Forestry engineering seedling culture device

A seedling raising device and engineering technology, applied in agriculture, application, cultivation and other directions, can solve the problems of inconvenient installation and disassembly, complex structure of the seedling raising device, complicated structure of the straightening mechanism, etc., to achieve rapid operation, excellent straightening effect, Improves the effect of straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

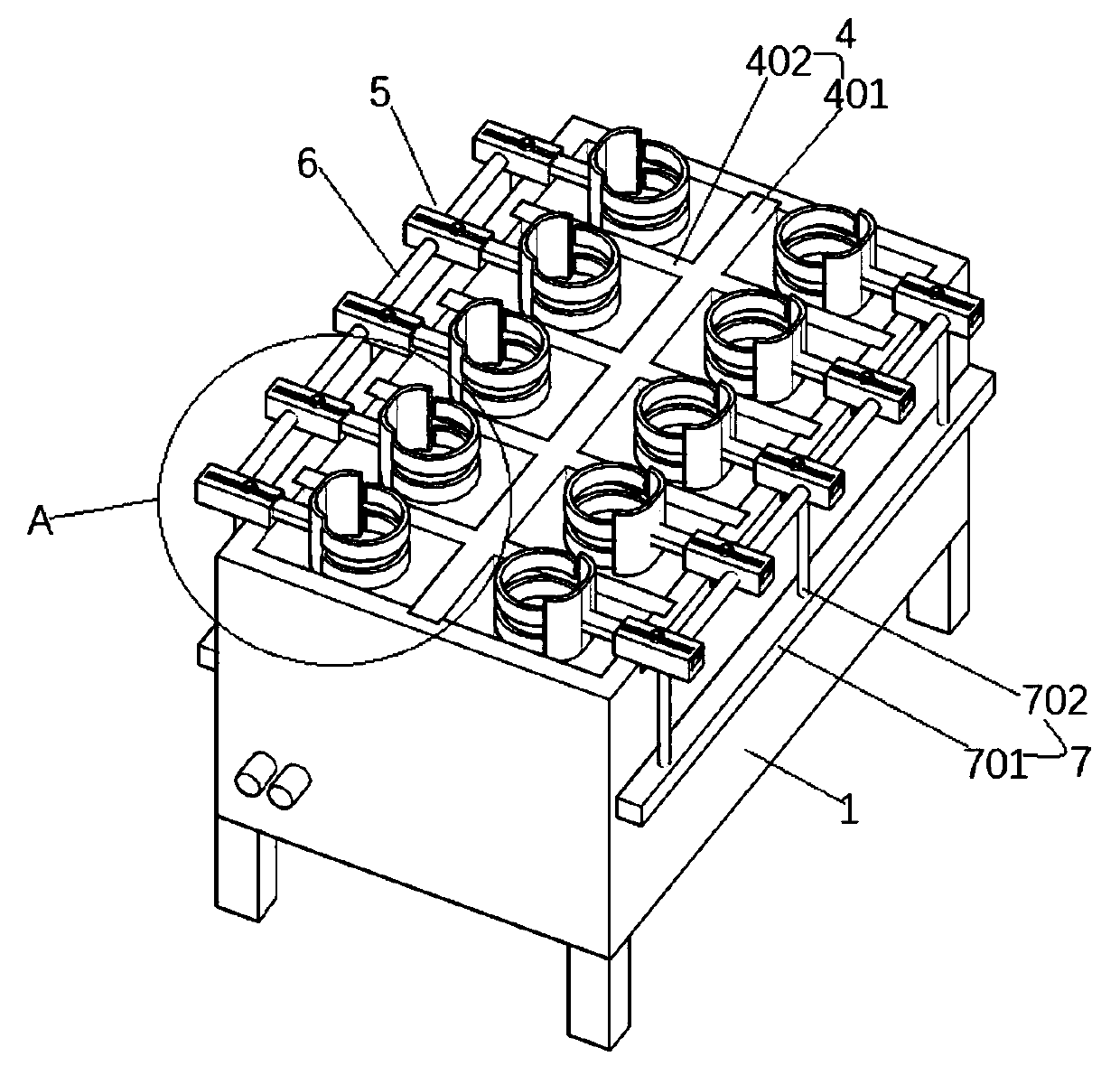

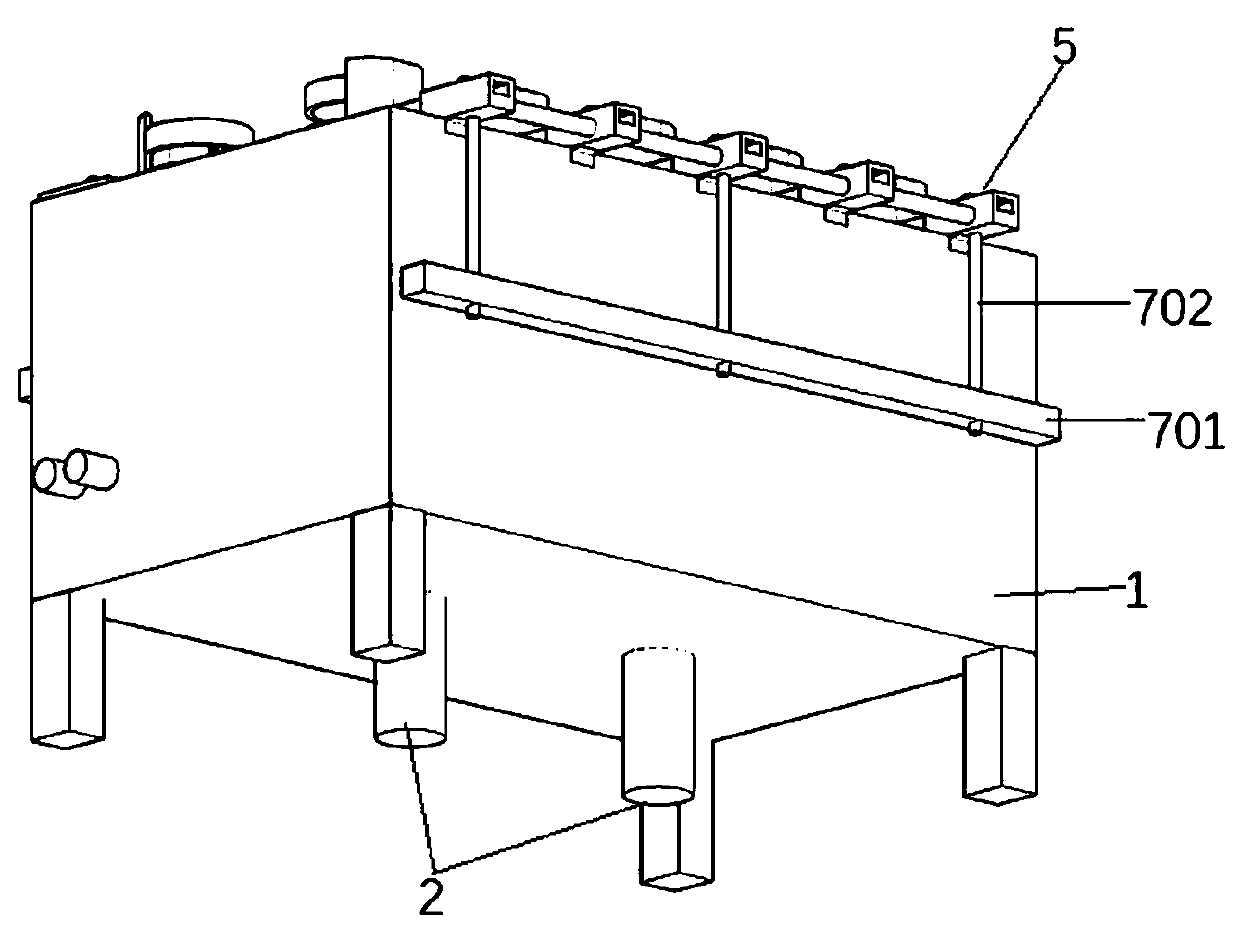

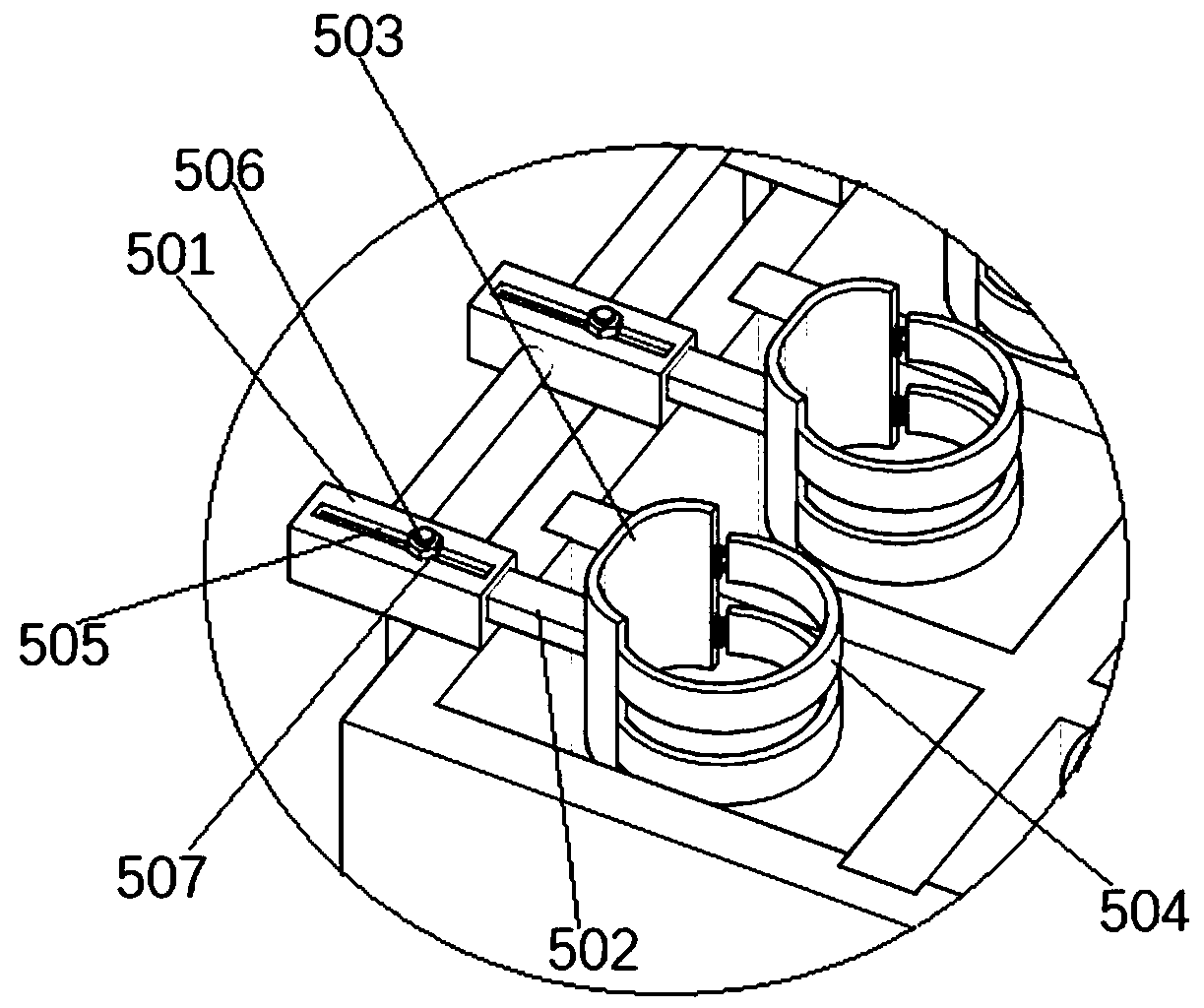

[0030] Such as Figure 1-5 In the shown embodiment, a forestry engineering seedling raising device includes a water tank 1, a lifting mechanism 2 arranged inside the