Patents

Literature

221results about How to "Improve straightening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

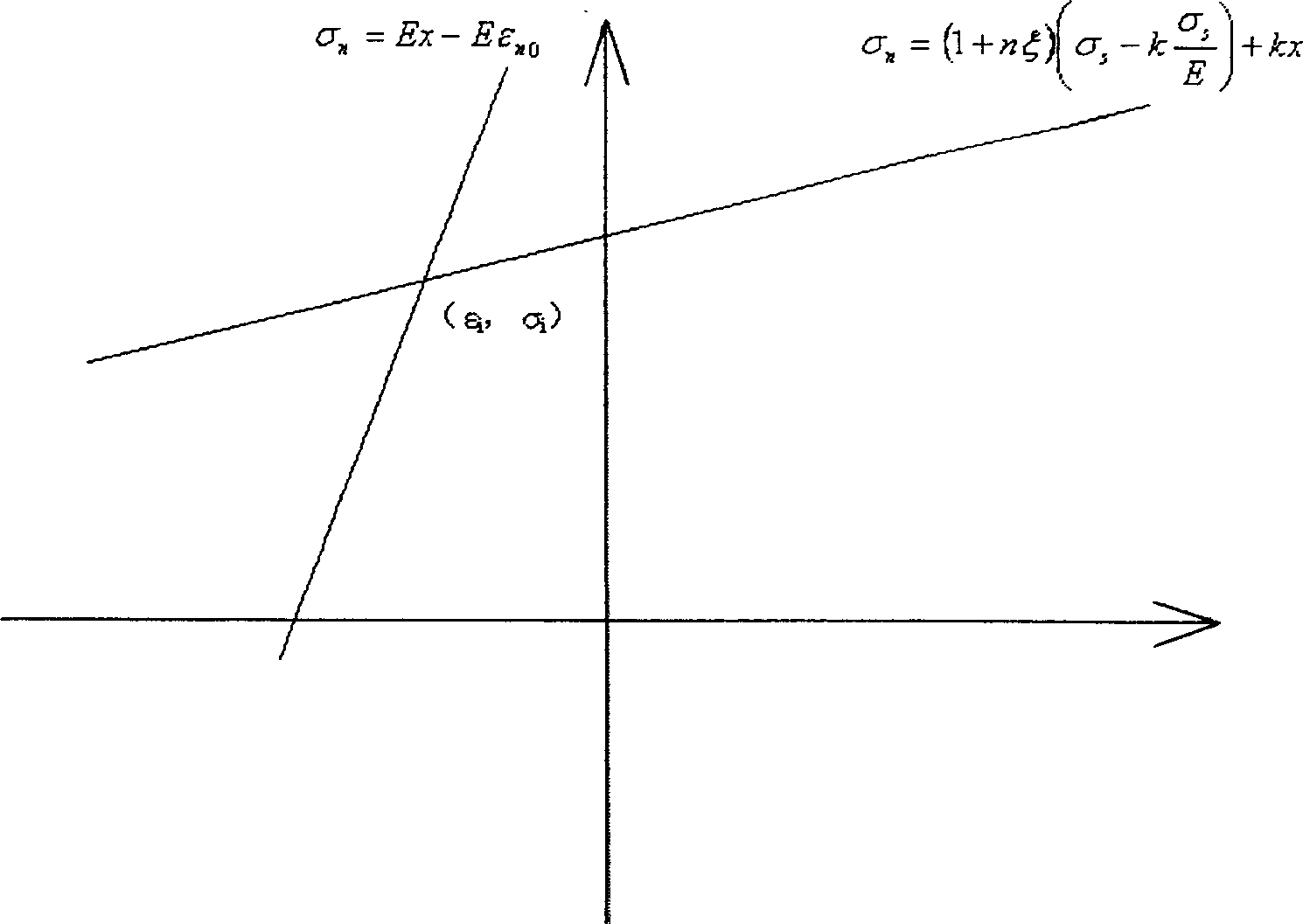

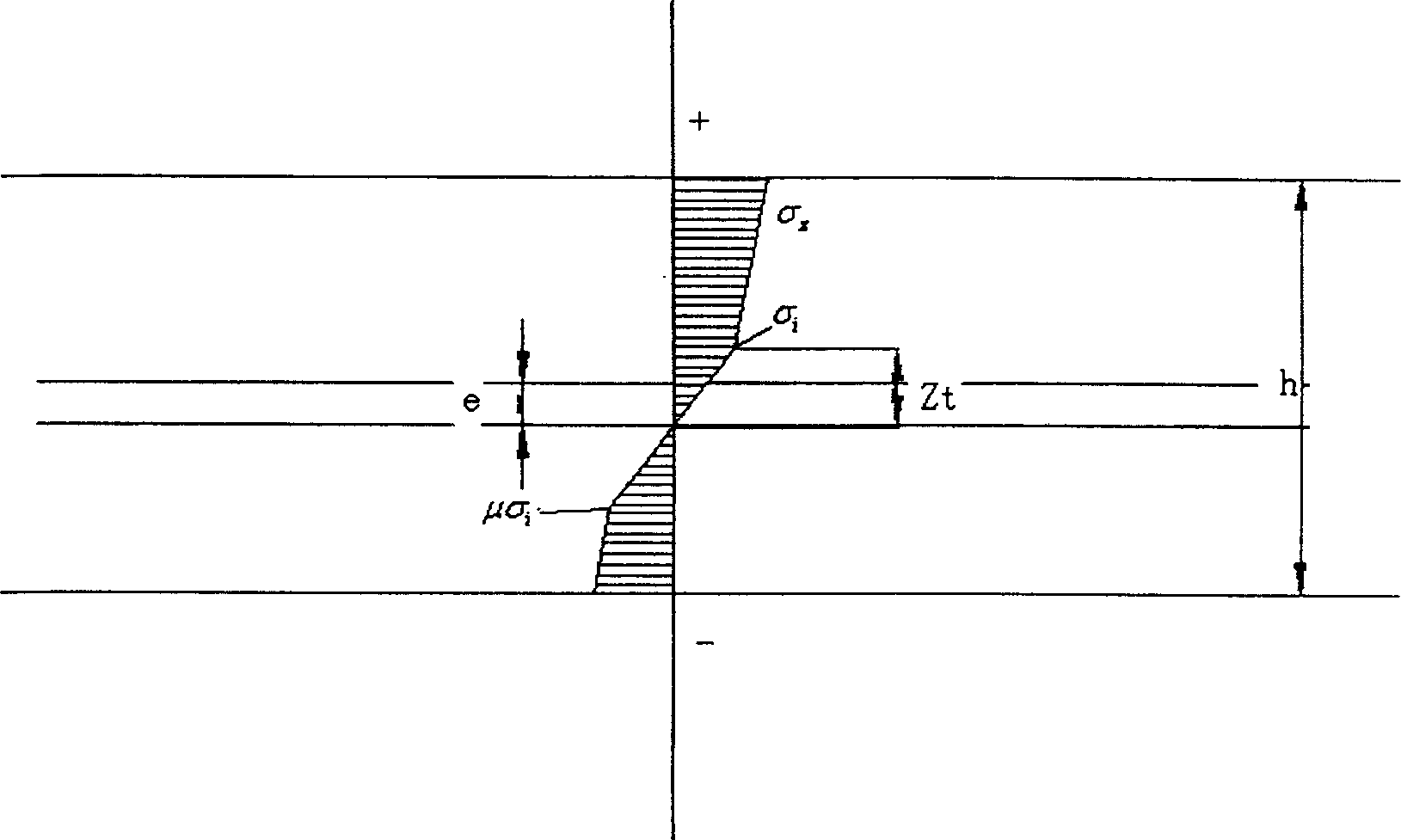

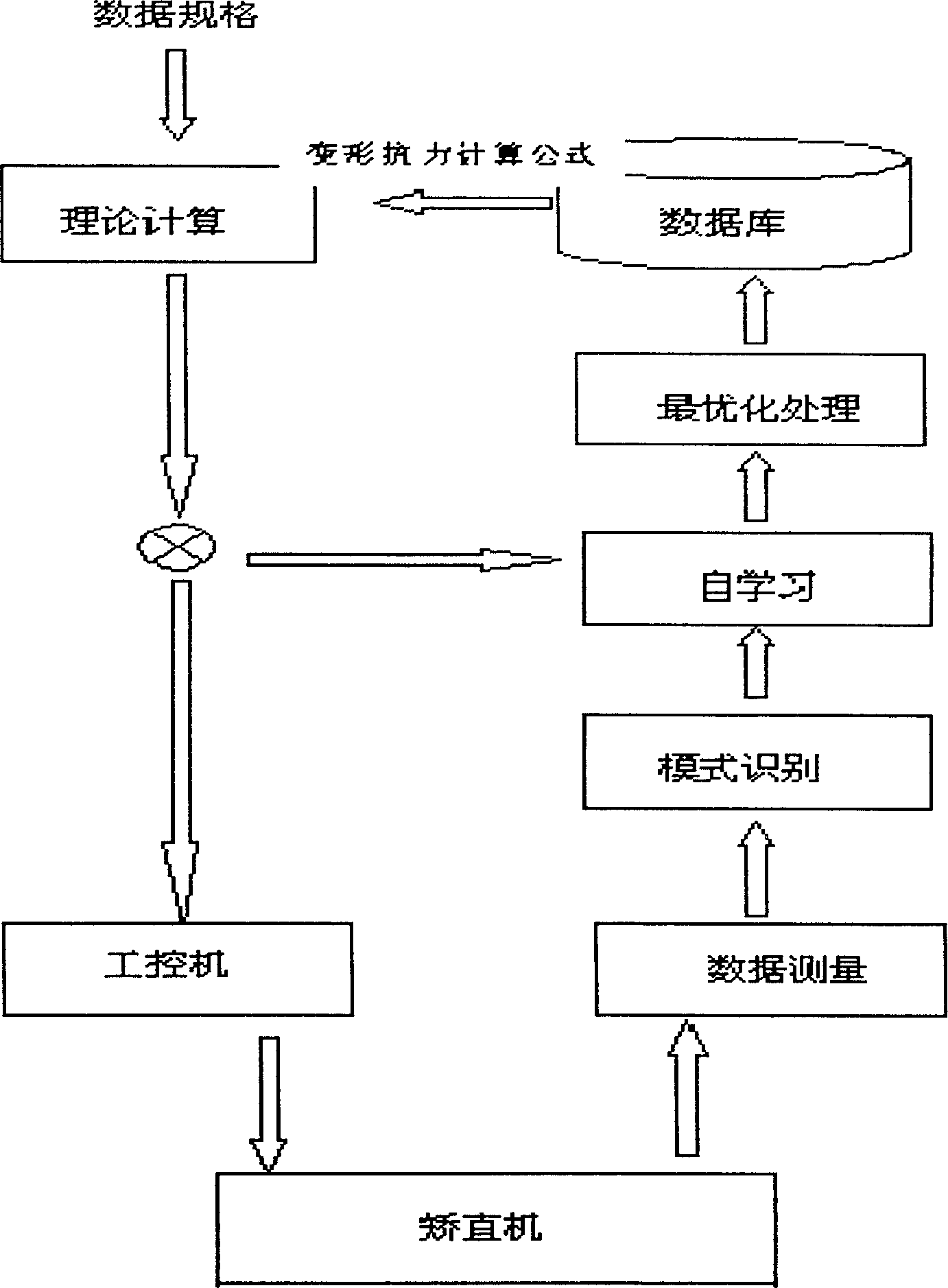

Automatic flattening process parameter optimization of metal plate band

InactiveCN1818913AImprove straightening qualityImprove straightening efficiencySpecial data processing applicationsEffect factorMetal sheet

The invention belongs to the metal sheet and strap straighten technology field, which is a technical parameter optimizing method of straightening the metal sheet and strap automatically. The existing technology is complexity during the process of the straighten of the sheet and strap, the effect factors of straightener such as bounce, abrasion and clearance of axletree etc, more wrap of the technical initialization between the theoretic calculation and factual operation that lead the request about the flat and straight of the production can not be satisfied. The invention is making the least optimizing process for the difference of the theoretic value and the fact measure value, that is correcting the undetermined variable in the theoretic calculating formulary of the straighten force - regressive coefficient a0, a1, a2, a3, a4, a5, a6, a7, that is the nearest value between the theoretic value and the fact measure value. The method of the invention can setup the technical parameter automatically, improve the quality and the efficiency of straighten, the online system base on the invention has successful apply on the 3500 millimeters thick sheet straightener, the average value of the measure straighten force is discrepance smaller +5% with the calculation value, the remnants curvature of the production is less than 1.5mm / m.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Transverse straightener

Owner:广州市力鼎汽车零部件有限公司

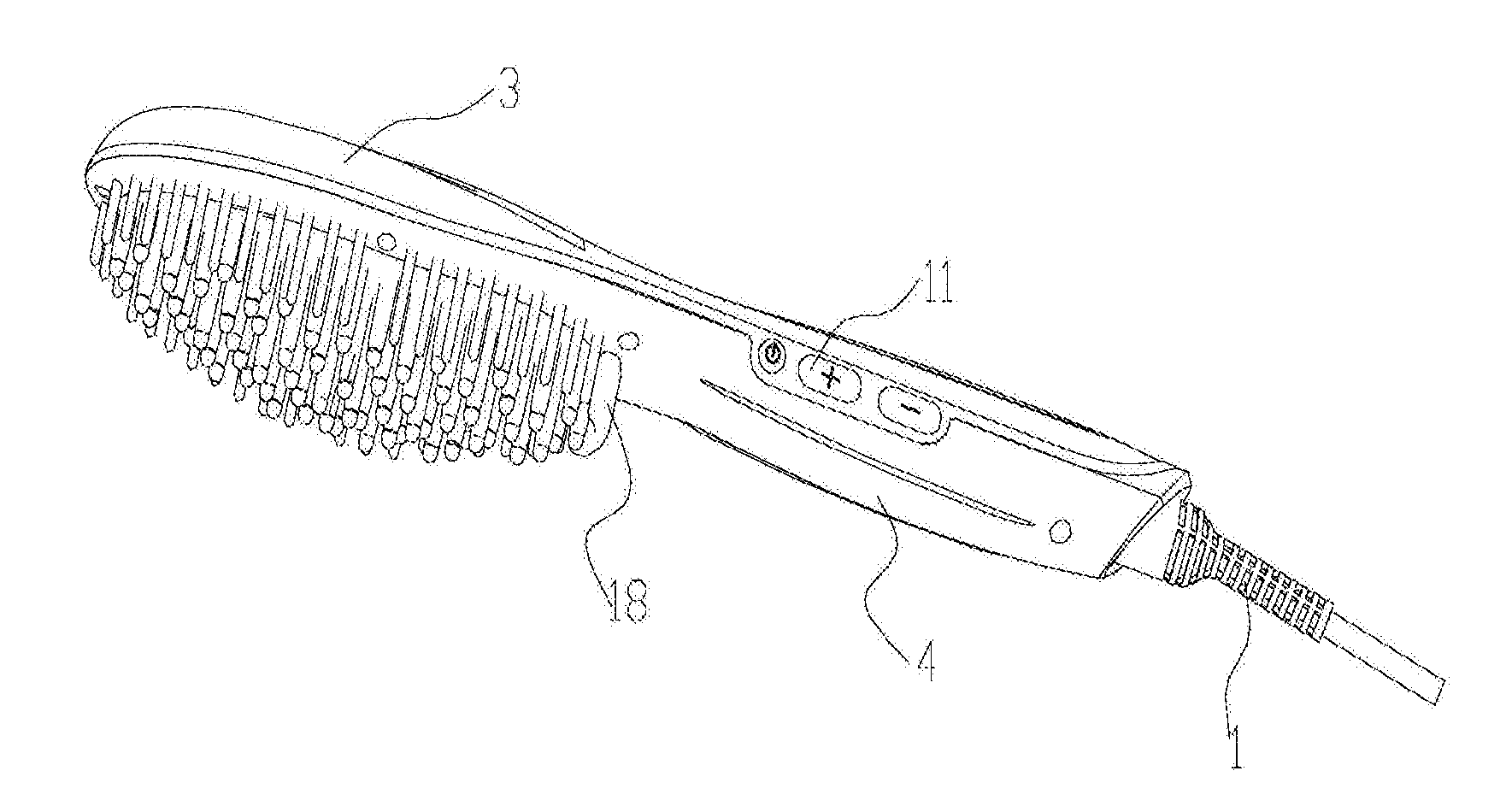

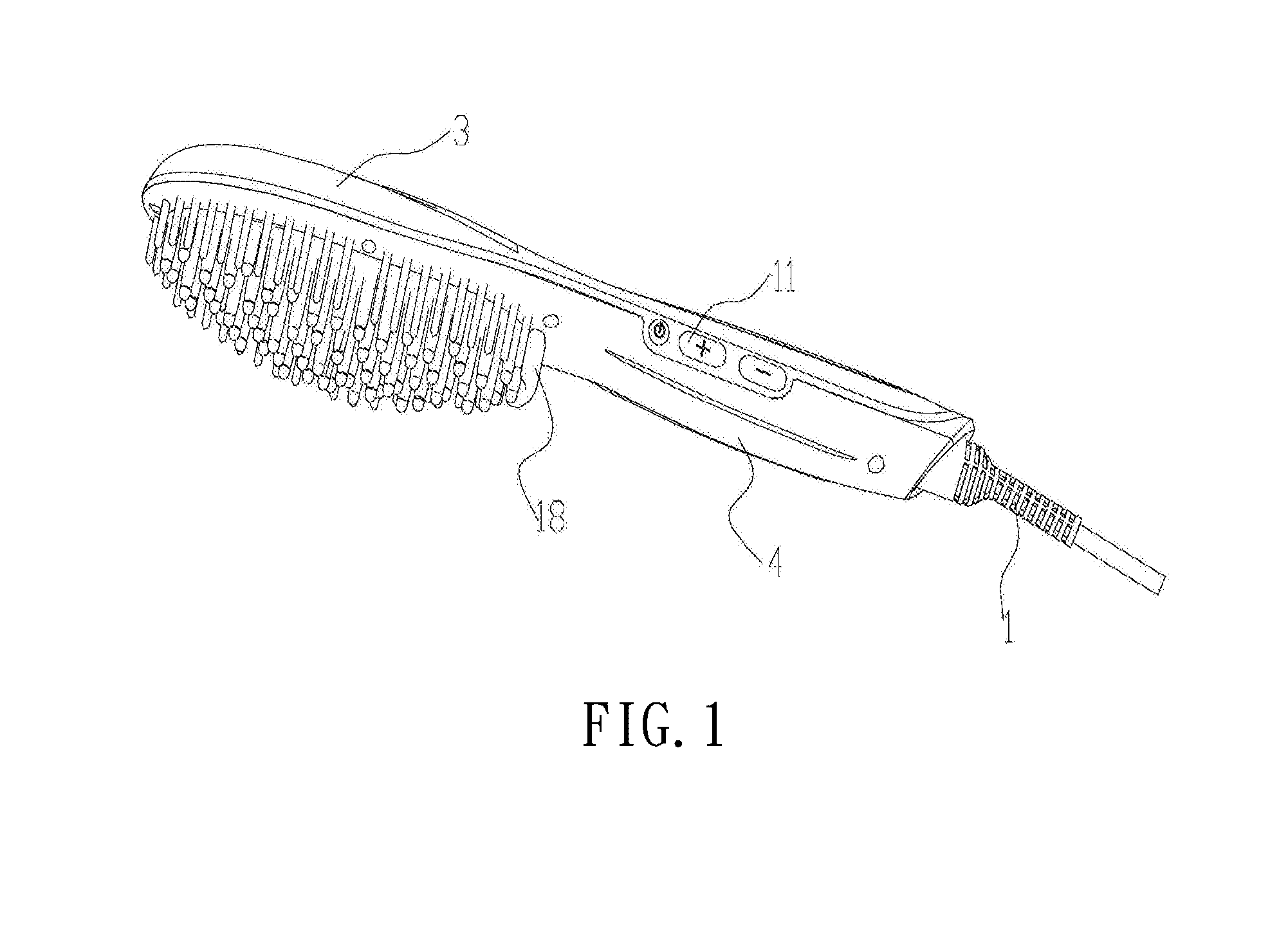

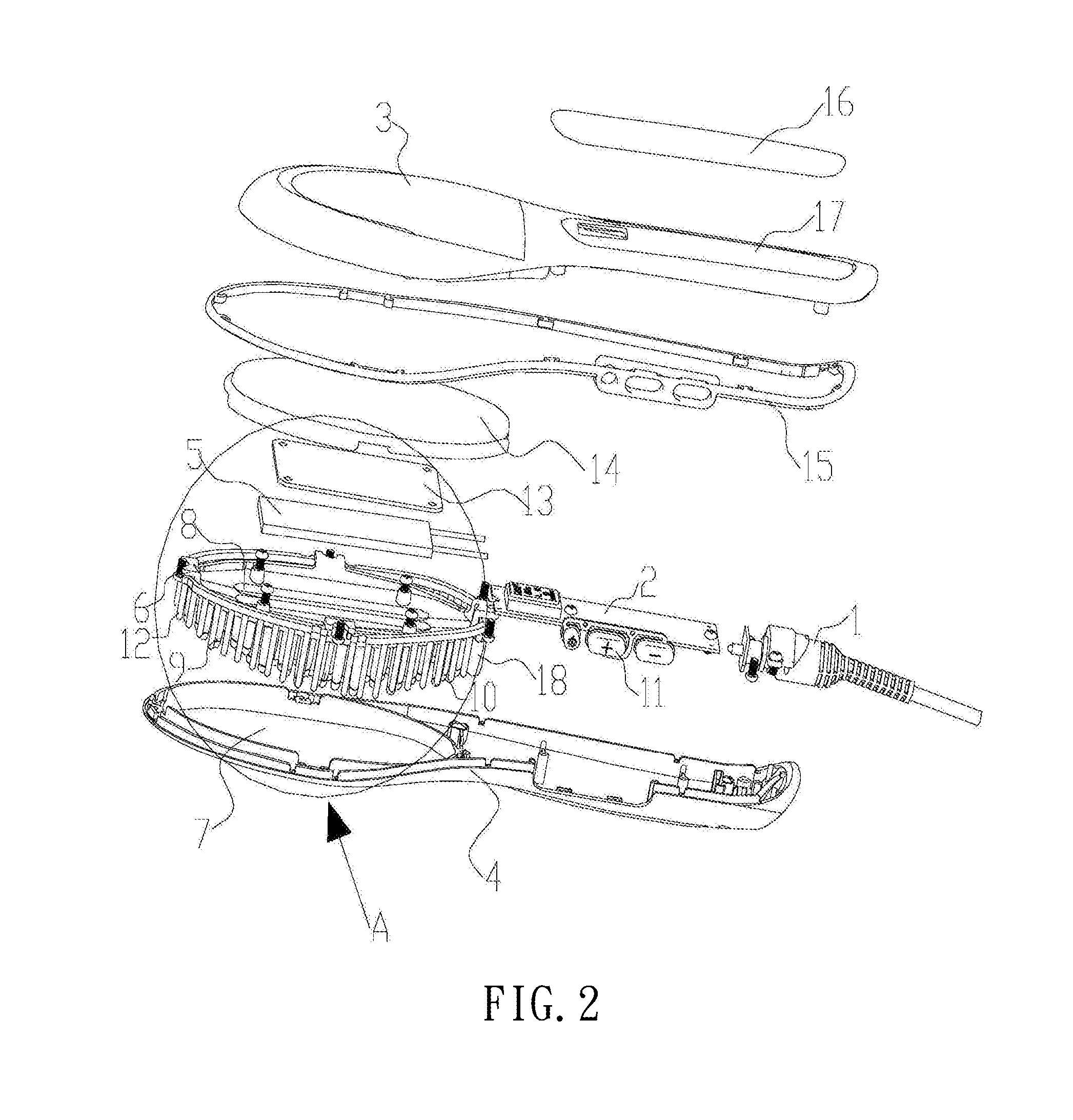

Hair straightener

InactiveUS20160227898A1Avoids hair cuticle damageShorten the timeCurling devicesHair straighteningBrush tooth

A hair straightener includes a power cord, a control circuit board, an upper shell, a bottom shell, an electric hot plate and a heat-conductive brush head. The upper shell and the bottom shell are fastened together with a first accommodation chamber defined therein. The bottom shell defines an opening. The control circuit board, the electric hot plate and the heat-conductive brush head are accommodated in the first accommodation chamber. The heat-conductive brush head has a heat-transfer plate attached to the back side thereof. The electric hot plate is mounted on the heat-transfer plate. The heat-conductive brush head has a plurality of heat-transfer brush teeth located on the front side thereof.

