Patents

Literature

457results about How to "Accurate entry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

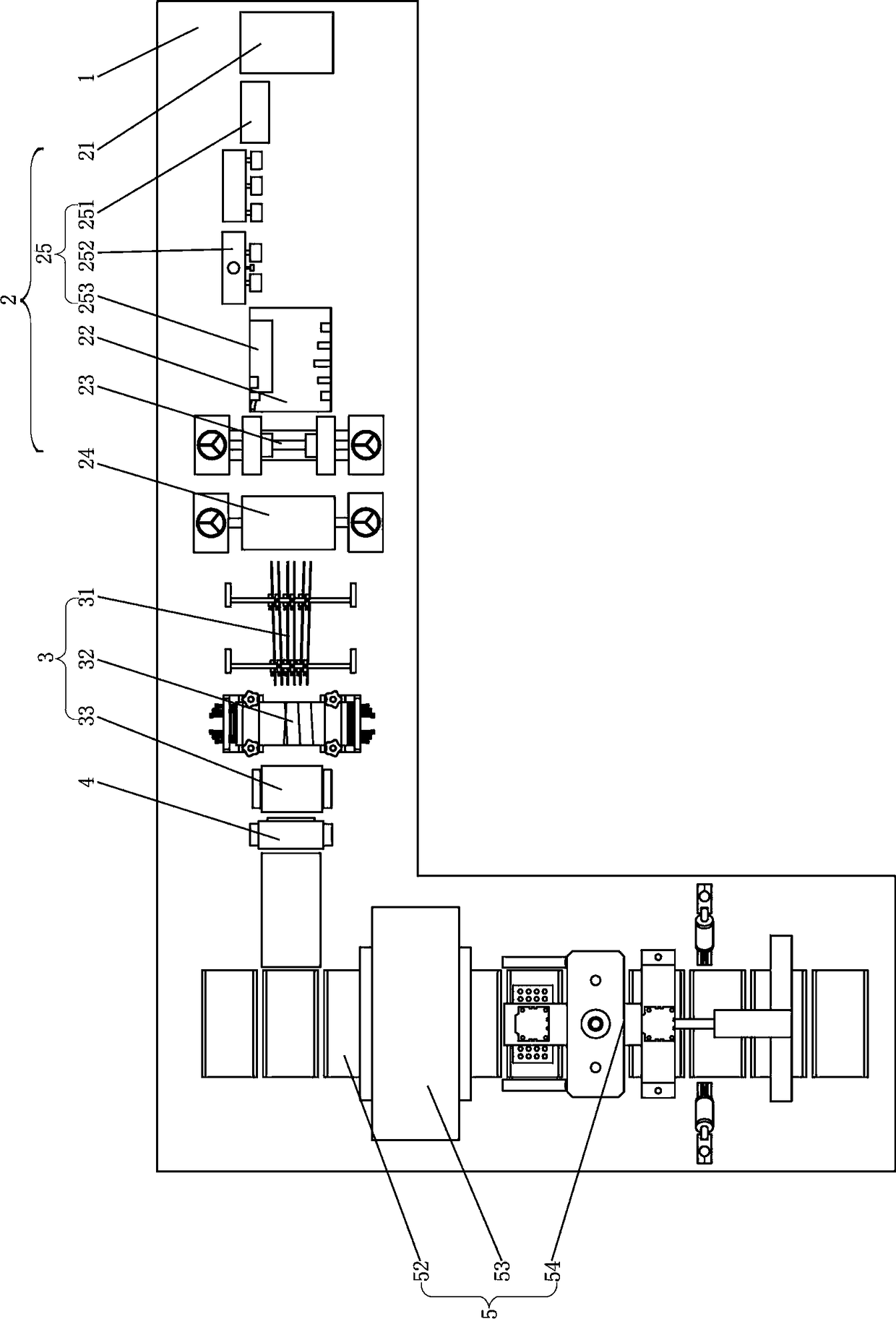

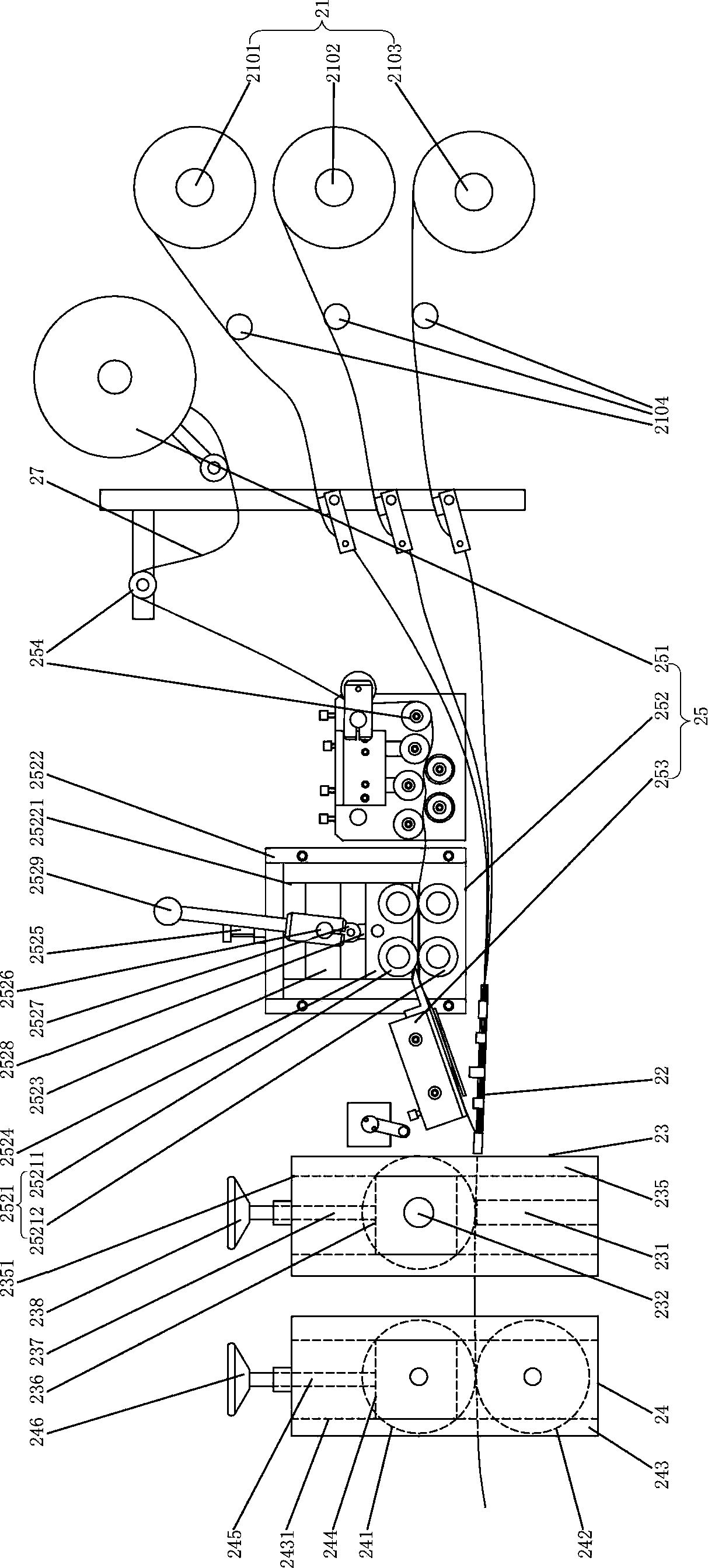

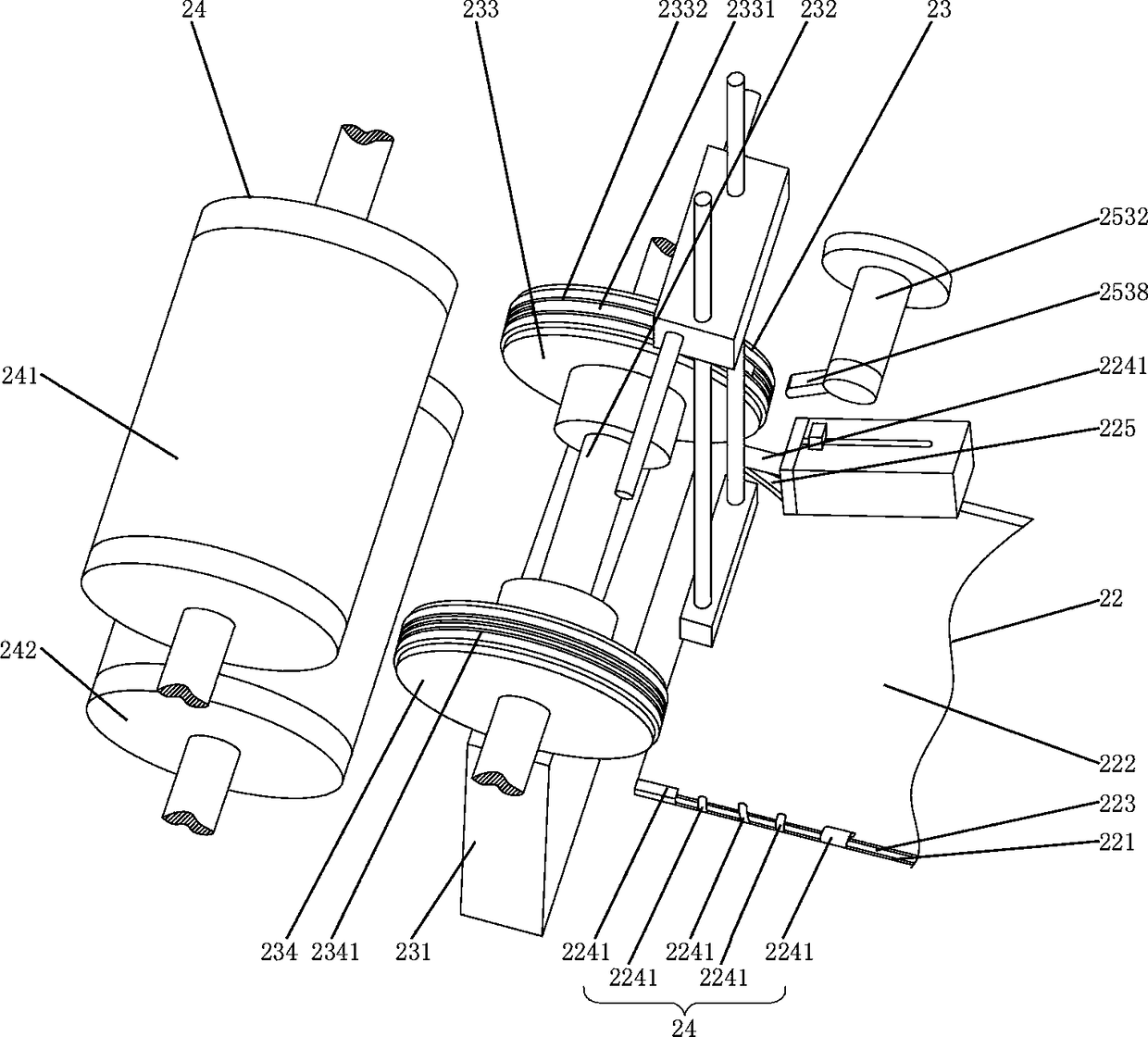

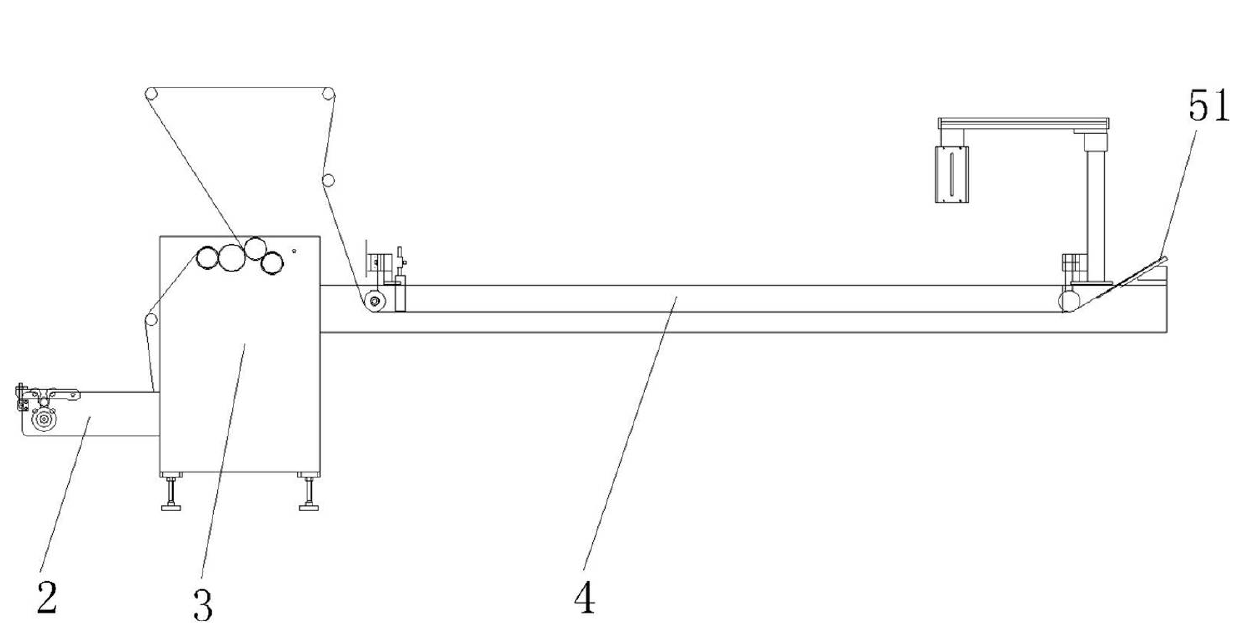

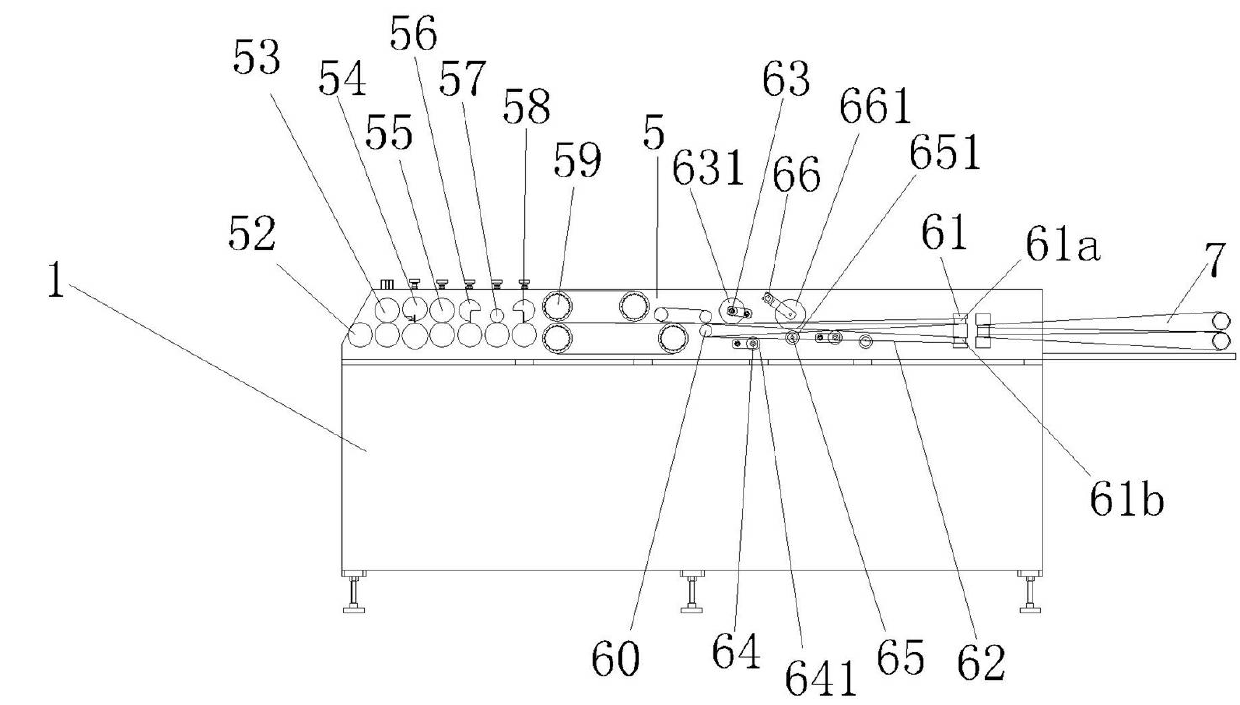

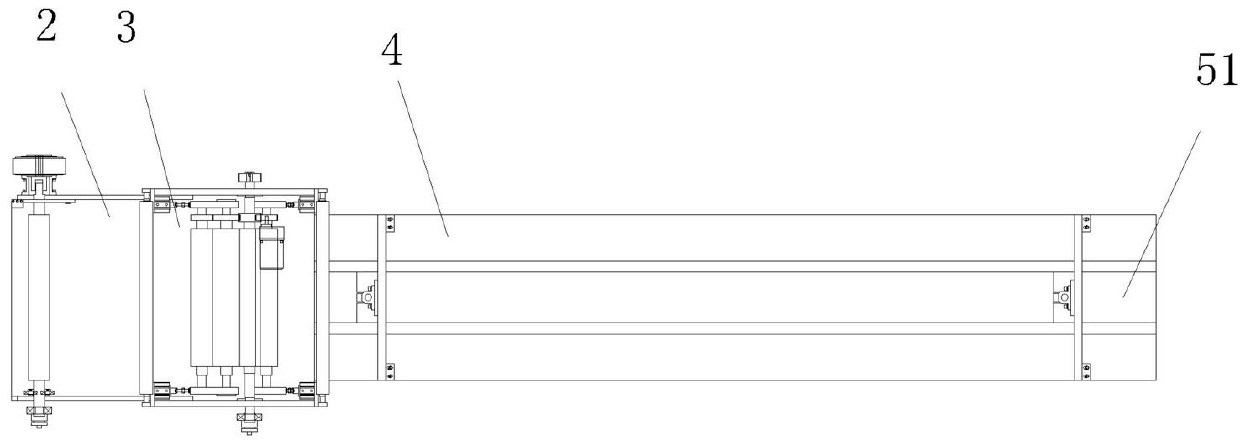

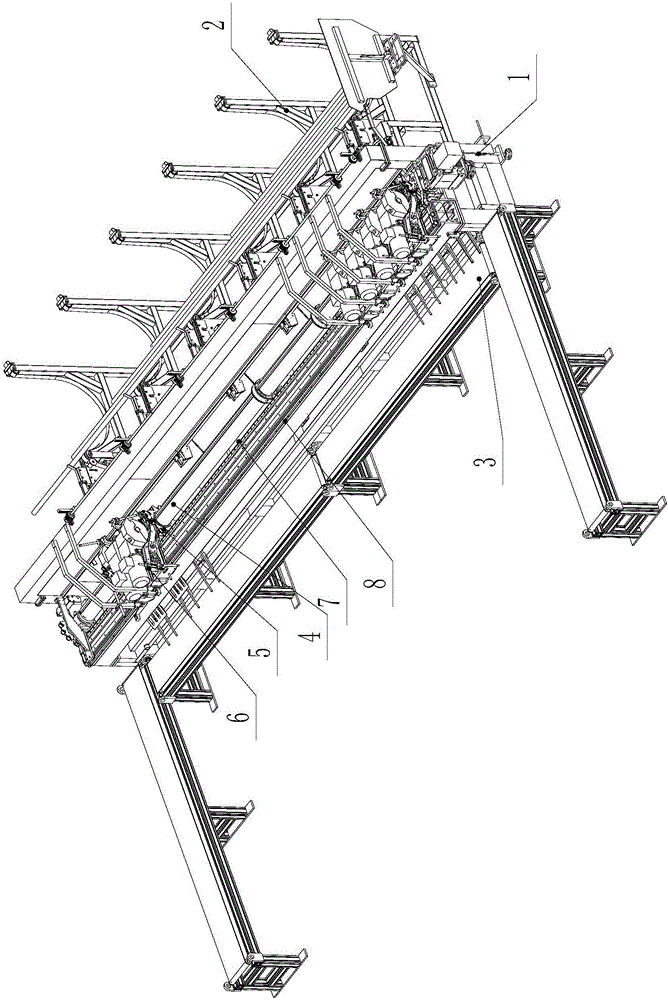

Full-automatic mask production line

The invention discloses a full-automatic mask production line. The production line comprises a machine frame, a mask fabric edge banding device, a mask surface folding device, a mask transverse sealing cutting device and an ear strip welding device; the mask fabric edge banding device comprises a fabric feeding device, a fabric edge folding device, a fabric splicing device, a fabric drawing mechanism and a nose bridge strip feeding device, the fabric edge folding device comprises a lower supporting plate and an upper pressing plate, the upper pressing plate is arranged above the lower supporting plate, two side edges of the lower supporting plate are provided with multiple edge folding side plates which are sequentially arranged from front to back, a nose bridge strip flowing pipe is arranged between the backmost edge folding side plate and the upper pressing plate, and the discharging port of the nose bridge strip feeding device faces the front end of the nose bridge strip flowing pipe; the fabric splicing device comprises a splicing motor, a first ultrasound mold, a rotary shaft, a first splicing wheel and a second splicing wheel, a strip-shaped groove is formed in the circumferential surface of the first splicing wheel, and the strip-shaped groove faces the rear end of the nose bridge strip flowing pipe. By means of the mask production line, edge banding process of fabrics can be automatically completed, and the nose bridge strip is accurately added into the edge banding parts of the fabrics.

