Patents

Literature

36results about How to "Precise locking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

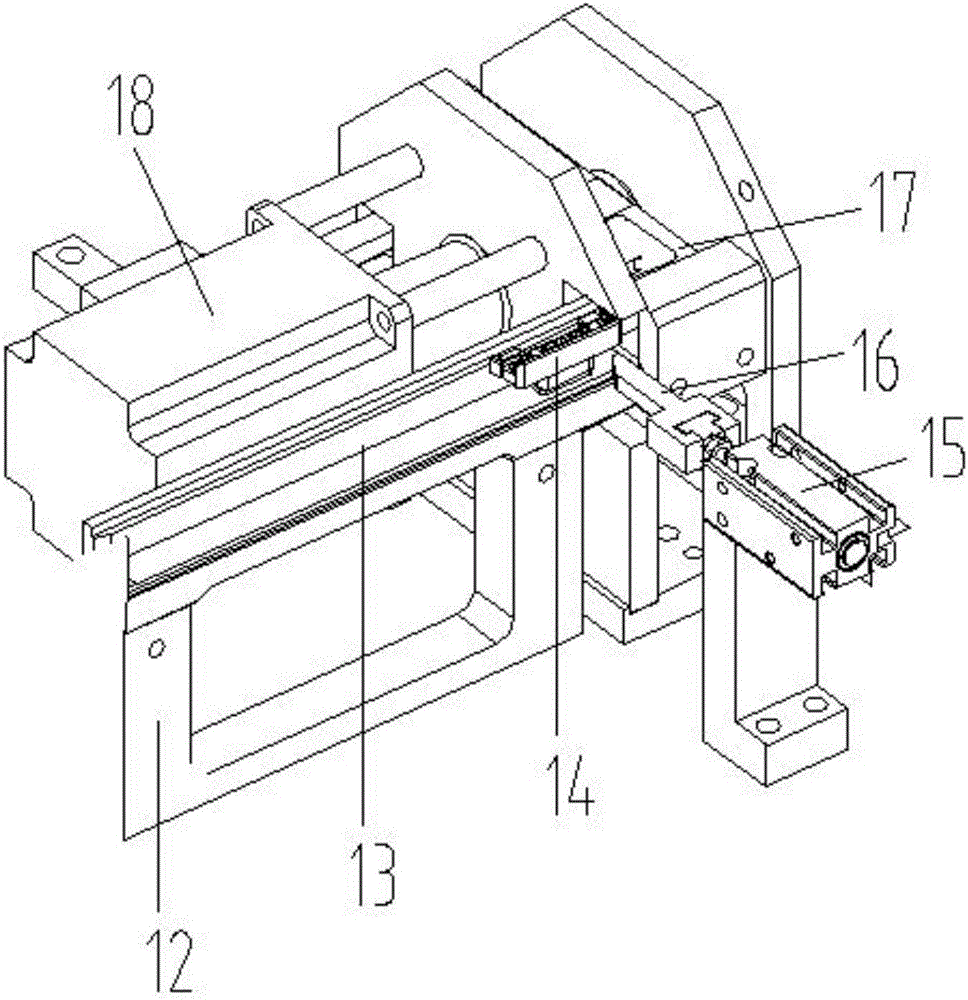

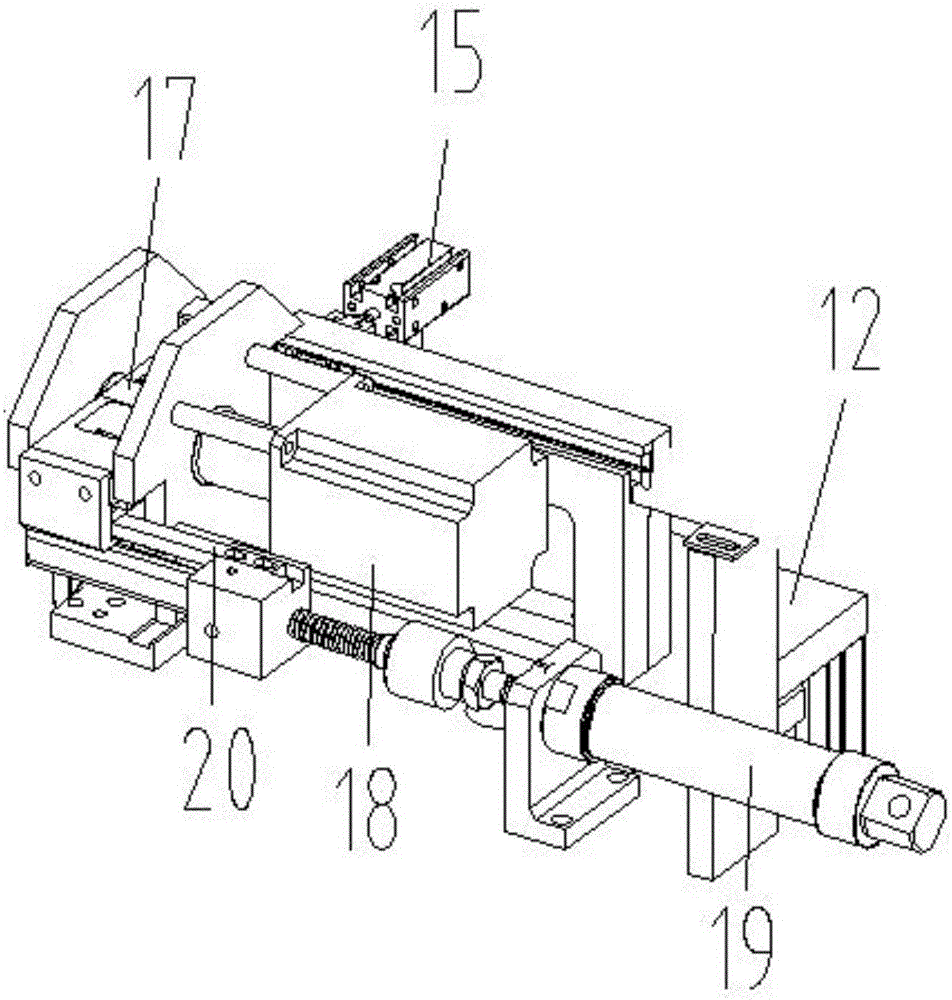

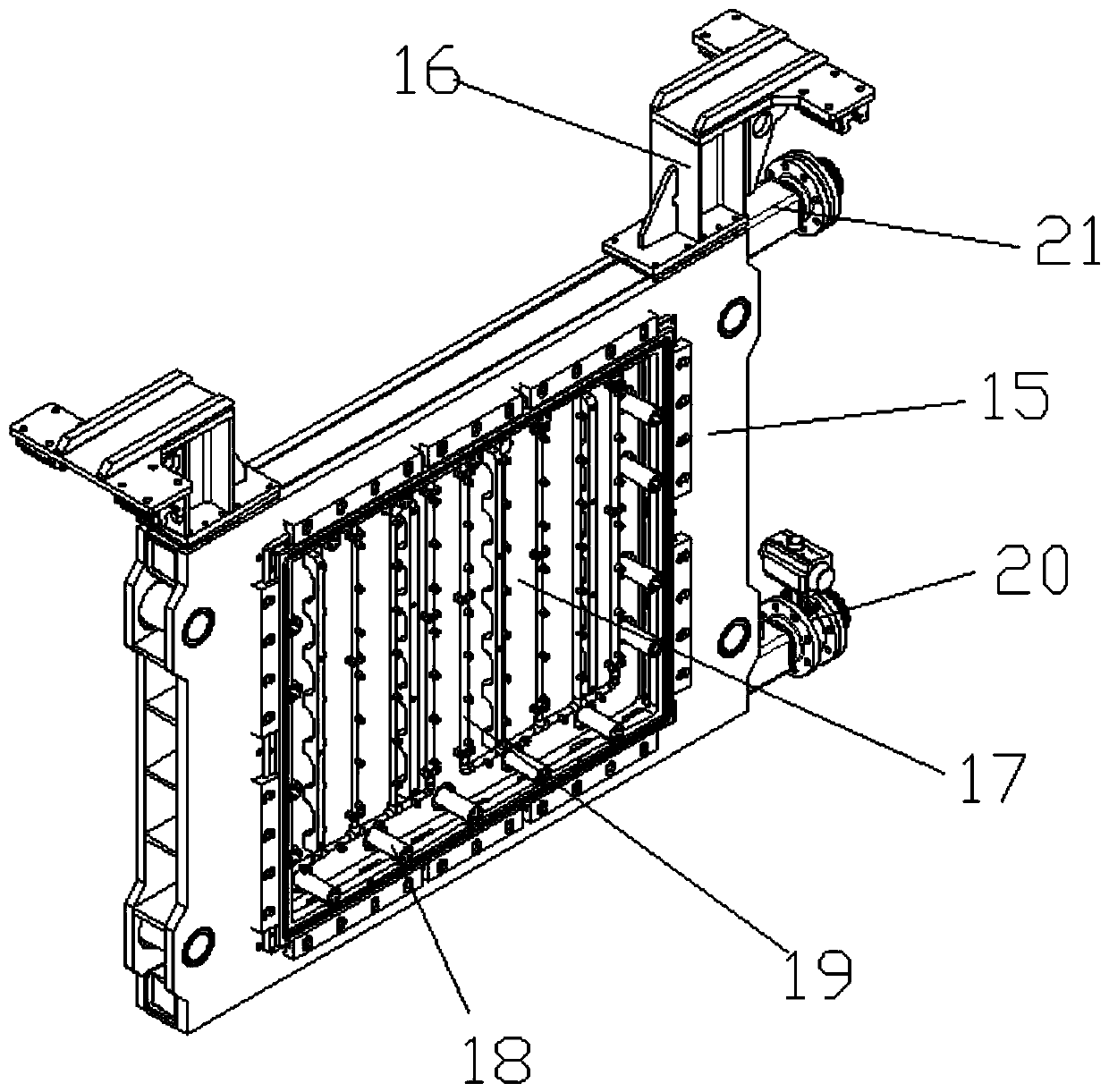

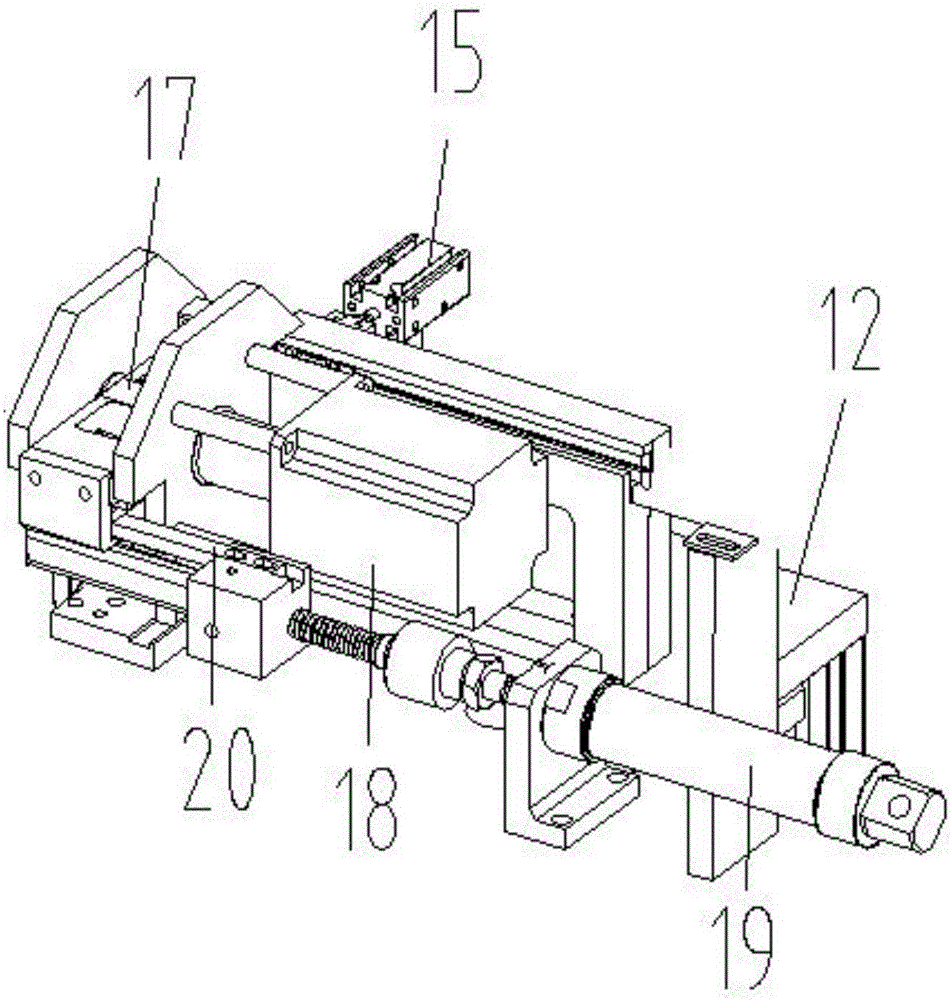

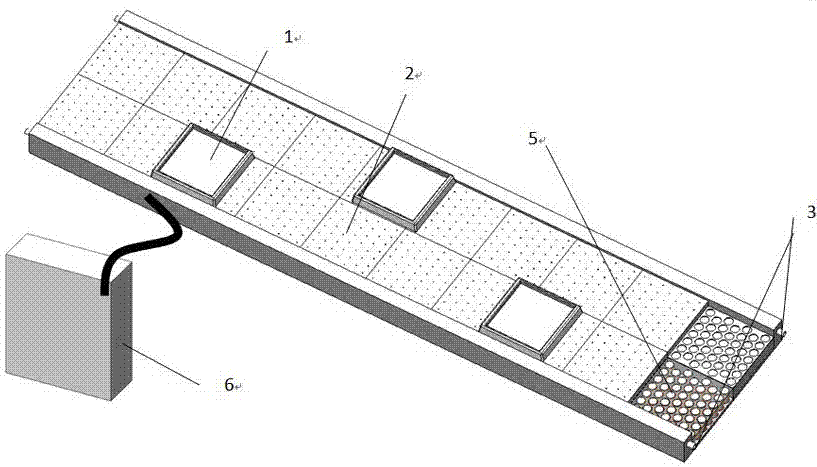

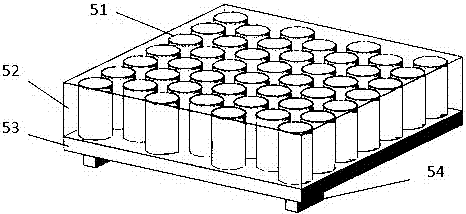

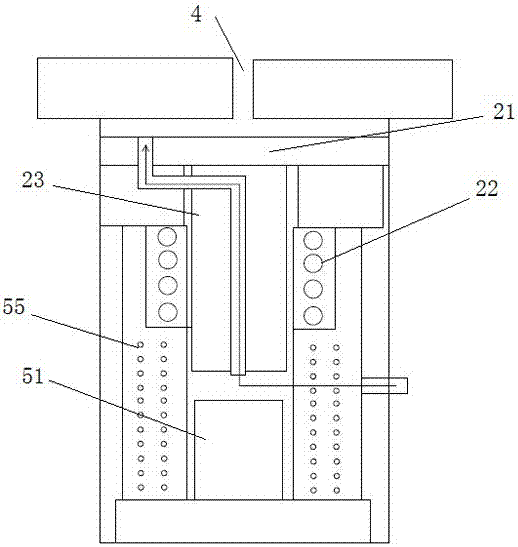

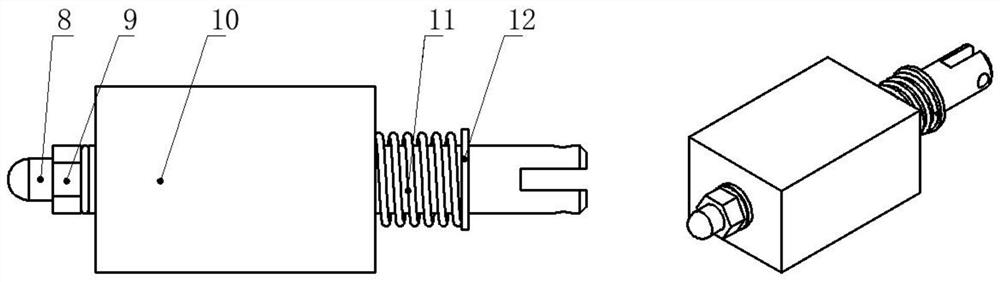

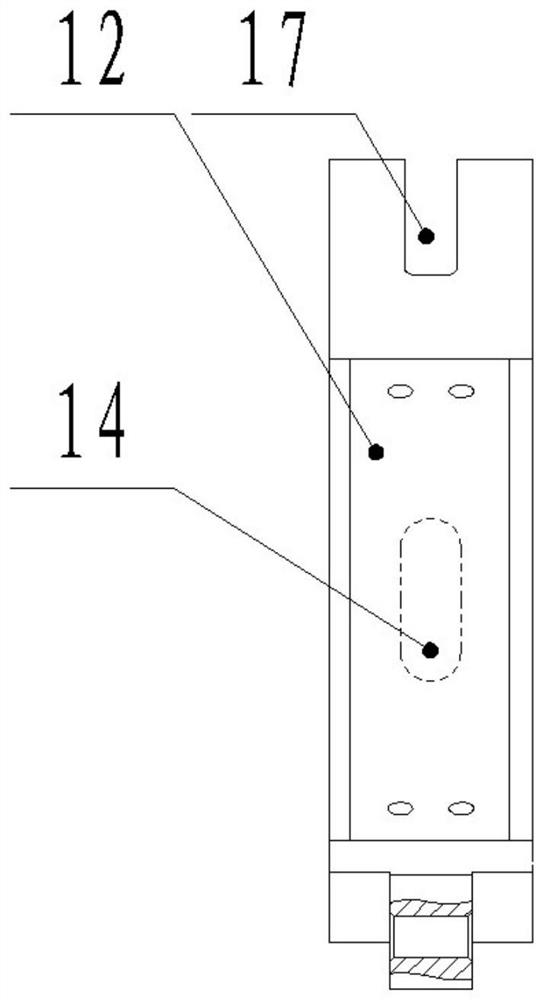

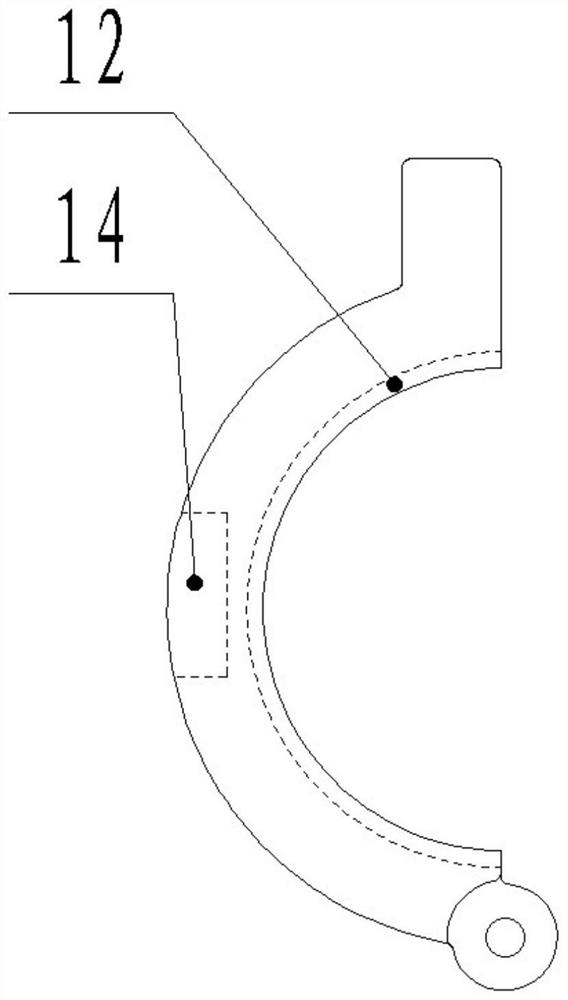

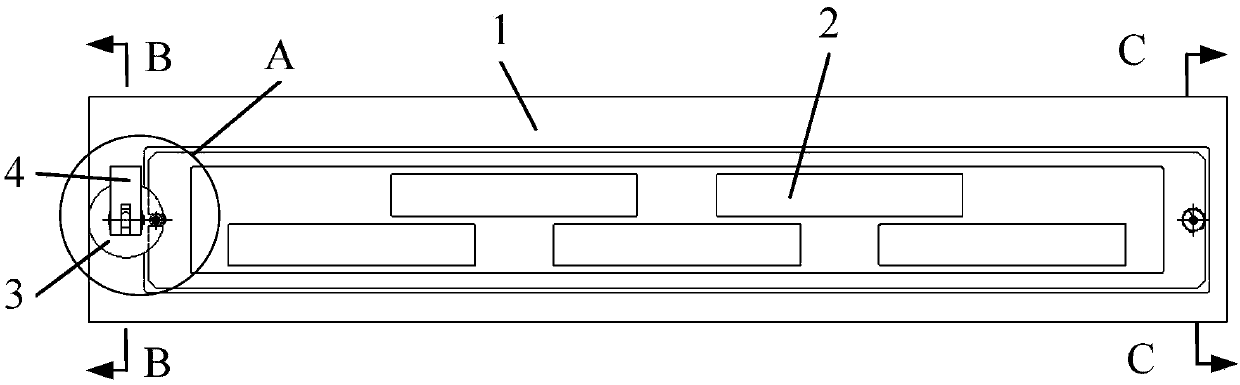

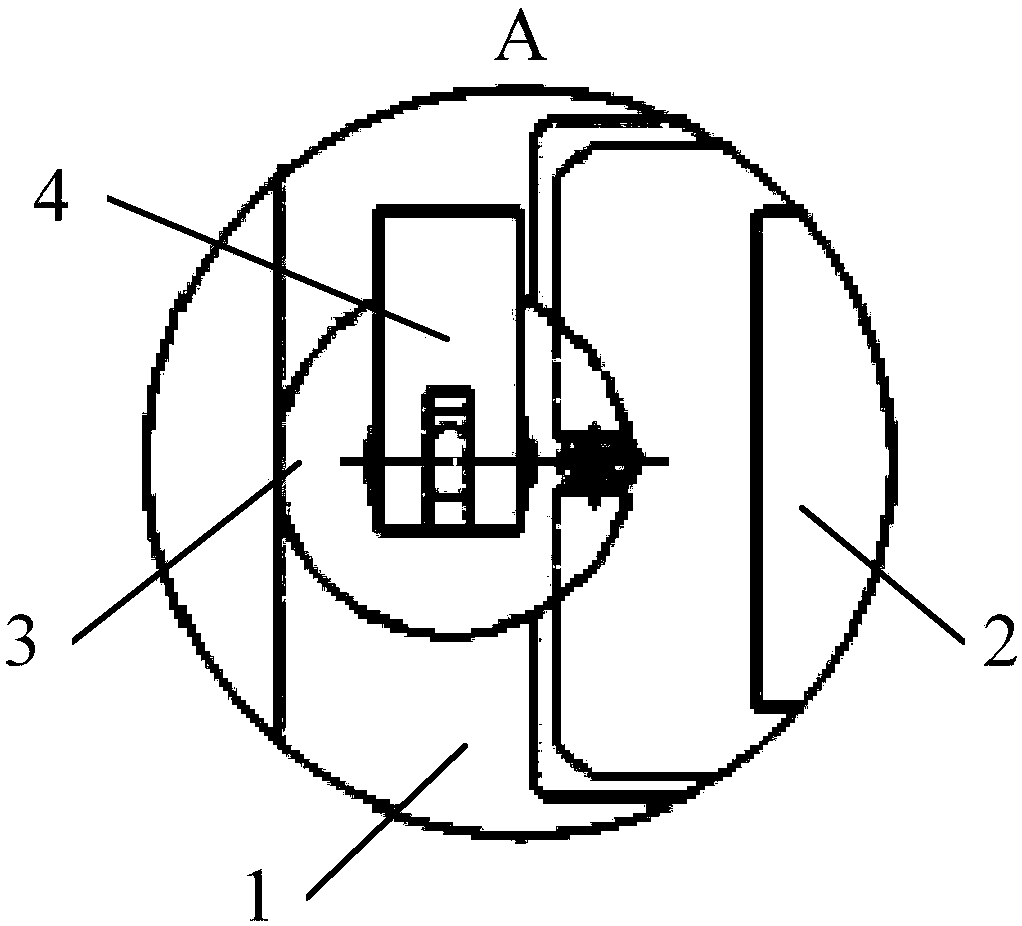

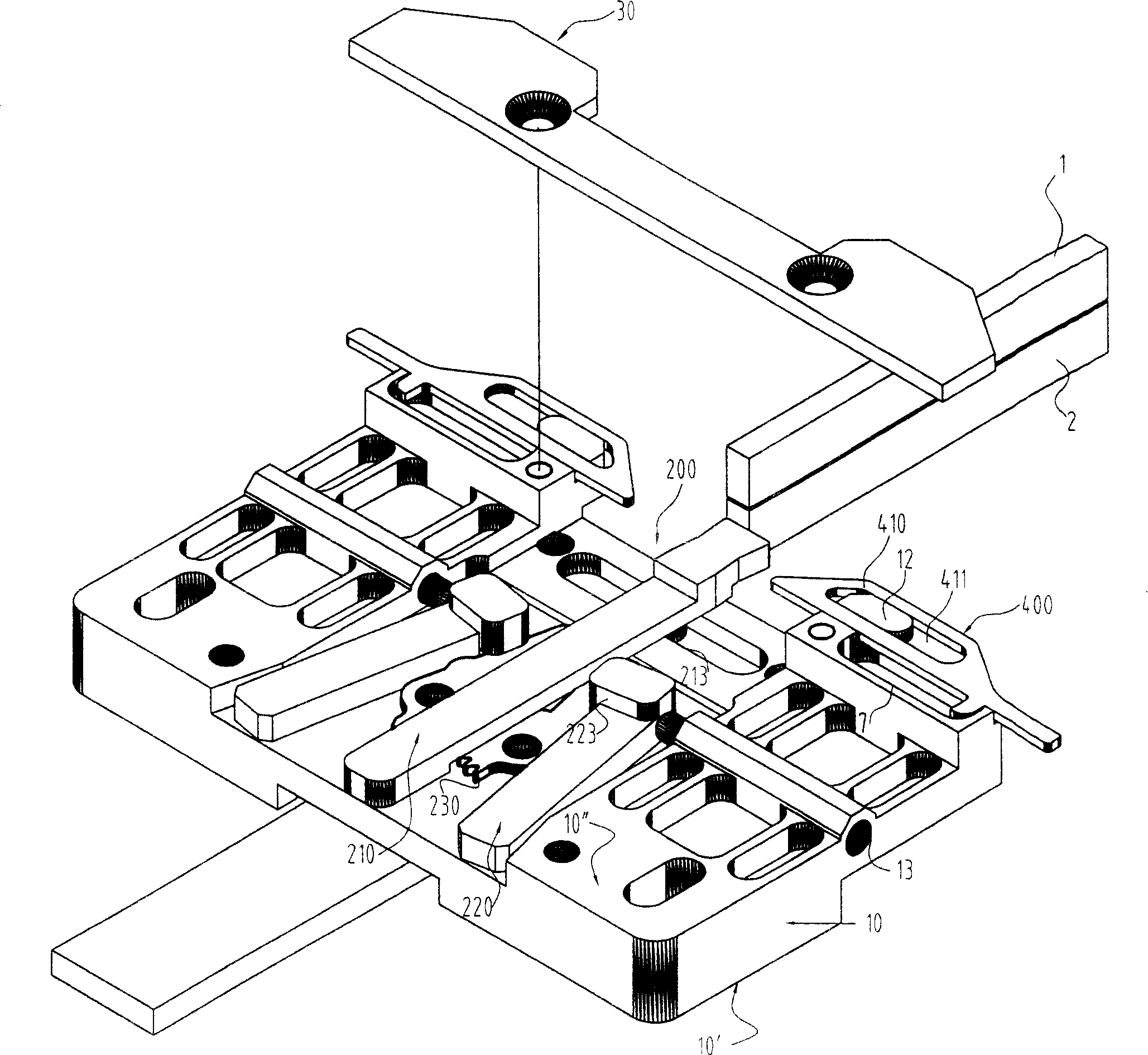

Universal test fixture for surface mounted technology (SMT)-based diode components

ActiveCN105158524AIncrease the scope of applicationImprove test efficiencyMeasurement instrument housingEngineeringTest fixture