water tank 1, an orifice 3 connected to the top of the lifting mechanism 2, and a sapling accommodating mechanism arranged on the upper end surface of the orifice 3 4 and the adjustable sapling straightening mechanism 5 that is arranged on the upper end of the water tank 1, the upper end of the sapling accommodation mechanism 4 was positioned at the inside of the water tank 1 when the lifting mechanism 2 fully contracted, and the lower end of the sapling accommodation mechanism 4 was positioned at the water tank 1 when the lifting mechanism 2 stretched out fully. the exterior of sink 1;

[0031] Described sapling accommodating mechanism 4 comprises Y to partition plate 401 and X to partition plate 402, and X direction partition plate 402 is arranged at the left end face and the right end face of Y to partition pla...

Embodiment 2

[0044] Embodiment 2 is basically the same as Embodiment 1 in terms of structure and working principle, the difference being that: the curved plate 503 and the rubber plate 504 are connected through another structural setting: the front and back of the curved plate 503 are symmetrically arranged with Lock seat, the front and rear ends of the rubber plate 504 are provided with lock heads, and the rubber plate 504 is installed on the arc-shaped plate 503 through the cooperation of the lock head and the lock seat. This connection method has the connection method of embodiment 1 The damaged rubber plate 504 can also be quickly replaced under the premise of advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com