Automatic bottom line changing device of computer embroidery machine

An embroidery machine and automatic technology, which is applied to the mechanism of the embroidery machine, embroidery machine, bobbin winding in the sewing machine, etc., can solve the problems of reducing the labor intensity of workers, increase the complexity of the equipment, improve the degree of automation, and reduce the workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail by the following examples.

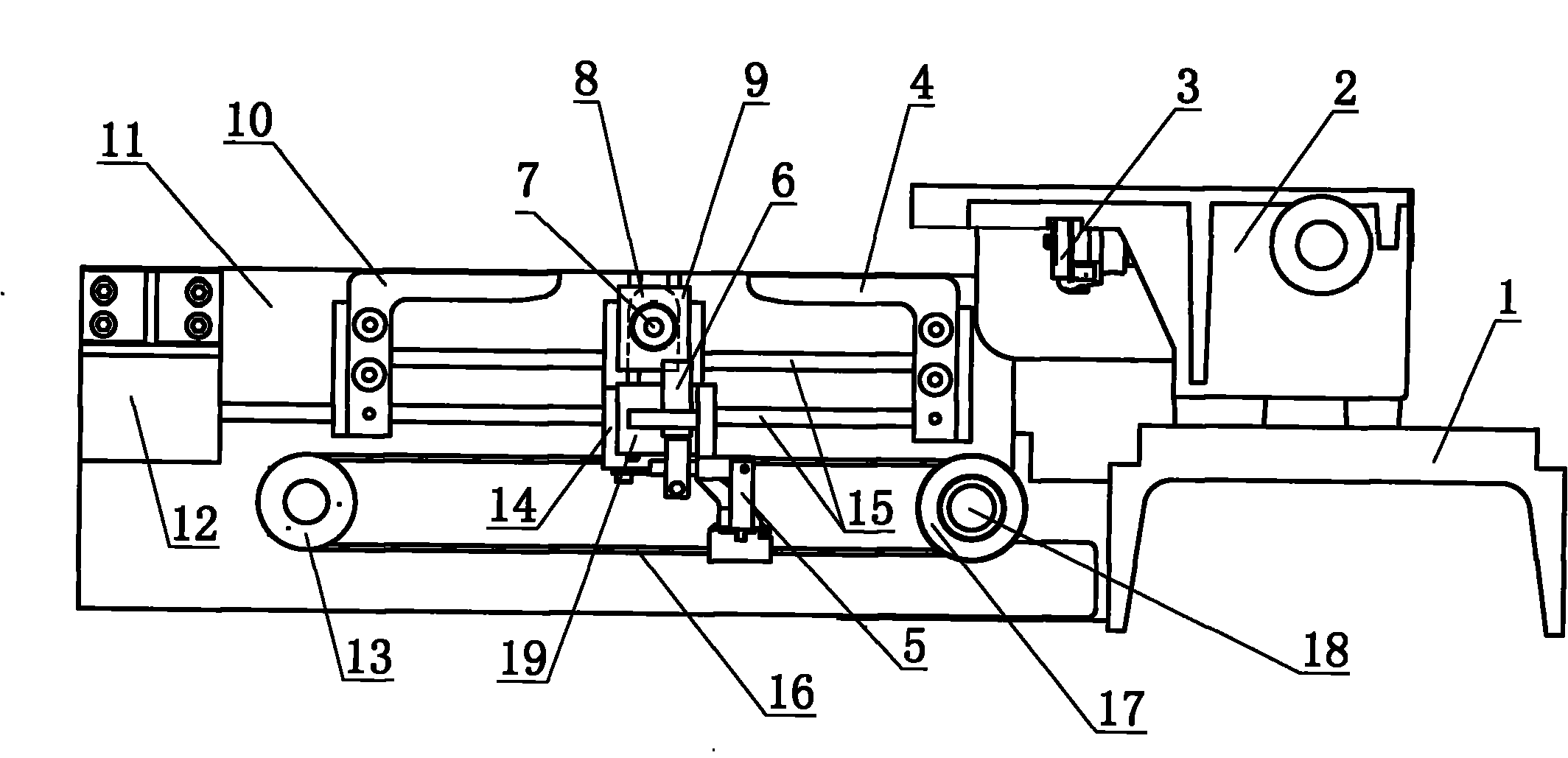

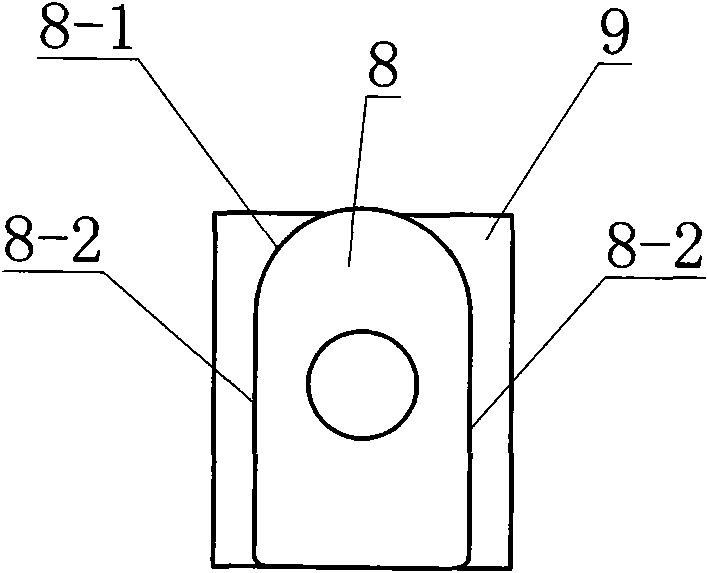

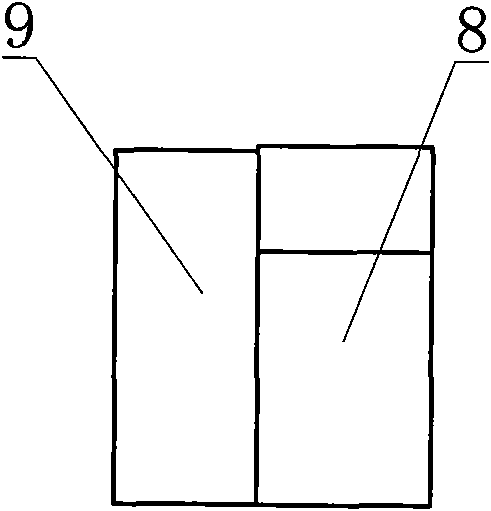

[0028] see Figure 1-Figure 4 As shown, an automatic bobbin thread changing device of a computerized embroidery machine is composed of a frame 1, a rotary hook box 2, a rotary hook 3, a bobbin storehouse 12 and its spare bobbin, a first guide plate 4, a second guide plate 10, an installation Plate 11, slide table 14, cylinder 6, bobbin claw 5, rotating block 9, positioning rotating block 8, horizontal guide bar 15 and horizontal belt transmission mechanism are formed. The hook 3 is placed in the hook box 2, the hook box 2 is fixed on the frame 1, and a mounting plate 11 is fixedly installed on the frame 1, one end of the mounting plate 11 is close to the hook box 2, and the mounting plate 11 The other end is fixed with bobbin chamber 12. On the mounting plate 11, two first guide plates 4 and the second guide plate 10 with the same shape and installed facing each other are fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com