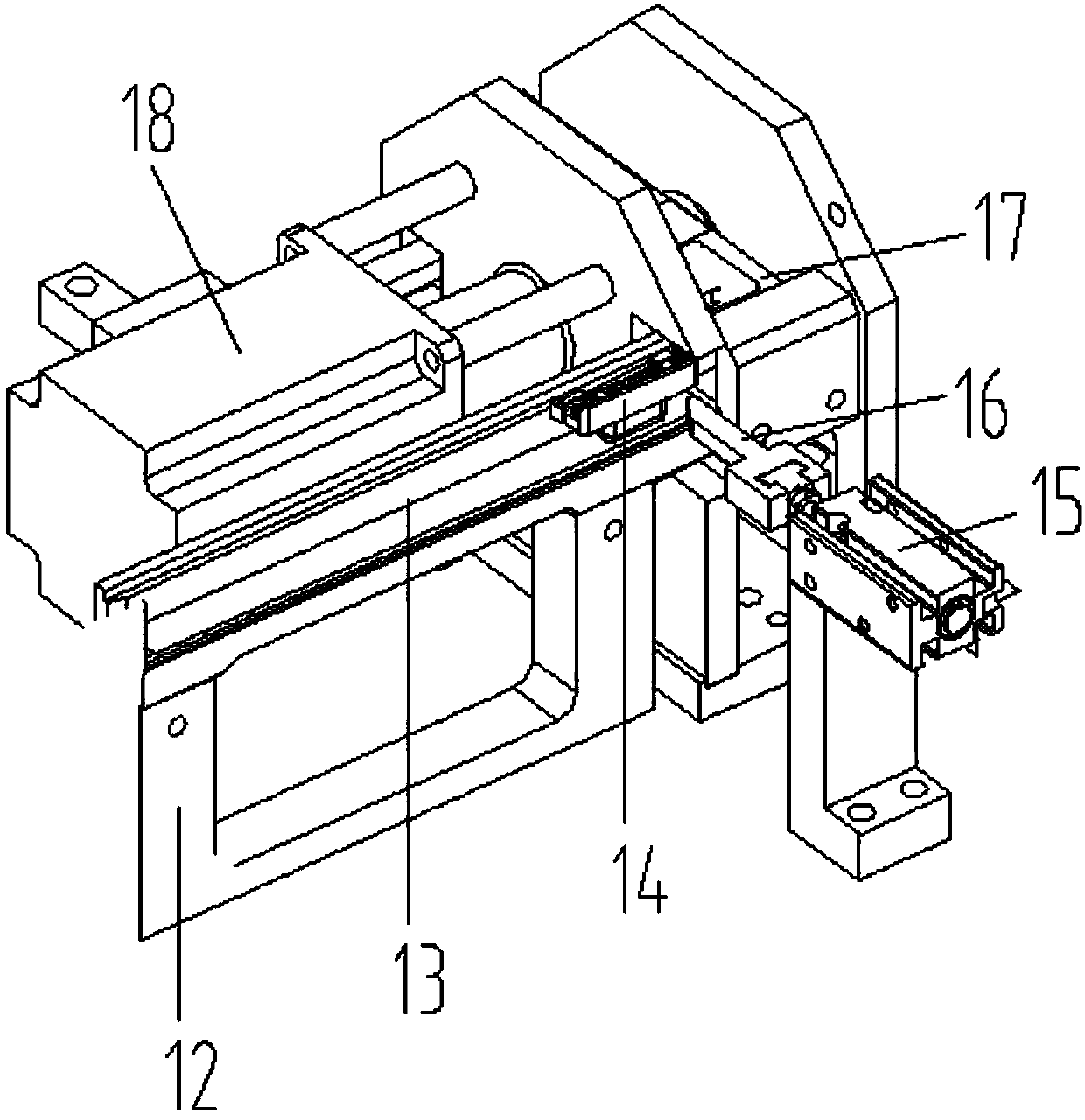

The invention discloses a universal test fixture for surface mounted technology (SMT)-based diode components, which comprises fore-and-aft sliding type positioning sliders, an elastic test probe module and a pull-out base plate. The fore-and-aft sliding type positioning sliders are composed of two sliders that are symmetrically arranged front and back. The two sliders are driven by screw-nut pairs arranged at the bottom thereof to move in opposite directions. The movable pull-out base plate is arranged close to the bottom. The left end of the movable pull-out base plate is connected with a reset device. On the pull-out base plate, the elastic test probe module is arranged between the two sliders. The elastic test probe module comprises a left test probe and a right test probe, wherein the two test probes are elastically flexible and are arranged right opposite to each other. According to the technical scheme of the invention, a to-be-tested component is placed in a variable placement groove. Under the fastening effect of the elastic test probes and the separating effect of the pull-out base plate, the to-be-tested component can be quickly replaced and tested. Meanwhile, by means of the two variable sliders and an elastic pressing bar, to-be-tested components of different specifications can be tested. Therefore, the testing efficiency and the testing precision are greatly improved. The universal test fixture is simple in structure, convenient to operate and use, and low in price.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