Owner:WU MARK

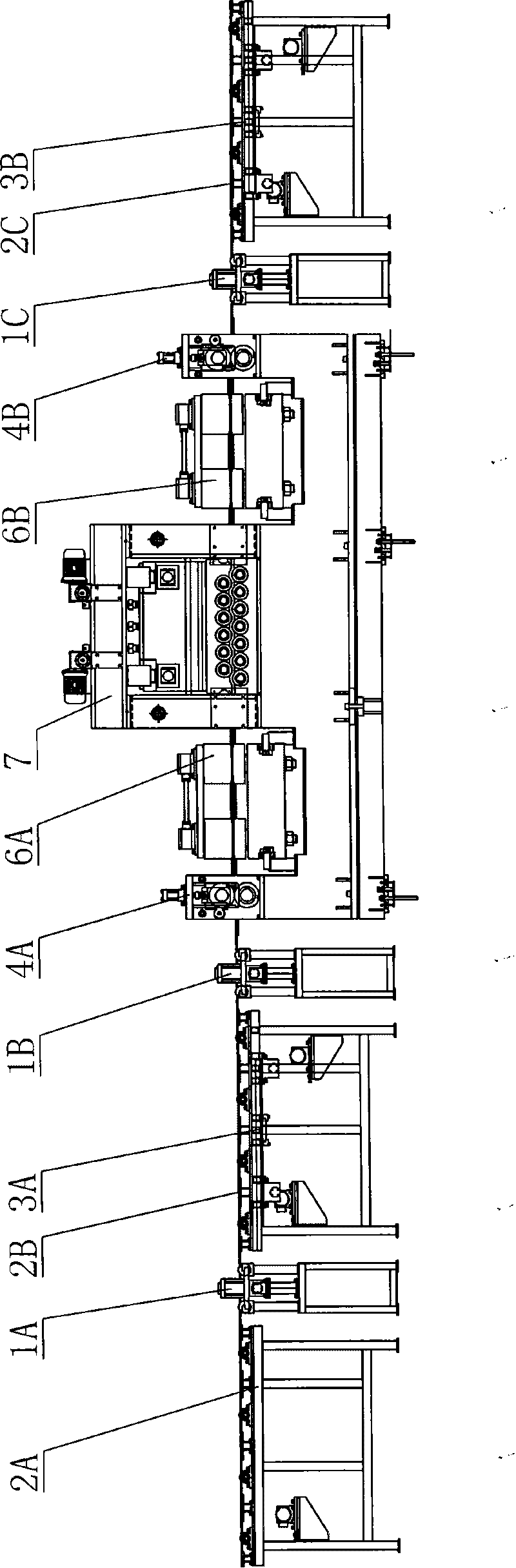

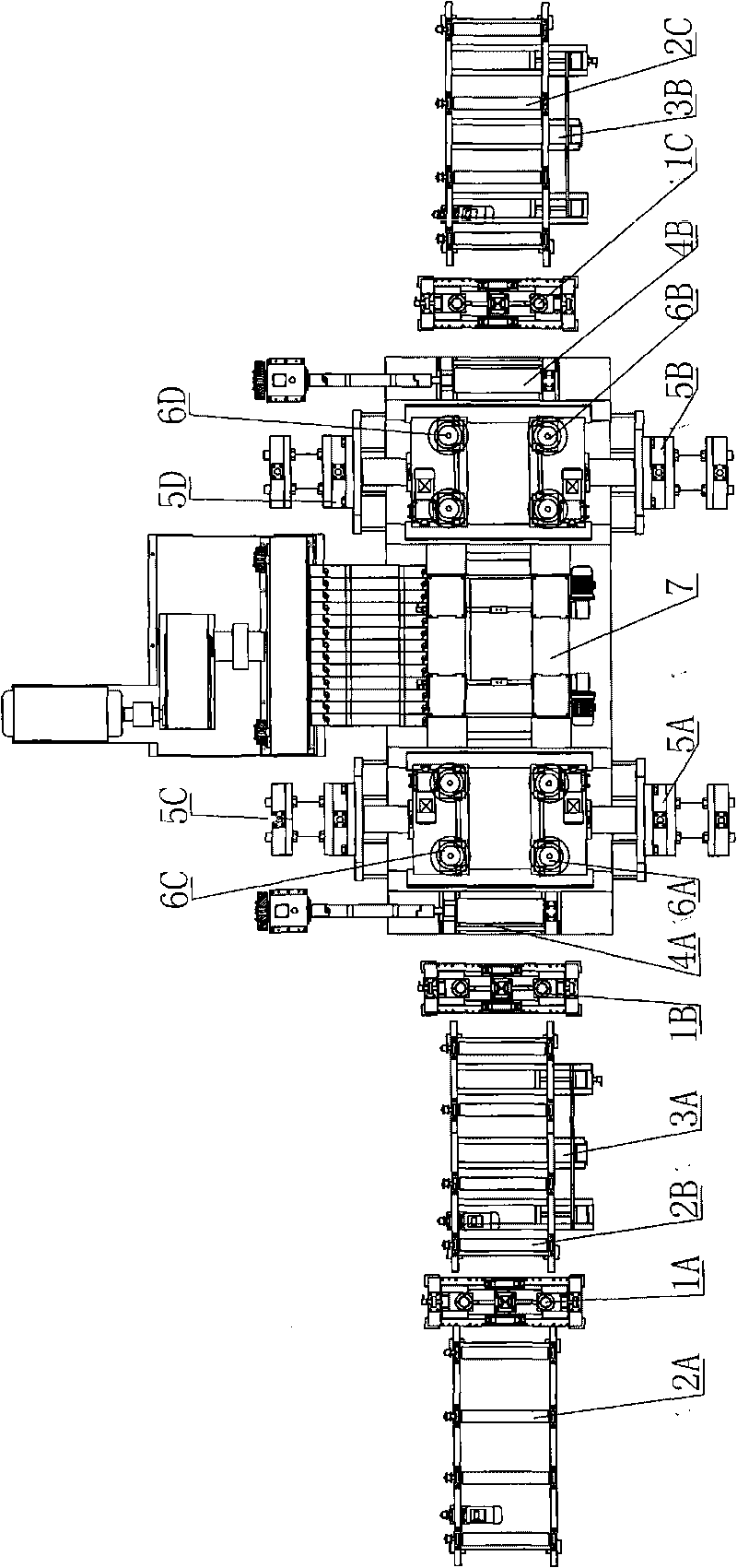

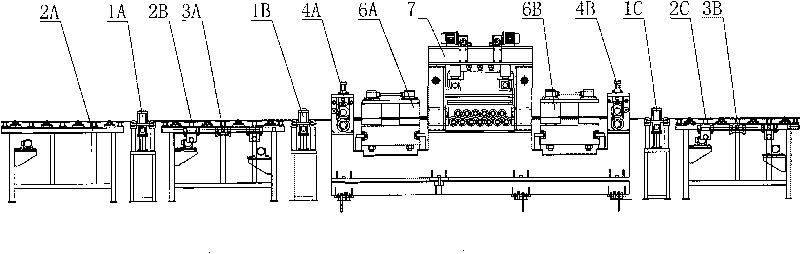

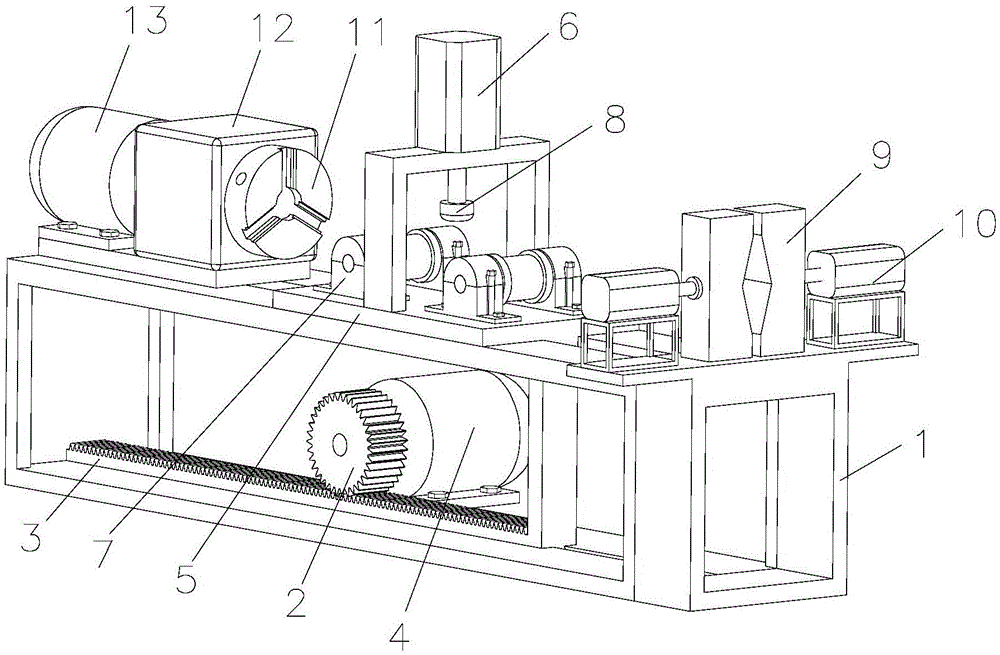

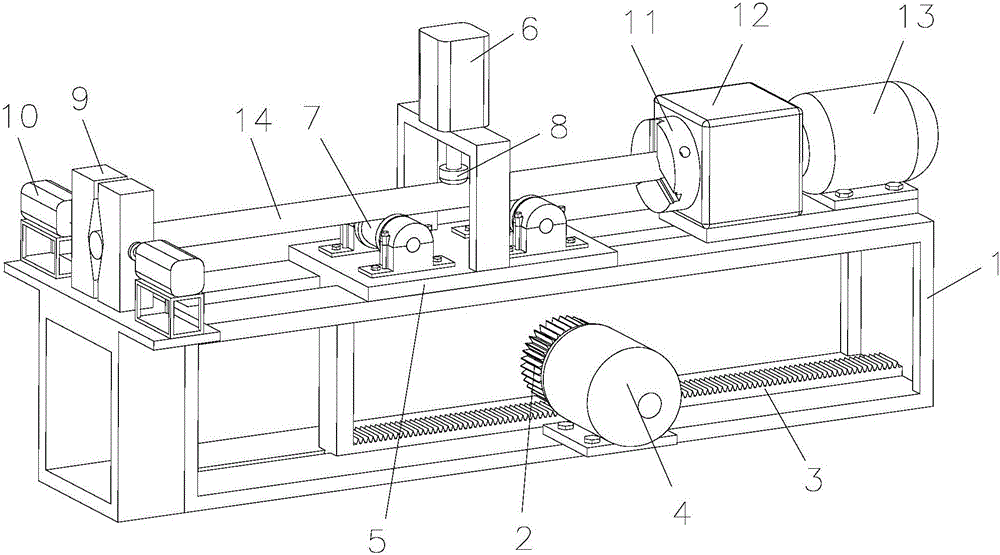

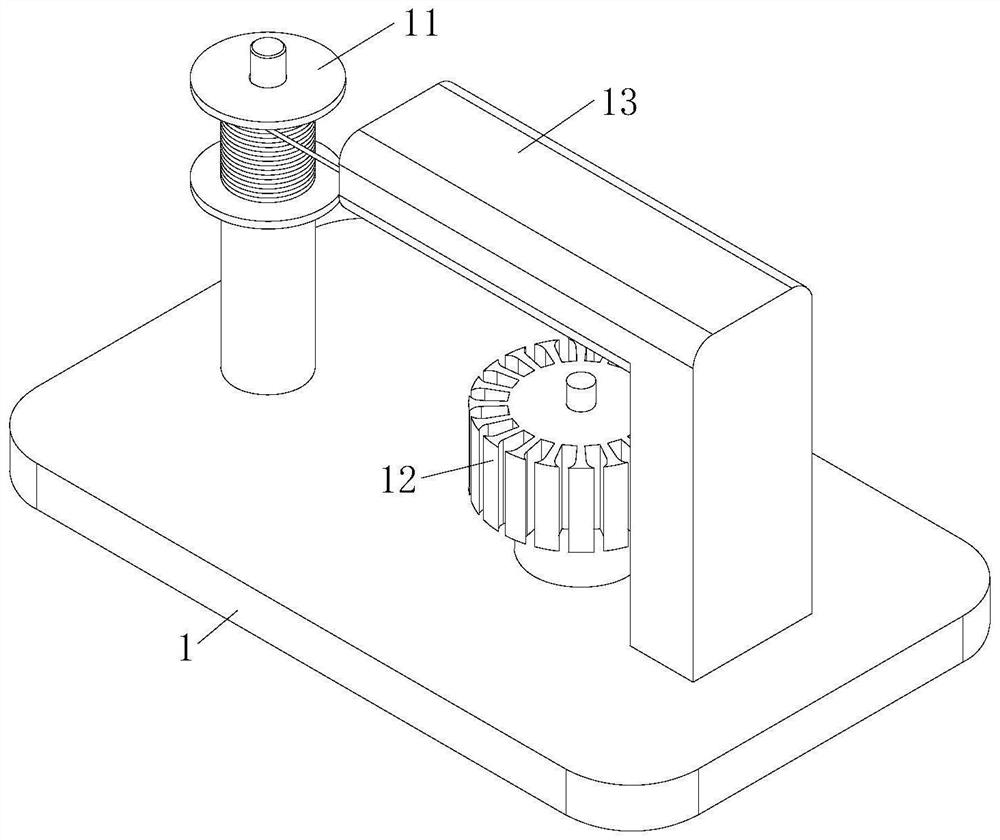

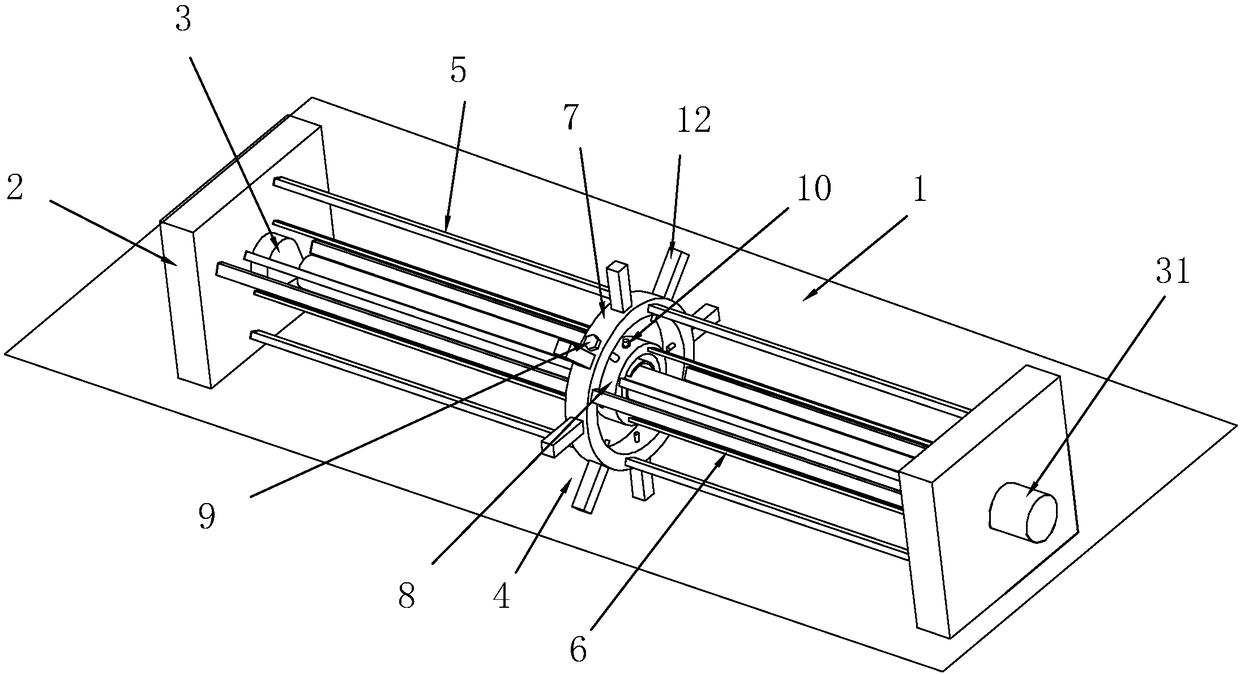

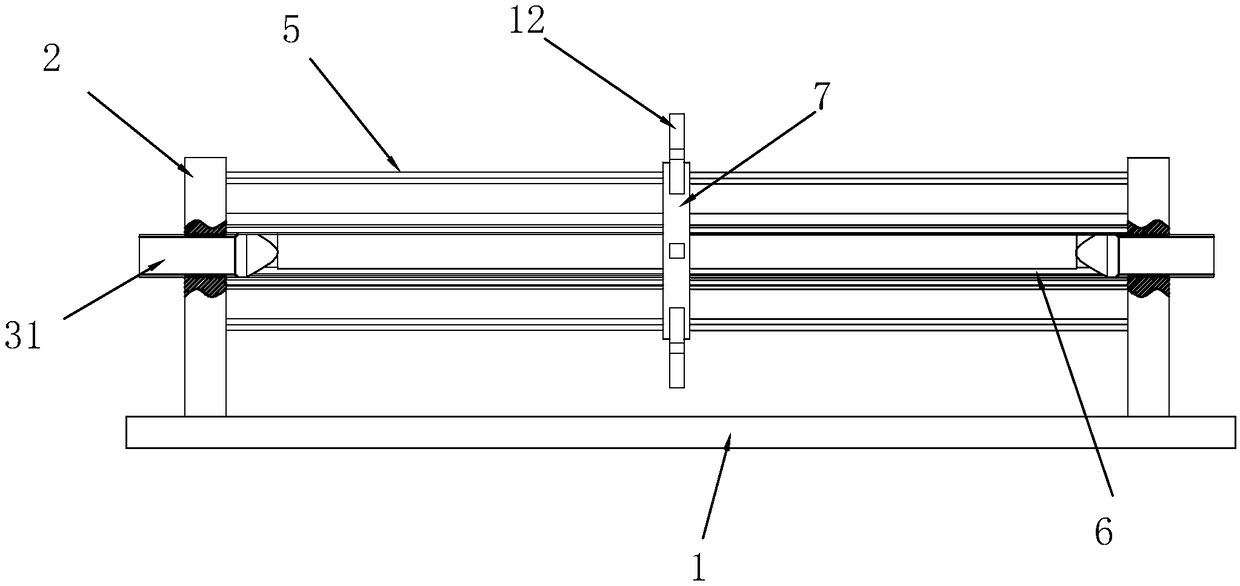

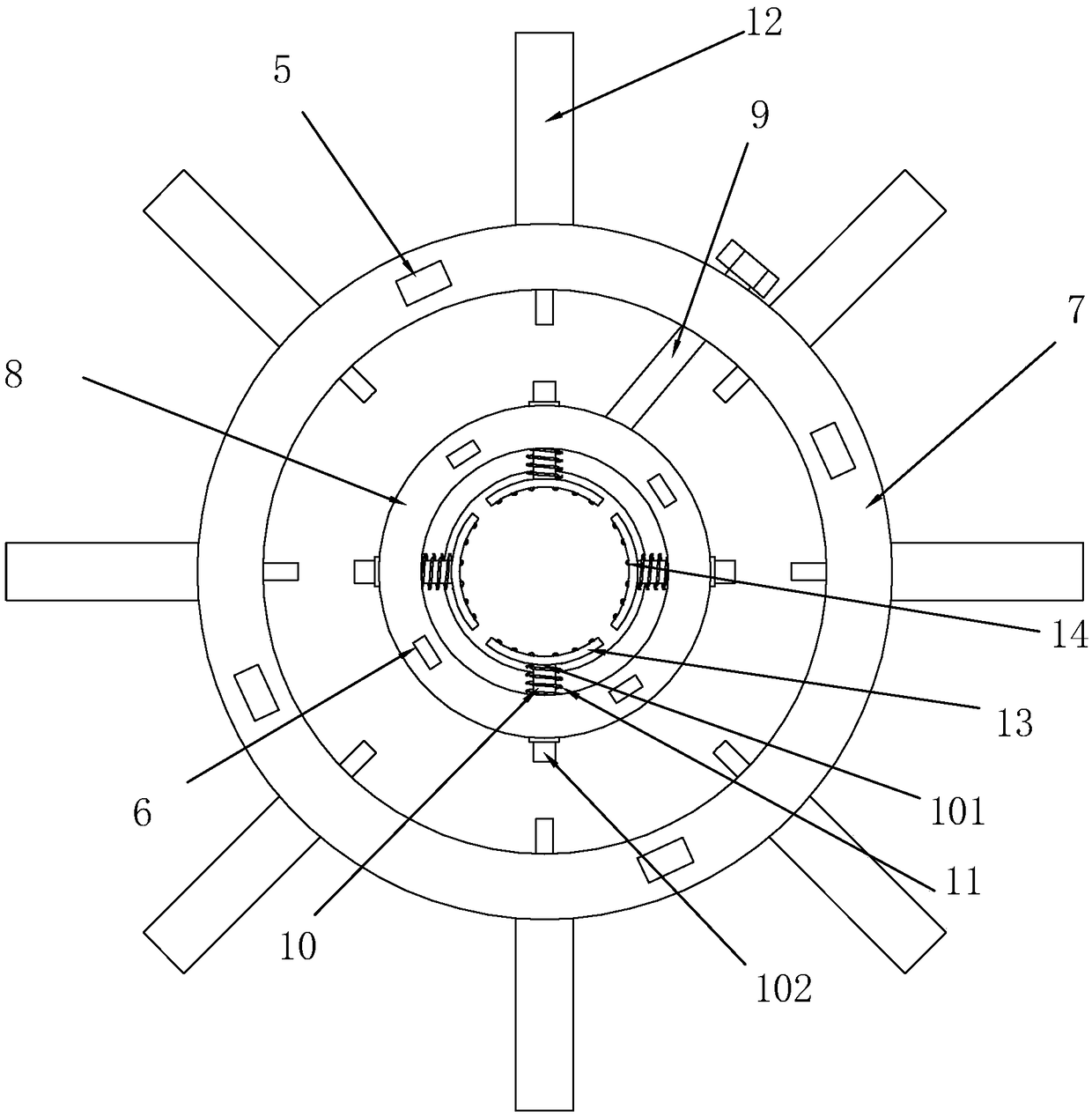

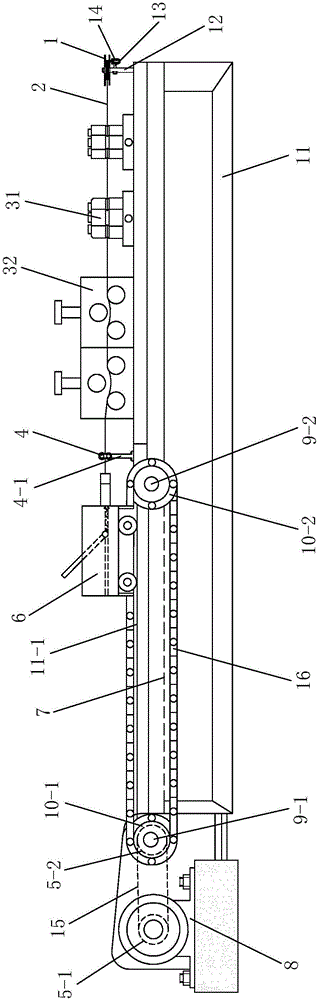

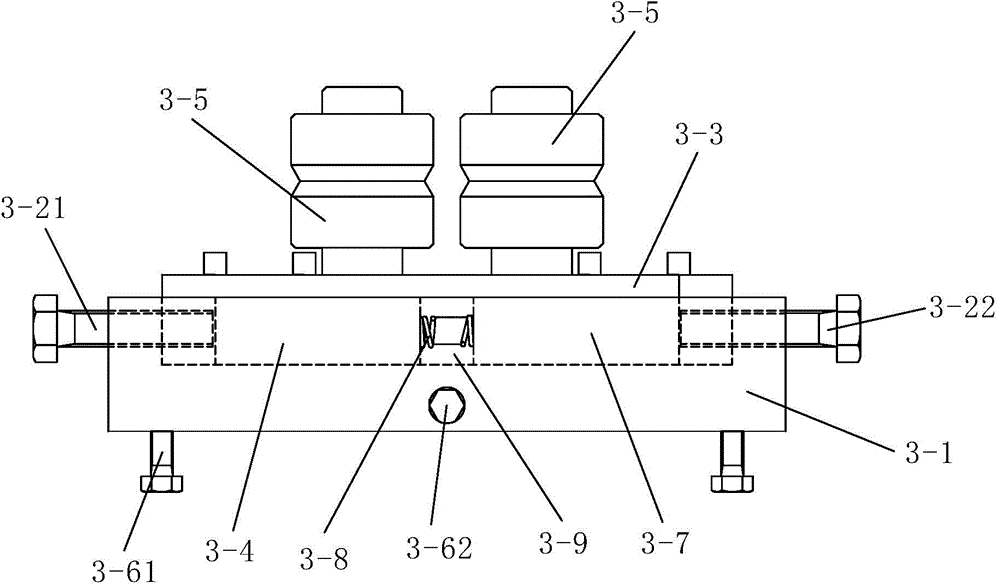

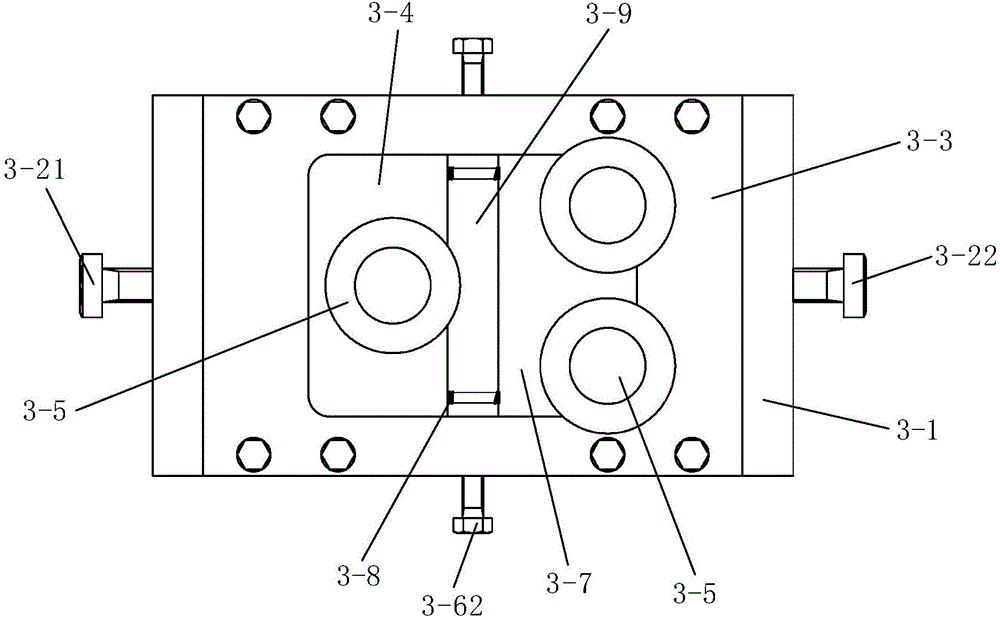

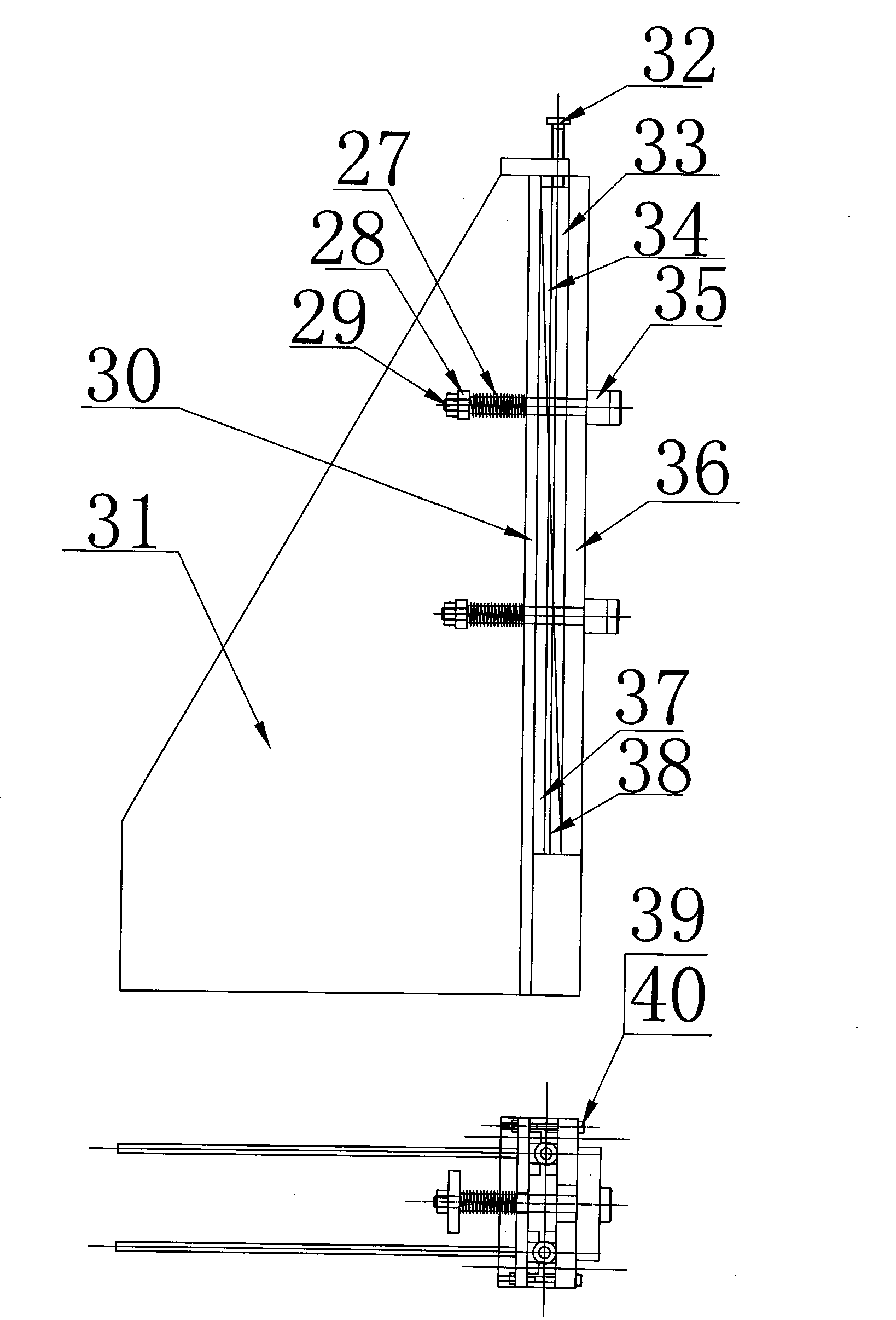

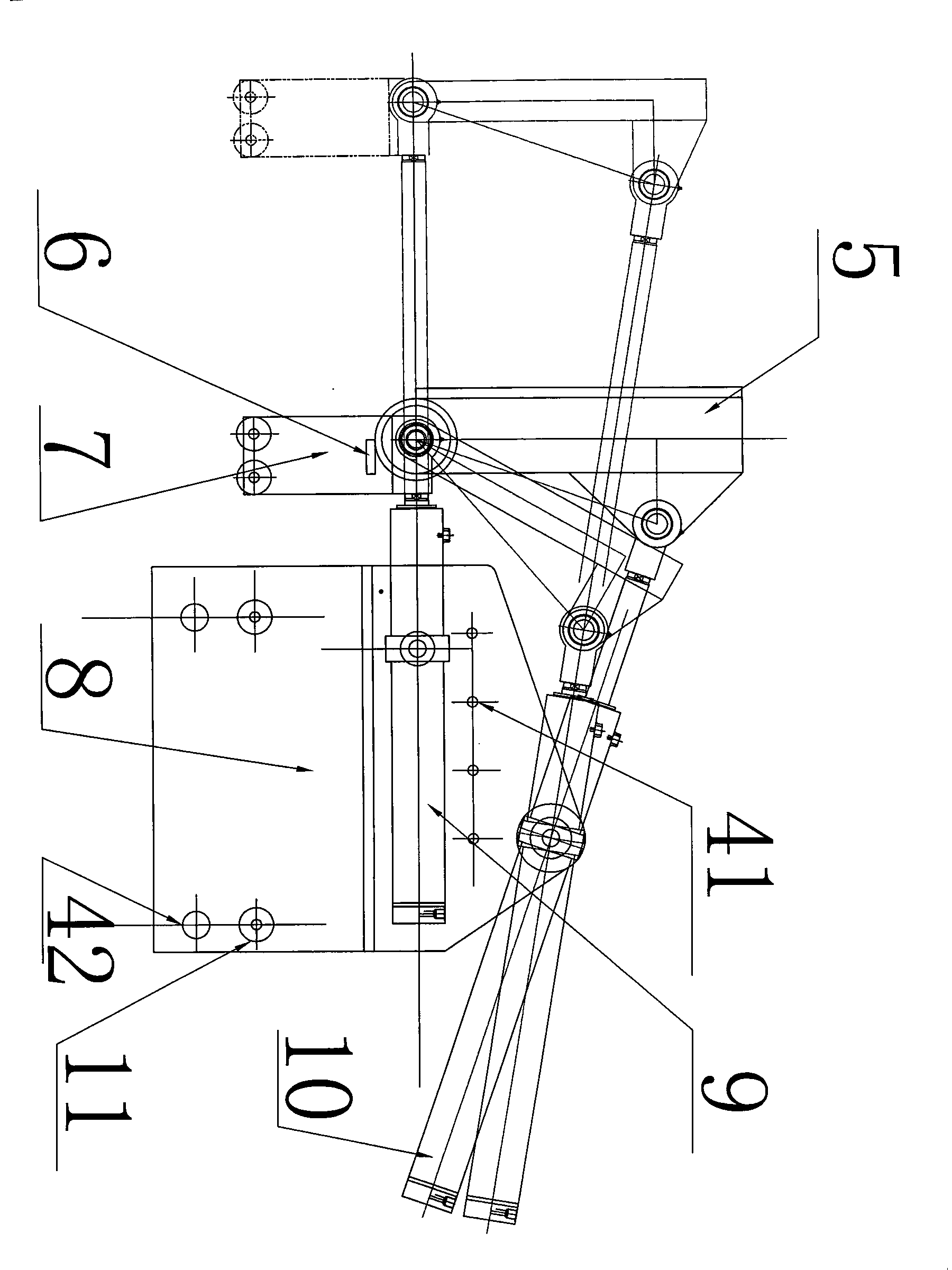

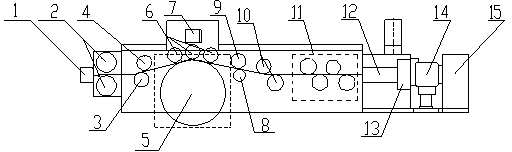

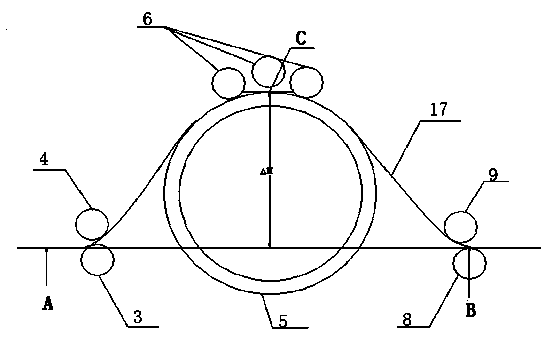

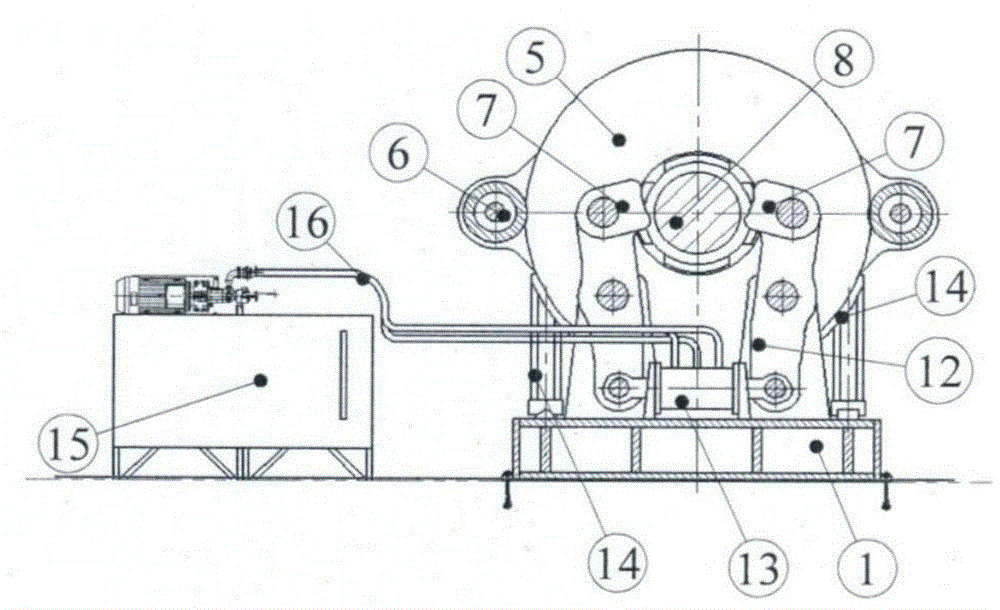

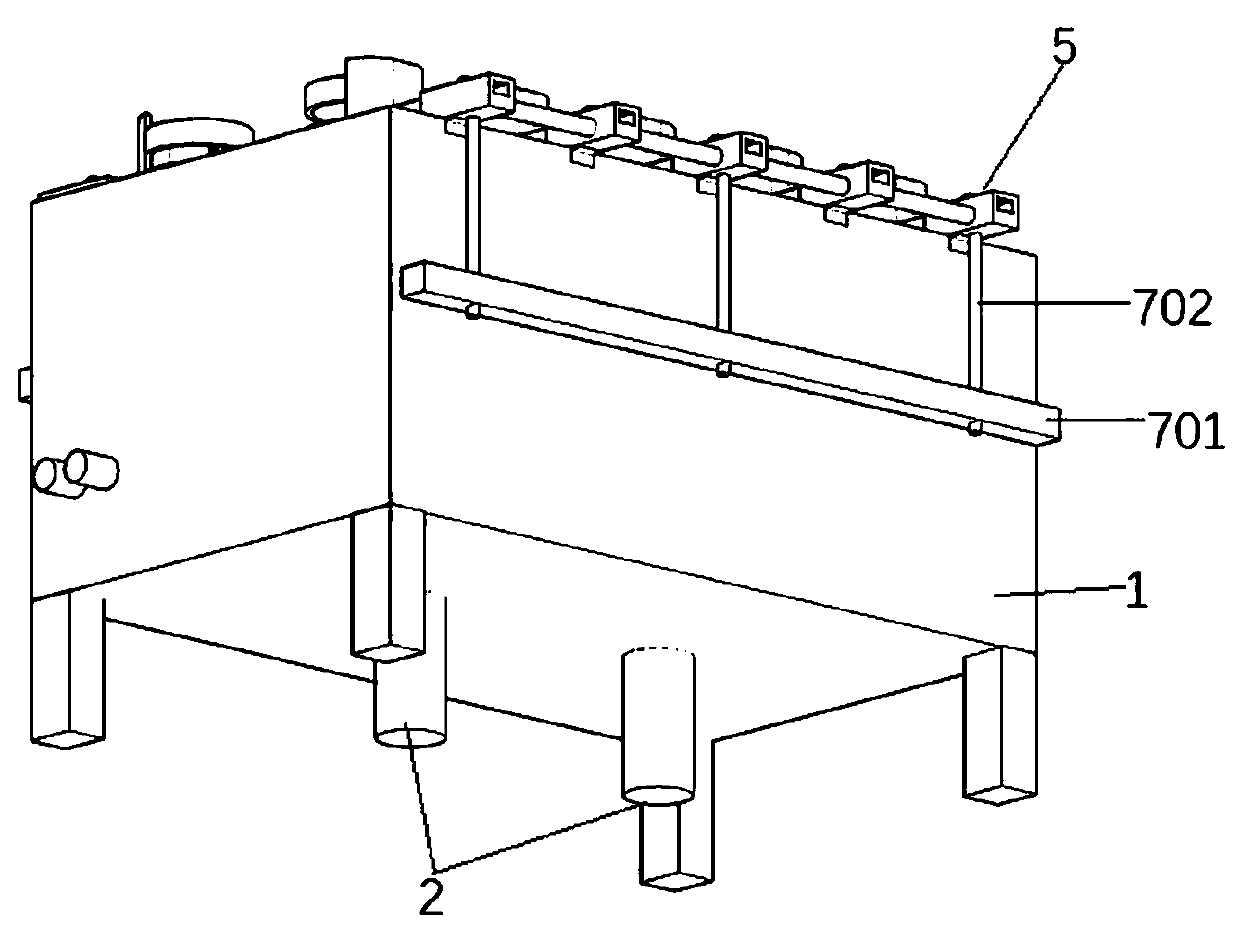

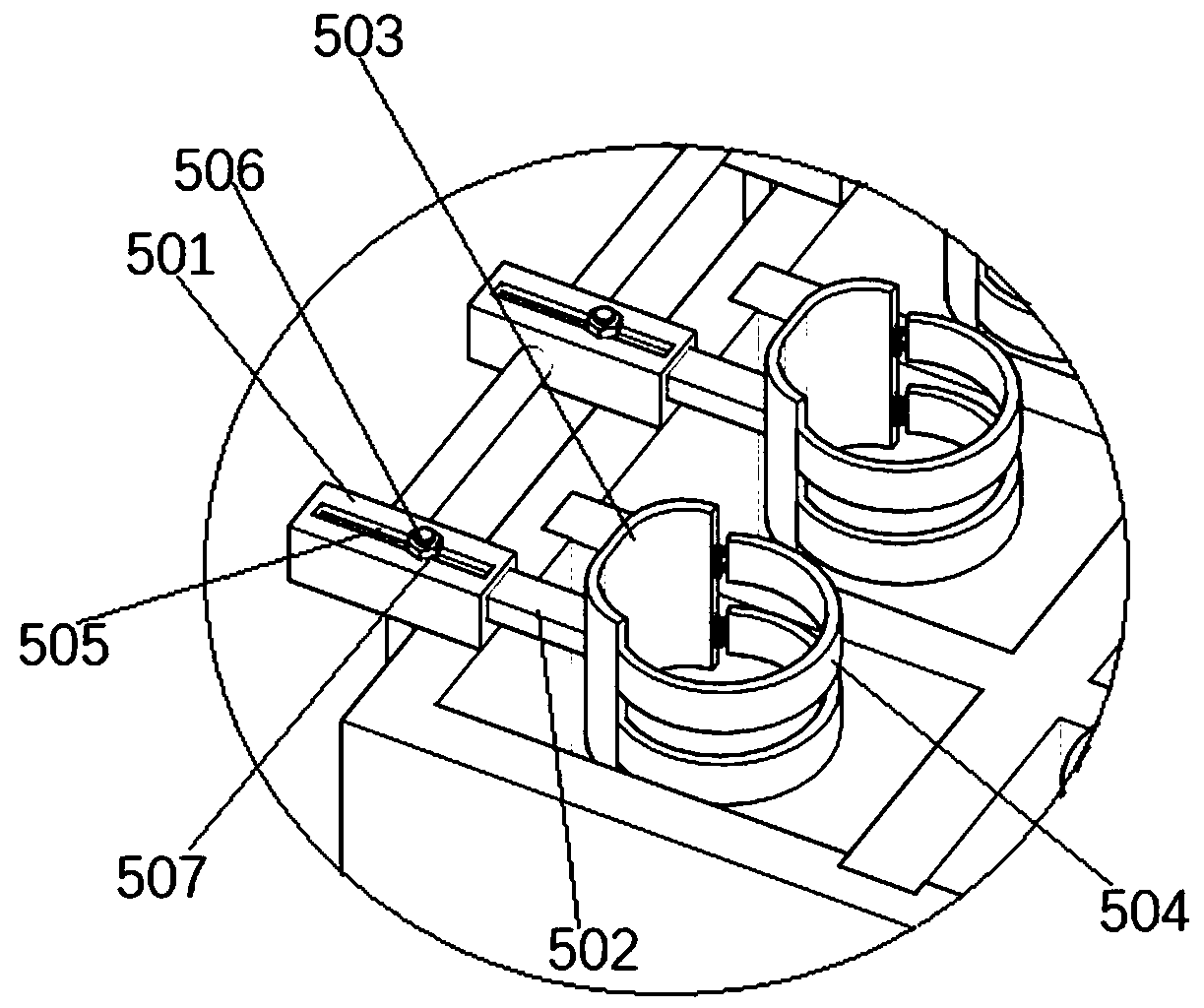

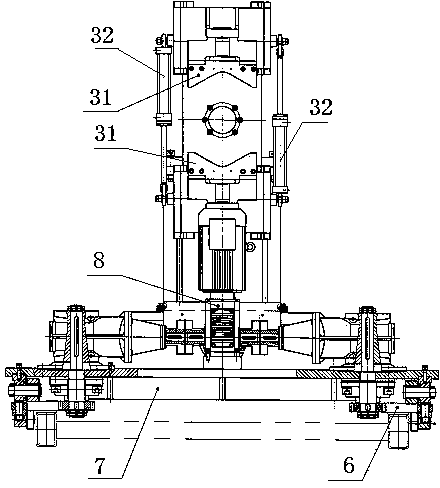

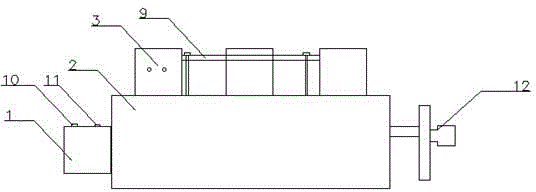

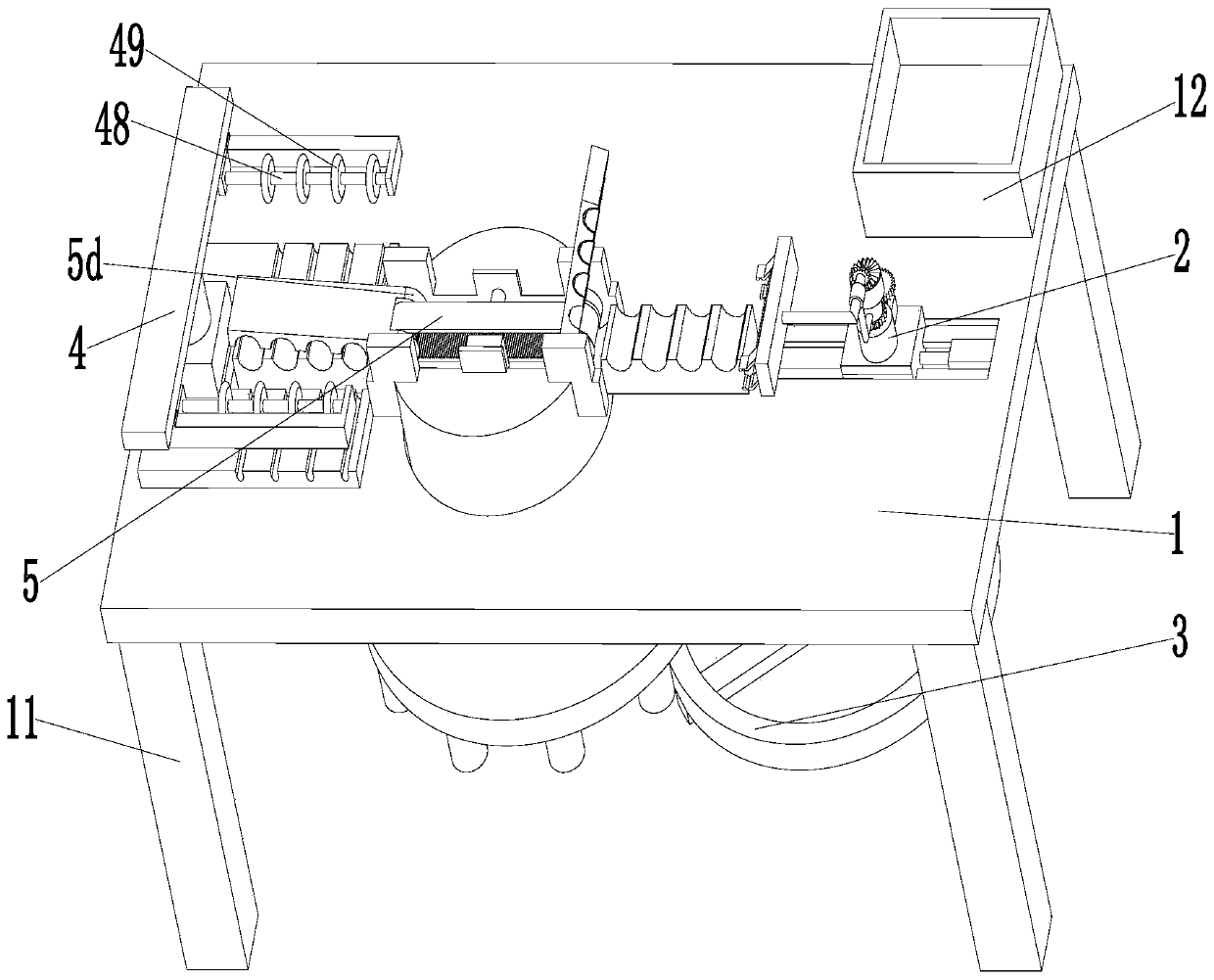

Full-automatic steel pipe straightener

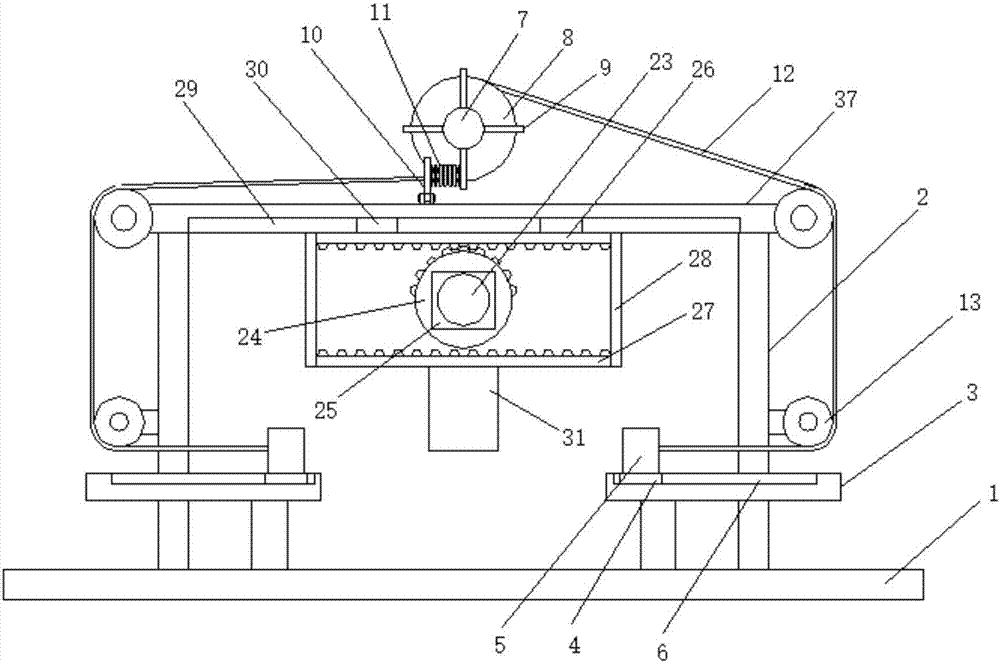

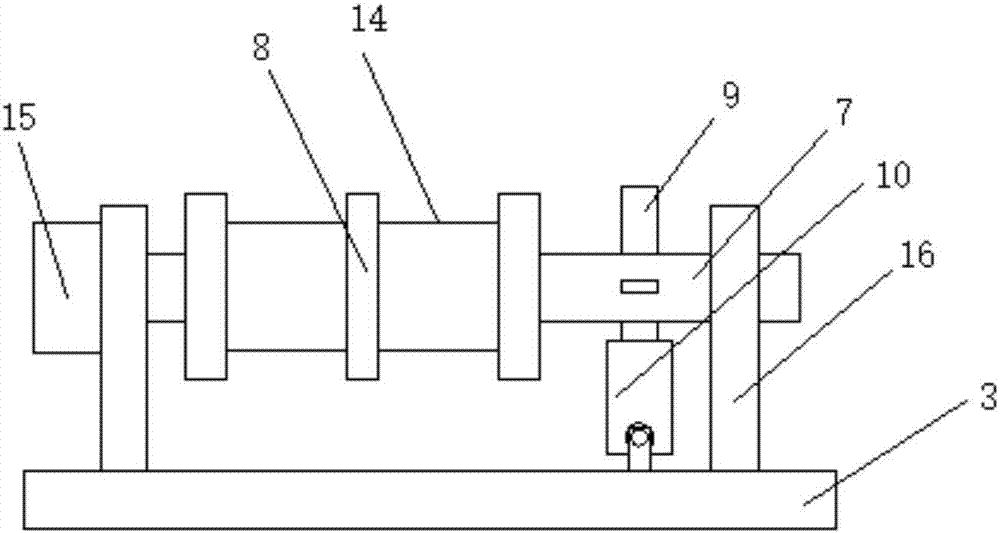

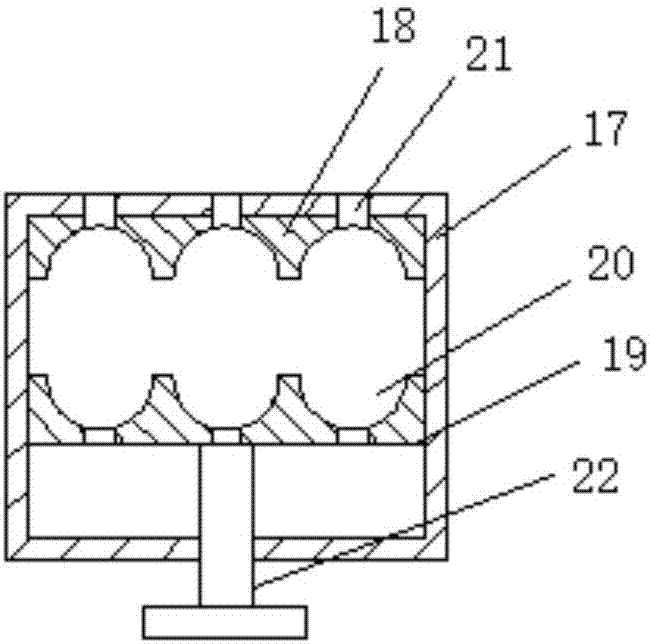

InactiveCN105880317AImprove straightening efficiencyMetal-working feeding devicesPositioning devicesLinear motionGear wheel

The invention relates to a full-automatic steel pipe straightener. A clamping mechanism, a rotating mechanism and a straightening mechanism are installed on a machine frame. The clamping mechanism is used for clamping one end of a steel pipe. The rotating mechanism can drive the steel pipe to rotate while the other end of the steel pipe is clamped. The straightening mechanism is installed between the clamping mechanism and the rotating mechanism in a sliding mode for straightening the bent portion of the steel pipe. The straightening mechanism is driven by a gear and rack driving mechanism to achieve reciprocating linear motion. According to the full-automatic straightener, multiple bent points on the steel pipe can be straightened, automation is achieved in the overall process, the problem that operation is complex due to the fact that according to a traditional method, multiple bent points on a steel pipe are treated one by one is solved, and the straightening efficiency is improved.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

Online heating distortion correcting device, system and method for profile

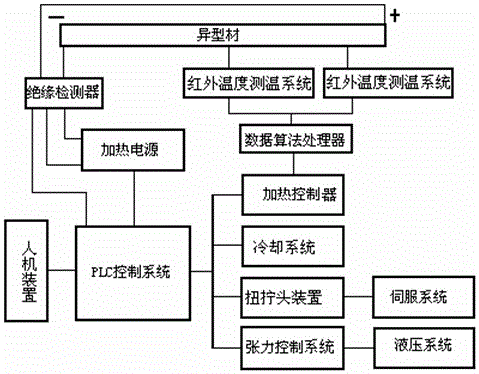

ActiveCN106216443AAdjust outputAddress straightening treatment requirementsShaping toolsMetal working apparatusTemperature controlBusbar

