Patents

Literature

387results about How to "Easy to straighten" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

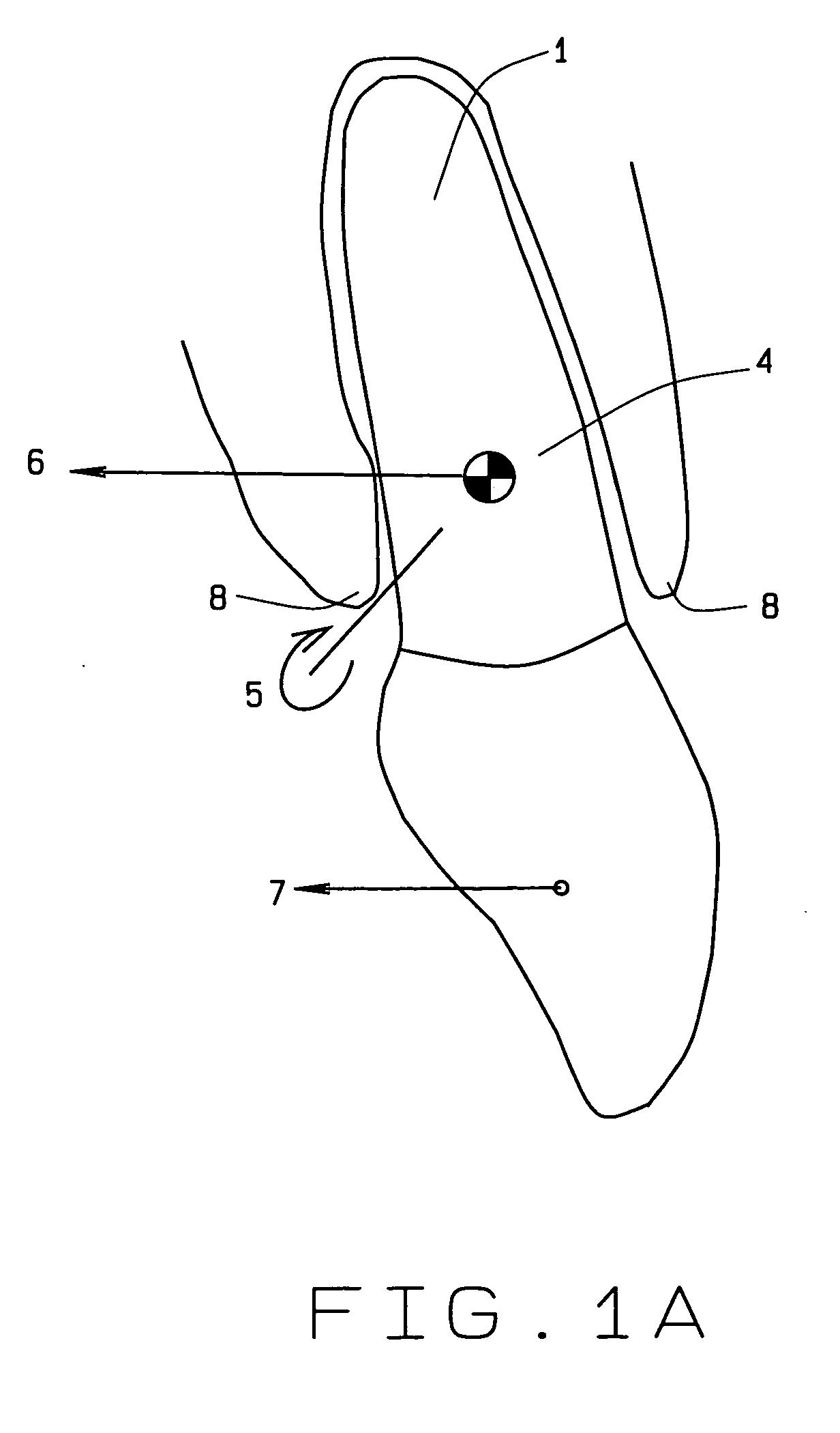

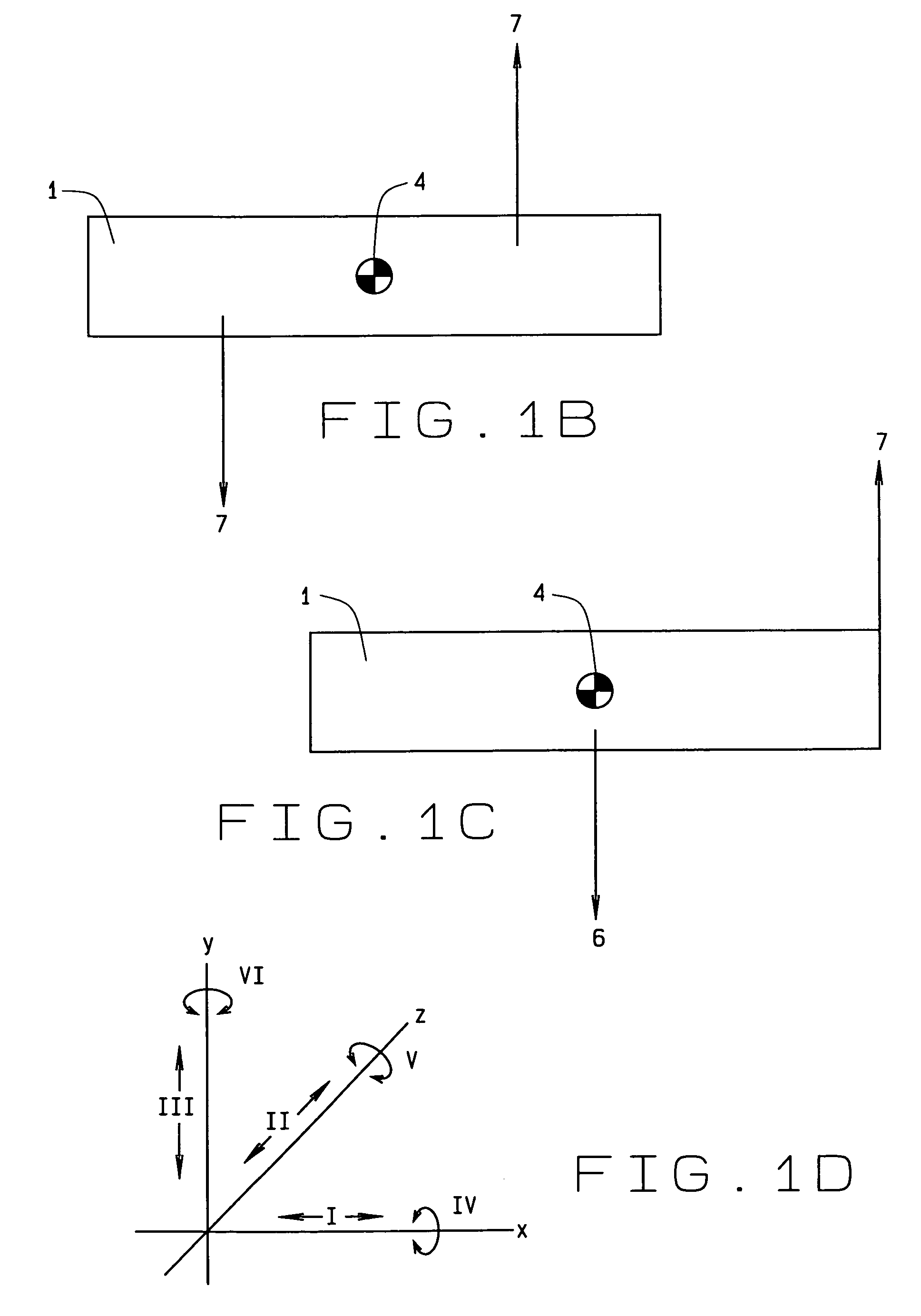

System and method for improved control of tooth movement with elastic repositioning appliances

InactiveUS20060223022A1Easy to controlGood tooth alignmentOthrodonticsDental toolsElectrical resistance and conductanceCoupling

Micro-regional force application improves the control of the orthodontic movement of teeth in all six degrees of freedom. Micro regional force application utilizes an elastic repositioning appliance, a tooth positioner, a polymeric shell, or preprogrammed series of polymeric shells. The key components of the invention are the envelope of freedom, the force applicators, force couplers, counterpart coupling, vector modifiers, seating guides, decouplers, and forced balance points. Further, computerized finite element analysis determines the center of resistance and the center of rotation for each tooth to be moved. The present invention gently rotates and translates one or more teeth to a desired straight position within a treatment plan.

Owner:SOLOMON FREDERICK

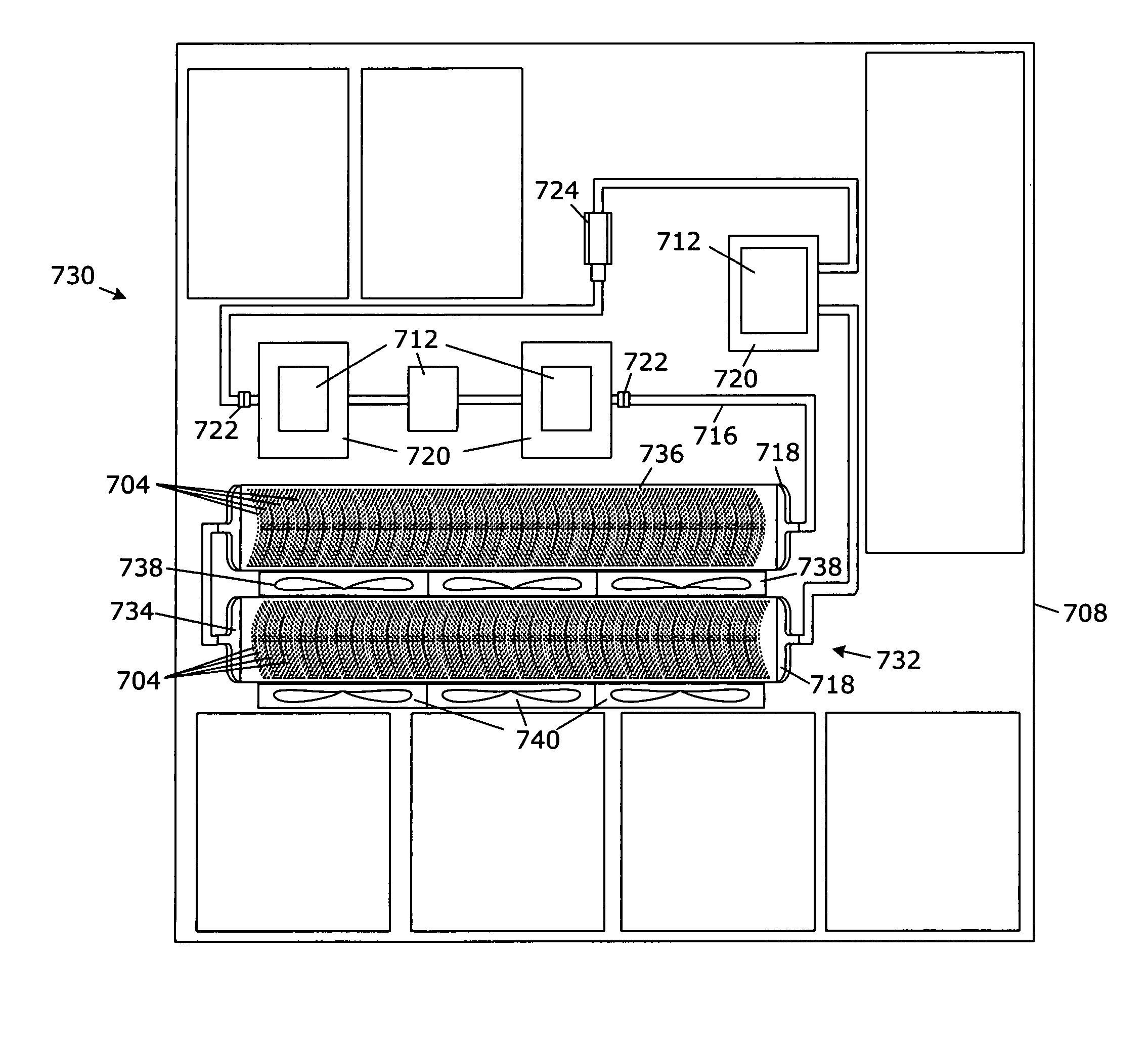

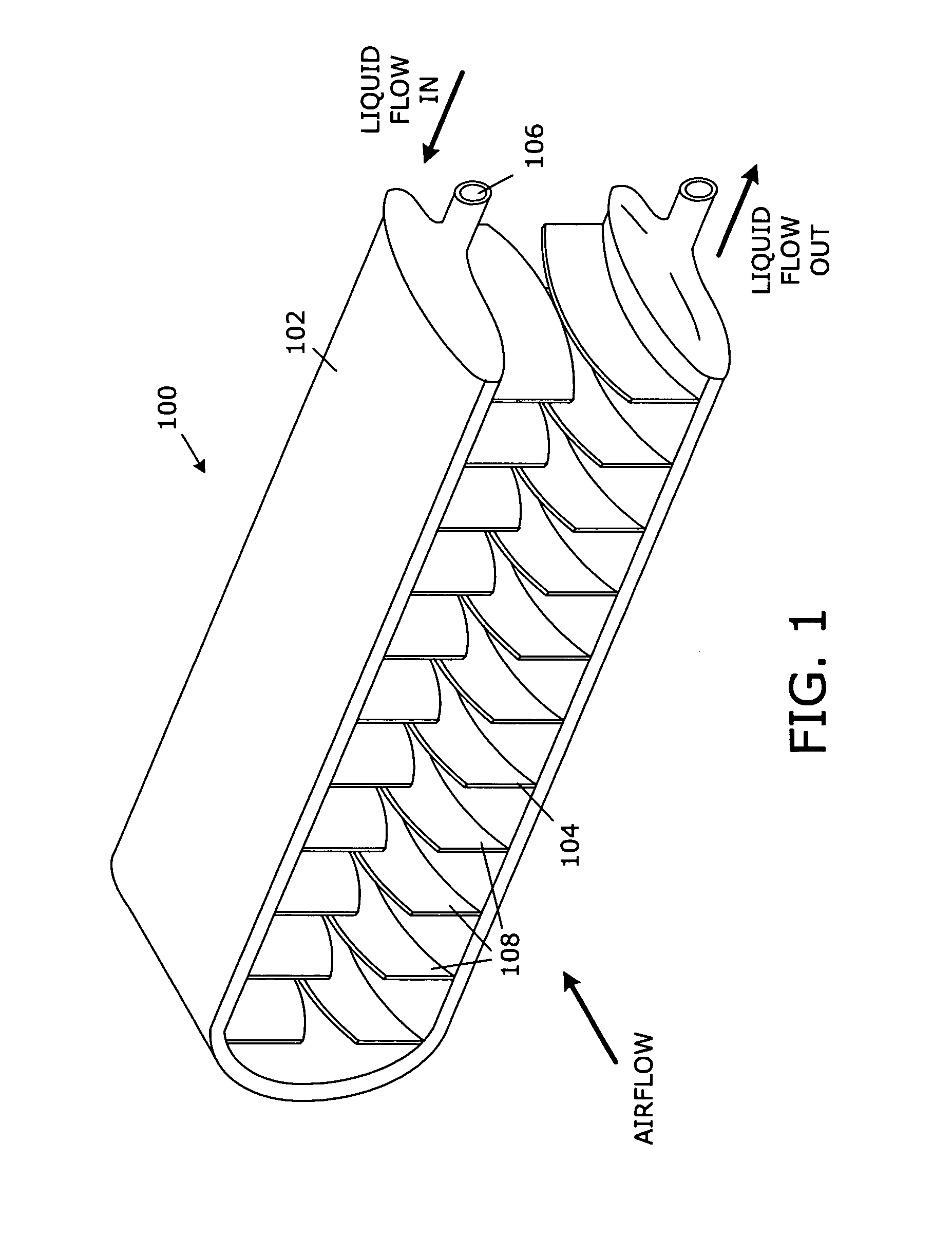

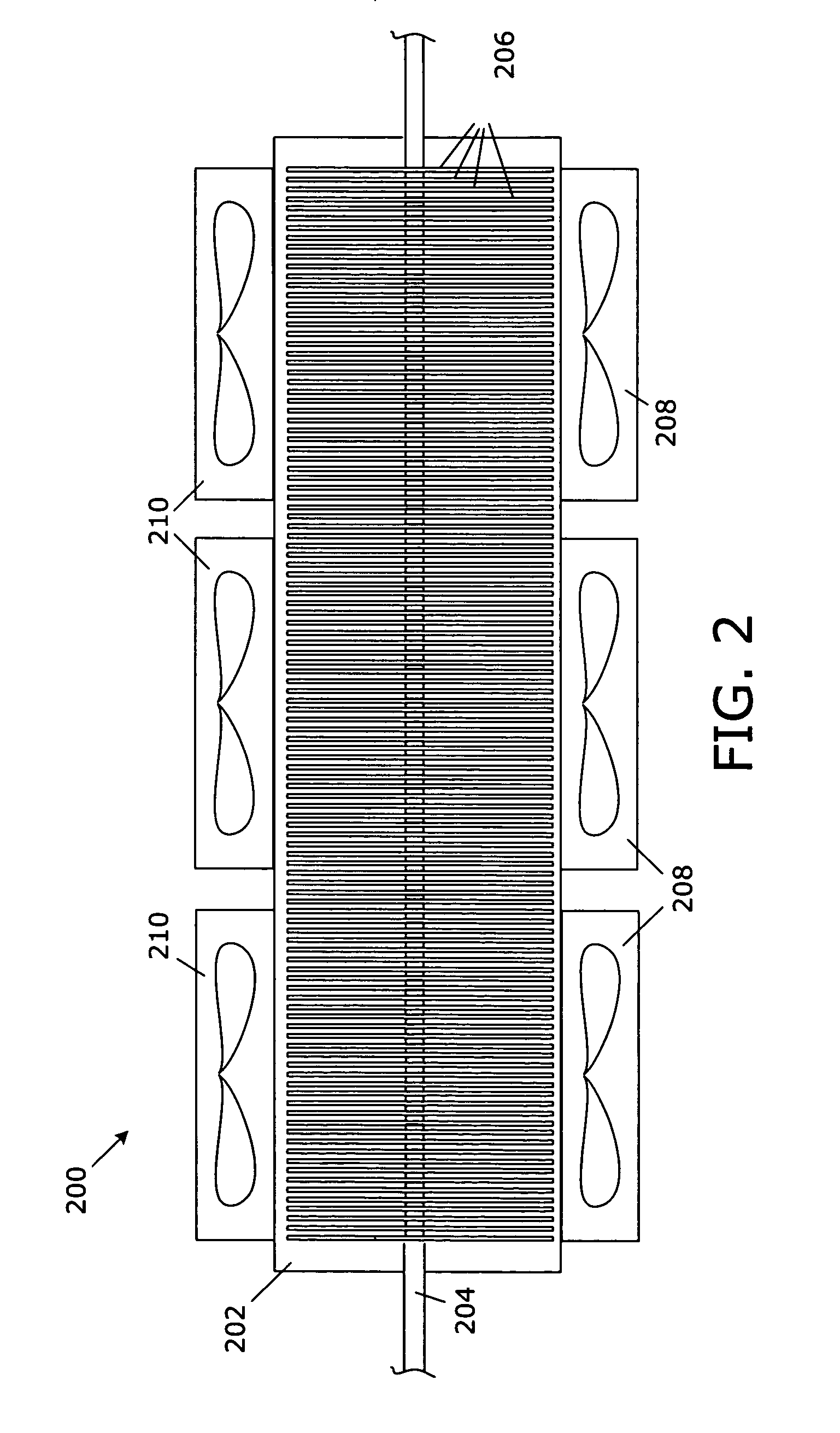

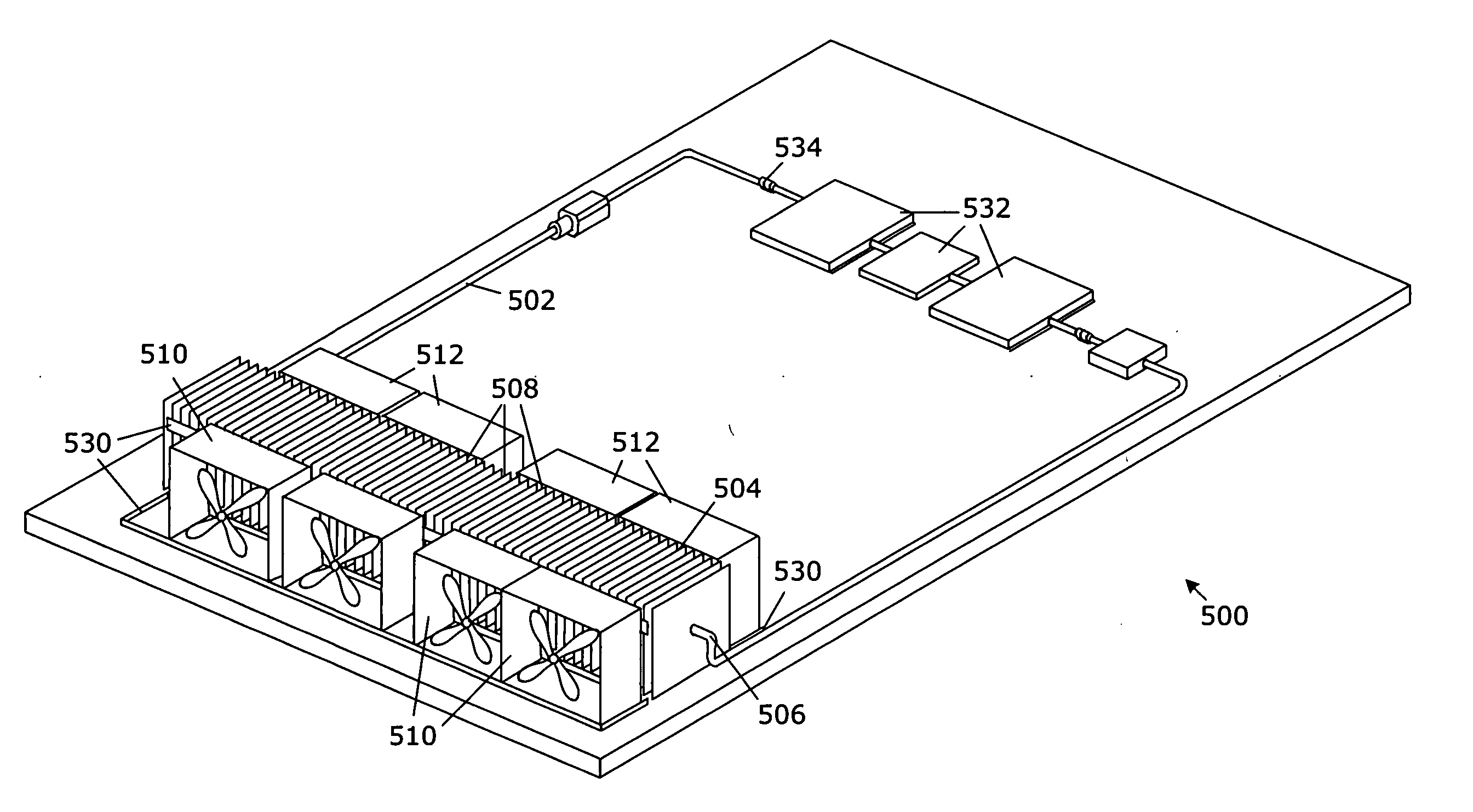

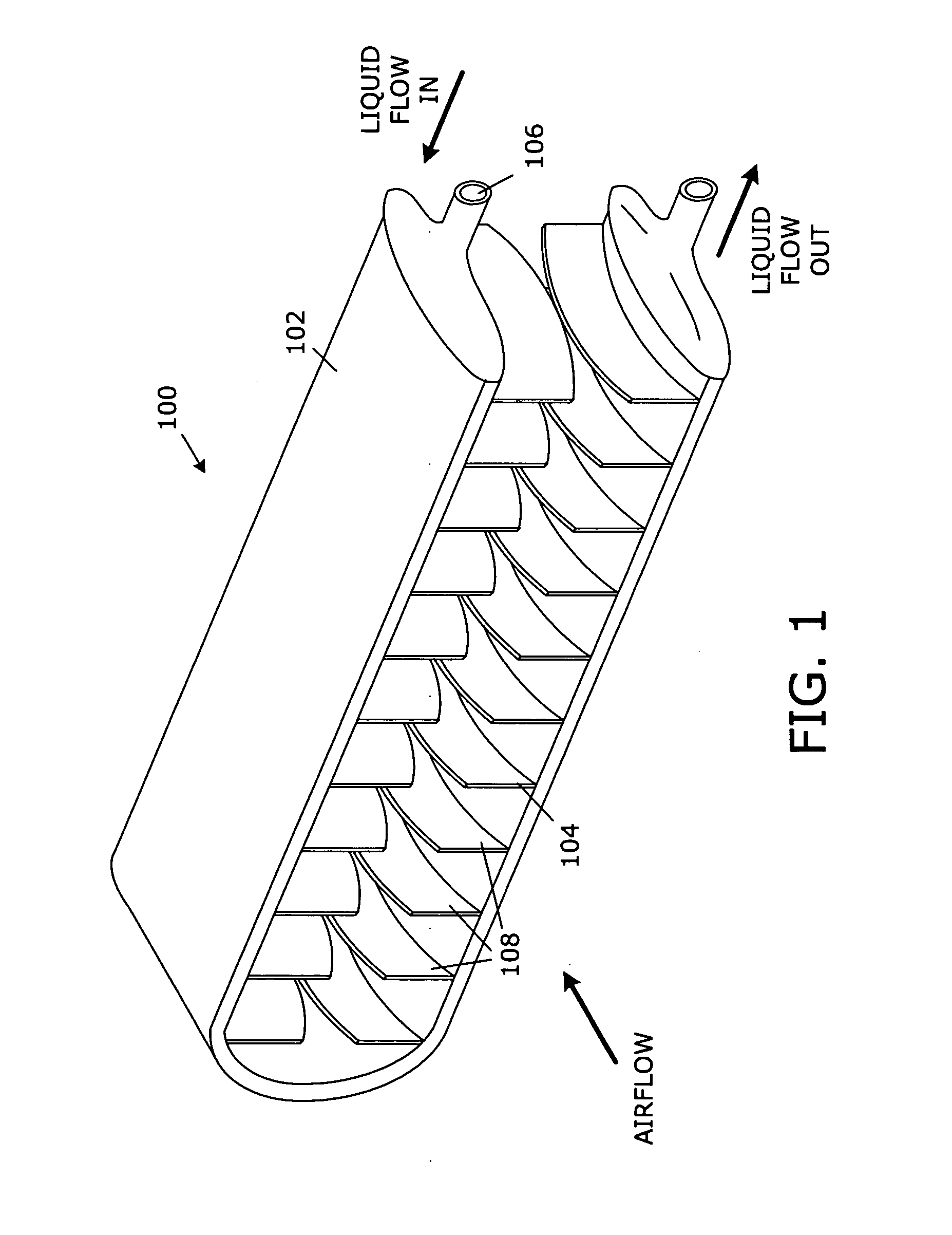

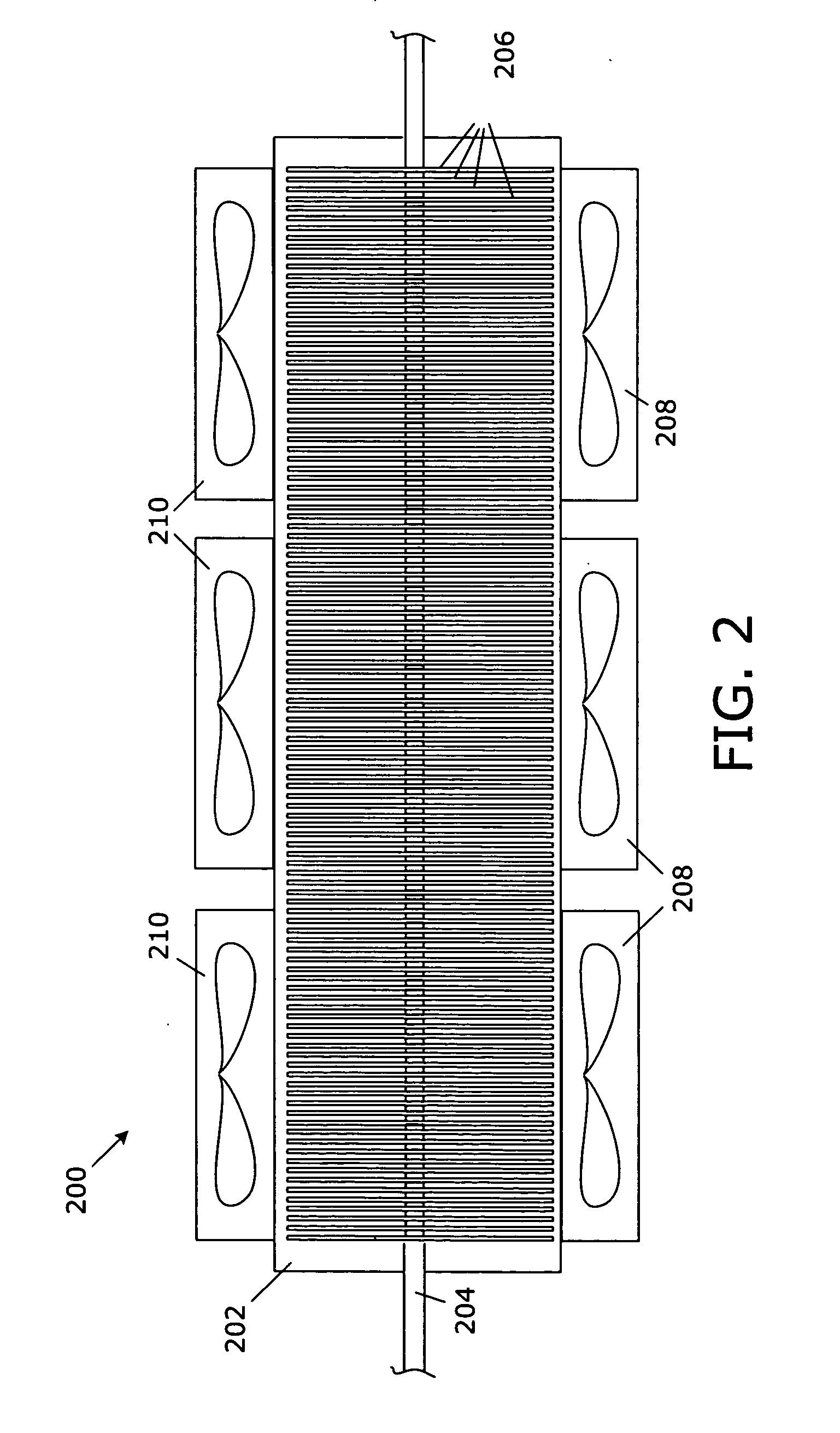

Heat exchanger including flow straightening fins

ActiveUS7142424B2Easy to straightenDomestic cooling apparatusDigital data processing detailsPlate heat exchangerEngineering

A heat exchanger includes a tube, and a plurality of fins coupled to the tube having a curved fan-stator shape that facilitates straightening of airflow from a fan.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

