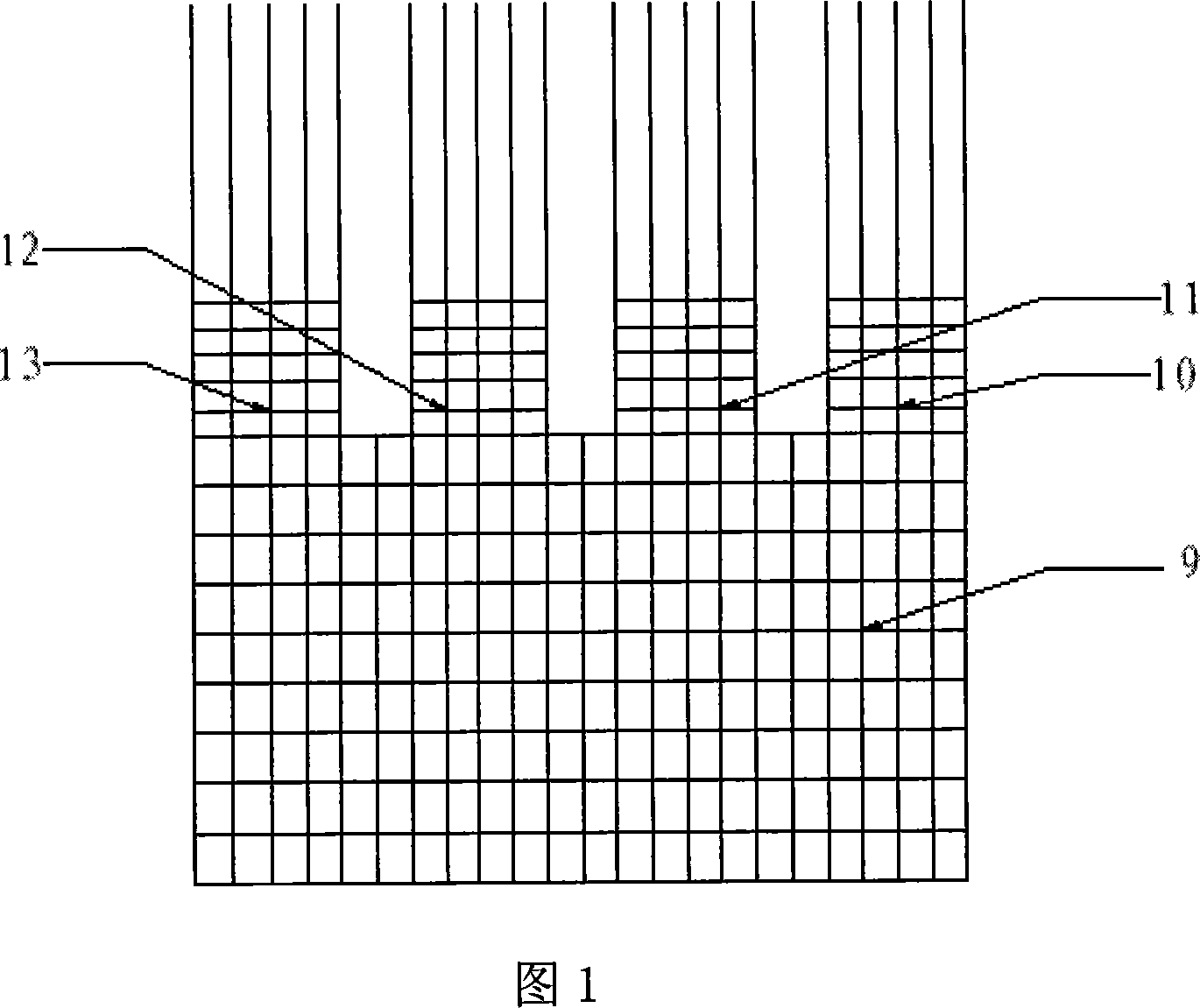

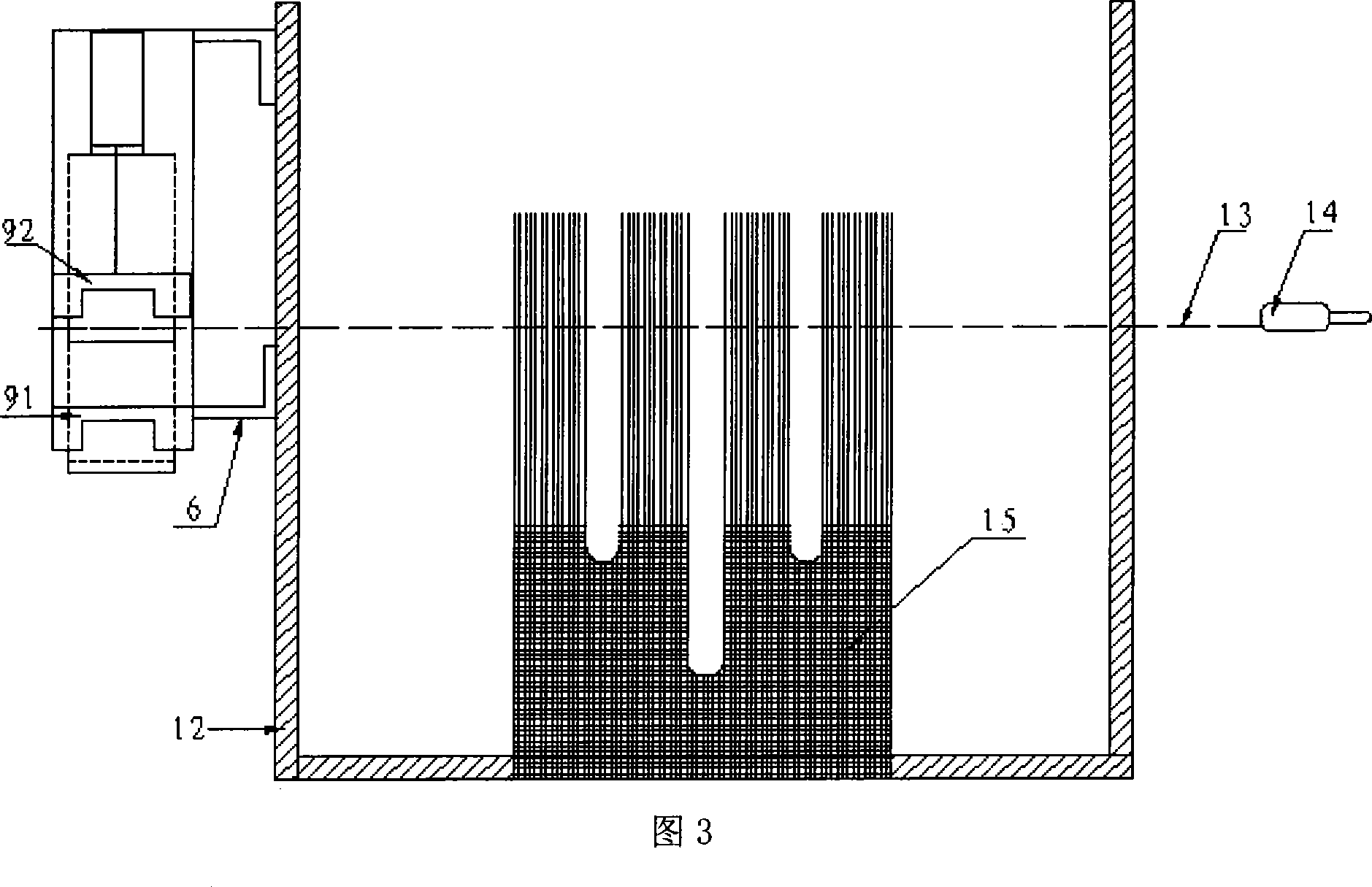

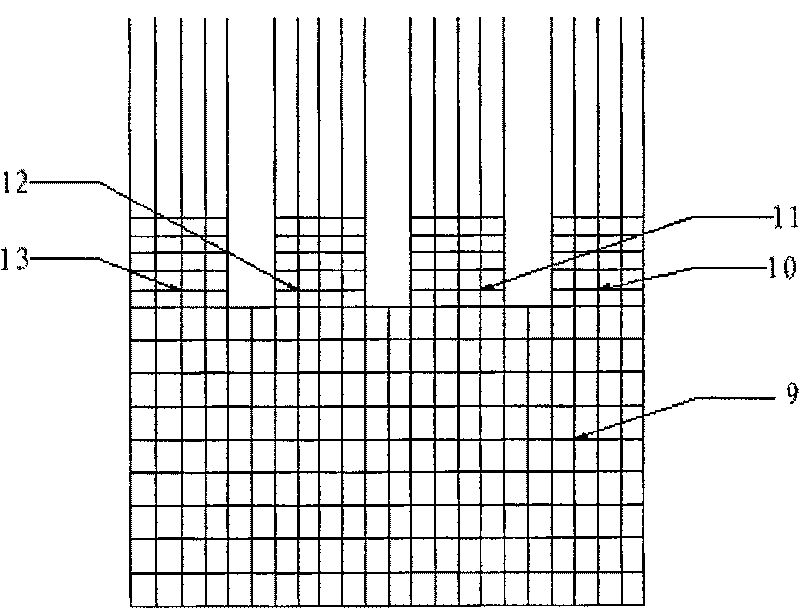

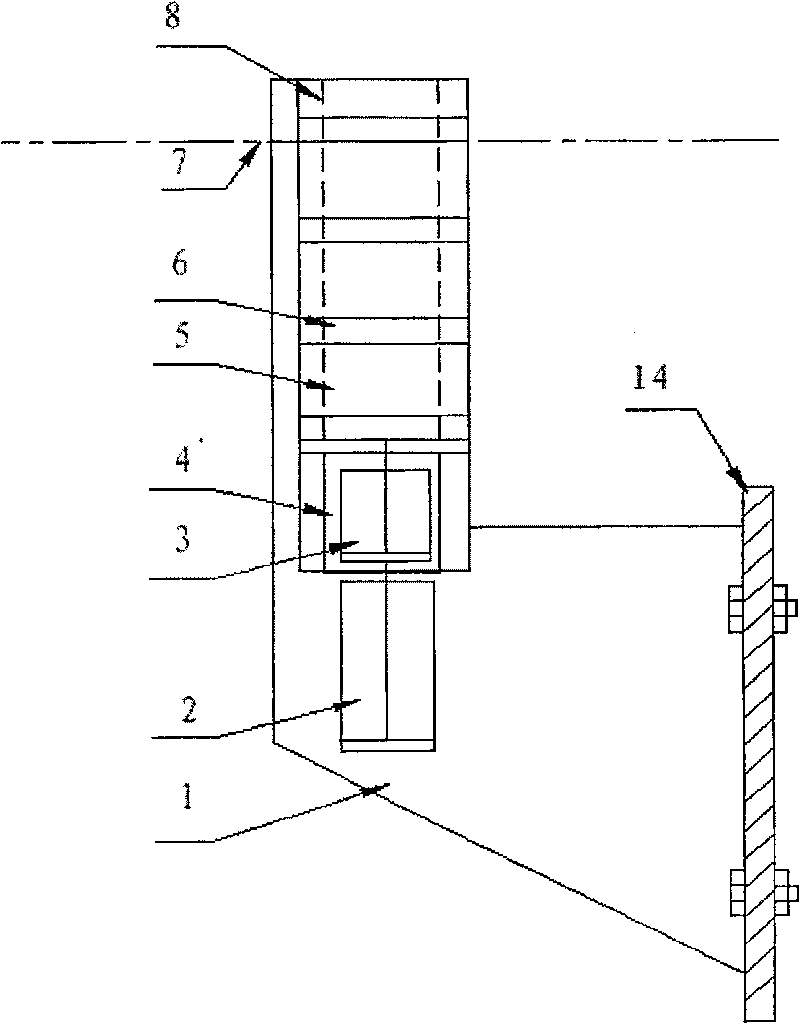

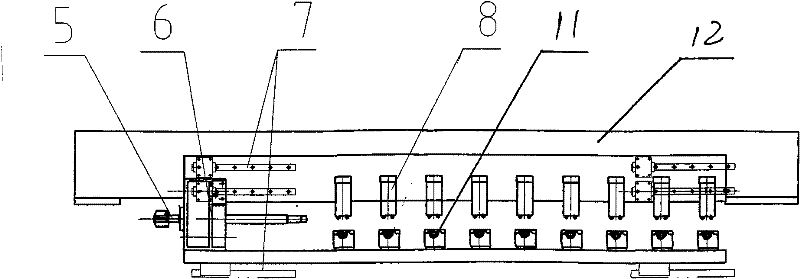

1*8 multiple shuttle box mechanism for rigid rapier weaving machine

The invention relates to a rigid rapier weaving machine 1*8 multiple box mechanism, wherein a moving slipway (9) is divided into a front slipway (91) and a rear slipway (92), the front slipway (91) and the rear slipway (92) are respectively provided with four-shuttle boxes (10), (11) which can slide from top to bottom, a cylinder (5) is mounted on a fixed mount (6), a piston rod of the fixed mount which is connected with the moving slipway (9) can lead the moving slipway (9) to move back and forth, cylinders (8), (7) are respectively mounted on the lower portion of the four-shuttle boxes (10), (11), and piston rods of the cylinders (8), (7) which are respectively connected with the four-shuttle boxes (10), (11) drive the four-shuttle boxes (10), (11) to slide. The invention can automatically position a required shuttle on the weft insertion operating position to carry out weft insertion, can realize automatic weave of various types hollow fabric (comprises: double-layer four bifurcation, four-layer double bifurcation type, three-layer double bifurcation tube, double-layer three bifurcation, tube generating tube, tube sleeving tube and the like) on the high accurate rigid rapier weaving machine.

Owner:DONGHUA UNIV

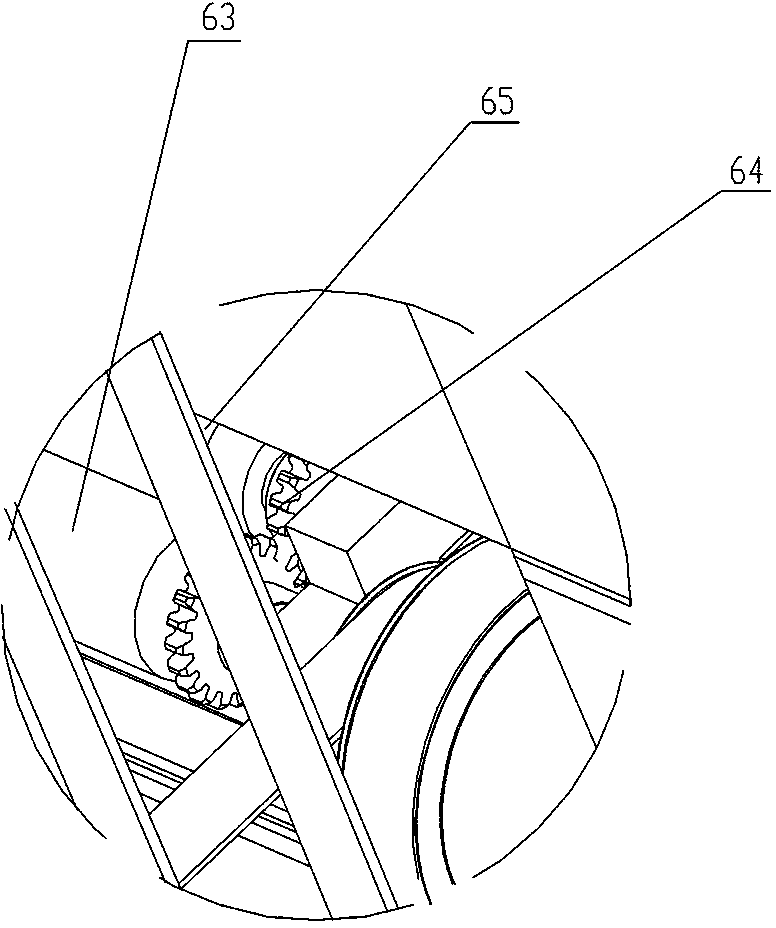

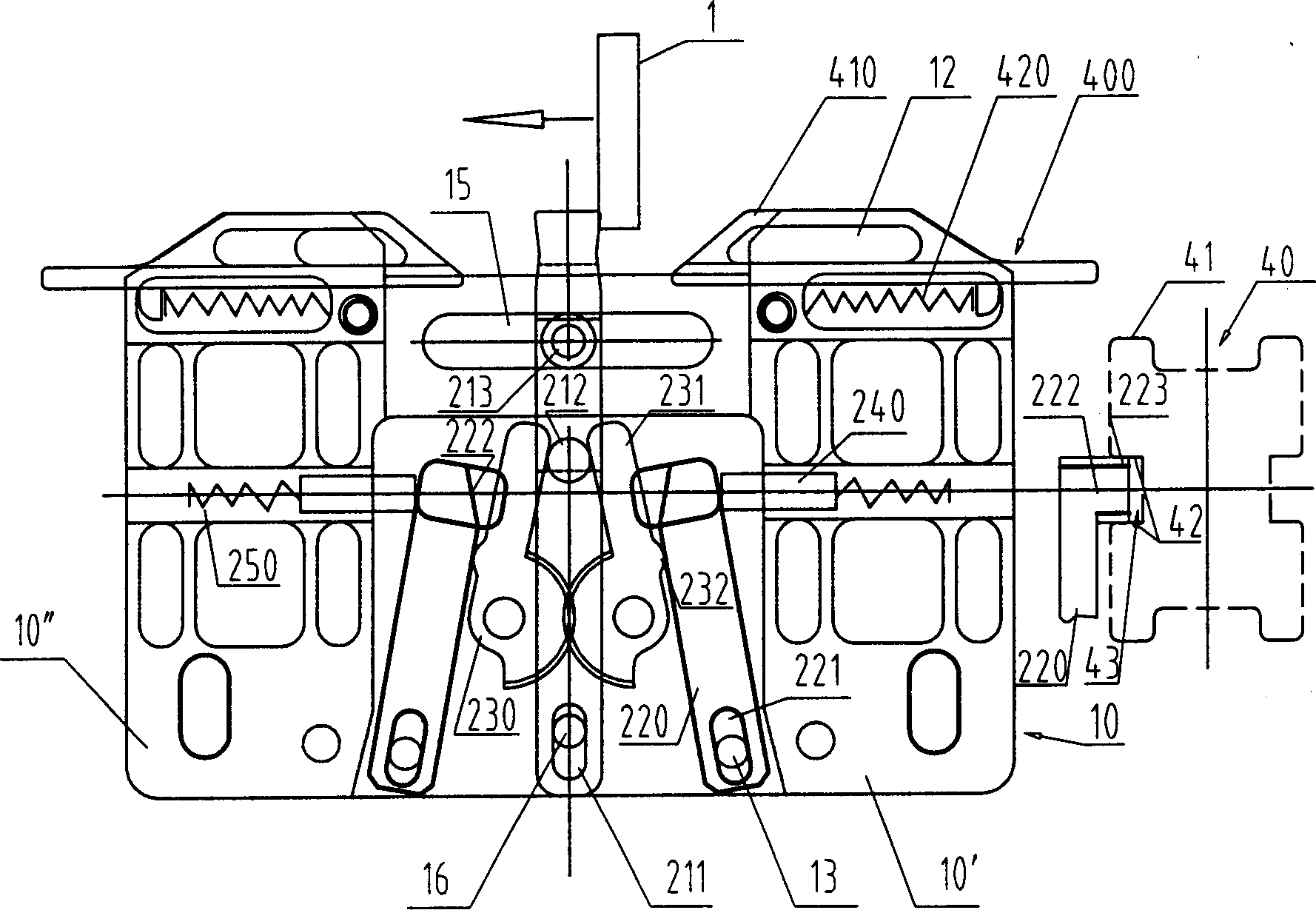

Intarsia shuttle box

The invention relates the appliqu¿ª shuttle box. The technology comprises the following steps: a box body, inside of it comprising locking apparatus and crashproof apparatus; outside of it comprising driver plate, spring seat, spring, mounting plate, limit switch swing block and limit switch device, the locking apparatus comprising many magnetic steels, and fixed on inside of box body; on the bottom end of driver plate there being two symmetrical trench walls; the limit switch device comprising limit switch shifting fork, slider and spring. The invention has the advantages of high precision and stabilization, simple structure, easy production, low cost and improving loom efficiency.