Owner:汕头市泰恩康医用器材厂有限公司

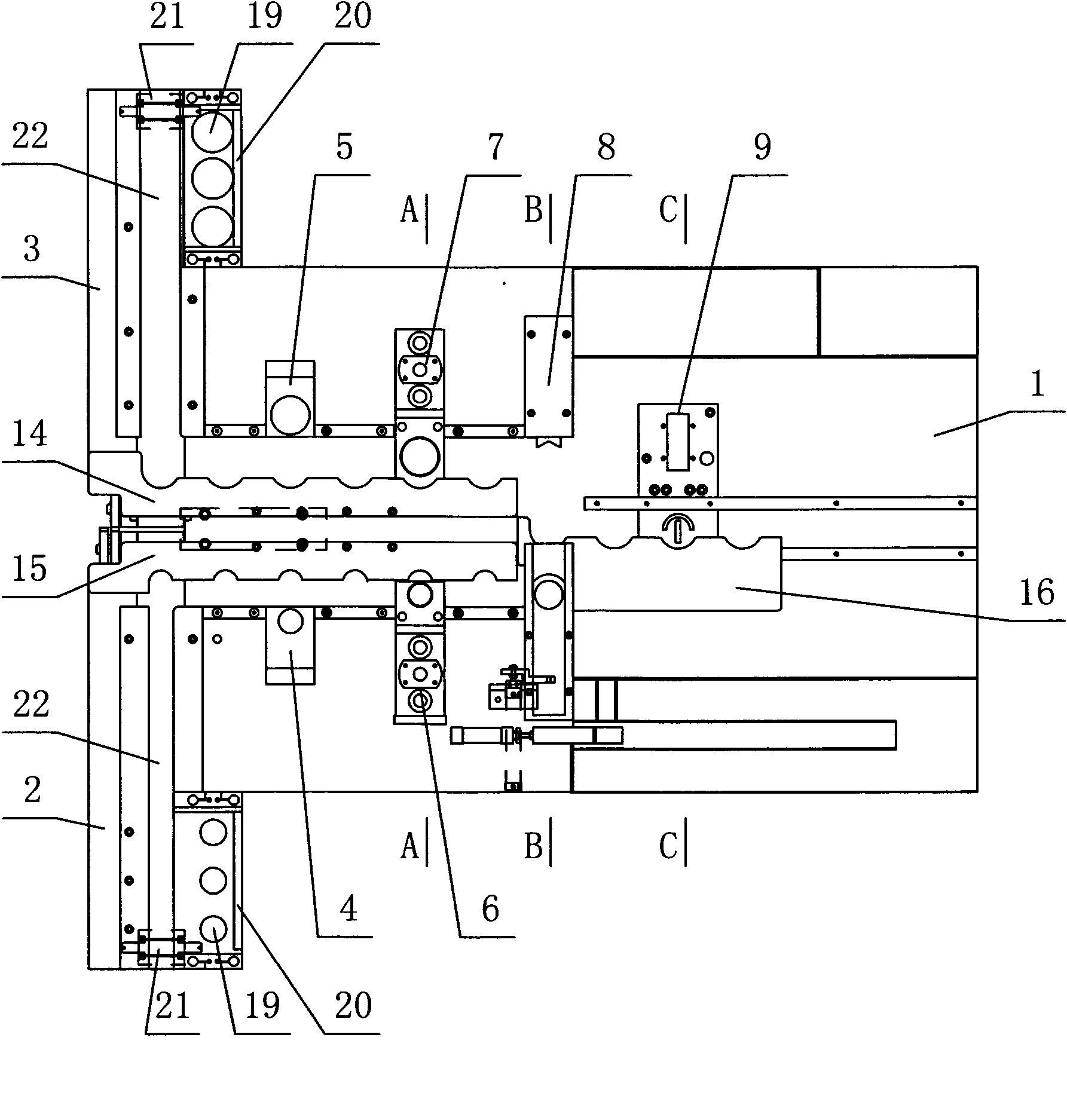

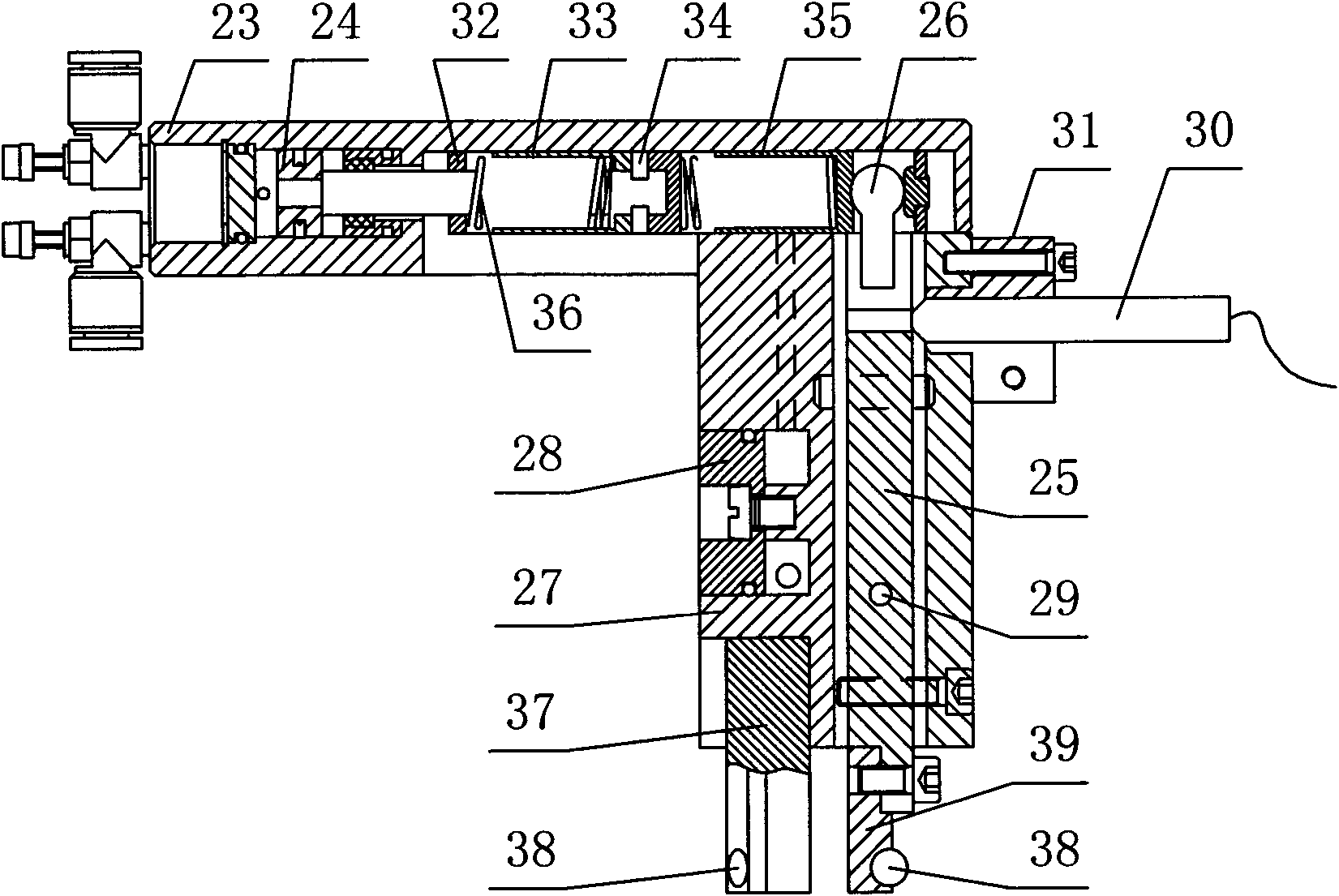

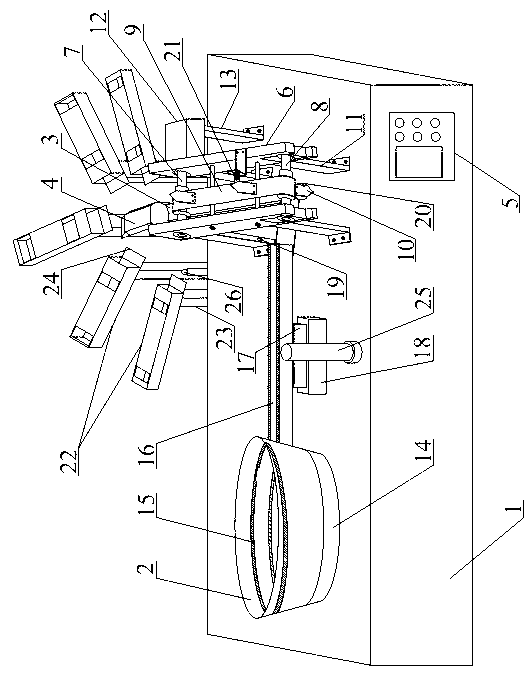

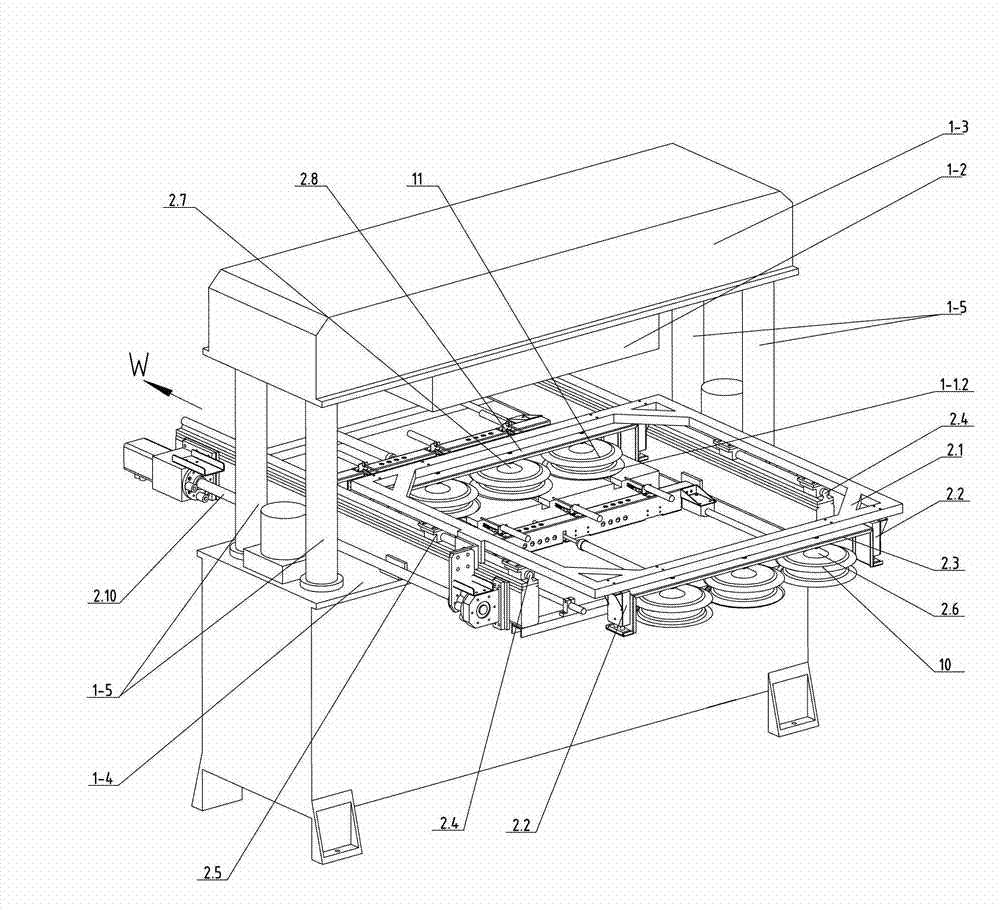

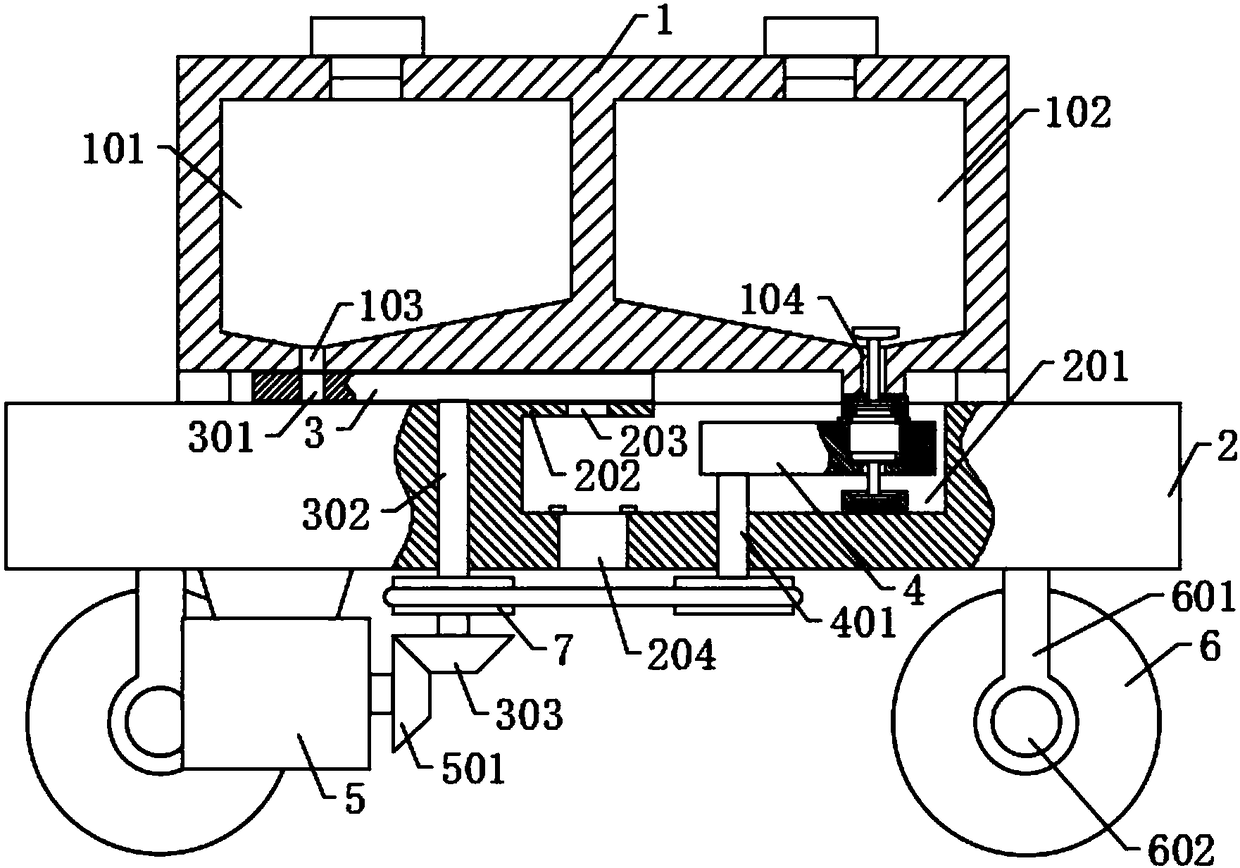

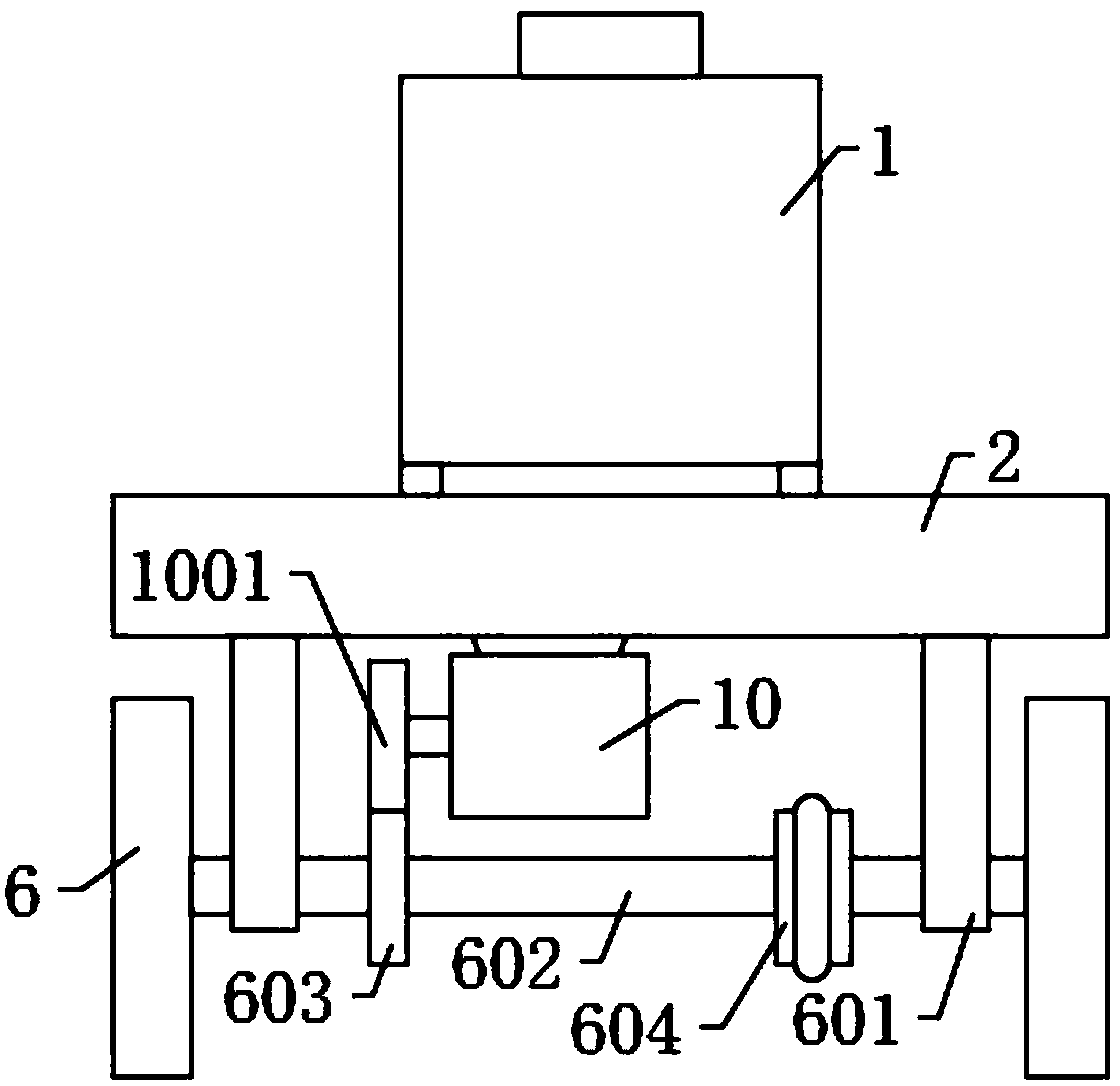

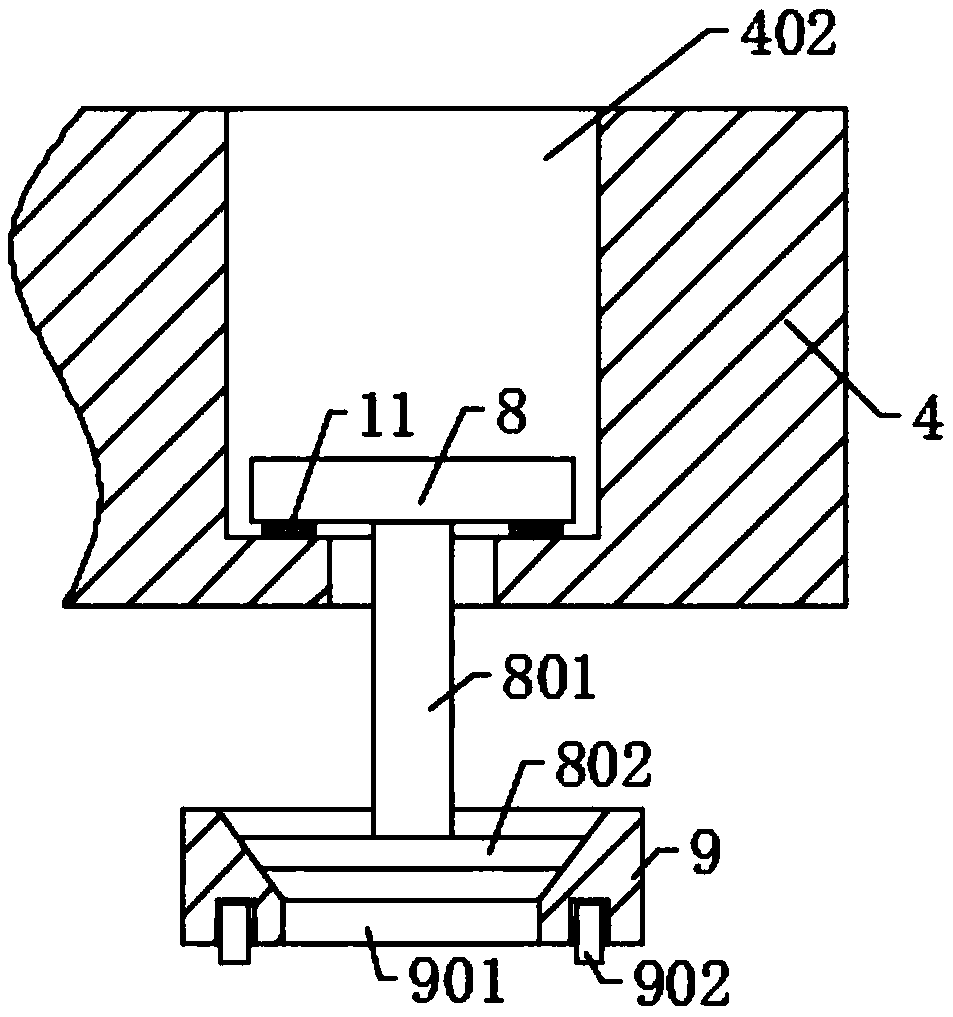

Full automatic bearing assembly machine

InactiveCN101943217AExquisite appearanceControl up and downBearing componentsEngineeringAssembly machine

The invention relates to a full automatic bearing assembly machine, a conveying device of an inner ring and an outer ring, a detecting device of the inner ring and the outer ring, a storing device of the inner ring and the outer ring, a closing device of the inner ring and the outer ring, an assembly device and a control device are sequentially arranged on the upper surface of a frame according to the processing sequence, a first shift sliding block is arranged on a linear guide track in the frame, a shift cylinder is fixed on the first shift sliding block, a telescopic rod is fixedly connected with the frame, curved mounting plates are respectively connected at the front and the back of a guide pole of a two-way cylinder which is fixed above the shift cylinder, the two curved mounting plates are respectively fixedly connected with an outer ring retainer plate and an inner ring retainer plate on the upper surface of the frame, a product shift cylinder is arranged in the position which corresponds to the assembly device in the frame, the product shift cylinder is fixed on a support above the second shift sliding block, the telescopic rod is fixedly connected with a product retainer plate on the upper surface of the frame, and the second shift sliding block is mounted on the linear guide track on the frame and connected with the shift cylinder via a connecting rod. The full automatic bearing assembly machine has reasonable structure, small volume, good running synchronization and high efficiency.

Owner:SHANDONG XUNJIE PRECISION EQUIP

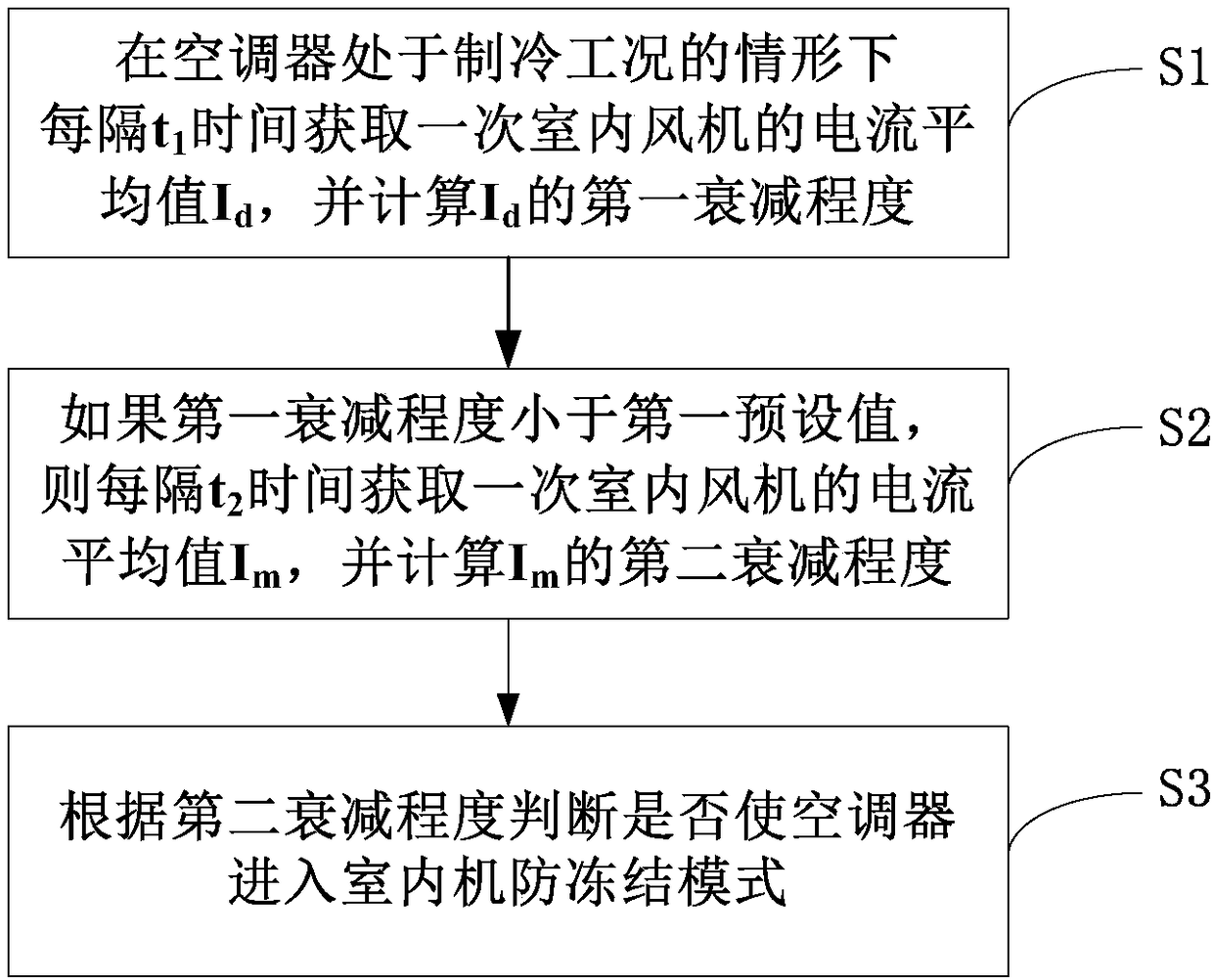

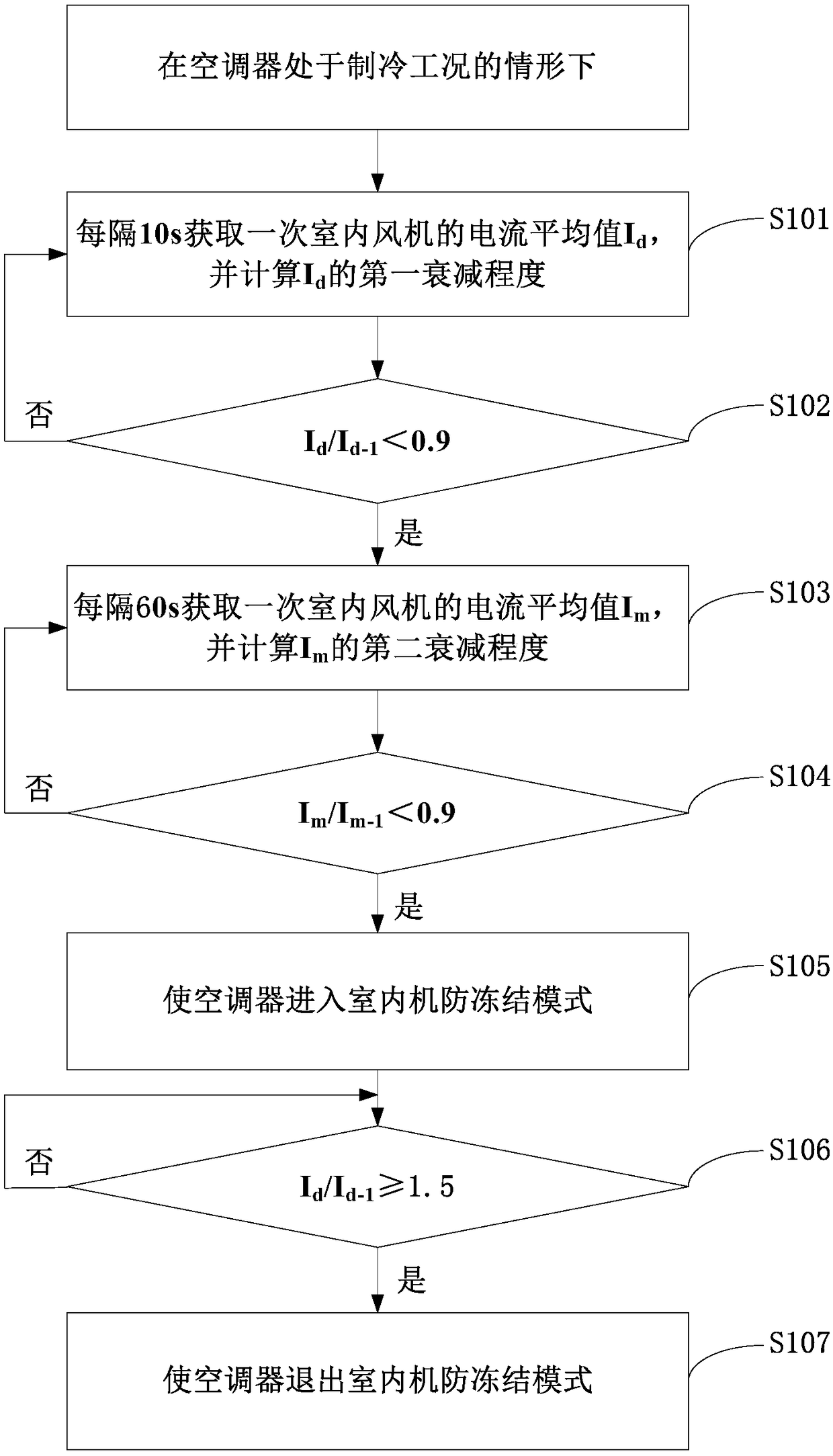

Indoor unit anti-freezing control method for air conditioner

ActiveCN108488998AImprove accuracyAvoid misjudgmentMechanical apparatusSpace heating and ventilation safety systemsUltrasound attenuationPower flow

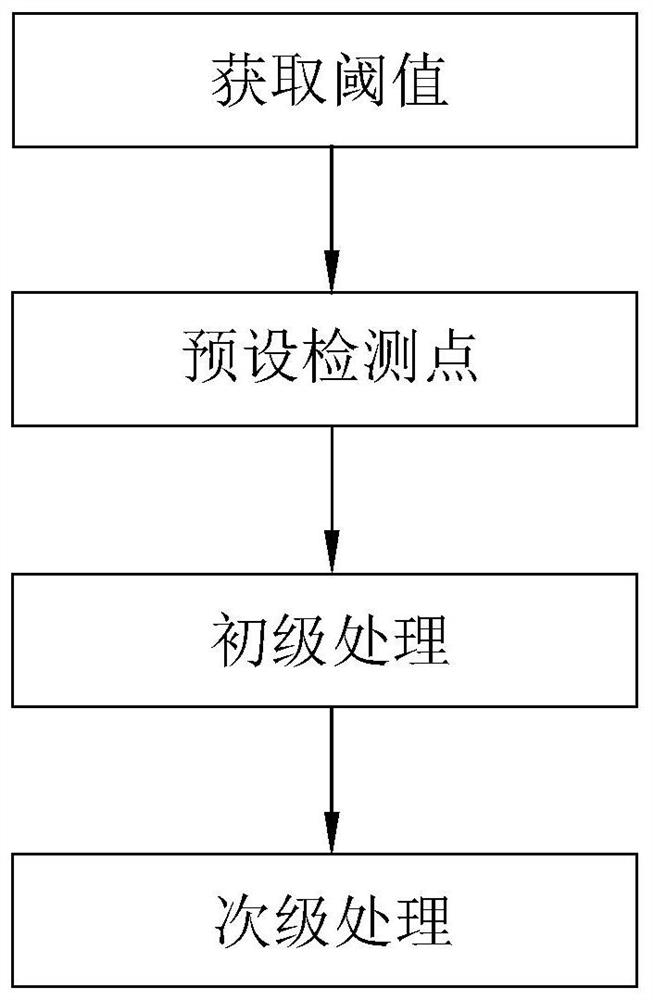

The invention belongs to the technical field of air conditioners, particularly relates to an indoor unit anti-freezing control method for an air conditioner, and aims at solving the problems that according to an existing air conditioner, accurate judgment on the freezing situation of an indoor unit is difficult according to the inner coil pipe temperature, and the accidental errors are likely to exist due to an existing point taking judgment method. The indoor unit anti-freezing control method comprises the steps that when the air conditioner is under the circumstance of a refrigeration work condition, the average current value Id of an indoor draught fan is obtained at the interval of t1, and the first attenuation degree of the Id is calculated; if the first attenuation degree is smallerthan the first preset value, the average current value Im of the indoor draught fan is obtained at the interval of t2, and the second attenuation degree of the Im is calculated; according to the second attenuation degree, whether the air conditioner enters an anti-freezing mode or not is judged; and accordingly, the problem that the mistaken judgment is caused by the current fluctuation phenomenonof the indoor draught fan of the air conditioner, the air conditioner frequently enters the indoor unit anti-freezing mode due to the mistaken judgment, and the air conditioner refrigeration effect is influenced is effectively solved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

