Milling machine ascending and descending locking device

A technology of locking device and milling machine, which is applied in the direction of large-scale fixed members, metal processing machine parts, metal processing equipment, etc., can solve the problems of increasing the operating force of operators, low locking accuracy, and inconvenience for users, etc., and achieves Simple structure, convenient installation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

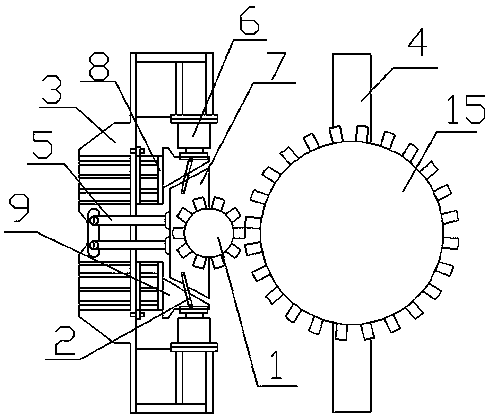

[0014] Such as figure 1 and figure 2 As shown, a milling machine lifting and locking device includes a locking gear 1, a hydraulic cylinder 2, a support 3, a pillar 4, a first driver 5 and a second driver 6, and the pillar 4 is provided with a lifting gear 15, and the The locking gear 1 is connected with the lifting gear 15, the first driver 5 is connected with the locking gear 1, the first driver 5 drives the locking gear 1, and the connection between the first driver 5 and the locking gear 1 is provided with Connecting plate 7, described support 3 is provided with chute 8, and described chute 8 is provided with wedge-shaped block 9, and described wedge-shaped block 9 is connected with second driver 6, and one end of described hydraulic cylinder 2 is connected with the second The driver 6 is connected, and the other end is connected with the connection board 7 .

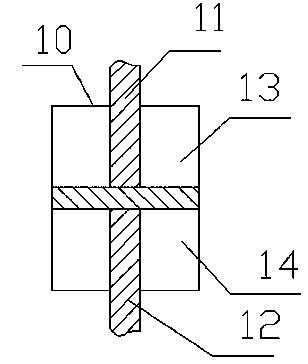

[0015] The hydraulic cylinder 2 is composed of a cylinder body 10, a first piston rod 11 and a second piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com