The invention discloses an online heating distortion correcting device for a profile, comprising a straightening cylinder; the straightening cylinder is connected with a tension control system, a main hydraulic pump station and a cooling system; one side of the strengthening cylinder is provided with a stretching head device, and one side of the stretching head device is provided with a twisting head device; the twisting head device is connected with an auxiliary hydraulic pump station; the stretching head device and the twisting head device are provided with same temperature measuring systems; a negative water cooled cable of the stretching head device is connected with a heating power supply, and a positive water cooled cable of the twisting head device is connected with the heating power supply through a conducting busbar; two ends of the profile are directly and electrically heated, distortion correction begins after two ends of the profile are heated to the set temperature, and the profile is rapidly and efficiently heated through the closed loop control of an infrared temperature measurement and temperature control system to the power supply; due to the control for the tension of a hydraulic system, the constant output of a stretching force is ensured, and stretching by using a constant stretching force is realized; and the twisting angle is precisely controlled, the problem that the online heating insulation distortion correction of the profile is difficult in the distortion process is solved, the degree of automation is high, the distortion correcting quality is improved, and the distortion correcting efficiency is increased.

Owner:XIAN JUNENG EQUIP TECH CO LTD

Steel rib straightening device for building

The invention discloses a steel bar straightening device for construction, which comprises a bottom plate, side plates are arranged on both sides of the end surface of the bottom plate, horizontal plates are also arranged on the two side plates, and clamping clamps are arranged on the two horizontal plates. Fixing device, the clamping and fixing device includes a fixed box, the inside of the fixed box is provided with a parallel constant pressure plate and a dynamic pressure plate, the top of the constant pressure plate is fixedly connected with the top wall of the fixed box, and the side of the dynamic pressure plate is connected with the inner wall of the fixed box Sliding connection, a support frame is arranged on the top plate, a first horizontal shaft is installed on the support frame, a turntable is arranged at one end of the first horizontal shaft, a rope winding roller is arranged on the first horizontal shaft, and the Both take-up grooves are wound with tension ropes. The invention has simple structure, can effectively straighten bent steel bars, has high straightening efficiency of steel bars, can be straightened permanently, can be aimed at straightening steel bars with different diameters, has wide application range, is easy to operate, and has strong practicability.