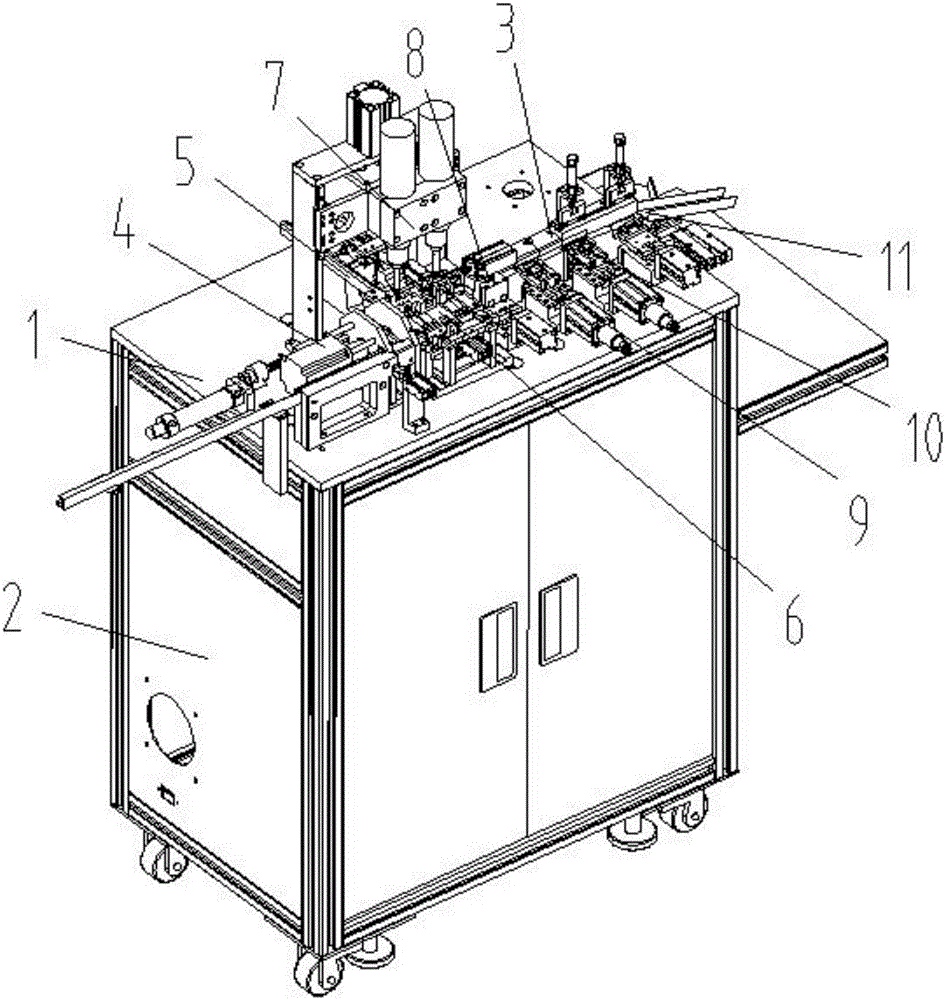

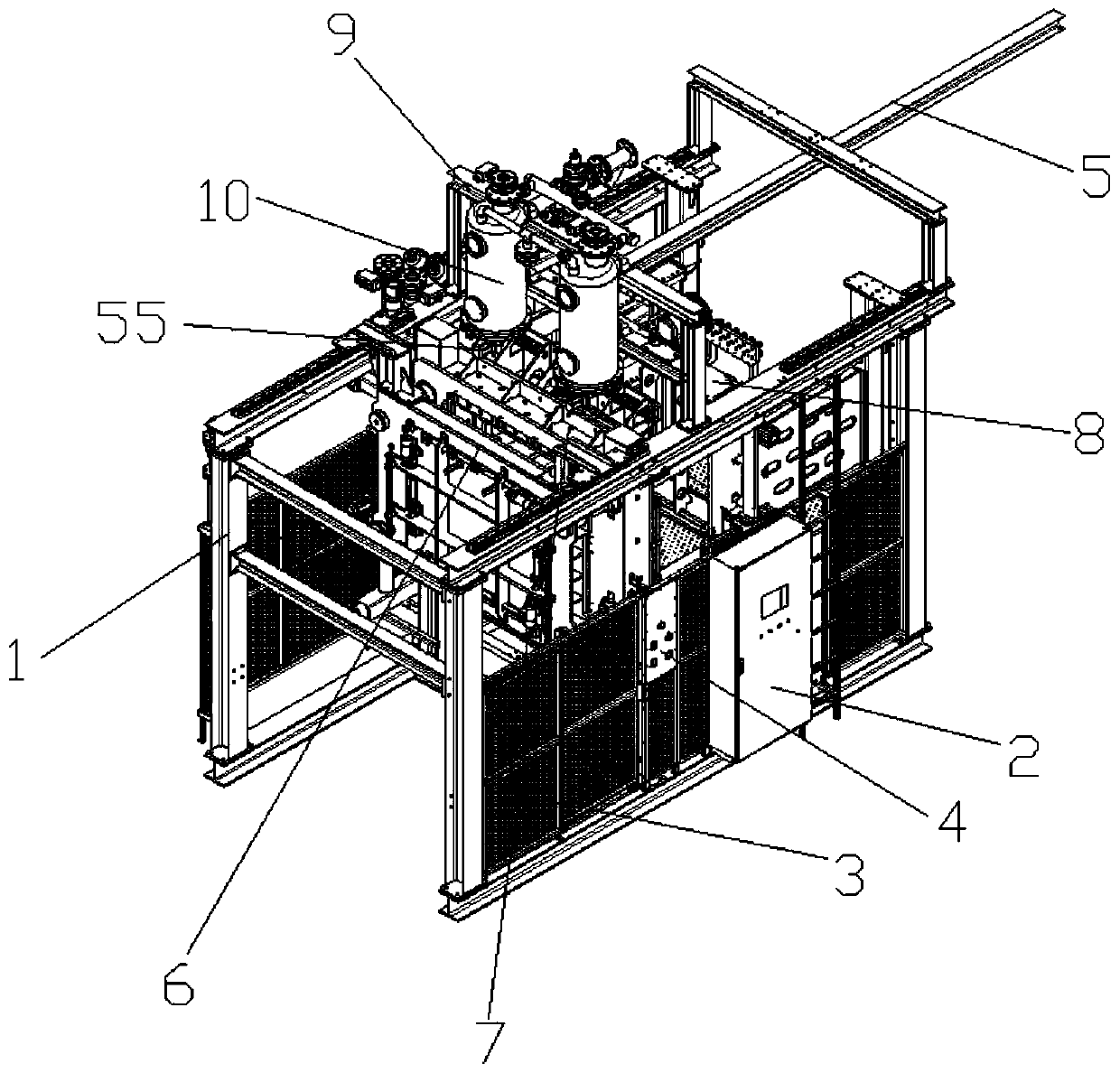

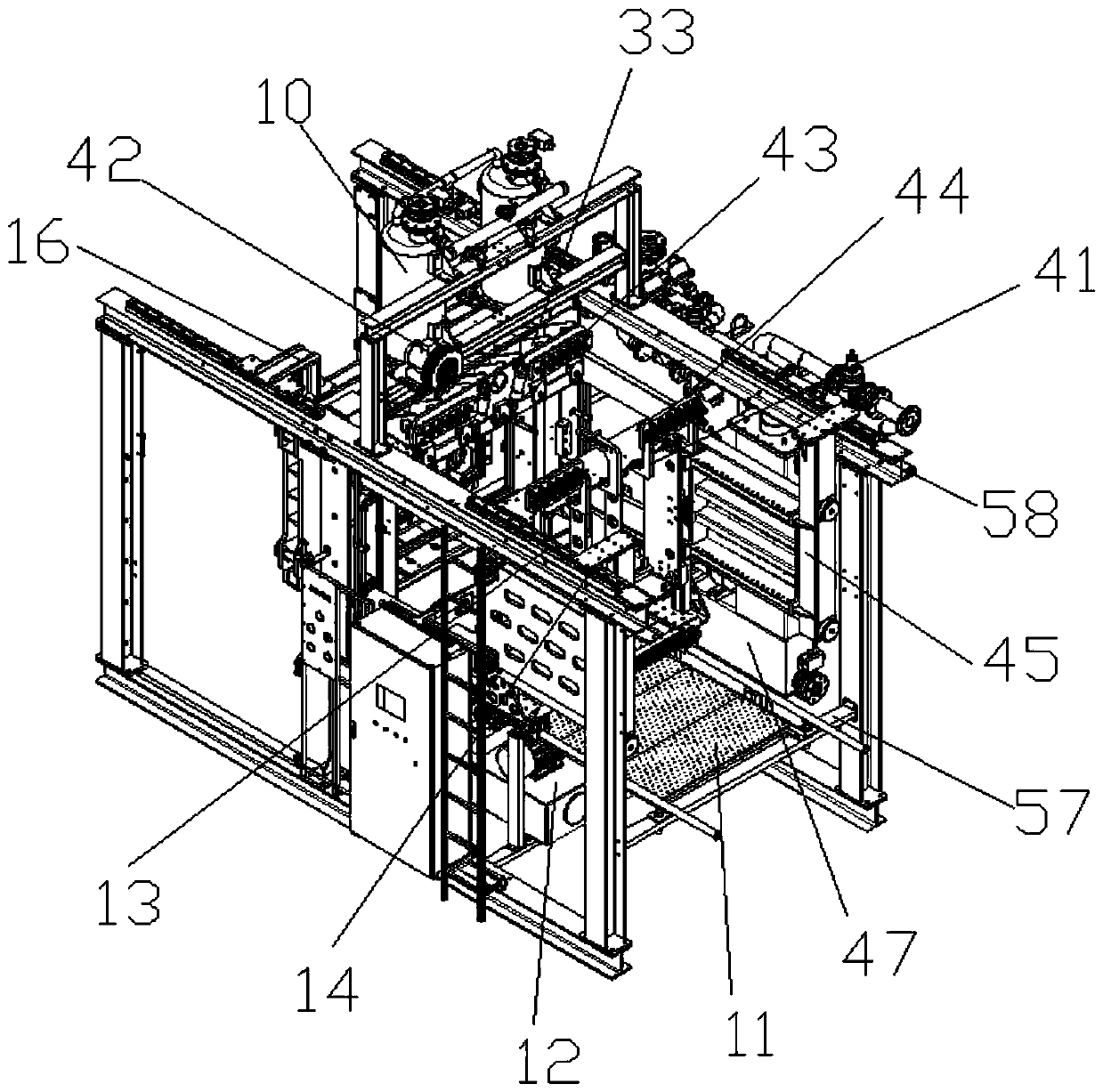

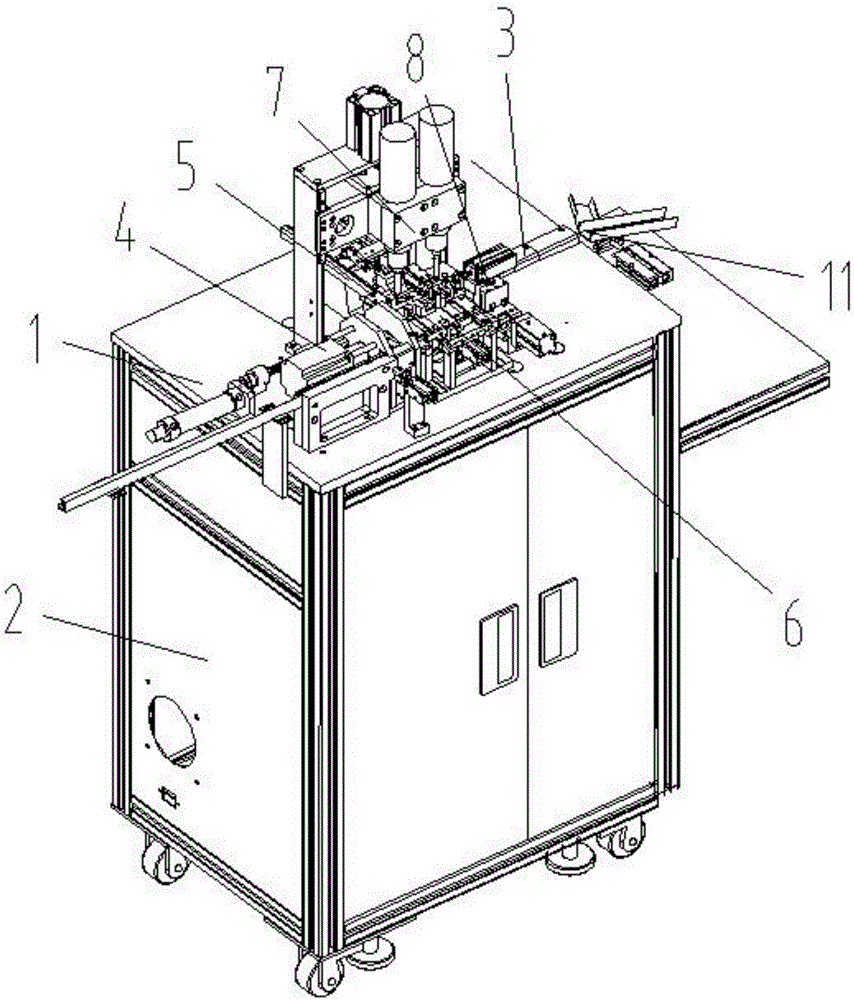

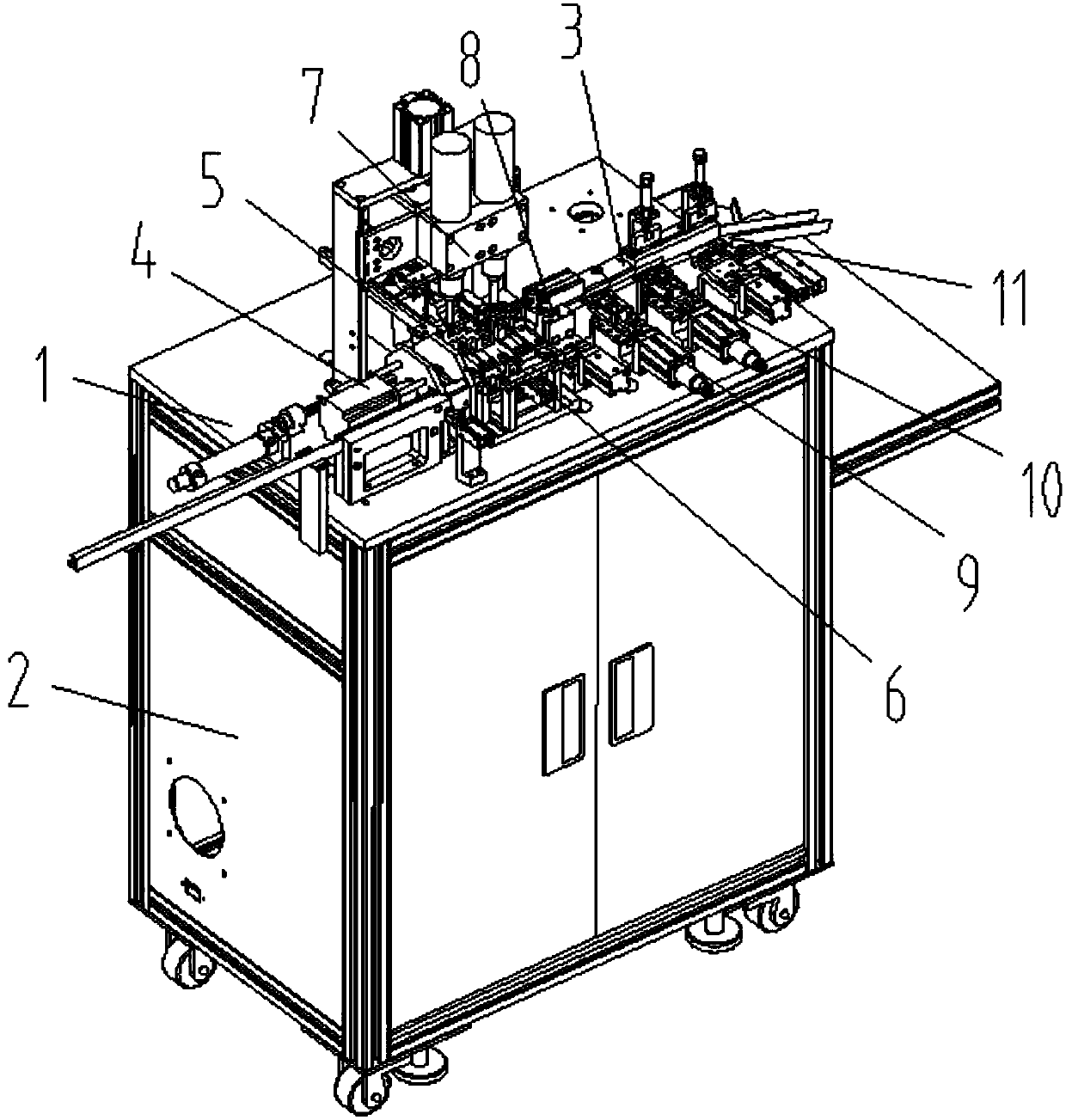

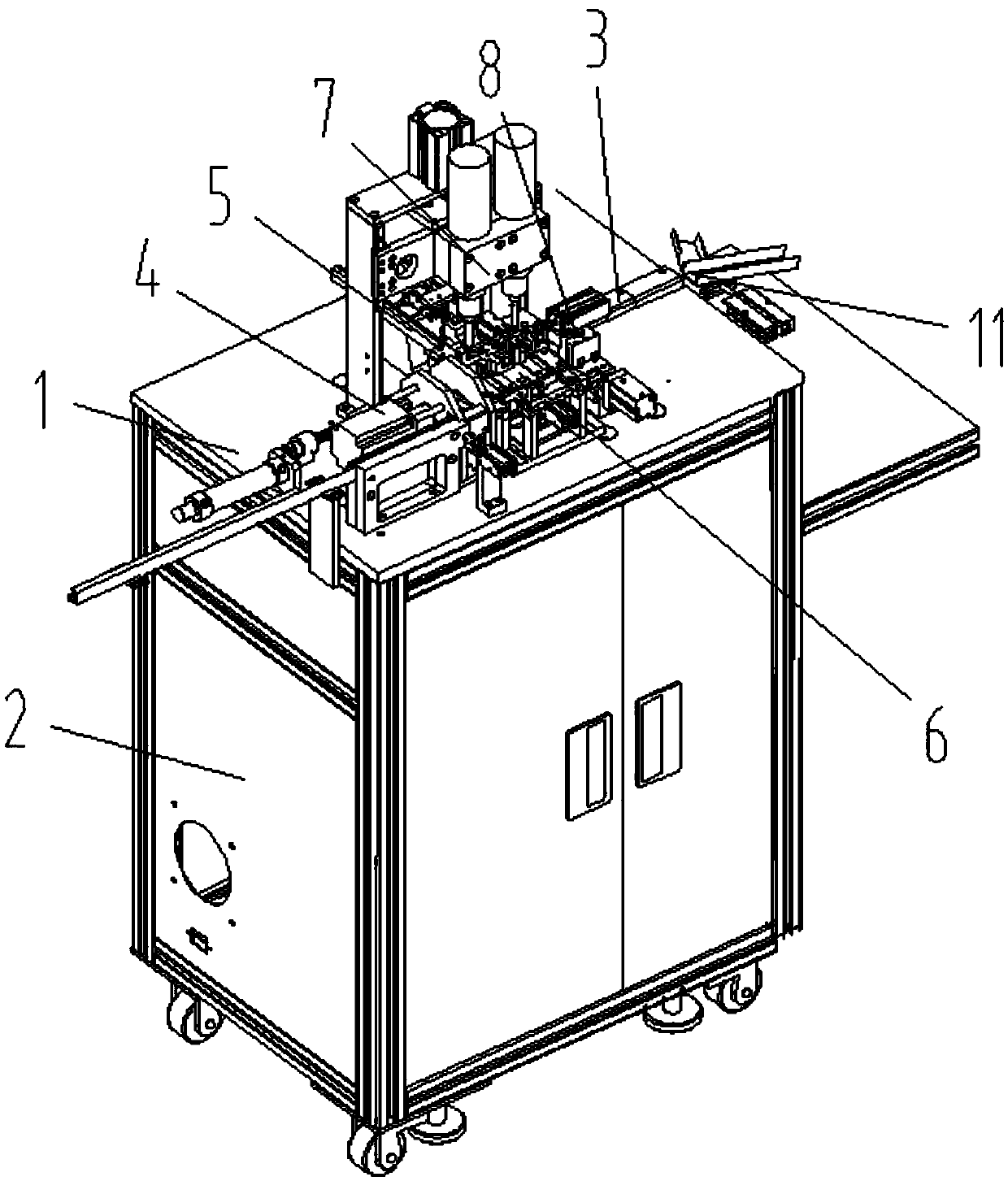

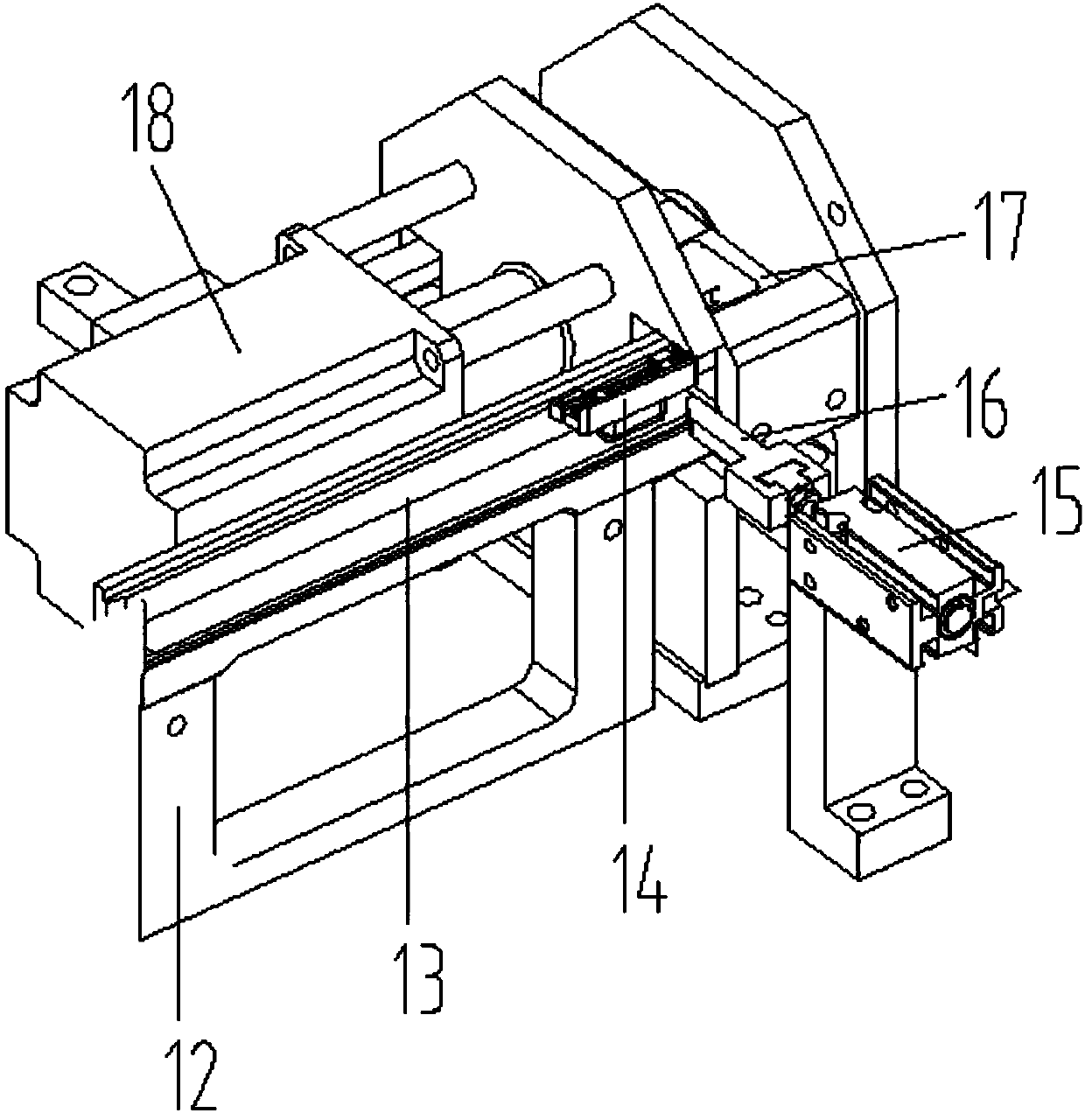

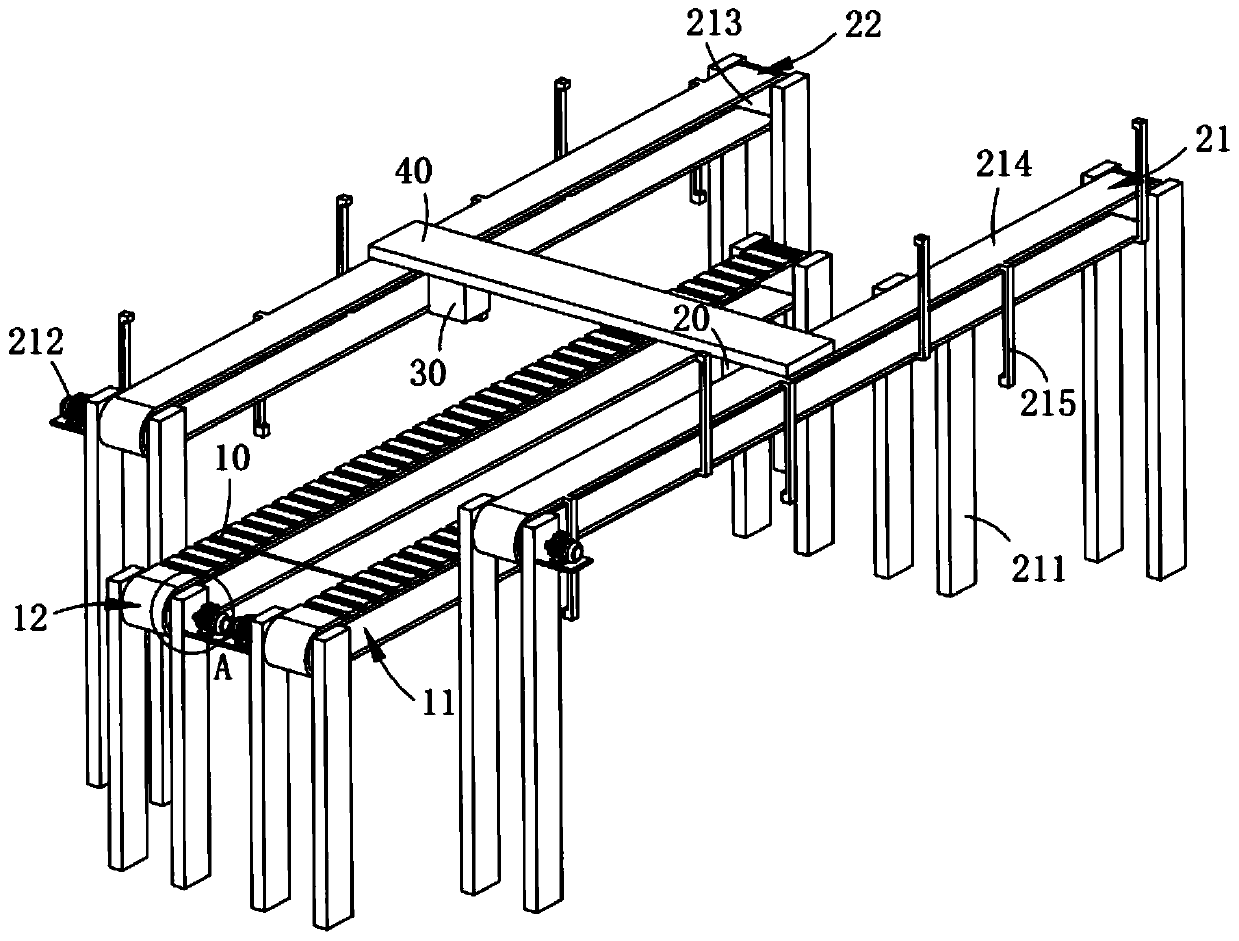

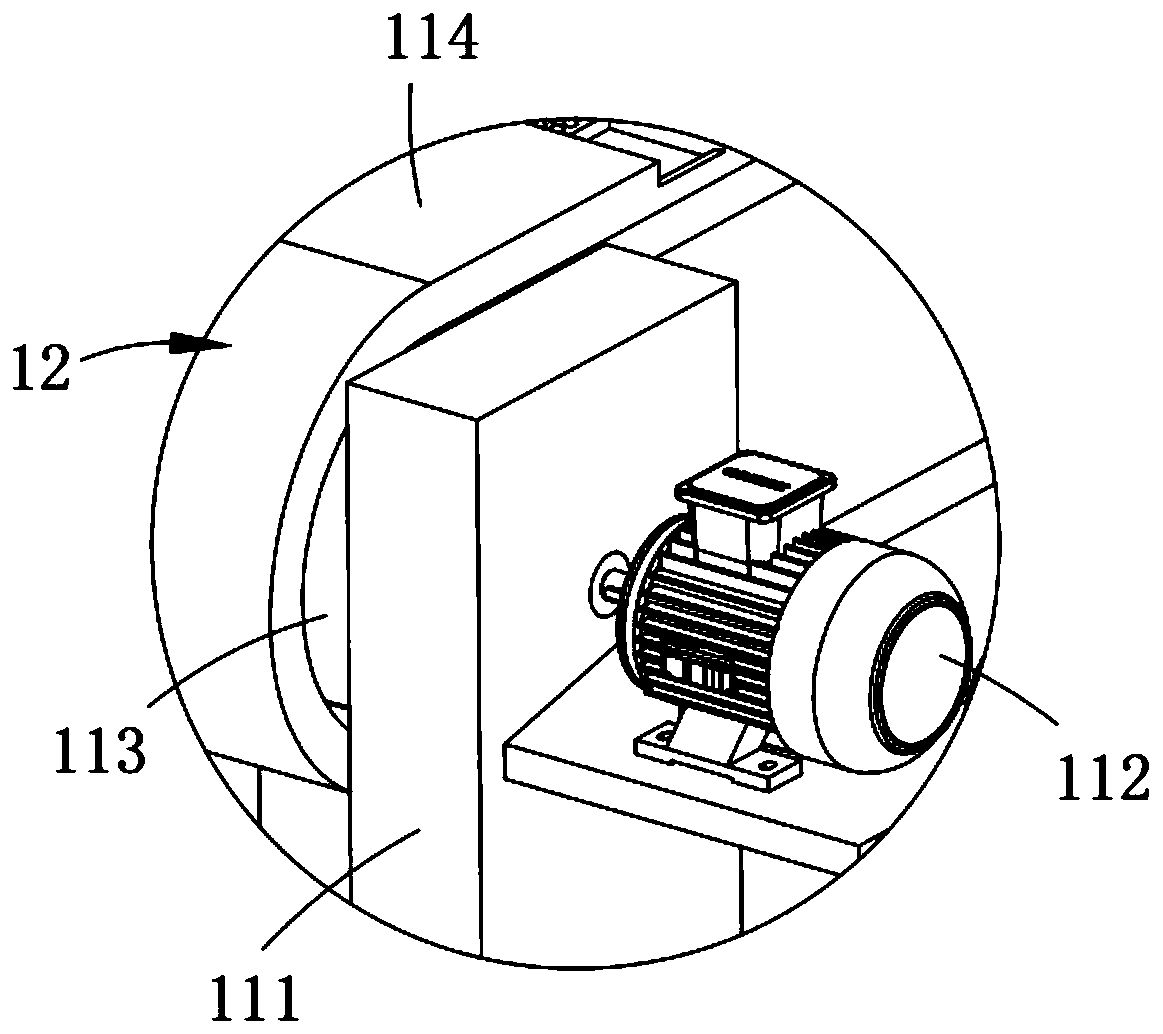

Full-automatic integrated processing machine of video graphics array (VGA) interface

ActiveCN106684669APrecise bending angleRealize automatic integrated processingContact member manufacturingContact member assembly/disassemblyGraphicsDistribution control

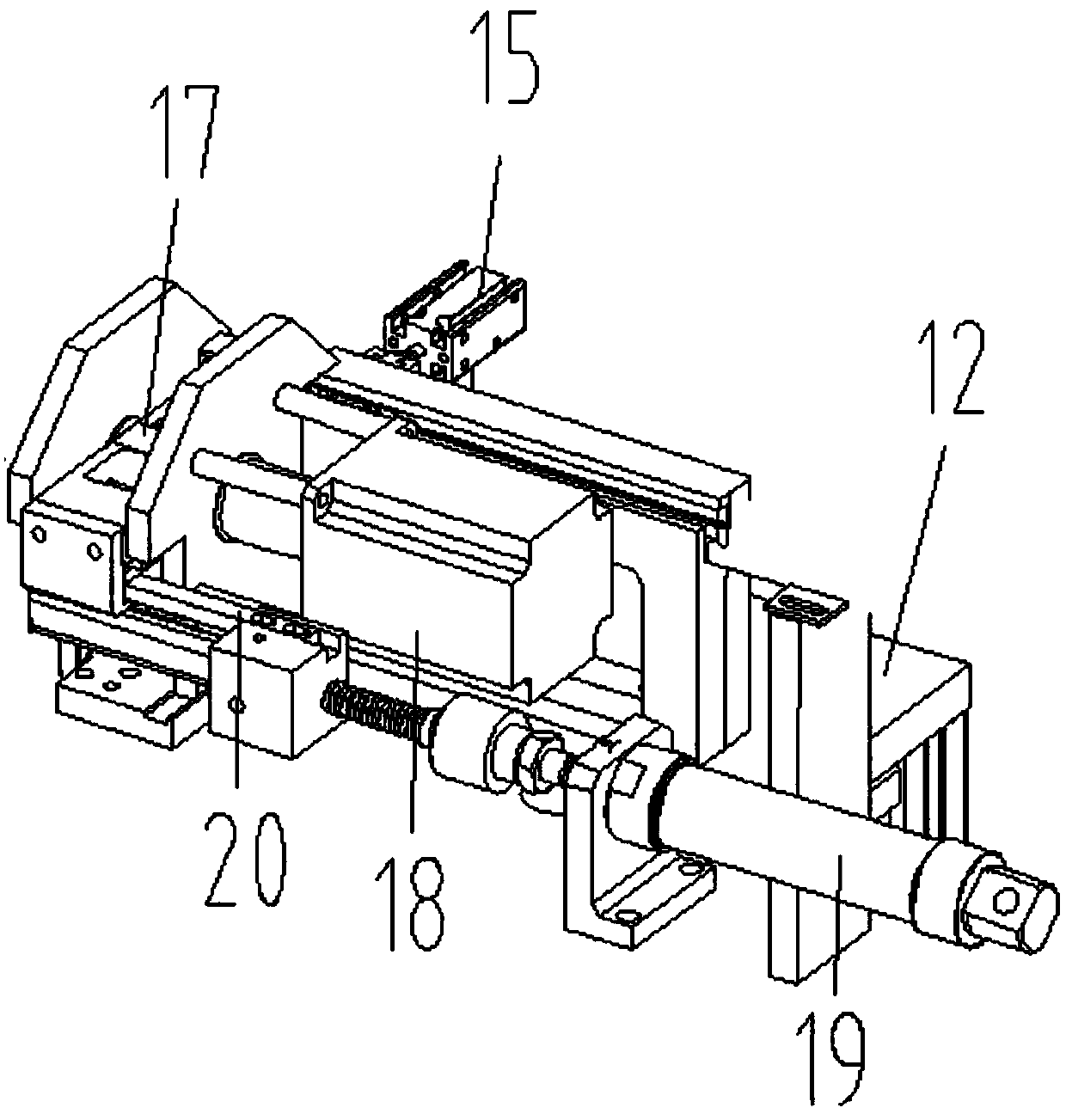

The invention relates to a full-automatic integrated processing machine of a video graphics array (VGA) interface. The full-automatic integrated processing machine comprises a rack and a power distribution control box, wherein a transmission groove is formed in the rack and is matched with a product, a clamping device, a bolt loading device and a bolt locking device are arranged at a left part of the transmission groove and are matched with one another, an upper bending device and a lower bending device are arranged at a right part of the transmission groove and are matched, detection devices are arranged at a left side of the upper bending device and a right side of the lower bending device, the upper bending device comprises an upper bending air cylinder, an upper bending block is connected with the upper bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an outer side, the lower bending device comprises a lower bending air cylinder, and a lower bending block is connected with the lower bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an inner side. By the full-automatic integrated processing machine, automatic integrated processing is achieved, meanwhile, the accurate bending angle of a terminal can be ensured, detection leakage is prevented, and the processing efficiency is improved.

Owner:秦轩汽车科技(天长)有限公司

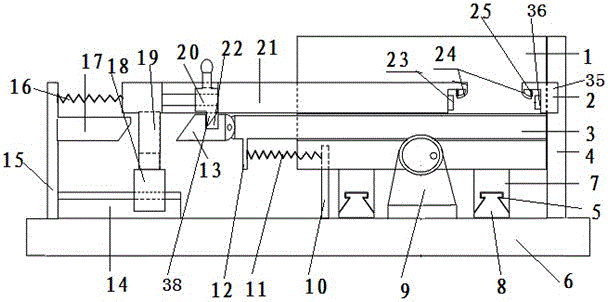

Novel vacuum foam-plastic hydraulic molding machine with double-rod oil cylinders

The invention discloses a novel vacuum foam-plastic hydraulic molding machine with double-rod oil cylinders. The novel vacuum foam-plastic hydraulic molding machine comprises a rack, an electric control cabinet, an instrument panel, a moving mold assembly, a fixed mold assembly, a mold mounting rack, a hydraulic oil tank, a rapid mounting rack, a condenser and a motor. The motor is mounted on thehydraulic oil tank. The moving mold assembly comprises a moving mold frame, a moving mold sliding block connecting plate and a moving mold heat isolation plate. A moving mold air inlet pipe and a moving mold drainage pipe are arranged on one side of the moving mold frame. Mold connecting rods and a moving mold steam outlet are mounted on the moving mold heat isolation plate. The moving mold frameis connected with the rack through the moving mold sliding block connecting plate. The fixed mold assembly comprises a fixed mold frame and a fixed mold fixed plate. The fixed mold frame is fixed to the rack through the fixed mold fixed plate. The two double-rod oil cylinders are mounted on the two sides of the fixed mold frame correspondingly. Piston rods of the double-rod oil cylinders are connected with the moving mold frame and the rapid mounting rack. Mold mounting is convenient, mold locking can be rapidly completed after mounting, automatic production is achieved, production efficiencyis high, and manufactured vacuum foam plastic is good in quality and uniform in size and density.

Owner:杭州阿司特智能机械有限公司

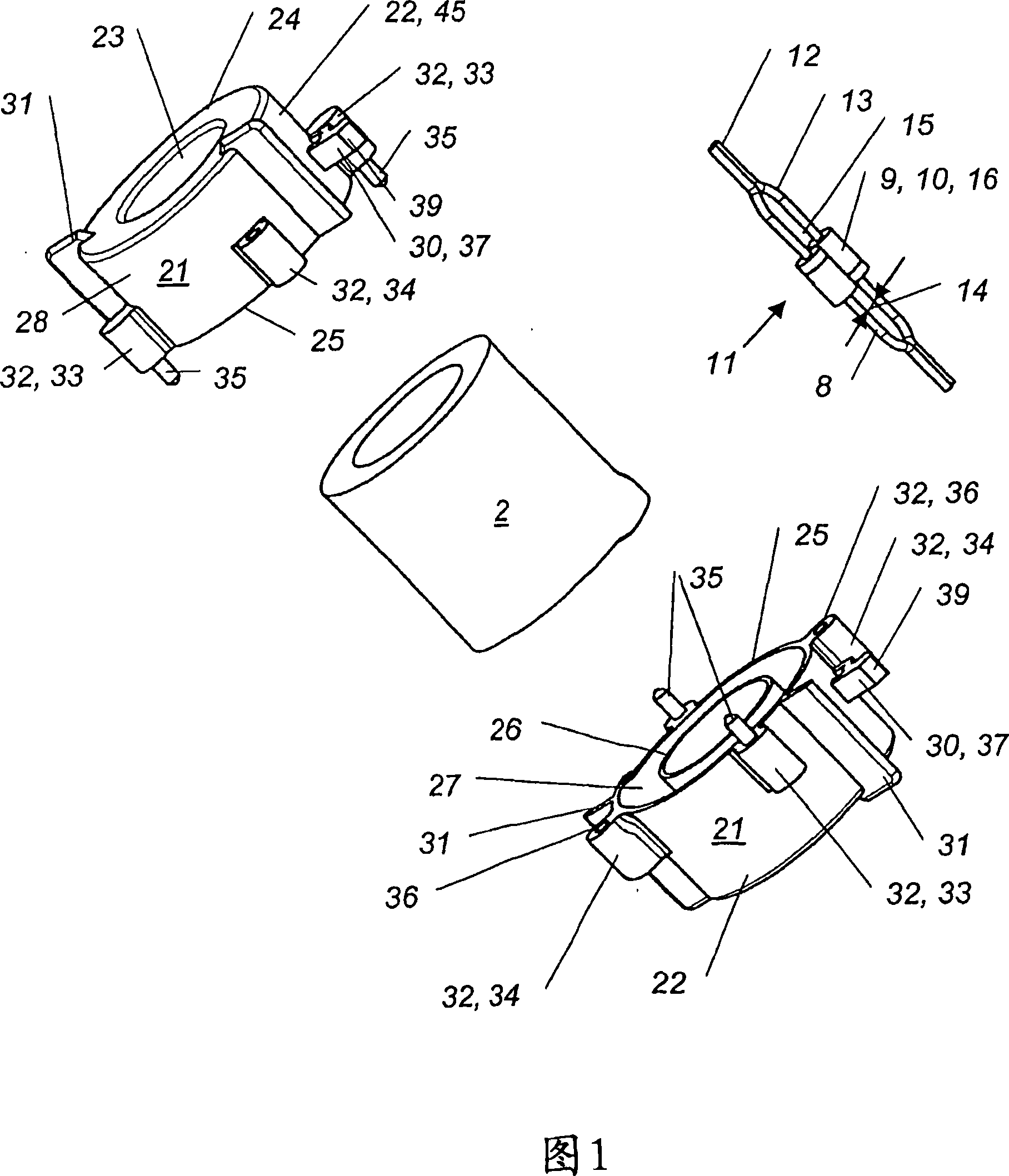

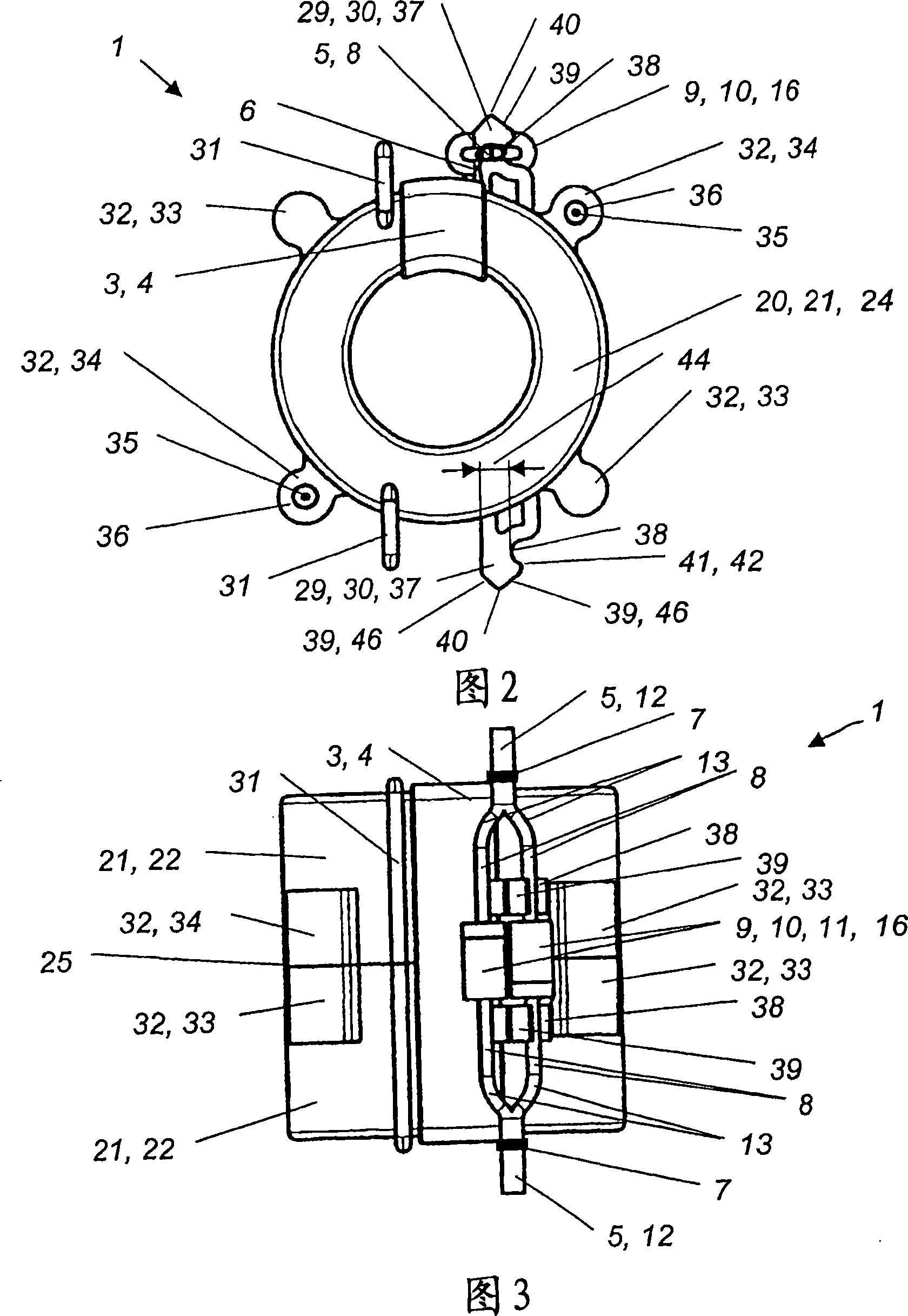

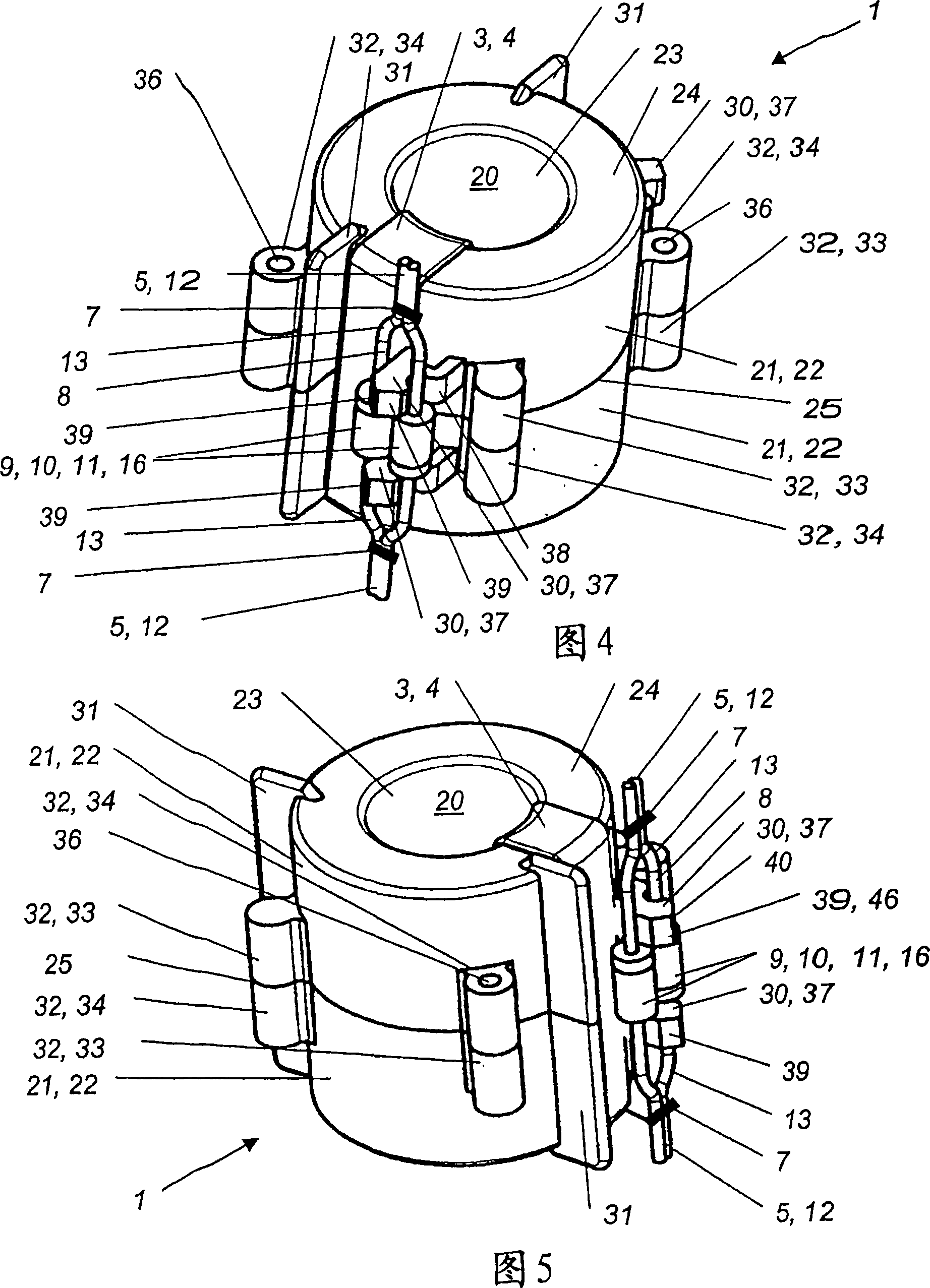

Housing

InactiveCN101073129AHigh degree of automationReduce manufacturing costsTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

The invention relates to a housing (20) for a magnet assembly (1), e.g. for housing a preferably annular magnetic core (2) of a differential current converter in a residual-current circuit breaker. According to the invention, the housing (20) consists of several parts and is configured from an insulation material. At least two conductive contacts (5) for connecting the ends (6) of at least one conductor loop (3), such as e.g. a secondary winding and / or a tertiary winding (4) of the differential current converter are configured on the housing. To improve the automated production of residual-current circuit breakers, the conductive contacts are configured as connecting conductors (8) of at least one electronic component.