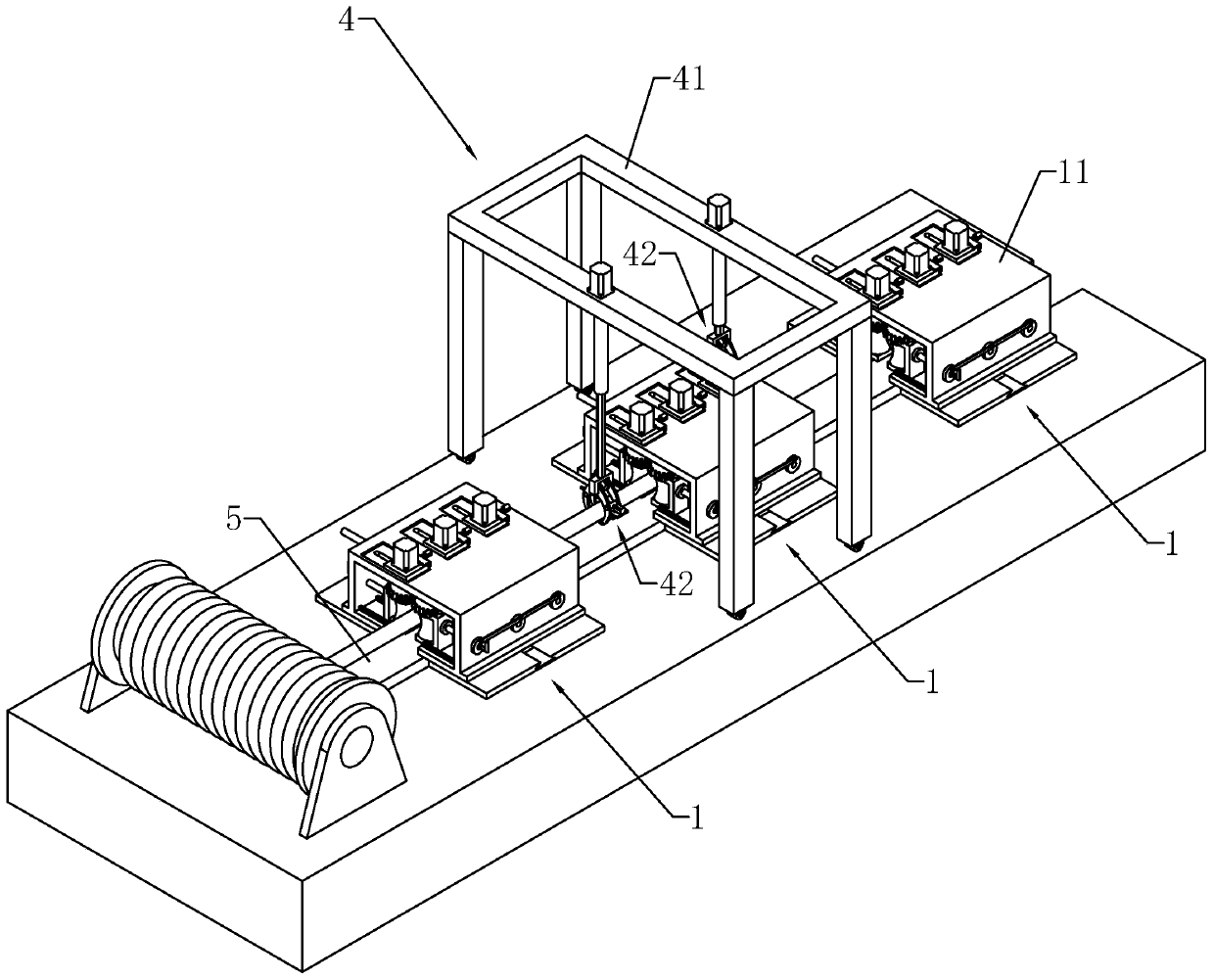

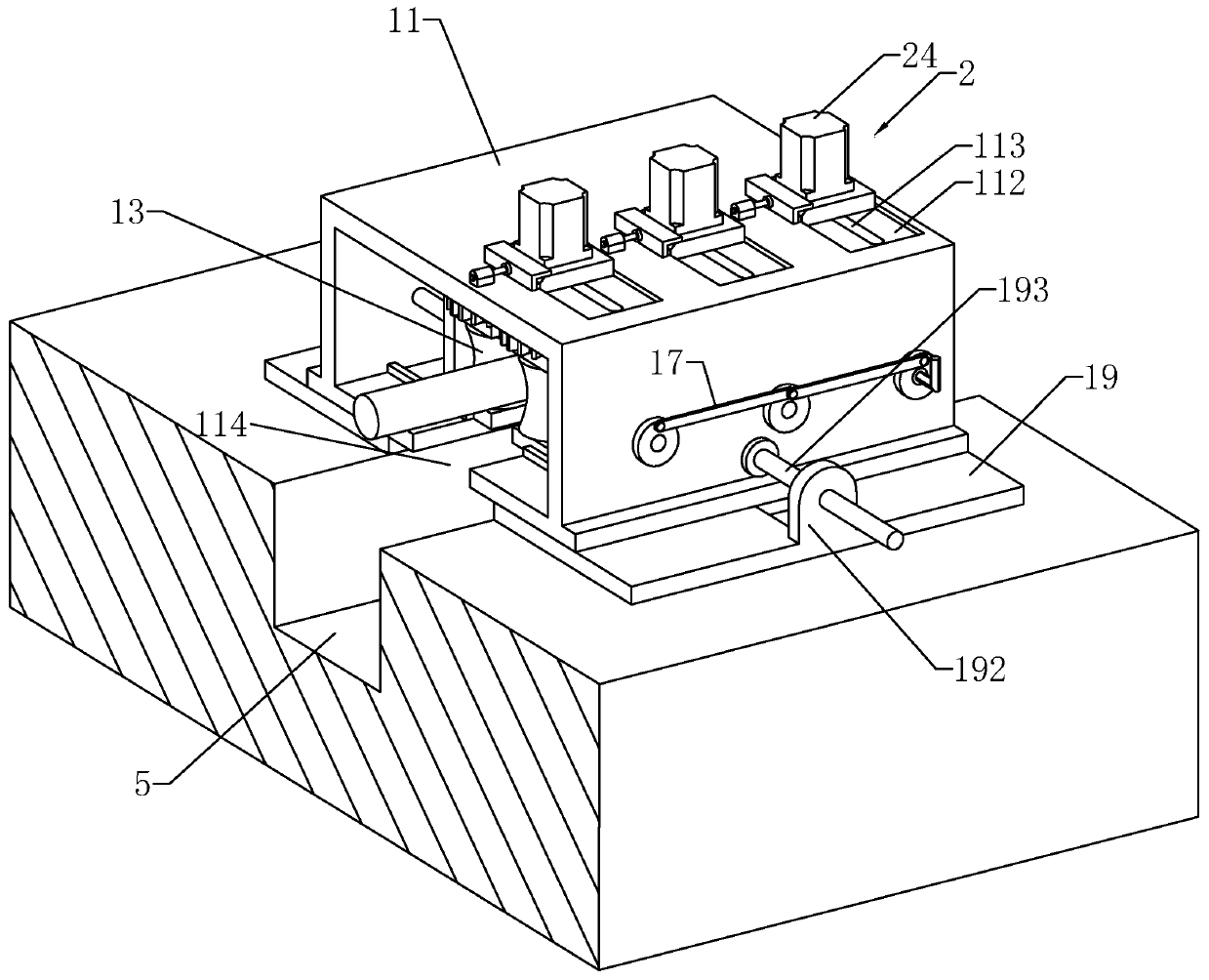

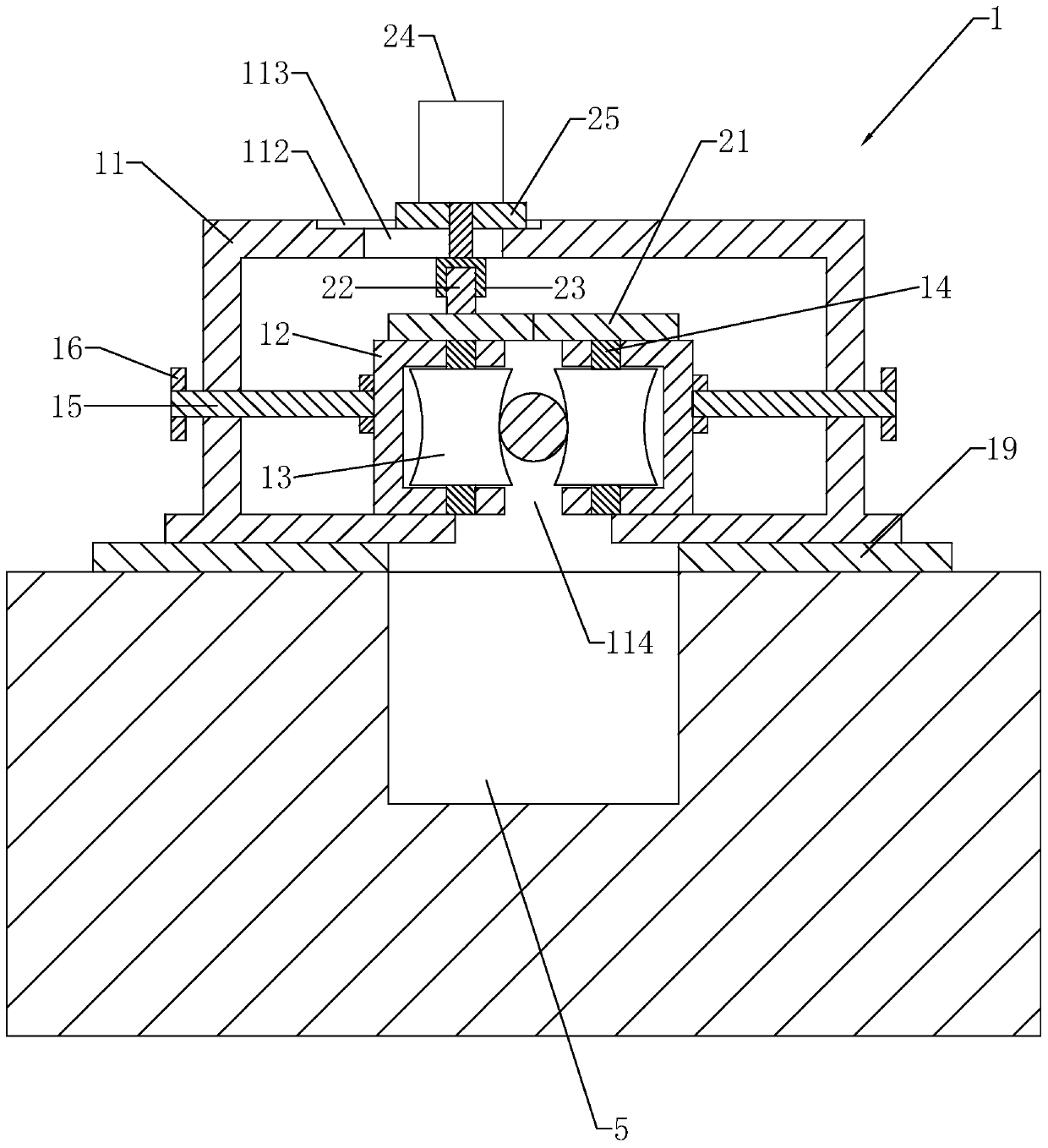

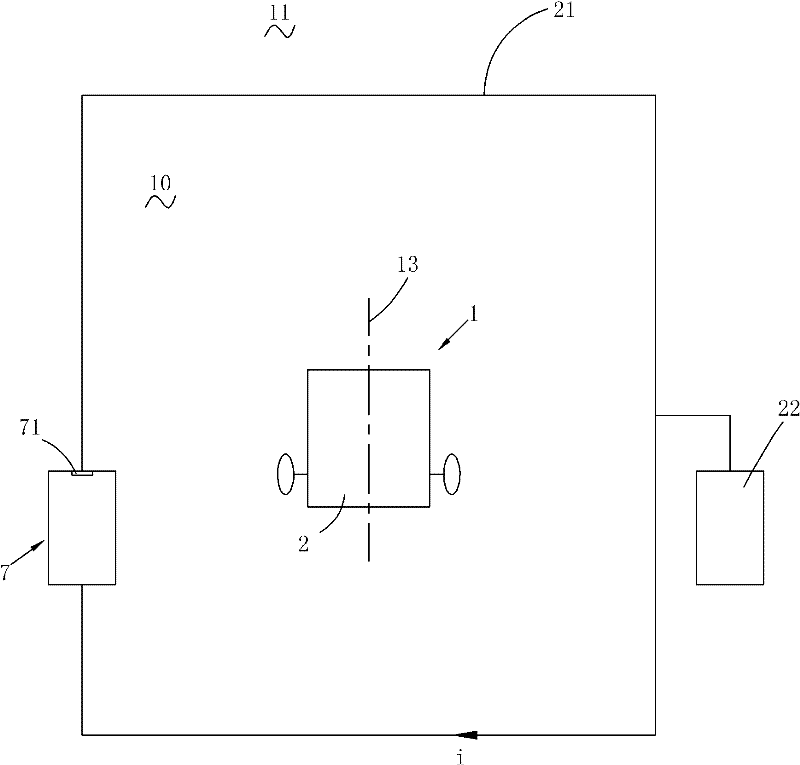

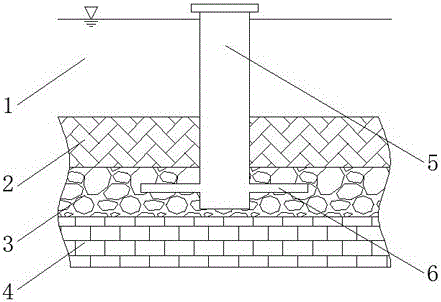

Direct-buried type high-voltage cable automatic laying device and laying method

The invention discloses a direct-buried type high-voltage cable automatic laying device. The direct-buried type high-voltage cable automatic laying device comprises a traction device for pulling a cable along the length direction of the cable trench, and a plurality of conveying devices arranged above the cable trench. The conveying device comprises a supporting frame and a plurality of sets of clamping wheels which are rotationally connected to the supporting frame and used for clamping cables. The clamping wheels are distributed in the length direction of the supporting frame. A plurality ofgroups of U-shaped sliding seats in one-to-one correspondence with the clamping wheels are arranged on the supporting frame in a mirroring manner, and the clamping wheel is located in the middle of the sliding base and is rotationally connected to the sliding base at the same time. Adjusting screw rods connected to the supporting frame in a threaded mode are horizontally and rotationally connected to the faces, deviating from each other, of the same set of sliding bases, a driving assembly used for driving the clamping wheels to rotate relatively is further arranged on the supporting frame, and an opening allowing a cable to be disengaged from the supporting frame downwards is formed in the supporting frame. The direct-buried type high-voltage cable automatic laying device has the advantages that the cable directly falls down to be rapidly separated from the conveying device, and then the effect of saving labor force is achieved.

Owner:南京飞阳输变电工程有限公司

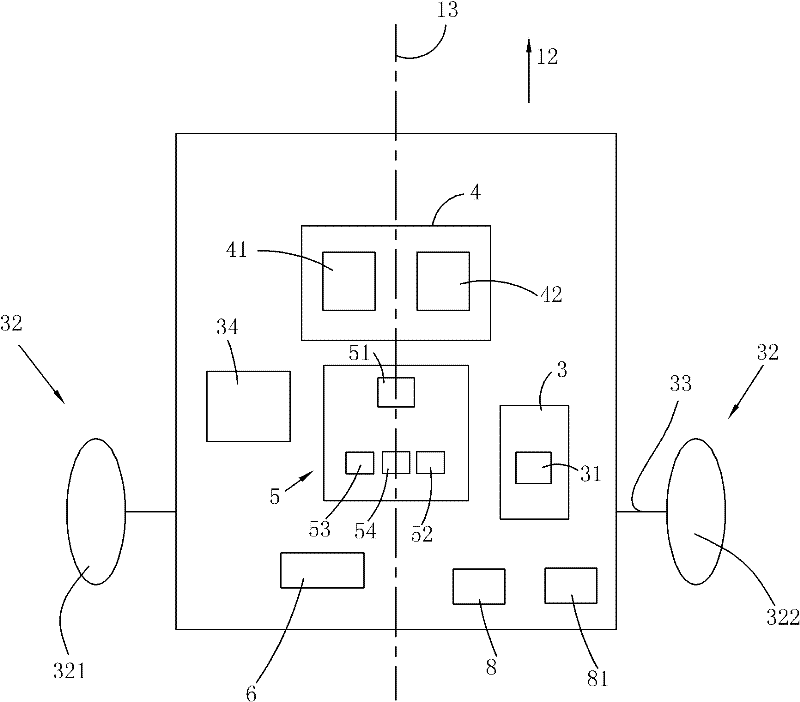

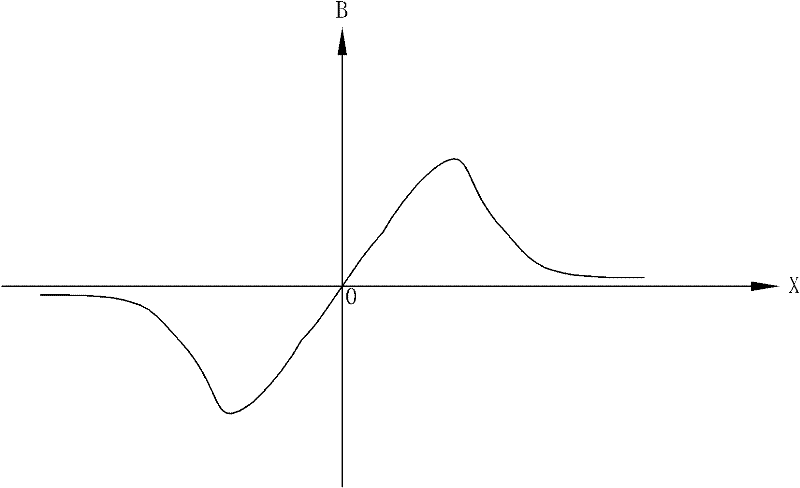

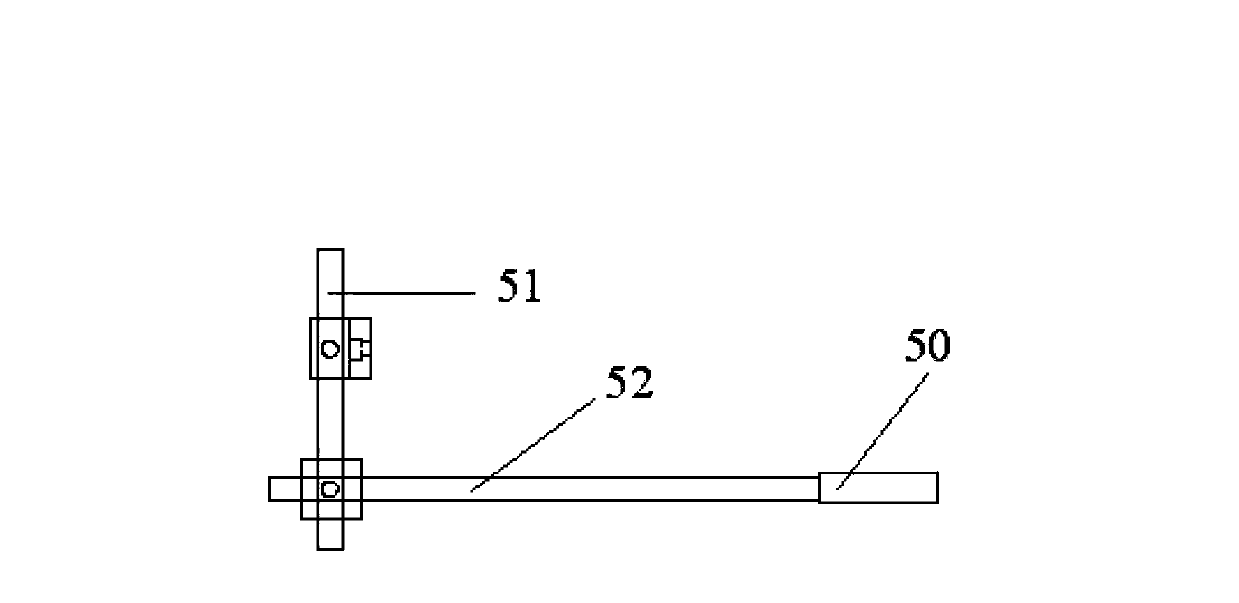

Control method of self-propelled device guidance system

ActiveCN102692922AAccurate entryPosition/course control in two dimensionsDocking stationGuidance system

The invention relates to a control method of a self-propelled device guidance system. When the self-propelled device enters a guidance operating mode, the self-propelled device searches for wire until a first sensing element and a second sensing element which are on the self-propelled device are located on both sides of the wire. The first sensing element and the second sensing element detect sensing signals transmitted from the wire respectively, and pass the sensing signals to a control unit. The control unit controls a drive unit and drives the self-propelled device to move along the wire, and the first sensing element and the second sensing element are kept to be symmetric with relation to the wire. The self-propelled device of the invention, guided by the wire, can quickly and accurately enter a docking station for charging.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Steel bar surface rust removal device for constructional engineering

PendingCN110948361AEasy straighteningFacilitate subsequent rust removalGrinding wheel securing apparatusGrinding drivesClassical mechanicsEngineering

The invention belongs to the technical field of constructional engineering and especially relates to a steel bar surface rust removal device for constructional engineering. For the problem that a traditional device can conduct rust removal only on straight steel bars, the invention proposes the following scheme: the device comprises a base and a mounting plate, wherein supporting legs are welded to the four corners of the bottom of the base. A lifting mechanism is mounted on the side, opposite to the mounting plate, of the base; and a straightening box is installed at the top end of the mounting plate; an installing top plate is horizontally welded to one side of the top end of the straightening box; an efficient grinding mechanism is installed on the installing top plate; supports which are symmetrically distributed at equal intervals are welded to the inner two ends of the straightening box; and straightening rollers are rotatably connected to the two corresponding supports. Throughthe arrangement of the straightening box, bent steel bars can be straightened in advance through the arrangement of the straightening rollers, thereby facilitating subsequent rust removal; and throughthe arrangement of the lifting mechanism, the distance between the straightening rollers can be adjusted, and the steel bars of different thicknesses can be straightened conveniently.

Owner:王毅

Liner paper packing machine for medical gloves

ActiveCN102673846AImprove efficiencyHigh precisionFolding thin materialsPackagingConveyor beltEngineering

The invention relates to a liner paper packing machine for medical gloves. The packing machine comprises a frame bottom plate, frame side plates, a paper feeding part, a printing part, a discharge part, a packing part and an output part. A guide roller, a traction roller, a cutting roller, a front auxiliary conveyor roller, a front folding line roller, a rear auxiliary conveyor roller, a rear folding line roller, a front and rear folding chain tightening row and a combined folding conveyor lower roller are arranged orderly and fixed rotatably between the frame side plates. An edge folding plate is placed between the guide roller and the discharge part. A combined folding roller cylinder is arranged on the frame bottom plate. The centre shaft of the combined folding roller cylinder is vertical to that of a combined folding conveyor roller. The combined folding roller cylinder comprises an upper combined folding roller cylinder and a lower combined folding roller cylinder. The upper and lower combined folding roller cylinders and the combined folding conveyor lower roller are provided with conveyor belt grooves. The upper and lower combined folding roller cylinders are connected with the combined folding conveyor lower roller through a twisted conveyor belt. The conveyor belt is connected between the conveyor belt grooves. The packing machine provided by the invention can greatly reduce the labor cost and increase the work efficiency.

Owner:杭州天琅自动化设备有限公司

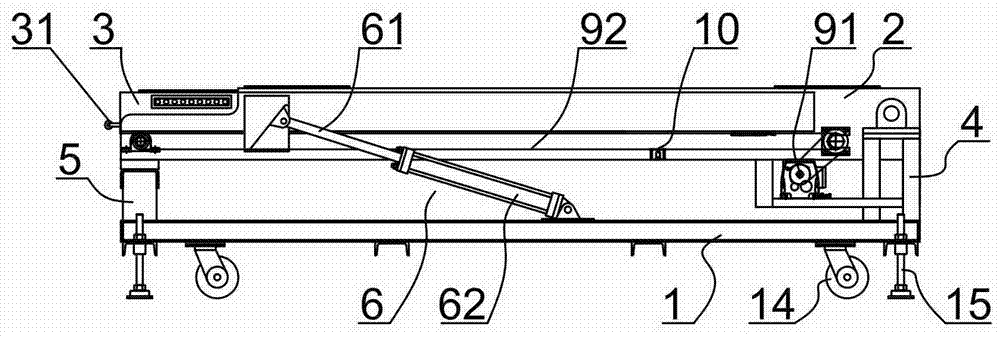

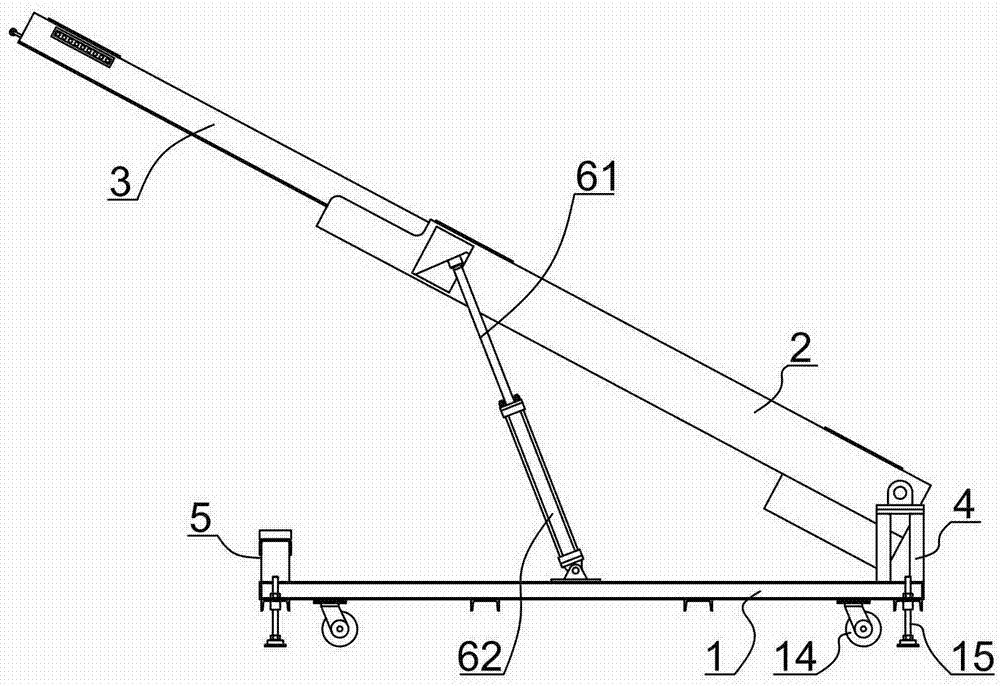

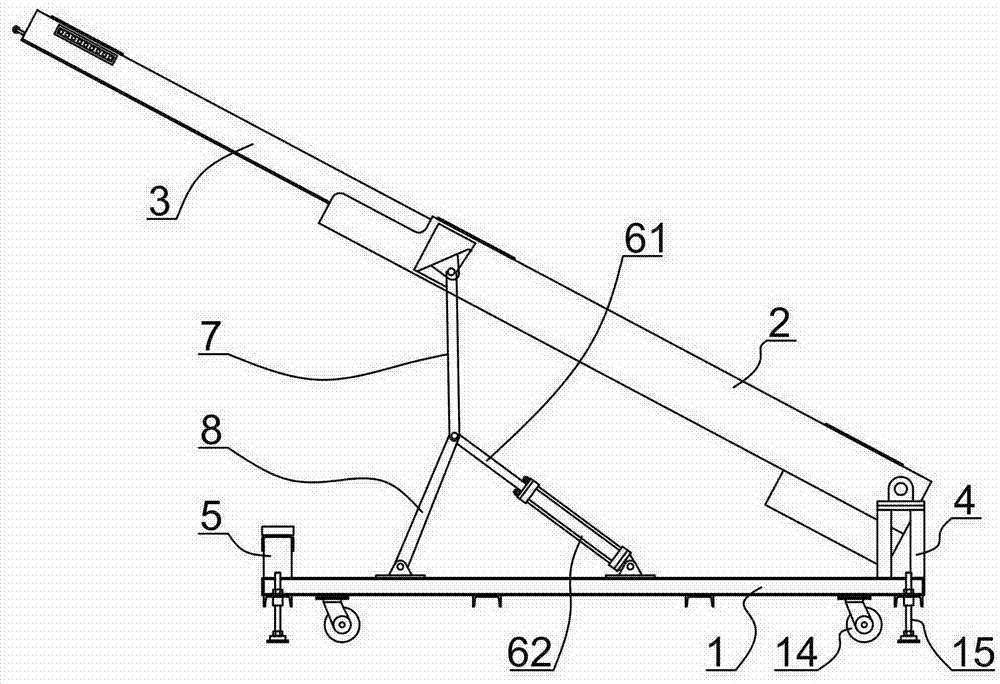

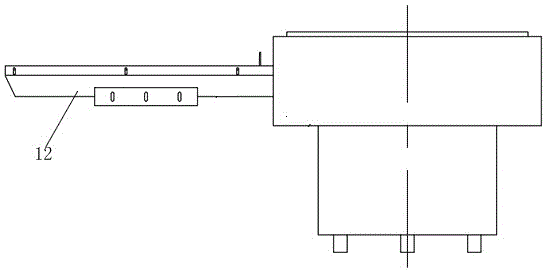

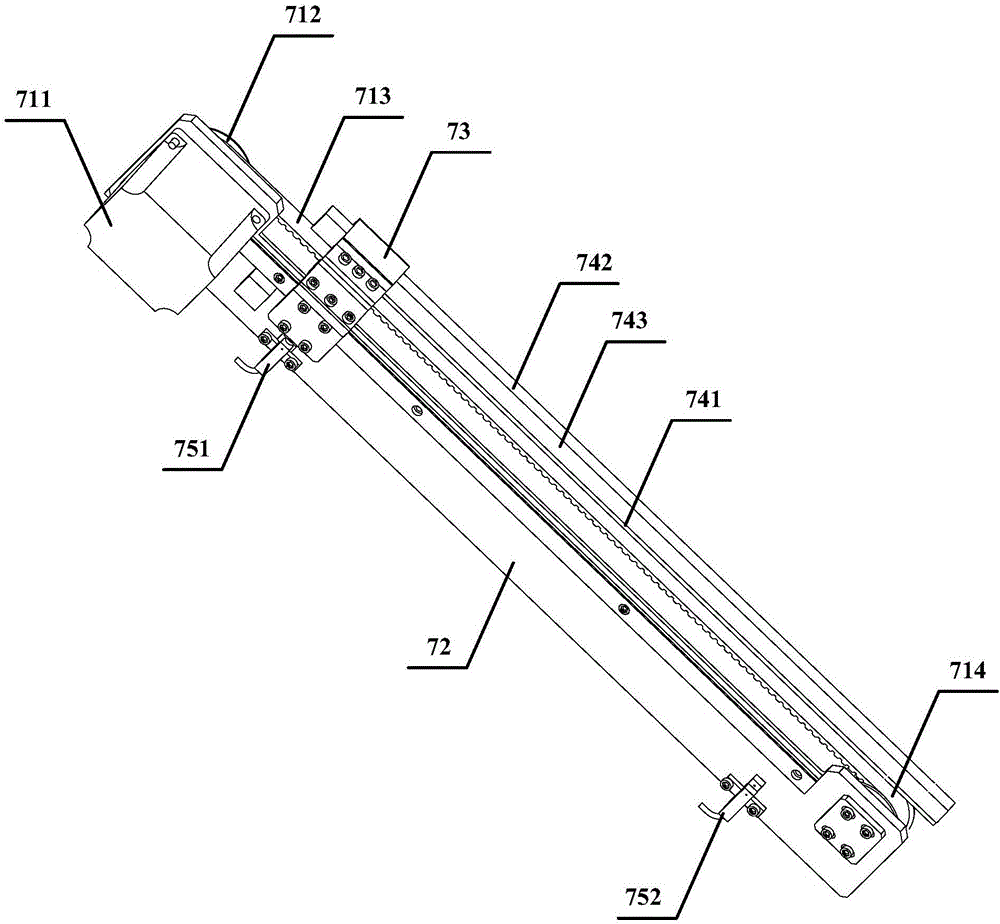

Telescopic belt conveyor

The invention discloses a telescopic belt conveyor. The telescopic belt conveyor comprises a base, a fixed frame arranged on the base, a movable frame slidingly connected in the fixed frame, a belt conveying mechanism and a movable frame driving mechanism. The movable frame driving mechanism comprises a driving motor and a driving chain associated with the driving motor. A chain locking mechanism is arranged on the fixed frame and comprises a self-resetting electromagnet which is arranged on the fixed frame and positioned below the driving chain, an iron core of the electromagnet is vertical, and a self-locking head is arranged at an exposed upper end of the iron core and is clamped in a gap between two adjacent shaft sleeves of the driving chain. The telescopic belt conveyor can enable the movable frame to position accurately and reliably, and is simple, quick and convenient in a positioning process.