Owner:宣城市万成机械科技有限公司

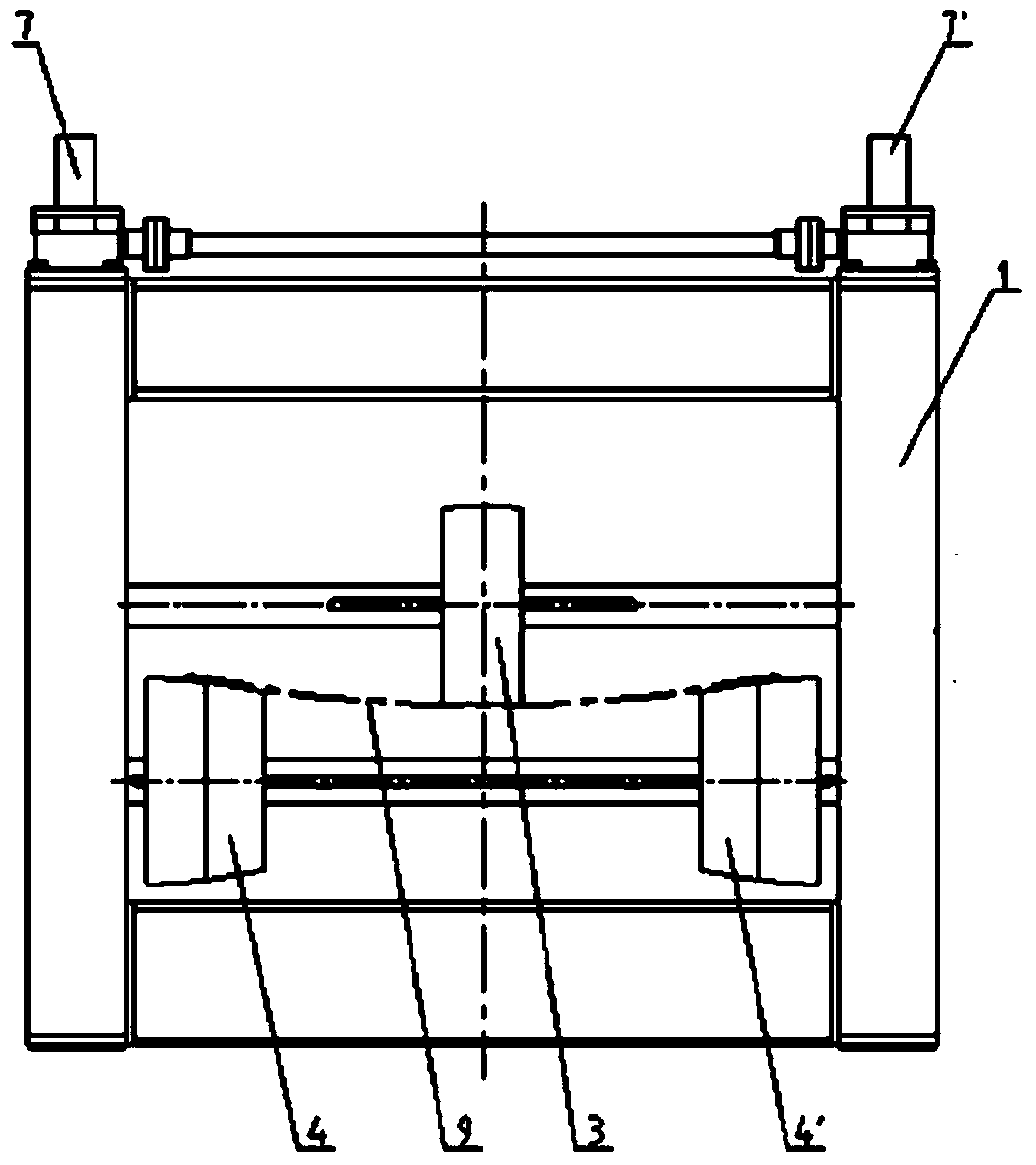

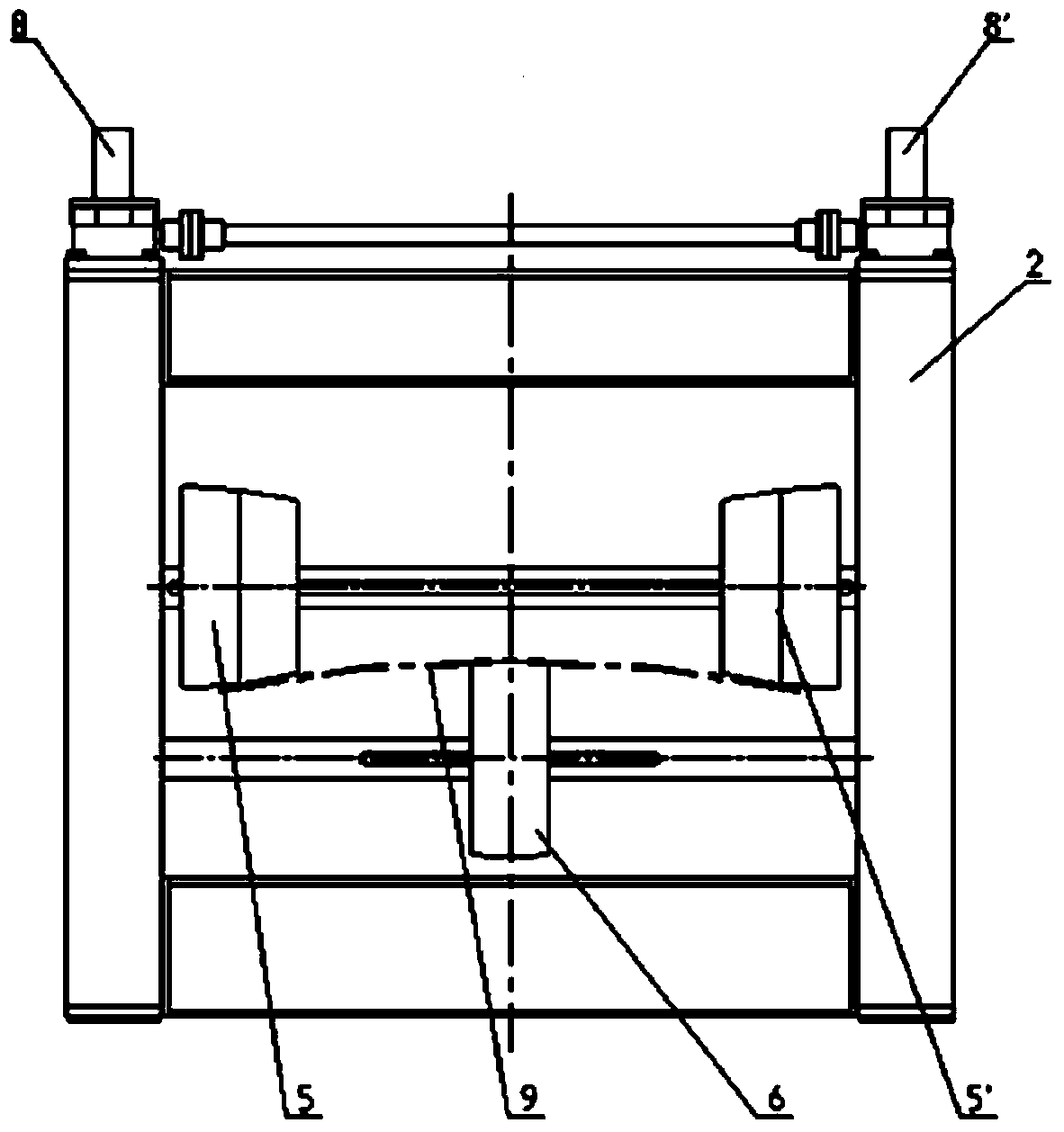

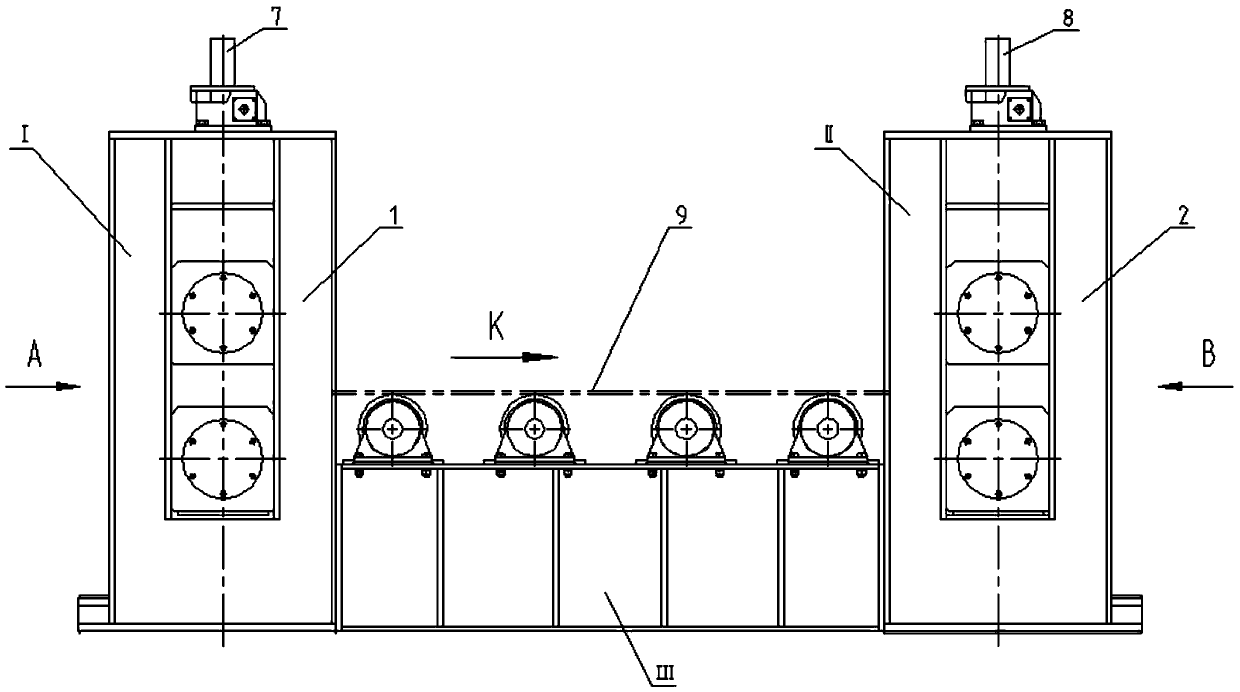

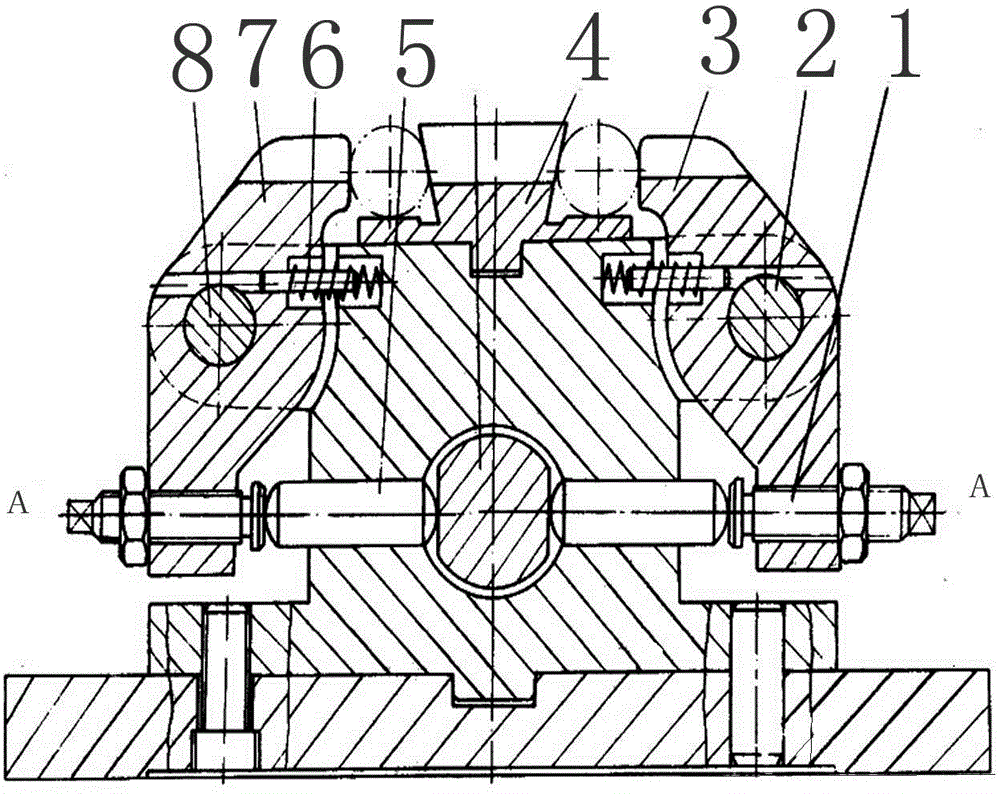

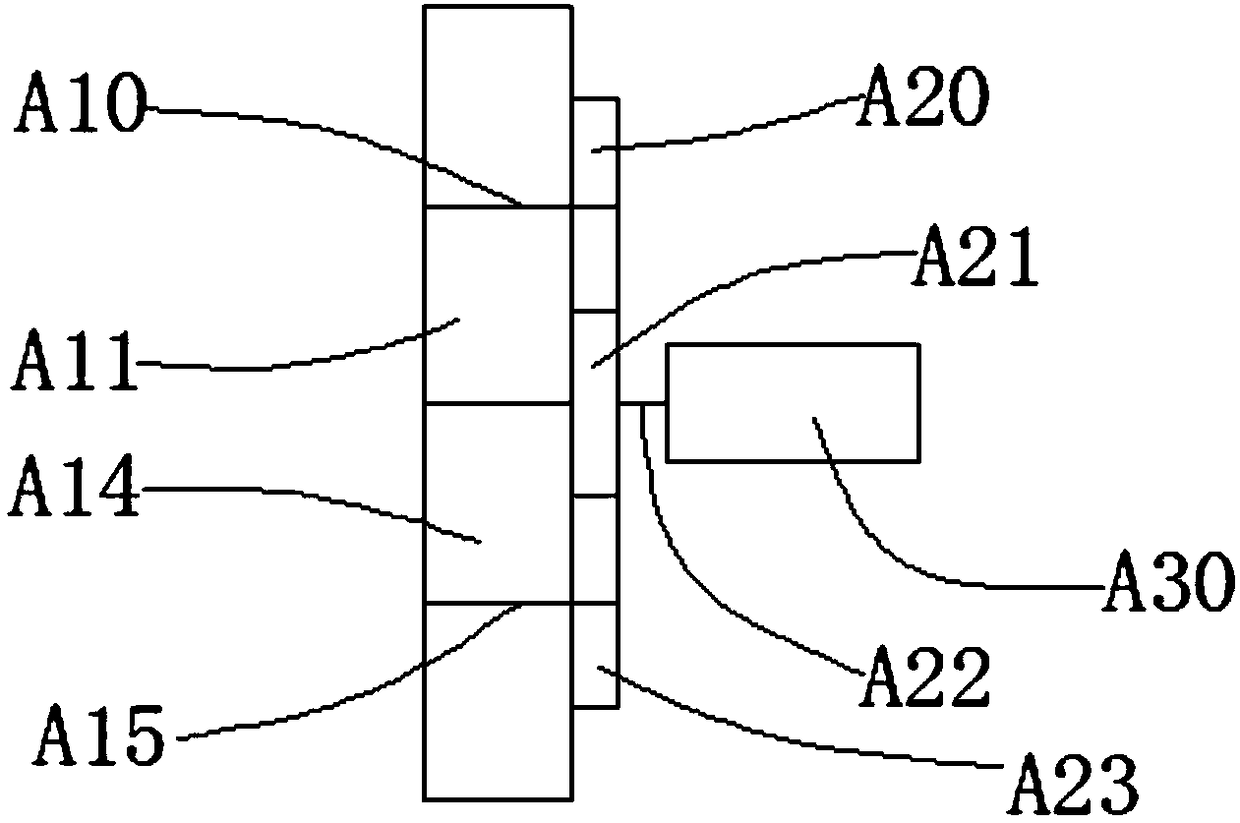

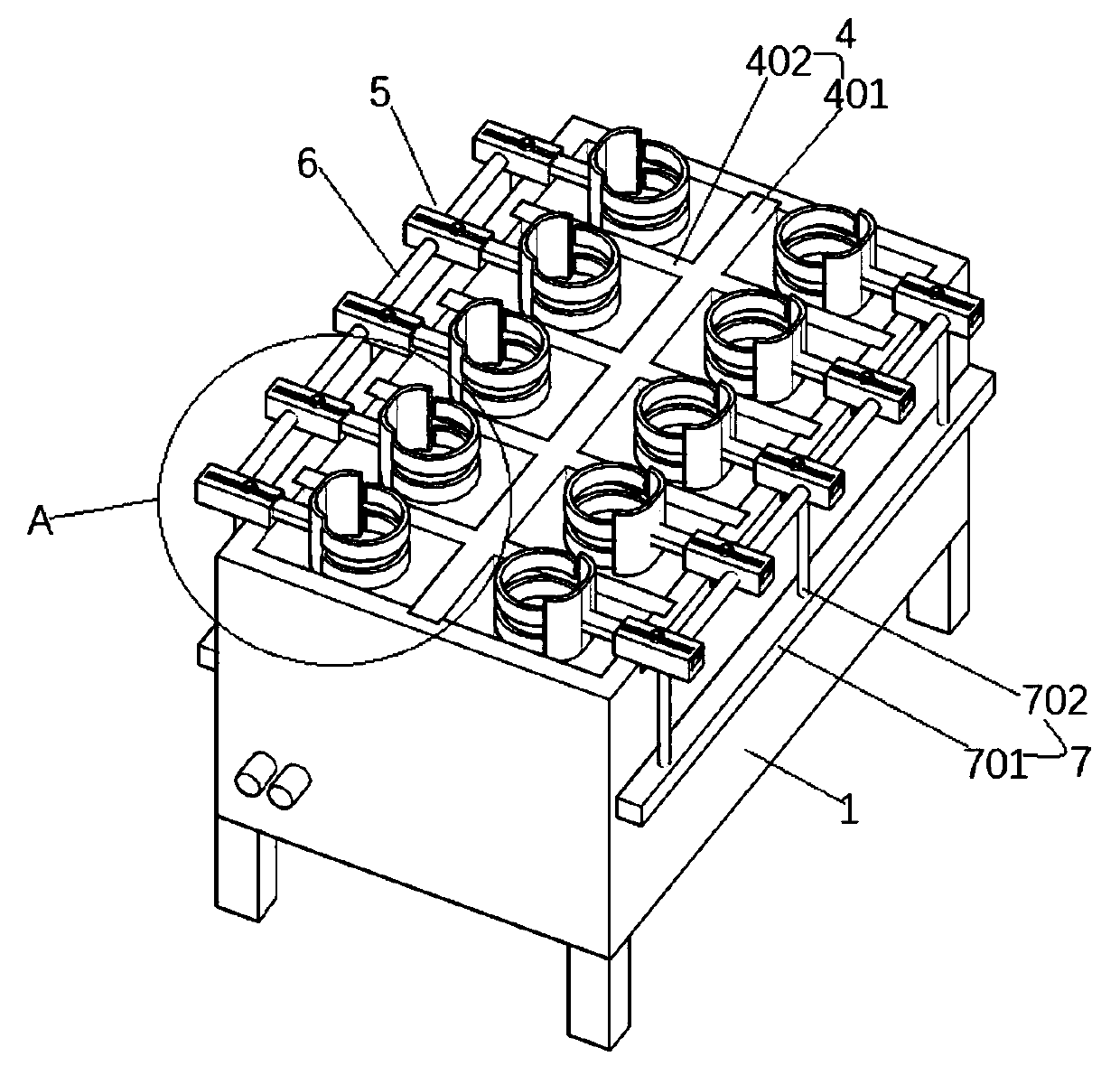

Flattener eliminating residual stress inside composite board

The invention discloses a flattener eliminating residual stress inside a composite board, and belongs to the field of composite board flattening machines. The flattener comprises a front flattener body, a rear flattener body, a connection rail between the front flattener body and the rear flattener body, a power transmission system driving the front flattener body and the rear flattener body to operate, and a pressing device adjusting reduction. The flattener is characterized in that working rollers of the front flattener body are arranged in the mode that an upper flattening roller is distributed in the middle of roller shafts, lower flattening rollers on the left and on the right are respectively distributed on the left side and on the right side of the roller shafts, working rollers of the rear flattener body are arranged in the mode that upper flattening rollers on the left and on the right are respectively distributed on the left side and on the right side of the roller shafts, a lower flattening roller is distributed in the middle of the roller shafts, all the flattening rollers can be adjusted horizontally on the roller shafts, and the roller surfaces are composed of a plurality of arches of different kinds of curvature, the arches are matched with the board shape of the composite board after being bent. The flattener has the advantage of being capable of eliminating the residual stress inside the composite board.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

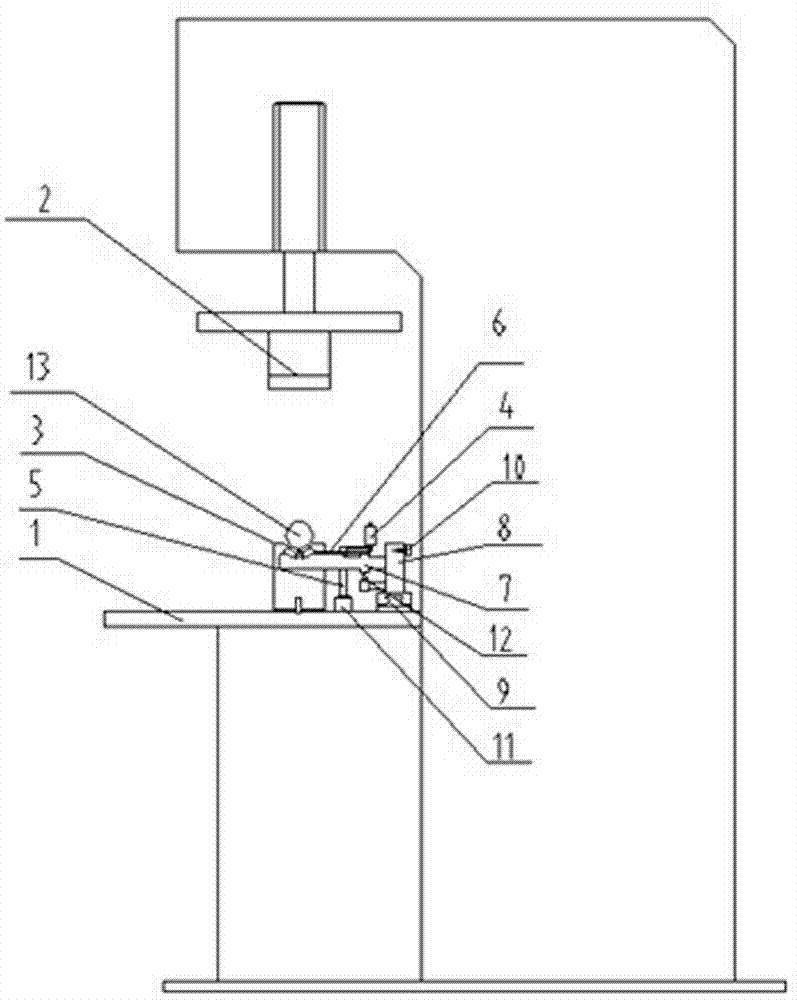

Straightening and measuring machine for slender shafts

InactiveCN103357710AHigh measurement accuracyImprove alignment accuracyAngles/taper measurementsMetal working apparatusIndustrial engineering

The invention discloses a straightening and measuring machine for slender shafts. The straightening and measuring machine for the slender shafts comprises a working table, a longitudinal pressing device, a fixed seat, a dial indicator, a dial indicator fixing frame and a lever, wherein the fixed seat is fixedly arranged on the working table, a product locating groove for locating a product is formed in the fixed seat, the longitudinal pressing device can move and position right above the fixing seat, the dial indicator fixing frame can be detachably fixed on the working table on one side of the fixed seat, the dial indicator is fixedly arranged on the dial indicator fixing frame, the lever is hinged to the dial indicator fixing frame, the side wall at one end in the length direction of the lever of the lever tightly abuts against the contact of the dial indicator, and the side wall at the other end in the length direction of the lever of the lever can tightly abut against the lower side of the circumferential surface of a workpiece. According to the straightening and measuring machine for the slender shafts, the pressing device for straightening and the dial indicator and the lever which are used for measuring are arranged on the working table at the same time, synchronous straightening and measuring of slender shaft workpieces can be achieved, namely, dynamic measurement and instant straightening can be achieved, the measurement accuracy and the straightening accuracy are high, the usage is convenient and the straightening efficiency is improved.

Owner:昆山诺丹舜蒲胶辊有限公司

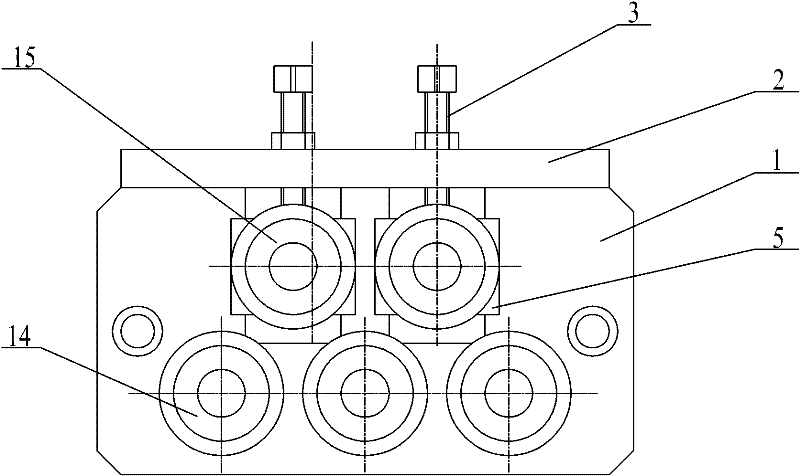

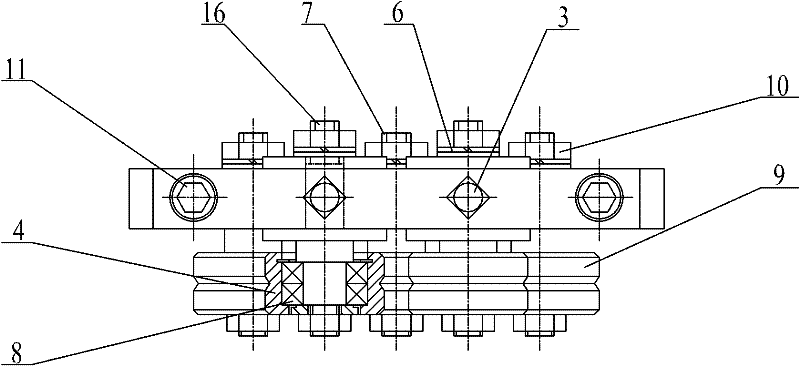

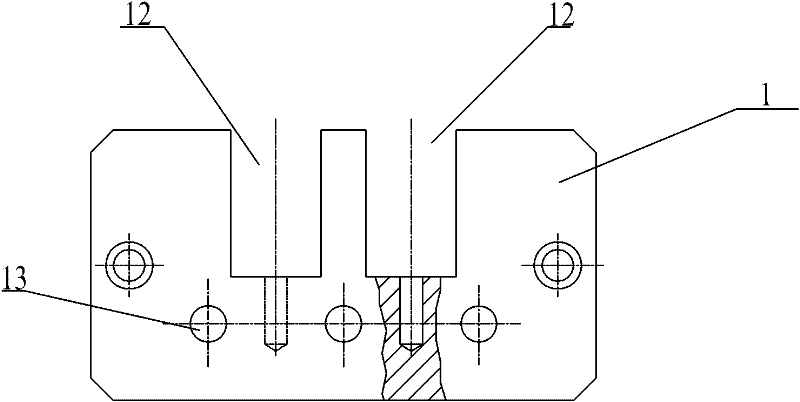

Clamp for rod material alignment

InactiveCN104438906AEasy to straightenImprove straightening efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:CHONGQING ZETIAN AUTO PARTS

Automatic winding equipment and winding method for motor coil

ActiveCN112821693AIncrease productivityHigh hardnessManufacturing dynamo-electric machinesElectric machinePiston rod

The invention belongs to the technical field of winding equipment, and particularly relates to motor coil automatic winding equipment and a winding method. The automatic winding equipment comprises a rack and a pay-off reel; a shell is fixedly connected to one side of the rack through a support, an air cylinder is fixedly connected to the bottom of the shell, a clamping plate is arranged at the top of a piston rod of the air cylinder, a first sliding hole is formed in the side, close to the piston rod, of the clamping plate, and the end of the piston rod is sleeved with the first sliding hole and slidably connected with the first sliding hole in a sealed mode. A top plate is fixedly connected to the position, corresponding to the clamping plate, of the top of the shell through a support, the side, away from the pay-off reel, of the first sliding hole communicates with a sliding barrel, a push rod is slidably connected into the sliding barrel, and the end of the push rod is connected with an annular clamping unit through a shifting fork; the air cylinder pushes the clamping plate to slide upwards and clamp an enameled wire, then the clamping unit is pushed to stretch the enameled wire, the enameled wire is straightened and stretched to generate plastic deformation, the hardness of the enameled wire is increased after cold drawing, and the production efficiency of the winding equipment is further improved.