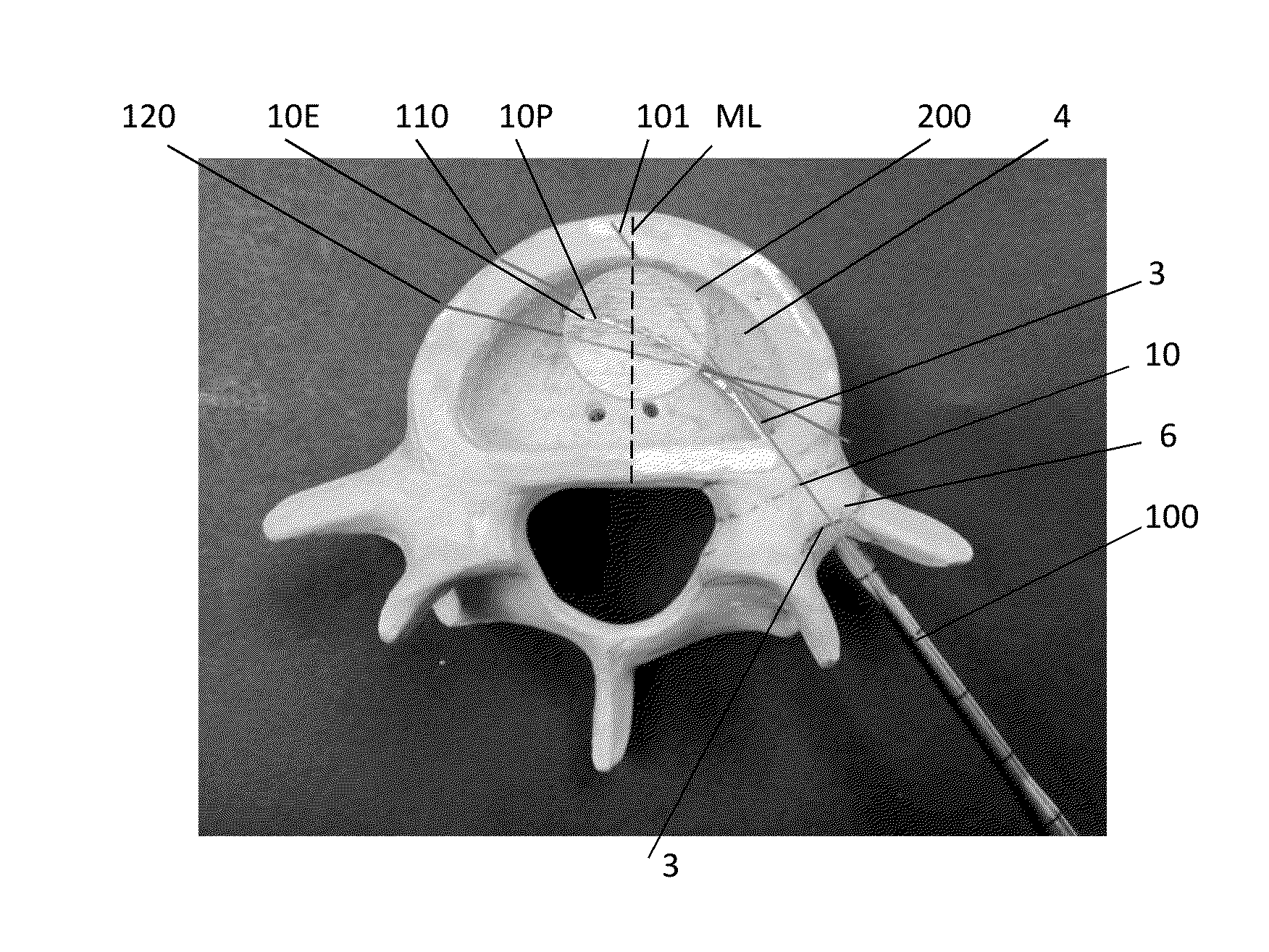

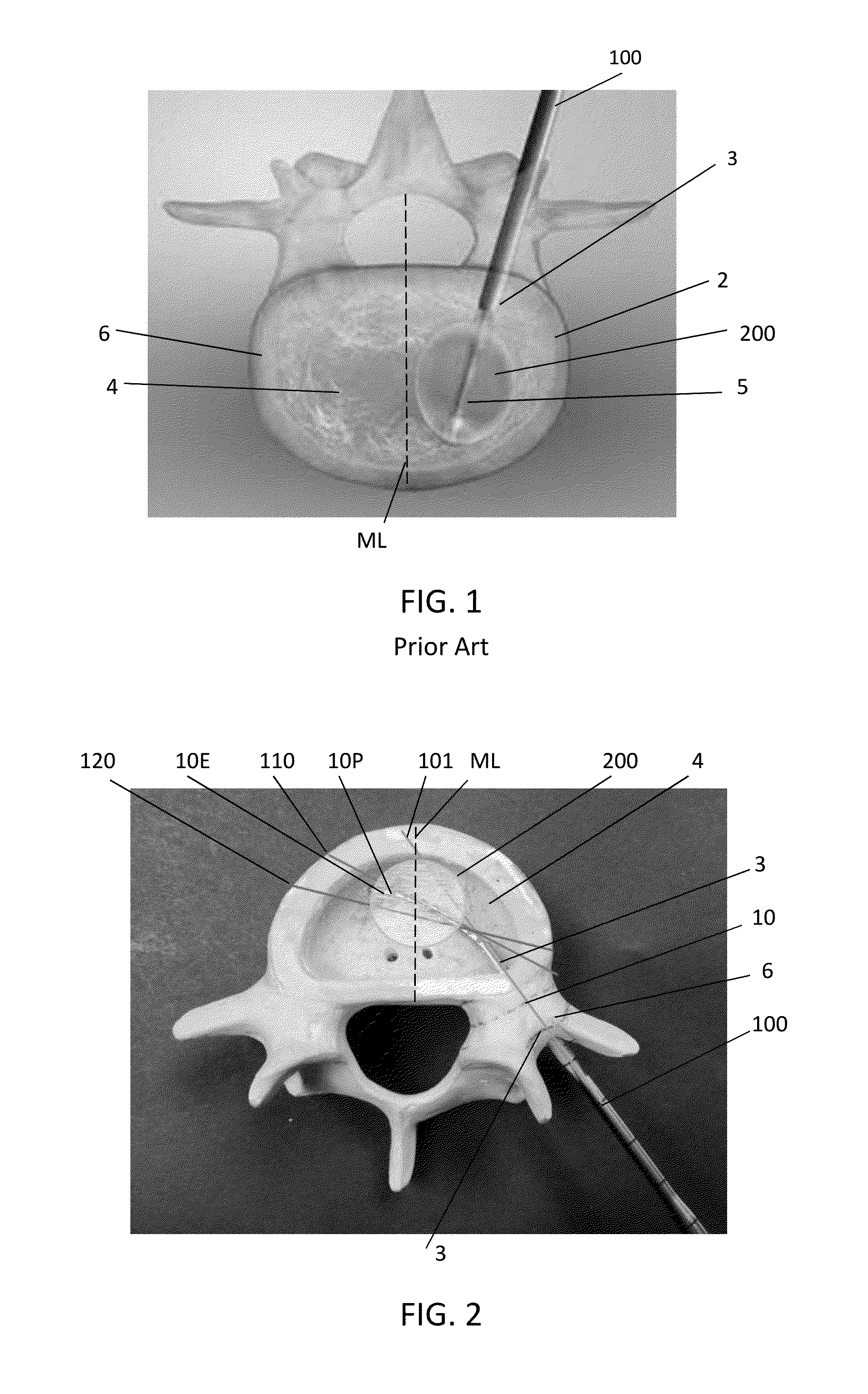

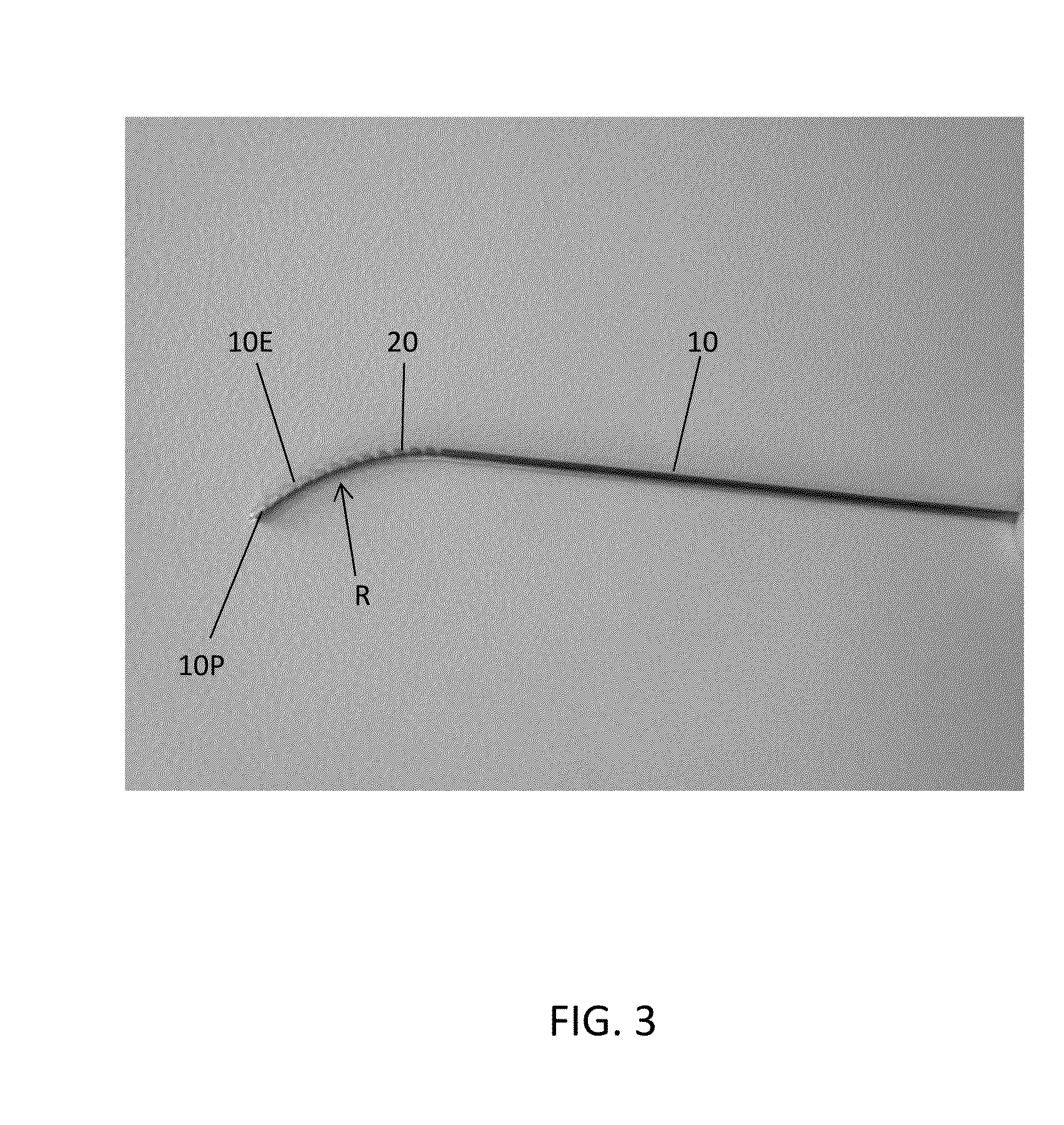

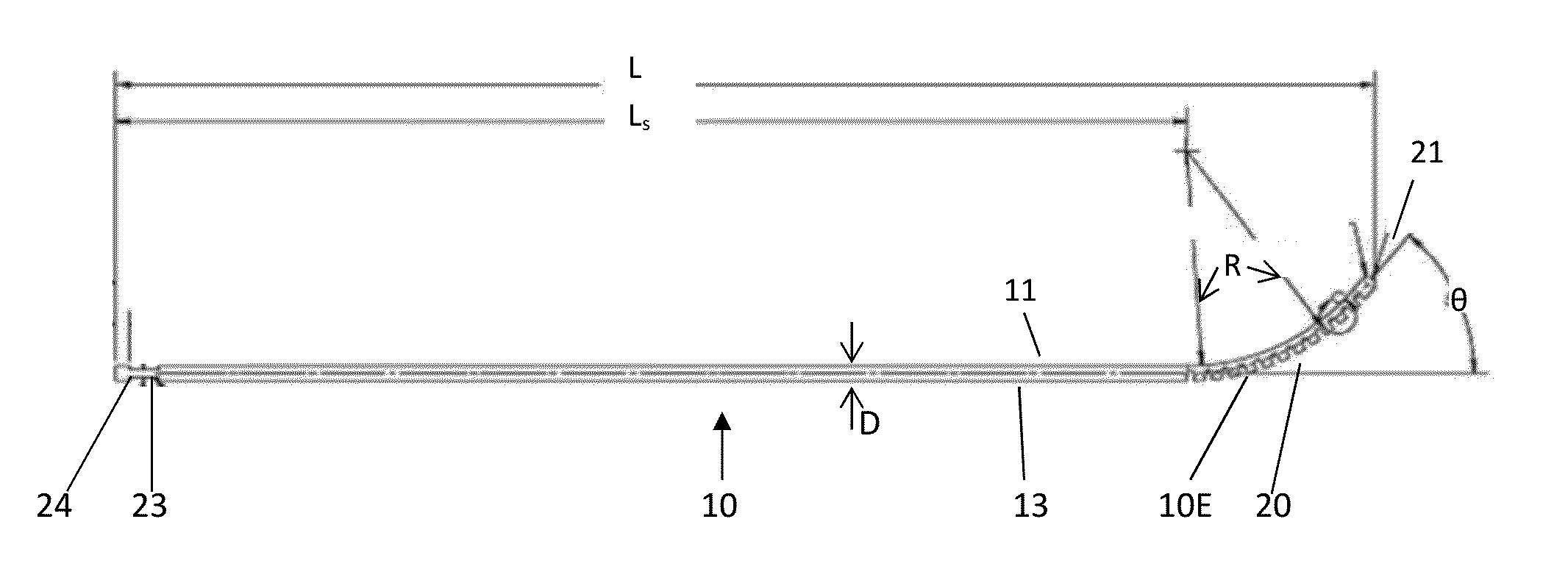

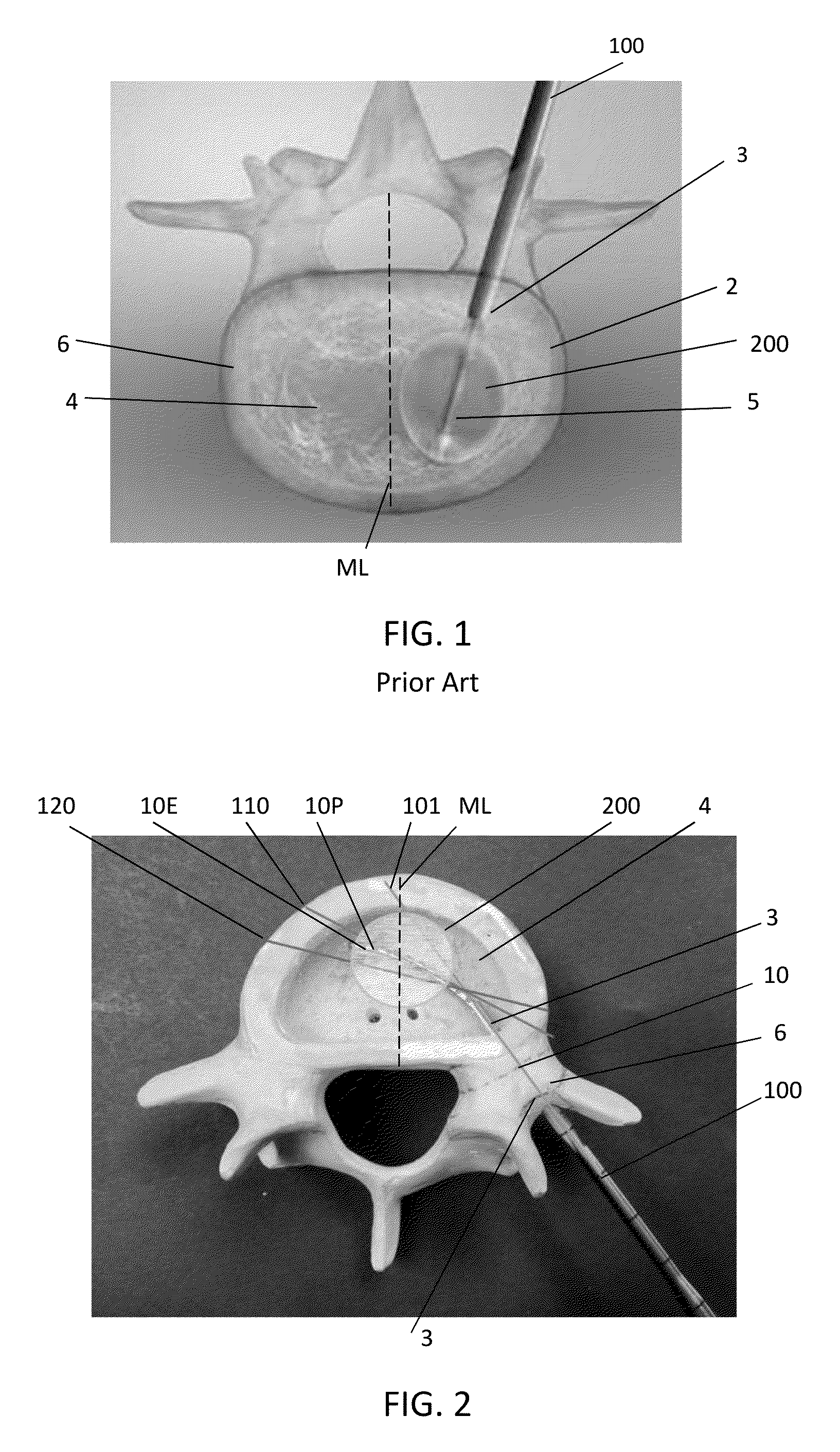

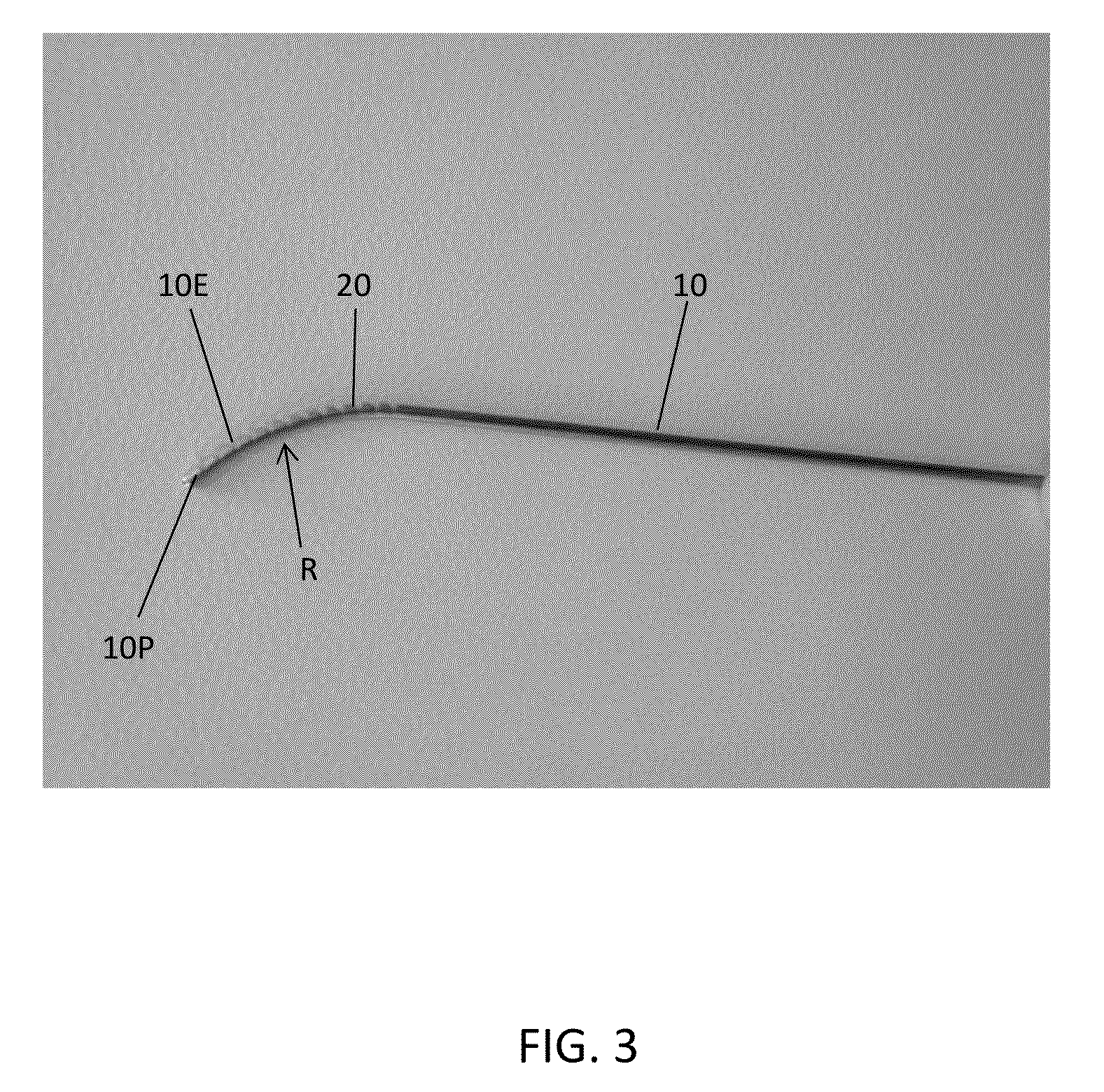

Tunneling device

ActiveUS20150182234A1Sufficient flexibilityEasy to straightenInternal osteosythesisBone drill guidesEngineeringMechanical engineering

Owner:SPINAL ELEMENTS INC

Tunneling device

Owner:SPINAL ELEMENTS INC

Heat exchanger including flow straightening fins

ActiveUS20050243514A1Easy to straightenDomestic cooling apparatusDigital data processing detailsStatorAirflow

A heat exchanger includes a tube, and a plurality of fins coupled to the tube having a curved fan-stator shape that facilitates straightening of airflow from a fan.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

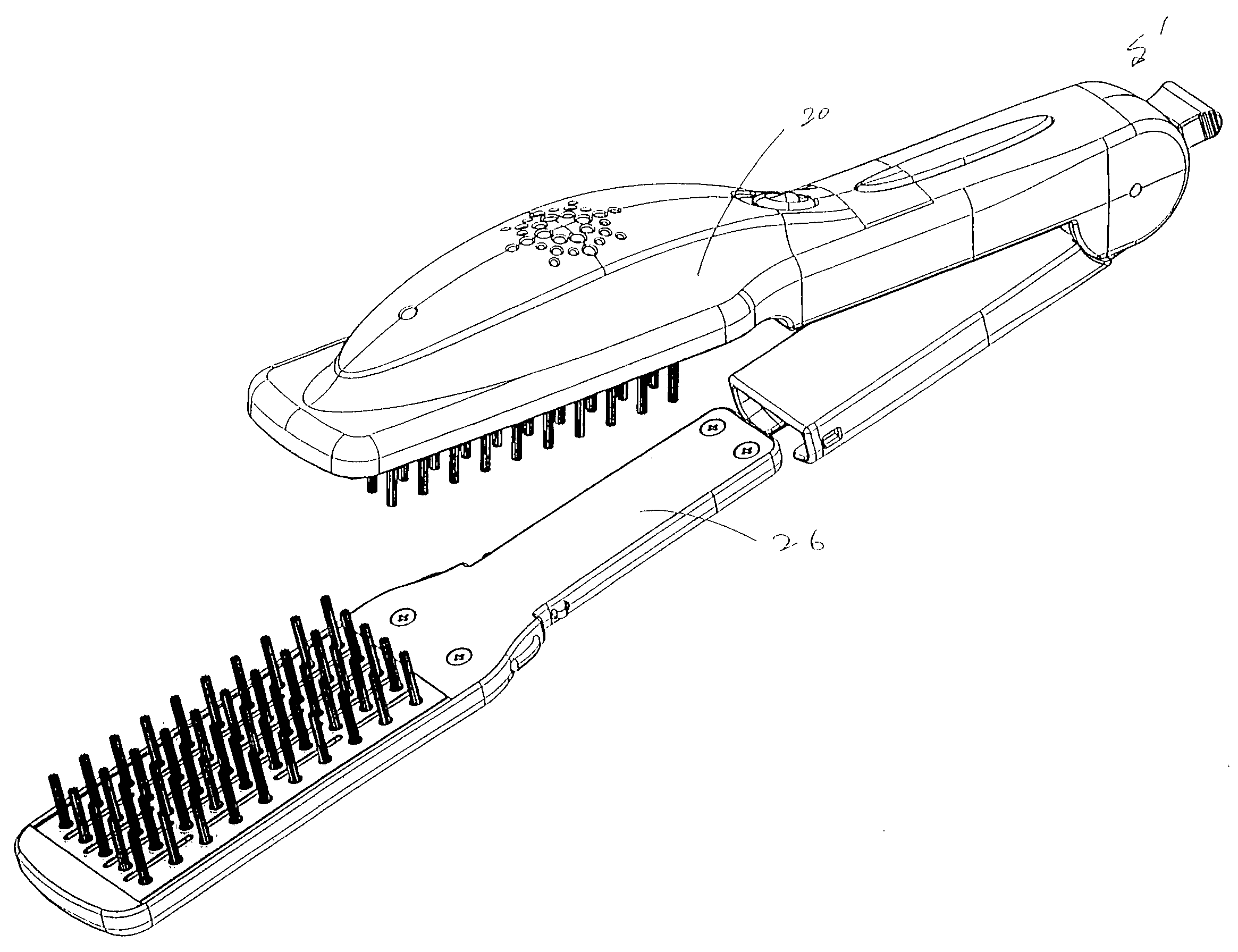

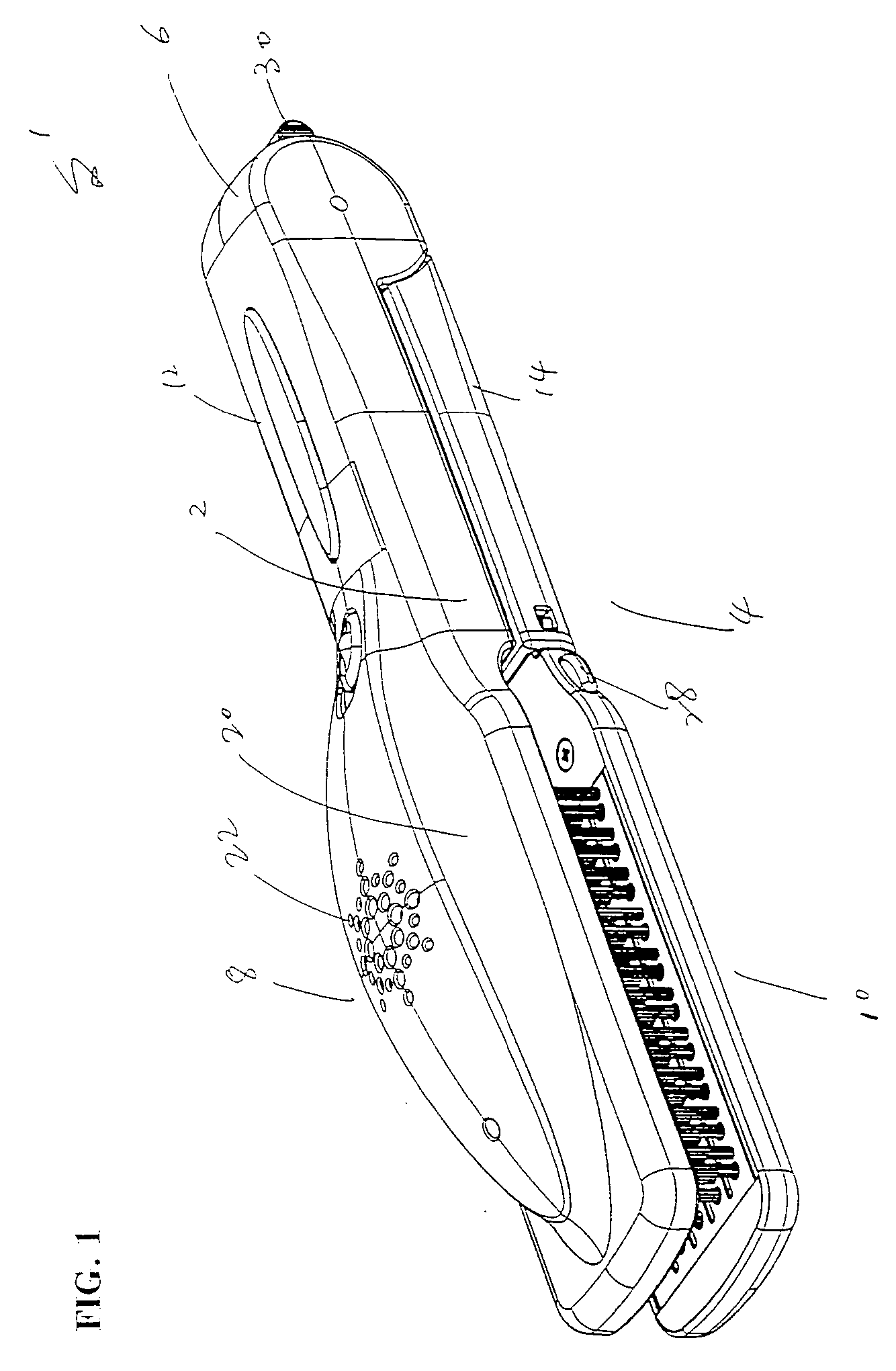

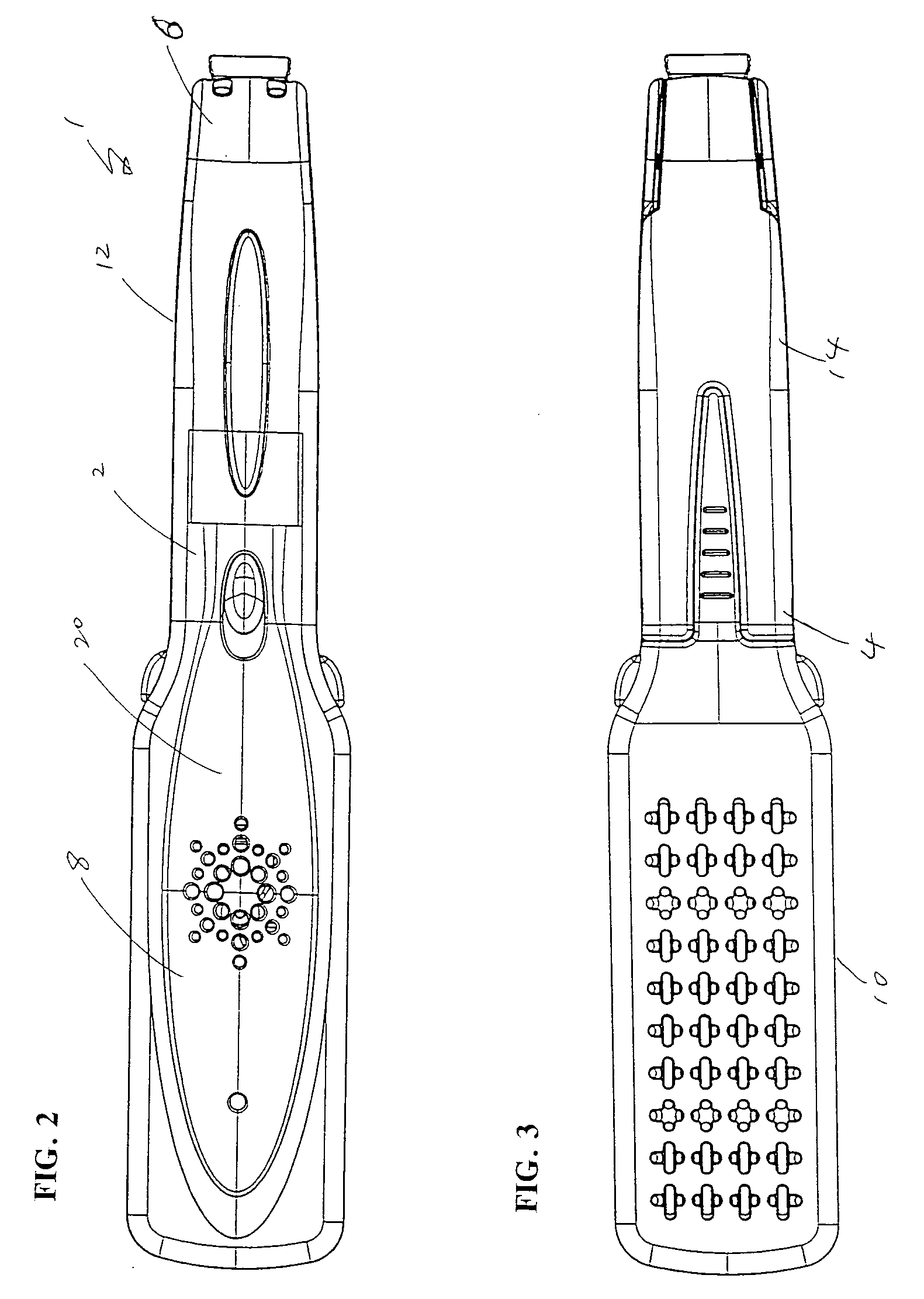

Device for treating hair

InactiveUS20050076930A1Easy to straightenConvenient treatmentBrushesCurling devicesBiomedical engineeringHair characteristics

