Steel bar surface rust removal device for constructional engineering

A technology for construction engineering and steel bars, which is applied in the field of derusting devices on the surface of steel bars for construction engineering, can solve problems such as difficult derusting operations, and achieve the effects of improving stability, improving stability, and facilitating fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

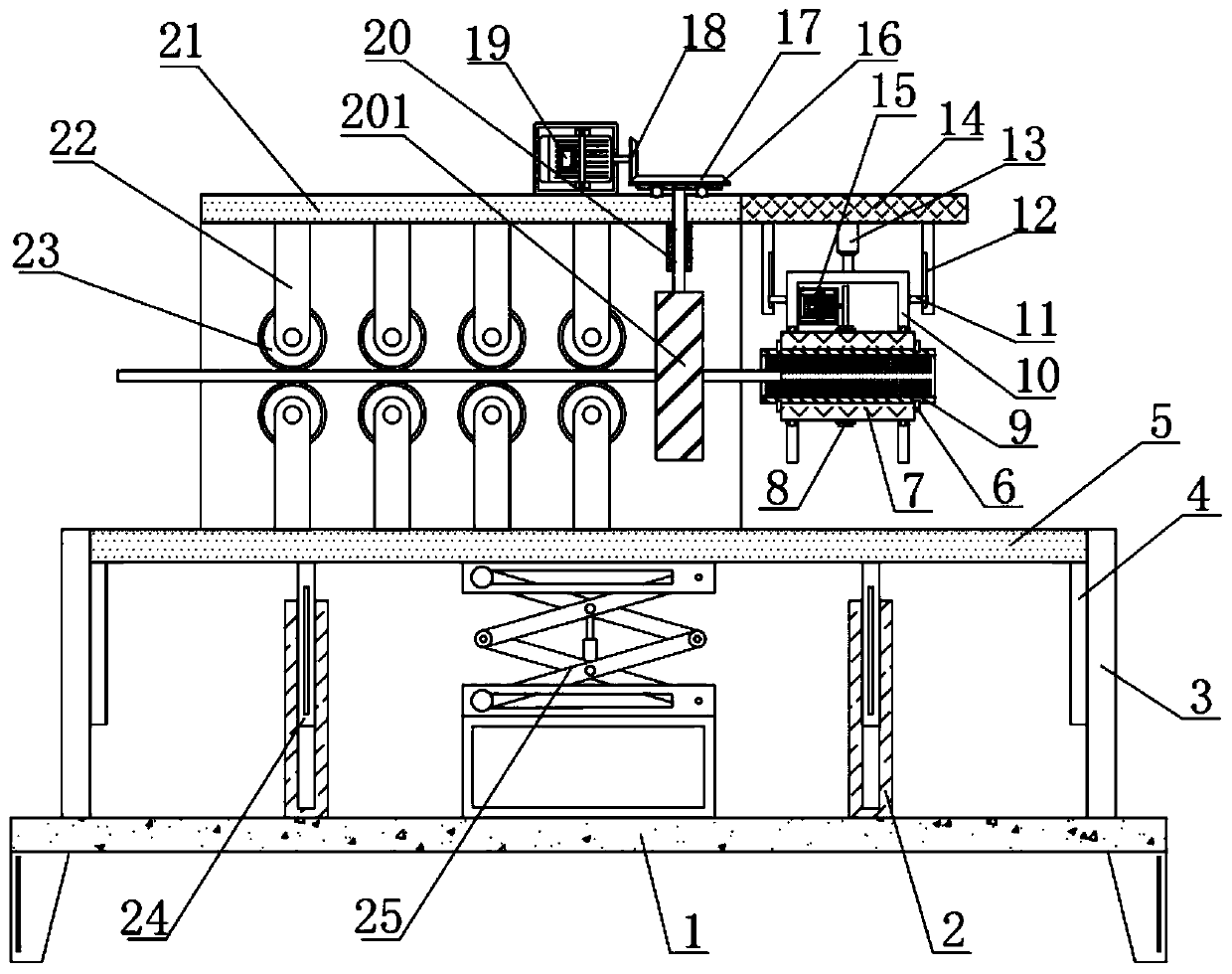

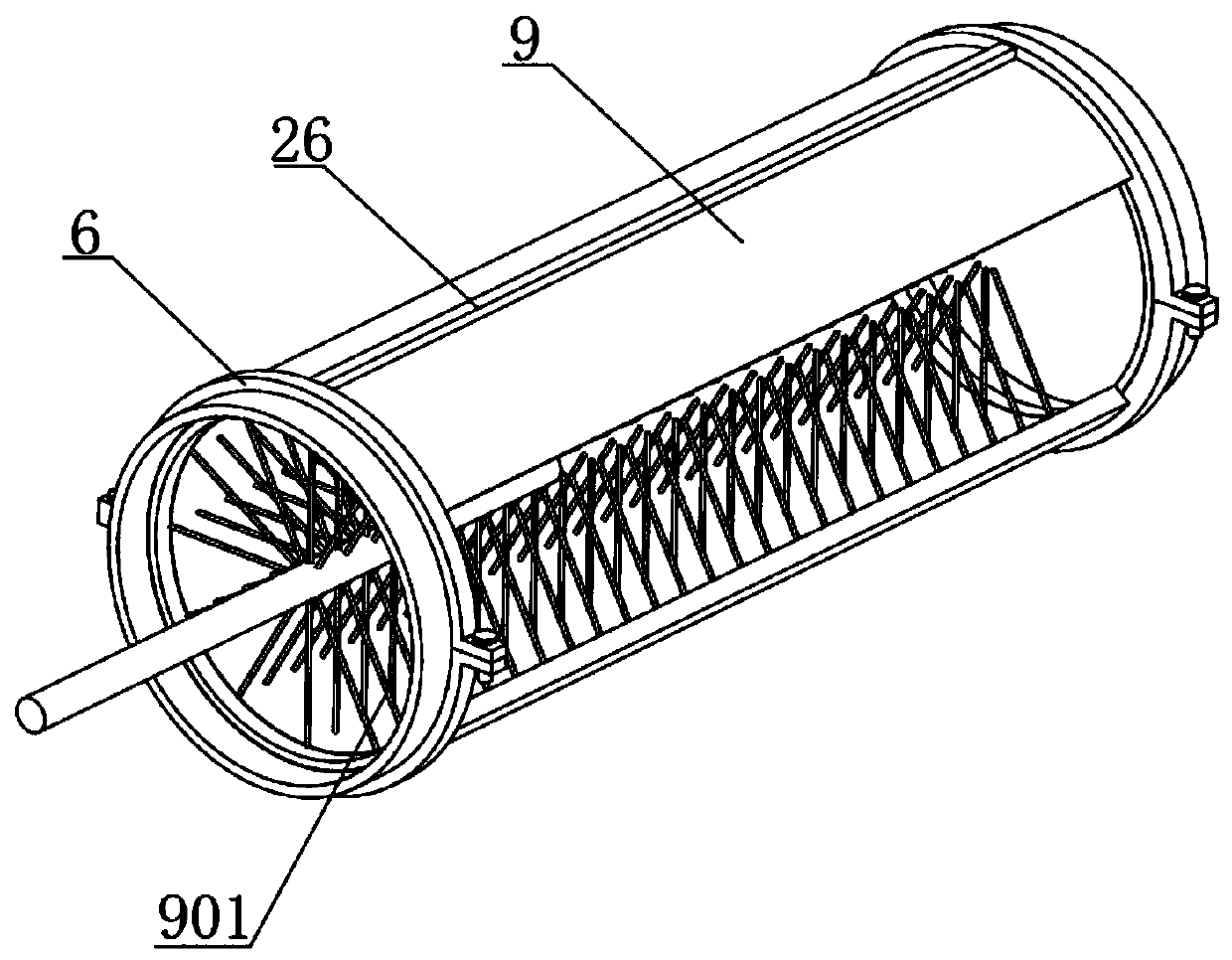

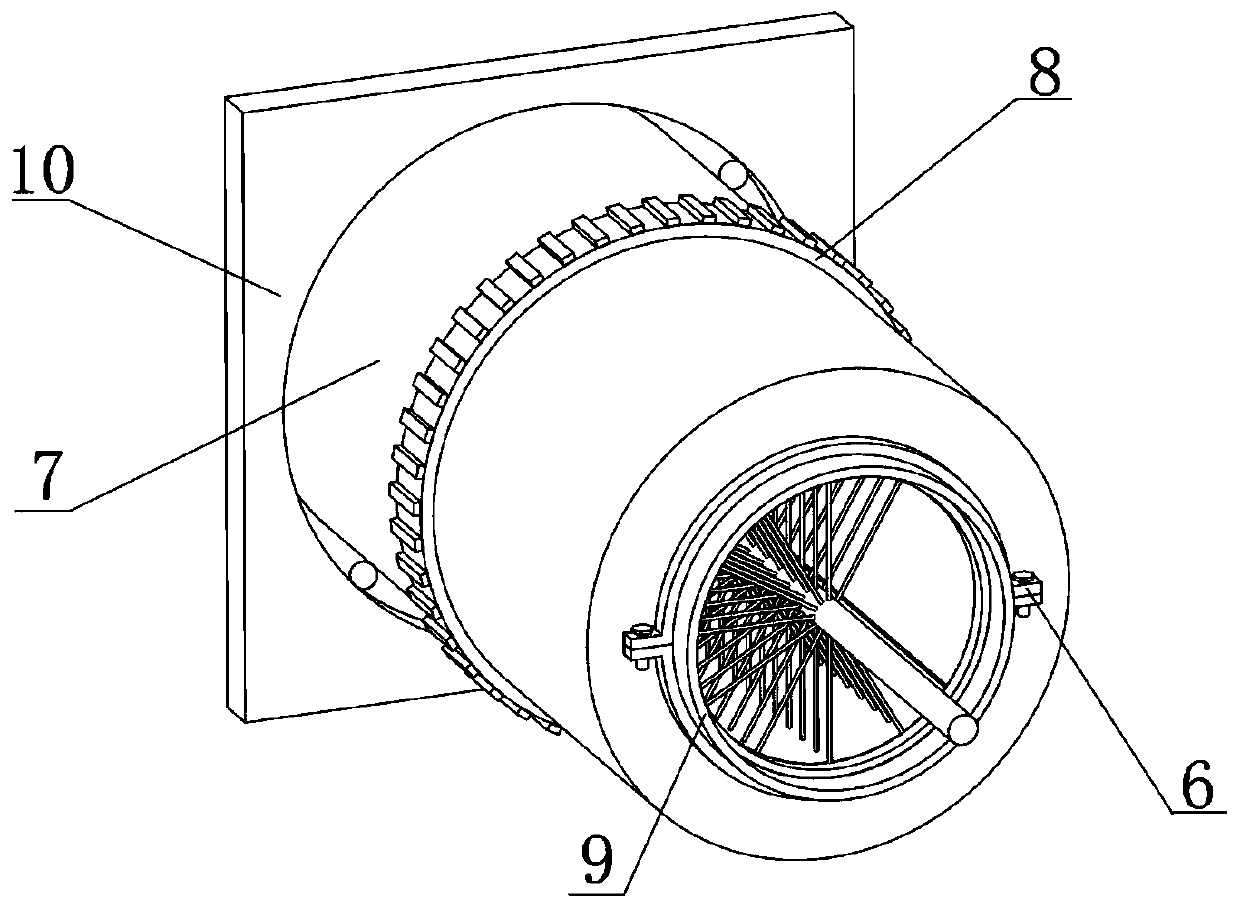

[0031] refer to Figure 1-4 , a steel bar surface derusting device for construction engineering, comprising a base 1 and a mounting plate 5 with legs welded at the four corners of the bottom, a lifting mechanism is installed on the opposite side of the base 1 and the mounting plate 5, and the top of the