Steel-bar arc-delivering straightening hoop bending machine

A hoop bending machine and straightening technology, applied in the field of steel bar hoop bending machines, can solve the problems that the axial twist of steel bars cannot be effectively cured, affect the quality of stirrup forming, and the opening of stirrups, etc., so as to improve the straightening effect and improve the The effect of straight efficiency and accurate feeding size accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

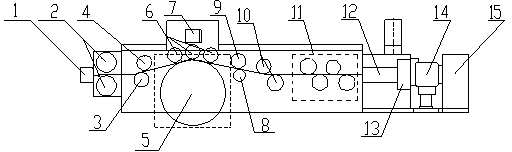

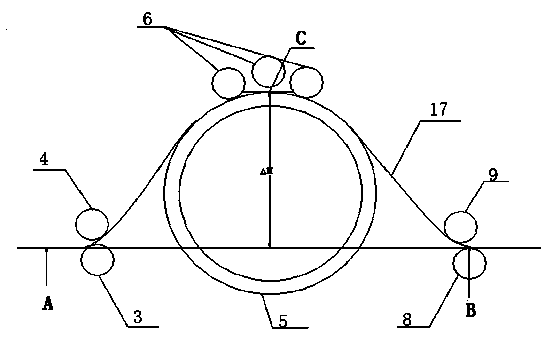

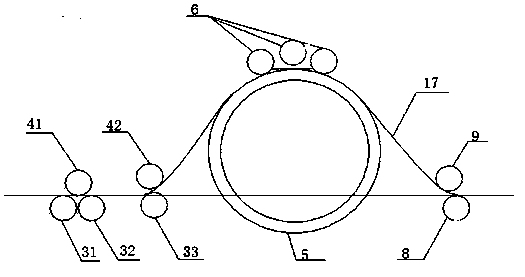

[0016] The invention provides a steel bar arc feeding straightening hoop bending machine, figure 1 It is a schematic diagram of Embodiment 1 of the present invention. It can be seen from the figure that the hoop bending machine sequentially includes a feed port 1, a feeding assembly for clamping the steel bar and transporting it backward, for controlling and guiding the delivery route of the steel bar, The guiding assembly for arc feeding is realized by changing the displacement of each wheel group in the vertical direction, the measuring assembly for measuring the current delivery length of the steel bar, the straightening assembly for the steel bar, the guiding guide 12, the shearing assembly 13, the bending assembly 14 and the reverse To the feeding assembly 15. Wherein, the feeding assembly includes a group of feeding wheels 2, and the two feeding wheels 2 are respectively located on the upper and lower sides of the central axis of the feed inlet 1, and are symmetrically d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com