Owner:SUN LUEN ELECTRICAL MFG

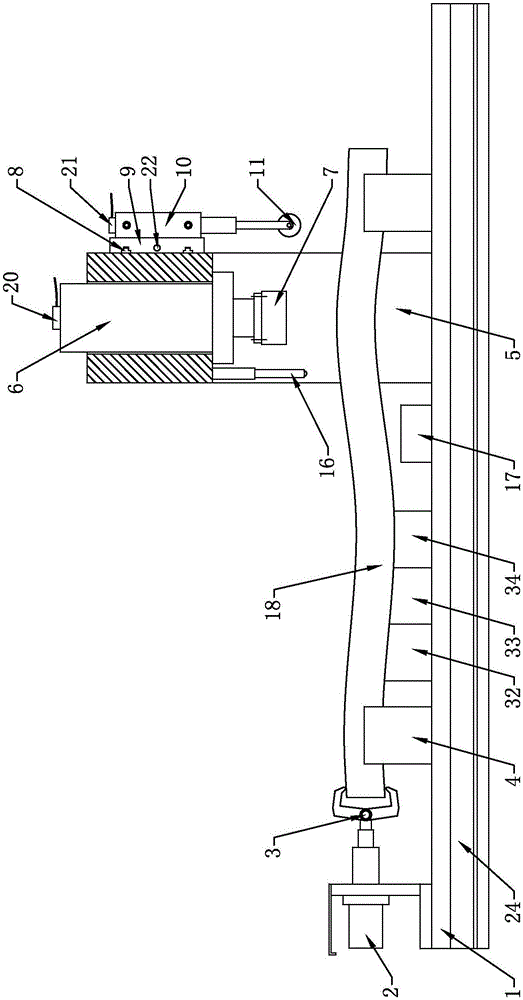

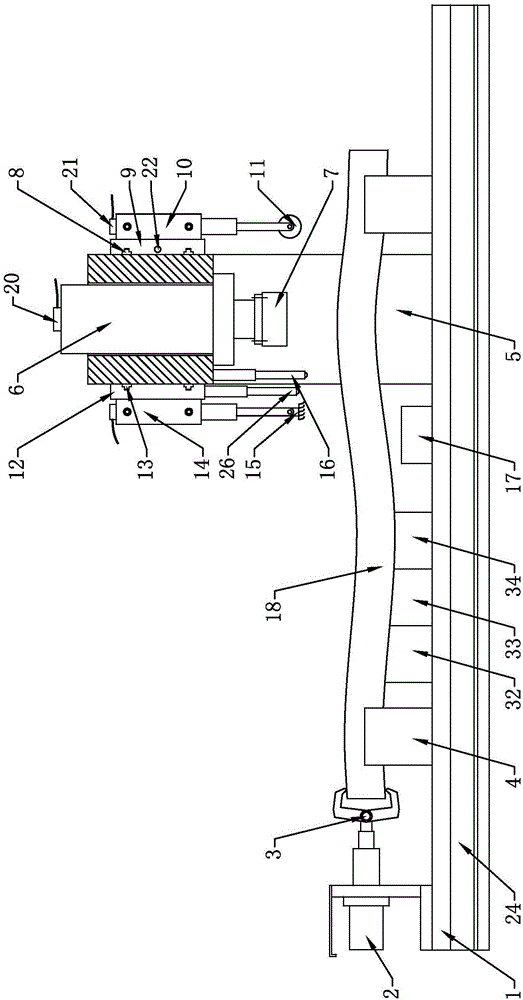

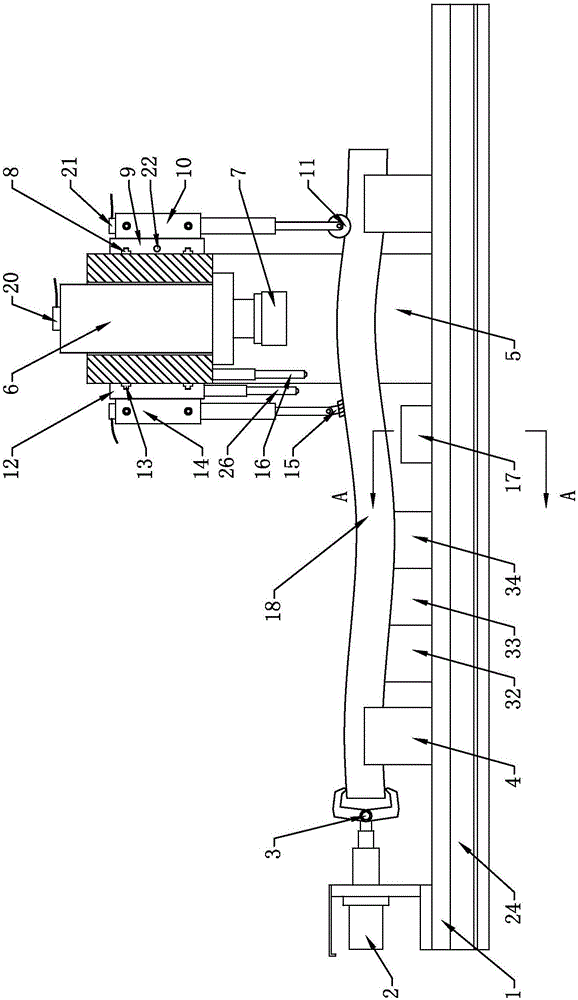

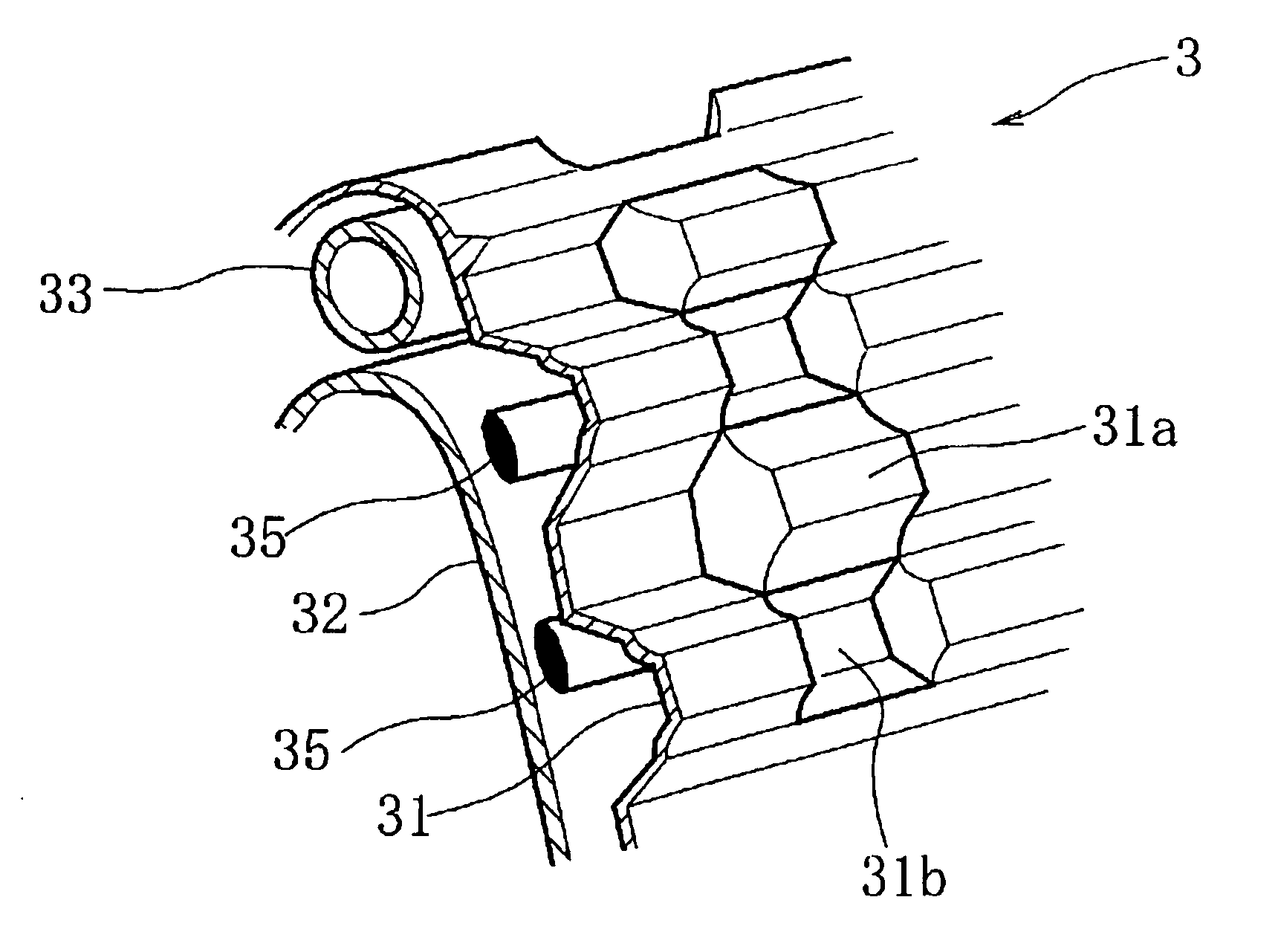

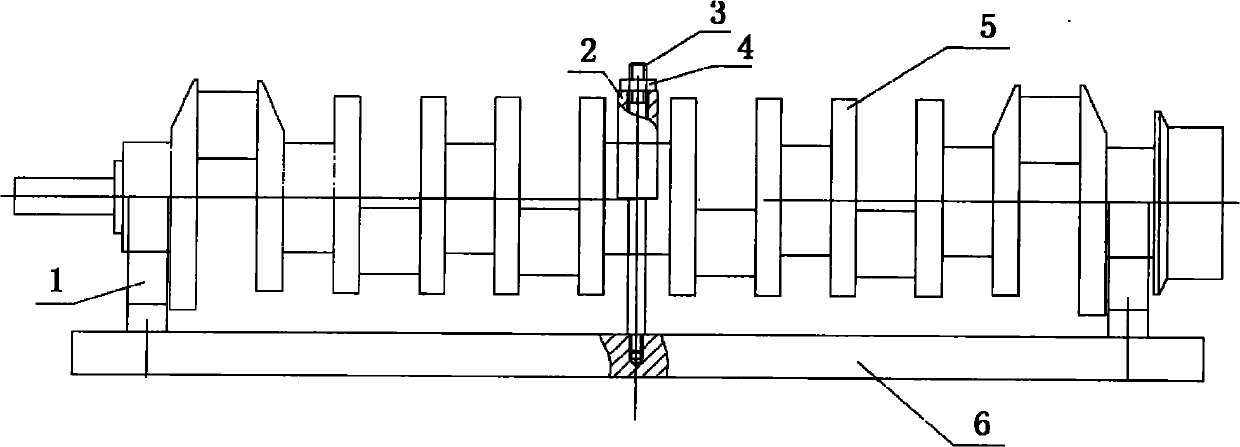

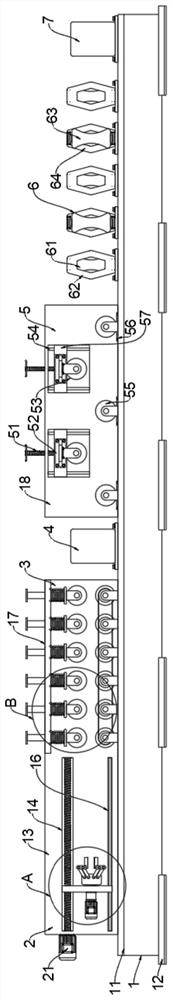

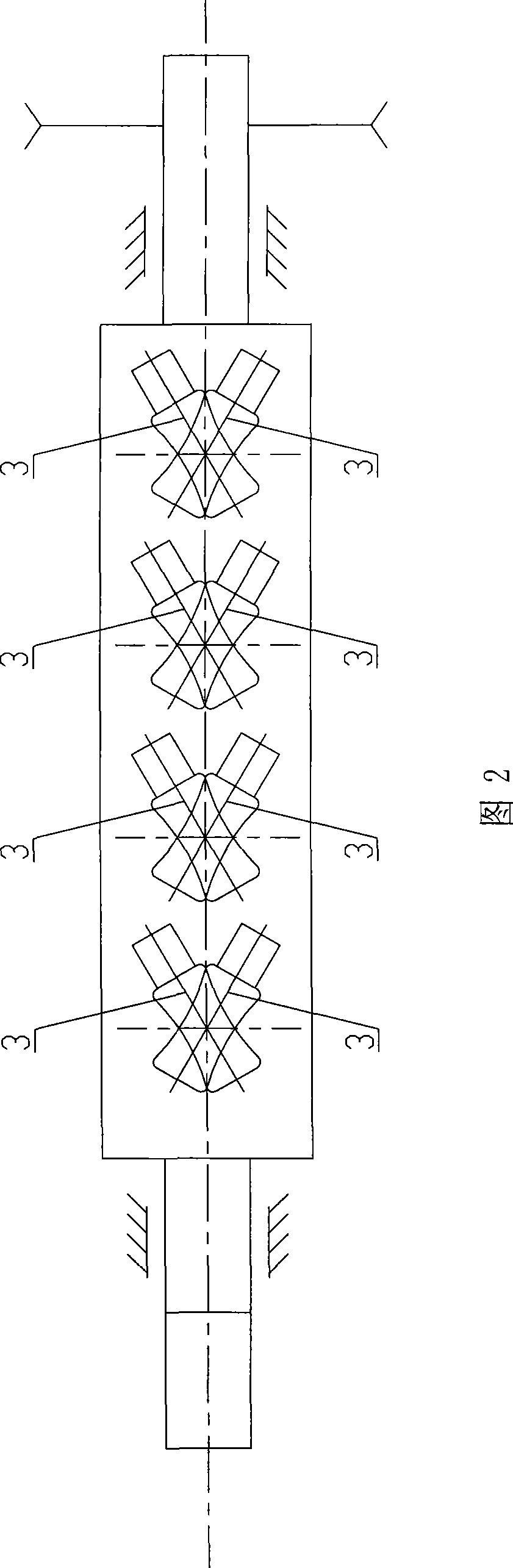

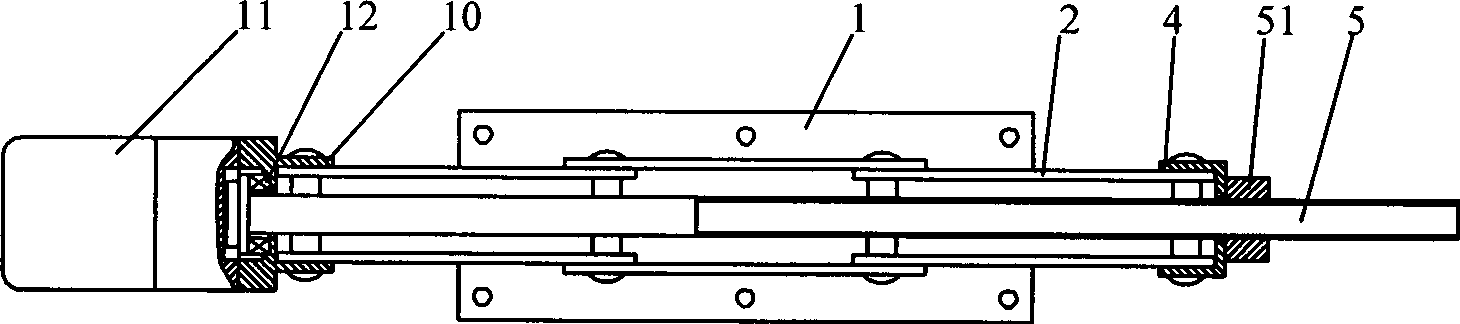

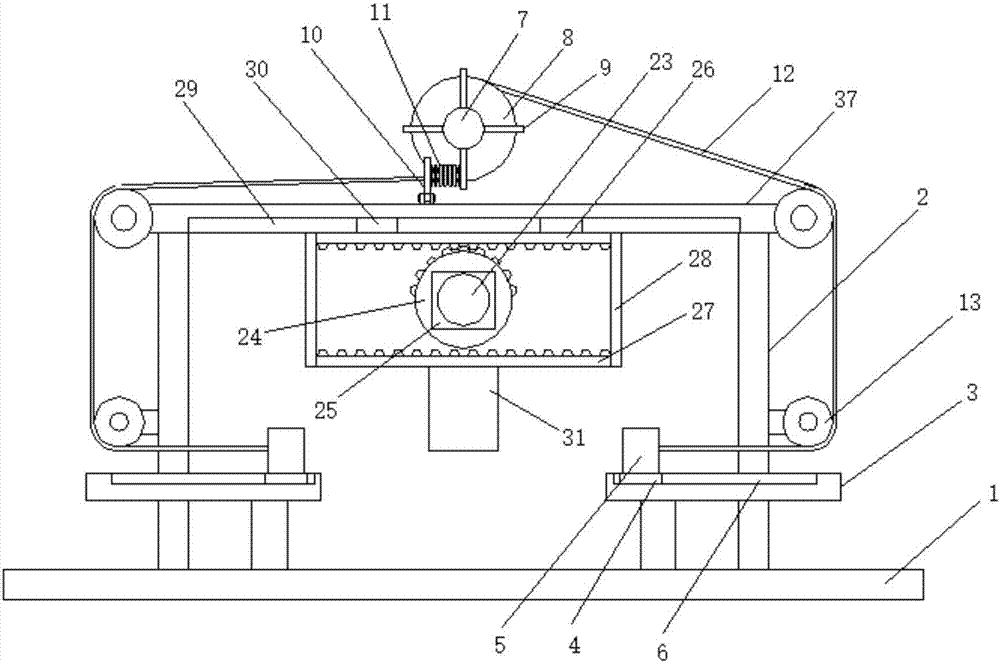

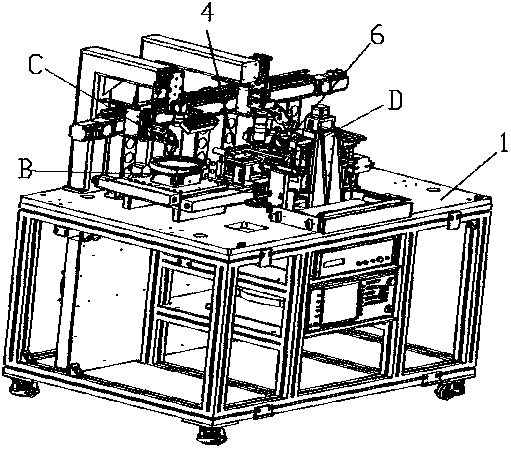

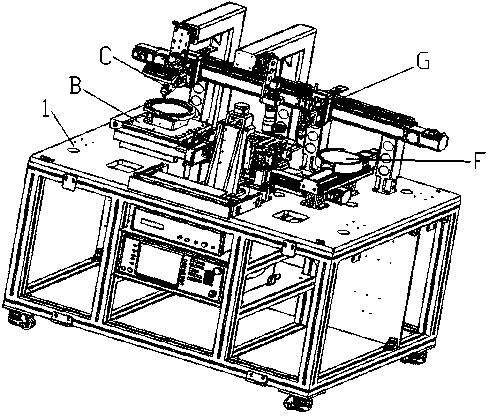

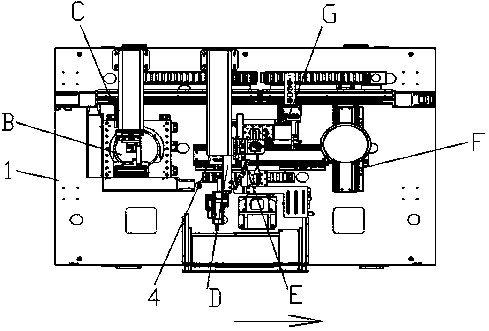

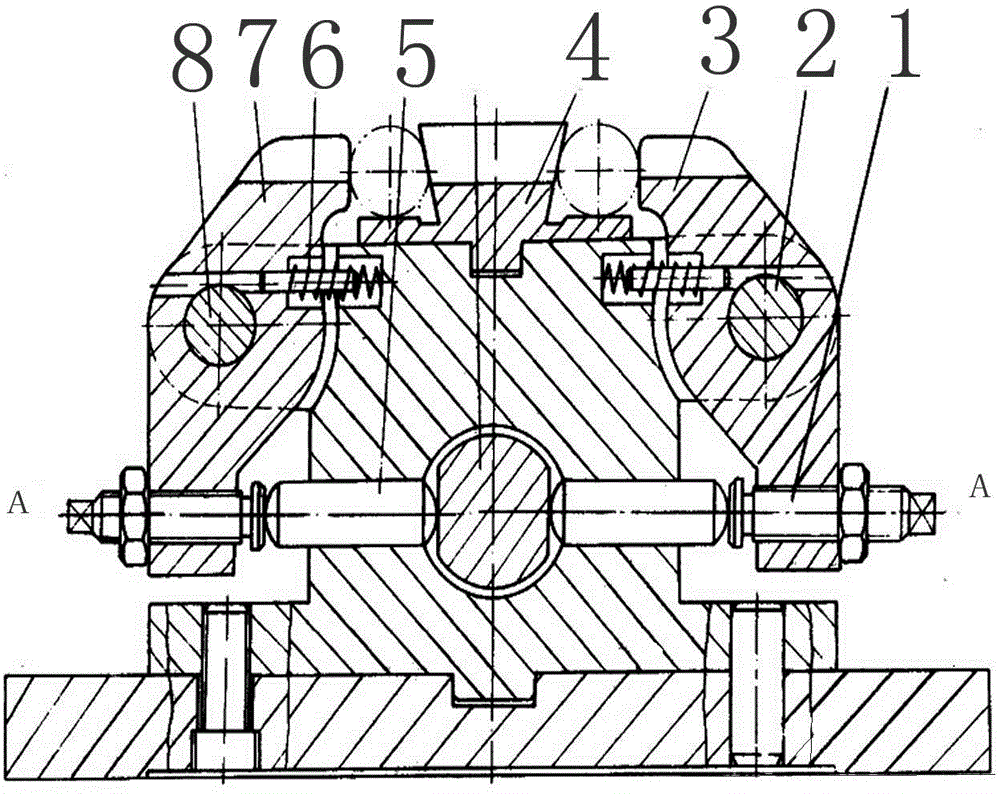

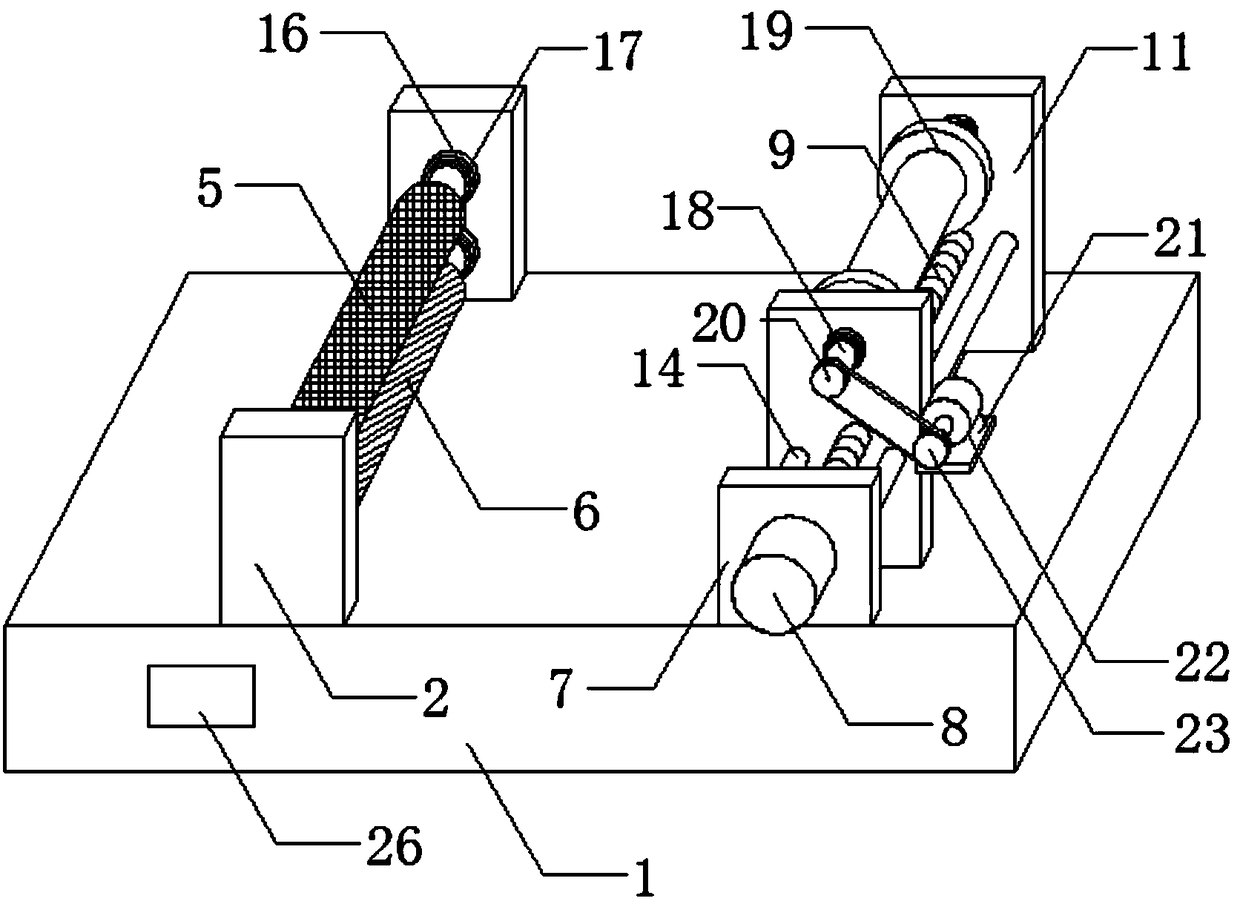

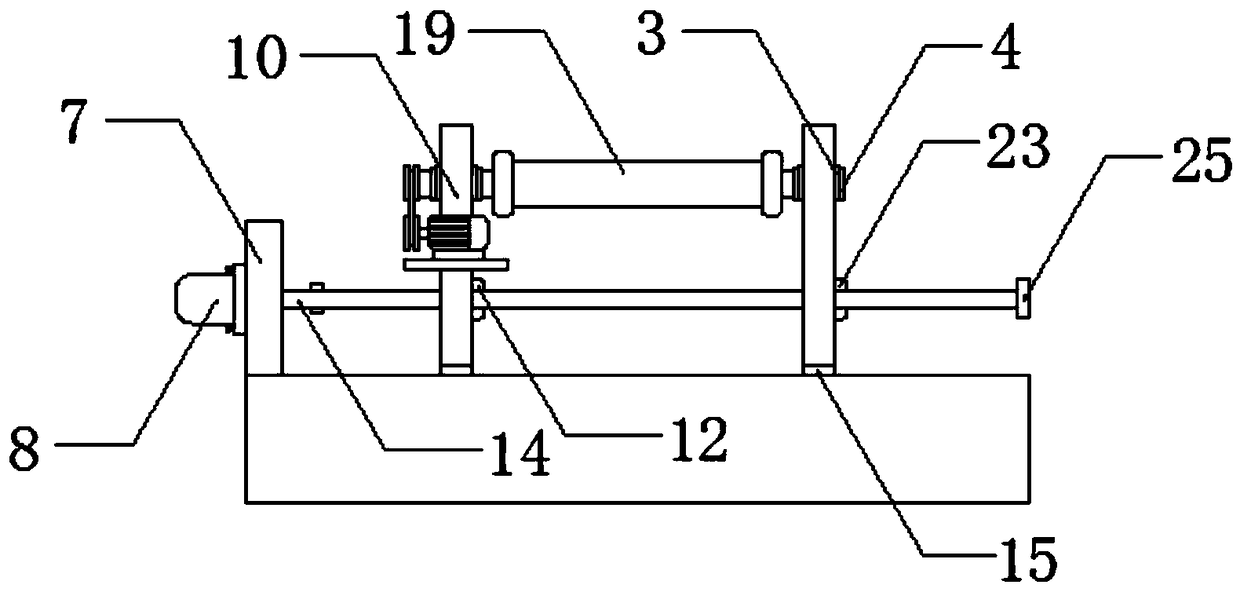

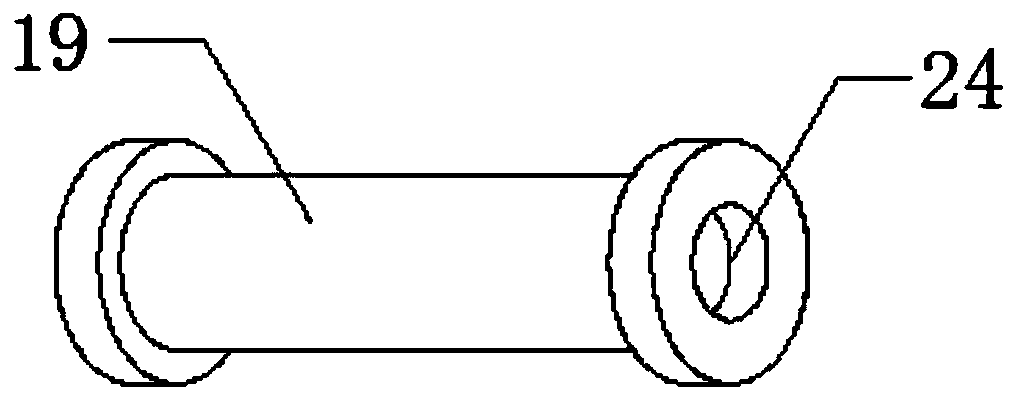

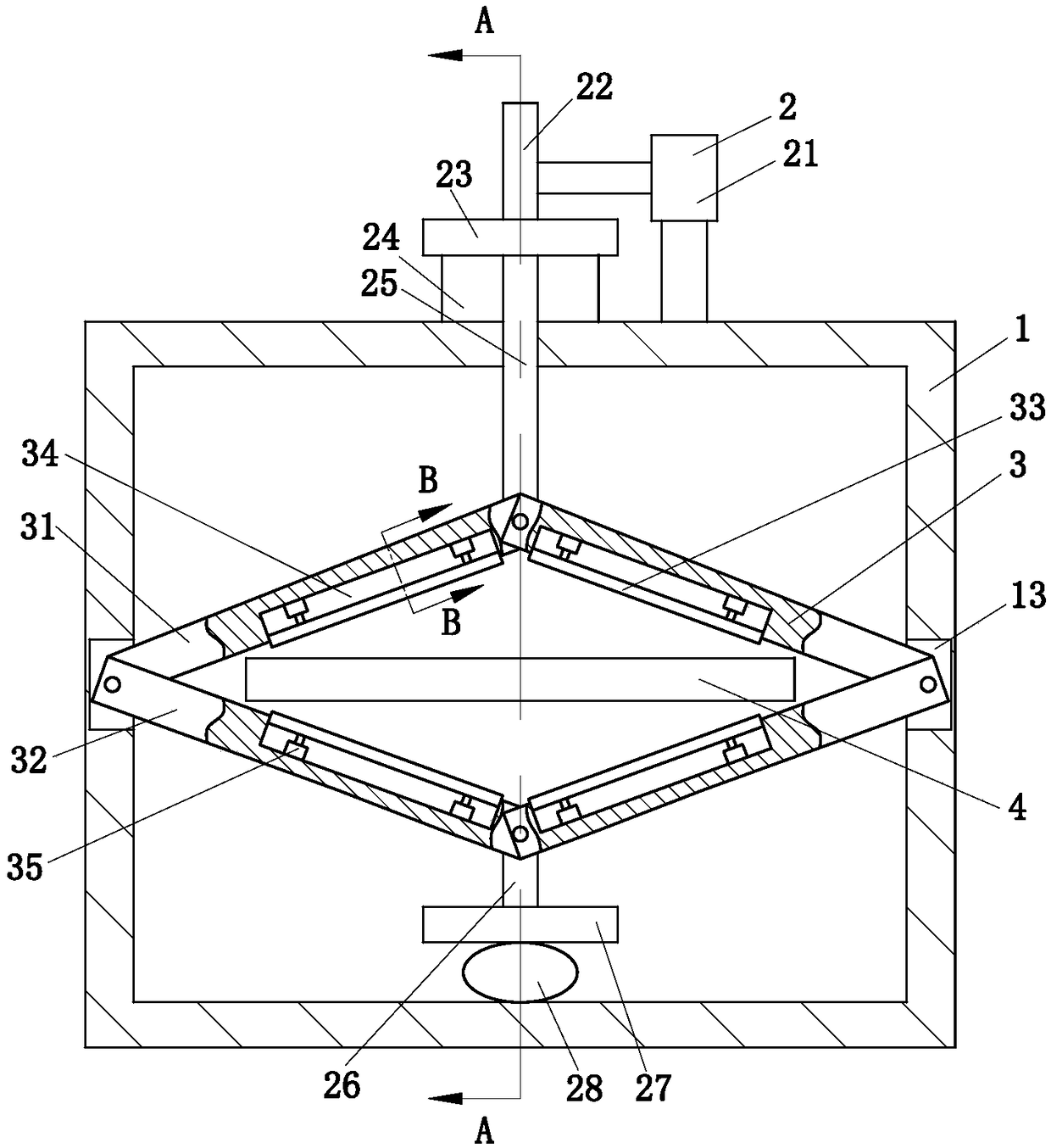

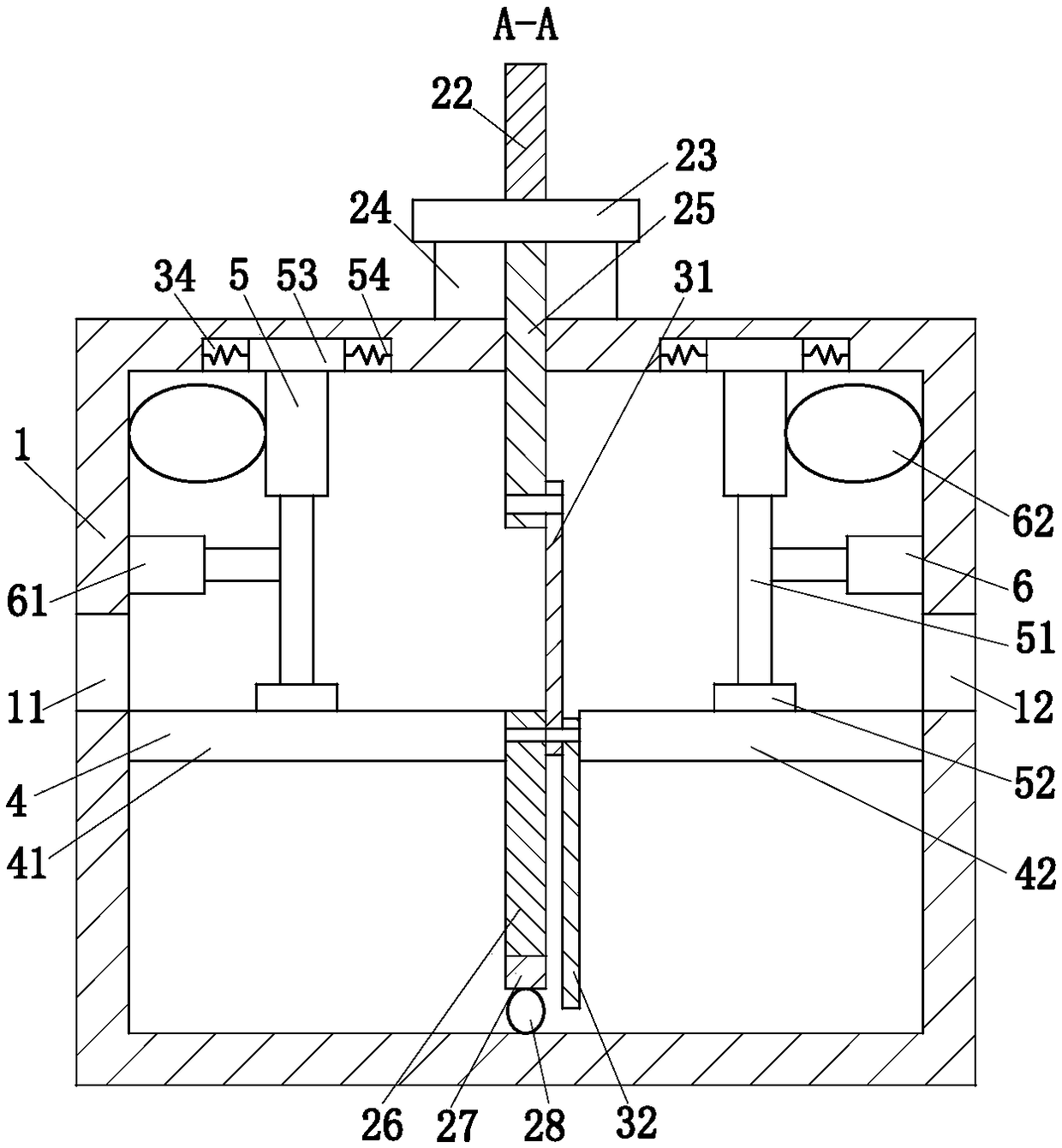

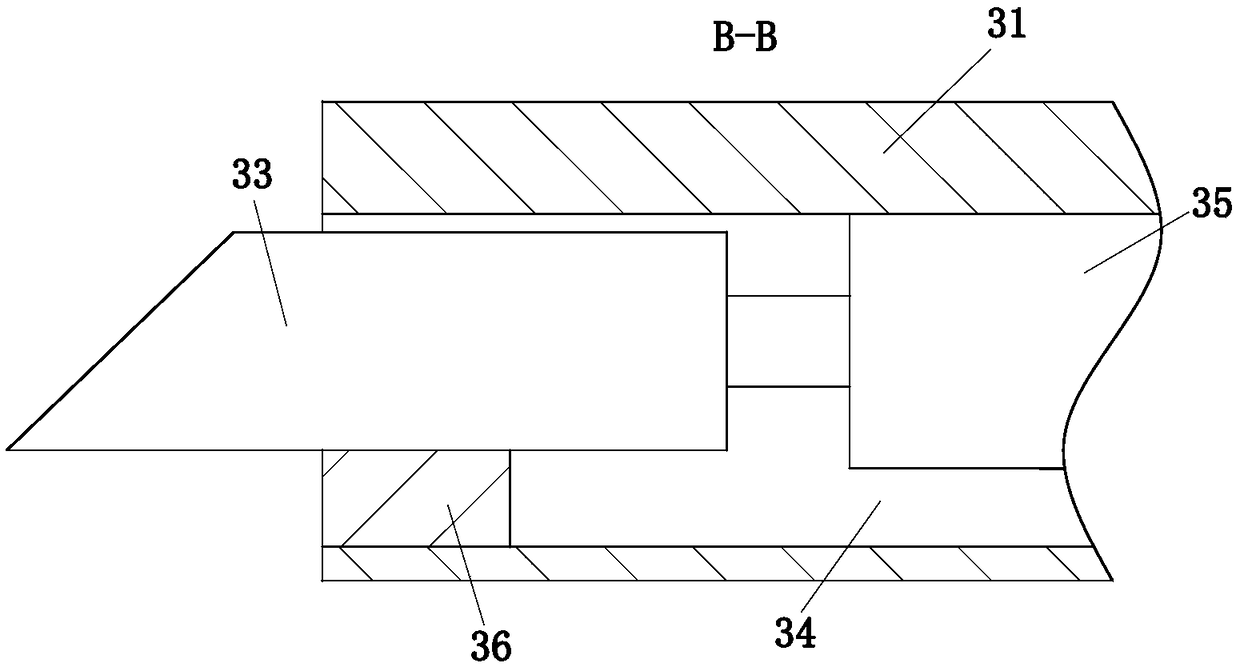

Detecting and straightening machine and method for shaft parts

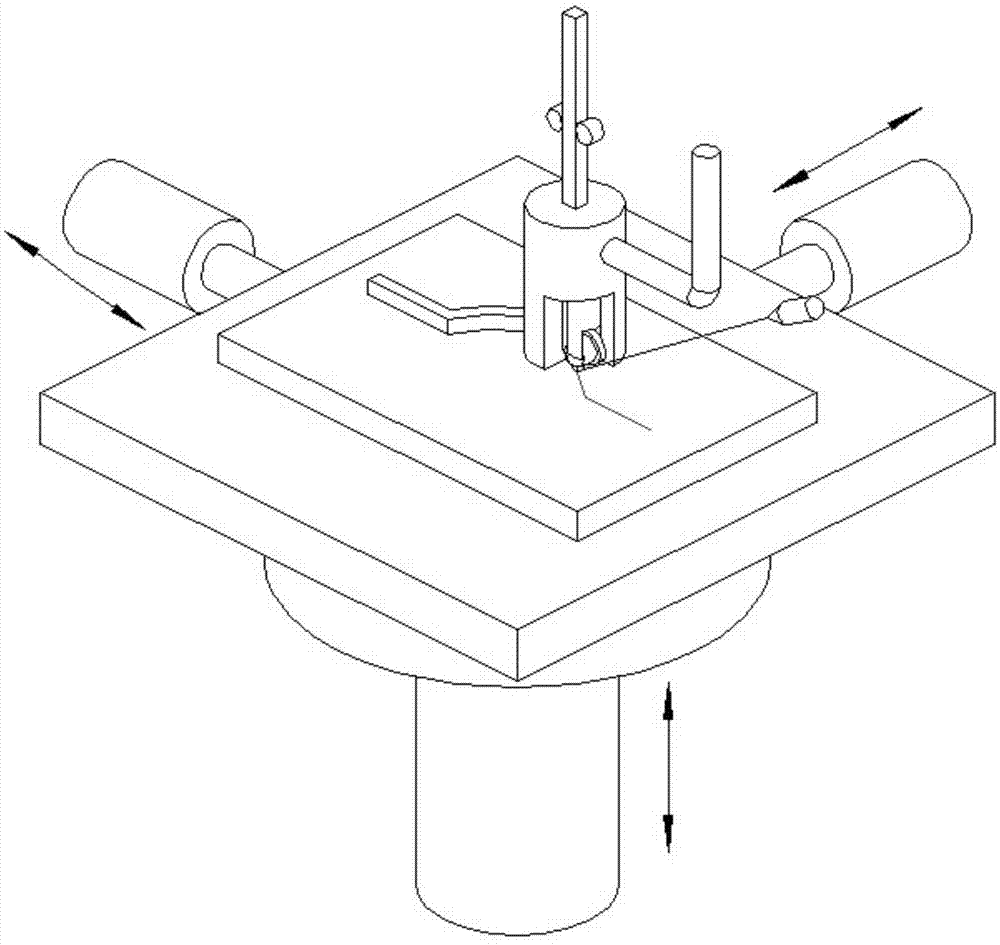

ActiveCN106734386AReduce measurement errorPlace stableGrinding machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses a detecting and straightening machine and method for shaft parts. The detecting and straightening machine comprises a console and a straightening machine body. The straightening machine body comprises a fixed work table and a movable main machine frame. The movable main machine frame can move on the fixed work table along the X axis and can feed data back to the console. A straightening hydraulic cylinder is arranged on the movable main machine frame and can straighten a workpiece. A rear bracket capable of moving along the Y axis is arranged on the rear side of the movable main machine frame. A measurement hydraulic cylinder is arranged on the rear bracket. A measurement rolling wheel is arranged below the measurement hydraulic cylinder. A displacement sensor for measuring the Y-axis movement amount and a displacement sensor for measuring the Z-axis movement amount are arranged on the movable main machine frame and the measurement hydraulic cylinder correspondingly. The displacement sensors can transmit information to the console. Detecting and straightening of the workpiece can be conducted on the same device and the same station through the same installation reference. When straightness detection is conducted on the workpiece, detection can be conducted on the workpiece on three-dimensional scale, and measurement errors are reduced.