Owner:冯加林

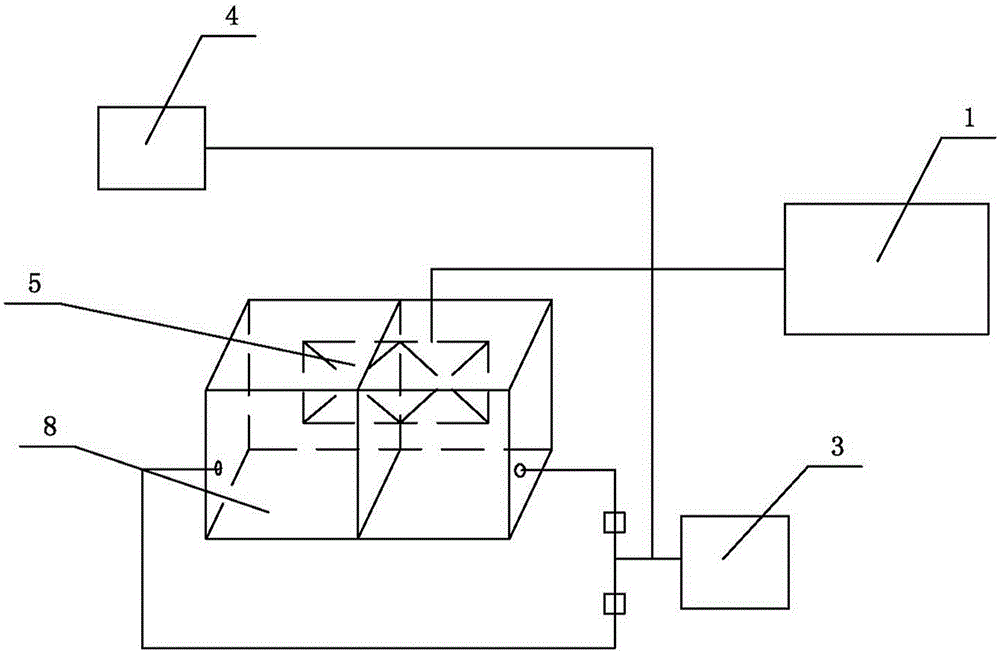

Real-time and online water quality monitoring system

ActiveCN105699618ANot easy to influenceReal-time monitoring of pollutionTesting waterWater sourceThe Internet

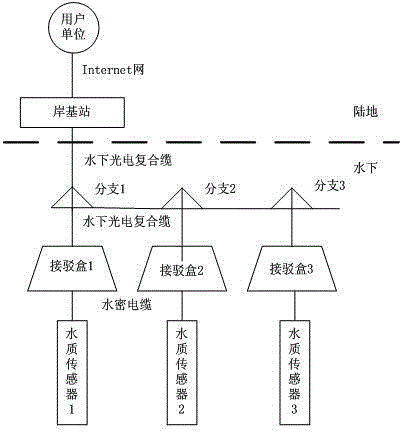

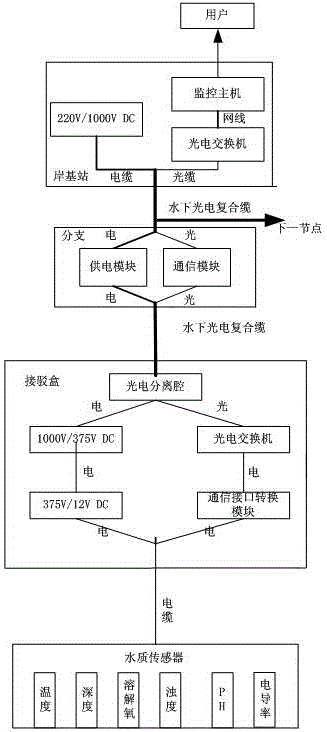

The invention discloses a real-time and online water quality monitoring system which comprises a shore-based station, branch units, an underwater photoelectric composite rope, shuttle boxes and water quality sensors; the shore-based station comprises a power supply unit, a power management unit and a data storage, display and management unit; the shore-based station is located on the ground and connected with a power grid and the internet and is responsible for supplying power to underwater equipment and uploading data collected by the underwater sensors to the internet; the underwater photoelectric composite rope comprises a power unit and an optical fiber unit and plays a role in transferring electricity and light information; each branch unit is composed of a power supply module and a communication module and achieves parallel connection of the shuttle boxes; the shuttle boxes are placed at multiple positions in water so as to observe the water source situation comprehensively, connected in parallel through the branch units and are responsible for supply and distribution of power, issuing of orders and upward transmission of collected data. The monitoring system is reliable and free of influence of an external environment; shuttle boxes monitoring of 24 hours can be achieved, and real-time early warning is achieved; transmitted data capacity is large.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Embroidery machine

ActiveCN108221212ASave installation spaceGood synchronizationEmbroidering machines apparatusEngineeringMechanical engineering

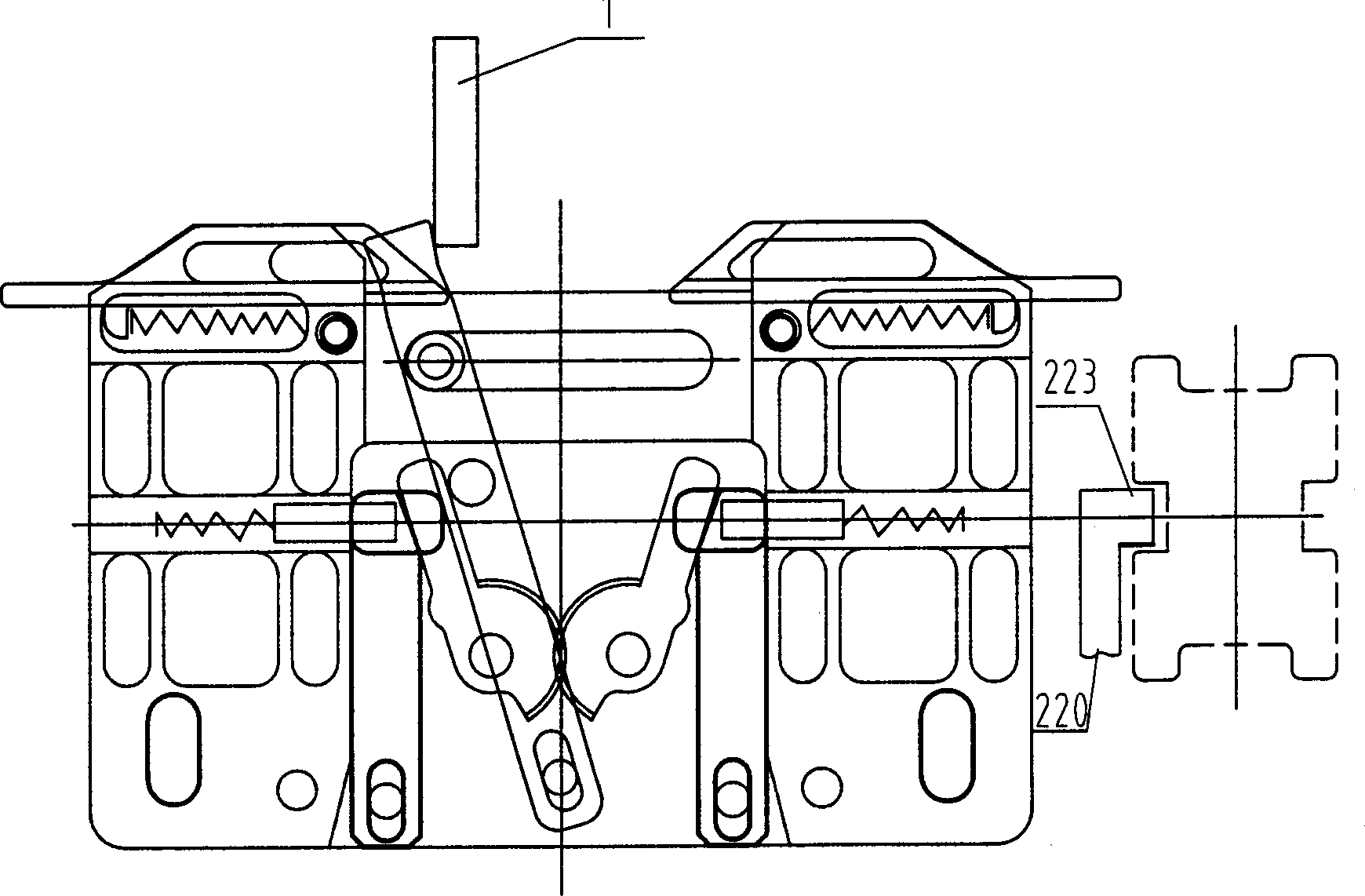

The invention discloses an embroidery machine and belongs to the technical field of embroidery. The embroidery machine comprises an embroidery machine head, a shuttle box, a thread buckling device anda thread trimming device, wherein a rotating shuttle is arranged in the shuttle box; the thread buckling device comprises thread buckling parts which are movably arranged on the shuttle box and are used for buckling the rotating shuttle; the thread trimming device comprises a fixed cutter and moving cutters moving relatively to the fixed cutter. The embroidery machine is characterized in that thethread buckling device also comprises a driving rotation shaft rotatably arranged on the shuttle box; at least two thread buckling parts are connected with the driving rotation shaft simultaneously;the thread trimming device comprises a main driving connection rod and branched connection rods; at least two branched connection rods are arranged on the main driving connection rod simultaneously; each branched connection rod drives the moving cutters to move respectively; the driving rotation shaft is driven by a first driver and drives at least two thread buckling parts to work; the main driving connection rod is driven by a second driver and drives at least two moving cutters to move. The embroidery machine disclosed by the invention has the advantages that the structures of the thread buckling device and the thread trimming device are simplified, and the requirements of the installation space are reduced.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