Owner:宁波亿普瑞物流自动化分拣设备有限公司

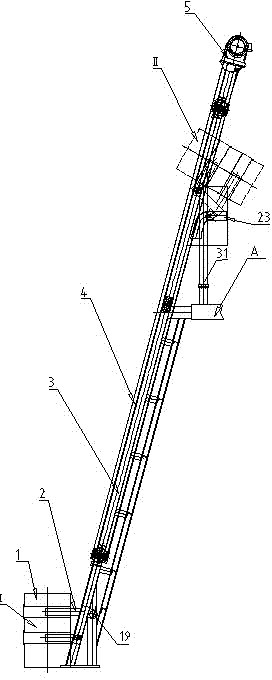

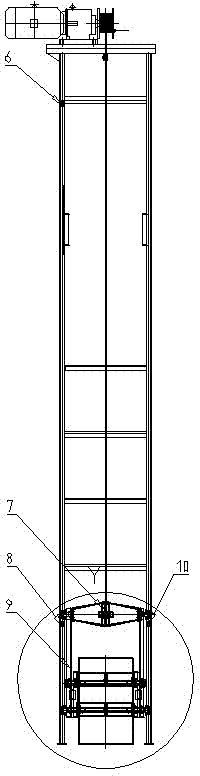

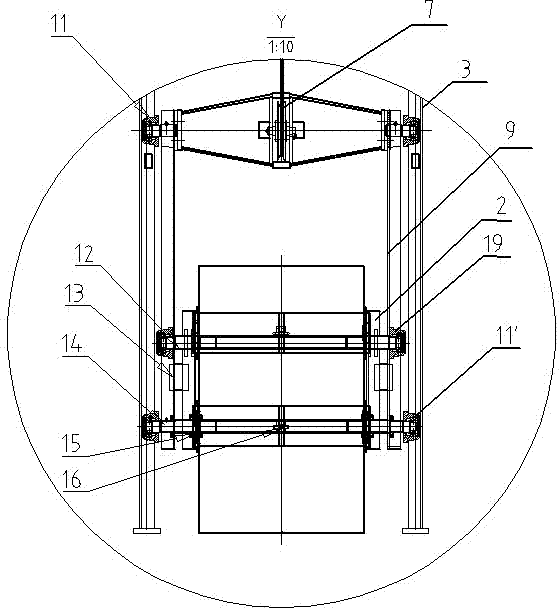

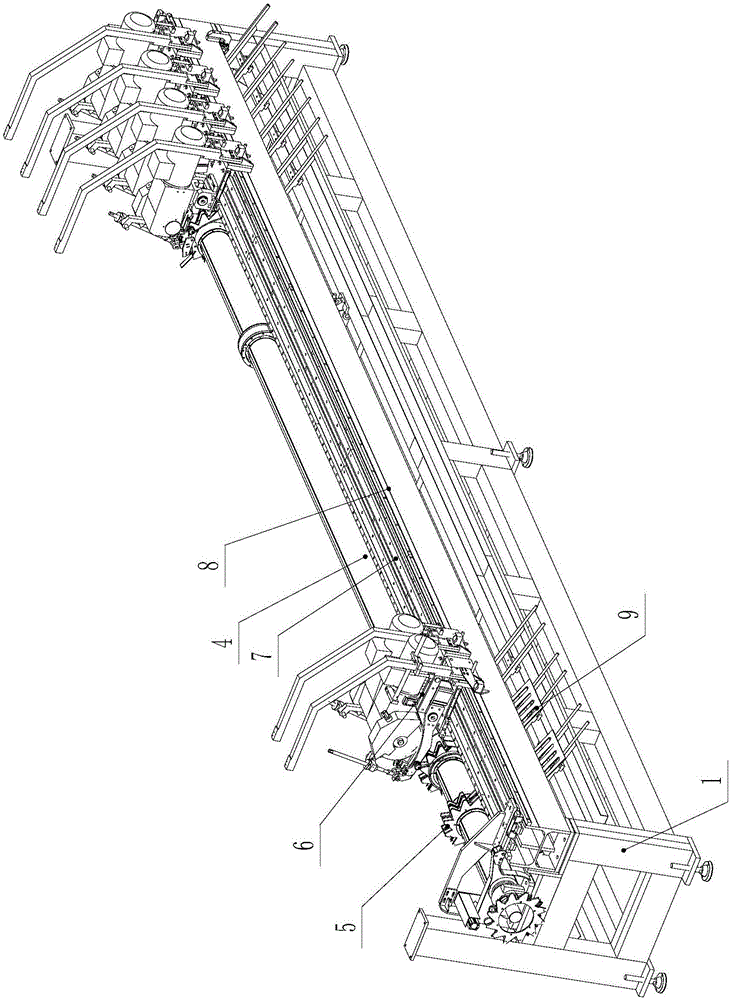

Detachable automatic-rollover-type material hoister

The invention relates to a detachable automatic-rollover-type material hoister. The detachable automatic-rollover-type material hoister is characterized in that a trolley frame and a hoisting frame are arranged, a material loading frame is obliquely fixed on the ground, a support beam is arranged at the back of the material loading frame, a curved rail is arranged on the material loading frame, a winch is fixed on the top of the material loading frame, the hoisting frame rolls in the material loading frame through two pairs of idler wheels arranged on the front portion and the rear portion of the hoisting frame, the front idler wheels of the hoisting frame and a pulley component are mounted with the same axis, and the rear idler wheels of the hoisting frame are fixed through a supporting shaft; and the trolley frame is rotatably arranged on the hoisting frame through the supporting shaft, trolley frame idler wheels are arranged at the back of the trolley frame and matched with the curved rail, the trolley frame is further provided with a hoop device which is provided with a locking device, a hopper is fixed on the trolley frame through the hoop device and the locking device, an upper limiting switch is arranged at the upper end of the material loading frame, a lower limiting switch is arranged at the lower end of the material loading frame, a sensor is further arranged at the lower end of the trolley frame, and the winch is connected with the pulley component through a steel wire rope. The detachable automatic-rollover-type material hoister is reasonable in structure and labor saving.

Owner:浙江省建设工程机械集团有限公司

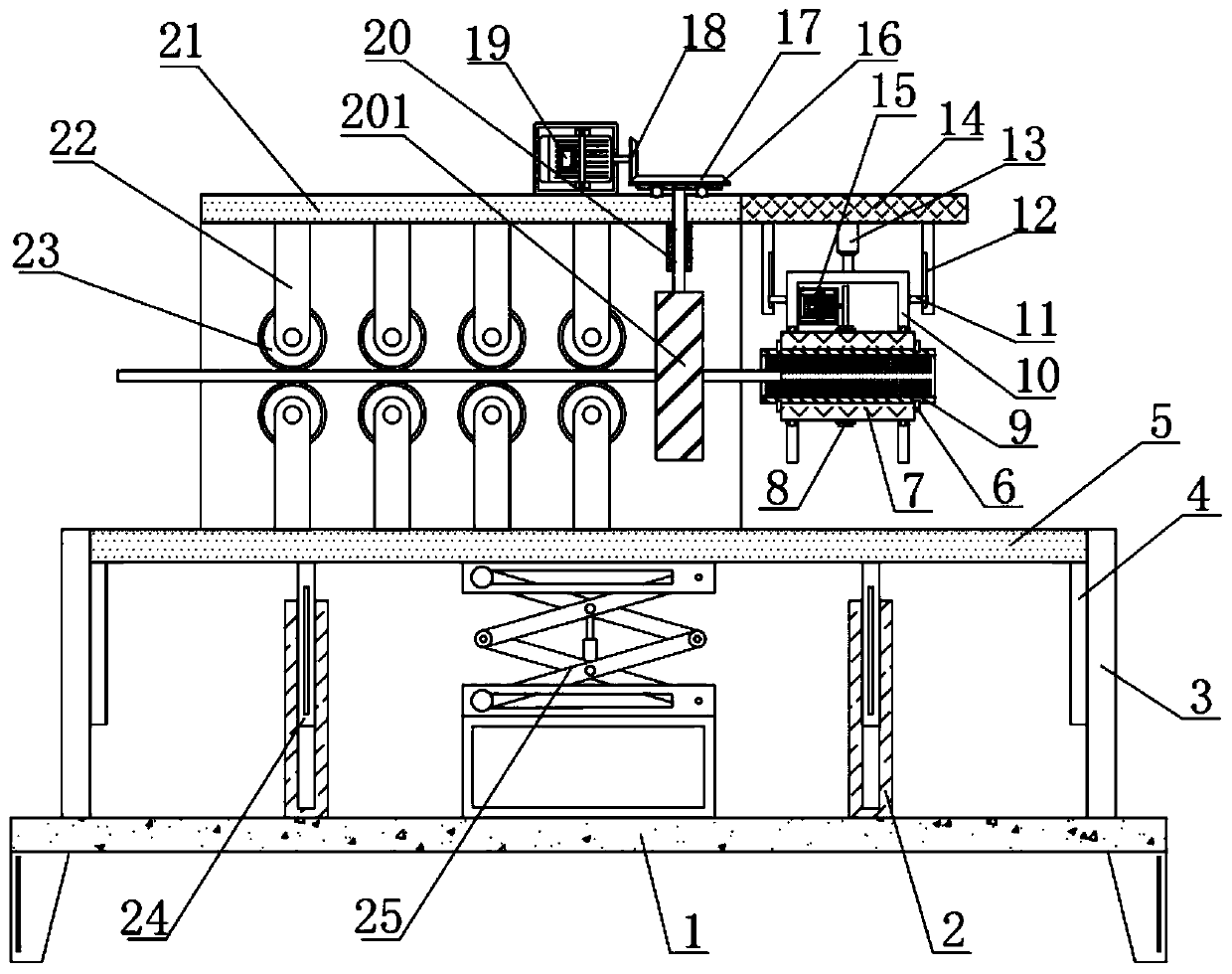

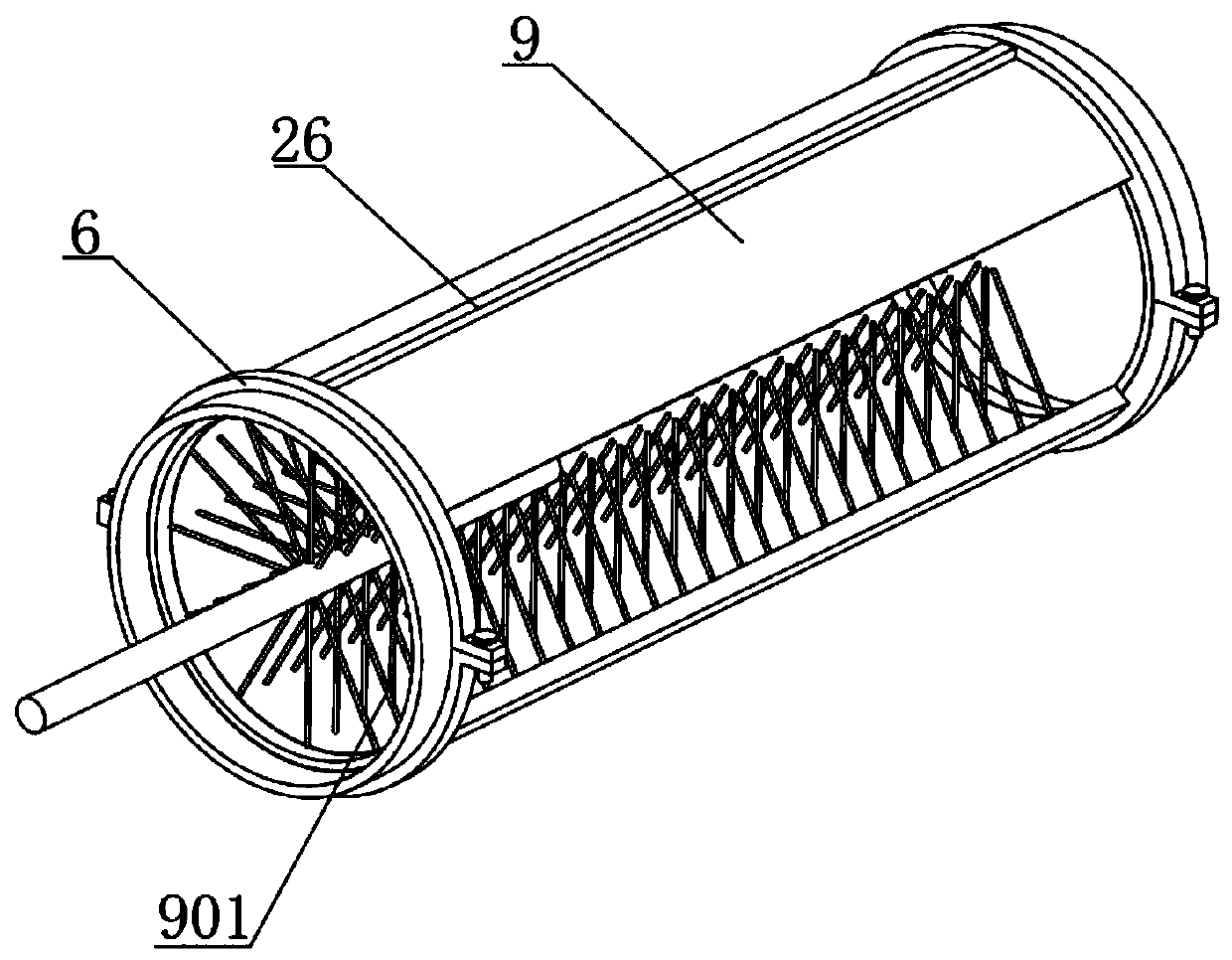

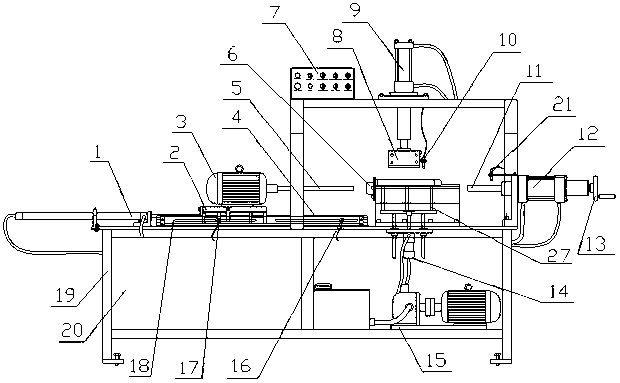

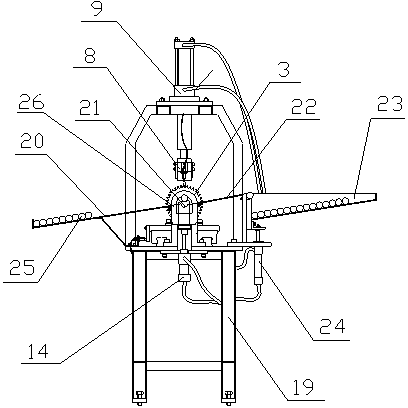

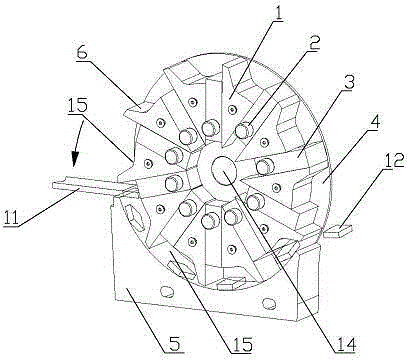

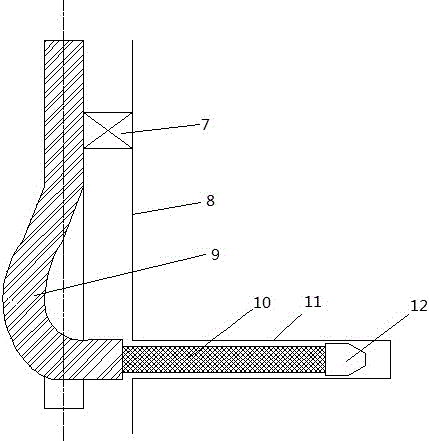

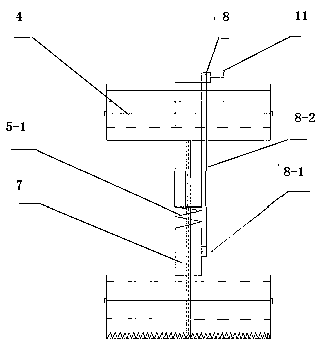

Automatic continuous inner hole polishing machine for steel tubes

InactiveCN103009225ARealize automatic feedingRealize dischargePolishing machinesSheet steelEngineering

The invention discloses an automatic continuous inner hole polishing machine for steel tubes. The automatic continuous inner hole polishing machine comprises a frame and a workbench arranged on the upper part of the frame, wherein an electric control device and a hydraulic device are arranged inside the frame; a fixing device, a sample conveying device and a polishing device are arranged on the workbench; the fixing device comprises an upper pressing die and a lower pressing die; a pressing oil cylinder is arranged above the upper pressing die; the sample conveying device comprises a feeding disk, a receiving disk and a connecting plate which is positioned between the feeding disk and the receiving disk; the polishing device comprises a polishing motor and a polishing shaft which is arranged at the front end of the polishing motor; the upper pressing die and the lower pressing die are positioned on the upper side and the lower side of the connecting plate respectively; the polishing motor is positioned in front of the connecting plate; the connecting plate is a steel plate with a certain inclination angle; and one end, which is close to the feeding disk, of the connecting plate is higher than the end, which is close to the receiving disk, of the connecting plate. The sample conveying device specific to the shapes of steel tubes is arranged, so that automatic feeding and discharging of steel tubes, and polishing of the inner walls of steel tubes under the condition of not turning round are realized.

Owner:QINGDAO ZHANGSHI MACHINERY

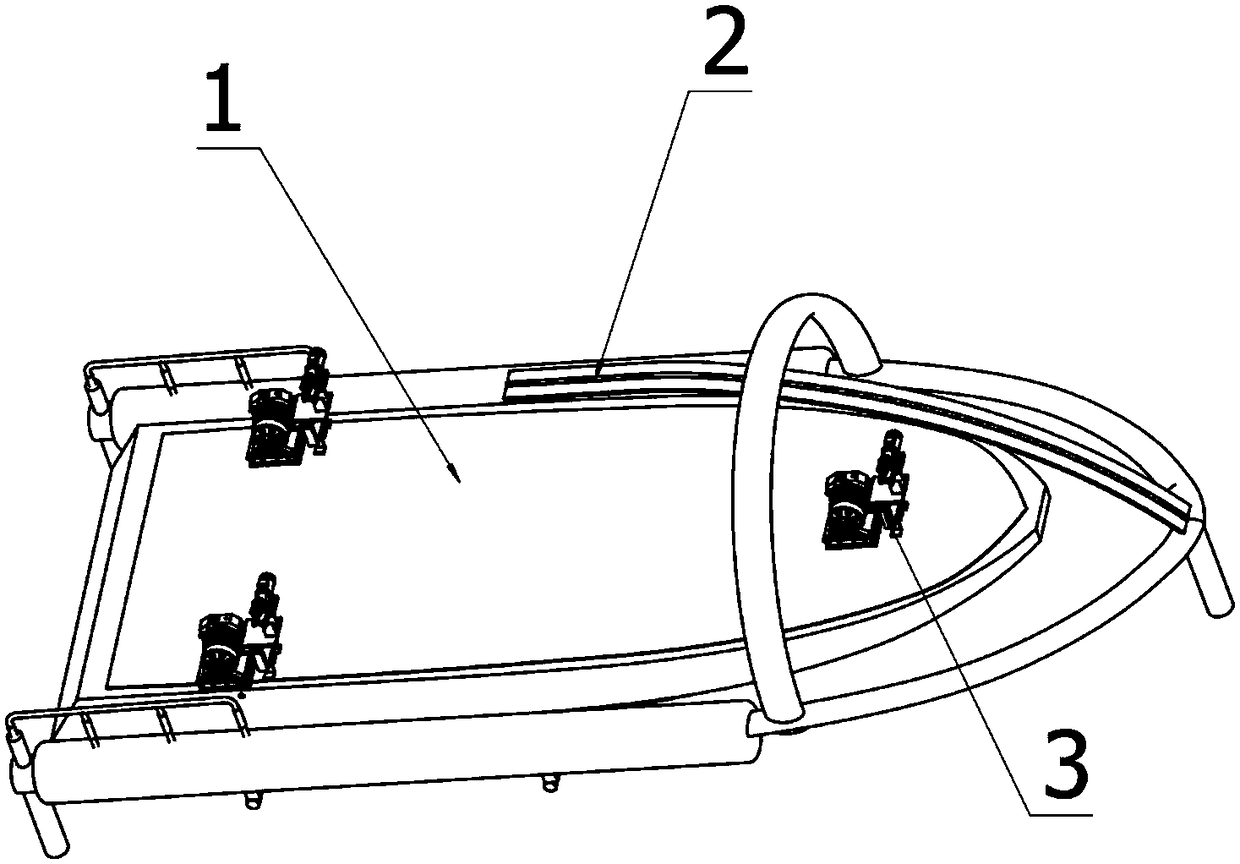

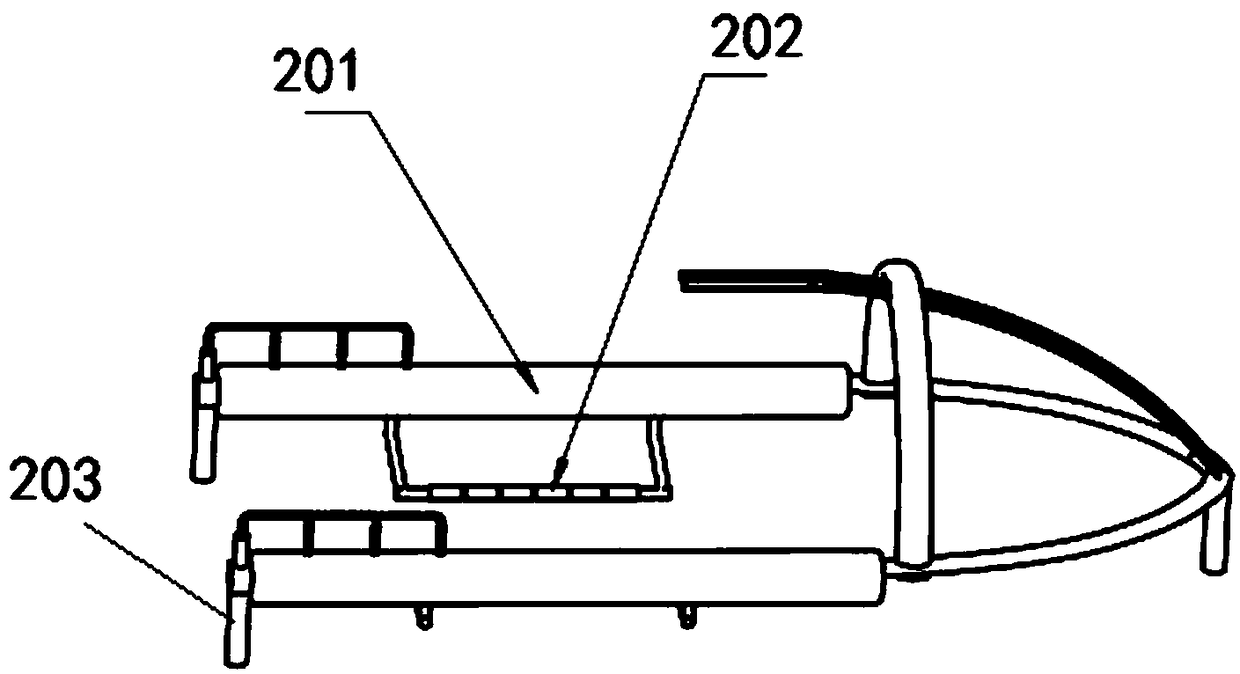

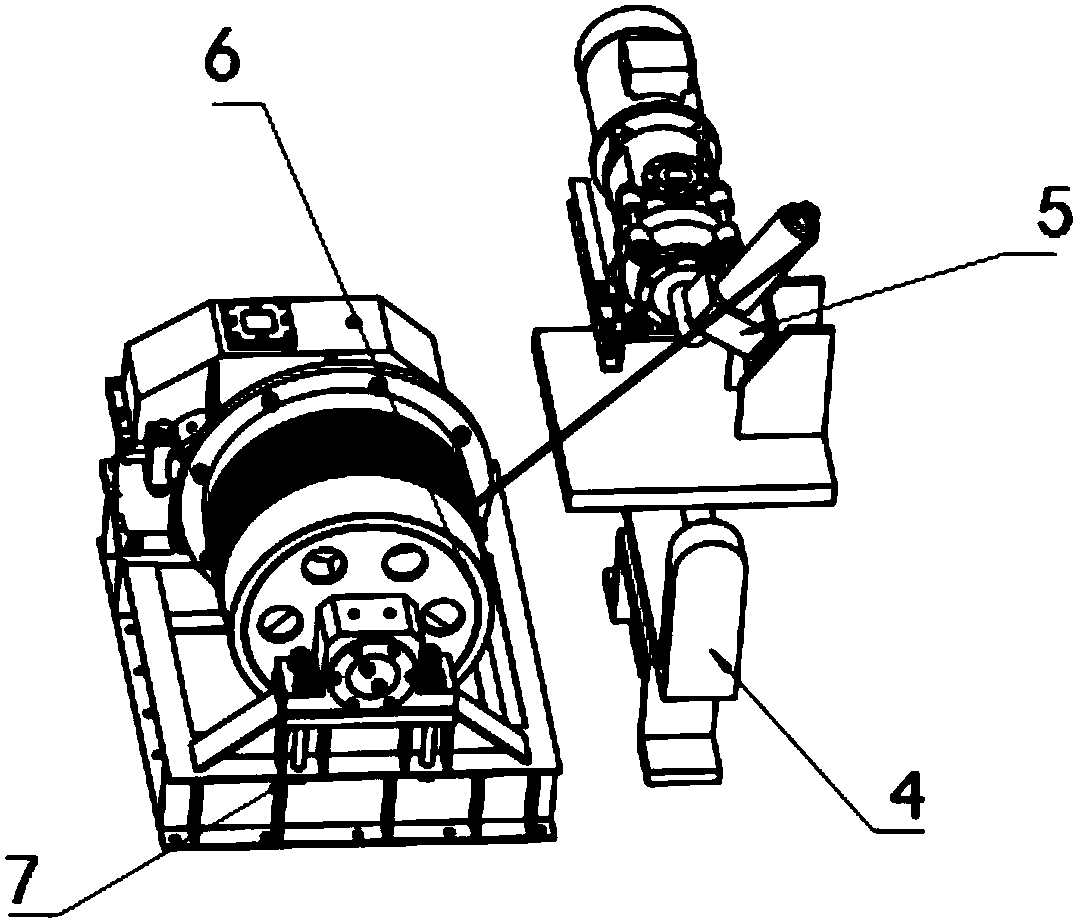

Unmanned ship cloth releasing and recovering device with dock ship as mother ship

ActiveCN108516054AImprove space utilization efficiencyAccurate entryBoat releasing/projecting devicesHoisting/lowering gearMarine engineeringSea state

The invention discloses an unmanned ship cloth releasing and recovering device with a dock ship as the mother ship. The unmanned ship cloth releasing and recovering device comprises a bracket mechanism and a guiding and winding mechanism. The bracket mechanism is arranged on the mother ship. The appearance of the bracket mechanism is matched with the appearance of an unmanned ship. The bracket mechanism is used for wrapping the whole unmanned ship and supporting the unmanned ship. The bracket mechanism is further used for releasing or locking the unmanned ship according to instructions. The guiding and winding mechanism is arranged on the unmanned ship and used for aiming at a cabin of the mother ship and ejecting out a steel cable so that the unmanned ship can drive into the bracket mechanism according to the designated trajectory. Thus, by means of the unmanned ship cloth releasing and recovering device, the 3-tonnage-level (7.5-m-length) unmanned ship can safely and reliably releaseand recover cloth under the 4-level sea state; the unmanned ship cloth releasing and recovering device has the advantages of being reliable in running, simple in structure, high in autonomy and the like; under the complicated marine environment, the efficiency of the unmanned operation ship is improved, the cloth releasing and recovering program of the unmanned ship is simplified, and the space utilization efficiency of the mother ship and the unmanned ship is improved.

Owner:SHANGHAI UNIV

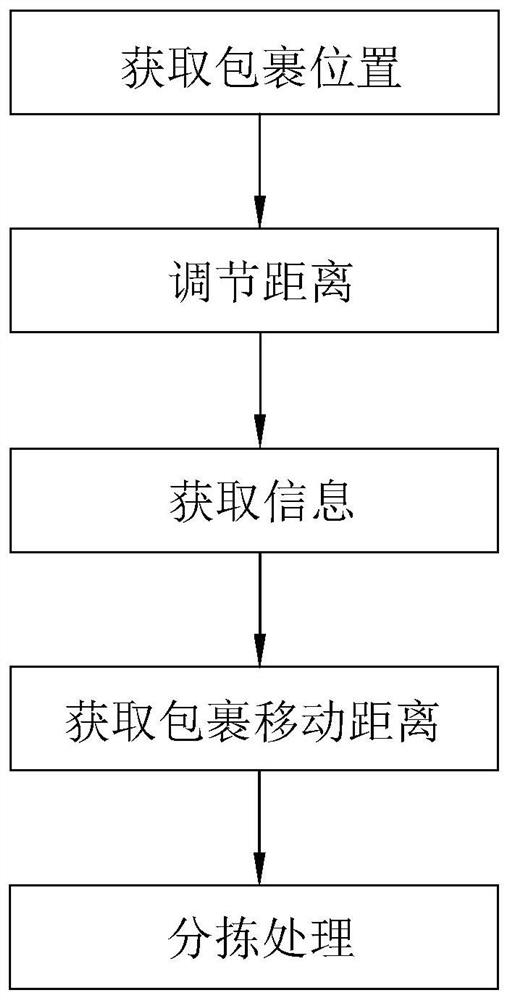

Automatic sorting method and device for parcels on sorting assembly line, and storage medium

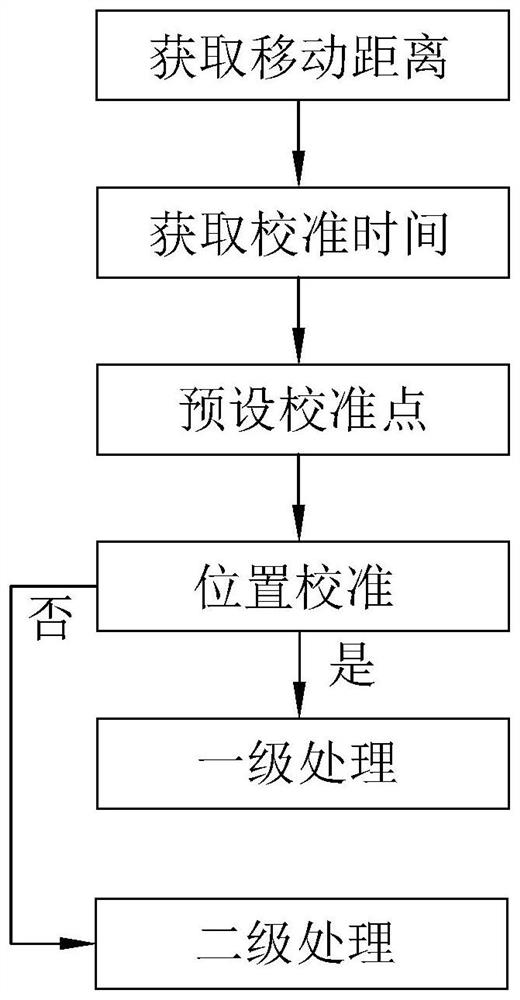

The invention relates to the technical field of sorting assembly lines, in particular to an automatic sorting method and device for parcels on a sorting assembly line, and a storage medium. The methodcomprises the steps that the positions of the parcels are obtained, specifically, the distance between the two adjacent parcels is obtained, and whether the distance between the two adjacent parcelsis less than the preset minimum distance or not is judged; the distance is adjusted, specifically, the distance between the two adjacent parcels is increased; information is obtained, specifically, the information of the parcels is obtained, target areas where the parcels need to enter and corresponding offset angles for entering the target areas are determined according to the information of theparcels, meanwhile parcel numbers are generated, and the parcel numbers are in one-to-one correspondence with the target areas where the parcels need to enter; obtaining of moving distances of the parcels is carried out, wherein the moving distances of the parcels are obtained; and sorting processing is carried out, specifically, the parcels are controlled to offset according to the correspondingoffset angles and enter the corresponding target areas. In the conveying process of the parcels, the spacing between the adjacent parcels is adjusted, the moving distances of the parcels are obtainedand calibrated, and thus the accurate rate of parcel sorting can be further increased.

