Patents

Literature

36results about How to "Easy to adjust the horizontal position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

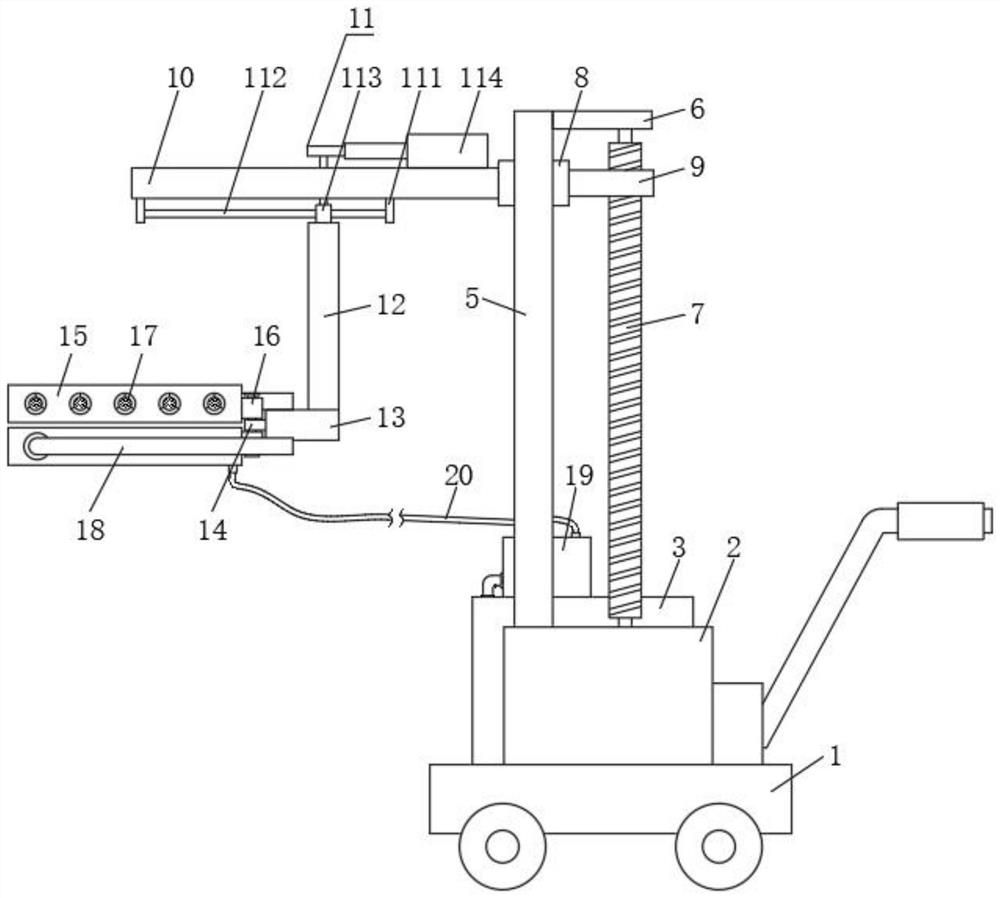

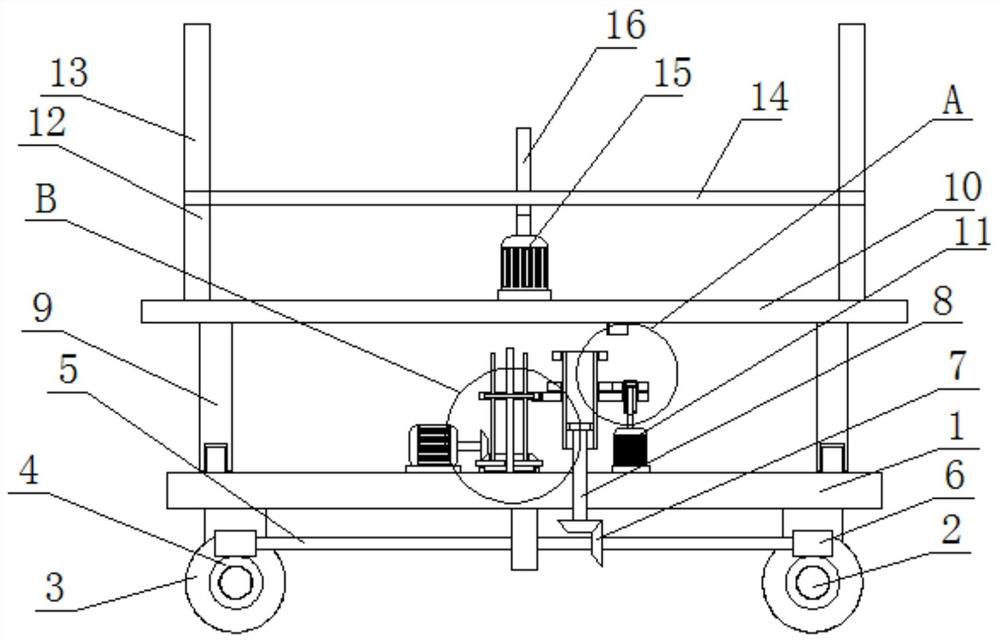

Fruit tree trunk spread brush machine for agricultural planting

InactiveCN111672652AEasy height adjustmentEasy to adjust spraying heightLiquid spraying apparatusPlant protectionFruit treeTree trunk

The invention relates to the technical field of agricultural planting, and discloses a fruit tree trunk spread brush machine for agricultural planting. The spread brush machine includes a walking trolley, a motor box and a coating box are fixedly arranged at the top of the walking trolley, the coating box is located on the back face of the motor box, a driving assembly is arranged in the motor box, and a supporting column is fixedly arranged at the top of the motor box. A fixing plate is fixedly arranged at the top end of the supporting column, a threaded rod is fixedly connected with the bottom of the fixing plate in a rotating mode, and the bottom of the threaded rod is connected with the driving assembly in a transmission mode. According to the spread brush machine, the driving assemblydrives the threaded rod to rotate, a connecting plate drives a movable block and a cantilever to lift, and the brushing height is convenient to adjust. A distance adjustment assembly is designed to adjust the distance between a brush applicator and an equipment machine body handily, the machine body can be brushed without moving near a fruit tree trunk, fruit trees with different thickness are convenient to brush, and the spread brush machine is wide in application range and facilitated in popularization.