Owner:MOELLER GEBAUDEAUTOMATION KG

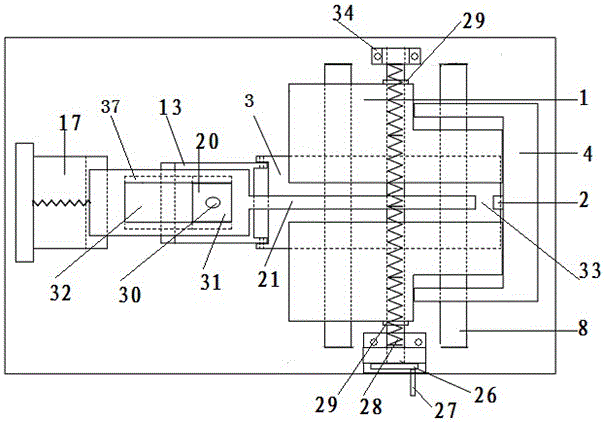

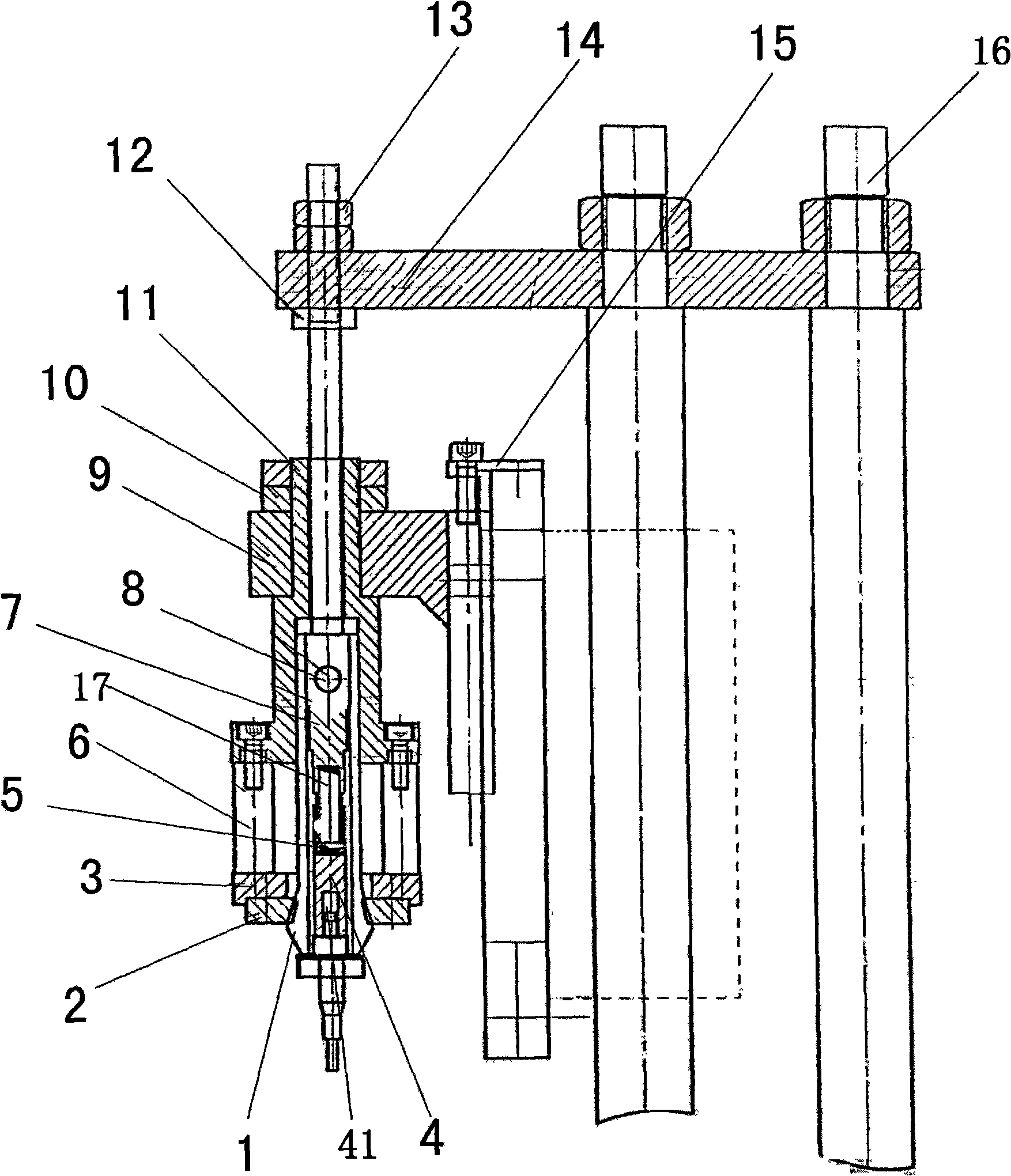

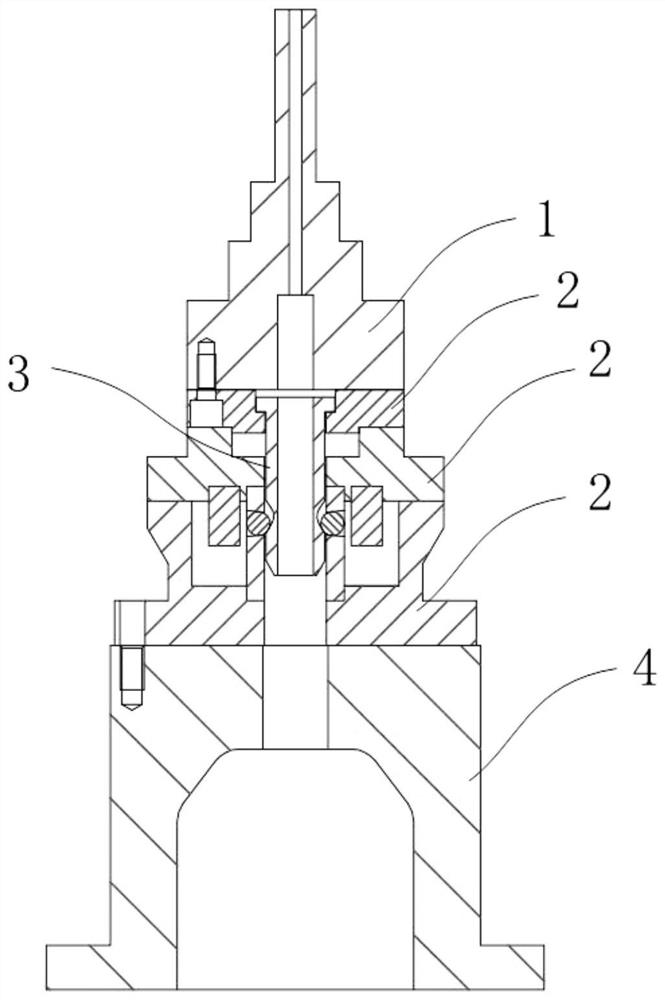

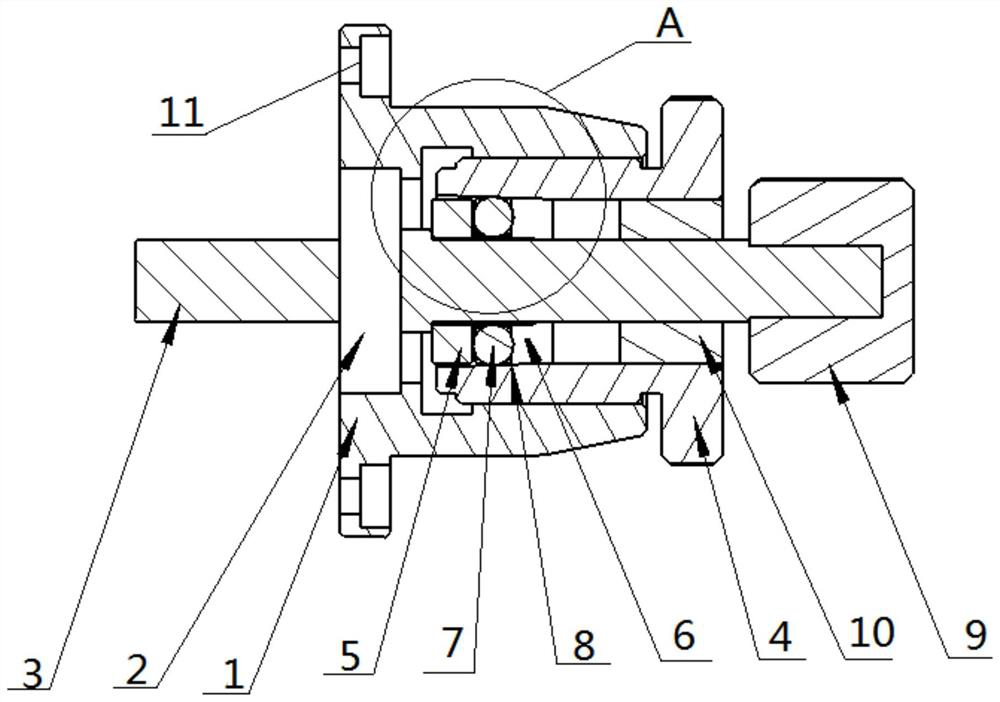

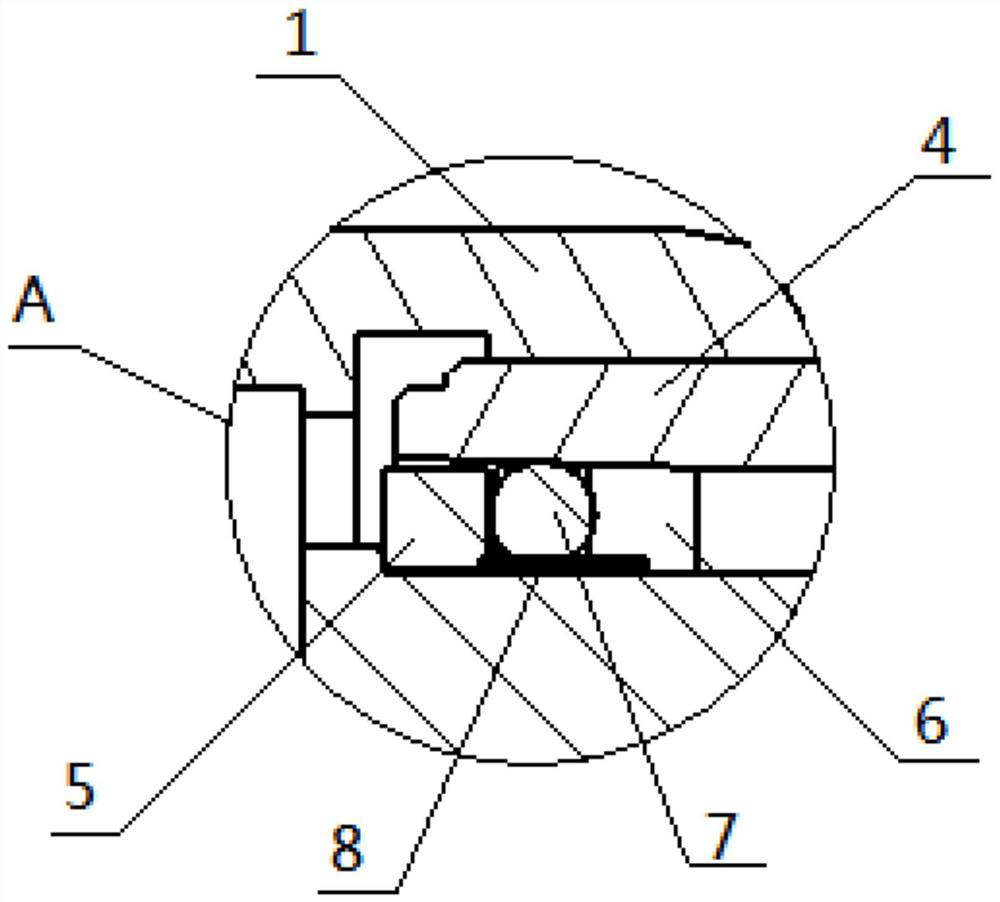

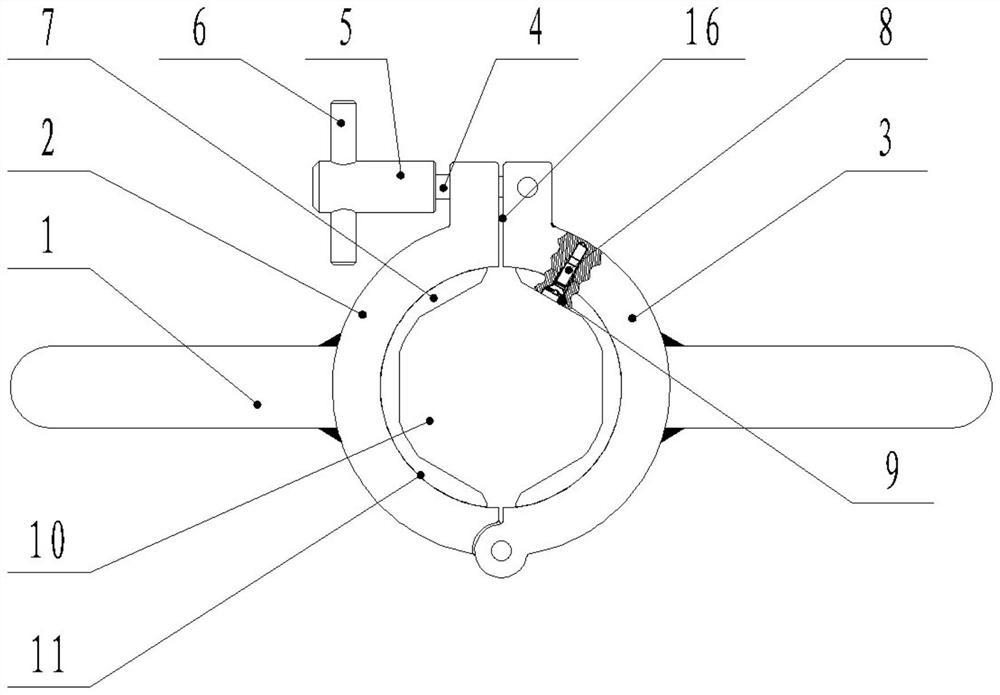

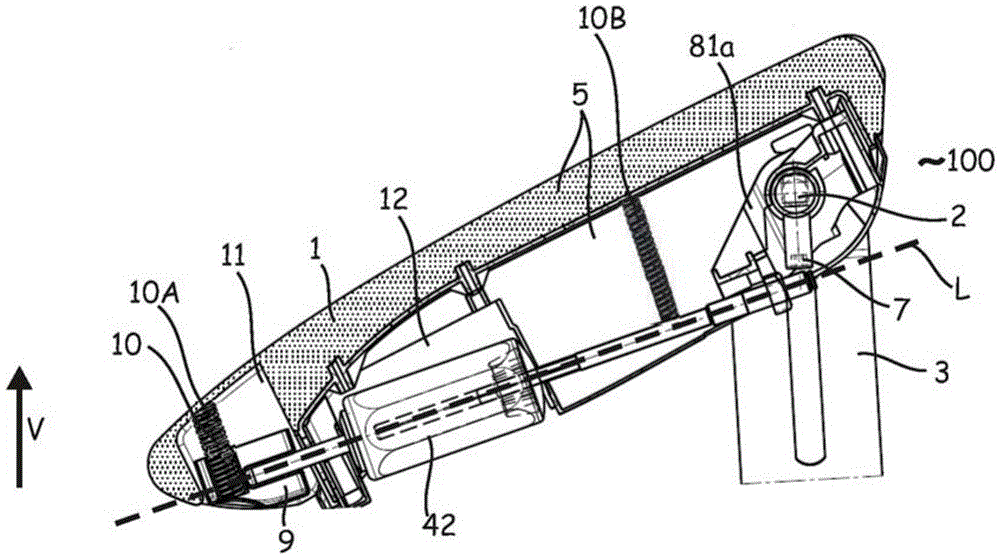

Gripper mechanism for spray pump locking notch machine

The invention relates to a gripper mechanism for a mouth locking machine of a spray pump. The gripper mechanism comprises a fixed plate, a retaining block, a gripper sleeve supporting seat, a gripper sleeve fixed sleeve, a gripper sleeve, a pull rod, a gripper, a positioning sleeve and a compression spring; wherein, the fixed plate is arranged on a guide pole; the retaining block is fixed on a master circular disc; the gripper sleeve supporting seat is fixed on the retaining block; the gripper sleeve fixed sleeve is arranged on the gripper sleeve supporting seat; the gripper sleeve is arranged on the bottom of the gripper sleeve supporting seat; the pull rod is arranged on the fixed plate and moves up and down along the fixed plate; the pull rod runs through the gripper sleeve fixed sleeve; the gripper is arranged on the lower end of the pull rod and moves up and down along the pull rod; the upper part of the gripper is positioned inside the gripper sleeve fixed sleeve; the lower part of the gripper runs through the gripper sleeve; the positioning sleeve is arranged on the lower end of the pull rod by a connecting pin and positioned inside the gripper; and the compression spring is arranged on the connecting pin and used for making the positioning sleeve return. Through the gripper mechanism, a lock mouth of the spray pump body and an aluminum shell is changed from semiautomatic assembly to full automatic assembly; the positioning sleeve can pre-guide the pump body rightly in order that the tight locking between the pump body and the aluminum shell is more accurate; the gripper mechanism has wide application range and high working efficiency, reduces assembling cost and greatly lightens the labor intensity of laborers.

Owner:上海飞弘自动化设备有限公司

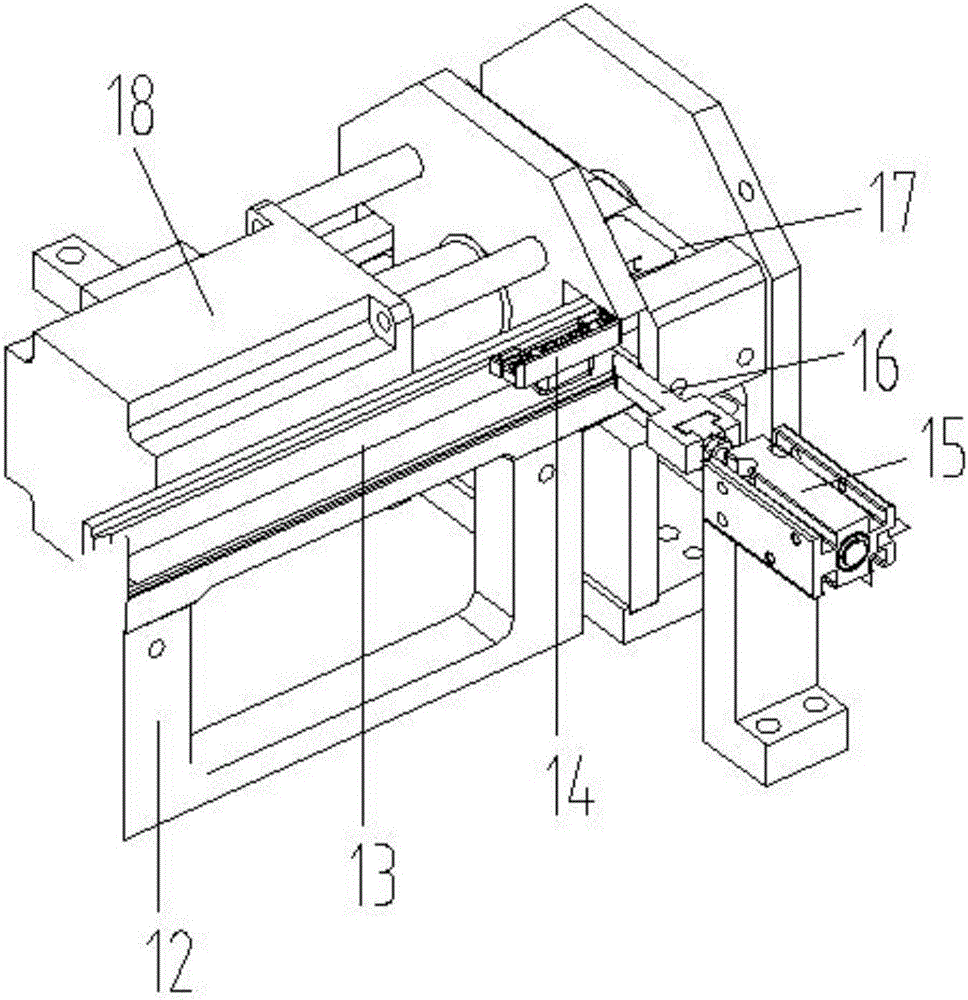

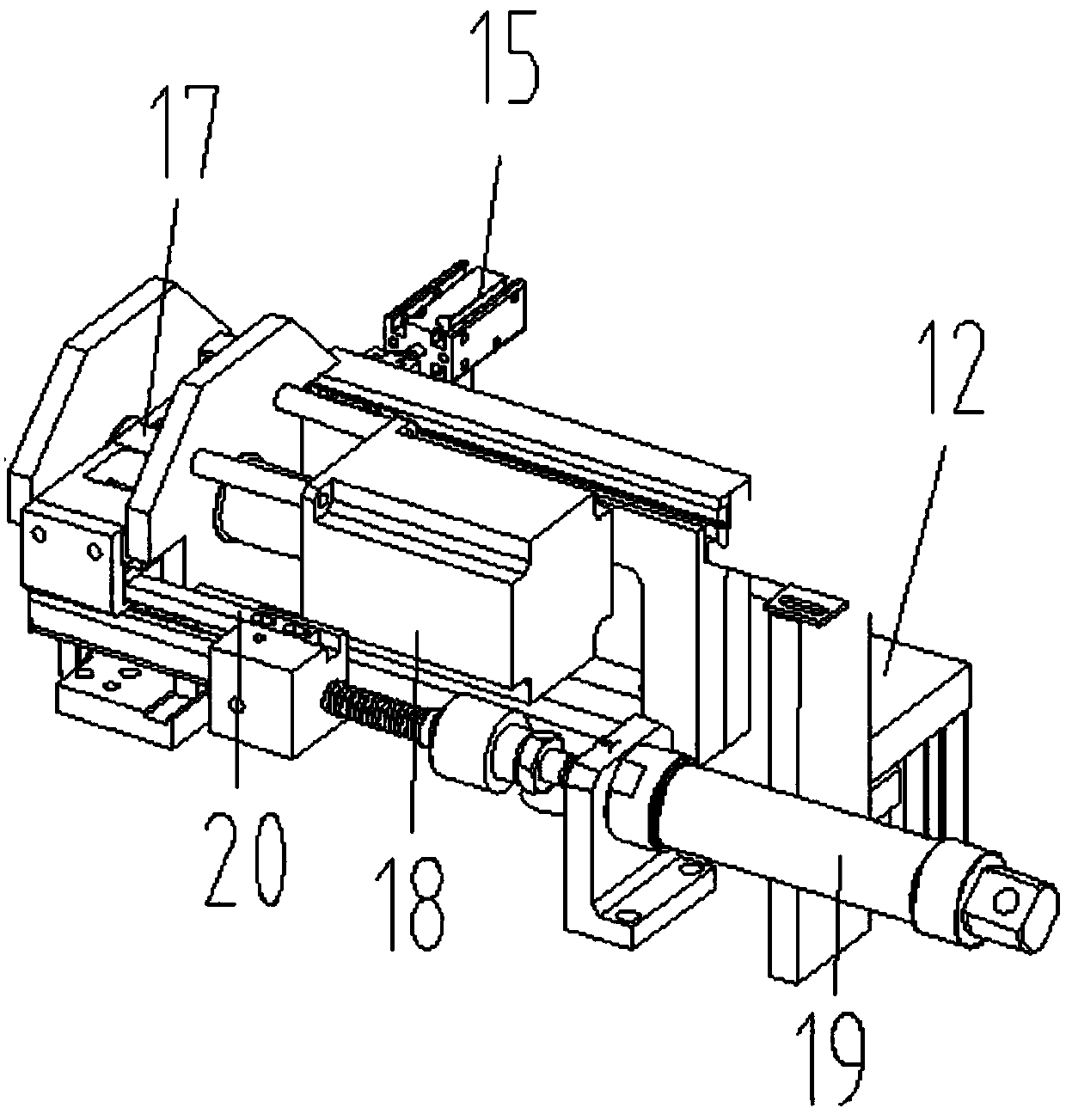

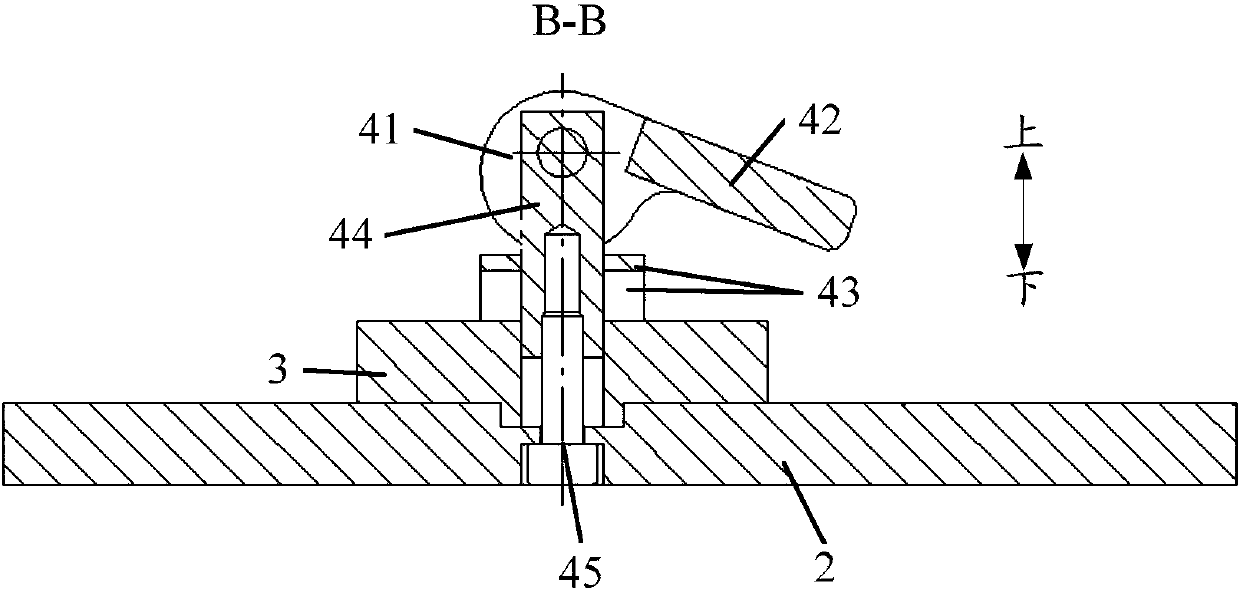

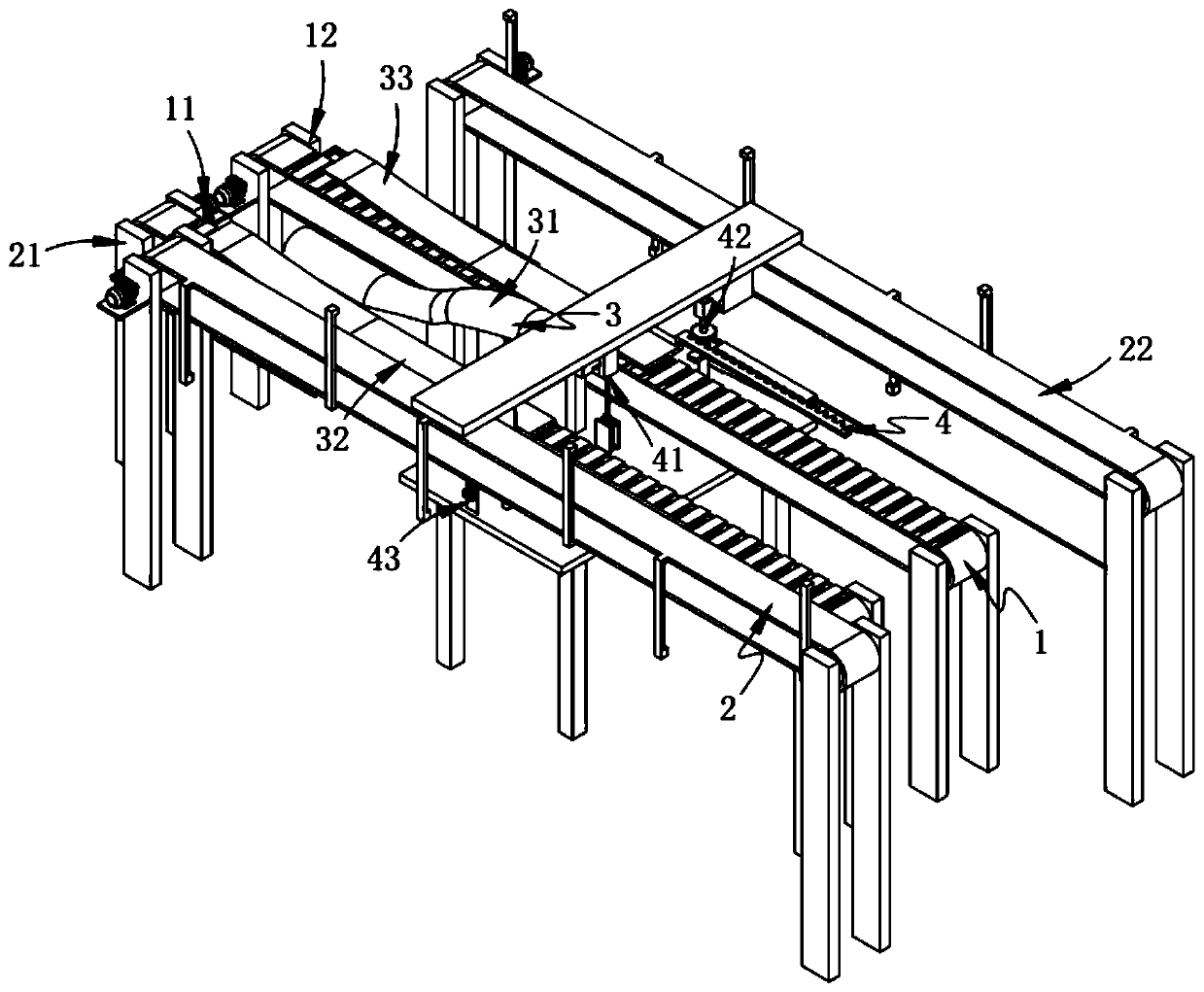

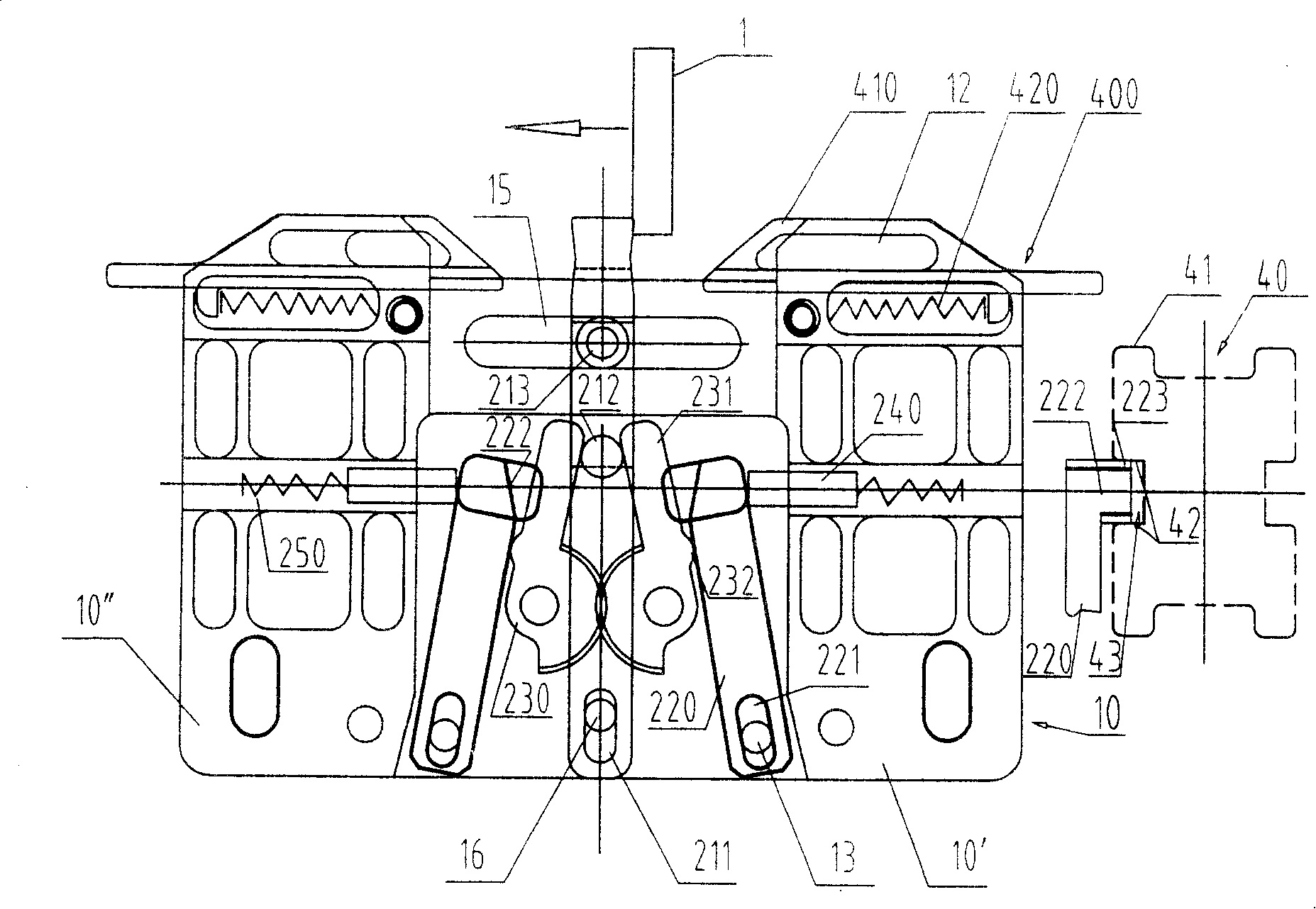

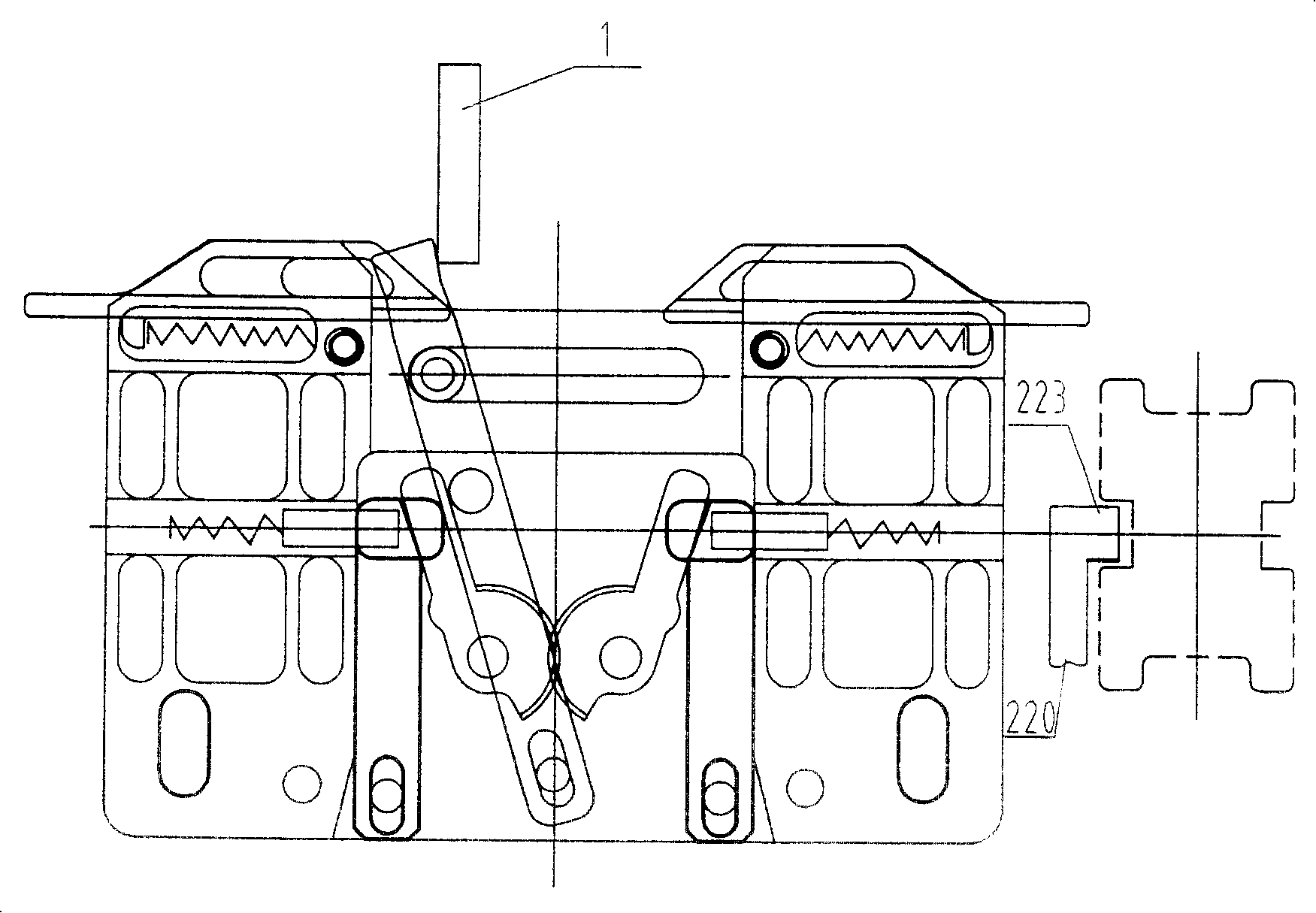

Automatic locking detection mechanism with VGA port

ActiveCN106624752APrecise lockingRealize automatic integrated lockingSortingMetal working apparatusDistribution controlLocking mechanism