Owner:SHENZHEN LUHUI LOGISTICS EQUIP CO LTD

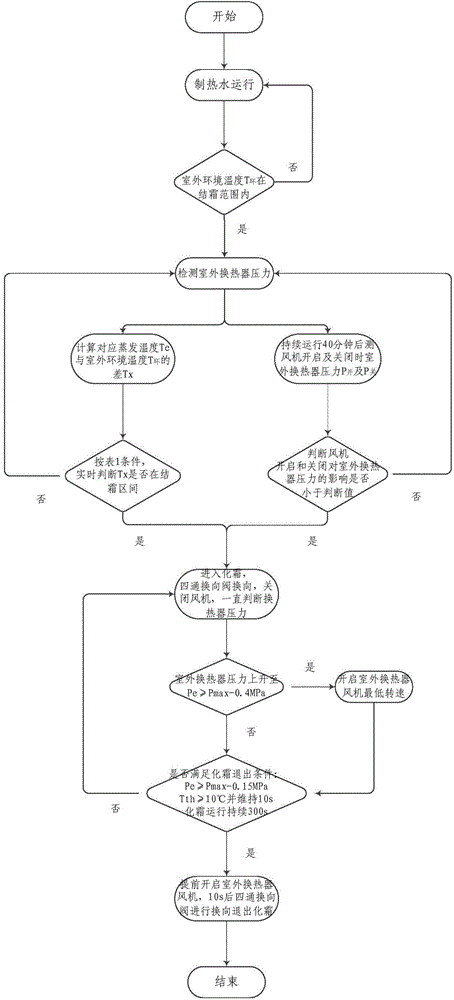

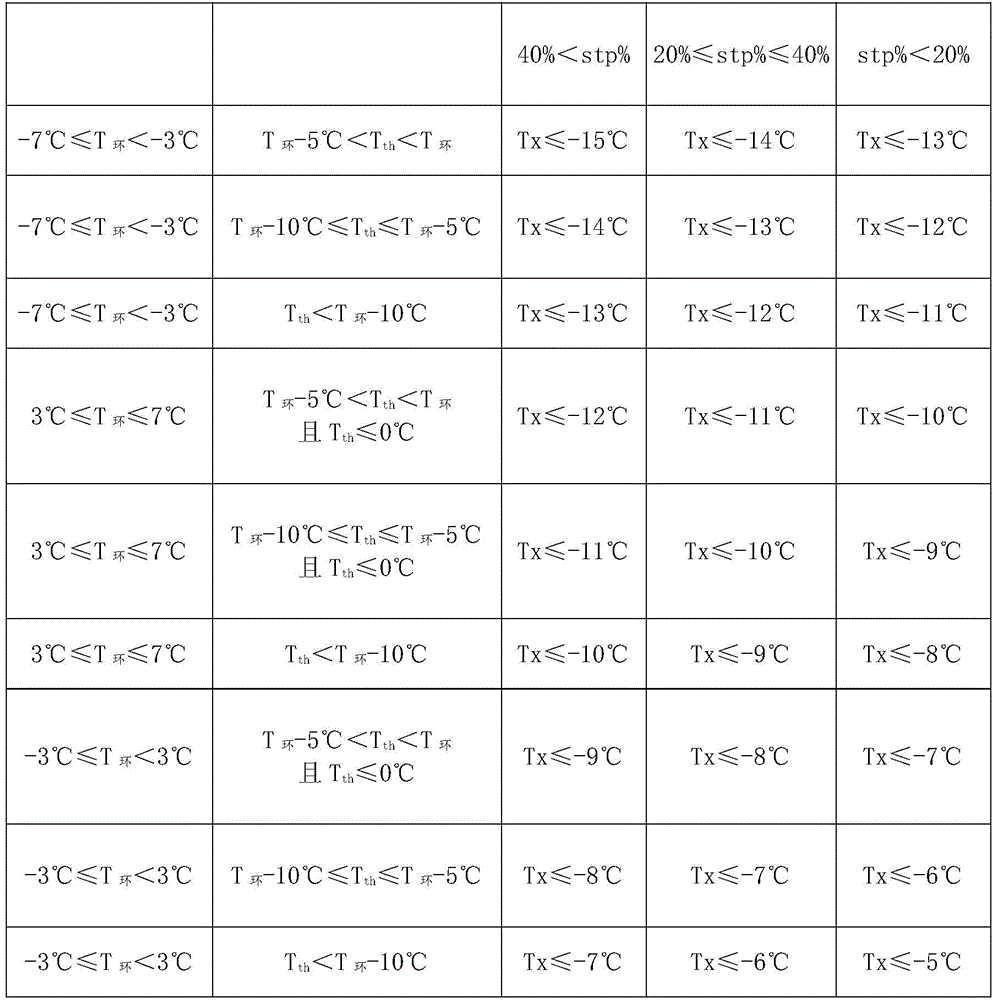

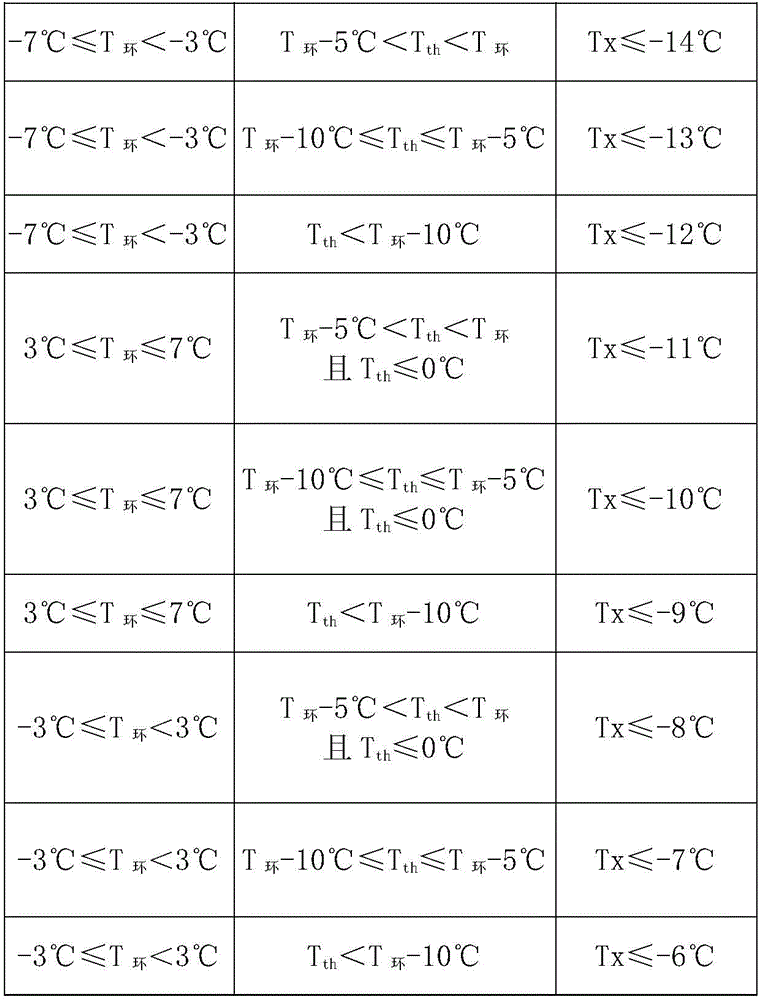

Efficient defrosting method and device implementing control according to fan speed and pressure

ActiveCN105737389AAccurate entryAccurate exitFluid heatersCorrosion preventionEngineeringRefrigerant

The invention provides an efficient defrosting method and device implementing control according to the fan speed and the pressure. The method comprises the steps of normally operating a fan of an outdoor heat exchanger and detecting the outdoor environment temperature T-environment in the normal water heating process of an air energy heat pump water heater; continuously carrying out water heating if T-environment is not within the preset frosting environment temperature interval; if T-environment is within the preset frosting environment temperature interval, detecting the pressure P-starting of refrigerating fluid of the outdoor heat exchanger, automatically calculating the evaporating temperature Te corresponding to the pressure in real time according to the physical characteristics of the refrigerating fluid, calculating the difference Tx between Te and T-environment, judging whether Tx is within the frosting temperature interval, and repeating the steps from the step of detecting P-starting to the step of judging whether Tx is within the frosting temperature interval if Tx is not within the frosting temperature interval; if Tx is within the frosting temperature interval, enabling the water heater to implement the defrosting program; stopping the defrosting program after defrosting is completed, and restarting the water heating program. A unit can be controlled to start defrosting or stop defrosting more accurately according to the judgment on the basis of the temperature and the pressure.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

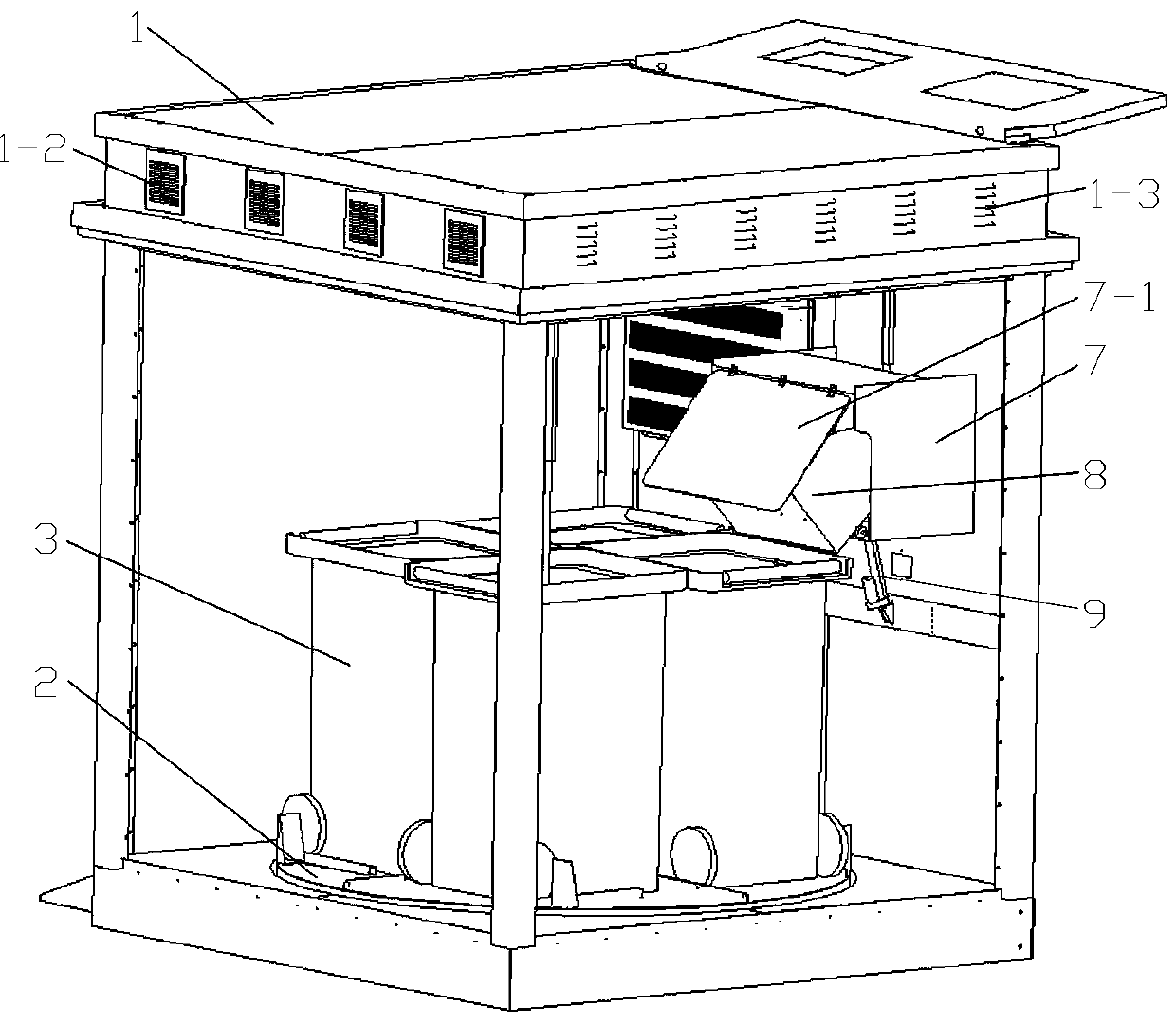

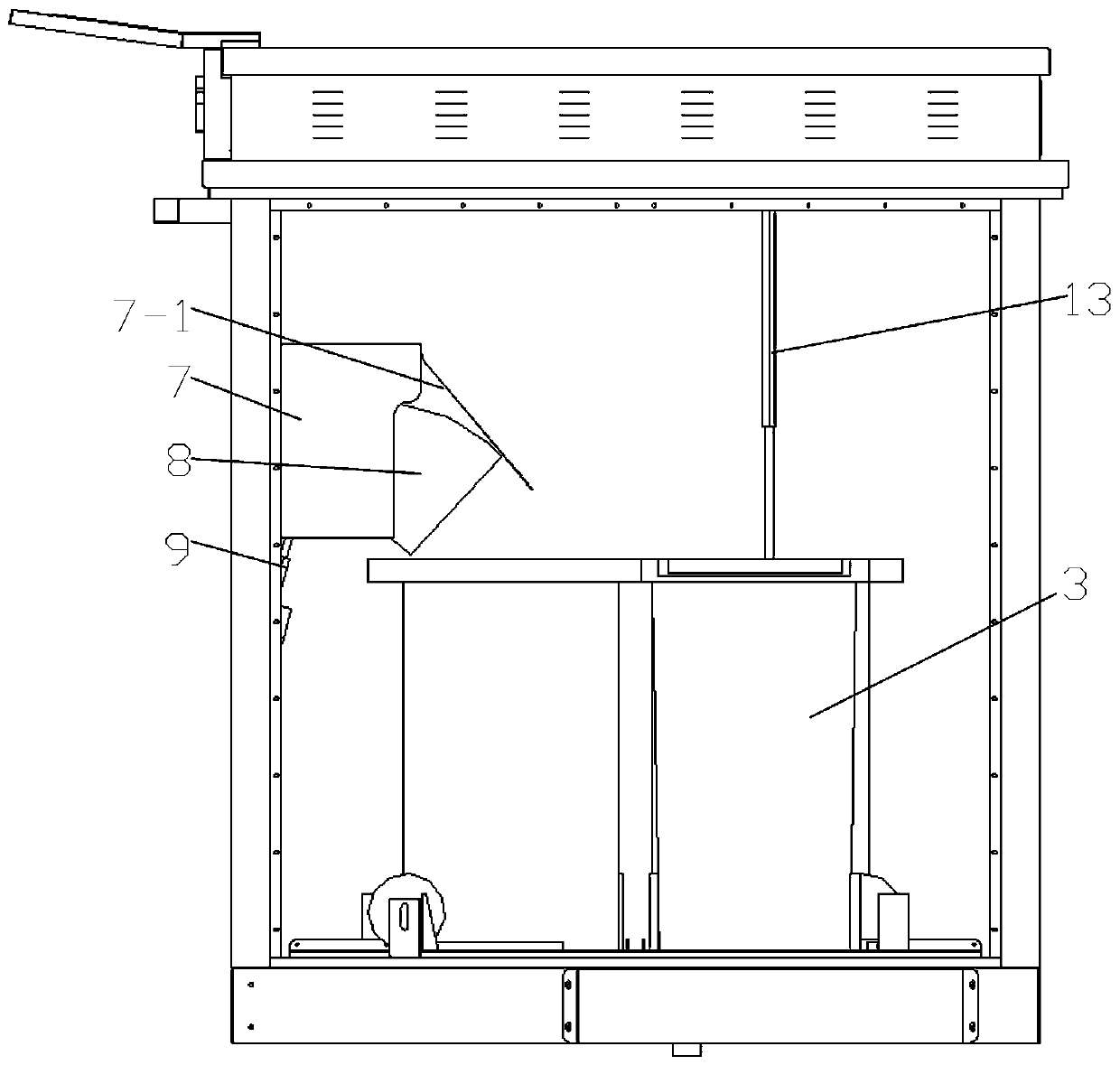

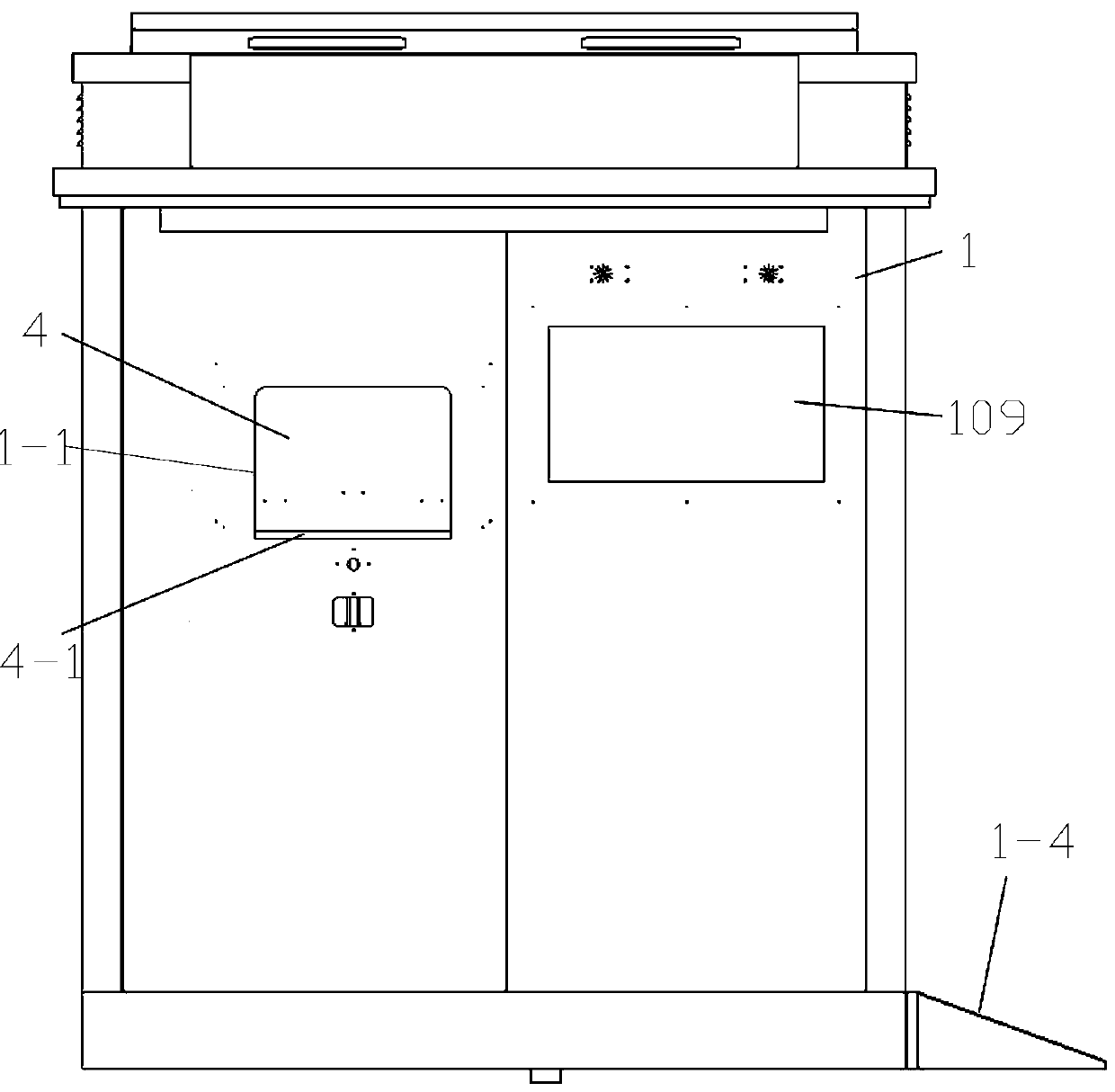

Intelligent garbage chamber with automatic dustbin replacing function

PendingCN111301902AIncrease capacity to accommodate recycling wasteEasy to placeRefuse receptaclesComputer hardwareAutomatic control

The invention discloses an intelligent garbage chamber with an automatic dustbin replacing function. The intelligent garbage chamber comprises a shell, and a dumping opening is mounted in the front face of the shell. A rotary disc for containing a dustbin is mounted on a bottom plate in the shell, and the rotary disc can rotate relative to the bottom plate. The rotary disc is of a round structure,and multiple separation tables are arranged on the rotary disc. The separation tables are arranged outwards from the center of the rotary disc, and divide the upper end face of the rotary disc into multiple independent areas. An outer blocking part is arranged in each independent area, the outer blocking parts are parallel to the separation tables, and a containing area for positioning and containing the dustbin is formed. A movable door mechanism is arranged on the dumping opening, and comprises a movable baffle arranged on the dumping opening and a baffle push rod motor for controlling themovable baffle to be opened and closed. The device is simple and reasonable, the rotary disc is high in stability, operation by a user is safe, easy and convenient, and automatic control over dustbinreplacement of the garbage chamber can be achieved.

Owner:HENAN TONGDA MULTIMEDIA MAKING

Tracking-type active radar calibrator based on transmitted signal reestablishing system

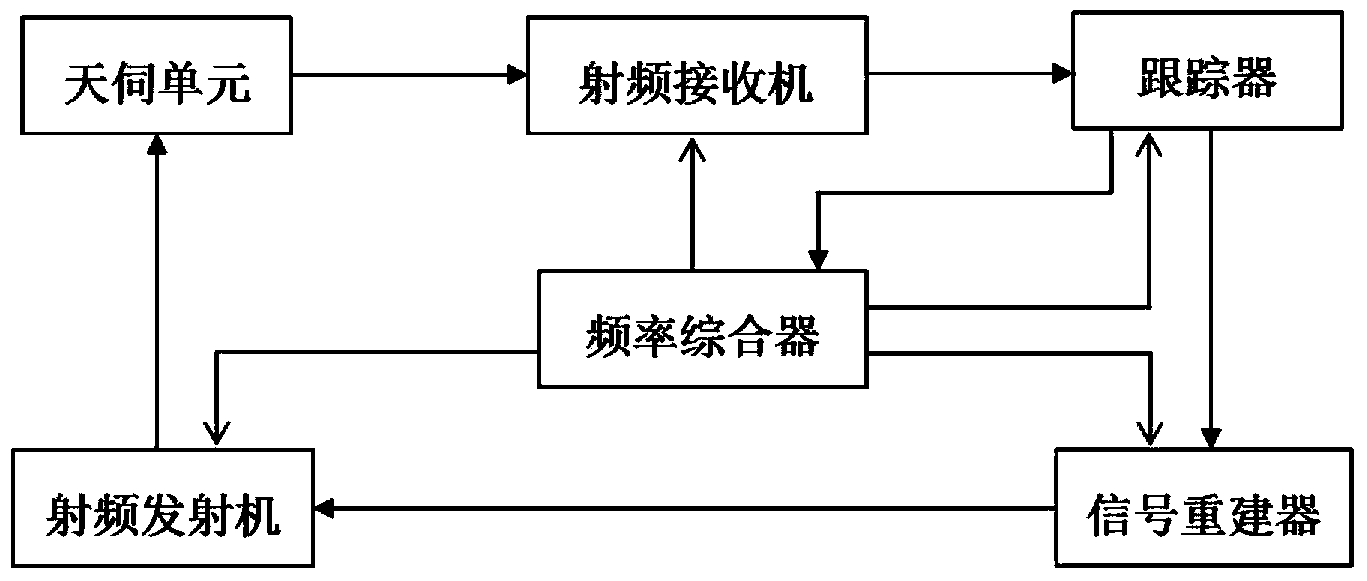

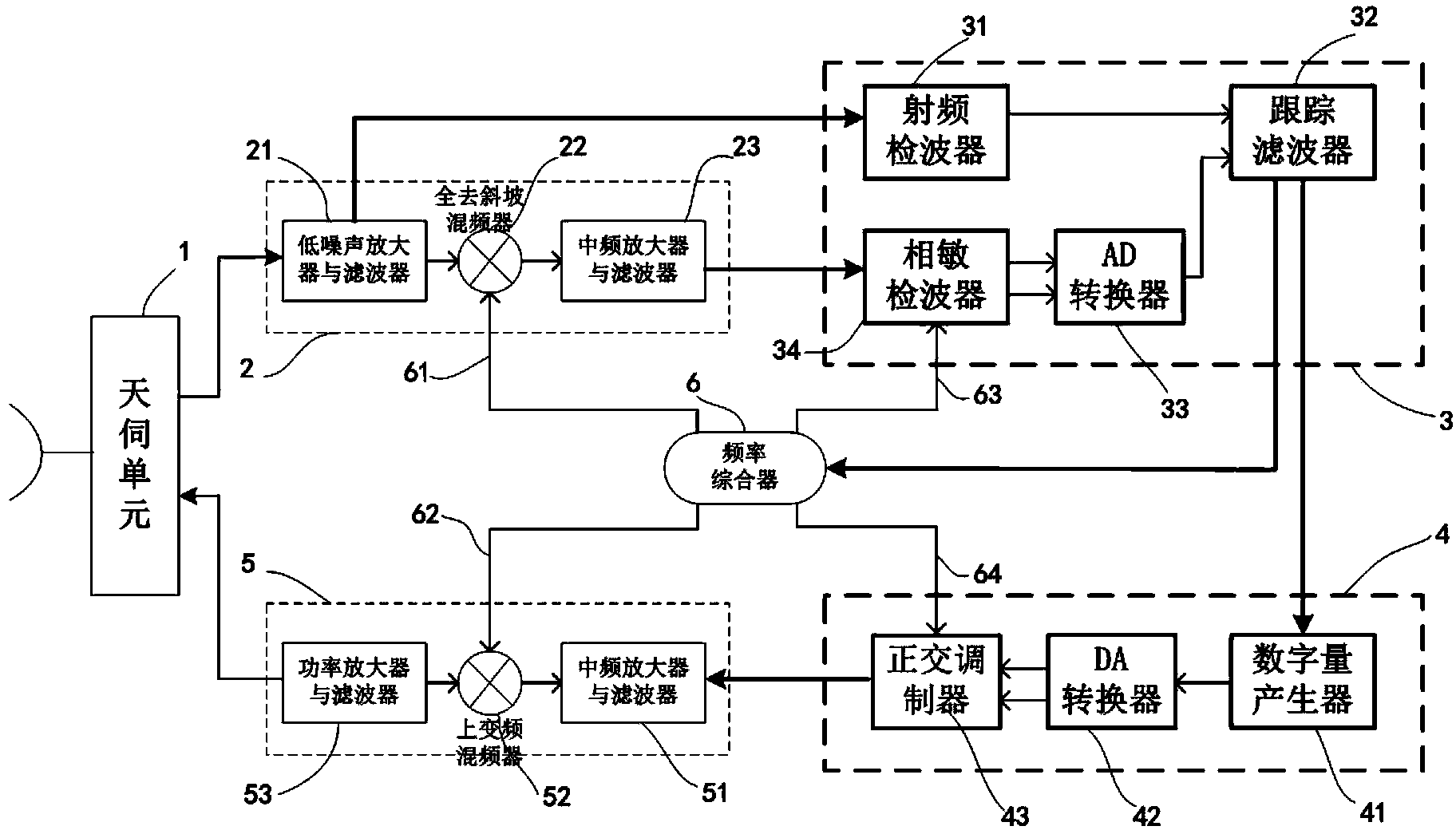

ActiveCN103454620AReduce layout requirementsFlexible layoutWave based measurement systemsFrequency synthesizerRadio frequency signal

The invention relates to a tracking-type active radar calibrator based on a transmitted signal reestablishing system. The tracking-type active radar calibrator comprises a servo unit (1), a radio frequency receiver (2) and a radio frequency transmitter (5). The tracking-type active radar calibrator further comprises a tracking device (3), a signal reestablishing device (4) and a frequency synthesizer (6), the tracker (3) is respectively connected with the radio frequency receiver (2), the frequency synthesizer (6) and the signal reestablishing device (4), and the signal reestablishing device (4) is further connected with the frequency synthesizer (6) and the radio frequency emitter (5). The tracking-type active radar calibrator can quickly capture tracking radar signals and reestablish radio frequency signals so as to send the signals to an on-orbit satellite radar, and realize the functions that at any position within the coverage range of the satellite radar signals, the radar signals can be captured and tracked quickly, signal emission time can be accurately set according to received signal intervals, and the radio frequency signals are reestablished to be sent to the radar.

