Rapid die-filling device of powder forming machine

A technology for forming machines and forming molds, applied in the direction of presses, manufacturing tools, etc., can solve the problems of time-consuming fine-tuning process and many bolts installed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

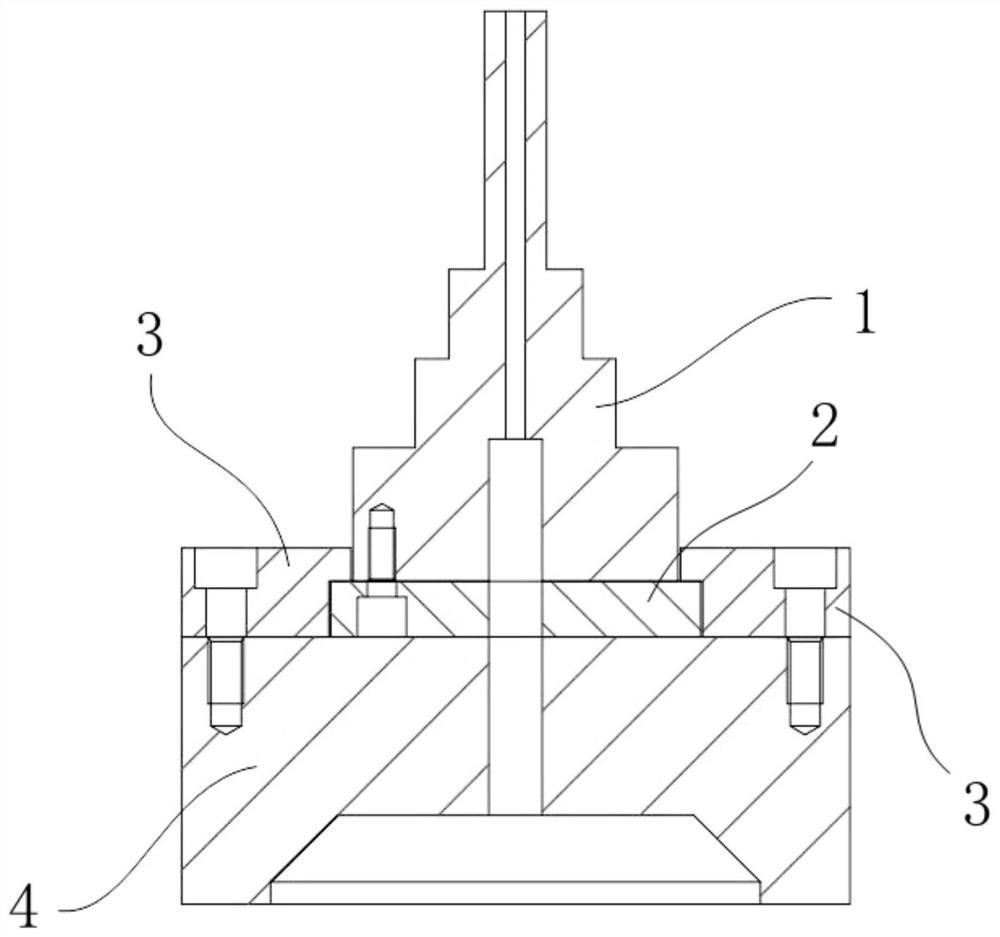

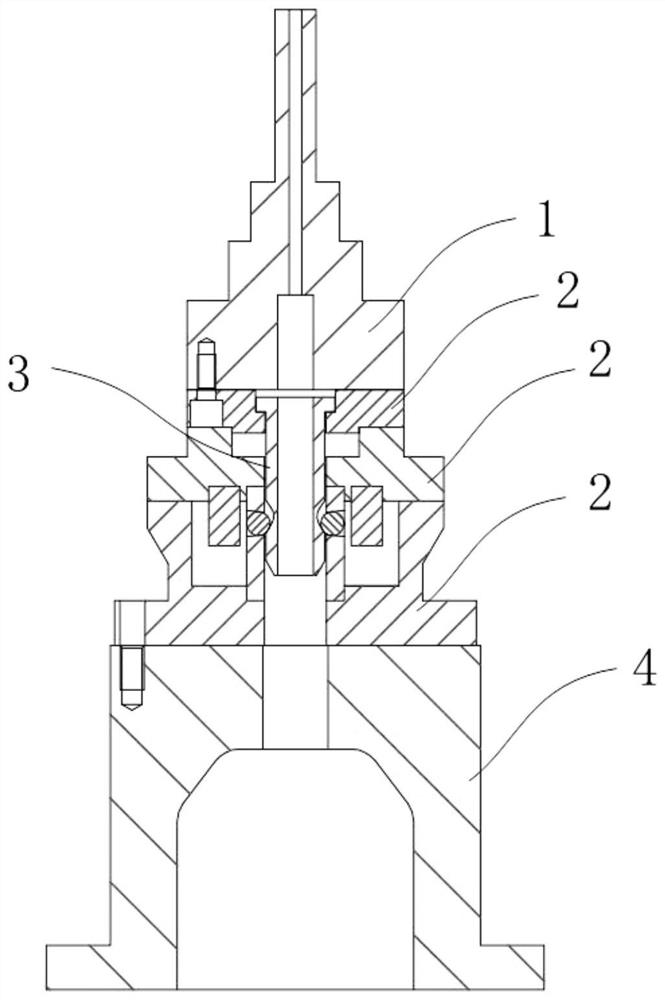

[0031] Such as figure 2 , 3 As shown in , 4, the quick mold loading device of the powder forming machine includes a positioning part 2 and a locking part 3, one end of the positioning part 2 is connected with the forming mold 1 by bolt fastening, and the other end is connected with the mold platform 4 of the powder forming machine by Bolt fastening method; there is a center-aligned installation method between the positioning part 2 and the forming die 1 and between the positioning part 2 and the mold platform 4 of the powder molding machine, so the positioning part 2 can position the forming die 1 on the powder At the center of the mold platform 4 of the molding machine, the locking part 3 has a quick locking device, which can quickly lock the forming mold 1, the positioning part 2 and the mold platform 4 of the powder molding machine as a whole.

Embodiment 2

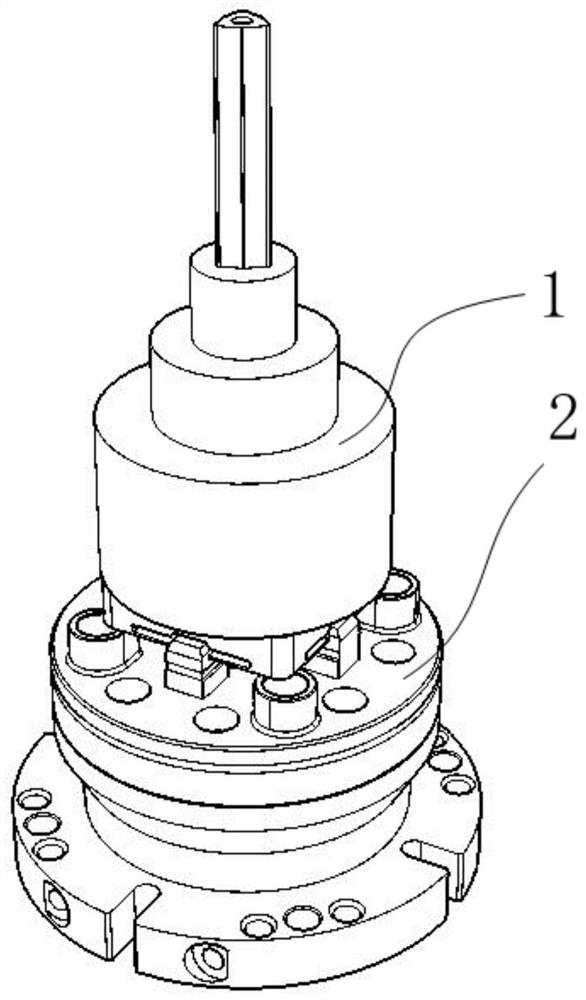

[0033] Figure 5-X It shows a quick mold loading device of a powder molding machine, including a positioning part and a locking part.

[0034] The positioning part comprises a first positioning device 21 and a second positioning device 22, wherein the first positioning device 21 comprises a first positioning surface 211 and a second positioning surface 213, and the second positioning device 22 comprises a third positioning surface 223 and a fourth positioning surface 224.

[0035] Such as Figure 8-10 As shown, the first positioning device 21 includes a first positioning surface 211, and the first positioning surface 211 includes a plurality of first positioning holes 212; the surface connected to the first positioning surface 211 on the forming die 1 also includes several positioning holes 11 ;

[0036] The first positioning hole 212 on the first positioning surface 211 has a corresponding positional relationship with the positioning hole 11 of the forming mold. After bein...

Embodiment 3

[0050] Others are the same as in Embodiment 2, wherein the locking mechanism is a pneumatic steel ball structure, the locking device 341 is a steel ball, and the controller 342 is a pneumatic valve. Since the pneumatic steel ball structure is a common technical means in this field, it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com