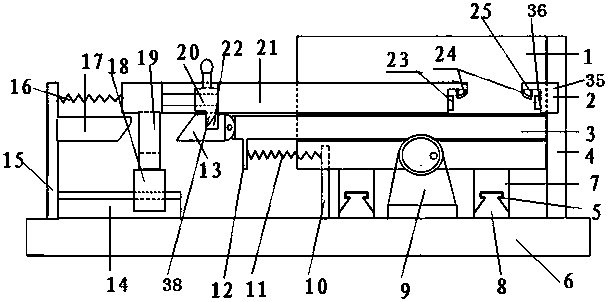

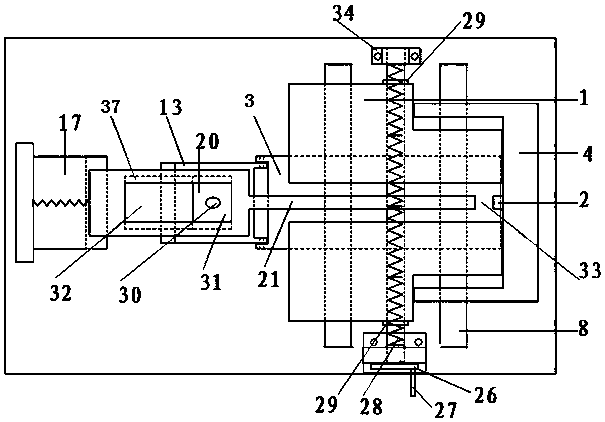

The invention relates to an automatic locking detection mechanism with VGA port which includes a rack and a power distribution control box. The rack is provided with a convey trough coordinating productions. A chucking mechanism, a bolt feeding mechanism and a bolt locking mechanism, all of which interworks and disposed on the left of the convey trough. The right of the convey trough is provided with a detection mechanism. The upside of the chucking mechanism is provided with a locking positioning mechanism. The locking positioning mechanism comprises a bolt positioning air cylinder disposed on the front and back sides of the convey trough. The bolt positioning air cylinder is connected with a set piece. A bolt set piece is located on the top of the convey trough. The connection of two bolt set pieces is provided with bolt positioning holes which match up bolts. The bolt positioning holes is coordinated with bolt open holes of productions of the convey trough. The automatic locking detection mechanism with VGA port realizes an automatic integration locking and detection and ensures precise place and tightening of the bolt at the same time and improves the yield of the bolt locking.

Owner:TIANCHANG GAOPENG EXPERIMENT EQUIP

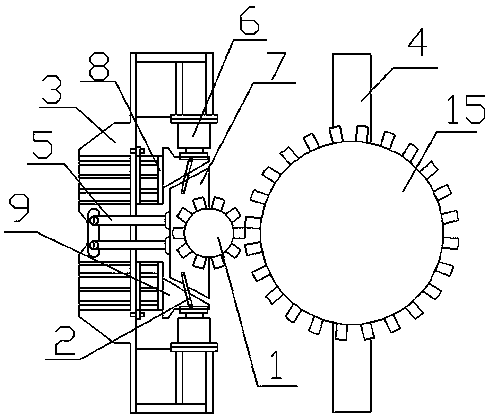

Milling machine ascending and descending locking device

InactiveCN103846686ATo achieve the purpose of lockingSimple structureLarge fixed membersHydraulic cylinderMechanical engineering

The invention discloses a milling machine ascending and descending locking device, which comprises a locking gear, a hydraulic cylinder, a support frame, a strut, a first driver and a second driver, wherein an ascending and descending gear is arranged on the strut, the locking gear is connected with the ascending and descending gear, the first driver is connected with the locking gear and drives the locking gear, a connecting part of the first driver and the locking gear is provided with a connecting plate, a chute is formed in the support frame, a wedge-shaped block is arranged on the chute, and is connected with the second driver, one end of the hydraulic cylinder is connected with the second driver, the other end of the hydraulic cylinder is connected with the connecting plate, in the use process, the transverse moving of the locking gear is controlled through the first driver, and the second driver controls the moving of the wedge-shaped block and the hydraulic cylinder for controling the position of the locking gear, so the locking goal is reached. The milling machine ascending and descending locking device has the advantages that the structure is simple, the locking is precise, the use and the installation are convenient, the operation is simple, and safety and reliability effects are realized.

Owner:杨永明

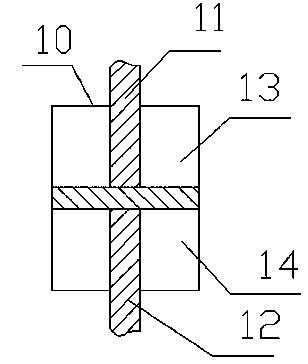

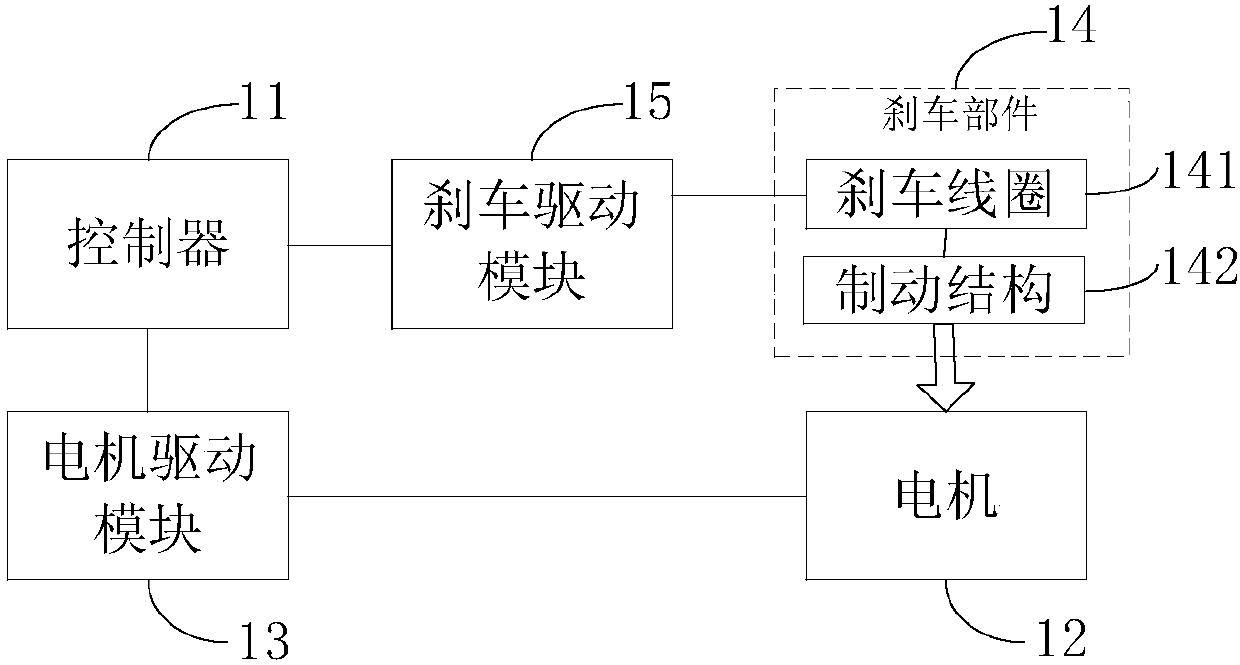

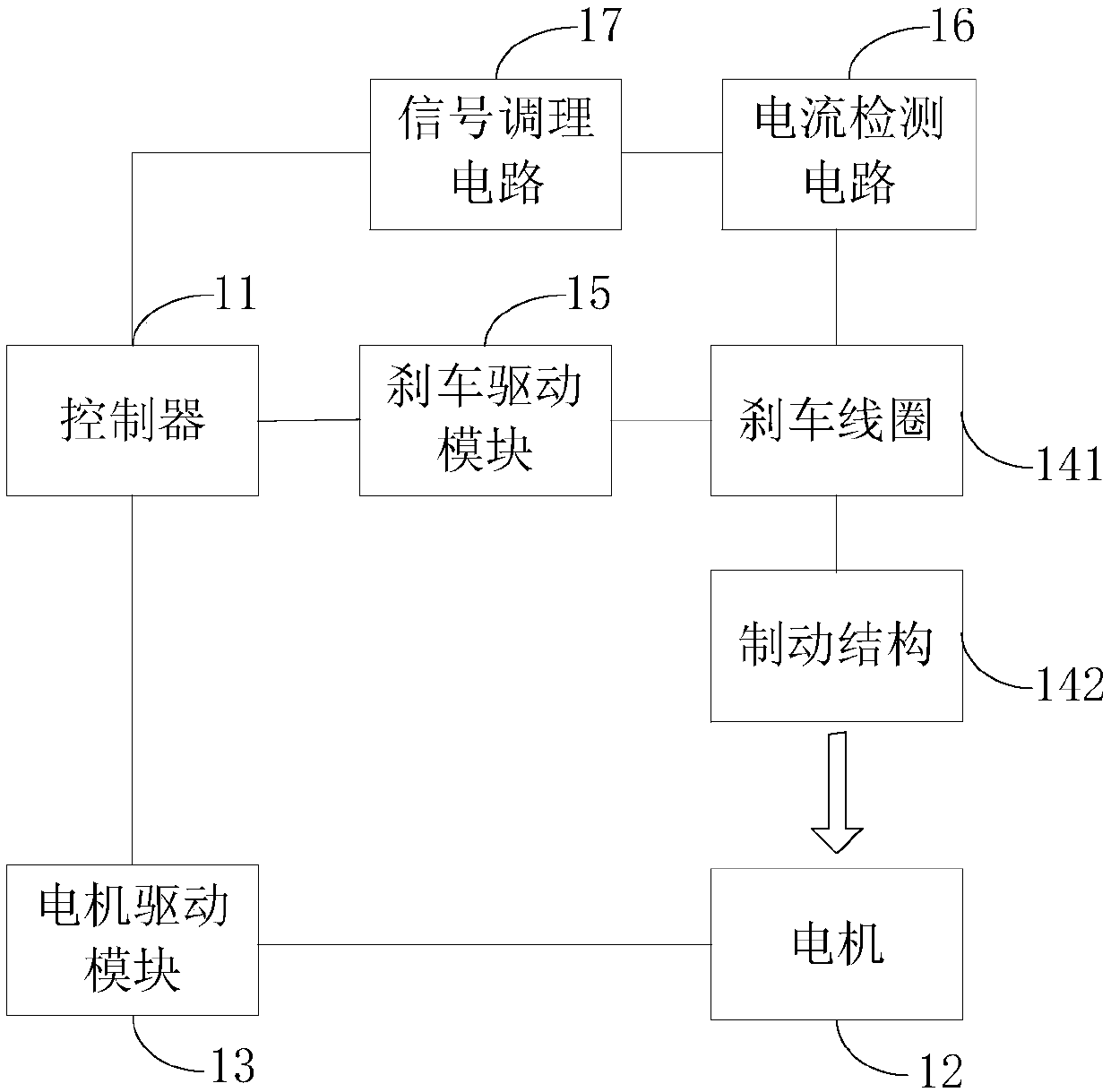

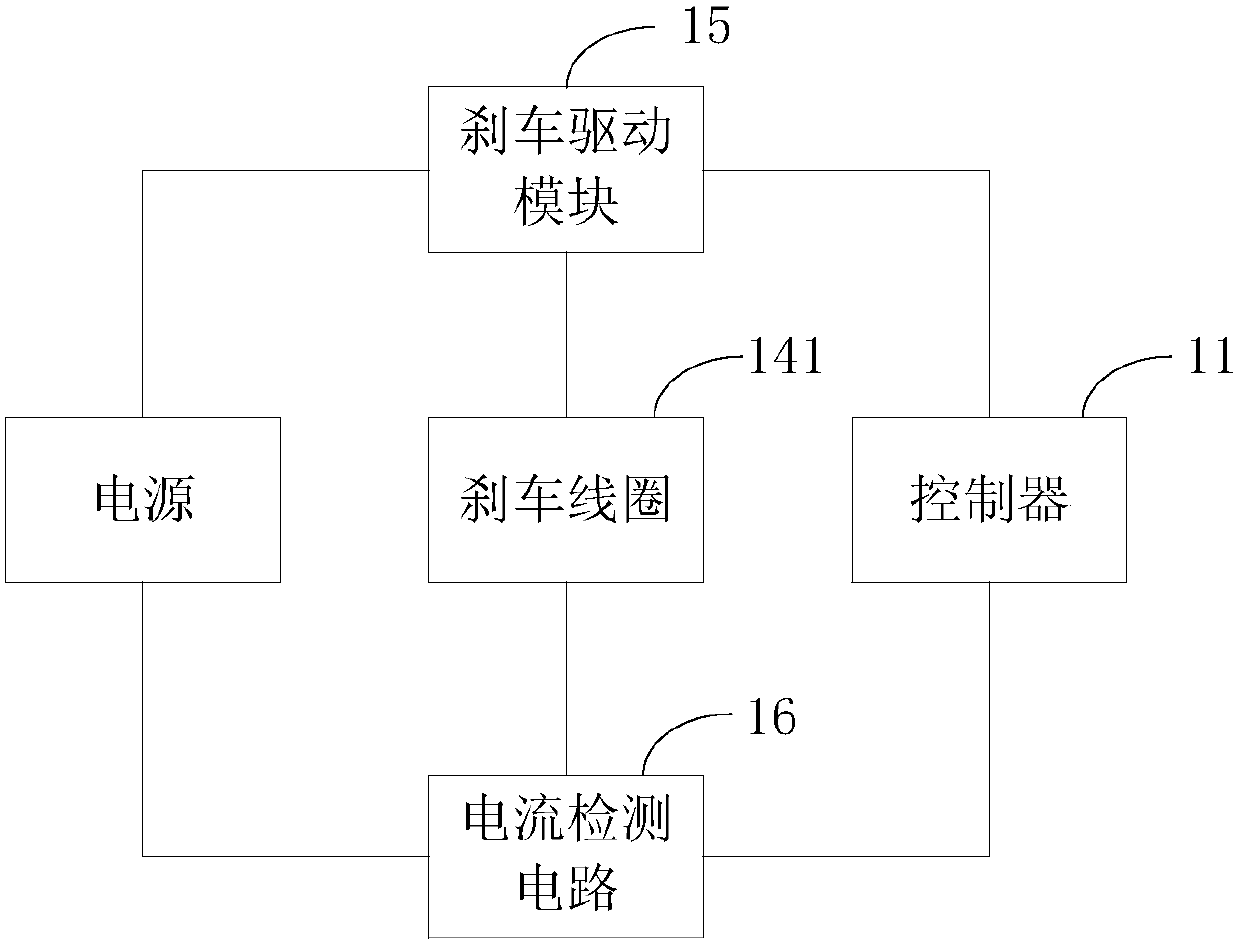

Holder and control method thereof

The invention discloses a holder and a control method thereof. The holder comprises: a controller, a motor, a motor drive module, a brake drive module, a brake coil and a brake structure; the controller is connected with the motor drive module and the brake drive module respectively; the controller is used for controlling the brake coil and the motor to be in a power-off state when the holder remains stationary for more than preset time, so that the brake structure brakes the motor; when the holder is unlocked, the controller controls the motor and the brake coil to be in a power-on state, sothat the brake structure is separated from the motor and the holder is unlocked. Therefore, after the controller applies a corresponding electrical signal to the brake coil to unlock the holder, the holder can be controlled accurately. In addition, the holder does not adopt a worm gear structure or a reduction motor, so high-speed rotation of the holder is not affected, and the problems of limit to the operation of the holder and low precision of a preset point are avoided.

Owner:ZHEJIANG DAHUA TECH CO LTD

Conveying device

The invention discloses a conveying device, and belongs to the field of automatic warehousing technologies and automatic production lines. The conveying device comprises an object carrying platform, an air-suspending platform and a controller; a magnetic component is arranged at the bottom of the object carrying platform; the air-suspending platform comprises an air valve module and an electromagnetic module which are arranged in the air-suspending platform; an air outlet is formed in the top of the air-suspending platform; an air inlet is formed in the side edge of the air-suspending platform; the controller is connected with the electromagnetic module; and under the electrification condition, the air valve module acts in a magnetic field generated by the electromagnetic module, and an airflow passage is formed among the air inlet, the air valve module and the air outlet, so as to generate air buoyancy to support the object carrying platform. The conveying device adopts modular design and is simple in wiring, precise positioning control and fixed position locking of the object carrying platform are realized, and conveying in any position can be realized.

Owner:沈路平

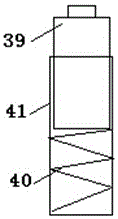

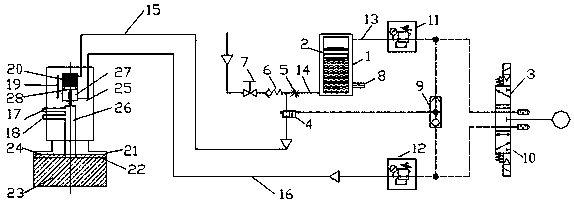

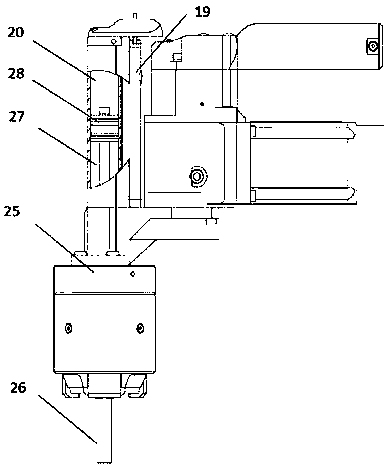

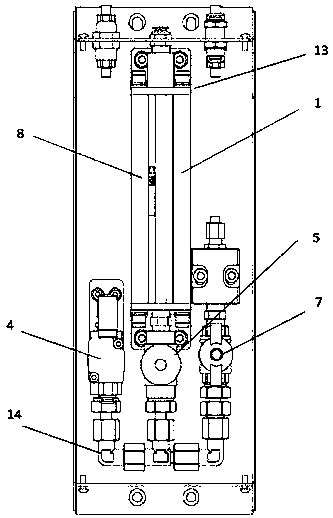

Method and system for accurately controlling position of liquid level pipe of filling head

InactiveCN110272014APrecise locking in any positionResolve locationLiquid transferring devicesControl systemEngineering

The invention provides a method and system for accurately controlling the position of a liquid level pipe of a filling head. According to the method, the liquid level pipe in the filling head extends out through hydraulic control and retracts through pneumatic control under the driving effect of liquid and gas double-medium composite action, so that the liquid level pipe is locked at any position. The control system comprises a hydraulic propulsion pipeline and a pneumatic retraction pipeline; the hydraulic propulsion pipeline is connected with an adjusting upper cavity of an actuating cylinder in the filling head, and the pneumatic retraction pipeline is connected with an adjusting lower cavity of the actuating cylinder in the filling head. According to the invention, the liquid level pipe extends and retracts through a process of air pressure-hydraulic pressure-hydraulic pressure-air pressure, air pushes liquid at first, then the liquid pushes the air, and when the liquid level pipe extends and retracts, running directions of fluids are opposite. Accurate control of the position of the liquid level pipe is realized, locking of the liquid level pipe at any position is realized accurately and reliably, and the problem of inaccurate position or repeated movement of the liquid level pipe under the action of filling pressure is solved.