Owner:泉州台商投资区秋鑫茶业有限公司

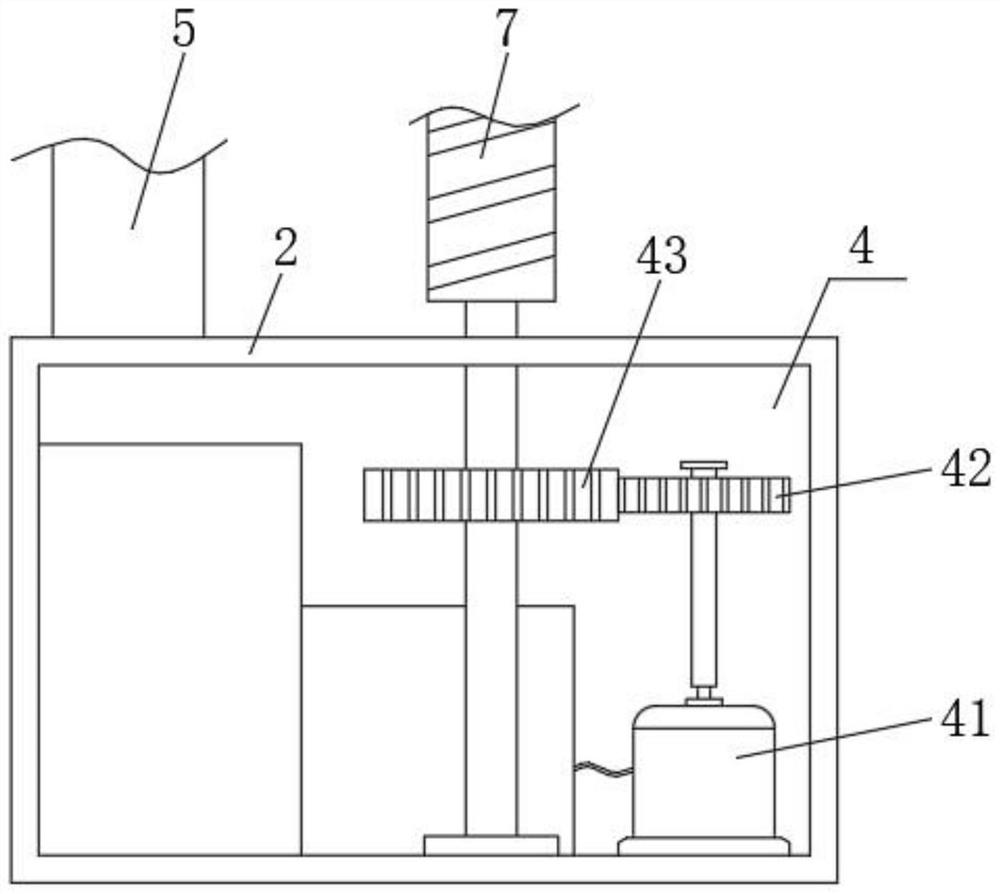

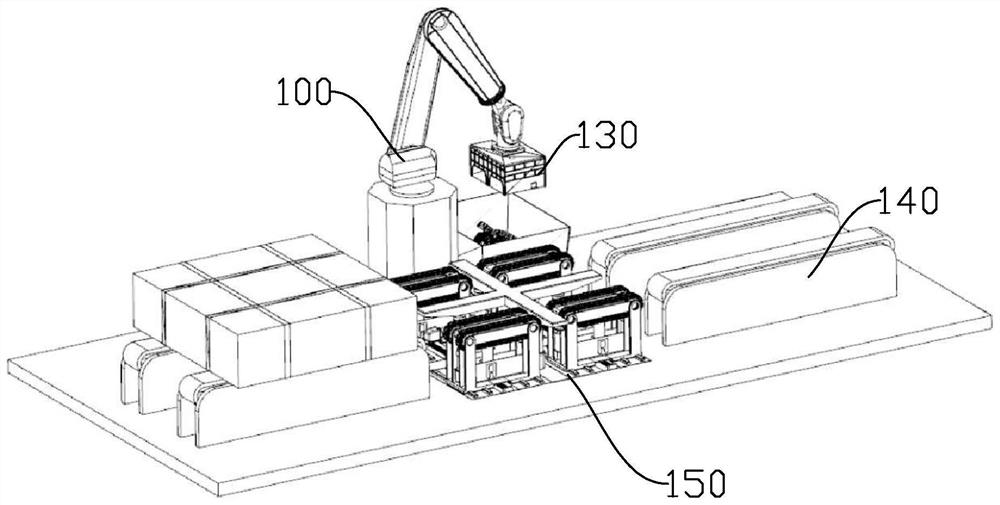

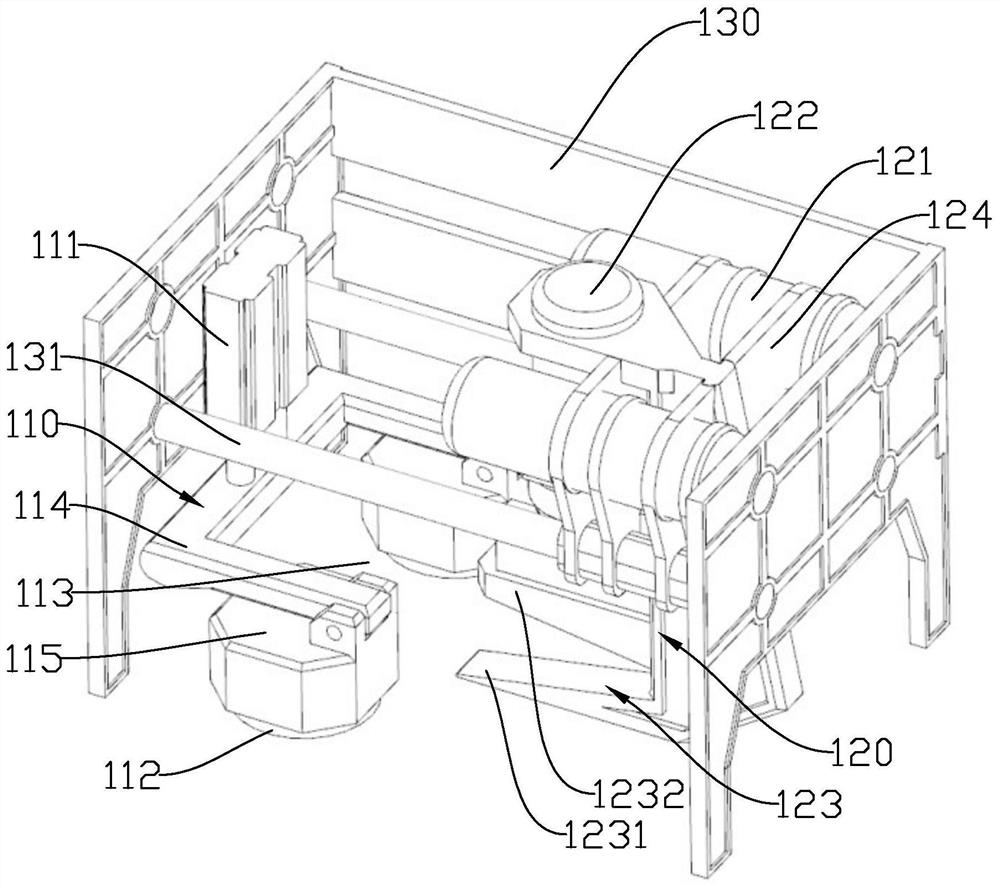

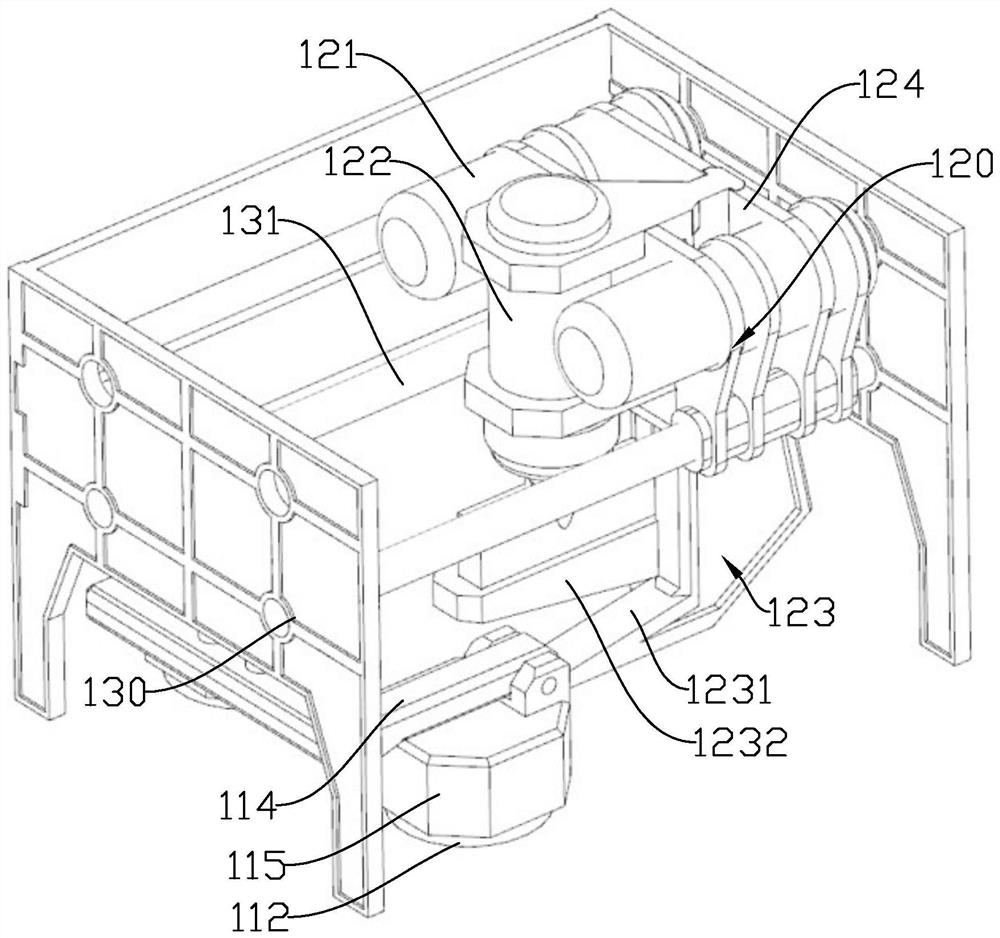

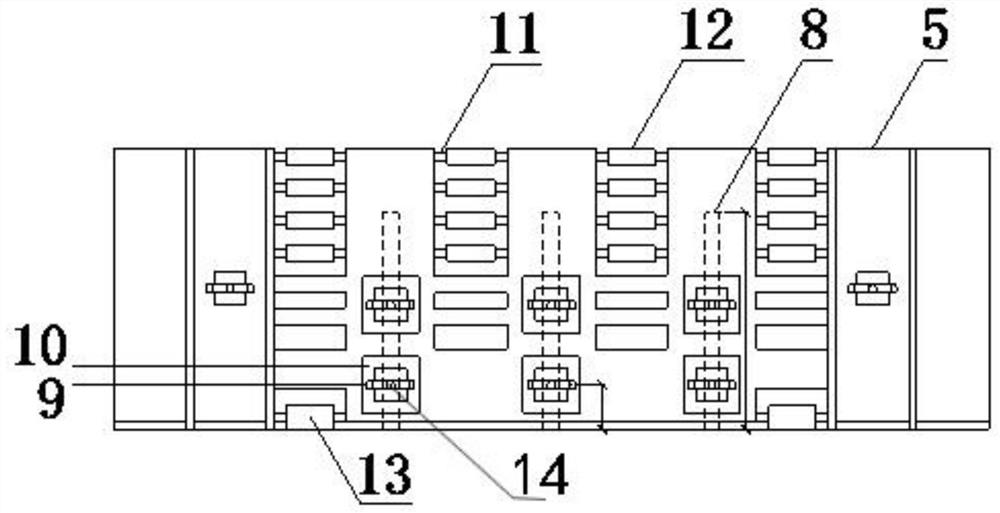

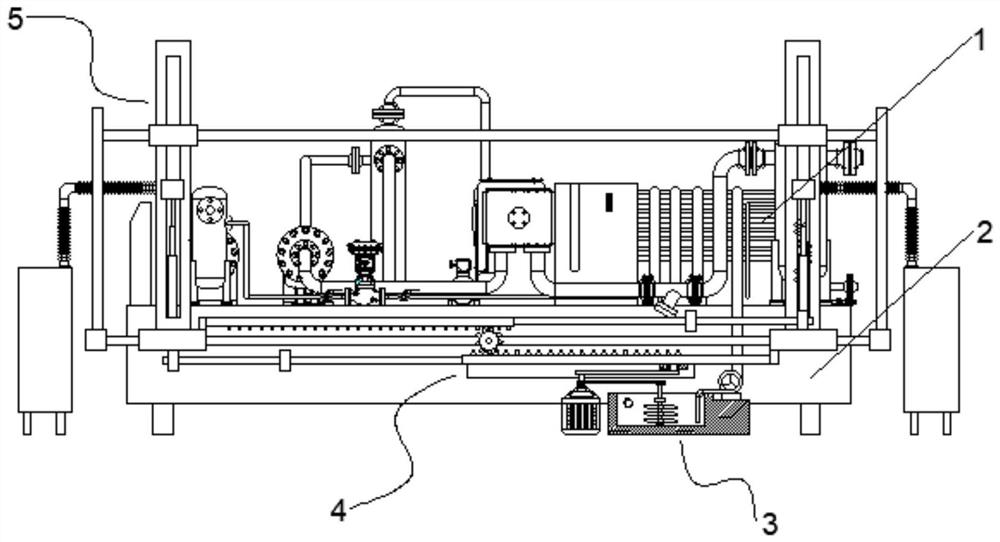

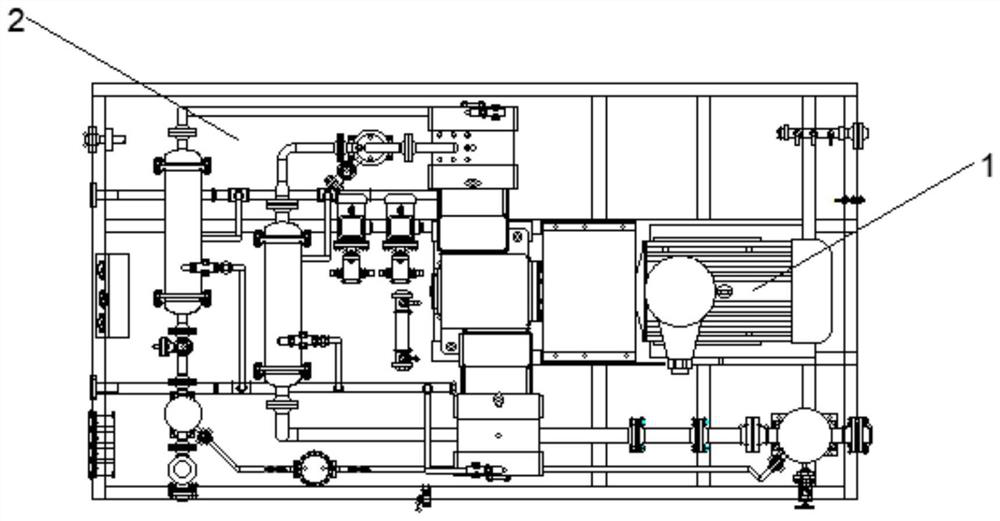

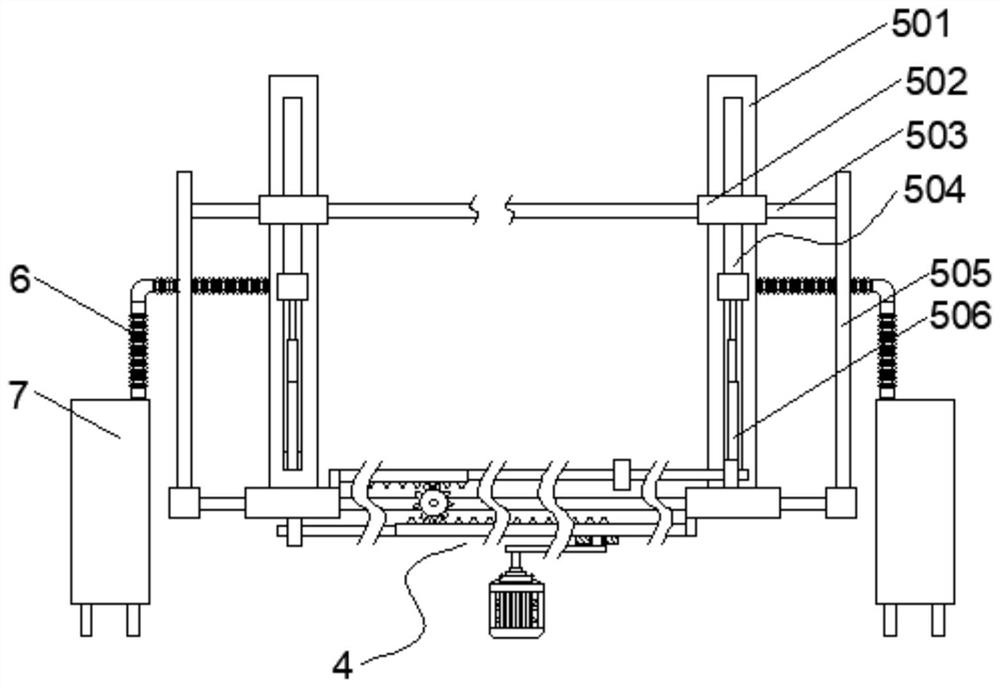

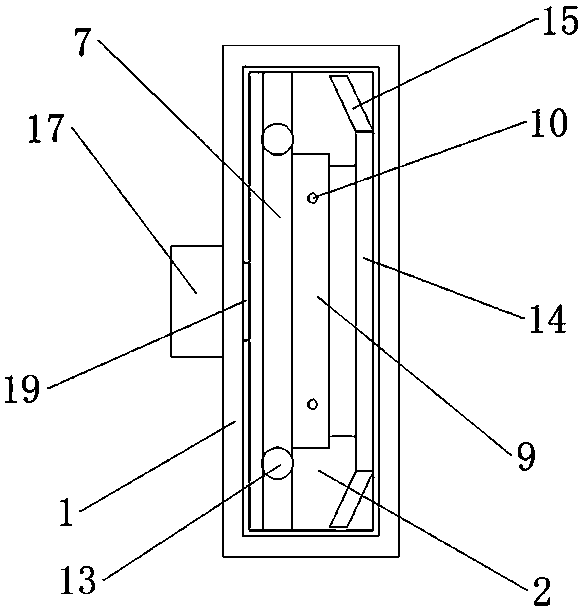

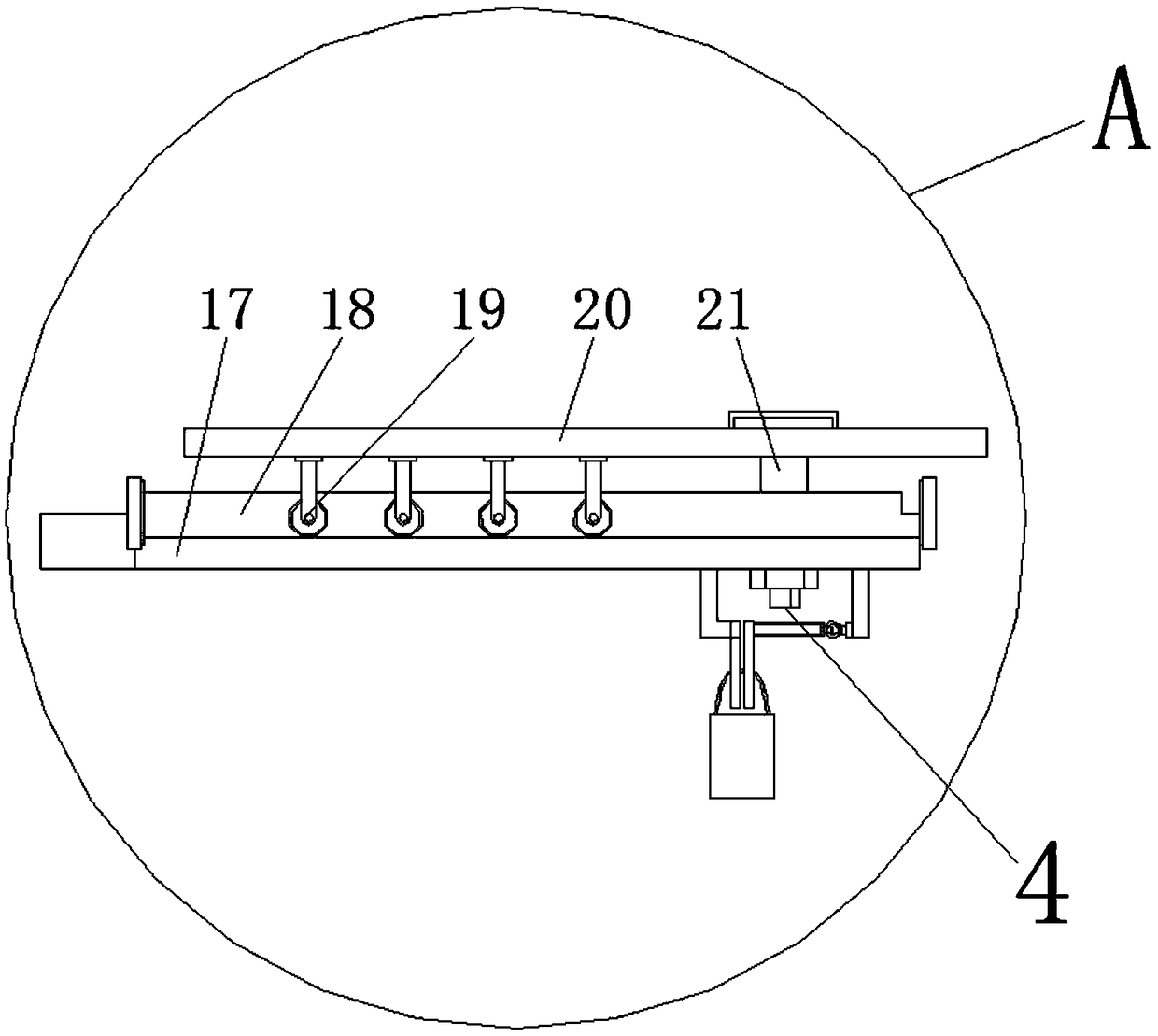

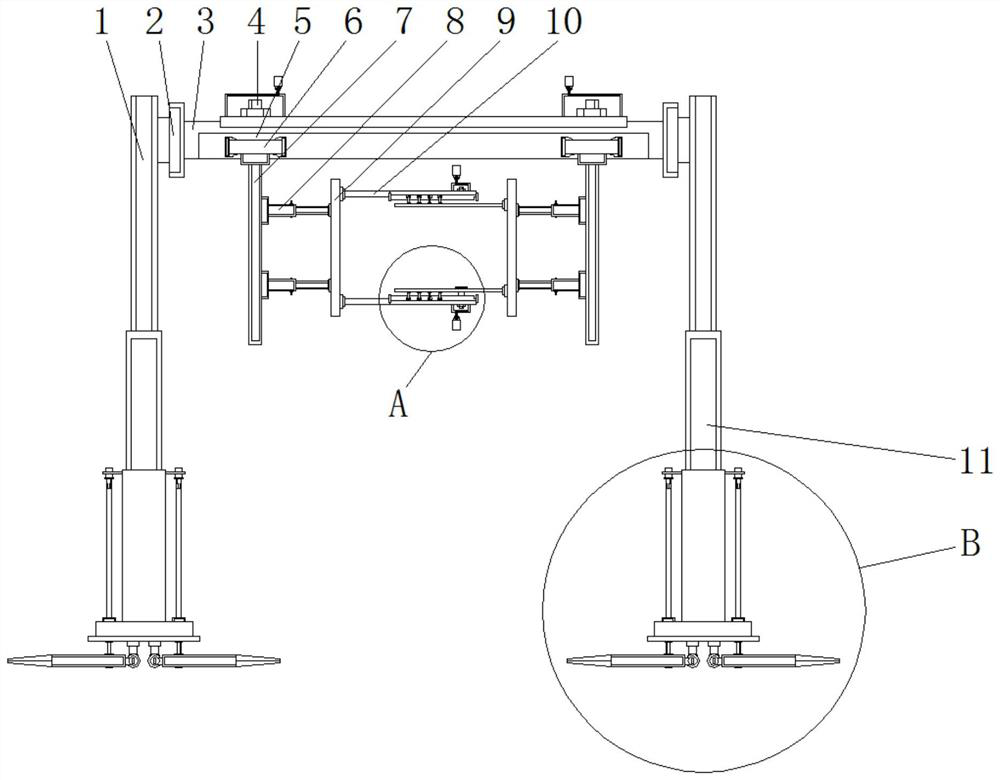

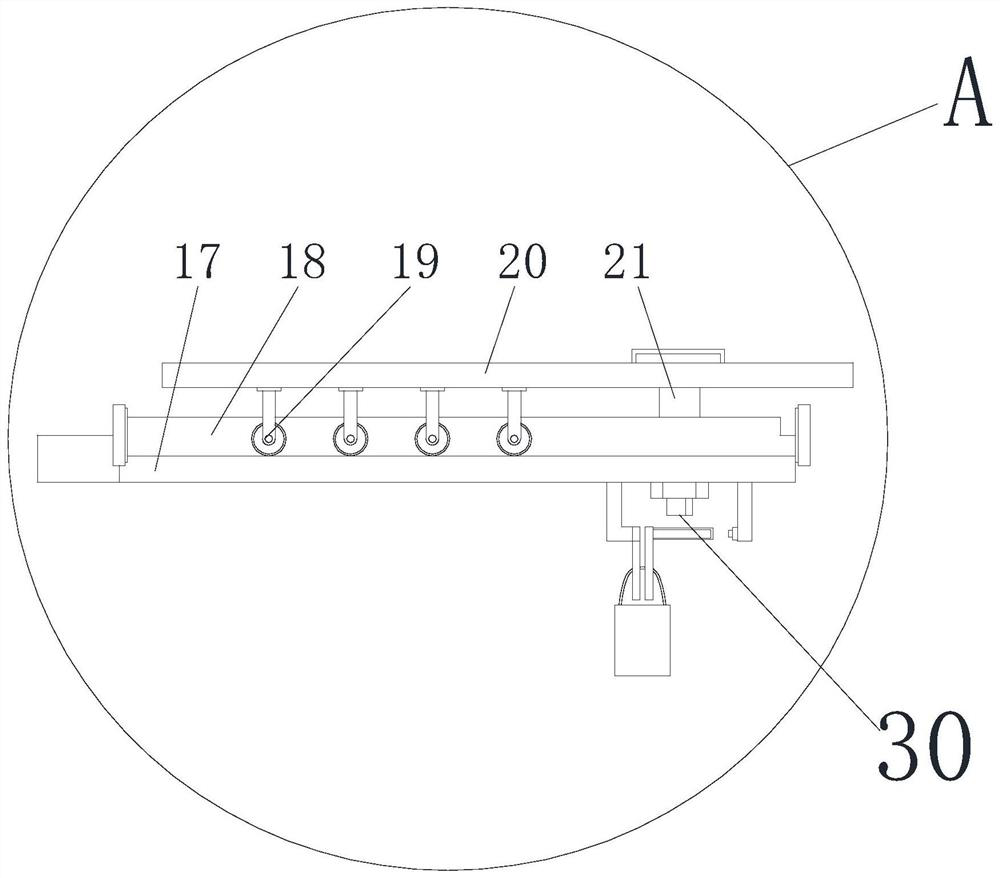

Electrolytic copper steel strip automatic unbundling system

ActiveCN113978867AEasy to cutEasy to handleConveyorsProcess efficiency improvementEngineeringSteel belt

The invention discloses an electrolytic copper steel strip automatic unbundling system, belongs to the field of disassembling equipment, and aims to automatically remove steel strips packed on electrolytic copper. The system comprises two conveying belt devices used for conveying electrolytic copper, wherein an electrolytic copper machining area is formed between the two conveying belt devices; the electrolytic copper machining area is provided with a multi-axis robot, four supporting frame devices and a cross-shaped bracket; the multi-axis robot is provided with a scanning device, an extracting component, a shearing component and a winding component; each supporting frame device comprises a jacking head used for jacking the electrolytic copper to remove steel strips on the electrolytic copper; the multi-axis robot adjusts positions of the extracting component, the shearing component and the winding component according to feedback information of the scanning device on positions of the steel strips; the extracting component is used for upwards extracting the steel strips and keeping the steel strips tight; the shearing component is used for shearing the steel strips; and the winding component is used for winding the cut steel strips into steel strip coil stocks.

Owner:甘肃海亮新能源材料有限公司 +1

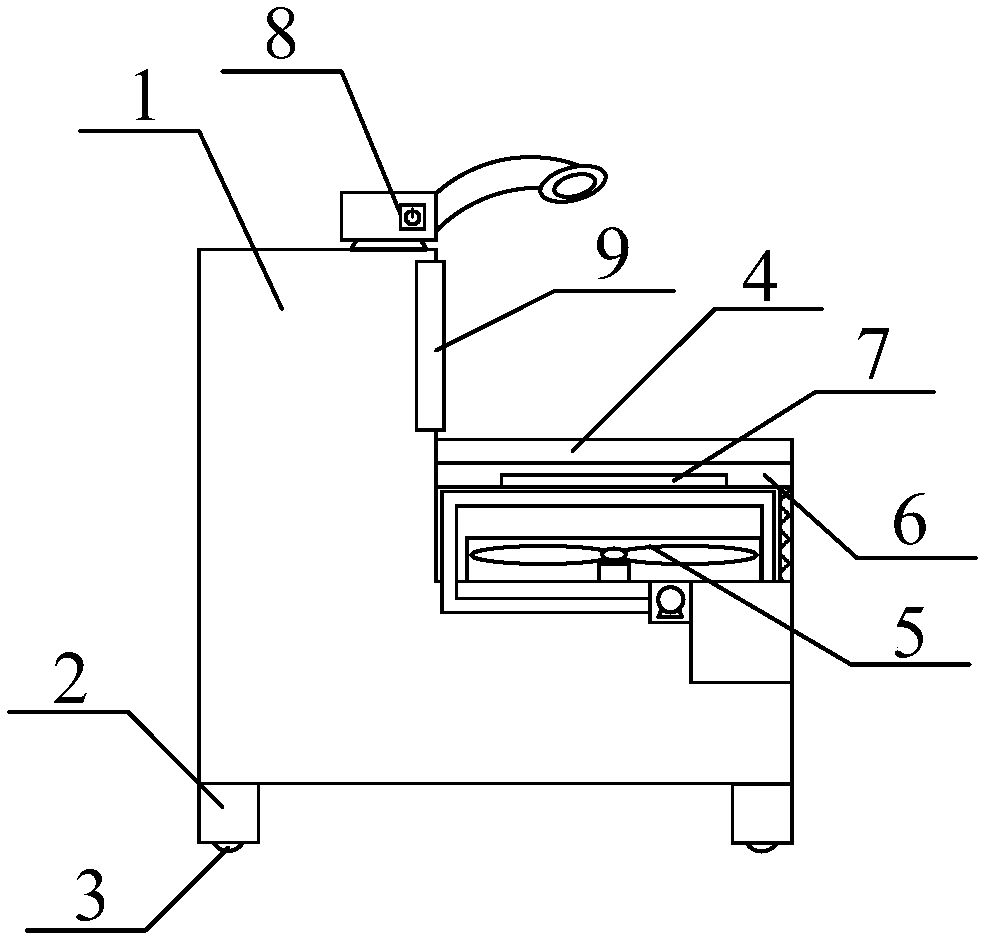

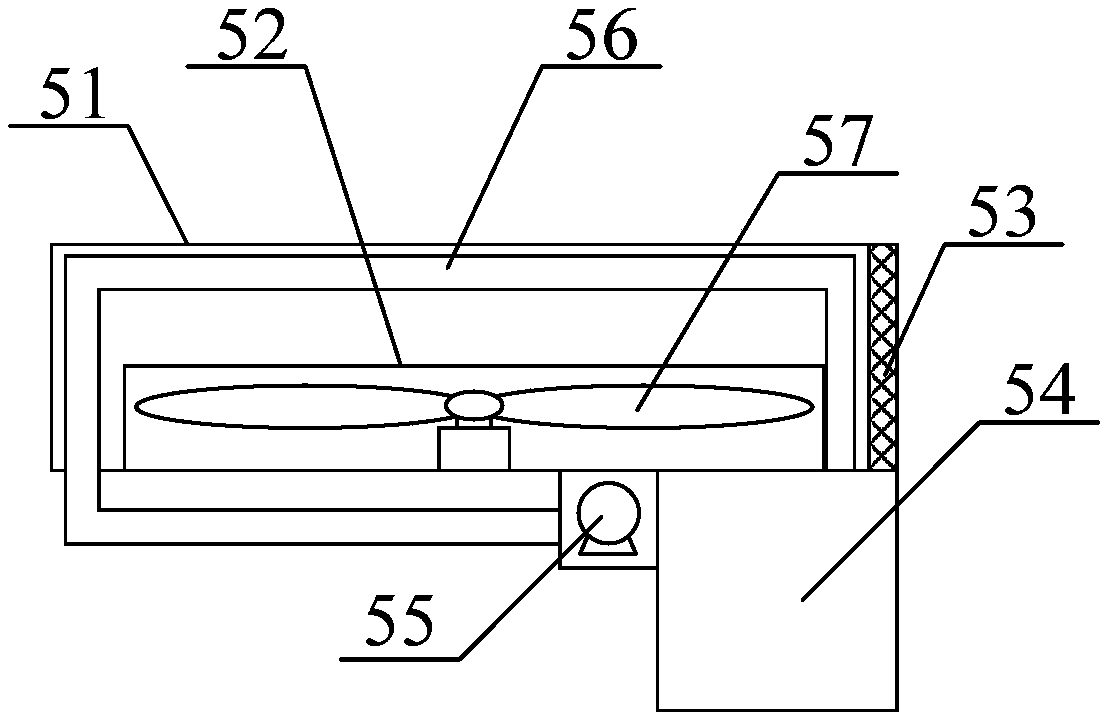

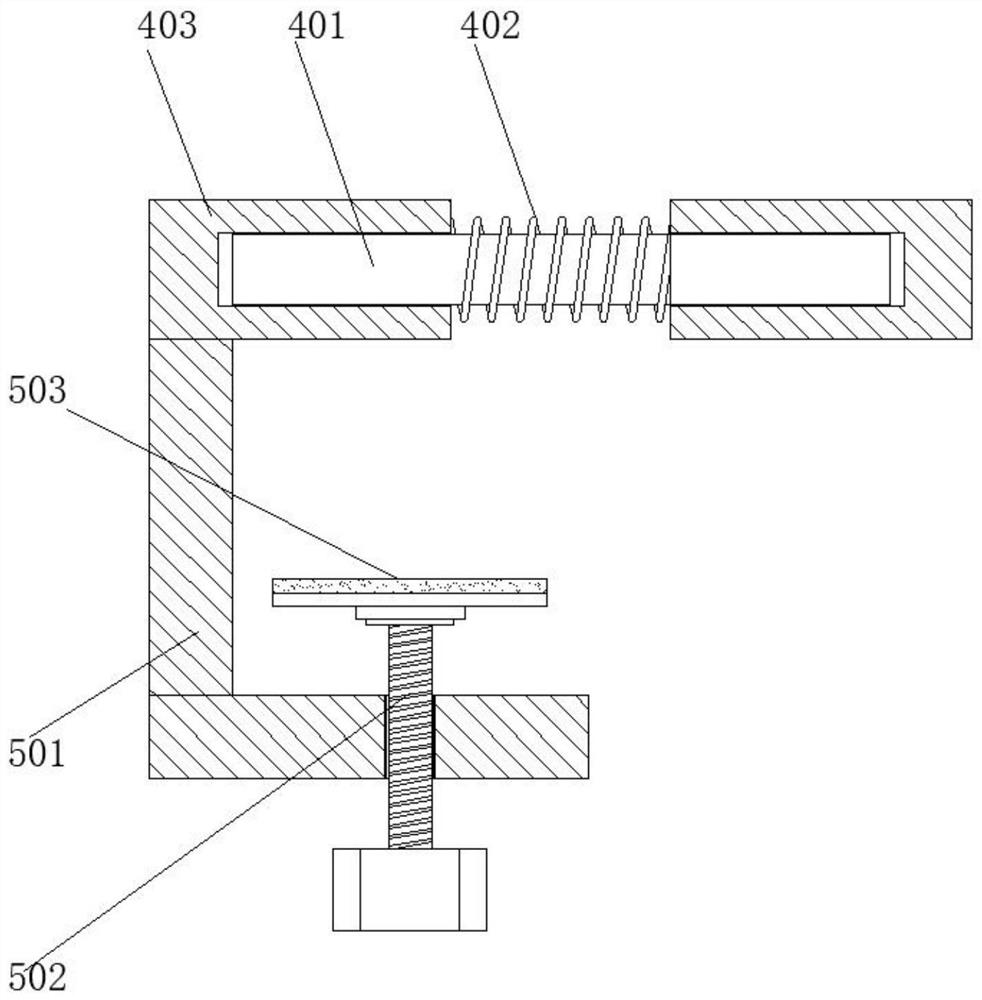

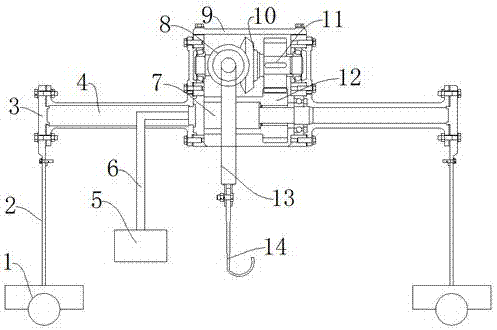

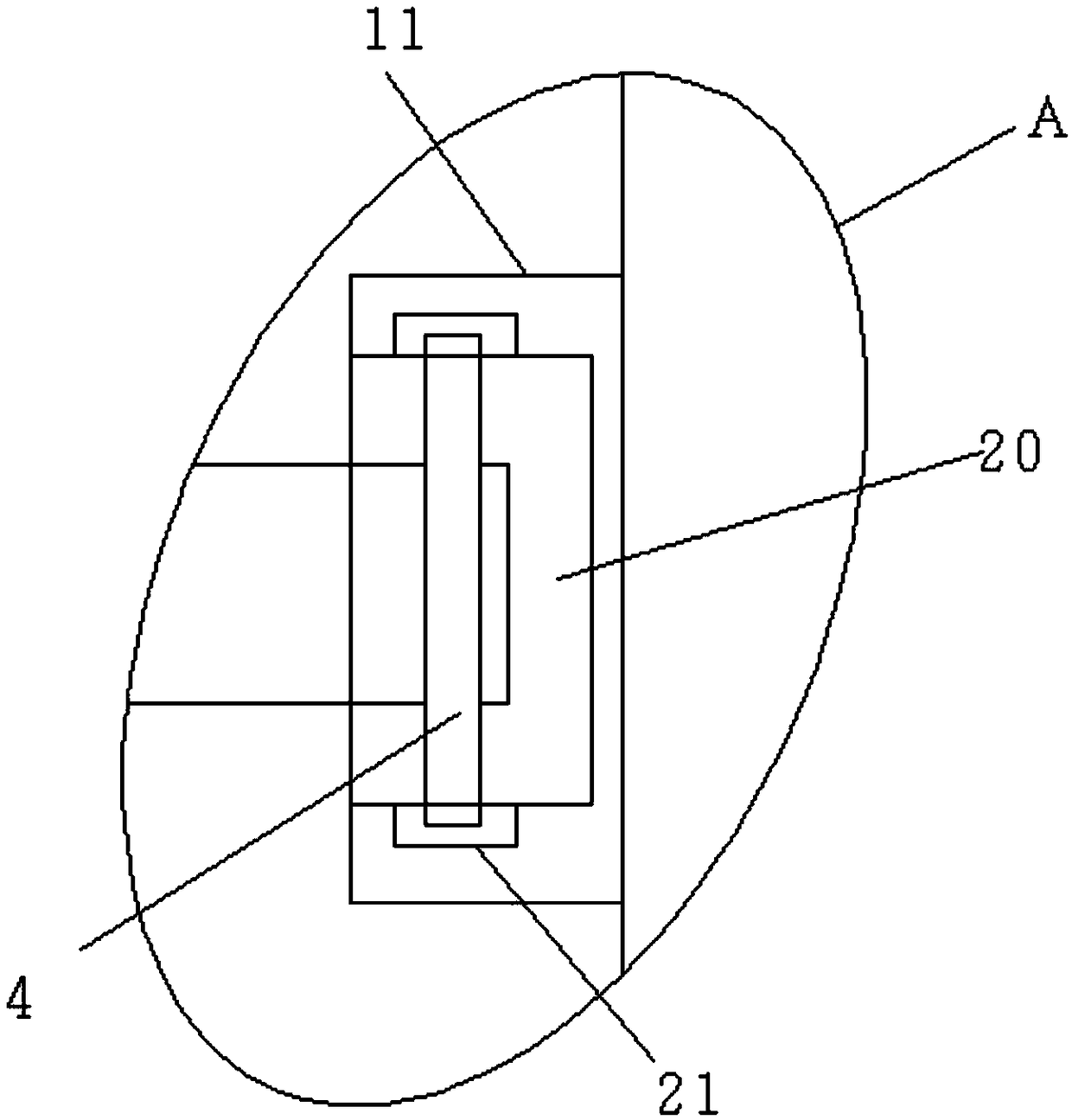

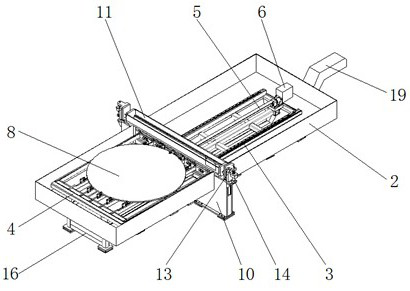

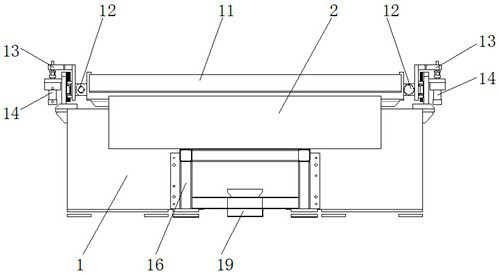

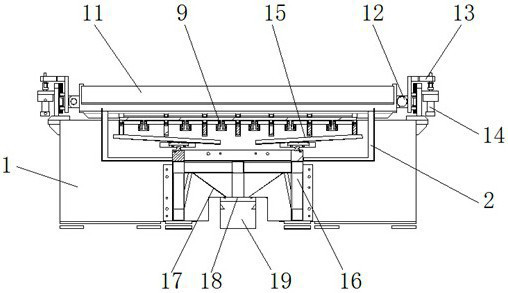

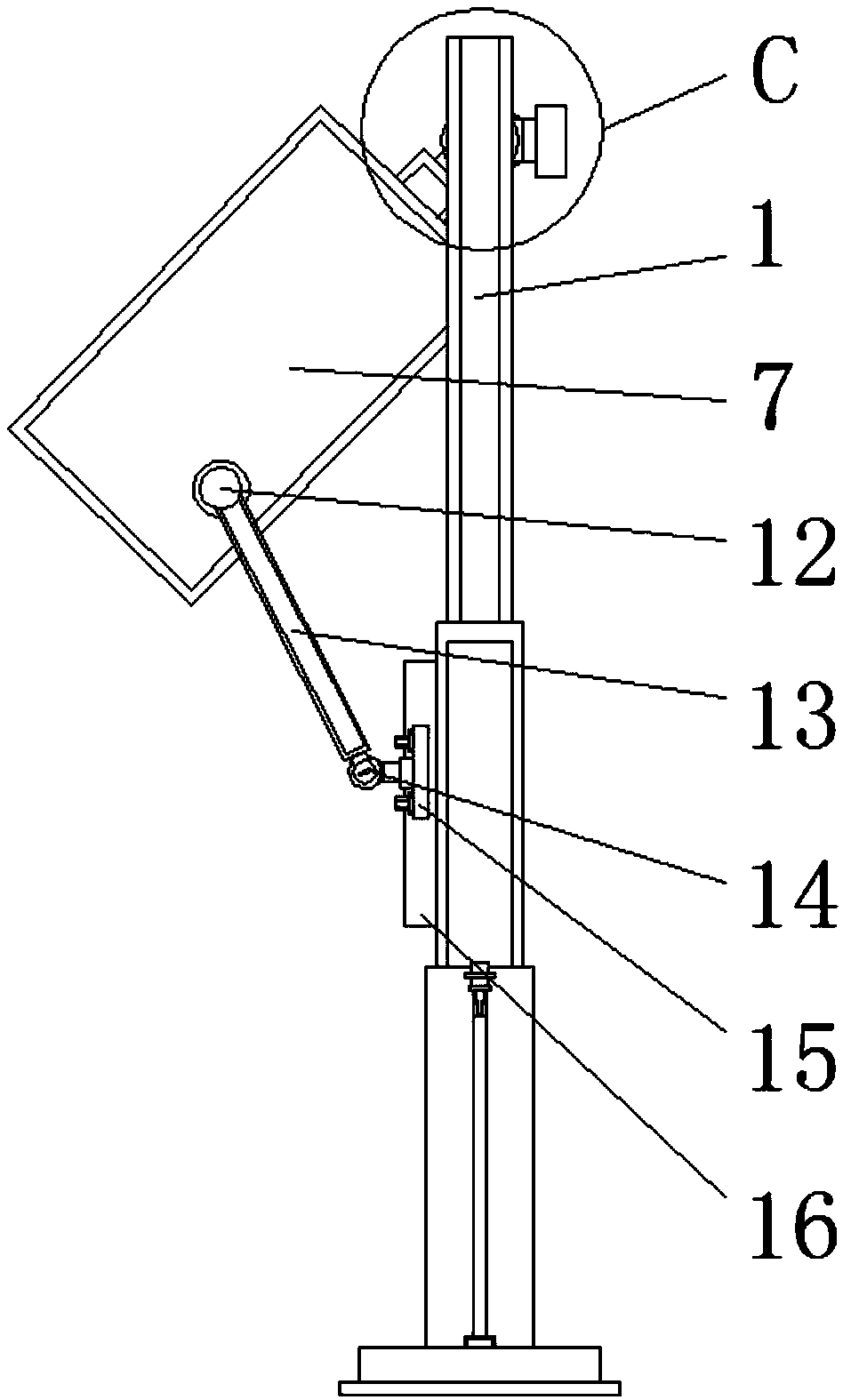

Multifunctional LED (light emitting diode) parallel exposure machine

InactiveCN107748482AEasy to adjust the horizontal positionEasy to adjust vertical positionPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringRadiation angle

The invention discloses a multifunctional LED (light emitting diode) parallel exposure machine. The multifunctional LED parallel exposure machine comprises an outer casing, support legs, spacers, a working frame structure, a heat radiating device, a lamp frame, a lamp source, an auxiliary illumination device and a control panel, wherein the support legs are welded at the left side and right side of the lower part of the outer casing; each spacer is arranged at the middle lower part of the corresponding support leg; the working frame structure is arranged at the right side of the upper part ofthe lamp frame. The multifunctional LED parallel exposure machine has the advantages that a longitudinal scale is arranged on a slide rail through an adjusting block, so that the transverse position of an exposure part on the working frame body can be conveniently adjusted; a transverse positioning frame is sheathed at the right side of the longitudinal scale, so that the longitudinal position ofthe exposure part on the working frame body can be conveniently adjusted; a dustproof net is arranged at the right side of a fixing framework, so that the dust is favorably prevented from entering thefixing framework, and the heat radiation effect on the lamp source is further improved by arranging a circulating pipe and a heat radiating fan; a lamp tube adopts a telescopic plastic corrugated tube, so that the radiation angle of an illumination lamp is conveniently adjusted, and the use function is further improved.