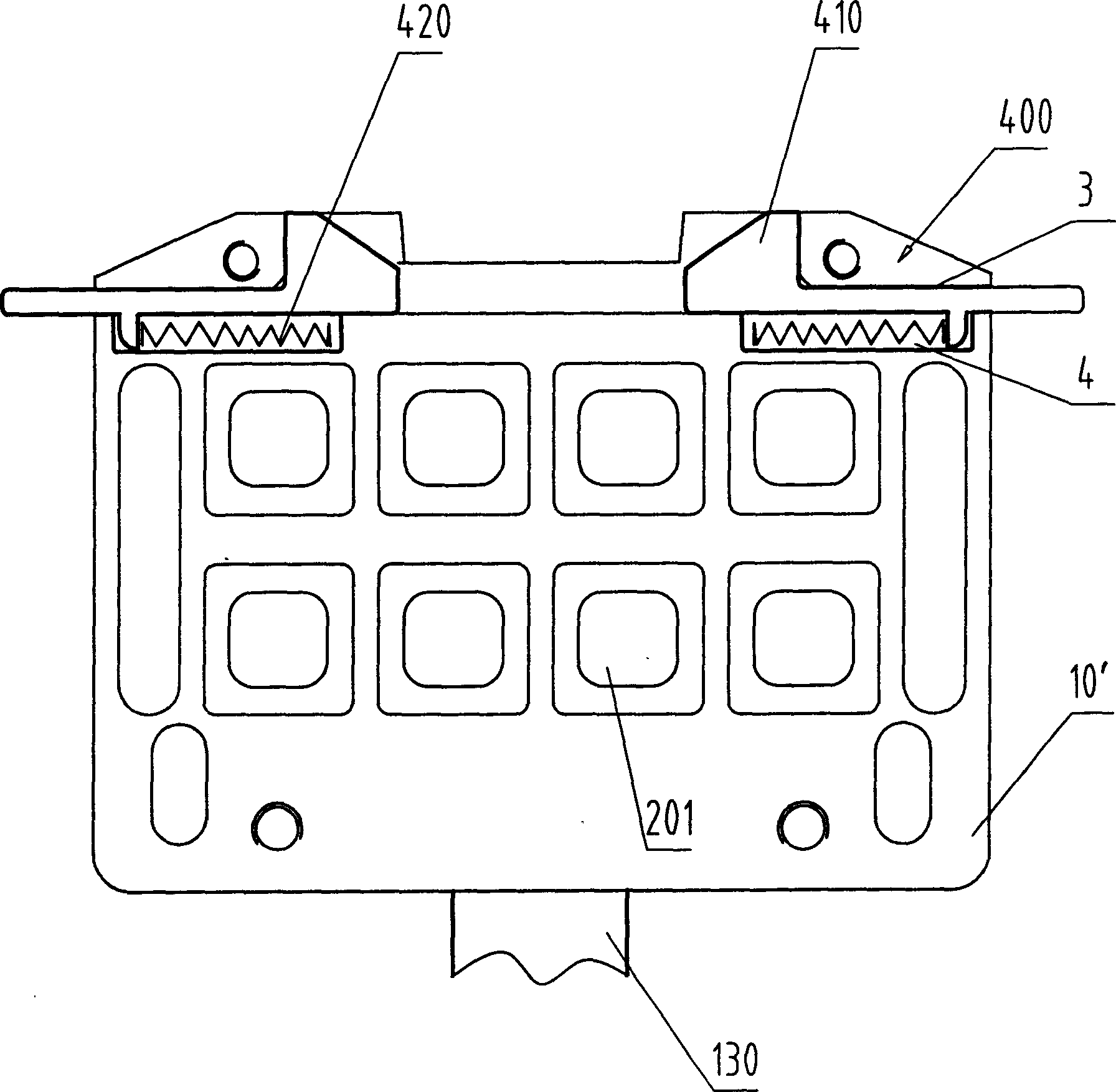

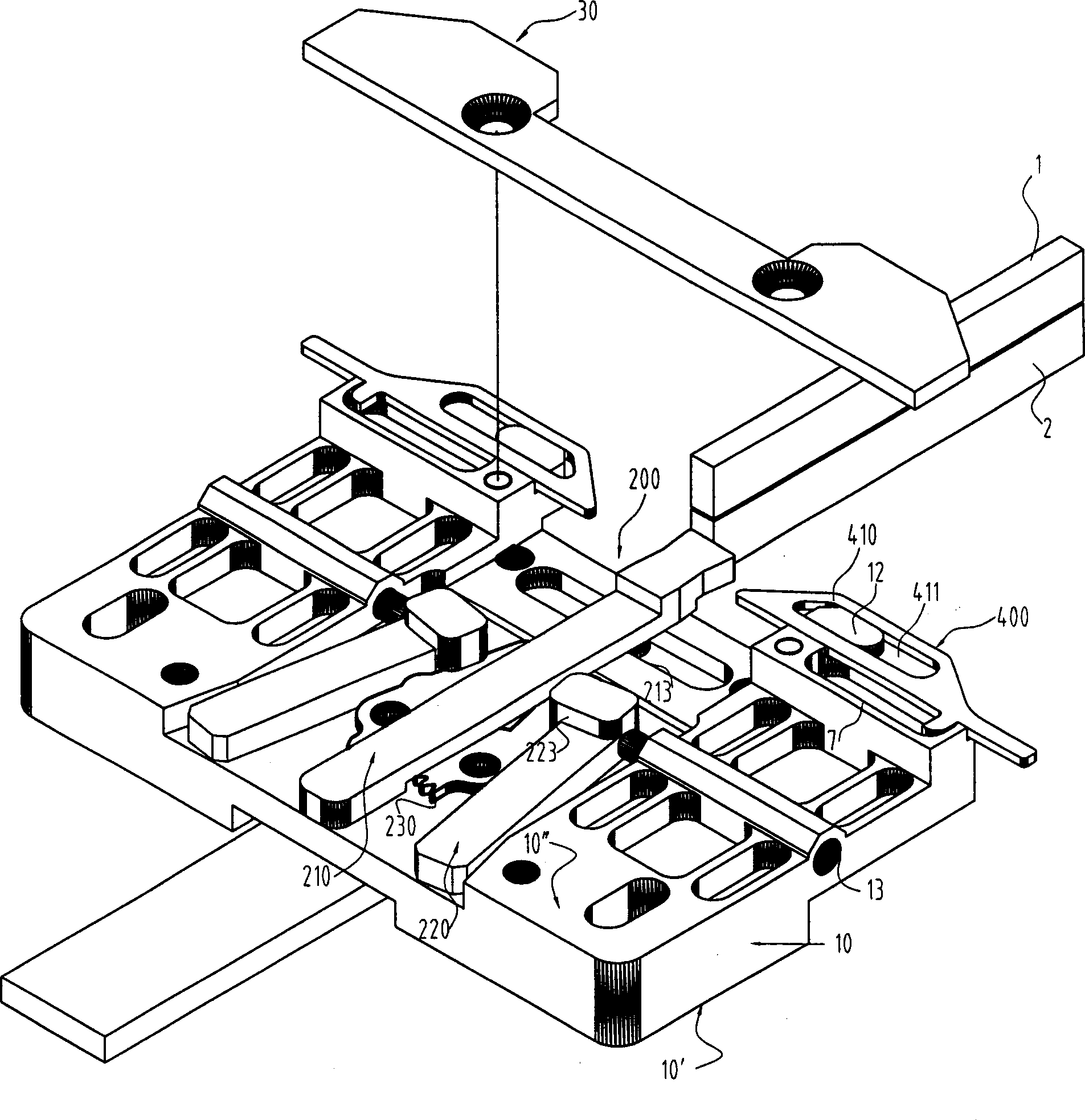

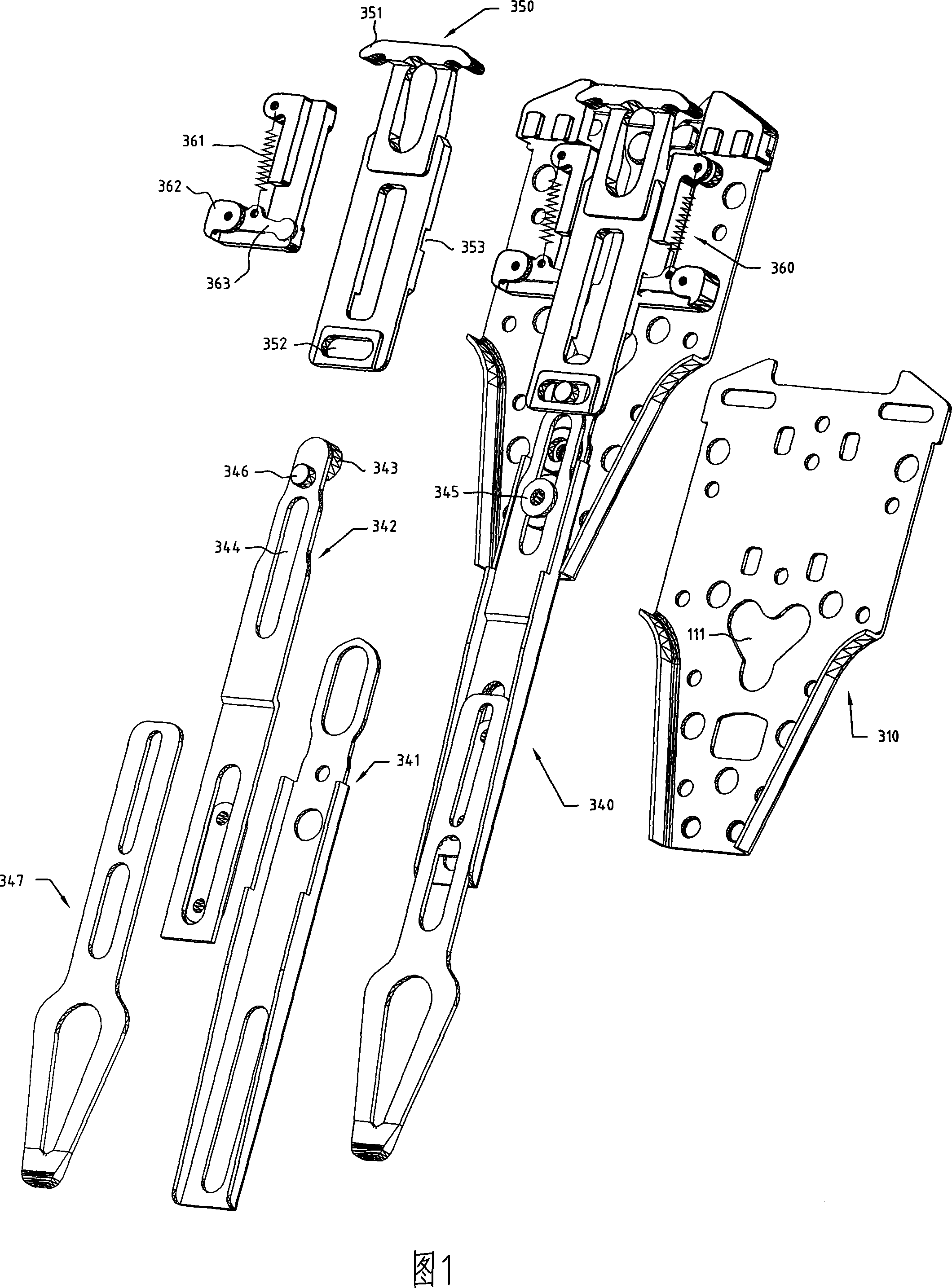

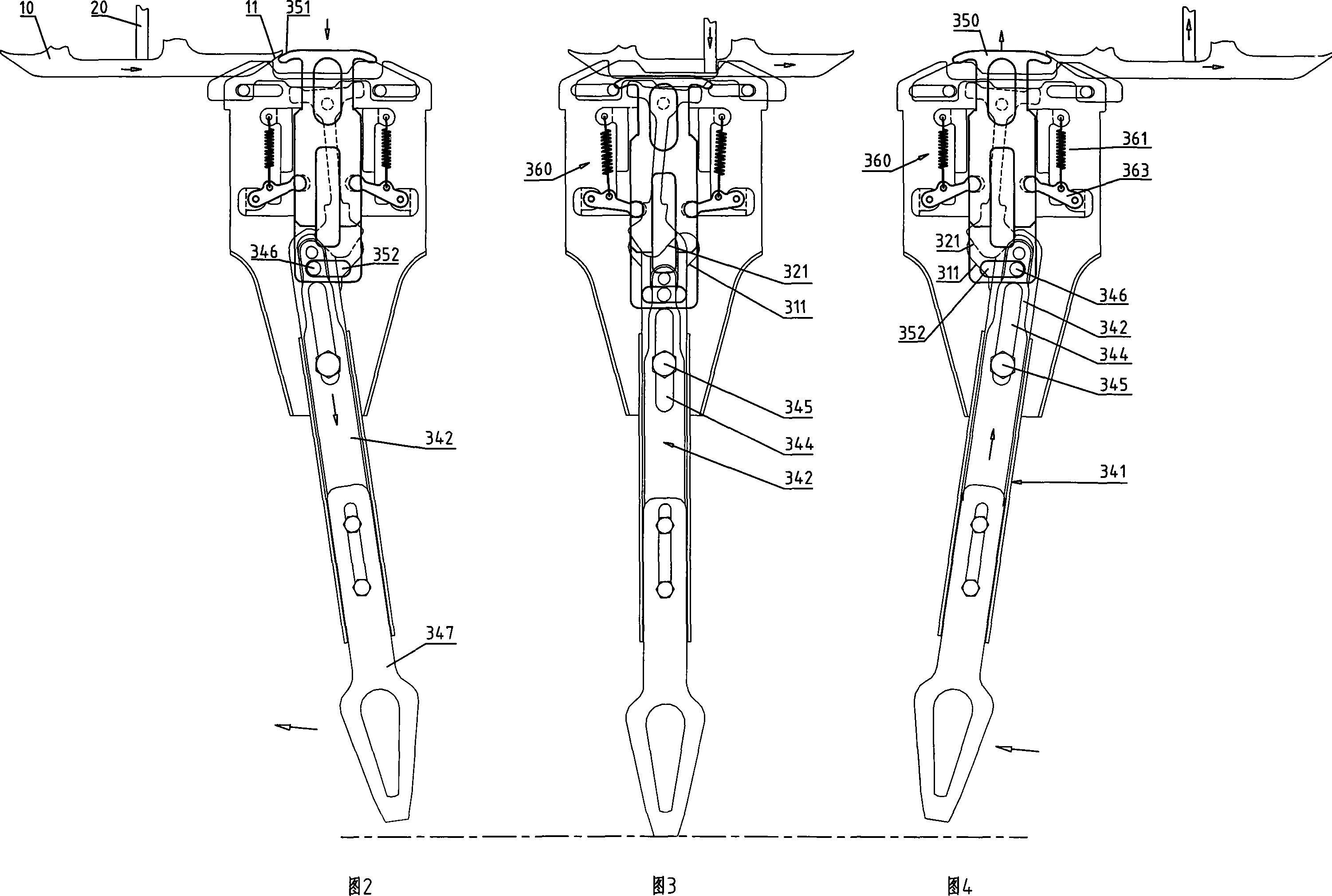

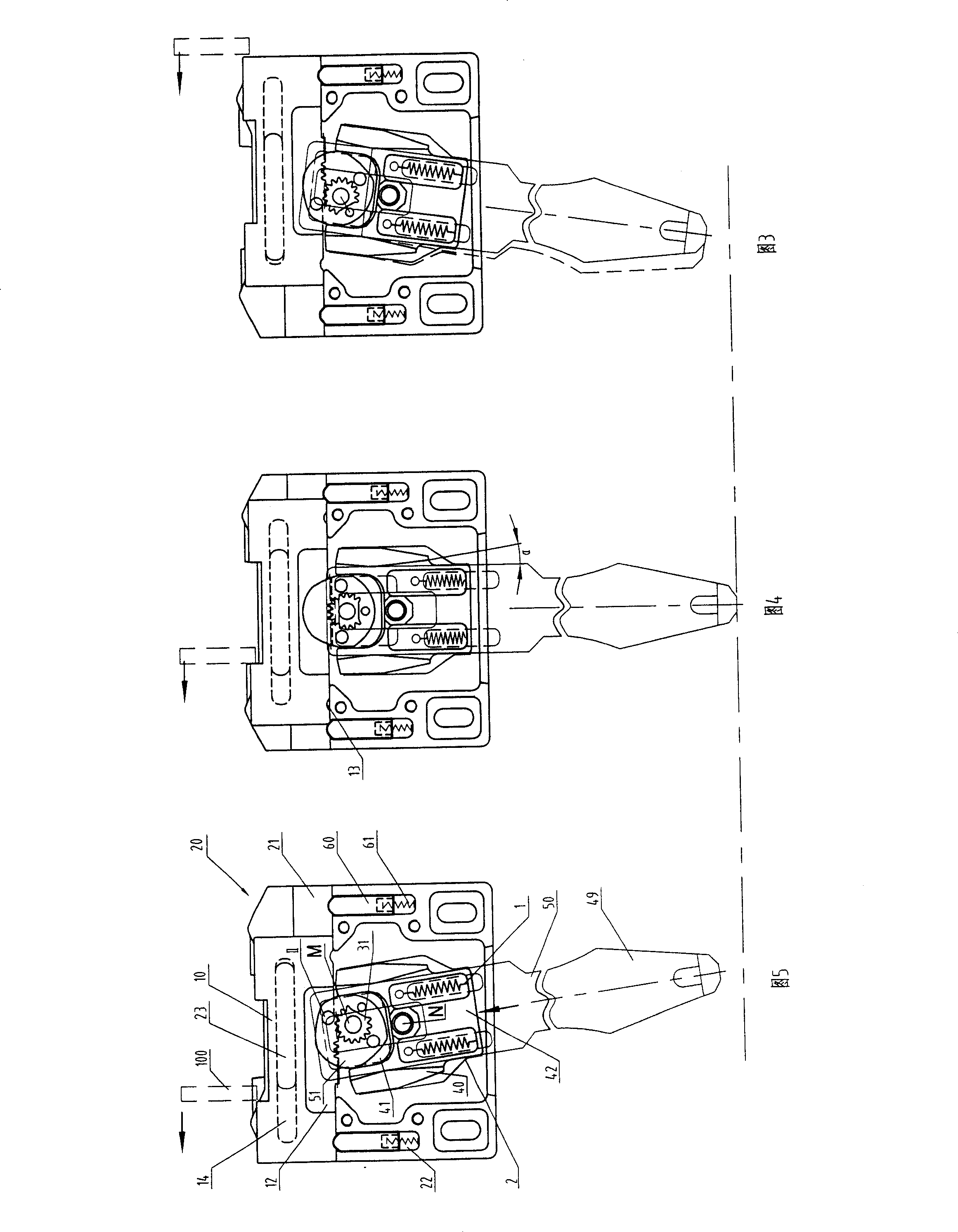

Intersia pattern shuttle box for flat-bed knitting machine

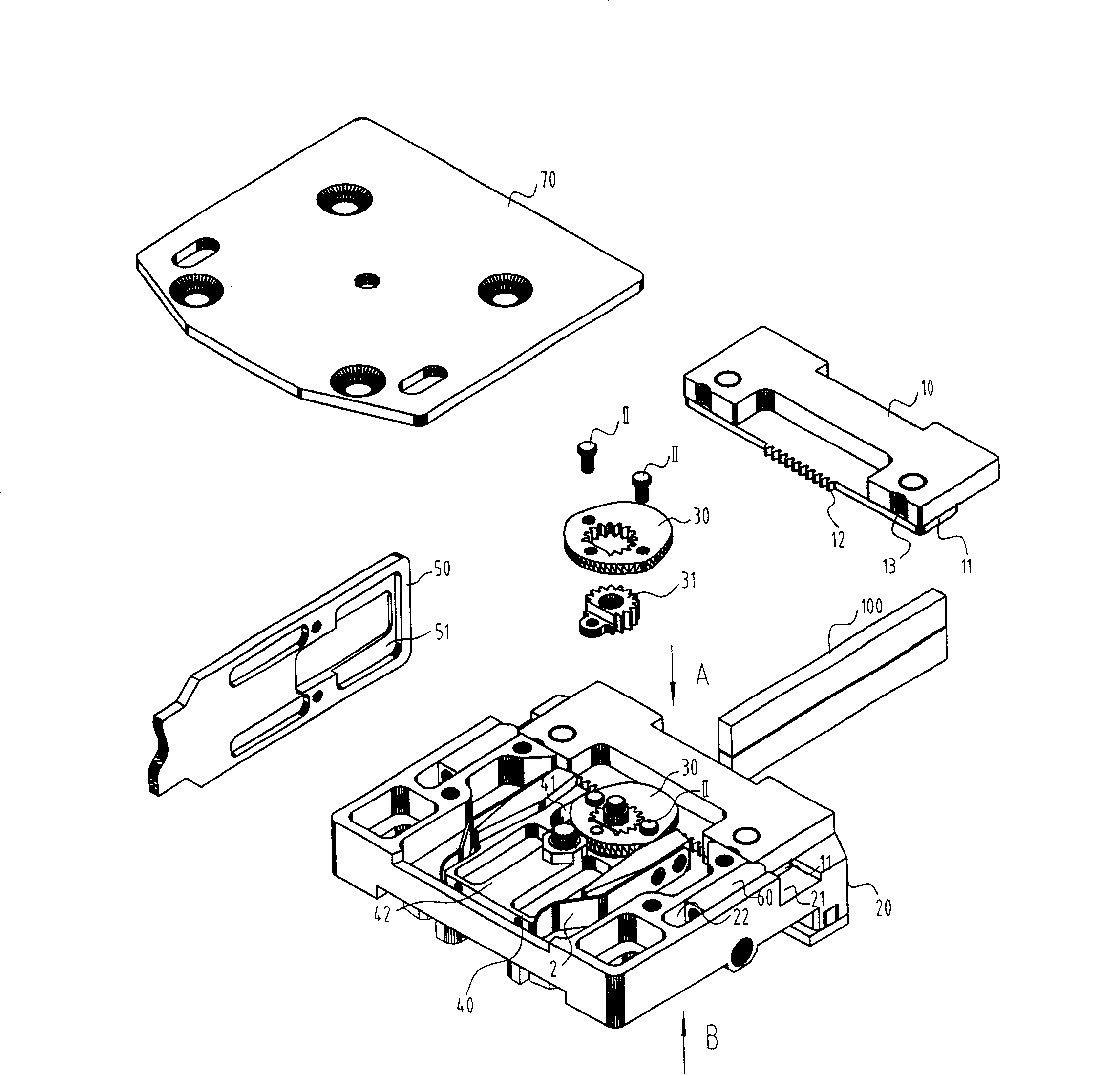

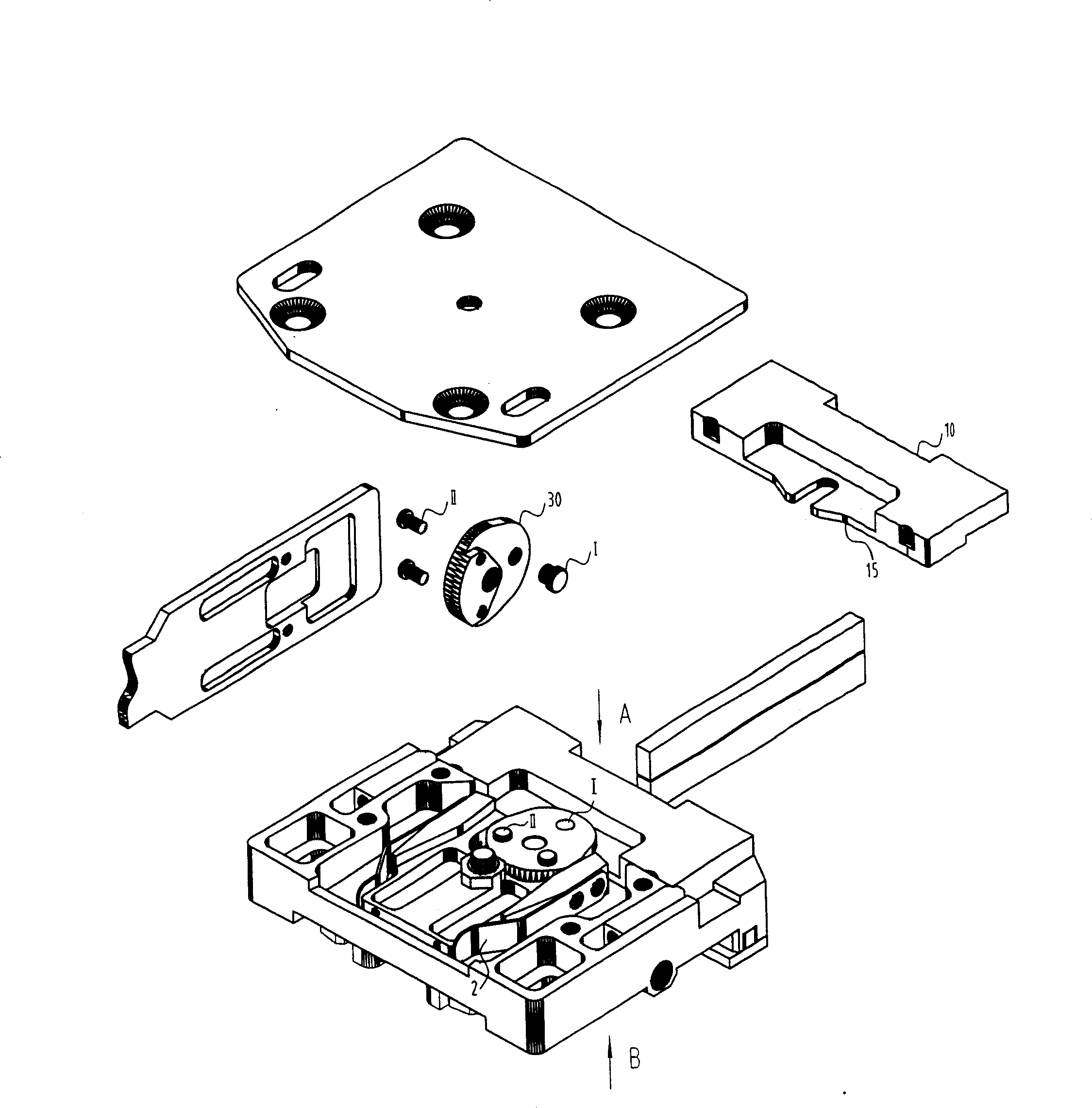

This invention relates to an applique shuttle box on a horizontal braider including a box, an outside cover plate, an inside cover plate, an anti-bumping device, a locking device and a yarn nozzle moving device, in which, the anti-bumping device and the locking device are set at the top and middle of the box, the nozzle moving device is set at the top of the outside of the box and right and left center, the outside and internal cover plates are connected with the outside and inside of the box, in which, the locking device is composed of two clamp pins, two release springs, two locking levers, a drive lever and a pair of incomplete gears, said nozzle device is composed of a drive plate, a leaf spring, a nozzle fixing plate, a spacing swing block and a spacing unit. Advantage: 1, the small transverse diameter of the shuttle box reduces idle running and increases weaving efficiency, 2, the location of the box is accurate and stable since the locking and the guide way are not coplanary, 3, light actions of locking and loosing, 4, simple structure of the devices in the box.

