Bar detection mechanism and working method thereof

A technology of bearing mechanism and moving mechanism, which is applied in the direction of conveyor objects, testing optical properties, single semiconductor device testing, etc., can solve the problems of heavy workload, low efficiency, and bar damage of operators, and achieve reasonable design and mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

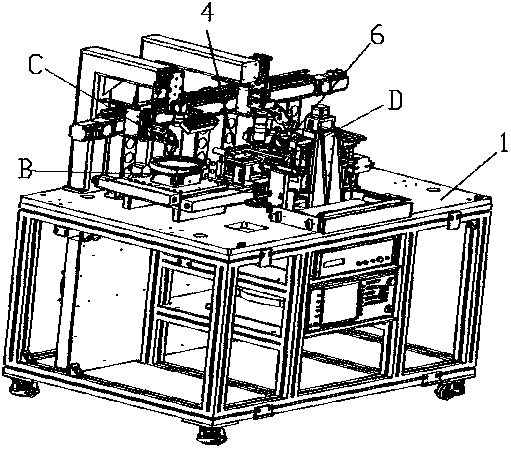

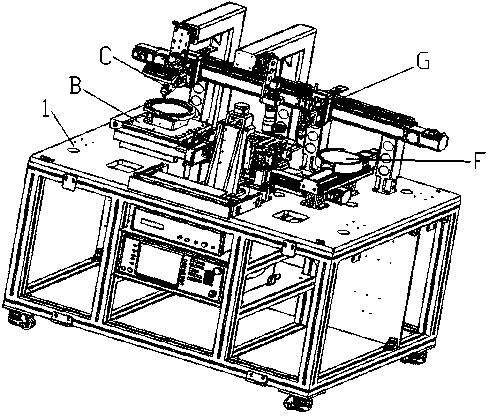

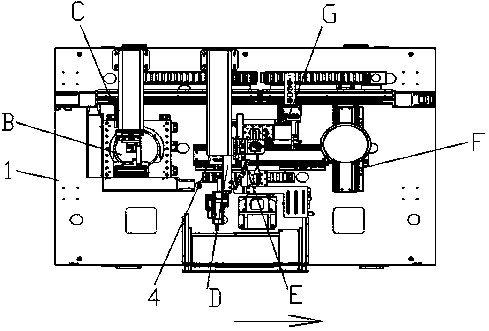

[0043] Bar bar detection mechanism of the present invention comprises frame 1 and the Bar bar carrying mechanism B (such as being located at frame 1) Figure 13 ) and Bar moving mechanism C (such as Figure 5-12 ), the frame includes a lower rectangular frame and a table top on the rectangular frame, each mechanism can be located on the table surface, and the Bar bar bearing mechanism B includes a base B1 on the frame 1 and a base B1 on the base B1. The loading tray B2 on the base, the loading tray B2 is driven by the horizontal and vertical drive mechanism B3 and the swing mechanism B4 on the base to realize the displacement of the loading tray B2; the Bar bar moving mechanism C includes 1 above the horizontal guide rail C1, the horizontal sliding seat C2 provided on the horizontal guide rail C1, and the lifting slide C3 provided on the horizontal sliding seat C2, and the lifting sliding seat C3 is provided with a bar suction head C4.

[0044] The loading tray B2 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com