Owner:NAT SPACE SCI CENT CAS

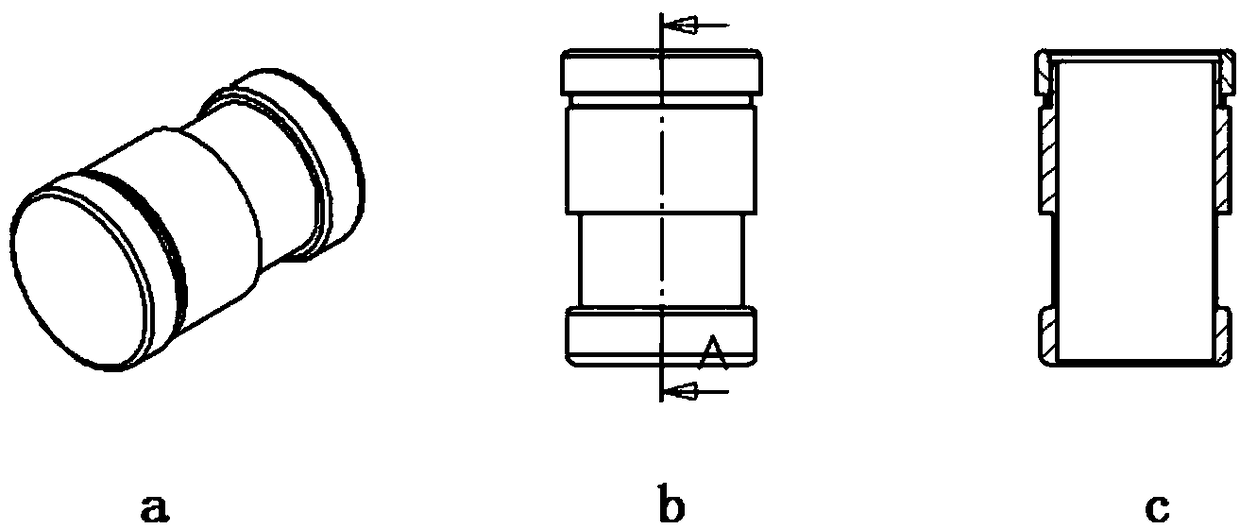

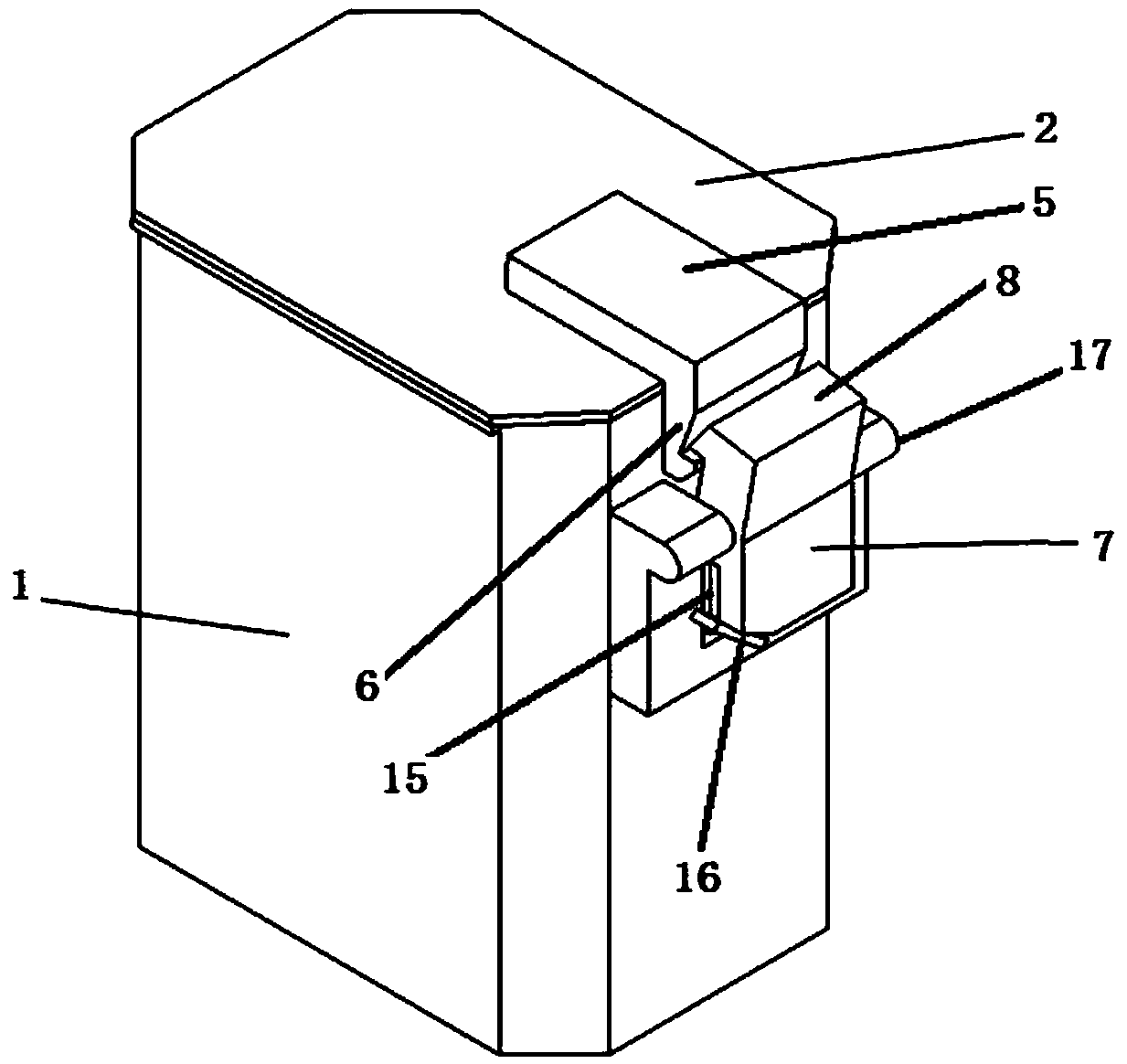

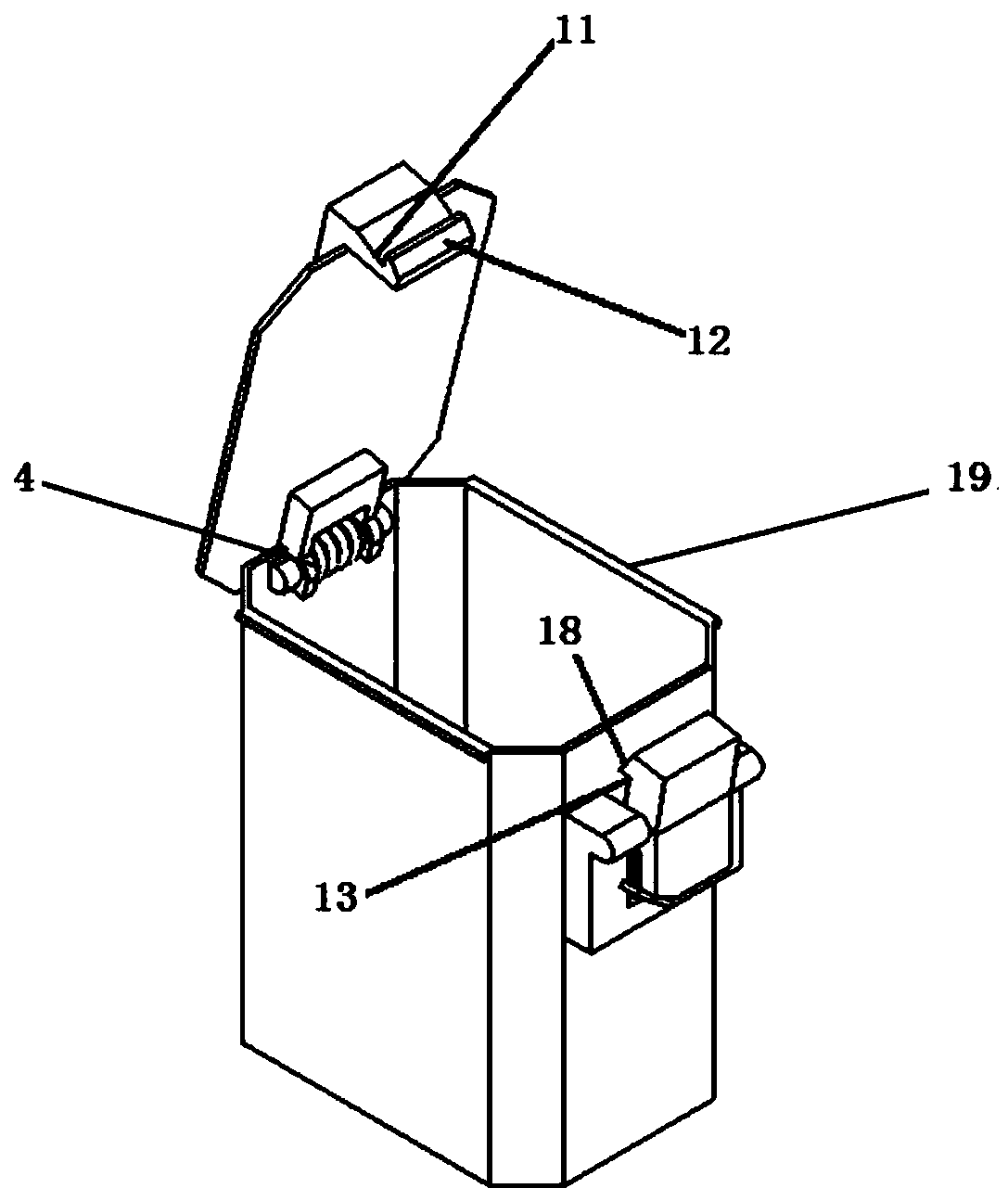

Material transfer box for sealing device and transfer method

PendingCN108792249AEasy to operate with robotic armSecurityLidsNon-removalbe lids/coversMaterial transferEngineering

The invention discloses a material transfer box for a sealing device. The material transfer box comprises a box body and a box cover with the inner side rotatably connected with the top of the box body through a torsion rotating shaft, an upper locking fit piece composed by an upper fixing part and an upper hook is fixedly arranged on the outer side of the box cover, a lower locking fit piece composed by a lower rotating part and a lower hook matched with the upper hook is arranged on the outer side of the box body, the lower rotating part is rotatably connected with the box body through a rotating shaft, and a compression spring is arranged in the gap between the outer wall of the box body and the lower rotating part. The mechanical arm can conveniently operate by arranging a switch on the side wall of the material box, by arranging a grabbing flip, the fact that the material box cannot fall off in the transporting process is ensured, the safety of the material in the transporting anddumping process of the material box is ensured, and meanwhile, the fact that the material can accurately enter a target container without loss is ensured.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Automatic sorting and weighing machine and working process thereof

ActiveCN103272781AGuarantee the order of transportationGuaranteed accuracySortingEngineeringCentral processing unit

The invention discloses an automatic sorting and weighing machine and a working process thereof, and solves the problems that a conventional device is seriously disturbed by human factors and the weighting is not accurate. The automatic sorting and weighing machine comprises a base, a material container, a conveying device, a weighing device, a sorting device and a material receiving device, wherein the material container is arranged above the base and fixedly connected with the base; the conveying device is connected with the material container and arranged on the base; the weighing device is connected with the conveying device and arranged on the base; the sorting device is connected with the weighing device; the material receiving device is connected with the sorting device; the weighing device comprises a weighing platform, a weight sensor and a CPU (central processing unit) , the weighing platform is connected with the conveying device, the weight sensor is arranged below weighing platform, and the CPU is connected with the weight sensor and arranged on the base; and the CPU is further connected with a controller arranged on the base. According to the automatic sorting and weighing machine and the working process thereof, the weighing device uses the weight sensor for measuring the wright of a material; and compared with a conventional measuring device, the precision is higher, the device is not disturbed by human factors, and the accuracy is guaranteed.

Owner:成都恒达光学有限公司

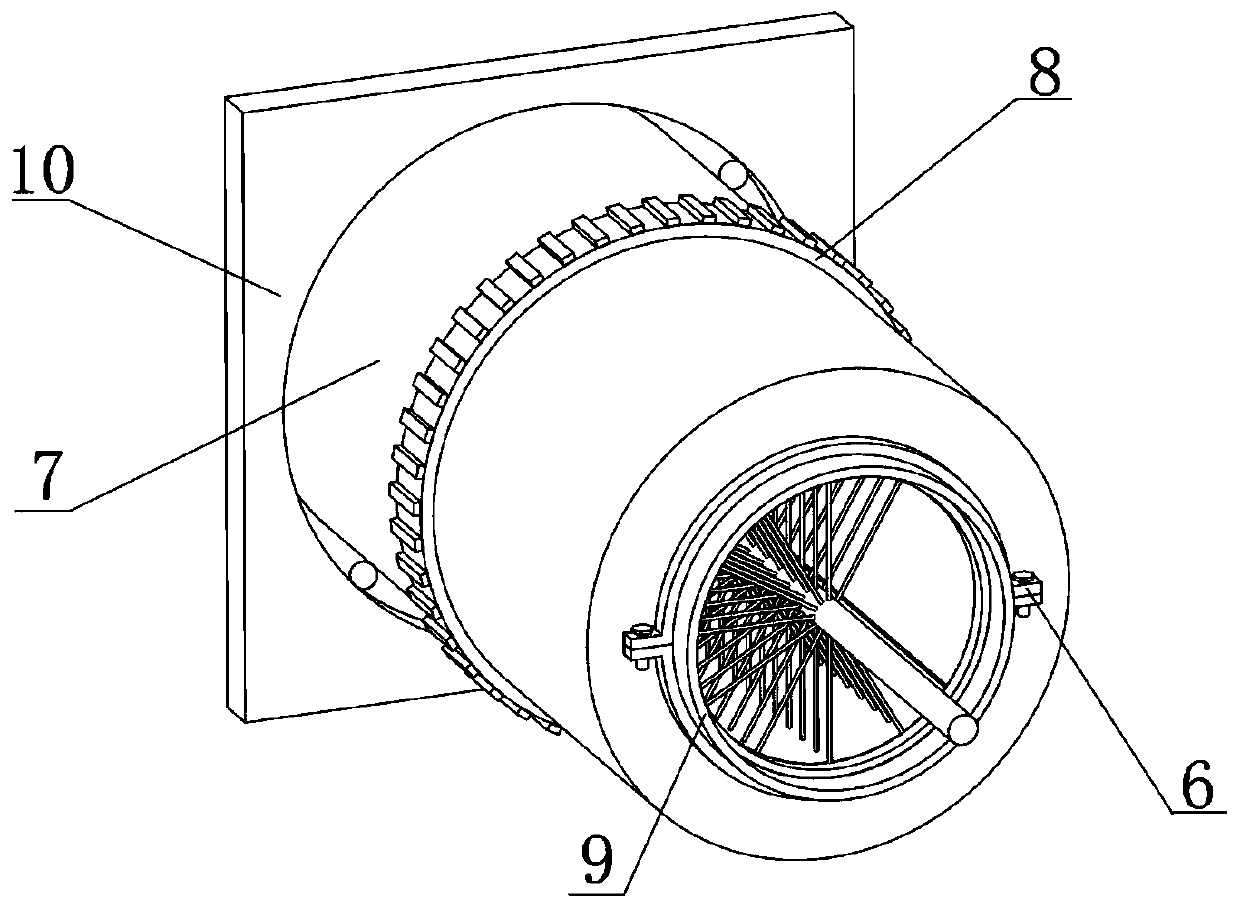

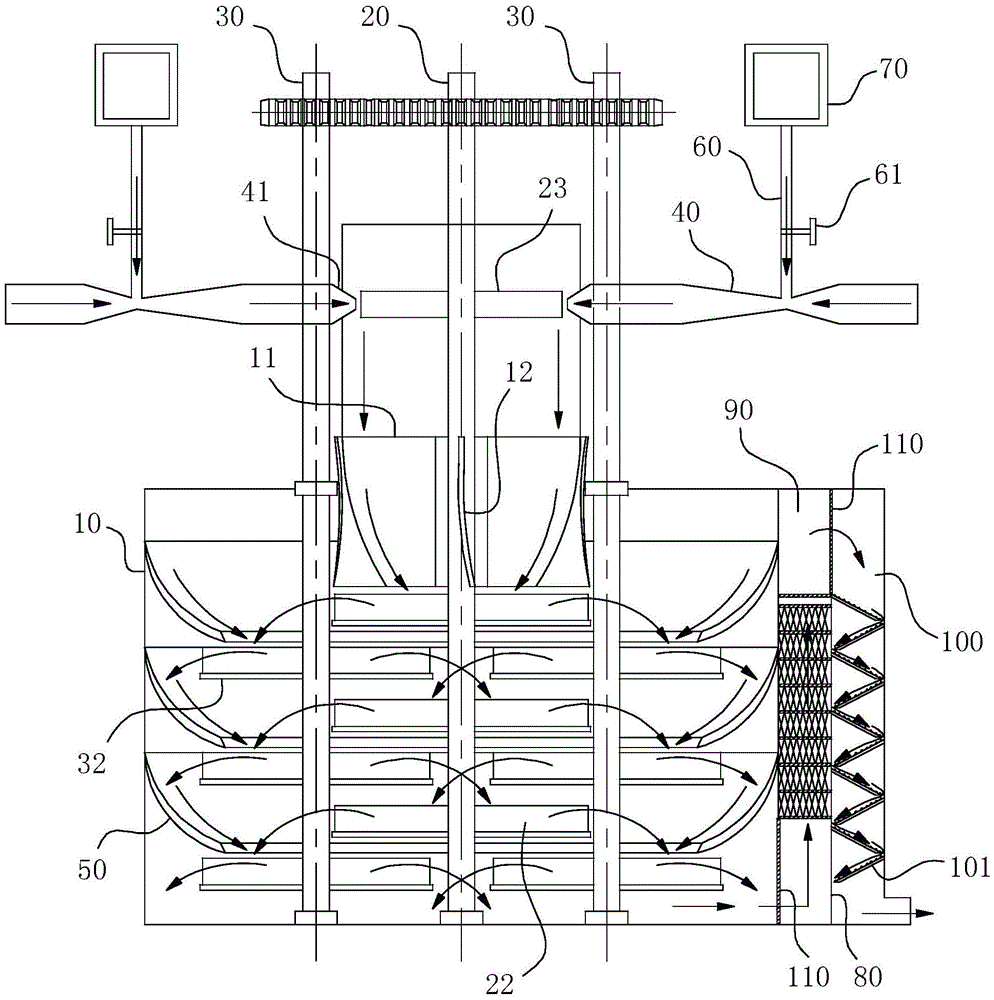

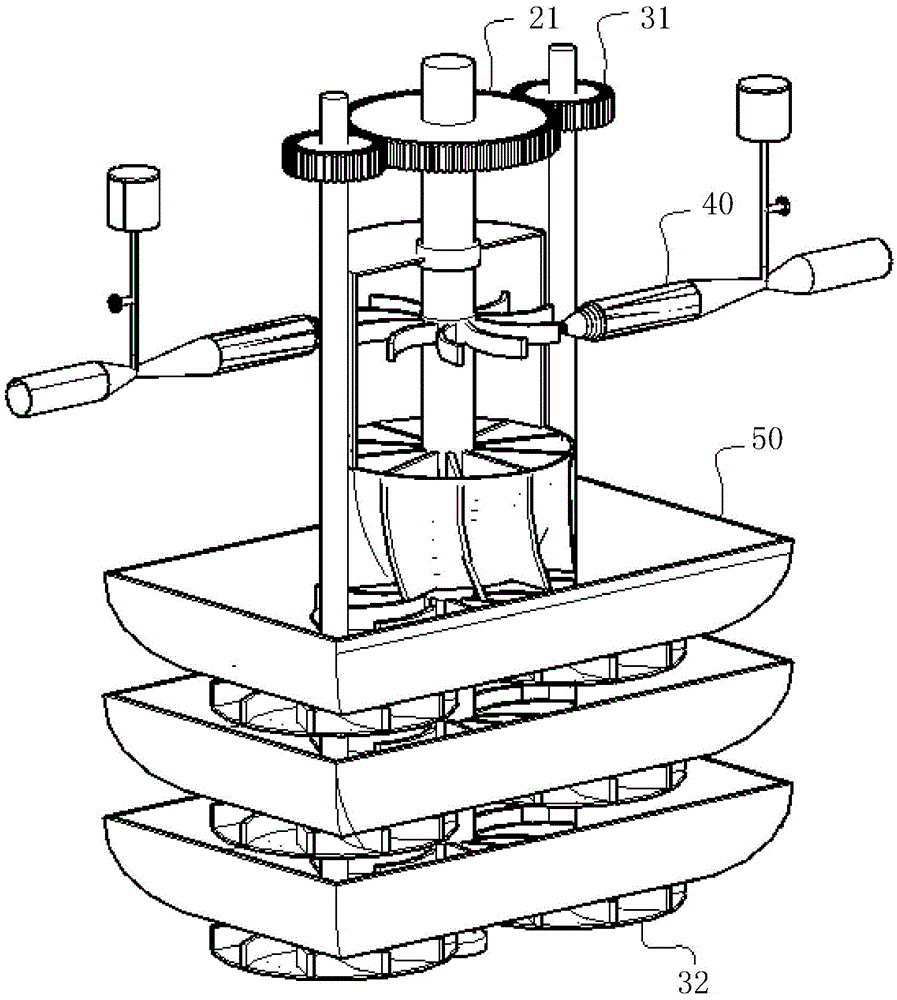

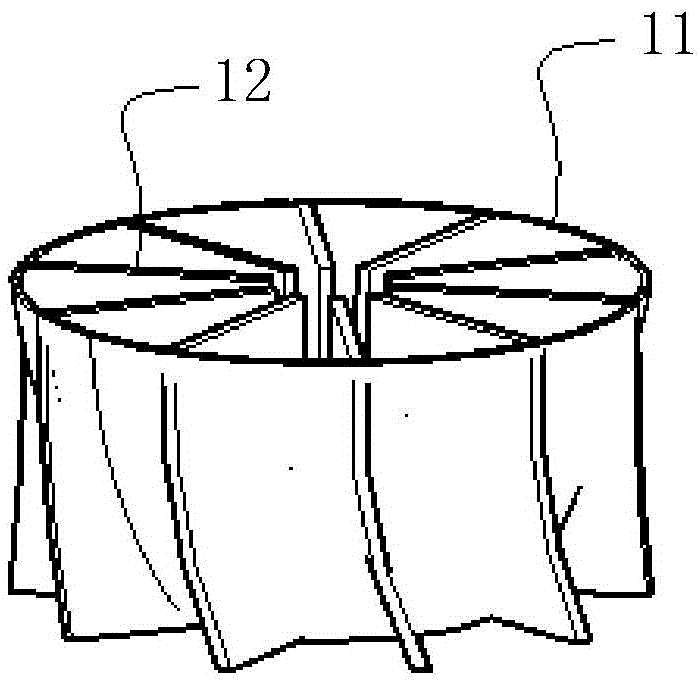

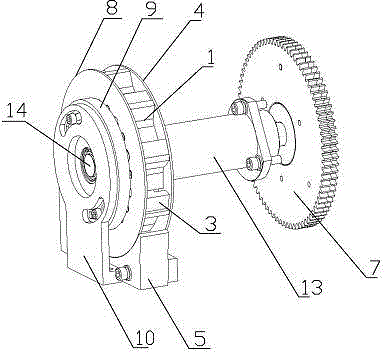

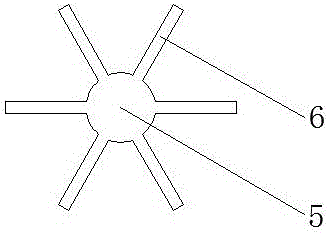

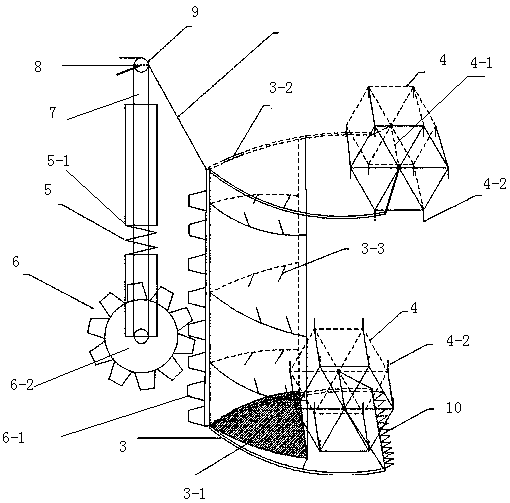

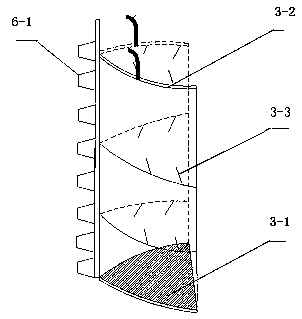

Multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive

ActiveCN105536610AReduce consumption costImprove the mixing effectRotary stirring mixersTransportation and packagingImpellerMixed flow

The invention relates to the field of coal slurry pretreatment, in particular to a multi-impeller mixed flow field ore pulp preprocessor based on ore pulp pipeline pressure drive. The multi-impeller mixed flow field ore pulp preprocessor comprises a mixing box, a driving rotary shaft and a driven rotary shaft. A driving gear is coaxially arranged on the driving rotary shaft, and a driven gear is arranged on the driven rotary shaft to form the meshing relation. A driving turbine is further coaxially arranged on the driving rotary shaft. A group of stirring impellers is fixed to the driving rotary shaft, and a group of stirring wheels is fixed to the driven rotary shaft respectively in a coaxial and mutual equal-height mode. In the vertical direction, the stirring impellers and projections of the stirring impellers produce intersections. A guide sleeve is arranged under the driving turbine. Guide blades are arranged inside the guide sleeve in a circinate mode, and the rotating direction of the mixed liquid guided by the guide blades is mutually identical to the rotating direction of the stirring impellers under the guide blades. The multi-impeller mixed flow field ore pulp preprocessor can play a very good hardening and tempering effect on floated coal slime, is especially suitable for slurry-mixing and quality-improving demands of fine coal difficult to float and is high in working efficiency, and the preprocessing process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

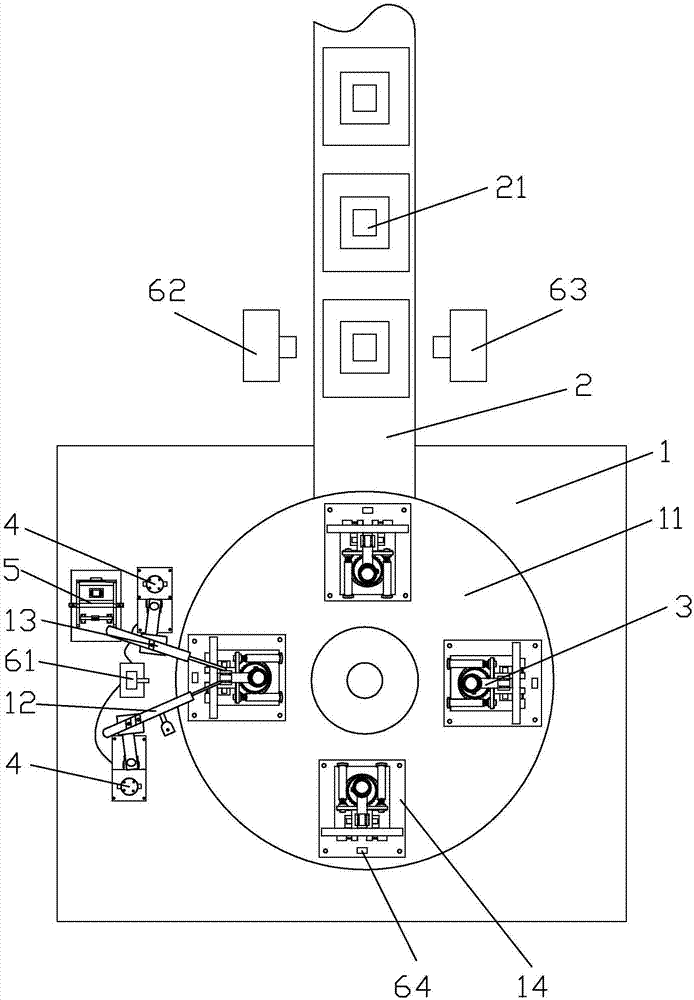

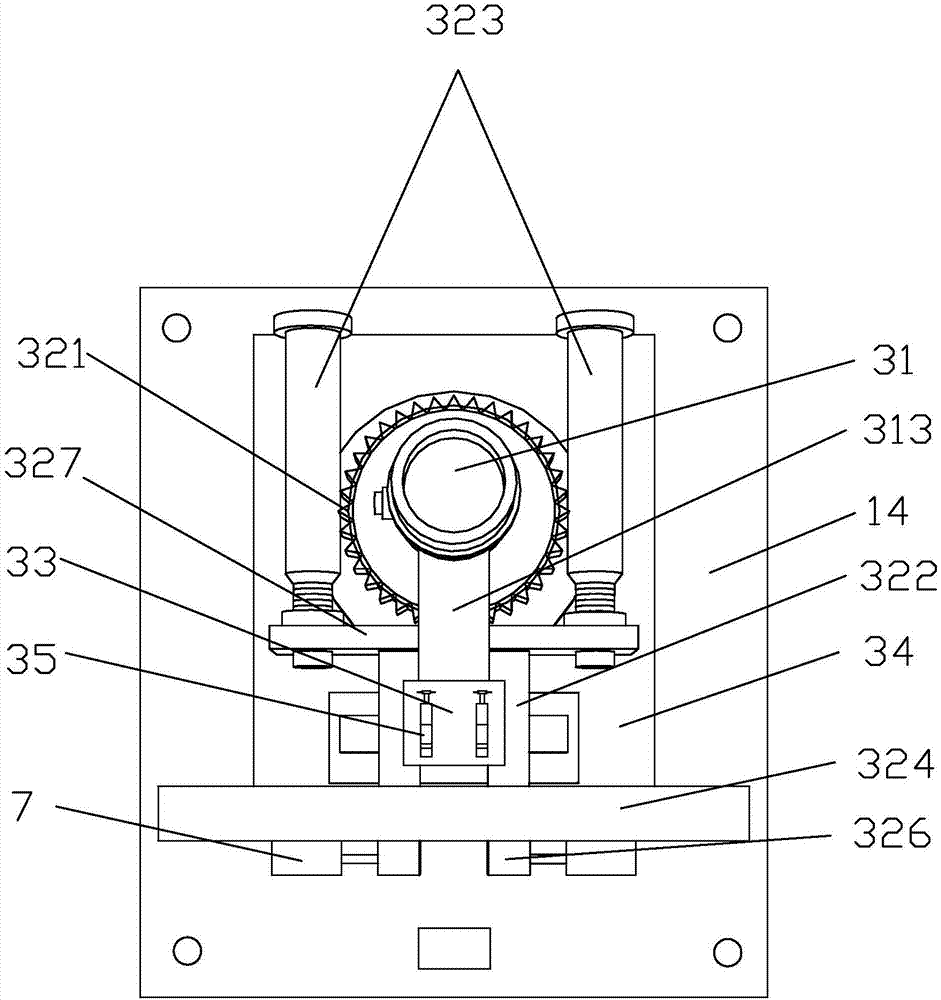

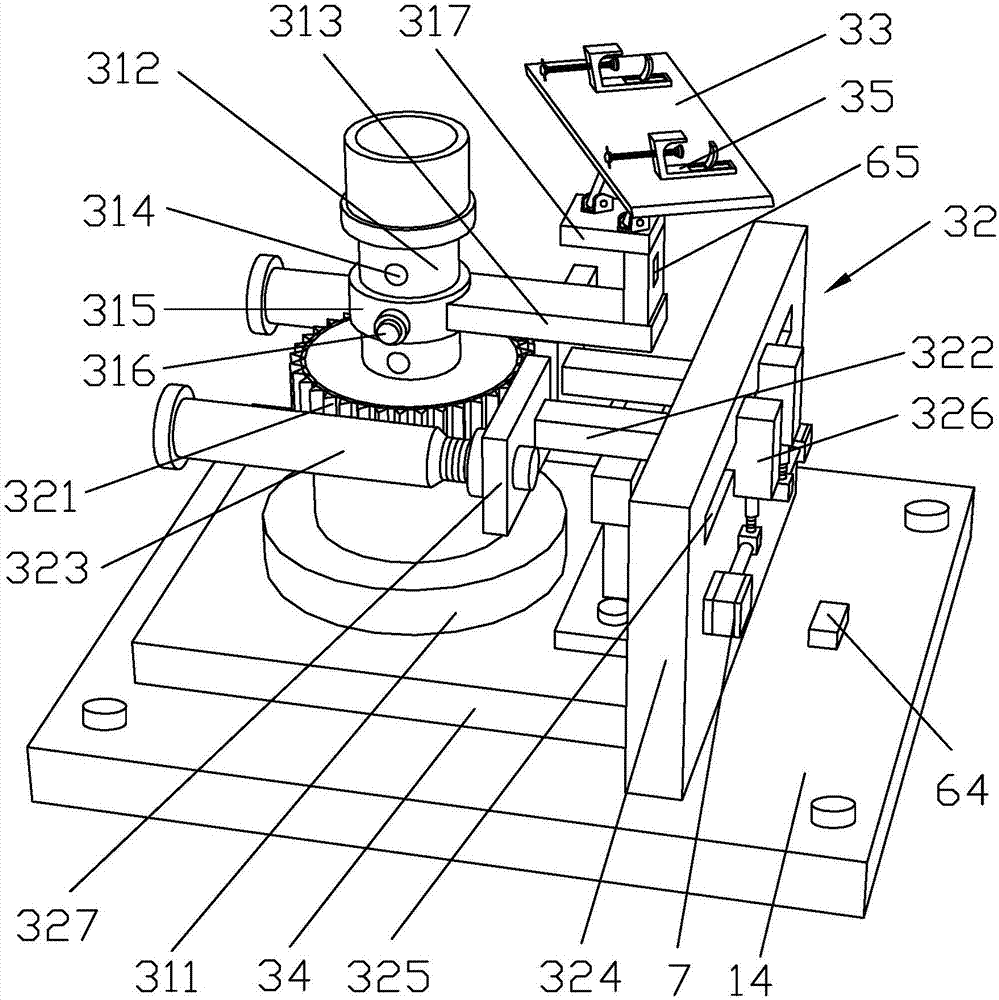

Turntable type flame welding machine

ActiveCN107378183AAvoid going off courseGuaranteed accuracyGas flame welding apparatusContinuous/uninterruptedInductor