Owner:深圳市磐锋精密技术有限公司

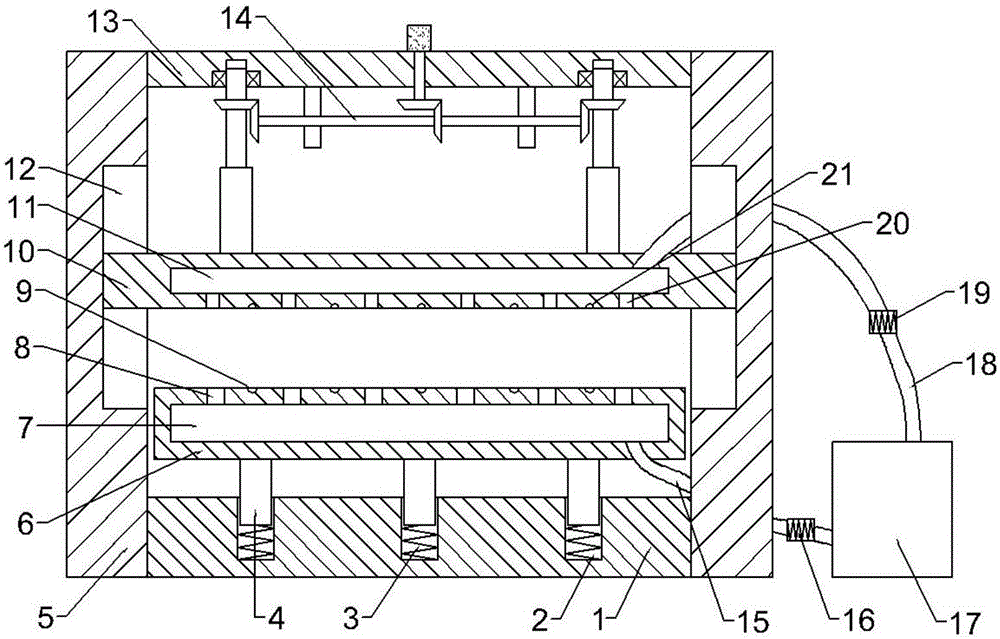

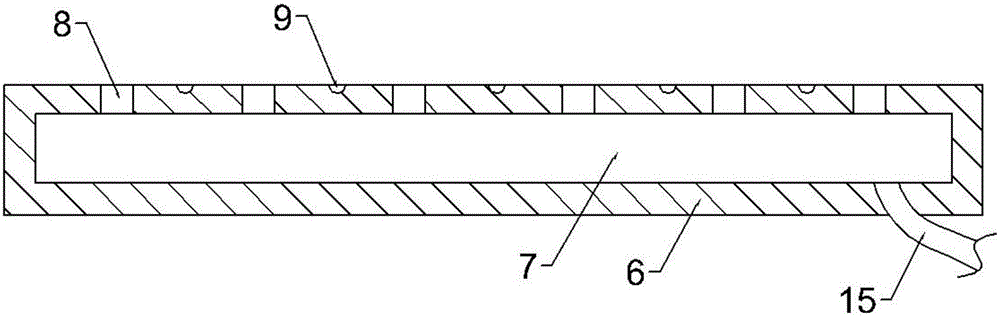

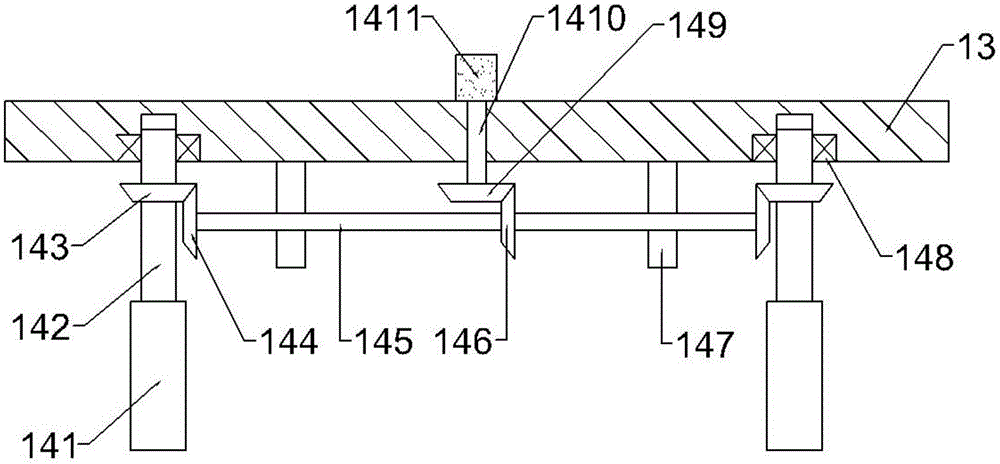

Feather straightening device for badminton production with steam-assisted function

The invention relates to a feather straightening device for badminton production with a steam-assisted function, which comprises a base, wherein support frames are arranged on two sides of the base; a plurality of grooves with upward openings are formed in the upper side of the base; springs are arranged on the bottom parts in the grooves; support pillars are also arranged in the grooves; the bottom ends of the support pillars are fixedly connected with the upper ends of the springs; a lower straightening plate is fixedly connected to the top ends of the support pillars; a lower cavity is arranged in the lower straightening plate; a plurality of lower through holes are formed in the upper side of the lower straightening plate; a steam generation device is arranged on one side of the base, and is connected with the lower cavity in the lower straightening plate through a lower steam inlet pipe. The feather straightening device provided by the invention has the beneficial effects that an upper straightening plate and the lower straightening late are utilized for straightening feathers, and steam is cooperated for steam-assisting the feathers, so that the feathers cannot be too dry and have higher toughness, and a straightening effect is effectively improved.

Owner:同码信息科技(常州)有限公司

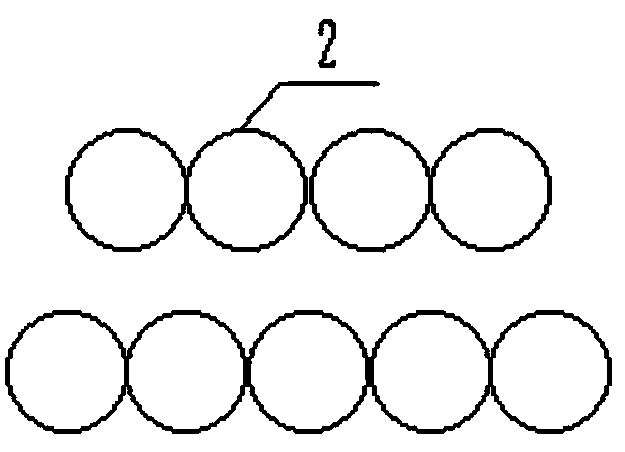

Straightening device for derusting machine

The invention relates to a straightening device for a derusting machine. The straightening device comprises a foundation; the upper part of the foundation is provided with uniformly distributed upper straightening mechanisms; the lower part of the foundation is provided with uniformly distributed lower straightening mechanisms; each upper straightening mechanism comprises an upper pin shaft; one end of the upper pin shaft correspondingly passes through the foundation; one end of the upper pin shaft passes through the foundation and is provided with a roller through a bearing; the roller can rotate relative to the upper pin shaft; each lower straightening mechanism comprises a lower pin shaft; one end of the lower pin shaft passes through the foundation; one end of the lower pin shaft correspondingly passes through the foundation and is provided with a roller through a bearing; the roller can rotate relative to the lower pin shaft; the roller of the upper straightening mechanism and the roller of the lower straightening mechanism are positioned on the same side of the foundation; and the roller of the upper straightening mechanism and the roller of lower straightening mechanism are correspondingly matched. The straightening device can straighten the steel wire passing through the upper straightening mechanism and the lower straightening mechanism, has a simple structure, is convenient to arrange and use, can straighten the steel wire before the steel wire is derusted, has high straightening efficiency, improves the working efficiency of the derusting machine, and is reliable and safe.

Owner:WUXI CHANGXIN TECH

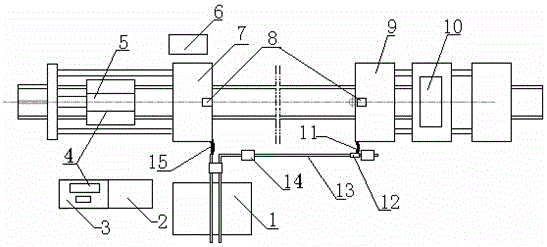

Pipe measuring and straightening integrated machine

ActiveCN108362193AImprove straightening efficiencyMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses a pipe measuring and straightening integrated machine, and the main points of the technical scheme of the invention are that the machine comprises a placement plane which is provided with two support seats; each support seat is provided with a jacking part; a measuring part is disposed between two support platforms, and comprises a main connecting bar, an auxiliary connecting bar, an adjustment ring, and a measuring ring; the main connecting bar passes through the adjustment ring, and the adjustment ring can slide in the length direction of the main connecting bar; theauxiliary connecting bar passes through the measuring ring, and the measuring ring can slide in the length direction of the auxiliary connecting bar; the measuring ring is located in the adjustment ring; the measuring ring and the adjustment ring are set concentrically; the machine also comprises a plurality of detection blocks, and two ends of each detection block are respectively a jacking end and a detection end; springs are connected between the jacking ends and the inner annular plane of the measuring ring; the machine also comprises a plurality of adjusting cylinders, wherein the stretching and drawing direction of the adjusting cylinders is the same as the radial direction of the adjustment ring. The machine is very high in pipe straightening efficiency.