Owner:张家港奇点光电科技有限公司

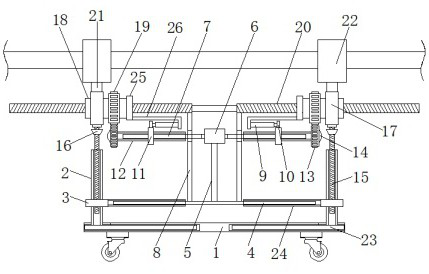

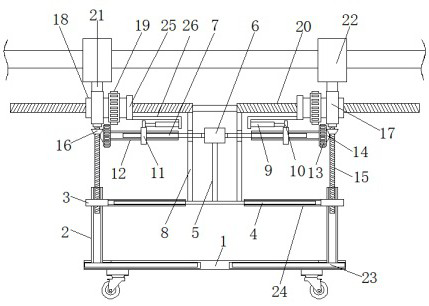

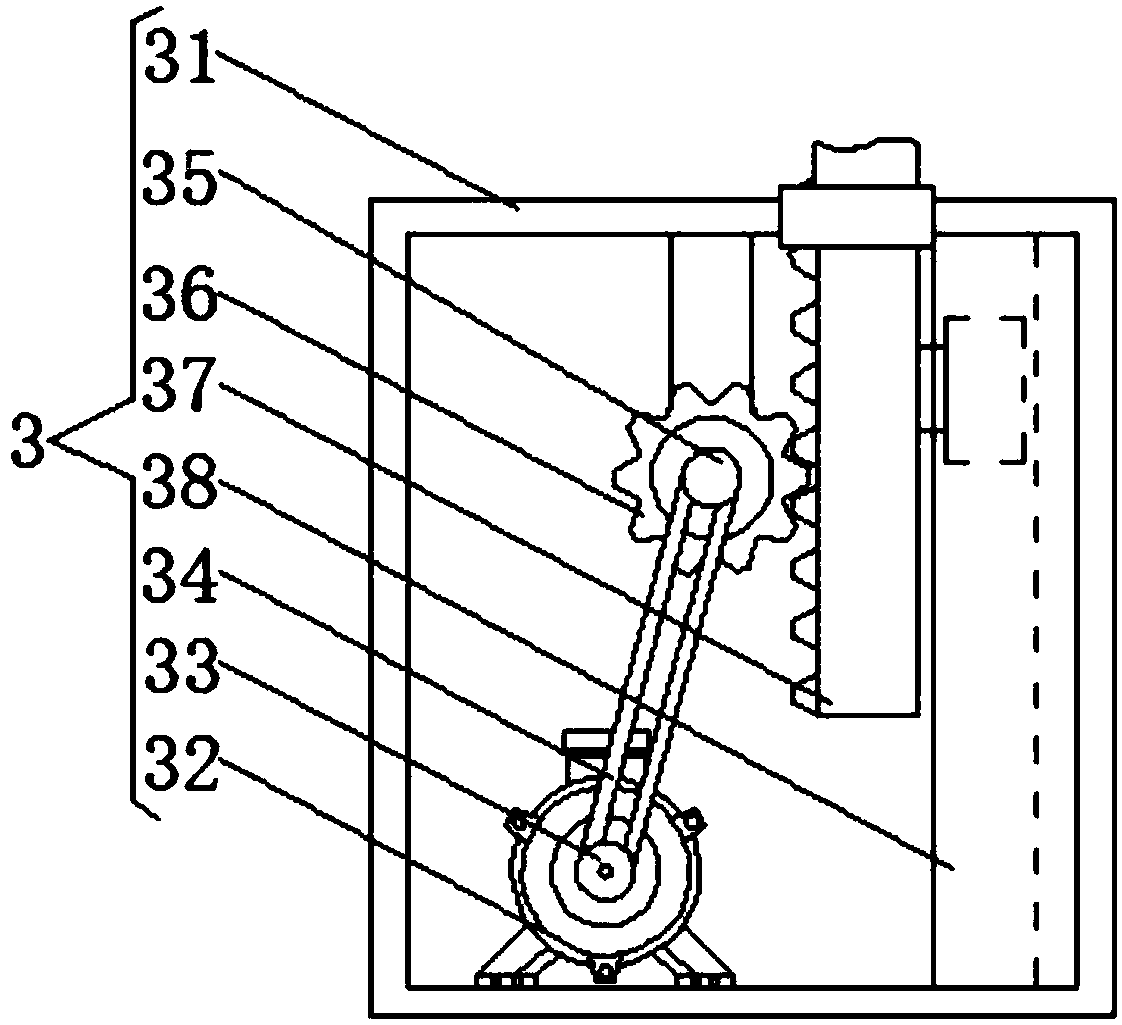

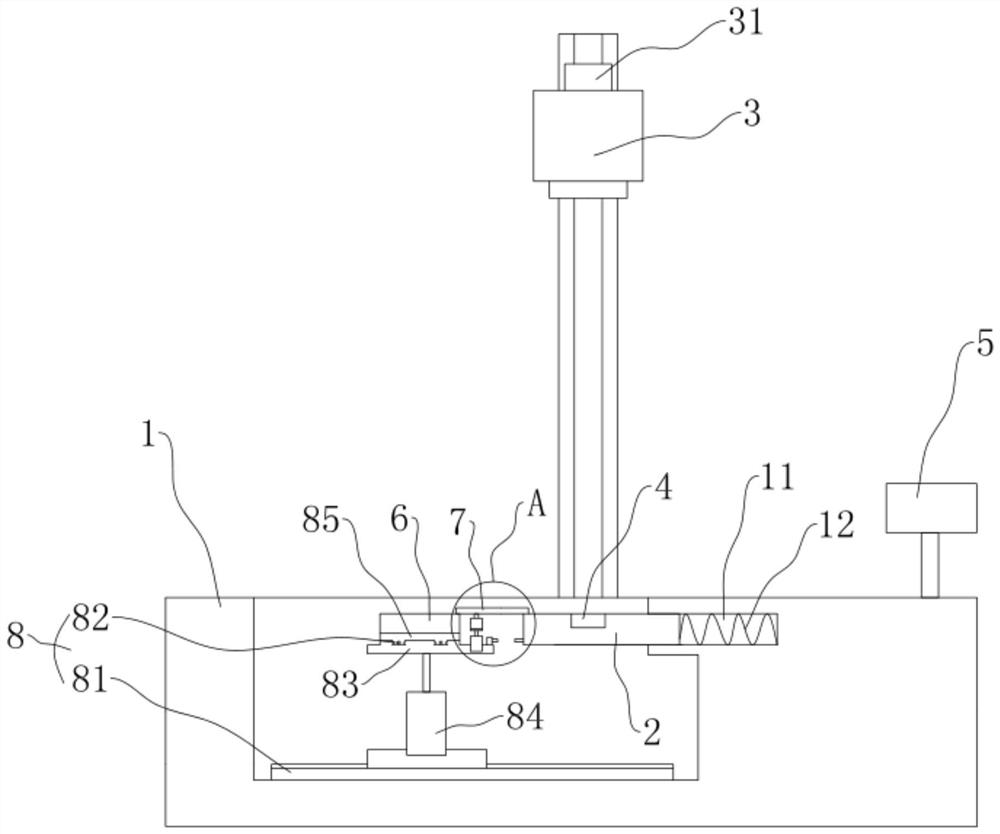

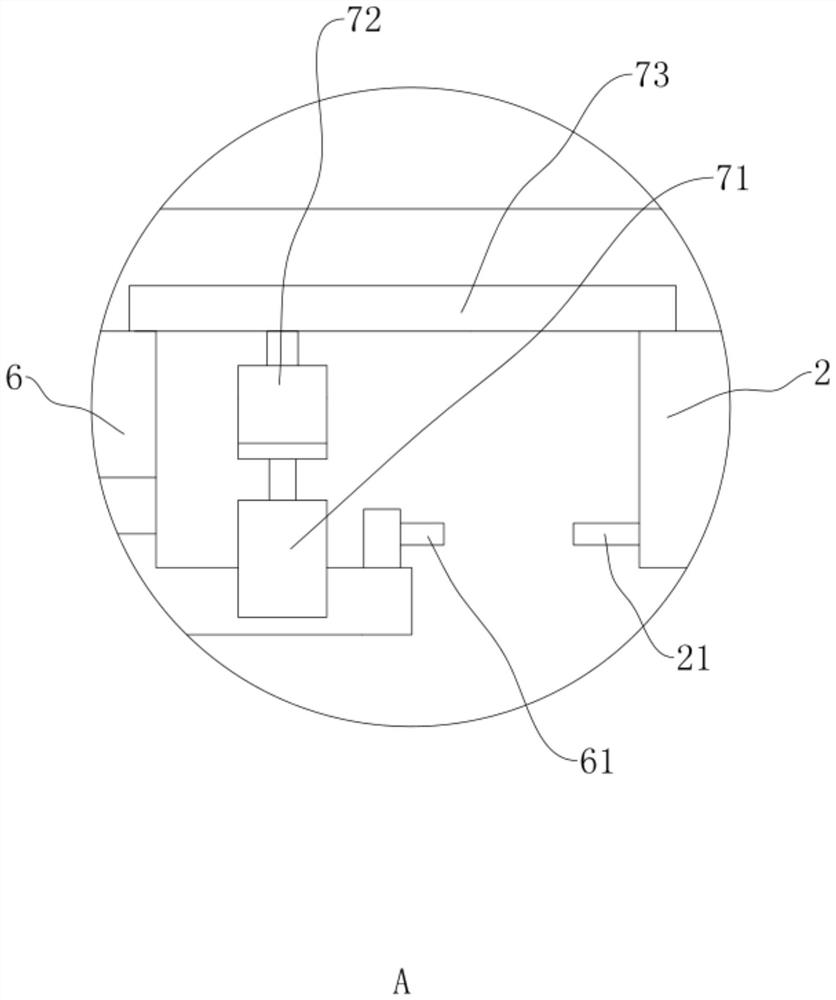

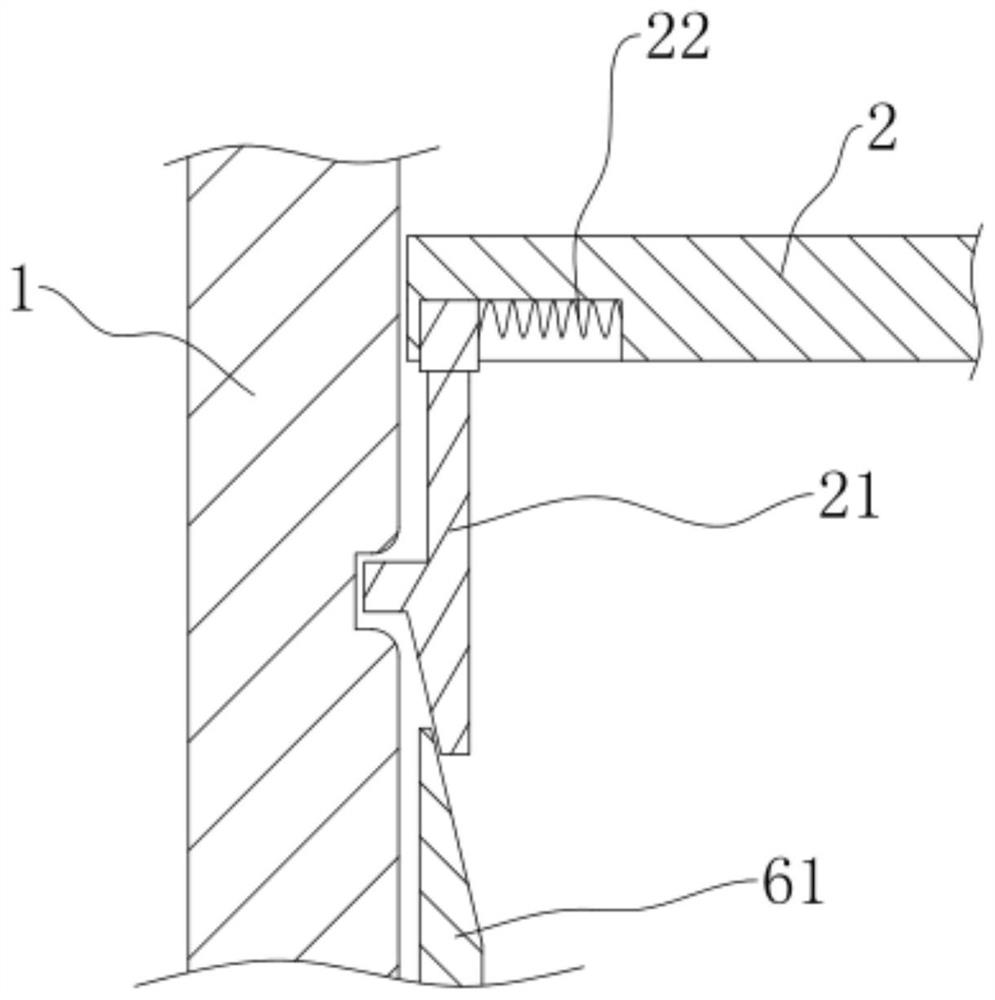

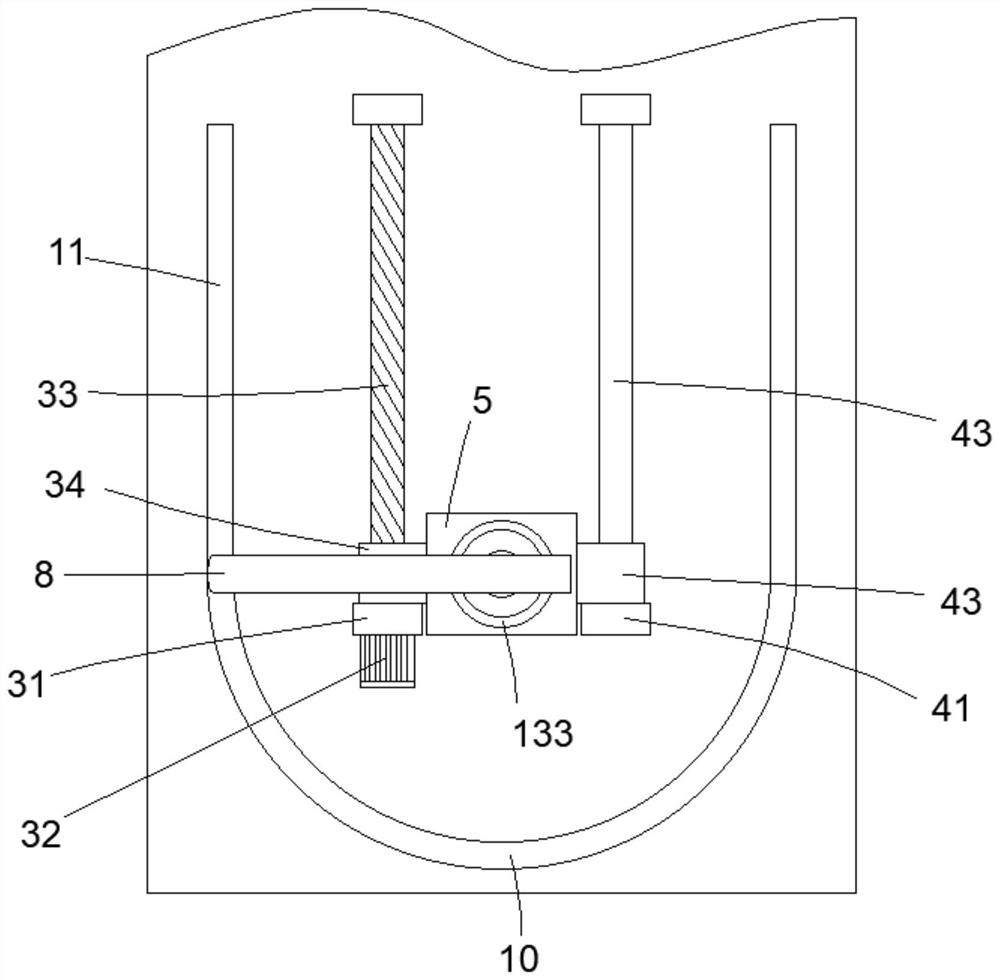

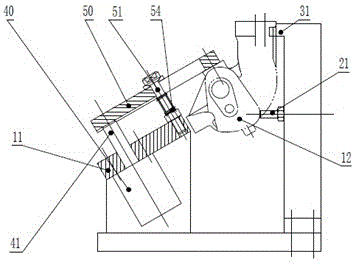

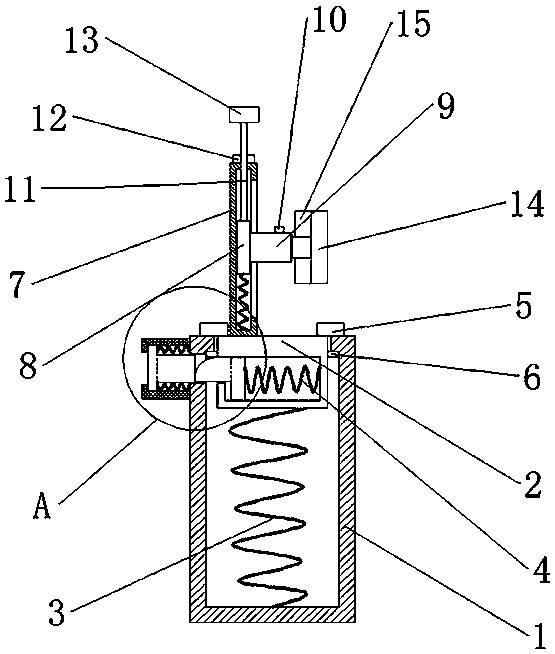

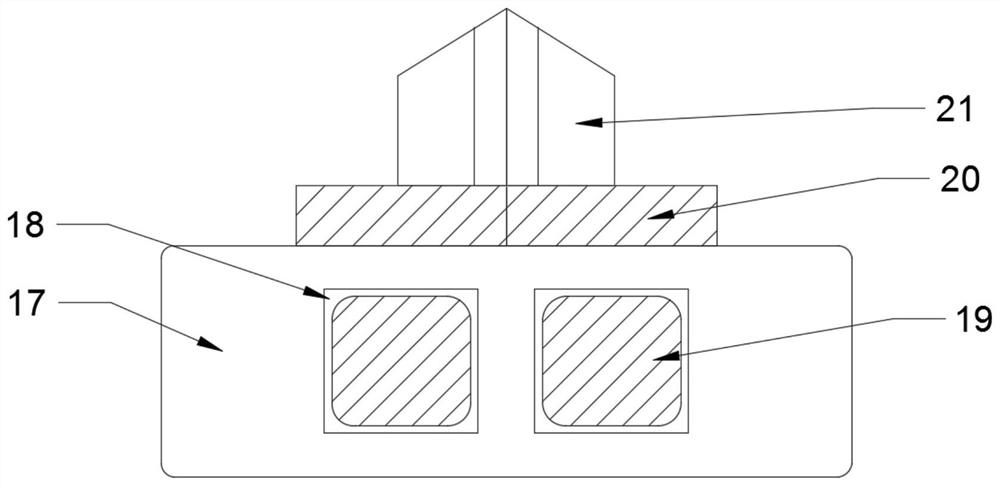

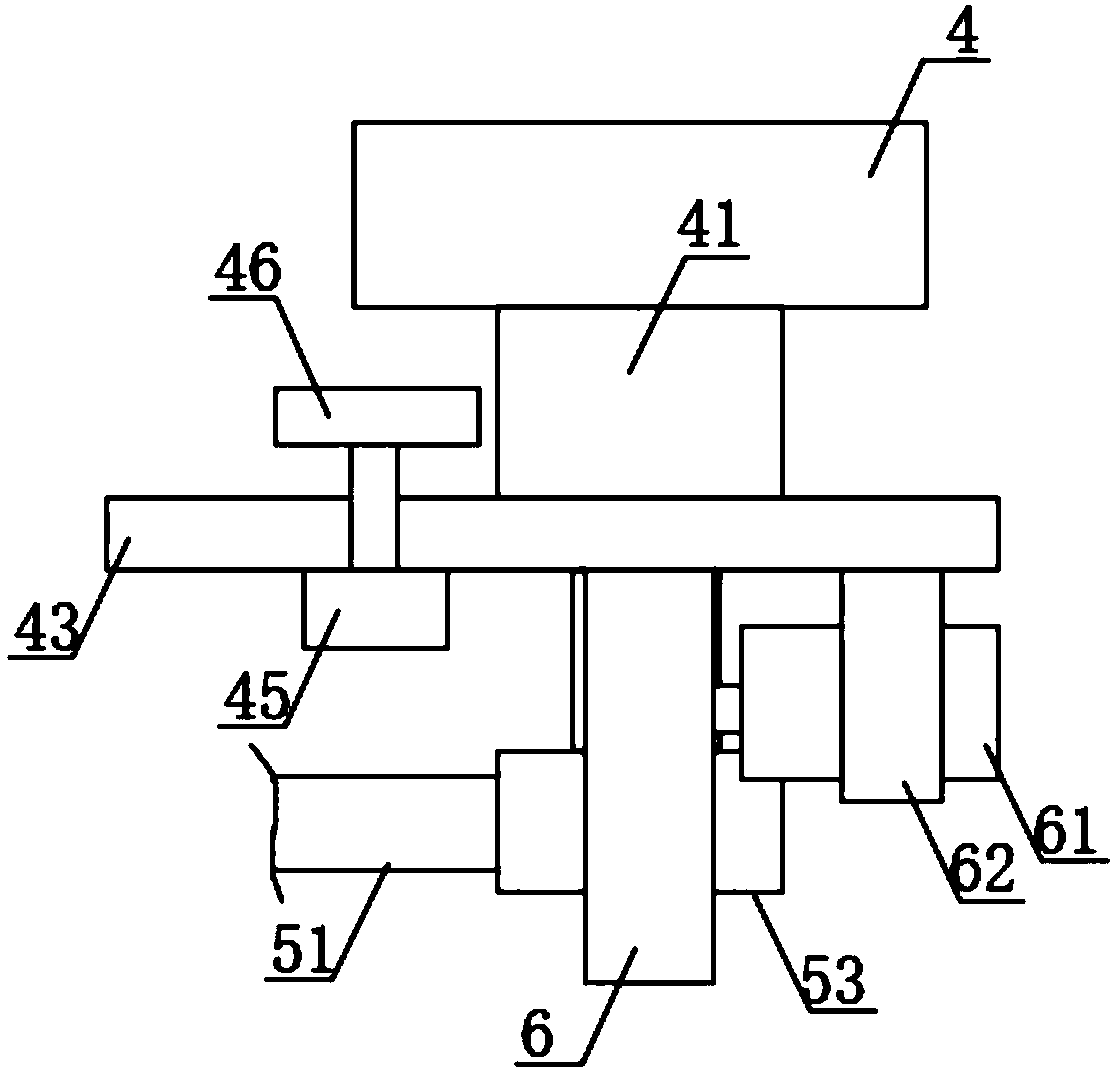

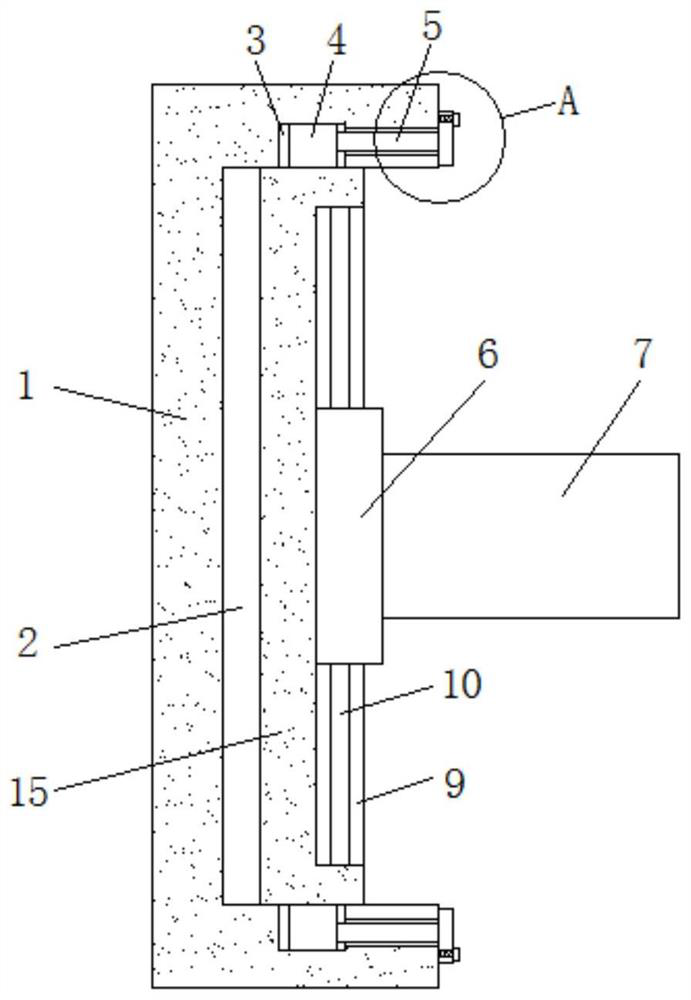

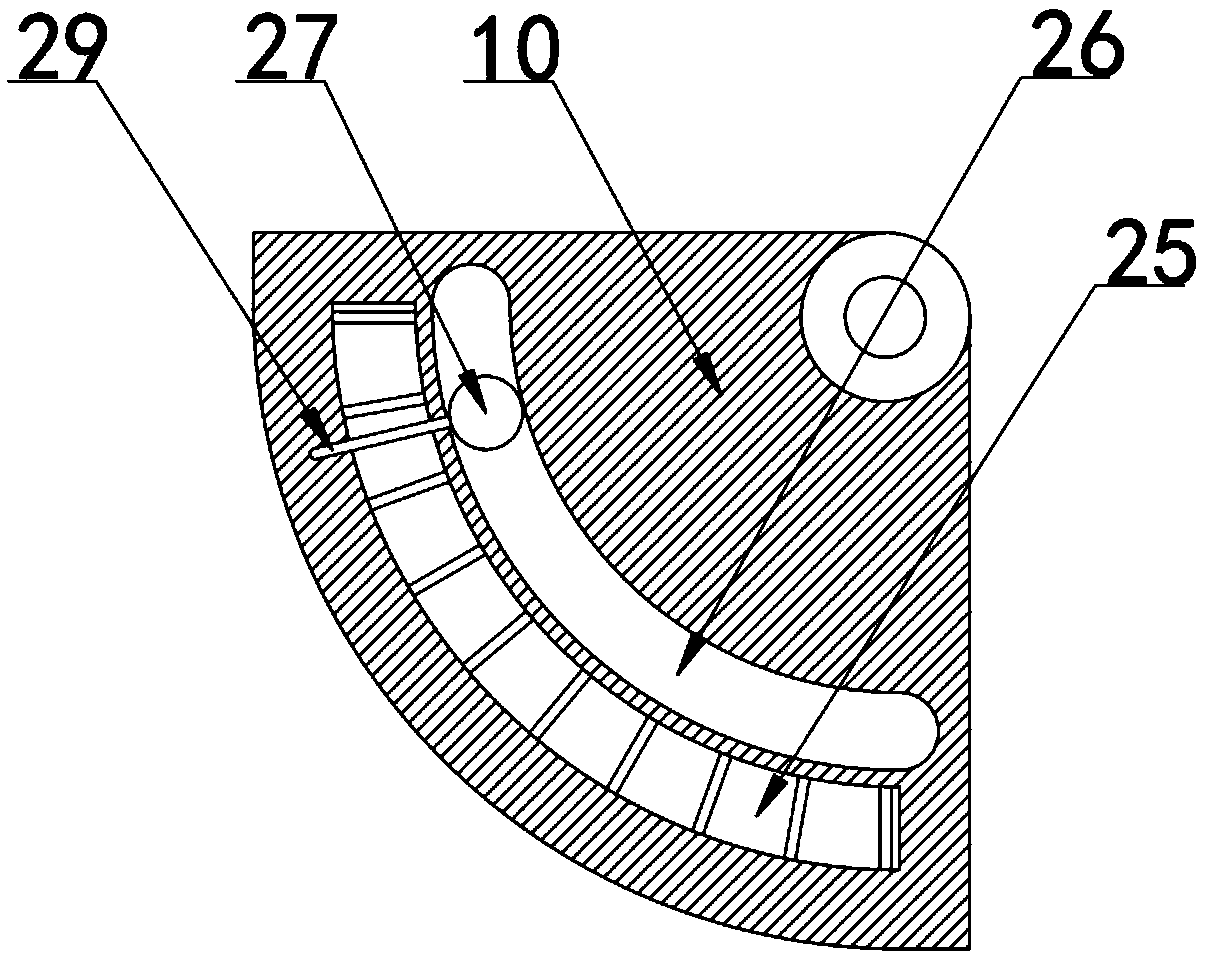

Tunnel steel formwork lining trolley convenient to center

InactiveCN112483128AStrong convenienceSmooth rotationUnderground chambersTunnel liningArchitectural engineeringElectric machinery

The invention belongs to the field of building construction machinery, and particularly relates to a tunnel steel formwork lining trolley convenient to center. A driving motor is fixedly arranged on the top of a base, and a transmission pipe is in transmission connection with an output shaft of the driving motor; the top end of a connecting shaft extends into the transmission pipe and is movably clamped with the inner wall of the transmission pipe; a supporting plate is glidingly connected with the top of the base; the transmission pipe is in movable transmission connection with the supportingplate; an output shaft of a lifting motor arranged at one side of the top of the base is in transmission connection with the transmission pipe; supporting rods are glidingly connected onto position limiting plates symmetrically and fixedly arranged on the top of the supporting plate; an arc-shaped edge beam is fixedly arranged on the top of each supporting rod; an adjusting motor positioned between the two position limiting plates is fixedly arranged on the top of the supporting plate; and an output shaft of the adjusting motor is respectively in transmission connection with the two supporting rods. The tunnel steel formwork lining trolley convenient to center has the advantages that in the use process, the position does not need to be adjusted for many times; in addition, the position and height of the arc-shaped edge beams can be adjusted again; and the lining at the designated position can be supported, and good convenience is achieved.