Owner:SHANDONG UNIV

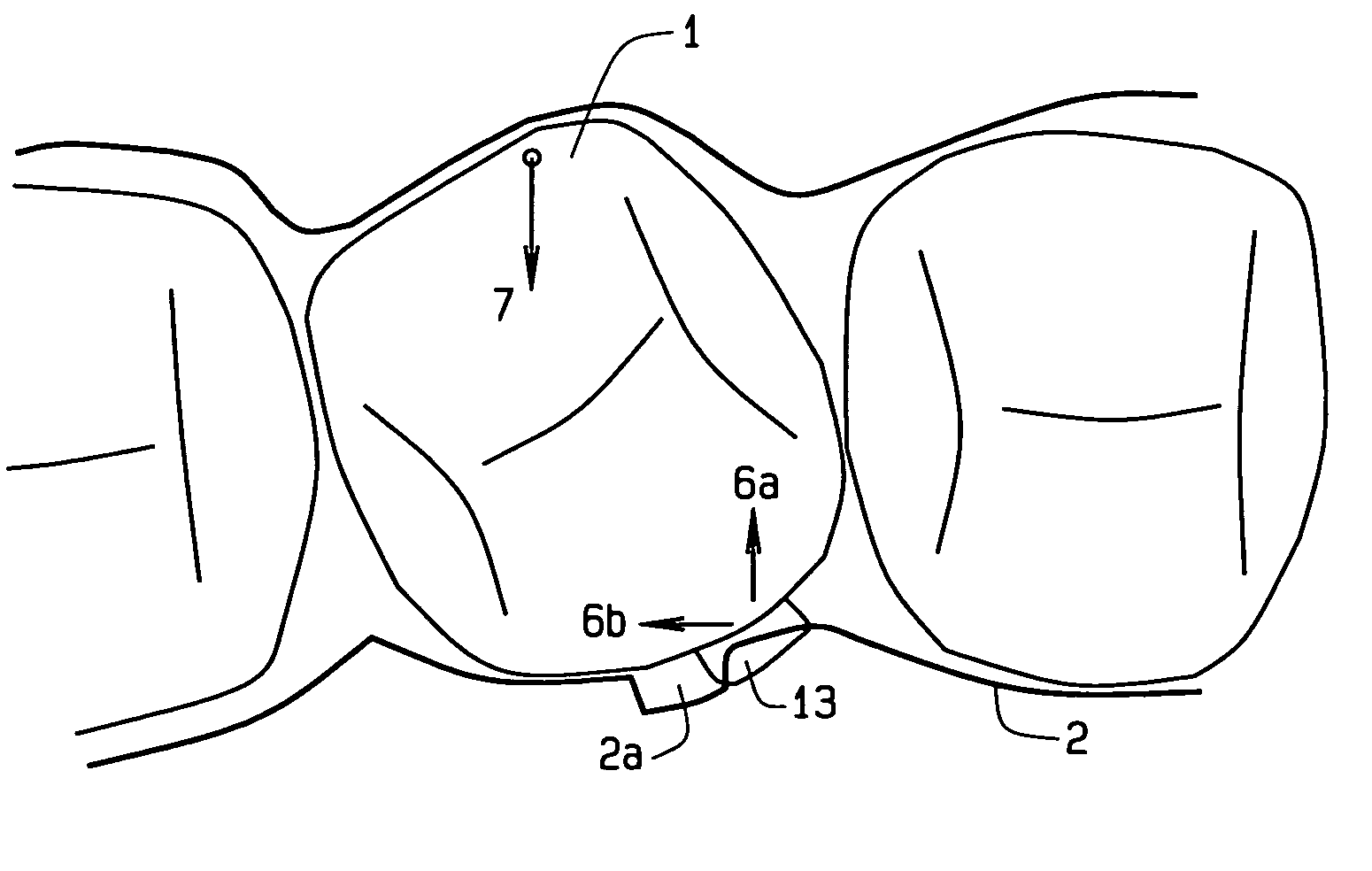

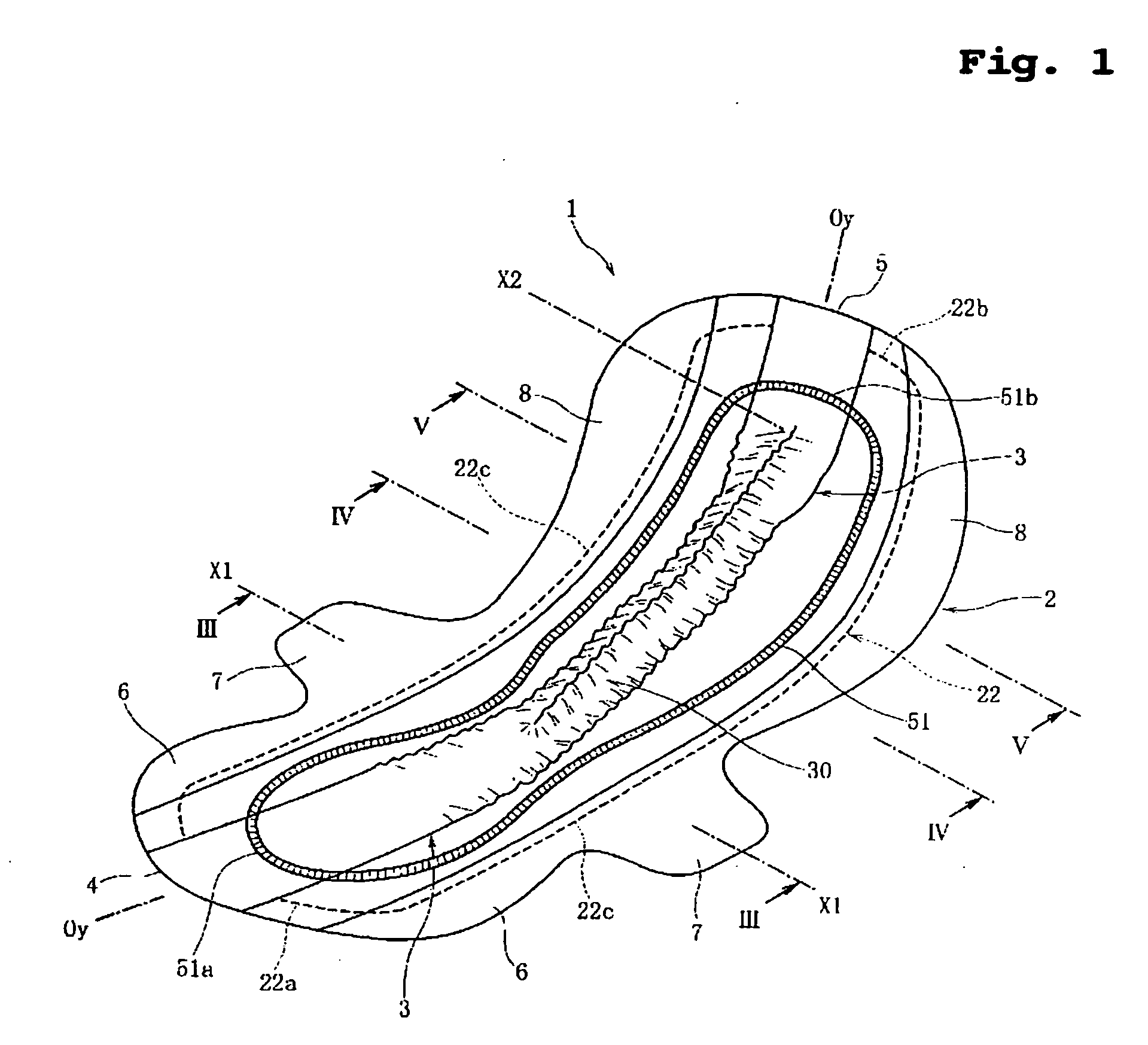

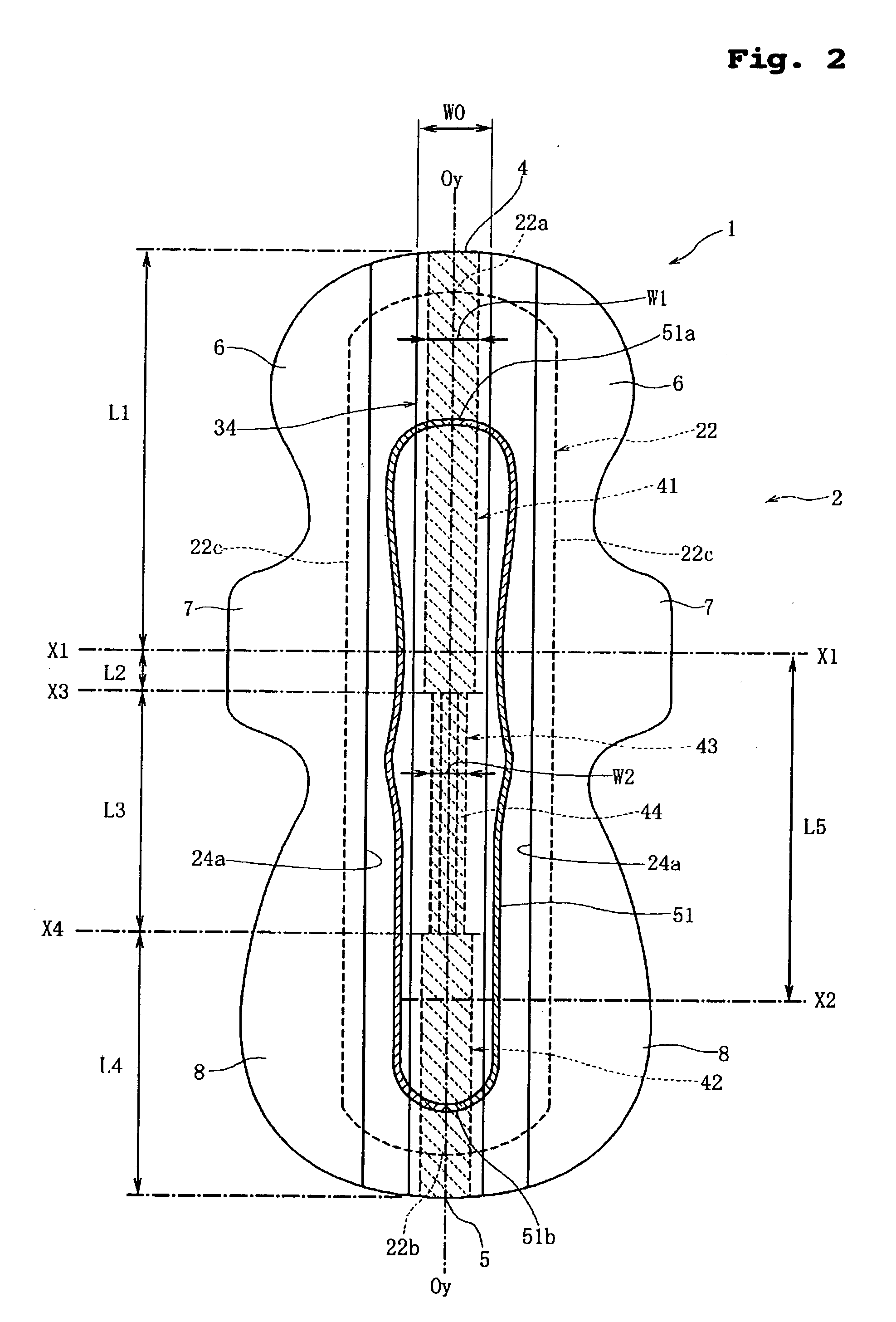

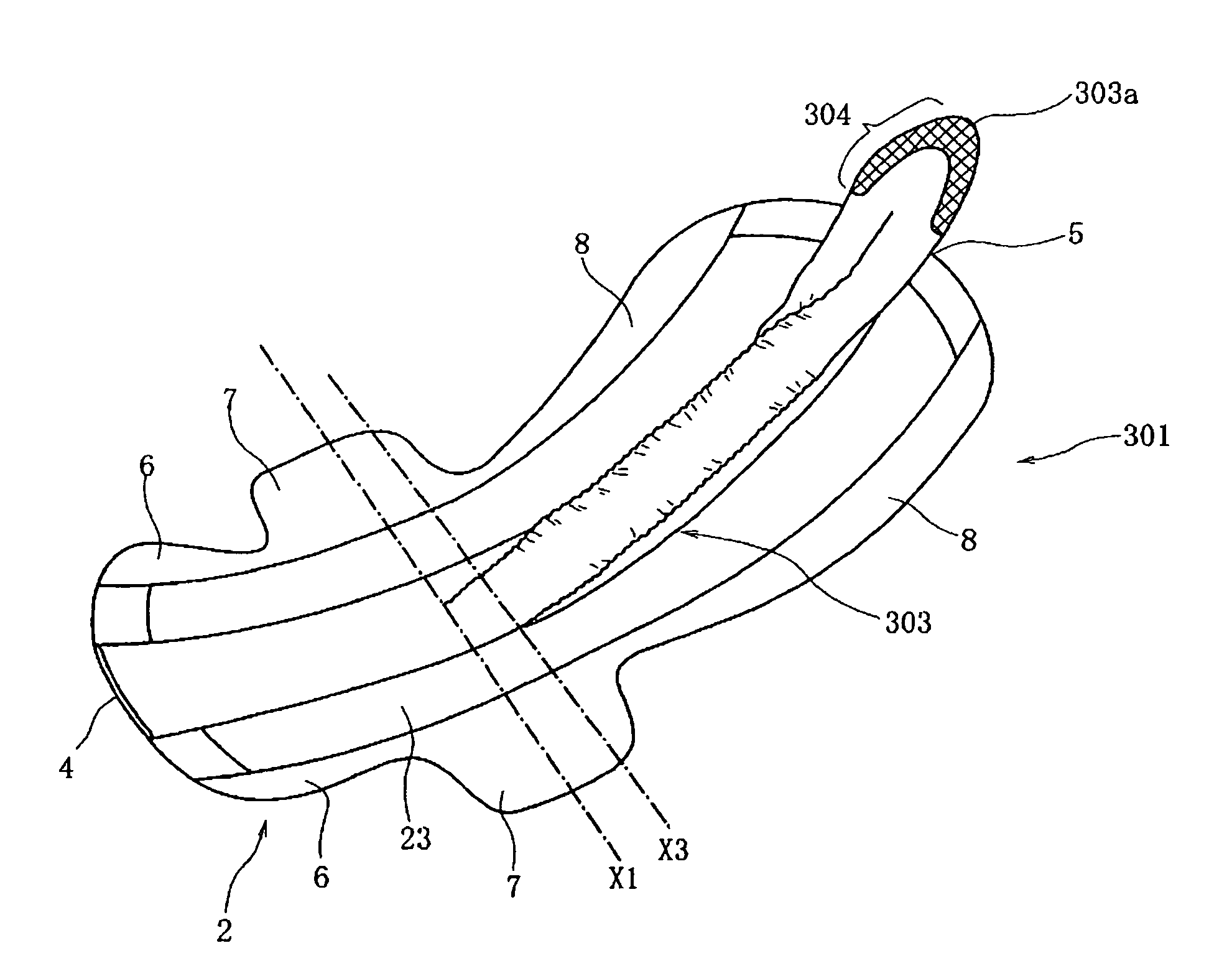

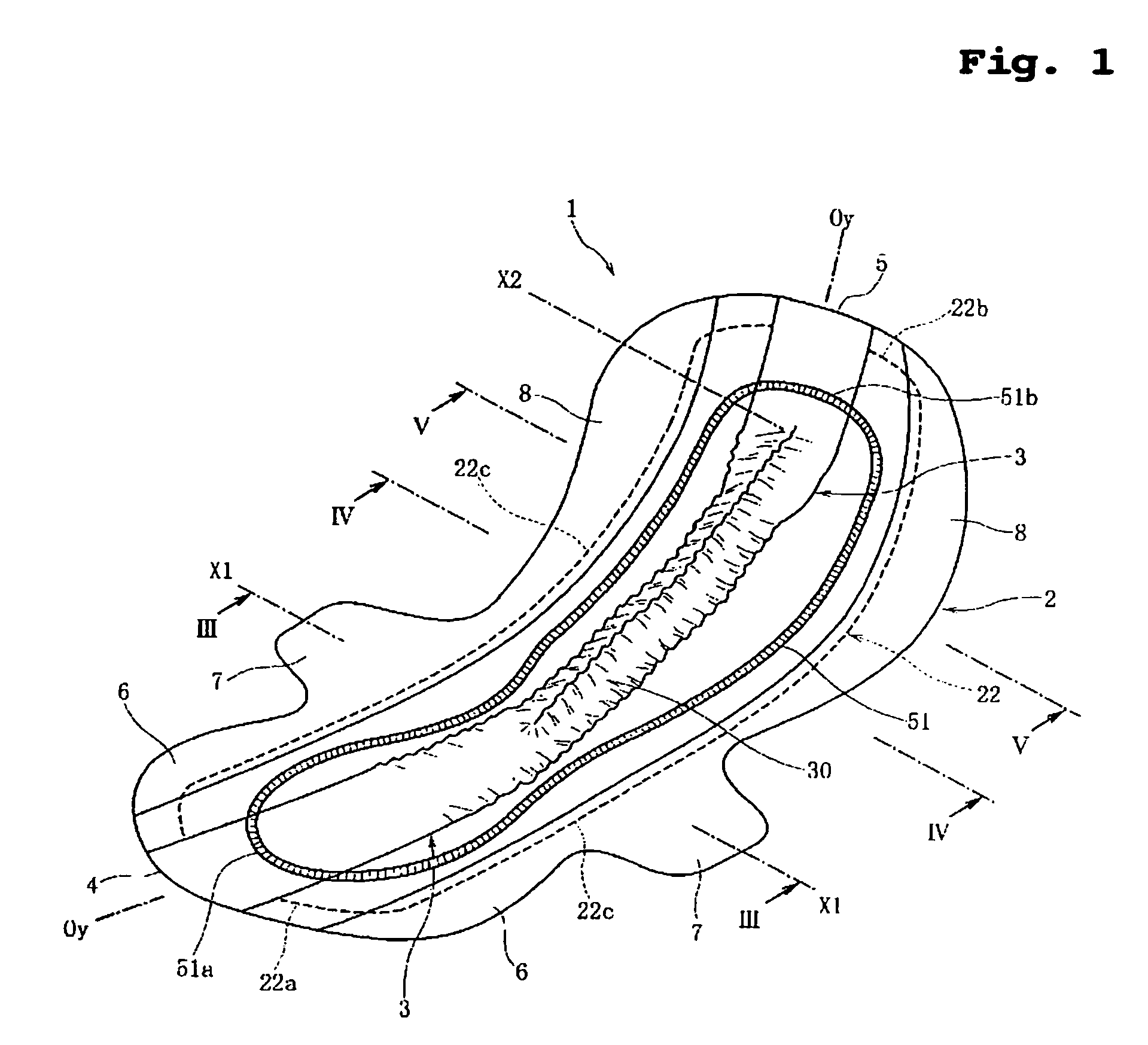

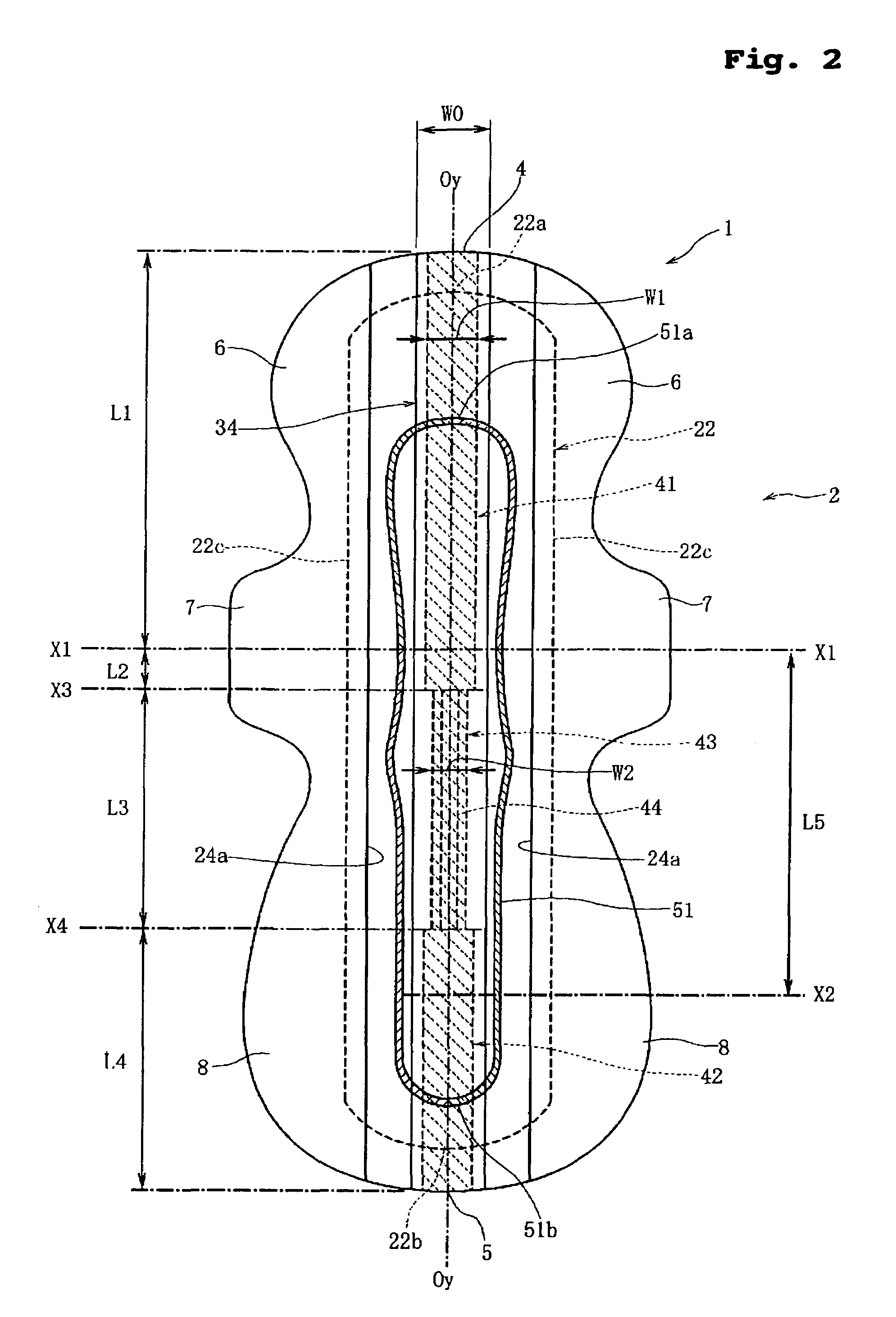

Sanitary napkin

InactiveUS20060282059A1Precise positioningEasily be in contactSanitary towelsBaby linensBiomedical engineeringBody surface

A sanitary napkin includes a main body having a liquid-absorbent layer for absorbing and retaining liquid and a projection disposed on a body surface of the main body. At least a portion of the projection is separably fixed to the body surface of the main body through a temporarily fixing means.

Owner:UNI CHARM CORP

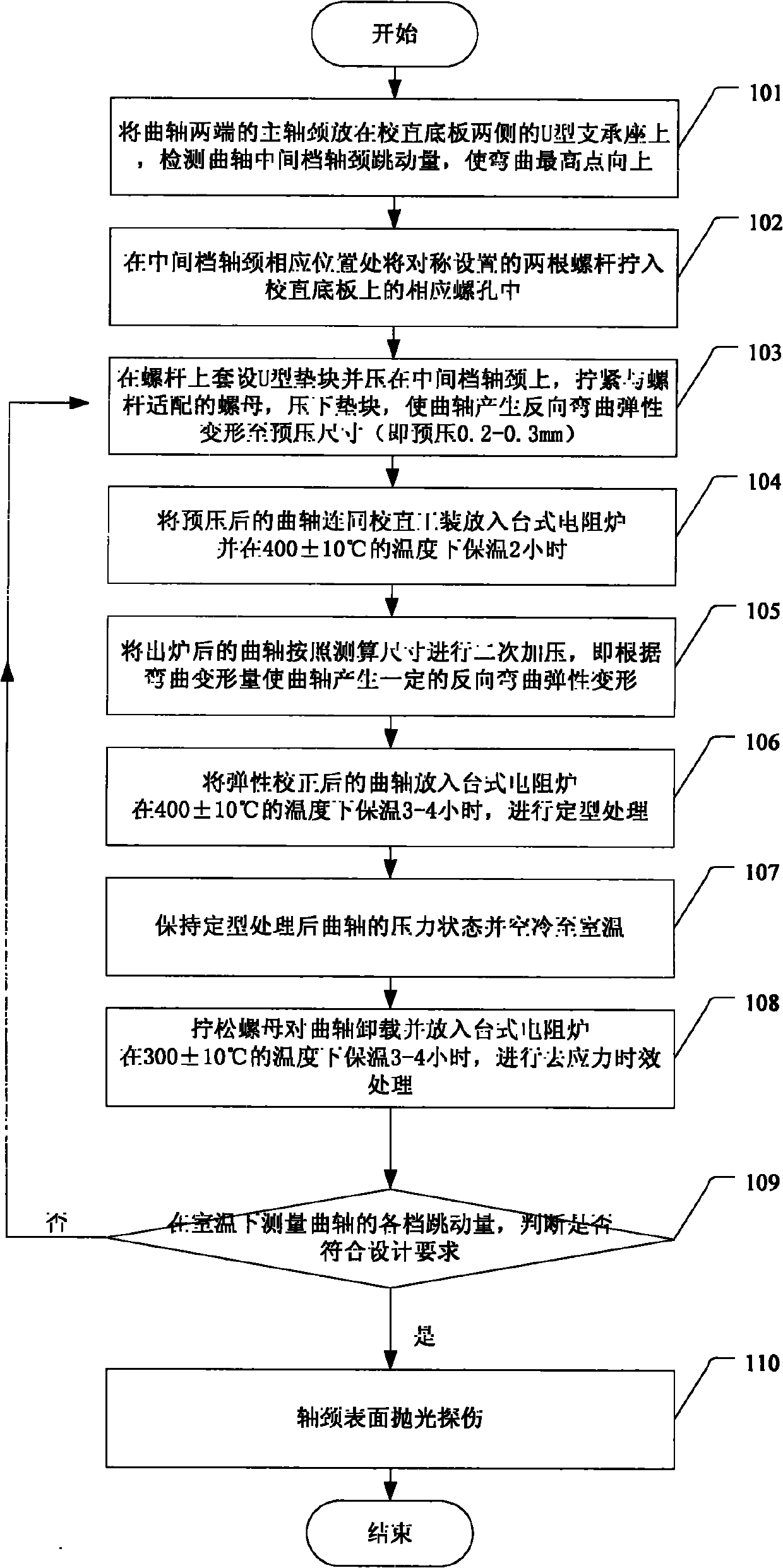

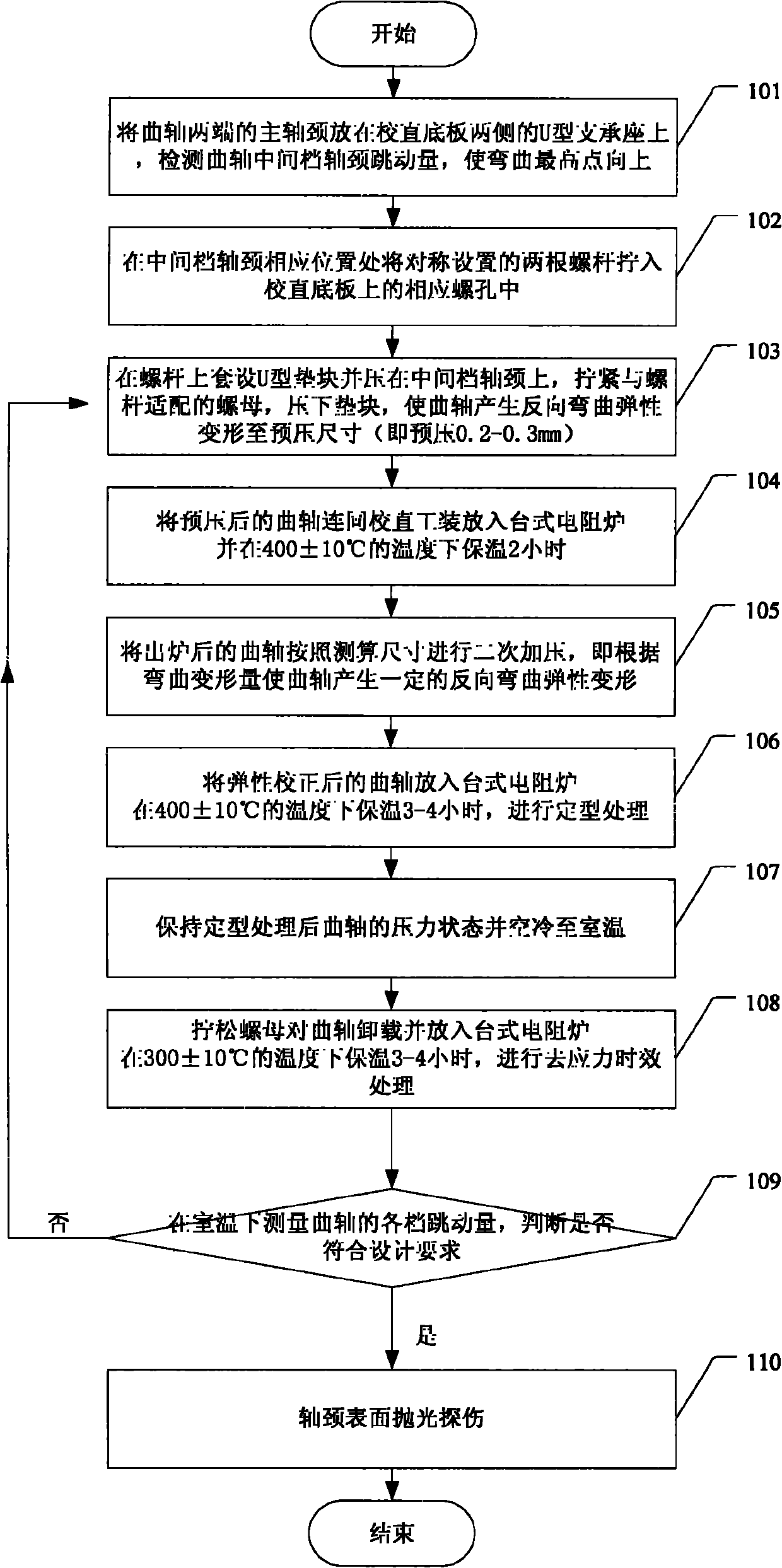

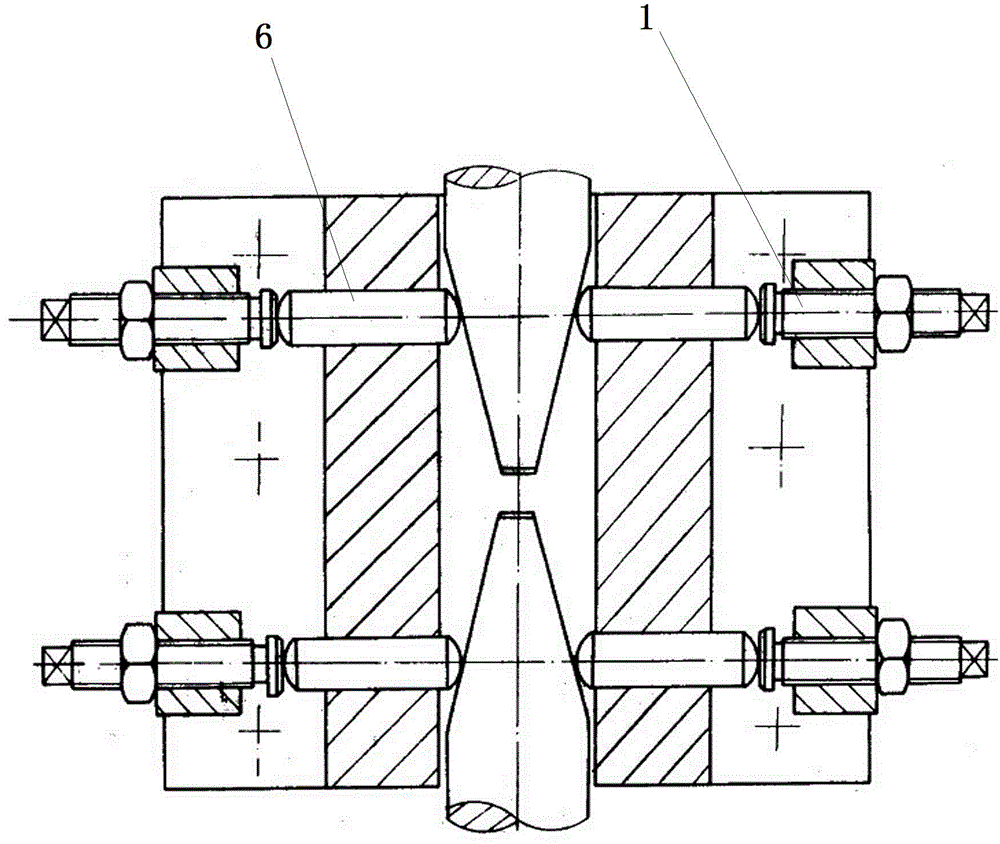

Method and tool for straightening bending deformation of crankshaft

ActiveCN102198457ASolve difficult straighteningSolve the problem of easy crackingRoom temperatureEngineering

The invention discloses a method for straightening bending deformation of a crankshaft. The method comprises the following steps of: performing elastic correction on the bent deformed crankshaft by using a straightening tool in a hot state, namely making the crankshaft generate certain reverse bending elastic deformation according to the bending deformation; performing setting treatment on the elastically corrected crankshaft at the temperature of 400+ / -10 DEG C; keeping the pressure state of the set crankshaft, and cooling the crankshaft to room temperature by air; and unloading the crankshaft, and performing stress removal aging treatment on the unloaded crankshaft at the temperature of 300+ / -10 DEG C. The invention also discloses a tool for straightening bending deformation of the crankshaft. The crankshaft is elastically corrected through the special straightening tool, the problems that the large crankshaft is difficult to straighten and easy to crack in the prior art are solved,and the straightening process is simple, convenient, safe and reliable.