Owner:冯加林

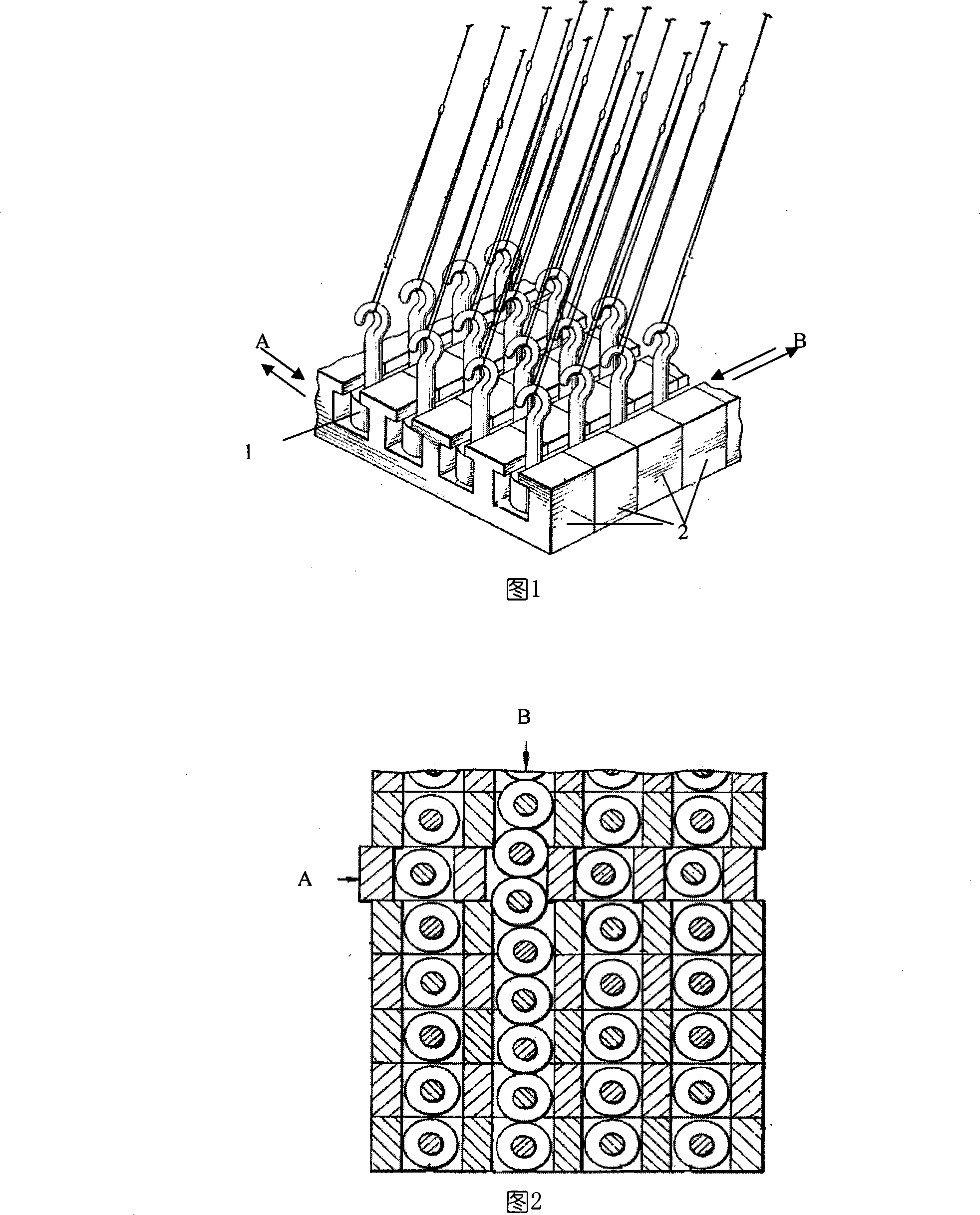

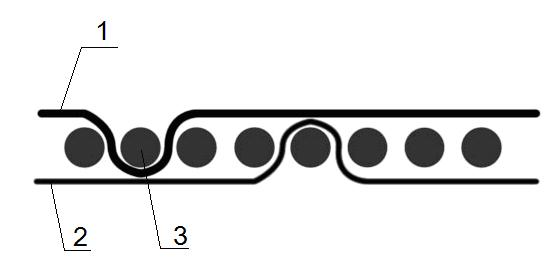

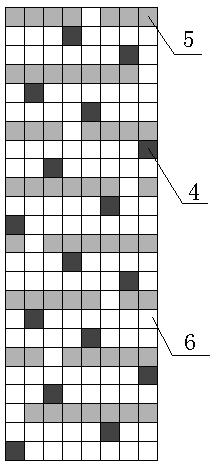

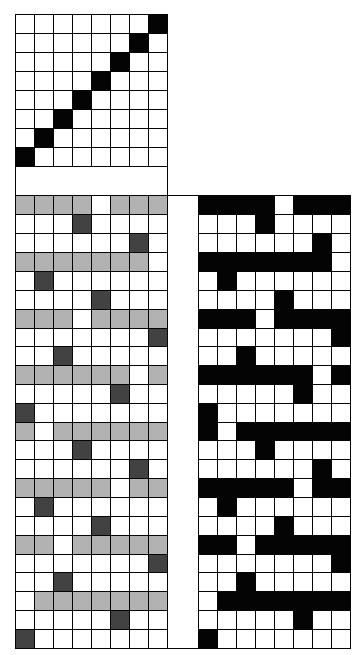

Method for antilocking for shuttle operation of three-dimensional textile machine

InactiveCN101245528AGuaranteed uptimeImprove the "stuck" phenomenon of inflexible lateral movementTwist lace-making machinesEngineeringMagnet

A method of the anti-blocking of the operation of the shuttle of a three dimensional fabric knitting machine arranges the shuttle in the slot of a shuttle box and the shuttle can be controlled to slide to and fro along the slot of the shuttle box; while the shuttle box can slide to and fro under the pushing of a shuttle box push bar; at the moment, a tiny transmission intermission exists between the shuttle box push bar and the shuttle box during design and mounting; besides, the lower plane part of each shuttle box is internally embedded with a plurality of shuttle box magnets arrayed in certain distance; while the upper plane parts of the bases of the shuttle boxes corresponding to the position of each shuttle box magnet is internally embedded with A-position magnets of the bases of the shuttle boxes with the same quantity; B-position magnets of the bases of the shuttle boxes with the same quantity are also embedded at the position which is one traverse step length to the A-position magnets of the bases of the shuttle boxes. The poles of the A-position magnets of the bases of the shuttle boxes and the B-position magnets of the bases of the shuttle boxes are collocated with the magnets of the shuttle boxes to form an 'opposite attraction' state to finish the automatic accurate contraposition of the shuttle boxes in A-position and B-position by the mutual attraction. Consequently, during the operation of the knitting machine, each push bar of the shuttle box pushes corresponding shuttle box in a not very accurate and in place mode; while the accurate position is automatically adjusted and reached by the opposite attraction of the shuttle box magnets to the magnets of the bases of the shuttle boxes, thus improving the operation state of the knitting machine to lead the knitting machine to be well-off and accurate.

Owner:CHANGZHOU BOLONG THREE DIMENSIONAL COMPOSITES

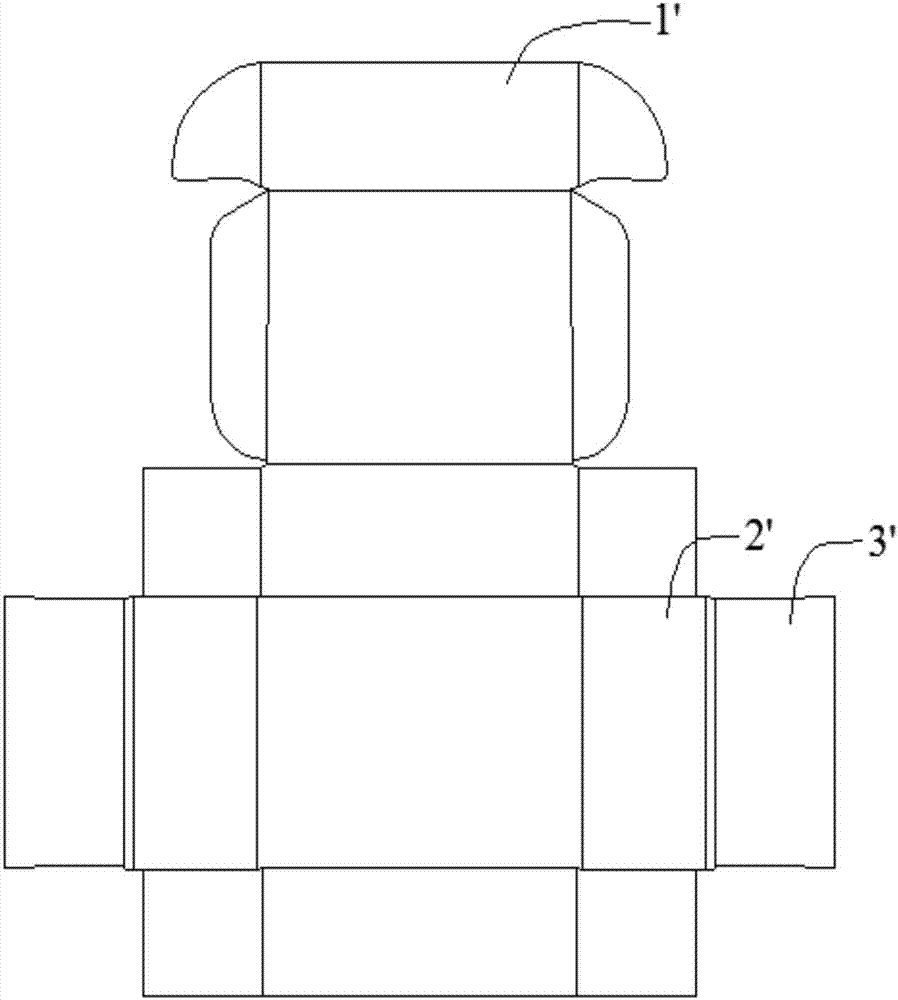

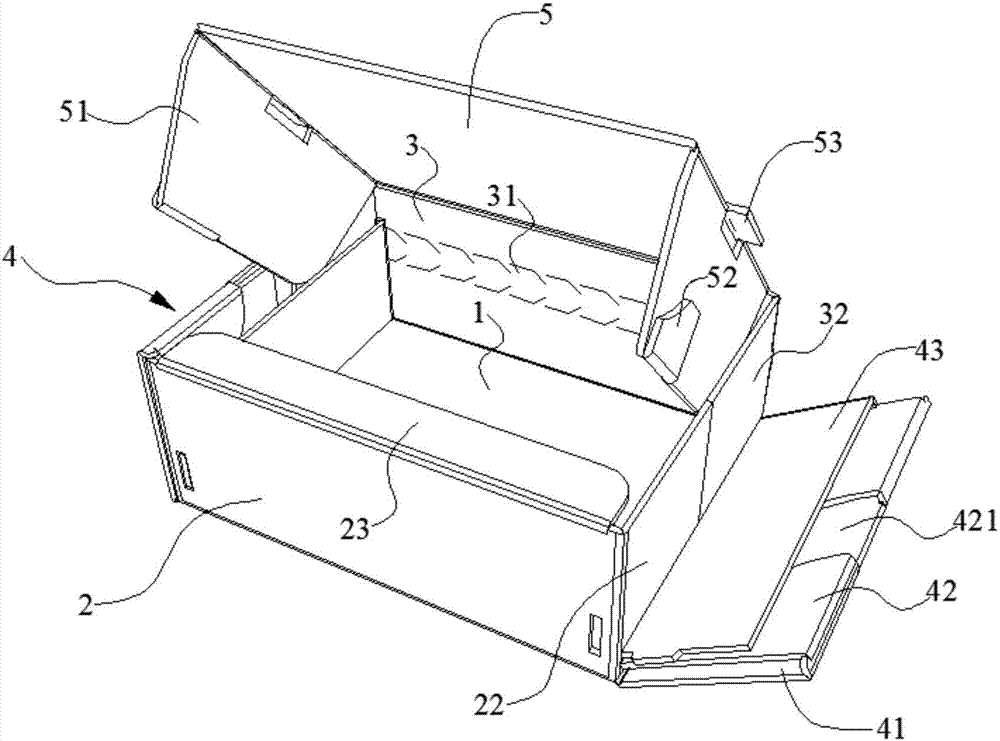

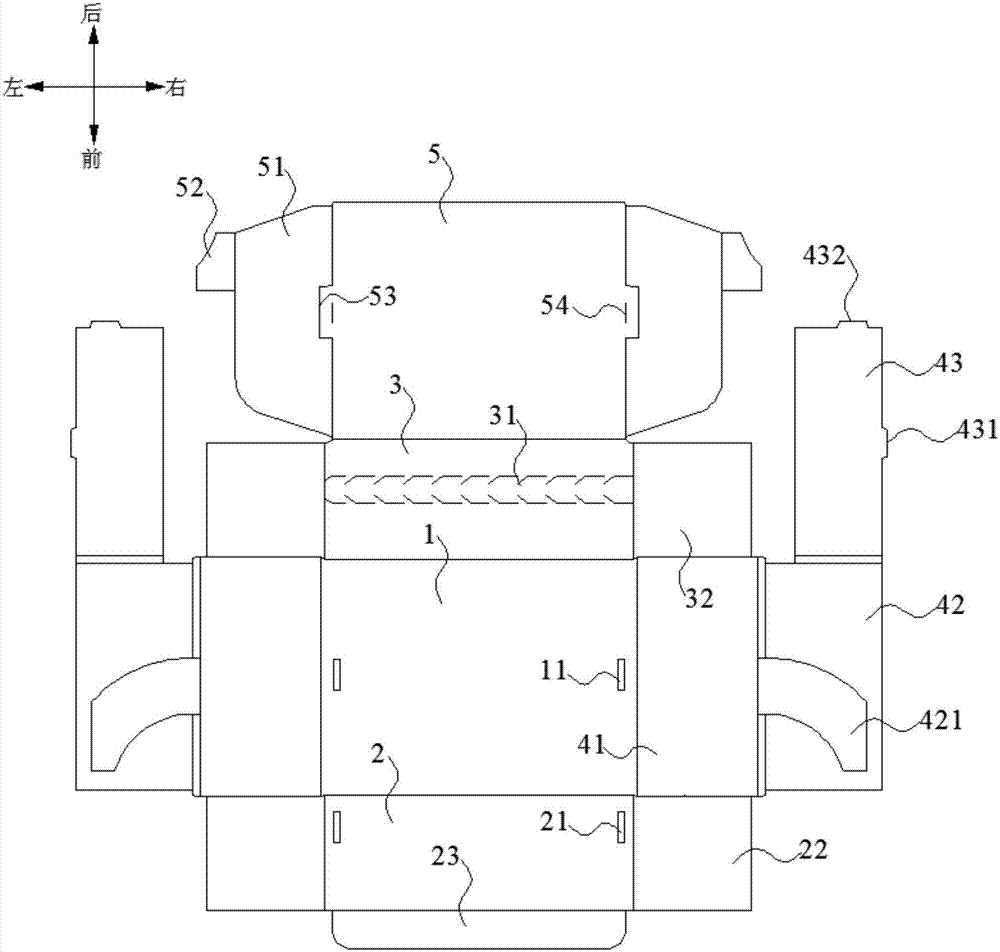

Locking shuttle box

PendingCN107323788AWith anti-theft functionLess materialRigid containersStructural engineeringMechanical engineering

The invention discloses a locking shuttle box and relates to the technical field of packaging tools. The shuttle box is of an integrally formed hexagonal structure and comprises a bottom plate and two side portions, wherein the bottom plate is connected to a front side plate and a back side plate; an upper cover plate extends on the back side plate, and an upper cover flap and a limiting plate are arranged on the left and right ends of the upper cover plate; and the two side portions are connected to the front side plate and the back side plate and are vertically arranged on the left and right sides of the bottom plate, a limiting groove is formed in each of the side portions, and is locked with the limiting plate. The invention provides the locking shuttle box to solve the problem that an existing shuttle box is not environment-friendly, does not have a theft-preventing function and is high in production cost.

Owner:北京阳光印易科技有限公司

Rigid rapier loom 1 multiple 4 multi-shuttle box mechanism

The invention relates to a 1X4 multiple-shuttlebox device of the rigid rapier weaving machine including the stroke controller multiple-shuttlebox. The stroke controller is made up of the first air cylinder and second air cylinder. The multiple-shuttlebox is made up of shuttle storing box, active slipway and directional runner. The first air cylinder and directional runner are fixed on the supporting frame; the second air cylinder is fixed on the active slipway; the rut shuttle way is opened in shuttle storing box to make shuttle go and out. The boss at the shuttle box back and active slipway back are connected with the sliding slot. The active slipway lower is connected with the piston of first air cylinder; the second air cylinder piston is connected with the shuttle box bottom. The stroke of first air cylinder is 2 times than the second one. The invention can solve the problems that the abb is not continuously in ordinary rapier weaving machine and the low precision of 1X4 shuttle box, so it can lead in four lonely continuously abb and spin many kinds of pipe fabrics.

Owner:DONGHUA UNIV

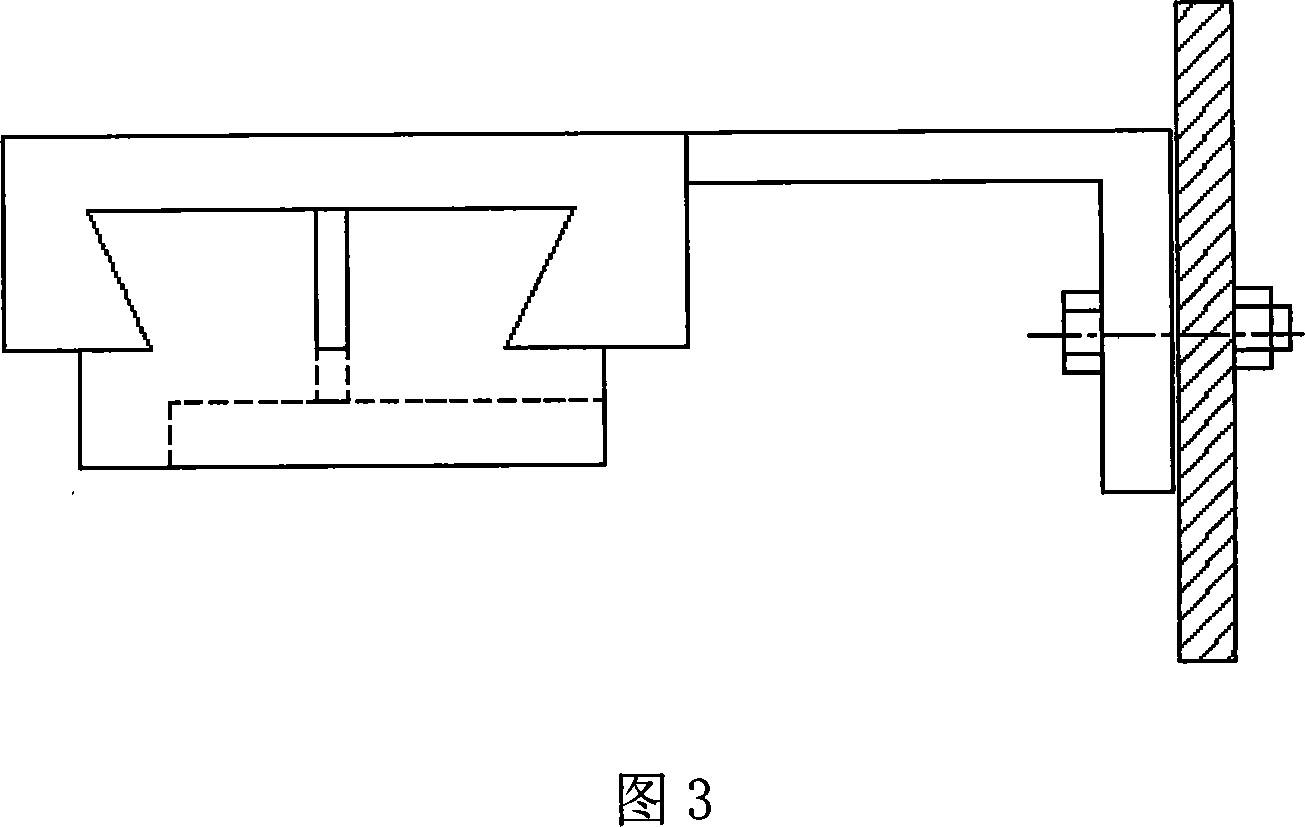

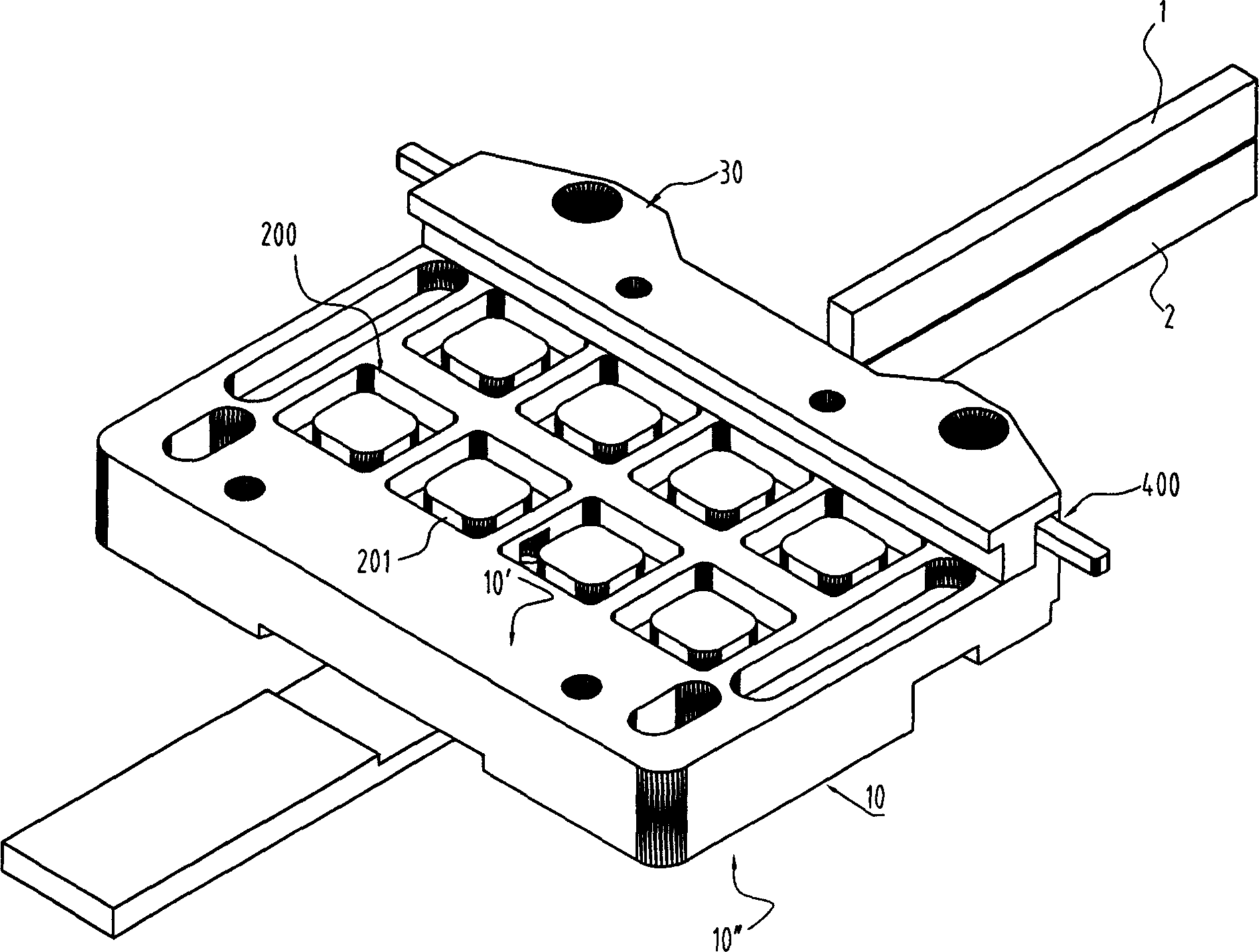

1*4 shuttle box device of full-automatic shuttle rapier loom

InactiveCN105803639AAddress electrificationSolve automation control problemsLoomsWeft yarnMaterial structure

The invention provides a 1*4 one-side multi-shuttle-box mechanism of a shuttle rapier loom. The mechanism comprises a loom race. The front end of the loom race is provided with a shuttle storage box. The rear end of the loom race is provided with a shuttle picking mechanism. The shuttle picking mechanism comprises a shuttle case. Shuttle stop controllers are arranged in the shuttle case. The rear end of the shuttle case is provided with a shuttle picking pneumatic controller. The shuttle storage box is provided with multiple semi-closed shuttle paths facilitating entering and exiting of a shuttle. The front end of each shuttle path is provided with a shuttle return pneumatic controller. A bottom plate of the shuttle storage box is connected with a shuttle box lifting eccentric cam. A back plate of the shuttle storage box is provided with the shuttle stop controllers corresponding to the shuttle paths respectively. By combining rapier telescopic control of a rigid rapier loom, multiple shuttle boxes of a shuttle loom and the weft carrying principle, by changing the shuttle box lifting control of the shuttle loom and the weft carrying way of the rapier loom, independent selection and insertion of multiple weft yarns can be achieved on the rigid rapier loom, and therefore automatic weaving of various types of tubular fabrics and specially-shaped section composite material structure body preformed bodies is achieved.

