Automatic sorting method and device for parcels on sorting assembly line, and storage medium

An automatic sorting and assembly line technology, applied in sorting and other directions, can solve problems such as low efficiency, inability to realize automatic work, complex structure of logistics sorting devices, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The following is attached Figure 1-9 The application is described in further detail.

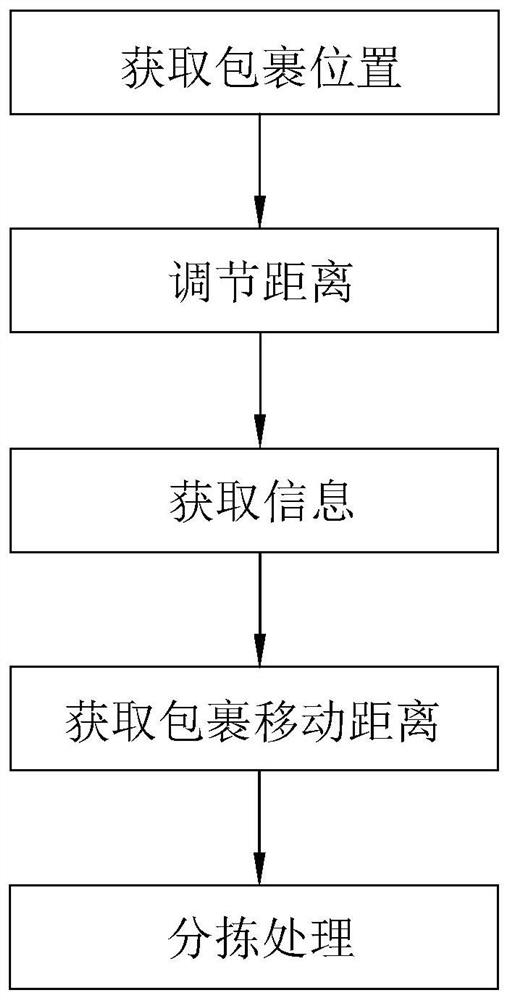

[0079] The embodiment of the present application discloses an automatic sorting method for parcels in a sorting line. refer to figure 1 , including the following steps:

[0080] Get the location of the package: Get the distance between two adjacent packages, and judge whether the distance between the two adjacent packages is less than the preset minimum distance, if it is judged to be yes, enter the step to adjust the distance; if it is judged to be no, enter step to obtain information;

[0081] Adjust the distance: increase the distance between two adjacent packages. When the distance between two adjacent packages is greater than the preset minimum distance, enter the step to obtain information;

[0082] Obtain information: Obtain the information of the package, determine the target area that the package should enter and the offset angle corresponding to the corresponding target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com