Owner:GUANGXI YUCHAI MASCH CO LTD

Sanitary napkin

InactiveUS7621899B2Prevent leakageEffective preventionSanitary towelsBaby linensBiomedical engineeringBody surface

A sanitary napkin includes a main body having a liquid-absorbent layer for absorbing and retaining liquid and a projection disposed on a body surface of the main body. At least a portion of the projection is separably fixed to the body surface of the main body through a temporarily fixing means.

Owner:UNI CHARM CORP

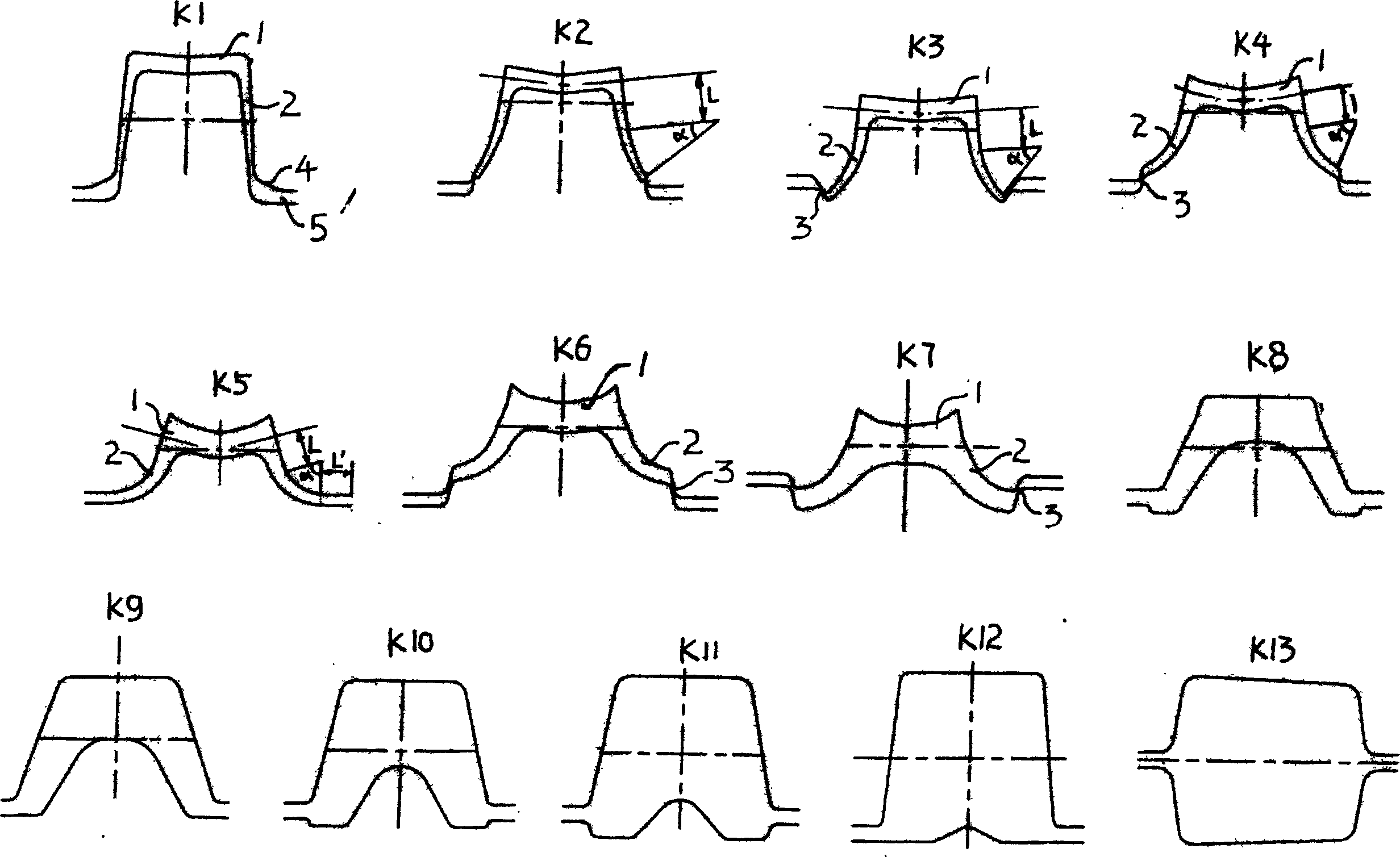

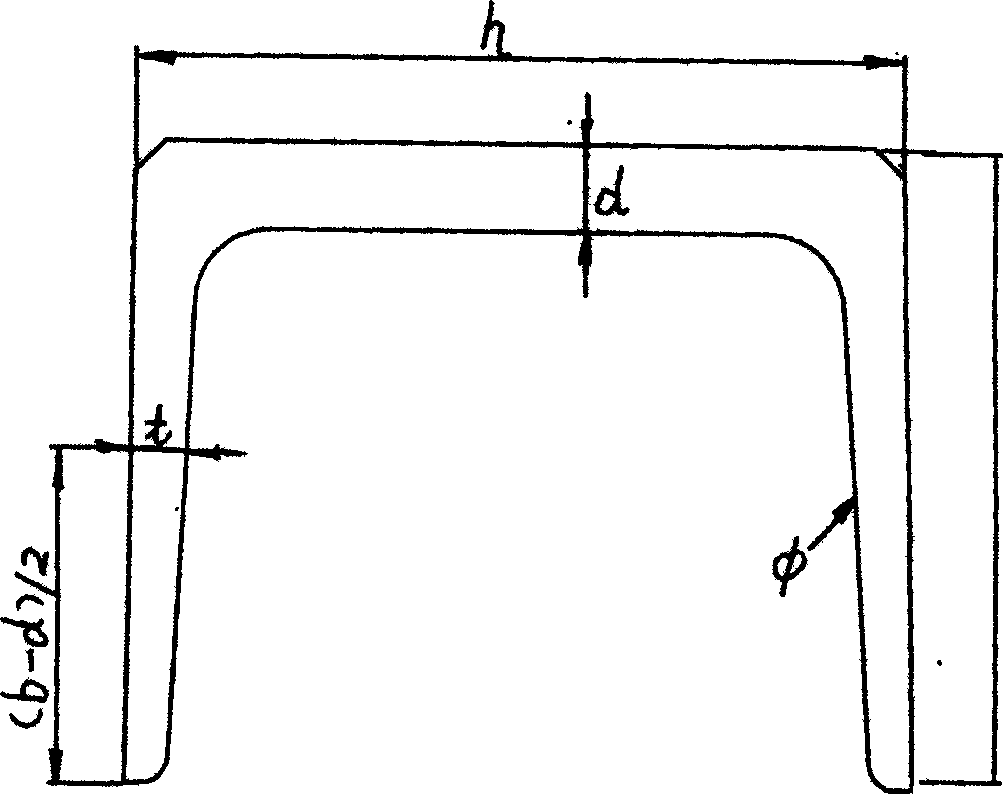

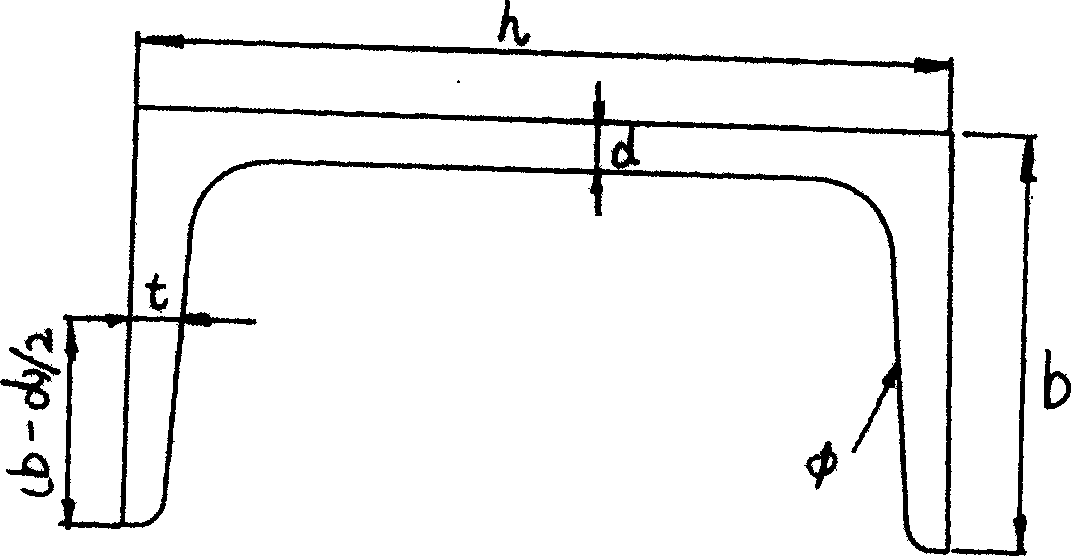

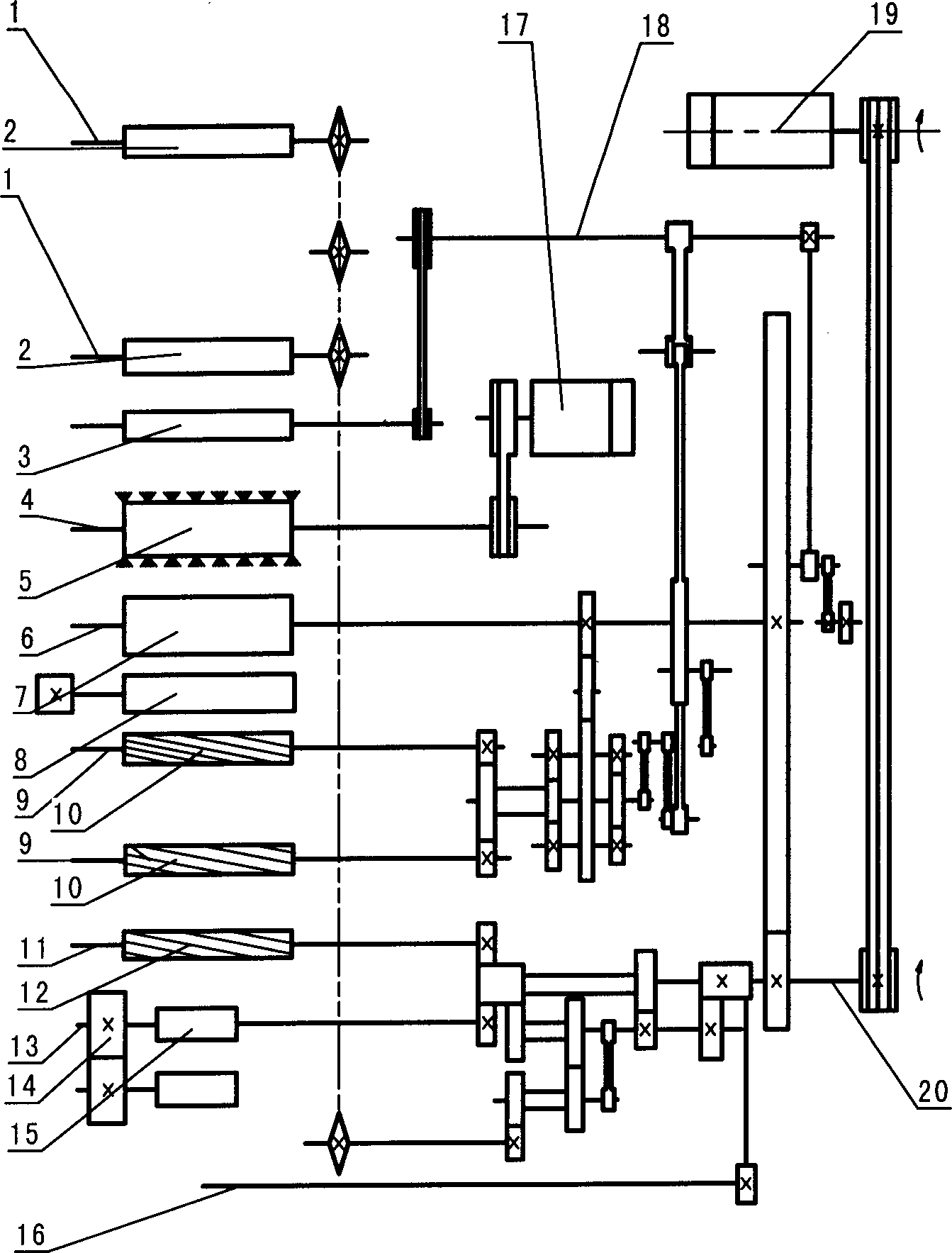

Rolling pass system for deformed channel steel

ActiveCN1608759AImprove deformation conditionsFavorable growthMetal rolling arrangementsLeg lengthChannel width

The present invention discloses one kind of rolling pass system for deformed channel steel with leg length / channel width ratio of 0.8-1.1 in small scale rolling mill. The rolling pass system consists of directly deepening coarse rolling pass, butterfly type middle rolling pass arranged in narrow-wide-narrow rule and straight leg finish gage pass with optimized nip condition. The present invention has improved deforming condition to realize rolling large steel material in small rolling mill, and has the positive effects of raising rolling capacity of rolling mill, reducing pass height, reducing depth of roller slot, decreasing rolling load, etc.

Owner:MAANSHAN IRON & STEEL CO LTD

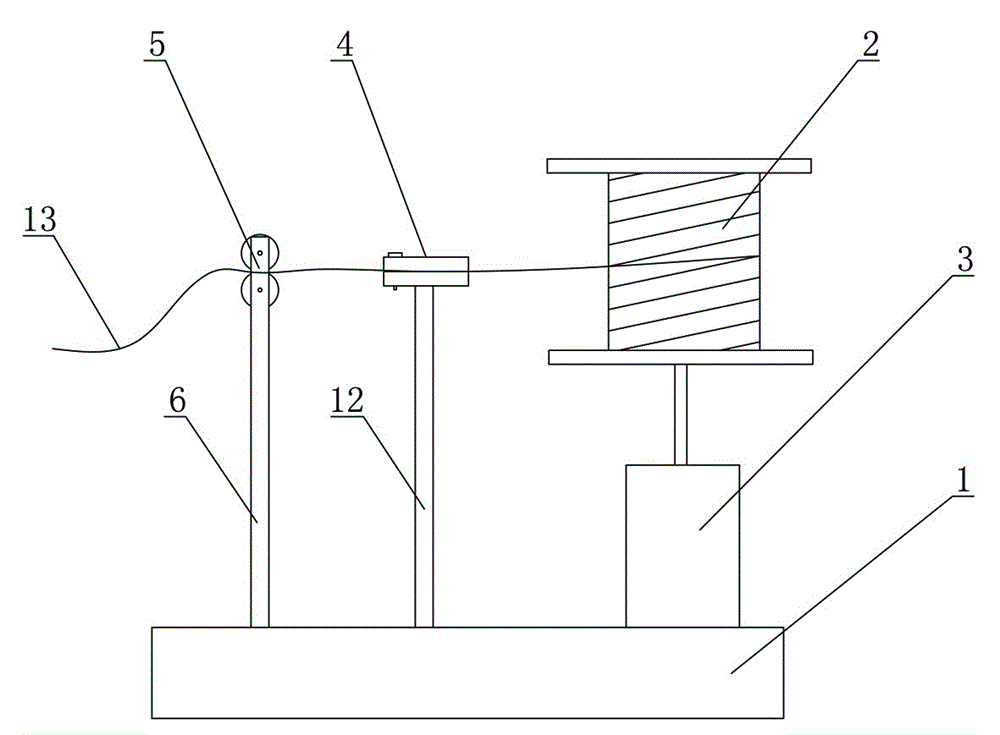

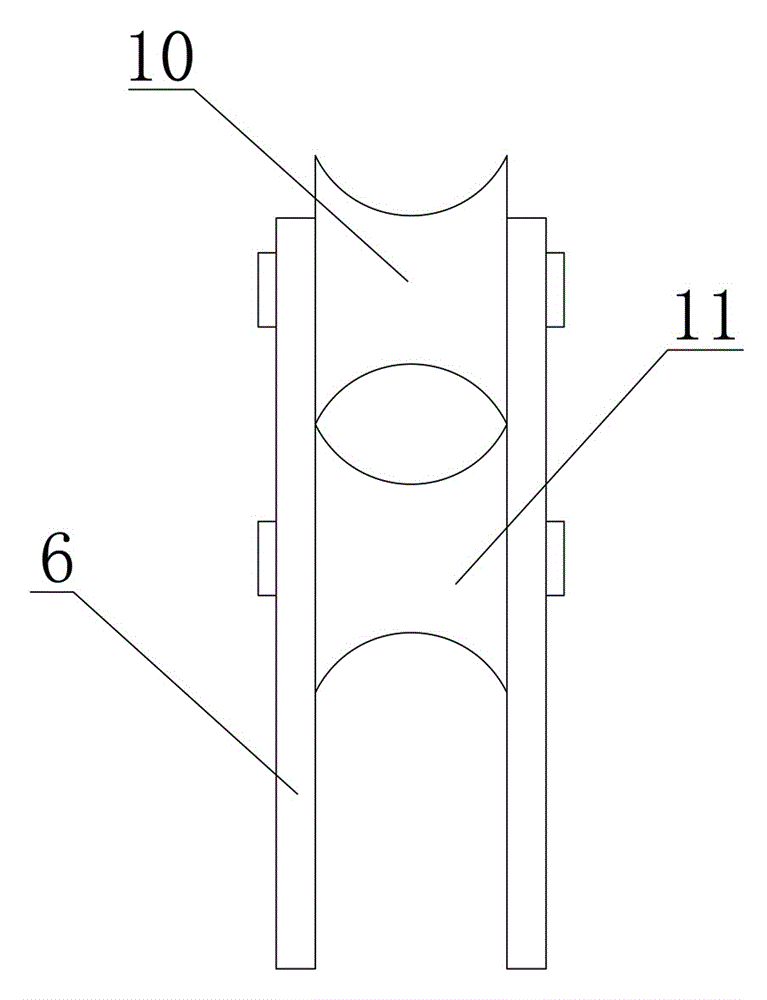

Old wire recovery device

The invention provides an old wire recovery device comprising a frame, a take-up reel mounted on the frame, a motor driving the take-up reel to move, and a wire smoothing device. The old wire recovery device is scientific in design, convenient to use and high in recovery quality, and wires can be automatically smoothed.

Owner:STATE GRID CORP OF CHINA +1

Manufacturing method of pup joint

InactiveCN101934469AAvoid quality problemsReduce restrictionsFurnace typesHeat treatment furnacesMedium frequencySharpening

The invention relates to a manufacturing method of a pup joint, which is characterized by comprising the following processing steps: (1) thermal treatment, straightening and flaw detection of a pipe body: the thermal treatment process comprises quenching and tempering; after thermal treatment is completed, carrying out full-length straightening on the pipe body with a six-roller straightener; and carrying out full-length flaw detection on the pipe body with a flaw detector; (2) saw-cutting: saw-cutting the pipe body after thermal treatment, straightening and flaw detection into a short material with a sawing machine; (3) initial machining: flattening the saw mouth of the end surface of the short material on the sawing machine, machining an excircle of the obtained short material into Phi132 plus or minus 0.3mm with the sawing machine, and then polishing the inner surface of the short material pipe body at 80-120mm from a port with an automatic sharpening machine to remove surface scale; (4) welding: directly welding a male joint and a female joint with two ends of the short material pipe body respectively on a continuous welding machine; (5) thermal treatment of welding seams: quenching and tempering the welding seams with a medium-frequency induction coil; and (6) machining. The manufacturing method has stable welding process and lower machining cost.

Owner:WUXI SEAMLESS OIL PIPE

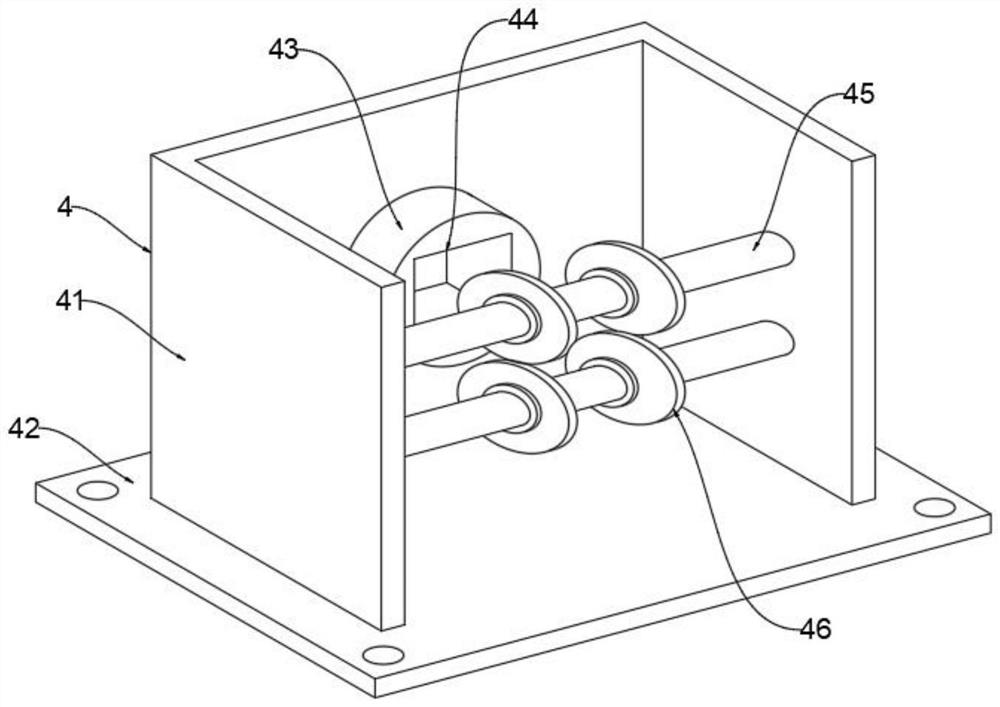

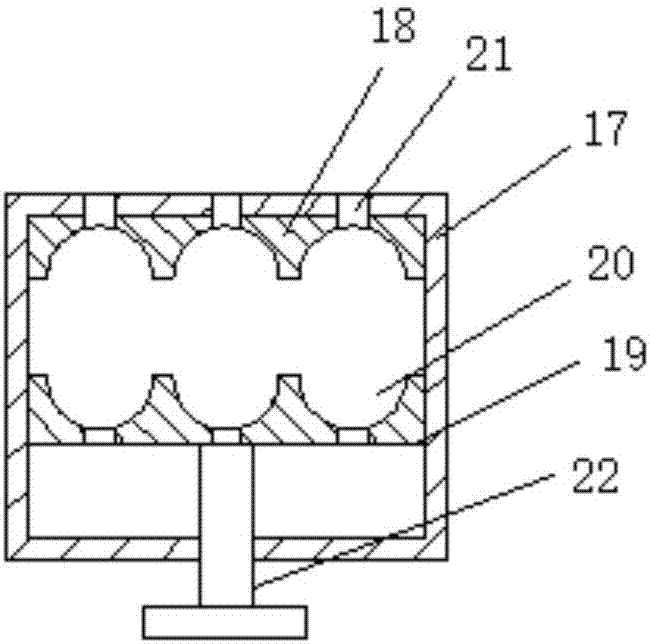

Straightening device for eliminating bending and distortion of aluminum profile

ActiveCN111790775AThe force of the roller pressure increasesReduce curvatureMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention discloses a straightening device for eliminating bending and distortion of an aluminum profile, relates to the related field of aluminum profile straightening, and aims to solve the problems that for an aluminum profile with large bending degree, the feeding position slips and the bending position is stressed to be prone to generating breaking cracks in an existing straightening device. A worktable top is arranged at the upper end of a worktable; a first supporting vertical plate is fixedly connected to the rear end of one side of the upper end of the worktable top; a first rectangular long groove is formed in the first supporting vertical plate; an overturning unit is arranged on one side of the front end of the first supporting vertical plate and comprises a sliding motor,a rotating screw rod and a sliding block; a rotating motor and a speed reducer are installed on one side of the middle of the sliding block, and a turntable is installed on the other side of the middle of the sliding block; an inner driving box is arranged on one side, away from the sliding block, of the turntable; rotating connecting rods are arranged at the upper end and lower end of the front end and rear end of the inner driving box; and rotating blocks are arranged on one sides, away from the inner driving box, of the rotating connecting rods.