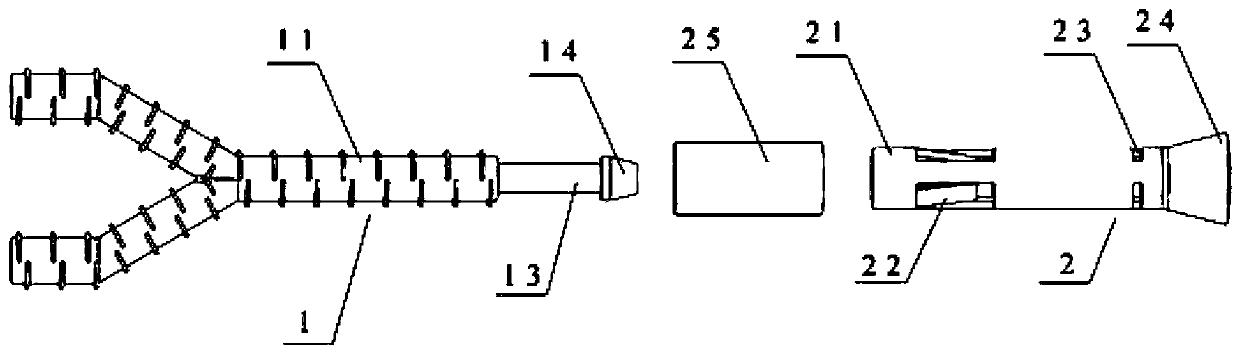

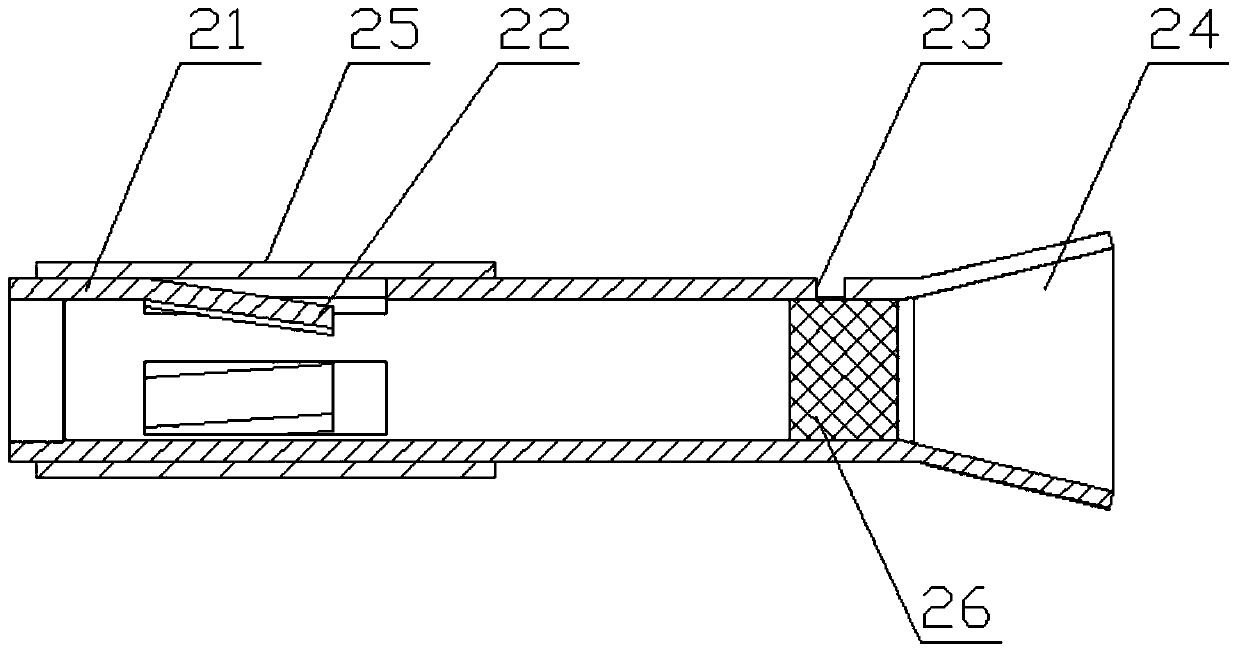

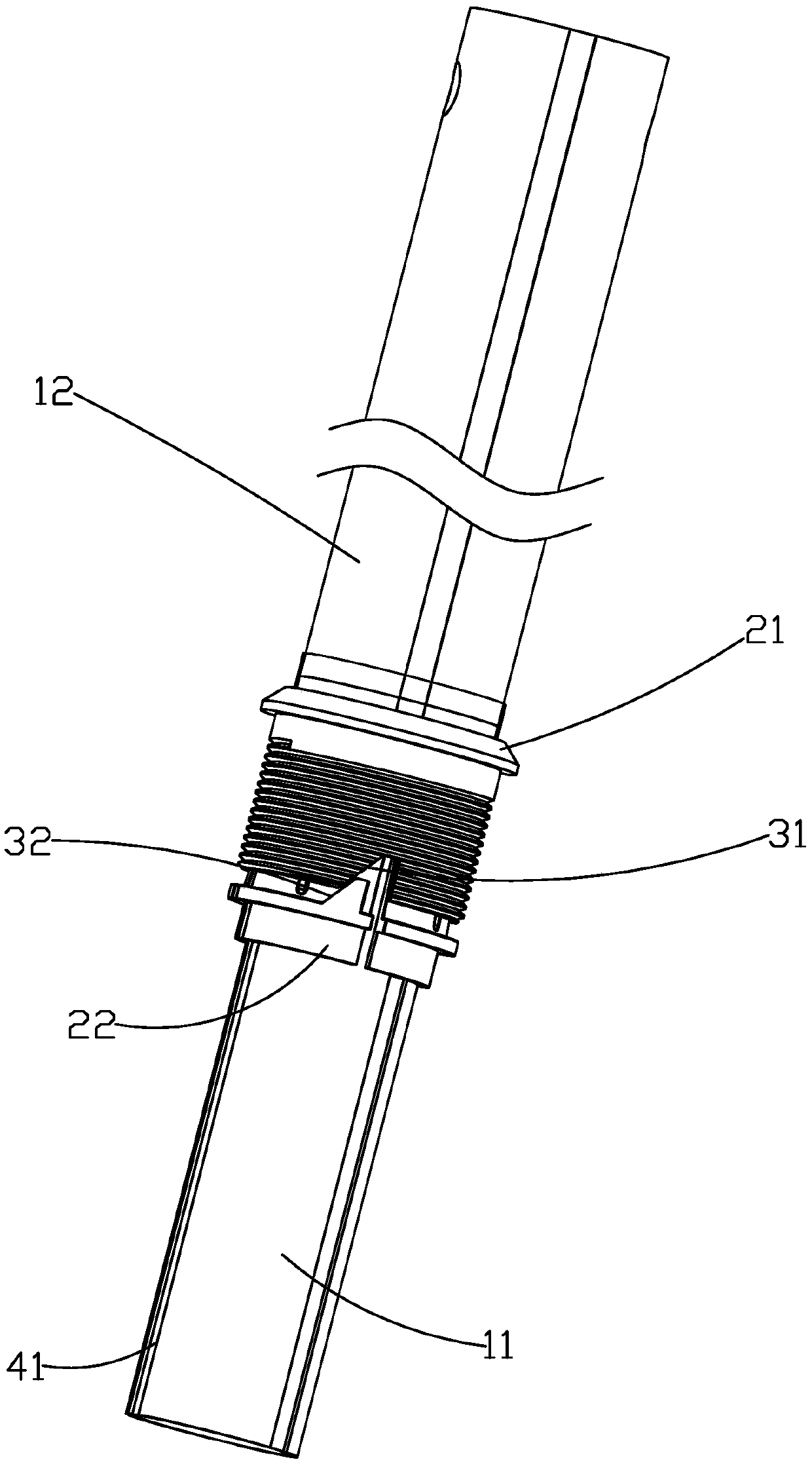

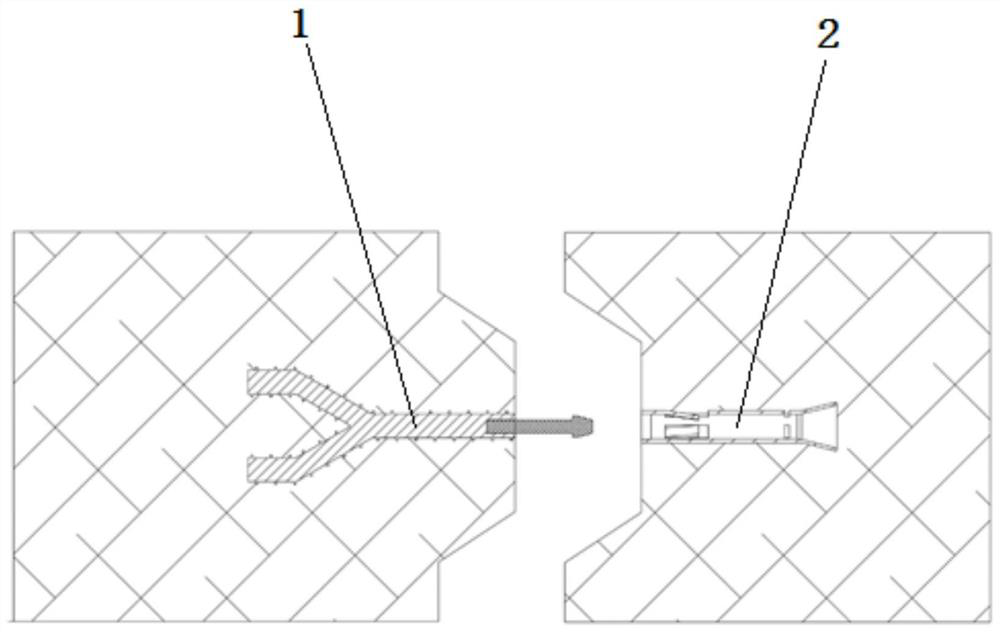

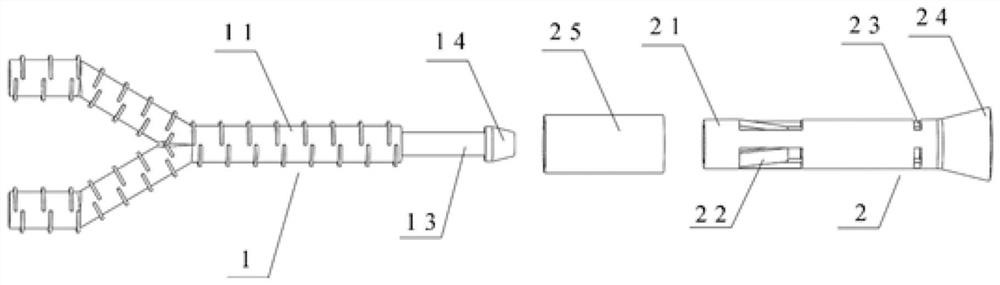

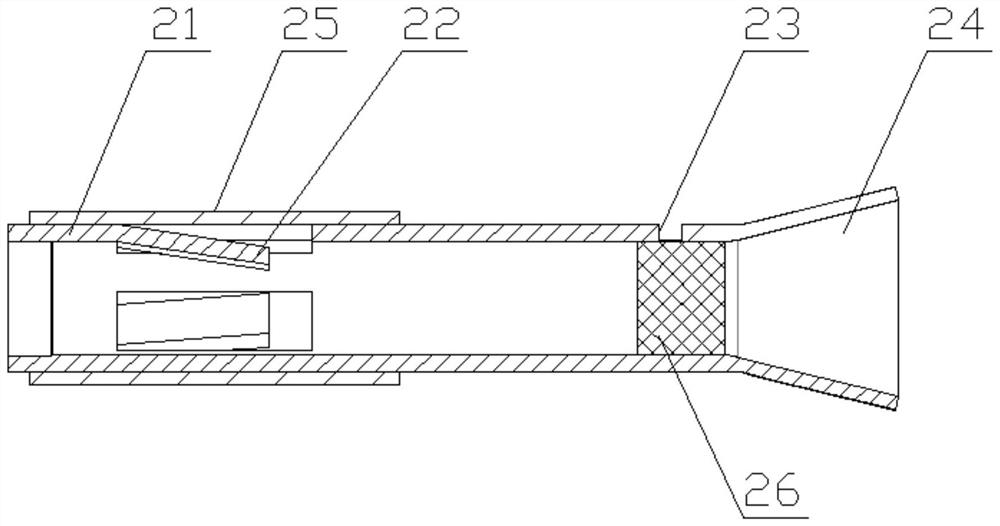

Push and press fastening type female head locking adjustable core joint and assembled building component

ActiveCN110761417AImprove structural performanceQuick insertBuilding constructionsJoint componentScrew thread

The invention belongs to the field of an engineering joint component, and concretely discloses a push and press fastening type female head locking adjustable core joint and an assembled building component. The push and press fastening type female head locking adjustable core joint comprises a female clamp joint module and a male insertion joint module which are respectively and fixedly arranged inthe assembled building component, wherein the female clamp joint module comprises a steel pipe and a horn tail part; the steel pipe is fixedly connected with the horn tail part; a plurality of stop valves are also arranged on the steel pipe; one end, far away from the horn tail part, of each stop valve is fixedly connected with the steel pipe; the other end of each stop valve is in a free state of extending in a direction towards the center axial line of the steel pipe; the male insertion joint module comprises a Y-shaped long threaded anchor bar, a plug pin screw bolt and a pin which are sequentially and fixedly connected; the Y-shaped long threaded anchor bar is embedded into the assembled building component; the pin is of a conical structure; and the big end surface of the conical structure is fixedly connected with the plug pin screw bolt. The function of automatic core regulation in the assembling process of the assembled building component can be realized; the splicing speed ishigh; and the adaptability is high.

Owner:HUAZHONG UNIV OF SCI & TECH +3

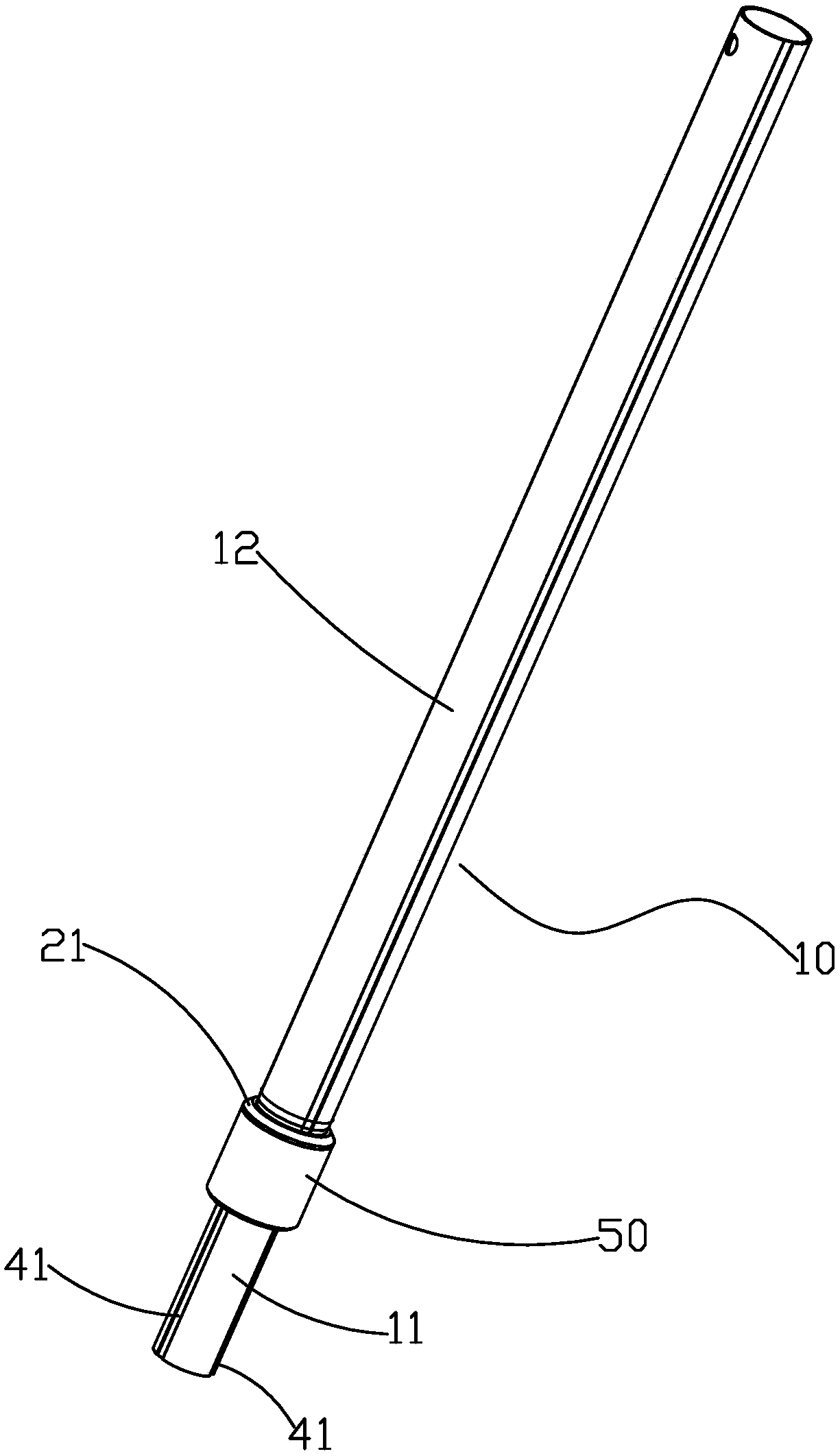

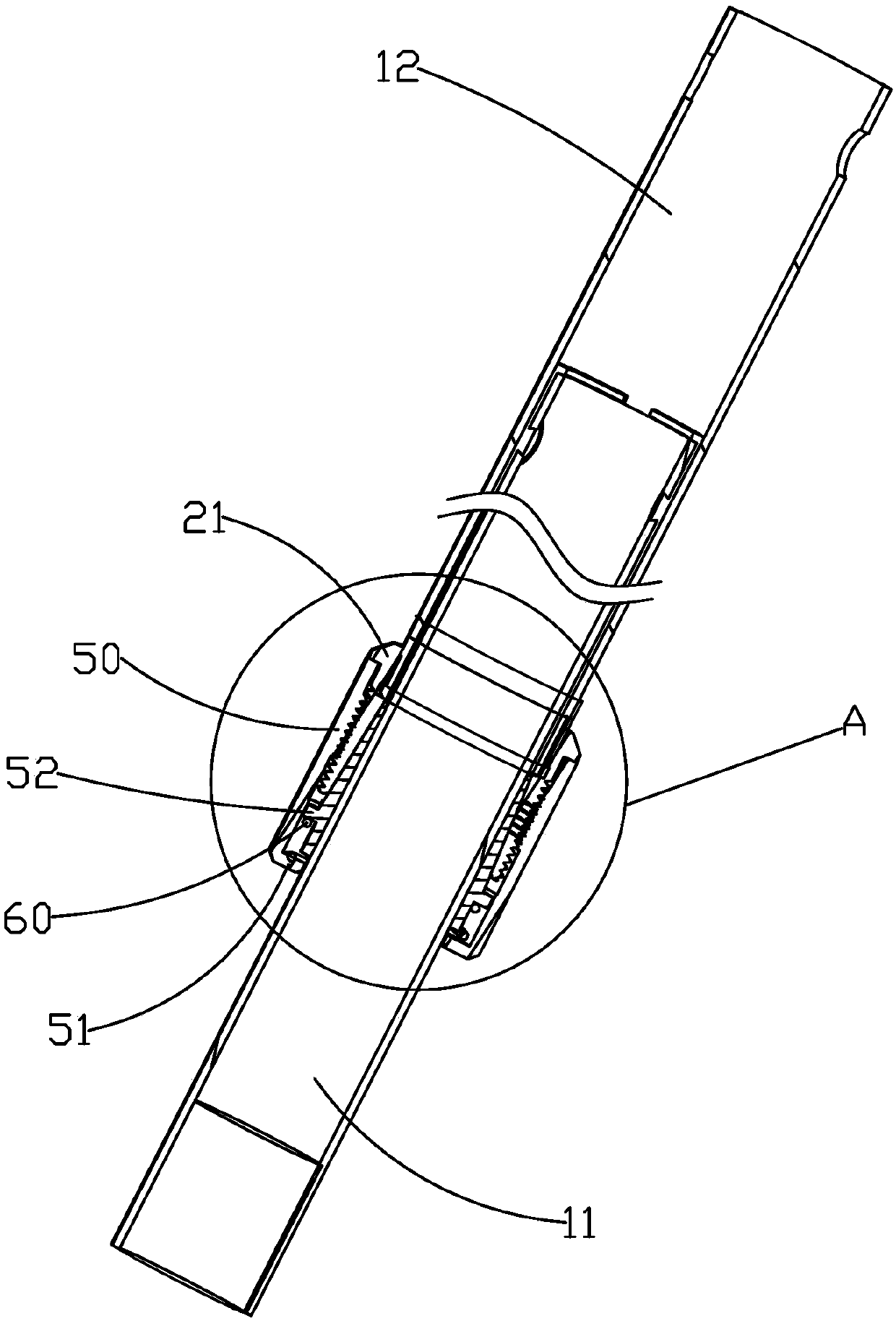

A locking structure applied to telescopic tube

ActiveCN106763039BEffective lockingConstant lengthRod connectionsLocking mechanismArchitectural engineering

Owner:ZHONGSHAN NIKOW PRECISION IND CO LTD

Push fastening female locking adjustable core connector and fabricated construction components

ActiveCN110761417BImprove structural performanceQuick insertBuilding constructionsJoint componentArchitectural engineering

The invention belongs to the field of an engineering joint component, and concretely discloses a push and press fastening type female head locking adjustable core joint and an assembled building component. The push and press fastening type female head locking adjustable core joint comprises a female clamp joint module and a male insertion joint module which are respectively and fixedly arranged inthe assembled building component, wherein the female clamp joint module comprises a steel pipe and a horn tail part; the steel pipe is fixedly connected with the horn tail part; a plurality of stop valves are also arranged on the steel pipe; one end, far away from the horn tail part, of each stop valve is fixedly connected with the steel pipe; the other end of each stop valve is in a free state of extending in a direction towards the center axial line of the steel pipe; the male insertion joint module comprises a Y-shaped long threaded anchor bar, a plug pin screw bolt and a pin which are sequentially and fixedly connected; the Y-shaped long threaded anchor bar is embedded into the assembled building component; the pin is of a conical structure; and the big end surface of the conical structure is fixedly connected with the plug pin screw bolt. The function of automatic core regulation in the assembling process of the assembled building component can be realized; the splicing speed ishigh; and the adaptability is high.

Owner:HUAZHONG UNIV OF SCI & TECH +3

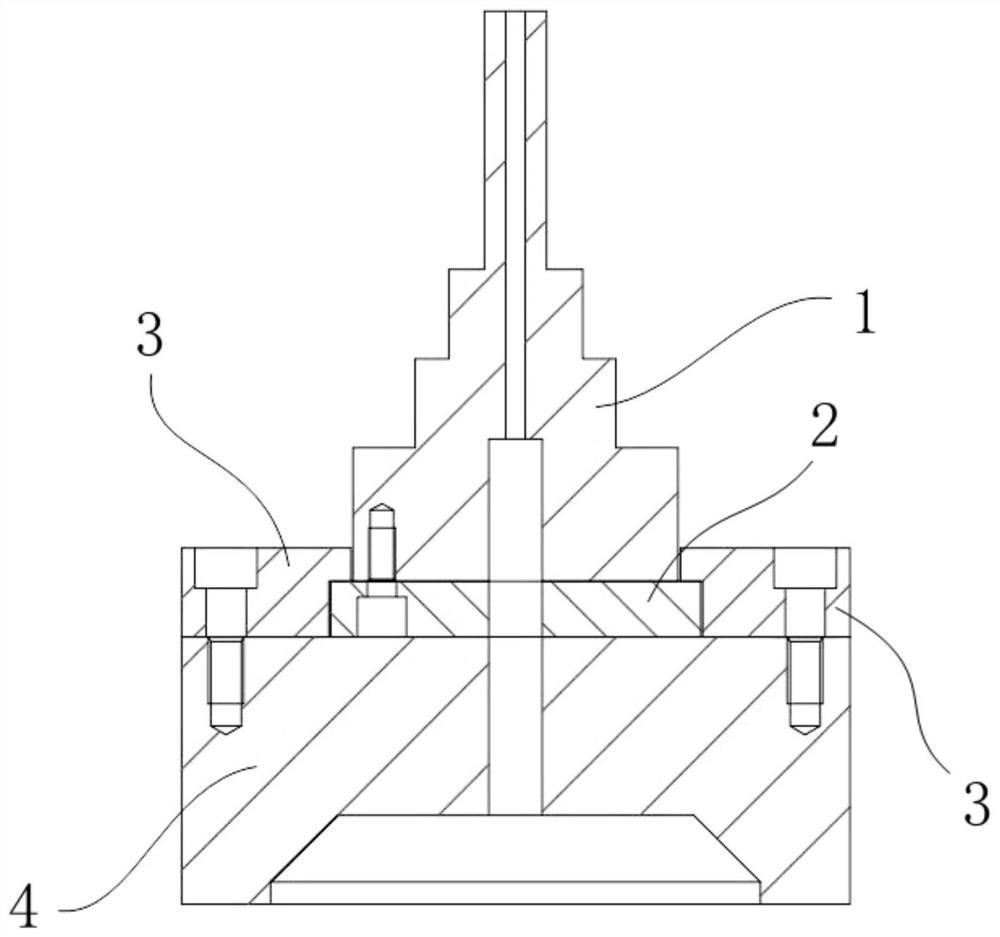

Rapid die-filling device of powder forming machine

The invention discloses a rapid die-filling device of a powder forming machine, which comprises a positioning part and a locking part, one end of the positioning part is connected with a forming die, and the other end of the positioning part is connected with a die platform of the powder forming machine; and the positioning part can position the forming die at a specific position of the die platform, and the locking part locks the forming die, the positioning part and the die platform of the powder forming machine into a whole. According to the rapid die-filling device of the powder forming machine provided by the invention, accurate positioning is achieved through the positioning part, rapid locking is achieved through the locking part, the time needed by die installation and debugging can be shortened, and therefore the production efficiency is improved.

Owner:宁波汇众粉末机械制造有限公司

A fully automatic integrated processing machine for vga interface

ActiveCN106684669BPrecise bending angleRealize automatic integrated processingContact member manufacturingContact member assembly/disassemblyGraphicsDistribution control

The invention relates to a full-automatic integrated processing machine of a video graphics array (VGA) interface. The full-automatic integrated processing machine comprises a rack and a power distribution control box, wherein a transmission groove is formed in the rack and is matched with a product, a clamping device, a bolt loading device and a bolt locking device are arranged at a left part of the transmission groove and are matched with one another, an upper bending device and a lower bending device are arranged at a right part of the transmission groove and are matched, detection devices are arranged at a left side of the upper bending device and a right side of the lower bending device, the upper bending device comprises an upper bending air cylinder, an upper bending block is connected with the upper bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an outer side, the lower bending device comprises a lower bending air cylinder, and a lower bending block is connected with the lower bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an inner side. By the full-automatic integrated processing machine, automatic integrated processing is achieved, meanwhile, the accurate bending angle of a terminal can be ensured, detection leakage is prevented, and the processing efficiency is improved.

Owner:秦轩汽车科技(天长)有限公司

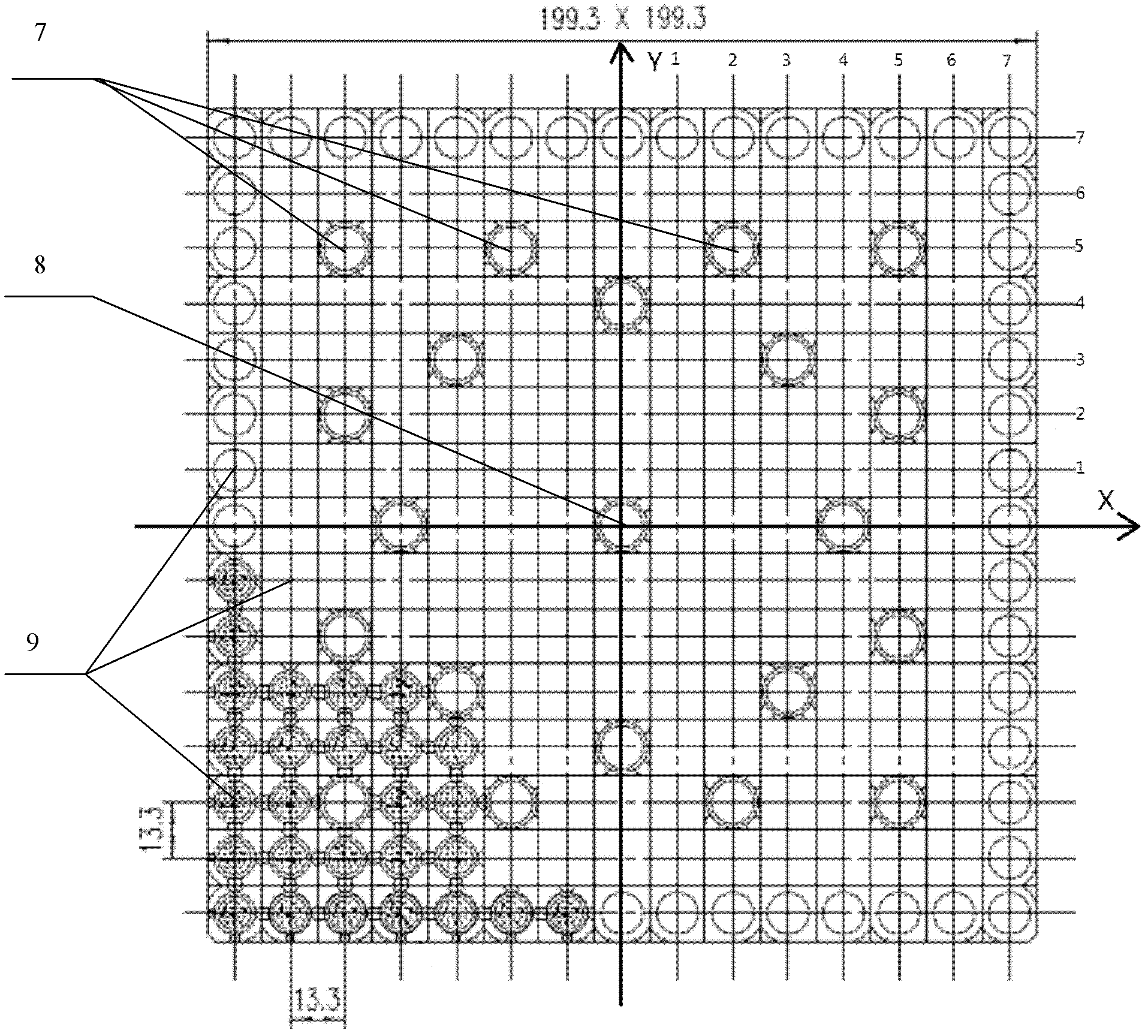

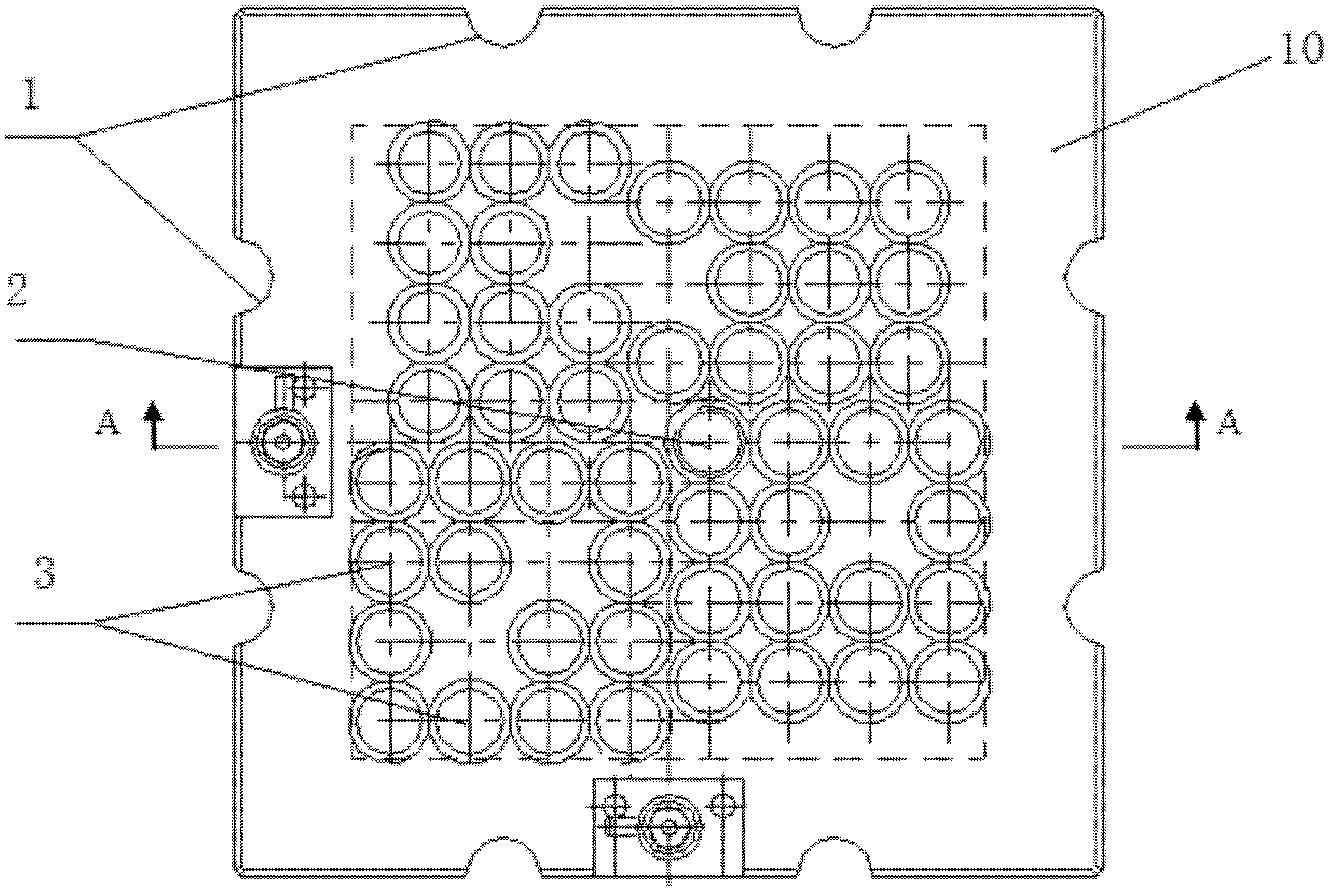

A Universal Test Fixture for Surface Mount Diode Components

ActiveCN105158524BPrecise positioningReduce test cycle extension issuesMeasurement instrument housingTest efficiencySurface mounting

The invention discloses a universal test fixture for surface-mounted two-pole components, which includes a front and rear sliding positioning slider, an elastic test probe module and a pull-out base plate. The screw and nut set at the bottom drive the two sliding bodies to move towards each other, and there is a movable pull-out bottom plate near the bottom. The test probe module includes elastically expandable left test probes and right test probes placed facing each other. In the present invention, the device under test is placed in a variable placement slot, and the rapid replacement and testing of the device under test can be realized through the fastening of the elastic test probe and the detachment of the drawing bottom plate, and the variable two sliders And the elastic pressure rod can realize the test of different specifications of the device under test, greatly improve the test efficiency and test accuracy, and also has the characteristics of simple structure, convenient operation and use, and low price.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