Owner:温州因非科技有限公司

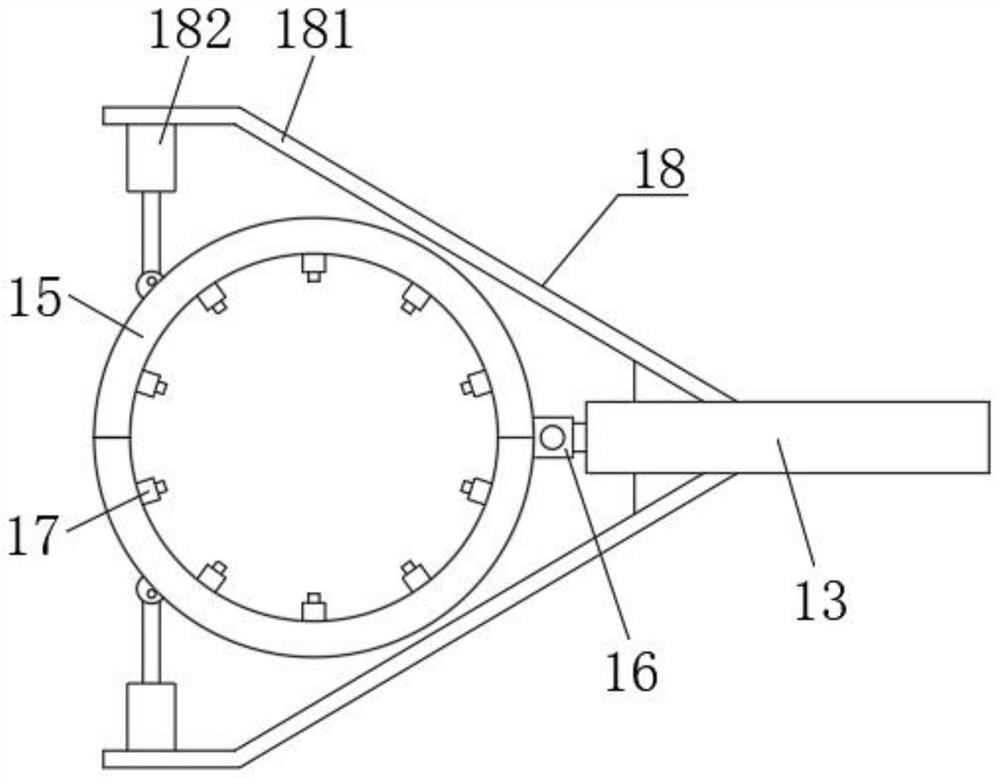

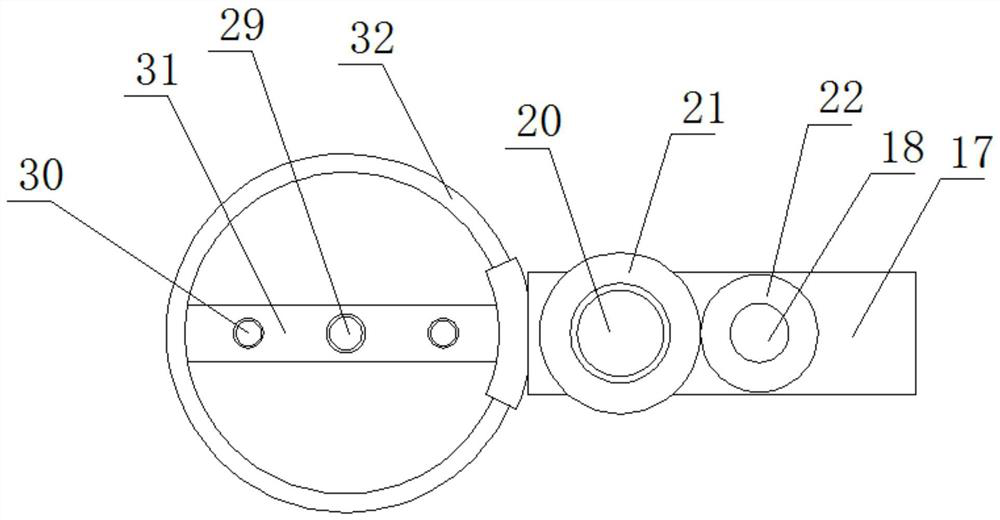

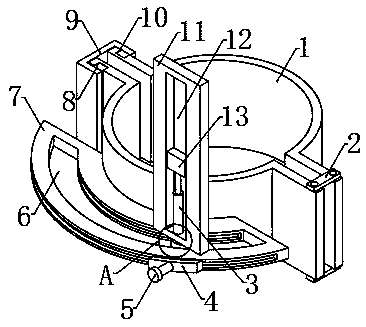

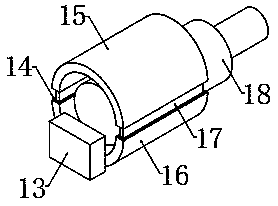

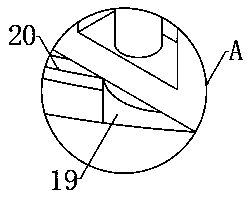

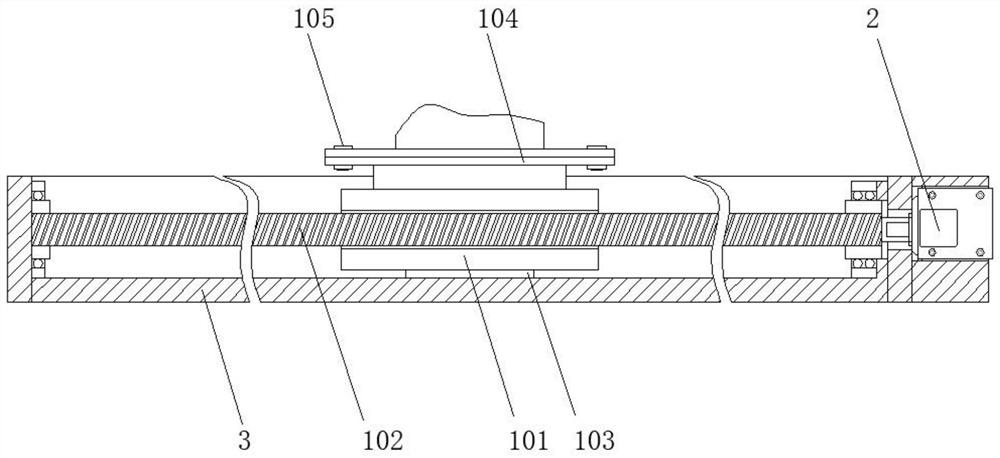

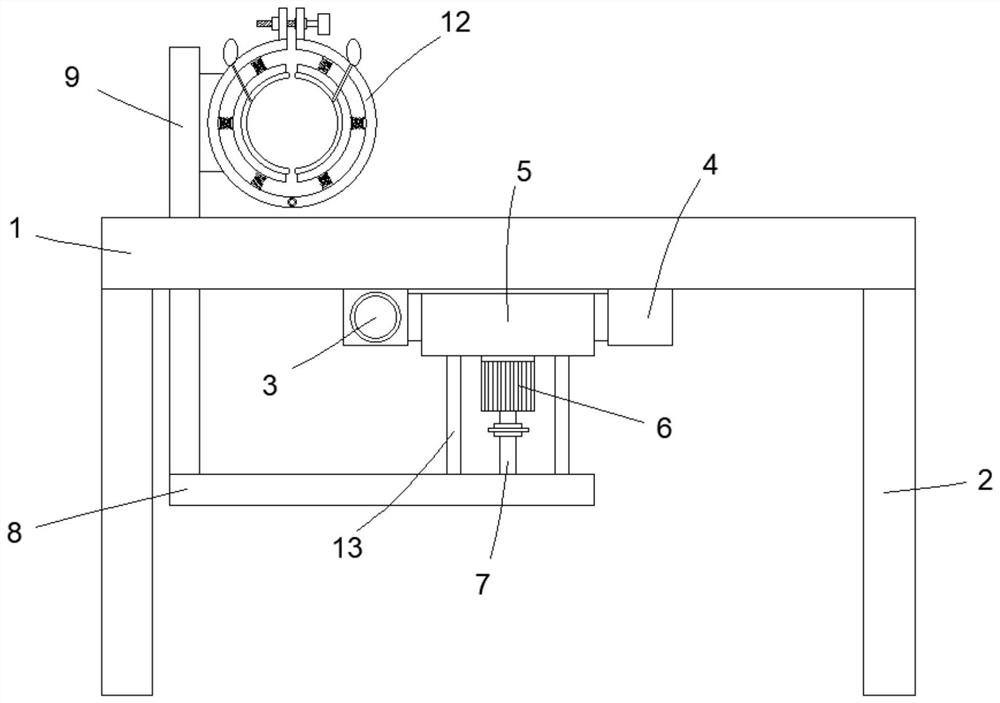

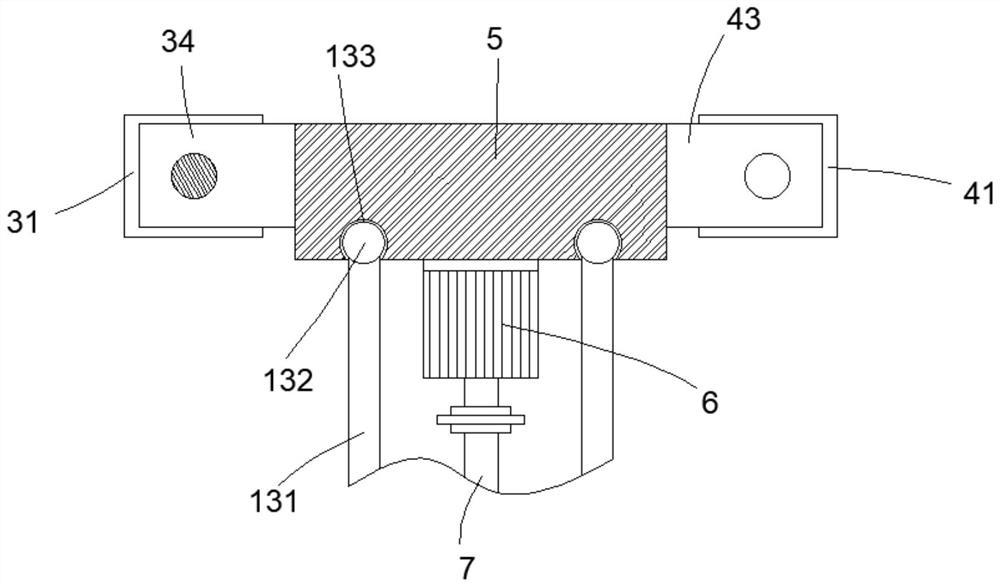

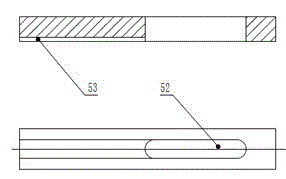

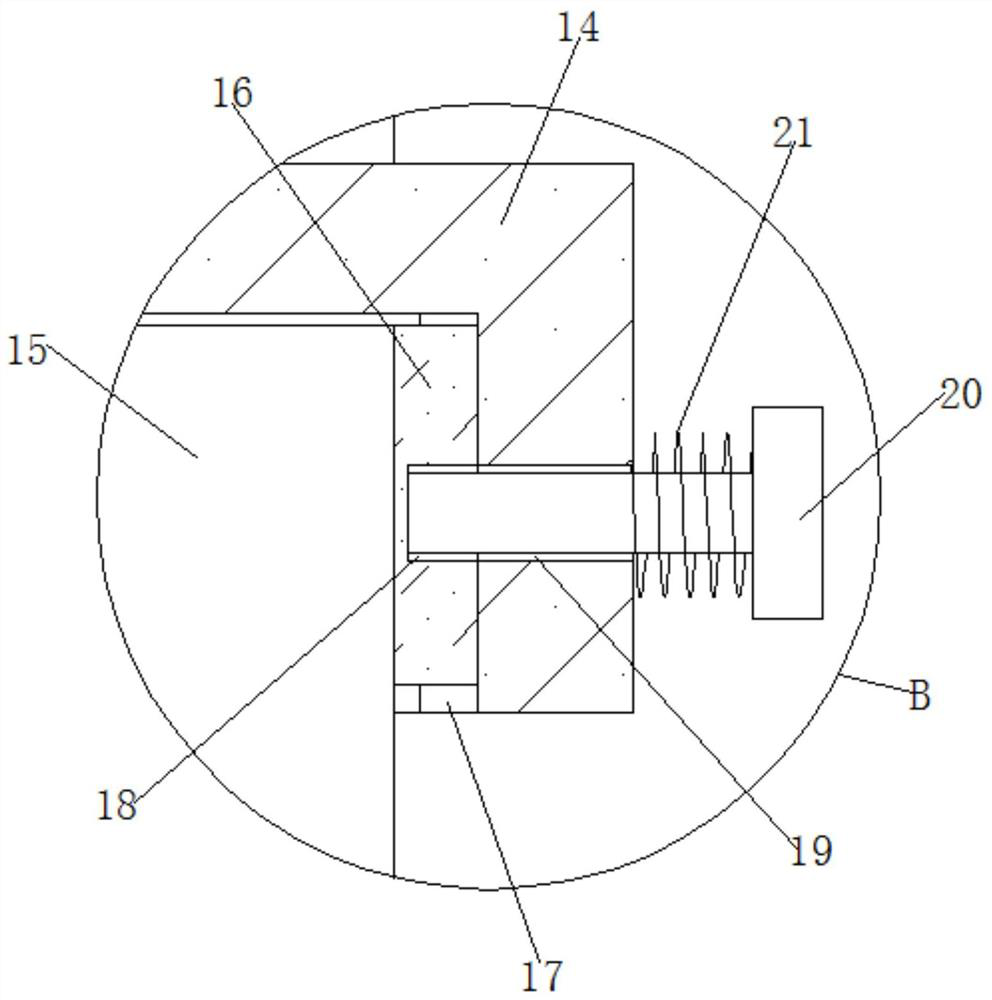

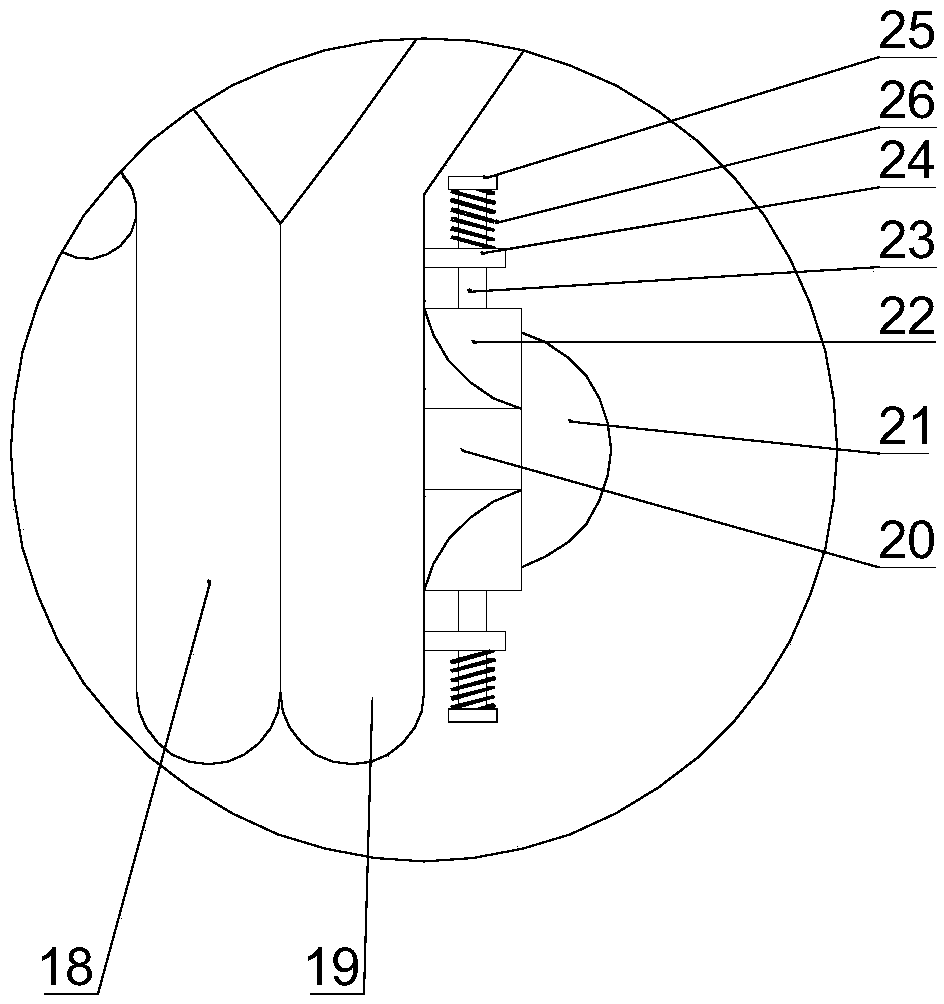

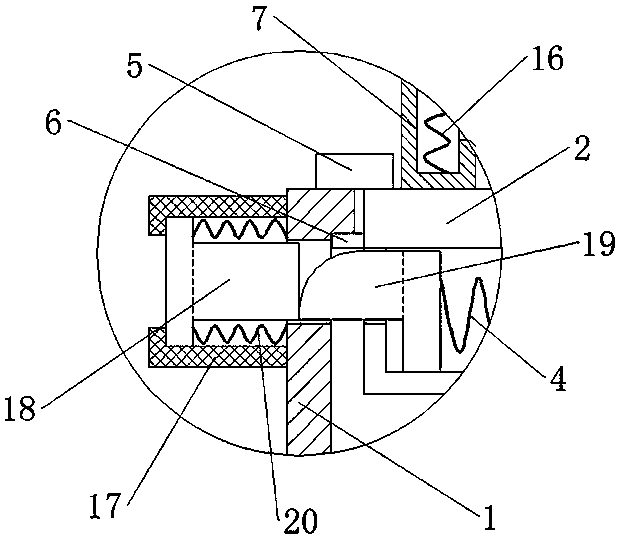

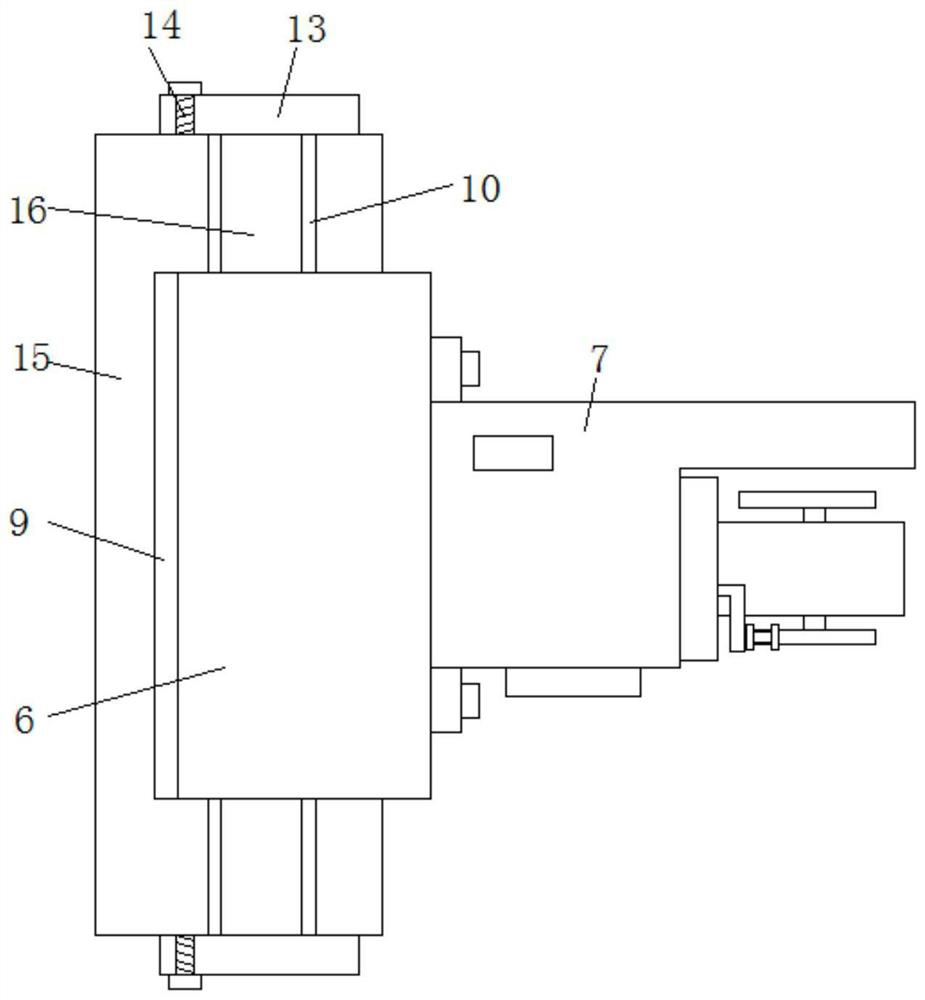

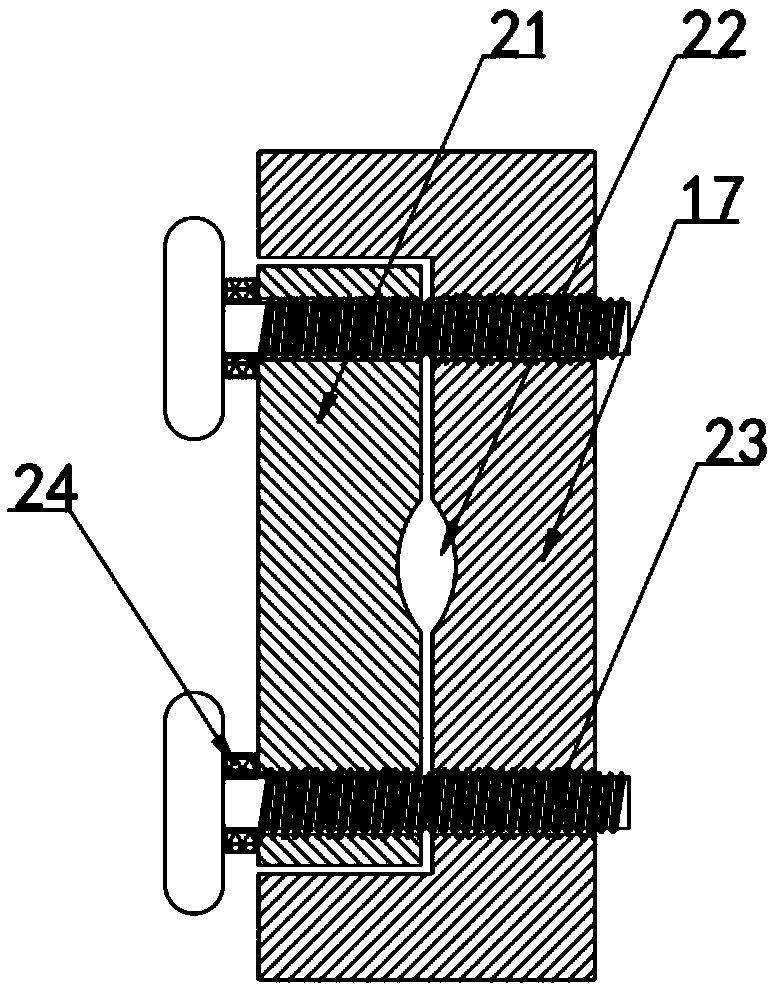

Mounting structure of ultrasonic flowmeter probe

InactiveCN110907007AInstalled and disassembledImprove the protective effectVolume/mass flow measurementVolume meteringEngineeringSlide plate

The invention discloses a mounting structure of an ultrasonic flowmeter probe. The mounting structure comprises two clamping plates, the two clamping plates are sleeved on a pipeline to be measured; the sliding plate slides into the first sliding groove, therefore, the clamping plates are fixed, the probe body can be fixed on a pipeline to be detected, the probe body is convenient to mount and dismount; the clamping groove is clamped with the clamping plate, therefore, the probe body is fixed on the bottom plate, the probe body can be conveniently protected; the probe body is prevented from being impacted and damaged; sliding a first slider, the first sliding block drives the sliding rod to move; the probe body is driven to move horizontally; the position of the probe body in the horizontal direction is conveniently adjusted; the mechanical telescopic rod moves to drive the second sliding block to vertically move, so that the bottom plate is driven to move, namely the probe body is driven to vertically move, the position of the probe body in the vertical direction is conveniently adjusted, the position of the probe body can be conveniently adjusted, and the accuracy of measurementdata of the ultrasonic flowmeter is conveniently improved.

Owner:西安西派测控技术有限公司

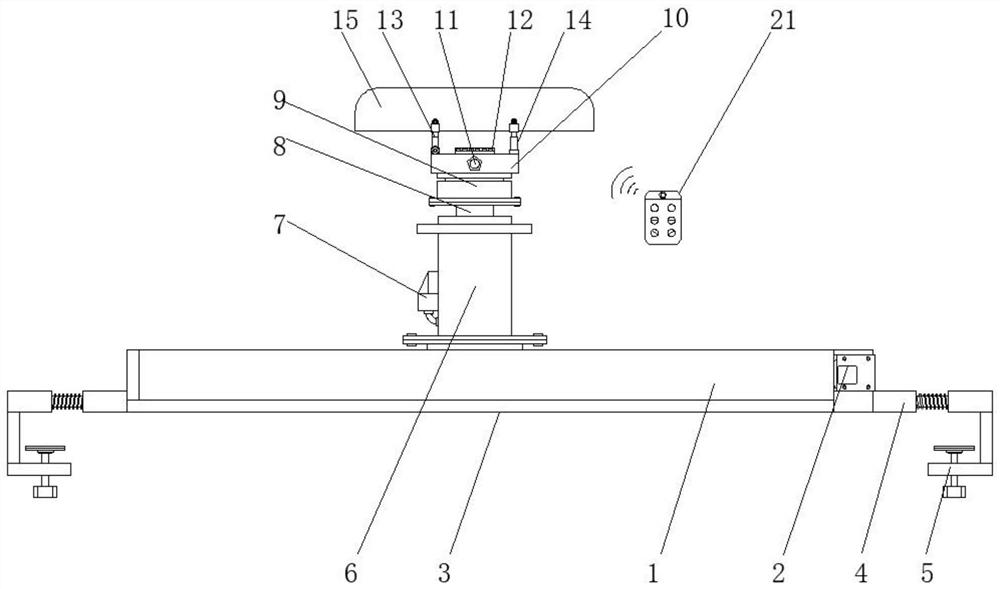

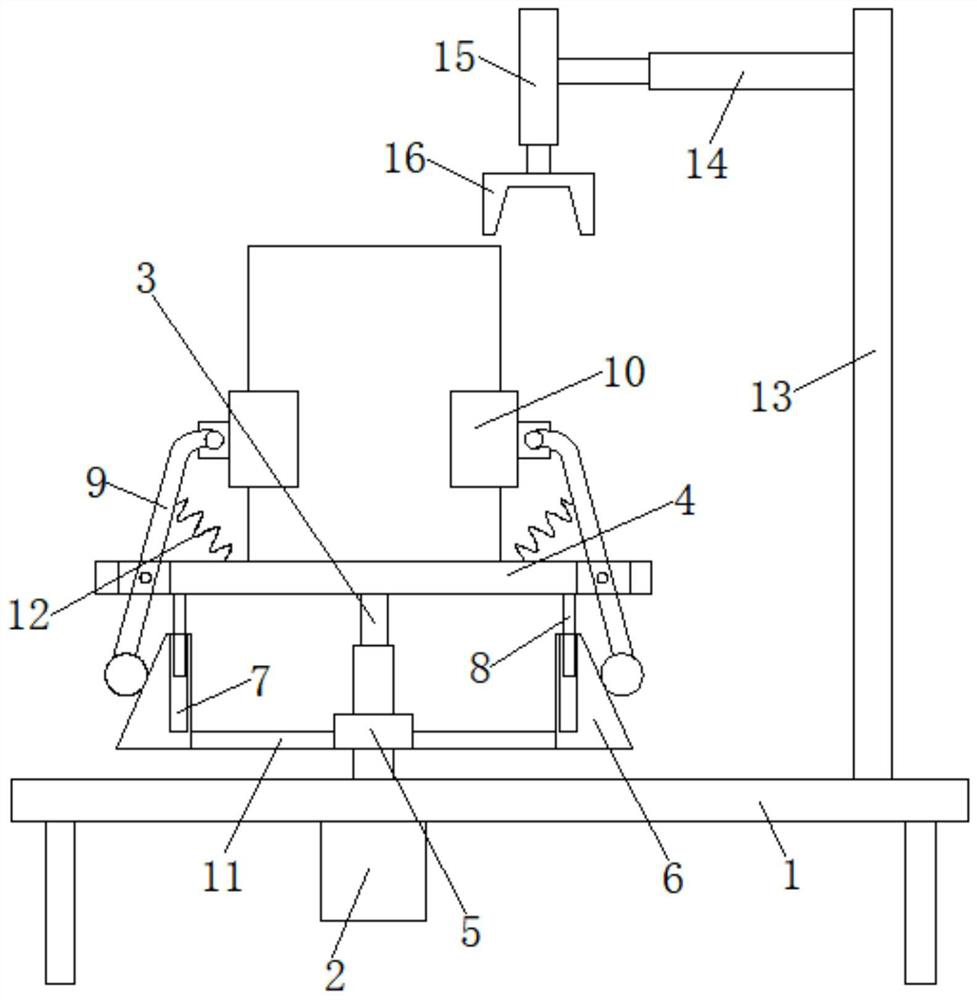

Orthopedic rehabilitation supporting device

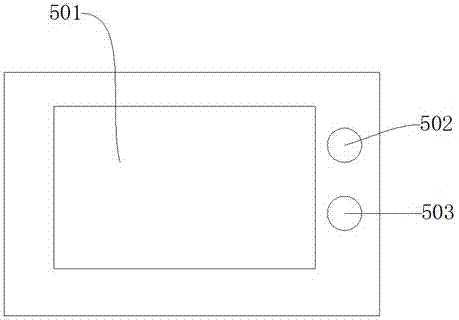

InactiveCN112089557AEasy to adjust the horizontal positionAvoid problems that require holding the same position for long periods of timeDiagnosticsNursing bedsPhysical medicine and rehabilitationOrthopedic department

The invention discloses an orthopedic rehabilitation supporting device. The device comprises a translation mechanism, a supporting plate and a remote controller, wherein a servo motor is installed ata right end of the translation mechanism, a bottom plate is connected to a lower portion of the translation mechanism, telescopic assemblies are installed at a left end and a right end of the bottom plate correspondingly, and a fixing mechanism is installed below the telescopic assembly; an air cylinder is installed above the translation mechanism, an air pump is fixed to an outer wall of a left side of the air cylinder, a piston telescopic rod is connected to an upper portion of interior of the air cylinder, a base is connected to a top end of the piston telescopic rod, a supporting plate ishinged to upper portions of a first electric push rod and a second electric push rod, a partition pad is connected to an inner surface of the supporting plate, and the remote controller is connected to an input end of a wireless signal receiver through a wireless signal. The invention can carry out remote electric adjustment, reduces workload of medical staff, and effectively avoids a problem thata patient can only maintain one posture for a long time, which easily causes the patient's leg fatigue and discomfort.