Owner:大冶市华厦铝业有限公司

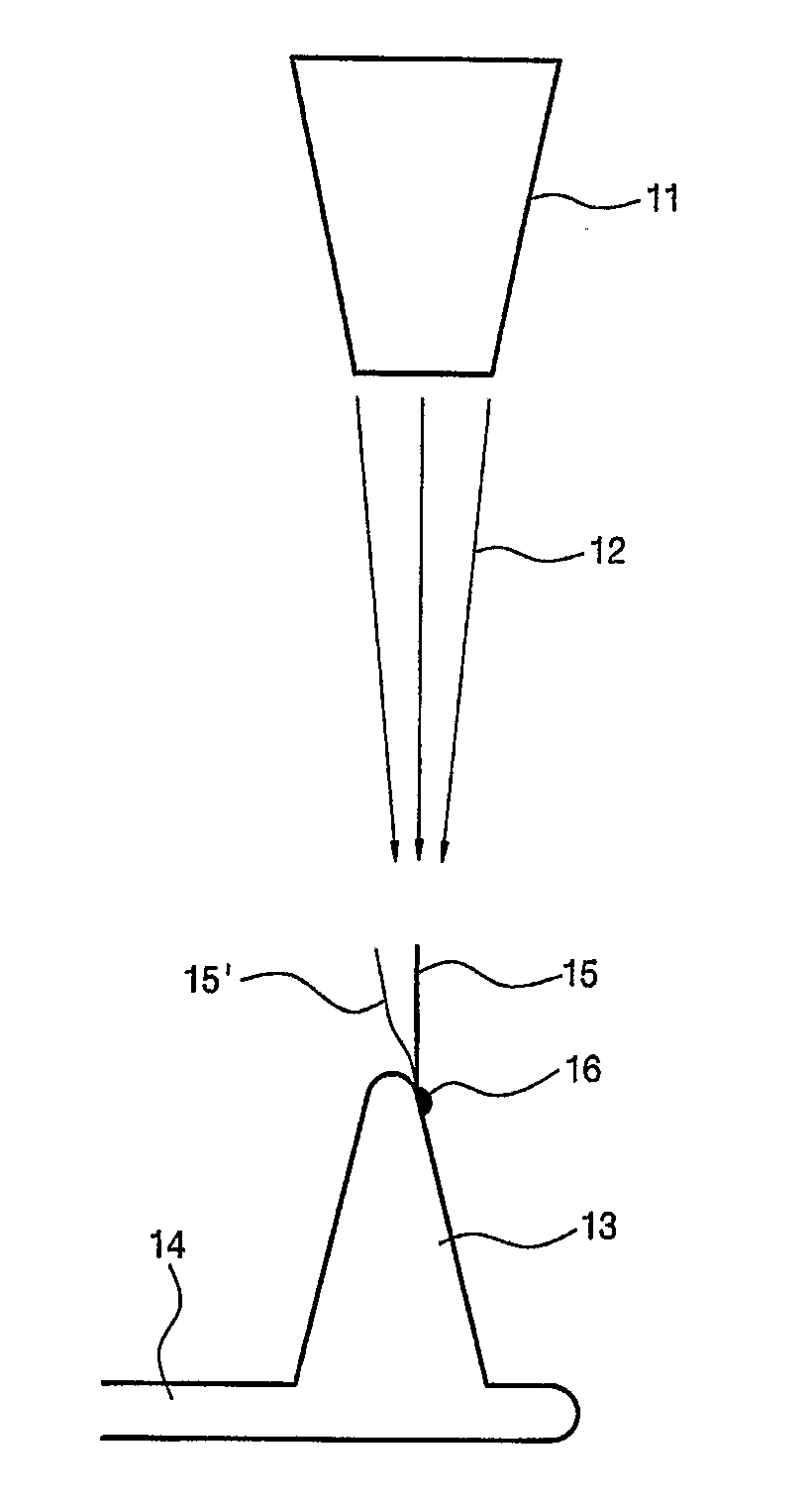

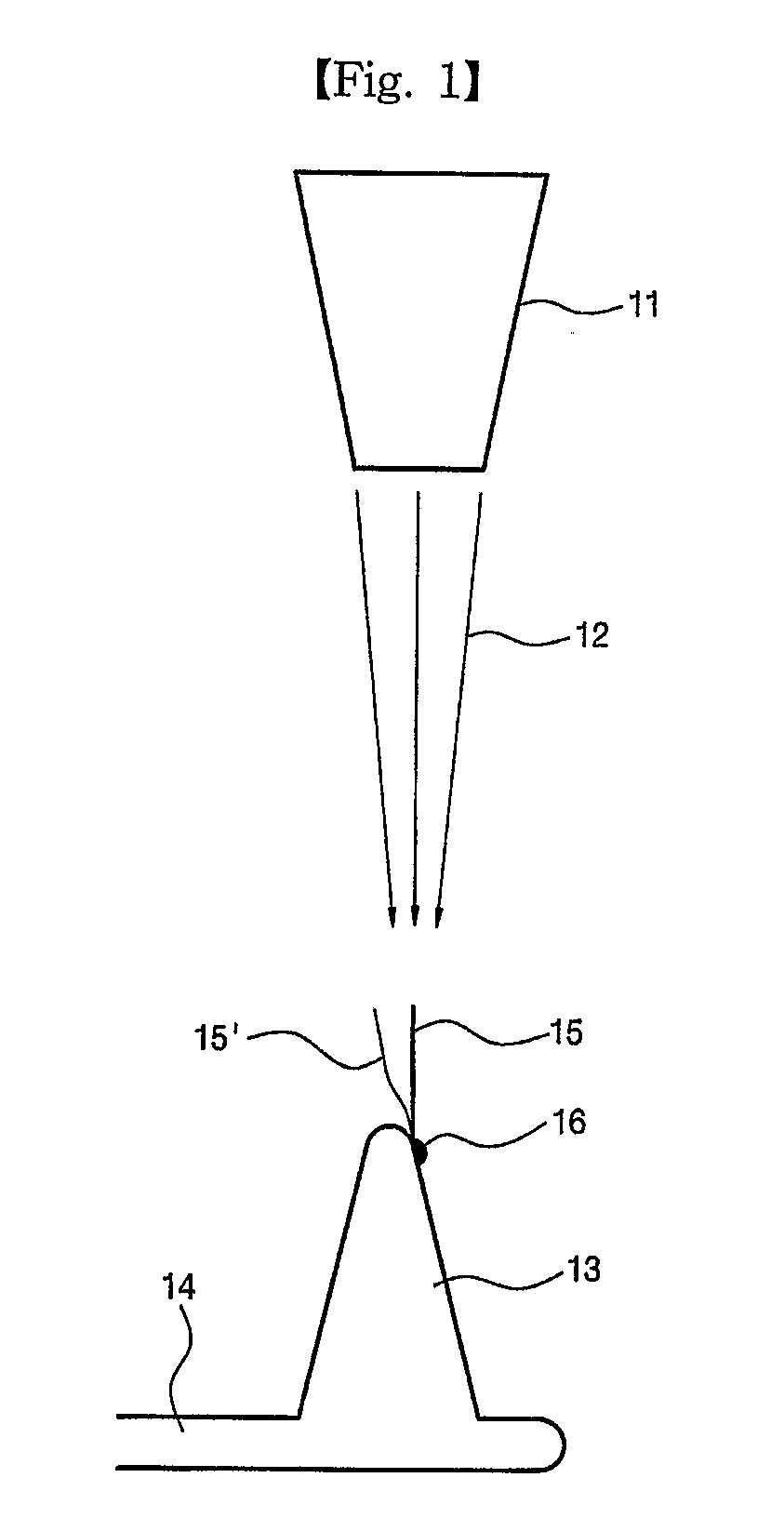

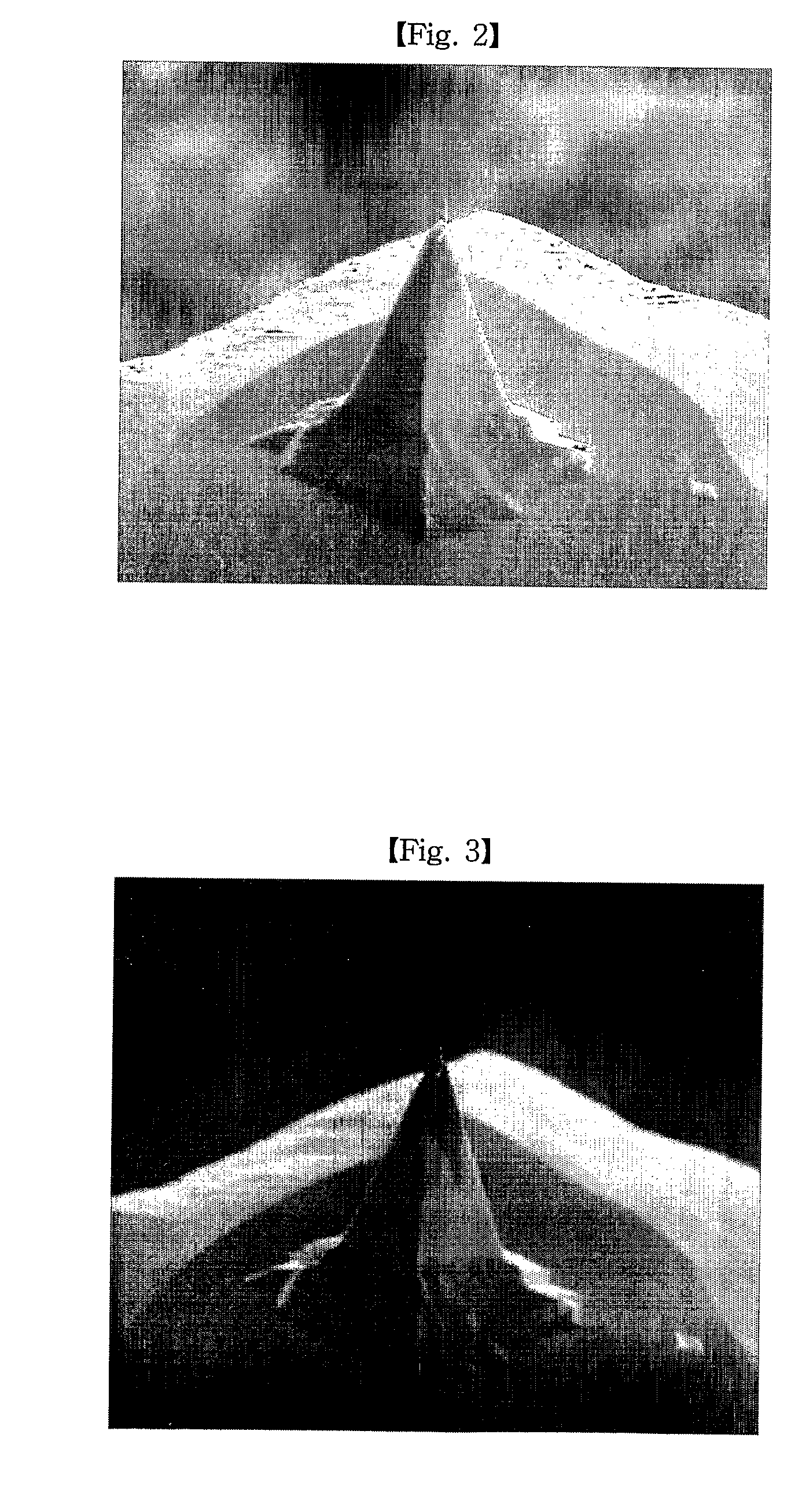

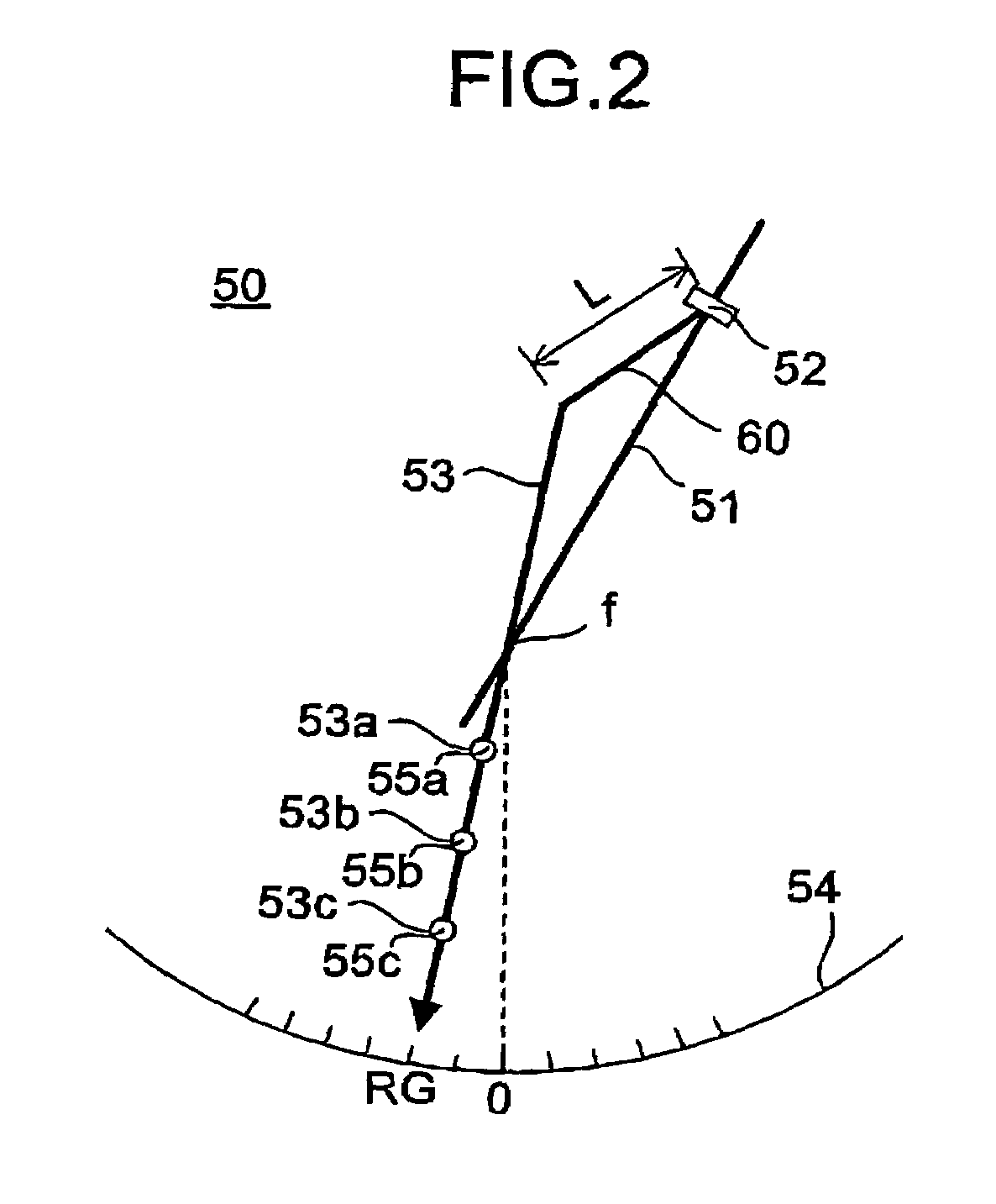

Method for fabricating spm and cd-spm nanoneedle probe using ion beam and spm and cd-spm nanoneedle probe thereby

ActiveUS20090106869A1Easily adjustEasily straightenNanosensorsInstrumental componentsPhysicsMicroscope

The present invention relates to a method for fabricating a scanning probe microscope (SPM) nanoneedle probe using ion beam which is preferably focused ion beam and a nanoneedle probe thereby. More particularly, the present invention relates to a method for fabricating a SPM nanoneedle probe capable of being easily adjusted with an intended pointing direction of a nanoneedle attached on a tip of the SPM nanoneedle probe and of being easily straightened with the nanoneedle attached on the tip of the SPM nanoneedle probe along the intended pointing direction, and to a SPM nanoneedle probe thereby. Also, the present invention relates to a method for fabricating a critical dimension SPM (CD-SPM) nanoneedle probe capable of precisely scanning the sidewall of an sample object in nanoscale using ion beam which is preferably focused ion beam, and to a CD-SPM nanoneedle probe thereby. More particularly, the present invention relates to a method for fabricating a CD-SPM nanoneedle probe capable of precisely scanning the sidewall of the sample object in nanoscale by bending a portion of an end of the nanoneedle attached on the tip of the SPM nanoneedle probe in a specific angle toward a direction other than an original direction in which the nanoneedle attached on the tip of the SPM nanoneedle probe extends out, and to a CD-SPM nanoneedle probe thereby. A method of fabricating scanning probe microscope (SPM) nanoneedle probe using ion beam, comprises: positioning the probe so that a tip of the probe on which the nanoneedle is attached faces toward a direction in which the ion beam is irradiated; and aligning the nanoneedle attached on the tip of the probe with the ion beam in parallel by irradiating the ion beam toward the tip of the probe on which the nanoneedle is attached. A method of fabricating a critical dimension scanning probe microscope (CD-SPM) nanoneedle probe using ion beam, comprises: screening a certain portion of the nanoneedle attached on a tip of the probe using a mask; and bending a part of the nanoneedle exposed out of the mask to align the part of the nanoneedle by irradiating the ion beam on the part of the nanoneedle exposed out of the mask, along the direction of the irradiated ion beam.

Owner:KOREA RES INST OF STANDARDS & SCI

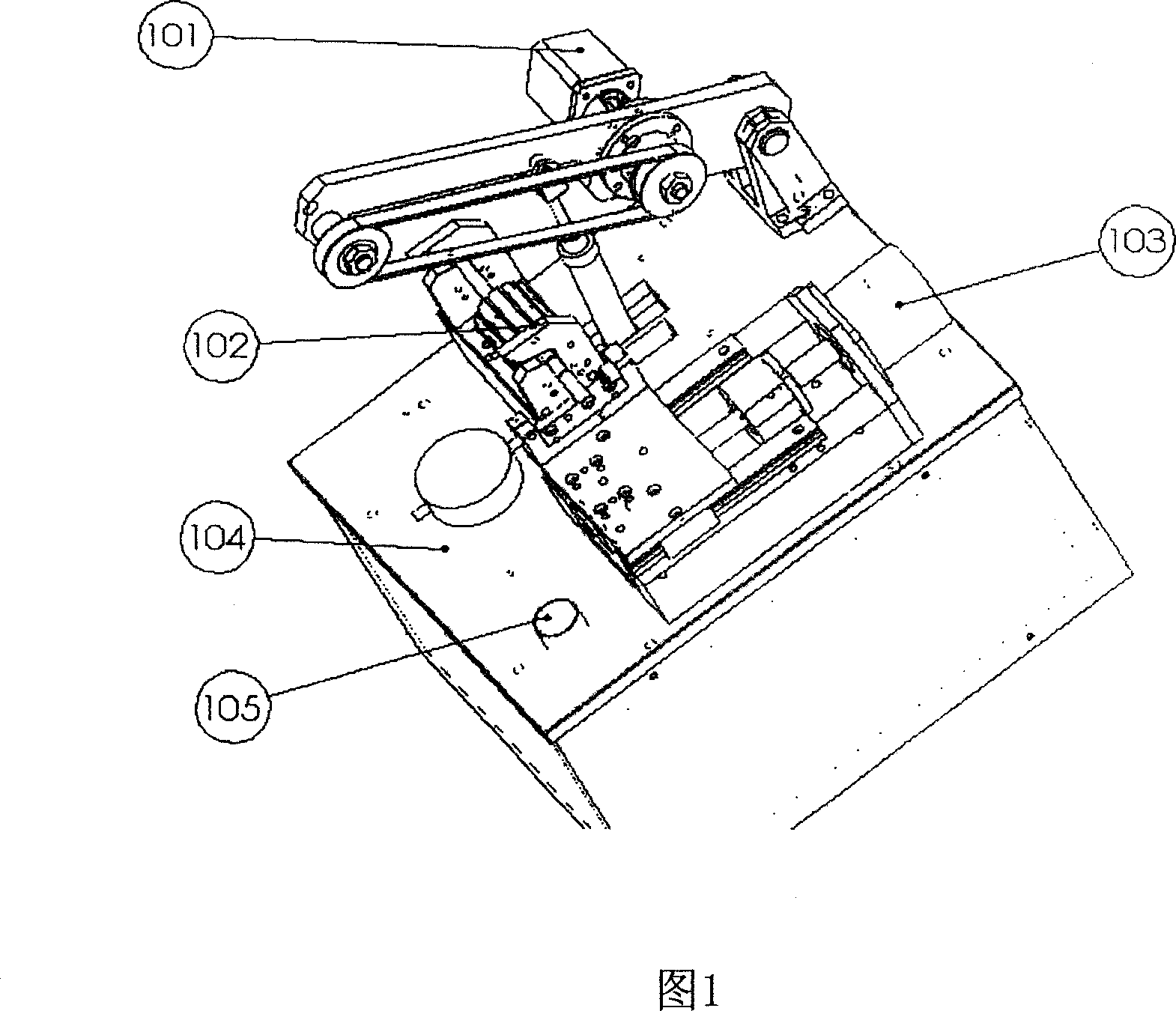

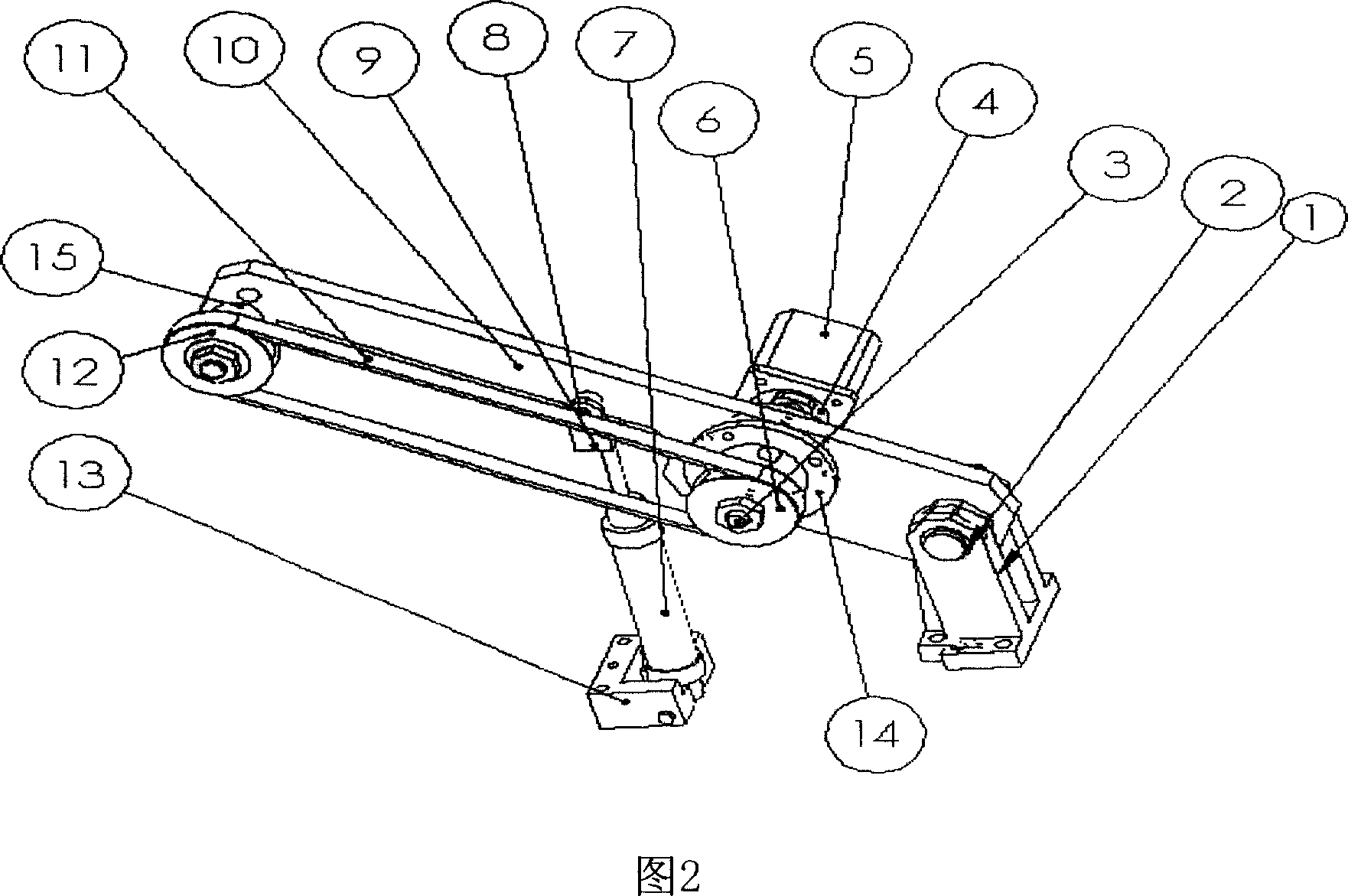

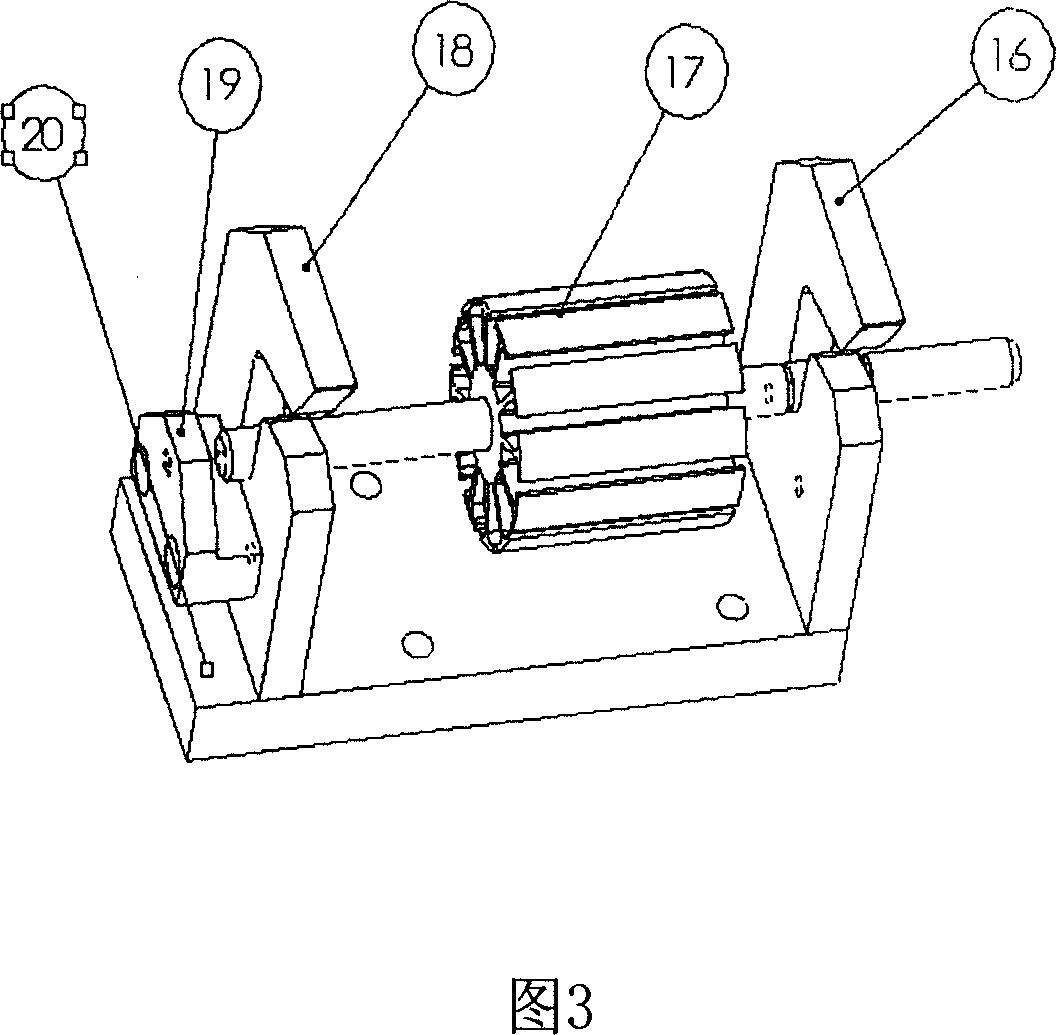

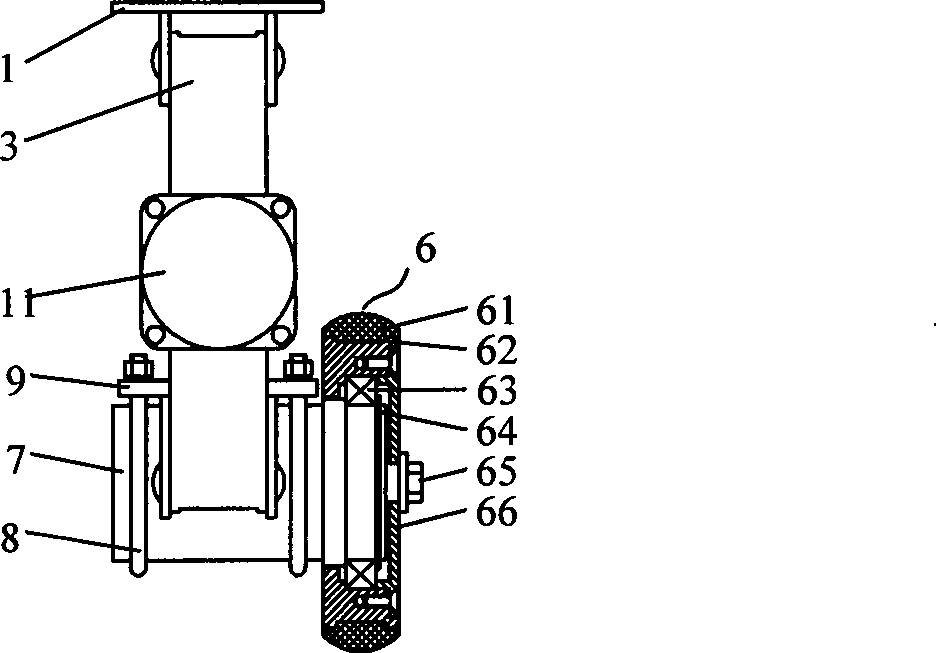

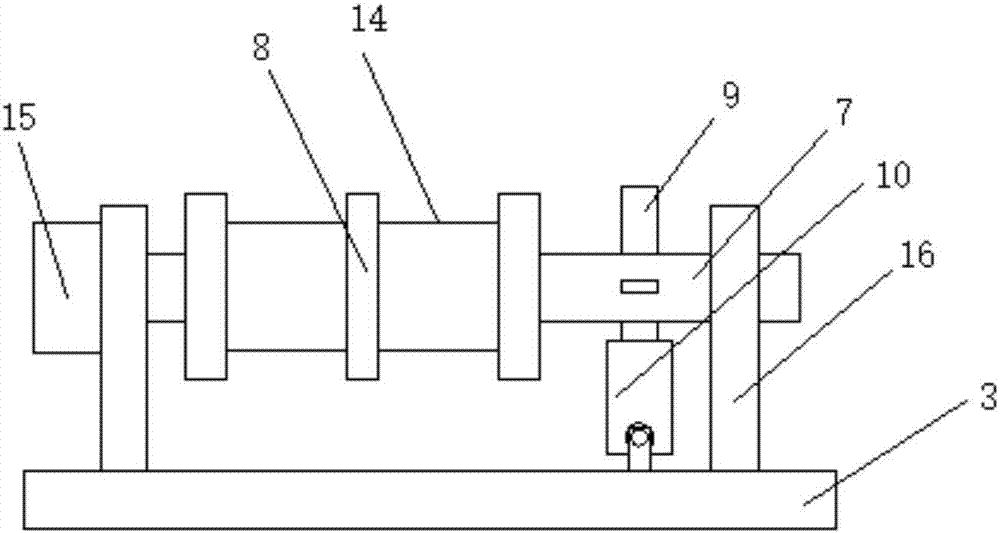

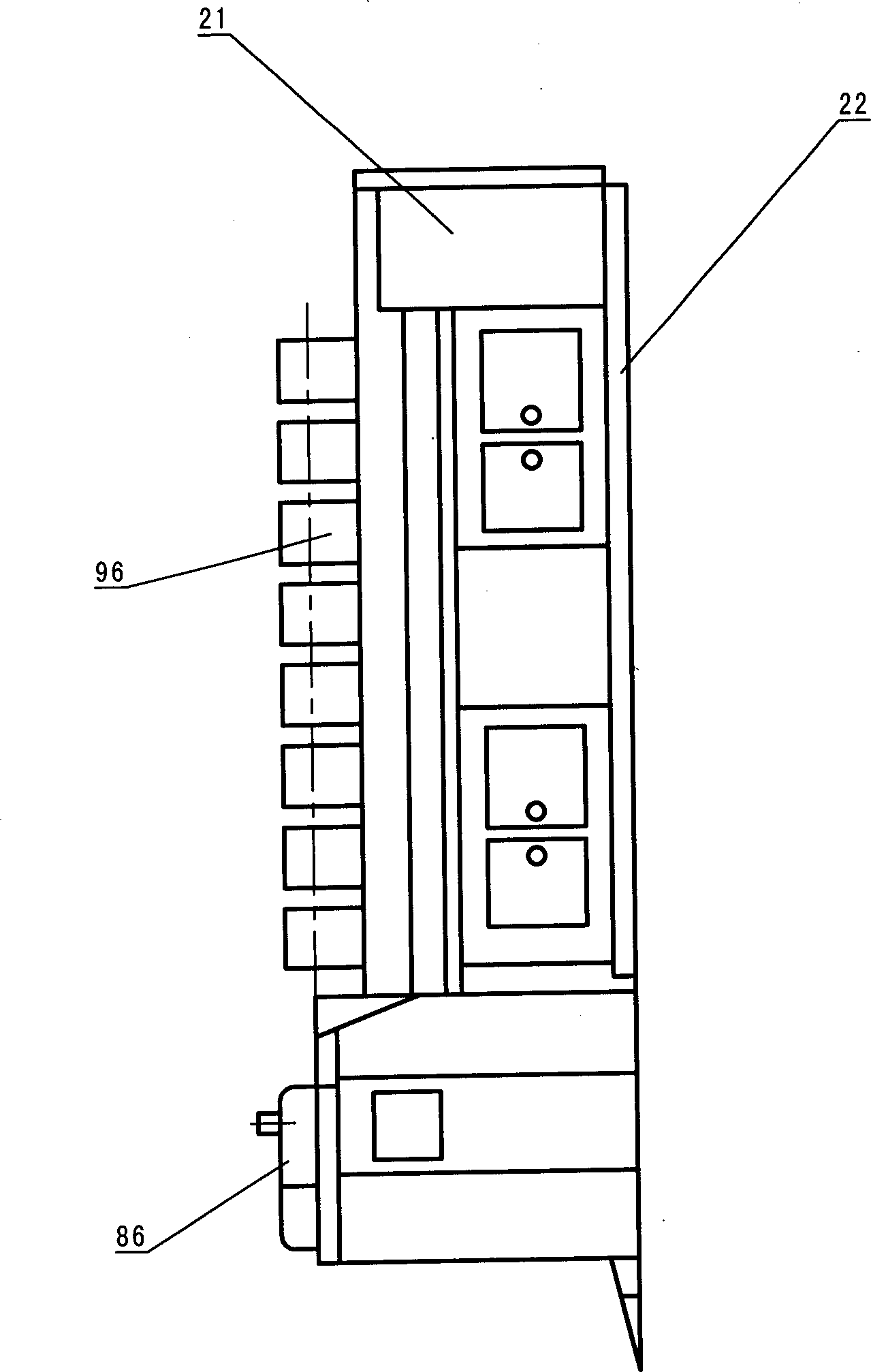

Alignment device of out shaft of rotor axis of electric engine

InactiveCN1967979AReduce labor intensityReduce processing costsManufacturing dynamo-electric machinesEngineeringCommunicator device

The invention relates to an output axle corrector of motor rotor axle, which comprises a bottom plate with roller driver; the under left of roller driver has compressing checking clamper; the front of bottom plate has one correcting table; the box under the bottom plate has drivers of motors and data communicator, which are connected to one computer to be controlled to process the data of clamper, and control the table to correct the output axle. The invention has simple structure and high accuracy.

Owner:SHANGHAI AEROSPACE AUTOMOBILE ELECTROMECHANICAL CO LTD

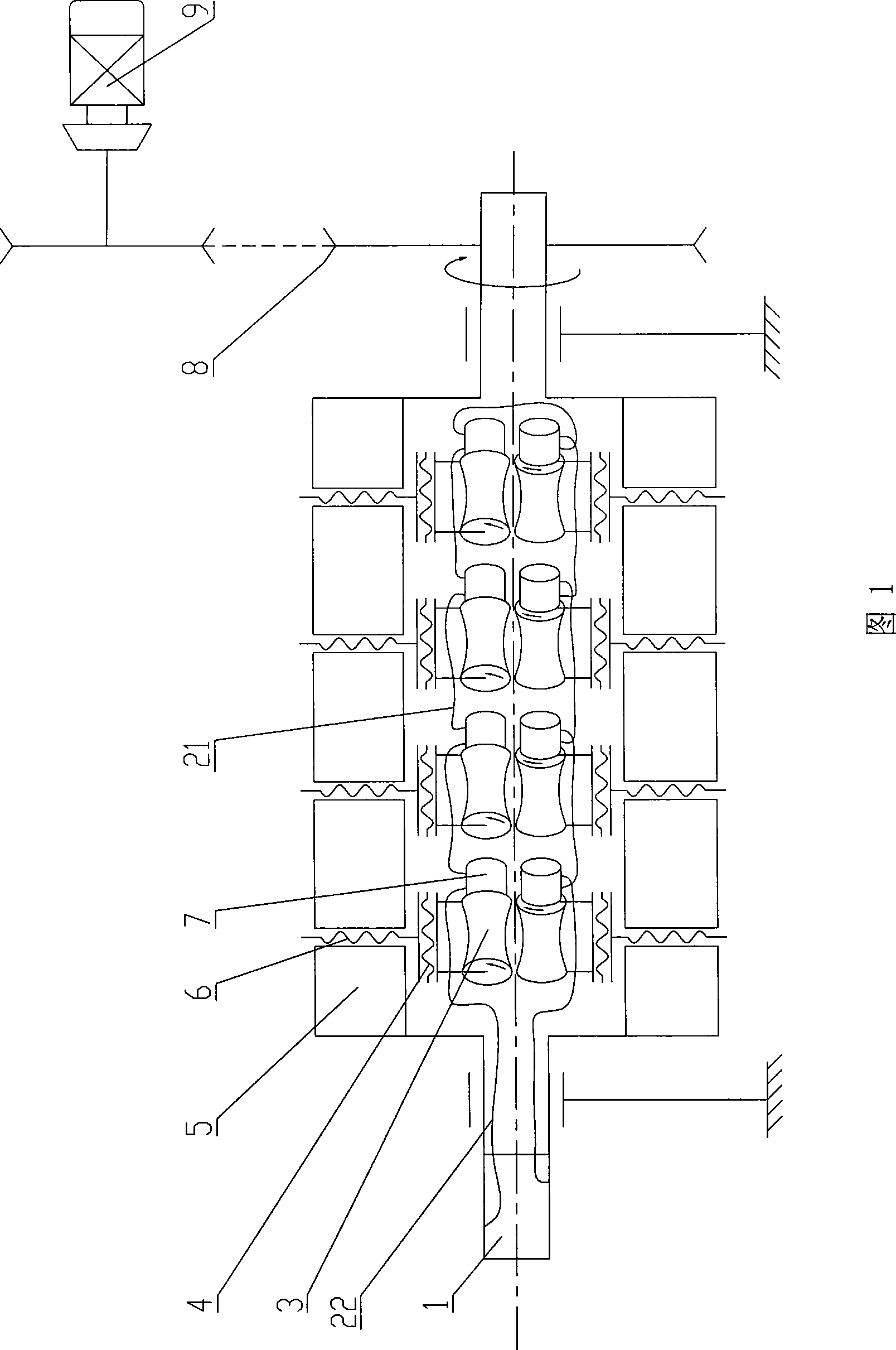

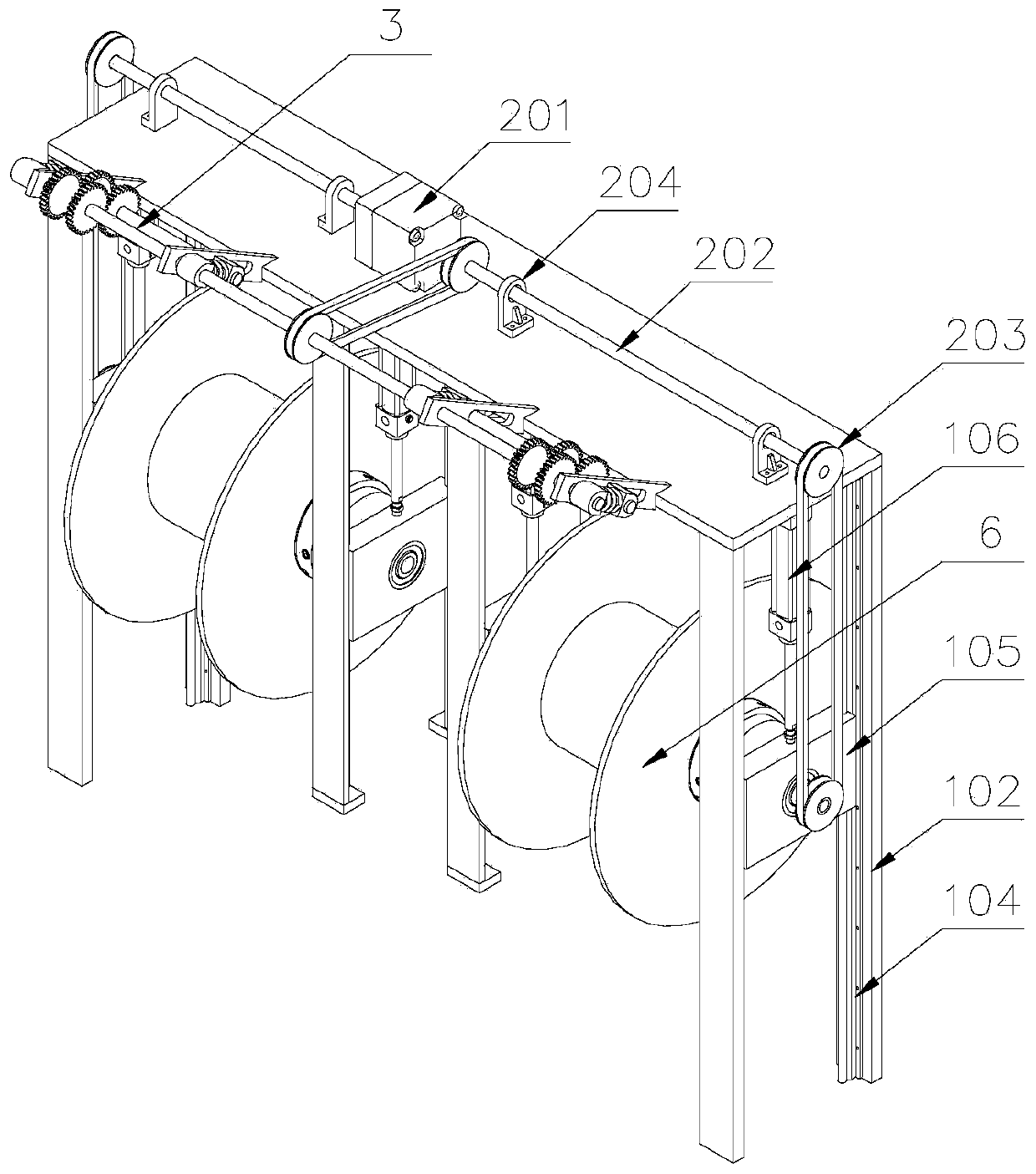

Planetary web roll rotating hub type flattening machine

The invention relates to a planetary inclined roll rotary hub straightening machine, comprising a rotary hub, a first power driving device for driving the rotary hub to rotate, at least two groups of straightening rollers arranged in the rotary hub and a second power driving device for driving the rotation of the straightening rollers. An upper straightening roller and a lower straightening roller of every group of the straightening rollers are symmetrically arranged at the two sides of a rotating axis and the straightening rollers are inclined in certain angle corresponding to the rotating axis. A structure combining the straightening rollers which can autorotate with the rotary hub which can implement revolution is adopted. Therefore, previous driven straightening rollers in the rotary hub are changed into driving straightening rollers. The rotating speeds of the rotary hub and the straightening rollers are matched to eliminate the puppet rotating phenomenon of straightened roundwood. The contact and the compression bending state of the straightening rollers and the straightened roundwood are improved, and the straightness is improved. The straightening rollers driven by a hydraulic motor clamp the straightened roundwood tightly and roll around the straightened roundwood to ensure the roundness. The planetary inclined roll rotary hub straightening machine is very beneficial to the straightening of super-long thin wall pipes.