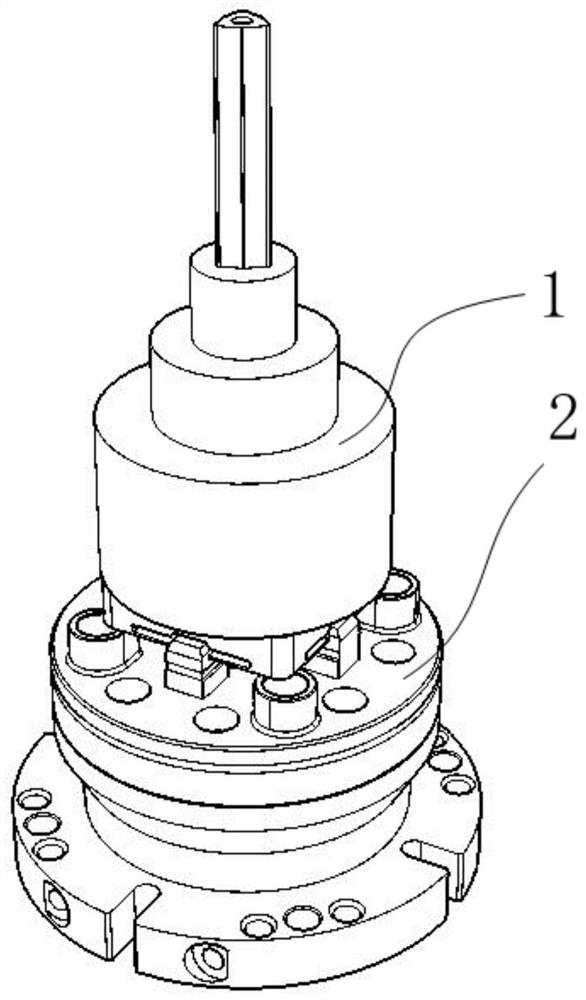

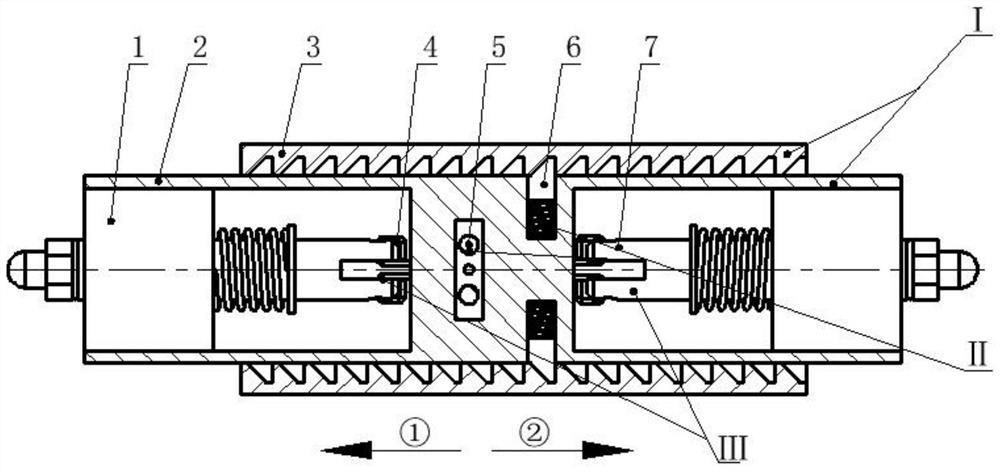

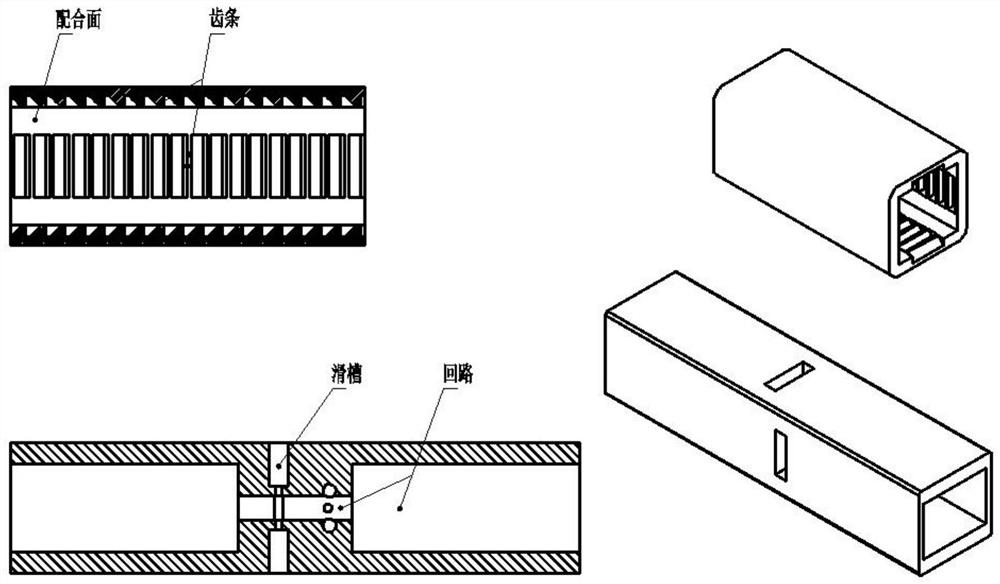

High-bearing bidirectional controllable locking mechanism

ActiveCN112157604AHighlight substantiveSignificant technological progressWork holdersBrakeClassical mechanics

The invention relates to a high-bearing bidirectional controllable locking mechanism. The locking mechanism comprises brakes, an inner or outer rod group and spring slider groups, wherein the brakes are fixed to an inner rod and connected with sliders through steel wire ropes separately; the spring slider groups are arranged in sliding grooves of the inner rod; when the brakes do not work, the sliders are clamped in an outer rod under the action of springs; when the brakes work, the brakes pull the corresponding sliders, the inner rod and the outer rod are in a free loose state, bidirectionalmovement can be achieved, the working conditions of the brakes can be changed, and the inner rod and the outer rod can achieve four working conditions, such as bidirectional movement, bidirectional locking, one side locking and the other side moving. The spring slider groups are in large-area contact with the outer rod and have high bearing capacity. The locking mechanism is applied to a deformable truss system, and the mechanism stability and the bearing capacity of the system can be significantly improved.

Owner:SHANGHAI UNIV

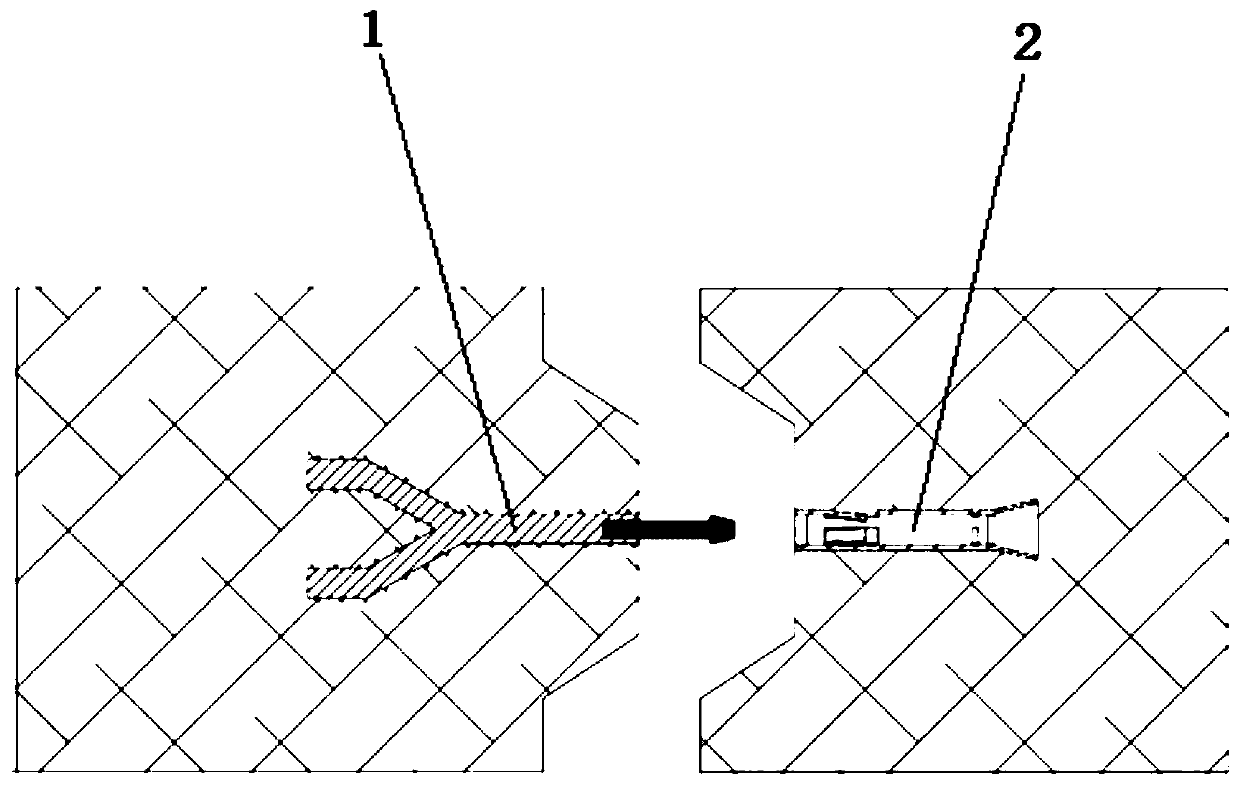

Positioning device for accurately positioning fuel rod replacing tool on extracted fuel rod

ActiveCN102339651BAchieve precise positioningPrecise lockingNuclear energy generationReactor fuel elementsMechanical engineeringPositioning system

Owner:QINSHAN NUCLEAR POWER

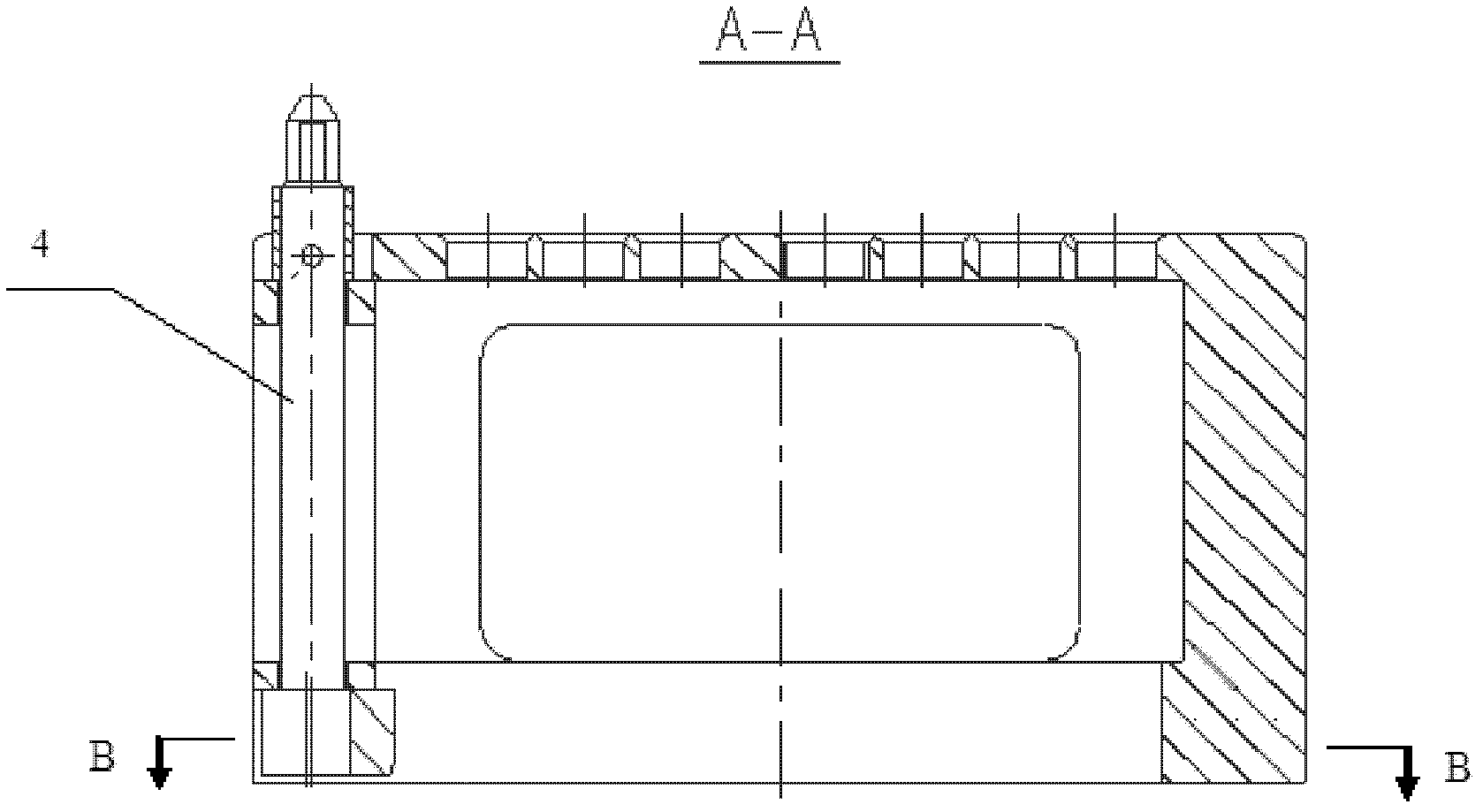

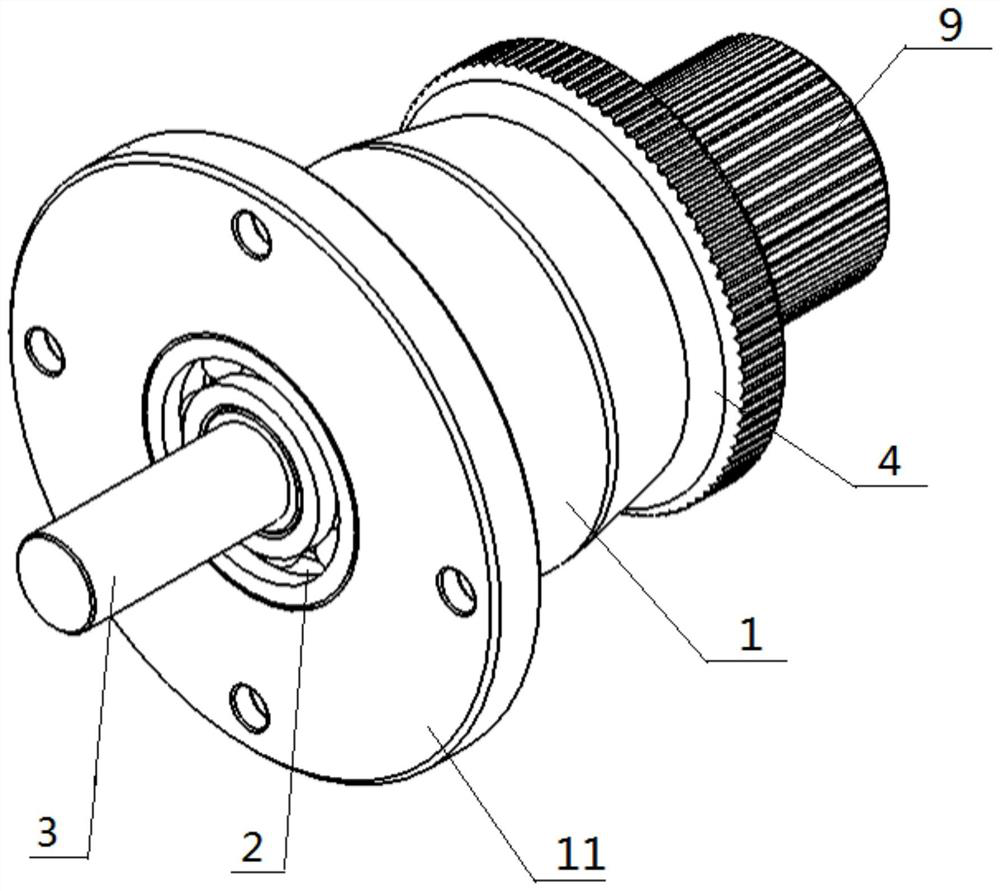

Fine adjustment locking mechanism for precision measurement

PendingCN114166261AImprove accuracyModerately adjust the rotation forceMeasurement apparatus caging devicesEngineeringSteel ball

The invention discloses a fine adjustment locking mechanism for precision measurement, and relates to the technical field of precision measurement. The device comprises a shell, and a bearing is fixedly inserted into one end of the shell; a fine adjustment screw rod is inserted and fixed in the center position in the bearing; the inner wall of the shell is in threaded connection with a locking screw sleeve; a check ring and an elastic bushing are respectively sleeved between the inner end part of the locking screw sleeve and the peripheral side surface of the fine adjustment screw rod; steel balls are arranged between the check ring and the elastic lining in an annular array mode. And an annular retainer matched with the steel balls is fixedly inserted into the inner wall of one end of the locking screw sleeve. According to the invention, centripetal force is generated by the inner conical surface of the locking screw sleeve and the check ring under the action of the plurality of steel balls, so that the elastic bushing deforms to generate friction force on the fine adjustment screw rod to form rotary damping, and the rotary damping can be adjusted and the rotary force can be properly adjusted by rotating the locking screw sleeve, so that the accuracy of manual alignment is improved, and the production efficiency is improved. After the scribed line is aligned, the rotating force of the locking screw sleeve is increased, the locking state can be kept, the locking is accurate, and the operation precision of measurement is ensured.

Owner:江西中船航海仪器有限公司

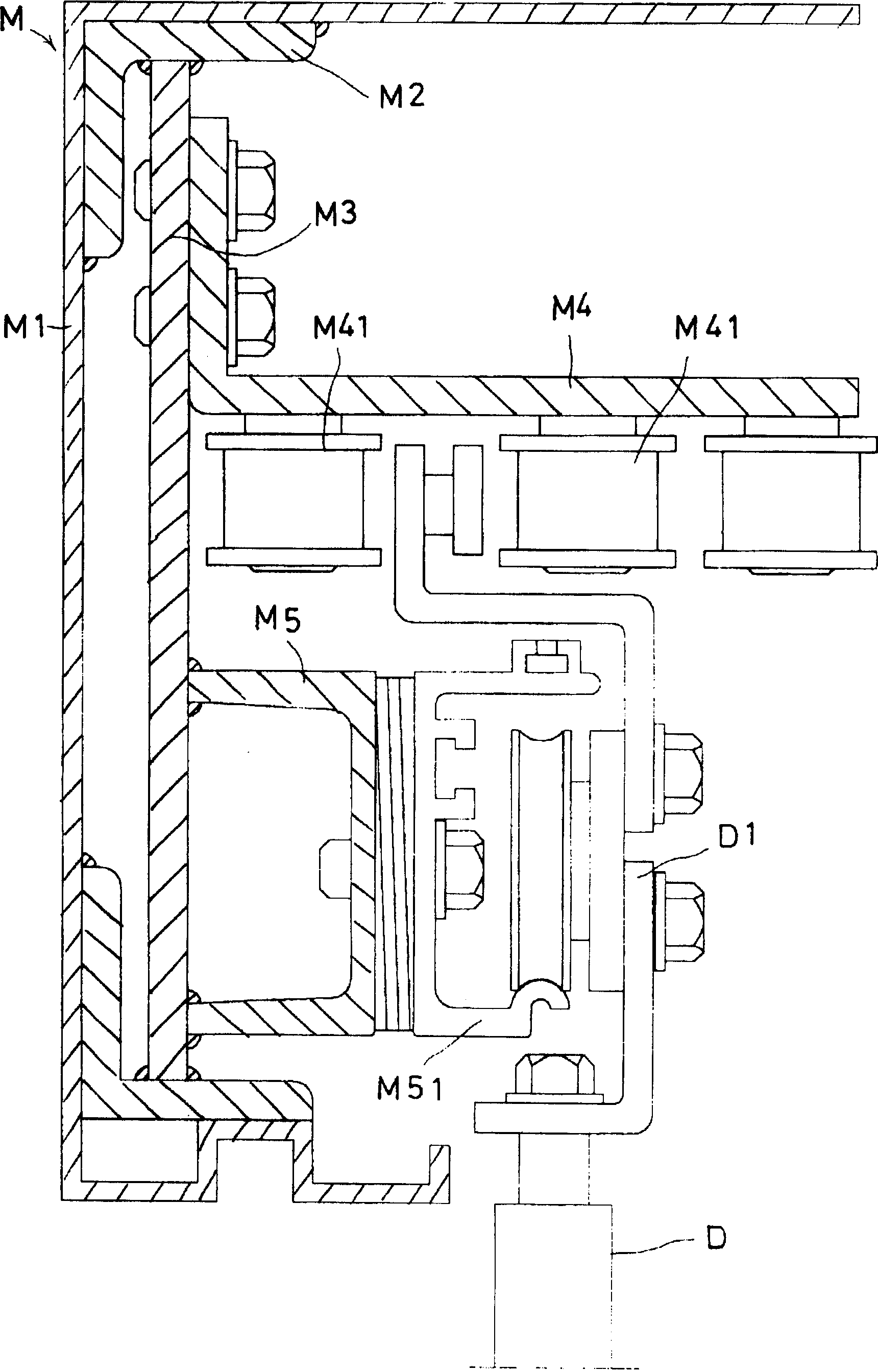

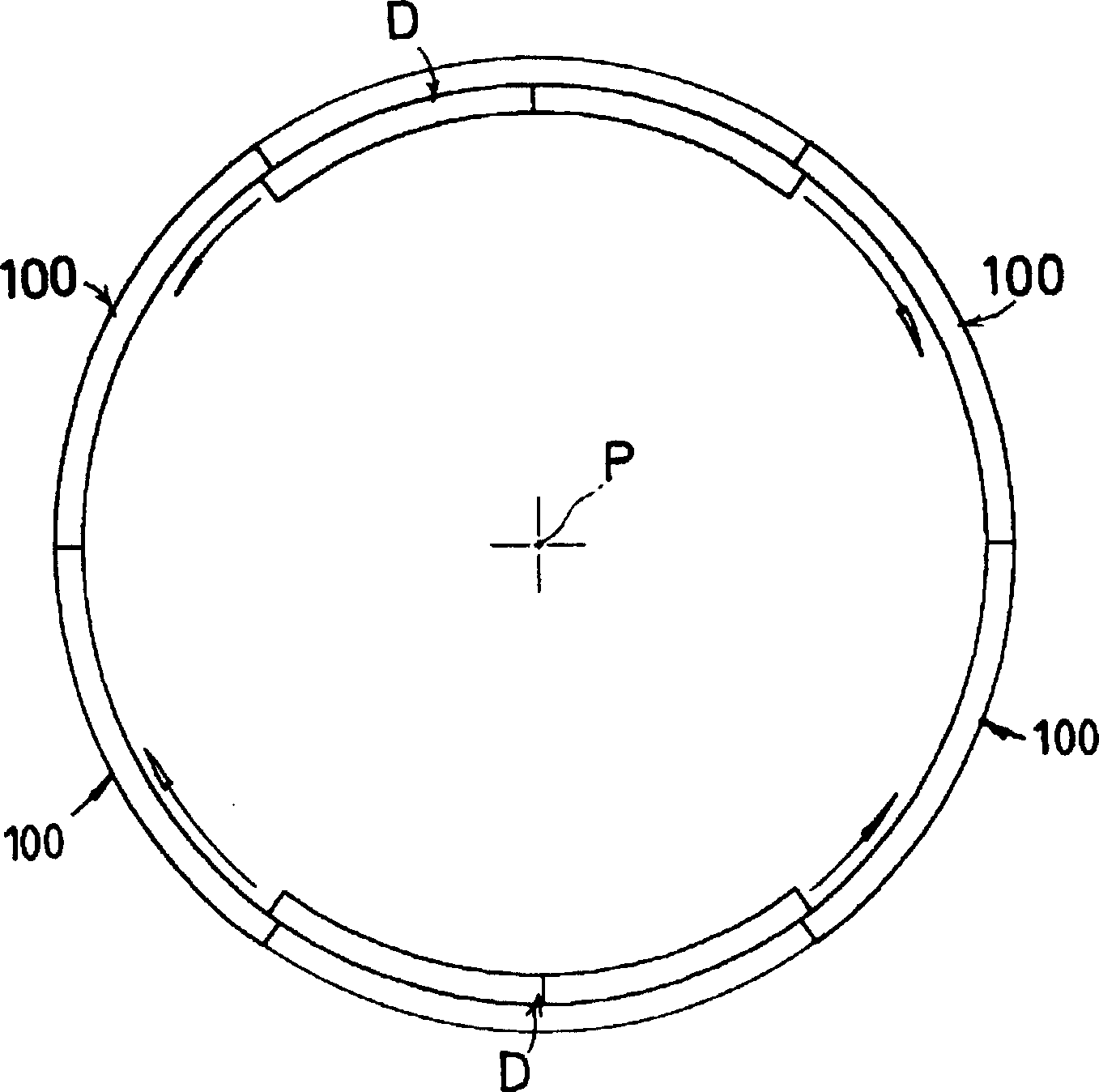

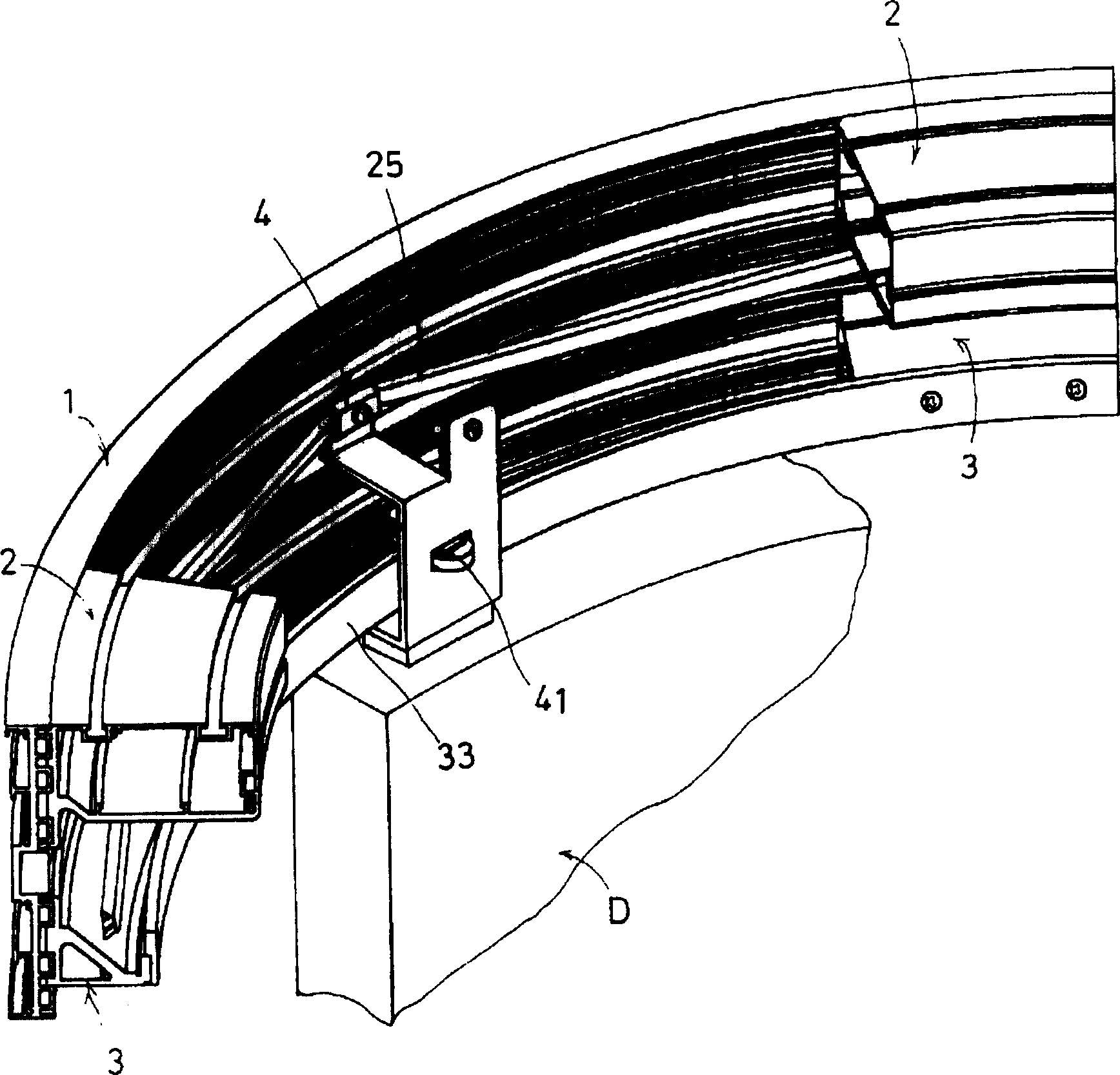

Modular automatic arc door with concentric circle

InactiveCN1134585CObvious advantagesObvious positive effectRevolving doorsPower-operated mechanismDrive motorEngineering

A modular automatic arc door with high-accuracy concentric circle is composed of main frame body in arc shape, internal arc surface whose curved arc surface uses the rotation center of automatic door as its circular center, more top holders fixed to inner surface of main frame body and having belt guide roller and drive motor, more bottom holders fixed to inner surface of main frame body and linked to arc track, and hanger sliding track above the door sash. Said top and bottom holders are arranged on circumference of main frame body in intervals. Its advantage is simple, quick and correct installation.

Owner:台湾肯捷特电机有限公司

Dismounting and mounting special tool of outer barrel nut of undercarriage support

PendingCN113561111AImprove the use of diversityPrecise lockingSpannersWrenchesWrenchIndustrial engineering

The invention relates to a dismounting and mounting special tool of an outer barrel nut of an undercarriage support.The tool structurally comprises a force application wrench rod group, a left wrench base body, a right wrench base body, a bushing group, a screw group, a locking sleeve, a locking sleeve wrench and a locking screw rod, the bushing group is mounted in the left wrench base body and the right wrench base body and is fixed through the screw group, the force application wrench rod group is fixedly connected with the left wrench base body and the right wrench base body, the left wrench base body and the right wrench base body are locked through the locking screw rod and the locking sleeve, and the bushing group can form an inner hexagonal hole so that the outer barrel nut can be dismounted. When the tool is used, the outer barrel nut is not damaged, the dismounted outer barrel nut can still continue to be used, a bushing has various sizes, can be replaced and can adapt to outer barrel nuts with different sizes, use is convenient, and the structure is compact and simple.

