Cu-Nb composite wire straightening device

A composite wire, cu-nb technology, applied in the field of Cu-Nb composite wire straightening device, can solve the problem of unfavorable Cu-Nb composite wire straightening, affecting the performance of Cu-Nb composite wire, and unsuitable for Cu-Nb composite wire straightening and other problems, to achieve the effect of being suitable for mass production, improving straightness and stability, and high straightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

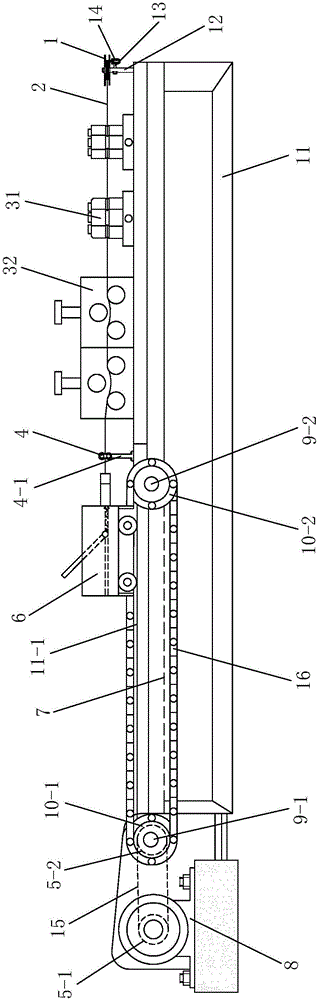

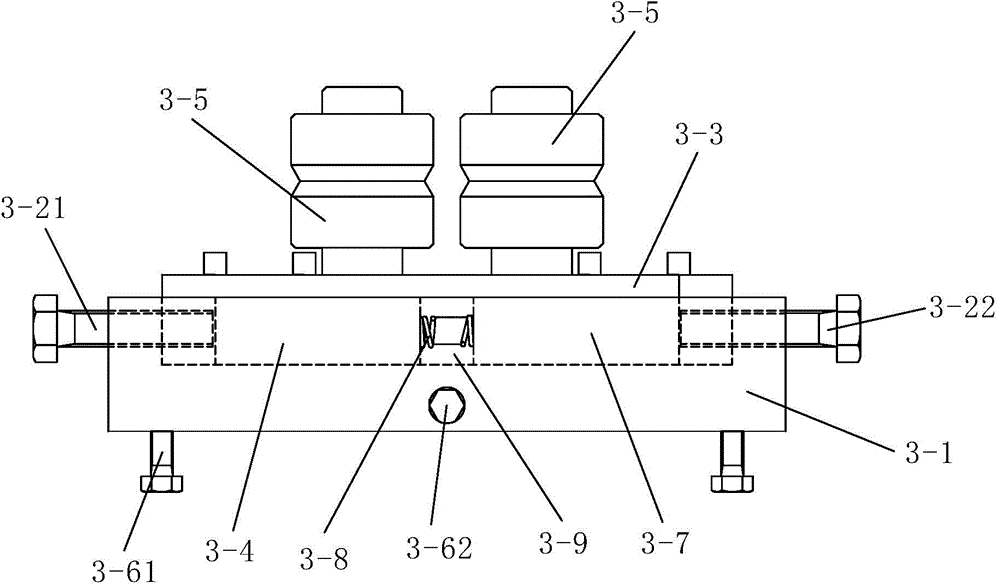

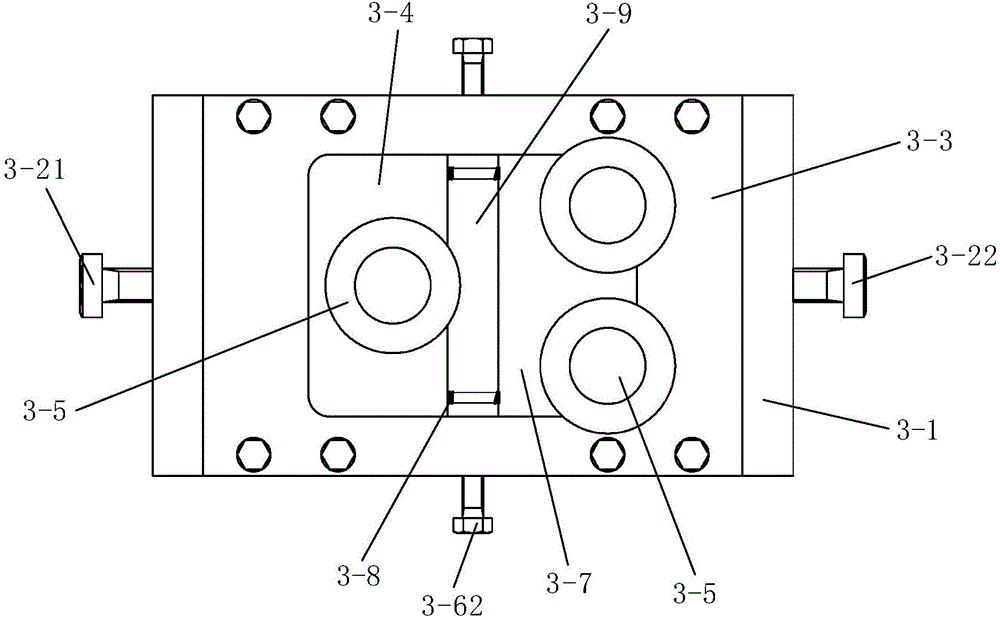

[0047] Such as figure 1 As shown, the present invention comprises a frame 11, on which a pay-off wheel 1, a first straightening unit 31, a second straightening unit 32, a guide wheel 4 and a wire rod for pulling Cu-Nb composite wire are installed in sequence on the said frame 11. 2 traction trolley 6, the Cu-Nb composite wire 2 is wound on the guide wheel 4, the pay-off wheel 1 is rotated and installed on the upper end of the pay-off reel shaft 12, and the lower end of the pay-off reel shaft 12 is fixed on the machine On the frame 11, the tension device 14 whose end is in contact with the lower end surface of the pay-off wheel 1 and prevents the Cu-Nb composite wire 2 from falling off is fixed on the pay-off reel shaft 12, the first straightening unit 31 and the second straightening unit 31 The straightening unit 32 has the same structure, the first straightening unit 31 is installed horizontally, the second straightening unit 32 is vertically installed, the guide wheel 4 is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com