Owner:DONGHUA UNIV

Yarn nozzle telescopic oscillating control mechanism for applique shuttle box

The invention relates to an adjustable swing controlling mechanism of a weft nozzle of an intarsia shuttle box, which comprises a bottom plate, a weft nozzle component part which is connected on the lower portion of the bottom plate, a driver plate which is positioned on the upper side of the weft nozzle component part and driver plate return component parts which are positioned on two sides of the driver plate, wherein the driver plate and the weft nozzle component part proceed on slip connection via a chute and a sliding pin which are respectively arranged on the driver plate and the weft nozzle component part which comprises a weft nozzle driver plate, a guide plate and a guide wheel, wherein a weft nozzle is arranged on the lower end of the weft nozzle driver plate, the guide wheel is hinged on the upper end of the guide plate which is glidingly connected on the weft nozzle driver plate and is provided with the chute, a shaft pin which drills through the chute and the weft nozzle driver plate are fixed on the bottom plate, the guide plate slips relative to the shaft pin via the chute and enables a weft nozzle plate to rotate around the shaft pin. The adjustable swing controlling mechanism has the advantages of simple structure, easy forced balance on two sides and convenient assemblage and debugging, has the accuracy of feeding movement which excels the prior technology.

Owner:冯加林 +1

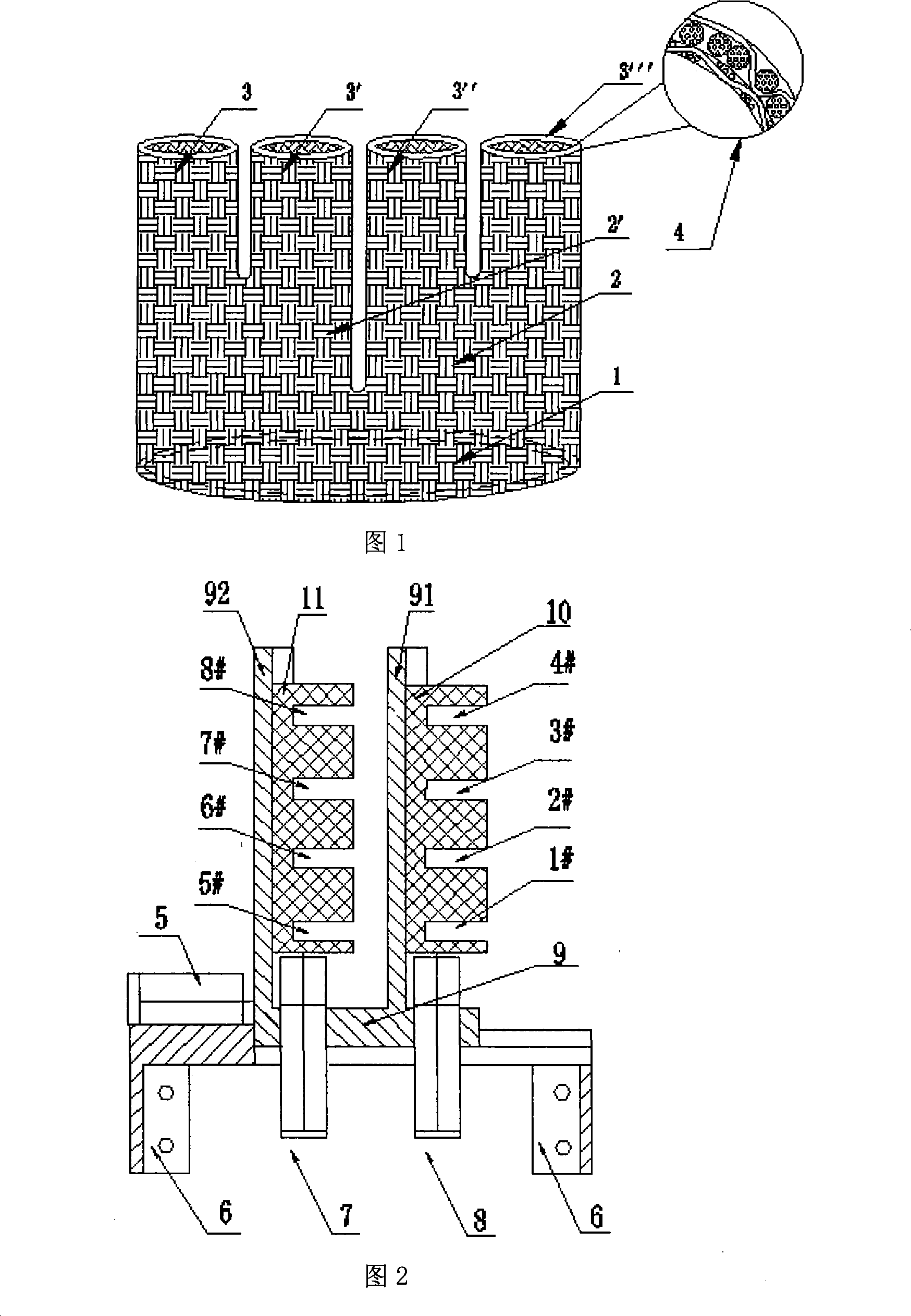

Aluminum silicate/nickel-chromium stainless steel wire fireproof rolling curtain cloth and manufacturing method thereof

InactiveCN102002789AImprove fire resistancePlay a supporting roleWoven fabricsAluminum silicateFire resistance

The invention discloses aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth and a manufacturing method thereof. Aluminum silicate yarns and nickel-chromium stainless steel wires are taken as raw materials to form a fabric through a weft backed weave structure. The warp yarns of the fabric are aluminum silicate / nickel-chromium stainless steel wire doubled wires, and weft yarns are two groups of aluminum silicate yarns and nickel-chromium stainless steel wire yarns, wherein the positive weft yarns are aluminum silicate yarns, and the reverse weft yarns are nickel-chromium stainless steel wires. The gram per square meter of the aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth is 800 to 1,200g / m<2>, the total tightness of the fabric is more than or equal to 115 percent, and the fire resistance temperature is 1,100 DEG C. The manufacturing method comprises the following steps of: (1) doubling the aluminum silicate yarns with the nickel-chromium stainless steel wires; (2) performing spooling, beaming, slashing and drawing processes on the doubled aluminum silicate / nickel-chromium stainless steel wires for weaving; (3) respectively quilling the aluminum silicate yarns and the nickel-chromium stainless steel wires for weaving; and (4) weaving the prepared warp yarns and weft yarns on a shuttle loom with a double-side multi-shuttle box mechanism according to the designed looming draft so as to prepare the aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth.

Owner:SICHUAN UNIV

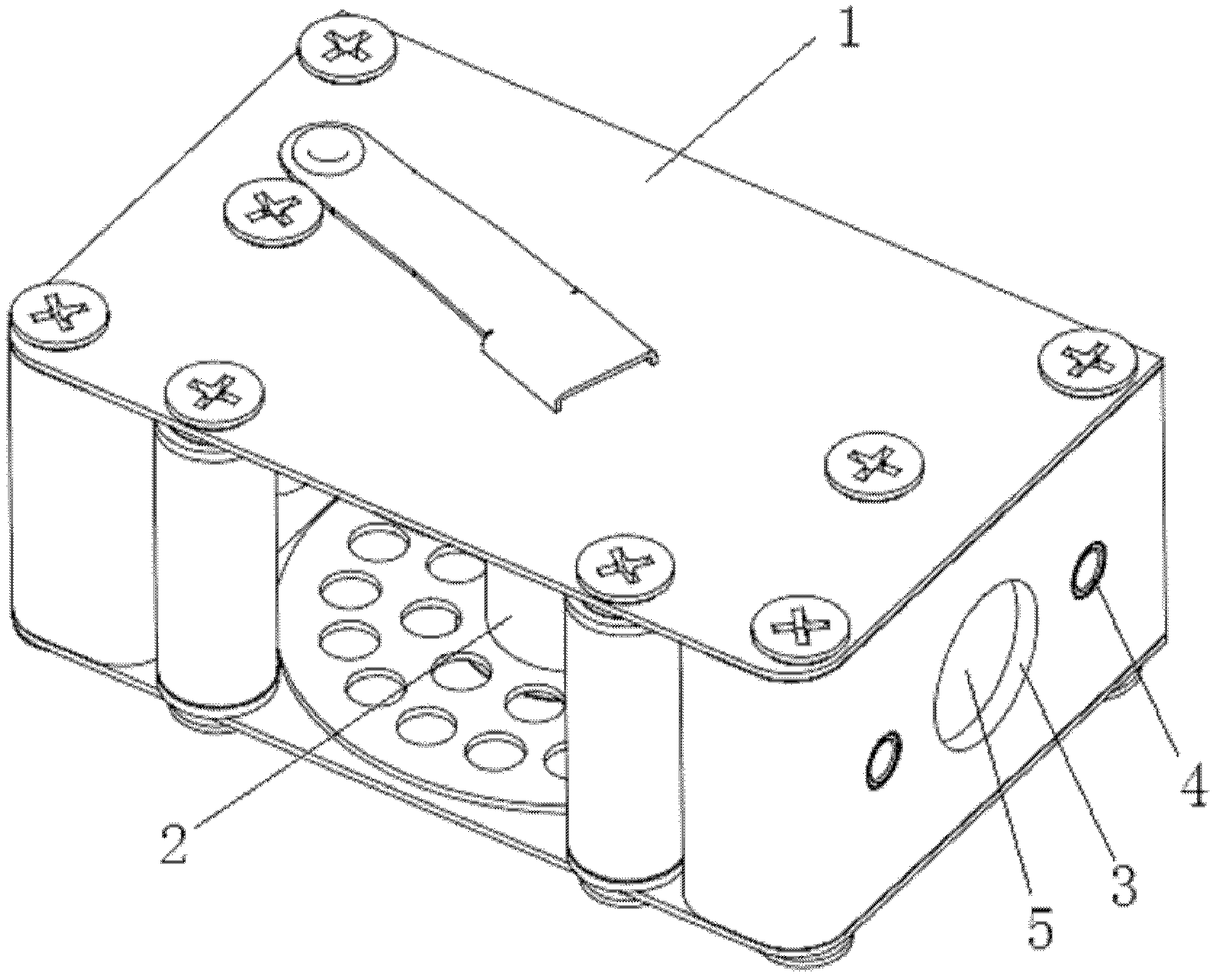

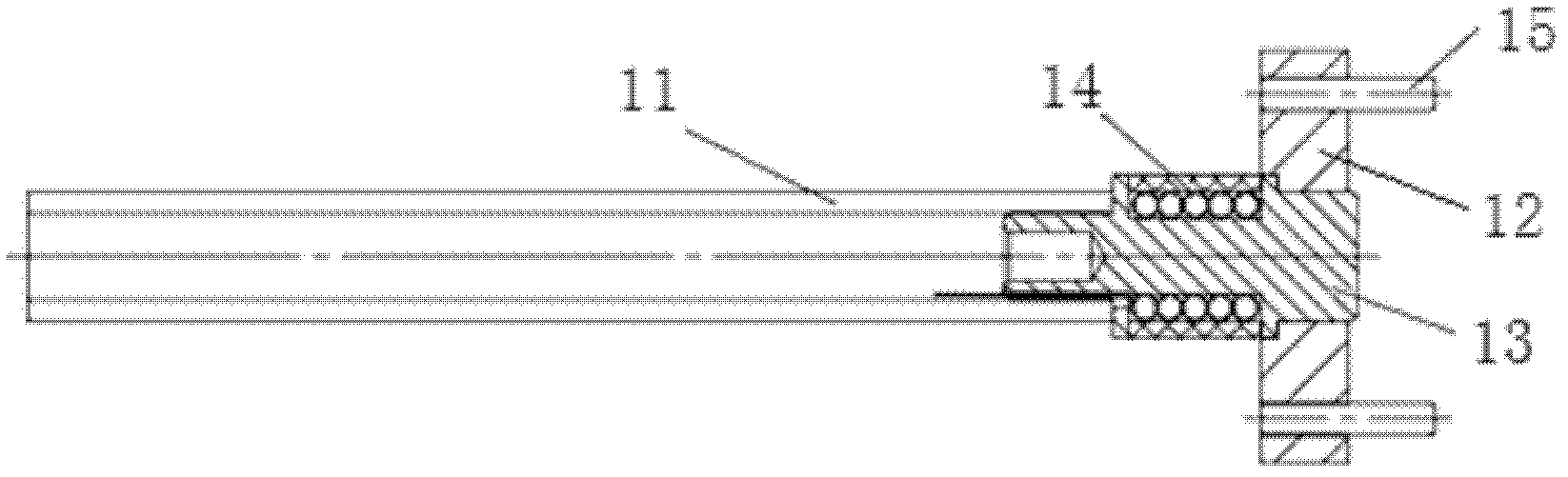

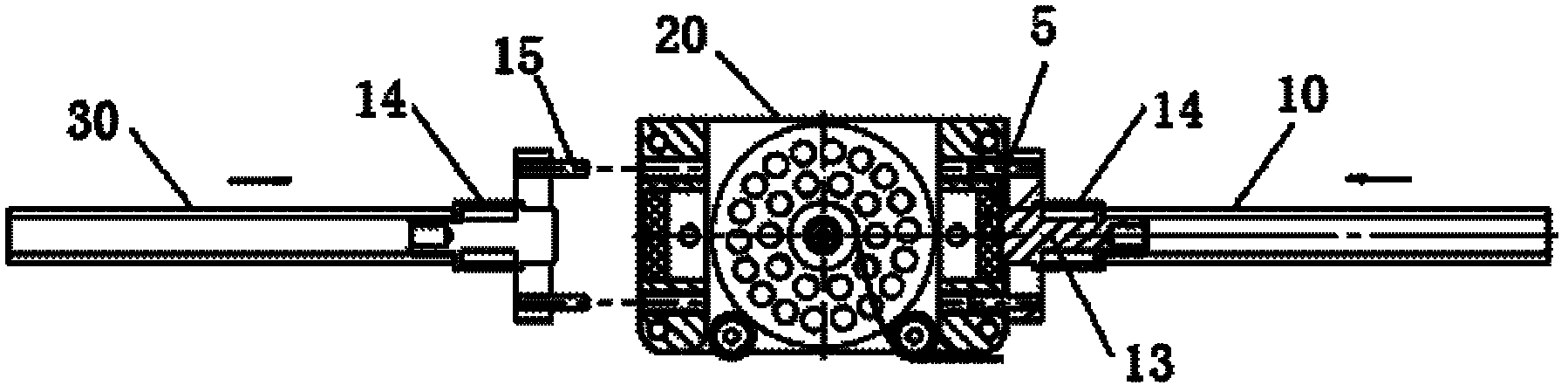

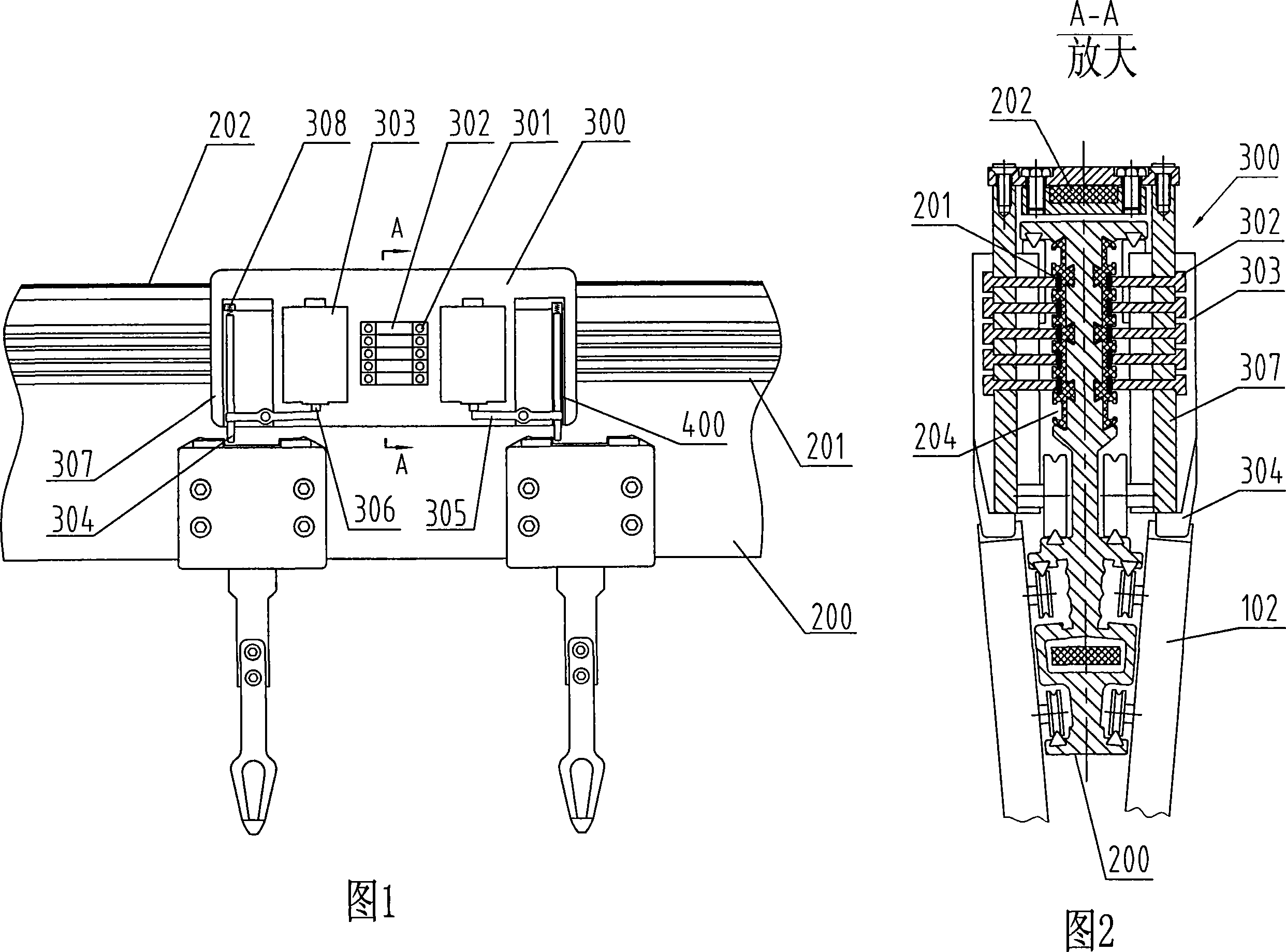

Electromagnetic weft insertion weft carrier, rapier for electromagnetic weft insertion as well as electromagnetic weft insertion method

The invention provides an electromagnetic weft insertion weft carrier with high efficiency of weft inserting and weaving, an electromagnetic weft insertion device and an electromagnetic weft insertion method. The electromagnetic weft insertion weft carrier provided by the invention comprises a shuttle box and a yarn storage device arranged in the shuttle box, wherein two corresponding side walls of the shuttle box are respectively provided with a permanent magnet used for electromagnetic weft insertion and at least one locating hole. According to the electromagnetic weft insertion weft carrier, a rapier for the electromagnetic weft insertion, and the electromagnetic weft insertion method provided by the invention, no an additional shuttle path is needed, the weft carrier is moved in the air by using an electromagnetic action and always in a controlled state so that the weft carrier is prevented from being hit, free flight of the weft carrier is prevented, and the service life of the weft carrier, success rate of weft insertion and weaving efficiency are all increased; in addition, the weft insertion device has the advantages of simple structure and convenience for operation.