Owner:吉林航空维修有限责任公司

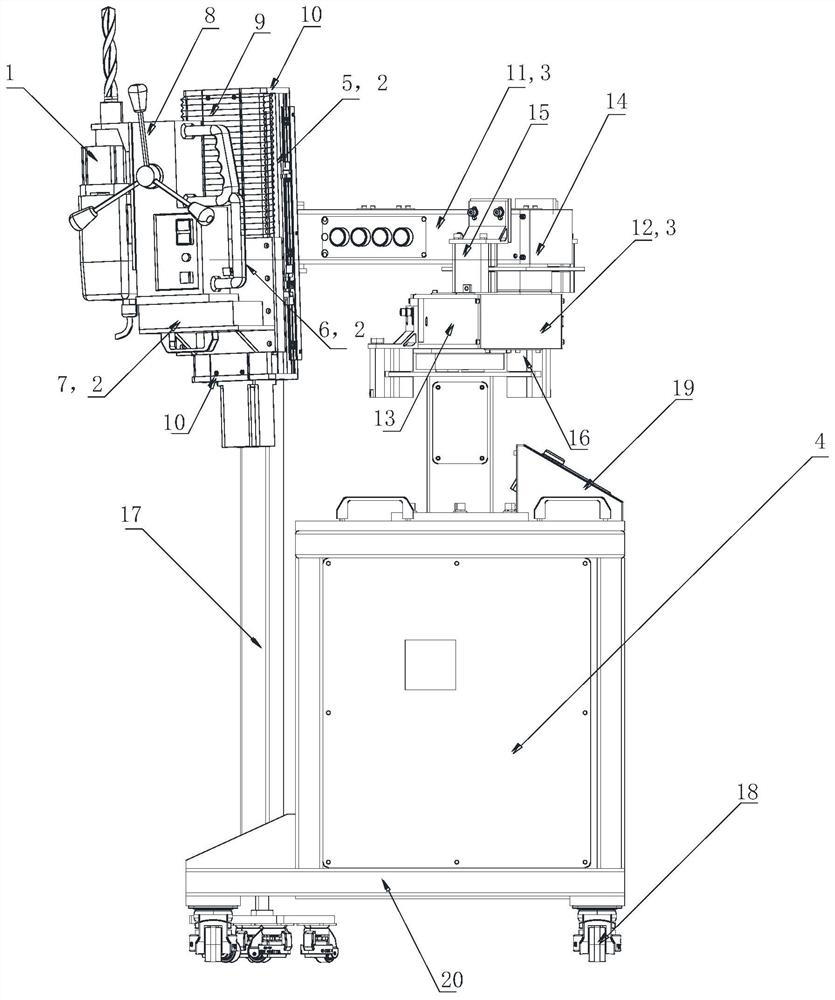

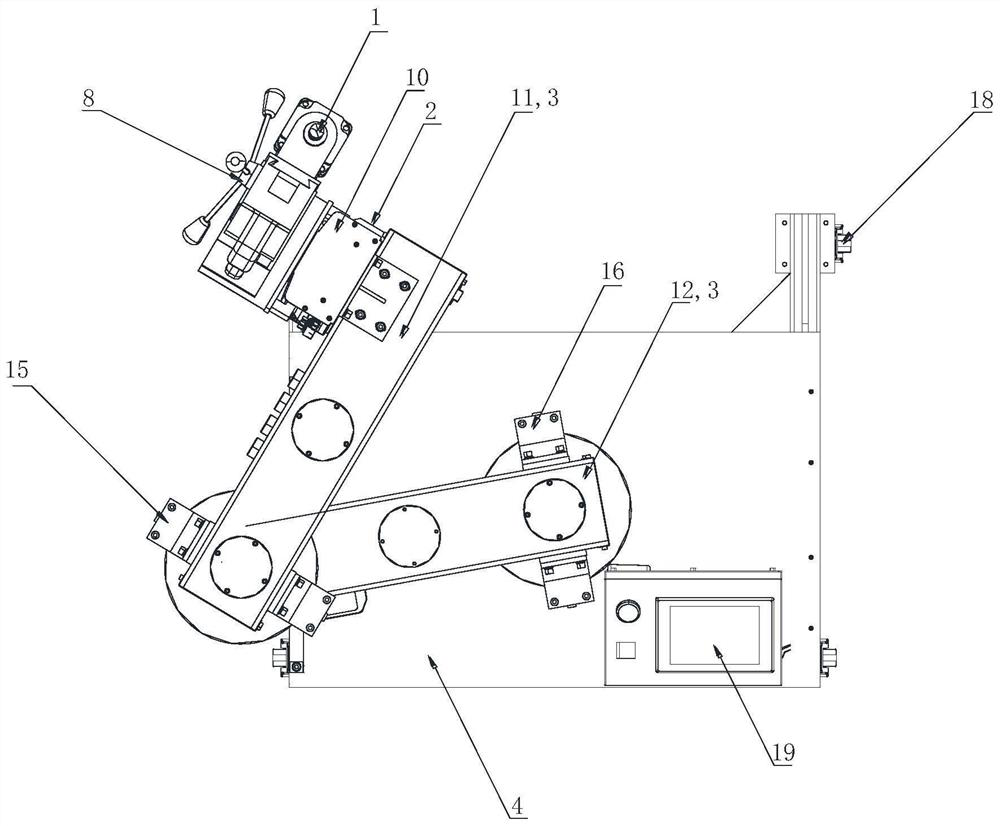

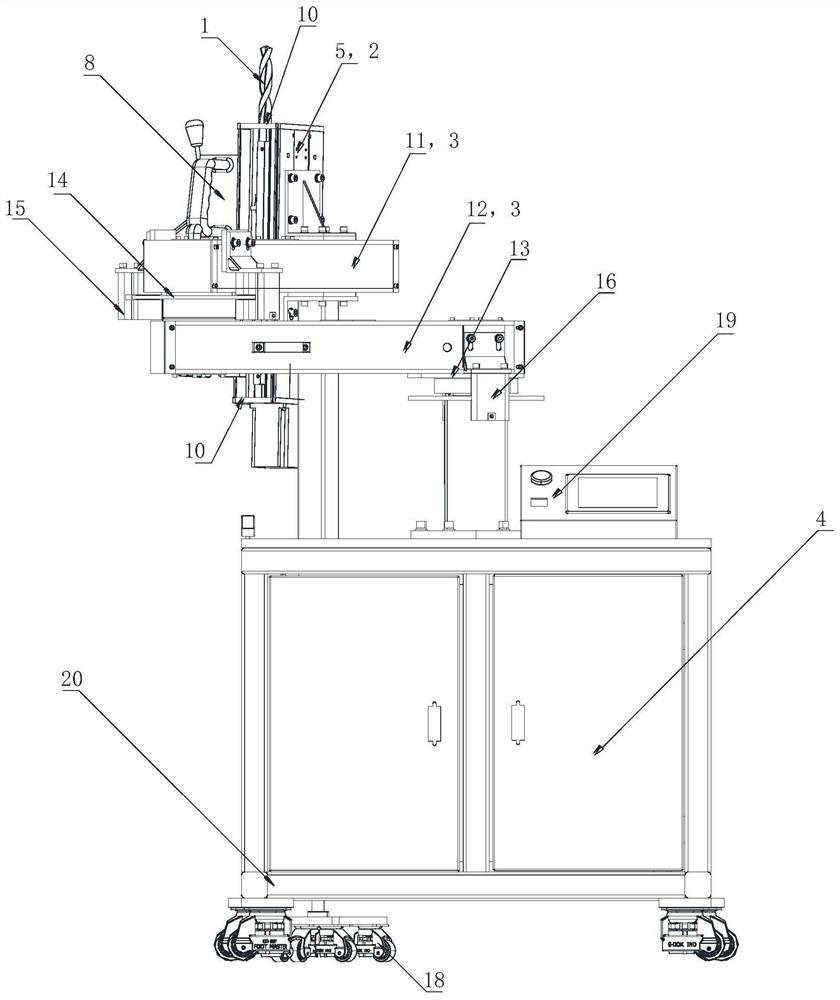

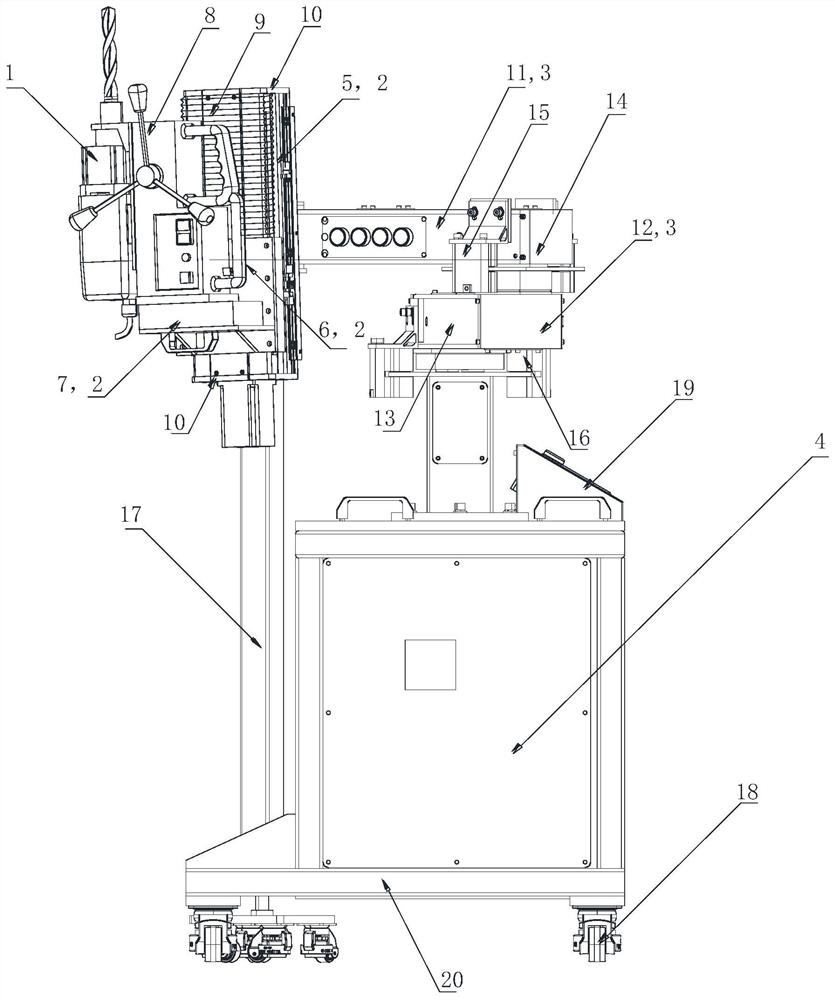

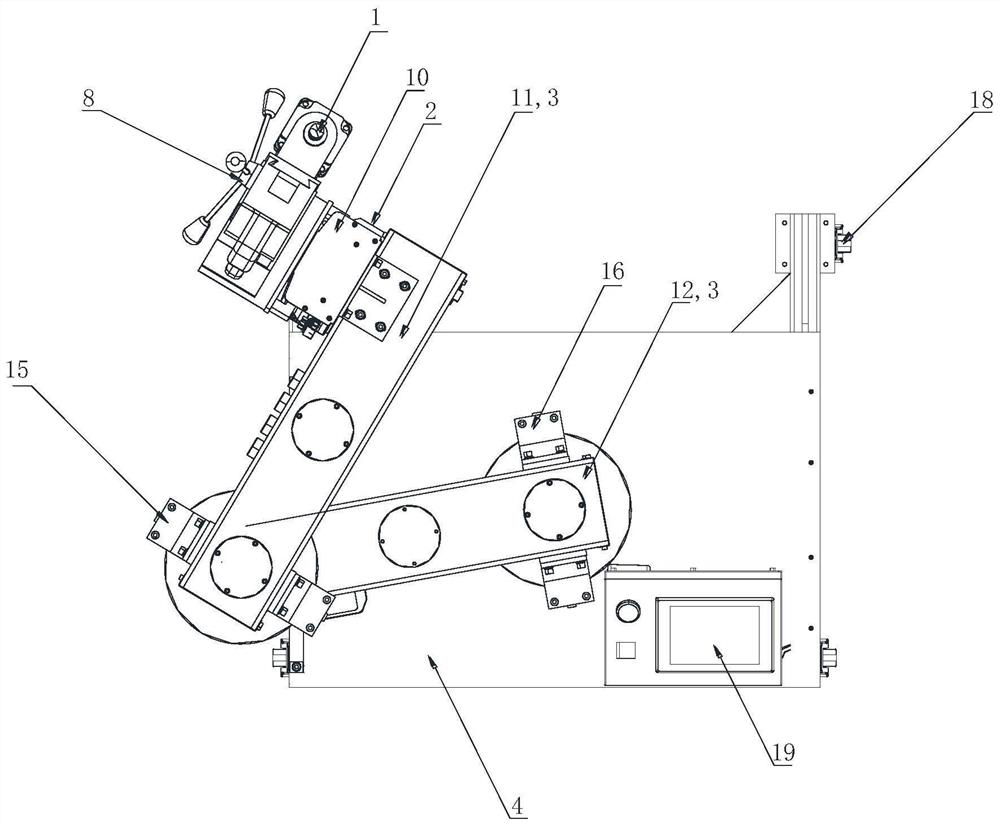

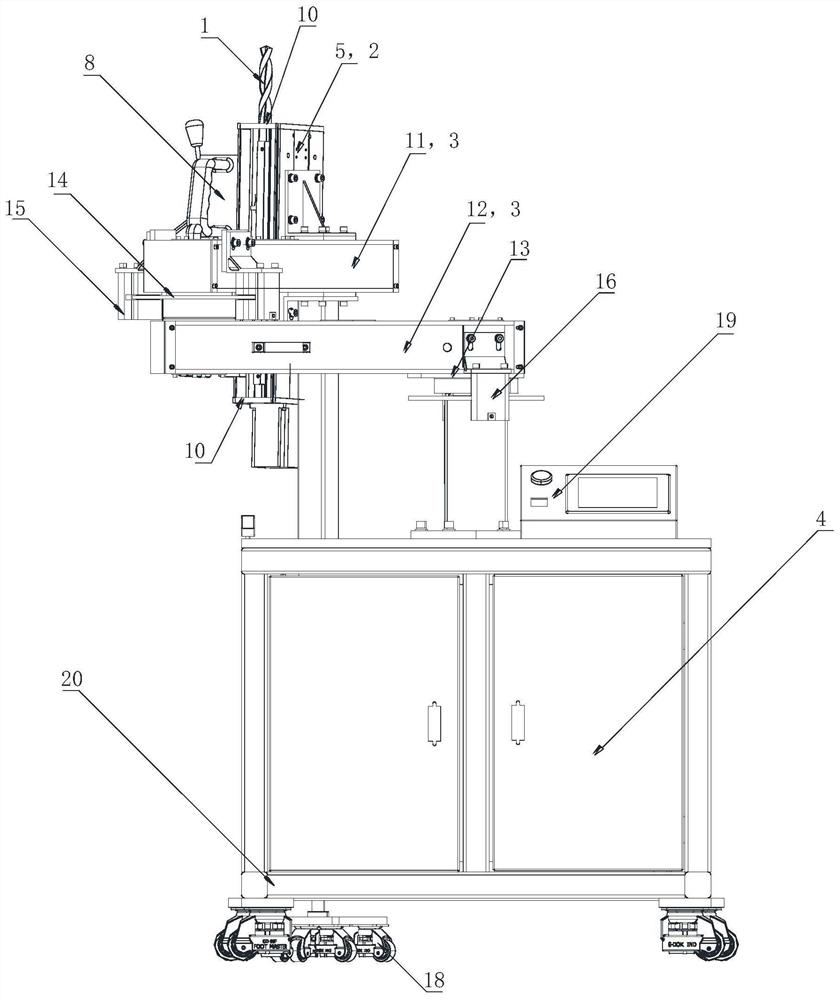

A kind of automatic drilling equipment

ActiveCN112170885BConvenient punching operationSimple structureBoring/drilling machinesRobotic armClassical mechanics

The invention provides an automatic drilling equipment, which includes a magnetic drill, which is arranged on a sliding table in a liftable manner, and the sliding table is connected with a multi-stage mechanical arm capable of translating and rotating, and the multi-stage mechanical arm is fixed on the control automatic drilling equipment. On the movable control cabinet. The present invention enables the magnetic drill to move up and down through the setting of the slide table, and enables the magnetic drill to rotate along the horizontal direction through the setting of the mechanical arm, thereby enabling the magnetic drill to realize the need for drilling holes at any position within a certain range. That is, through the setting of the automatic drilling equipment of the present invention, it is more convenient to automatically perform drilling operations on required positions.

Owner:CRRC QINGDAO SIFANG CO LTD

A VGA interface automatic locking detection mechanism

ActiveCN106624752BPrecise lockingEasy to detectSortingMetal working apparatusDistribution controlLocking mechanism

The invention relates to an automatic locking detection mechanism with VGA port which includes a rack and a power distribution control box. The rack is provided with a convey trough coordinating productions. A chucking mechanism, a bolt feeding mechanism and a bolt locking mechanism, all of which interworks and disposed on the left of the convey trough. The right of the convey trough is provided with a detection mechanism. The upside of the chucking mechanism is provided with a locking positioning mechanism. The locking positioning mechanism comprises a bolt positioning air cylinder disposed on the front and back sides of the convey trough. The bolt positioning air cylinder is connected with a set piece. A bolt set piece is located on the top of the convey trough. The connection of two bolt set pieces is provided with bolt positioning holes which match up bolts. The bolt positioning holes is coordinated with bolt open holes of productions of the convey trough. The automatic locking detection mechanism with VGA port realizes an automatic integration locking and detection and ensures precise place and tightening of the bolt at the same time and improves the yield of the bolt locking.

Owner:TIANCHANG GAOPENG EXPERIMENT EQUIP

Base plate assembly and digital printing apparatus

The invention provides a base plate assembly and a digital printing apparatus. The base plate assembly includes a substrate; a base plate attached to the upper surface of the base plate, wherein the first end of the base plate is rotatably connected with one end of the substrate; a regulating member rotatably installed on the other end of the substrate and cooperating with the base plate in orderthat the base plate can rotate to any position on the substrate; and a locking member cooperating with the regulating member in order that the regulating member and the substrate can be mutually pressed and locked, wherein when the regulating member and the substrate are mutually pressed and locked, the regulating member and the base plate are buckled and the base plate can be locked at any position. In the technical solution, the position of the base plate can be detected by using the regulating member, and the regulating member can be pressed on the substrate by using the locking member after the position is detected, and then the base plate can be locked by means of the buckling of the regulating member and the base plate. The locking manner avoids any movement phenomenon in a locking process so as to precisely lock the base plate to the position detected by the regulating member.

Owner:NEW FOUNDER HLDG DEV LLC +1

A continuous capping device for automatic assembly of power distribution cabinets

ActiveCN110086102BRealize continuous assembly workImprove work efficiencySwitchgearStructural engineeringMachine

Owner:国网甘肃省电力公司甘南供电公司

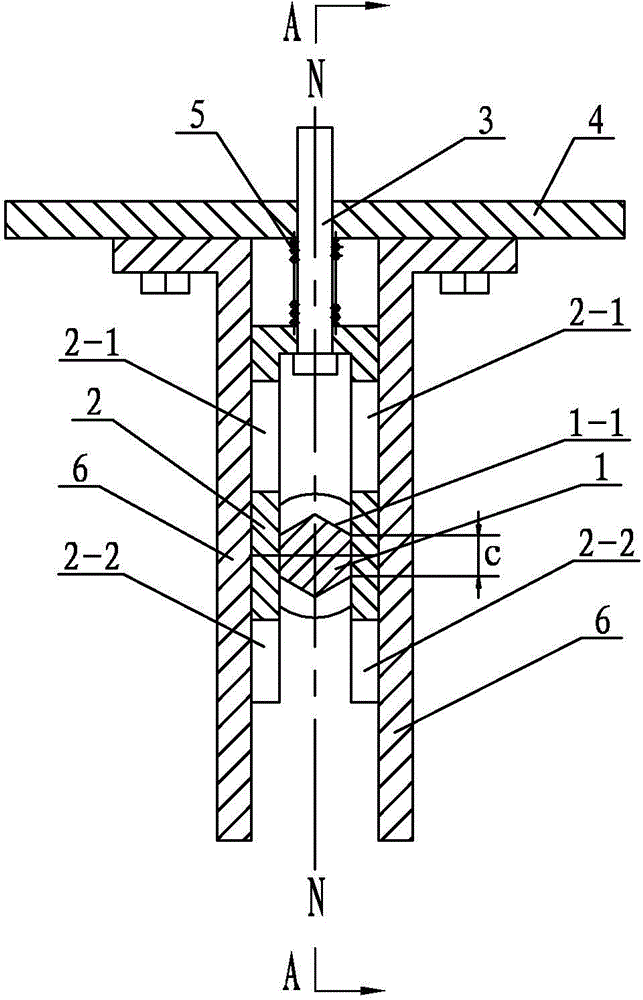

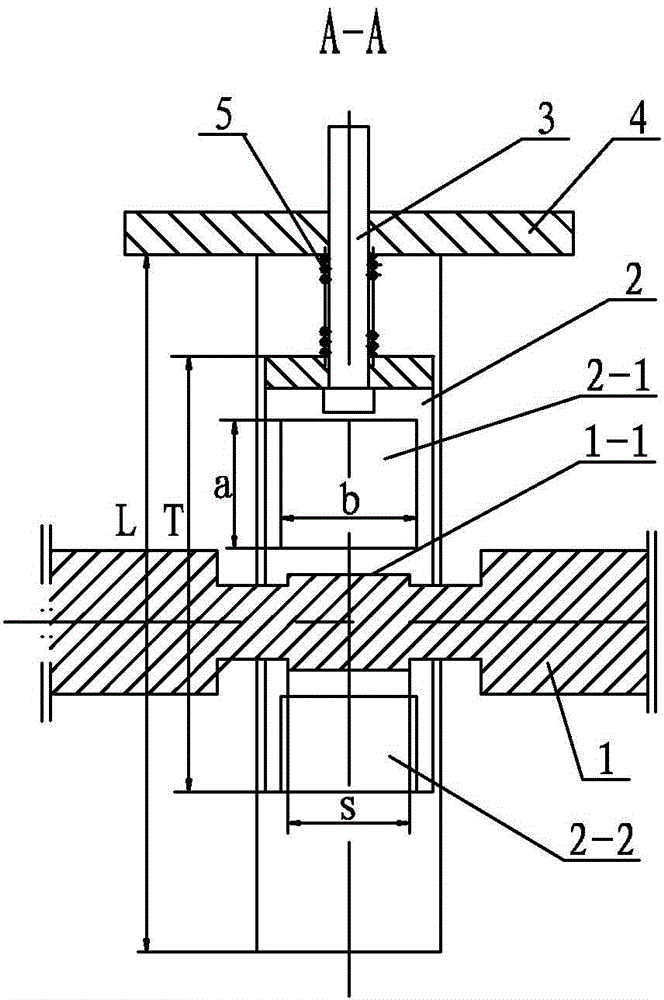

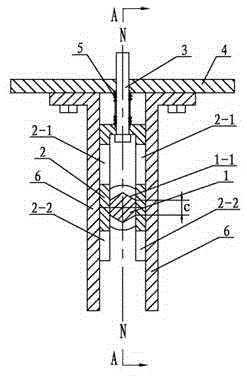

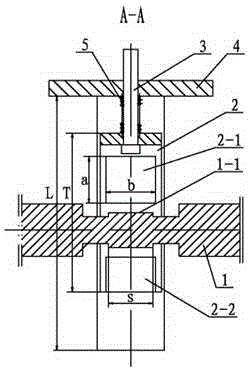

A locking mechanism for transmission

The invention discloses a locking mechanism for a transmission device, and relates to locking mechanisms. The locking mechanism for the transmission device solves the problems that an existing transmission device uses friction and pressure for locking, so that locking is not rapid, and the locking position is not accurate or stable. Through holes and grooves are formed in each side wall of inverted-U-shaped steel from the bottom end to the opening end. One end of a pull rod is arranged in a U-shaped groove of the inverted-U-shaped steel, and the other end of the pull rod penetrates through a bottom plate of the inverted-U-shaped steel, a spring and an upper fixing plate to be exposed out of the upper fixing plate. A hexagon locking section is arranged in the middle of a transmission shaft, the transmission shaft is horizontally arranged, and the hexagon locking section is placed in the U-shaped groove. The length s of the hexagon locking section is smaller than the width b of the through holes, and the circumscribed circle diameter of the hexagon locking section is smaller than the length a of the through holes. Two inverted-L-shaped guide plates are symmetrically arranged on the two sides of the inverted-U-shaped steel, the long edge plate of the inverted-L-shaped guide plates makes contact with the side wall of the inverted-U-shaped steel adjacent to the long edge plate, and the short edge plate of the inverted-L-shaped guide plates is connected with the upper fixing plate through a connecting component. The locking mechanism is used for transmission devices.

Owner:HARBIN INST OF TECH

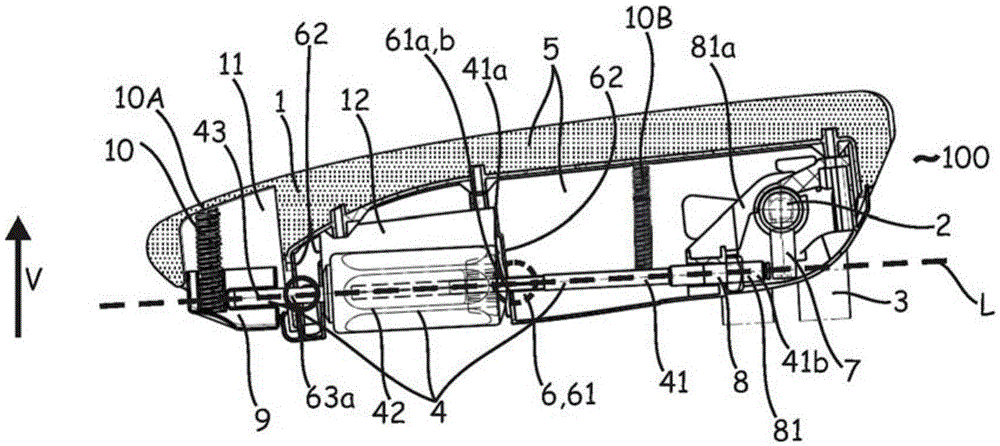

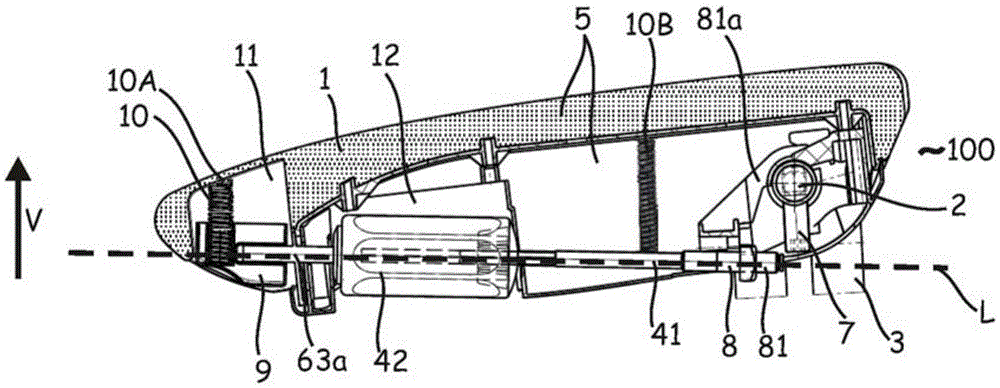

Seats, especially armrests for vehicle seats

Owner:GRAMMER AG

Locking mechanism for transmission device

The invention relates to a locking mechanism, in particular to a locking mechanism for a transmission device. The problems that an existing transmission device is locked through friction and pressure, so that locking is not rapid, and the locking position is not accurate and not stable are solved. A through hole and a groove are formed in each side wall of inversed-U-shaped steel from the bottom end to the opening end, one end of a pull rod is arranged in a U-shaped groove of the inversed-U-shaped steel, and the other end of the pull rod penetrates a base plate, a spring and an upper fixing plate of the inversed-U-shaped steel to be exposed outside the upper fixing plate; a hexagonal locking section is arranged in the middle portion of a transmission shaft, the transmission shaft is horizontally arranged, the hexagonal locking section is located in the U-shaped groove, the length s of the hexagonal locking section is smaller than the width b of the through holes, and the diameter of a circumscribed circle of the hexagonal locking section is smaller than the length a of the through holes; two inversed-L-shaped guide plates are symmetrically arranged on the two sides of the inversed-U-shaped steel, a long-edge plate of each inversed-L-shaped guide plate is in contact with the adjacent side wall of the inversed-U-shaped steel, and a short-edge plate of each inversed-L-shaped guide plate is connected with the upper fixing plate through a connecting element. The locking mechanism is used for the transmission device.

Owner:董艳华

Automatic drilling equipment

ActiveCN112170885AConvenient punching operationSimple structureBoring/drilling machinesDrill holeGeotechnical engineering

The invention provides automatic drilling equipment. The automatic drilling equipment comprises a magnetic drill; the magnetic drill is arranged on a sliding table in a liftable mode; the sliding table is connected with a multi-stage mechanical arm capable of horizontally moving and rotating; and the multi-stage mechanical arm is fixed to a movable control cabinet for controlling the automatic drilling equipment. According to the invention, through the arrangement of the sliding table, the magnetic drill can move up and down; and through the arrangement of the mechanical arm, the magnetic drill can rotate in the horizontal plane direction, and then the magnetic drill can meet the requirement for drilling at any position within a certain range. That is to say, through the arrangement of theautomatic drilling equipment provided by the invention, it is more convenient to automatically perform drilling operation on the needed position.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com