Detachable automatic-rollover-type material hoister

A material hoist and automatic technology, applied in cranes, transportation and packaging, etc., can solve the problems of inability to lift colloidal or liquid materials, inability to realize convenient interchange of hoppers, and spillage, etc., to achieve a stable process without spillage, and a simple structure. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

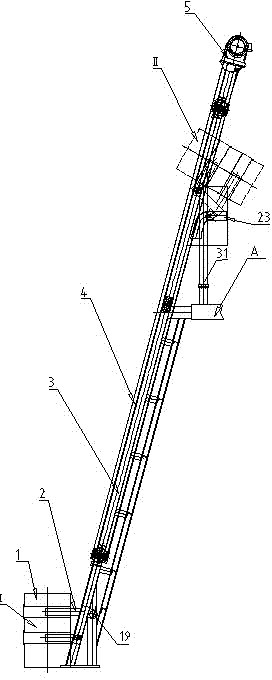

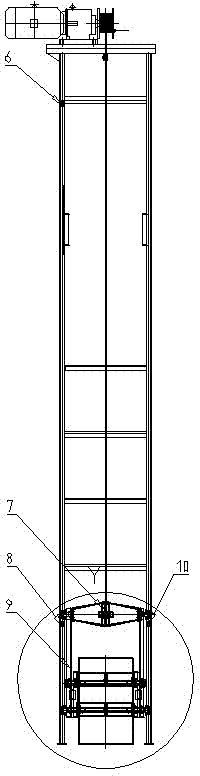

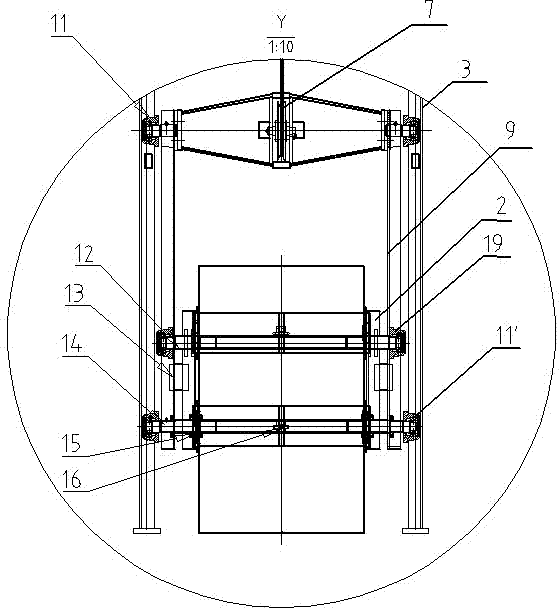

[0021] see Figure 1~Figure 5 , The present invention includes a hopper 1, a trolley frame 2, a feeding frame 3, a wire rope 4, a hoist 5, a pulley assembly 7, an upper limit switch 6, a lower limit switch 8, a lifting frame 9, and a sensor 10.

[0022] The loading rack 3 is inclined and fixed on the ground, and the included angle between the loading rack 3 and the horizontal plane is preferably 75°. The back of the feeding rack 3 is provided with a support beam 31, which is bolted and fixed with the main chassis A of the mixing station, and a section of curved track 23 is arranged in the upper part of the feeding rack 3. The hoist 5 is bolted and fixed on the top of the feeding rack 3 , and the center position of the reel is consistent with the central position of the feeding rack 3 . The lifting frame 9 is provided with two front rollers 11 and two rear rollers 11', and the front rollers 11 and the rear rollers 11' roll up and down in the track of the feeding frame 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com