Owner:JINGWEI TEXTILE MASCH CO LTD

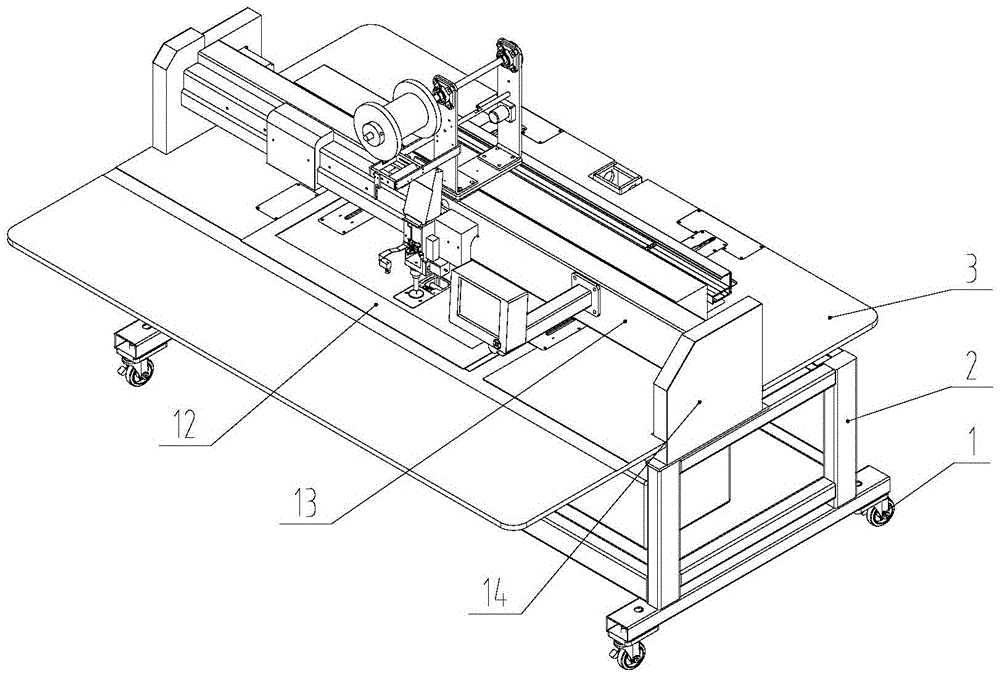

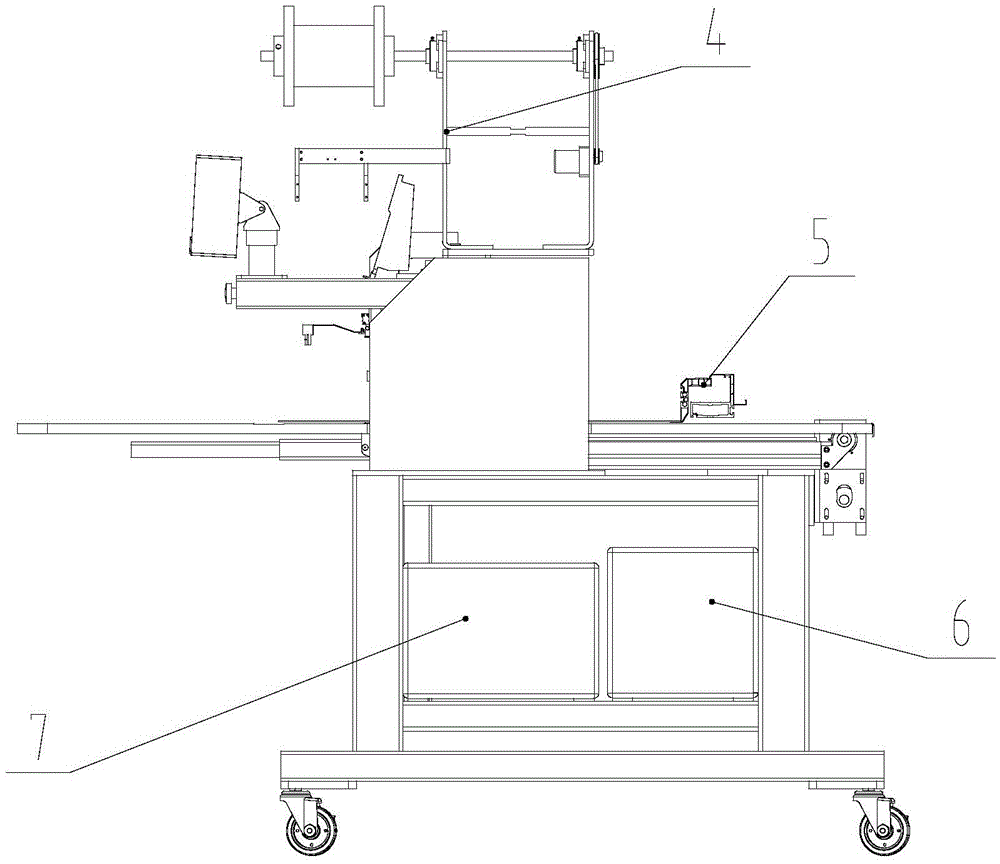

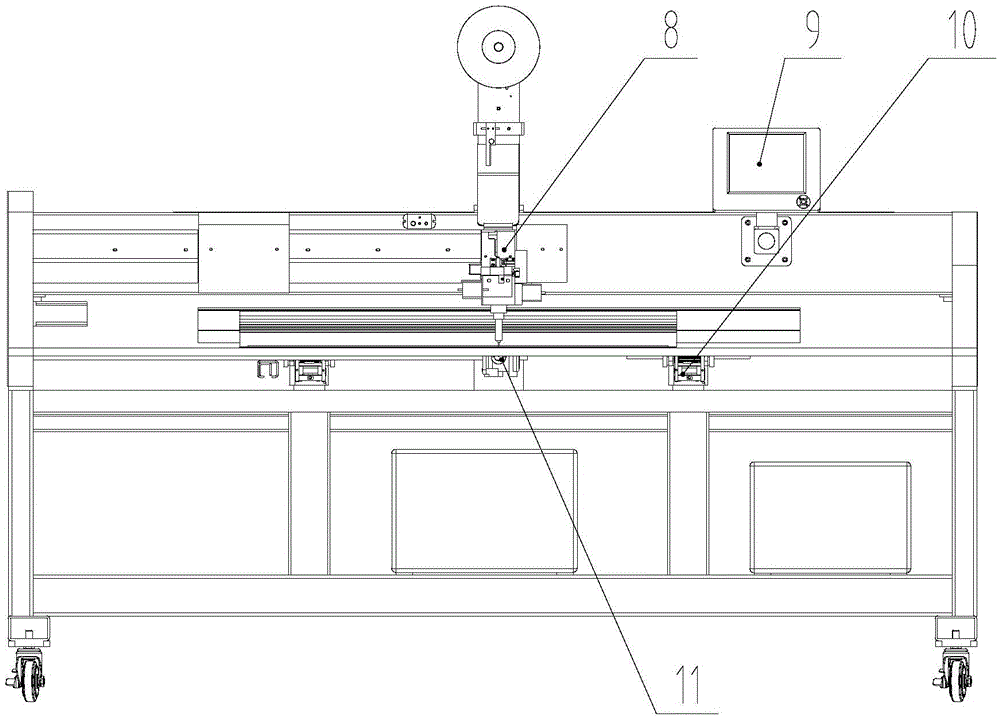

Full-automatic wiring machine

The invention discloses a full-automatic wiring machine. A base of the full-automatic wiring machine is of a bridge type structure. Square boxes are fixed on the two sides of the base, a girder is erected above the square boxes, a platen is fixedly arranged in the middle of the base, an X-direction driving device is installed on the platen, and a clamping frame is fixedly arranged at the front end of the X-direction driving device. A wiring machine head is installed in the middle of the girder of the base and corresponds to a rotating shuttle box below the platen. A Y-direction driving device is installed on the base and below the platen, connected with the X-direction driving device and driven by a Y-direction driving motor. An automatic wire feeding device is fixedly arranged in the middle of the girder and over the wiring machine head. By means of the automatic wiring machine, accuracy and efficiency of wiring can be greatly improved, the full-automatic wiring machine is different from the prior art that each pattern needs a corresponding template, full automation is achieved, labor cost is saved, skillful labor skills and experience are not needed, the automation degree is high, and operation of green hands can be facilitated.

Owner:上工富怡智能制造(天津)有限公司

High-precision embroidery machine combining Z-axis movement with Y axis

The invention discloses a high-precision embroidery machine combining Z-axis movement with a Y axis, which consists of a cross beam on a frame and a frame arranged below the cross beam. A machine head mounting plate and a shuttle box body mounting plate on the cross beam are respectively provided with an upper shaft and a lower shaft; a machine head is mounted on the upper shaft of the machine head mounting plate; a shuttle box body component is mounted on the lower shaft of the shuttle box body mounting plate; a linear guide rail and an upper and lower shaft conjoining box body are further arranged at the end part of the cross beam; the machine head and the shuttle box body component are respectively formed into a whole by the machine head mounting plate and the shuttle box body mounting plate through the upper and lower shaft conjoining box body; the upper and lower shaft conjoining box body is connected with a ball screw and a servo motor; the left-right movement, namely the X-direction movement is achieved by the servo motor through the ball screw and the linear guide rail; and synchronously, the servo motor drives the upper shaft and the lower shaft to rotate through the ball screw and the upper and lower shaft conjoining box body, so as to drive the machine head and the shuttle box body component to carry out the Z-axis movement. The front-rear movement, namely the Y-direction movement of the frame is achieved by a Y driving motor through driving a synchronous belt and a sliding block. The high-precision embroidery machine combining the Z-axis movement with the Y axis is applicable to embroidery machines.