Owner:广东冠邦科技有限公司

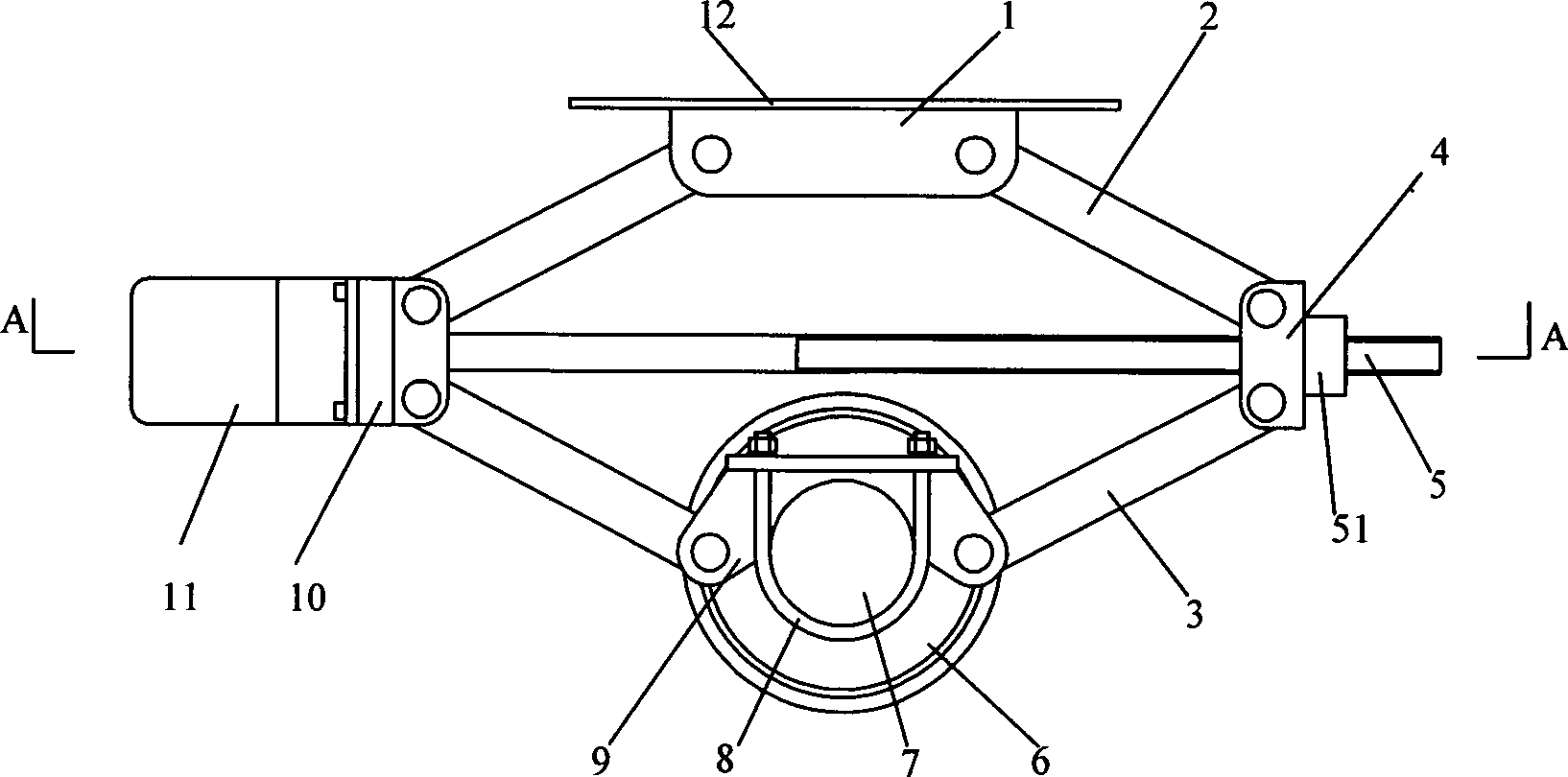

Vehicle transverse swinging parking device

The invention discloses a vehicle transverse swinging stopping device, which comprises a lifting mechanism and a transverse swinging mechanism, wherein the lifting mechanism comprises a lifting power unit, screw mandrels, nuts screwed on the screw mandrel, two upper stay bars and two lower stay bars; the two upper stay bars and the two lower stay bars respectively take the screw mandrels and the nuts as movable pairs to form an upper plane four-bar mechanism and a lower plane four-bar mechanism; and the transverse swinging mechanism comprises a transverse swinging power unit and a transverse driving wheel. The vehicle transverse swinging stopping device adopts a movable pair type plane four-bar mechanism which is combined with a transverse driving wheel structure to complete lift and sideslip of the tail of a vehicle, is convenient to put straight the tail of the vehicle under the condition of parking, does not require arrangement of complex pipelines and lines, is simple and convenient to arrange, has low manufacturing cost and light weight, accords with the development trends of light weight, energy saving and emission reduction of the modern vehicle, and is suitable for parking of middle-size and small-size vehicles such as sedans, etc. in a narrow place.

Owner:CHONGQING UNIV

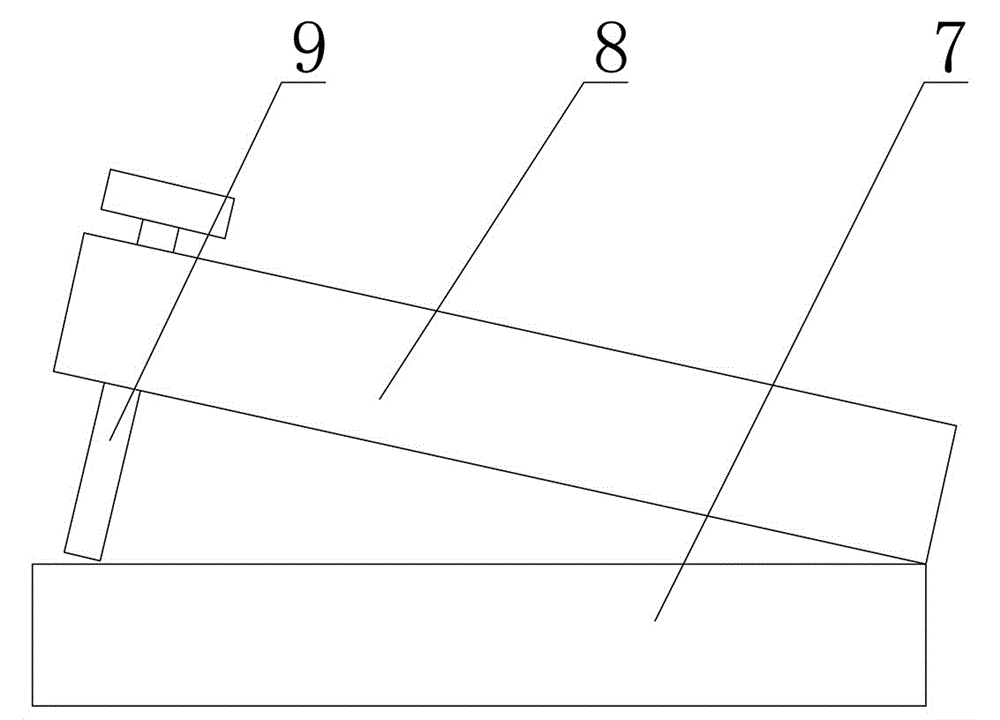

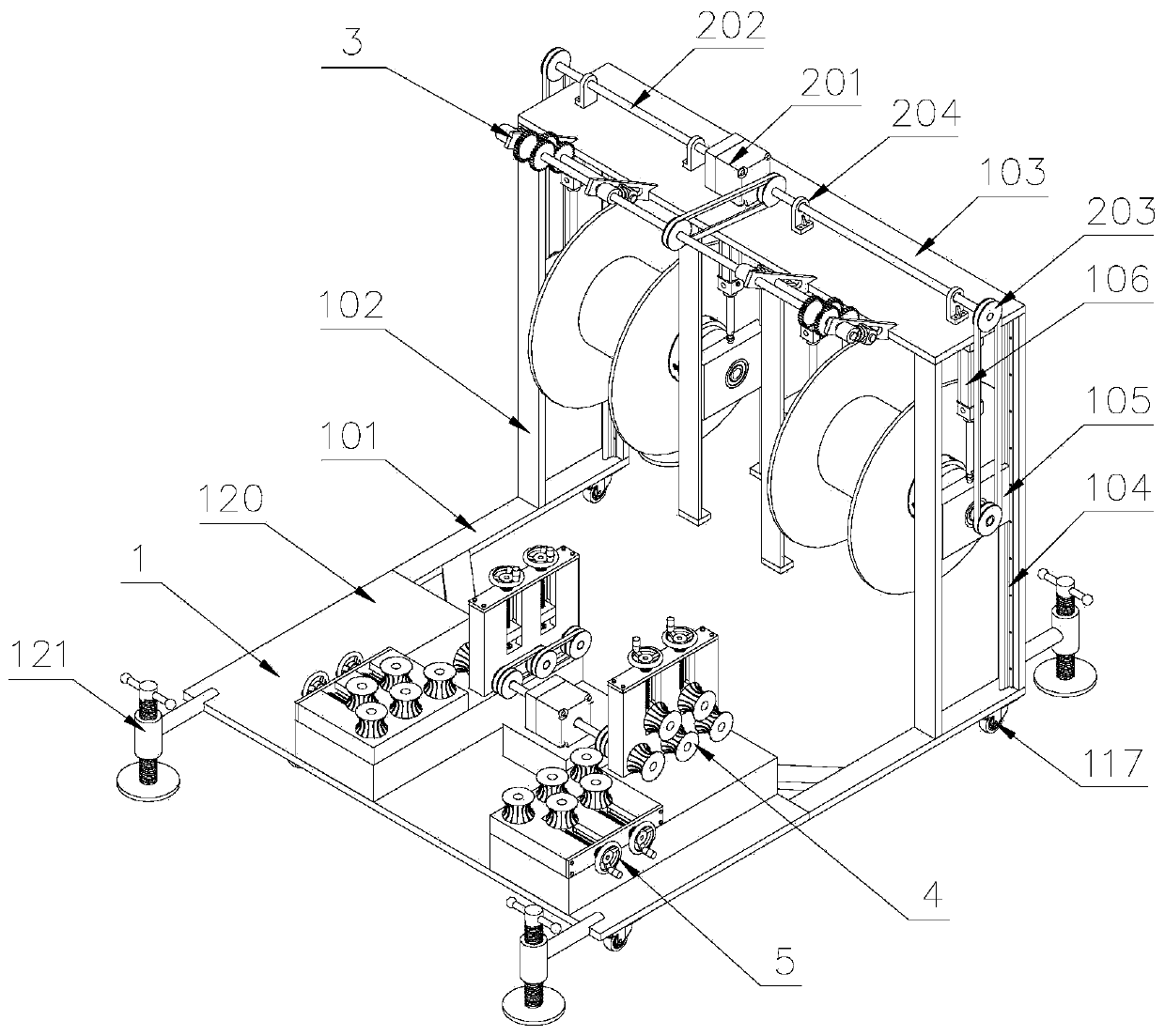

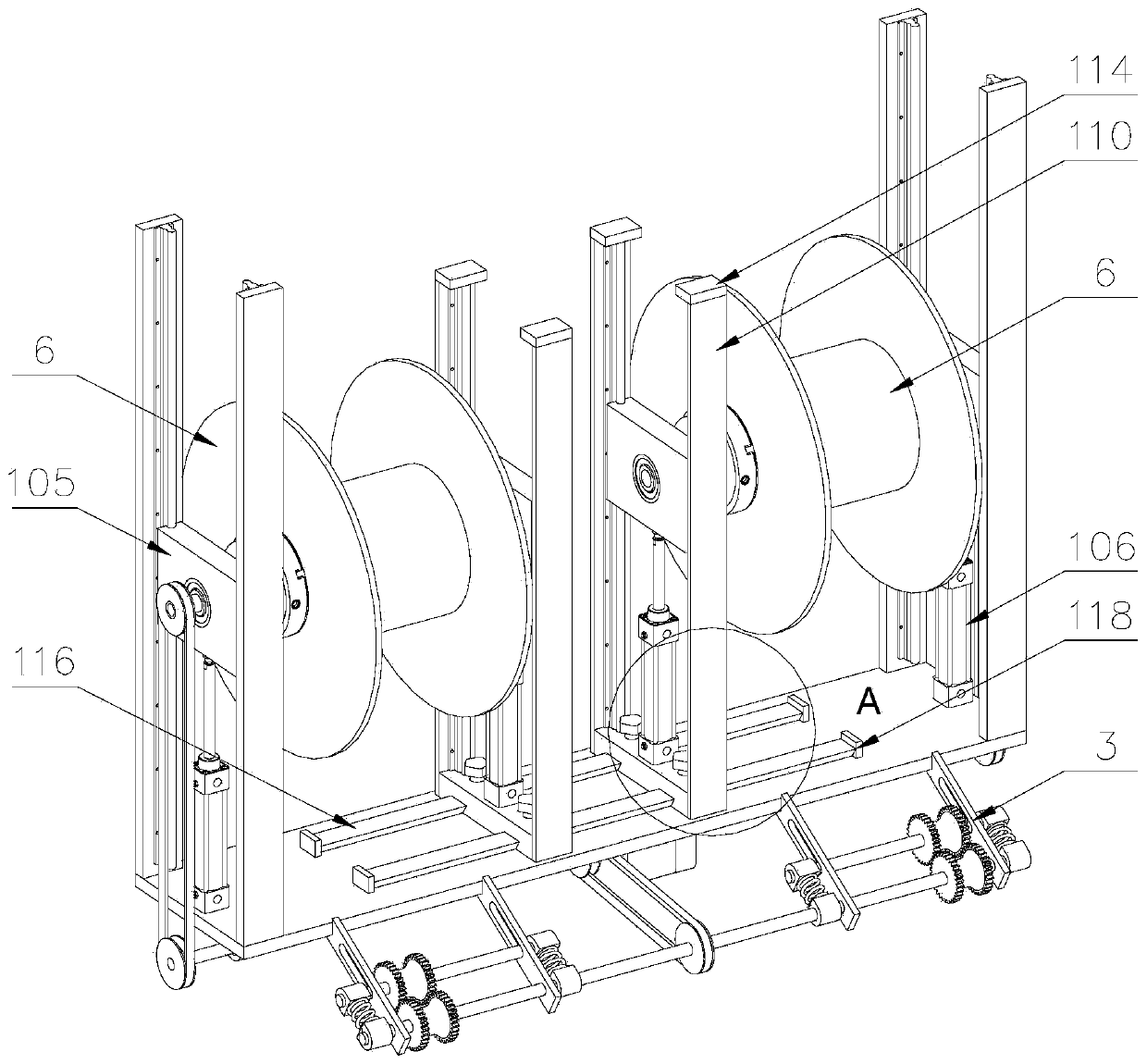

Multi-cable pay-off device for cable erection

ActiveCN110589602AGuaranteed stabilityPrevent disengagementFilament handlingApparatus for laying cablesVehicle frameEngineering

The invention discloses a multi-cable pay-off device for cable erection. A first slide block is arranged at one side of a vertical column, first slide rails are arranged at the two ends of the first slide block, and a clamping jaw is arranged at one side of the first slide block; a first belt wheel is arranged at one end of a first rotary shaft; a clamping jaw is arranged on a second slide block;the upper end of the first slide block is connected with a top plate through a first oil cylinder; the upper end of the second slide block is connected with the second slide block through a second oilcylinder; and a drive device comprises a first double-end motor arranged on the upper part of the top plate, second rotary shafts connected with the two ends of an output shaft of the first double-end motor, and second belt wheels installed on the second rotary shafts, and the second belt wheels are connected with the first belt wheel through a belt. According to the multi-cable pay-off device for cable erection, the clamping jaws are arranged at the two ends of a vehicle frame, and a reel is supported by virtue of the clamping jaws, so that the reel is prevented from being separated from a pulley during rotation, and the stability of the reel is ensured; and moreover, the drive device is arranged on the upper part of the top plate, and the reel is driven to rotate by virtue of the drivedevice, so that manual wire drawing is avoided, the labor amount of workers is reduced, and the pay-off efficiency is increased.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Steel rib straightening device for building

The invention discloses a steel bar straightening device for construction, which comprises a bottom plate, side plates are arranged on both sides of the end surface of the bottom plate, horizontal plates are also arranged on the two side plates, and clamping clamps are arranged on the two horizontal plates. Fixing device, the clamping and fixing device includes a fixed box, the inside of the fixed box is provided with a parallel constant pressure plate and a dynamic pressure plate, the top of the constant pressure plate is fixedly connected with the top wall of the fixed box, and the side of the dynamic pressure plate is connected with the inner wall of the fixed box Sliding connection, a support frame is arranged on the top plate, a first horizontal shaft is installed on the support frame, a turntable is arranged at one end of the first horizontal shaft, a rope winding roller is arranged on the first horizontal shaft, and the Both take-up grooves are wound with tension ropes. The invention has simple structure, can effectively straighten bent steel bars, has high straightening efficiency of steel bars, can be straightened permanently, can be aimed at straightening steel bars with different diameters, has wide application range, is easy to operate, and has strong practicability.

Owner:宣城市万成机械科技有限公司

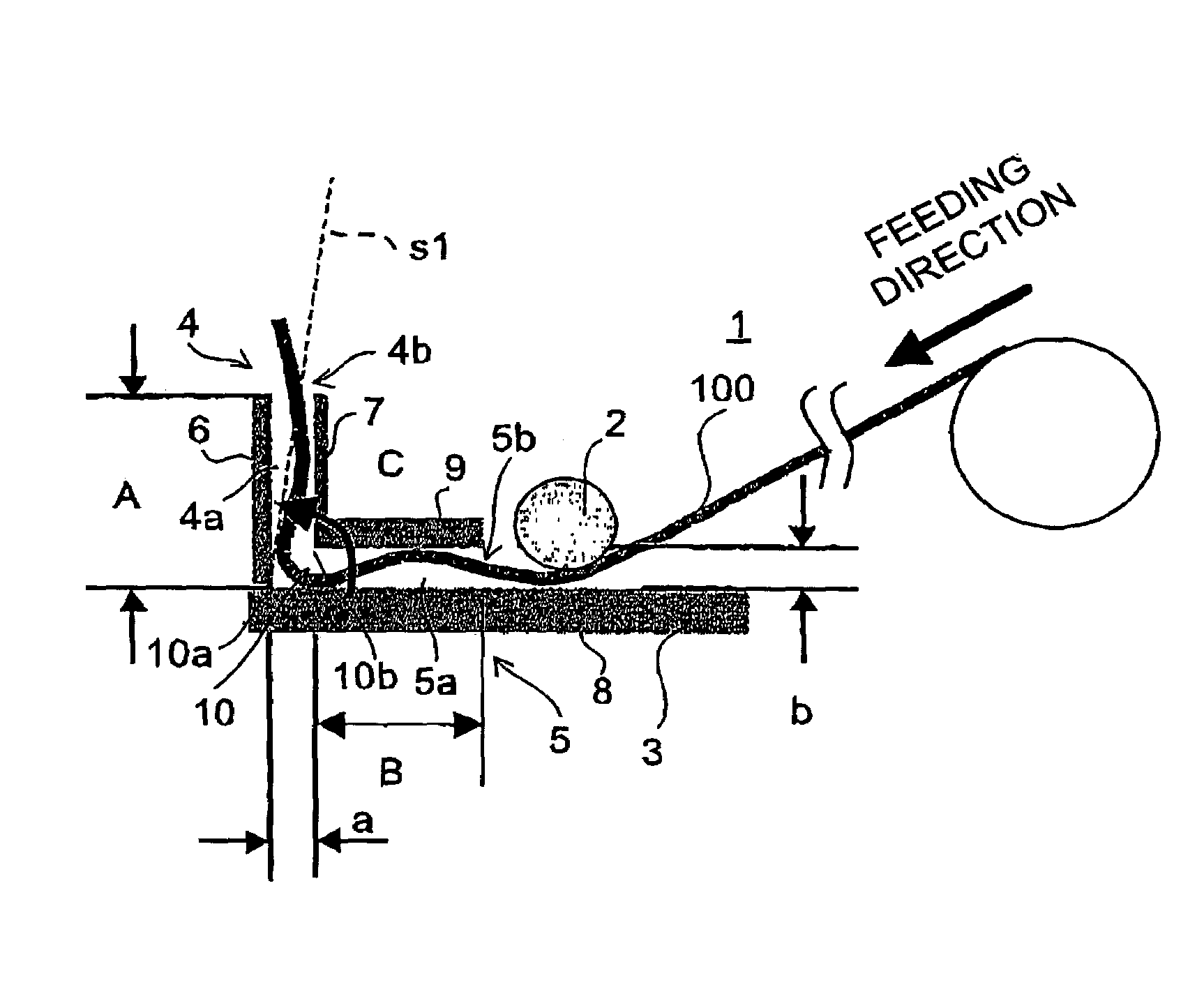

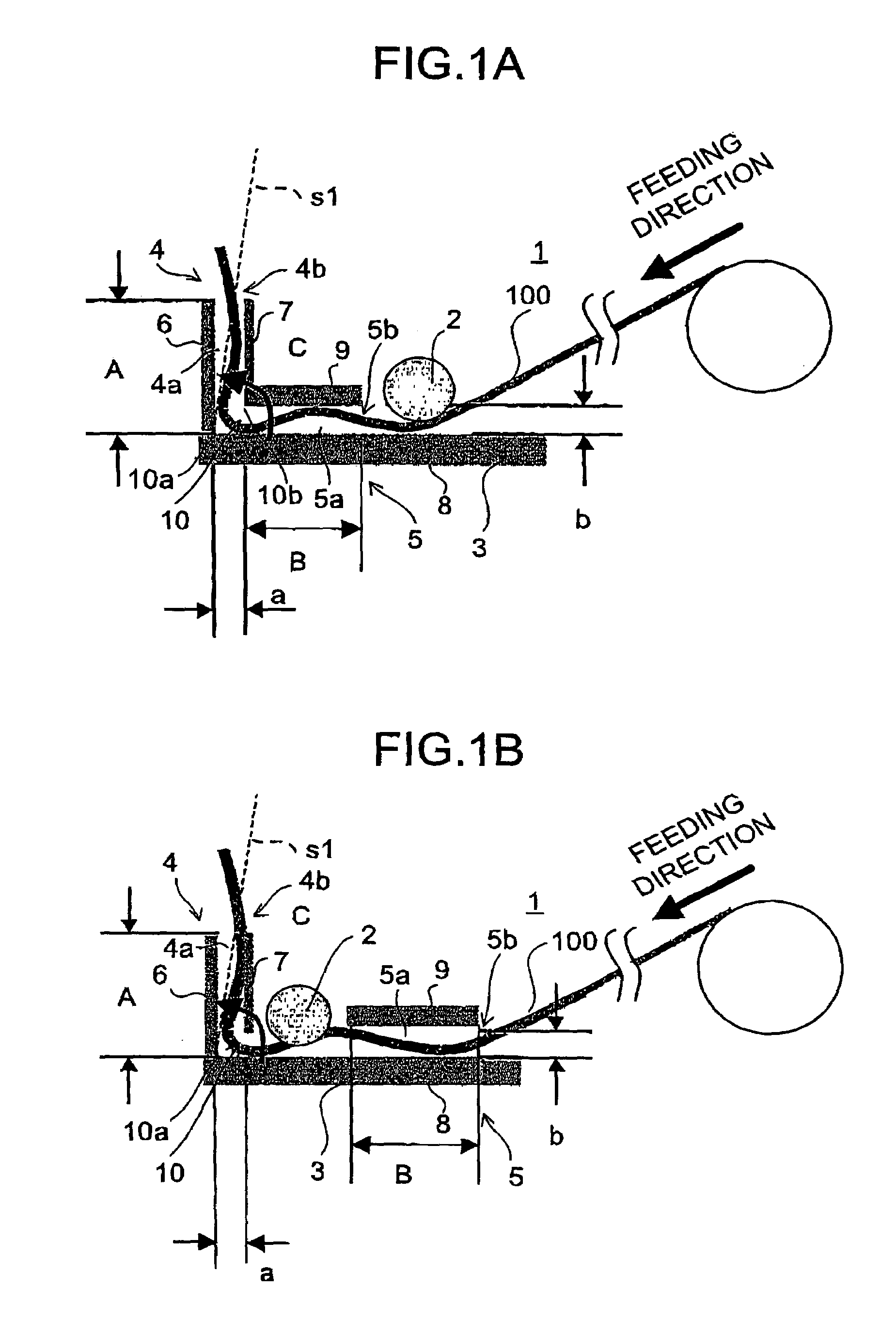

Curl straightening method for image receiving paper for sublimation dye transfer and curl straightening device therefor

ActiveUS7166191B2Easy to handleEasy to straightenProjector film strip handlingCamera film strip handlingRolling paperPulp and paper industry

To provide a curl straightening method for image receiving paper for sublimation dye transfer, which is capable of realizing a smaller roll core diameter of the roll paper. The curl of an image receiving paper 100 for sublimation dye transfer having stiffness from 500 to 2,500 mg in a direction parallel to the printing direction, which is measured according to JIS L1085, JIS L1096, is straightened by allowing the image receiving paper 100 to pass through gaps 4a, 5a of a guide 3 that bends the image receiving paper 100 in a reverse curling direction.