Owner:徐州市瑞泰钢管有限公司

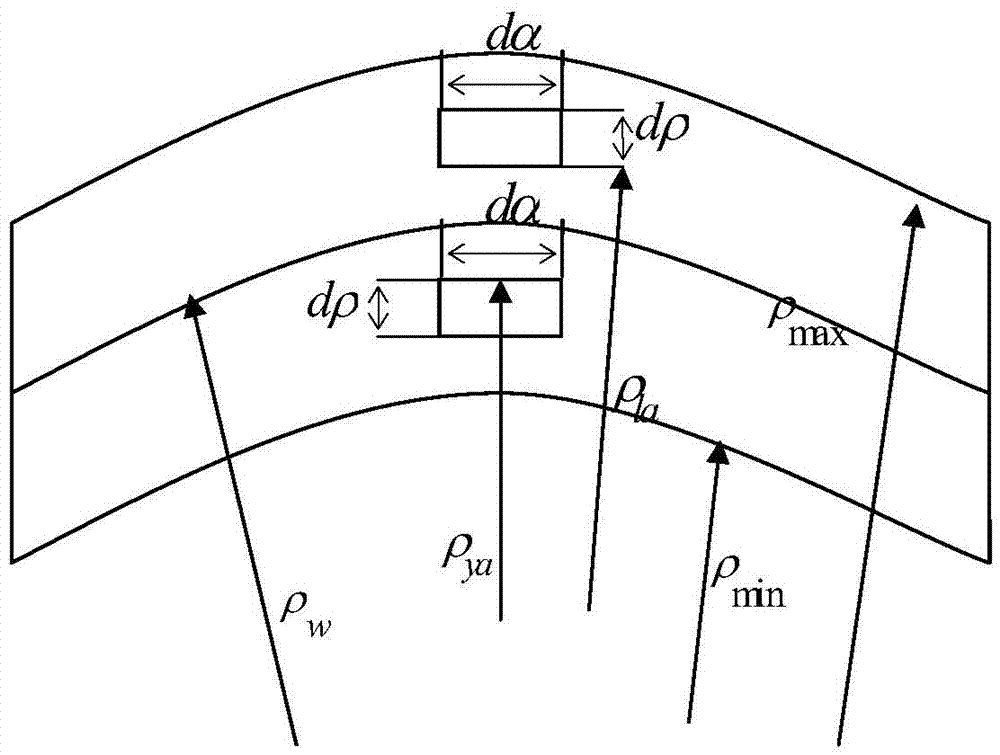

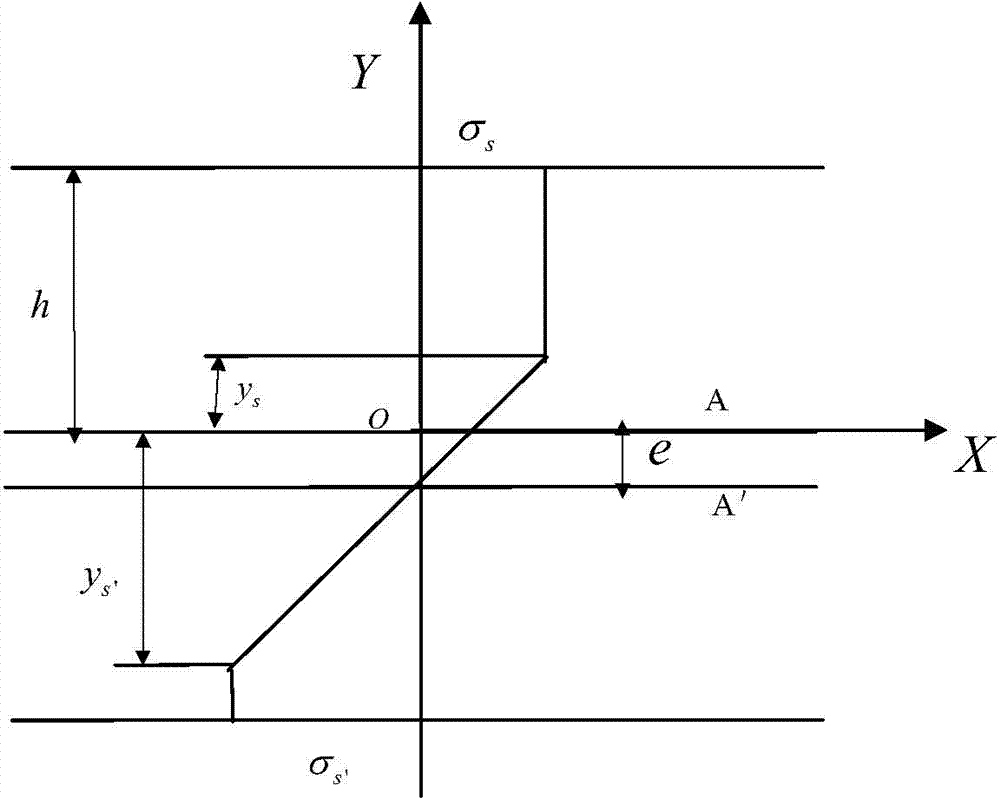

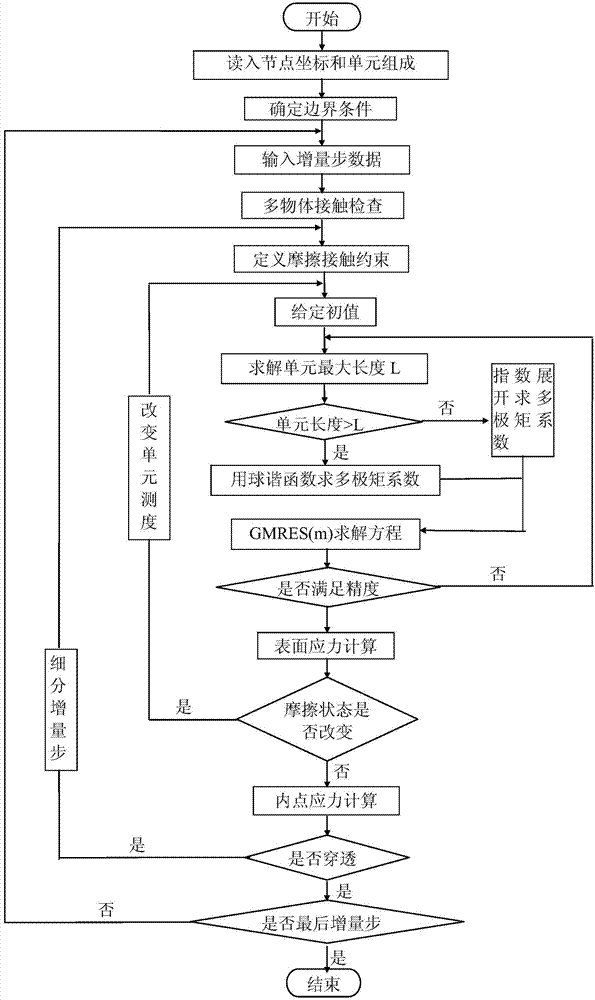

Method for calculating straightening force of roller type straightening machine through multi-pole boundary element method

InactiveCN103678932AHigh precisionImprove straightening efficiencySpecial data processing applicationsEngineeringElastic plastic

The invention provides a method for calculating straightening force of a roller type straightening machine through a multi-pole boundary element method, and belongs to the technical field of roller type straightening. The method is characterized in that the method includes the steps of firstly, calculating and considering straightening force of deviation of a neutral layer, secondly, calculating and considering straightening force of the bauschinger effect, thirdly, using an independently developed three-dimensional elastic-plastic multi-object contact multi-pole boundary element method program package for calculating straightening force, finally, giving comprehensive consideration to the three factors, and utilizing weight, occupied in straightening force, of each factor to obtain the size of straightening force in the roller type straightening process at last. The method has the advantages that a more accurate straightening force calculating formula is obtained, theoretical support is provided for design of the straightening machine, straightening force calculation is more accurate, the straightening effect is improved effectively, and accordingly the product quality is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

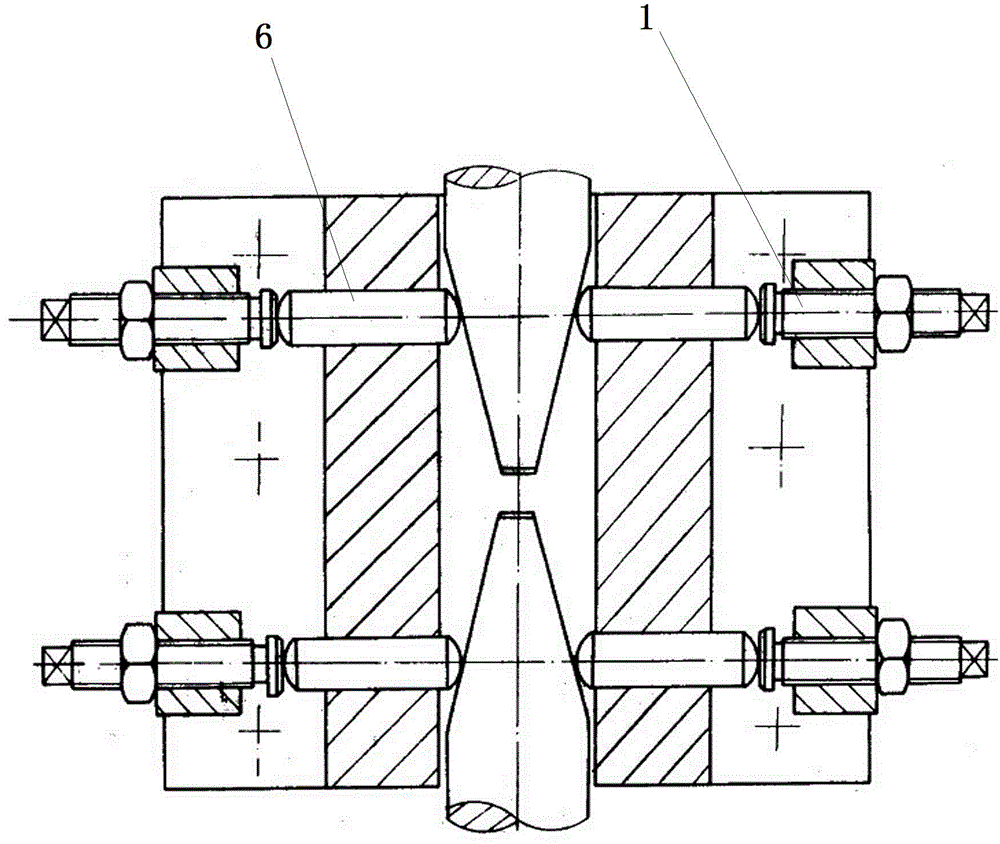

Cu-Nb composite wire straightening device

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Process for producing large-diameter core rods of pipe tandem mills

InactiveCN101905408AImprove alignment efficiency and accuracyReduce curvatureMetal working apparatusNuclear engineering

The invention discloses a process for producing large-diameter core rods of pipe tandem mills, having the characteristics of improving the straightening efficiency of the core rods. The process for producing core rods of large-diameter pipe tandem mills comprises the following steps of core rod blank forging, first-time straightening, surface rough turning, tempering treatment, second-time straightening and finish turning in sequence, wherein in the steps of first-time straightening and second-time straightening, firstly the core rods are placed on a lathe for marking the bent positions of the core rods and measuring the bending values, and then targeted straightening is carried out on the core rods according to the marks and the bending values. Therefore, the core rods are straightened on a free hydraulic forging press according to the marked positions and the bending values so that the straightening efficiency and accuracy are greatly improved; and in addition, the whole-length bending of the straightened core rods is only 3.5 mm and is even lower, and when the large-diameter core rods are turned, the process can ensure that qualified finished products can be processed by using less turning allowances. The process is especially suitable for popularization and application in the production of the large-diameter core rods.

Owner:攀钢集团成都钢铁有限责任公司

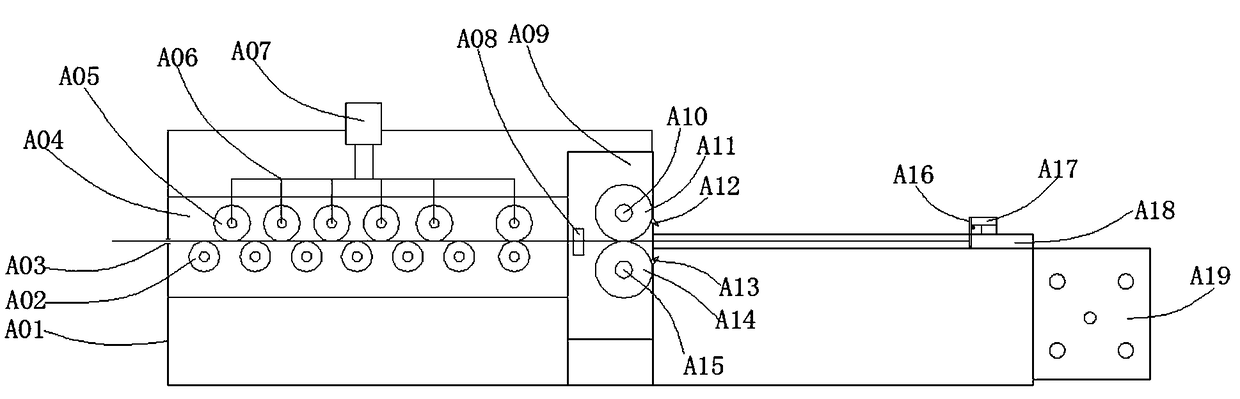

Construction reinforcement machining device and application method thereof

The invention provides a construction reinforcement machining device and an application method thereof. The construction reinforcement machining device comprises a first bracket, a straightening machine and a shearing machine; the straightening machine is arranged at one end of the first bracket; the straightening machine comprises a traction wheel, a feed port, a pressing wheel, a second bracket,a hydraulic cylinder, a first motor, a driving chain wheel, a bracket, a chain, a fourth shaft and a driven chain wheel; and the shearing machine is arranged at the middle part of the first bracket.The construction reinforcement machining device adopts integral design of straightening and shearing; after reinforcements are straightened by the straightening machine, the reinforcements enter a receiving frame of the shearing machine through a positioning hole; and the position of a travel switch is set according to a needed length, so that the straightened reinforcements are shorn off according to the needed length, the repeated carrying operation in reinforcement machining is reduced, the production time and the labor amount are saved, the production efficiency is improved, and the production cost is reduced.

Owner:浙江聚光交通设施有限公司

Hydraulic straightening platform

The invention provides a hydraulic straightening platform which can straighten and align overlapped workpieces. A set of shape steel bottom beams which are arranged in a criss-cross mode and meet the requirement for the height difference, adjustable end socket columns, movable end socket bases, tilt angle detection devices, T-shaped movable centers, movable pushing and straightening columns, track idler wheels, abrasion resistance blocks, straight-movement oil cylinders and inclined-pushing oil cylinders are stably connected together through hinge pins and rib plates to form the hydraulic straightening platform. The two ends of each shape steel bottom beam are connected with the corresponding adjustable end socket column and the corresponding movable straightening end socket base respectively, the straight-movement oil cylinders and the inclined-pushing cylinders are simultaneously hinged to the straightening end socket bases, the track idler wheels and the tilt angle detection devices are simultaneously hinged to the piston rod ends of the straight-movement oil cylinders, the T-shaped movable centers are arranged on the adjustable end socket columns, and the piston rod end of the corresponding straight-movement oil cylinder and the piston rod end of the corresponding inclined-pushing oil cylinder are hinged to the two ends of each movable pushing and straightening column respectively.

Owner:YANGZHOU LISHEN ELEVATORING EQUIP

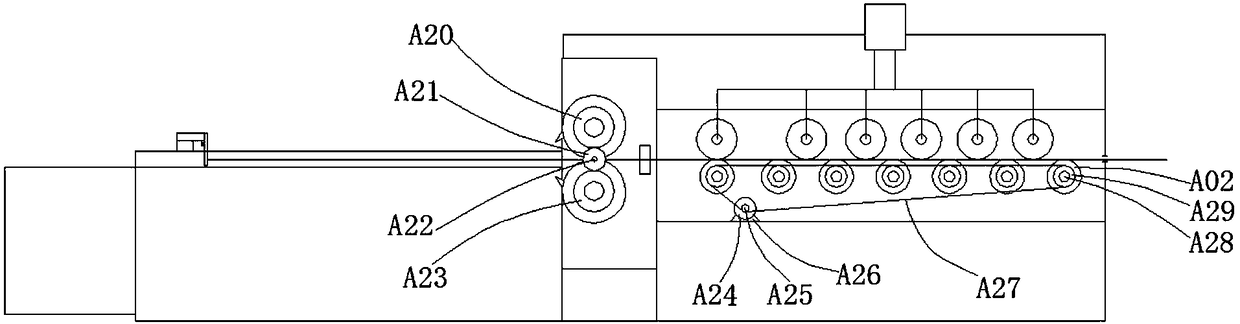

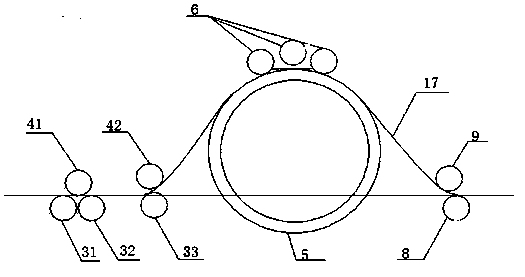

Steel-bar arc-delivering straightening hoop bending machine

The invention relates to a steel-bar arc-delivering straightening hoop bending machine. The steel-bar arc-delivering straightening hoop bending machine is characterized by sequentially comprising a feeding port, a delivering assembly, a guiding assembly, a measuring assembly, a straightening assembly, a material-guiding guide tube, a shearing assembly, a bending assembly and a reverse delivering assembly, wherein the delivering assembly is used for clamping a steel bar and delivers the steel bar backwards, the guiding assembly is used for controlling and guiding the delivering path of the steel bar and achieving arc-delivering through change of displacement of each wheel set in the perpendicular direction, and the measuring assembly is used for measuring the current delivering length of the steel bar. The delivering assembly comprises a pair of delivering wheels, and the two delivering wheels are located on the upper side of the middle axis of the feeding port and the lower side of the middle axis of the feeding port respectively and are symmetrically distributed. The measuring assembly comprises a set of metering wheels which are vertically distributed. The straightening assembly comprises a perpendicular straightening assembly and a horizontal straightening assembly, wherein the horizontal straightening assembly is composed of two sets of plane straightening wheels. The steel-bar arc-delivering straightening hoop bending machine guarantees the quality of the straightened steel bar, improves straightening efficiency, reduces production cost, and has positive significance in straightening and bending of the steel bar.

Owner:姜勇

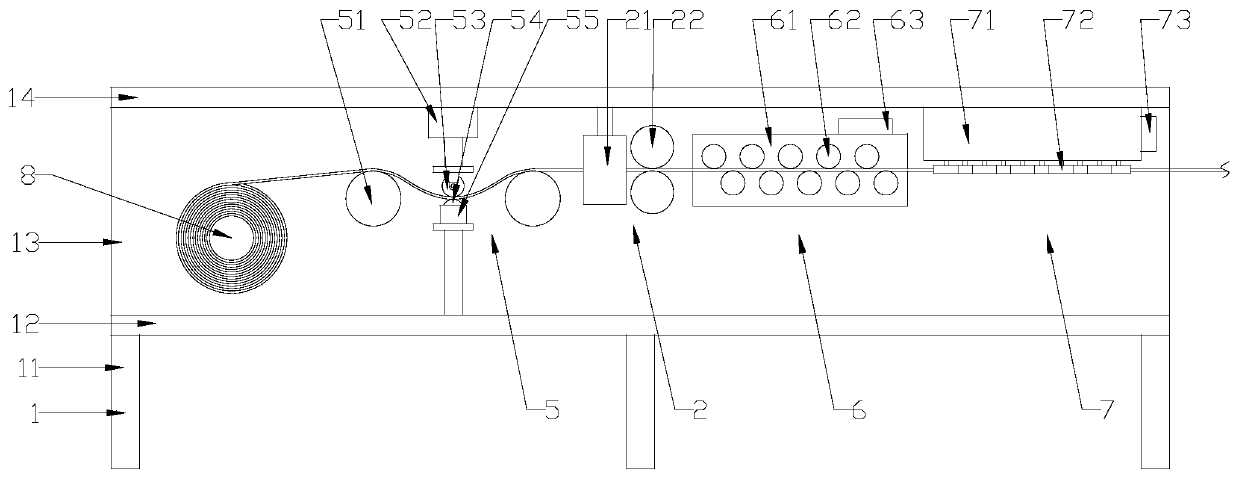

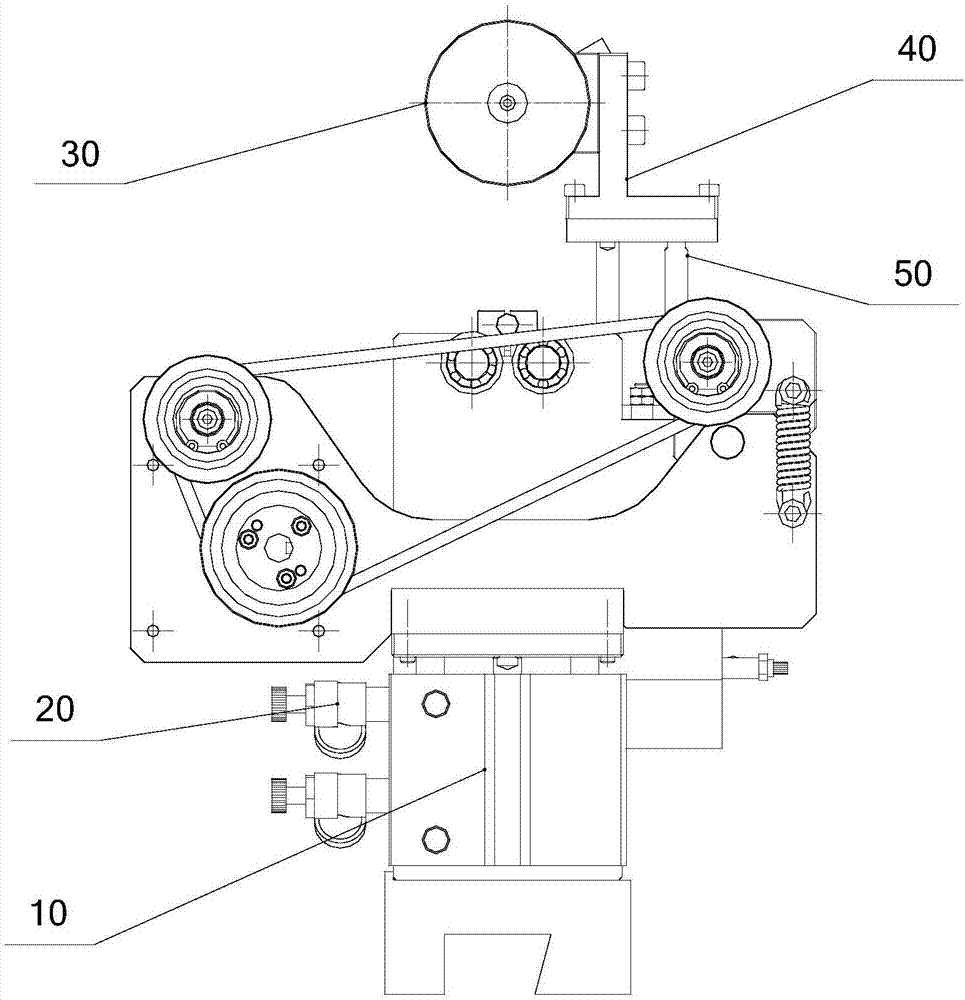

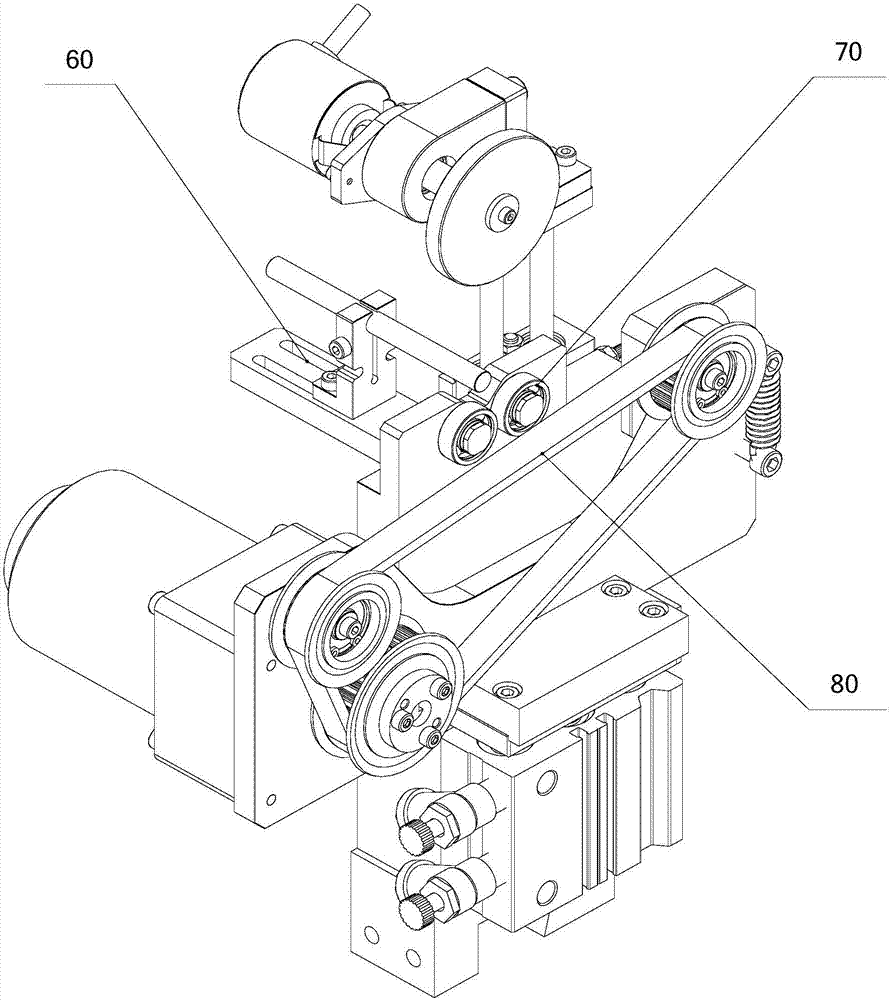

Wire rod straightening device for screw

InactiveCN110052559AImprove straightening efficiencyAchieve initial straighteningWire rodEngineering

The invention discloses a wire rod straightening device for a screw. The wire rod straightening device for the screw comprises a rack, a guiding unit, a pre-bending unit, a longitudinal straighteningunit, a transverse straightening unit and an input roller. The pre-bending unit comprises an upper compression roller driven by an air cylinder to move up and down and a lower compression roller located below the upper compression roller and driven by a third motor to rotate. Side compression rollers are separately arranged on two sides of the upper compression roller and the lower compression roller. The longitudinal straightening unit comprises a first straightening box, a plurality of longitudinal straightening wheels fixed to the first longitudinal straightening box and a fourth motor which drives the longitudinal straightening wheels to rotate. The transverse straightening unit comprises a second straightening box, a plurality of transverse straightening wheels fixed to the second straightening box and a fifth motor which drives the transverse straightening wheels to rotate. Heating strips are also separately arranged in the first and second straightening boxes. The wire rod straightening device for the screw can straighten big and small curves of the wire rod.