Owner:THE SECOND PEOPLES HOSPITAL OF NANTONG

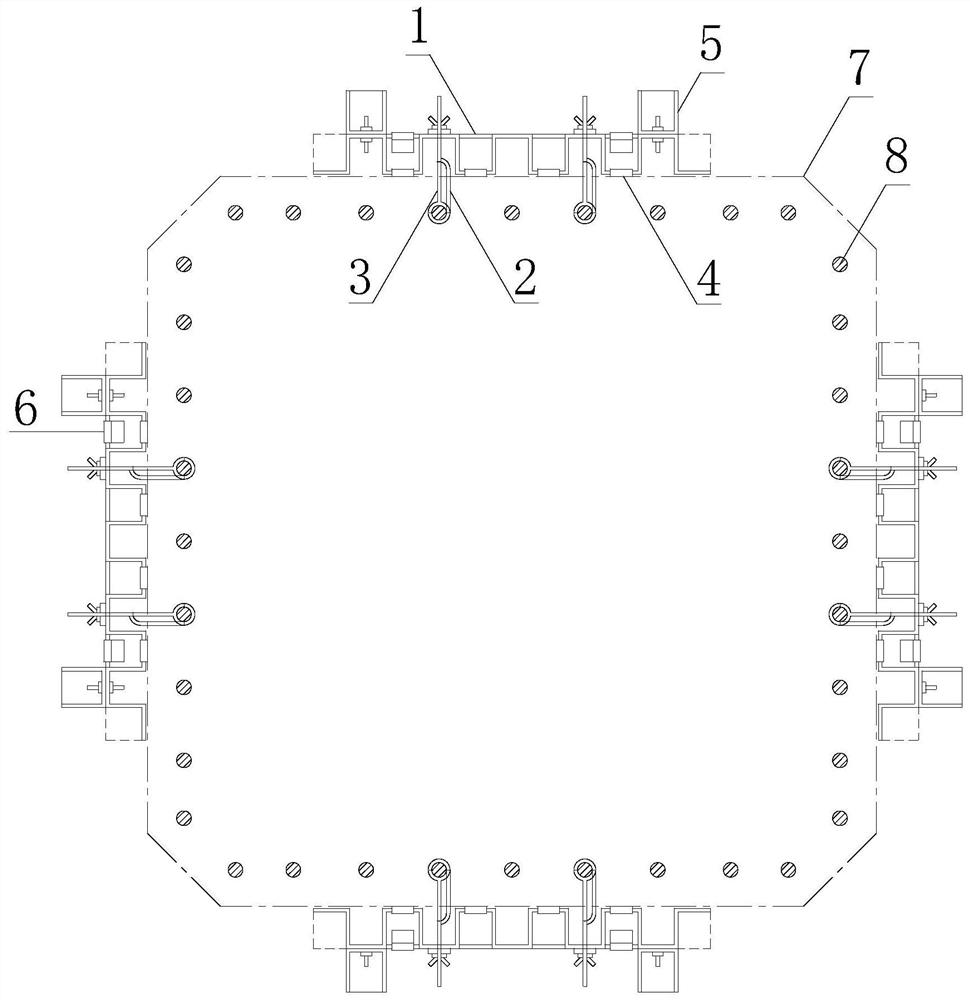

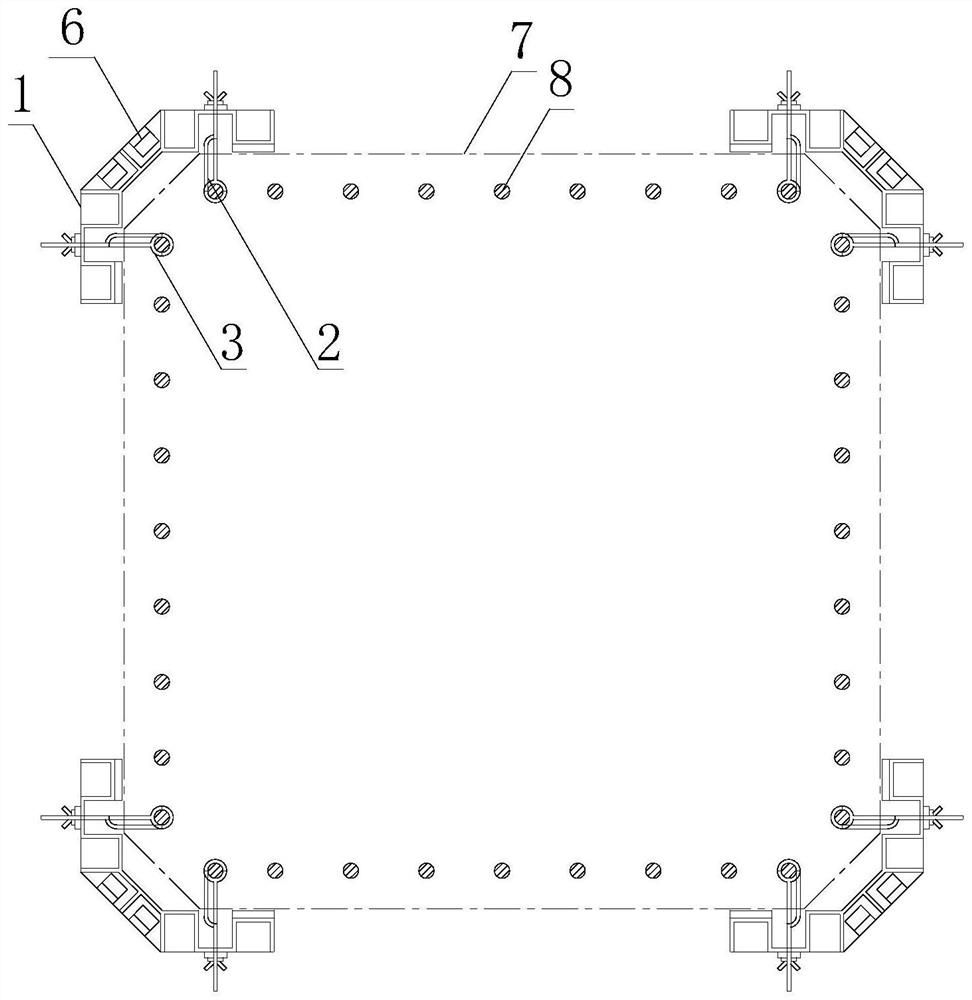

Guide device for assembling and positioning prefabricated polygonal bridge pier and design method

PendingCN112081013AReduce weightMeet the needs of transition convenienceBridge structural detailsBridge erection/assemblyPilot holeArchitectural engineering

The invention relates to the technical field of infrastructure construction, in particular to a guide device for assembling and positioning a prefabricated polygonal bridge pier and a design method. The guide device comprises a plurality of position limiting plate assemblies, wherein the position limiting plate assemblies are connected with the bridge pier to form a guide surface; each position limiting plate is at least connected with two positioning pull buckle assemblies and two positioning top buckle assemblies; one end of each positioning pull buckle assembly and one end of the corresponding positioning top buckle assembly are connected with the corresponding position limiting plate through a screw bolt; and the other end of each positioning pull buckle assembly and the other end of the corresponding positioning top buckle assembly are connected with a corresponding embedded steel bar. The guide device and the design method have the advantages that assembly type components are used and combined to form a whole; field transportation and movement are convenient; the embedded steel bars of the structure per se are used for positioning and force bearing; the installation is convenient; the device is light and ingenious; guide hole passages formed by the position limiting plates in a vertical curved surface form have the big upper side and the small lower side, the bridge pierpositioning deviation in the construction process can be allowed, and the construction difficulty is reduced; and the plates are mutually combined, position limiting holes are transversely adjustable,and adaptability to different types of polygonal prefabricated bridge piers can be realized.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD +1

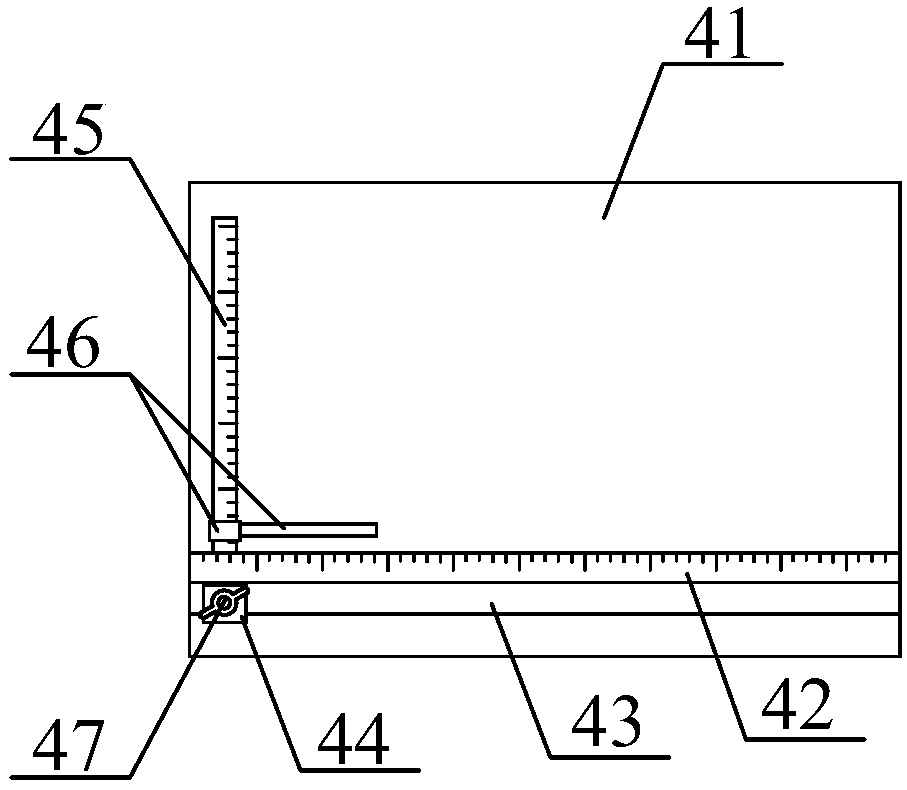

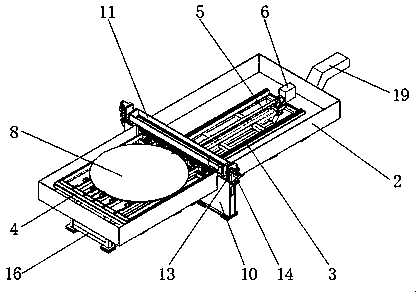

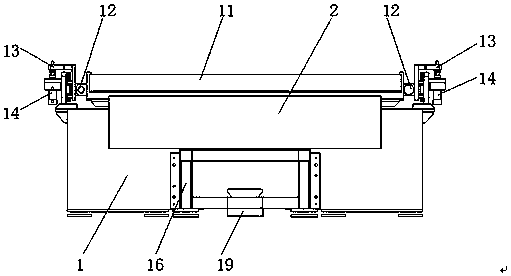

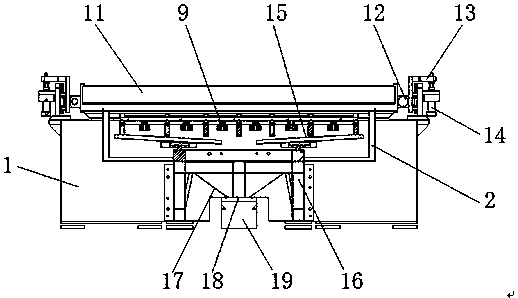

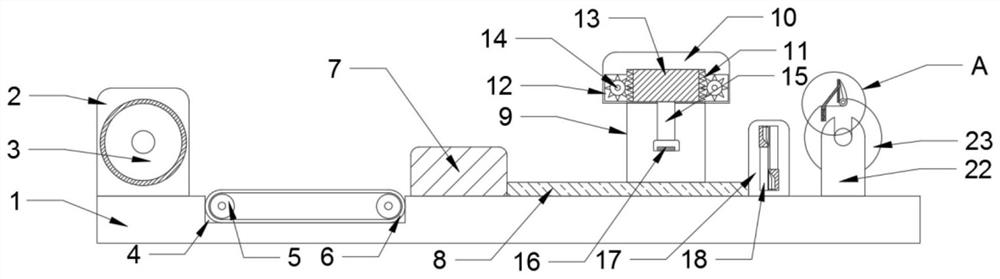

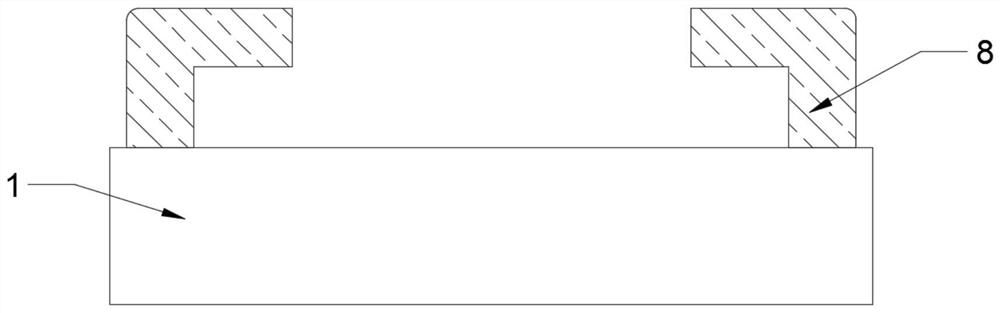

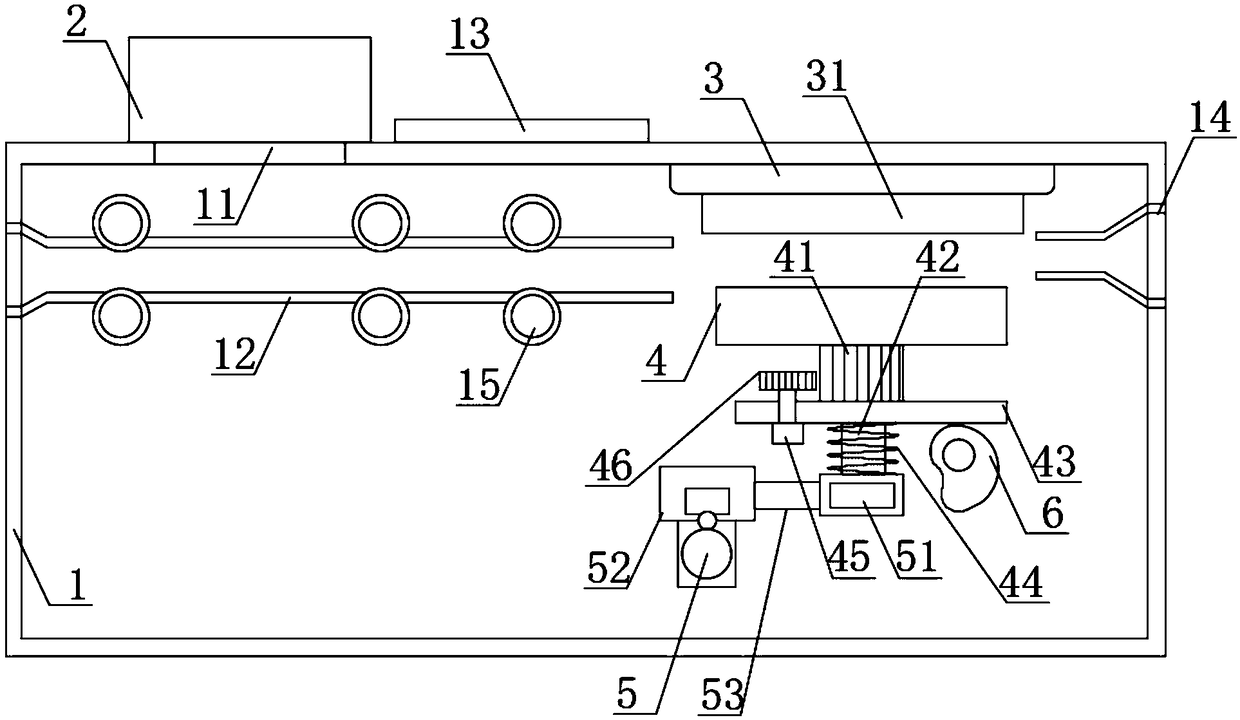

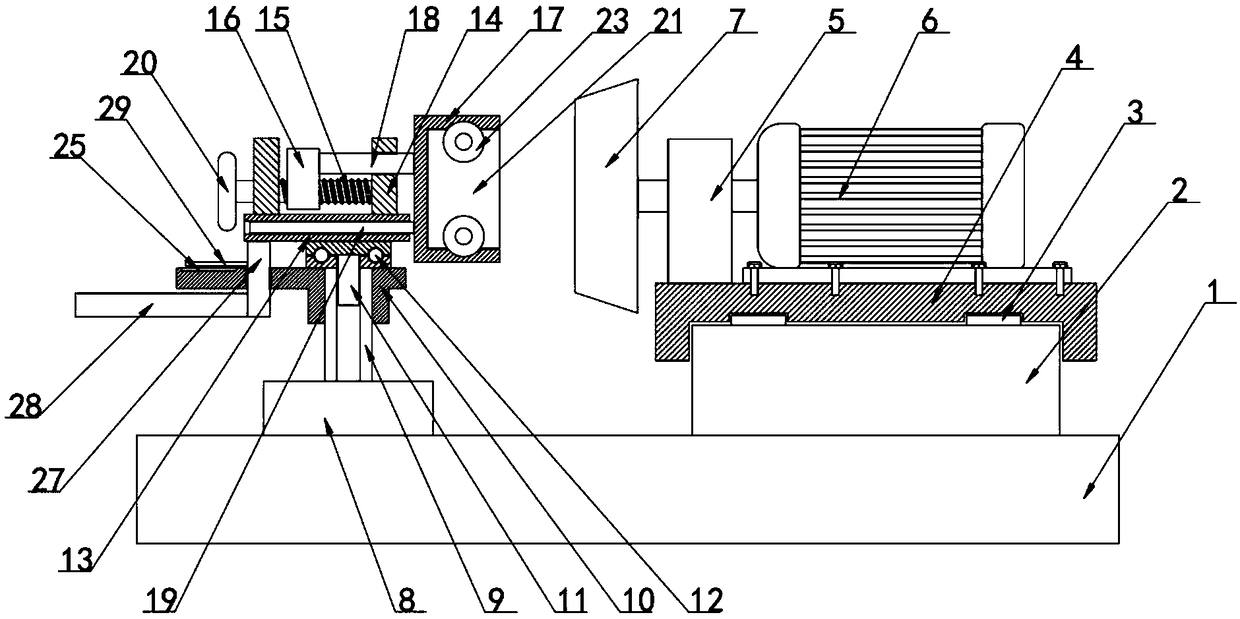

Workbench special for baffle plate drilling

ActiveCN110802247AEasy to drillImprove drilling efficiencyLarge fixed membersPositioning apparatusEngineeringWorkbench

The invention discloses a workbench special for baffle plate drilling. The workbench special for baffle plate drilling comprises a drilling workbench and chip guide plates, wherein a lathe body is installed inside the drilling workbench, a chip removing bin is arranged at the bottom of the lathe body, one end of a moving workbench is in transmission connection with a servo motor through a lead screw, rolling supporting wheels are installed at the position, at the bottom of the moving workbench, of the surface of the lathe body, two ends of a pressing body are connected with connecting plates through connecting shafts, and the bottoms of the connecting plates are connected with a fixed seat through pressing oil cylinders; and the chip guide plates are arranged at the position, below the moving workbench, of the interior of the lathe body, and a support frame is arranged in the drilling workbench. According to the workbench special for baffle plate drilling, workpieces placed on the surface of the moving workbench can horizontally move through the moving workbench in sliding connection with the interior of the lathe body, a drill bit can conveniently penetrate through the pressing body to accurately drill the workpieces through the fixing effect of the pressing body, the drilling efficiency of a baffle plate is improved, the drilling precision is improved, the labor cost is reduced, and the use cost of a cutter is reduced.

Owner:SHANDONG TARGUS PRECISION MACHINE

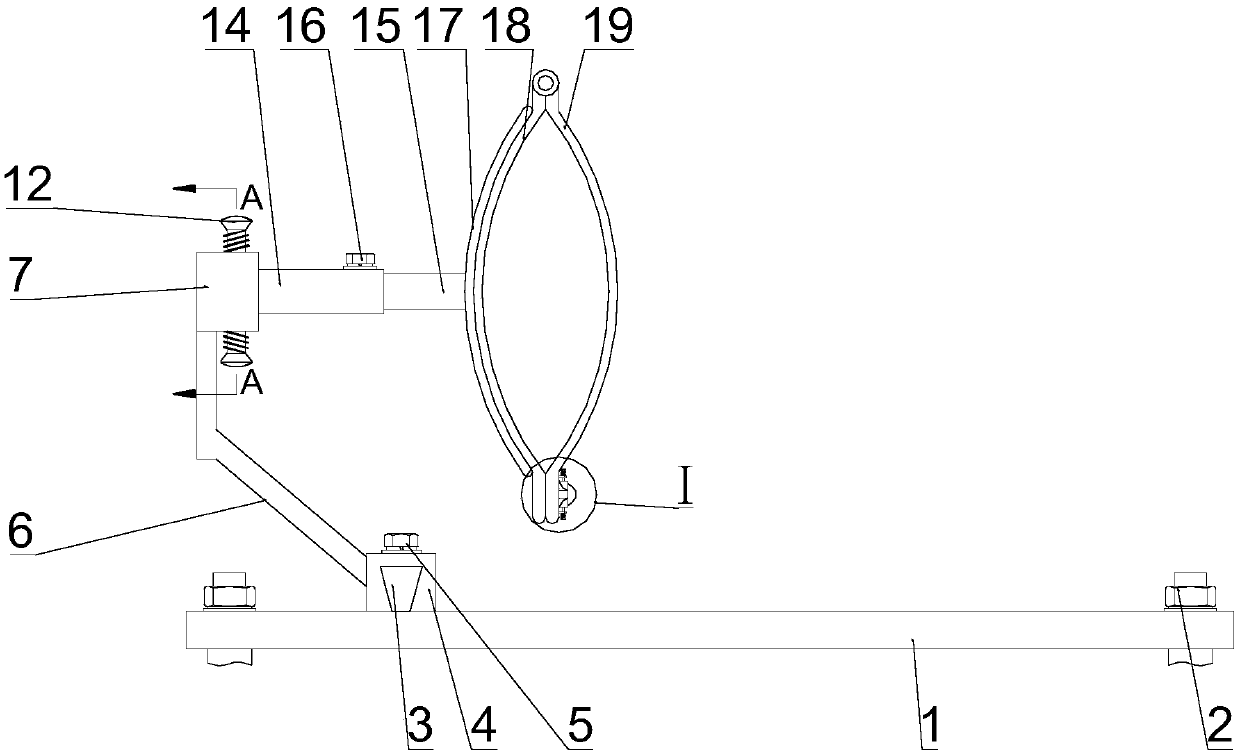

Device capable of positioning and installing flying pipe

InactiveCN112361073ASolve the problem of inconvenient positioning of long pipesEasy to adjust the horizontal positionPipe laying and repairThreaded pipeEngineering

The invention discloses a device capable of positioning and installing a flying pipe, and relates to the technical field of flying pipe installation. By aiming at the problem that a long pipeline is inconvenient to position when an existing flying pipe is installed, the following scheme is provided, wherein the device comprises a bottom plate, first threaded pipes are slidably connected to the twosides of the top of the bottom plate, movable rings are movably arranged on the outer portions of the first threaded pipes in a sleeving manner, and the sides, close to each other, of the two movablerings are fixedly connected with a telescopic mechanism; and the top of the telescopic mechanism is fixedly connected with a driving transmission mechanism, a first screw rod is arranged in each first threaded pipe in a threaded sleeved manner, a second bevel gear is fixedly arranged on the outer ring of each first screw rod in a sleeving manner, and the top of each first screw rod is rotationally connected with a horizontal adjusting mechanism. According to the device, the horizontal position and height of a containing plate can be conveniently adjusted, pipelines of different sizes can be conveniently borne and positioned, manual positioning operation is not needed, labor is saved, efficiency is high, the whole device has multiple purposes, the practicability of the device is improved,and the device is suitable for market popularization.