The invention mainly discloses a turntable type flame welding machine. The technical scheme of the turntable type flame welding machine is characterized by comprising a workbench and a conveying rail, wherein a rotary table, a welding gun, a wire feeding gun and an induction device are arranged on the workbench; the rotary table is driven to rotate by a first driver, machining stations are distributed on the rotary table in the circumferential direction, and the machining stations are provided with machining clamps and induction switches; the machining clamps comprise rotating devices, locking devices and supporting plates, the rotating devices are driven by a second driver, and the supporting plates are used for fixing welding workpieces through fixing clamps; the welding gun and the wire feeding gun are connected with angle adjusting mechanisms respectively, and the wire feeding gun is further connected with a wire feeding device; and the induction device is connected with the first driver and the second driver, and the induction device comprises a first inductor and a second inductor. The turntable type flame welding machine is stable in work, accurate in positioning, capable of effectively improving the welding quality and ensuring the uniformity of welding joints, high in automation degree, capable of working continuously and reducing the labor intensity of workers, and capable of automatically welding large-batch products.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

Material cutting push device of candy molding machine

InactiveCN104642687ASmooth and accurate deliveryAchieve reductionConfectionerySweetmeatsMolding machineDrive shaft

The invention discloses a material cutting push device of a candy molding machine. The device comprises a transmission shaft seat; a transmission shaft is rotatably arranged in the transmission shaft seat; the shaft end of the transmission shaft is fixedly connected with a cutting disc; a plurality of cutting tool bits are evenly distributed on the surface of the cutting disc; a sliding groove is formed between every two adjacent cutting tool bits along the radial direction of the cutting disc; each sliding groove is internally connected with a push sliding block in a sliding way; each push sliding block is connected with a working surface of a cutting cam in a contacting way by a roller wheel arranged on the push sliding block; a material containing groove is formed between every two adjacent cutting tool bits along the circumferential direction of the cutting disc; arc-shaped material guide seats are arranged under the cutting disc at intervals. The material cutting push device of the candy molding machine not only is reasonable in structure, stable in material input and high in production efficiency, but also is compact in structure and simple in transmission.

Owner:江苏海特尔机械有限公司

Natural gas horizontal well completion method

ActiveCN106285617AIncrease the number ofAvoid or reduce downhole complicationsConstructionsLiquid/gas jet drillingSoil scienceCement slurry

The invention relates to a natural gas horizontal well completion method. According to the technical scheme, the natural gas horizontal well completion method comprises the steps that the target well depth is drilled at a time with a large-size drill bit, and a large hole is formed; a plurality of horizontal branch holes are drilled out in a natural gas hydrate reservoir through the horizontal well technology; and the contact surface area between the reservoir and the holes is increased to the greatest extent. The natural gas horizontal well completion method has the beneficial effects that the downhole complex conditions in the exploitation process is avoided or decreased; the number of the holes can be greatly increased; the bare area and the depth of the natural gas hydrate reservoir are increased to the greatest extent by the holes; the recovery ratio is greatly increased; the well spacing number and the development investment are decreased; and a window sealant is adopted, thus, a cement slurry system is stable, strength development is rapid, the thickening time is adjustable, hydrate layer sealing shallow water-gas channeling can be effectively prevented, and the construction performance is good.

Owner:HUAXIN TANGSHAN PETROLEUM EQUIP CO LTD

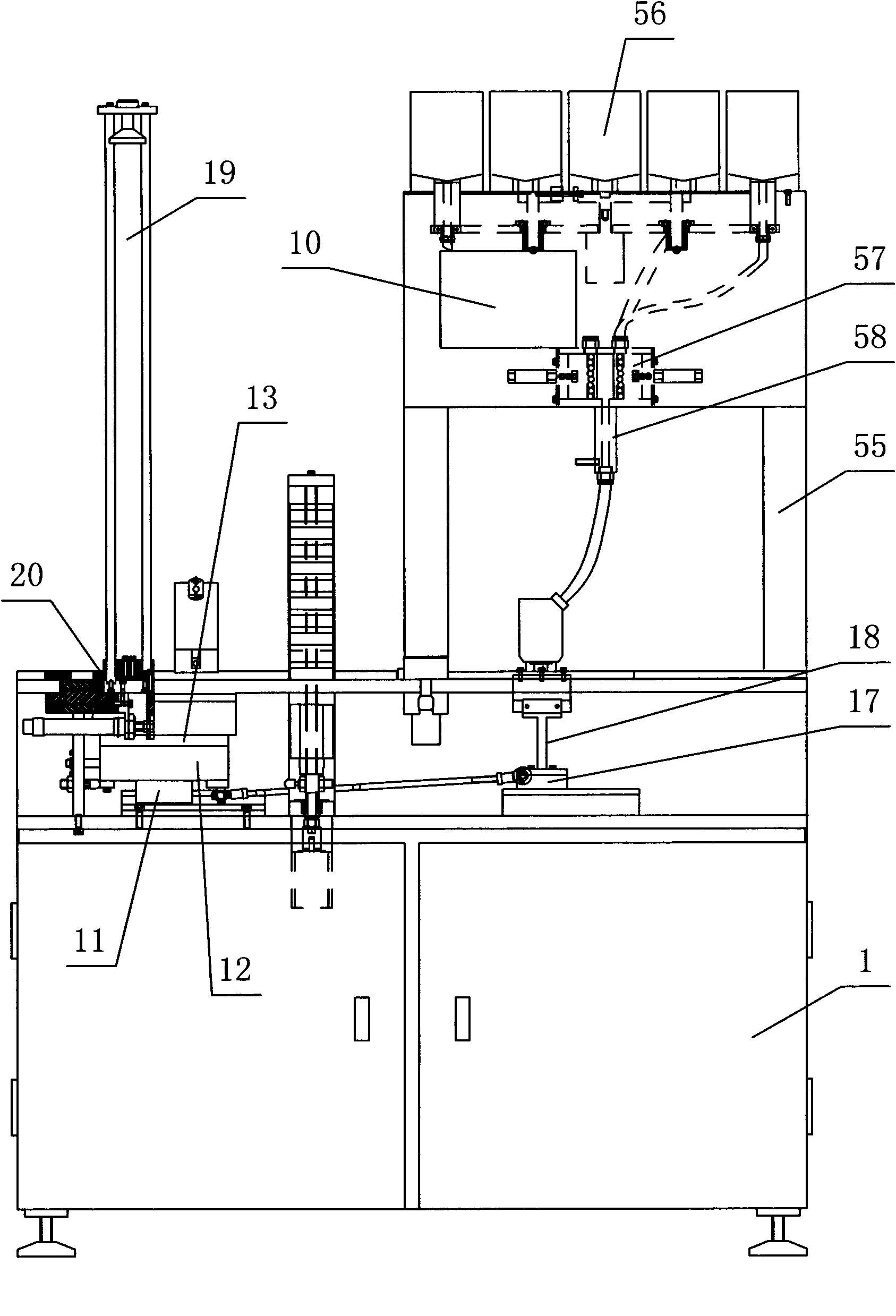

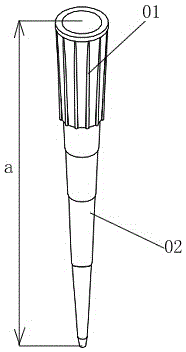

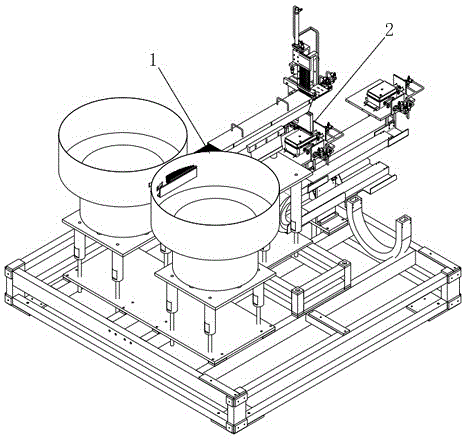

Boxing mechanism of automatic arrangement boxing machine for gun heads

ActiveCN105035385AAccurate entryImprove efficiencyIndividual articlesMechanical engineeringEngineering

The invention provides a boxing mechanism of an automatic arrangement boxing machine for gun heads. The boxing mechanism comprises a positioning block and a conveying mechanism. Every time after the positioning block clamps a row of arranged gun heads, a gun head box is placed on the conveying mechanism, and the conveying mechanism conveys the gun head box to the position below the positioning block. A first positioning mechanism and a second positioning mechanism are further arranged between the positioning block and the conveying mechanism in sequence. The first positioning mechanism is used for achieving positioning between the first positioning mechanism and the row of gun heads on the positioning block, the second positioning mechanism is used for achieving positioning between the second positioning mechanism and each row of insertion holes in the gun head box, and the relative position between the first positioning mechanism and the second positioning mechanism is fixed. The gun heads on the positioning block can fall into the insertion holes in the gun head box after passing through the first positioning mechanism and the second positioning mechanism in sequence. Through the boxing mechanism of the automatic arrangement boxing machine for the gun heads, it is guaranteed that the gun heads on the positioning block enter the gun head box accurately without deviating and falling out, so that the efficiency and accuracy of gun head boxing are improved.

Owner:上海伦恩通用技术有限公司

Lotus stem reaping and collection device

ActiveCN110447382AImprove harvesting efficiencyImprove securityHarvestersGear transmissionEngineering

The invention discloses a lotus stem reaping and collection device. The device comprises a ship body and a reaping device connected with the ship body; the reaping device comprises an annular detachable collection groove, rotary auxiliary collection devices, a damping device, a gear transmission lifting device and a cutting blade set; the annular detachable collection groove is connected with theship body through the gear transmission lifting device; the upper and lower ends of the front portion of the annular detachable collection groove are respectively provided with the rotary auxiliary collection devices; the damping device is installed at the portion, connected with a lifting arm, above a gear of the gear transmission lifting device; a pulley is arranged on the lifting arm; a steel wire used for connecting the ship body with the annular detachable collection groove is arranged on the pulley; a rocking bar arranged on the ship body is connected with one end of the steel wire, andthe other end of the steel wire is fixedly connected with the annular detachable collection groove. According to the lotus stem reaping and collection device, the efficiency and safety of artificial cleaning and collection for withered lotus stems are greatly improved, and the problems are solved to a certain degree that in lotus planting water, lotus stems are inconvenient to reap, and organic matter pollution is caused.

Owner:XUZHOU UNIV OF TECH

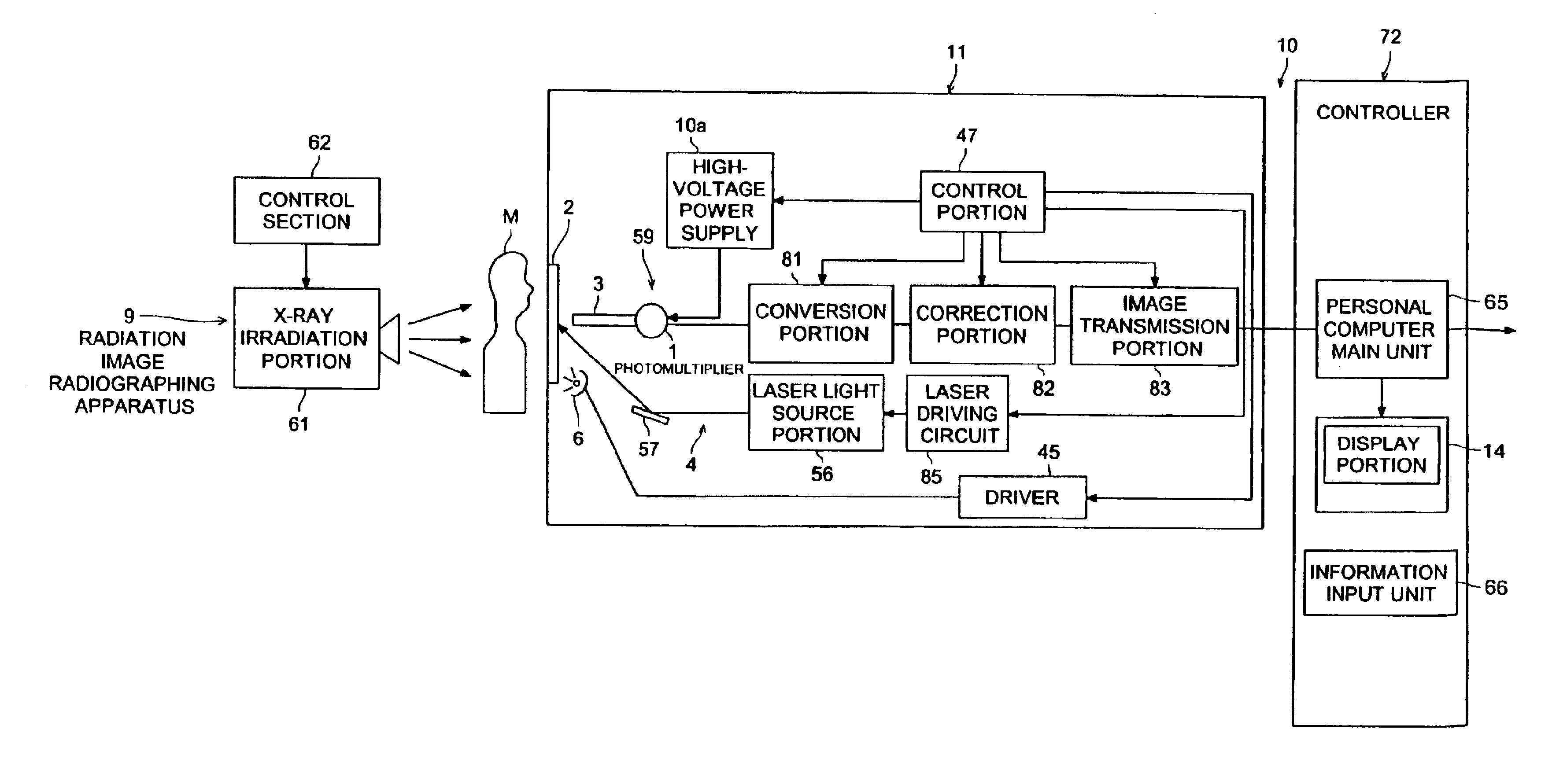

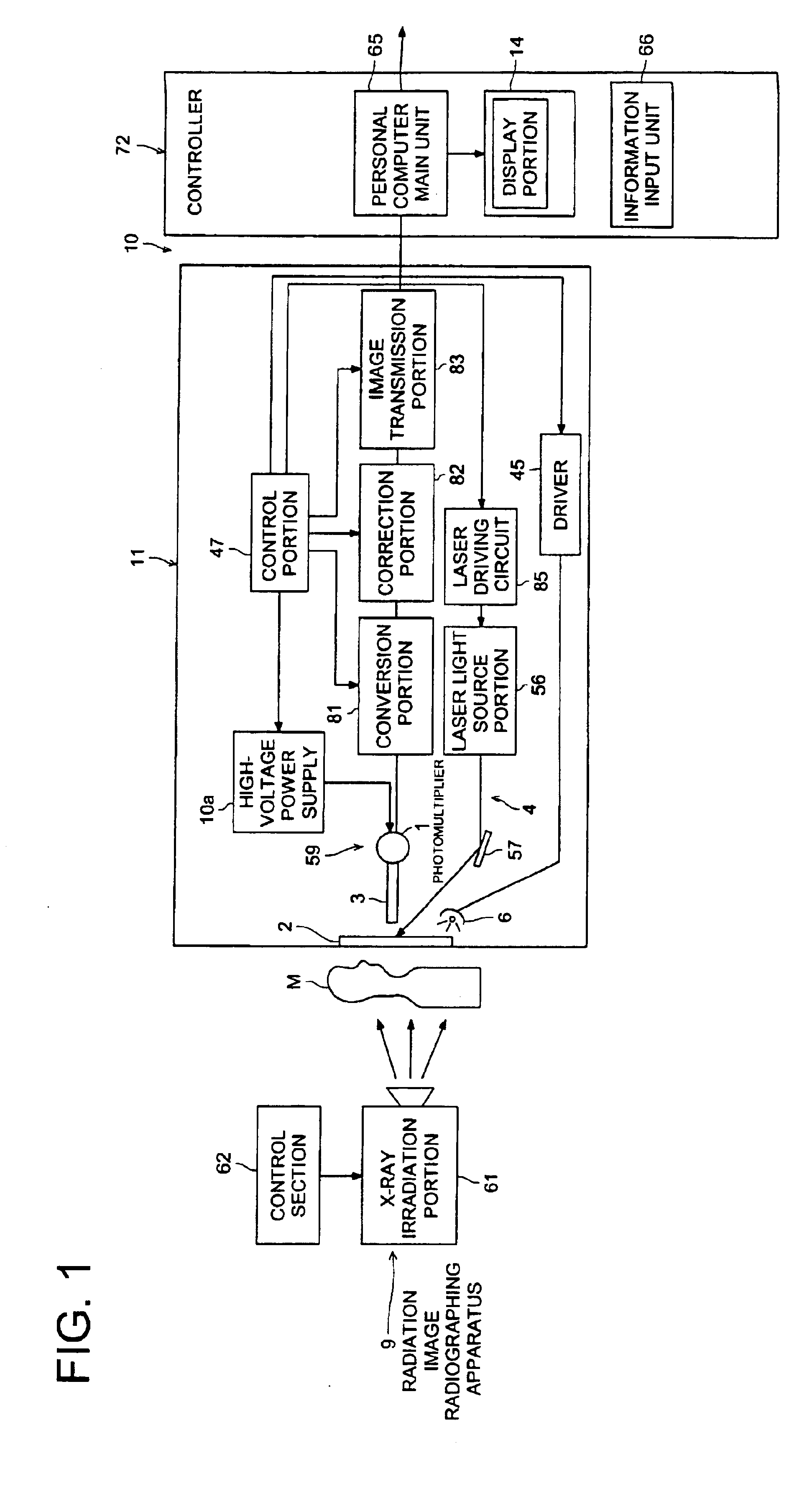

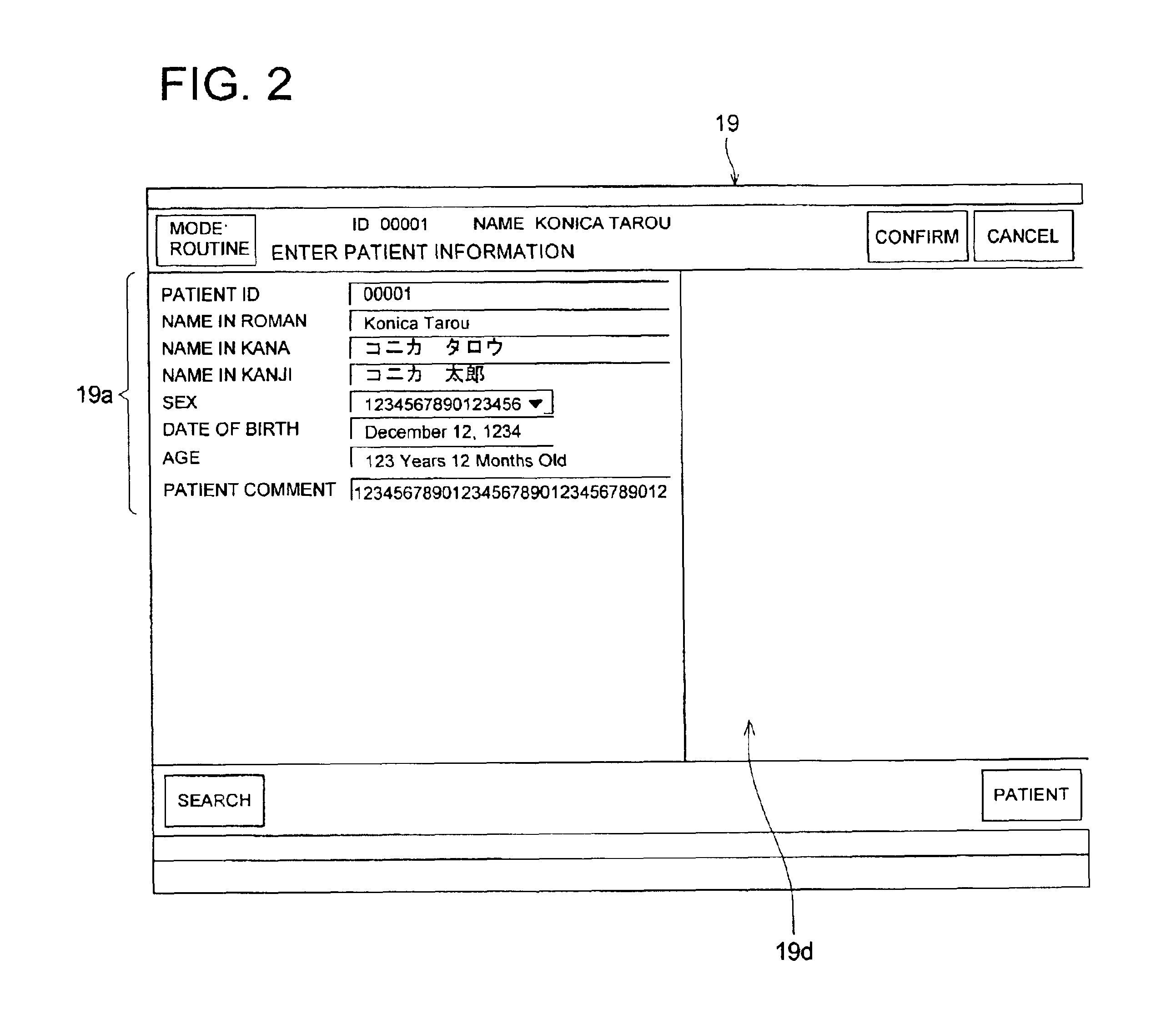

Radiation image radiographing apparatus

InactiveUS6920465B2Accurate entryAccurate and reliable entryData processing applicationsMedical imagesComputer scienceStress radiography

A radiation image radiographing apparatus includes an information input section having an input screen with which a patient information item and a radiographing information item are inputted; a memory section; an image input section to conduct inputting a radiation radiography image; a control section to check whether a predetermined set of patient information items of the patient are inputted in the memory section when the image input section starts inputting a radiation radiography image of the patient. When the predetermined set of patient information items are not inputted in the memory section, the control section prohibits inputting a radiation radiography image of the patient and controls the information input section to indicate an un-inputted patient information item on the input screen in such a way that the un-inputted patient information item is inputted on the input screen.

Owner:KONICA CORP

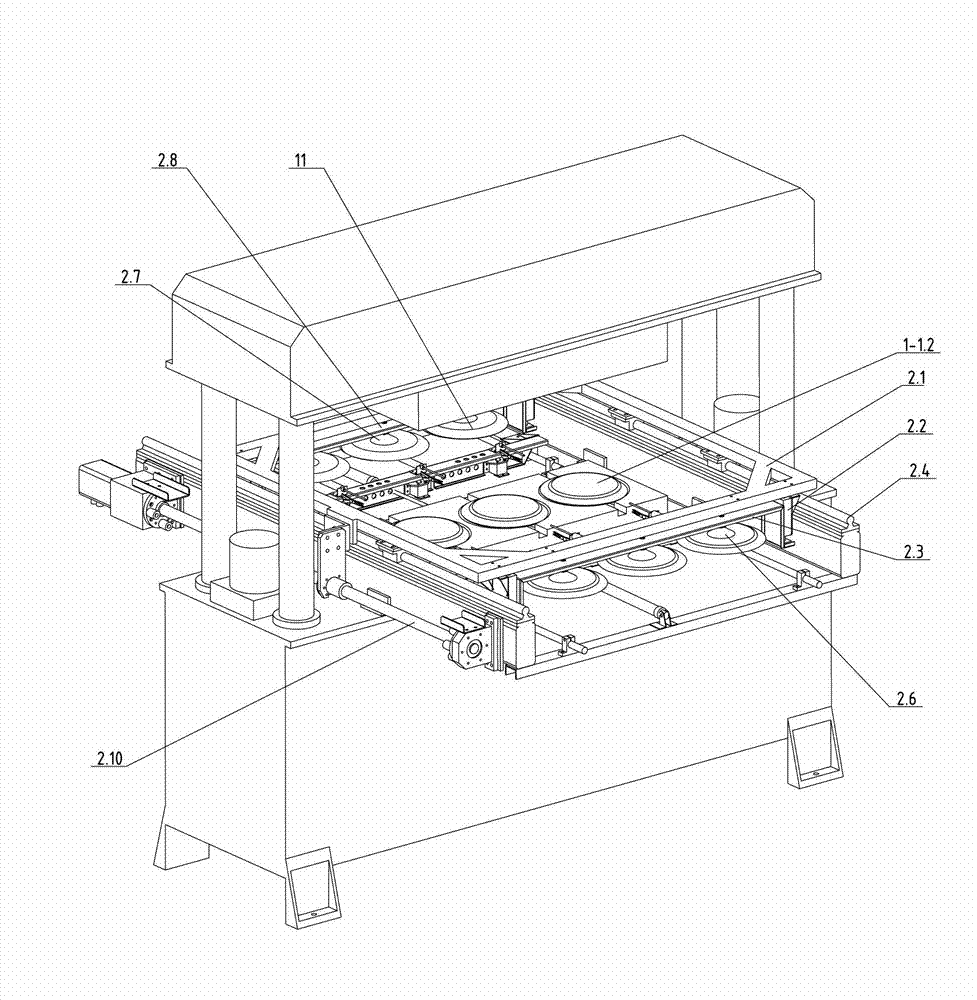

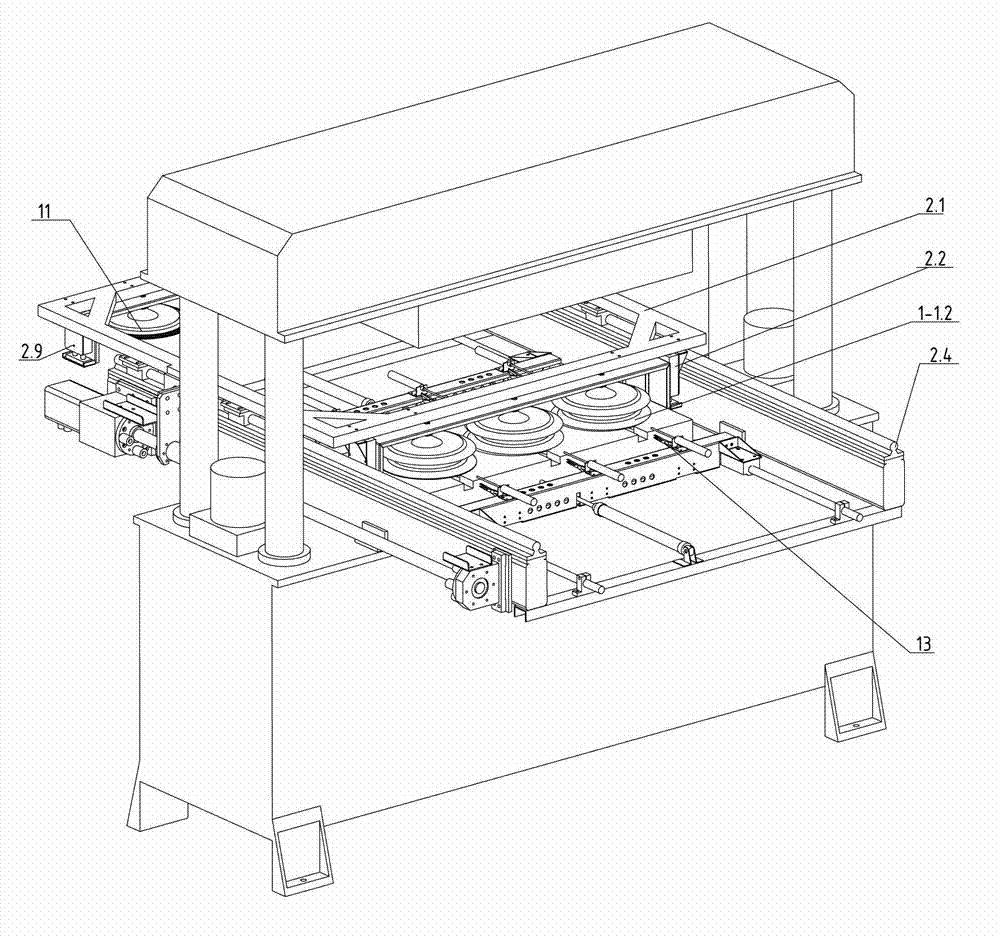

Automatic edge cutting method for plant fiber molding product and automatic edge cutting machine

ActiveCN103042639AAccurate cutting edge positioningHigh speedMetal working apparatusFiberEngineering

The invention relates to an automatic edge cutting method for a plant fiber molding product and an automatic edge cutting machine. The purposes are that the method has the characteristic of automatic and accurate location, and the automatic cutting machine has the characteristic of stable work. The technical scheme includes that the automatic edge cutting method for the plant fiber molding product proceeds as follows: 1), sucking the product with edges to be cut; 2), driving away waste edges from an edge cutting position; 3), positioning the product to be cut and a product with cut edges respectively; 4), cutting out deckle edges; 5), enabling a front row and a rear row of sucking disk sets to reach the corresponding positions respectively; and 6), sucking the product with edges to be cut and the product with cut edges; repeating from the step 2) to the step 6), and proceeding the circulation over and over again. The automatic edge cutting machine for the plant fiber molding product comprises an edge cutting and die assembly mechanism, wherein the edge cutting and die assembly mechanism comprises an upper edge cutting mold, a lower edge cutting mold, an upper installation plate, a lower installation plate and a power mechanism. The automatic edge cutting machine for the plant fiber molding product is characterized in that a product transferring mechanism and a waste edge moving out mechanism are also arranged on the automatic edge cutting machine.

