Water quality automatic sampling method and device

An automatic sampling and water quality technology, applied in sampling devices, measuring devices, sampling, etc., can solve the problems of easy sealing at the bottom, easy blockage of pinch valves, poor reliability, etc., to increase the time of sampling coverage and reduce sampling waste. Area, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

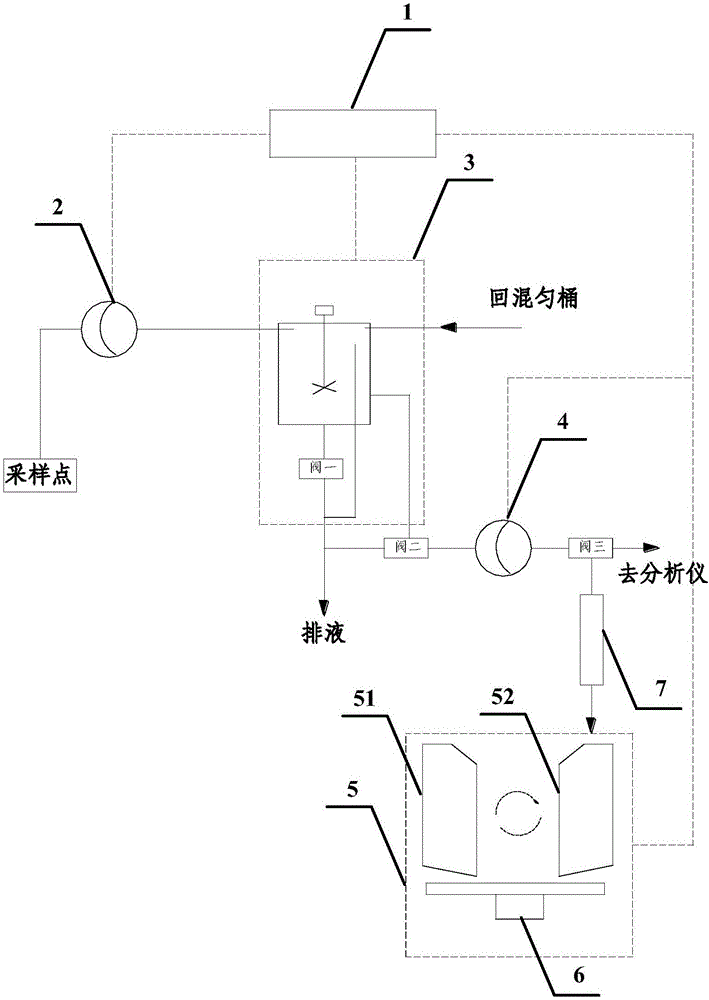

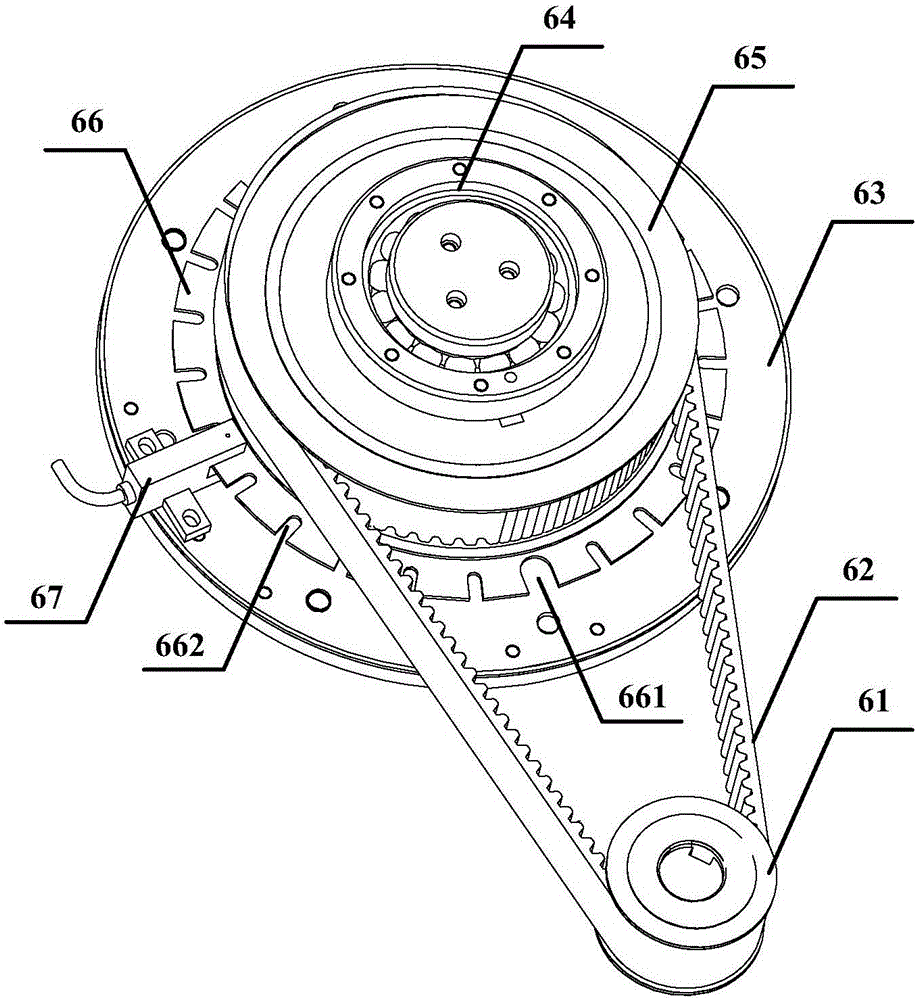

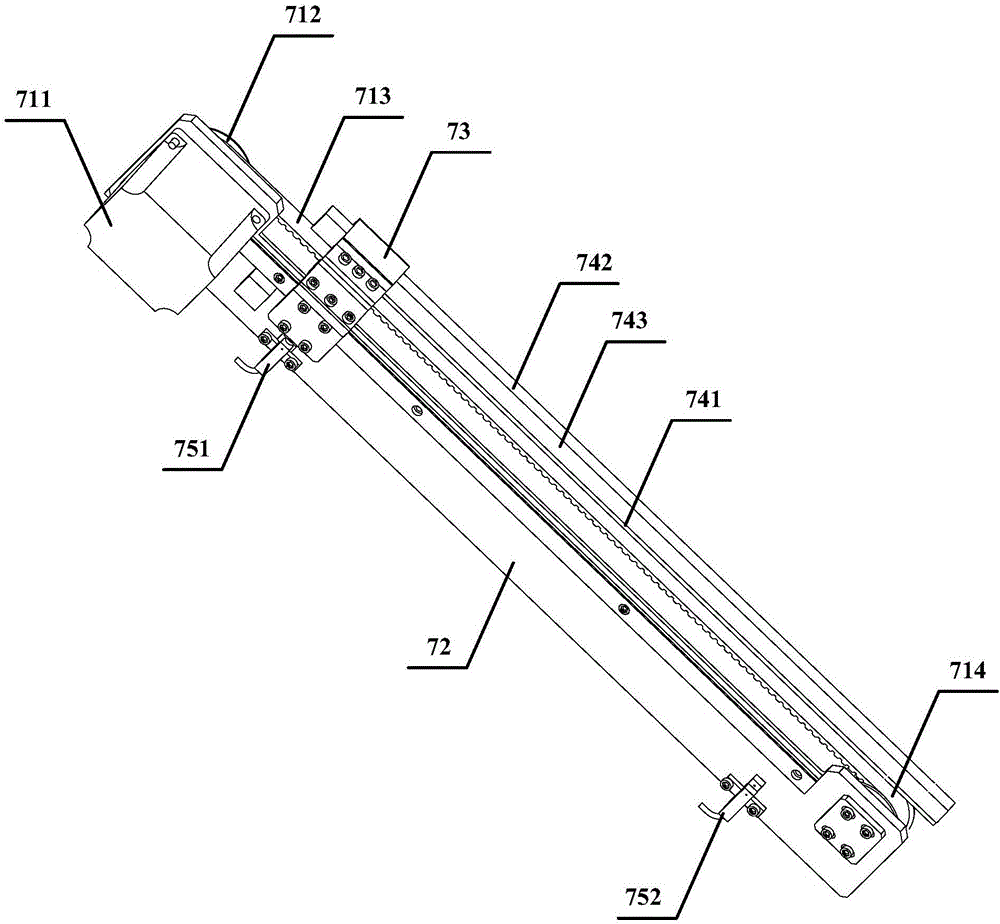

[0057] figure 1 Schematically provides a simplified structural diagram of the water quality automatic sampling device of the present embodiment, figure 2 A schematic structural diagram of the rotary positioning device of the automatic water quality sampling device of this embodiment is given schematically, image 3 Schematically shows the structural diagram of the axial positioning device of the automatic water quality sampling device in this embodiment, as shown in Figure 1-3 As shown, the automatic sampling device includes: a control unit 1 and a sampling pump 2, and the automatic sampling device further includes:

[0058] Mixing unit 3, the mixing barrel in the mixing unit has and only one;

[0059] The sample supply pump 4, the sample supply pump is connected to the mixing unit, and when the forward rotation is forward, the current water sample will be sent to the analyzer and the sample retention unit 5 at the same time, and the water sample in the sample retention unit...

Embodiment 2

[0104] An application example of the water quality automatic sampling device in embodiment 1 of the present invention in the field of water quality monitoring.

[0105] In this application example, the mixing unit includes a mixing bucket, and a liquid discharge port is provided under the mixing bucket; a plurality of slits (such as 25) are provided on the code disc of the rotary positioning device, including 1 characteristic slits, and the rest are ordinary slits, and a sample bottle is placed on the rotary positioning device and at the position corresponding to each slit; the axial positioning device is provided with a sample retention / cleaning position and an emptying position, and the The emptying position is the lower limit switch position of the axial positioning device, and the sample retention / cleaning position is set between the upper and lower limit switches.

[0106] The operation flow of the water quality sampling method in this application example is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com