A kind of automatic drilling equipment

A drilling equipment, magnetic drilling technology, applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems of difficult to accurately control the position of the magnetic drill, difficult to ensure the drilling accuracy, etc., to achieve The structure is simple and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments will be described in detail below in conjunction with the drawings in the embodiments of the present invention.

[0033] During drilling operations, there are many special positions and working conditions that are not suitable for manual drilling operations, and automatic drilling equipment is required to assist drilling. At present, some of the existing automatic drilling equipment can only realize the linear movement of the drill along the track, which cannot meet the needs of drilling at any position; and some automatic drilling equipment has low control accuracy for the drilling position. To sum up, there is currently a need for an automatic drilling device that can automatically and accurately move the drill to any required drilling position to achieve precise drilling operations.

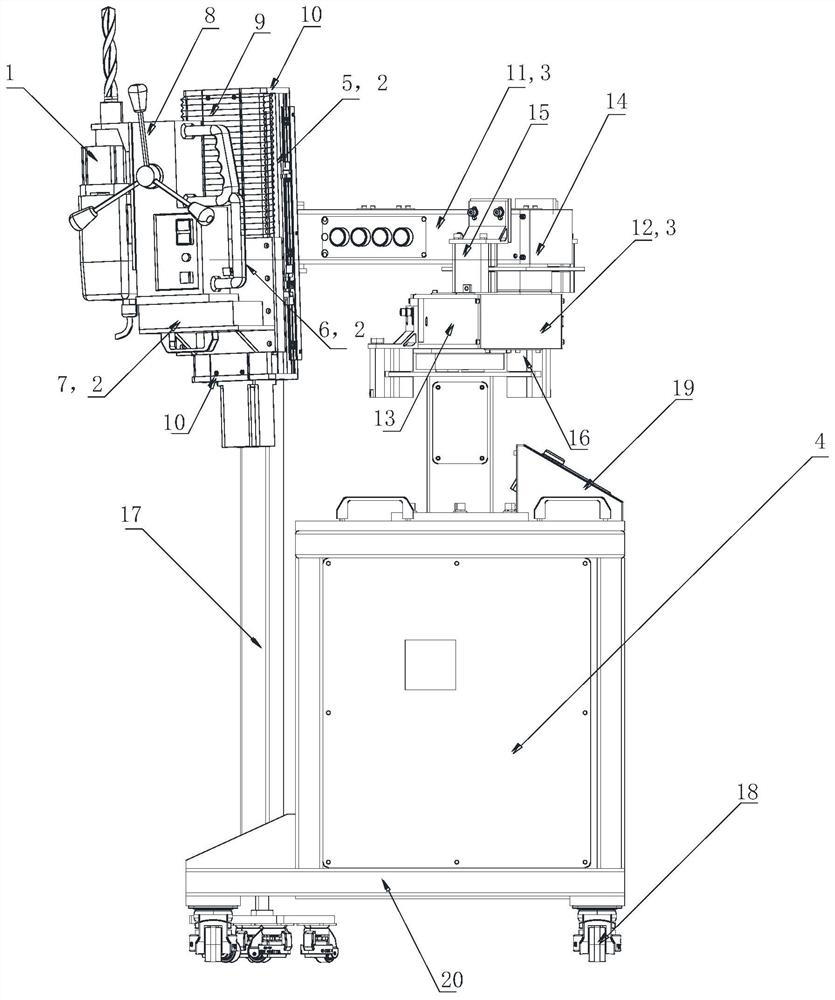

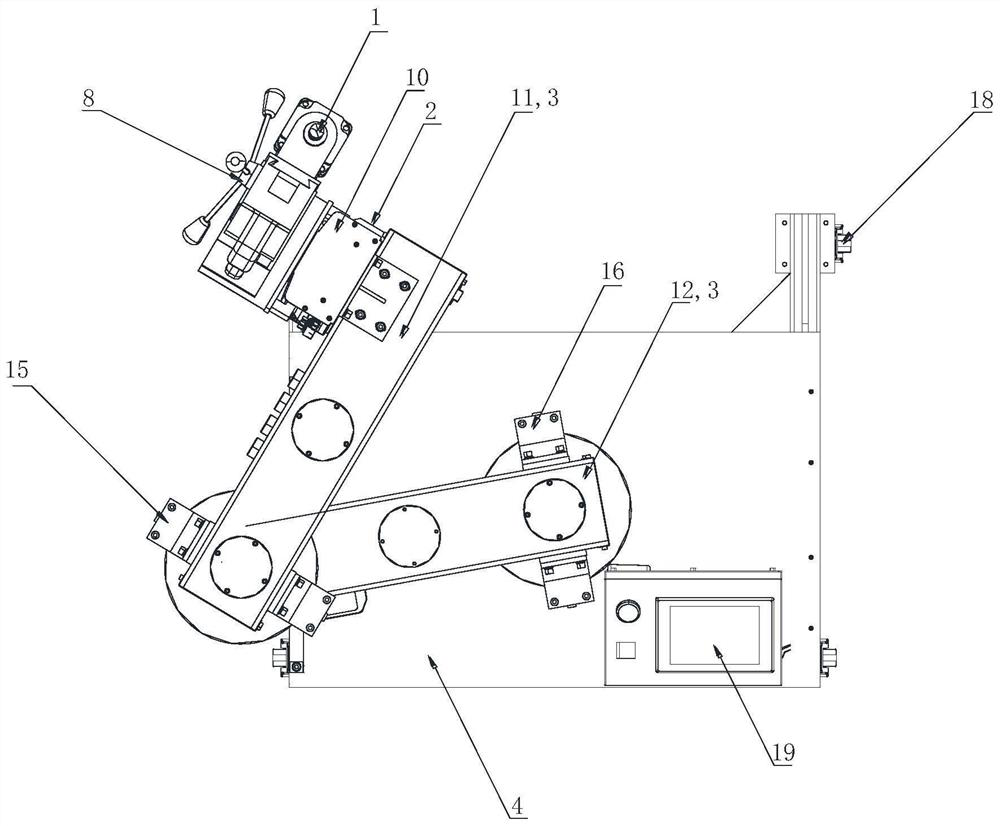

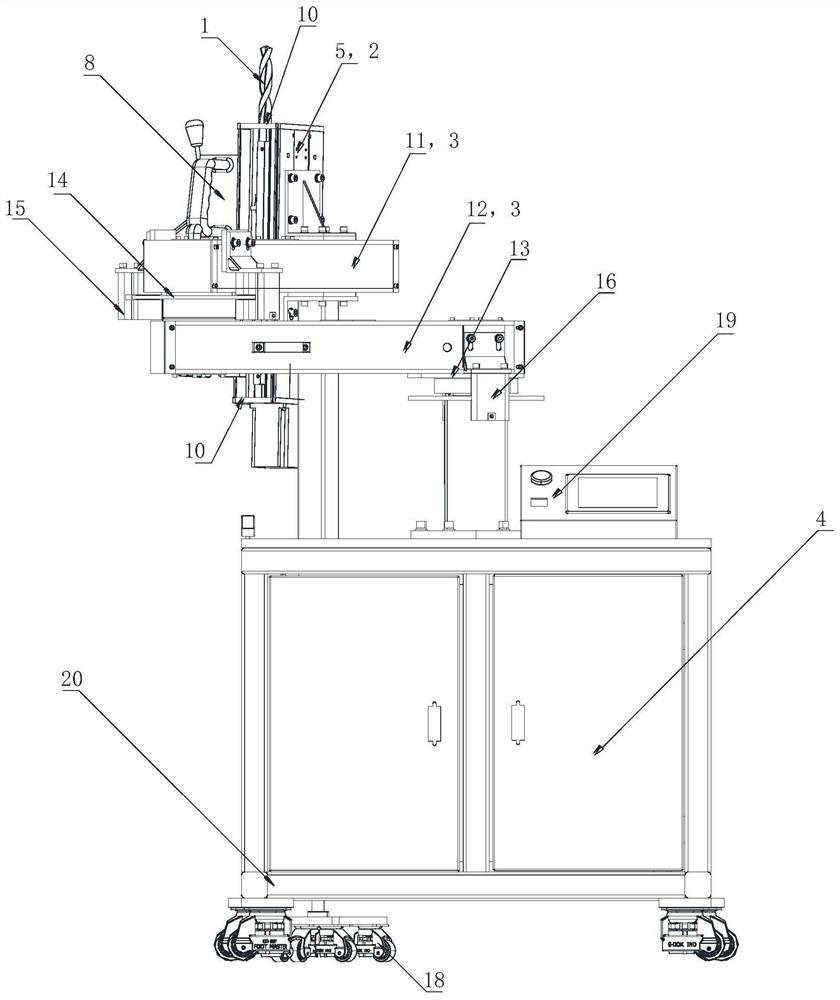

[0034] The present invention as Figure 1-3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com