Owner:EURASIA EP MACHINERY +1

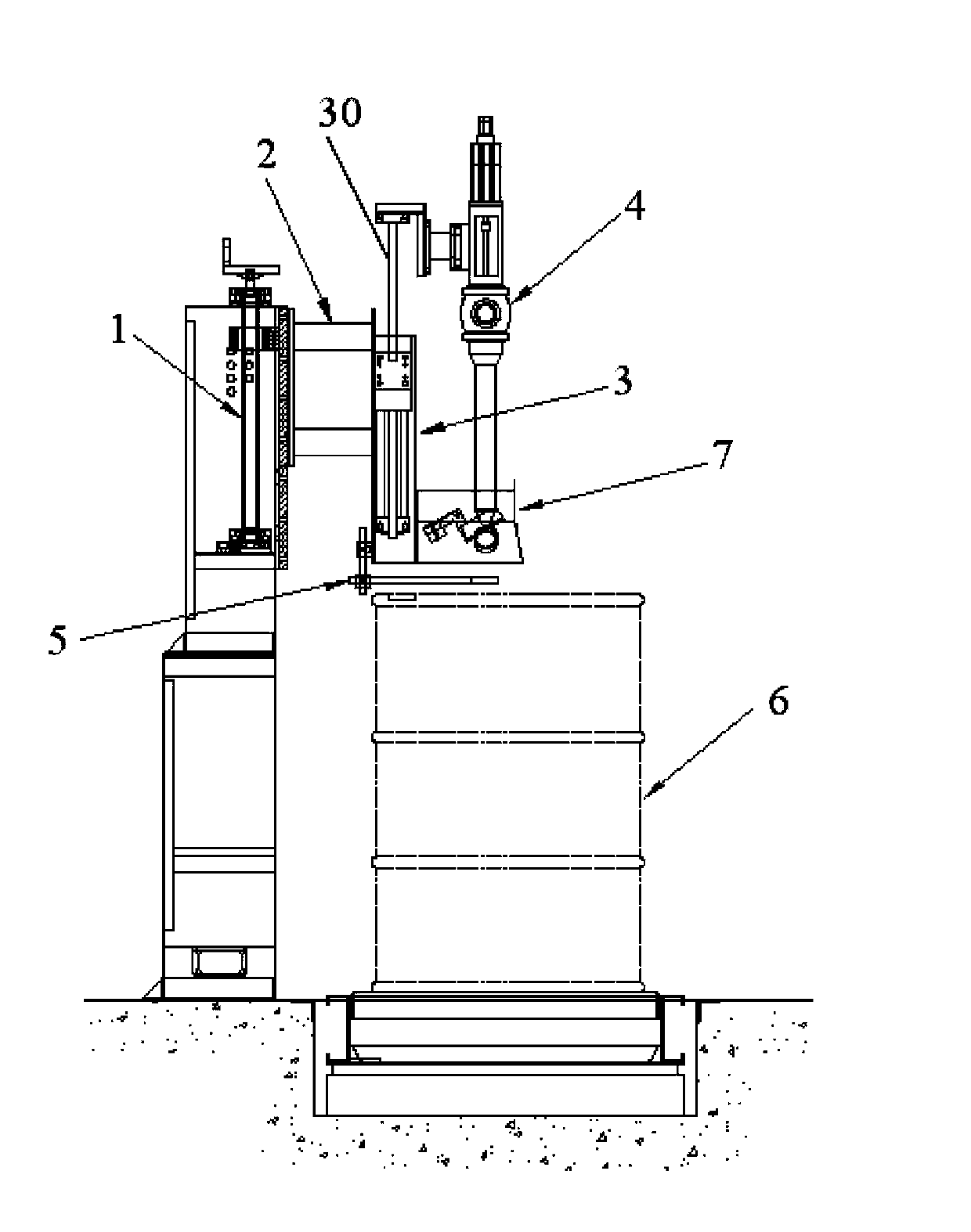

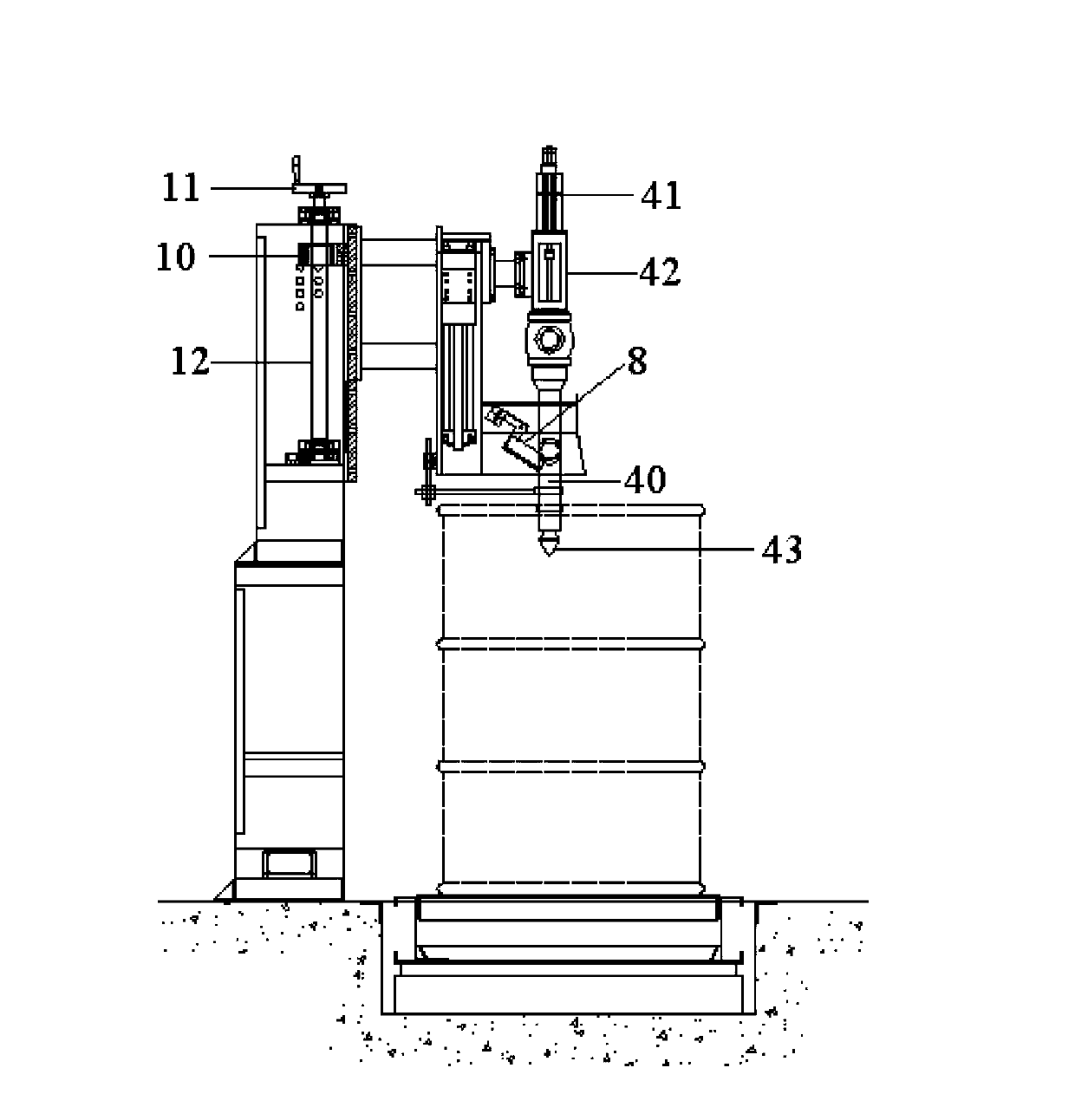

Liquid filling machine positioner

The invention discloses a liquid filling machine positioner. The liquid filling machine positioner comprises a screw elevator, a driving device, a filling gun, and a material storage barrel correspondingly arranged below the filling gun, the driving device is in positioning connection with a transmission nut on the turbine worm elevator through an elevating crossbeam, and the filling gun is driven by the driving device and moves up and down relative to the material storage barrel; and the positioner also comprises a hole aligner fixedly arranged on the elevating crossbeam and positioned over the material storage barrel, the hole aligner has a circular ring rightly facing against the gun body of the filling gun, the circular ring is matched with the filling gun body, and the projection of the circular ring oriented to the material storage barrel can be placed in the mouth of the material storage barrel, so the fast and accurate entrance of the filling gun body to the mouth of the material storage barrel can be ensured, and the production efficiency is substantially improved.

Owner:KUNSHAN LIGU WEIGHING IND

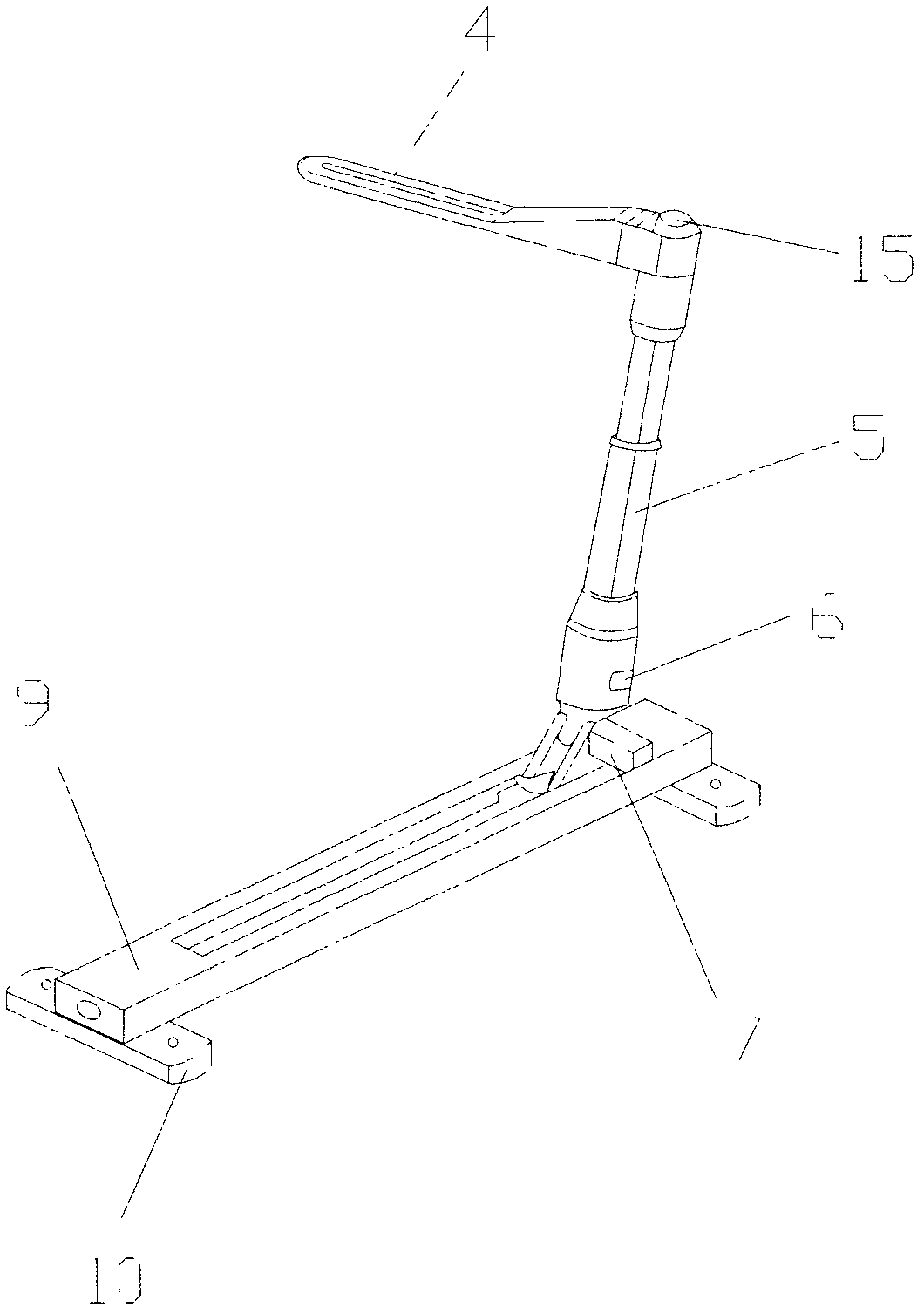

Sowing apparatus for vegetable plantation

ActiveCN108156906AEven numberHigh precisionWatering devicesCultivating equipmentsEngineeringVegetable farming

The invention discloses a sowing apparatus for vegetable plantation, and belongs to the technical field of vegetable plantation. The sowing apparatus comprises a box, a fixed plate, a rotation disc, and a rotation rod. Through a seed box, seeds fall in the placing hole of the rotation disc; the size of the placing hole determines the number of filled seeds; the water amount of a water tank is thesame for each watering, the seed number for each sowing is uniform, and the water amount is uniform. When the placing hole of the rotation disc rotates to a top hole, seeds fall into soil through thetop hole and a bottom hole, sowing is finished, then a water storing tank in the rotation rod rotates to the bottom hole later, through a raised block, a moving plate is jacked up, water moves along awater guiding disc and is sprayed on the seeds through the bottom hole, and watering is finished. Sowing and watering are finished continuously, and the work efficiency is improved. An axle is connected to a second motor through a grooved wheel and a drive plate so as to rotate a moving wheel intermittently; during the stop period, sowing and watering are performed, seeds and water are accuratelyadded into a hole, and the sowing precision is further improved.

Owner:HEXIAN LVYUAN VEGETABLE PLANTATION CO LTD

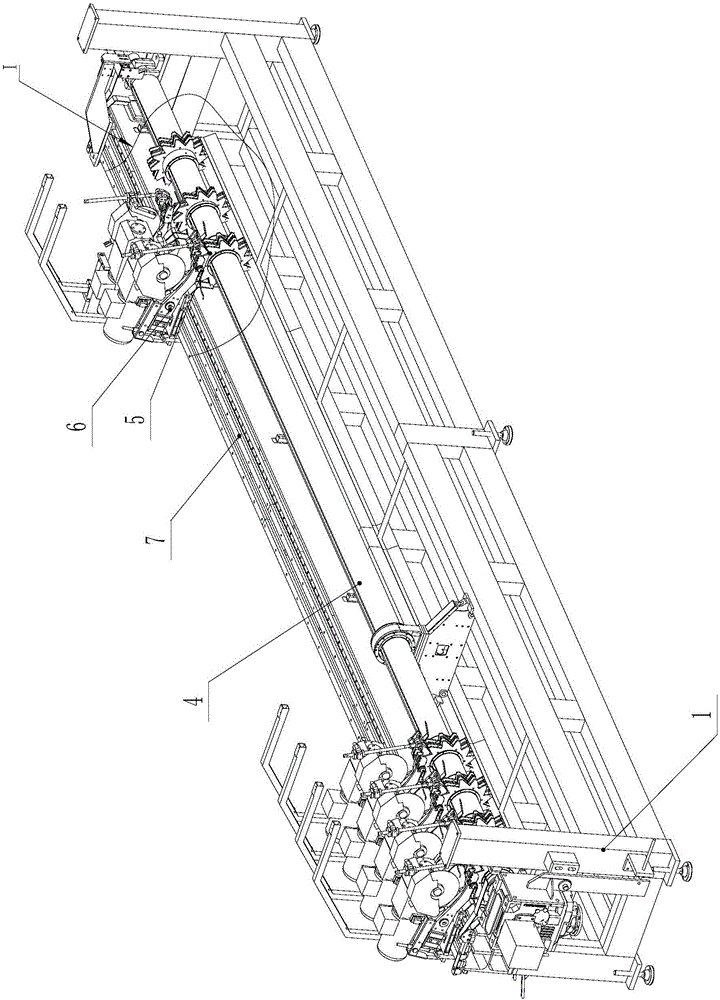

Pipe multi-head sawing machine

The invention discloses a pipe multi-head sawing machine. The pipe multi-head sawing machine comprises a rack and a plurality of sawing heads arranged on the rack. A feed spindle is rotationally mounted on the rack and driven by a rotary feed power device. Material poking gear sets are mounted on the feed spindle and each provided with circumferentially-formed material poking gears. Feed clearances are arranged on each material poking gear set, and the depth of the feed clearances is larger than the pipe diameter of a pipe. The sawing heads are arranged on the rack and located on the rotating downstream sides of the material poking gear sets. Saw blades of the sawing heads are located at the upper sawing stations of the material poking gear sets and correspond to the positions of the feed clearances, and the length of the parts, stretching into the feed clearances, of the saw blades is larger than the pipe diameter of the pipe. Automatic feeding devices used for transversely feeding the pipe into material poking gear grooves of the material poking gear sets are arranged on the rotating upstream sides of the material poking gear sets. According to the multi-head sawing machine, taking, feeding, sawing and discharging are completed within one rotating period through the rotary material poking gear sets, and the sawing efficiency is greatly improved.

Owner:SUZHOU KINKALTECK MACHINERY TECH

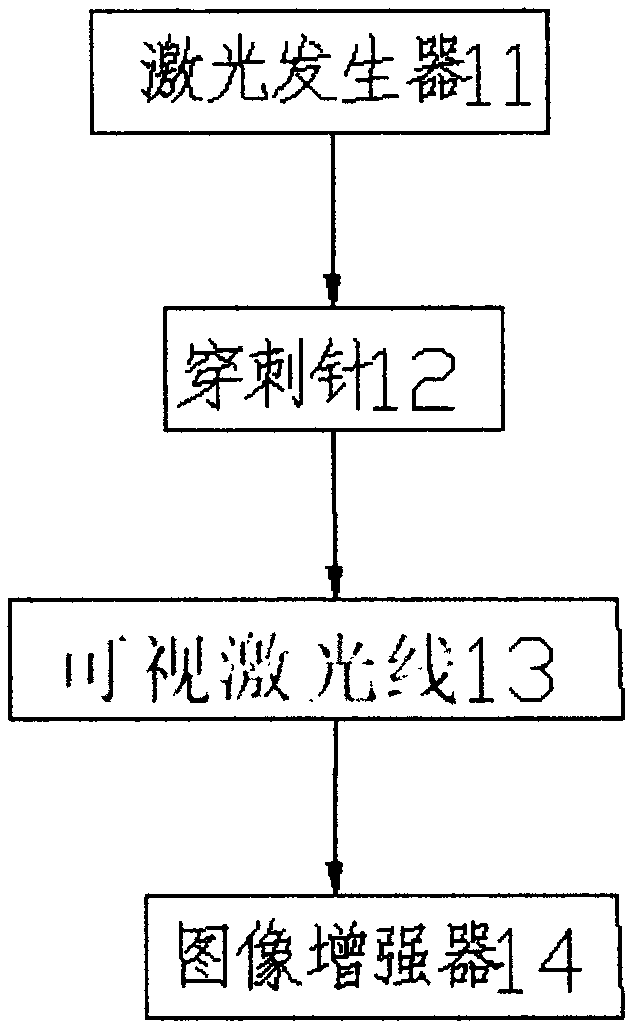

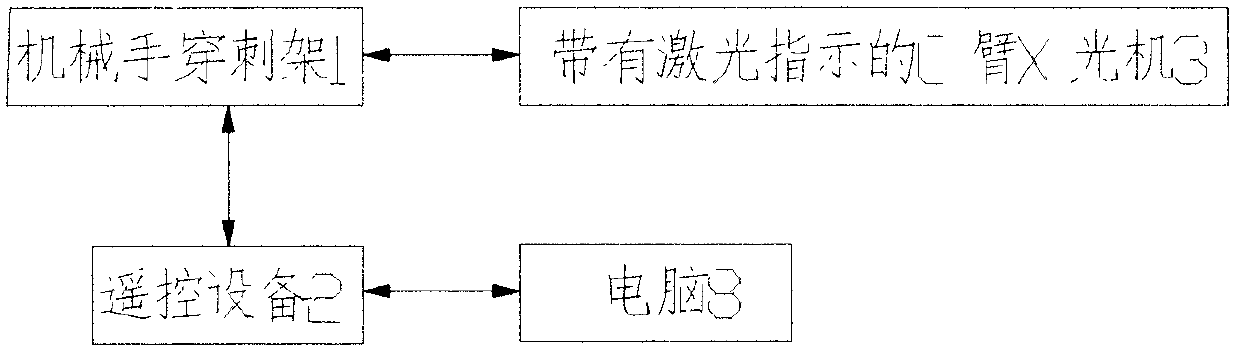

Manipulator puncture system for percutaneous renal operation

Owner:GUANGDONG ZHONGKE TINGE MEDICAL EQUIP CO LTD

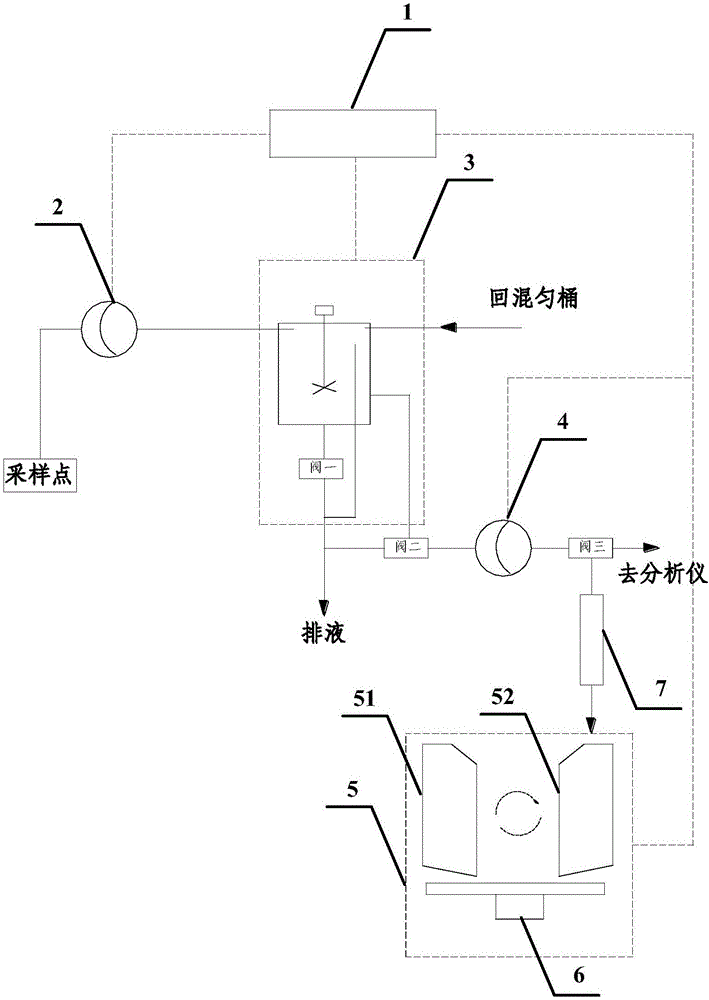

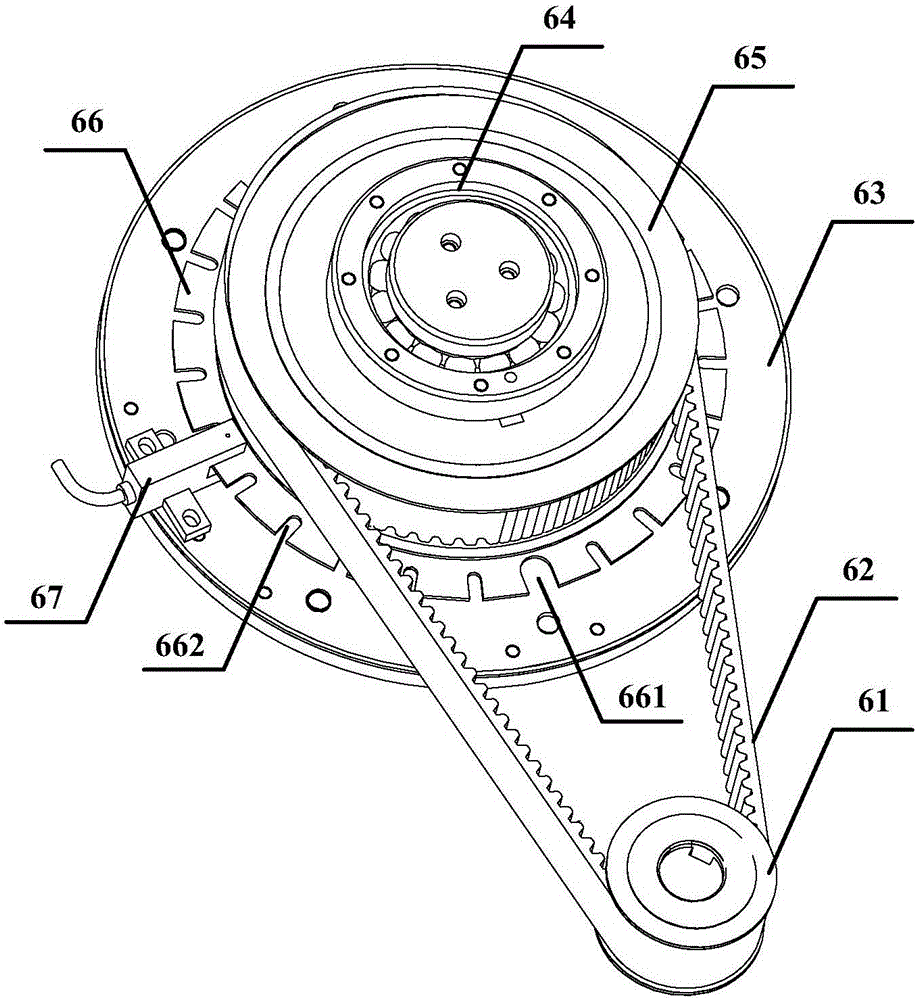

Water quality automatic sampling method and device

InactiveCN106840764AAccurate entryImprove stabilityWithdrawing sample devicesBlind zoneComputer science

The invention relates to a water quality automatic sampling method which comprises the following steps: (A1) a control unit receives a sampling command, and controls a sampling pump to acquire a water sample to be detected to a mixing unit; (A2) when the current sampling finishes, a sample feed pump simultaneously outputs the current water sample to two streams, one stream is delivered to an analyzer for analysis, and the other stream is delivered to a sample reservation unit for sample reservation; (A3) the current water sample in the mixing unit is evacuated, and the next sampling process is started; (A4) the analyzer analyzes the current water sample and transmits the analytic result to the control unit for judgment: if the water sample is not satisfactory, the control unit controls the sample reservation unit to reserve the current water sample; if the water sample is satisfactory, the control unit controls the shape feed pump to rotate reversely so as to evacuate the current water sample; and the step (A4) and next water sampling process are performed simultaneously. The invention also relates to a water quality automatic sampling device. The method and device have the advantages of high stability, high reliability and the like, and does not have sampling blind zones besides the mixing unit for sample feed and sample discharge.

Owner:FOCUSED PHOTONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com