Flexible screen pipe with automatic reset function

A flexible screen and automatic reset technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of accumulation increase and affecting the downhole operation ability of flexible screen, so as to reduce running resistance and improve Extended length, not easy to twist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] After entering the horizontal section, the conventional flexible screen is swayed by resistance, which leads to the accumulation of frictional force, which seriously affects the downhole operation ability of the flexible screen.

[0037] In view of the above problems, this embodiment provides a flexible screen tube with an automatic reset function. After entering the horizontal section, the axis of each screen tube is kept consistent under the action of the reset element, which is not easy to twist, reduces the running resistance, and enhances the extension. length, which solves the above problem.

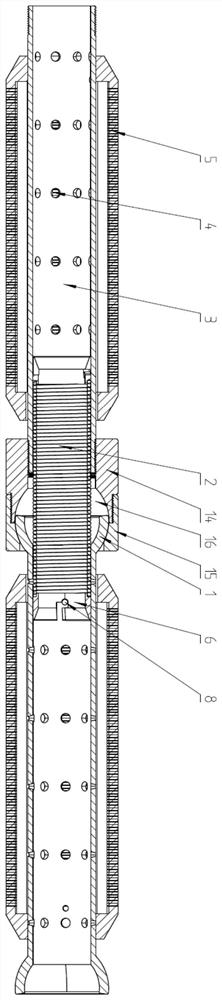

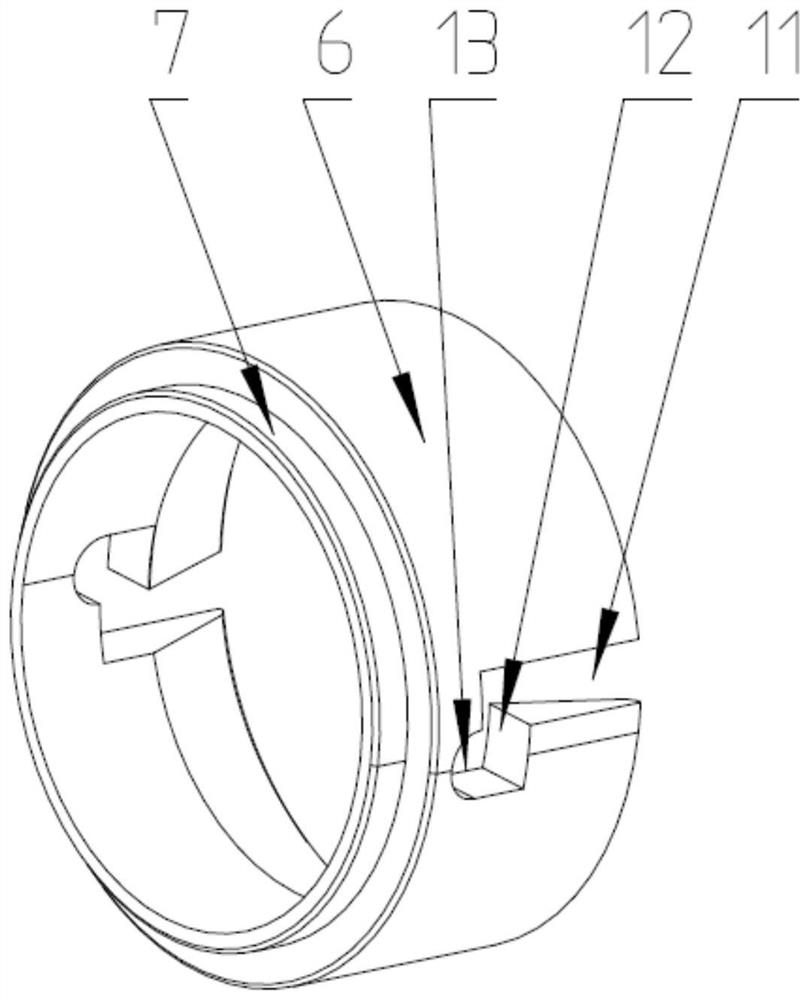

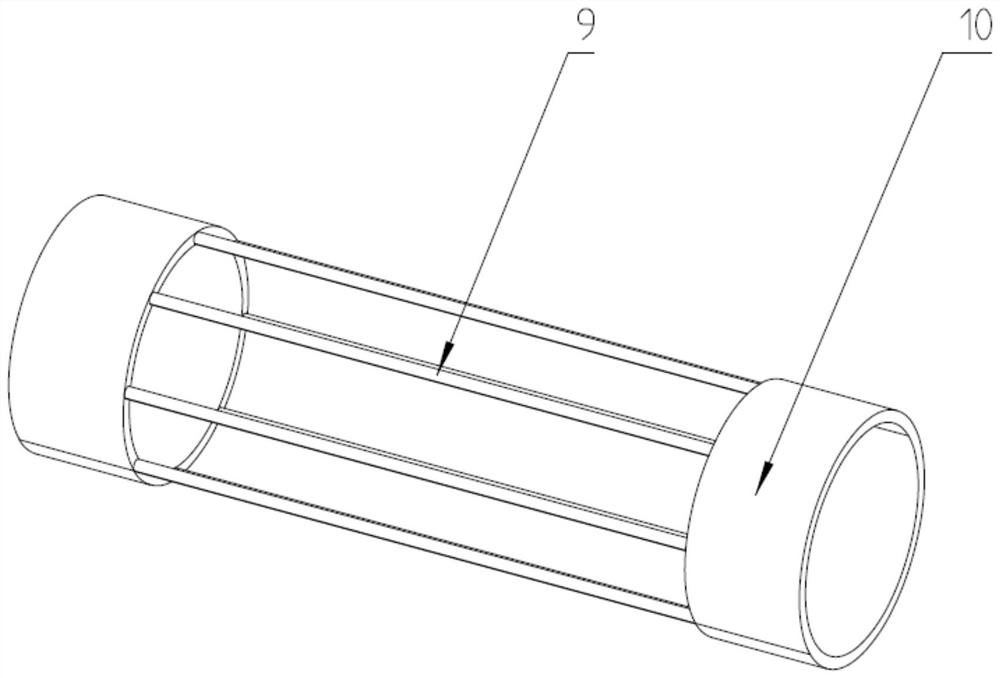

[0038] see Figure 1-3 , a flexible screen tube with automatic reset function, which specifically includes the following structure:

[0039] At least two sieve tubes, at most two ball heads 1 are set at both ends of the screen tubes; that is, at least one end of the two connected sieve tubes has a ball head 1; that is, multiple sieve tubes can be assembled in sequence , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com