Straightening and measuring machine for slender shafts

A measuring machine and slender shaft technology, applied in angle/taper measurement, metal processing, metal processing equipment, etc., can solve problems such as bending and wasting time, achieve easy use, improve straightening efficiency, and measure and straighten accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

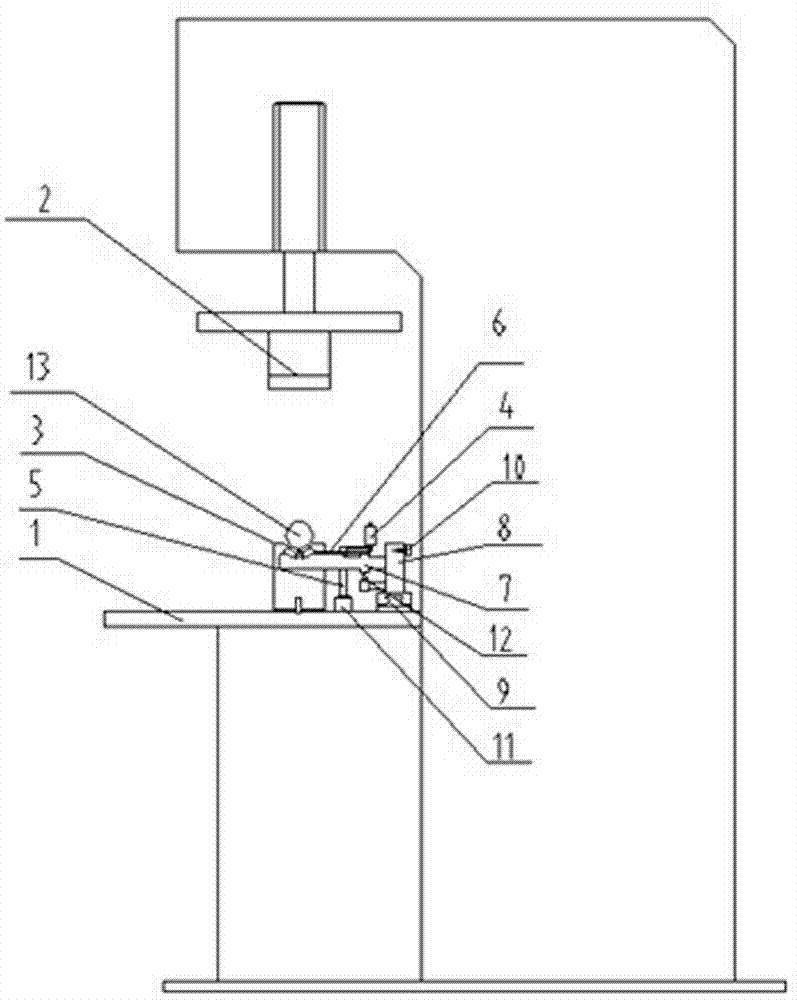

[0012] Embodiment: a slender shaft alignment measuring machine, including a workbench 1, a longitudinal pressing device 2, a fixed seat 3, a dial indicator 4, a dial indicator fixed frame 5 and a lever 6, and the fixed seat 3 is fixed on the working On the table 1, the fixed seat 3 is provided with a product positioning groove for positioning the product, the longitudinal pressing device 2 can be moved longitudinally and positioned directly above the fixed seat 3, and the dial gauge fixed frame 5 can be disassembled and fixed on the side of the fixed seat 3 On the workbench 1, the dial indicator 4 is fixed on the dial indicator fixing frame 5, the lever 6 is hinged on the dial indicator fixing frame 5, and the side wall of one end of the lever 6 along its length direction is tightly against the dial indicator 4. The contact, the side wall of the other end of the lever 6 along its length direction can be close to the lower side of the circumferential surface of the workpiece. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com