Owner:HUAIBEI LINGUANG DRILLING ELECTROMECHANICAL ENG

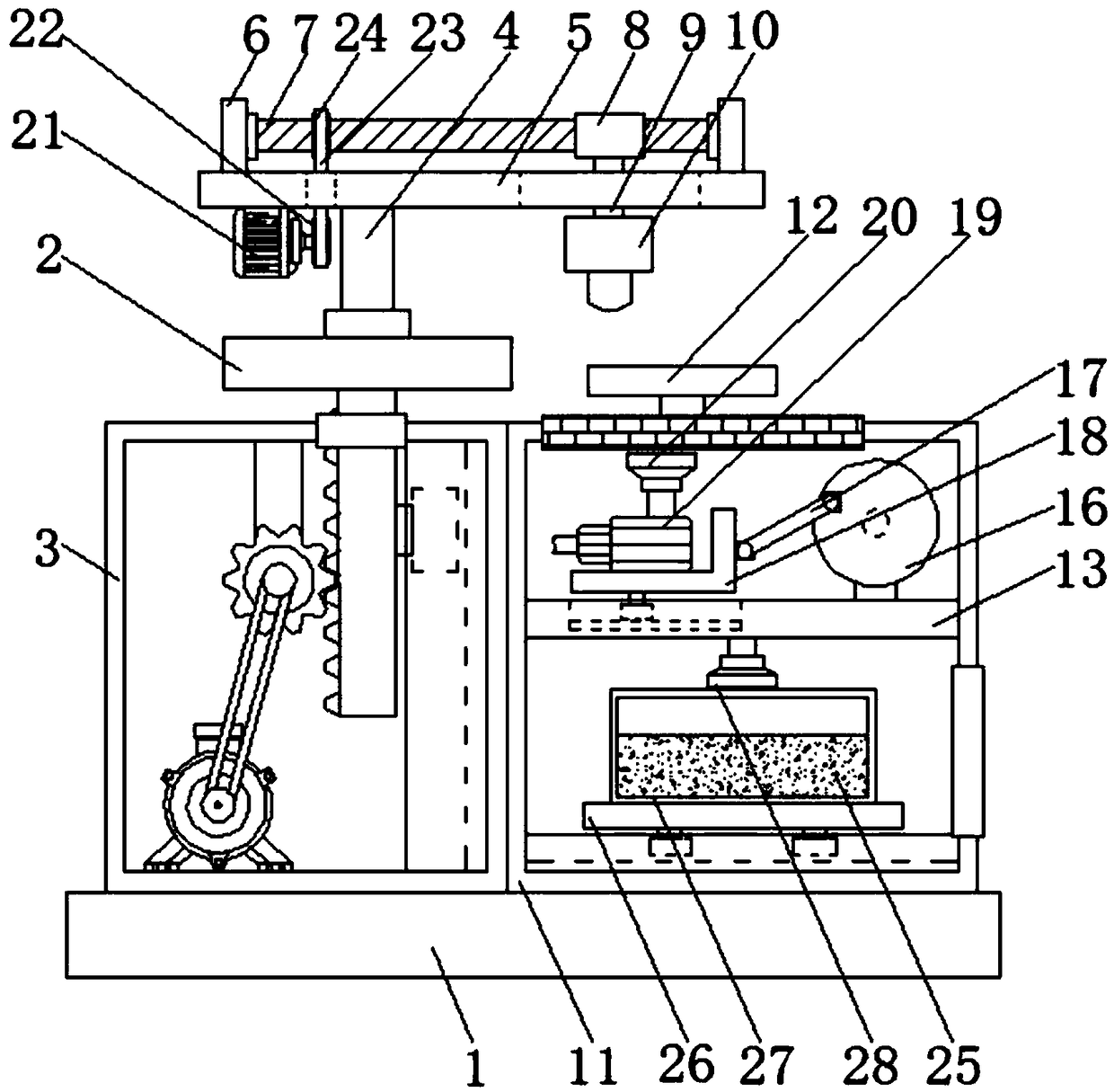

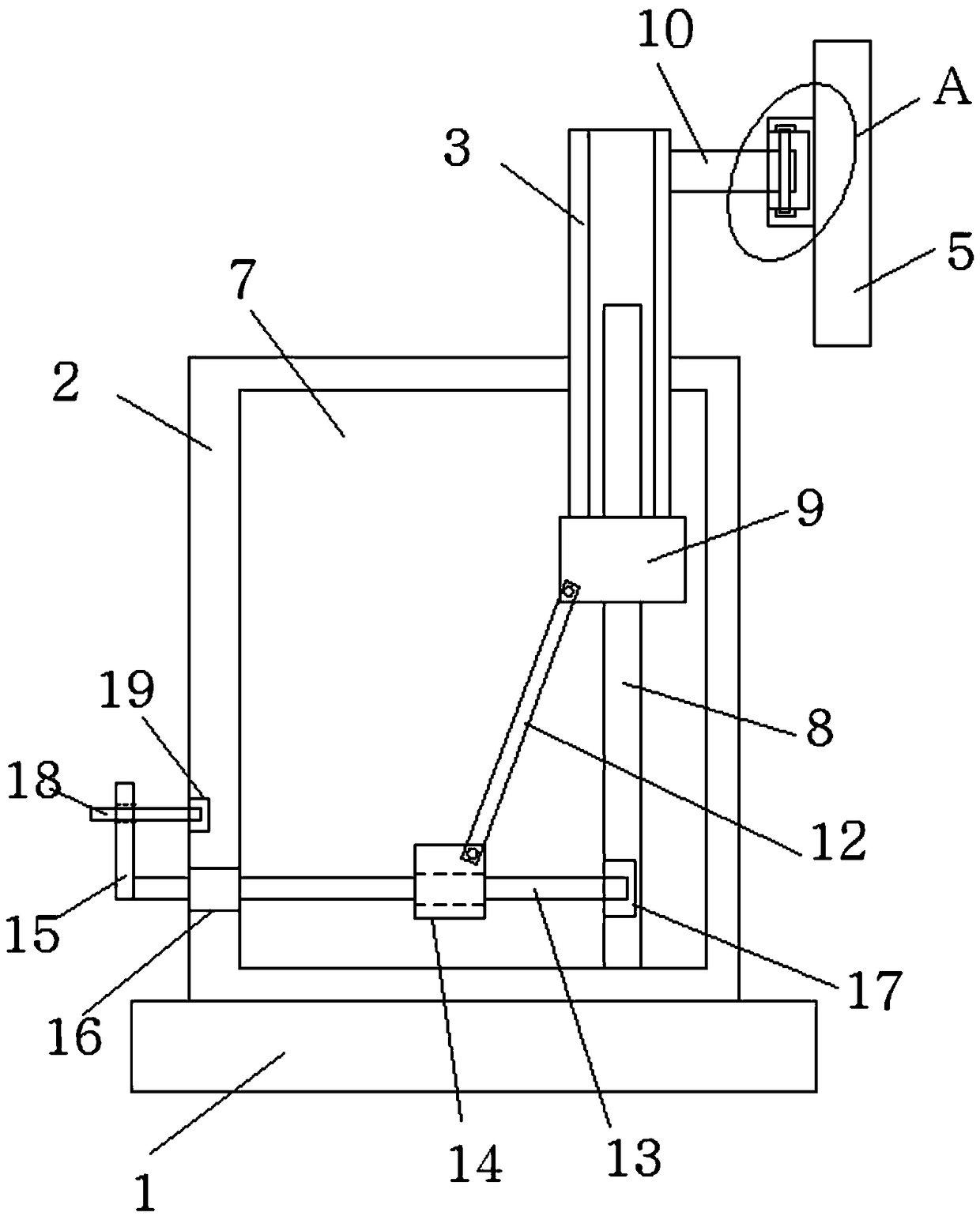

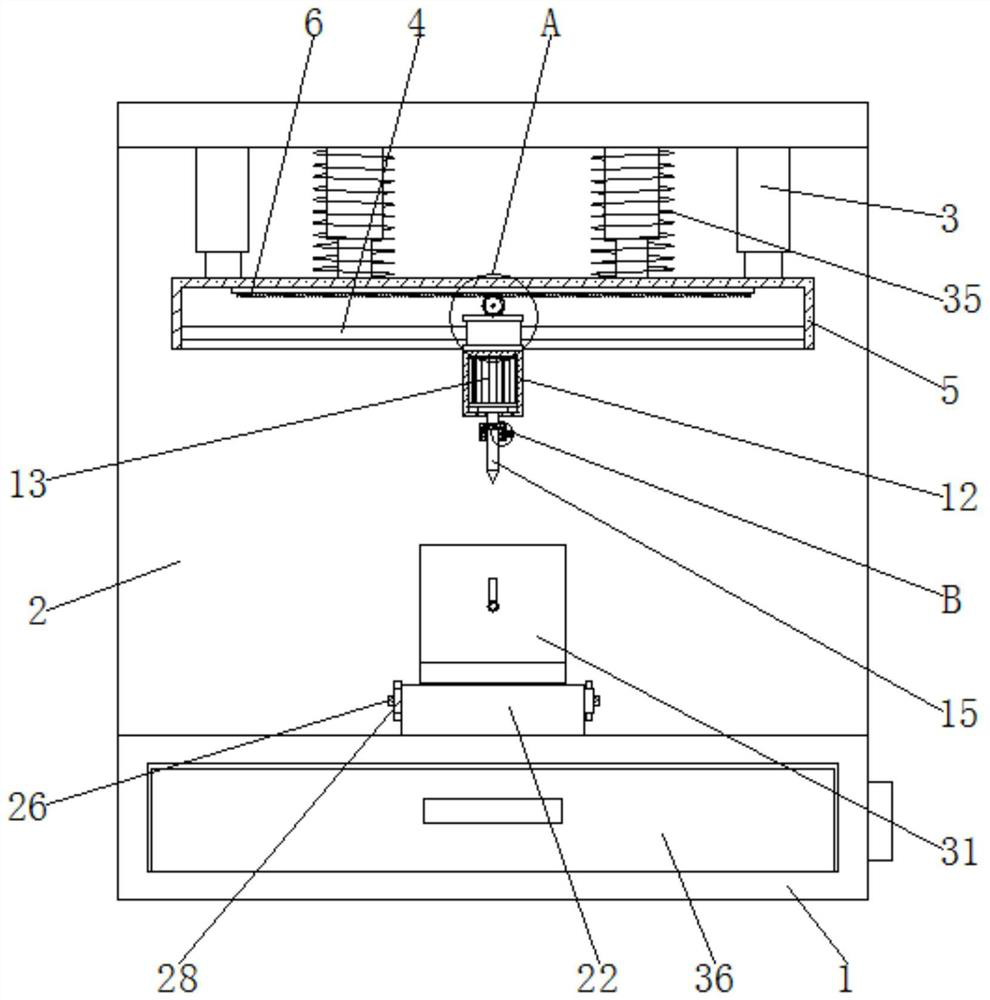

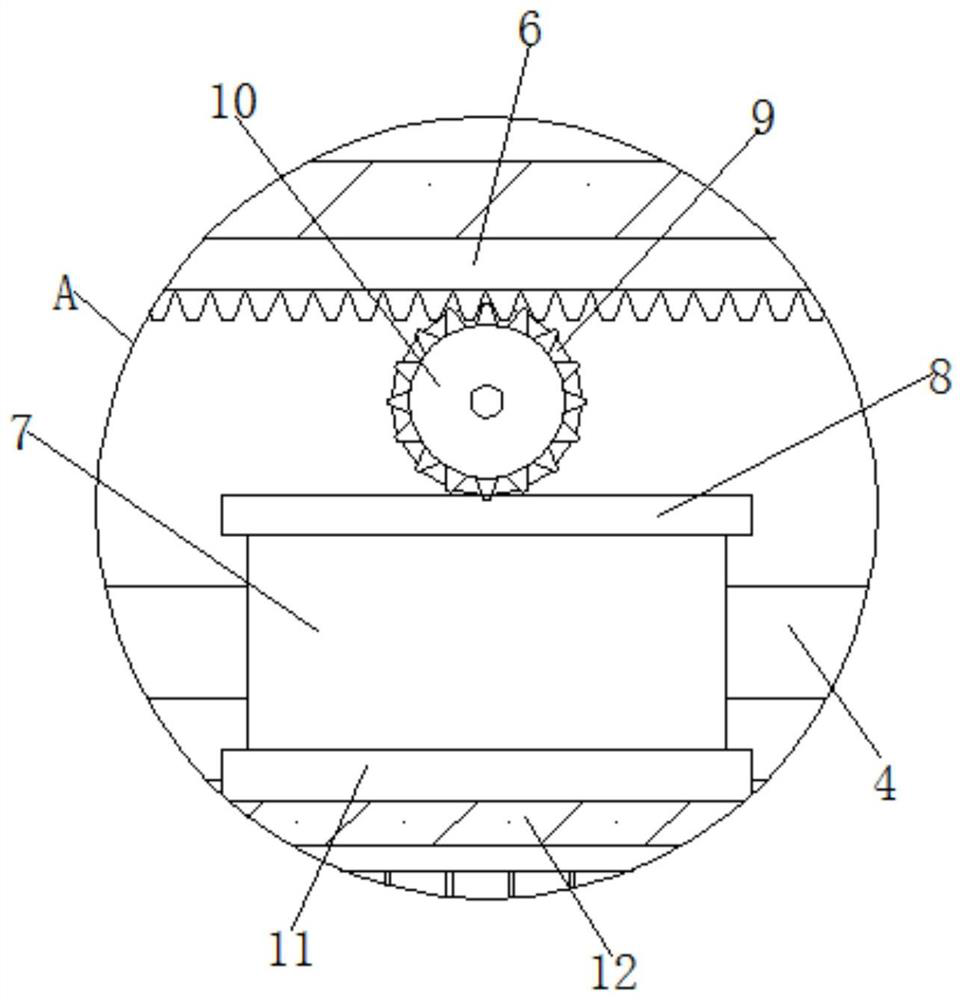

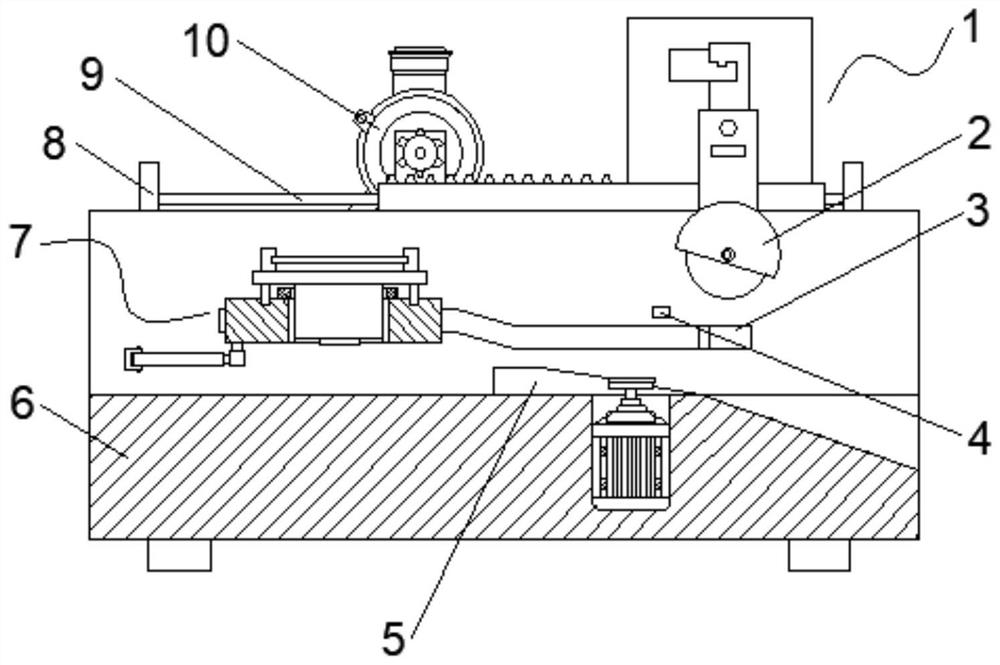

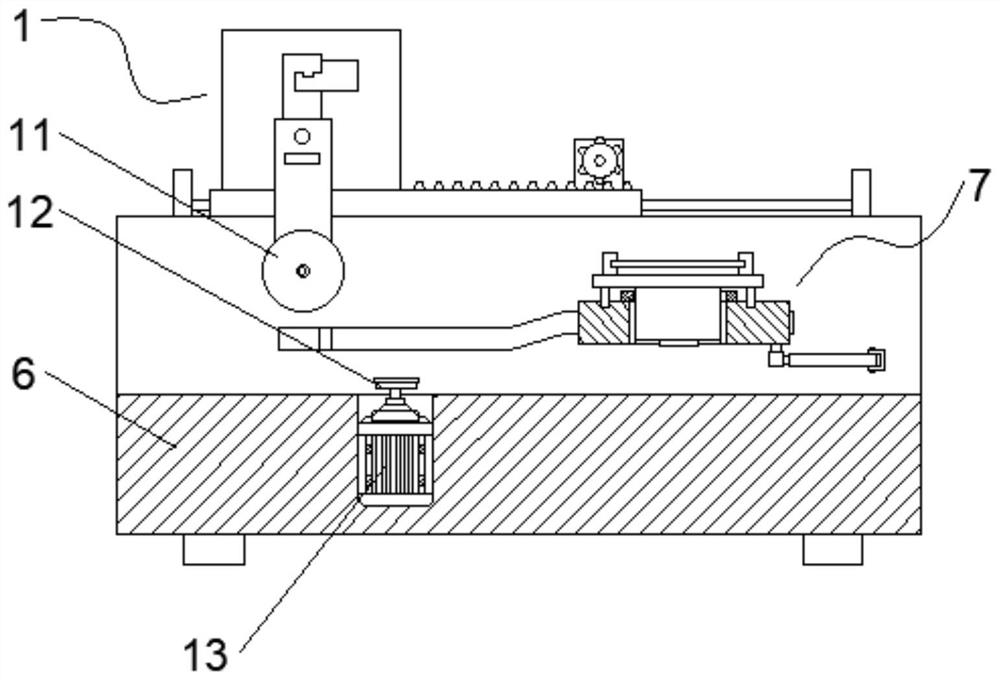

Marking machine having dust-removing function

InactiveCN108099424AWith dust removal functionHealth hazardDirt cleaningOther printing apparatusEngineeringHuman health

The invention discloses a marking machine having a dust-removing function. The marking machine comprises a base, wherein a lifting device is fixedly connected on one side of the top part of the base,a supporting plate is fixedly connected to the top part of the lifting device, a supporting shaft is rotatably connected to the top part of the supporting shaft, a top plate is fixedly connected to the top part of the supporting shaft, both sides of the top part of the top plate are fixedly connected with vertical plates respectively, a lead screw is rotatably connected between opposite sides of the two vertical plates, and the surface of the lead screw is in threaded connection with a movable block. The marking machine relates to the related technical field of marking machines. The marking machine having the dust-removing function pumps out smoke dust debris by means of a sucking pump, and conveys the smoke dust debris into a material discharge for undergoing adsorption treatment by meansof an adsorption solution, thereby avoiding harms to the human health due to pollution caused by the smoke dust debris, being conductive to improving the processing effect, ensuring the processing quality, being able to place the materials on a workbench conveniently, being capable of marking the materials of different heights, and improving the convenience in the using process.

