Guide device for assembling and positioning prefabricated polygonal bridge pier and design method

A guiding device and polygonal technology, applied in the direction of bridge construction, bridges, bridge parts, etc., can solve the problems of slow hoisting and assembling speed, invisible, time-consuming, etc., and achieve the effect of reducing the difficulty of hoisting, internal self-balancing, and realizing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of the present invention are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

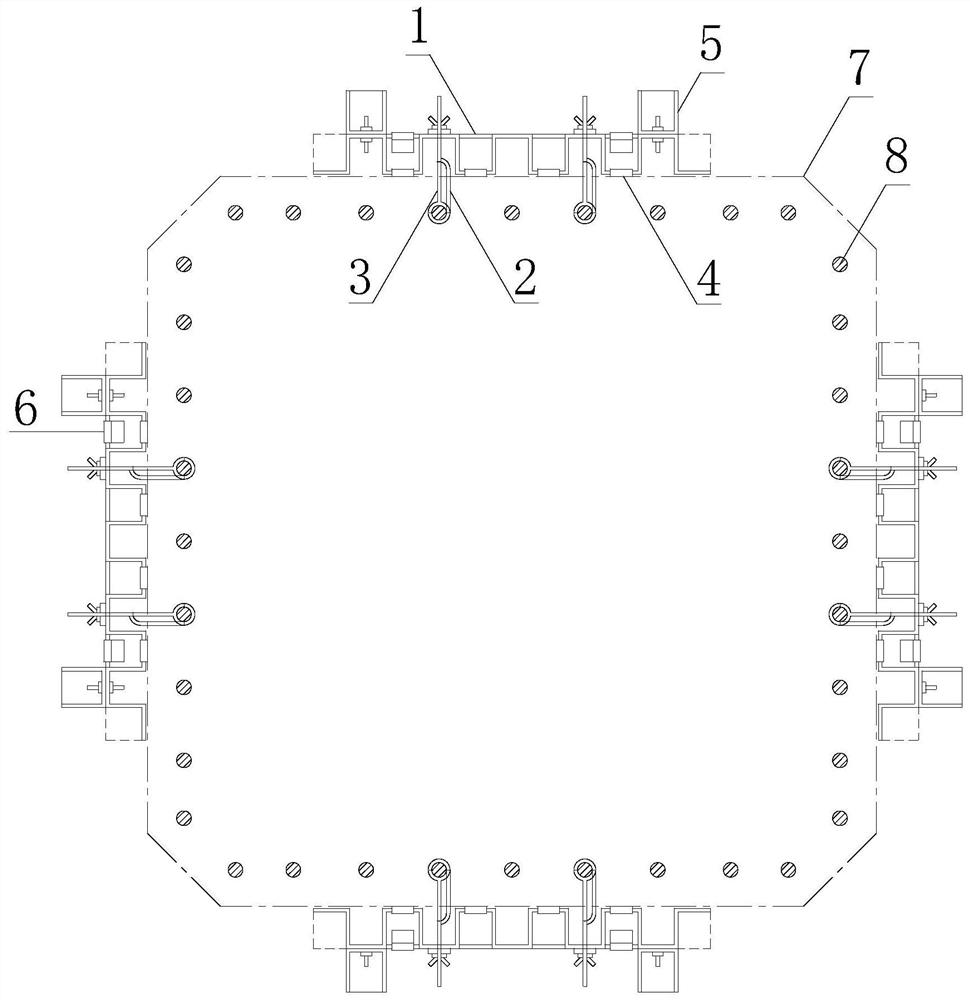

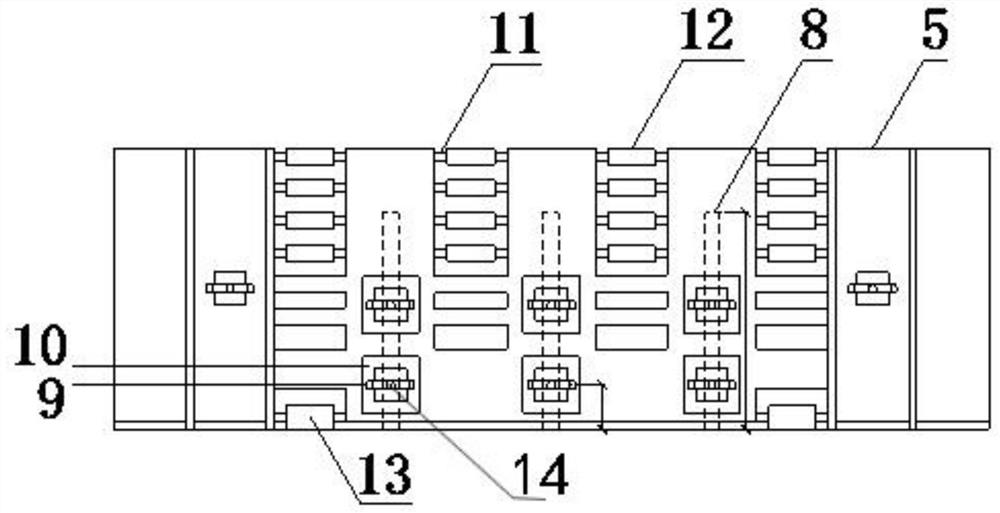

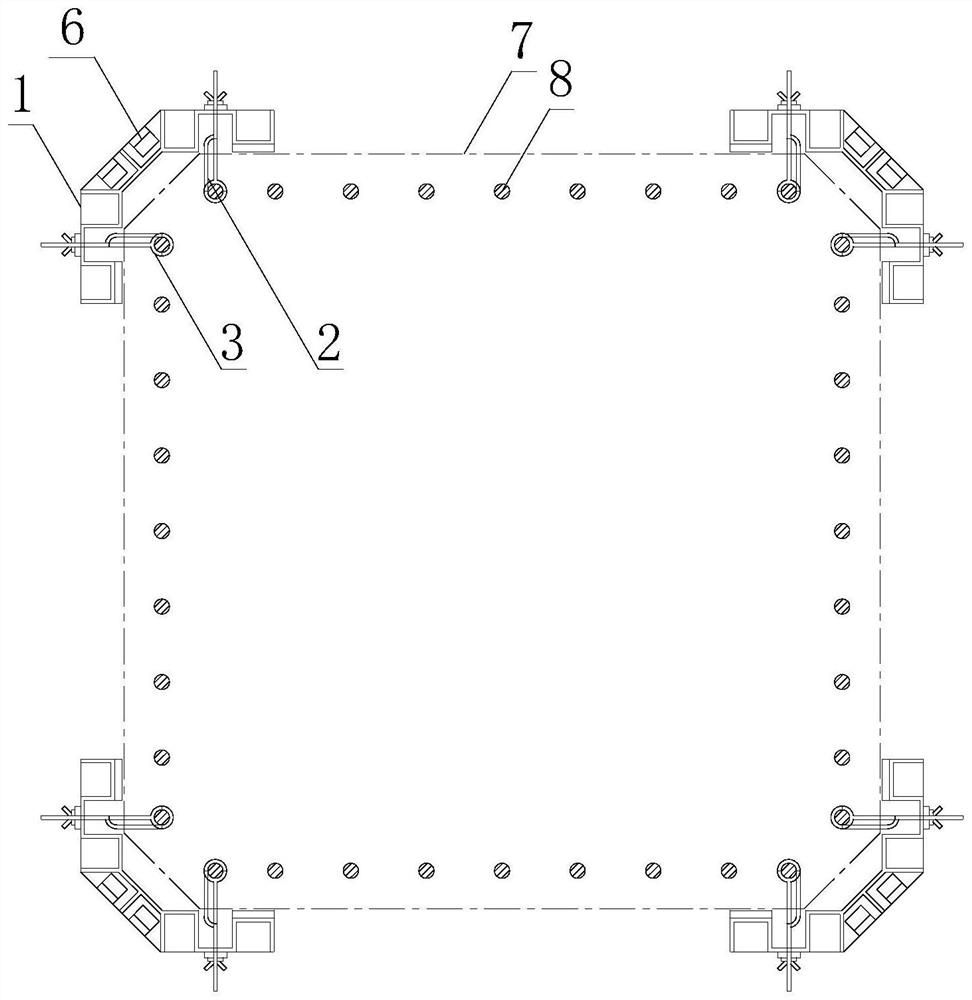

[0045] The guiding device for hoisting and positioning of bridge piers involved in this patent is mainly composed of the following parts: a limiting plate assembly, a positioning buckle assembly, a positioning top buckle assembly, a sliding assembly, a moving assembly, and the like. Each assembly is composed of a plurality of structural structures of the same type and their connecting bolts.

[0046] In the patent of the present invention, the limiting plate assembly, one of the components of the device, is composed of multiple limiting plates, which are directly in contact with the pier to form the main guiding surface. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com