Owner:浙江盛名机电制造有限公司

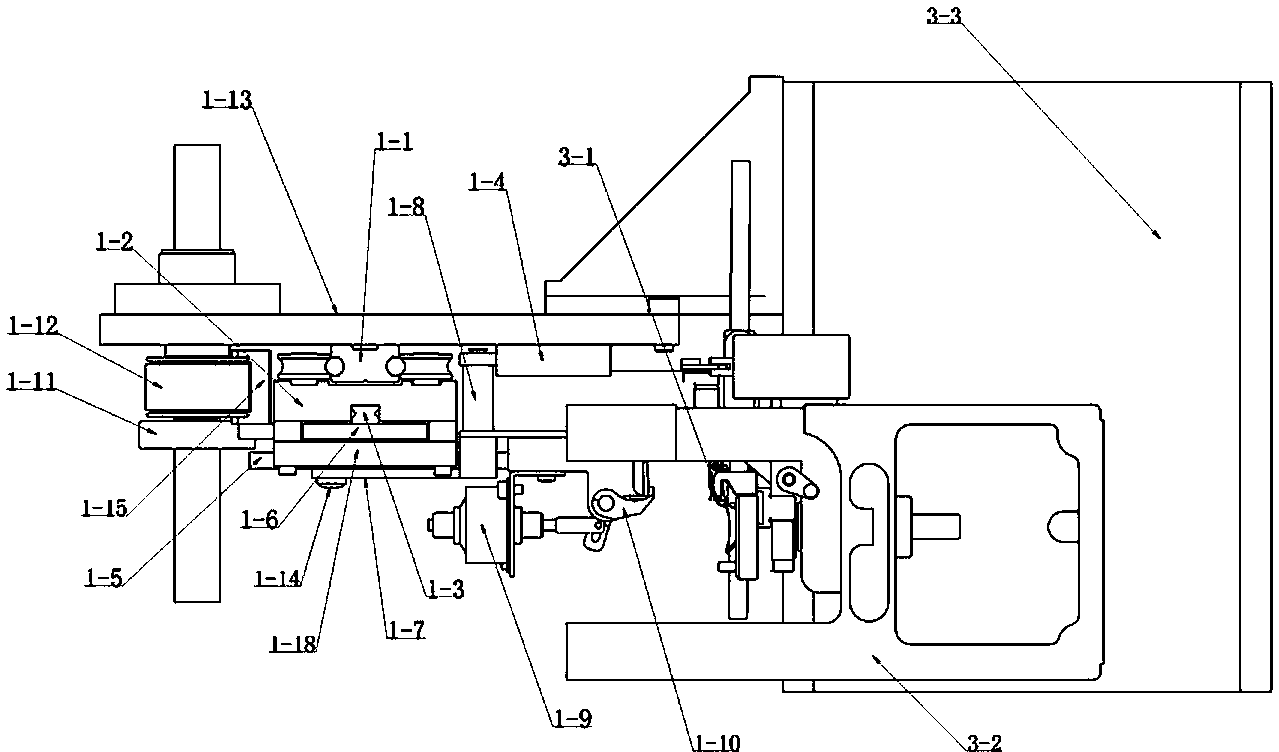

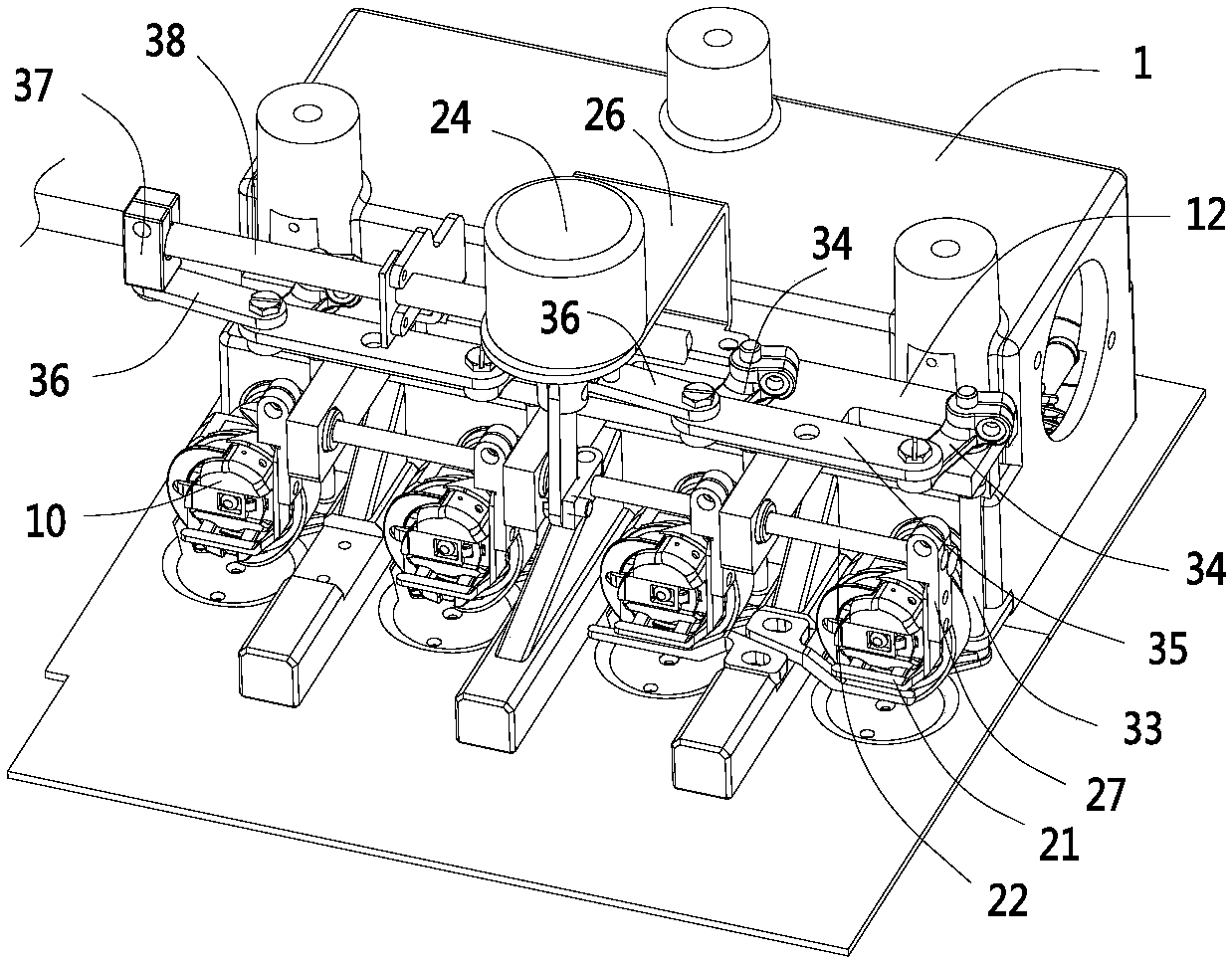

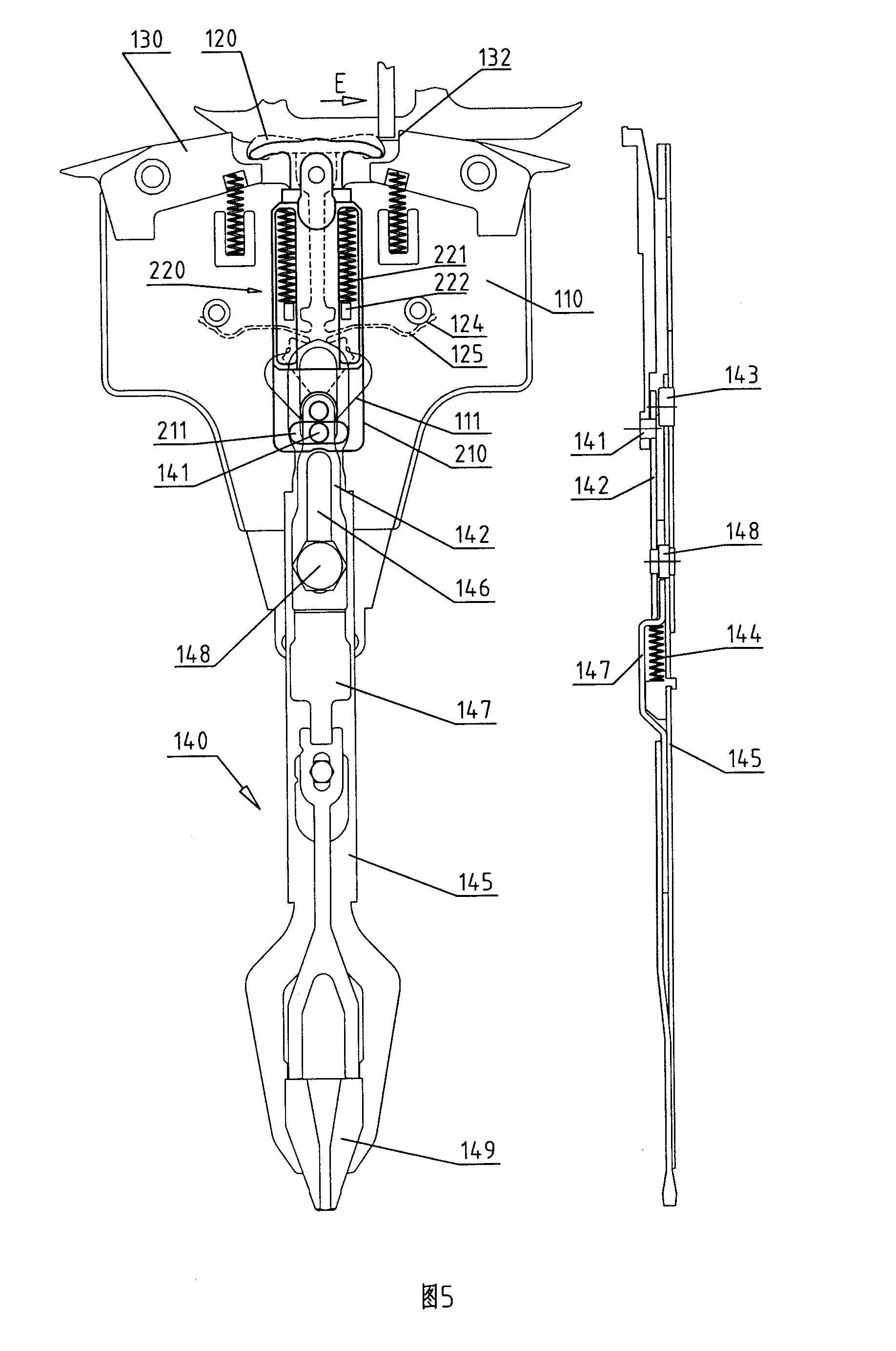

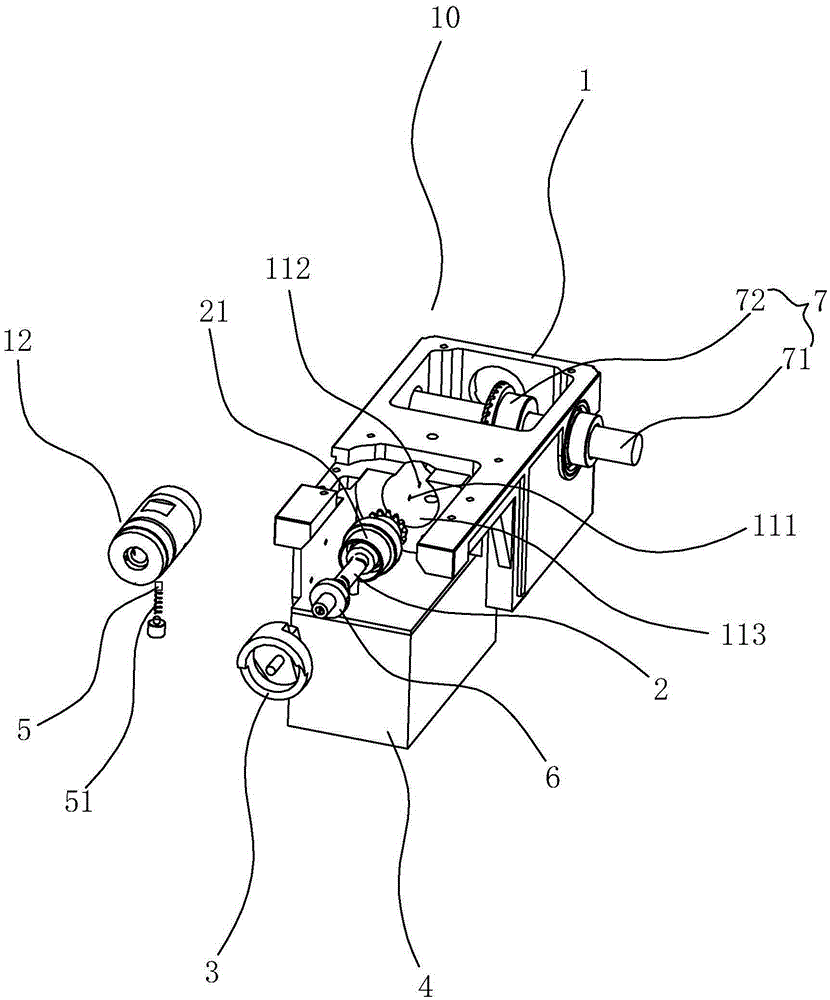

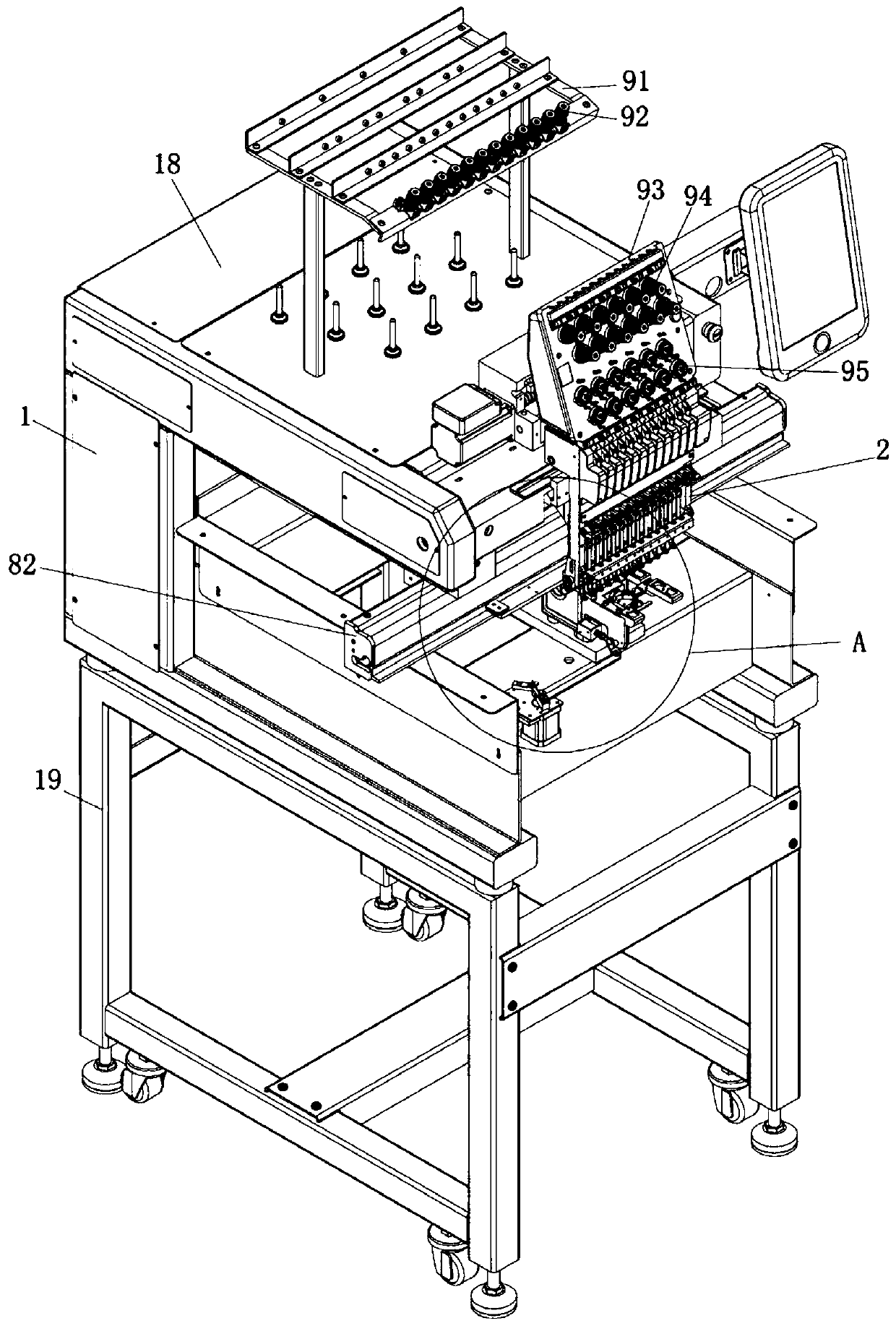

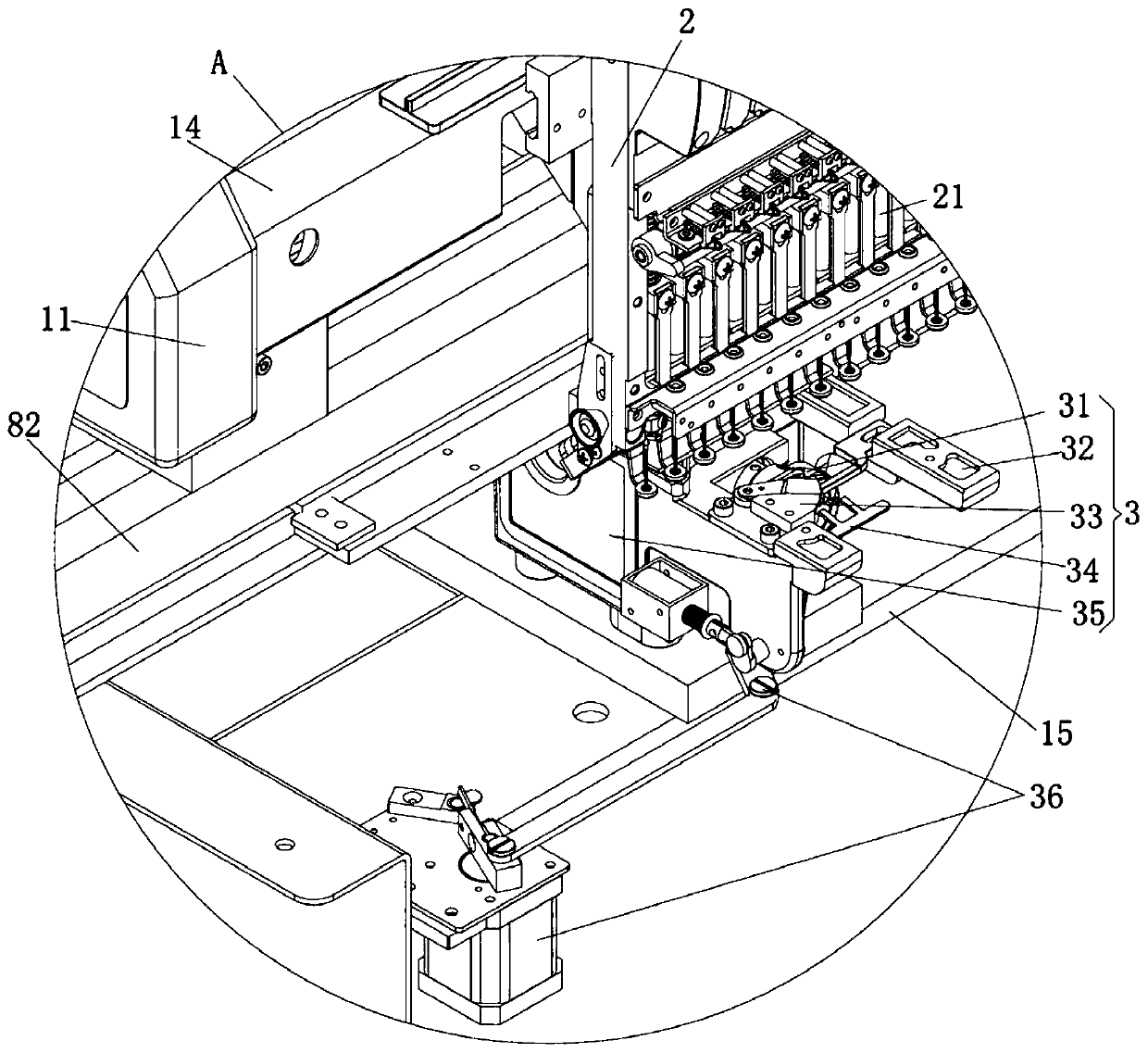

Automatic thread replacement device and embroidery machine

ActiveCN106480616AShorten the timeImprove work efficiencyEmbroidering machines apparatusEngineeringMechanical engineering

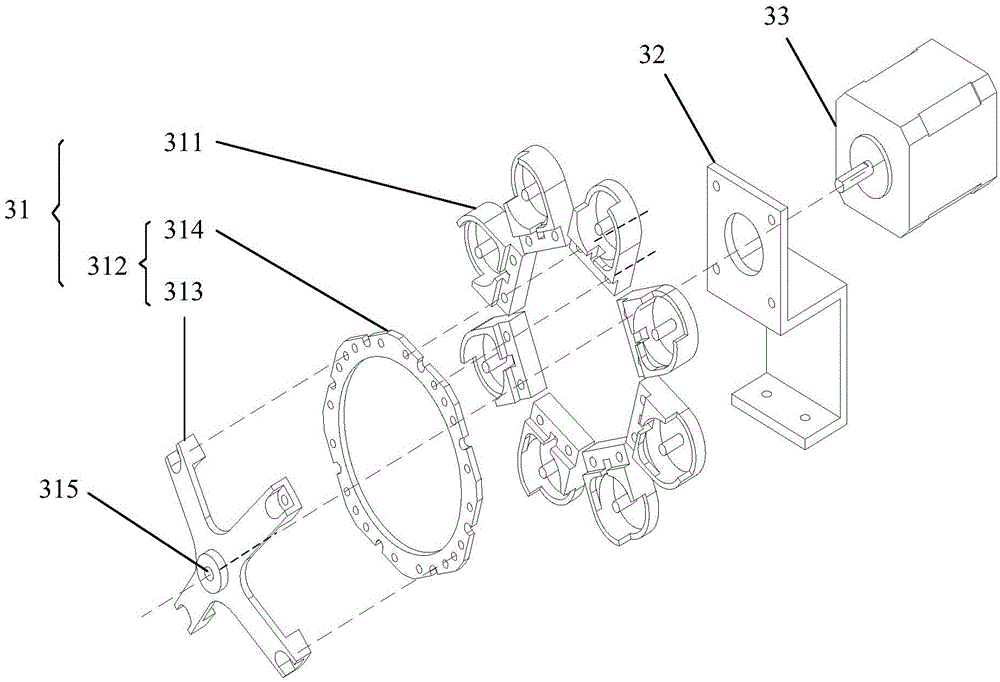

The invention provides an automatic thread replacement device and an embroidery machine, wherein the automatic thread replacement device comprises a bottom thread replacement mechanism fixed on a mounting plate, and a bottom thread feeding mechanism for placing a full bottom thread rotating shuttle. The mounting plate is fixed in a rotating shuttle box for placing a sewing shuttle. The bottom thread replacement mechanism comprises a drive component and a grab component. The drive component is connected with the grab component to drive the grab component from the rotating shuttle box to remove the empty sewing shuttle and grab the full bottom thread rotating shuttle from the bottom thread feeding mechanism to move into the rotating shuttle box. The automatic thread replacement device has the advantages of being capable of shortening the time for the automatic bottom thread replacement of the embroidery machine, and improving the working efficiency of the embroidery machine.

Owner:BEIJING DAHAO TECH

Rapier loom and wefting insertion method thereof

The invention discloses a rapier loom and a wefting insertion method thereof. The rapier loom comprises a rack, a battening mechanism, multiple shuttle boxes and left and right wefting insertion mechanisms located on two sides of the rack respectively, the shuttle boxes are located above the battening mechanism, each shuttle box is internally provided with a shuttle, the left wefting insertion mechanism comprises a left rapier and a left driving unit which are connected, the right wefting insertion mechanism comprises a right rapier and a right driving unit which are connected, the left driving unit is used for driving the left rapier to move to grab the shuttle from the shuttle box, put the shuttle back to the shuttle box, extend the shuttle into a shuttle port and exchange the shuttle with the right rapier, and the right driving unit is used for driving the right rapier to move to grab the shuttle from the shuttle box, put the shuttle back to the shuttle box, extend the shuttle intoa shuttle port and exchange the shuttle with the left rapier. By means of the method, automatic wefting insertion of section wefts can be achieved, and the problems of excessively long weft dragging length caused by the section weft insertion of a weft insertion manner and tangling wefts are prevented.

Owner:DING SHENG SILK

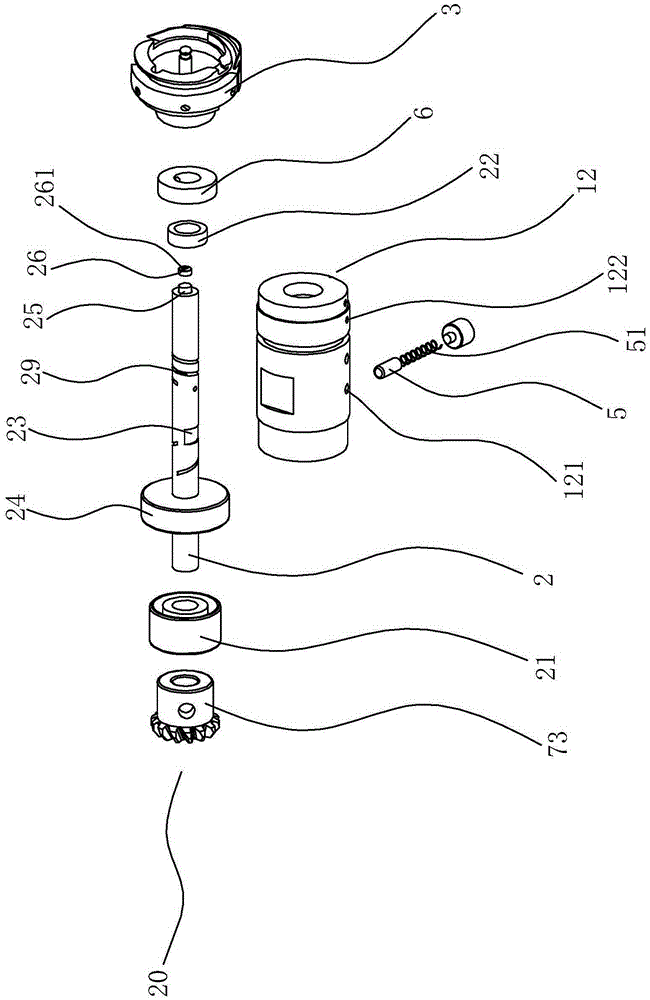

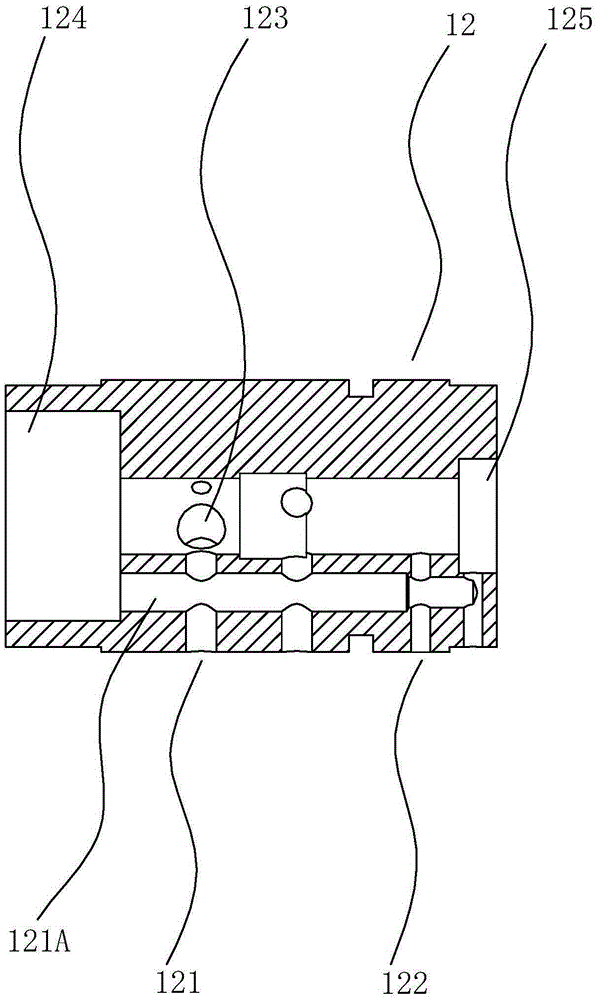

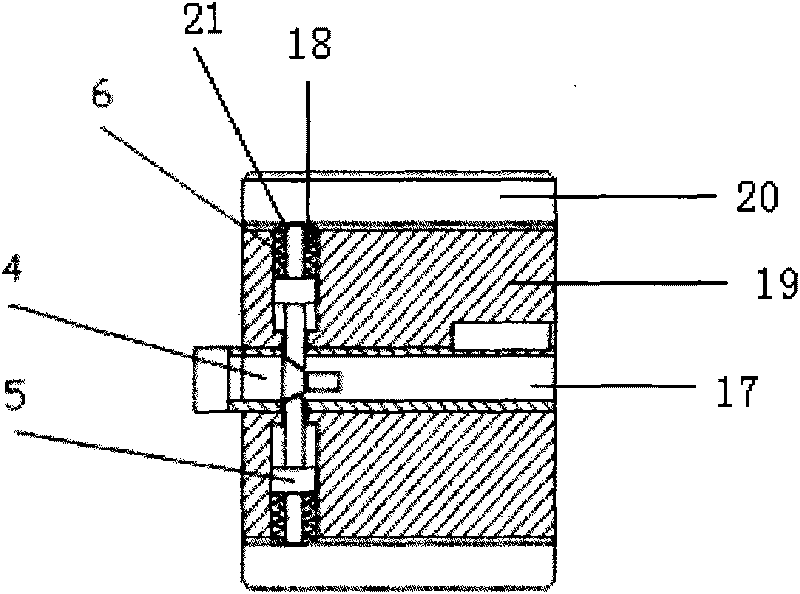

Automatic-oiling rotating shuttle shaft structure and rotating shuttle box of embroidery machine