Owner:XINGUANG NUMERICAL CONTROL TECH

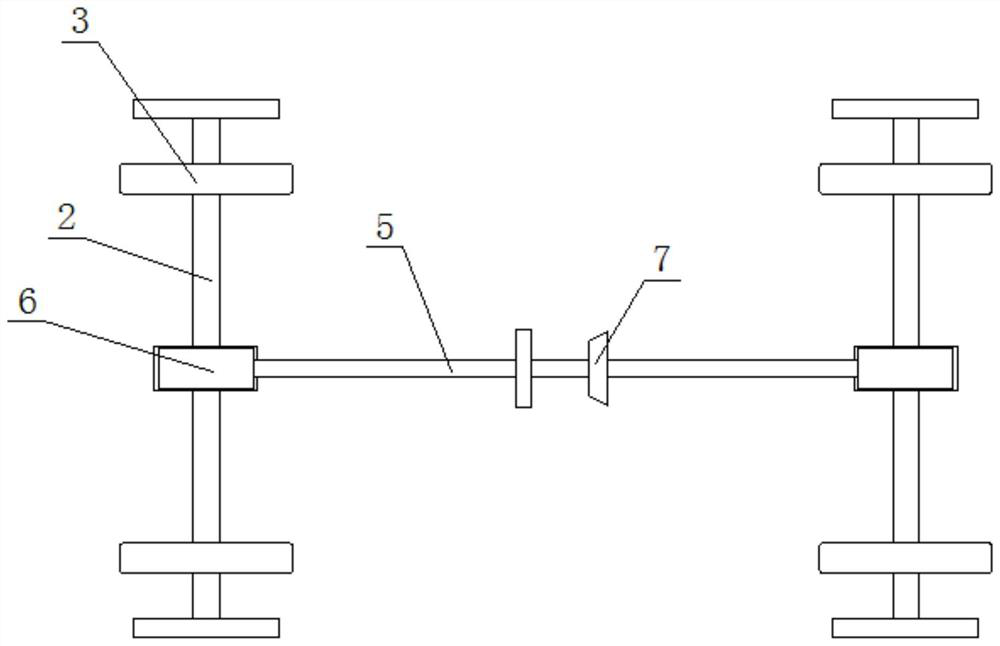

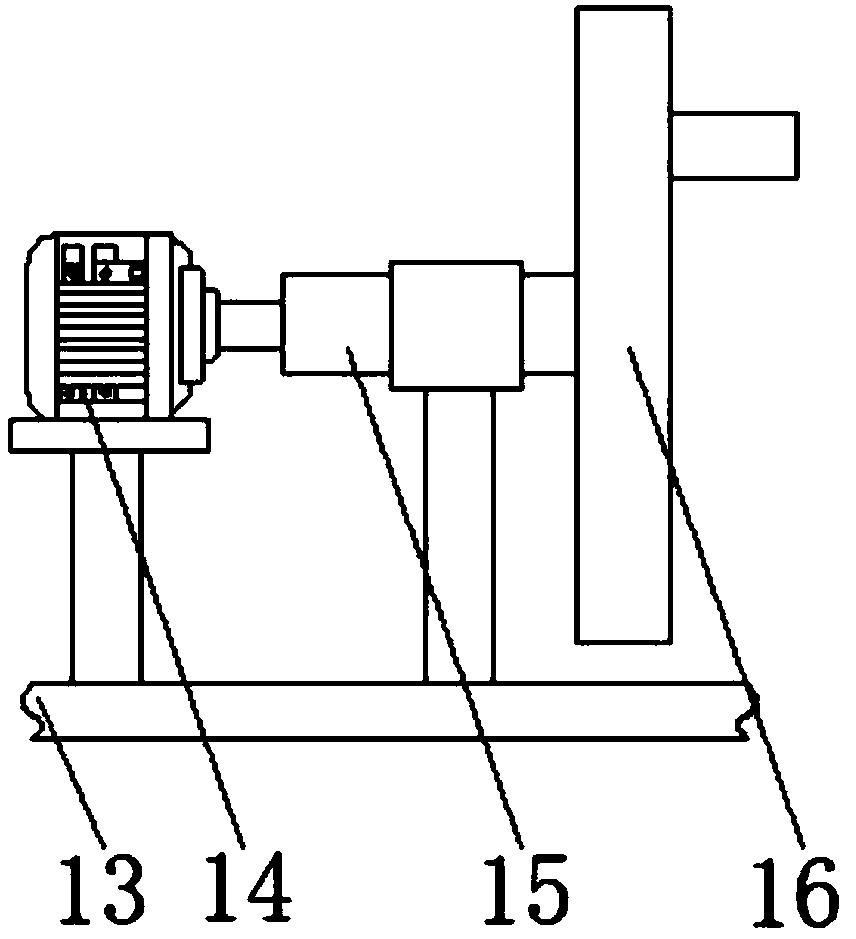

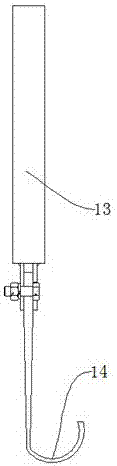

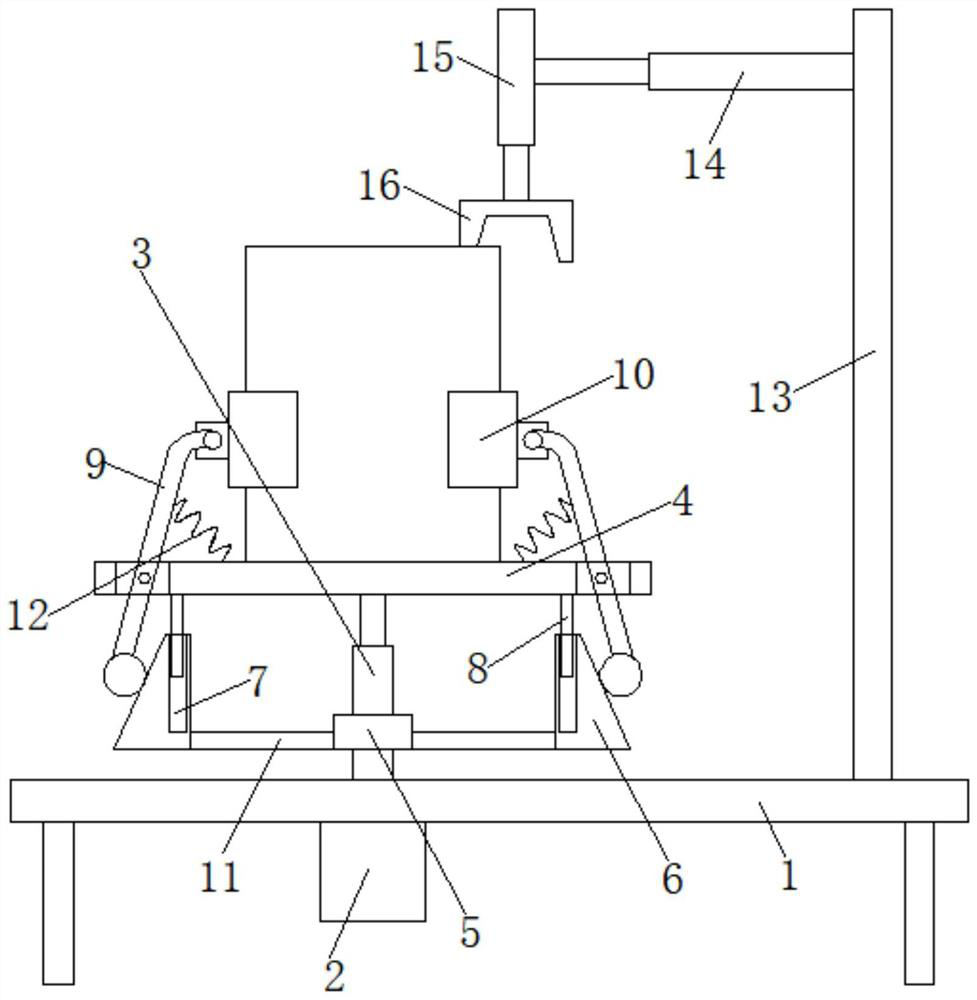

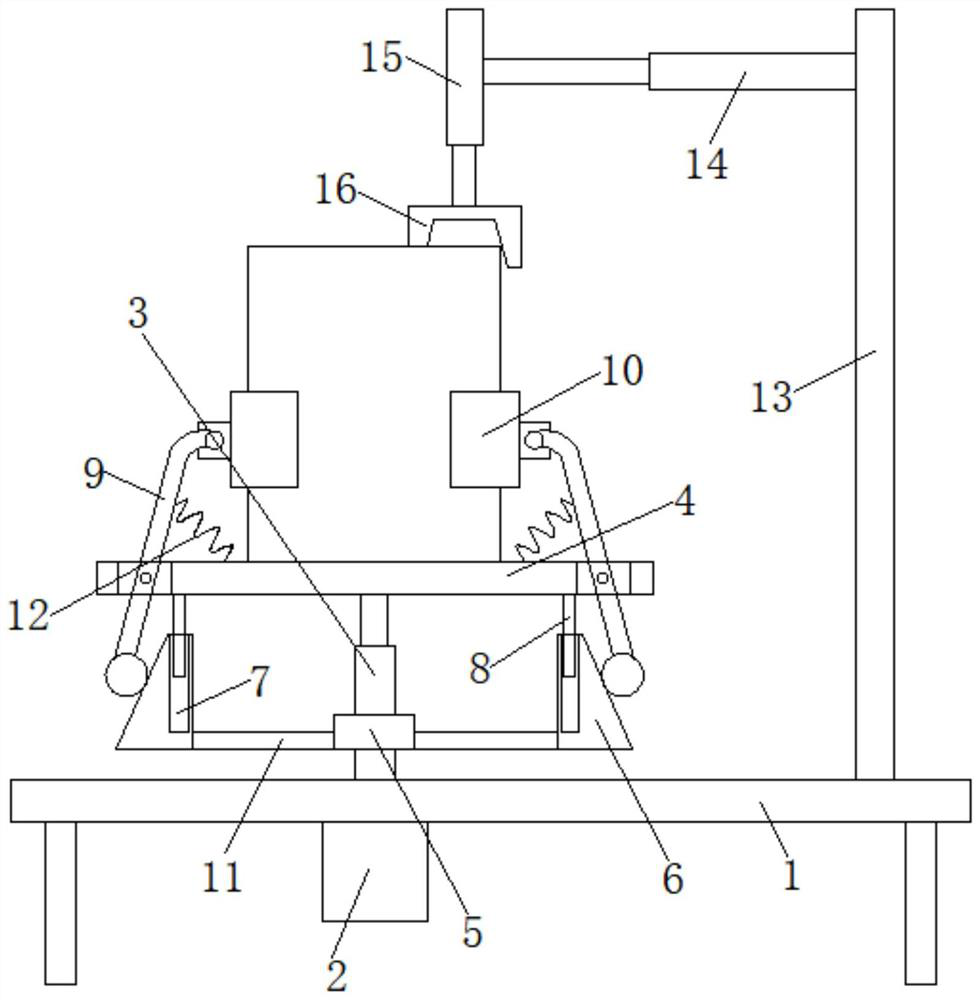

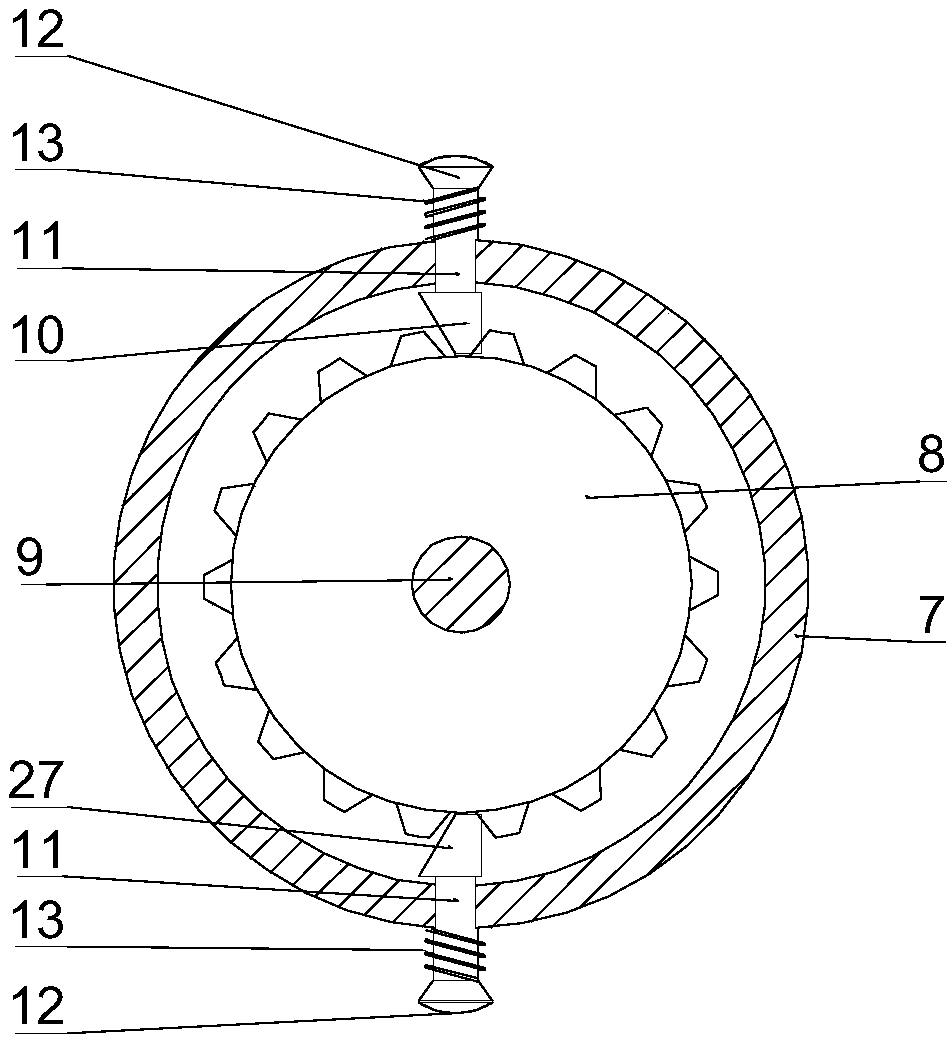

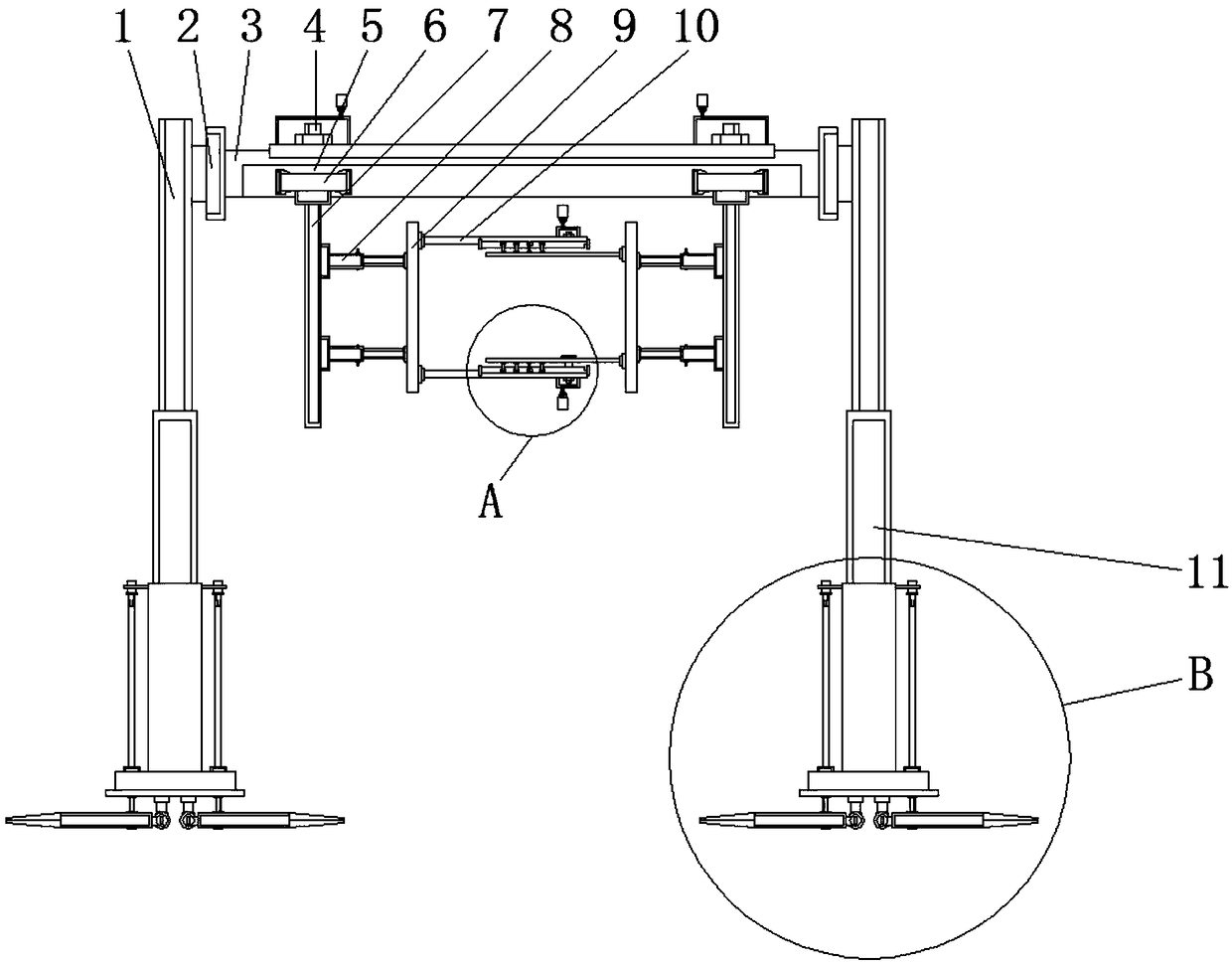

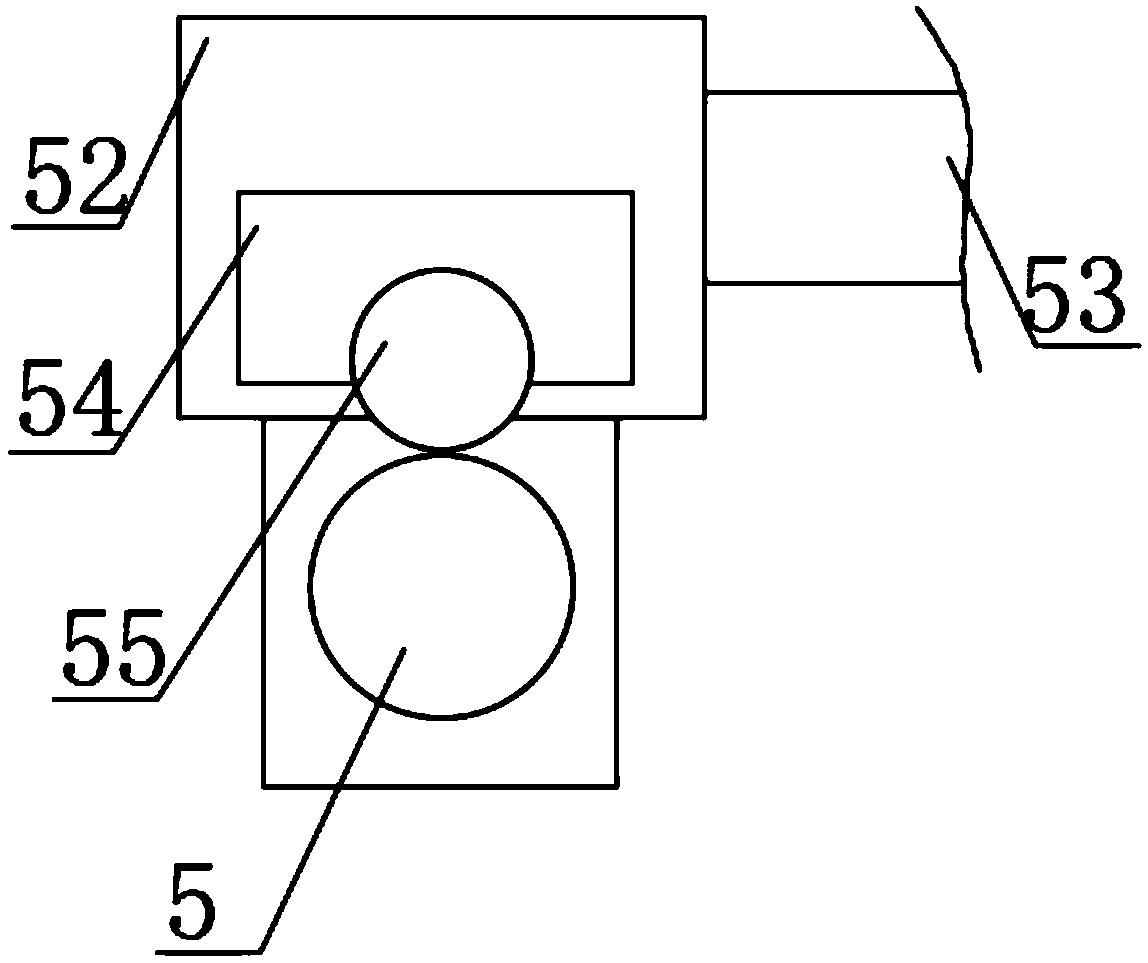

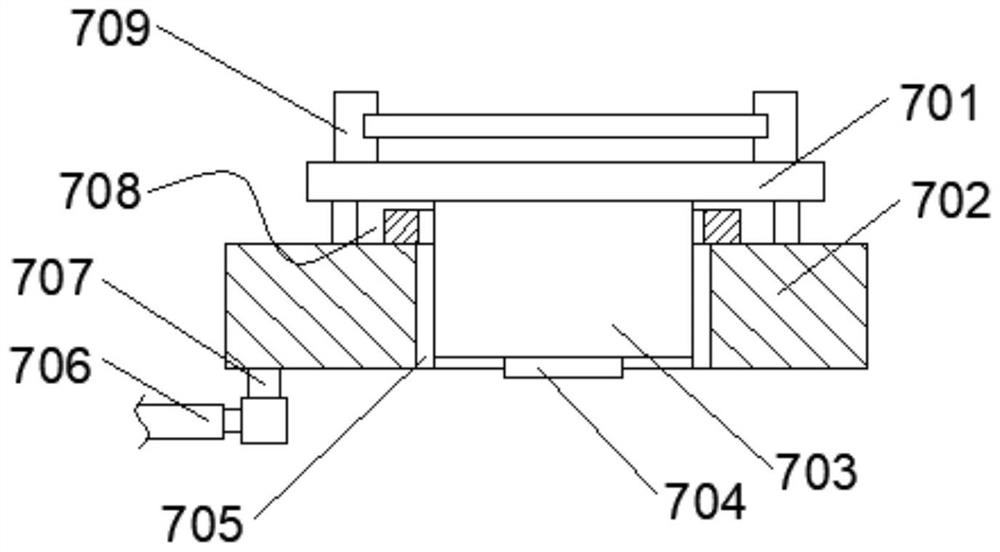

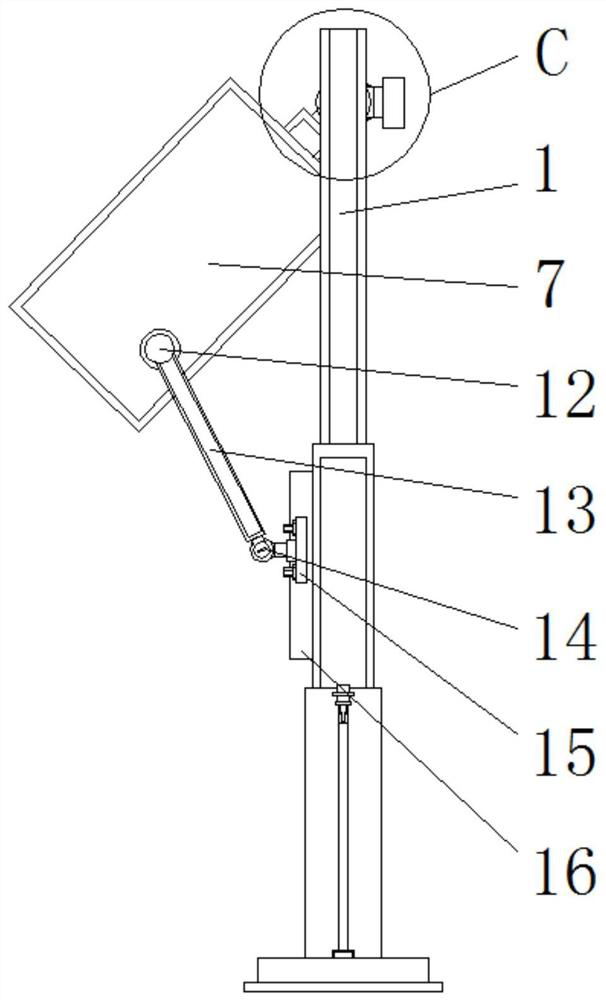

Lifting device for rotor mounting for motor production

InactiveCN107188046AEasy to adjust the horizontal positionIncrease flexibilityTrolley cranesWinding mechanismsDrive wheelInformation transmission

The invention discloses a hoisting device for installing a rotor used in motor production, which belongs to the field of hoisting equipment and includes a beam, a control box and a cable. An assembly frame is arranged at both ends of the beam, and a supporting column is arranged below the assembly frame. Universal wheels are installed at the bottom of the support column, the control box is arranged at the bottom of the information transmission link, and a motor is arranged above the information transmission link, and the motor is connected with the gear box through the driving wheel and the driven wheel. A protective cover is provided above the gear box, the gear box is connected to the cable through a winch, a hook is provided at the bottom of the cable, and the control box is composed of a touch screen, a switch button and a terminal post. The invention is easy to move, compact in structure, and easy to maintain. At the same time, the rotor can be controlled to lift or lower by touch, and the operation is more intuitive and convenient. At the same time, the single-rope design of the invention facilitates adjustment of the horizontal position of the rotor, thereby improving the flexibility of rotor installation. Spend.

Owner:荣成市志诚电机厂

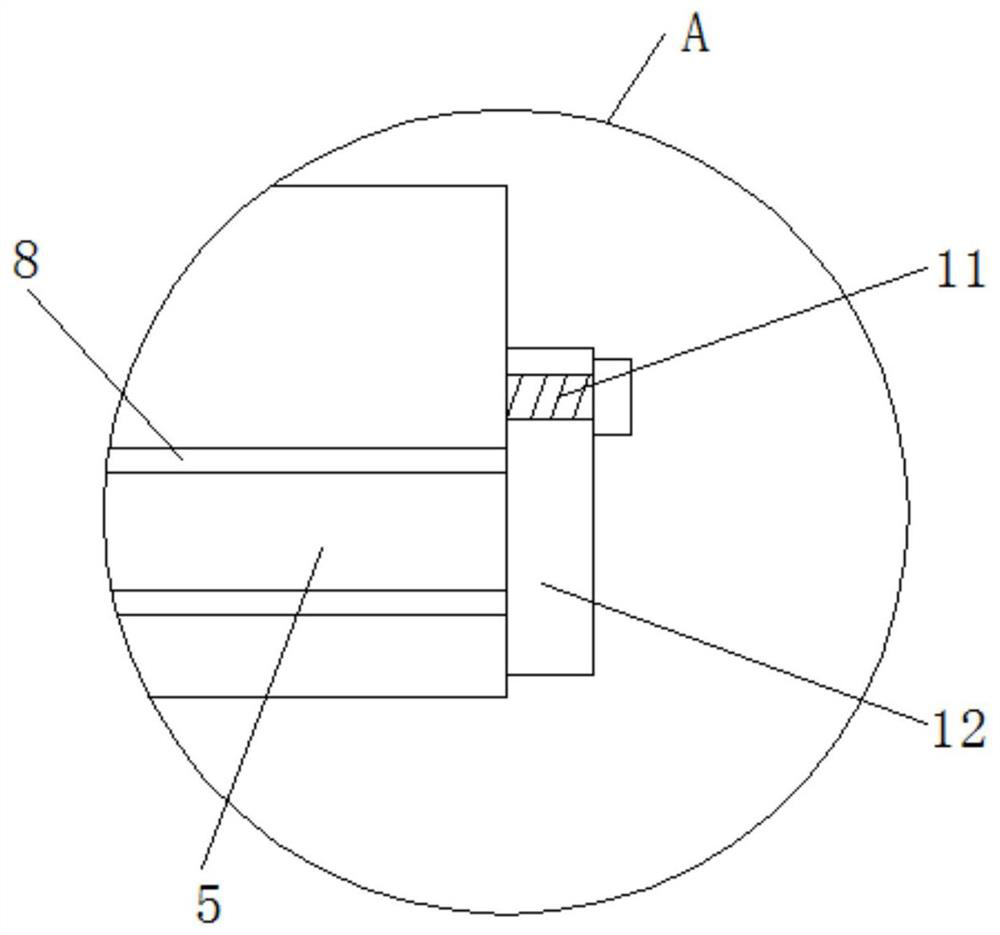

Automatic focusing method of laser cleaning machine

ActiveCN112495943AEasy to determineAccurate focusMountingsCleaning processes and apparatusEngineeringMechanical engineering

The invention discloses an automatic focusing method of a laser cleaning machine, and relates to the technical field of laser cleaning. According to the technical scheme of the automatic focusing method of the laser cleaning machine, the automatic focusing method of the laser cleaning machine is characterized by comprising the following steps that S1, a focus measuring seat is aligned with a lasercleaning head; S2, a vertical displacement mechanism is controlled through a controller to enable the vertical displacement mechanism to drive the laser cleaning head to move; S3, the strength of received signals is analyzed by the controller, the strongest signal value is selected, the corresponding position of the strongest signal value is determined, and the focusing point of the laser cleaning head on the focus measuring seat is determined; S4, the to-be-cleaned surface of a to-be-cleaned workpiece is aligned with the focus measuring seat on the same horizontal plane; and S5, the focus measuring seat is horizontally moved out , and the to-be-cleaned workpiece is driven to move to the position of the focus measuring seat, and then the automatic focusing operation between the to-be-cleaned workpiece and the laser cleaning head can be completed. According to the automatic focusing method of the laser cleaning machine, focusing can be carried out under the condition of not damaging the to-be-cleaned workpiece, the focusing is automatically carried out, the focusing is more accurate, and the effect of improving the focusing convenience and the focusing precision is achieved.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD +1

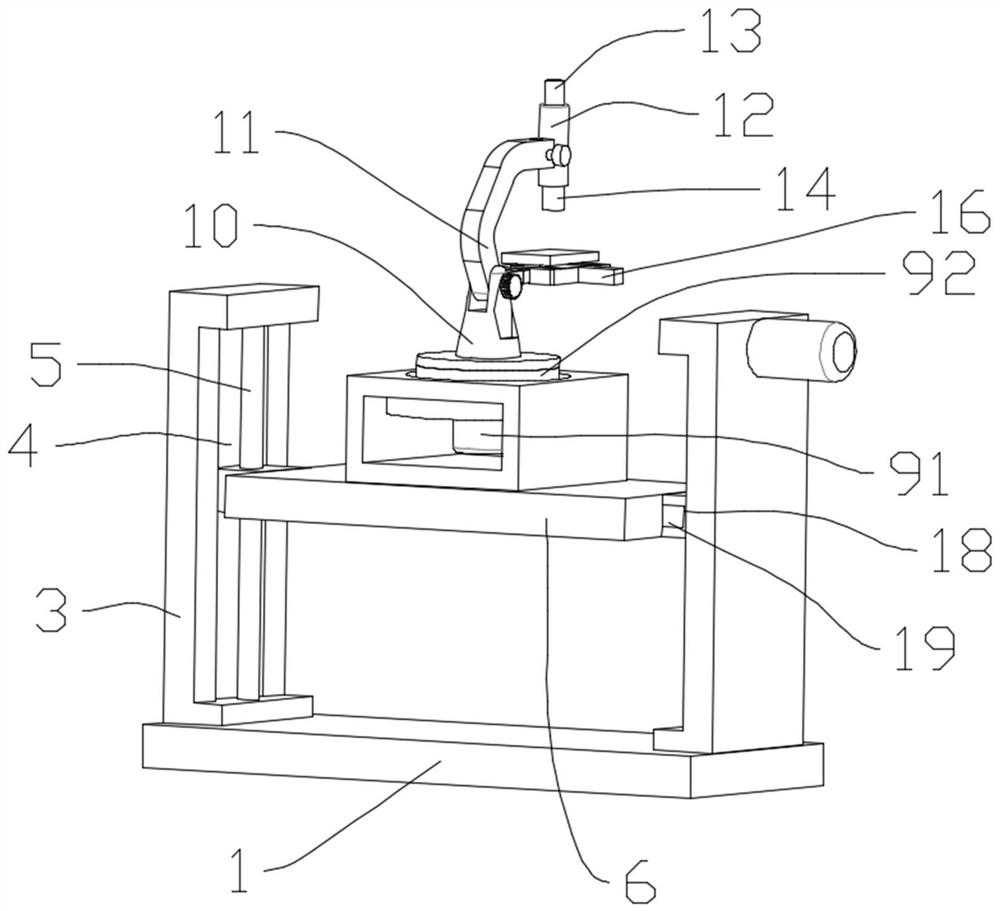

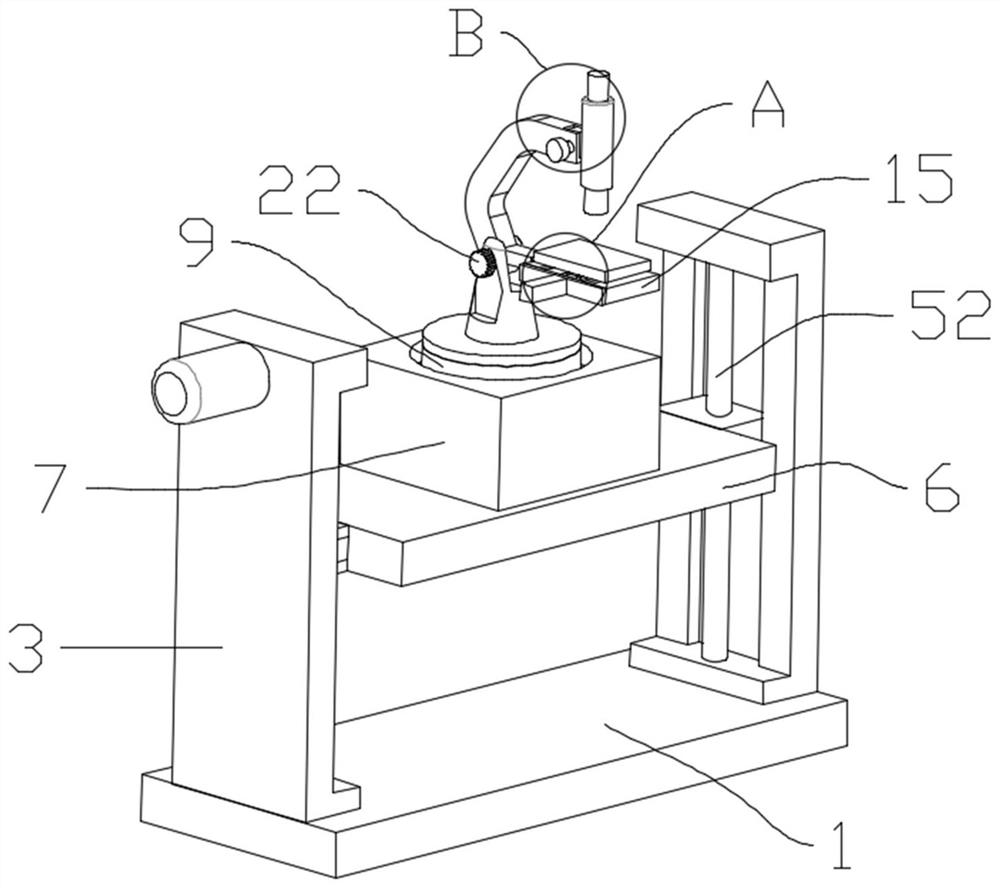

Objective optical system

The invention discloses an objective lens optical system. The objective lens optical system is characterized by comprising a base for mounting a microscope body; two symmetrical mounting plates are fixedly mounted on the upper surface of the base, and first mounting grooves are formed in the two mounting plates; and a first moving mechanism is mounted in the first mounting groove. A supporting plate is mounted on the first moving mechanism, an adjusting seat is fixedly mounted on the supporting plate, a second mounting groove is formed in the upper surface of the adjusting seat, a rotating mechanism is arranged in the second mounting groove, and the microscope body is fixedly mounted on the rotating mechanism. The microscope body comprises a rotating seat, a microscope arm, a lens barrel, an electronic eyepiece, an objective lens and a carrier bracket, so that the overall height of the microscope body can be adjusted conveniently. According to the system, an operator can conveniently adjust the horizontal rotation angle of the microscope body according to different illumination intensities.

Owner:南京甬宁科学仪器有限公司

Mounting and fastening device for orthopedic splint

PendingCN114533370AReduce discomfortImprove protectionOperating tablesDiagnosticsSplint deviceEngineering

According to the technical scheme, the installing and fastening device for the orthopedic splint is characterized in that the installing and fastening device comprises a bed body, supporting legs are fixedly connected to the periphery of the lower surface of the bed body, a driving mechanism is fixedly arranged on one side of the lower surface of the bed body, and a guiding mechanism is fixedly arranged on the other side of the lower surface of the bed body; a moving seat is arranged between the driving mechanism and the guiding mechanism, a first servo motor is fixedly installed on the lower surface of the moving seat, the output end of the first servo motor is in transmission connection with a rotating shaft through a coupler, the bottom end of the rotating shaft is fixedly connected with a rotating arm, and a connecting rod is welded to the upper surface of the other end of the rotating arm; one end of the bed body is provided with an arc-shaped slide way for rotation of the connecting rod; the driving mechanism is arranged to drive the moving seat to move, so that the moving seat can conveniently drive the clamping plate fastening mechanism to move, the horizontal position of the clamping plate fastening mechanism can be conveniently adjusted, and different positions of the legs can be conveniently fixed.

Owner:LUOYANG ORTHOPEDIC TRAUMATOLOGICAL HOSPITAL

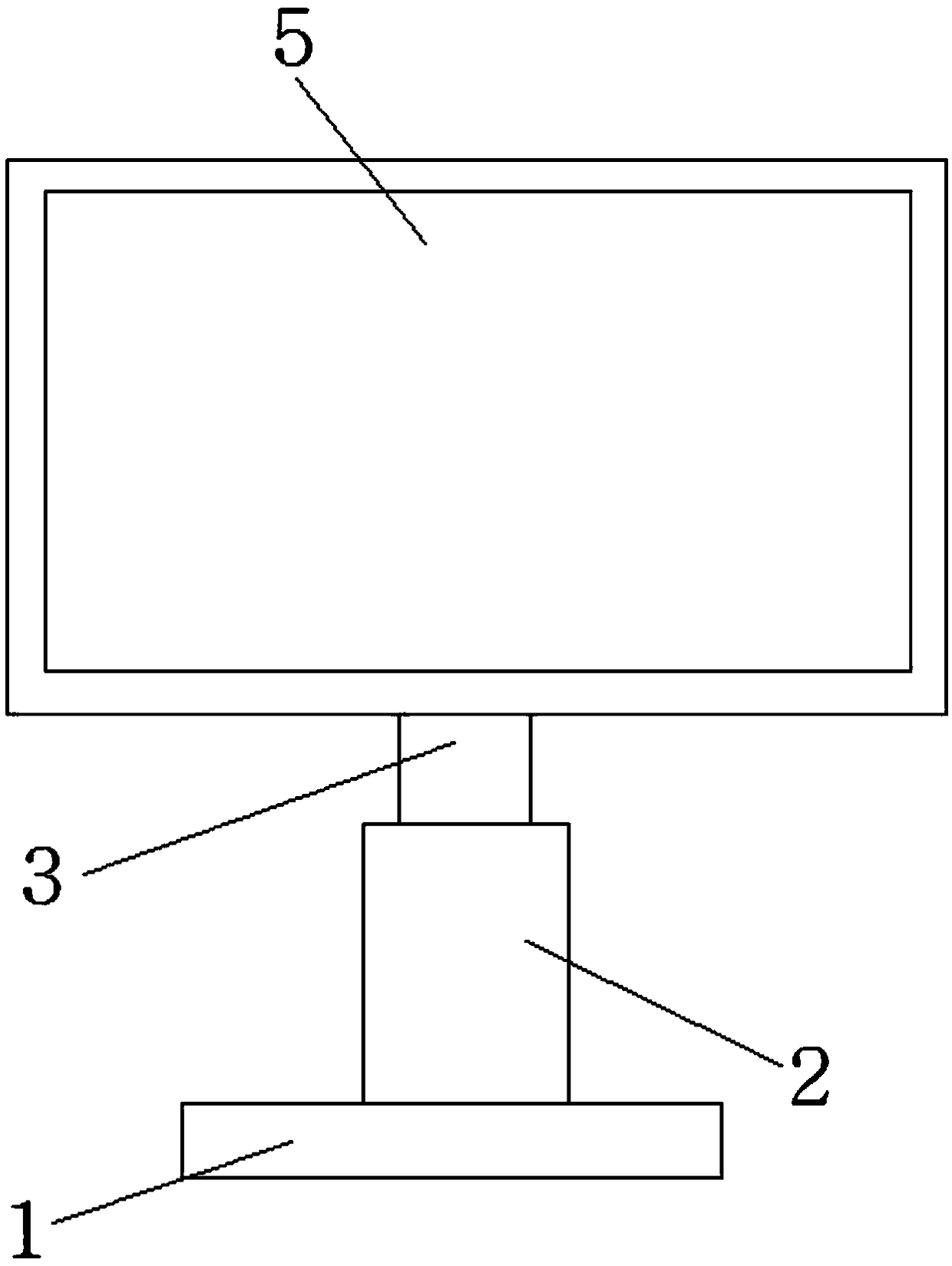

PC display for engineering mechanical industry on-line financing service

InactiveCN108916575AEasy to adjust the height positionEasy to adjust horizontal positionStands/trestlesProtecting eyeDisplay device

The invention discloses a PC display for engineering mechanical industry on-line financing service. The PC display comprises a base. The top side of the base is fixedly provided with an adjusting box.The adjusting box is provided with a placing cavity. The inner wall of the bottom side of the placing cavity is fixedly provided with a sliding rod. The top end of the sliding rod is extended out ofthe adjusting box. The sliding rod is slidably sleeved with a slider positioned in the placing cavity. The top side of the slider is fixedly provided with an adjusting rod sleeves the sliding rod. Thetop end of the adjusting rod is extended out of the adjusting box, and one side of the adjusting rod is fixedly provided with a fixing rod. One end, away from the adjusting rod, of the fixing rod isrotatably connected with an assembling plate. The PC display for the engineering mechanical industry on-line financing service is capable of, while heights of workers are different, adjusting a heightposition of a display body through a screw rod and the slider, and conveniently adjusting a horizontal direction position of the display body, is beneficial to protect eyes, simple in structure, andconvenient to use.