Owner:HAIYAN NEW SHENGDA FASTENER

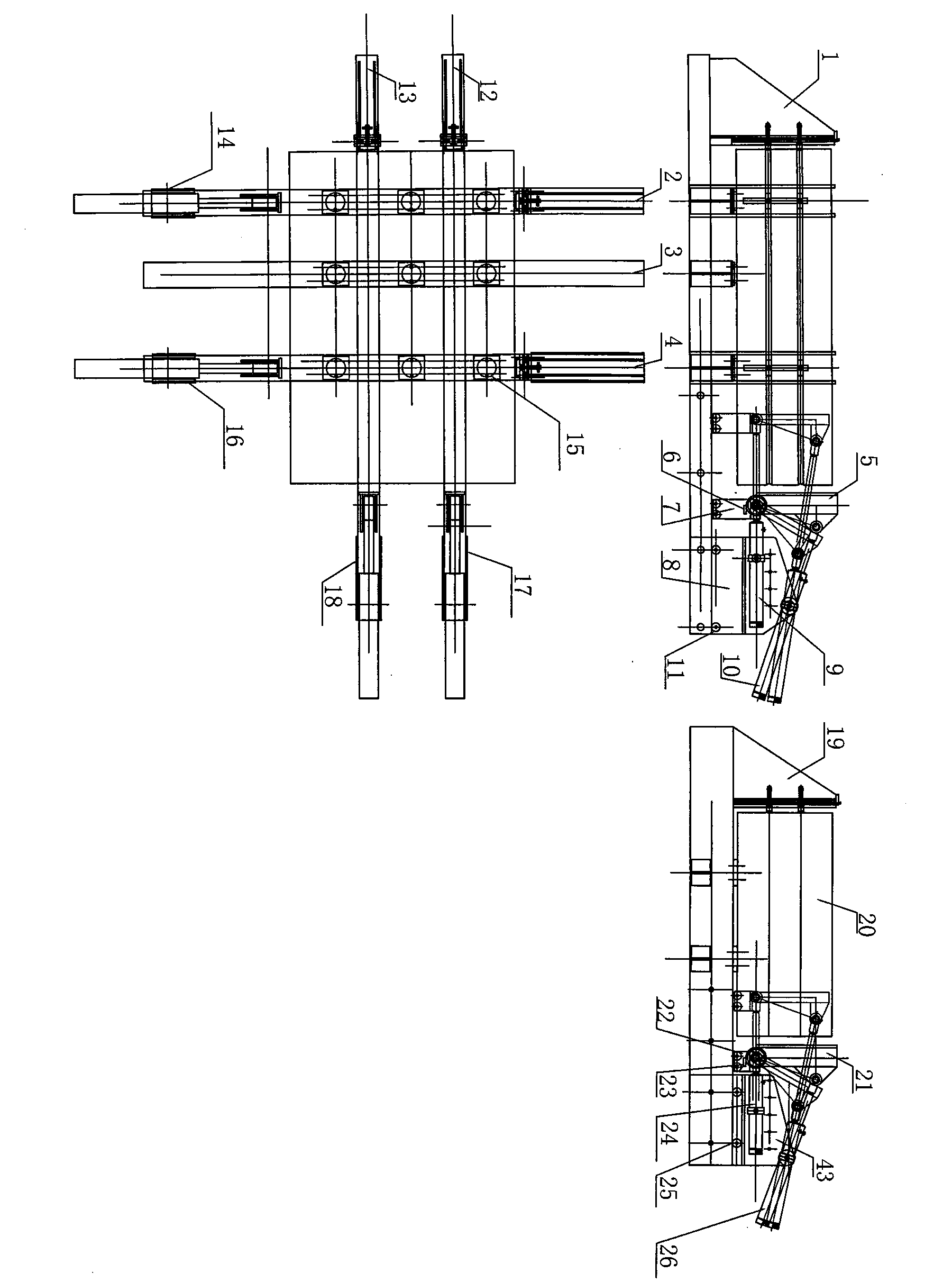

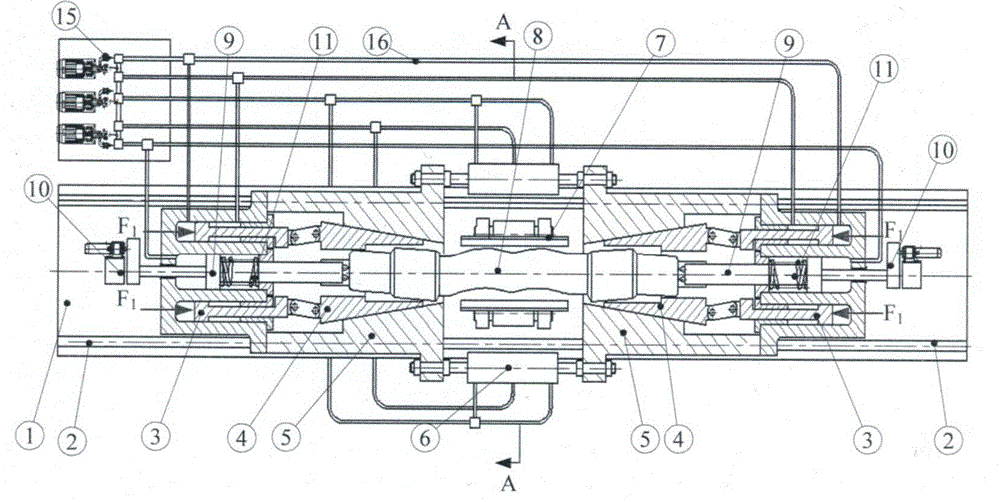

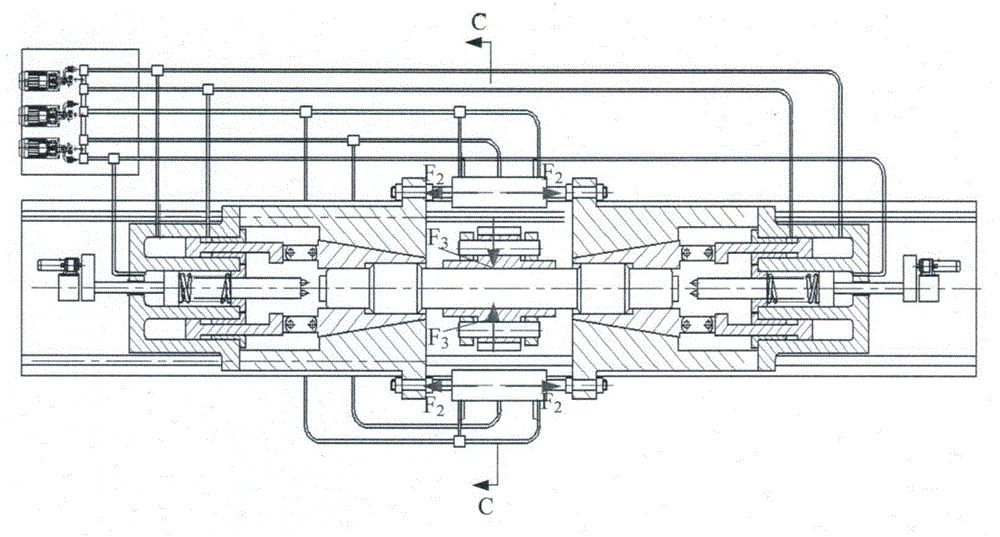

Straightening method and device for thick shaft like parts

InactiveCN104475496AReduce straightening forceReduce reboundShaping toolsHydraulic cylinderControl system

The invention provides straightening method and device for thick shaft like parts. The method is mainly applied to the straightening of the thick shaft like part; a clamping head is used for applying an axial loading force on a straightened shaft; the bent and deformed clamped end is straightened during clamping by the clamping head; under the effect of the axial loading force, a hydraulic cylinder is used for applying a straightening loading force for a sectioning reverse bending straightening die, so as to straighten the bent and deformed shaft body under the effects of the axial loading force and the straightening loading force. According to the method, the tensile reverse bending straightening method and device are adopted, the resilience value after straightening from bending is decreased, the force for reverse bending straightening is lowered down, straightening device bending detecting system and straightening displacement analyzing calculating control system are decreased, and a plurality of bent and deformed shaft bodies can be straightened at a time; the process is simple, and the straightening efficiency is high; the method and device are suitable for cold and hot straightening processes of steps and polish rod thick shafts like parts such as a train shaft and a car transmission shaft.

Owner:YANSHAN UNIV

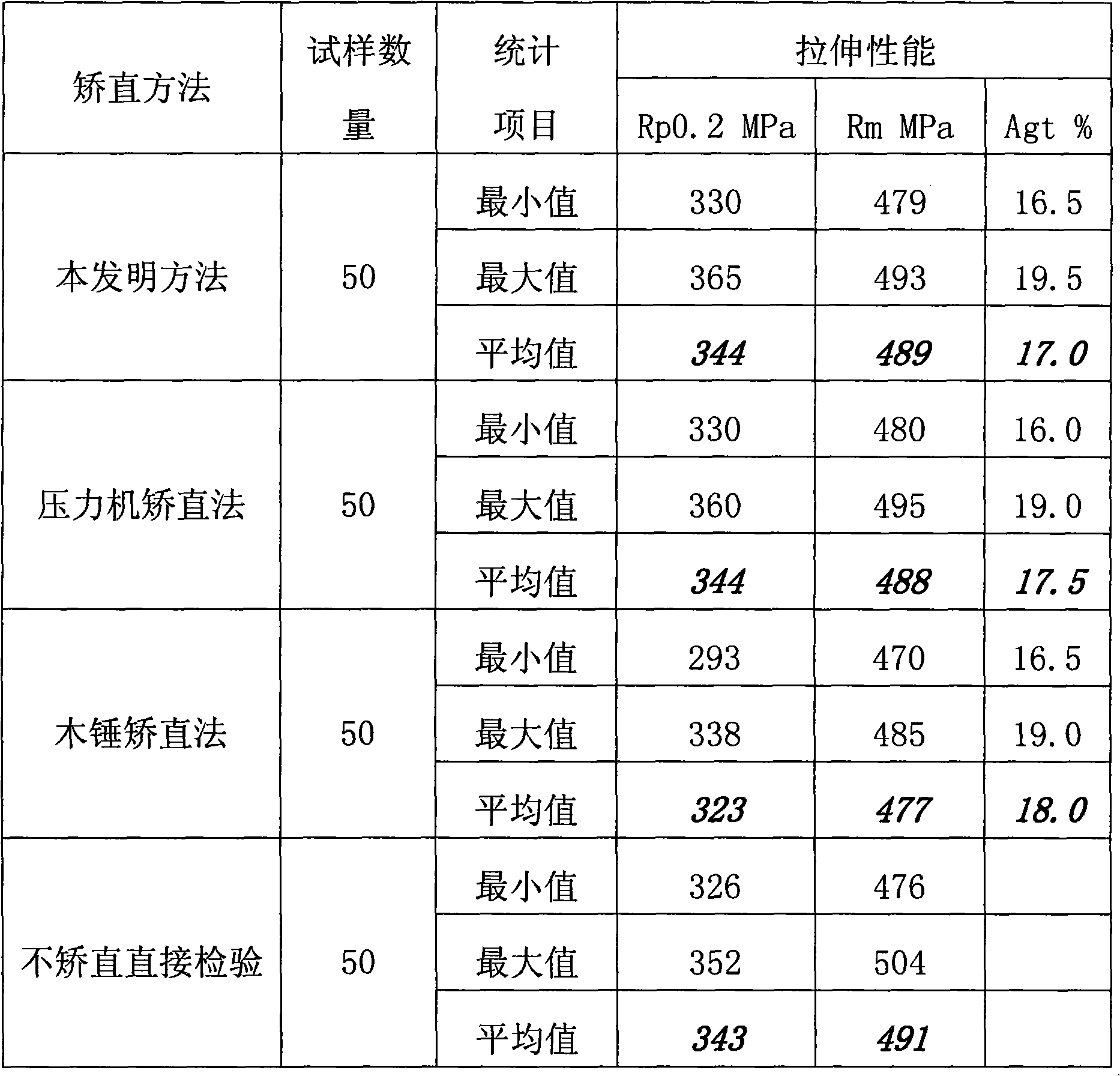

Method for aligning rod bundle checkout sample

InactiveCN101256125AImprove straightening effectImprove straightening efficiencyPreparing sample for investigationTest sampleEngineering

The invention provides a straightening process of bull rod test sample, which includes the following steps: at first straightening holding parts on double ends of the bull rod test sample and holding it in one central line as much as possible, then fastening the holding parts on double ends of the bull rod test sample tightly on the stretching equipment, loading and stretching, decelerating tension speed when approach to flat, stopping loading as soon as the test sample is straightening, controlling the loaded load below the yield load of the test sample strictly. Using the straightening method, can overcome the defects existing in the bull rod test sample straightening process, the straightening effect is good, straightening efficiency is high, and the method has little affects on the performance of the test sample.

Owner:MAANSHAN IRON & STEEL CO LTD

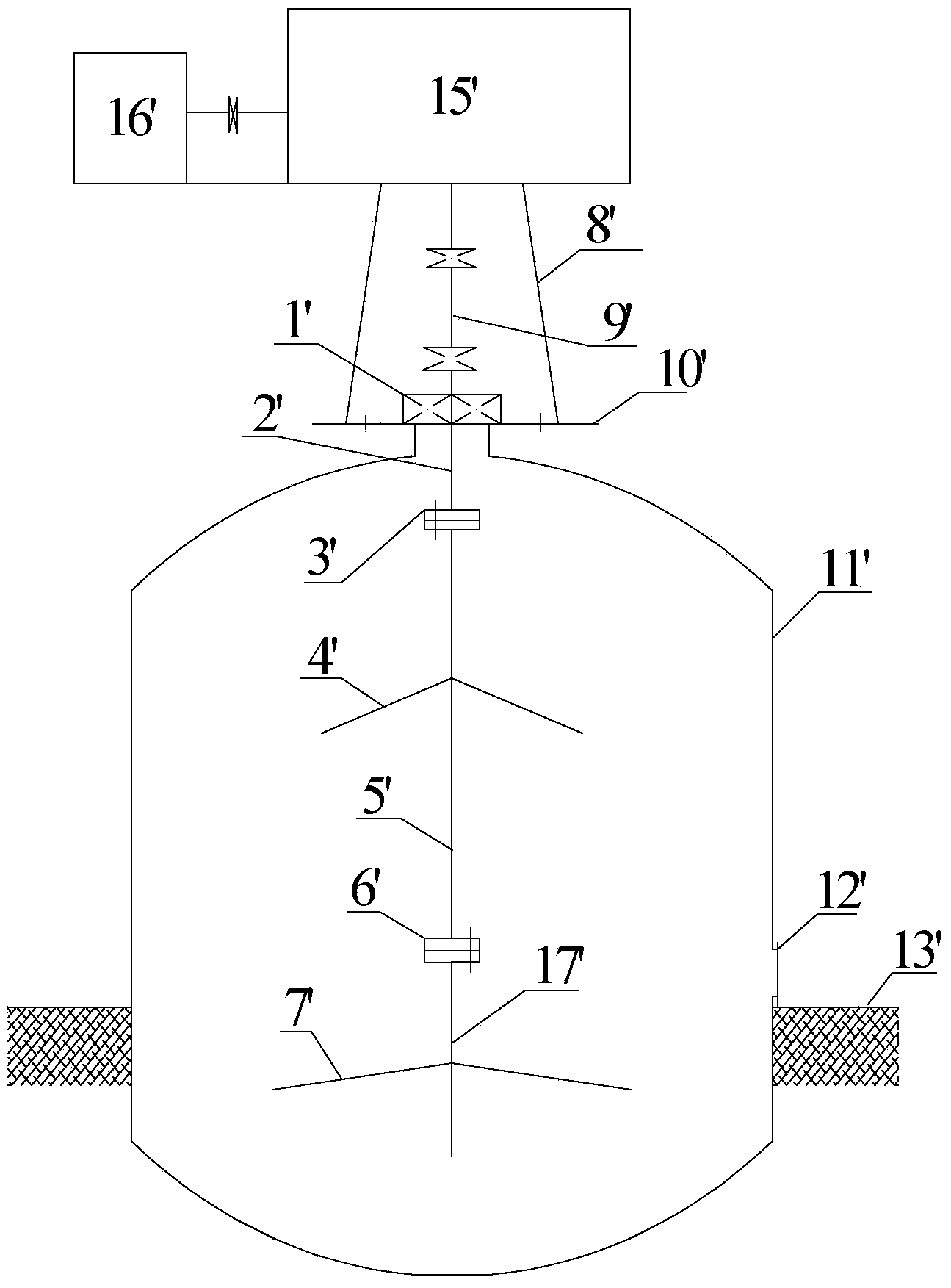

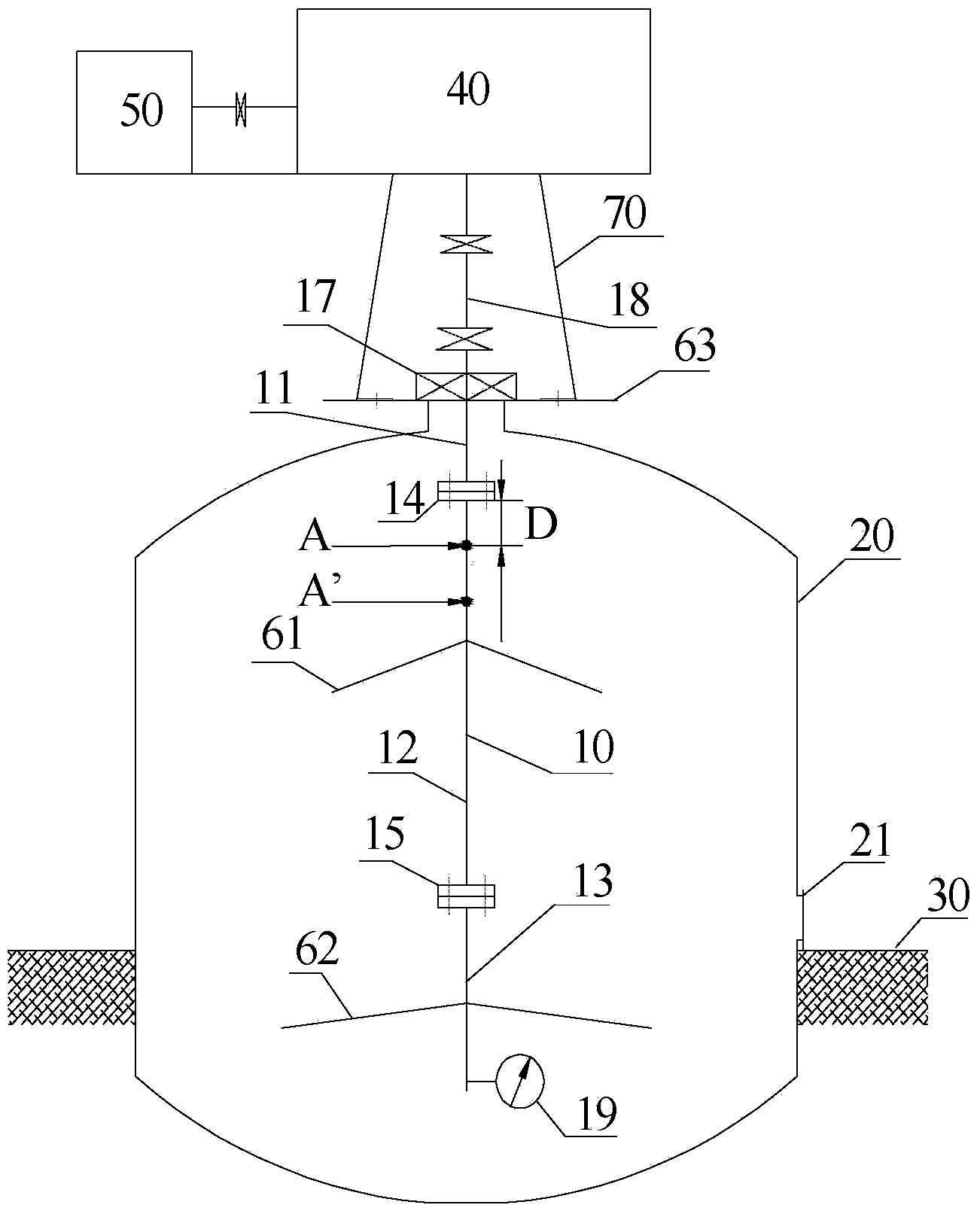

Method for straightening stirrer shaft

ActiveCN103447357ANo installation deviationReduce labor intensityChemical/physical processesMechanical engineering

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

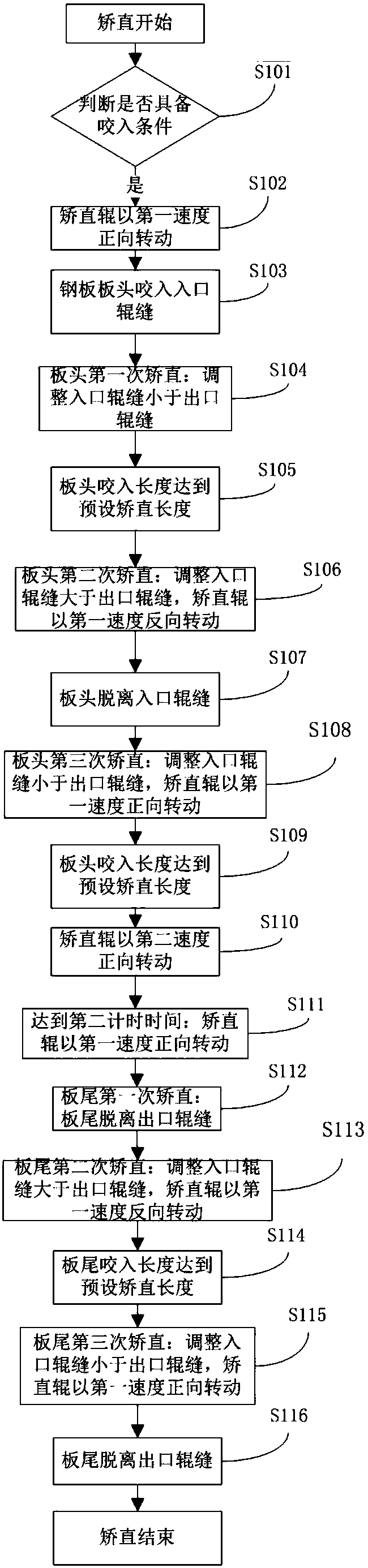

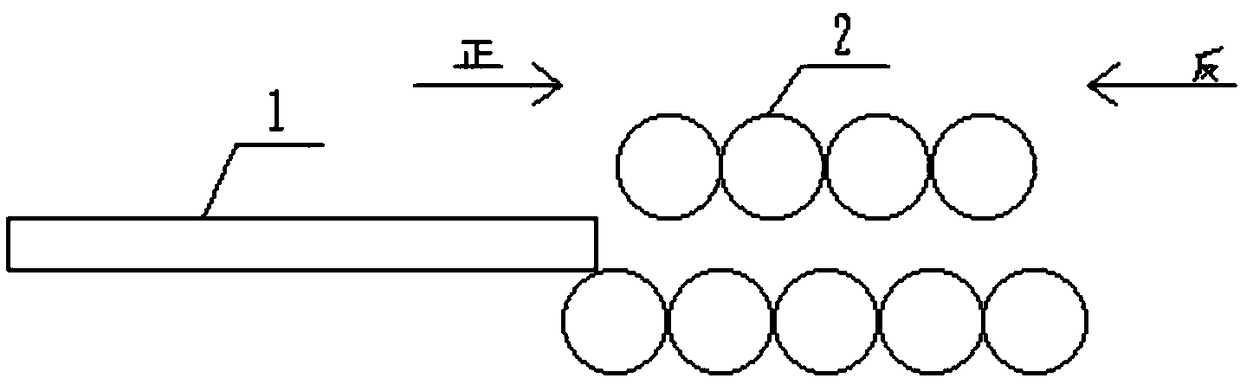

Straightening control method of steel plate

ActiveCN108089466AShorten straightening timeImprove straightening efficiencyProgramme control in sequence/logic controllersSheet steelSteel plates

The application discloses a straightening control method of a steel plate. The method comprises: if a straightening machine has a biting condition, a controller controls a straightening roller rotateforwardly at a first speed and the head of a to-be-straightened steel plate is bitten into an entrance roller slit of the straightening roller; whether the biting length of the head of the to-be-straightened steel plate reaches a preset straightening length is detected; if so, first straightening of the head of the steel plate is completed and the straightening roller is controlled to rotate reversely at a first speed, so that the straightening roller completes second straightening of the plate head along an opposite direction; and if the head of the to-be-straightened steel plate is separatedfrom the entrance roller slit, the straightening roller is controlled to rotate forwardly at a first speed. Therefore, the straightening time of the steel plate is shortened effectively, so that thestraightening efficiency of the steel plate is improved effectively.