Owner:DAI NIPPON PRINTING CO LTD

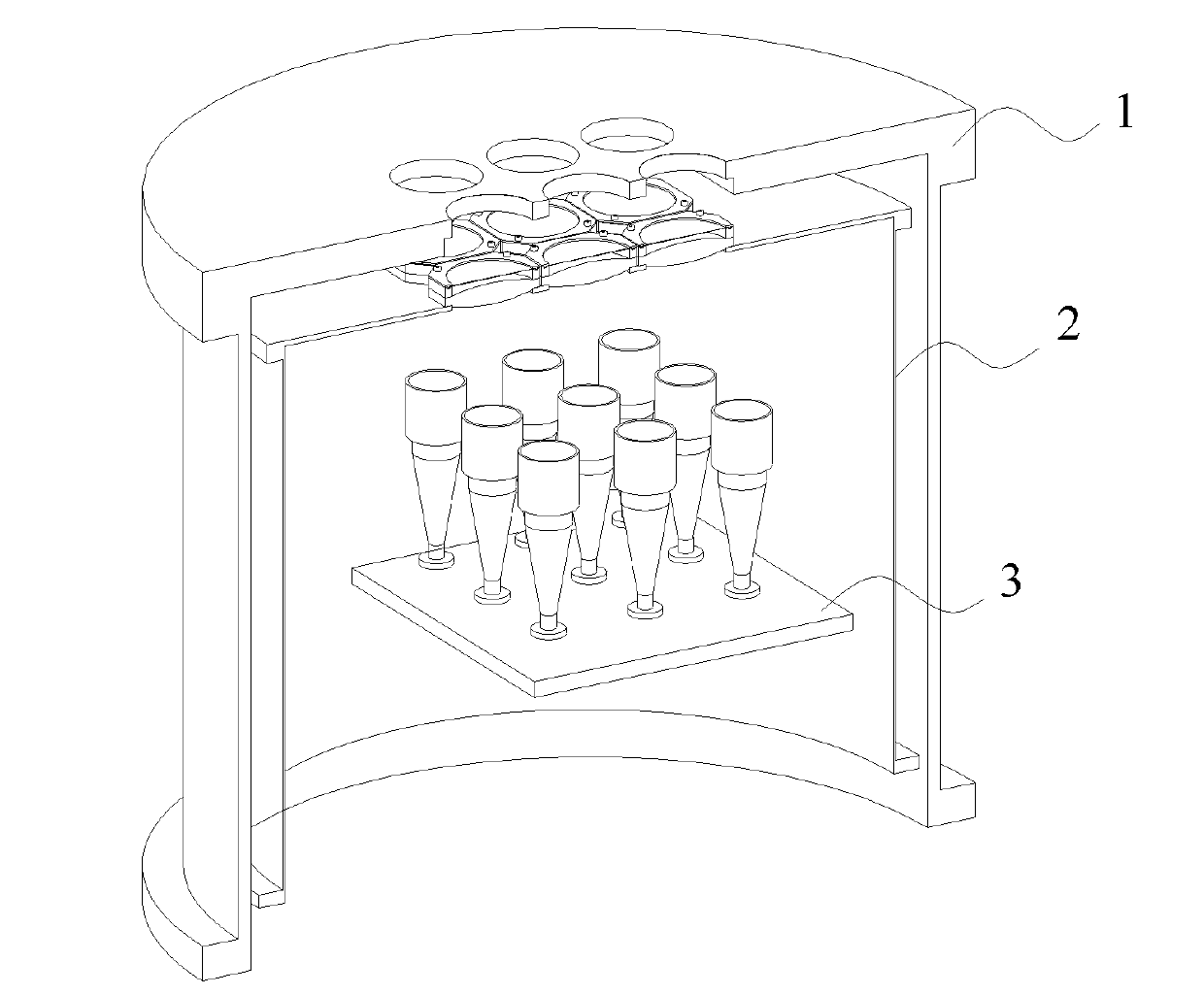

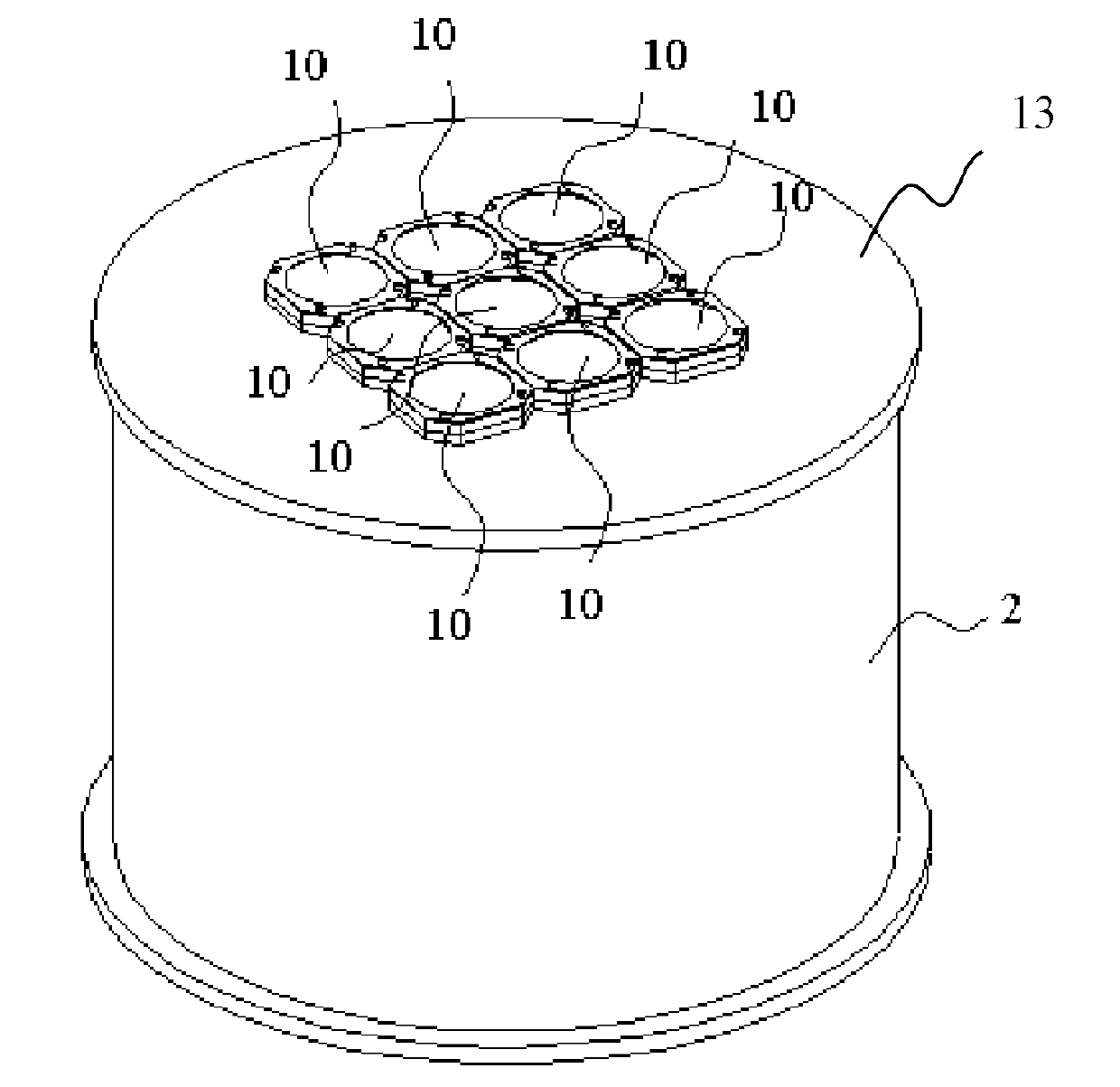

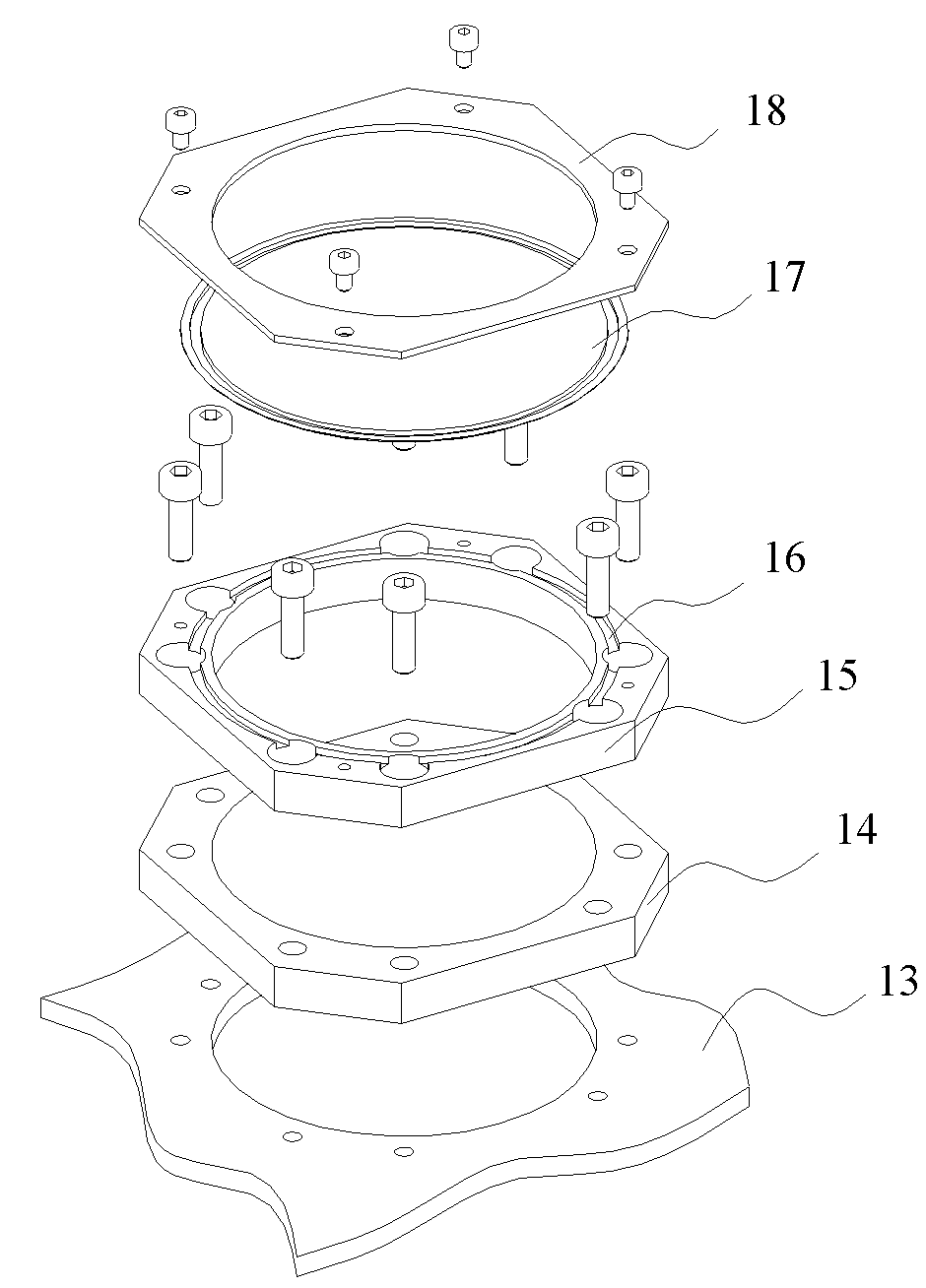

Millimeter wave multi-pixel refrigeration receiver dewar

The invention relates to a millimeter wave multi-pixel refrigeration receiver dewar. The cold shield of the dewar can effectively shield the thermal radiation without affecting the sensitivity of a receiver, thereby lowering the requirement of the refrigerating machine on refrigeration power. The millimeter wave multi-pixel refrigeration receiver dewar comprises a vacuum chamber and a cold shield arranged in the vacuum chamber, wherein the cold shield is provided with a plurality of circular windows; the circular windows are corresponding to detectors arranged in the cold shield; each circular window comprises a through hole and a dielectric lens; the through hole is arranged on the upper surface of the cold shield; the dielectric lens covers on the through hole and has certain thickness; and the edge of the dielectric lens is fixed on the upper surface of the cold shield.

Owner:ZIJINSHAN ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

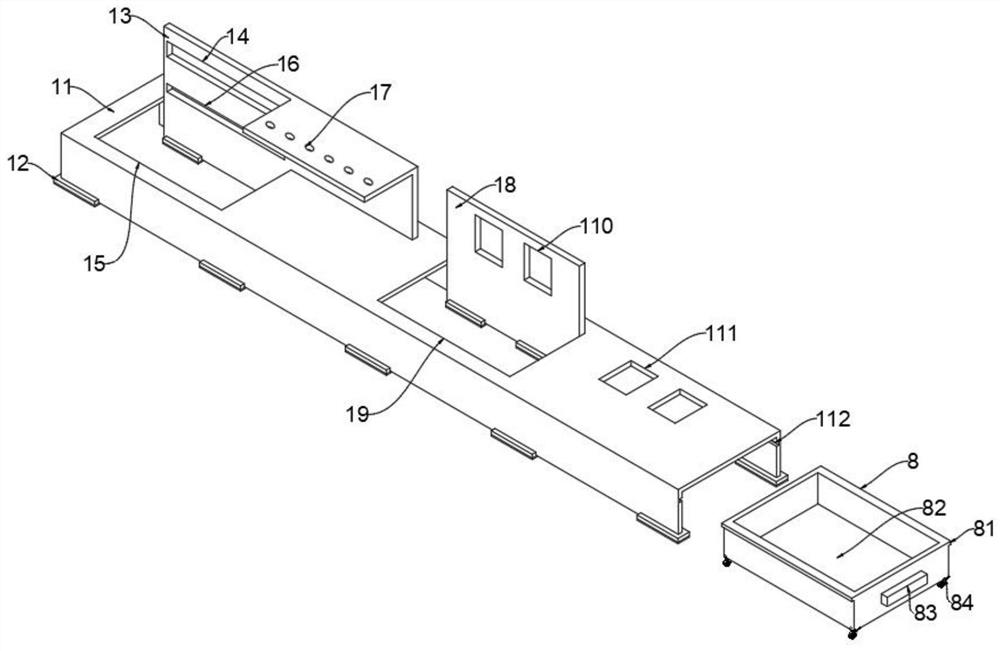

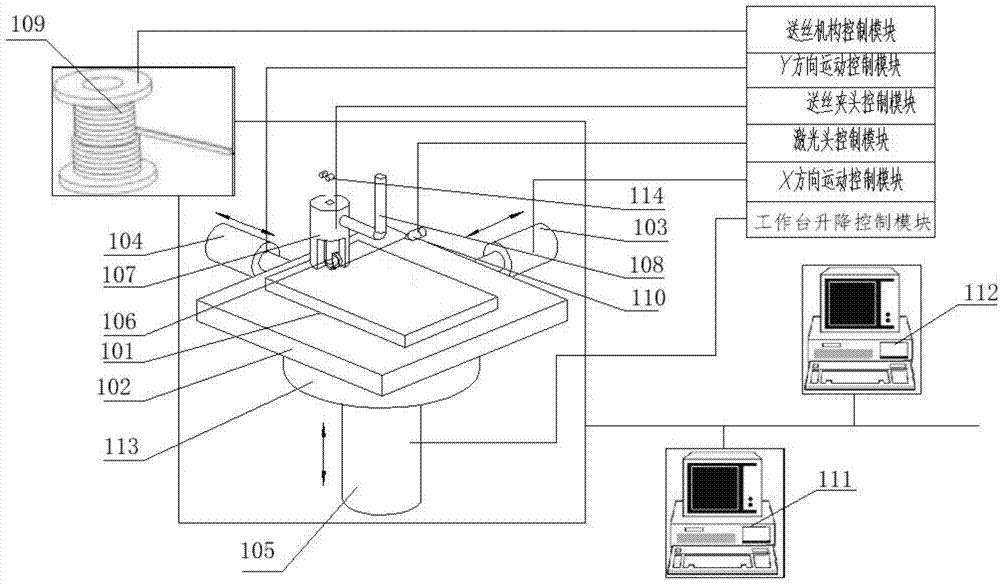

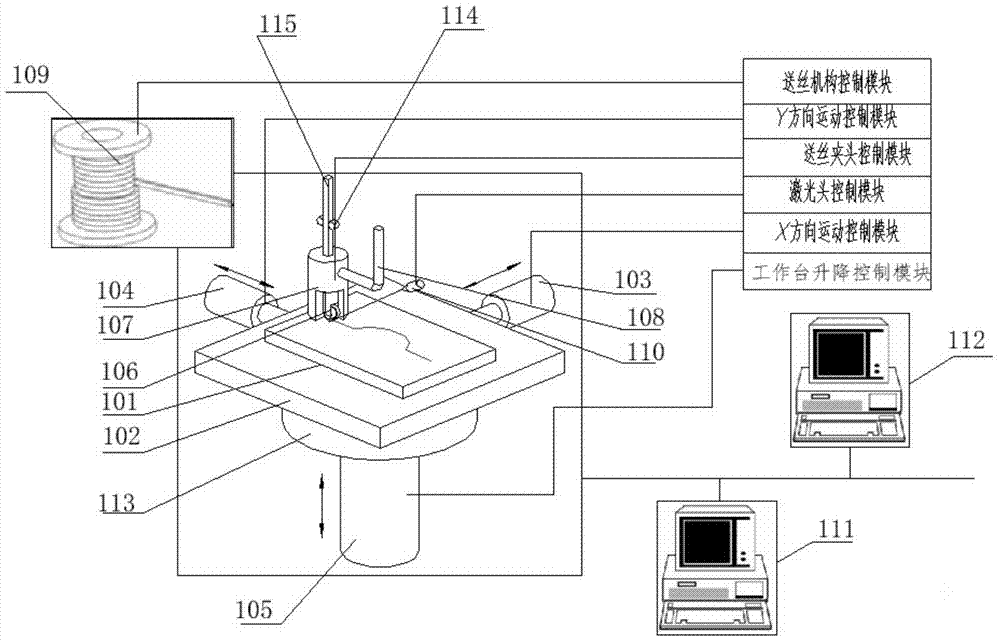

Method for rapid prototyping by taking wire as raw material and rapid forming machine

InactiveCN104259352AReduce consumptionEasy to straightenGlass making apparatusWire articlesEngineeringRapid prototyping

The invention discloses a method for rapid prototyping by taking a wire as a raw material and a rapid forming machine. The method includes that firstly, the wire is pulled on a forming board to form a linear or curved flat trajectory shape to be combined on the forming board and kept in the corresponding shape; secondly, the wire is taken as a benchmark to perform rapid prototyping layering to have the wire stacked up and increased, two situations are included in that 1), other wires are tightly stacked up on the wire to form a space shaped needed by components, the wires are metallurgically combined therein, and the components required in shape can be finally obtained; 2), the other wires and the wire are adhered side by side to form a panel structure, metallurgical combination among the wires is achieved, the wires on the panel structure are stacked up in layer according to required trajectory shape and length to form the space shape required by the components, metallurgical combination among the wires is achieved, and the components required in shape are finally obtained. The method is convenient to operate, stable and reliable and low in production cost.

Owner:SOUTH CHINA UNIV OF TECH

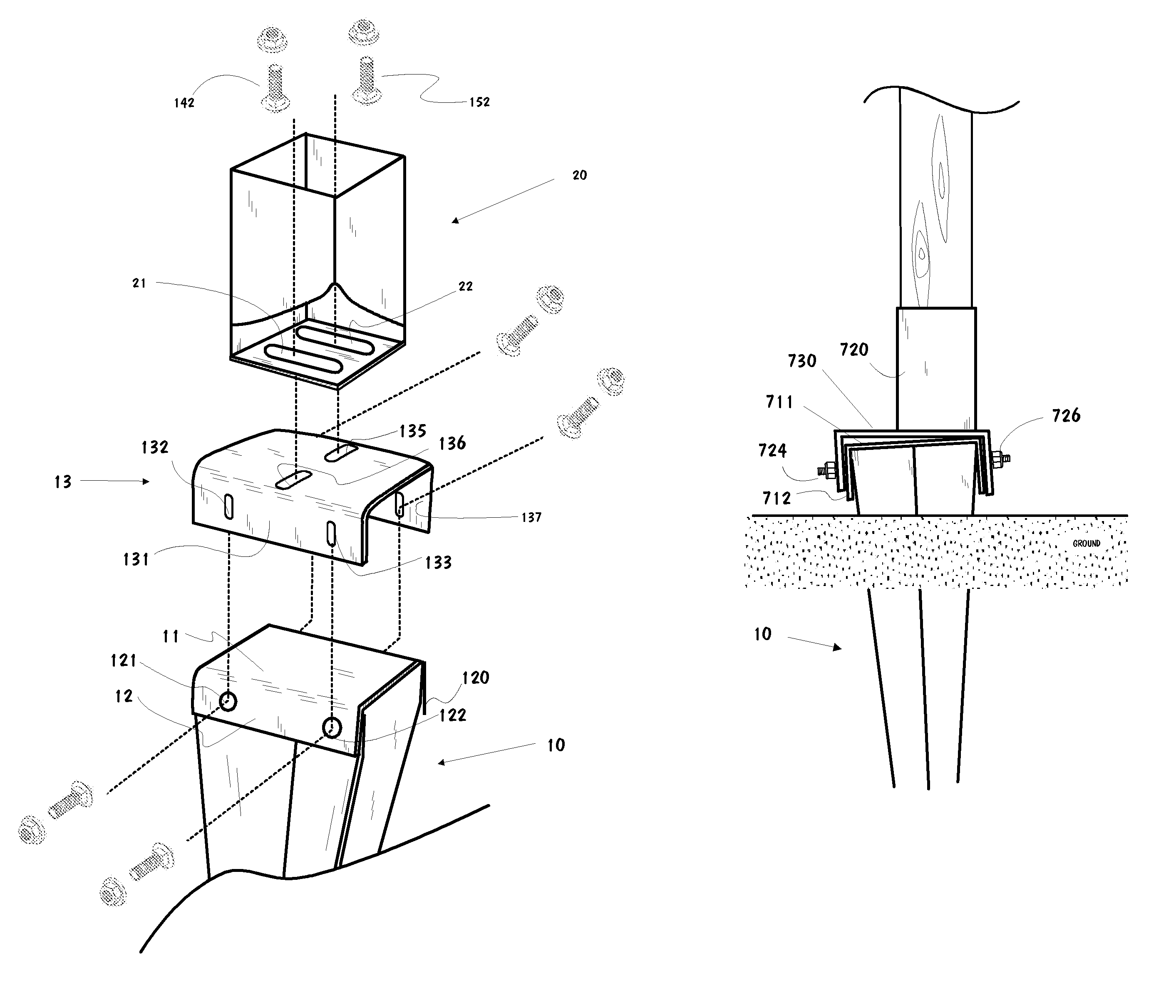

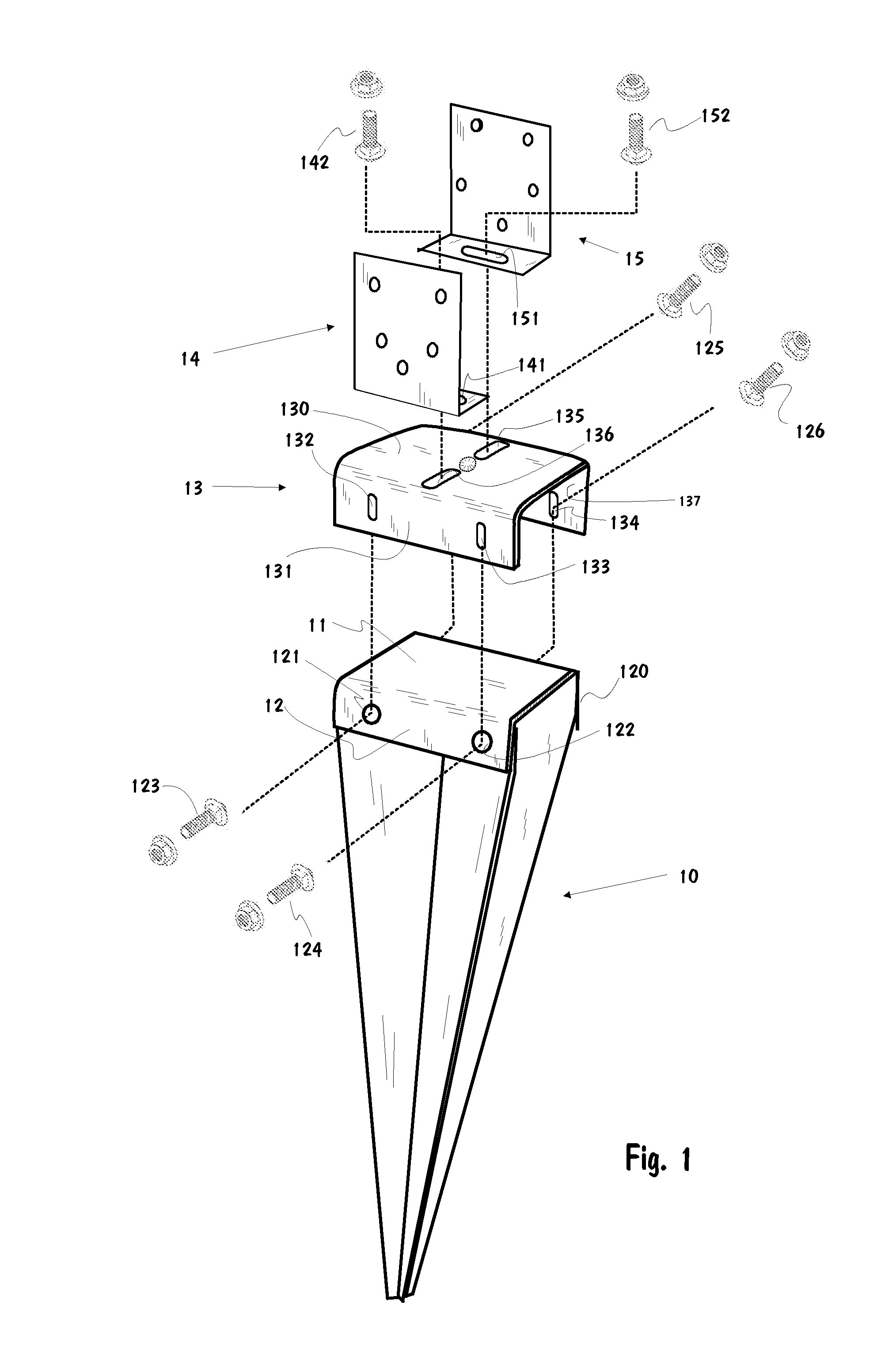

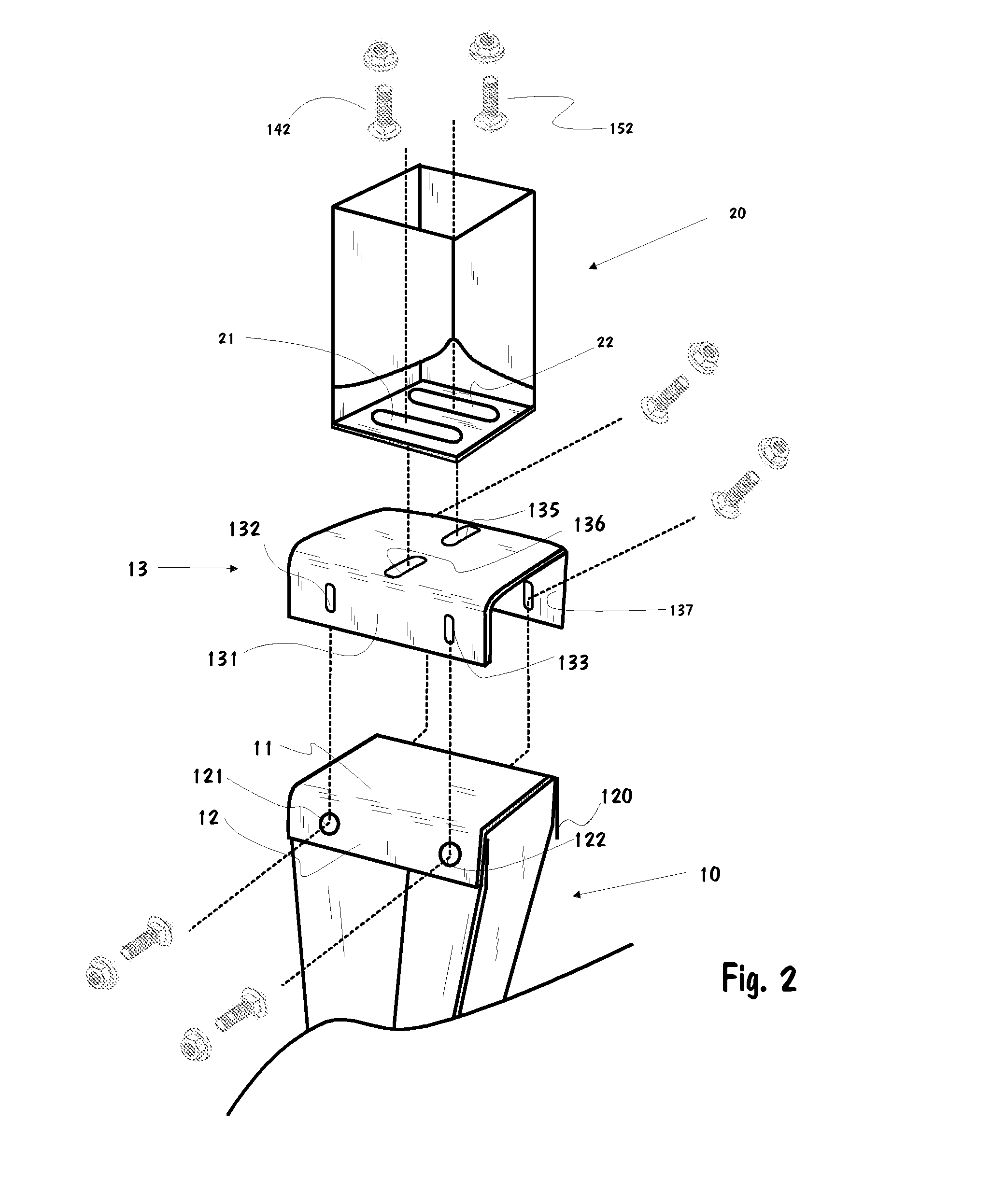

Ground anchor with tilt compensation

During ramming of a metal ground anchor for a fence post by applying force on its top plate, the anchor is often tilted, subsequently resulting in the tilted fence post. The tilt is compensated by utilizing a compensation plate (13), the dimensions and form of which correspond to the dimensions and form of the top plate (11) welded onto the ground anchor (10). The compensation plate is located above the top plate (11) and a post holder (2) is attached thereto. Downwards-protruding mounting flanges (131, 137) are located on two opposite edges of the compensation plate, aligning with downwards-protruding fixing flanges of the top plate. Elongated adjustment slots (132, 133) in the mounting flanges are aligned with holes in the fixing flanges of the top plate, enabling the flanges to be attached with bolts. The adjustment slots allow adjusting the compensation plate before the bolts are tightened.

Owner:PAANANEN TUOMO

Bar detection mechanism and working method thereof

PendingCN110487513AEasy to straightenEasy to moveTesting optical propertiesConveyor partsEngineeringMechanical engineering

Owner:福州中科光芯科技有限公司

Comber

InactiveCN1356419ASolve the problem of unfavorable lifeSufficient starting torqueCombing machinesElectrical controlCotton fibre

A comber for carding and straightening cotton fibres is composed of geared head, main driver, carding unit, tail unit and electric controller. It features use of dual-speed motor, electromagnetic braking, two-point grasp of jaws for decreasing loss of long fibres, pneumatic pressing, lower curve stretching for higher uniformity, centralized suction of dropped fibres, PCL control, failure display and photoelectric detection with higher sensitivity.

Owner:山西经纬合力机械制造公司总厂

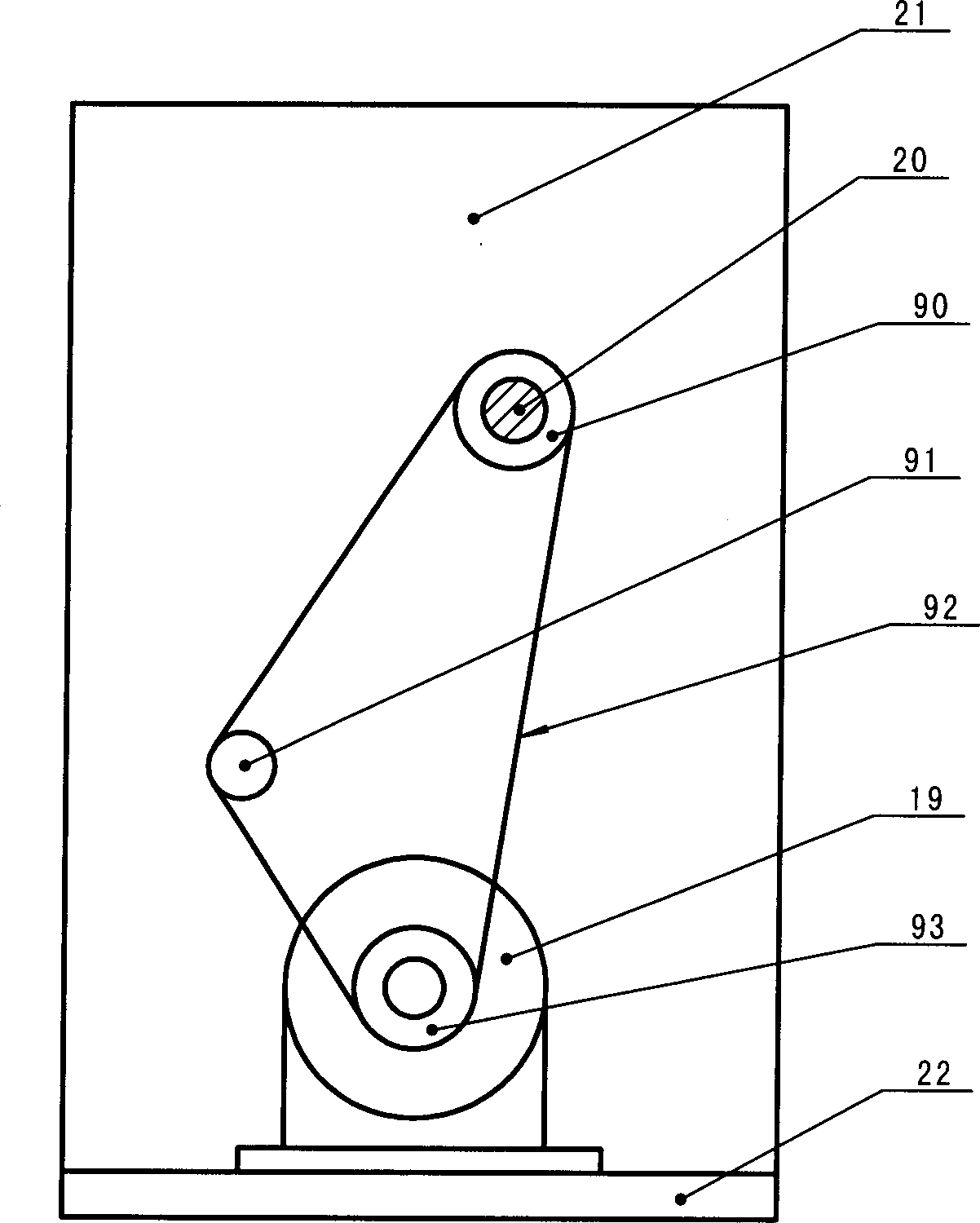

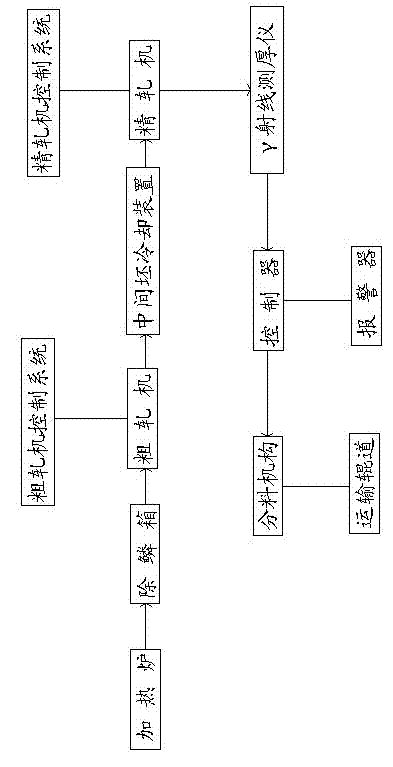

Rolling system for medium and thick steel plate in thin gauge

InactiveCN103071675ASolve the temperature drop quicklyEasy to straightenRoll mill control devicesMeasuring devicesSteel platesSheet steel

The invention discloses a rolling system for a medium and thick steel plate in a thin gauge. The rolling system comprises a heating furnace, a descaling box, a roughing mill, an intermediate blank cooling device, a finishing mill, a thickness tester and a conveying roller way; the rolling system is characterized in that the roughing mill is connected with a roughing mill control system; the finishing mill is connected with a finishing mill control system; the thickness tester is connected with a controller; and the controller is connected with an alarm. The rolling system provided by the invention solves the problems that the temperature drop is fast, the temperature difference between the head and the tail of a steel plate is large, and the plate shape is hard to control when the thick gauge steel plate is rolled, and thus, the rolling system creates good conditions for straightening the steel plates.

Owner:JIGANG GRP

Clamp for rod material alignment

InactiveCN104438906AEasy to straightenImprove straightening efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:CHONGQING ZETIAN AUTO PARTS

Winding device of data cable

The invention discloses a winding device of a data cable. The winding device comprises a working table. One end of the top portion of the working table is provided with a guiding mechanism, the otherend of the top portion of the working table is fixedly provided with a stepper motor fixing board. One side of the stepper motor fixing board is fixedly provided with a stepper motor. A transmission shaft of the stepper motor is fixedly connected with one end of a lead screw. The lead screw is correspondingly connected with a first lead screw nut arranged in the bottom portion of a first connection board and a second lead screw nut arranged in the bottom portion of a second connection board in a threaded mode. According to the winding device of the data cable, a first guiding roller and a second guiding roller are arranged to guide the data cable, and on the other hand convenient to straighten the data cable; and the surface of the first guiding roller and the surface of the second guidingroller are both provided with bristles which are convenient to clean dust on the surface of the data cable; the stepper motor is arranged to drive the first connection board and the second connectionboard to move conveniently, so that installation and dismantle of the winding device are conducted conveniently.

Owner:吴江市凯宝电器有限公司

Garment fabric cutting device

ActiveCN108914528ACropping effectImprove shear efficiencySevering textilesUltimate tensile strengthUtilization rate

The invention belongs to the technical field of garment processing machinery and specifically relates to a garment fabric cutting device. The device comprises a box body; the device also comprises a drive unit, a cutting unit and a cutting table; the drive unit is used for driving the cutting unit to cut fabric; the cutting unit is used for cutting fabric; the cutting table is used for providing cutting position for fabric. By means of the cooperation of the drive unit, the cutting unit and the cutting table, the fabric is cut by the cutting unit which is driven by the drive unit, which not only alleviates labor intensity, but also increases fabric cutting efficiency; at the same time, the power source generated in the drive unit during driving is utilized so that the source utilization rate is increased; the fabric scraps in the fabric cutting drops to the bottom of the box to avoid the fabric scraps affecting the cutting of the fabric, thus improving the cutting effect of the fabric.

Owner:浙江平步服饰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com