Owner:芜湖市联网汇通电子科技有限公司

A special workbench for drilling baffles

ActiveCN110802247BEasy to drillImprove drilling efficiencyLarge fixed membersPositioning apparatusEngineeringWorkbench

The invention discloses a special workbench for drilling baffles, which includes a drilling workbench and a chip guide plate. A bed is installed inside the drilling workbench, and a chip removal chamber is arranged at the bottom of the bed. One end of the mobile workbench is connected to the servo motor through a screw, the bed surface at the bottom of the mobile workbench is equipped with a rolling supporting wheel, and the two ends of the binder are connected to the connecting plate through a connecting shaft. The bottom of the connecting plate is connected with the fixed seat through the pressing oil cylinder; the chip guide plate is arranged inside the bed below the mobile workbench, and the support frame is installed inside the drilling workbench. In the present invention, the mobile workbench that is slidingly connected inside the bed enables the workpiece placed on the surface of the mobile workbench to move horizontally, and through the fixing effect of the binder body, it is convenient for the drill bit to pass through the binder body to accurately drill the workpiece, improving the The drilling efficiency of the baffle plate improves drilling accuracy, reduces labor costs, and reduces tool usage costs.

Owner:SHANDONG TARGUS PRECISION MACHINE

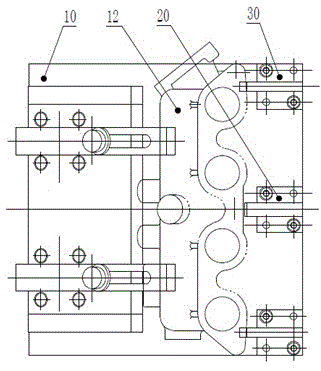

An engine intake pipe clamp

InactiveCN103170862BStable clampingImprove stabilityPositioning apparatusMetal-working holdersMechanical engineeringEngineering

The invention relates to a special fixture capable of stably clamping an air inlet pipe of an engine. The fixture is composed of a locating block, a locating seat, a fixture body, a pressure cylinder and a press board in a combined mode, wherein pressing force is provided by the pressure cylinder, and the horizontal position of a workpiece can be freely adjusted through the locating seat. The air inlet pipe of the engine can be stably clamped to facilitate processing of the bottom surface, the same position of the workpiece is clamped every time, and the pressing force is provided by the pressure cylinder, so that working efficiency is high, the structure is simple, clamping operation is convenient, the fixture is long in service life, and stability of the workpiece is high. The fixture can achieve effective and fixed clamping of the air inlet pipe of the engine and other irregular workpiece.

Owner:繁昌县金牛机械铸造有限责任公司

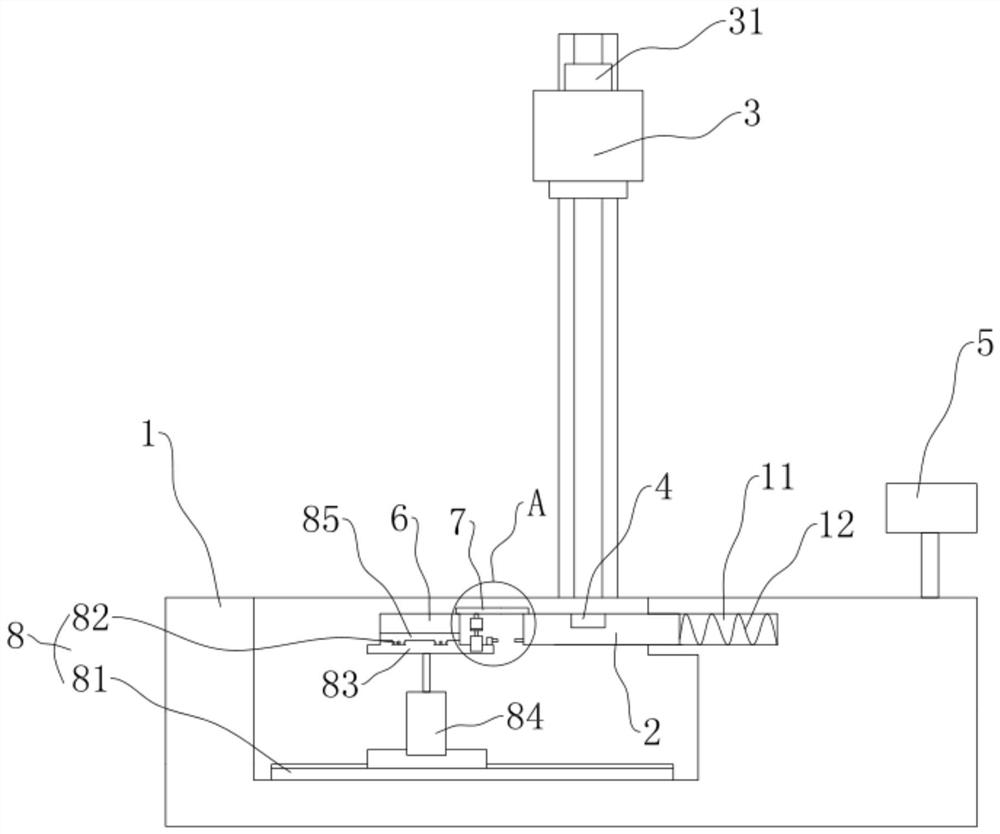

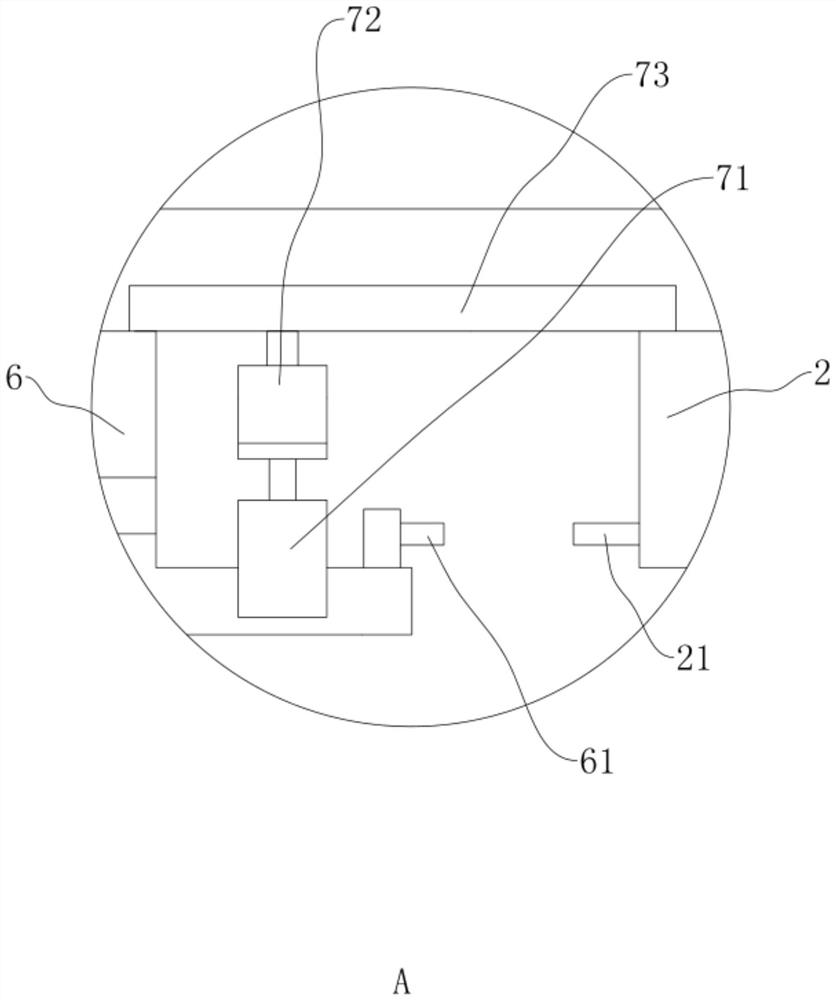

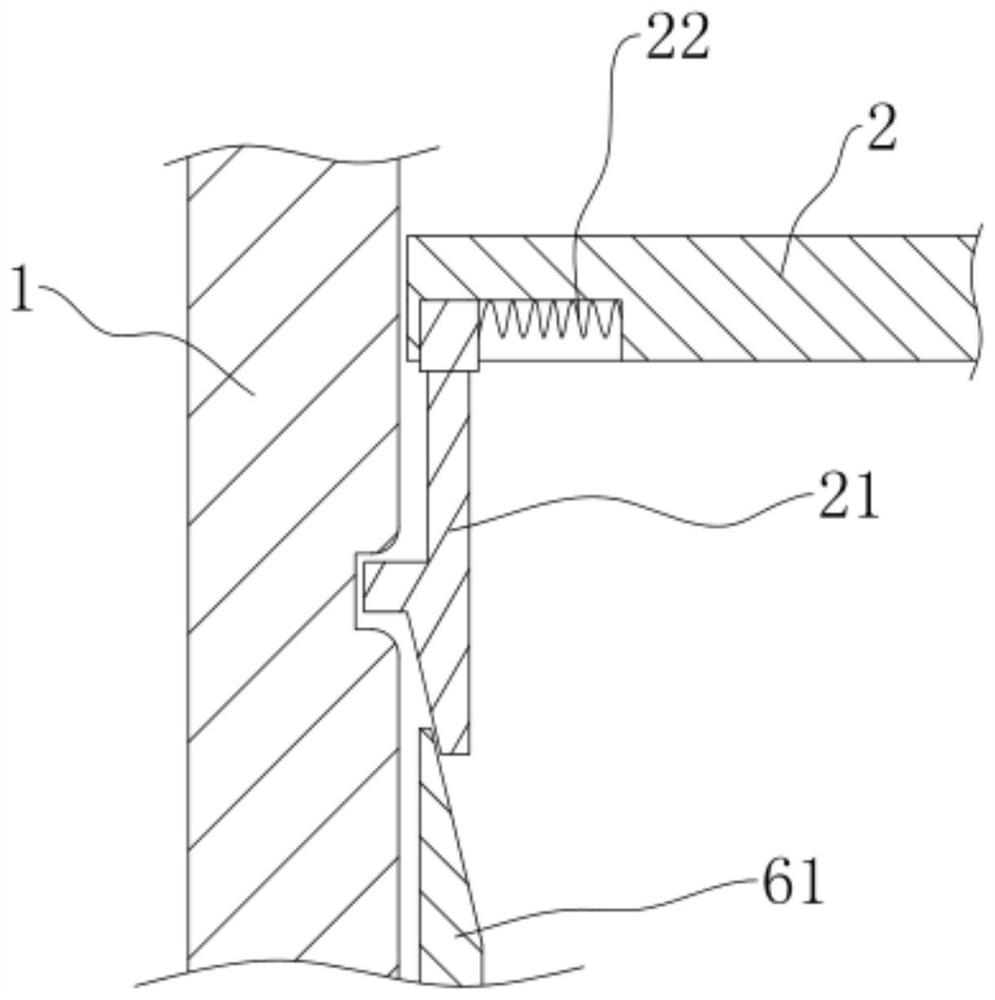

Intelligent equipment shell production equipment and process

InactiveCN113084628AEasy to polishEasy to adjust the horizontal positionEdge grinding machinesGrinding drivesElectric machineryProcess engineering

The invention discloses intelligent equipment shell production equipment and process, relates to the technical field of intelligent equipment shell production, and provides the following scheme aiming at solving the problems that when existing equipment shells are machined, openings of the shells are inconvenient to polish quickly, and time and labor are wasted by manual fixing. The intelligent equipment shell production equipment comprises a containing plate, a driving motor is fixedly connected to the bottom of the containing plate, a lifting extrusion mechanism is fixedly connected to an output shaft of the driving motor, and a grinding mechanism fixedly connected with the containing plate is arranged at the right side of the lifting extrusion mechanism. According to the intelligent equipment shell production equipment and process, the shells can be automatically clamped and fixed conveniently and rapidly, manual operation is not needed, labor is saved, efficiency is high, the openings of the shells of different sizes can be ground conveniently and rapidly, and the applicability of the device is improved.

Owner:JIANGXI UNIV OF TECH

Bamboo processing perforating device

InactiveCN112549196AHorizontal displacement stabilityEasy to adjust the horizontal positionStationary drilling machinesScrew threadDrill bit

The invention belongs to the technical field of bamboo processing perforating devices, and particularly relates to a bamboo processing perforating device which comprises a bottom shell and a drill bit. A first fixing shell is fixedly connected to the top of the bottom shell, and an electric push rod and a telescopic assembly are fixedly connected to the top of the inner wall of the first fixing shell; and the bottom end of the electric push rod and the bottom end of the telescopic assembly are fixedly connected with one second fixing shell, the opposite inner walls of the second fixing shell are fixedly connected with same sliding rods, and the number of the sliding rods is two. According to the bamboo processing perforating device, by arranging a movable block, a movable groove, a first threaded column and a threaded cap, the movable block moves in the movable groove by unscrewing the threaded cap, so that the movable plate drives two arc-shaped limiting plates to move, a fixing device is convenient to move, bamboos are convenient to punch side by side, and punching operation in various modes is convenient; and when the movable plate is moved to a proper position, the movable plate can be conveniently fixed by tightening the threaded cap.

Owner:朱达平

Supercharging device for chemical process

ActiveCN114688098AEasy to cleanHighly easy to controlPump componentsPumpsEngineeringStructural engineering

The supercharging device for the chemical process comprises a base, supercharging equipment is arranged at the top of the base, a transmission mechanism is arranged on the front face of the base, and cleaning mechanisms used for cleaning dust on the surface of the supercharging equipment are symmetrically arranged on the two sides of the transmission mechanism. The cleaning mechanism comprises a moving mechanism located over the supercharging equipment, a moving plate is arranged on the front face of the moving mechanism, a first sliding groove is formed in the moving plate, an electric push rod is fixedly installed at the bottom of the inner wall of the first sliding groove, and the horizontal height of a first rack is adjusted through stretching and retracting of the electric push rod; the dust collection device is simple in structure and easy to fit the structure of the supercharging equipment, the horizontal position of the dust collection head is conveniently controlled by moving the movable shell on the first rack, the longitudinal angle is adjusted through the dust collection head, dead corners of the structure of the supercharging equipment are conveniently cleaned, the cleaning efficiency is improved, and meanwhile the influence on the structure of the supercharging equipment during manual cleaning is reduced.

Owner:BENGBU AIPU COMPRESSOR MACHINERY

Rapid mounting structure wide in application range and used for information communication equipment

InactiveCN108679392AEasy to moveEasy to adjust the horizontal positionStands/trestlesEngineeringSurface plate

The invention discloses a rapid mounting structure wide in application range and used for information communication equipment, and relates to the technical field of the information communication equipment. A sleeve is convenient to move by releasing a first puller bolt, so that the horizontal position of the information communication equipment installed between an arc panel and a convex panel is convenient to adjust; a corresponding pulling handle is pulled open and is rotated and adjusted when the information communication equipment installed between the arc panel and the convex panel needs to be rotated and inclined in a certain direction, and when an upper wedge block and a lower wedge block are clamped between two teeth of a gear, the position of the information communication equipmentis fixed, the inclination angle is convenient to adjust, and the signal direction is convenient to adjust accordingly; after the information communication equipment is put into the arc panel and theconvex panel, a hemisphere is directly limited by the plane side of a limiting block, and the mounting efficiency is improved; a fixing block is pulled open and the plane of the limiting block is disengaged from the hemisphere when the information communication equipment needs to be taken out, and operation is easy and rapid.

Owner:佛山博发智能科技有限公司

Automatic edge aligning device of shell fabric compounding machine

InactiveCN108454221AHeight adjustableEasy to adjust the horizontal positionLamination ancillary operationsControlling laminationEngineering

The invention discloses an automatic edge aligning device of a shell fabric compounding machine and belongs to the field of edge aligning devices. The automatic edge aligning device of the shell fabric compounding machine comprises an outer shell with an upward opening, wherein a base box is in sliding connection in the outer shell, a pair of limiting blocks are fixedly connected to the base box,a tension spring is connected between the lower end of the base box and an inner bottom plate of the outer shell, a firs through hole is formed on a lateral wall of the outer shell, a second through hole matched with the first through hole is arranged on a lateral wall of the base box, a clamping block is in sliding connection in the base box, one end of the clamping block sequentially penetratesthrough the second through hole and the first through hole, a first compression spring is connected between the other end of the clamping block and an inner wall of the base box, a button frame corresponding to the first through hole is fixedly connected to a lateral wall of the outer shell, and a button is in sliding connection in the button frame. The automatic edge aligning machine has easinessin adjusting the heights of opposite edge plates and the positions of the opposite edge plates in the horizontal direction and convenience in use.

Owner:JIANGSU JINFENG LIGHT IND EQUIP CO LTD

Computer numerical control (CNC) automatic lathe for punching and shearing cut-to-length line of silicon steel sheet

InactiveCN112975419AEasy to adjust the horizontal positionAccurate entryOther manufacturing equipments/toolsPositioning apparatusNumerical controlPunching

The invention relates to the technical field of cut-to-length lines of silicon steel sheets, in particular to a computer numerical control (CNC) automatic lathe for punching and shearing a cut-to-length line of a silicon steel sheet. The CNC automatic lathe comprises a pedestal, and a base is arranged above the left side of the pedestal and above the bottom of the base; a steel sheet roller is arranged in the middle of the front side of the base, a groove is formed in the right side of the base, and the groove is formed in the pedestal; gears are arranged at the ends of the right and left sides of the groove, and a belt is arranged on the outer sides of the gears; and a baffle is arranged above the right side of the groove. The CNC automatic lathe has the beneficial effects that through the opening structure of the baffle, the silicon steel sheet can be located in the middle of the upper portion of the pedestal after passing through the baffle from left to right, the horizontal position of the silicon steel sheet is easy to adjust, and the silicon steel sheet can accurately enter clamping plates. The position of a pull rope is controlled through elastic action of a spring, and therefore the clamping block is driven by the pull rope to close, and the end of the silicon steel sheet can be firmly fixed through the clamping block in the rotating process of a winding barrel.

Owner:刘炎岗

Anti-theft fixing frame for power station monitoring

The invention discloses an anti-theft fixing frame for power station monitoring. The fixing frame comprises vertical rods, main supporting frames, a rotating shaft, a lower connecting rod body, a first locking rod, locking holes and a fixing plate; connecting rods are welded to the right sides of the vertical rods, a transverse frame is fixedly connected to inner side ports of the two connecting rods, a special-shaped lock is embedded in the upper surface of the transverse frame, a transverse slideway is arranged at the bottom of the transverse frame, a transverse sliding block is arranged inthe middle of the transverse slideway, the lower side of the transverse sliding block is fixedly connected with a connecting plate, a transverse telescopic rod is installed at the right side of the connecting plate, and the connecting plate is fixedly connected with an outer side port of a monitor fixing frame body through the transverse telescopic rod. The anti-theft fixing frame for power station monitoring has a good anti-theft structure, a monitor is prevented from thefts, the overall anti-theft work is also conducted on an outer frame of the monitor, the cost caused by damage and thefts is reduced, the fixing frame is easy to install and saves effort, and the monitor inspection work intensity of people is reduced.

Owner:JIANGSU KE JI ELECTRIC POWER CO LTD

A method for automatic focusing of laser cleaning machine

ActiveCN112495943BAvoid damageEasy to determineMountingsCleaning processes and apparatusEngineeringAutofocus

The invention discloses an automatic focusing method for a laser cleaning machine, which relates to the technical field of laser cleaning. The key points of the technical solution are as follows: S1, aligning the focus measuring seat on the laser cleaning head; S2, controlling the vertical displacement through a controller mechanism, so that the vertical displacement mechanism drives the laser cleaning head to move; S3, the controller analyzes the strength of the received signal, selects the strongest signal value and determines its corresponding position, and determines the focus point of the laser cleaning head on the focus measuring seat ; S4. Align the surface of the workpiece to be cleaned with the focus measuring seat on the same horizontal plane; S5. Move the focus measuring seat horizontally, drive the workpiece to be cleaned to move to the position of the focus measuring seat, and the workpiece to be cleaned and the laser cleaning can be completed. AF job between heads. The present invention can perform focus adjustment and focus without damaging the workpiece to be cleaned, and the focus is performed automatically, the focus adjustment and focus are more precise, and the focus convenience and focus accuracy are improved.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD +1

Stamping mechanism of stamping machine

PendingCN109435511AEasy to adjust the horizontal positionImprove applicabilityStampingEngineeringTouch panel

The invention discloses a stamping mechanism of a stamping machine. The stamping mechanism of the stamping machine comprises a mechanism frame, a lead screw and a rectangular sliding rod. A transparent window is formed in the upper end of the mechanism frame, and a shooting mechanism is fixedly connected with the upper end of the transparent window. A liquid crystal touch panel is fixedly connected with the middle of the upper end of the mechanism frame. A paper guide groove is fixedly connected with the left side of an inner cavity of the mechanism frame, and paper guide wheels are movably connected with the inner side of the paper guide groove in a clamped mode. A paper outlet groove is fixedly connected with the right side of the inner cavity of the mechanism frame. A shock pad is fixedly connected with the right portion of the upper side of the inner cavity of the mechanism frame, and a stamp pad is fixedly connected with the lower end of the shock pad. The lead screw is fixedly connected with the middle of the inner cavity of the mechanism frame, and a sliding mechanism sleeves the upper end of the lead screw in a connected mode. A reset spring sleeves the outer side of a telescopic rod in a connected mode, an installation base plate is fixedly connected with the upper end of the telescopic rod, and a stamp is fixedly connected with the upper end of the installation base plate through a connecting column. The stamping mechanism can accurately judge and adjust the angle and the position of the stamp and conduct accurate stamping.

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

Multi-angle cutting and edging numerical control machine tool

PendingCN114833585AImprove processing efficiencyImprove stabilityOther manufacturing equipments/toolsMetal working apparatusNumerical controlElectric machinery

The multi-angle cutting and edging numerical control machine tool comprises a machine tool body, a working groove is formed in the top of the machine tool body, limiting grooves are formed in the inner walls of the two sides of the working groove, a steering mechanism is arranged in the working groove, and the steering mechanism comprises a supporting plate; the four corners of the supporting plate are slidably connected with the corresponding limiting grooves through fixing pins, a rotating groove is formed in the top of the supporting plate, a rotating seat is rotatably connected to the inner wall of the rotating groove through a bearing, and an operation plate is fixedly connected to the top of the rotating seat; a supporting plate slides to a set position under the limiting condition of four fixing pins, a rubber plate abuts against an anti-skid plate, and a stepping motor operates to be matched with the anti-skid plate to drive a rotating base to rotate, so that a part on an operation plate is changed by a horizontal angle, and cutting equipment and grinding equipment can conveniently conduct cutting and edge grinding operation on the part by multiple angles; therefore, the machining efficiency of parts is improved.

Owner:杨炳森

Fixed-length electronic weft accumulator with positioning structure and for air-jet loom

PendingCN112176505ASolve the inconvenience of position adjustmentPrecise positioningLoomsAir-jet loomStructural engineering

Owner:奉化惠邦精密机械有限公司

A fixed frame for anti-theft power station monitoring

The invention discloses a fixed frame for anti-theft power station monitoring, which includes a vertical bar, a main support frame, a rotating shaft, a lower connecting rod body, a first locking rod, a locking hole and a fixing plate, and a connecting rod is welded on the right side of the vertical bar , and the inner ports of the two connecting rods are fixedly connected with a horizontal frame, the upper surface of the horizontal frame is inlaid with a special-shaped lock, the bottom end of the horizontal frame is equipped with a horizontal slideway, and the middle of the horizontal slideway The position is provided with a horizontal slider, and the lower side of the horizontal slider is fixedly connected with a connecting plate, and the right side of the connecting plate is installed with a horizontal telescopic rod, and the connecting plate is fixedly connected with the outer port of the monitor fixed frame through the horizontal telescopic rod , the anti-theft-type power station monitoring fixed frame has a good anti-theft structure, not only anti-theft for the monitor itself, but also for the overall anti-theft work on the outer frame of the monitor, reducing the cost of damage and theft, and the device is easy to install It saves labor and reduces the intensity of people's monitor inspection work.

Owner:JIANGSU KE JI ELECTRIC POWER CO LTD

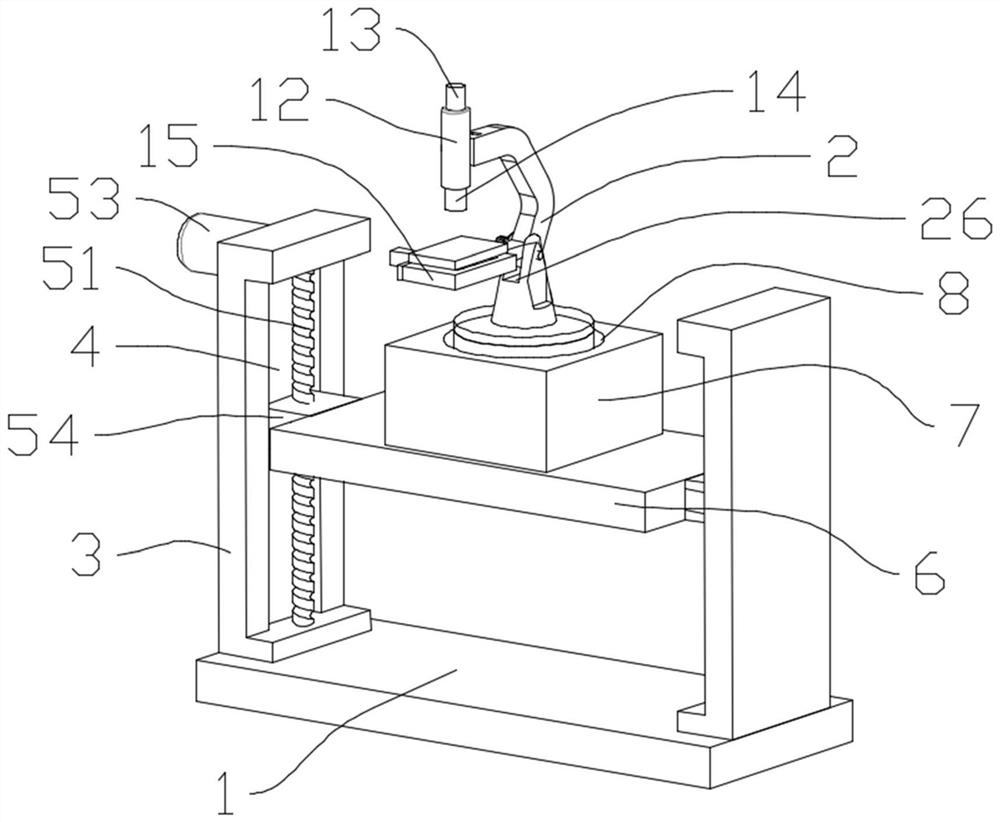

Multifunctional sharpening machine

PendingCN109227234AEasy sharpening operationImprove sharpening efficiencyGrinding carriagesOther manufacturing equipments/toolsFixed frameEngineering

The invention discloses a multifunctional sharpening machine which comprises a workbench. A first fixing table is arranged at one end of the top of the workbench. A guide rail is arranged at the top of the first fixing table. A movable table is arranged at the top of the guide rail. A first fixing frame is arranged at the top of the movable table. A motor is arranged at one side of the first fixing frame, a grinding wheel is arranged at the output end of the motor, a second fixing table is arranged at the other end of the top of the workbench, a supporting column is arranged at the top of thesecond fixing table, a positioning table is arranged at the top of the supporting column, a rotating rod is arranged at the bottom of the positioning table, and a rotating bearing is arranged at the top of the rotating rod. By arranging the guide rail and the movable table, the grinding wheel is driven to move transversely, a threaded block is driven by a threaded shaft, the threaded block is usedfor pushing a first connecting rod, an installing frame is driven, by arranging the rotating bearing, rotation of the fixing plate is achieved, and the sharpening efficiency is improved by multiply adjusting the positions of a tool and the grinding wheel.

Owner:ZHENGJIANG DANTU DISTRICT NINGBO RUN TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com