The invention discloses an automatic-oiling rotating shuttle shaft structure and a rotating shuttle box of an embroidery machine. The automatic-oiling rotating shuttle shaft structure comprises the rotating shuttle box, a rotating shaft and a rotating shuttle, wherein the rotating shaft is in transmission connection with the rotating shuttle box; the rotating shuttle is in transmission connection with the rotating shaft; the rotating shuttle box comprises a box body and a shaft sleeve which is arranged at the periphery of the rotating shaft in a sleeving way; an axial hole which is used for fixing the shaft sleeve is formed in the box body; an axial oil storage hole which does not penetrate through the rotating shaft, a plurality of oil grooves which are formed in the outer surface of the rotating shaft and a connecting hole which is communicated with the oil storage hole and the outer surface of the rotating shaft are formed in the rotating shaft; the rotating shaft is also provided with an oil absorption piece which is contained in the oil storage hole and an oil soaking screw which is fixedly arranged at the opening end of the oil storage hole; an oil outlet hole which is communicated with the oil storage hole and the exterior is formed in the oil soaking screw; the rotating shaft is rotationally connected to the box body; an oil inlet passage and an oil outlet passage are formed in the shaft sleeve; one section of each of the oil grooves is connected with the oil inlet passage when the rotating shaft rotates. The automatic-oiling rotating shuttle shaft structure disclosed by the invention has high practicability, can solve practical problems and can be widely promoted and applied to a market.

Owner:JIANGXI HEFENG ELECTRONICS MACHINES

Single-head plain embroidery machine of light structure

PendingCN109972312AHigh precisionReasonable structureAutomatic machinesAuxillary devicesFailure rateEngineering

The invention discloses a single-head plain embroidery machine of a light structure. The machine comprises a rack, a machine head, a color changing mechanism, a plain embroidery shuttle box provided with a thread cutting mechanism and an embroidery frame moving mechanism, the rack comprises two brackets opposite to each other, at least two beams and at least two bottom beams, and each bracket is composed of an upper cross arm, a column and a lower cross arm which are connected in sequence and form a C-shaped structure; the beams are arranged between the upper cross arms of the two brackets, the bottom beams are arranged between the lower cross arms of the two brackets, and the embroidery frame moving mechanism is hoisted below the beams; the shuttle box is arranged on one bottom beam, themachine head and the color changing mechanism are arranged on the beam above the shuttle box, a needle rod frame is arranged on the front portion of the machine head, and the color changing mechanismdrives the needle rod frame to move and switch different needle rods to the positions over the shuttle box, so that color changing is completed. The machine is convenient to move, reduces cost, improves the embroidery efficiency and is suitable for pattern plate making and personalized embroidery; the needle rod switching accuracy is high, the sound is low, the speed is high, the color changing noise is reduced, and the color changing failure rate is reduced.

Owner:DONGGUAN BAOLUN COMPIZED EMBROIDERY MACHINERY CO LTD

Novel single-end multifunctional high speed computerized embroidery machine

InactiveCN105155152ASimple structureImprove performanceAutomatic machinesAuxillary devicesElectric machineryEngineering

The invention discloses a novel single-end multifunctional high speed computerized embroidery machine, comprising a rack; a Y axis guide rail designed in the axial direction of the Y axis and a rotary shuttle box are arranged at the upper end of the rack; the upper end of the Y axis guide rail is provided with an X axis guide rail designed in the axial direction of the X axis, a corresponding X axis slide seat is arranged at the upper end of the X axis guide rail, the upper end of the X axis slide seat is provided with a machine head seat designed in the axial direction of the Y axis, the front end of the machine head seat is provided with a plain embroidery machine head designed in the axial direction of the Z axis; a main motor is arranged at the lower end of the machine head seat and is connected with a lower shaft belt wheel; an upper shaft belt wheel corresponding to the lower shaft belt wheel is arranged at the rear end of an upper shaft arranged in the axial direction of the Y axis; the front end of the upper shaft is provided with an upper shaft bevel gear, a machine head bevel gear corresponding to the upper shaft bevel gear is arranged on the plain embroidery machine head. The novel single-end multifunctional high speed computerized embroidery machine has the advantages of simple structure, more stable performances, more precise embroidery, high speed up to 1200 revolutions per minute, small noise, and suitability for design of families, individuals and designers to give play to infinite originality or small-batch and various sampling of companies or plants.

Owner:DONGGUAN BAOLUN COMPIZED EMBROIDERY MACHINERY CO LTD

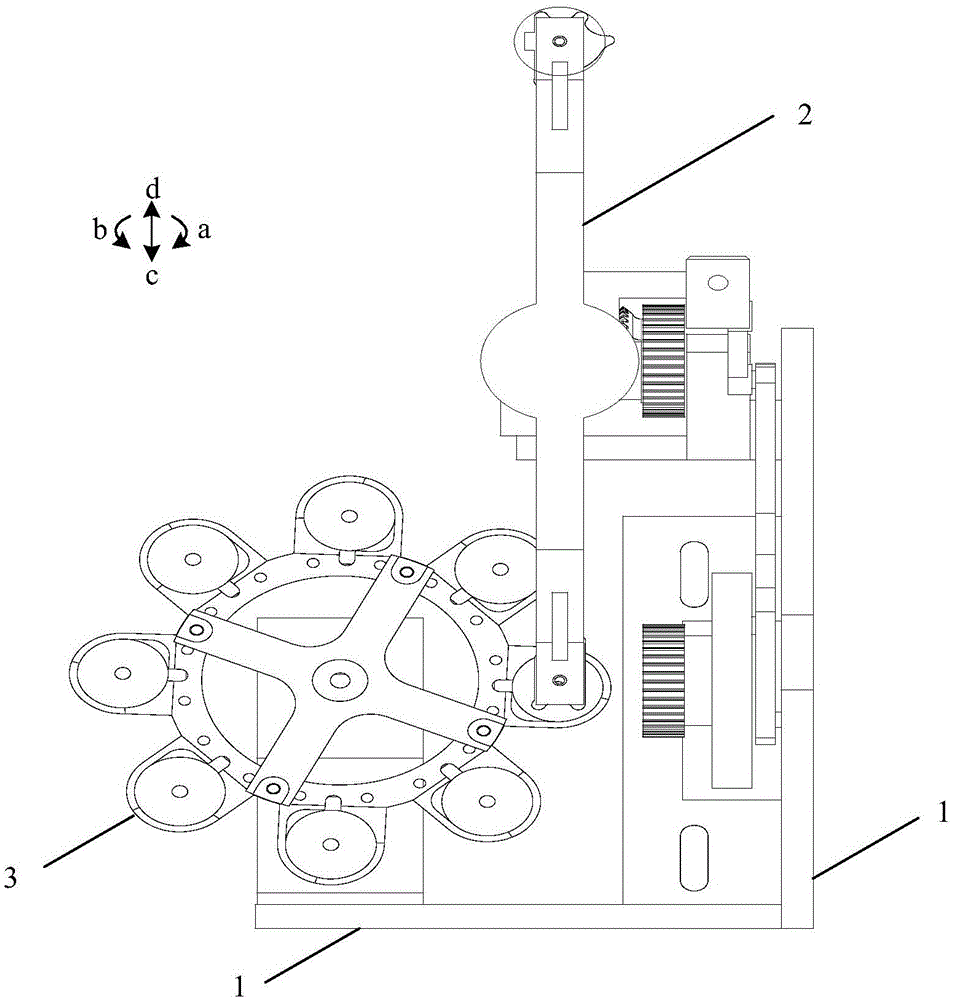

Device for rotating multi-shuttle box

The invention provides a device for rotating a multi-shuttle box, which is characterized in that a base is provided with a first bracket, a second bracket and a third bracket; the first bracket is provided with a first air cylinder which is connected with a hollow rotating shaft; the hollow rotating shaft is arranged on the second bracket and the third bracket and connected with a turntable and the multi-shuttle box; one side of the turntable is provided with rolling wheels which are uniformly distributed on the outer edge of the turntable; the rolling wheels are connected with a second air cylinder through push pins; the other side of the turntable is provided with a turntable positioning element; the multi-shuttle box comprises a main body and a shuttle box arranged on the external side of the main body; the connecting surface of the main body and the shuttle box is provided with a shuttle locking hole; a push rod shaft which is connected with the hollow rotating shaft is arranged in an axial hole inside the main body; a lock shuttle rod is arranged in a radial hole; one end of the lock shuttle rod abuts on the push rod shaft and the other end is arranged at the shuttle locking hole; and a compression spring is arranged between the lock shuttle rod and the connecting surface of the main body and the shuttle box. The invention can ensure the parallel relationship of two strings of weft all the time, thereby avoiding the twist phenomenon.

Owner:DONGHUA UNIV

Separated lockstitch sewing device and sewing method

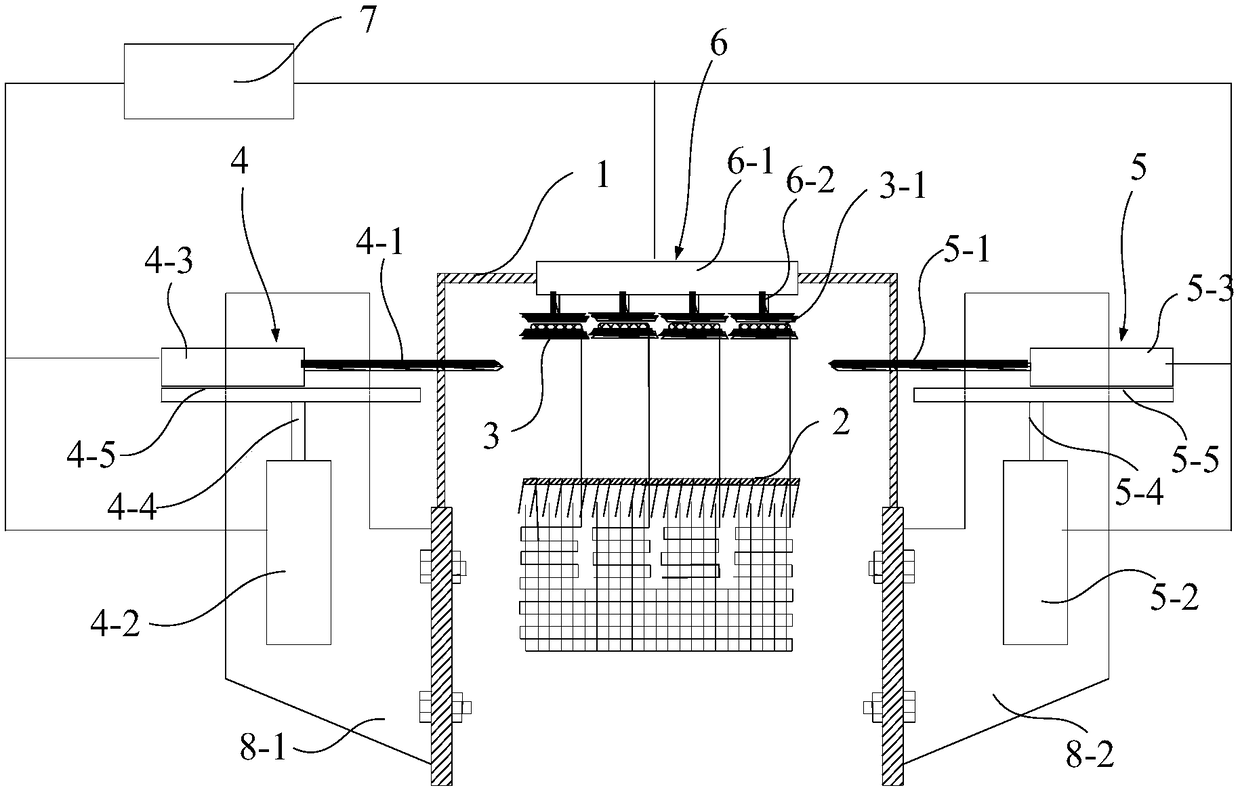

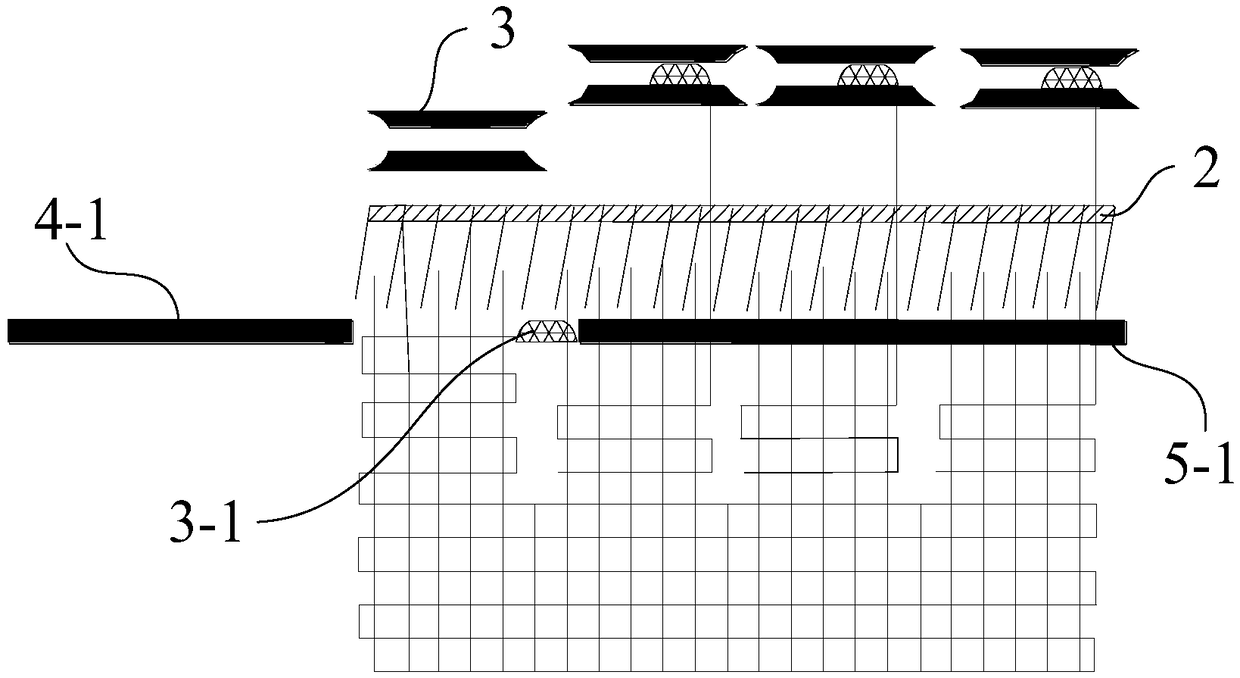

ActiveCN110004598ASpacing controllableControllable tensionSewing-machine control devicesTake-up devicesControllabilityGeneratrix

The invention belongs to the technical field of sewing and discloses a separated lockstitch sewing device and sewing method. By split arrangement of a machine head component and a shuttle box component, in sewing, the machine head component is suspended above a to-be-sewn material through a first slide rail, a shuttle unit is arranged below the to-be-sewn material through a second slide rail, anda needle unit and the shuttle unit are controlled to synchronously move along a to-be-sewn portion to realize lockstitch sewing of sewing points in sequence. By adoption of the method, mechanical sewing of a conical structure with generatrix direction length greater than 1.5m and small end size less than 60mm is realized, staggering, slipping and creasing of thin-film material layers of a conicalmultilayer flexible thin film composite product are avoided, and sewing efficiency is improved. In addition, stitch pitch controllability, sewing thread tension controllability and sewing quality stability are realized, and the method is suitable for batch production.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Movement mechanism for yarn mouth on intarsia shuttle box

The inventions relates to a yarn nozzle motion mechanism of intarsia shuttle box in flat knitting machine, comprising case, driving plate, limit swing block, fixed plate for yarn nozzle, outer cover plate and is characterized in that it contains cam, extension spring, buffer spring. Driving plate is slipped on the upper end of case outer and cam, limit swing block are articulated on the case outer under the driving plate from the top down orderly. Fixed plate for yarn nozzle is cut into limit swing block and two ends of extension spring are connected to fixed plate for yarn nozzle and limit swing block respectively. One end of two buffer spring is fixed to two sides of limit swing block and the other end is leaned against two sides of fixed plate for yarn nozzle in press. Driving plate is connected to cam, which is connected to limit swing block and fixed plate for yarn nozzle in driving style. Outer cover plate is connected to the outer of case. The merit is that it makes loom speed and weaving efficiency increase that small driving gap, stable operation, because the rotary of limit swing block is accomplished by pinion-and-rack contacting and cam moving.

Owner:冯加林

Yarn feeding device for computer flat machine

The present invention relates to a yarn feeding device of a computerized knitting machine and has the technical proposal that the present invention comprises a shuttle bar, a shuttle box and a shuttle box controlling mechanism, wherein, the shuttle box controlling mechanism is arranged on two sides of the upper part of the shuttle bar, the shuttle box is arranged on two sides of the lower part of the shuttle bar, and the shuttle box controlling mechanism is connected with the shuttle box in a rotary way through a clip flap on the controlling mechanism to drive the shuttle box to move together along the shuttle bar. The present invention has the advantages that the shuttle box controlling mechanism formerly arranged on the nose connecting frame is arranged on the shuttle bar, on one hand, the weaving wire on a wire frame is directly guided on the shuttle box, and the weaving wire is not required to be bended, thereby, the mutual entanglement and whipping together cannot be caused, the suffered pulling force is small and the force distribution is uniform, thus being favorable to the improvement of the quality of weaving; on the other hand, the controlling of the shuttle box on the shuttle bar is executed by the shuttle box controlling mechanism through a computer order, thereby, the driving structure is simple, and the occupied space is small, but the operation is accurate and effective, more shuttle boxes can be arranged on the shuttle bar to meet the needs of more weaving patterns and more complex weaving patterns, so as to provide superior knitting performance for the computerized knitting machine, and to greatly increase the performance-to-price ratio.

Owner:冯加林 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com