Liquid filling machine positioner

A positioning device and filling machine technology, applied in liquid bottling, liquid processing, packaging and other directions, can solve the problems of waste of raw materials, inaccurate aiming of the filling gun body, reducing the production efficiency of the filling machine, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

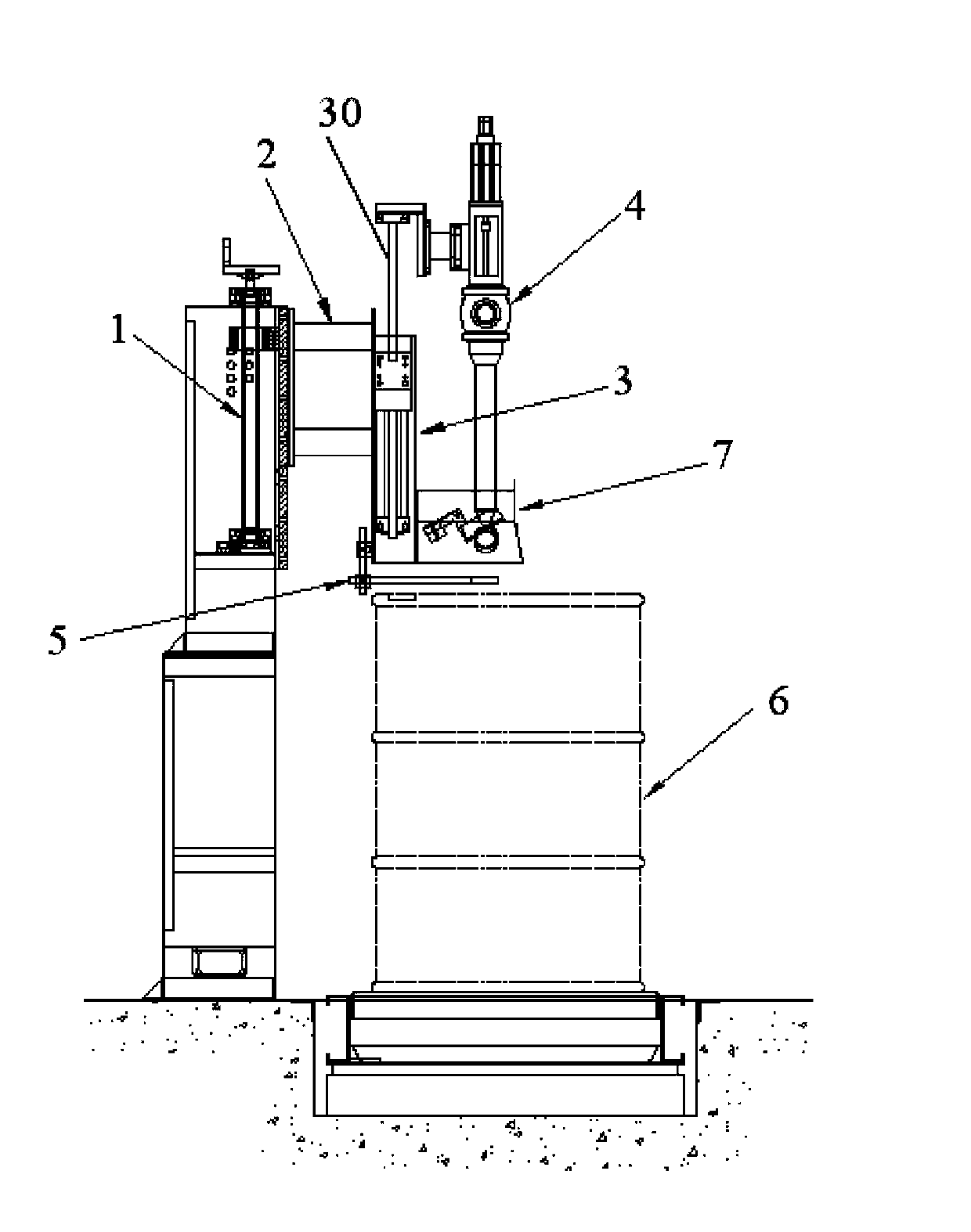

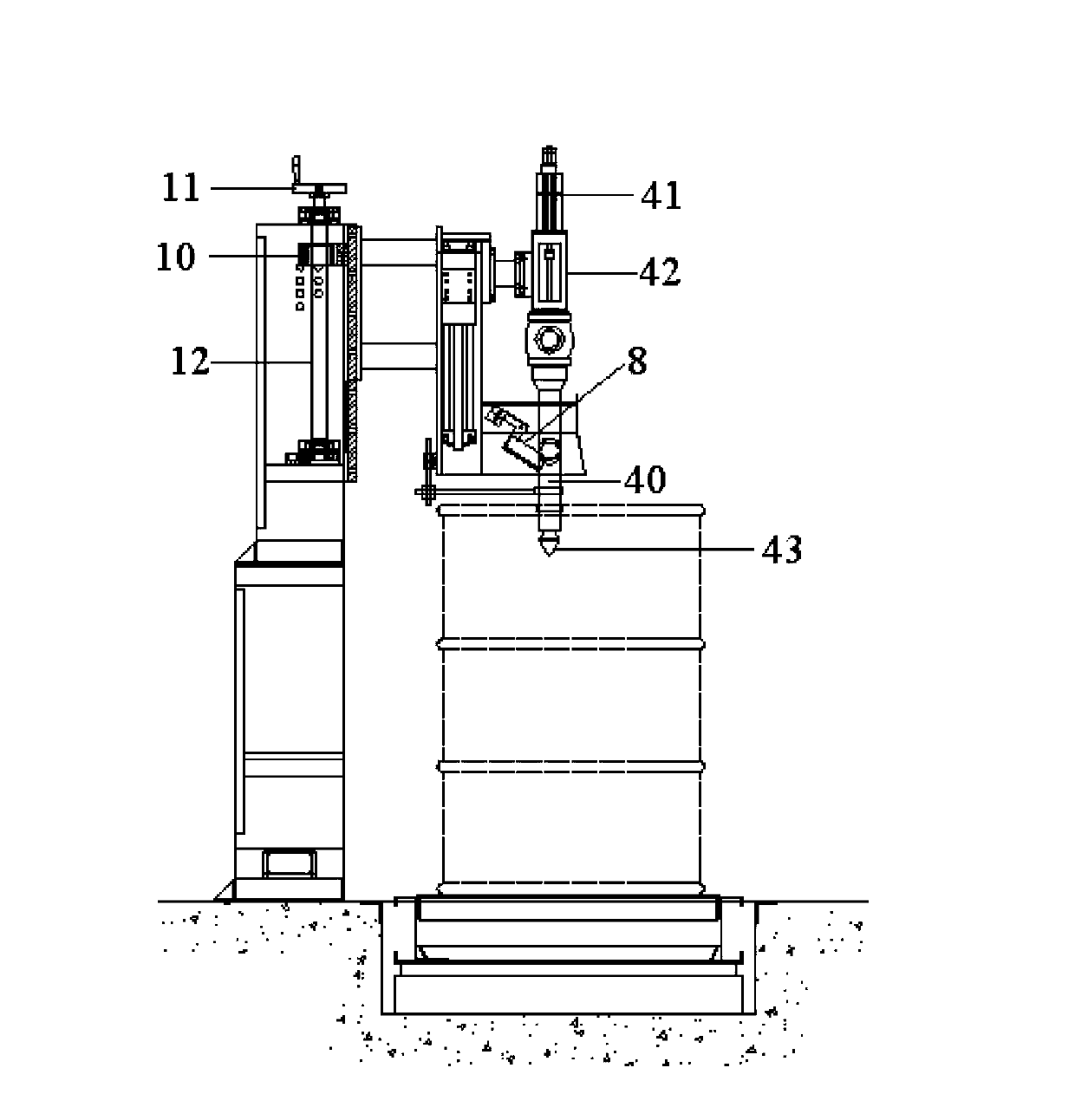

[0020] The embodiments of the positioning device of the liquid filling machine of the present invention will be described in detail below with reference to the accompanying drawings.

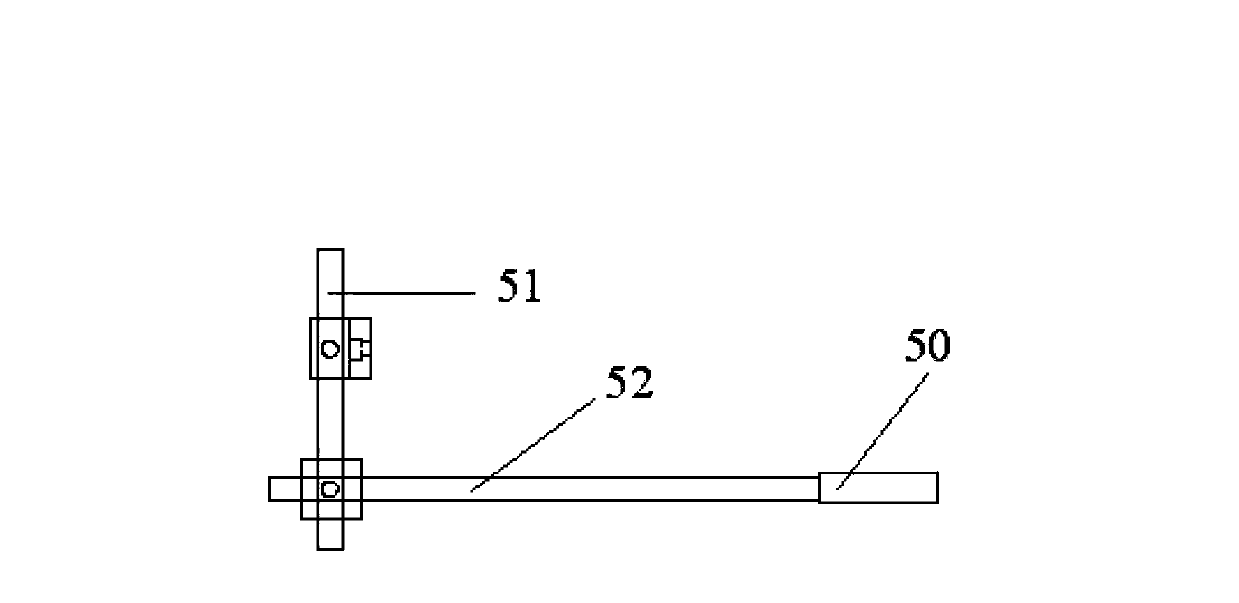

[0021] A positioning device for a liquid filling machine according to the present invention includes a screw lifter 1, a driving device 3, a filling gun 4 and a storage tank 6 correspondingly arranged below the filling gun, and the driving device 3 passes through a lift The beam 2 is positioned and connected to the lifting nut 10 on the screw lifter, the filling gun 4 is driven by the driving device 3 and moves up and down relative to the storage barrel 6; it also includes a positioning device arranged on the lifting beam 2 and The hole aligner 5 located above the storage barrel 6 has a circular ring 50 facing the filling gun gun body 40, the ring matches the filling gun gun body, and the The projection of the circular ring towards the storage barrel can just be placed in the mouth of the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com