Owner:SHANXIN SOFTWARE CO LTD

Forestry engineering seedling culture device

InactiveCN111264236AImprove operational efficiencyImprove straightening effectCultivating equipmentsTree rootForest industry

The invention relates to the technical field of forestry devices, in particular to a forestry engineering seedling culture device. The forestry engineering seedling culture device comprises a water tank, a lifting mechanism arranged in the water tank, a pore plate connected with the top of the lifting mechanism, a seedling accommodating mechanism arranged on the upper end face of the pore plate and an adjustable seedling straightening mechanism arranged at the upper end of the water tank; the upper end of the seedling accommodating mechanism is positioned in the water tank when the lifting mechanism is completely contracted; and the lower end of the seedling accommodating mechanism is positioned outside the water tank when the lifting mechanism completely extends out. According to the forestry engineering seedling culture device, the adjustable seedling straightening mechanism is simple in structure and convenient to mount and dismount, when the adjustable seedling straightening mechanism is used together in cooperation with a supporting mechanism, the device is high in structural stability and convenient to use, component parts are convenient to maintain and replace, and the device is high in straightening efficiency and extremely good in straightening effect; after seedlings are cultivated, the seedlings are moved out from the side faces, the operation is rapid, tree roots and trunks are hardly damaged, and the survival rate of the transplanted seedlings is greatly increased; and the device is convenient to maintain.

Owner:令狐荣钢

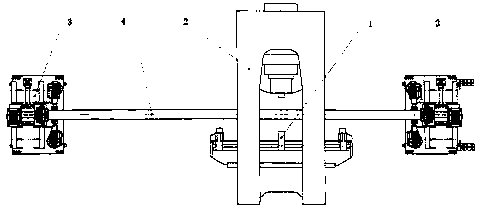

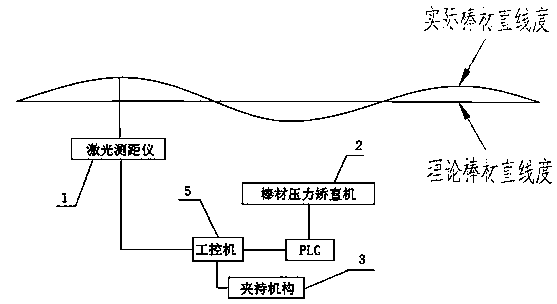

Non-contact laser online detection bar straightness mechanism and detection method

ActiveCN104014613AImprove reliabilityDoes not affect productionMetal working apparatusProgrammable logic controllerData acquisition

The invention discloses a non-contact laser online detection bar straightness mechanism and a detection method. The mechanism includes a laser rangefinder, an industrial control computer, a programmable logic controller and a clamping mechanism. The laser rangefinder is mounted on a bar pressure straightening machine and used for acquiring distance data to the bar surface on a real-time basis, and there is a gap between the laser rangefinder and the bar in the data acquisition; the industrial control computer is connected with the laser rangefinder, and used for receiving and processing the data acquired by the laser rangefinder, drawing a straightness curve of the bar, and converting the analysis results into action commands and feeding the action commands back to the programmable logic controller; the programmable logic controller is connected with the industrial control computer, and used for receiving the signals sent in by the industrial control computer and outputting action instruction to a bar pressure straightening machine; and the clamp mechanism is connected to the industrial control computer, and used for clamping bar at both ends, so that the bar passes before the laser rangefinder. The invention provides basis for bar straightening, improves the straightening efficiency and the rate of qualified products, and can be widely used in metallurgy and other heavy machinery industries.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

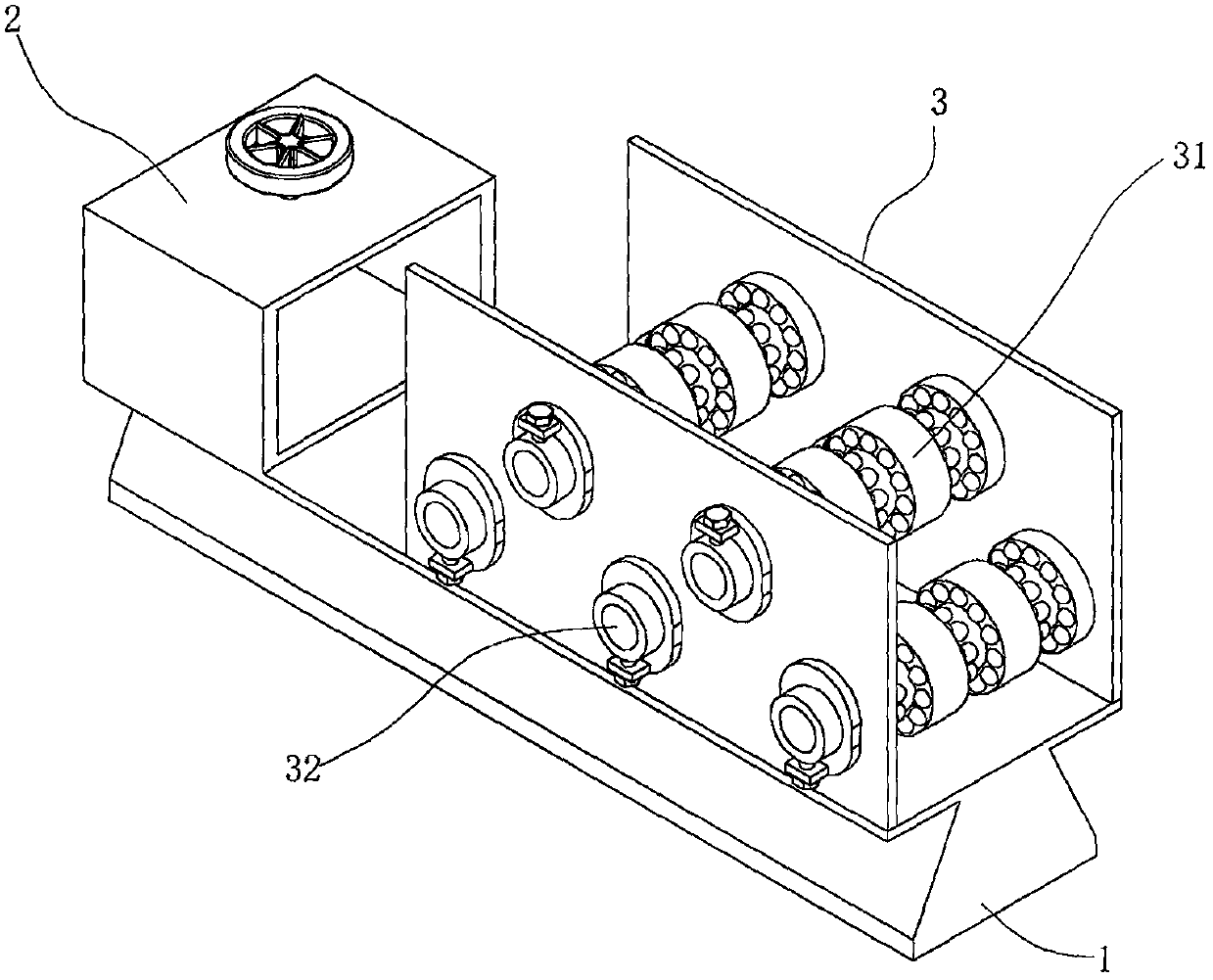

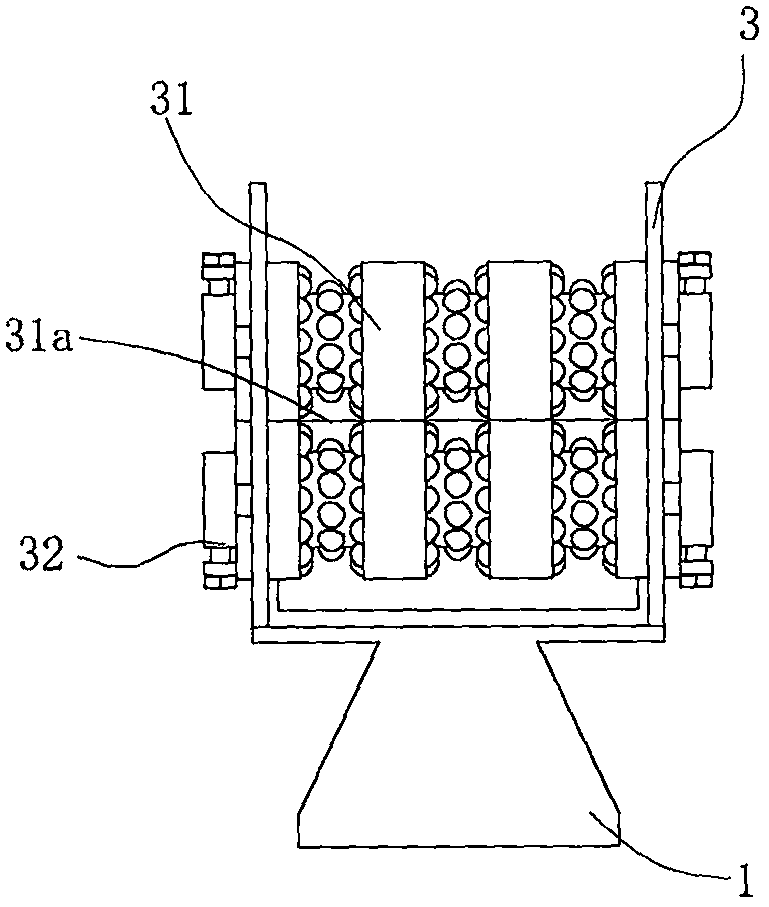

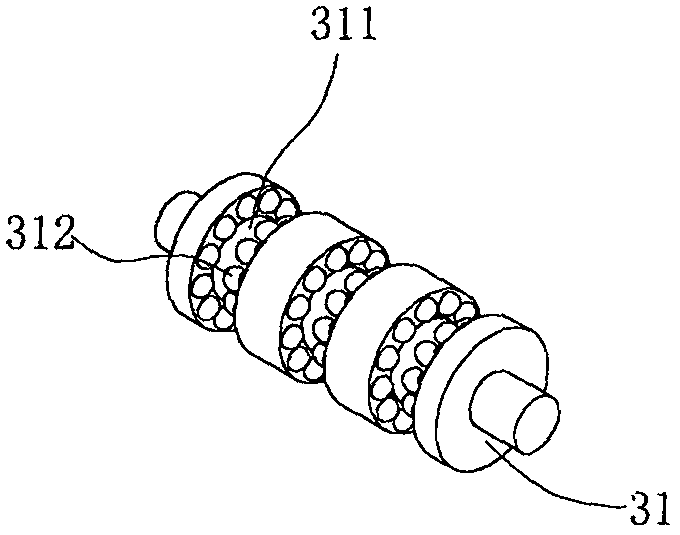

Bar straightening mechanism

The invention relates to a bar straightening mechanism, which includes a workbench, a pulling part, and a straightening part. There are grooves, and balls are arranged in the grooves, and the grooves on the upper and lower two sets of straightening rollers are opposite to form straightening holes for bars to pass through. The bar can be straightened at multiple angles through the straightening hole, and due to the existence of balls, there will not be too much friction between the bar and the straightening roller, and there will be no impact on the straightening roller. The surface is damaged.

Owner:余姚市奥祥轴承有限公司

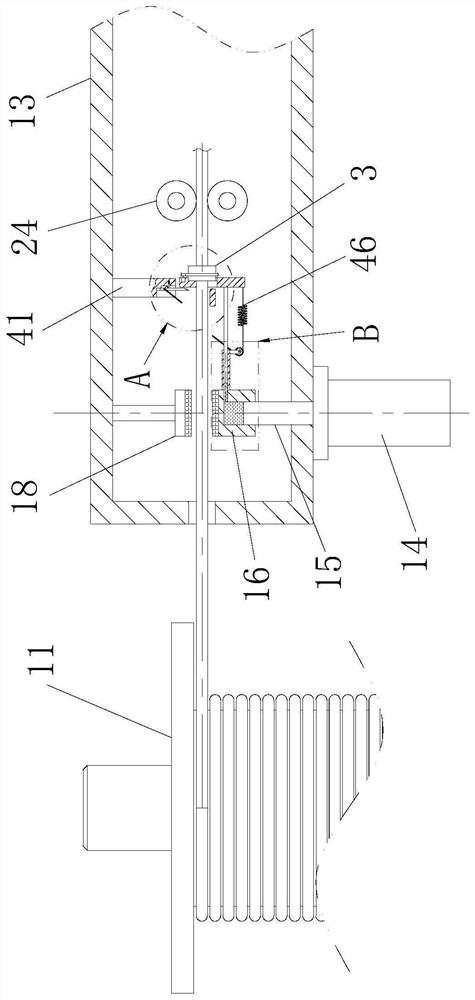

Inductance coil wire pin automatic straightener

ActiveCN103909175BImprove applicabilityHigh degree of automationCoils manufactureInductorEngineering

The invention relates to straightening machines of pins, in particular to an automatic straightener of inductance oil lead pins. The automatic straightener of inductance oil lead pins comprises a controller, a straightening part and a fixing part. The straightening part is arranged above the fixing part and comprises a die core in the center and a plurality of cylinders around. The upper surface of the die core is horizontal; pin positions are arranged on the periphery of the upper surface of the die core. The cylinders are as many as the pin positions; the die core corresponds to an inductance coil in specification. The cylinders fit the die core at the pin positions. The cylinders clamp the die core and leave the die core under control of the controller, so that the lead pins are straightened. The automatic straightener of inductance oil lead pins has the advantages that the blank of automatic straightener of inductance oil lead pins is filled and increase of automation level is promoted.

Owner:合肥云路聚能电气有限公司

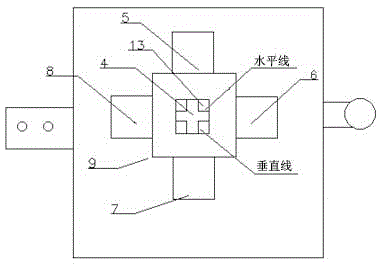

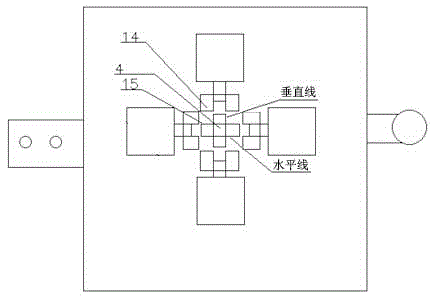

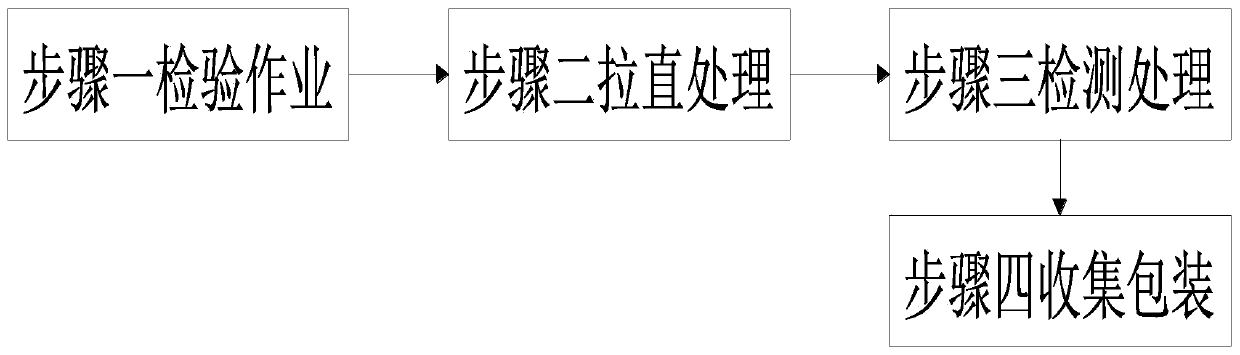

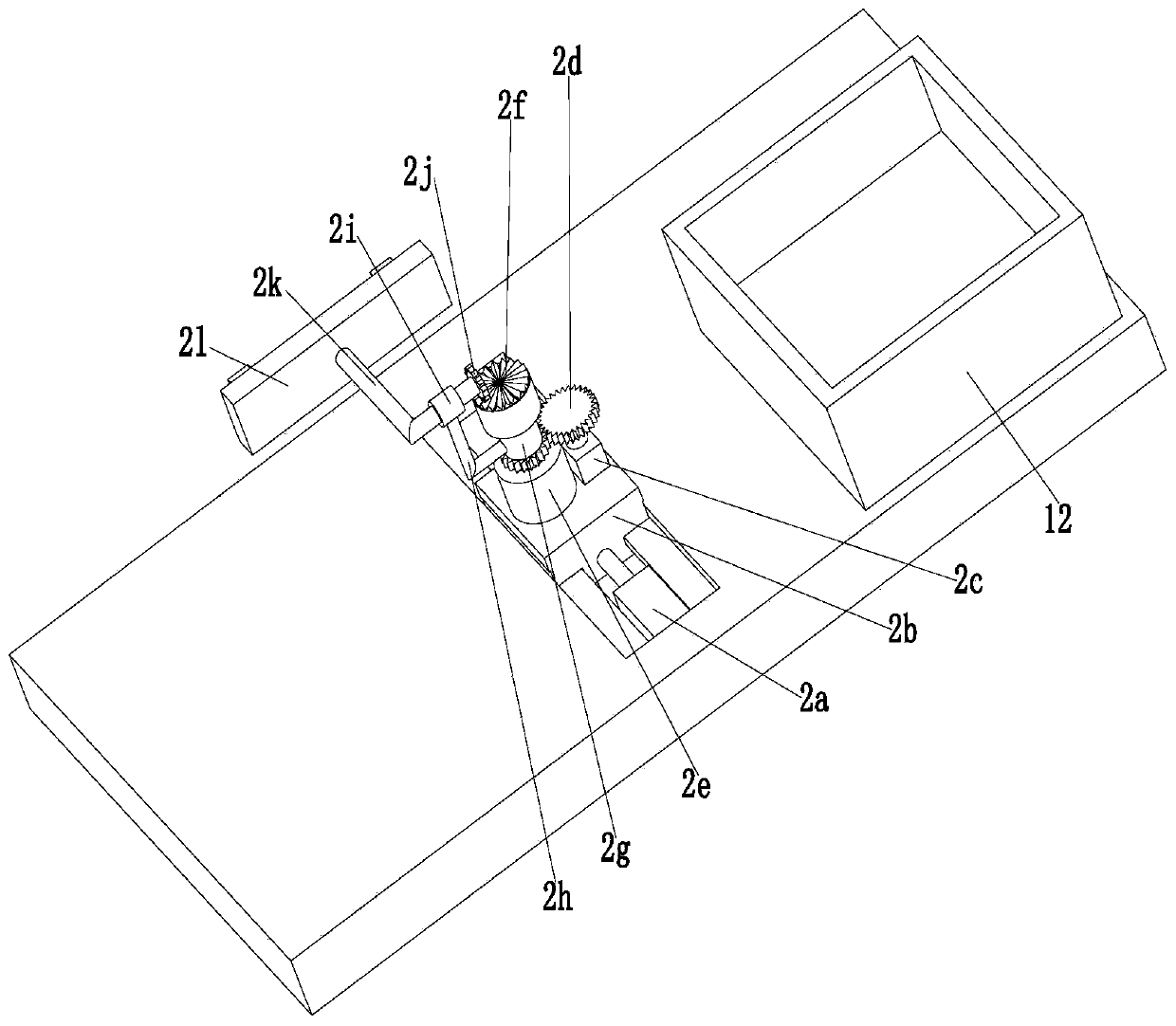

Light-emitting diode aftertreatment process

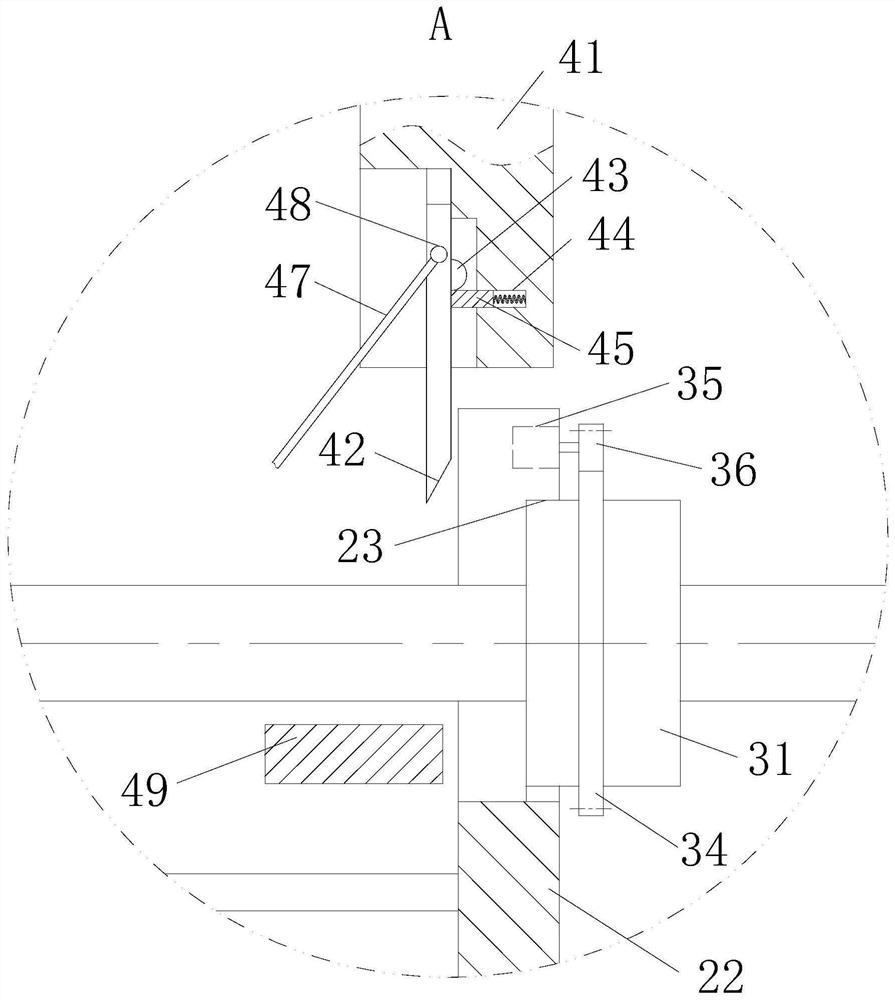

ActiveCN111283117AEasy to operateHigh straightening efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMaterials science

The invention relates to a light-emitting diode aftertreatment process. The light-emitting diode aftertreatment process mainly comprises the following multiple procedures of inspection operation, straightening treatment, detection treatment, collection packaging and the like. Adopted straightening equipment comprises a bottom plate, a taking device, a rotating device, a straightening device and aclamping device. The following problems existing during straightening of an existing light-emitting diode pin that a, when the traditional light-emitting diode pin is straightened, the middle end of alight-emitting diode needs to be manually held, the pin of the light-emitting diode is clamped by fingers to be straightened, consequently the work efficiency is low, mass production cannot be met, and when straightening is conducted manually through the fingers, the fingers are prone to being stabbed by the pin of the light-emitting diode; and b, when being straightened manually, the pin of thelight-emitting diode is often pulled cut due to excessive force, and consequently raw materials are wasted can be solved; and the straightening efficiency is high, the straightening effect is good, and the phenomenon that the pin is pulled cut is avoided.

Owner:深圳市世鸿鑫科技有限公司

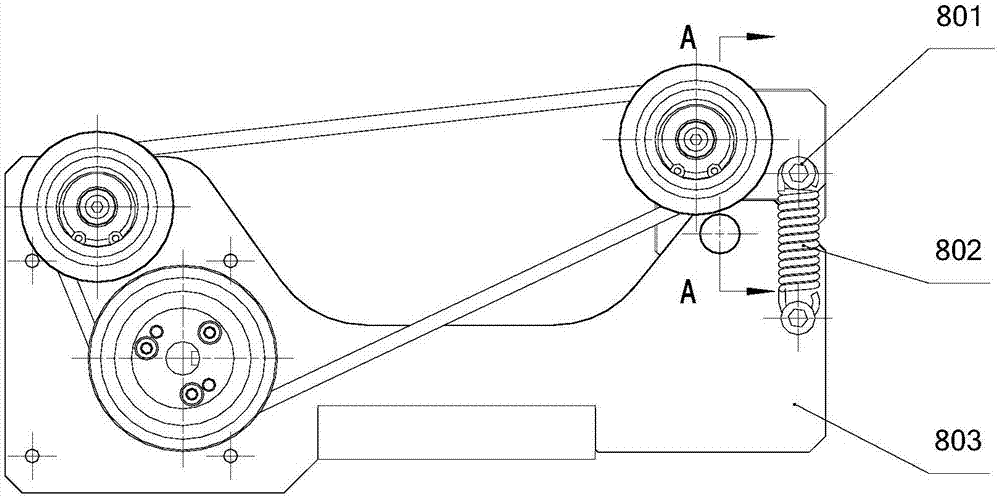

Straightening machine and belt friction driving device thereof

ActiveCN107377678APrevent slidingAvoid Feedback Angle ErrorsMetal working apparatusEngineeringFriction force

Owner:CHANGCHUN HUIKAI TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com