mounting plate 5 is installed Straightening box 21, the top side of straightening box 21 is horizontally welded with installation top plate 14, and installation top plate 14 is equipped with high-efficiency grinding mechanism, and the inner two ends of straightening box 21 are all welded with the support 22 of equidistant symmetrical distribution, and Corresponding to the two brackets 22, there are straightening rollers 23 connected in rotation. The straightening box 21 is equipped with a guide mechanism near the side where the top plate 14 is installed. The end of the extension rod of the rod 13 is fixed with a mounting bracket 10 by bolts, and the mounting bracket 10 is rotat...

Embodiment 2

[0042] refer to figure 1 and Figure 5 , a steel bar surface derusting device for construction engineering. Compared with Embodiment 1, this embodiment also includes a reinforcement mechanism installed on the opposite side of the base 1 and the mounting plate 5, and the reinforcement mechanism includes two welded on both sides of the base 1. The cylinder body 2, the inner wall of the cylinder body 2 is all slidably connected with a reinforcing rod 24, the top of the reinforcing rod 24 is welded to the mounting plate 5, and the peripheral outer wall of the reinforcing rod 24 is welded with a semicircular protruding rod 27.

[0043] When the present invention is in use: through the setting of the reinforcing rod 24 and the cylinder body 2, the support and positioning effects thereof are used to effectively improve the stability of the mounting plate 5 when it moves up and down, and the semicircular protruding rod 27 provided prevents the reinforcing rod 24 from contacting the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com